Patents

Literature

36results about How to "Good tension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

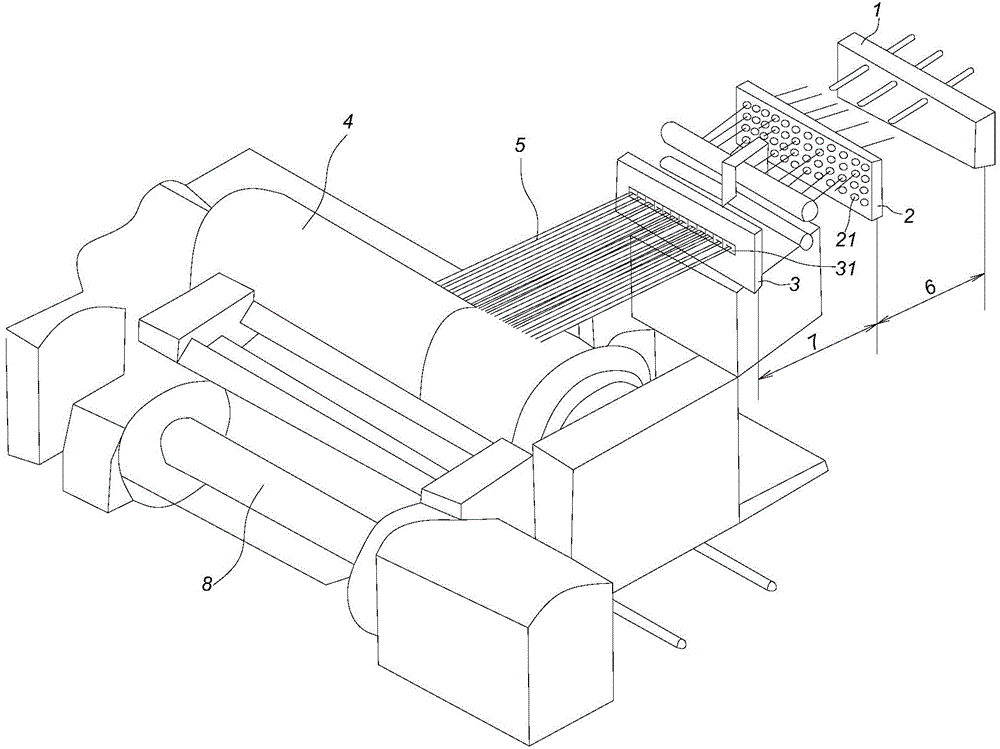

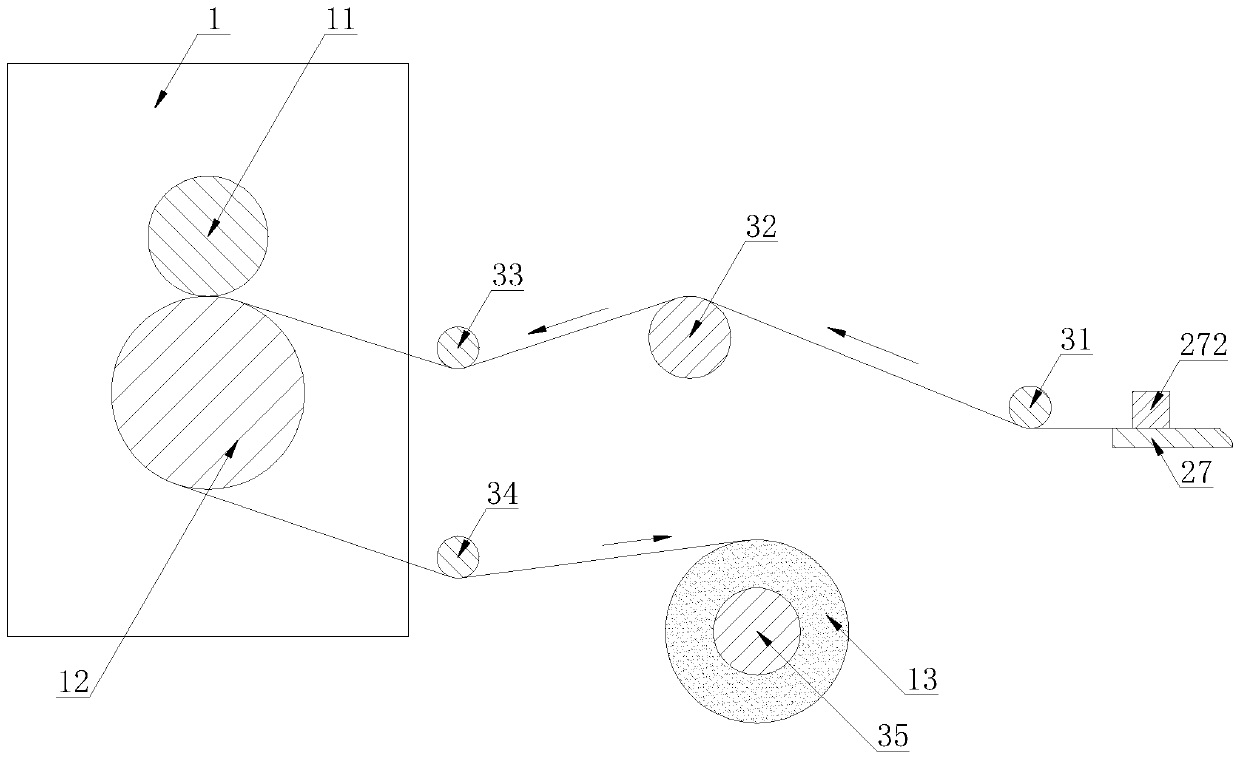

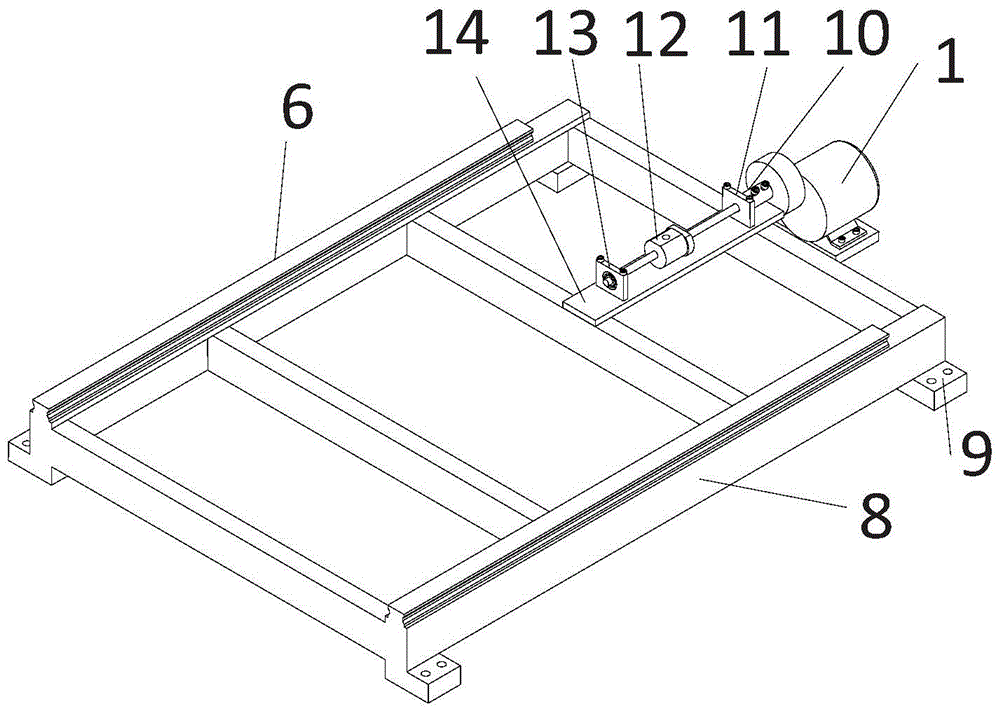

Anti-twisting type sectional warping machine

The invention discloses an anti-twisting type sectional warping machine. The anti-twisting type sectional warping machine comprises a bobbin creel, a yarn fixing rack, a yarn distributing device and a drum, wherein the bobbin creel comprises a rack, yarn guiders, a flexible cover and yarn cone shafts; yarn cones are placed on the yarn cone shafts; the yarn cone shafts are fixed on the rack; each yarn cone shaft is provided with the corresponding yarn guider; and the flexible cover is fixed on the rack and covers the yarn cones. The anti-twisting type sectional warping machine is simple in structure; the circumstance that warp yarns are twisted together and are knotted in a warping process is avoided effectively; and the warping efficiency is improved.

