Patents

Literature

241results about How to "Change the tension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

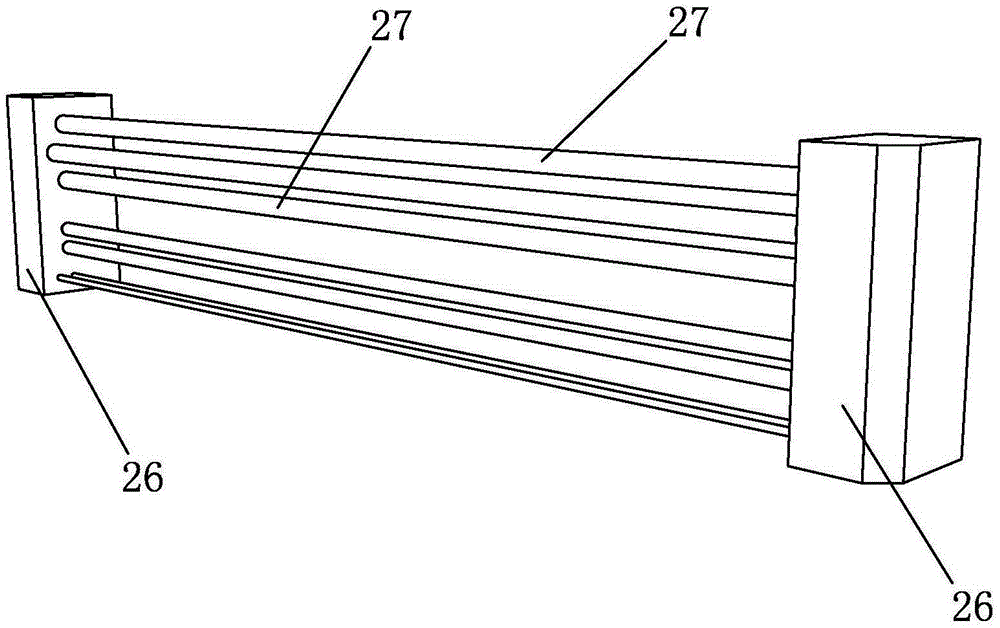

Anti-twisting type sectional warping machine

The invention discloses an anti-twisting type sectional warping machine. The anti-twisting type sectional warping machine comprises a bobbin creel, a yarn fixing rack, a yarn distributing device and a drum, wherein the bobbin creel comprises a rack, yarn guiders, a flexible cover and yarn cone shafts; yarn cones are placed on the yarn cone shafts; the yarn cone shafts are fixed on the rack; each yarn cone shaft is provided with the corresponding yarn guider; and the flexible cover is fixed on the rack and covers the yarn cones. The anti-twisting type sectional warping machine is simple in structure; the circumstance that warp yarns are twisted together and are knotted in a warping process is avoided effectively; and the warping efficiency is improved.

Owner:佛山市三水三强塑胶有限公司

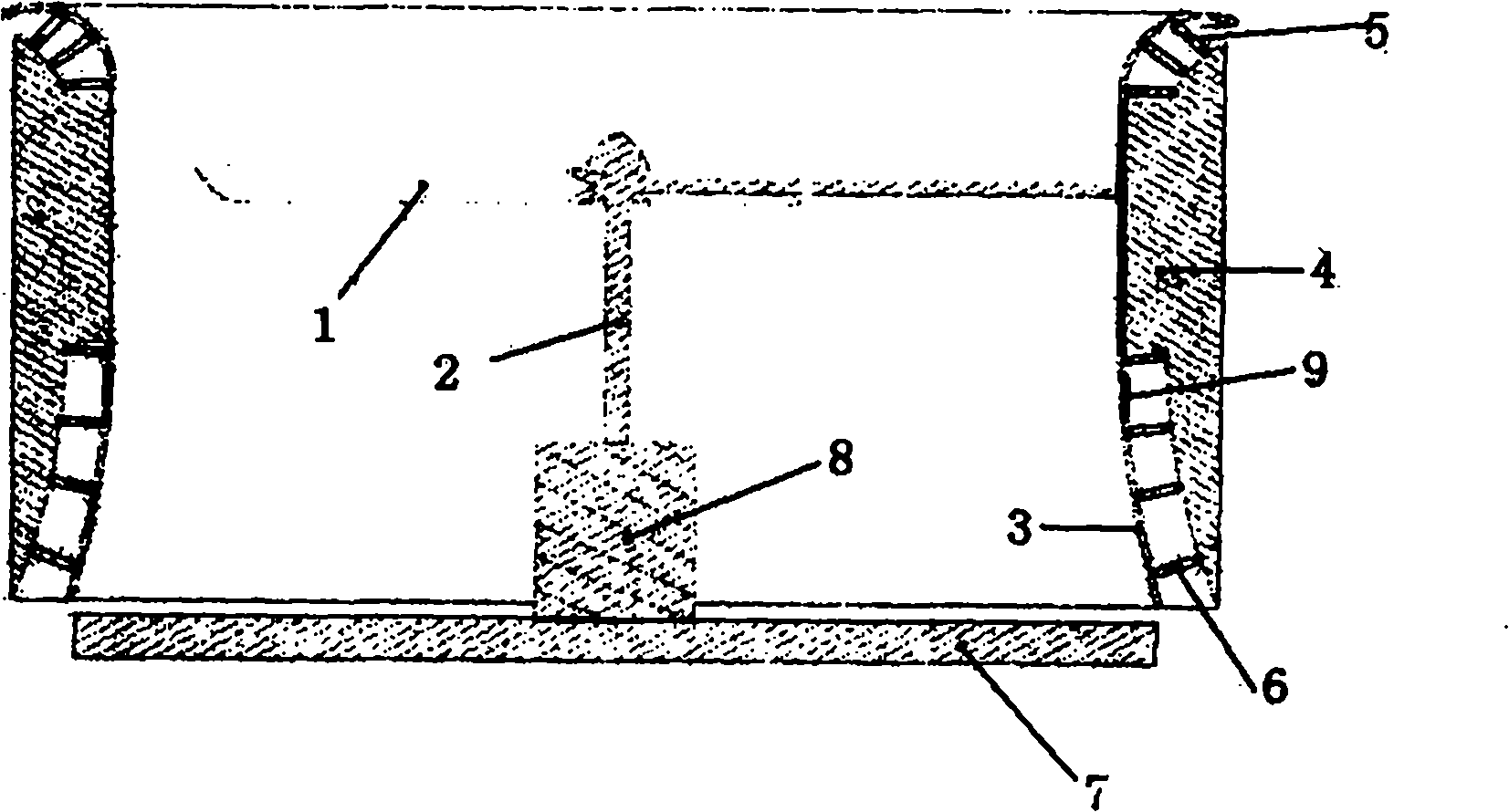

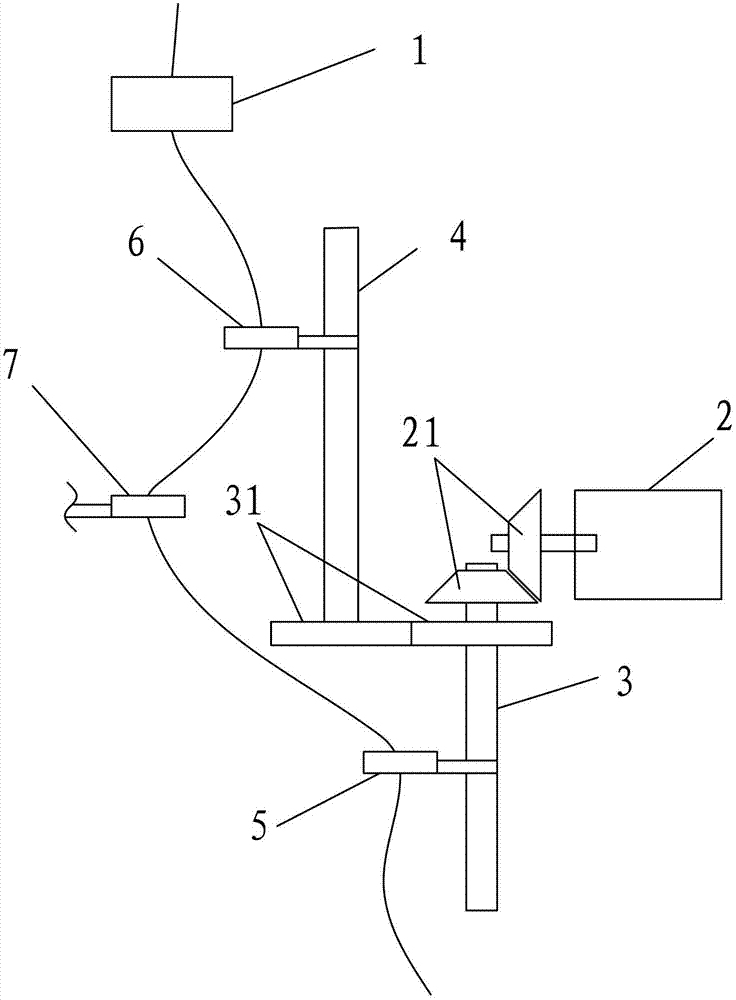

Multifunctional critical-current uniformity non-destructive and continuous detection device of superconducting band material

InactiveCN102788837AAccurate determination of lengthAvoid damageMaterial magnetic variablesNon destructiveLaser ranging

The invention discloses a multifunctional critical-current uniformity non-destructive and continuous detection device of a superconducting band material. The multifunctional critical-current uniformity non-destructive and continuous detection device is characterized in that a pay-off disc and a take-up disc are respectively arranged above the left upper part and the right upper part of an opened Dewar bottle which contains liquid nitrogen; the pay-off disc, the take-up disc and the Dewar bottle are respectively arranged in a sealing box; the Dewer bottle is internally provided with a guide wheel I, a guide wheel II, an excitation device, a magnetic-field measuring instrument and a guide wheel III in sequence from left to right; a height-adjustable top guide wheel is also arranged between the guide wheel I and the guide wheel II; an encoder is arranged above the left side of the guide wheel I or the right side of the guide wheel III of the Dewar bottle; and the excitation device, the magnetic-field measuring instrument, the encoder, a laser range finder I and a laser range finder II are respectively and electrically connected with a monitoring and controlling system. The multifunctional critical-current uniformity non-destructive and continuous detection device disclosed by the invention has the advantages that on the basis of testing the critical-current uniformity of the superconducting band material in a non-contact and continuous manner, the length of the band material also can be measured, the destructed position is accurately positioned, the change of the characteristic of the critical current of the band material can be tested when the tension and the bending degree are variable, and the destruction to the superconducting band material is less in testing.

Owner:SOUTHWEST JIAOTONG UNIV

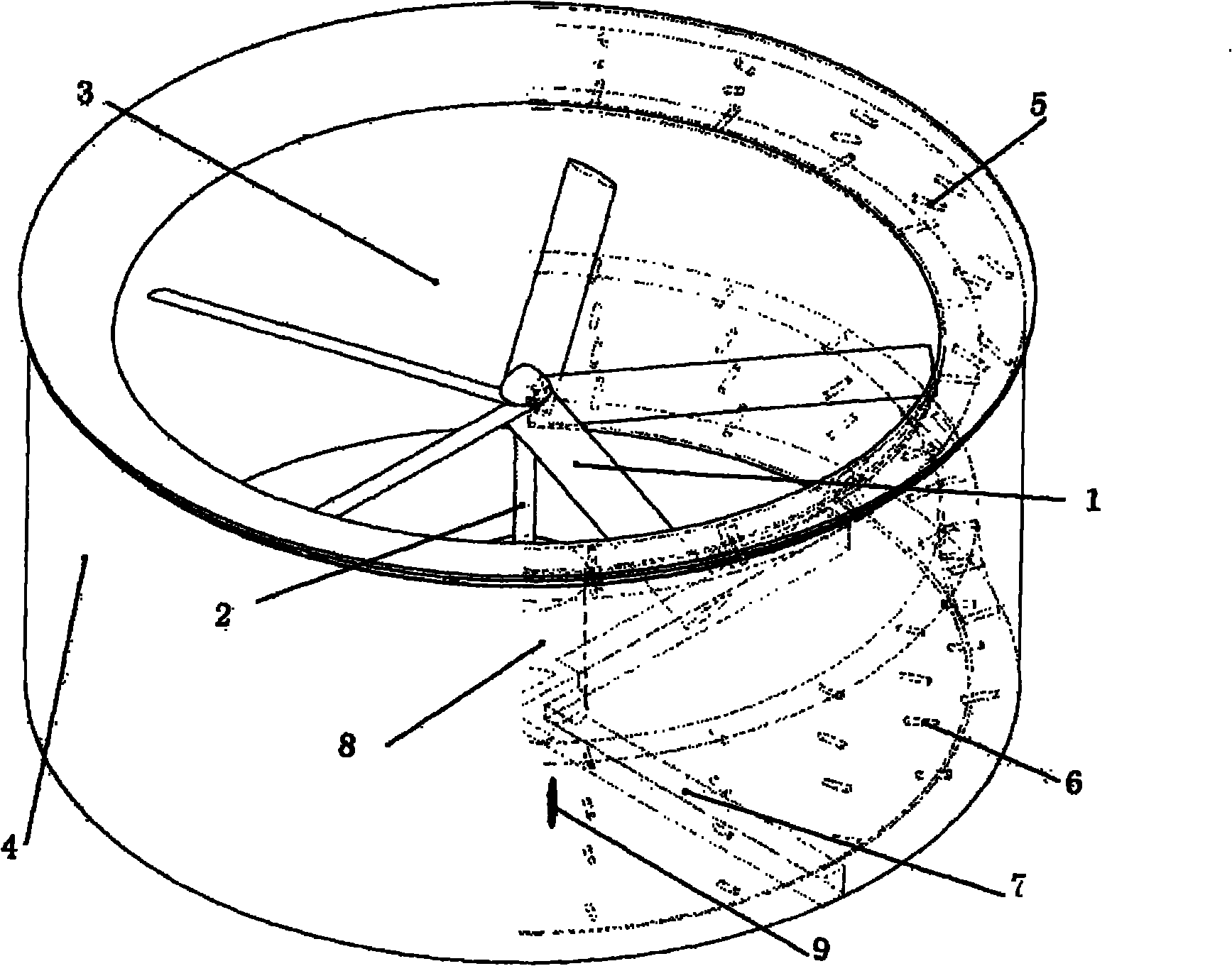

Lip and spread angle variable efficient duct

The invention relates to a lip and spread angle variable efficient duct which is made of flexile duct wall materials. The upper end and the lower end of the outer side of the duct are fixed with at least one actuating cylinder, and the other end of the actuating cylinder is connected to a positioning rack. A numerical value sensor is arranged on the side wall above a spread opening of the duct and used for sensing whether air flow is separated or not due to the increased spread angle of the opening and feeding a sensor signal back to an ECU (Electronic Control Unit). Part or all regions of the inner wall of the duct are provided with pit features which can be adjustable pit flexible pasters consisting of MEMSs (Micro Electro Mechanical Systems). The duct can be used for regulating the lip and the tail spread angle in real time, can improve the efficiency of duct propellers, and can change the duct pull force under the condition of no change of other control conditions, improve the control accuracy, and reduce the coupling function in the aircraft control.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Lubricant useful for improving the oil separation performance of a vapor compression system

ActiveUS20060166843A1Suppress tendencyImprove solubilityLiquid carbonaceous fuelsBase-materialsOil separationEngineering

Polymeric additives are disclosed for compressor lubricants which can reduce the tendency of the lubricant to become entrained in compressed gases and be carried forward as fine dispersed droplets in compressed gas systems such as compressed air, natural gas, and compression refrigeration systems.

Owner:THE LUBRIZOL CORP

Three-dimensional ink for wall paper and preparation method thereof

The invention relates to a three-dimensional ink for wall paper. The three-dimensional ink is prepared from the following raw materials in parts by weight by adding the raw materials into an agitating vessel and uniformly mixing and stirring the raw materials: 100 parts of acrylic resin emulsion, 0.1 to 25 parts of a filler, 0 to 15 parts of a pigment, 1 to 20 parts of thermal expansion micro-balloons, 0.5 to 10 parts of a film-forming agent, 0.5 to 3 parts of a defoaming agent and 0.5 to 2 parts of a thickening agent, wherein the filler is titanium pigment, and the pigment is an organic tinting pigment. The preparation method of the three-dimensional ink for wall paper comprises the following steps of: taking the raw materials in parts by weight, firstly adding the acrylic resin emulsion into the agitating vessel, adding the titanium pigment into the acrylic resin emulsion, and agitating the mixture uniformly; grinding the mixture of the titanium pigment and the acrylic resin emulsion in the agitating vessel by using grinding equipment; adding the film-forming agent, the defoaming agent and the thickening agent into the agitating vessel, and agitating the mixture uniformly; adding the thermal expansion micro-balloons into the agitating vessel, and agitating the mixture uniformly; and finally, adding the organic tinting pigment into the agitating vessel, and agitating the mixture uniformly to obtain the three-dimensional ink for wall paper.

