Portable tension-adjustable pay-off rack device for outdoor optical cable

A technology for outdoor optical cables and pay-off racks, which is applied in the directions of transportation and packaging, delivery of filamentous materials, and thin material processing, etc. The effect of improving precision and improving the pass rate of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

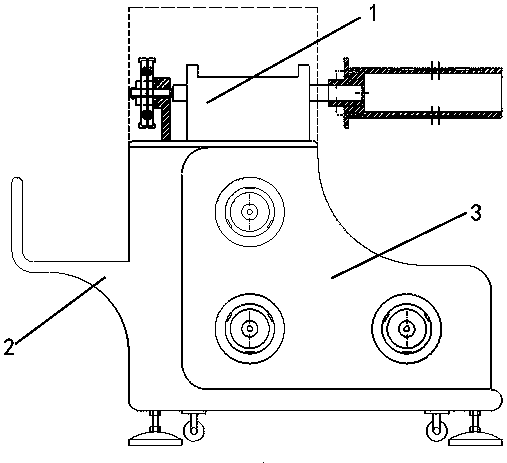

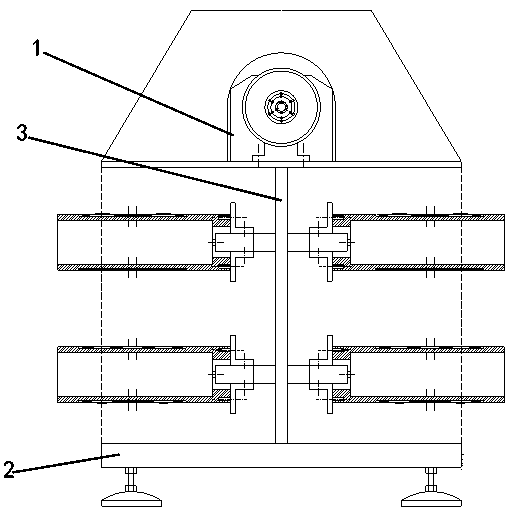

[0029] Such as Figure 1-2 As shown, the present invention provides a portable adjustable tension pay-off stand device for outdoor optical cables, including a pay-off assembly 1 , a pay-off stand support assembly 2 and a wire preparation barrel assembly 3 .

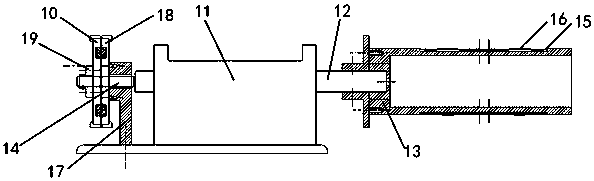

[0030] Such as image 3 As shown, the pay-off assembly 1 includes a pay-off shaft bearing seat 11, a pay-off shaft 12, and a support cylinder 13. The pay-off shaft passes through the pay-off shaft bearing seat and extends toward both ends of the pay-off shaft bearing seat Extend to get reliable and stable support; one end of the pay-off shaft is used to connect with the matching threaded shaft section 14, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com