Owner:佛山市三水三强塑胶有限公司

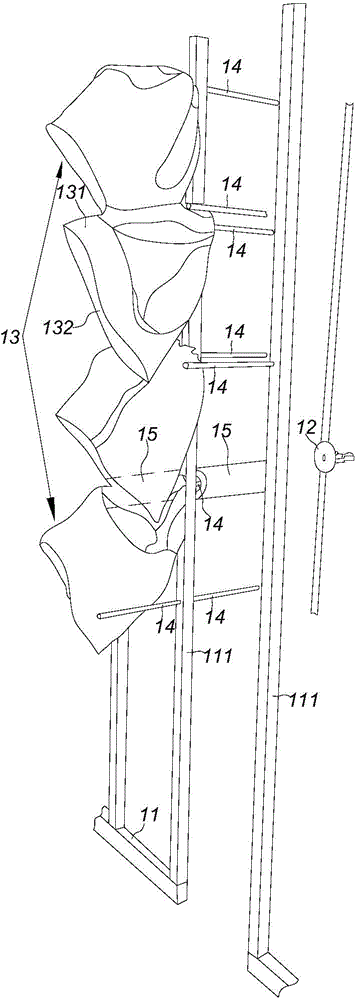

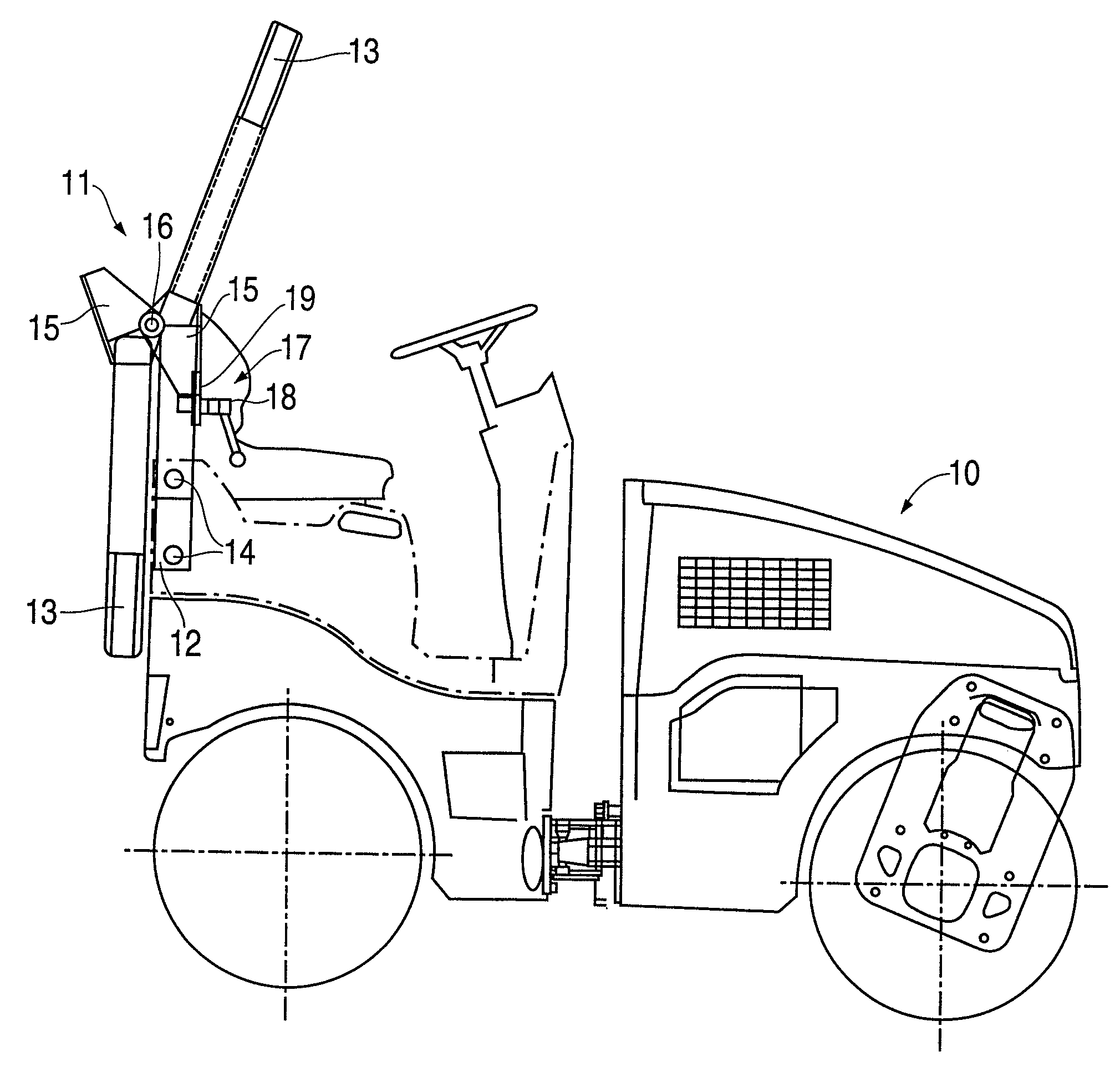

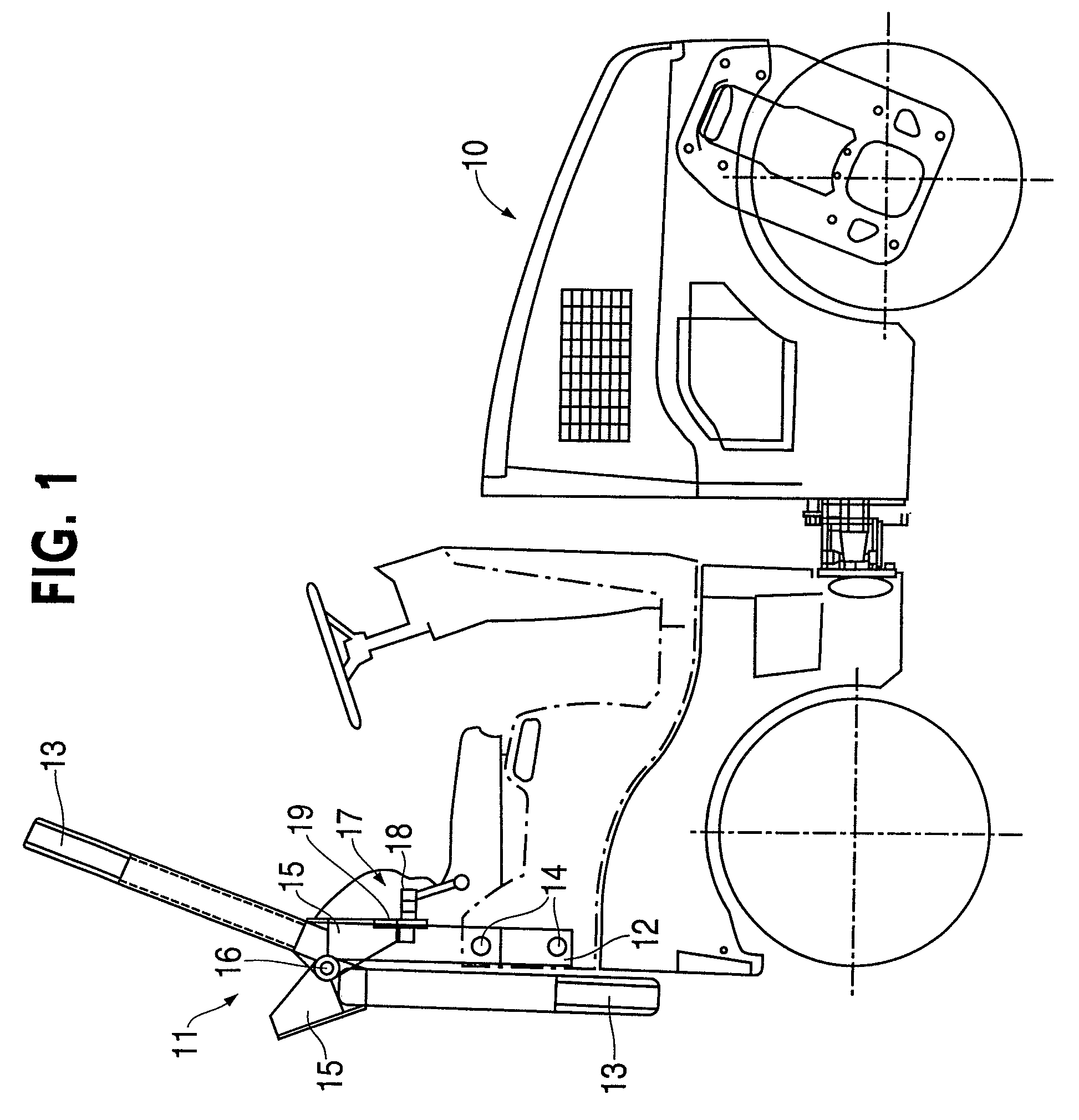

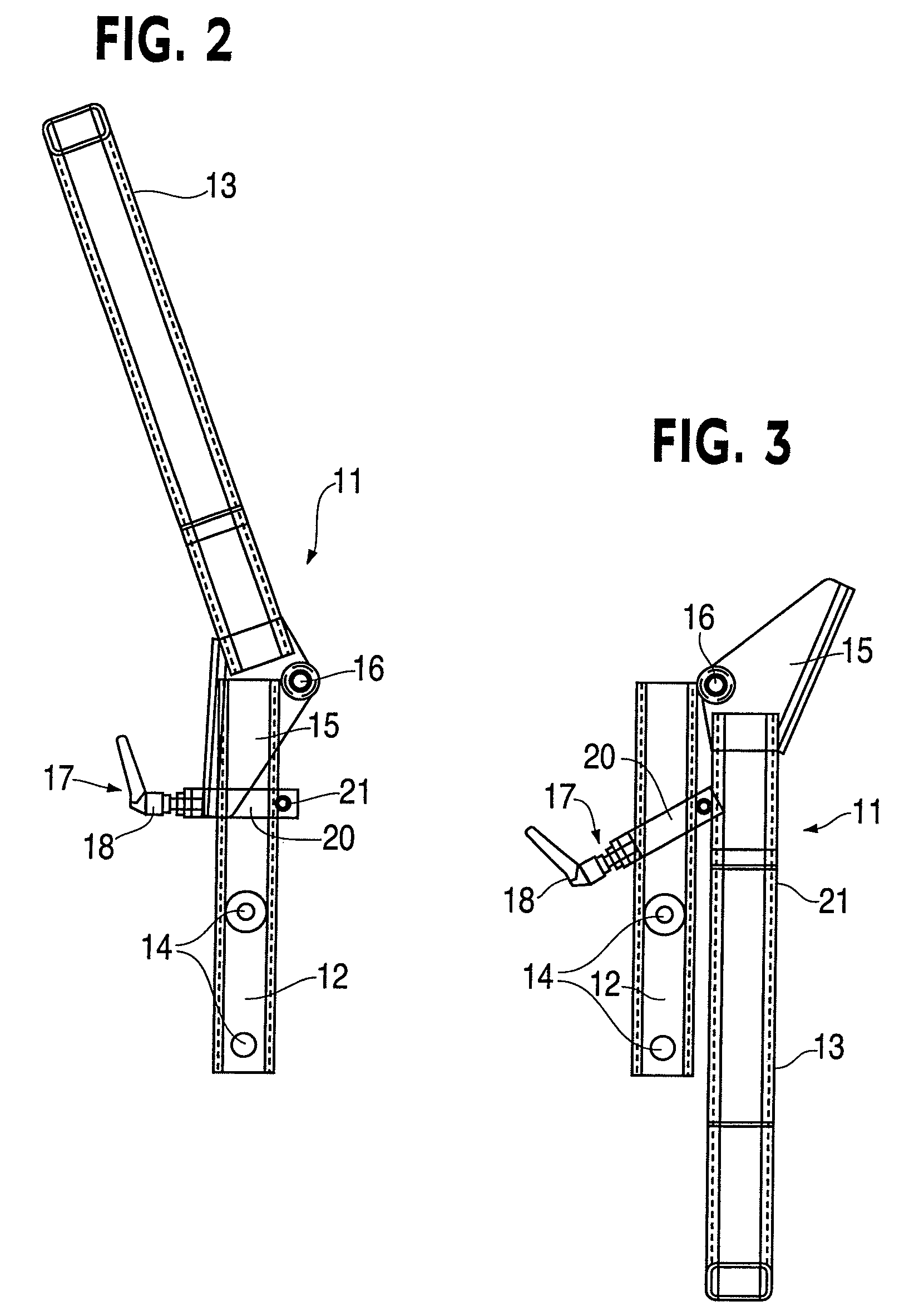

Swiveling roll bar

ActiveUS7677599B2Increase stiffnessGood tensionVehicle seatsSoil-shifting machines/dredgersSacroiliac jointFlexural strength

The invention relates to a swivelable roll bar, in particular for construction vehicles, with two vertical carriers, each of which has a pair of spars, whereby in each, one spar is connected swivelably through a link joint with the another spar, and the link joint comprises a lock and a stop. The stop consists of a joint stiffener, which is built as an extension of one spar and partially grips about the end of the other. In addition to that, the lock has a continuously adjustable final control element, with which the joint stiffener can be braced against the other spar. With the grip about the other spar, the flexural strength of the link joint of the swivelable roll bar is increased. Further, the bracing of the joint stiffener against the other spar eliminates the play in the link joint. The joint stiffener is preferably built as a U-shaped tubular segment that is attached to the latter as an extension of the spar.