Owner:GUANGDONG YULAN GRP

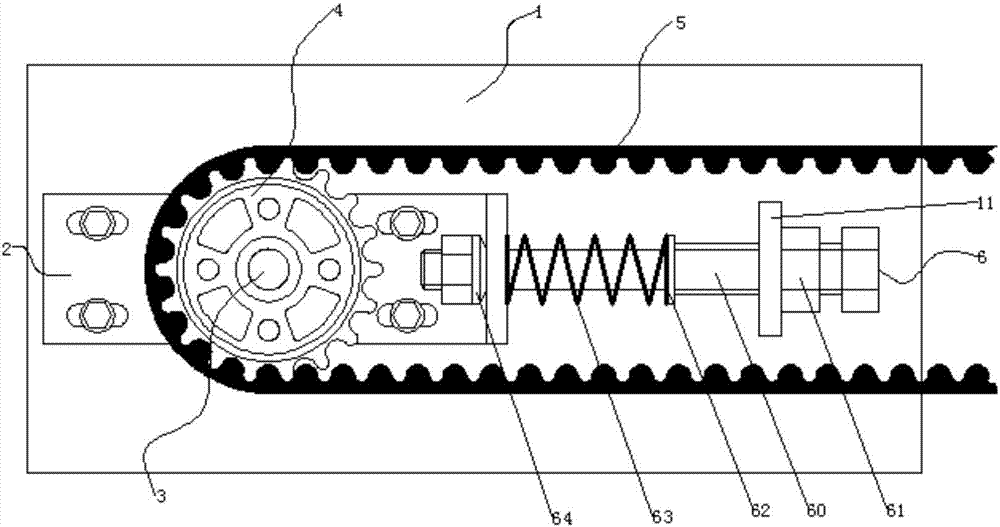

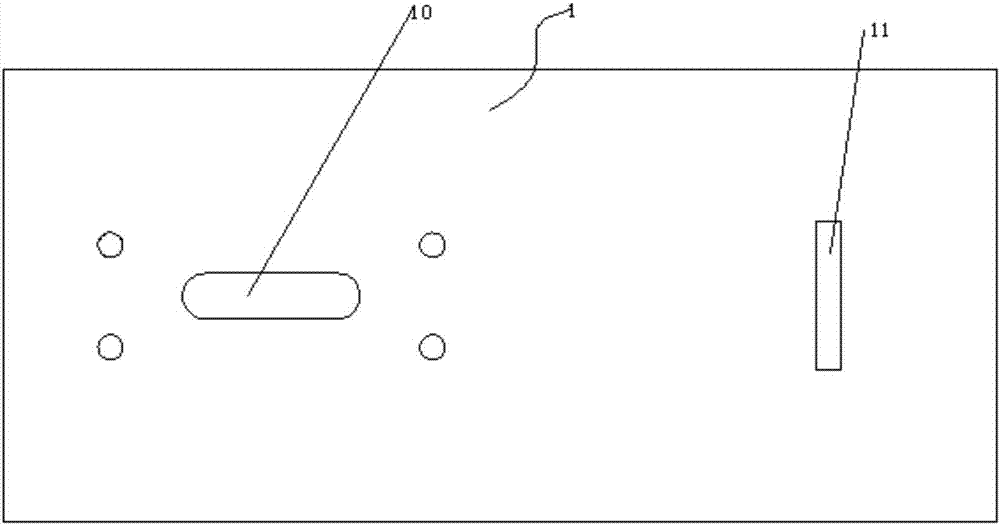

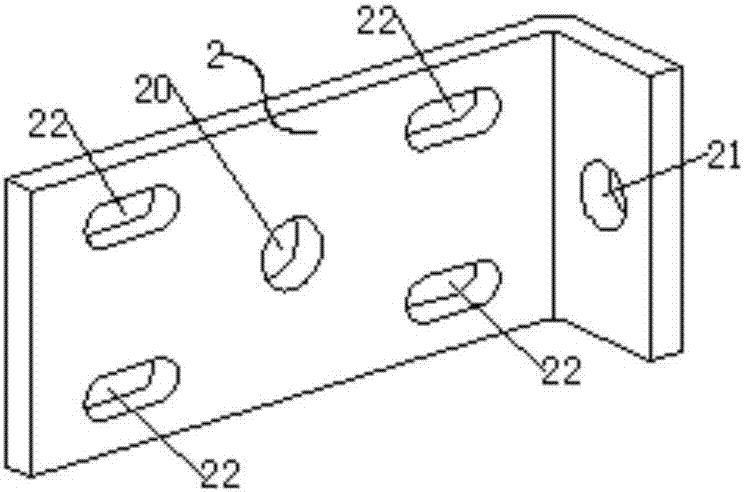

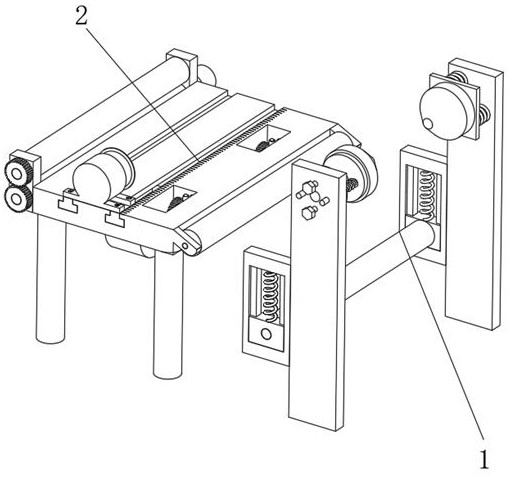

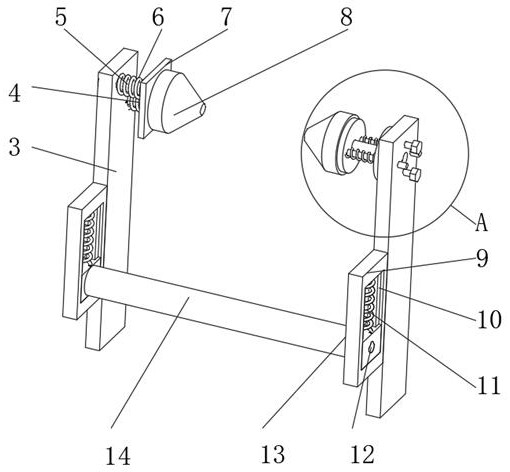

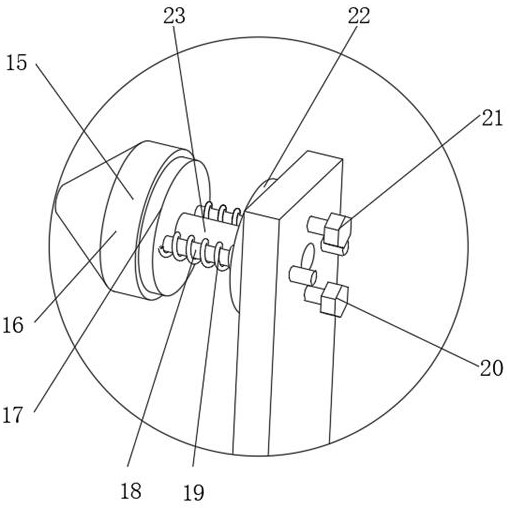

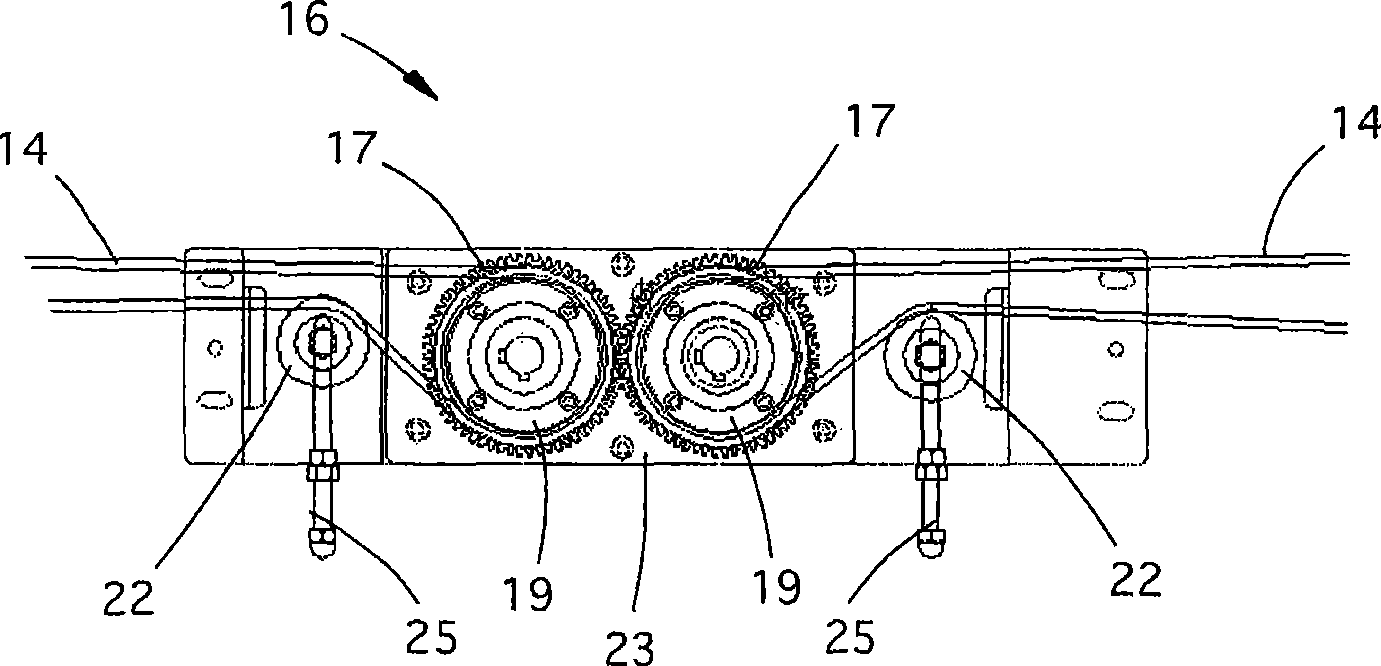

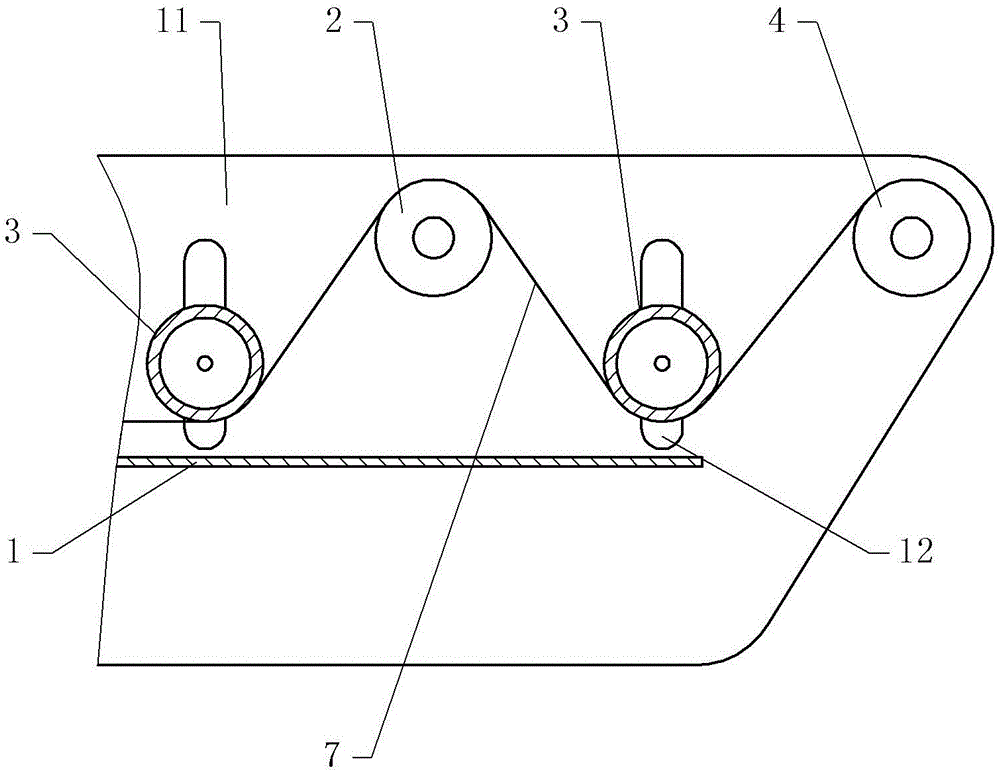

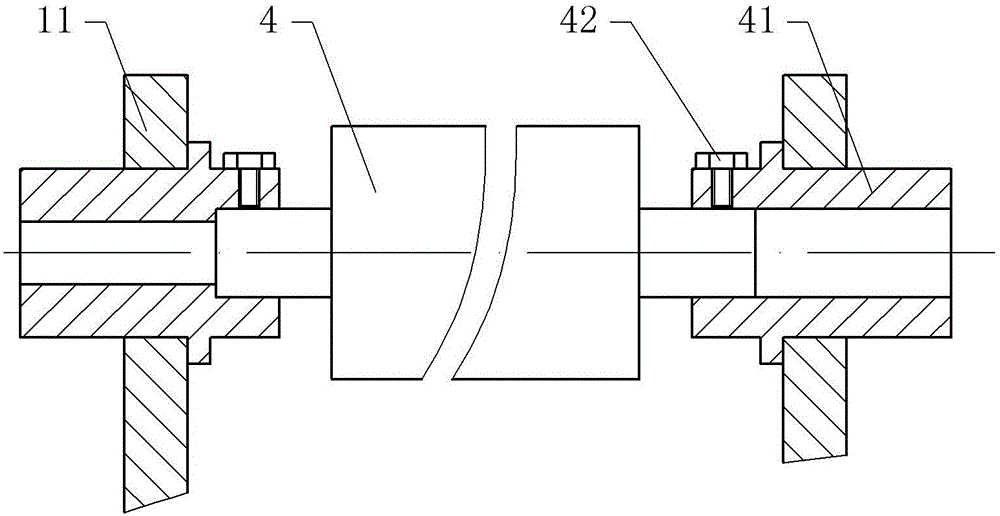

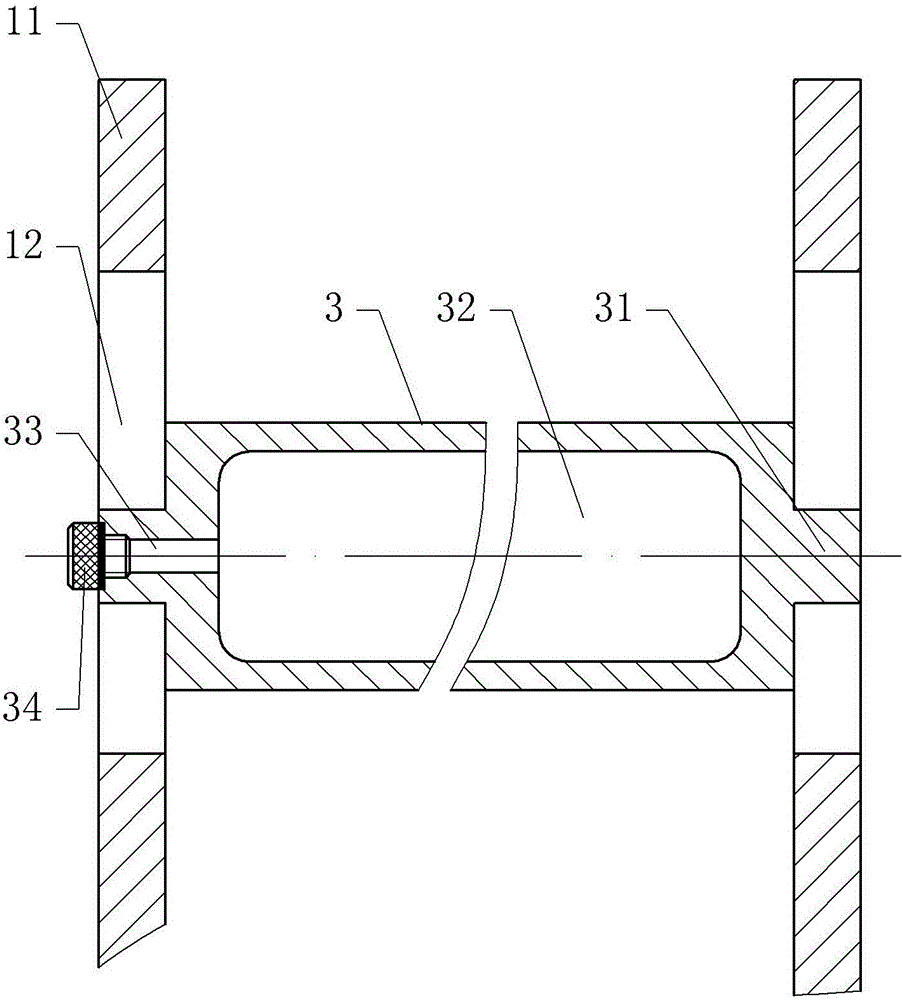

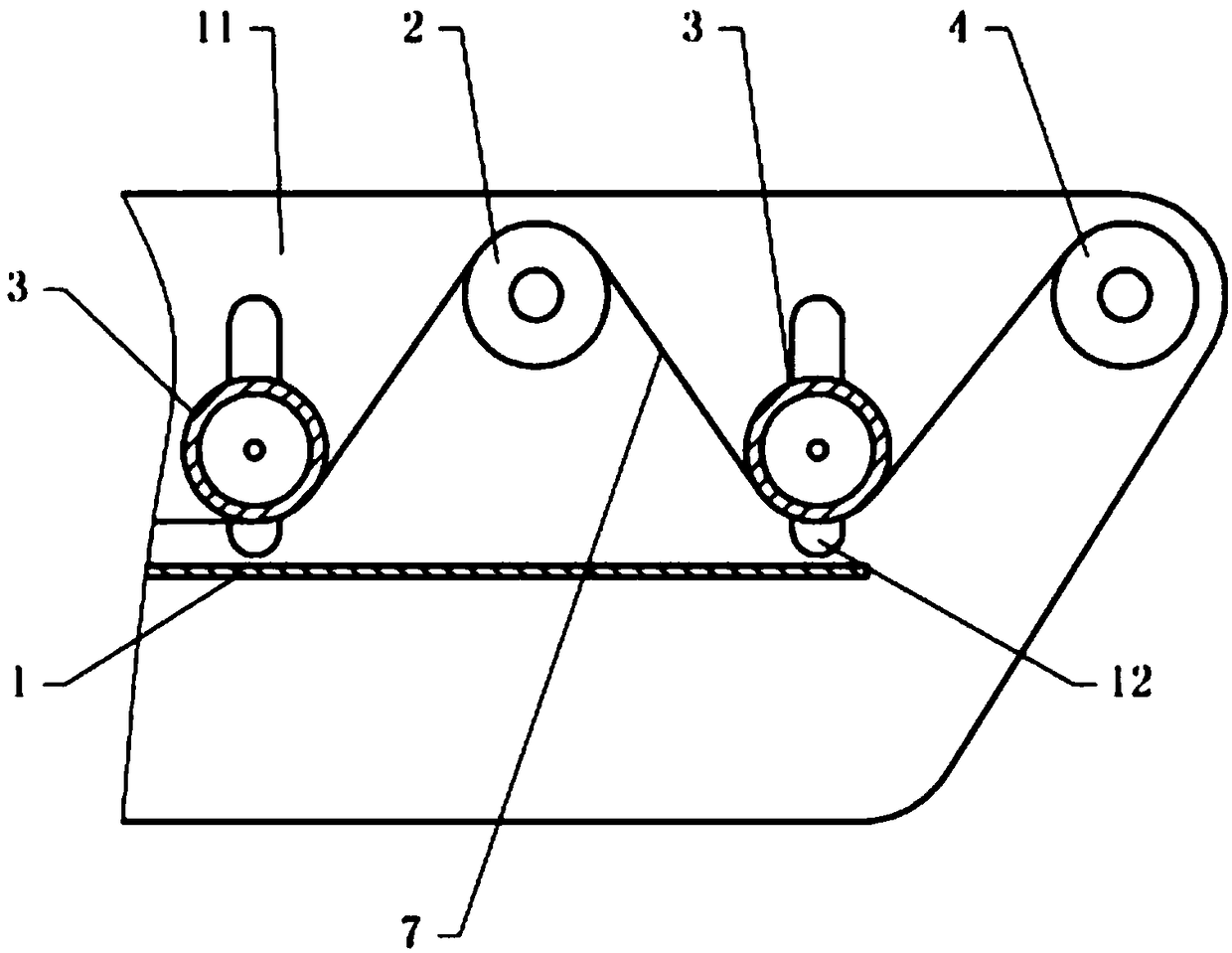

Synchronous belt anti-vibration tensioning device

PendingCN107202137AFirmly connectedAvoid mechanical interferenceGearingStructural engineeringMachine

The invention discloses a synchronous belt anti-vibration tensioning device. The synchronous belt anti-vibration tensioning device comprises a machine base plate, an adjusting plate, a drive rotating shaft, a synchronous belt wheel, a synchronous belt and an adjusting structure; a first long groove hole and an adjusting fixing plate are arranged on the machine base plate, a shaft hole is formed in the middle of the adjusting plate, an adjusting hole is formed in the adjusting plate, four second long groove holes are formed in the adjusting plate, the adjusting plate and the machine base plate are connected in a manner that bolts penetrate the second long groove holes, the position of the shaft hole corresponds to the position of the first long groove hole in the machine base plate, the drive rotating shaft penetrates the first long groove hole and the shaft hole to be connected with the synchronous belt wheel, the synchronous belt is connected with the synchronous belt wheel, and the adjusting structure is composed of a bolt part, a first tightening nut, a blocking piece, a spring, a membrane spring and a second tightening nut. According to the technical scheme, wear of the synchronous belt is reduced, tensioning reliability and mechanical vibration resistance performance are ensured, and the phenomenon that tooth jumping appears in the synchronous belt is avoided.

Owner:王萌

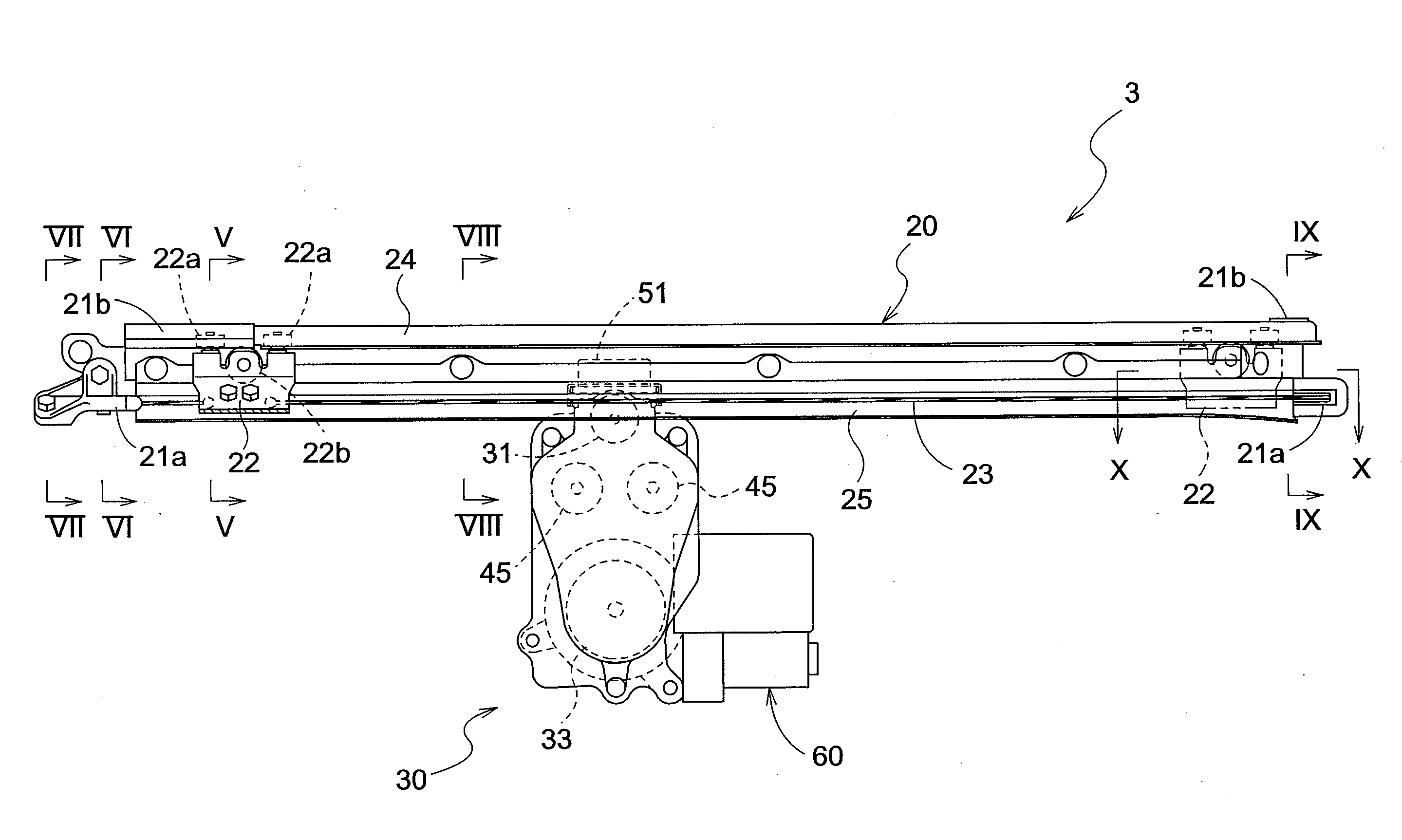

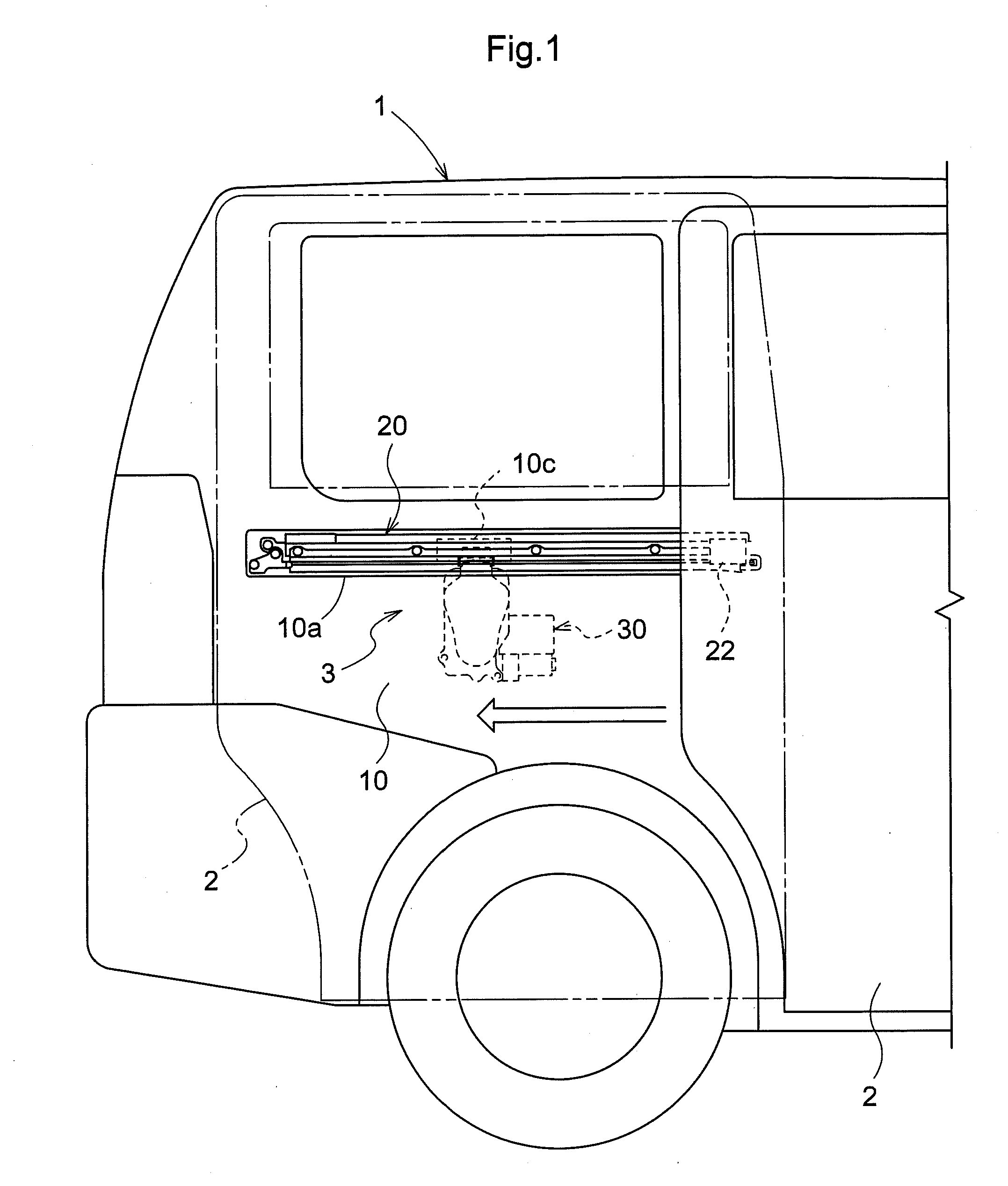

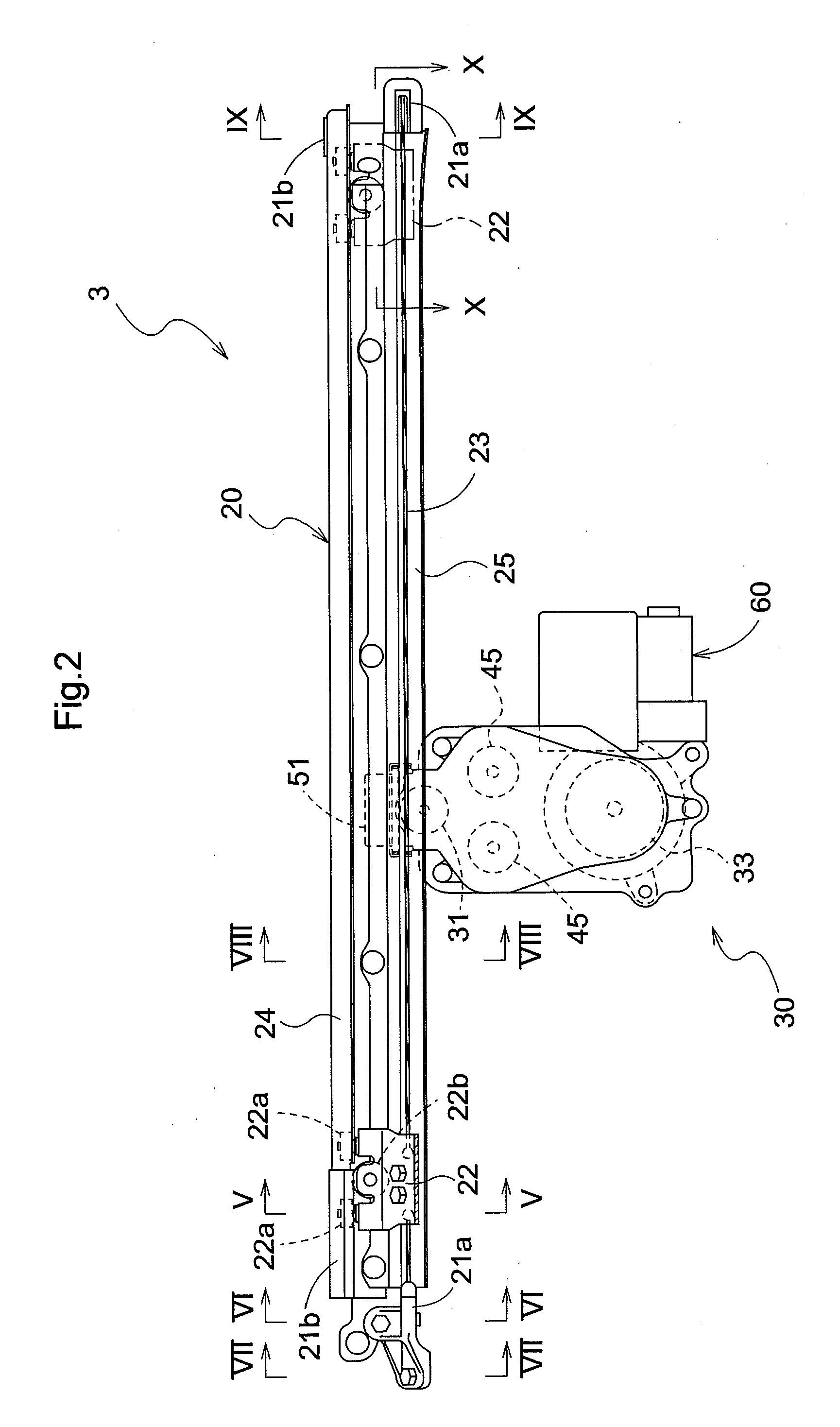

Vehicle door opening/closing apparatus

InactiveUS20100199567A1Avoid changeChange the tensionMan-operated mechanismPower-operated mechanismDrive wheelEngineering

A vehicle door opening / closing apparatus includes a rail for a sliding door fixed to the outside of a vehicle cabin and extending along a front-back direction of the vehicle, a support member for supporting the sliding door and movable along the rail, first and second pulleys supported respectively to opposed longitudinal ends of the rail, a cable turned around by the first and second pulleys and retained to the support member, thus being arranged in the form of a loop and a drive unit for rotatably supporting a drive wheel around which the cable is wound and configured for moving the support member back and forth according to a rotational direction of the drive wheel, the drive unit being fixed to the side of vehicle cabin. The drive unit is supported to the rail such that the drive unit is pivotable between a first posture where the drive unit projects relative to an attaching face of the rail to be attached to a vehicle body and a second posture where the drive unit is disposed along said attaching face.

