Carbon cloth tension automatic control device in low temperature carbonization furnace system

An automatic control device, low-temperature carbonization technology, applied in non-electric variable control, mechanical pressure/force control, control/regulation system, etc., can solve the problem of no overshoot PID algorithm feedback control strategy, and limit the research and development of graphitized fibers and promotion and application, to achieve the effect of fast response, good stability and convenient process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

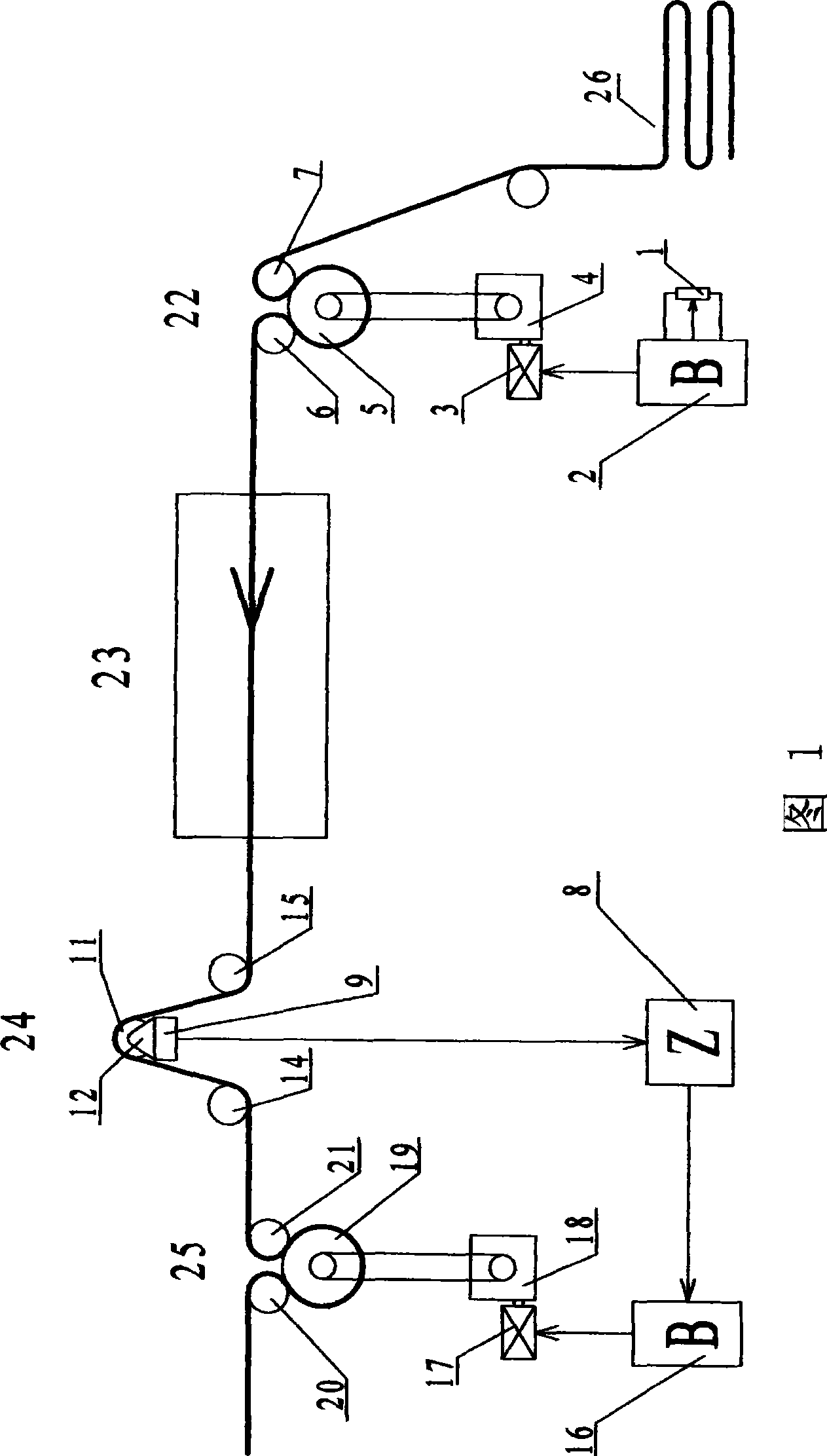

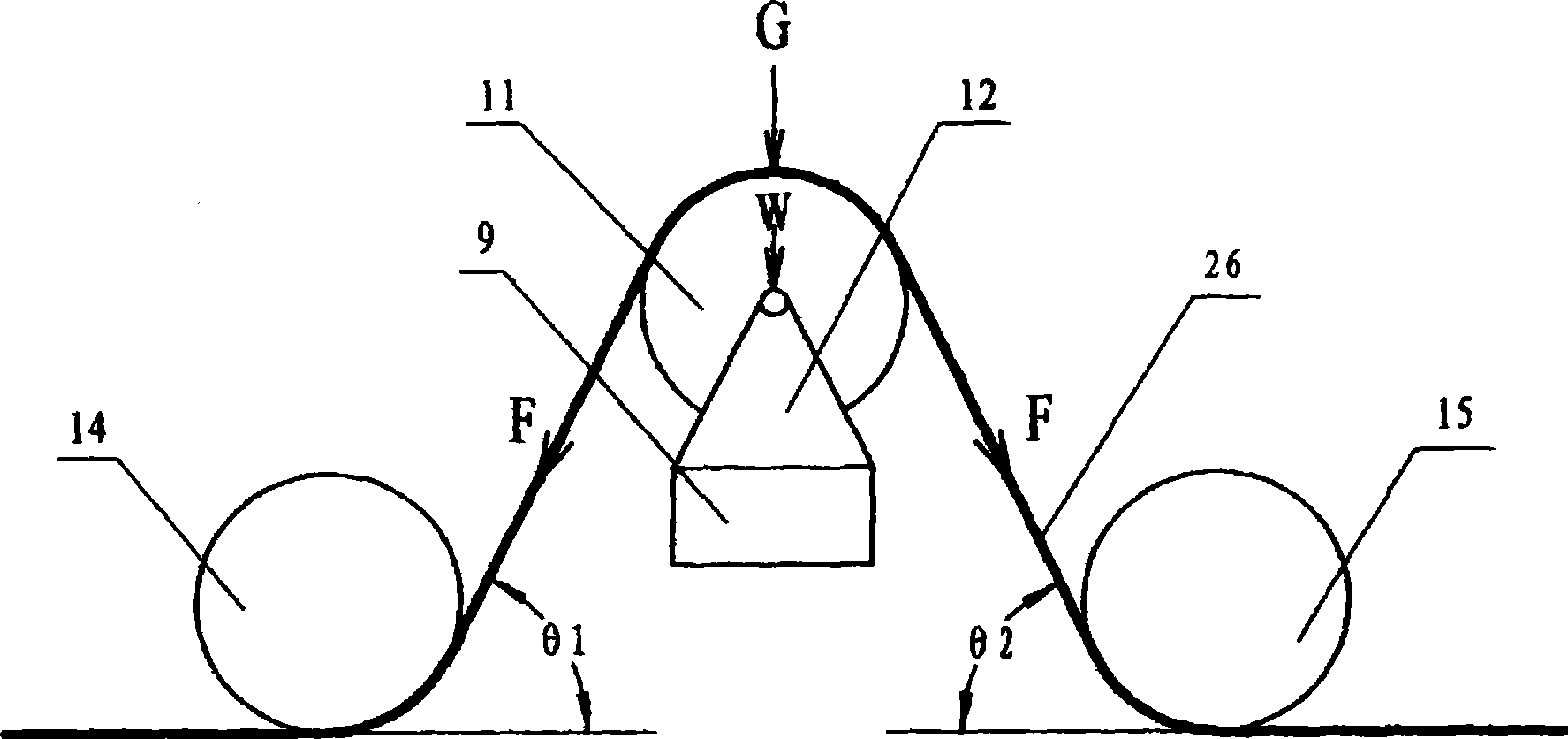

[0021] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented under the premise of the technical solution of the present invention, and detailed implementation methods and processes are provided, but the protection scope of the present invention is not limited to the following implementations example.

[0022] As shown in Figure 1, this embodiment includes: potentiometer 1, inlet frequency conversion controller 2, tension controller 8, outlet frequency conversion controller 16, inlet drive roller 22, tension roller 24, and outlet drive roller 25, wherein: the inlet drive The roller 22 is placed in front of the low-temperature carbonization furnace 23, the potentiometer 1 is connected to the inlet frequency conversion controller 2 to control the inlet drive roller 22, and the tension roller 24 and the outlet drive roller 25 are placed in sequence behind the low-temperature carbonization...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com