Owner:BOMAG

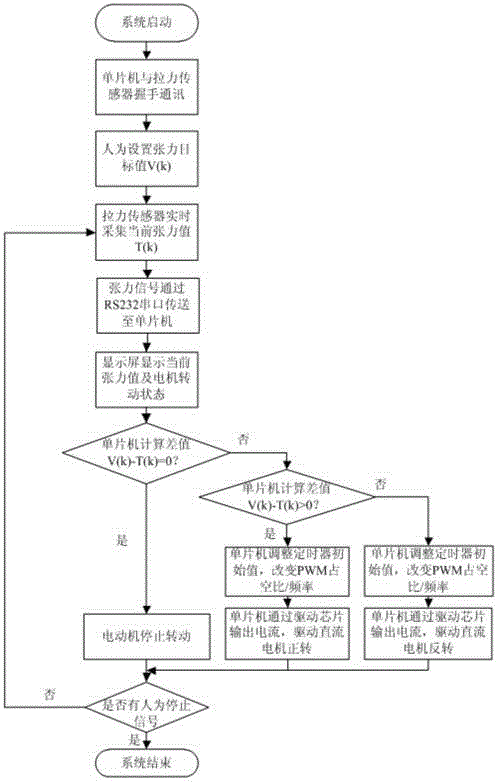

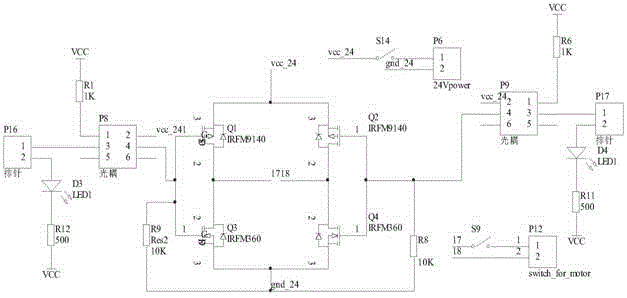

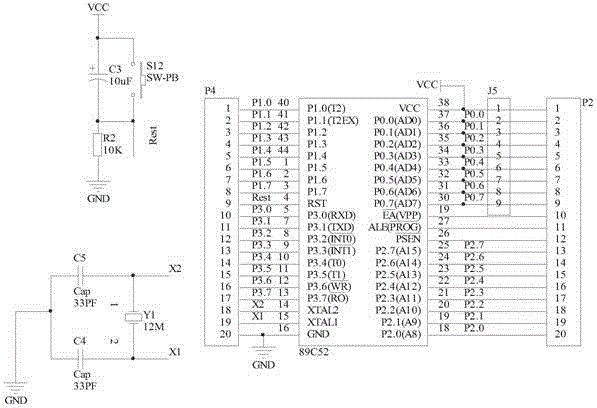

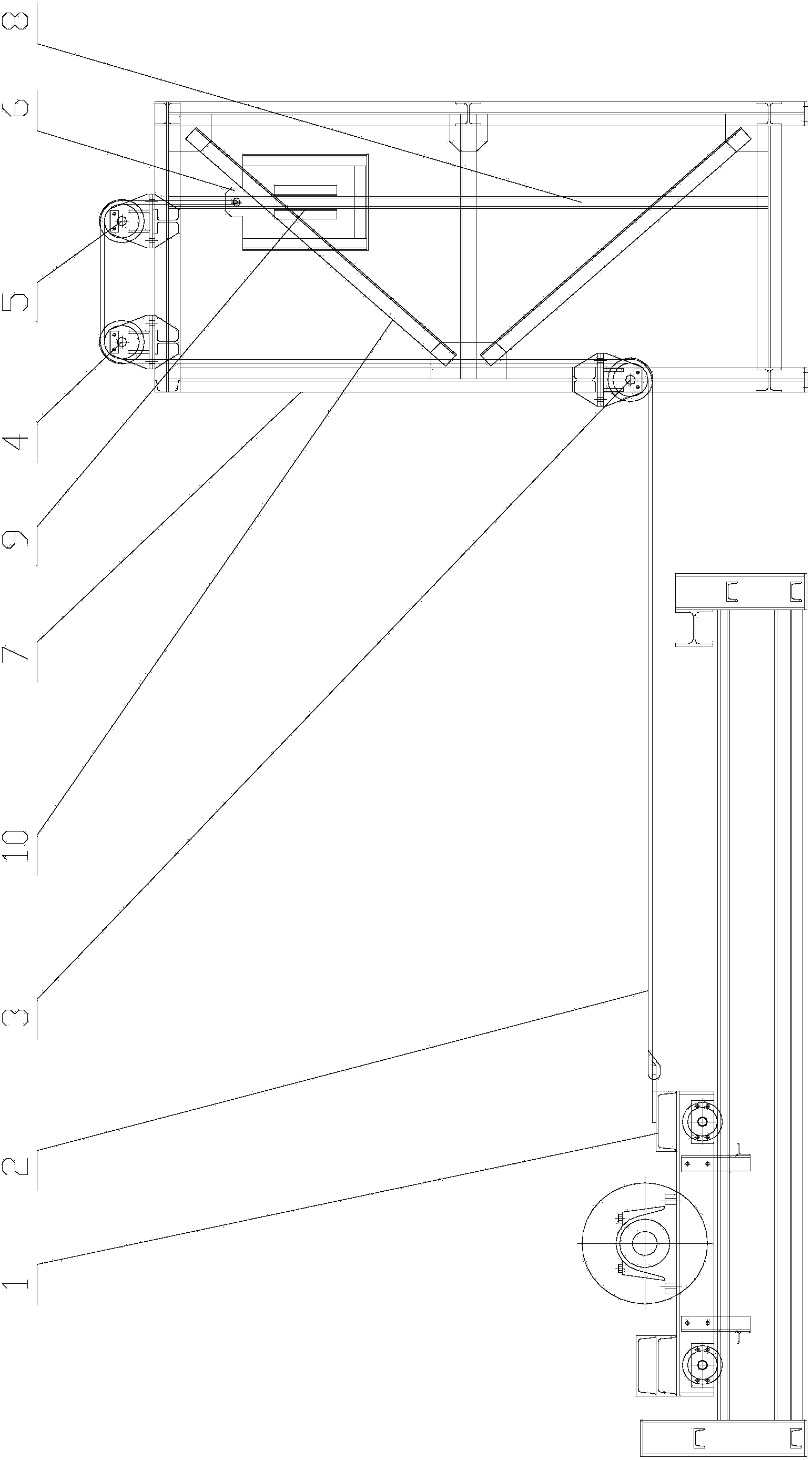

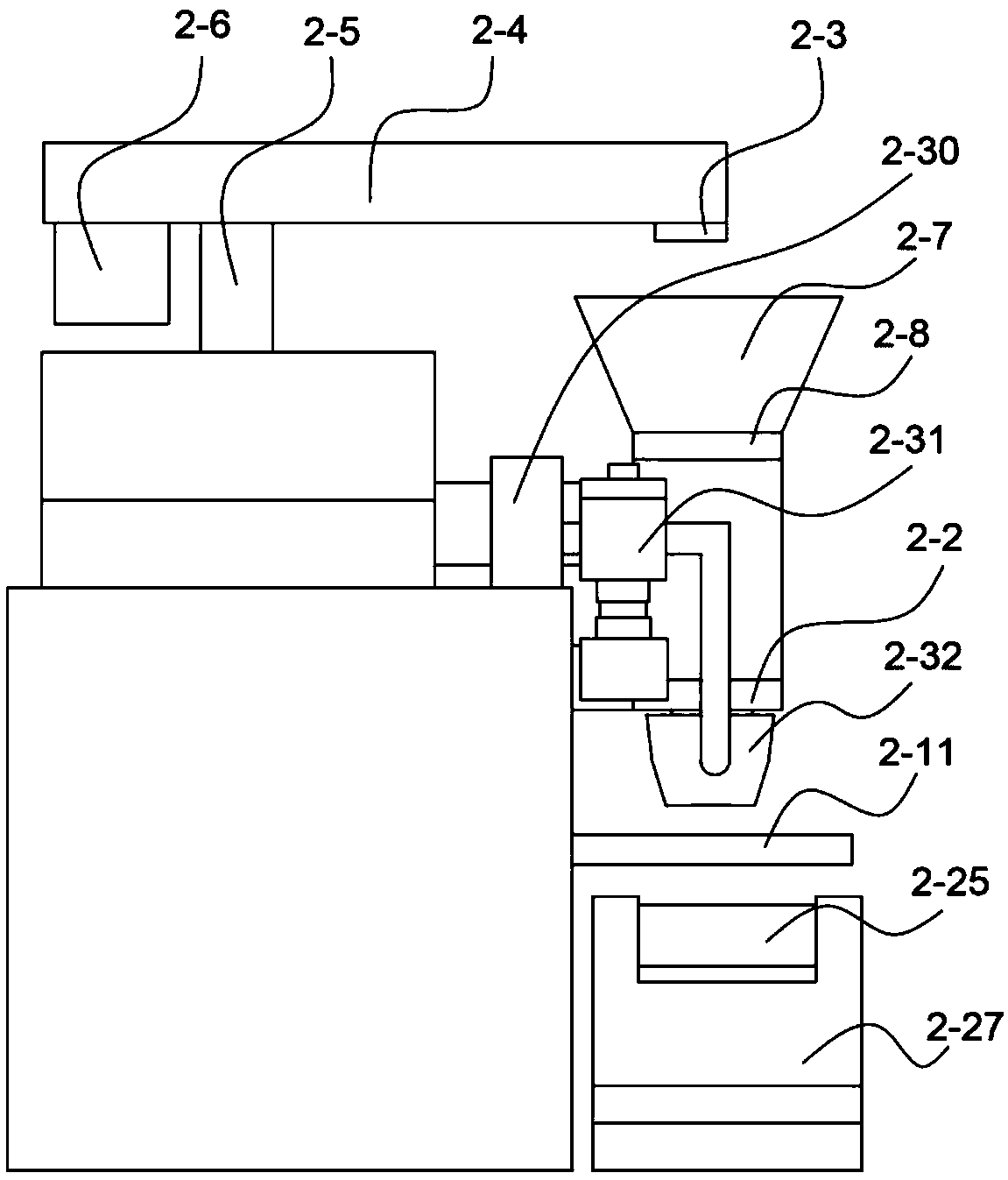

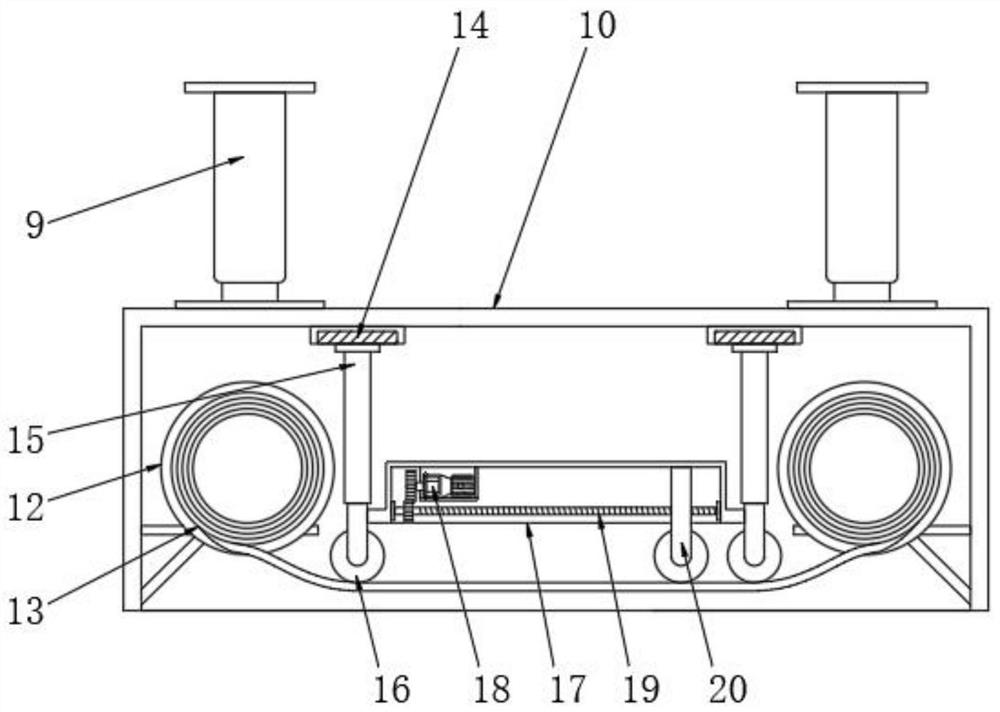

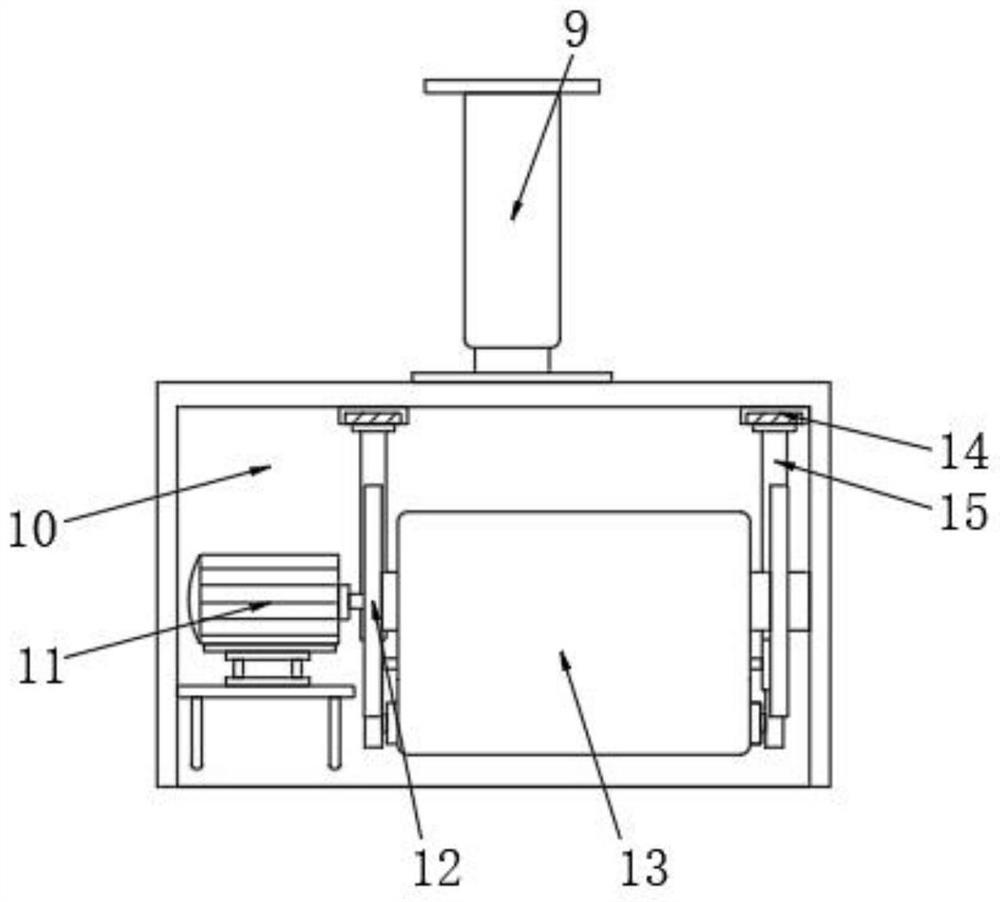

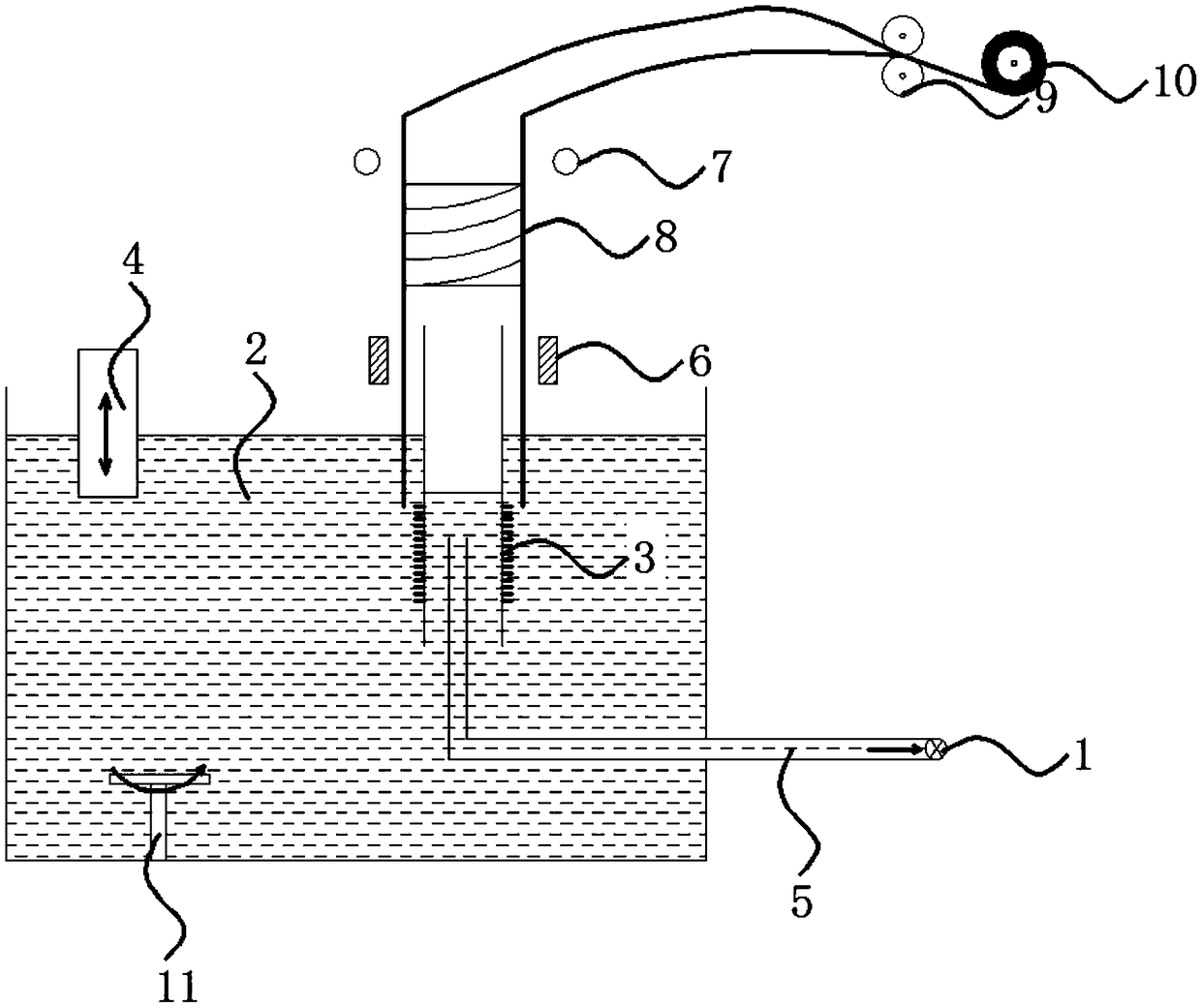

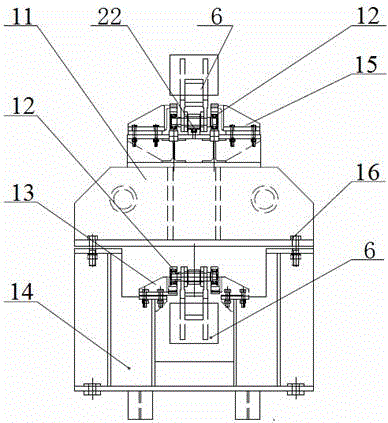

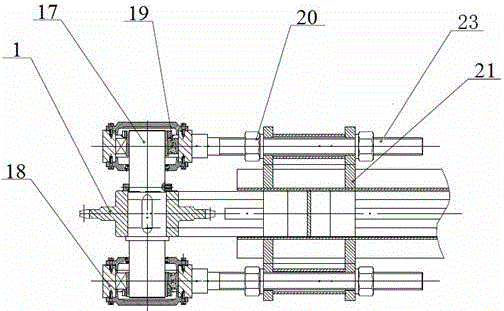

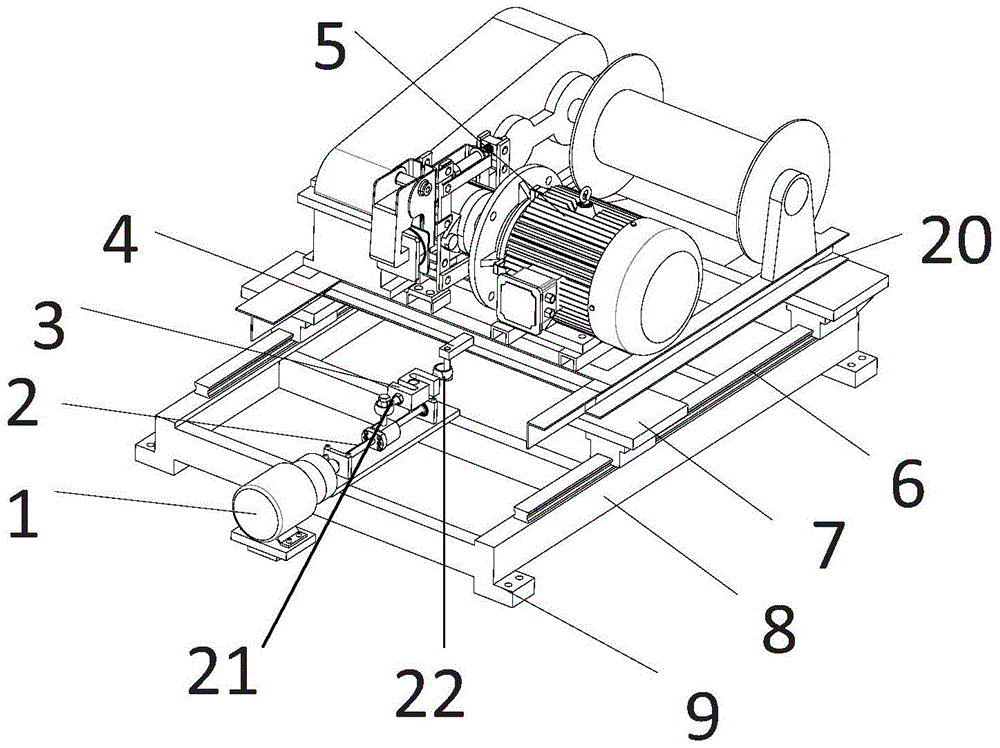

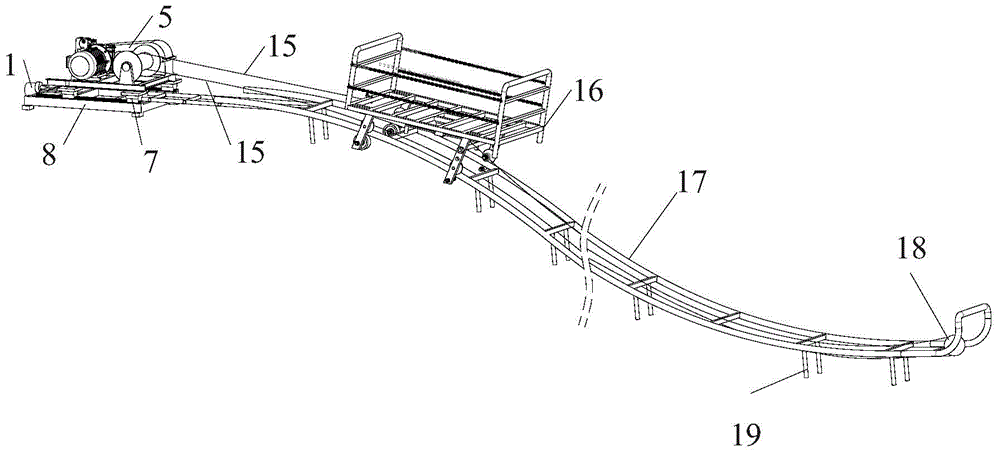

Tension adjusting device and method for steel wire ropes of bidirectional traction type rail transport machine

InactiveCN104692273AGuaranteed traction effectExtended service lifeWinding mechanismsEngineeringWire rope

The invention relates to a tension adjusting device and method for steel wire ropes of a bidirectional traction type rail transport machine. The adjusting device comprises a tension adjusting mechanism and a control system, wherein the tension adjusting mechanism comprises a motor, a lead screw, a lead screw nut and a tension sensor, an output shaft of the motor is connected with the lead screw, the lead screw nut is connected onto the lead screw, one end of the tension sensor is connected with the lead screw nut, the other end of the tension sensor is connected with a mounting base of a winch in the bidirectional traction type rail transport machine, and the mounting base is connected with a supporting frame fixed on the ground through a linear sliding mechanism; the control system comprises a signal feedback unit, a control unit, an execution unit and a power supply, the signal feedback unit consists of the tension sensor, and the execution unit consists of the motor. With the adoption of the adjusting device, the tension of the steel wire ropes can be adjusted automatically in real time, so that the steel wire ropes are in the optimal tensioned state all the time.