Owner:AISIN SEIKI KK

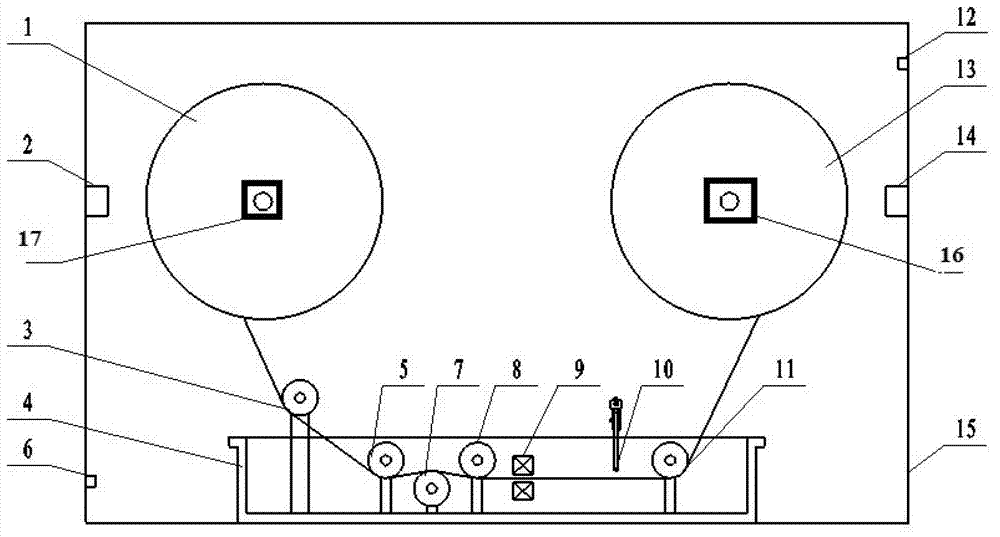

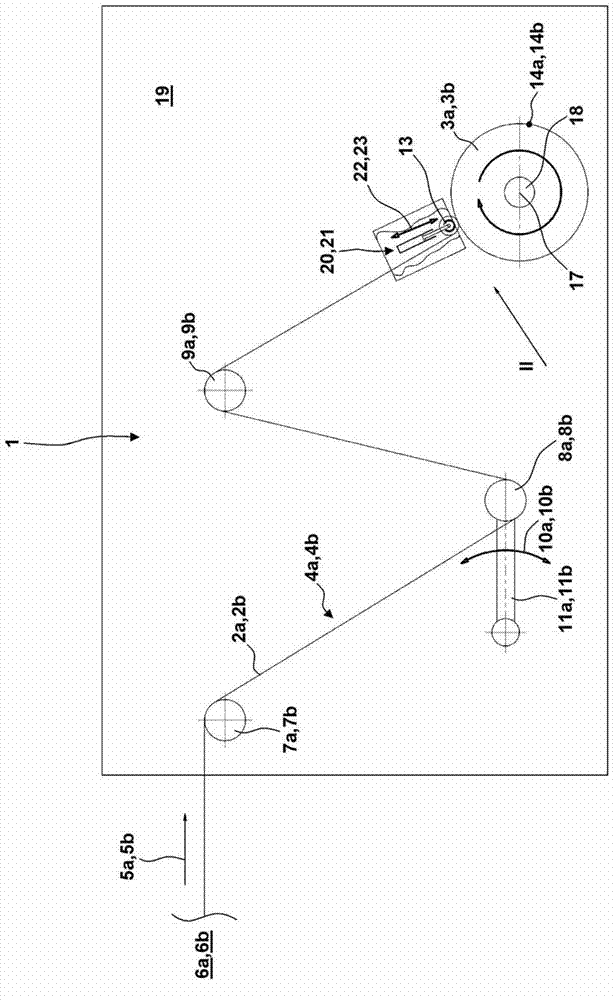

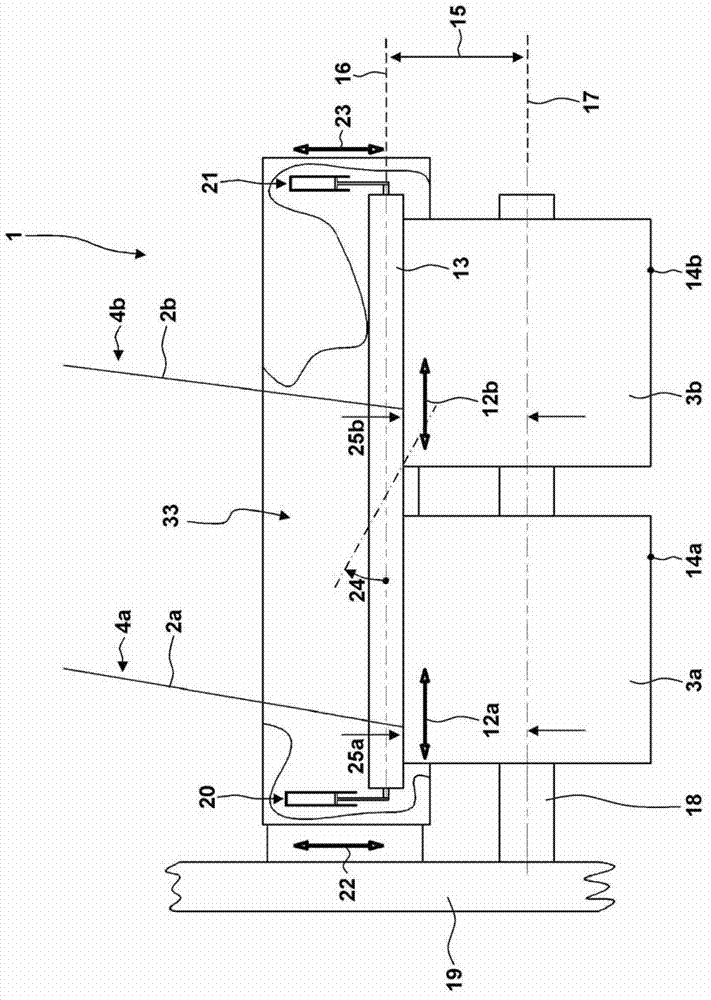

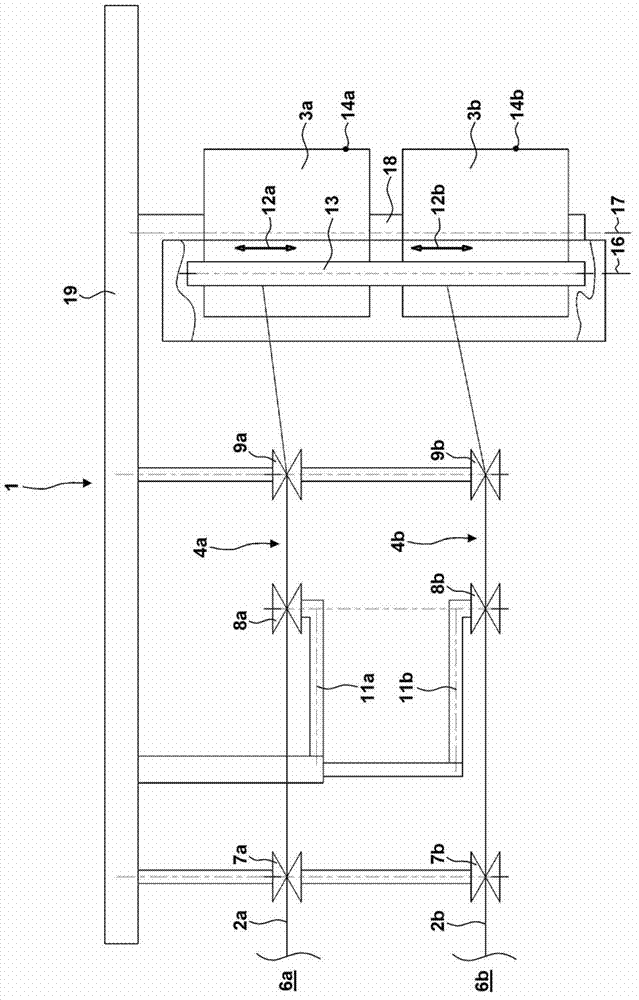

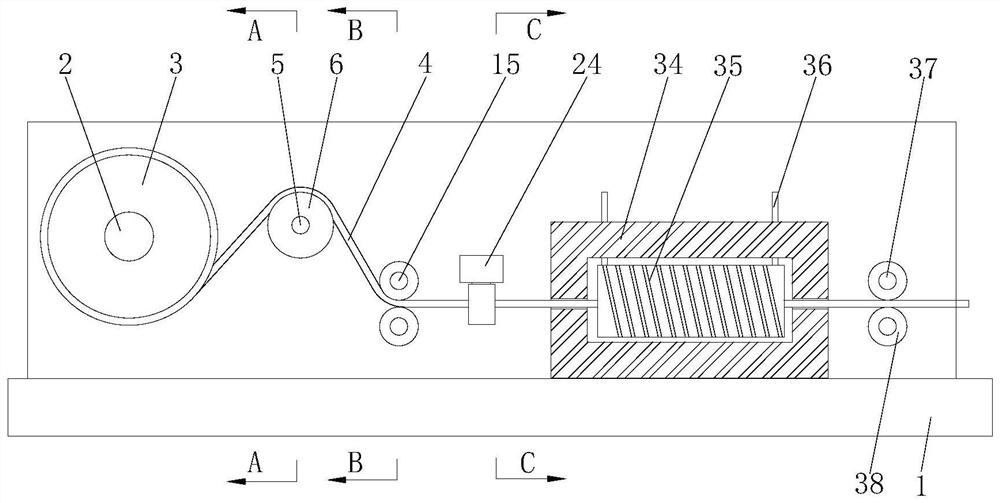

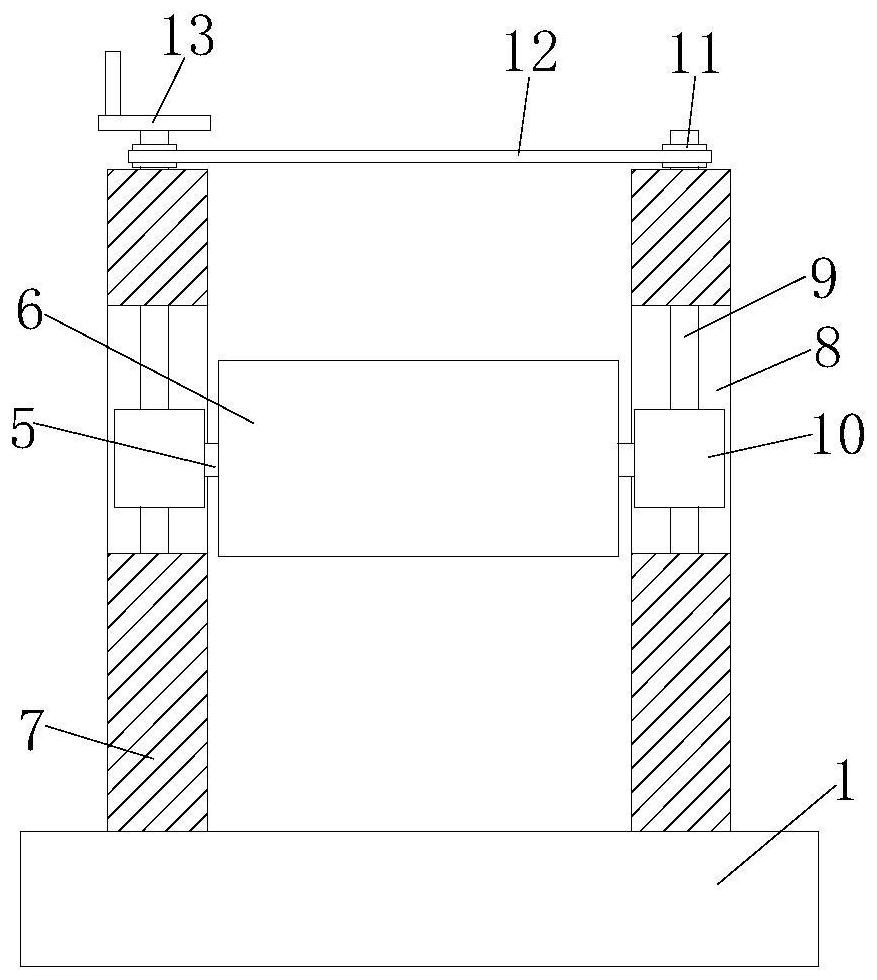

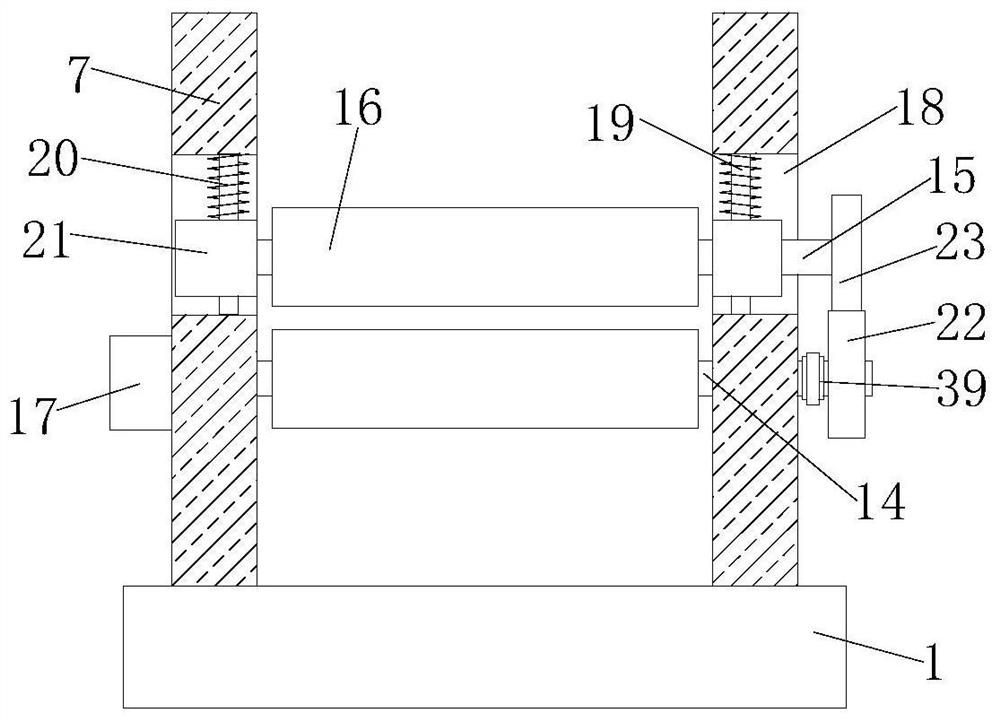

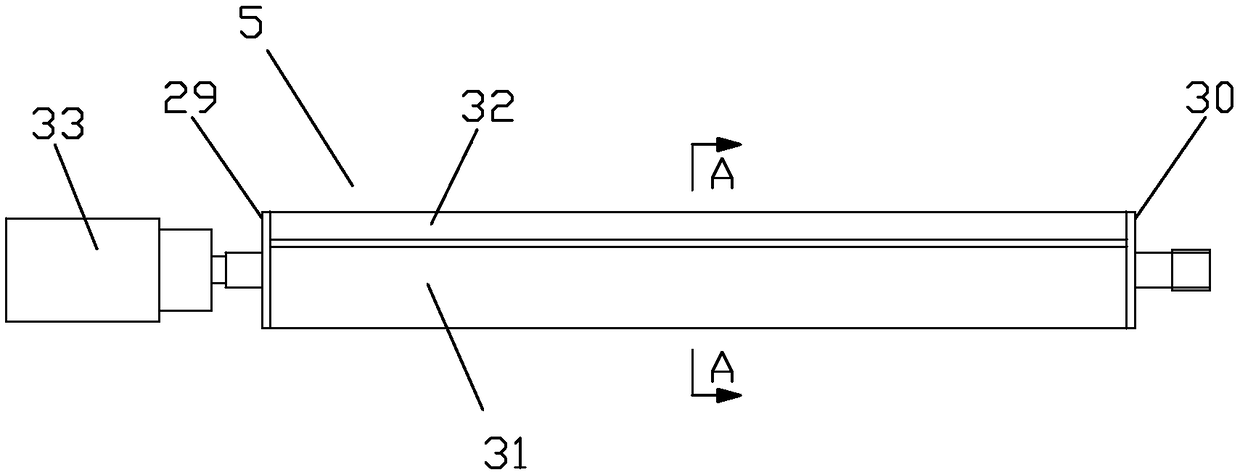

Winding machine and method for controlling the same

InactiveCN102951494AResistance to changes in relative tensionChange the tensionFilament handlingTension measurementWinding machineControl signal

The invention relates to a method for controlling a winding machine (1). The method involves performing parallel winding of continuously running goods (2a, 2b) to be wound to coils (3a, 3b) that are supported on a common spindle (18). Control signals are produced, and actuators (20, 21) are subjected with the signals, where the actuator changes contact force of a pressure roller (13) at the coils depending on the signals. The signals are provided depending on voltage of the goods to be wound and / or deflection of dancer rollers (8a, 8b). Rotational speed of the coils is controlled depending on the voltage of the goods and / or the deflection of the dancer rollers.

