Extrusion assembly of extrusion equipment

A technology of equipment and components, applied in the field of plastic manufacturing, can solve problems such as difficulty in controlling the tension force of plastic films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

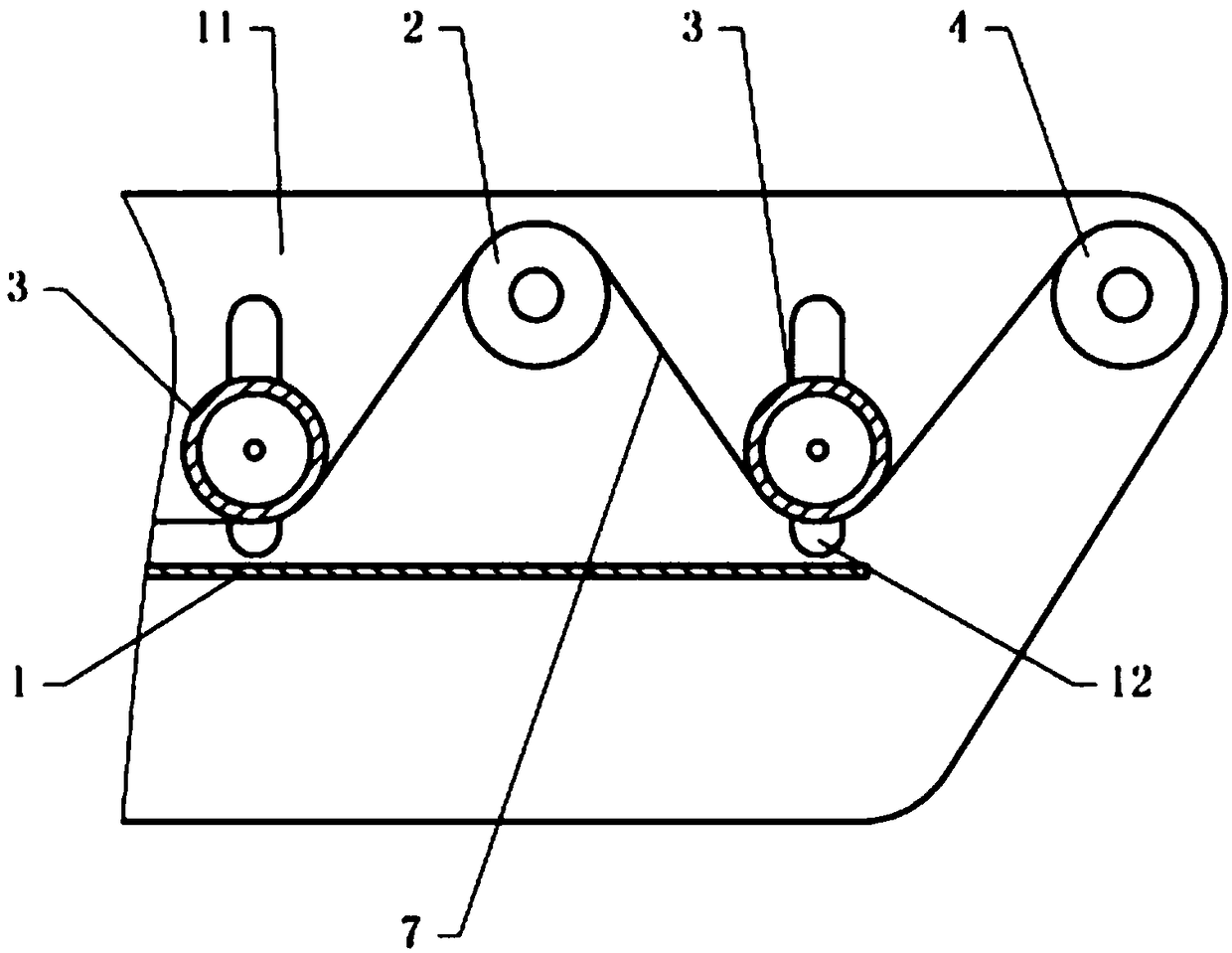

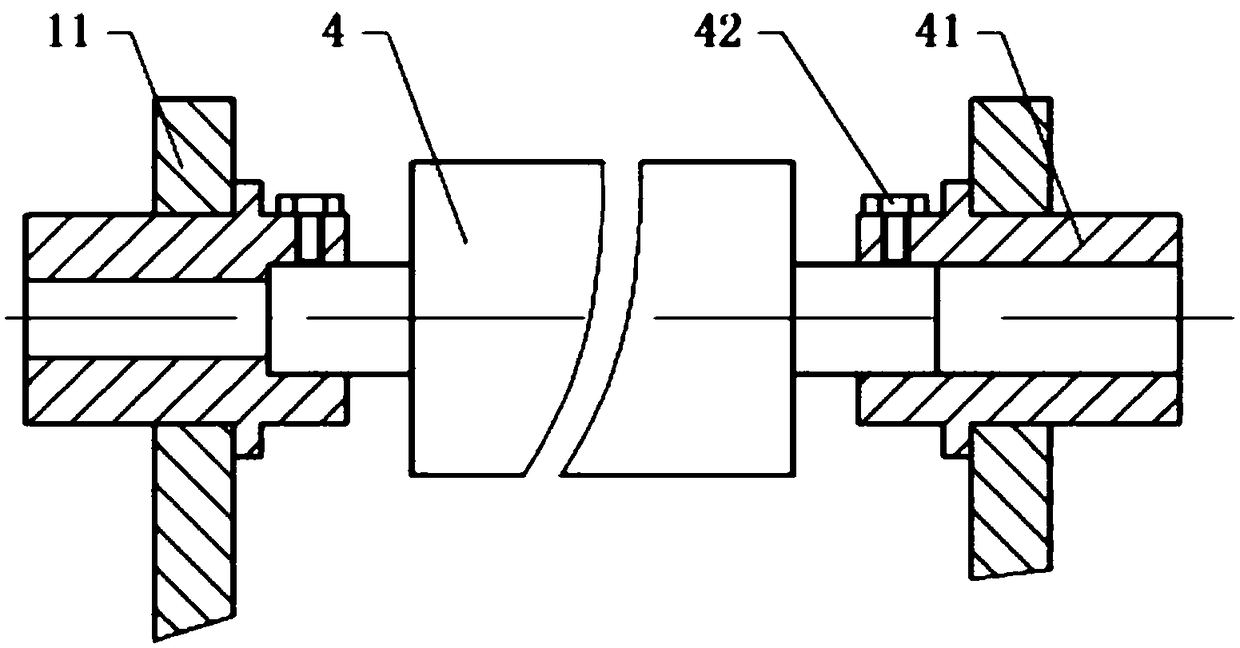

Method used

Image

Examples

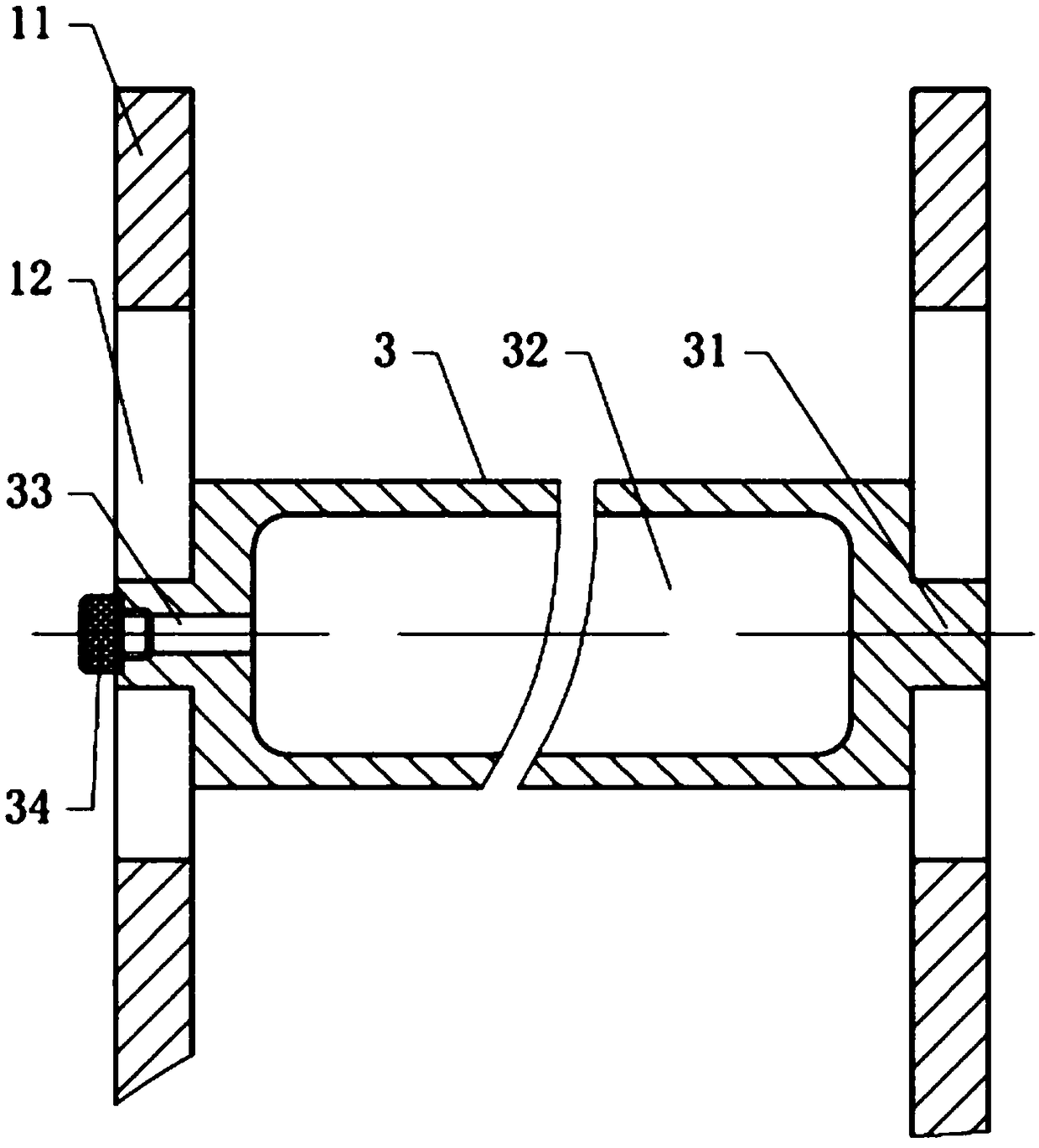

Embodiment 2

[0029] Such as Figure 4 As shown, the difference between the second embodiment and the first embodiment is that the second embodiment does not provide a liquid inlet hole communicating with the cavity, that is, the cavity cannot be filled with liquid, but the rotation pin at both ends of the tension roller is removed from the A shaped hole is provided, and a counterweight is threadedly connected to the discharging end of the rotating pin, so that the counterweight can be replaced.

[0030] According to the thickness and material of the film, when the film needs to have different tensions, by changing different counterweights, the tension rollers can have different qualities, and the tension of the film will be changed accordingly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com