Adjustor capable of automatically adjusting yarn tension

A technology of yarn tension and automatic adjustment, applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., can solve the problems of high labor intensity and inconsistent tension fluctuation, and achieve the effect of changing the size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The preferred embodiments of the present invention will be described in further detail in conjunction with the accompanying drawings.

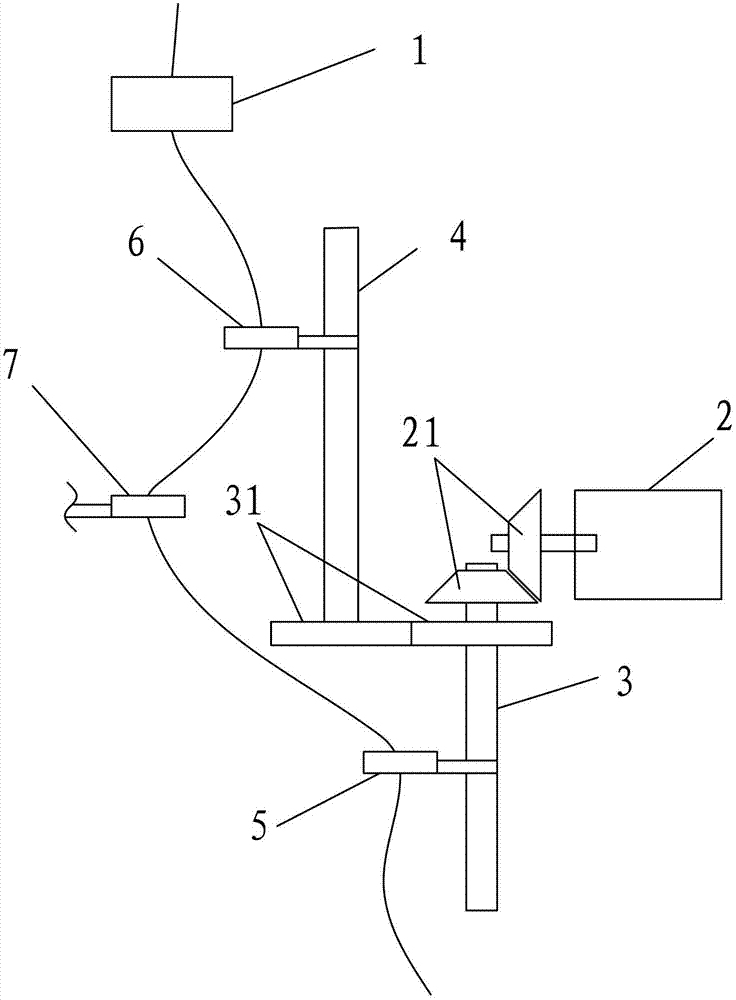

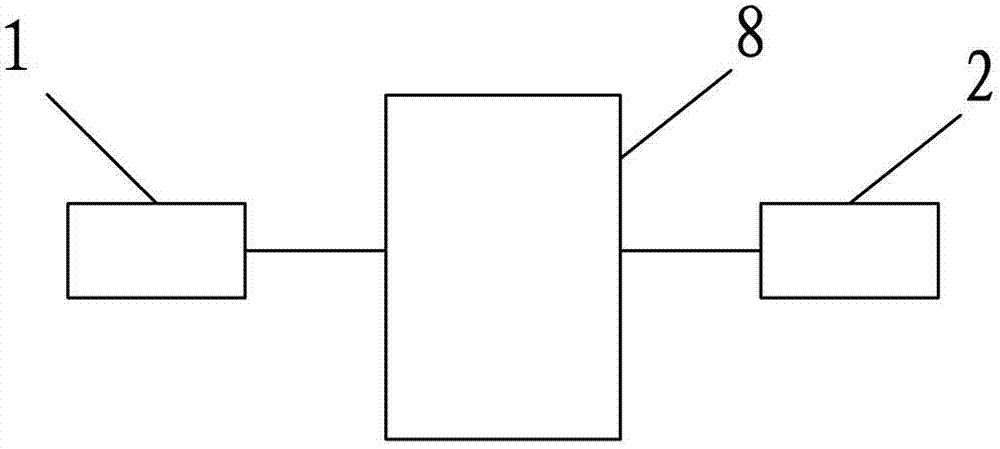

[0017] An adjuster for automatically adjusting yarn tension includes a tension detector 1 , a servo motor 2 , a first shaft 3 , a second shaft 4 , a first yarn guide 5 and a second yarn guide 6 .

[0018] The reason why the present invention adopts the servo motor 2 is that the rotation precision of the servo motor can be electrically and accurately controlled, which is beneficial to control the precision of the yarn tension change.

[0019] The servo motor 2 drives the first shaft 3 to rotate through the bevel gear 21 , and the first yarn guide 5 is installed on the first shaft 3 and rotates as the first shaft 3 works. The first shaft 3 and the second shaft 4 are driven through a pair of transmission gears 31, so the rotation direction of the second shaft 4 is opposite to that of the first shaft 3, and the second yarn guide 6 is instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com