Owner:GEORG SAHM GMBH & CO KG

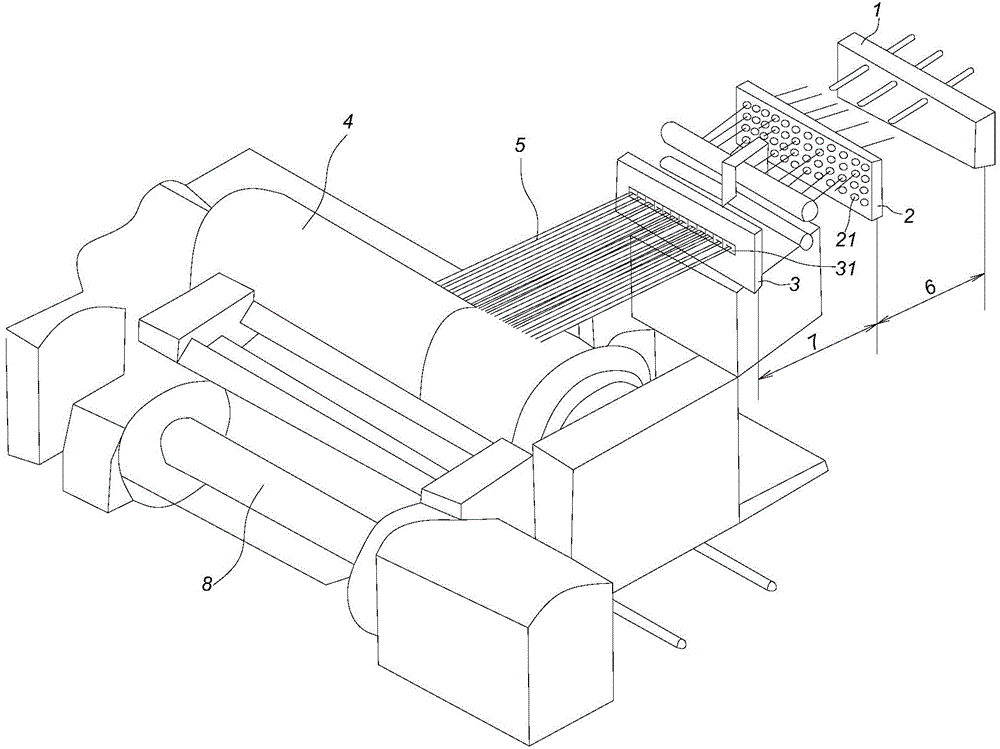

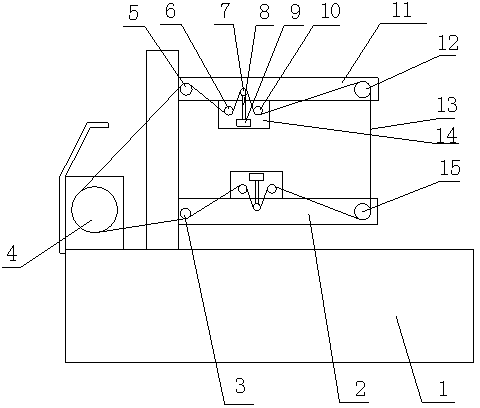

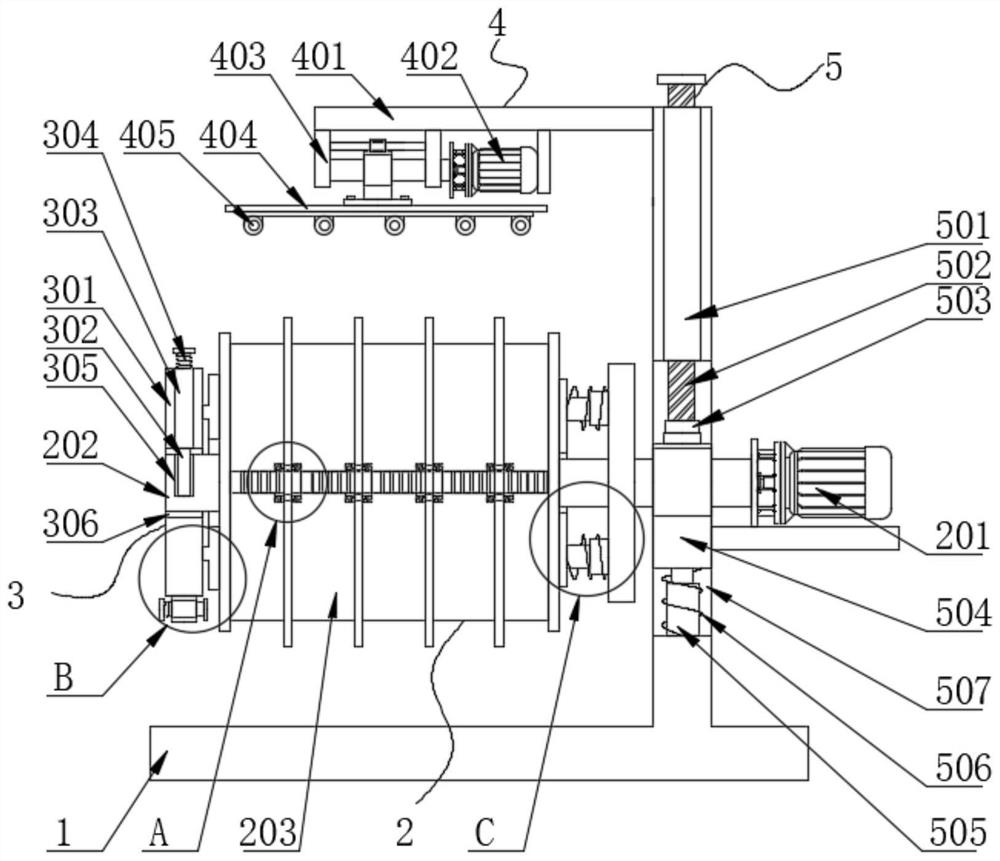

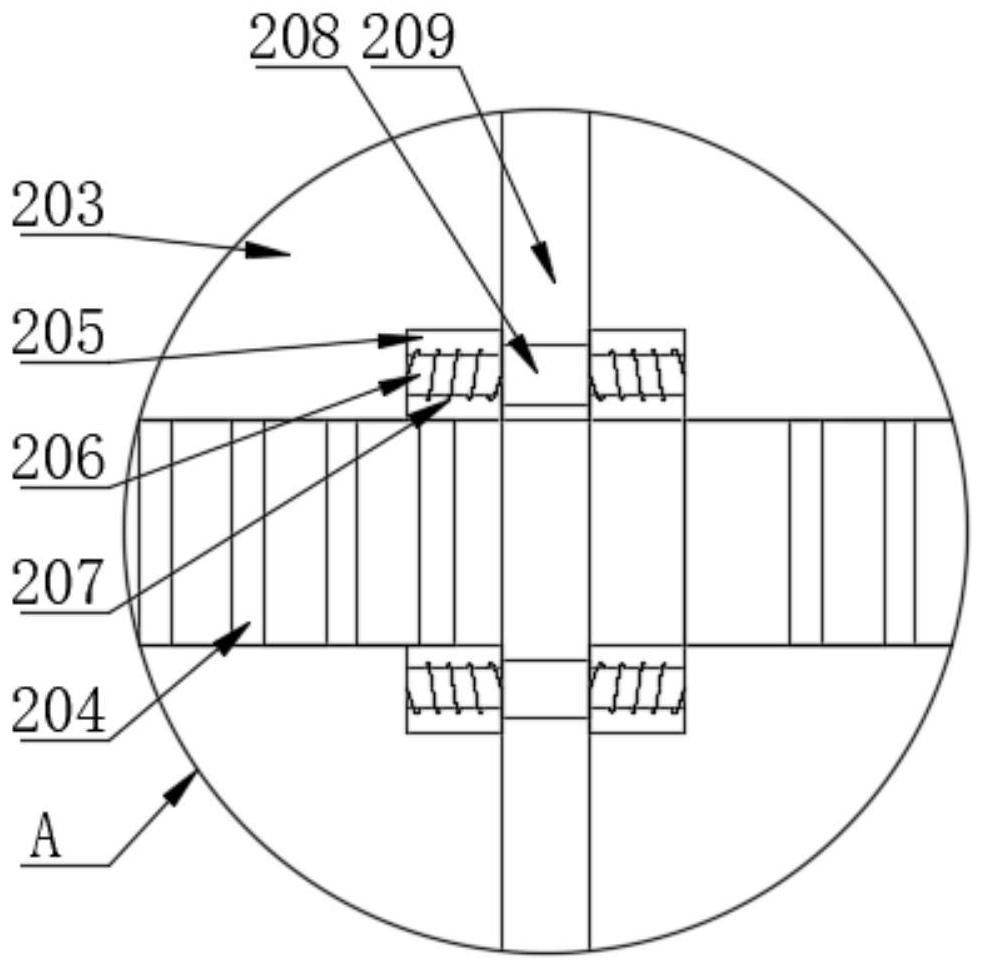

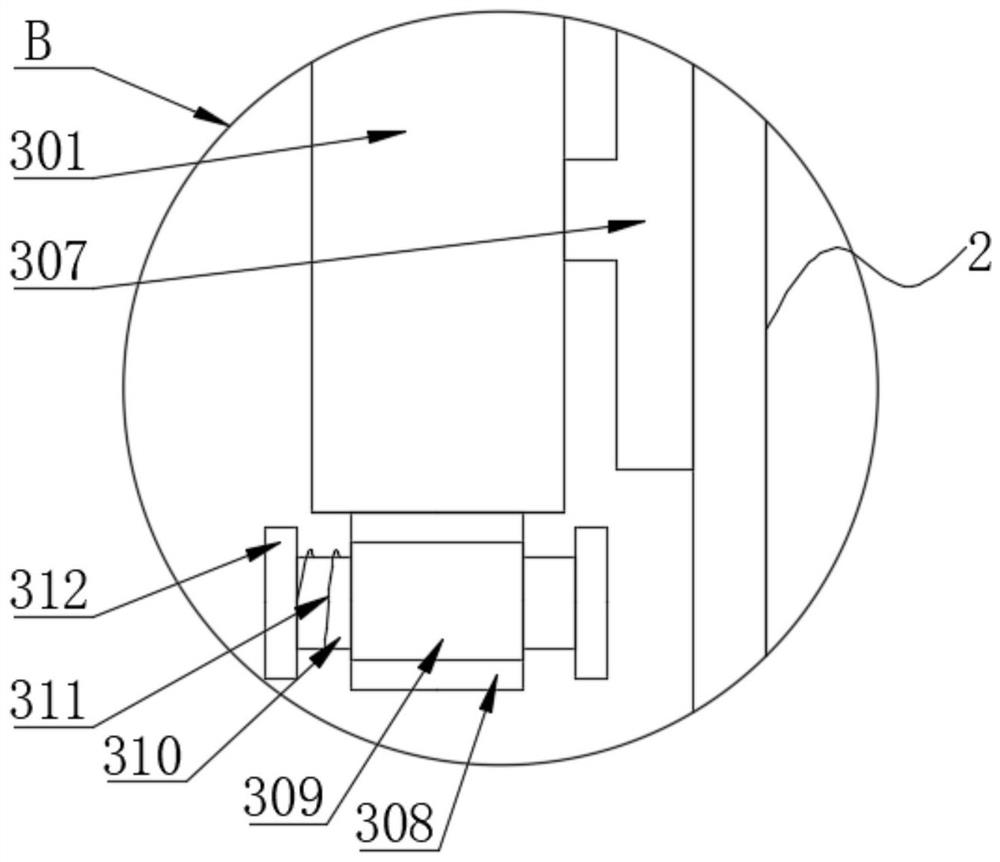

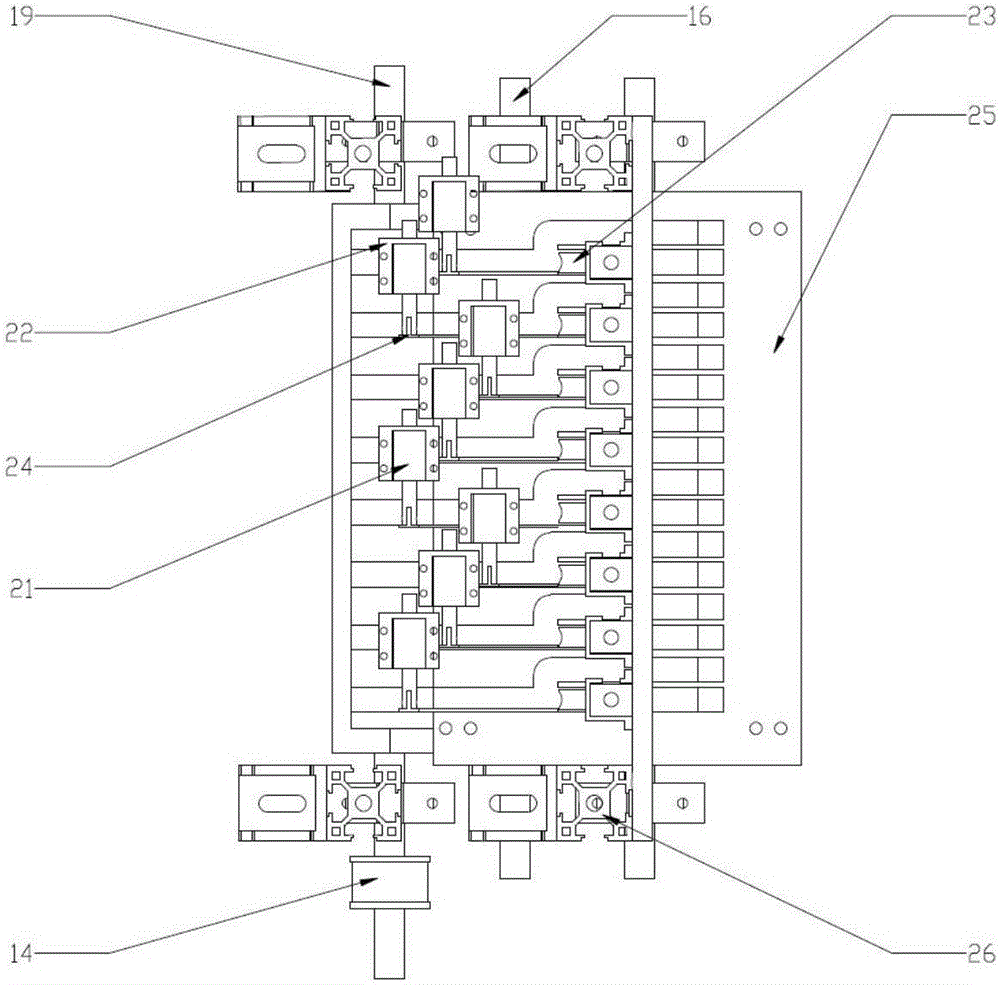

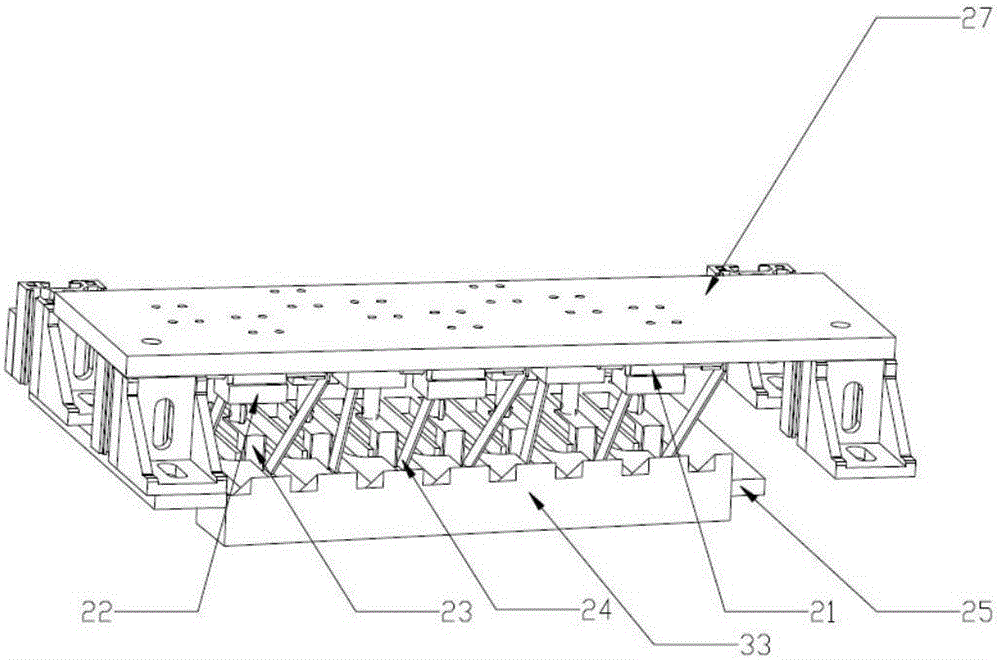

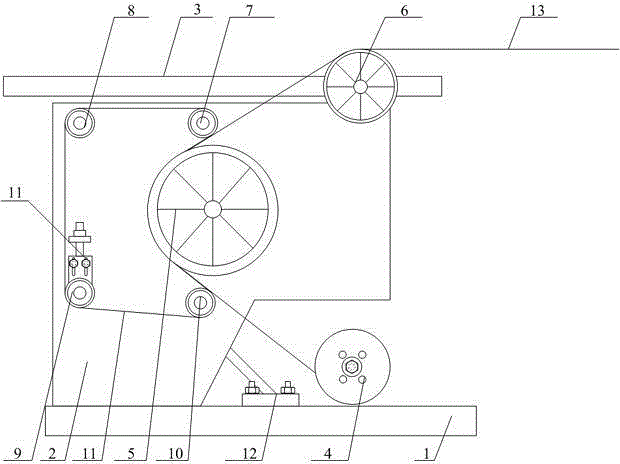

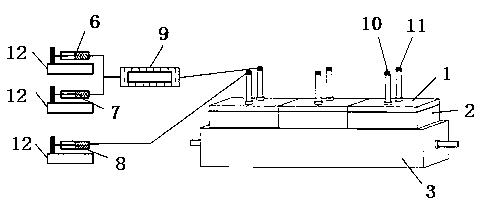

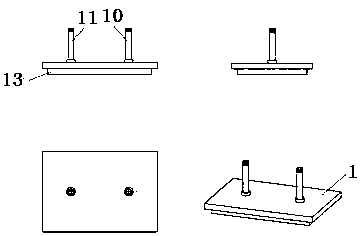

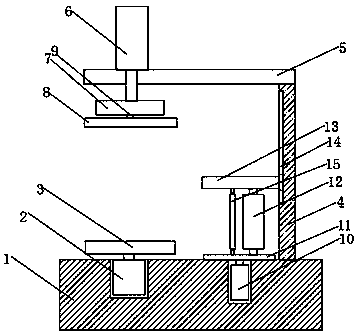

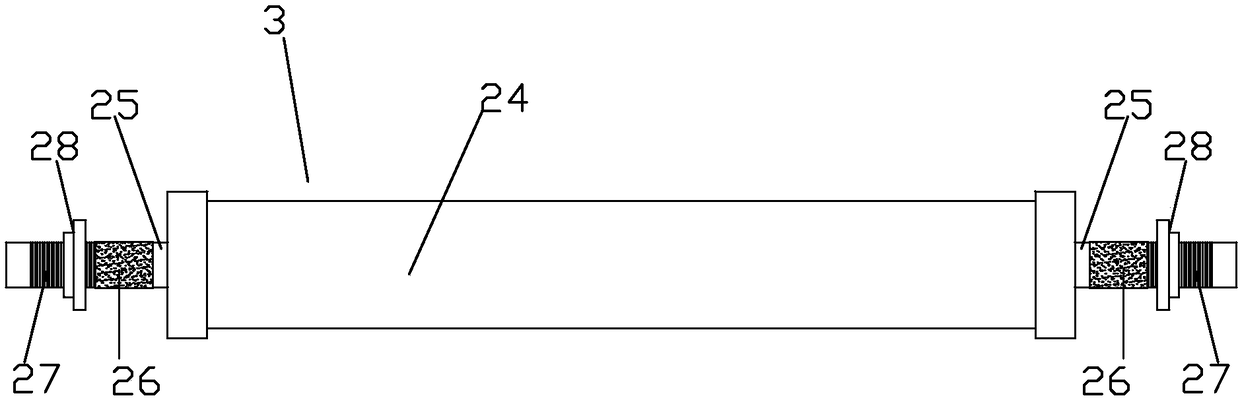

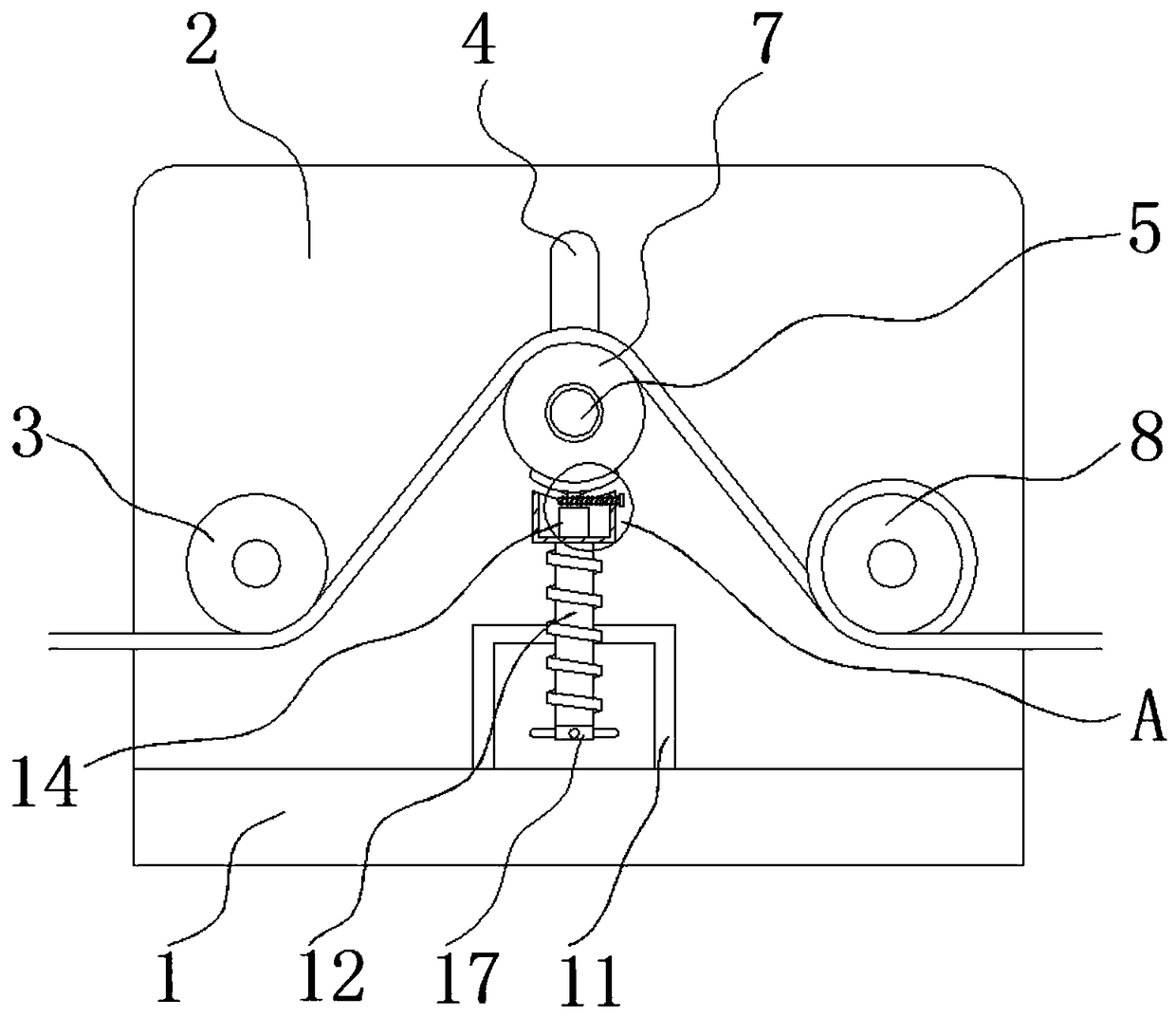

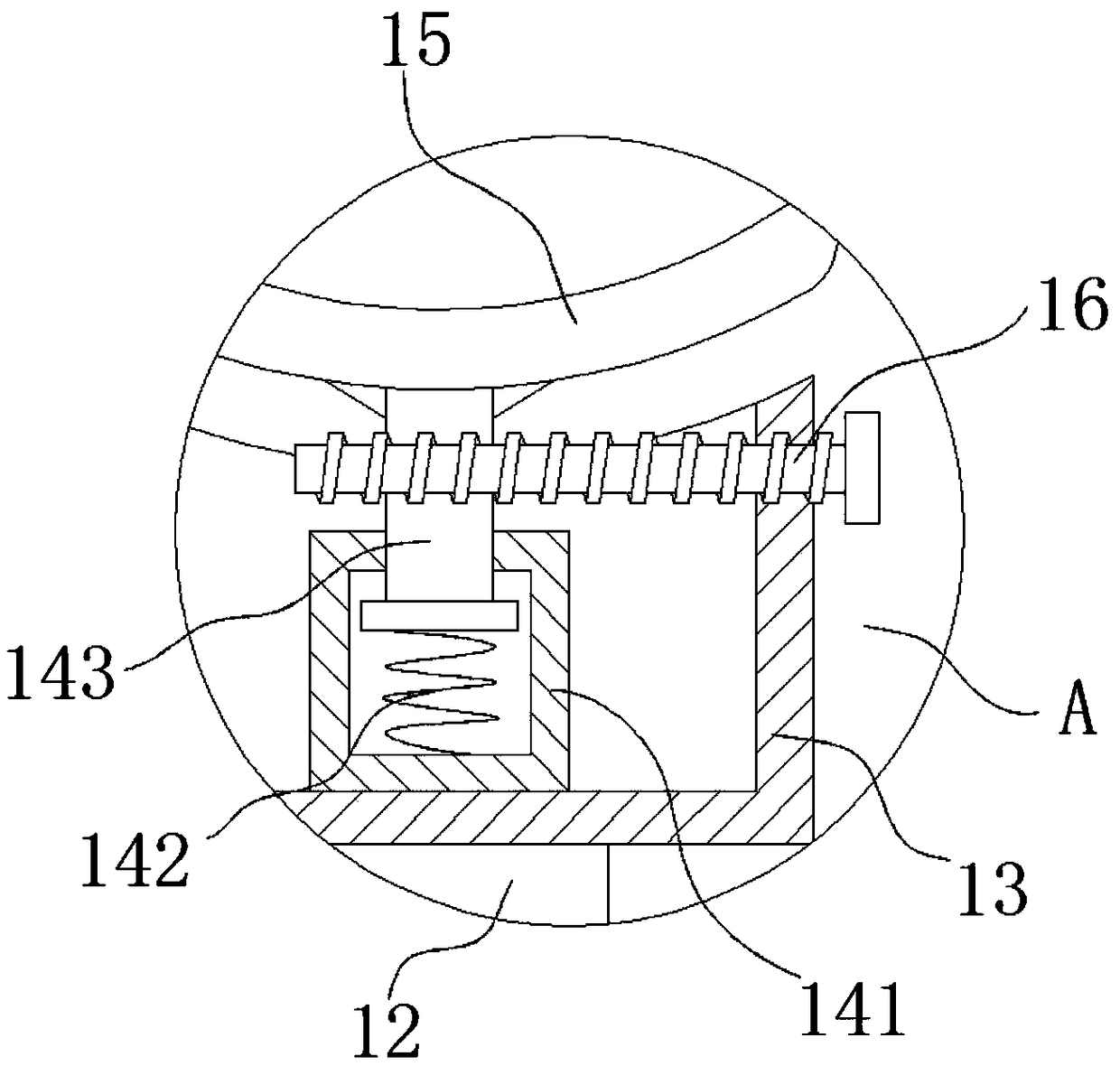

Linear cutting machine

InactiveCN103406616AChange the tensionElectrical-based machining electrodesElectrical-based auxillary apparatusMeasurement deviceEngineering

The invention relates to a linear cutting machine, comprising a base, a wire storage barrel, a coil holder, and a wire electrode, wherein the wire electrode achieves wire-driving and tensioning of the wire electrode in coordination of the wire storage barrel and a guide wheel; wire electrode tension measurement devices are arranged on an upper bracket arm and a lower bracket arm of the coil holder; the tension measurement device comprises two guide wheels, a regulating wheel, a regulating rod and a sensing element; the two guide wheels are arranged at two sides of the regulating rod, and symmetrical relative to the center shaft of the regulating rod; the regulating rod is a hydraulic rod; the position of the regulating rod is controlled by the sensing element; the positions of the upper bracket arm and the lower bracket arm of the coil holder can be adjusted.

Owner:昆山瑞钧机械科技有限公司

Take-up structure with anti-winding effect for textile operation

The invention discloses a take-up structure with an anti-winding effect for textile operation, and belongs to the technical field of textile assistive devices. The take-up structure comprises a rack,one side of the rack is movably connected with a winding mechanism, one side of the winding mechanism is provided with a clamping mechanism, and the top of the winding mechanism is movably connected with the rack through a lifting mechanism; and the top of one side of the rack is fixedly connected with a wire arranging mechanism, the winding mechanism comprises a first motor, and an output shaft of the first motor is fixedly connected with a first rotating shaft. According to the take-up structure, by the arrangement of the winding mechanism and the wire arranging mechanism, wire harnesses canbe effectively prevented from being wound with one another during winding, the multiple wire harnesses can be taken up at the same time, the separation effect during simultaneous winding of the multiple wire harnesses can be guaranteed through a baffle connected to the outer wall of a winding drum, and burrs of the wire harnesses during pulling can be avoided through a smooth guide sleeve; and the winding efficiency is remarkably improved while winding of thread bodies is avoided, and the requirement for adapting to the textile operation is met.