Owner:SOUTH CHINA AGRI UNIV +1

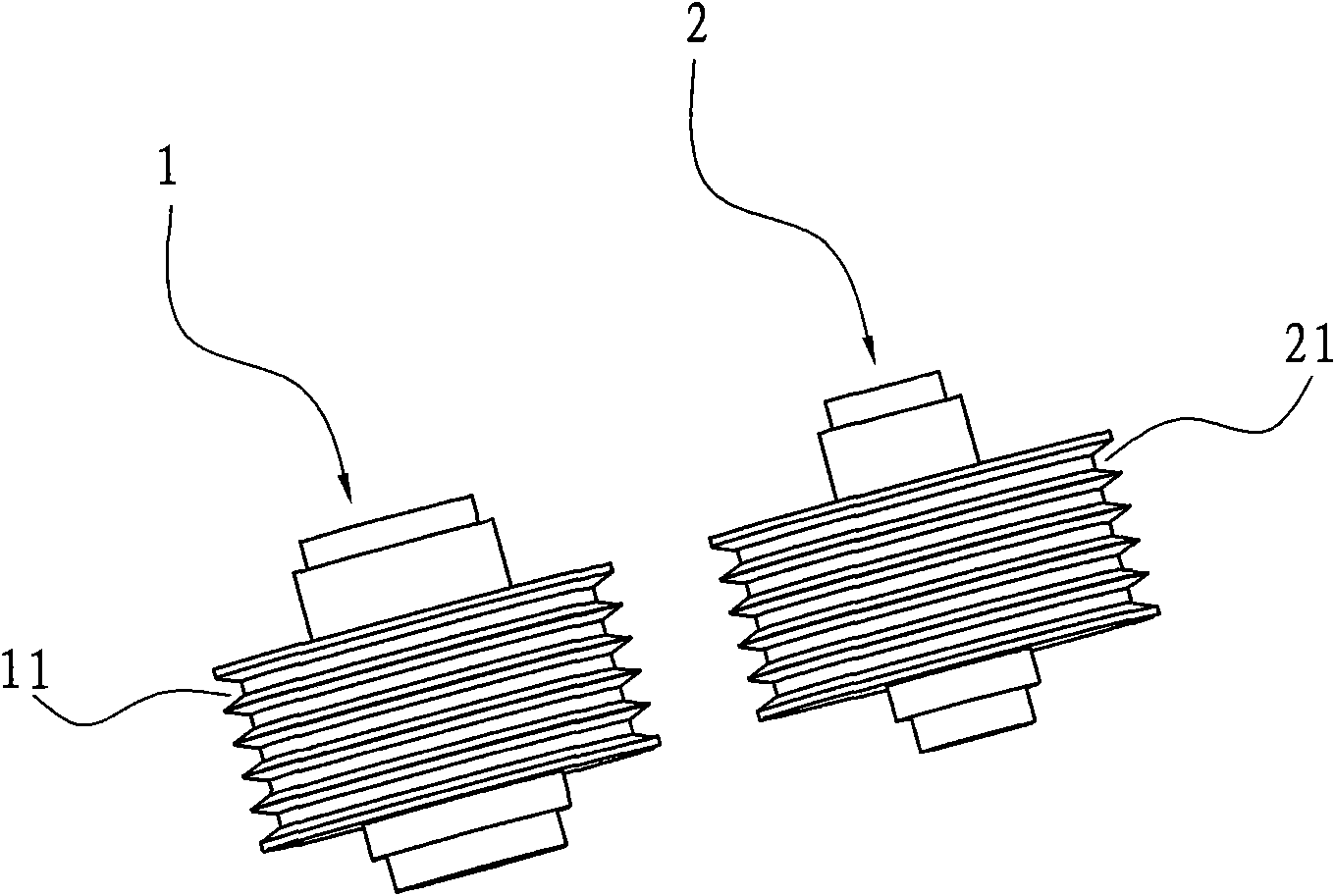

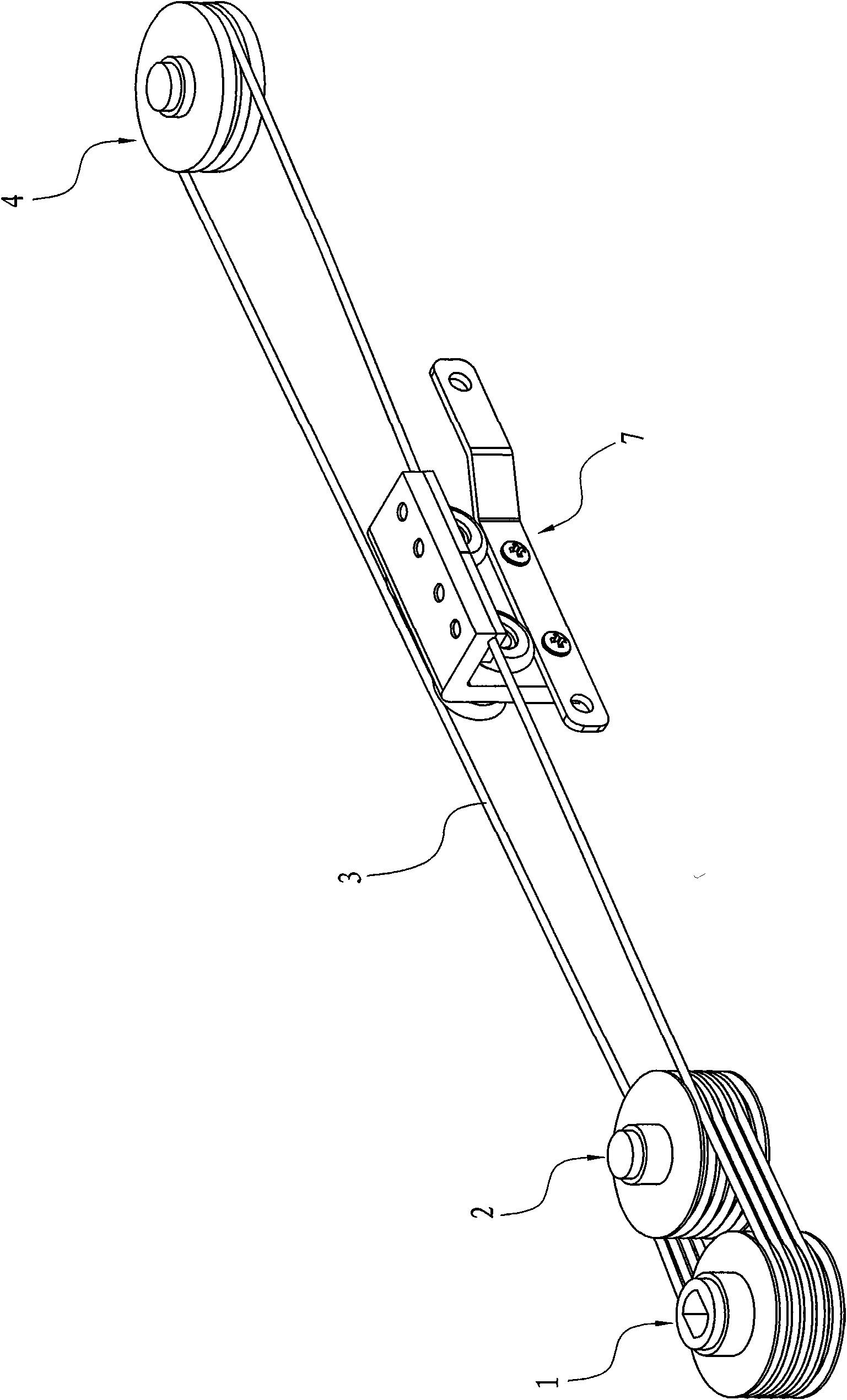

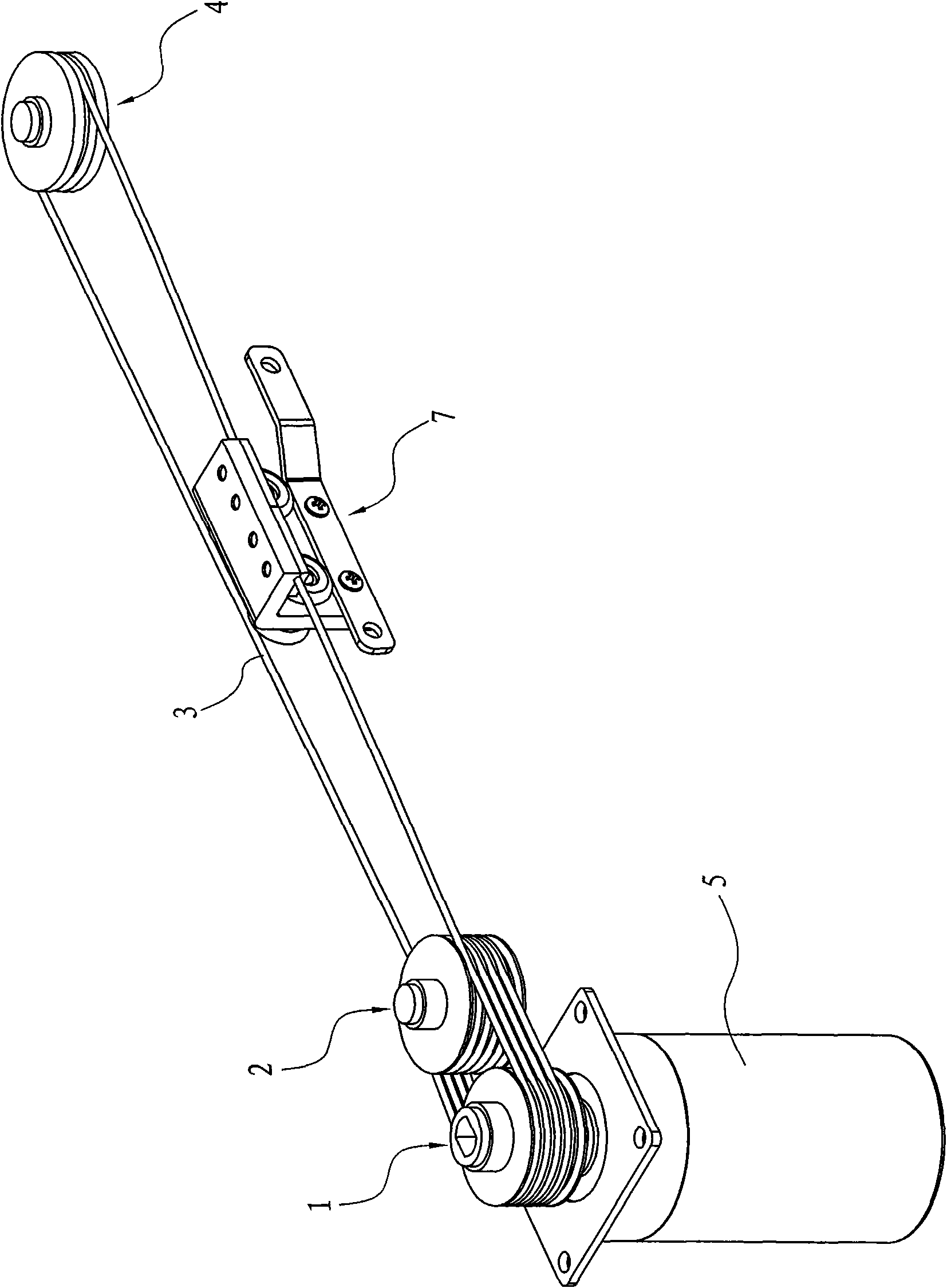

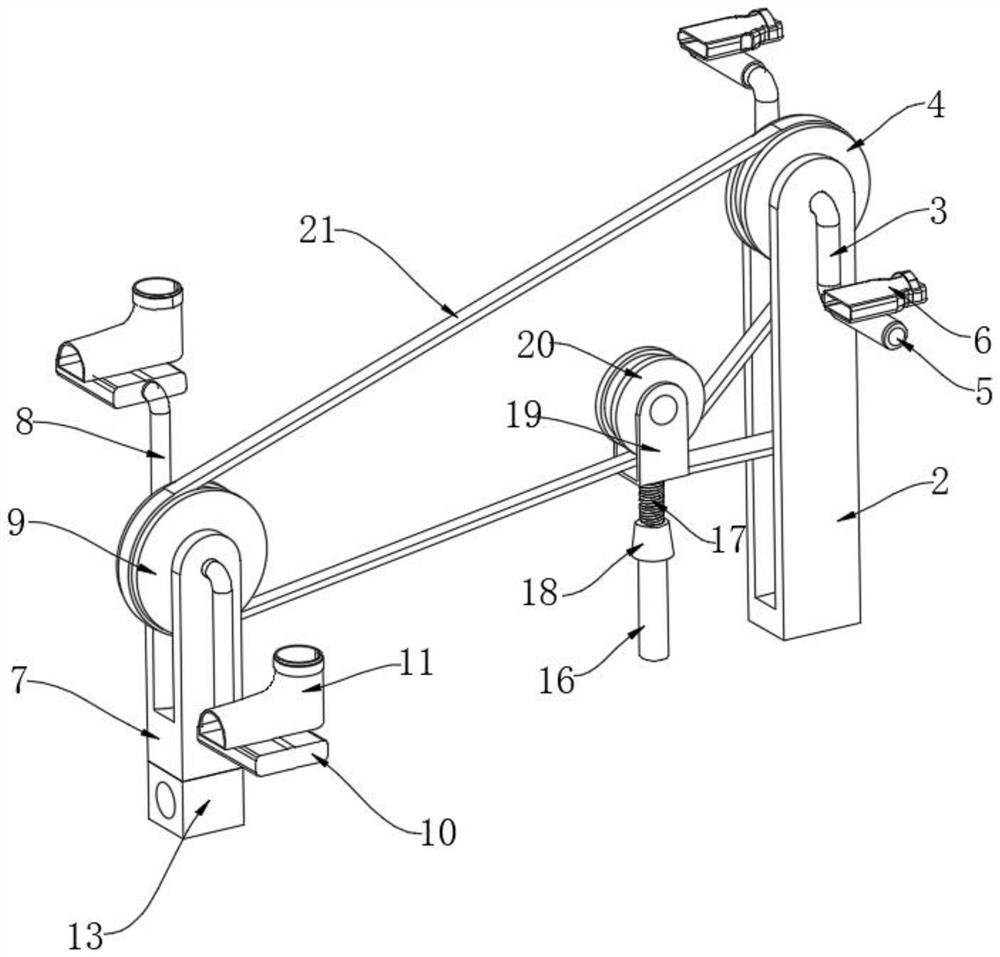

Rope traction mechanism and push-pull window with same

The invention relates to a rope traction mechanism and a push-pull window using the rope traction mechanism, wherein the rope traction mechanism comprises a first tensioning wheel and a second tensioning wheel, a steering wheel and a rope. The outer peripheral wall of each tensioning wheel is provided with at least two annular grooves which are spaced from each other. The two tensioning wheels areadjacent to and spaced from each other in the same row. Rotating shafts of the tensioning wheels are parallel to each other. At least one tensioning wheel is driven by an externally-connected power to rotate. The steering wheel is away from the first and the second tensioning wheels. The rope enters a wire inlet end of the first tensioning wheel, starts from the steering wheel, extends past the first annular groove of the first tensioning wheel in a direction adjacent to the first tensioning wheel, and then goes past the first annular groove of the second tensioning wheel and finally back tothe second annular groove of the first tensioning wheel, thereby forming a complete winding circle. The winding of the rope continues, and then at least one subsequent winding circle is formed. Finally, the rope comes out of a wire outlet end of the first or the second tensioning wheel and is wound back to the steering wheel to be from head-end connection with the wire inlet end.

