Chemical fiber silk tensioning mechanism

A technology of tensioning mechanism and chemical fiber yarn, which is applied in the textile field, can solve the problems of affecting the life of the spring, troublesome adjustment, easy to be pulled apart, etc., and achieve the effect of prolonging the service life, optimizing the performance and stabilizing the tension force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

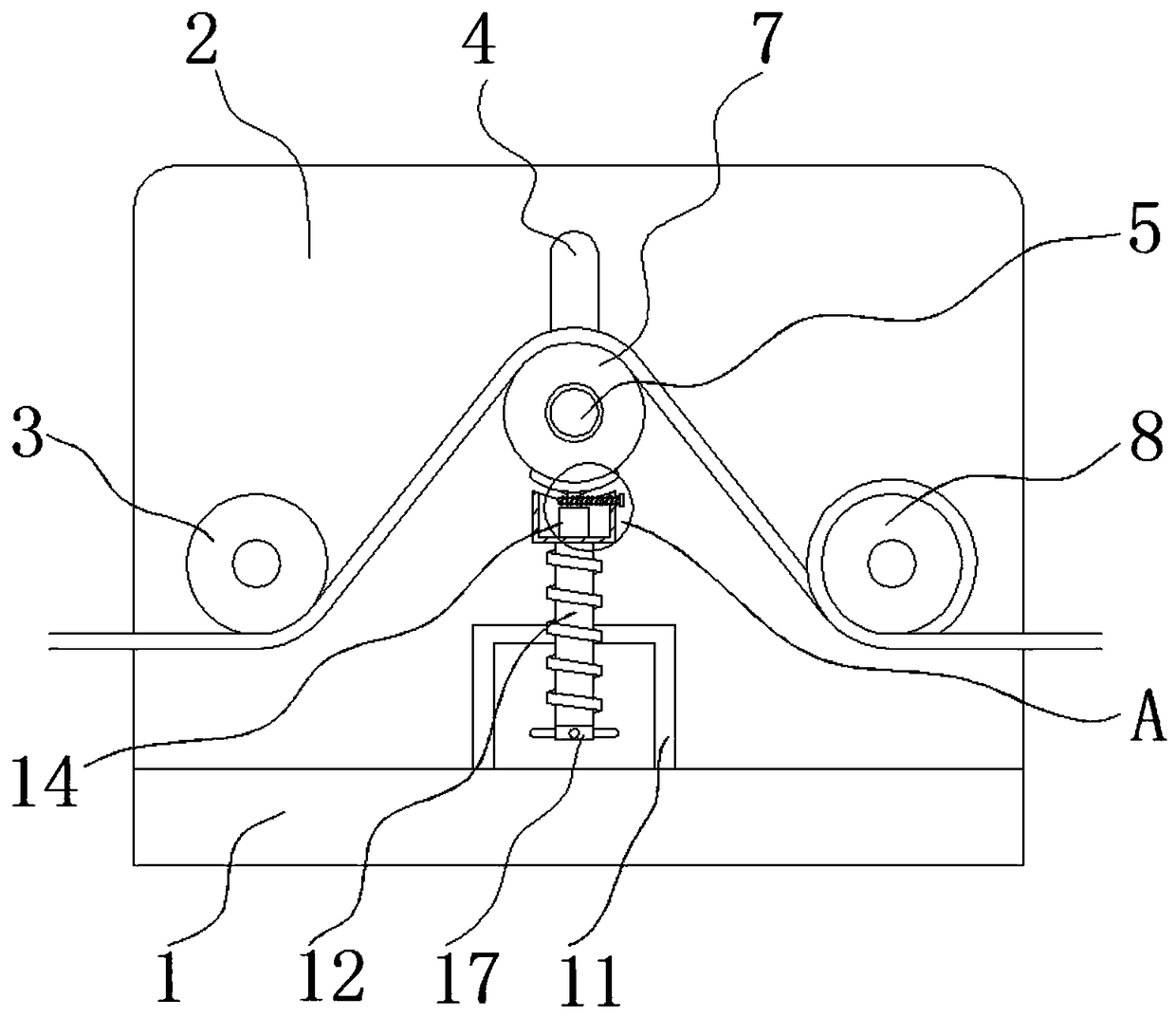

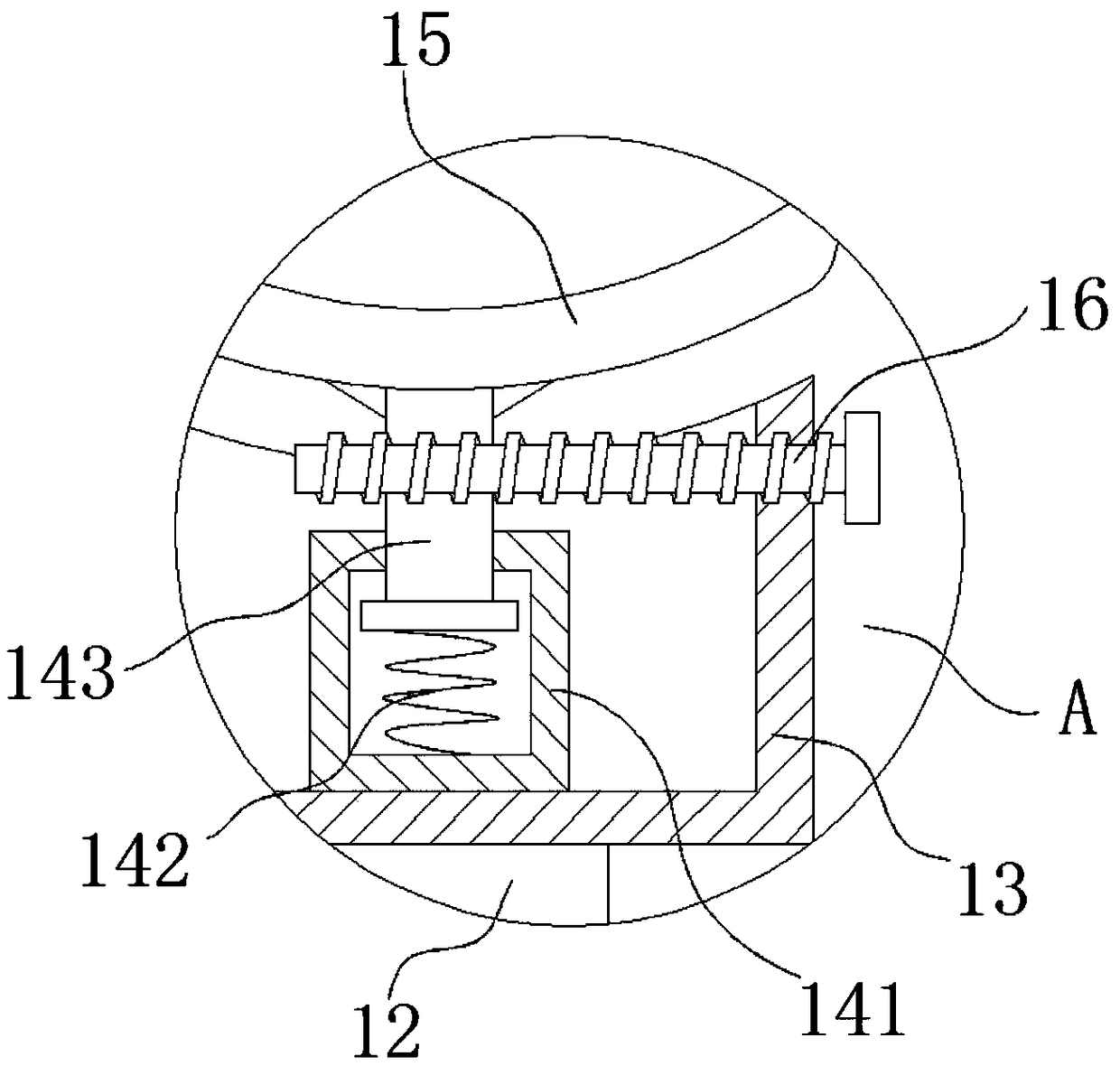

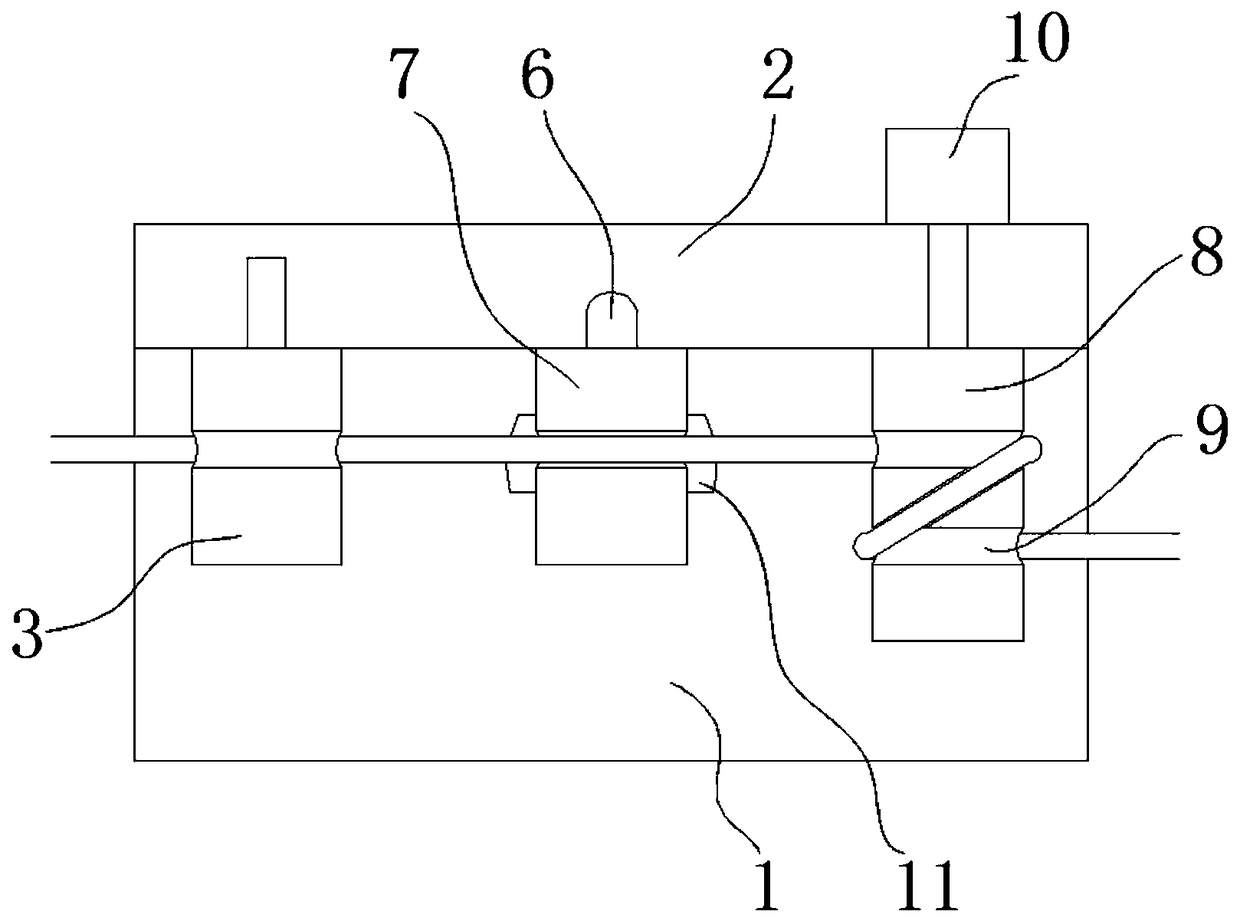

Embodiment 1

[0027] Embodiment one: refer to Figure 1-3 , a chemical fiber thread tensioning mechanism, comprising a bottom plate 1, a fixed plate 2 is welded on the upper part of the bottom plate 1, an installation groove is opened on the upper part of the fixed plate 2, and a bearing is fixedly connected to the inside