Owner:青岛富思特纺织股份有限公司

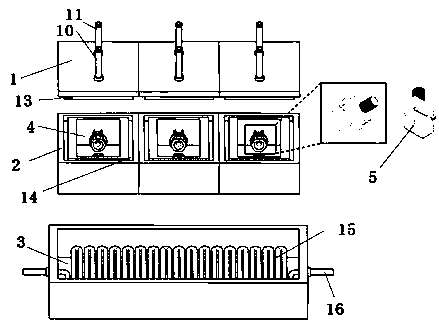

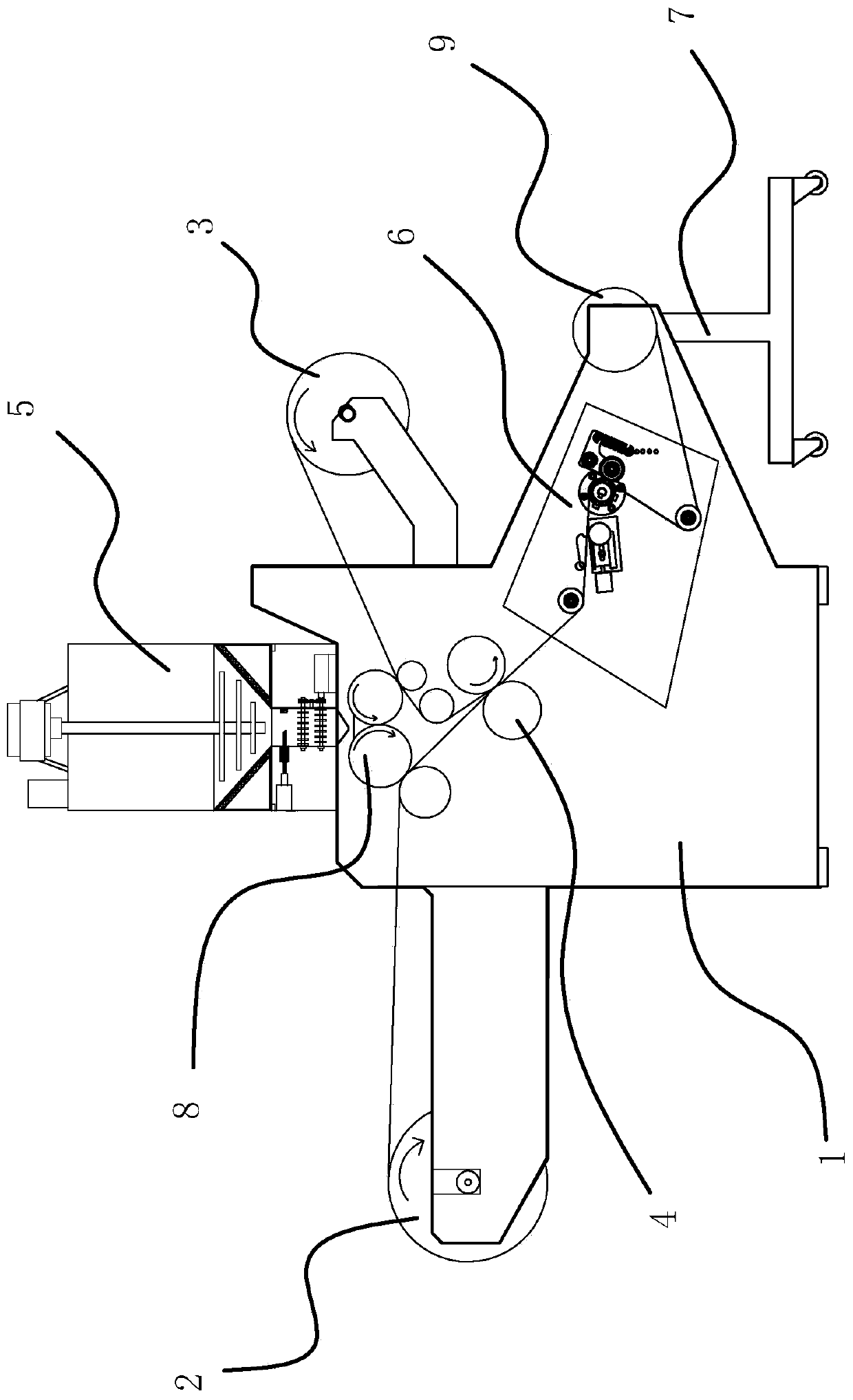

Soybean seed grading device based on embedded machine vision

InactiveCN106311629AMultiple Surface ParametersAccurate identificationSortingGradingCollection systemEngineering

The invention relates to a soybean seed grading device based on embedded machine vision. The soybean seed grading device comprises a sloping mechanical preliminary sorting system, an embedded machine vision system, an intelligent control system, an automatic aligning system, a seed self-rotating and real-time eliminating system and a collecting system. When the soybean seed grading device is started, soybean seeds are sorted by the sloping mechanical preliminary sorting system, the most inferior soybean seeds are sorted out and put into a waste tank, and the remaining soybean seeds are conveyed into the automatic aligning system; by utilization of circular grooves in the surface of a conveying belt in the automatic aligning system, the soybean seeds are automatically aligned, and the aligned soybean seeds are conveyed into the seed self-rotating and real-time eliminating system; when entering a dark box in the seed self-rotating and real-time eliminating system, the soybean seeds perform self-rotating action under the action of a secondary sorting mechanism; through an image acquiring device, the surface parameters of the soybean seeds in the self-rotating state are acquired by the embedded machine vision system in real time, and then the soybean seeds are distinguished and analyzed; and according to feedback information of the embedded machine vision system, the soybean seeds of different qualities are sorted and put into different collectors, thereby achieving multi-grade sorting of the soybean seeds. The soybean seed grading device has the characteristics of being light and convenient, efficient and correct, and can be applied to sorting of grain seeds.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Brushing and arranging device for clothes production

The invention discloses a brushing and arranging device for clothes production. The brushing and arranging device comprises a machine body. A support is arranged on the machine body and provided with a cloth inlet roller and a cloth outlet roller. A feed roller, a tensile force control device and a fabric expanding device are arranged on the support. A transmission roller and a cleaning device are arranged in the machine body. Spray nozzles are arranged on the cleaning device. A transitional roller and a drying device are arranged in the machine body. A first brushing roller, a second brushing roller, a third brushing roller and a fourth brushing roller are arranged in the machine body. A first cloth pressing roller is arranged between the first brushing roller and the second brushing roller. A second cloth pressing roller is arranged between the third brushing roller and the fourth brushing roller. A cloth arranging device is arranged on the machine body. A cloth discharge device is arranged on a machine frame. The brushed fabric is smooth, free of creases, consistent in tightness and good in brushing effect, heat retention property and softness are improved, product quality is improved, brushing is achieved on two sides at the same time, production efficiency is improved, and the technological process is shortened.

Owner:SHAOXING HENRY TIE FASHION

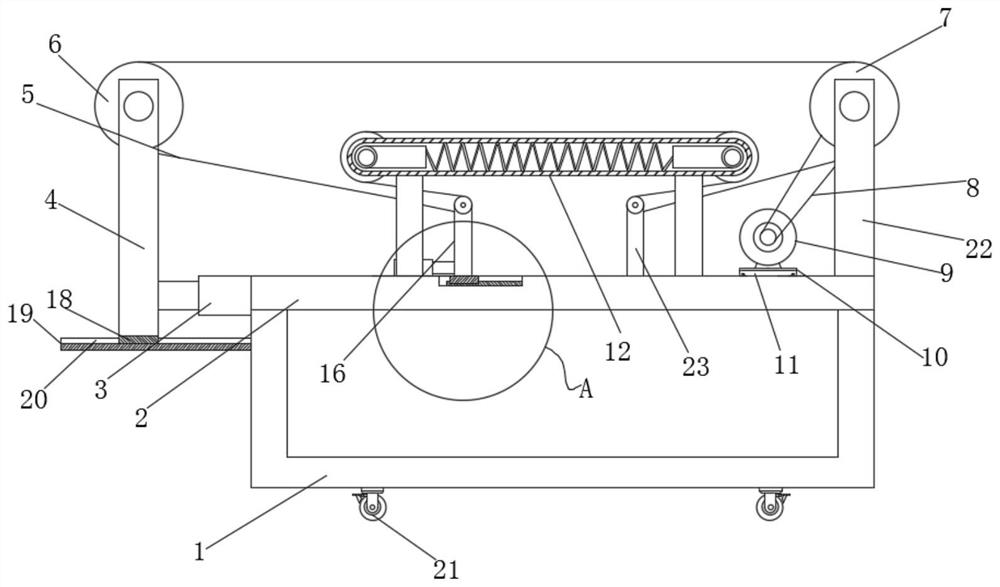

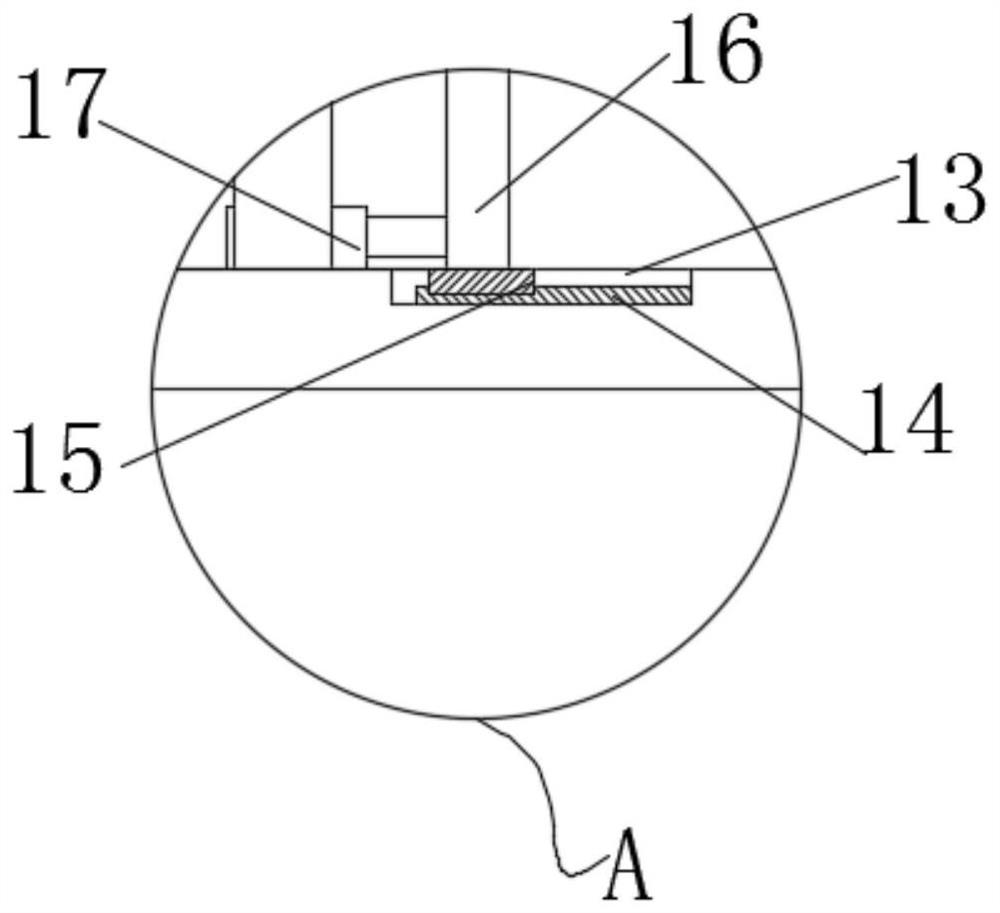

Varnished wire take-up machine

InactiveCN105035864AAdjustable tensionChange the tensionFilament handlingInsulation layerLeather belt

The invention discloses a varnished wire take-up machine, and belongs to the field of cable production equipment. The take-up machine comprises a guide wheel, a traction wheel and a take-up disc. The guide wheel is located above the front portion of the traction wheel, and the take-up disc is located below the front portion of the traction wheel; a varnished wire is sequentially wound around the guide wheel and the traction wheel to be connected with the take-up disc; a belt rotating mechanism for compressing the varnished wire is arranged on the outer side of the traction wheel, and the belt rotating mechanism is tightly attached to the traction wheel; and the take-up disc and the traction wheel are connected with a driving mechanism. Through cooperation of the guide wheel, the traction wheel and a belt, the varnished wire is compressed and collected and is prevented from being directly drawn; stress of the varnished wire is greatly reduced, and the phenomena that the varnished wire is scratched, and an insulation layer is damaged are effectively avoided; the varnished wire is compressed through the belt, the contact area among the traction wheel, the belt and the varnished wire is greatly increased, and the wire take-up process is more stable and reliable; and compressing is carried out through the belt, and the insulation layer of the varnished wire is protected better.

Owner:江苏五洲电磁线有限公司

Edge cutting device capable of effectively preventing cloth from wrinkling

InactiveCN111826931ANo creases appearGuaranteed dimensional accuracySevering textilesStructural engineeringMechanical engineering

The invention discloses an edge cutting device capable of effectively preventing cloth from wrinkling, and relates to the technical field of cloth processing. To solve the wrinkle problem, specifically, the edge cutting device comprises a material guide mechanism and a cutting mechanism, wherein the material guide mechanism comprises two vertical plates fixed to the ground, as well as an adjustable clamping assembly, a damping clamping assembly and a tensioning assembly which are arranged on the outer walls of the vertical plates, the adjustable clamping assembly comprises pressing springs andfirst ejector pins, the tensioning assembly comprises tensioning springs and a tensioning roll, a tensioning frame is fixedly installed on the outer wall of each vertical plate, and a first sliding groove is formed in the inner wall of each tensioning frame. According to the edge cutting device, the damping clamping assembly and the tensioning assembly are arranged, when a conveying assembly is used for conveying, the damping clamping assembly can provide moving damping force for rotation of a cloth roll, due to the damping force, the two tensioning springs are pressed, thus downward tensionforce is generated for the cloth, so that the whole cloth is in a tension state, then wrinkles are avoided, and further, the size accuracy of a cutting assembly during cutting is guaranteed.