Owner:瞿德阳

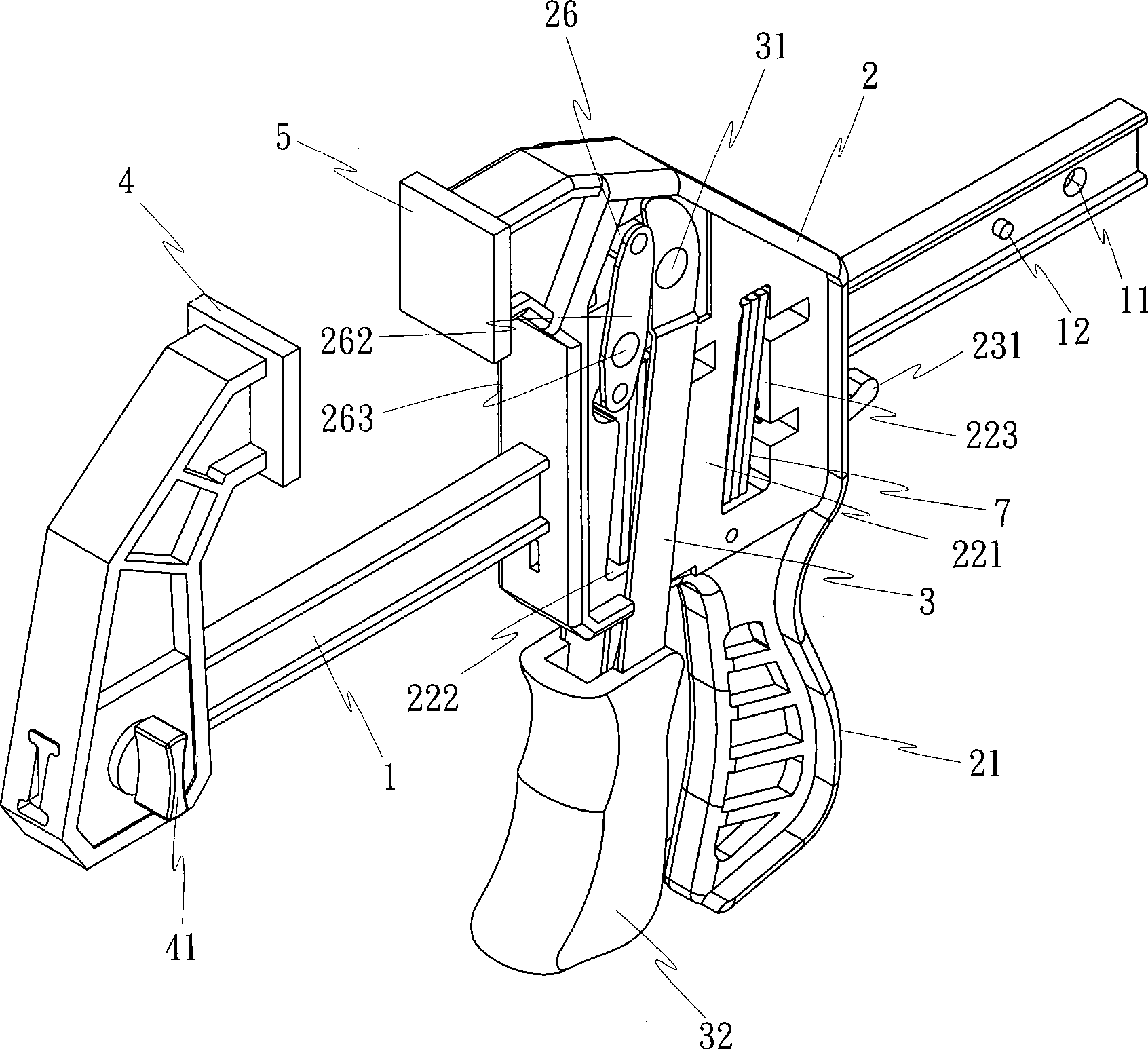

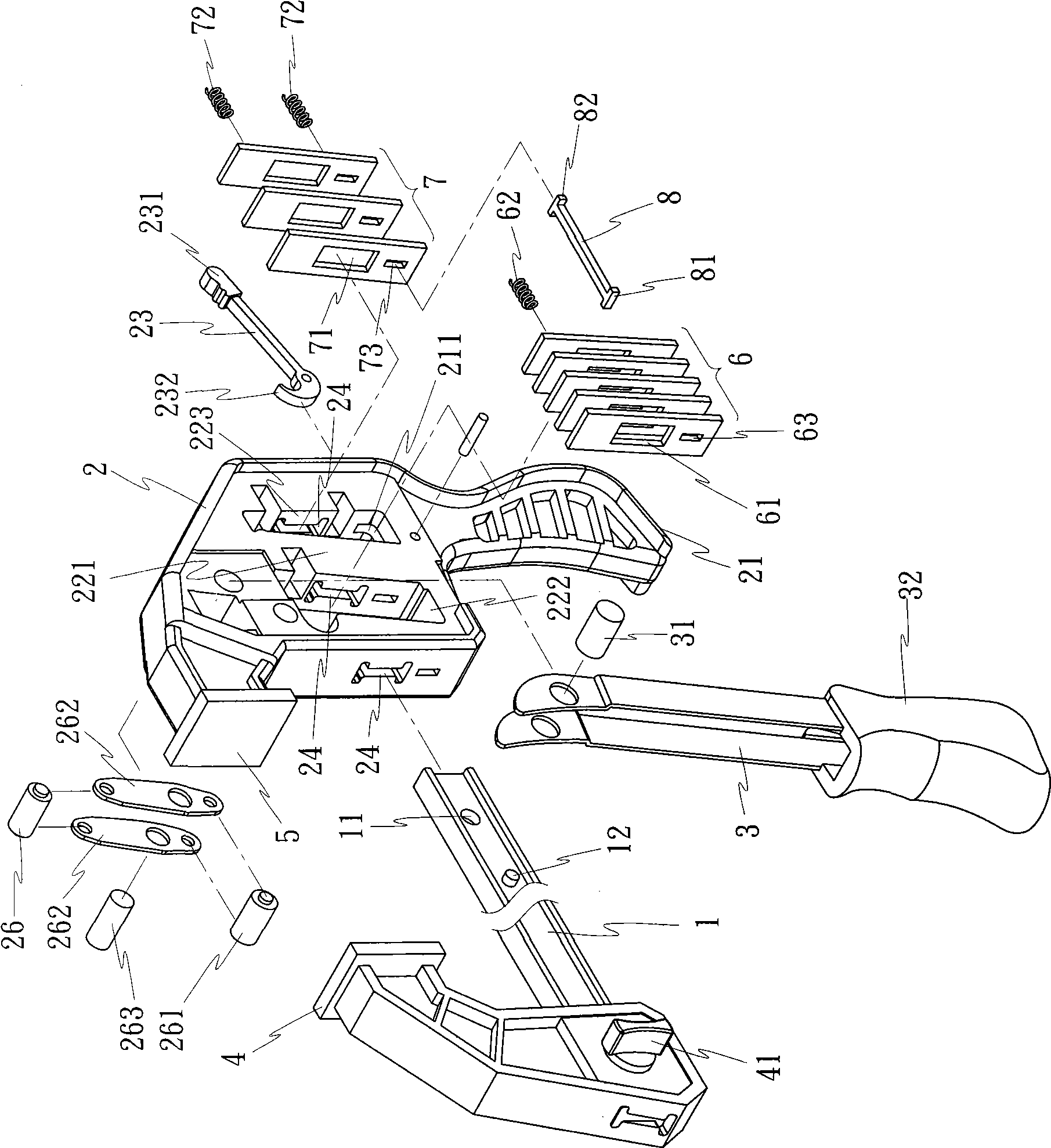

Handheld rapid fixture

The invention provides a handheld rapid fixture, which comprises a shifting lever, a fixed handle, a drive handle, a first grip block, a second grip block and other members. The shifting lever penetrates through the fixed handle, a group of action plates and a group of stop plates. One end of the body of the shifting lever is provided with the first grip block through locking. The second grip block is arranged above the fixed handle which is pivotally connected with the drive handle. A movable apical axis is erected on the fixed handle and is provided with a beam barrel at another end. When the drive handle is pressed, the top end of the body of the drive handle drives the apical axis, and furthermore, the action plate is pressed by the beam barrel. The dislocated shift of the action plate is used for driving the shifting lever to generate unidirectional displacement, thus causing the two grip blocks to generate the operation function of gripping or expanding. The handheld rapid fixture saves more labor in operation and has better holding force and stretching tension.

Owner:SHENG PU PROMOTION

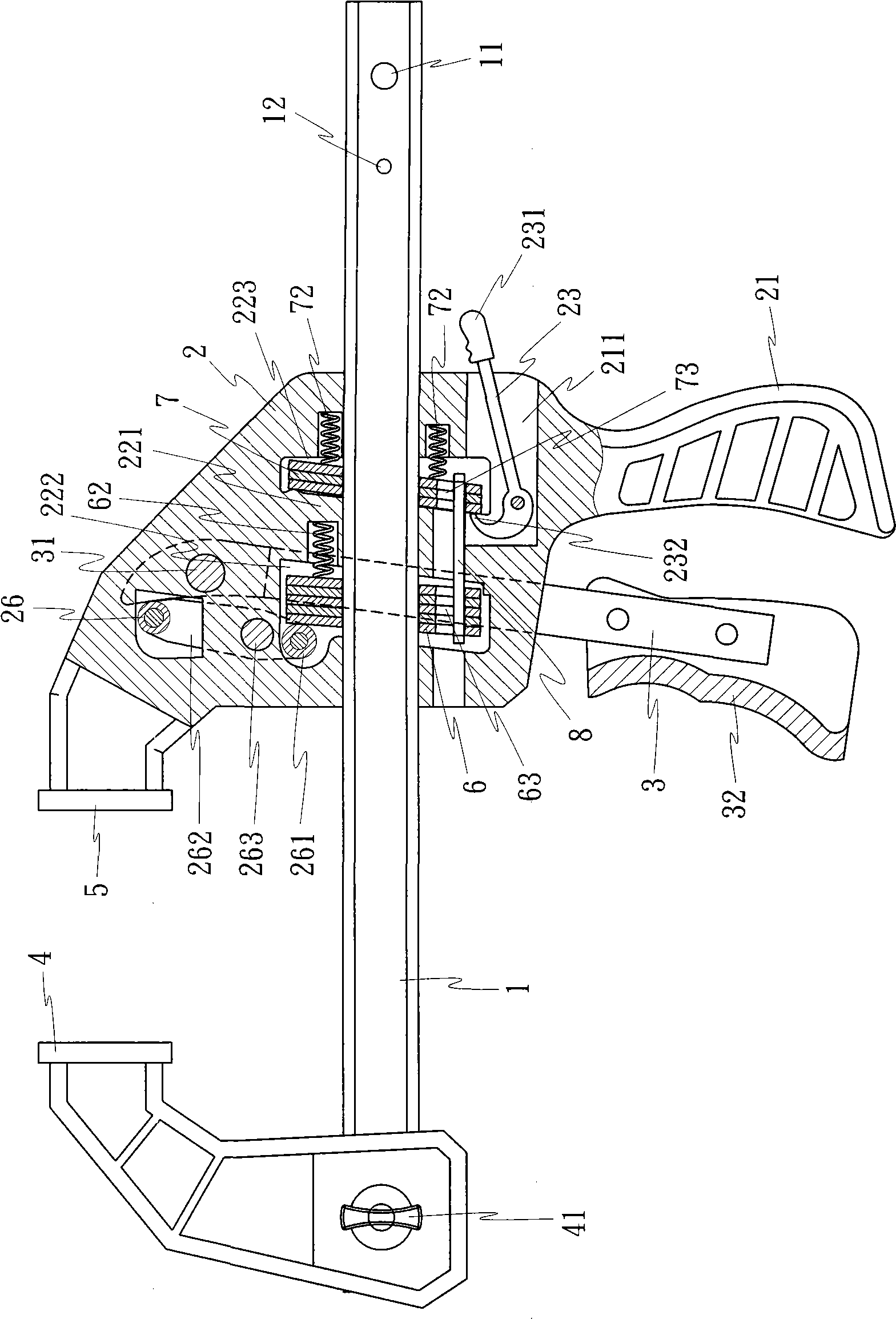

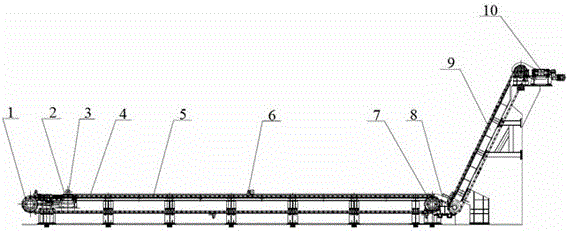

Gravity tensioning device of belt conveyor

The invention discloses a gravity tensioning device of a belt conveyor, and relates to the field of belt conveyors. The gravity tensioning device of the belt conveyor solves the problems that in the using process of the belt conveyor, with an existing tensioning mechanism, a belt of the belt conveyor can not be tensioned all the time, and use of the belt conveyor is seriously influenced because of instability of the tensioning state of the belt. The gravity tensioning device of the belt conveyor comprises a machine frame, a steel wire rope, a first turning pulley, a second turning pulley, a third turning pulley, a weight box, a gravity tensioning frame, a sliding rod and a hollow sliding rail. According to the gravity tensioning device of the belt conveyor, due to the design of the weight box and the turning pulleys, the steel wire rope can have a horizontal tensile force on the machine frame so that the belt of the belt conveyor can be tensioned, meanwhile, the weight box can only slide along the sliding rod, it is avoided that the tensile force is not even because the weight box waggles, and the belt can be tensioned well. The gravity tensioning device of the belt conveyor is suitable for the field of belt conveyors.

