Device and method for quickly calibrating mechanical tensiometer

A technology of calibration device and calibration method, which is applied in force/torque/power measuring instrument calibration/testing, measuring devices, instruments, etc., can solve problems such as assembly errors cannot be eliminated, assembly efficiency is reduced, overshooting, repetition, etc., to achieve The tension control accuracy is improved, the tension calibration efficiency is improved, and the effect of strong field practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further elaborated below in conjunction with embodiment.

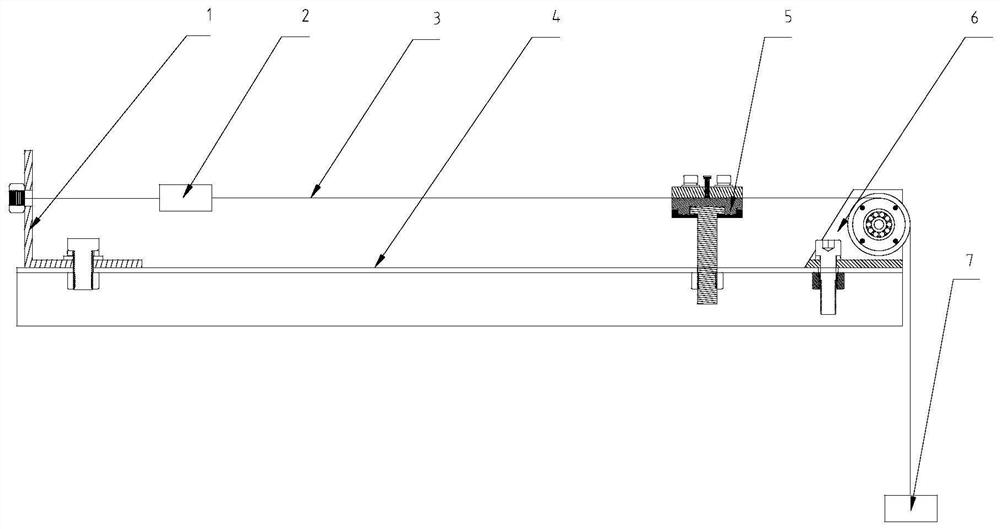

[0041] Such as figure 2 As shown, the present invention provides a quick calibration device for a mechanical tensiometer, which includes a connection assembly 1 , a sensor 2 , a rope 3 to be tested, a groove rail 4 , a fastening assembly 5 , a pulley assembly 6 and a weight 7 .

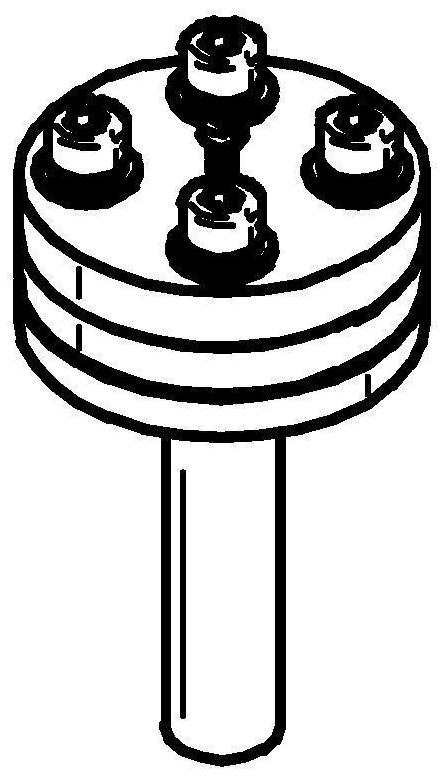

[0042] The grooved rail 4 is placed horizontally, and the connecting assembly 1 is an L-shaped structure, including a first side plate and a second side plate perpendicular to each other. The first side plate of the connecting assembly 1 is fitted and fixed on one end of the grooved rail 4, and the pulley assembly 6 is fixed on On the other end of the grooved rail 1, the bottom of the fastening assembly 5 is fixed at the middle position of the grooved rail 4, and a square groove is arranged on the top;

[0043] The second side plate of the connection assembly 1 is perpendicular to the groove rail 4, and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com