Owner:安徽工美服装有限公司

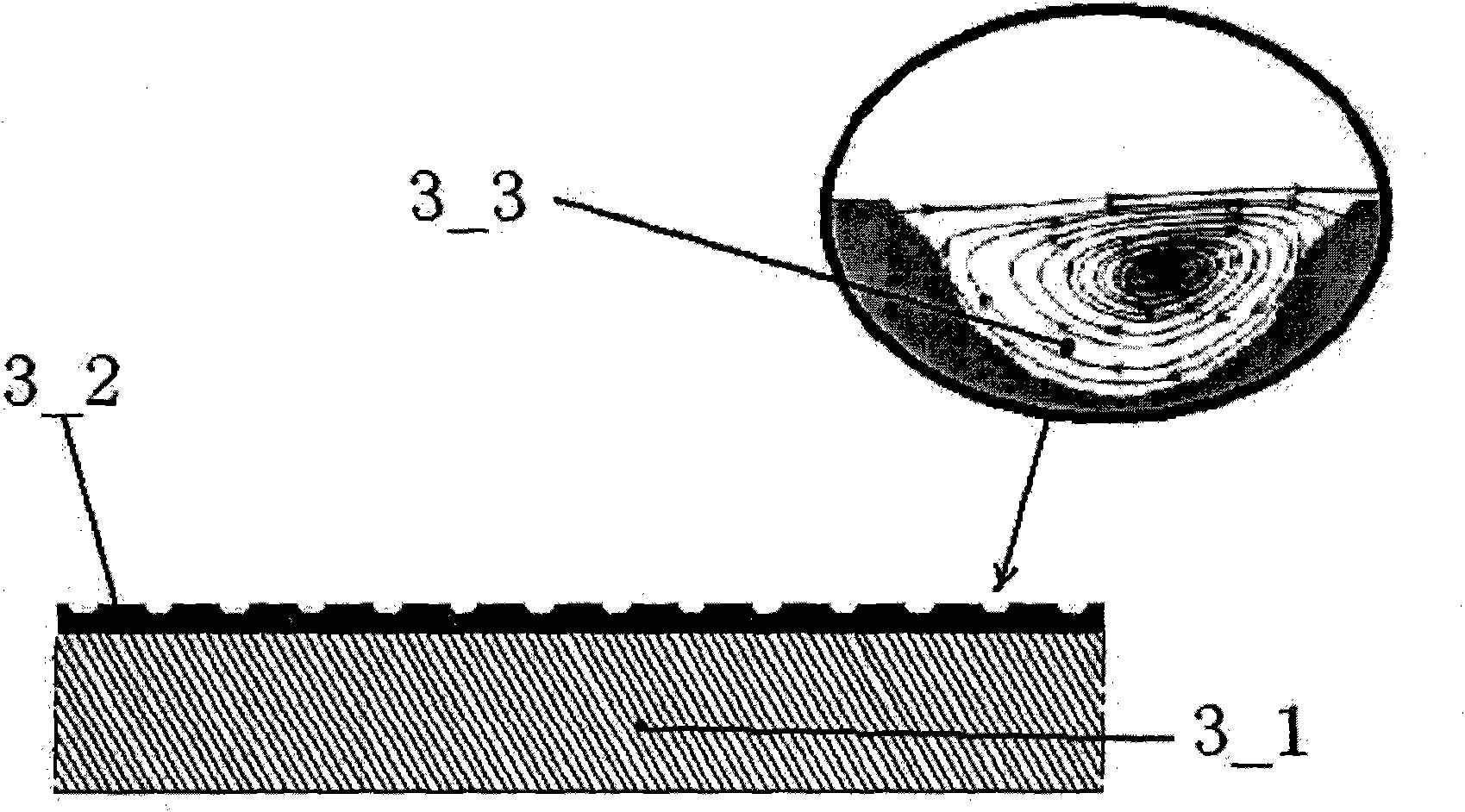

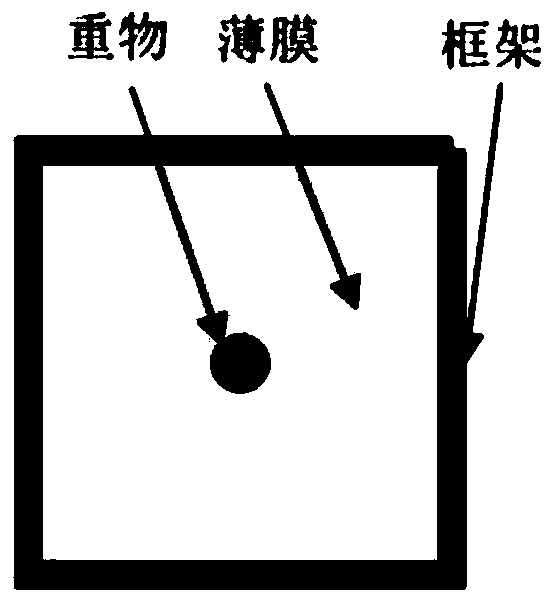

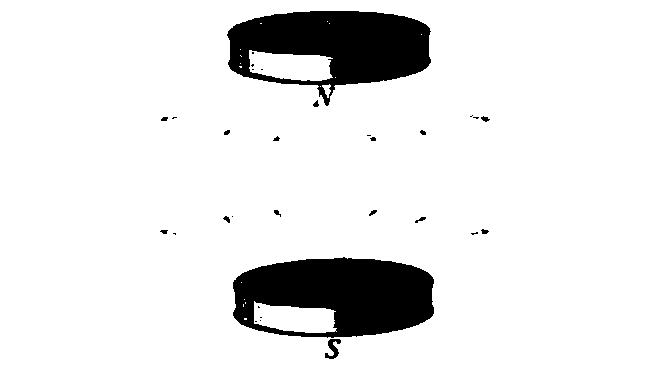

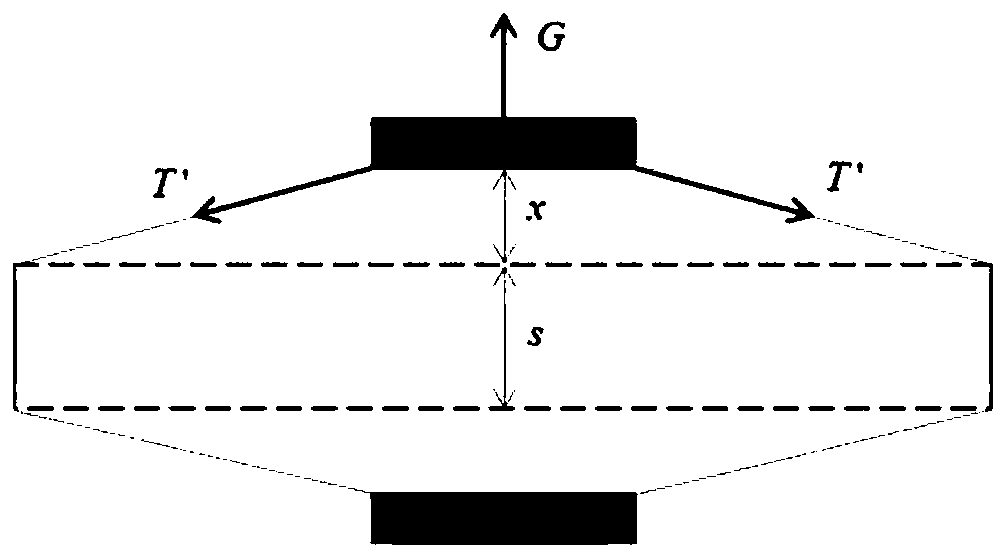

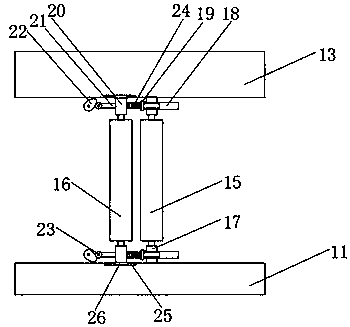

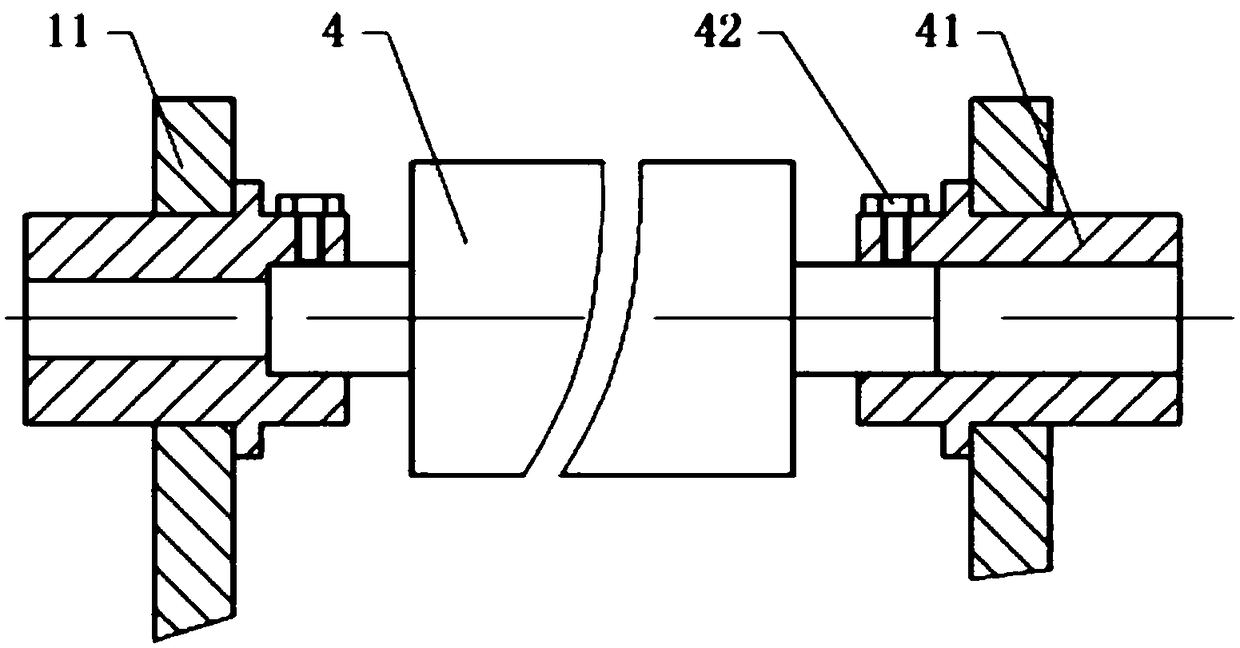

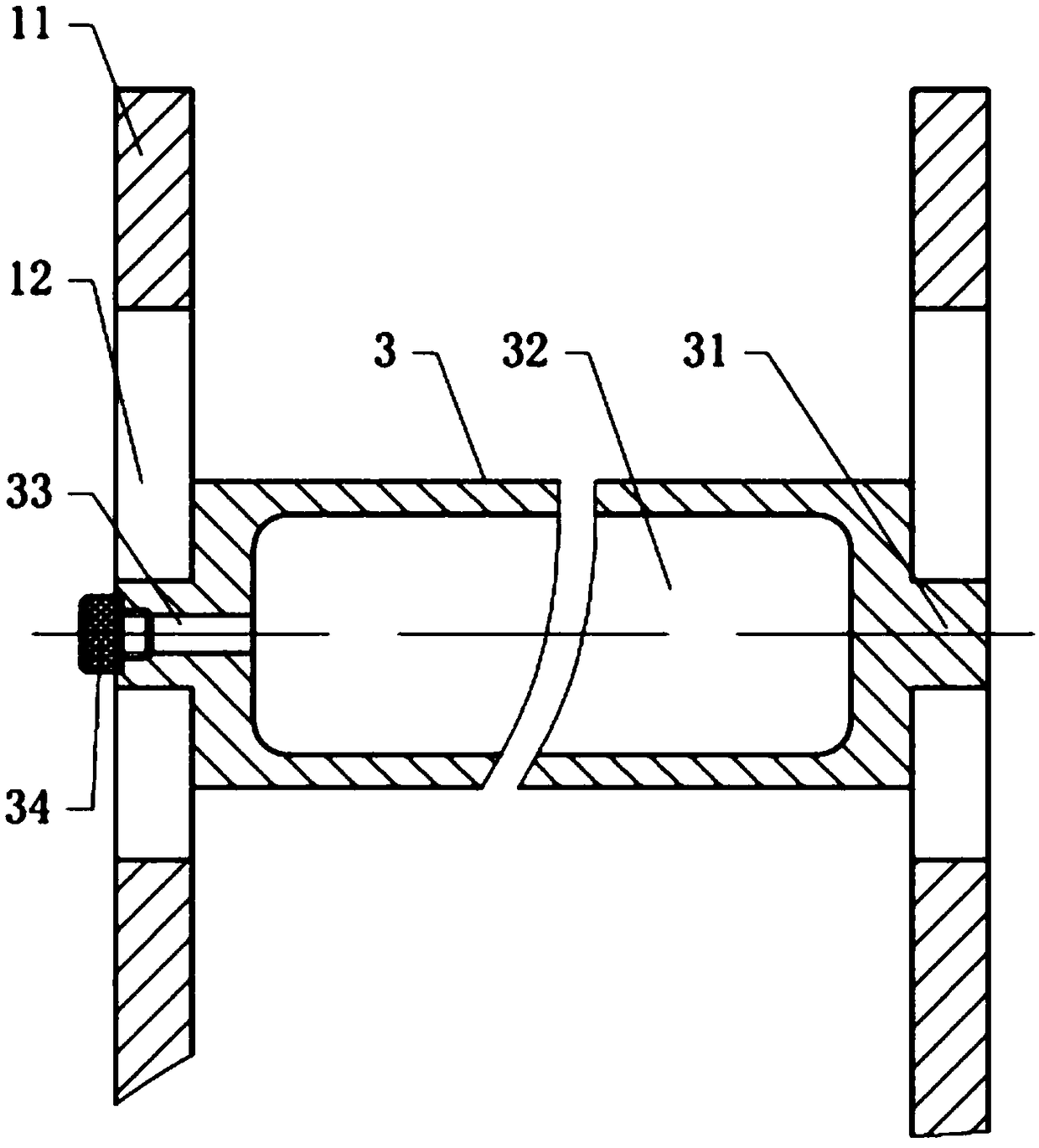

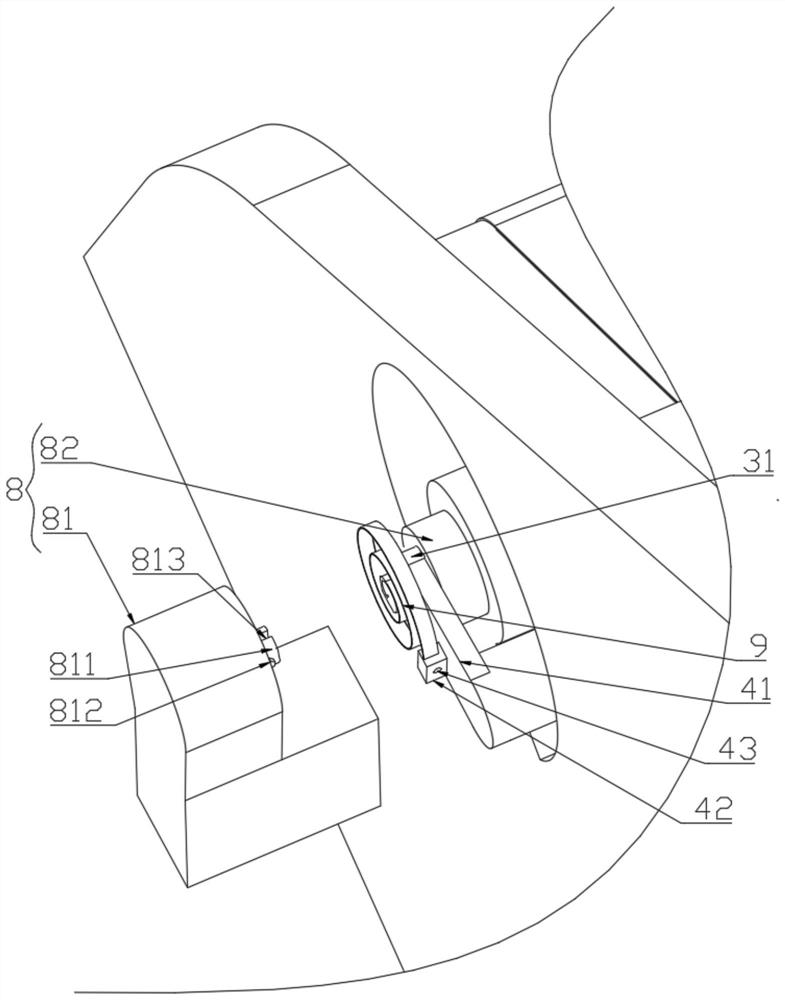

Acoustic supermaterial structure of adjustable double-layer thin film plate based on repulsion force of permanent magnet

ActiveCN109493840AStructural sound insulation can be adjustedChange the tensionSound producing devicesMagnetic tension forceRepulsion force

The invention discloses an acoustic supermaterial structure of an adjustable double-layer thin film plate based on repulsion force of a permanent magnet, and belongs to the field of low frequency anechoic devices. The structure includes a plurality of single cellular structures which are arranged in an array mode, each single cellular structure comprises an upper layer supporting plate structure and a lower layer supporting plate structure, the upper layer supporting plate structure and the lower layer supporting plate structure are fixed through adjustable screw rods, the upper layer supporting plate structure and the lower layer supporting plate structure are both provided with a thin film, and repulsive permanent magnets as bearing loads are arranged at the centers of the thin films. According to the double-layer thin film plate supermaterial, the film prestressing force is changed through the magnetic action of permanent magnet, and the range of adjustable sound insulation band iswidened compared with a film plate structure of an ordinary mass block. By adjusting the distance between the two layers of plates, the magnetic force can be adjusted indirectly, thus, the film tension can be adjusted, the adjustment mode is simple and easy to be achieved, and the structure can play the role of adjustable low frequency silencing in a certain frequency range.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Multi-tissue vitrification in-situ preservation device and method

The invention discloses a multi-tissue vitrification in-situ preservation device and method. The preservation comprises a preservation box, wherein a cover plate is arranged above the preservation box, and a water-bath slot is formed below the preservation box; fixed structures are arranged in the preservation box, input structures and an output structure are arranged above the preservation box, the input structures are a first injection syringe and a second injection syringe, a mixing cavity is formed among the first injection syringe, and the second injection syringe and the preservation box; and the fixed structures are carrying tool brackets, and tissue carrying tools are arranged above the carrying tool brackets. The carrying tool brackets are cooperatively arranged, and the distancebetween the two carrying tool brackets is finely adjusted by virtue of a rotary carrying tool, so that the tension of tissues is changed, and uniform concentration of solutions surrounding the tissuesin the perfusion process is guaranteed. The research on the influence of protecting agents with different concentrations on the tissue vitrification preservation result has the advantages that multiple groups of samples can be simultaneously protected, the consistency of other experiment conditions can be adequately guaranteed, and experiment results are relatively accurate and reliable.

Owner:银丰低温医学科技有限公司 +1

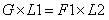

Method and device for changing prestress of lifting arm of flat-head tower crane

The invention relates to the technical field of a flat-head tower crane, in particular to a method and a device for changing prestress of a lifting arm of the flat-head tower crane. An inhaul cable structure is arranged on each of a balance arm and a lifting arm; the computational formula of the inhaul cable pulling force of the lifting arm is obtained according to the moment balance principle; so that the component force of the inhaul cable pulling force of the lifting arm on the vertical direction causes a bending moment on the root part of the lifting arm opposite to the gravity and loading direction of the lifting arm; and the bending moment can enable the lifting arm to generate a prestress. Therefore, the pulling force of the lifting arm inhaul cable can be changed by adjusting the position of the hinged points of the inhaul cable and the balance arm or the lifting arm to further change the prestress of the lifting arm so as to improve the lifting capacity of the lifting arm.

Owner:SHANDONG FORYOU +1

Plastic thin film laminating machine

The invention provides a plastic thin film laminating machine. The plastic thin film laminating machine comprises a rack, a first unwinding roller, a second unwinding roller, a pair of laminating rollers, a gluing mechanism, a traction mechanism and a winding mechanism. The first unwinding roller and the second unwinding roller are rotatably connected to the rack, the laminating rollers are rotatably arranged at the position, between the gluing mechanism and the traction mechanism, of the rack, the winding mechanism comprises a transfer base and a winding roller, the two ends of the winding roller are provided with winding rotating shafts, one end of the rack is provided with a C groove allowing the winding rotating shafts to transversely slide in, the transfer base is provided with a supporting structure for supporting the winding rotating shaft to rotatably adjust the height of the winding roller, and a driving motor, a driven shaft, a winding shaft sleeve and a gear assembly are arranged on one side of the rack. The supporting structure in the winding mechanism can adjust the height of the U supporting part, the winding rotating shaft can be aligned with a shaft hole of a driven shaft, and the driven shaft drives the winding roller to rotate more stably.

Owner:浙江天畅塑胶有限公司

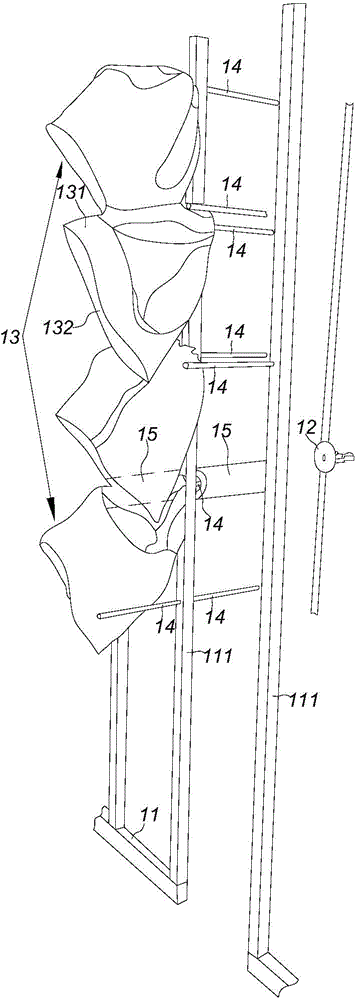

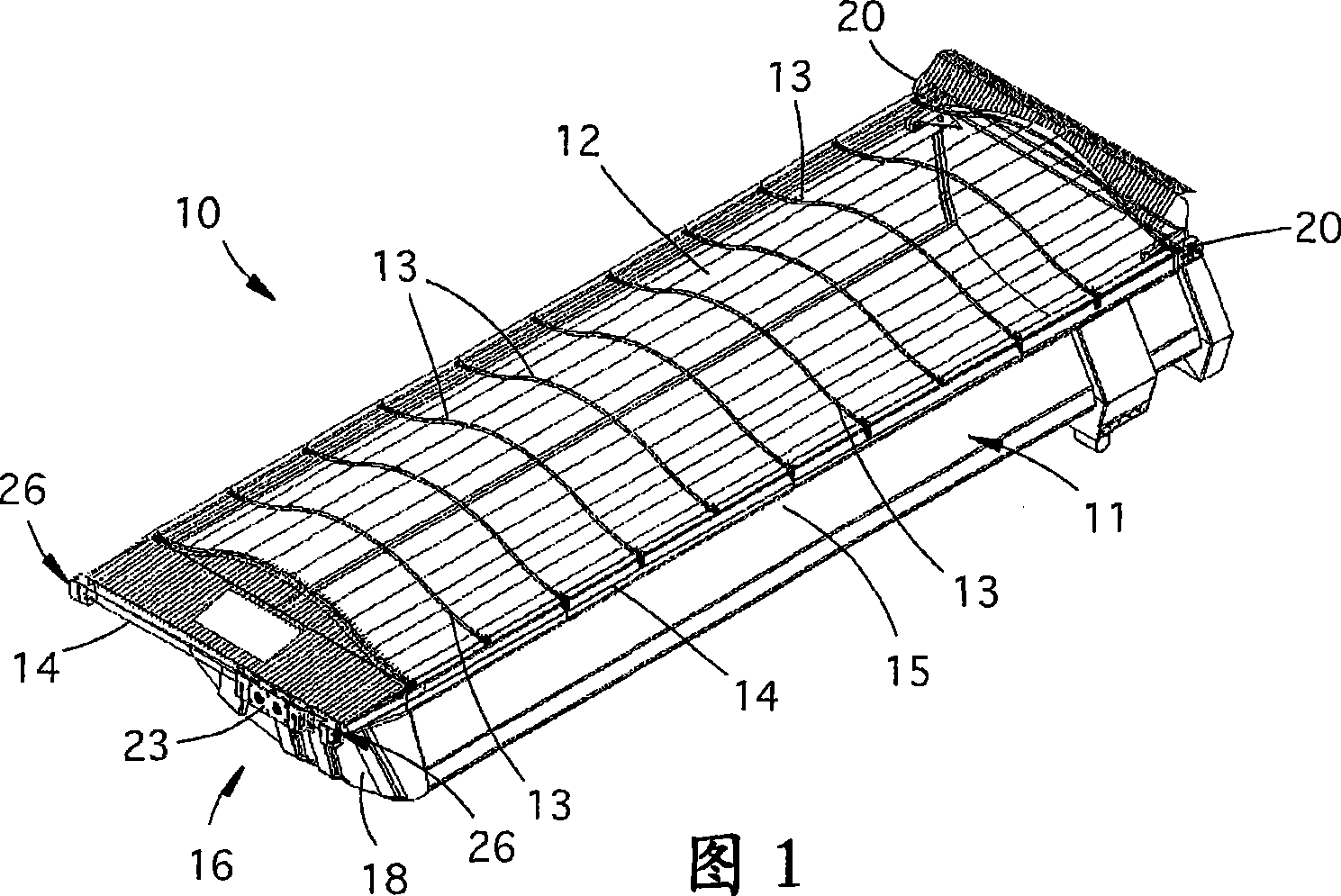

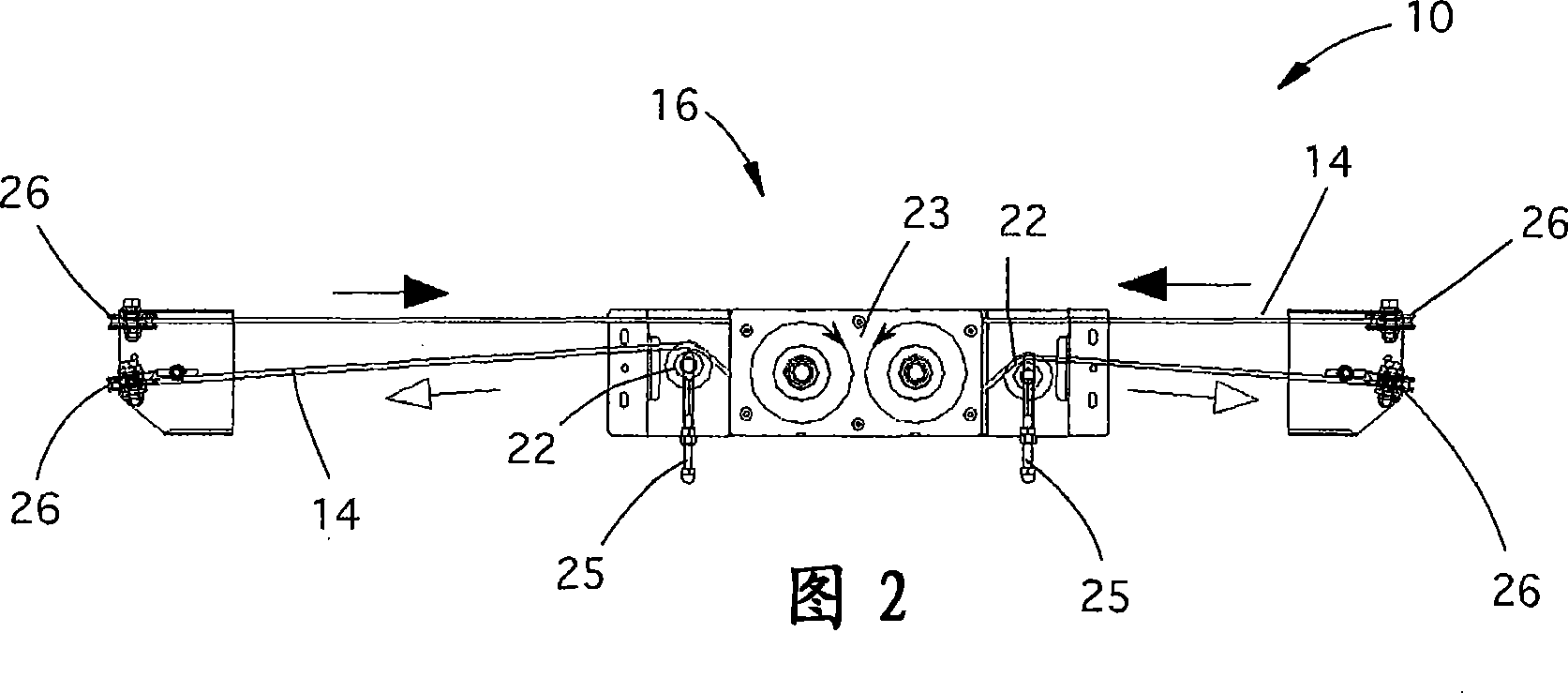

Sport device capable of making the covering element relevant with the transportation means slide

InactiveCN101396983AShorten the timeLow costRailway componentsLoad coveringEngineeringMotion transfer

The invention relates to a motile device which can cause a transportation-related covering element to slide. Regarding a motile device (10) used in a sliding element (13), the sliding element is used for covering an industrial transportation body (11), and the motile device comprises two cables (14) which are formed into a closed loop and are parallel to each other along the side faces (15) of both side parts of the body. The sliding element is attached to each cable. The motile device also comprises a transmission mechanism (16) used for restricting the cables so as to deliver movement to the two cables in a simultaneous and coordinated manner. The transmission mechanism comprises a pair of gears (17) meshed with each other mutually and at least a pair of motile pulleys (19), at least one of the gears is driven, and the motile pulleys are mounted coaxially on the corresponding gears so as to rotate together with the gears. Each cable is kinematically mounted on the corresponding pulley, so that the two pulleys which are controlled by the gears meshed with each other mutually rotate at the same time to limit the simultaneous and coordinated movement of the cables and the sliding element.

Owner:WENZHOU CRAMARO MASKING SYST

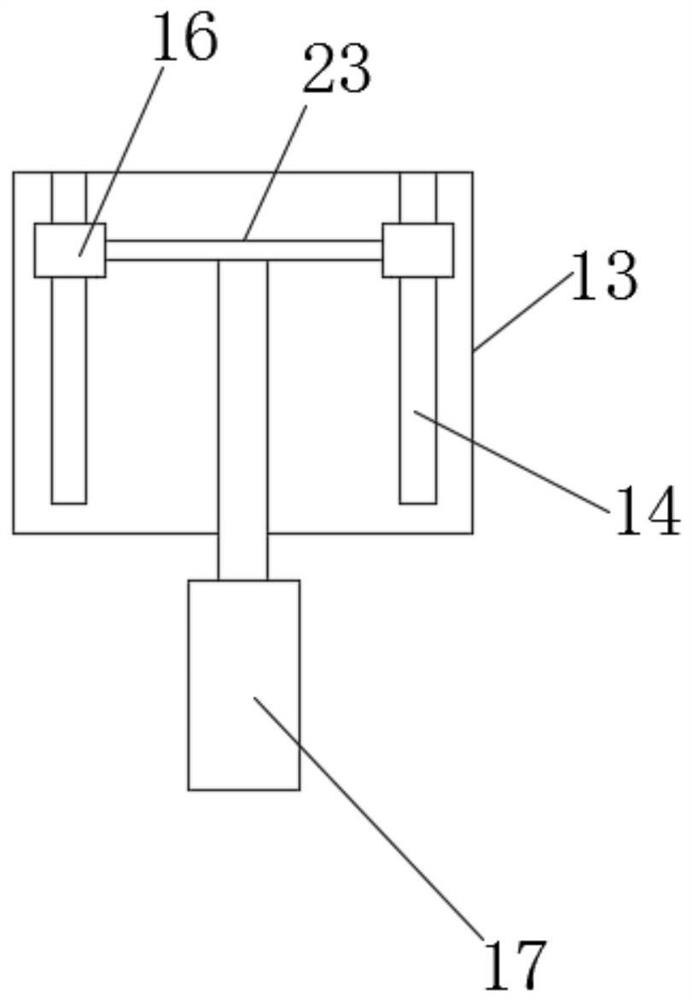

Novel winding machine winding method and device thereof

InactiveCN110589051AFully packagedChange gapWrapping material feeding apparatusWrapping with article rotationWinding machineElectric machinery

The invention provides a novel winding machine winding method and device thereof, and relates to the technical field of winding machines. The novel winding machine winding device comprises a base, a vertical plate is welded to one side of the top of the base, a top seat is vertically welded to the top of the vertical plate, a servo motor is embedded in one side of the interior of the base, a driving end of the servo motor penetrates through the top of the base to be fixedly connected with a rotating disc, the side, close to the vertical plate, of the interior of the base is fixedly connected with a first air cylinder, the piston end of the first air cylinder is fixedly connected with a bottom plate through the base, a top plate is arranged above the bottom plate, and a winding roller is arranged between one side of the top of the bottom plate and the top plate. By means of the arranged moving mechanism, a second tensioning roller can be driven to move, so that the distance between a first tensioning roller and the second tensioning roller is changed, so that the tensioning degree of a winding film is changed, and the object is wound more tightly.

Owner:玉门金环密封材料有限公司

Adjusting type belt conveying device

InactiveCN111674842AAdjustable lengthAvoid the downside of taking up spaceConveyorsDrive wheelTransmission belt

Owner:蚌埠联玺自动化设备有限公司

Heating system of continuous annealing wire drawing machine

The invention belongs to the technical field of continuous annealing wire drawing machines, particularly relates to a heating system of a continuous annealing wire drawing machine, and aims to solve the problems that the temperature of the existing continuous annealing wire drawing machine is difficult to fully utilize during wire drawing, the tension during wire drawing is inconvenient to adjust,the position of a steel wire is easy to change during conveying, and the heating is unstable. According to the scheme, the heating system of the continuous annealing wire drawing machine comprises abase, two symmetrically-arranged supporting plates are fixedly installed at the top of the base, a first rotating shaft is rotationally connected to the two supporting plates, the outer side of the first rotating shaft is fixedly sleeved with a pay-off roller, and the outer side of the pay-off roller is wound with a copper wire; and a second rotating shaft is rotationally connected to the two supporting plates, the outer side of the second rotating shaft is fixedly sleeved with a tension roller, and the two supporting plates are rotationally connected with a third rotating shaft and a fourth rotating shaft. The heating system is easy to operate and convenient to use, can heat and stretch the copper wire, can change the tension of the copper wire, can position the position state of the copper wire, and is convenient for people to use.