Owner:JIANGSU JIANGDA MACHINERY

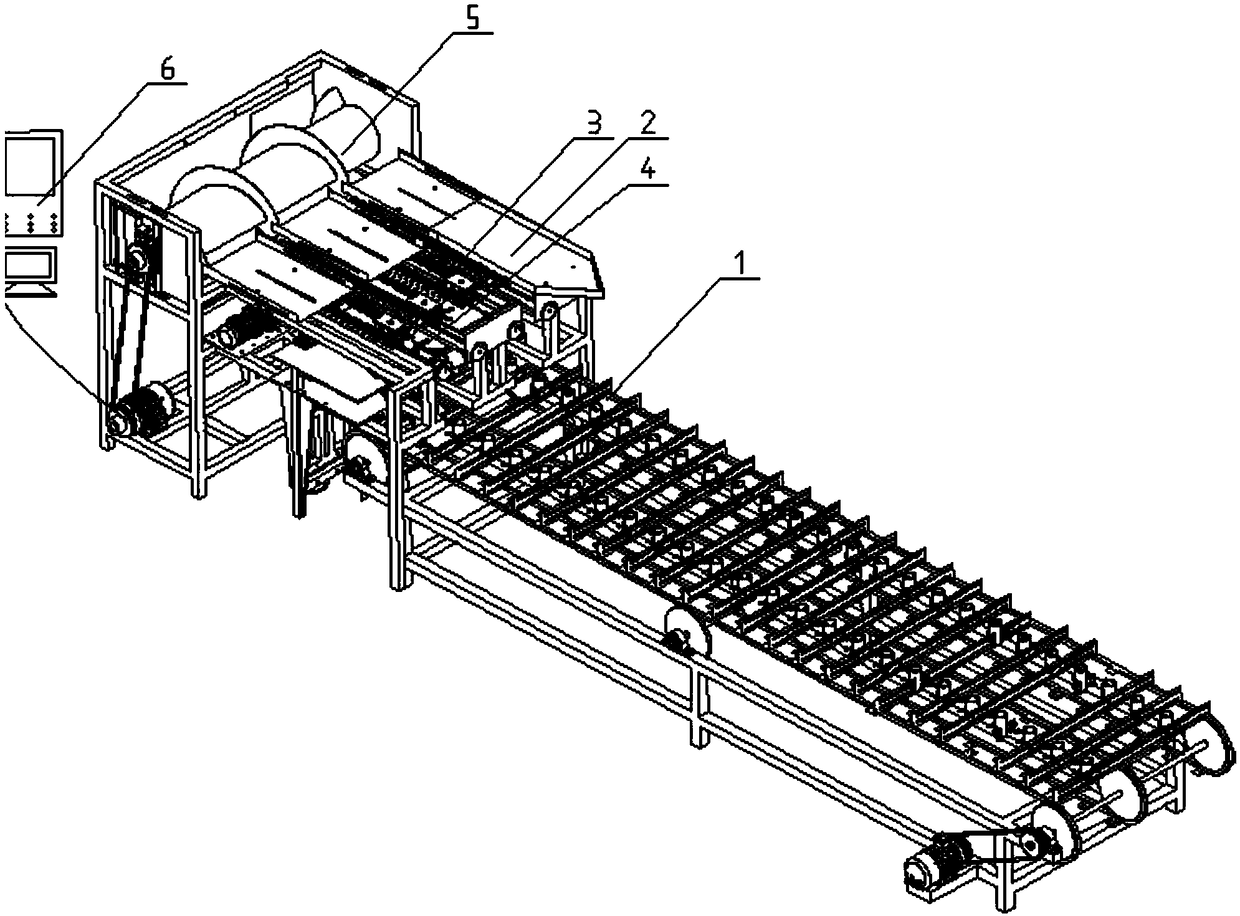

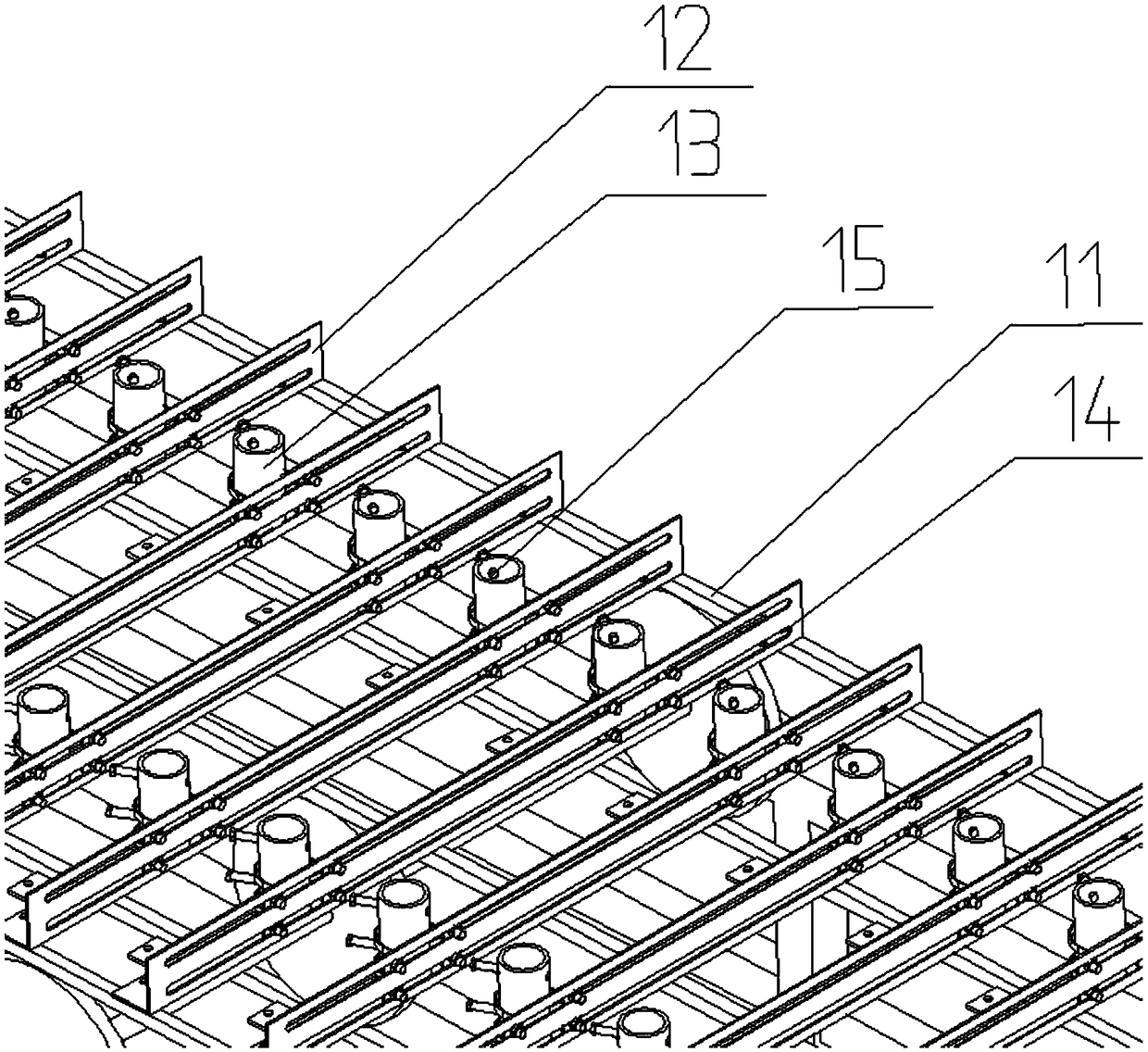

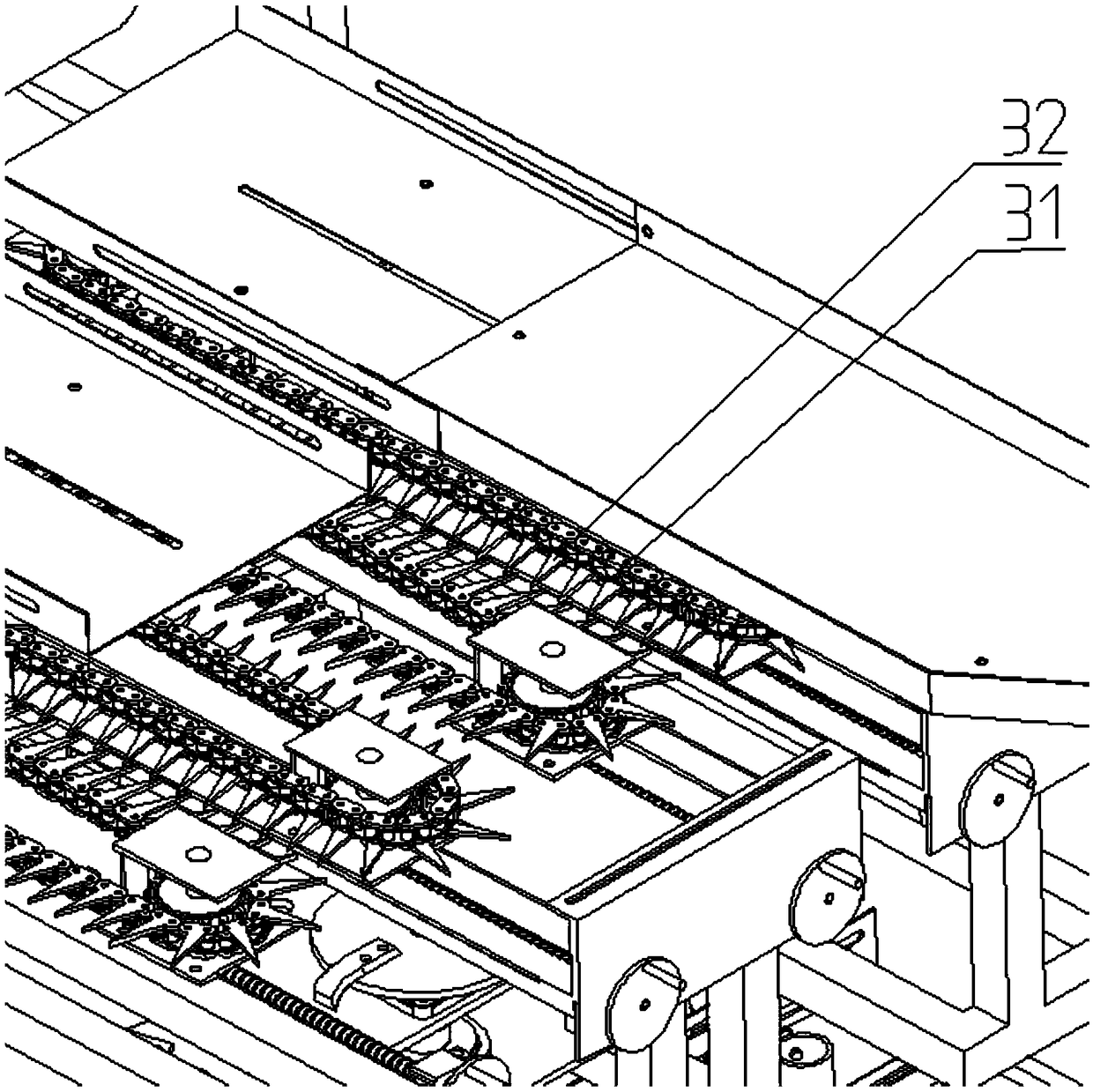

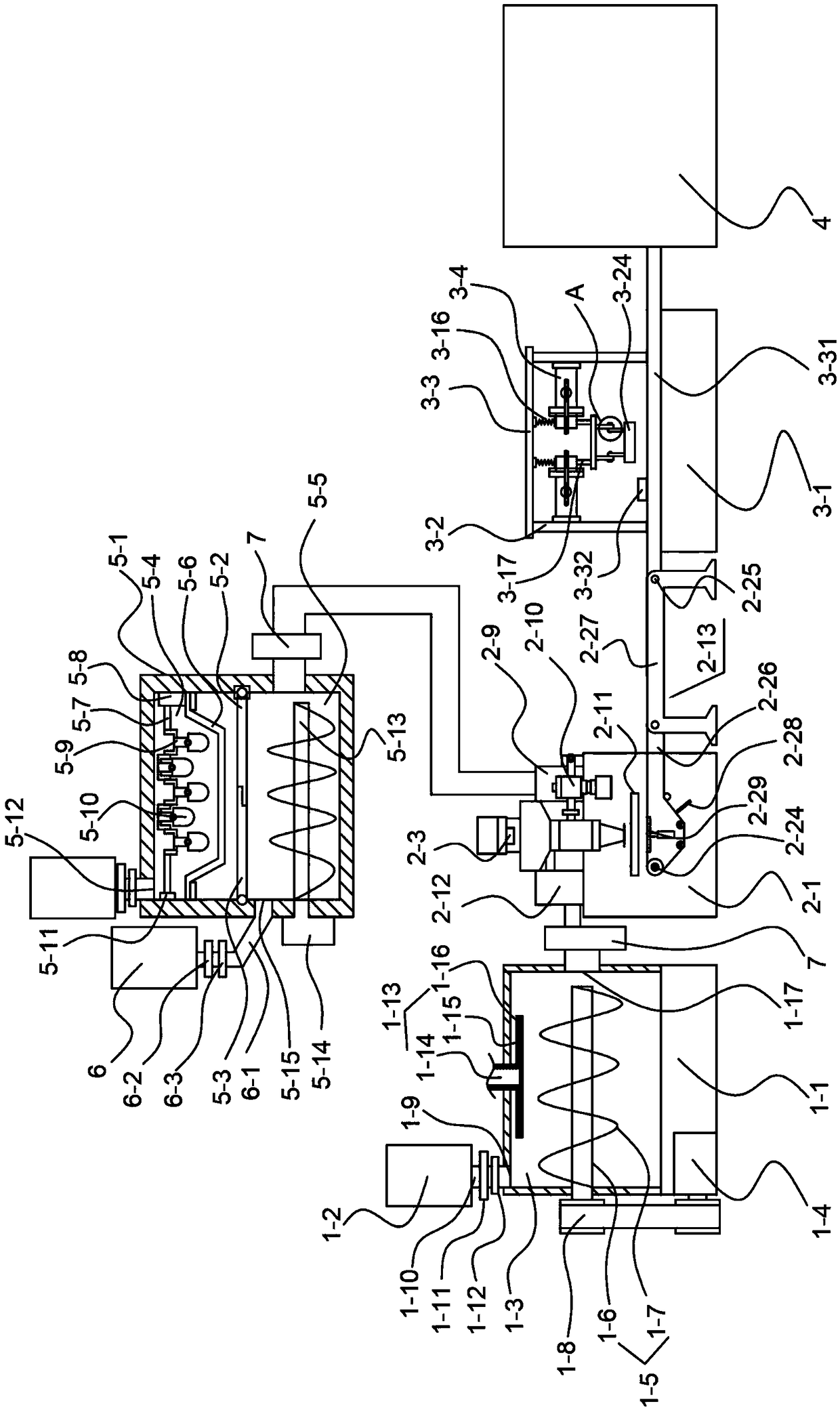

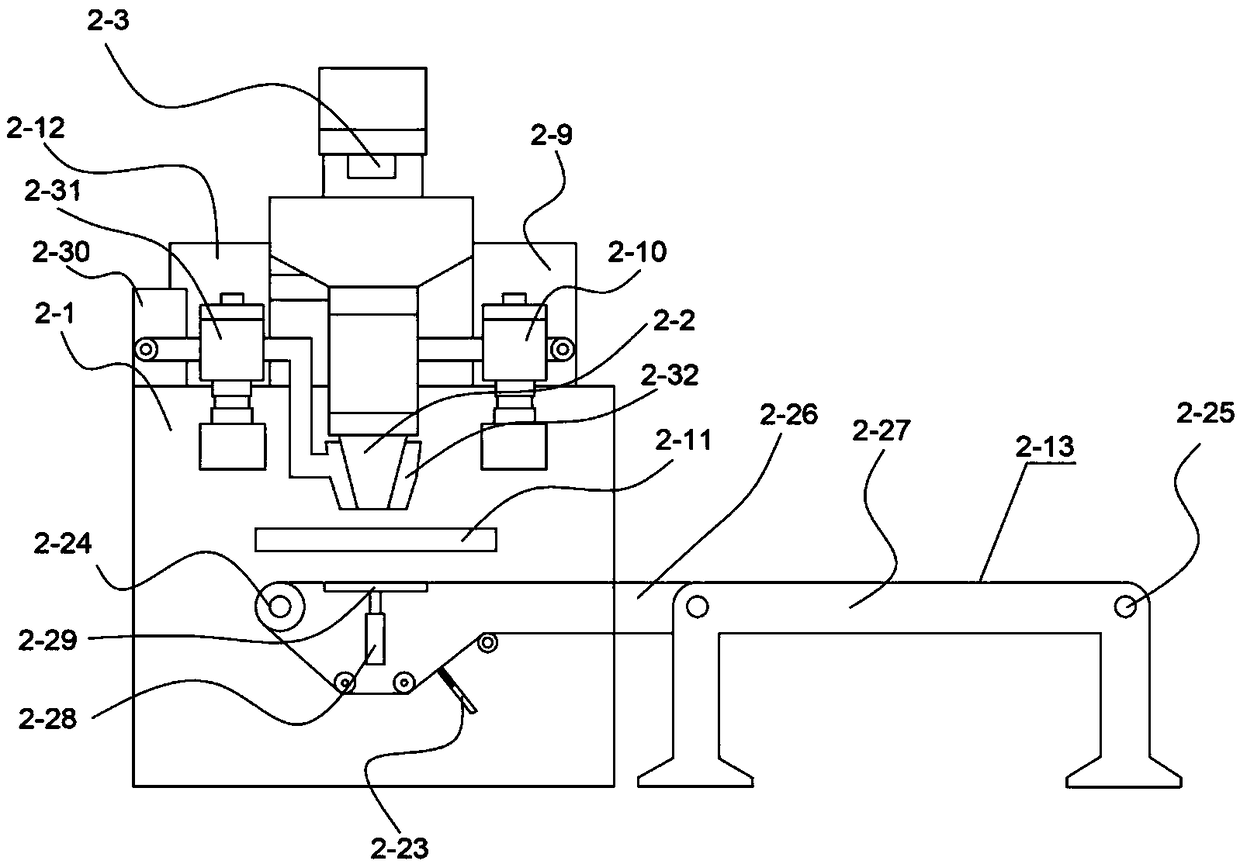

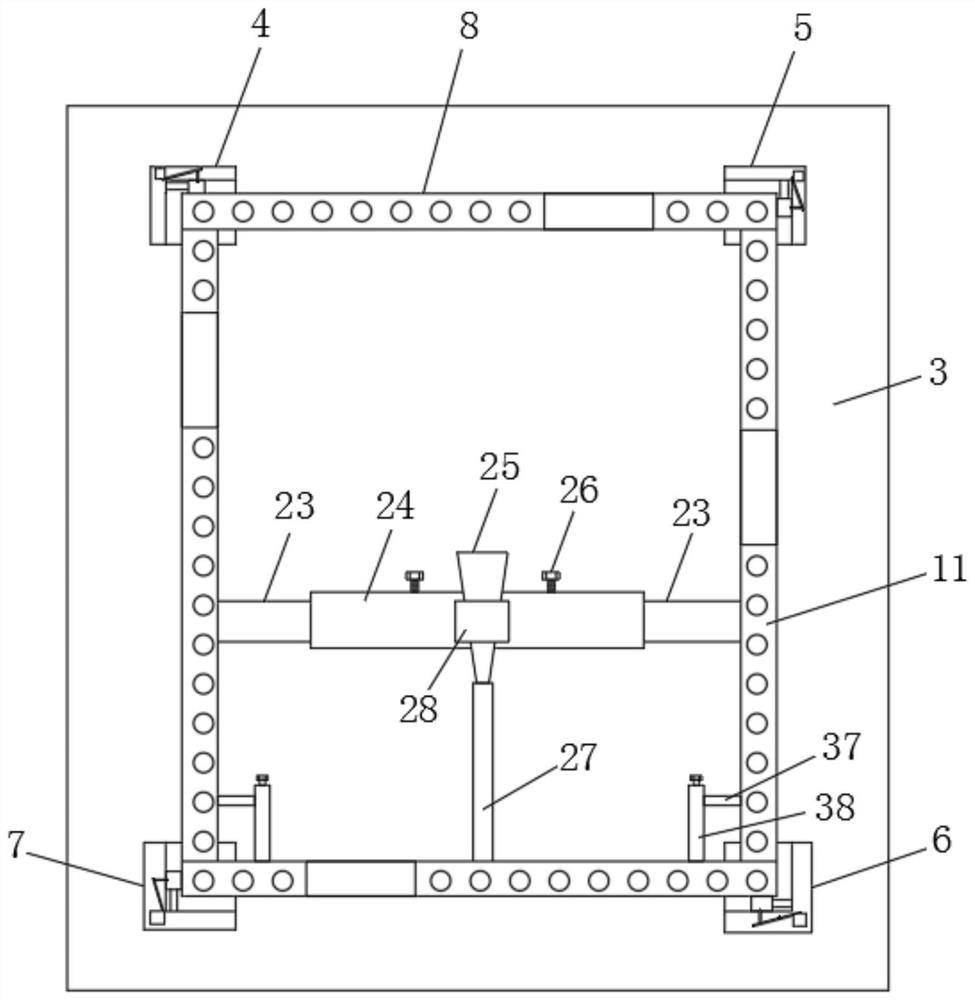

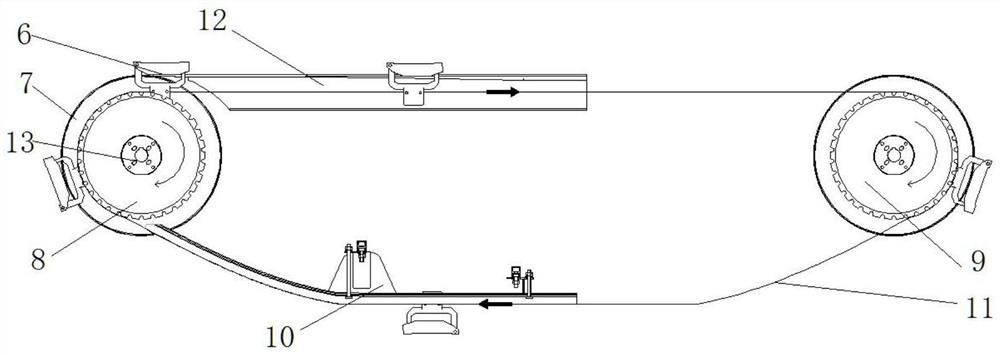

Multifunctional test bench for plucking chain type sunflower header test

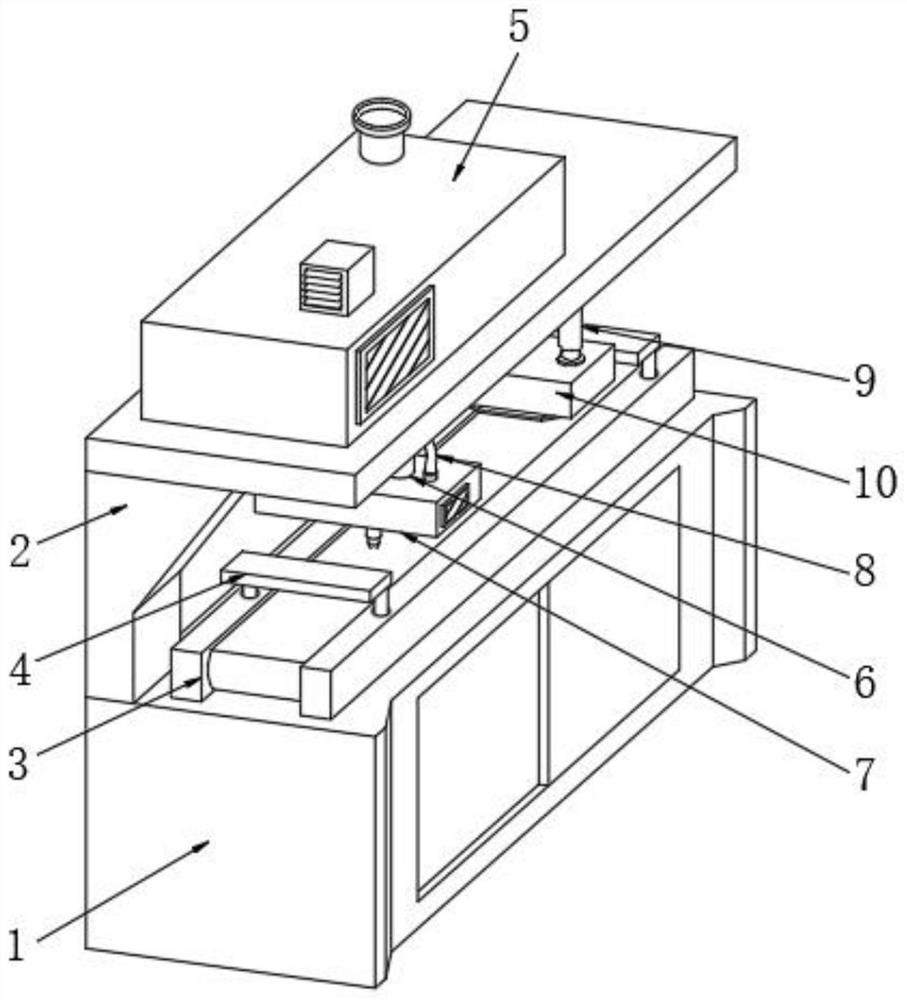

The invention relates to a multifunctional test bench for a plucking chain type sunflower header test. The multifunctional test bench for the plucking chain type sunflower header test comprises a feeding mechanism, dividing mechanisms, a plucking mechanism, a cutting mechanism, a conveying mechanism and a controller, wherein the feeding mechanism is used for driving plant fixing devices to move and then conveying plants to the cutting mechanism, the plant fixing devices are used for placing the plants, wherein the spacing between adjacent plant fixing devices can be adjusted; the dividing mechanism