of the installation groove, and the inner ring of the bearing is interference connected There is a connecting shaft, the feeding shaft 3 is sleeved on the upper part of the connecting shaft, one side of the feeding shaft 3 is provided with a tension shaft 7, one side of the tension shaft 7 is provided with a discharge shaft 8, and the upper part of the bottom plate 1 is welded with Connecting frame 11, the top of connecting frame 11 is provided with threaded hole, and the internal screw thread of threaded hole is connected with screw rod 12, and the upper side of screw rod 12 is connected with limited box 13 by bearing, and the inside of limited box 13 is connected with con...

Embodiment 2

[0031] Embodiment two: refer to Figure 1-3 , a chemical fiber tensioning mechanism, as a further preference, the upper part of the limit box 13 is provided with a connecting hole, and the internal thread of the connecting hole is connected with a fixing bolt 16, and the upper part of the sliding rod 143 is provided with a positioning hole, and the fixing bolt 16 through the positioning hole.

[0032] Correspondingly, for the above-mentioned structure, the positions of the sliding rod 143 and the limit box 13 are fixed. When the limit box 13 drives the fixed rod 141 to move up and down, the slide rod 143 moves together with the fixed rod 141, so that the tension can be adjusted. The adjustment is more precise and the tension is more stable.

[0033] To sum up, the present invention can adjust the structure according to the change of the tensioning requirement of the chemical fiber, thereby greatly optimizing the performance of the tensioning mechanism and prolonging the servi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com