Owner:王小珍

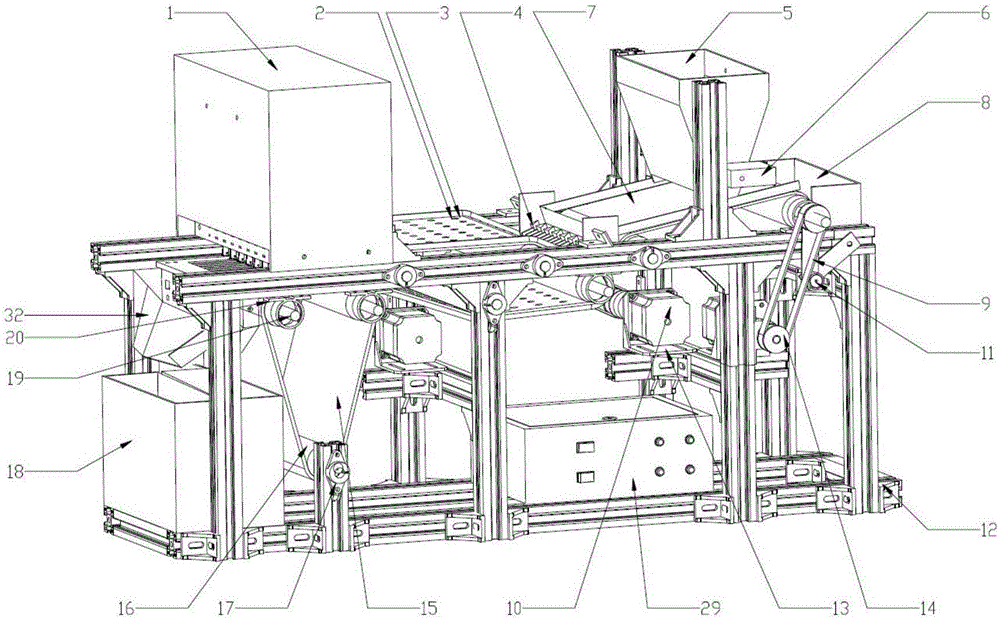

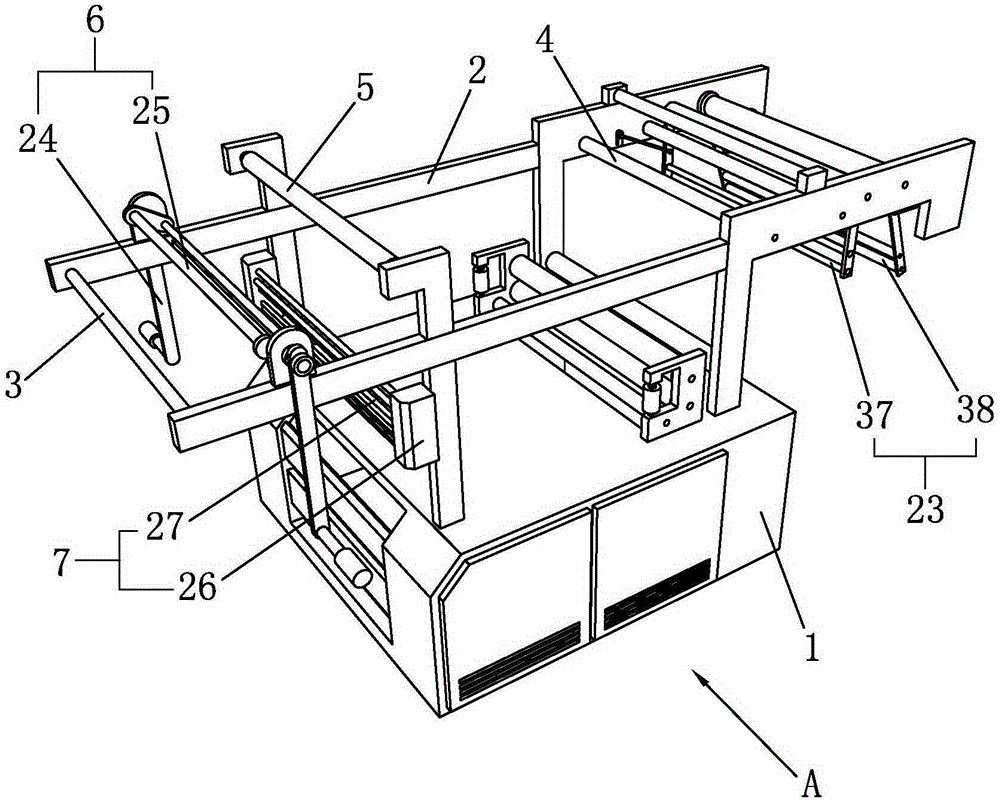

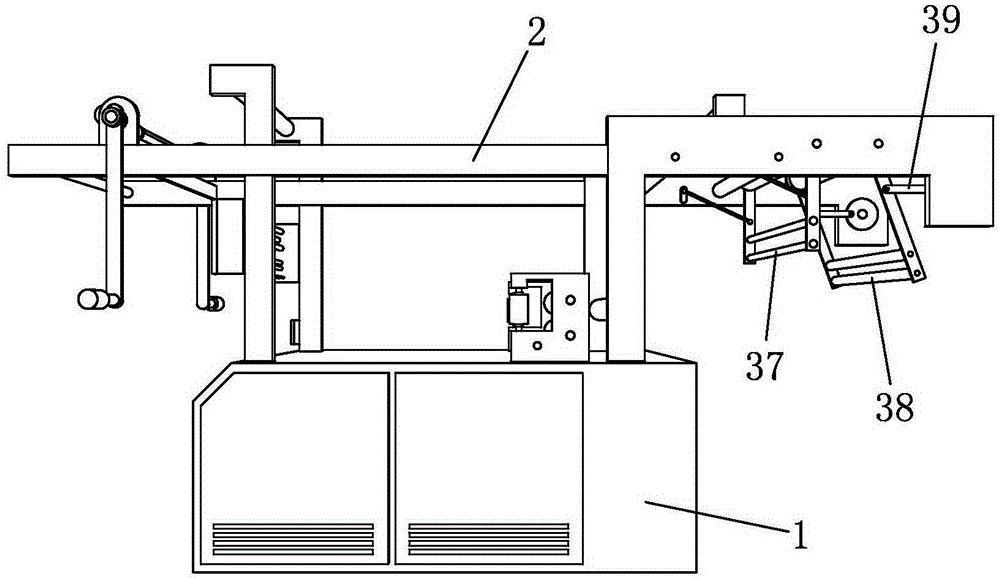

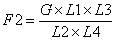

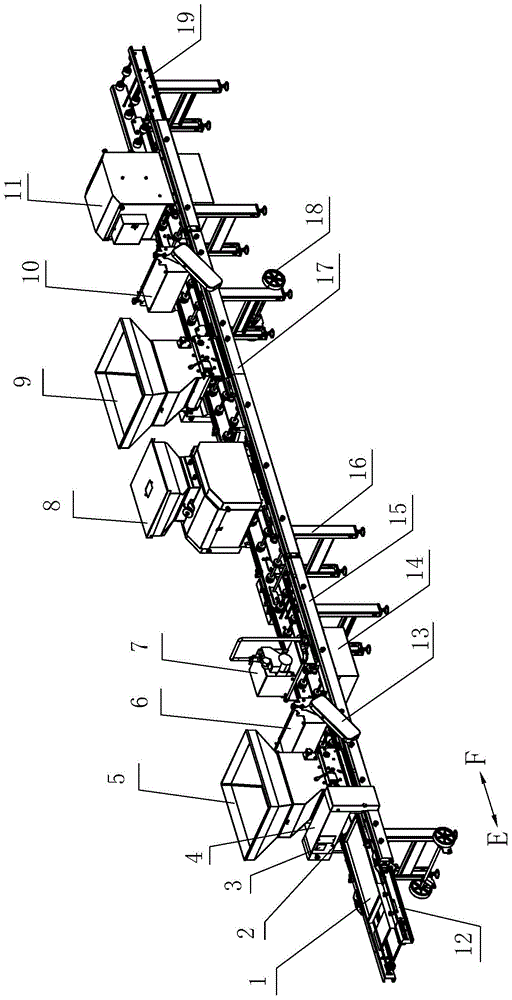

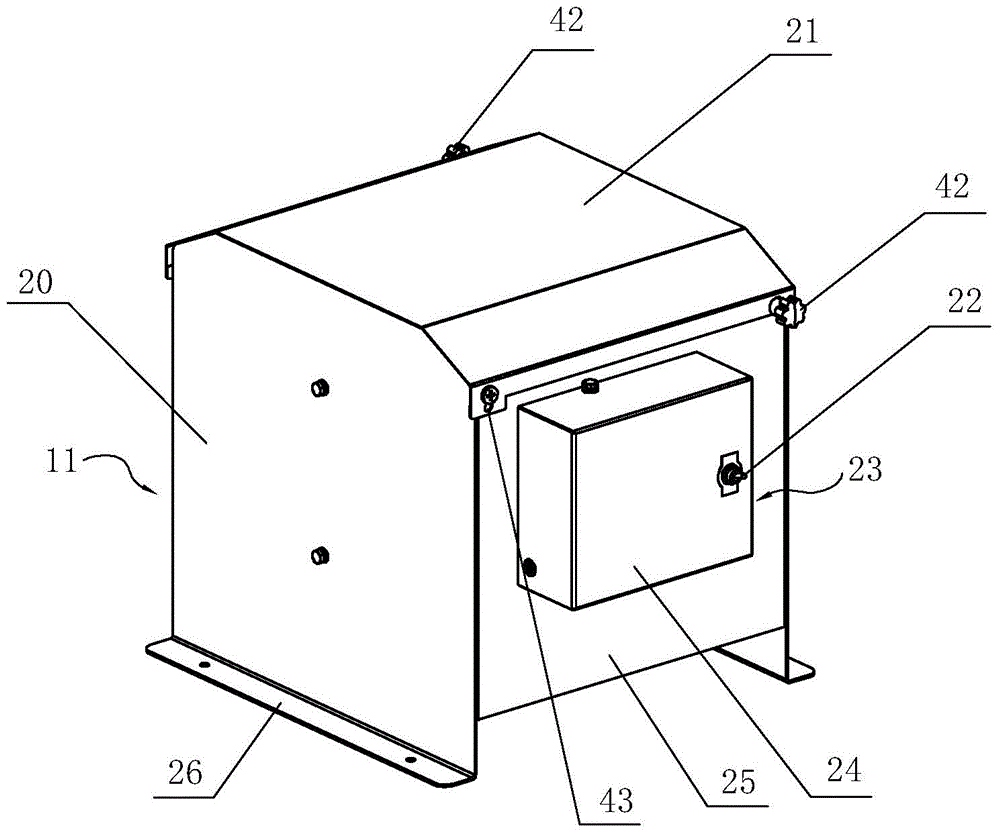

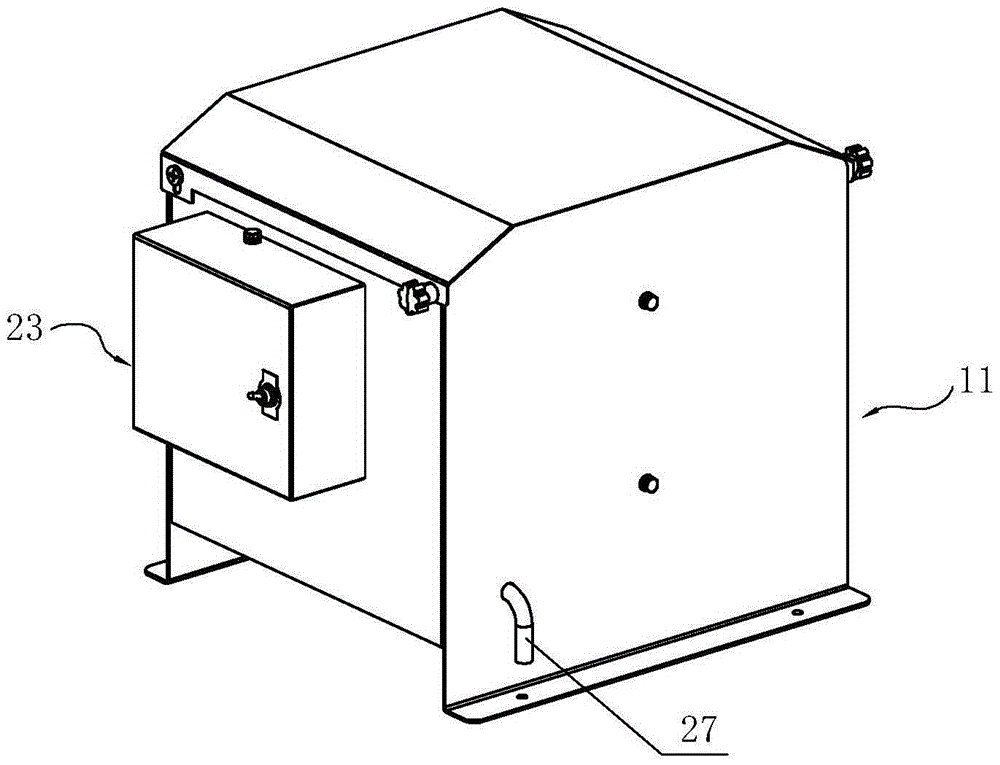

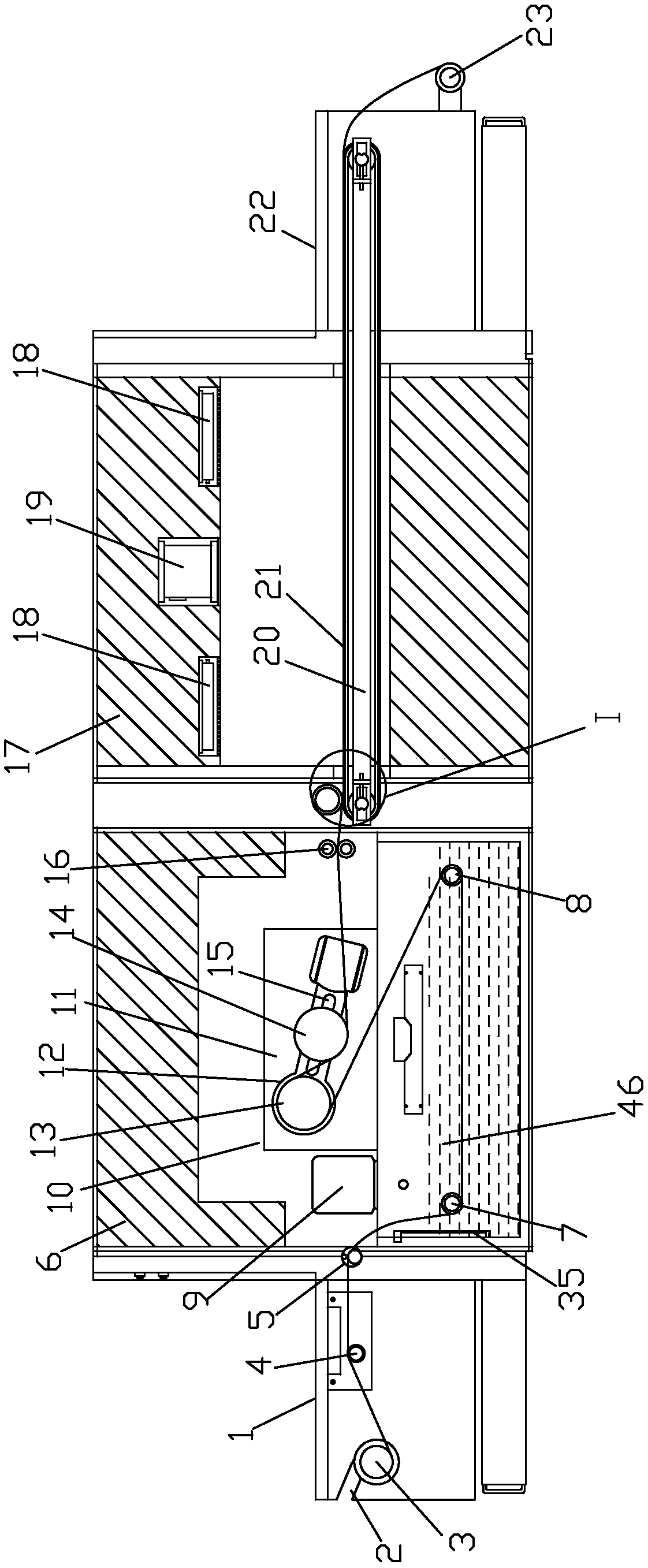

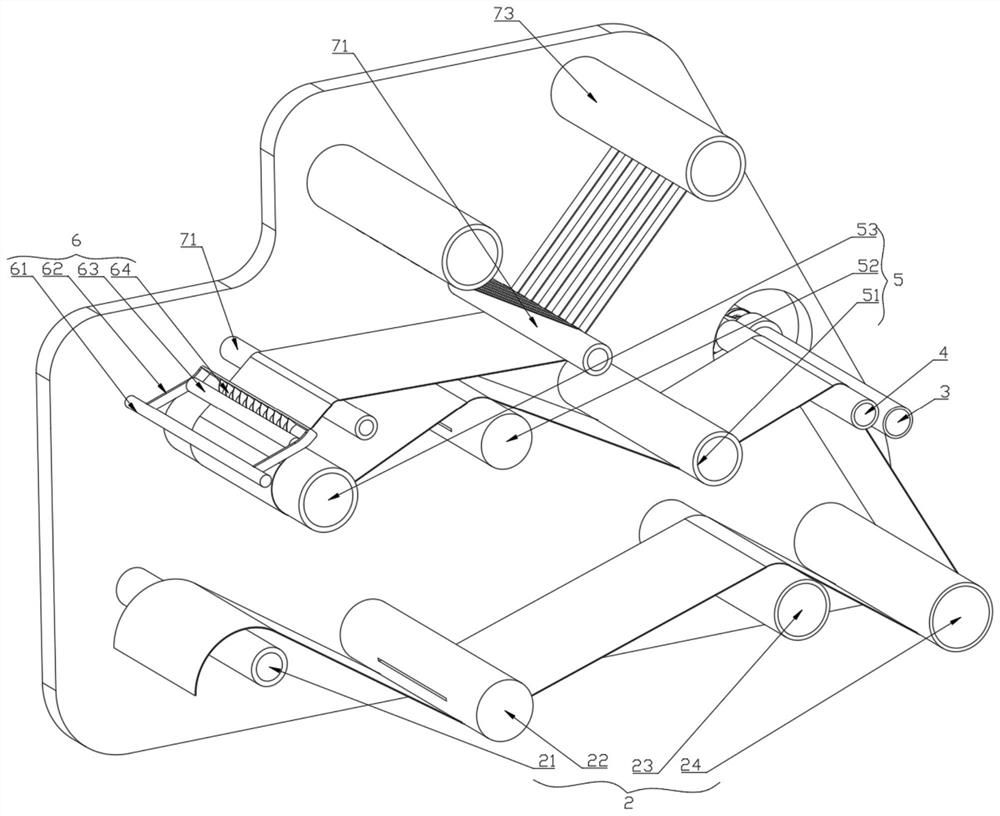

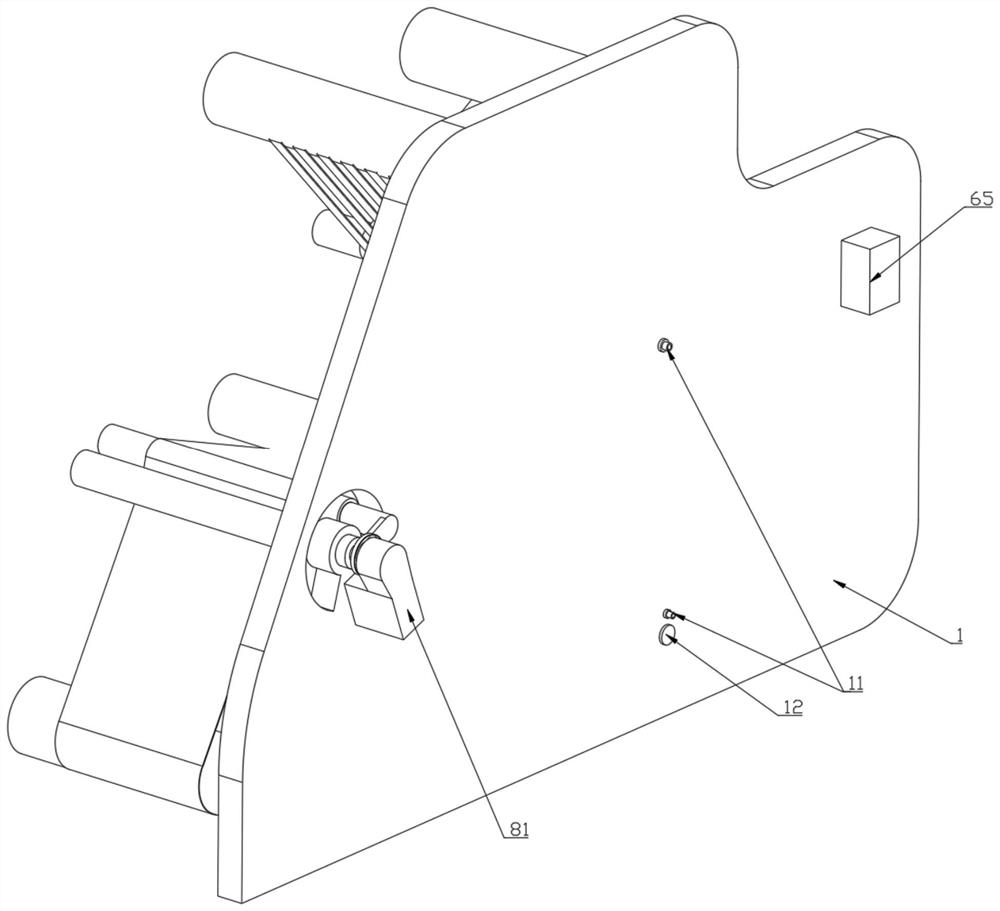

Rice Seedling Seeder

ActiveCN103947341BAvoid water sprayingImprove work efficiencySeed depositing seeder partsRegular seed deposition machinesEngineeringElectric control

The invention relates to a paddy rice seedling-cultivation sowing machine belonging to a sowing machine. The paddy rice seedling-cultivation sowing machine comprises a bracing frame and a conveying guide rail arranged on the bracing frame; the paddy rice seedling-cultivation sowing machine also comprises a conveying motor, a soil paving apparatus, a soil brushing apparatus I, a water spraying apparatus, a sowing apparatus, a soil covering apparatus and a soil brushing apparatus II which are successively arranged on the conveying guide rail; and the paddy rice seedling-cultivation sowing machine also comprises an atomization apparatus arranged behind the soil brushing apparatus II and on the conveying guide rail. The atomization apparatus comprises an atomization box, a spray device and an electric control device; the atomization box is fixedly connected with two conveying guide rails; the spraying device comprises a water pump, a water suction pipe, a water outlet pipe, an atomization water pipe, an atomization nozzle and atomization water pipe positioning devices; the atomization water pipe positioning devices are arranged on two opposite sidewalls in the atomization box; the atomization nozzle is connected with the atomization water pipe; the atomization water pipe is positioned on the atomization water pipe positioning device; and the power supply of the electric control device is electrically connected with the water pump.

Owner:LIUZHOU WULING LIUJI POWER

Device for textile fabric padding

ActiveCN109267269AFlexible padding unitWide range of applicationsLiquid/gas/vapor treatment machines driving mechanismsLiquid/gas/vapor removal by squeezing rollersElectric machineryTextile

The invention discloses a device for textile fabric padding. The device comprises a cloth feeding mechanism and a padding mechanism, wherein a padding tank is formed in the padding mechanism, a firstpadding rotation shaft and a second padding rotation shaft are arranged in the padding tank, the upper end of the padding tank is provided with a movable roller, the movable roller comprises a first roller, a second roller, a roller support and movable frames, two ends of the roller support are both provided with movable frames, the first roller and the second roller are both installed on the roller support, the first roller is fixedly connected to the movable frames, the second roller is movably connected to the movable frames, the surfaces of the movable frames are provided with sliding openings, lead screw modules are installed in the movable frames, and the second roller penetrates through the sliding openings to be connected with the lead screw modules. A movable roller is designed and consists of a fixed roller body and a movable roller body, the movable roller body is controlled by a motor, the separation distance between the movable roller body and the fixed roller body can beadjusted, accordingly the rolling rate is controlled, and the device for textile fabric padding is more flexible and wider in application range.

