Mechanism for continuously stretching and slitting raw material belt

A technology of raw material tape and stretching components, which is applied in the direction of thin material processing, winding strips, sending objects, etc., and can solve the problems of not being able to control the tension well and stably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described below in conjunction with the drawings and specific implementations.

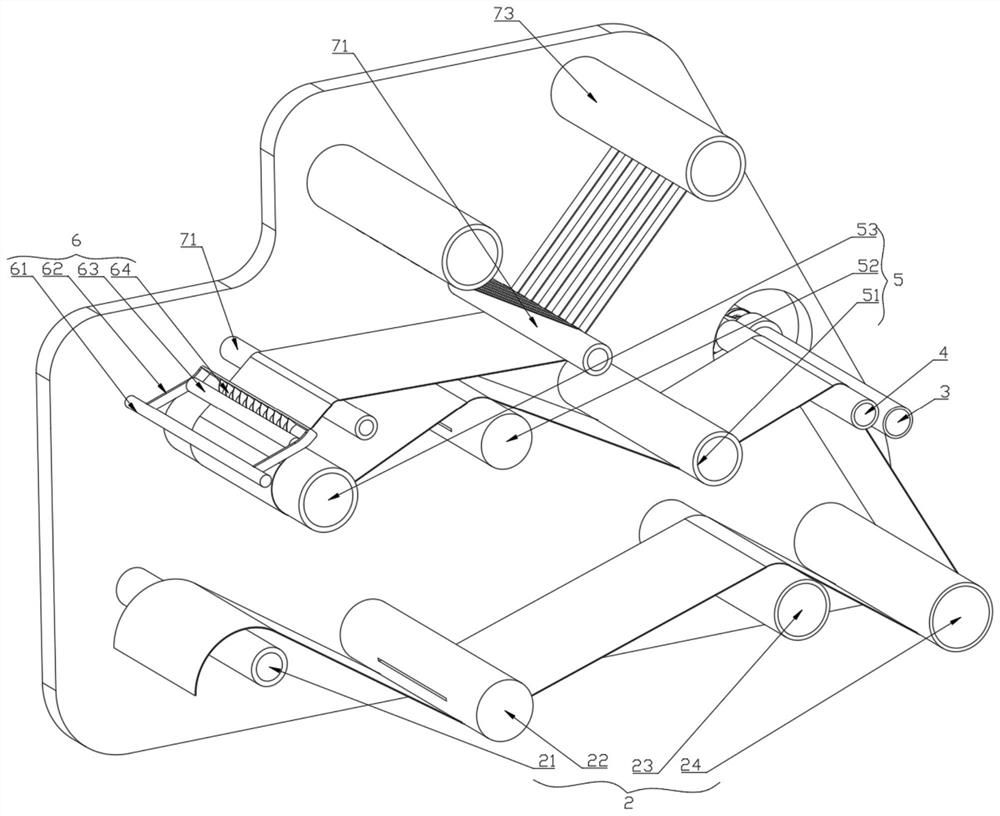

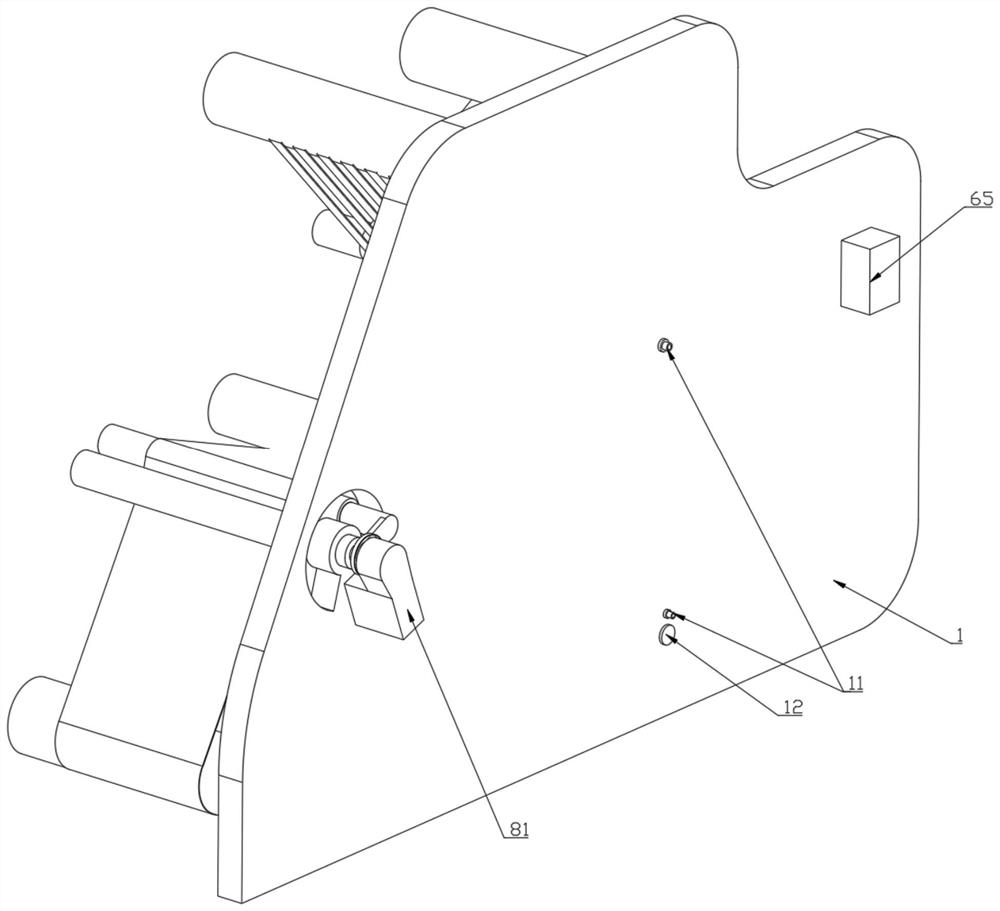

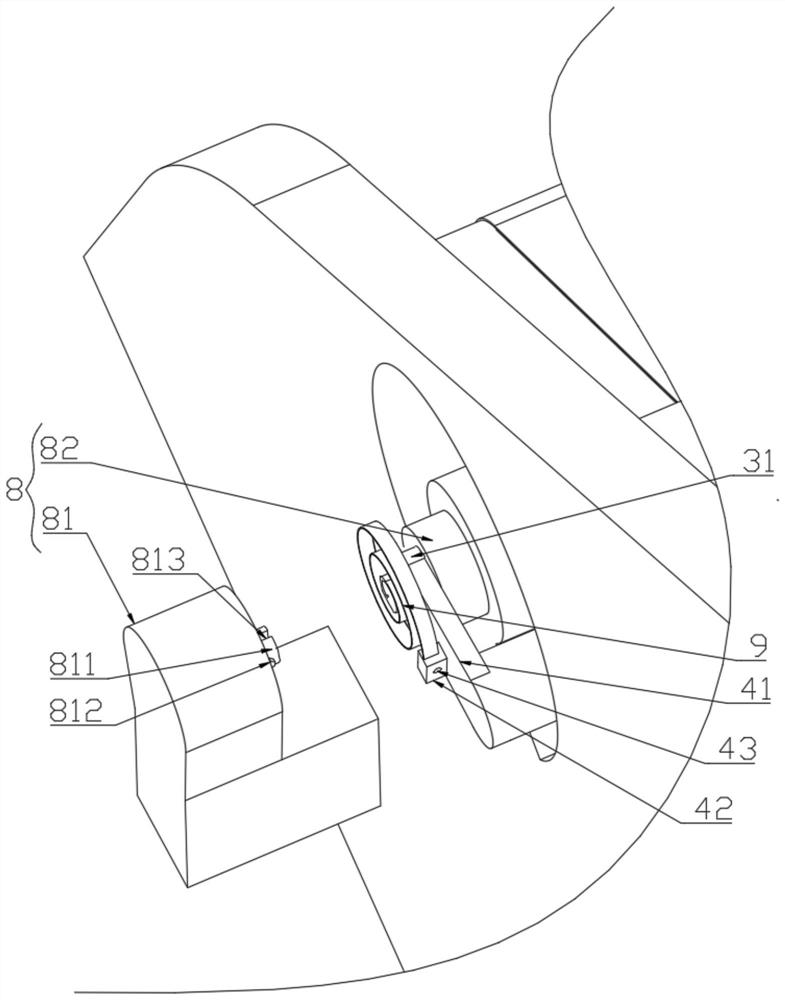

[0025] Such as Figure 1-3 As shown, this embodiment provides a continuous stretching and slitting mechanism for raw material tape, which includes a fixed plate 1 and a heating and stretching assembly 2 and a cooling assembly 5 mounted on the fixing plate 1. The heating and stretching assembly 2 is connected to the A pre-tightening shaft 3 and an adjusting shaft 4 are arranged between the cooling components 5; the adjusting shaft 4 rotates around the axis of the pre-tightening shaft 3, and the end connecting the adjusting shaft 4 and the pre-tightening shaft 3 is provided with The coil spring 9 and the elastic force adjusting device 8 make the adjusting shaft 4 always have a movement tendency of winding the raw material belt on the rotating shaft of the pre-tensioning shaft 3. When the heating and stretching assembly 2 stretches...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com