Owner:淄博泓润纺织印染有限公司

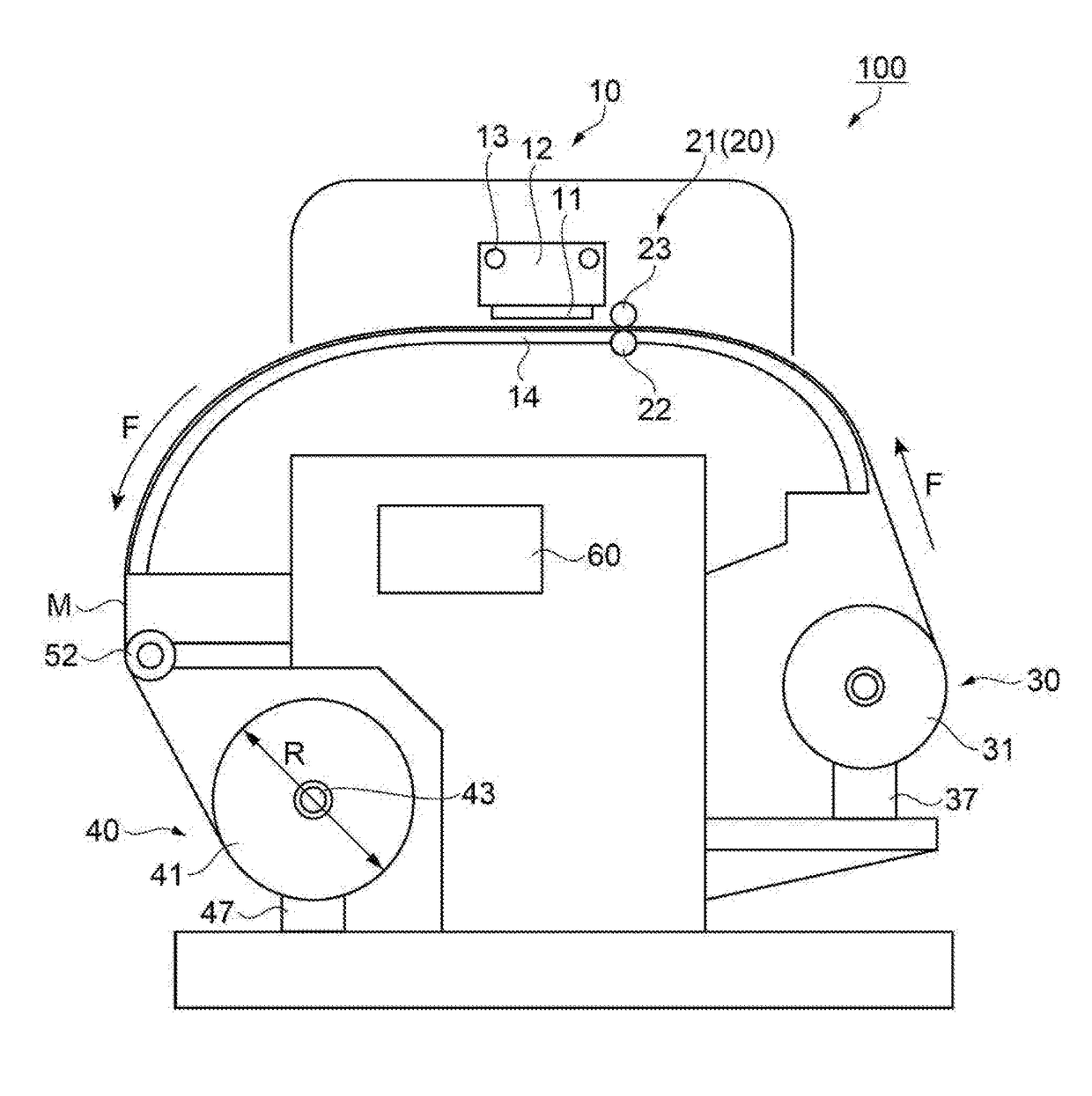

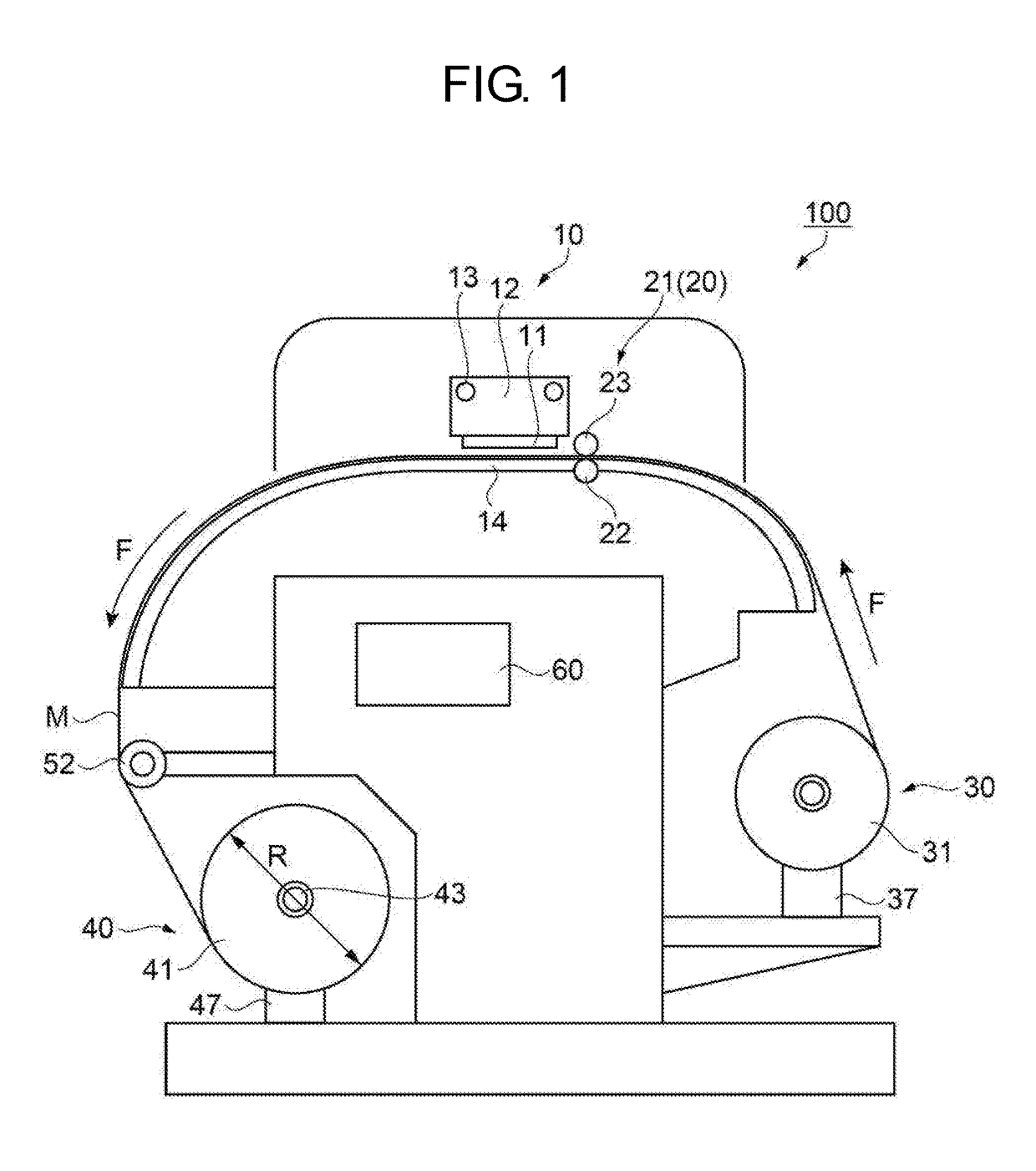

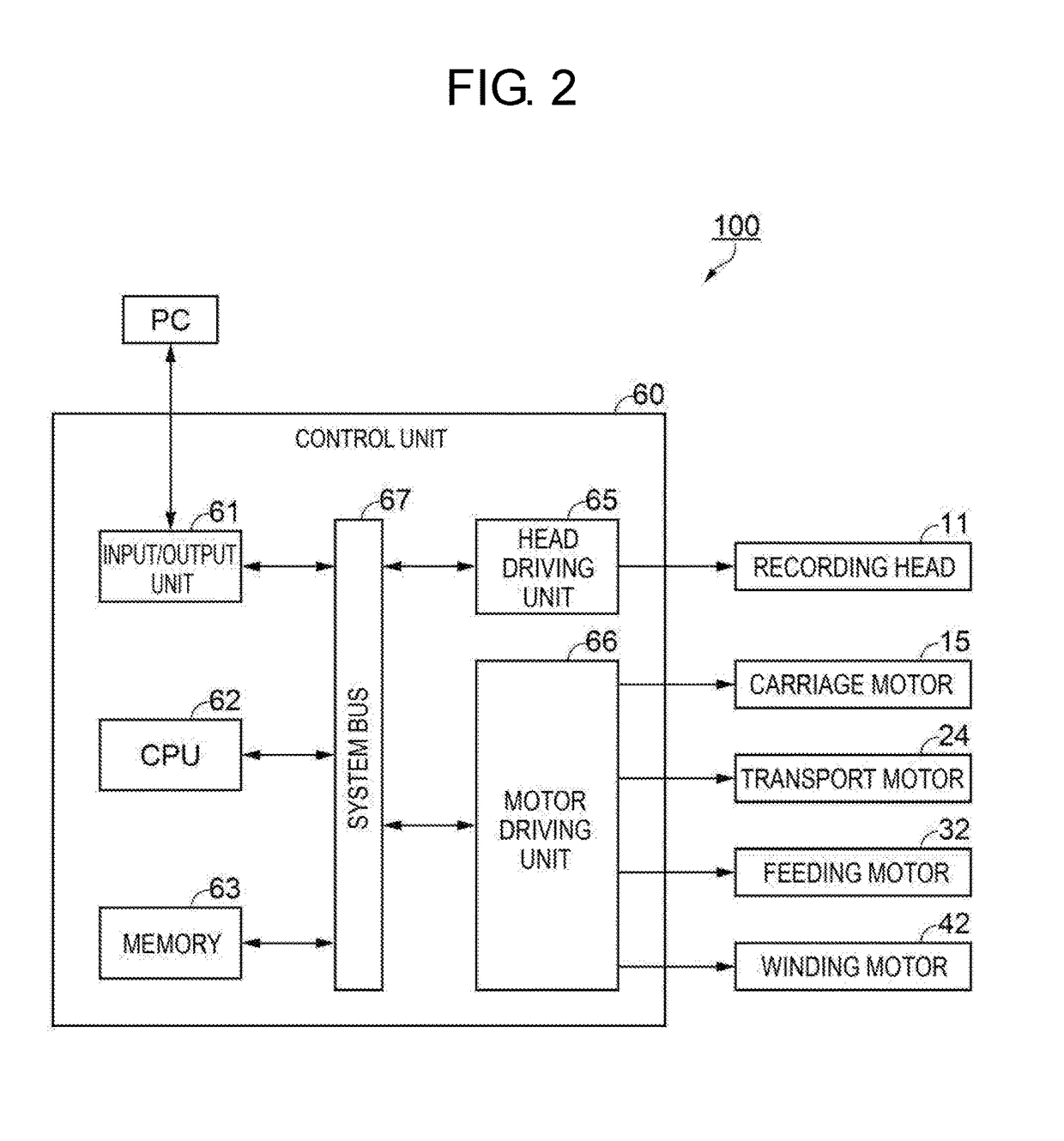

Printing apparatus

ActiveUS20170348988A1Prevent excessive displacementInhibition of defect generationOther printing apparatusEngineeringMechanical engineering

A printing apparatus is provided with: a recording head that performs printing on a medium fed out from a transport roller pair; a feeding unit that feeds the medium to the transport roller pair; and a winding unit that winds, into a roll shape, the medium subjected to the printing by the recording head. The winding unit winds the medium while adjusting a front tension acting on the medium between the transport roller pair and the winding unit, depending on a diameter of the medium wound into the roll shape. The feeding unit feeds the medium while adjusting a back tension acting on the medium between the transport roller pair and the feeding unit, depending on changes in the front tension.

Owner:SEIKO EPSON CORP

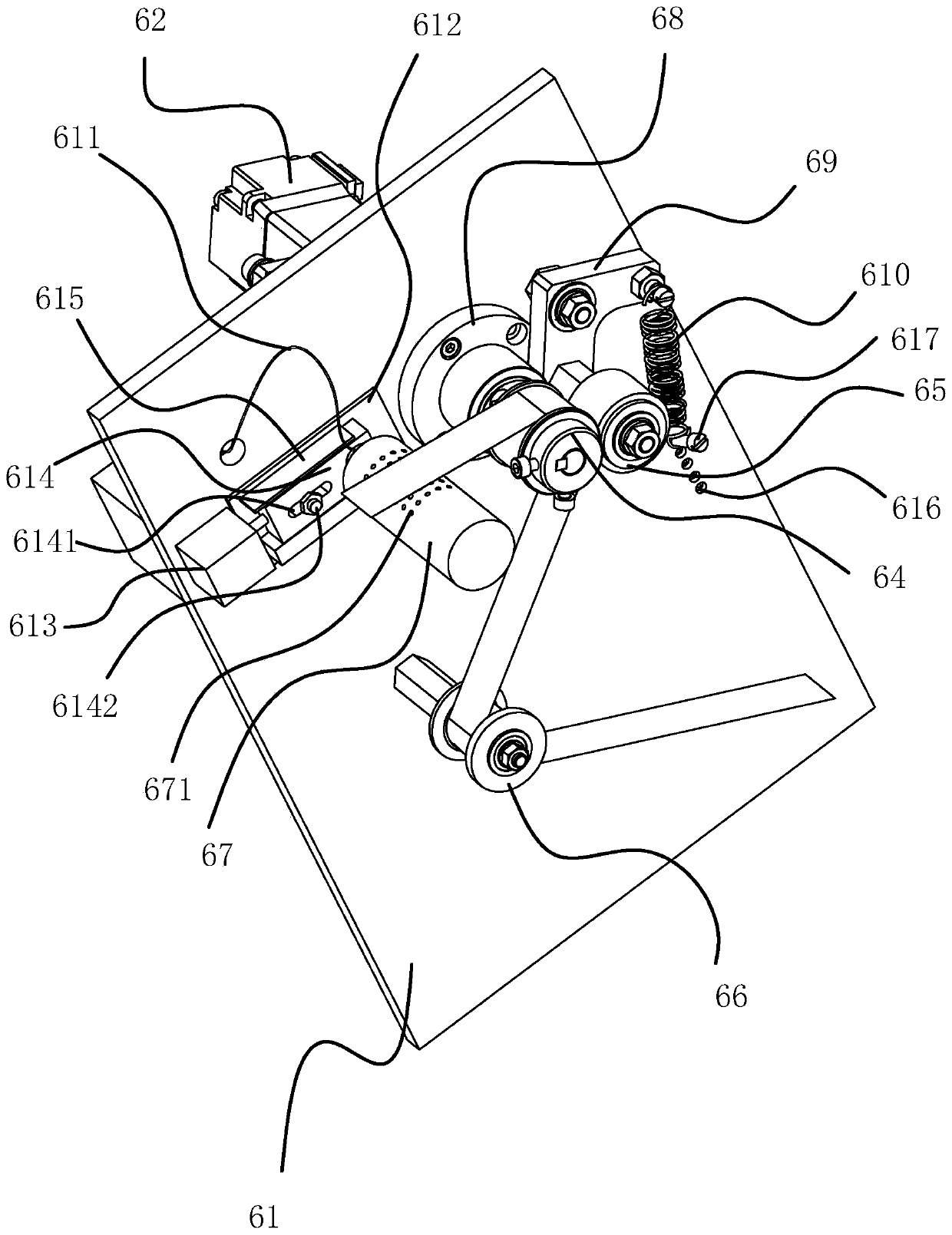

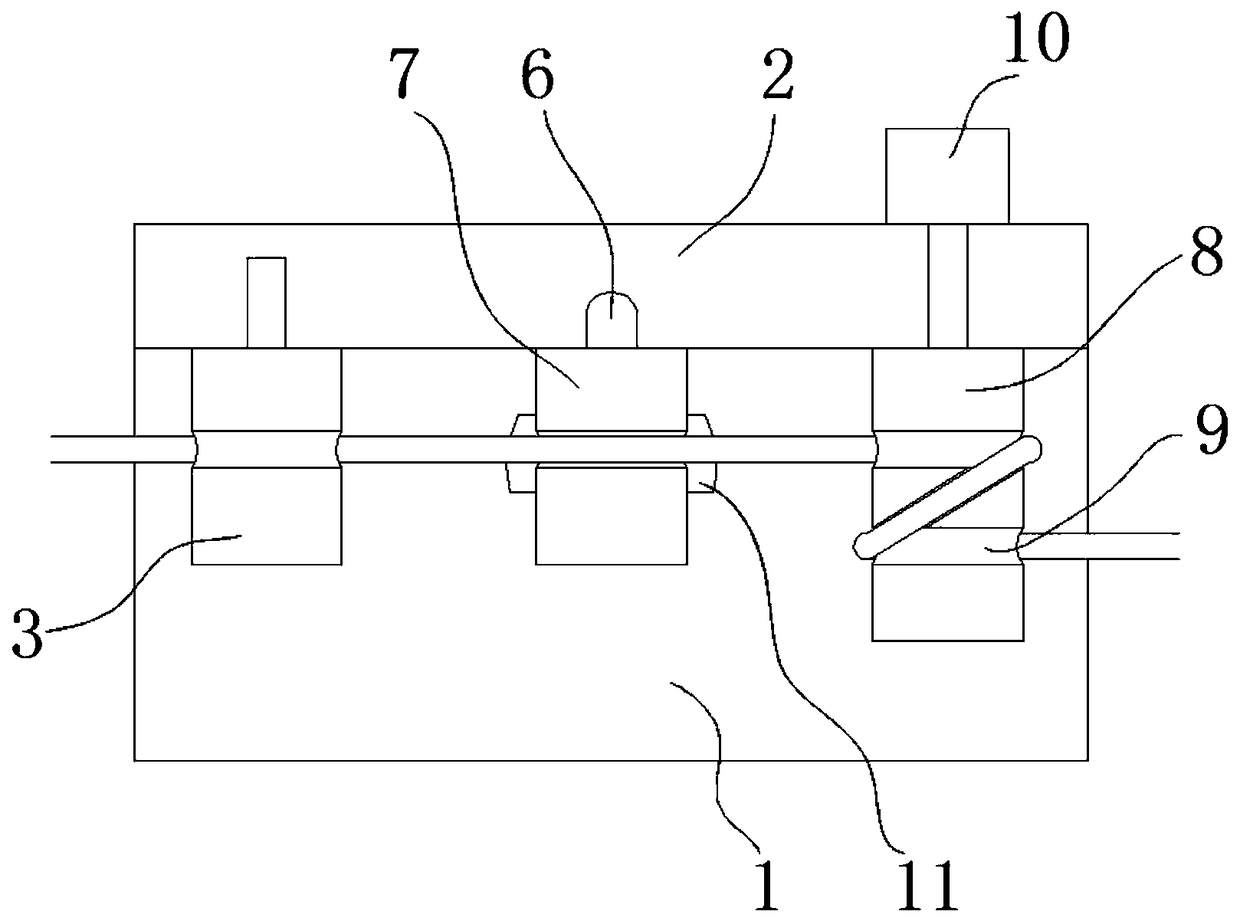

Chemical fiber silk tensioning mechanism

The invention discloses a chemical fiber silk tensioning mechanism. The chemical fiber silk tensioning mechanism comprises a bottom plate, wherein the upper portion of the bottom plate is fixedly connected with a fixed plate, the upper portion of the fixed plate is rotationally connected with a feeding shaft, a tensioning shaft is arranged on one side of the feeding shaft, and a discharging shaftis arranged on one side of the tensioning shaft; the upper portion of the bottom plate is fixedly connected with a connecting frame, the upper portion of the connecting frame is connected with a screwrod, and the upper side of the screw rod is rotationally connected with a limiting box; and the interior of the limiting box is connected with a connecting device, and the upper side of the connecting device is connected with a contact block. The chemical fiber silk tensioning mechanism can adjust the tensioning strength according to the demands of chemical fiber silk and can realize slight adjustment of the strength, a fixed bolt and a sliding rod can be connected or separated as required, the tensioning strength can be stable and accurate during connection, a buffering effect can be playedduring separation, when the fixed bolt and the sliding rod are separated, a spring can only bear pressure but not tension, the spring is prevented from being straightened, and the service life of thespring is prolonged.

Owner:长兴九鑫环保科技有限公司

Automatic extrusion device

The invention discloses an automatic material extruding device, which relates to the field of plastic manufacturing; the support of the automatic material extruding device, a feeding roller, a flattening roller and an output roller, and a drive motor for driving the rotation of the feeding roller and the output roller; the driving motor and the feeding roller and the output roller The rollers are driven by a chain, the feeding roller is located between the flattening rollers, and both the feeding roller and the output roller are located above the flattening rollers, and the output roller is set on either side of the left and right sides of the bracket; a set of opposite ear plates are fixed on the bracket , the feeding roller and the output roller are rotatably connected to the ear plate, and the ear plate is provided with a strip hole, and the two ends of the flattening roller are provided with a rotating pin that matches the strip hole, and the rotating pin is inserted into the corresponding strip hole. And the flattening roller can slide up and down relative to the strip hole. This device sets the tension roller in a floating state, and tensions the film by the gravity of the tension roller itself, so that the force on the film is always in a relatively constant state, so that the tension of the film is kept constant.

Owner:重庆敏驰塑胶有限公司

Extrusion assembly of extrusion equipment

The invention discloses an extrusion assembly of extrusion equipment, and relates to the field of plastic manufacturing. The extrusion assembly of the extrusion equipment comprises a support, a feeding roller, flattening rollers, an output roller and a driving motor driving the feeding roller and the output roller to rotate. The driving motor is in chain transmission with the feeding roller and the output shaft, the feeding roller is located between the flattening rollers, and the feeding roller and the output roller are located above the flattening rollers. The output roller is arranged on any side of the left side and the right side of the support. The support is fixedly provided with a pair of oppositely-arranged lug plates, the feeding roller and the output roller are rotationally connected with the lug plates, the lug plates are provided with strip-shaped holes, rotating pin shafts matched with the strip-shaped holes are arranged at the two ends of the flattening rollers, the rotating pin shafts are inserted into the corresponding strip-shaped holes, and the flattening rollers can slide up and down relative to the strip-shaped holes. Tensioning rollers are set to be in a floating state, a film is tensioned through self-gravity of the tensioning rollers, the stress of the film is always in a relatively constant state, and thus the tension of the film keeps constant.

Owner:NINGBO ZHENHAI XIANGAO ELECTROMECHANICAL

Mechanism for continuously stretching and slitting raw material belt

The invention discloses a mechanism for continuously stretching and slitting a raw material belt, and belongs to the field of slitting mechanisms. The mechanism for continuously stretching and slitting the raw material belt comprises a fixed plate, a heating and stretching assembly and a cooling assembly, wherein the heating and stretching assembly and the cooling assembly are installed on the fixed plate; a pre-tightening rotating shaft and an adjusting rotating shaft are arranged between the heating and stretching assembly and the cooling assembly; the adjusting rotating shaft rotates aroundthe axis of the pre-tightening rotating shaft; and a coil spring and an elastic force adjusting device are arranged at the end part, connected with the pre-tightening rotating shaft, of the adjustingrotating shaft, so that the adjusting rotating shaft always has a motion trend of winding the raw material belt on the pre-tightening rotating shaft. According to the mechanism for continuously stretching and slitting the raw material belt, the raw material belt is pulled to rotate and be wound around the pre-tightening rotating shaft through the adjusting rotating shaft, so that the tensioning force of the raw material belt is changed, and cutting is neat when the raw material belt is slit.

Owner:FUJIAN BANG UP FLUORINE PLASTIC PROD

Adjustor capable of automatically adjusting yarn tension

The invention mainly discloses an adjustor capable of automatically adjusting yarn tension. The adjustor comprises a tension detector, a servo motor, a first shaft, a second shaft, a first yarn guide and a second yarn guide, the servo motor is connected with and drives the first shaft provided with the first yarn guide to rotate, the first shaft and the second shaft provided with the second yarn guide are in mesh transmission through gears, and a yarn penetrates through the first yarn guide and the second yarn guide sequentially and penetrates through the tension detector for tension detection. The servo motor directly or indirectly drives the first shaft and the second shaft to rotate, and the first shaft and the second shaft are in mesh transmission through the gears, so that the first shaft and the second shaft rotate oppositely, and finally the first yarn guide and the second yarn guide are staggered by opposite angles. By the means, the yarn passing path and the yarn passing curvature are changed, so that yarn tension is changed.

Owner:SHAOXING UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com