are arranged in parallel one another at equal intervals and the spacing between adjacent dividing mechanisms can be adjusted, and both the positions of the cutting mechanism and the conveying mechanism can be adjusted; the controller is used for controlling and storing the speeds of the feeding mechanism and the plucking mechanism and the speed and the torque of the cutting mechanism. The multifunctional test bench for the plucking chain type sunflower header test disclosed by the invention can simulate harvesting for the plants with different row spacings and tests influence of the speeds of the plucking mechanism, the cutting mechanism and the conveying mechanism on the harvesting effect, the spacing of two cutters on the harvesting effect and the positions of the cutters and theconveying mechanism on the harvesting effect, thereby being rich in functions and further being capable of realizing 'one machine multi-purposes'.

Owner:HUAZHONG AGRI UNIV

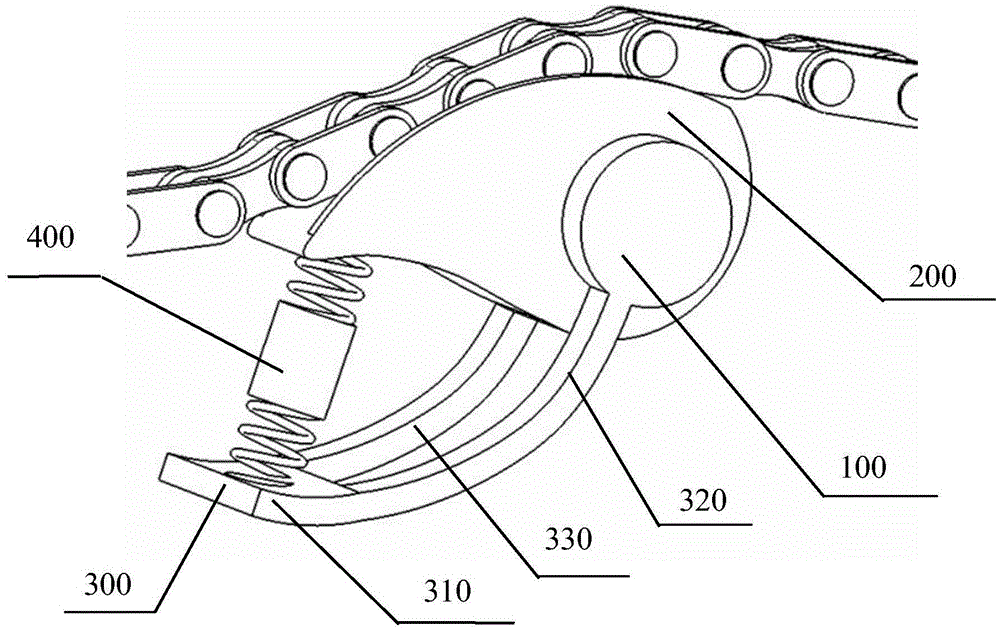

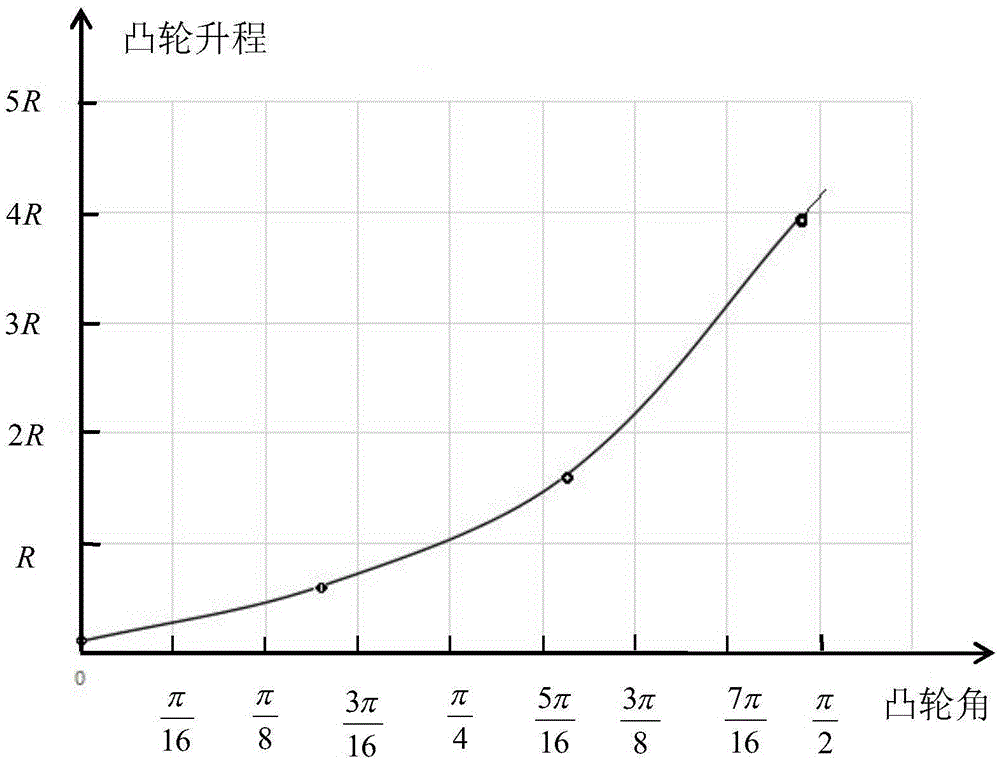

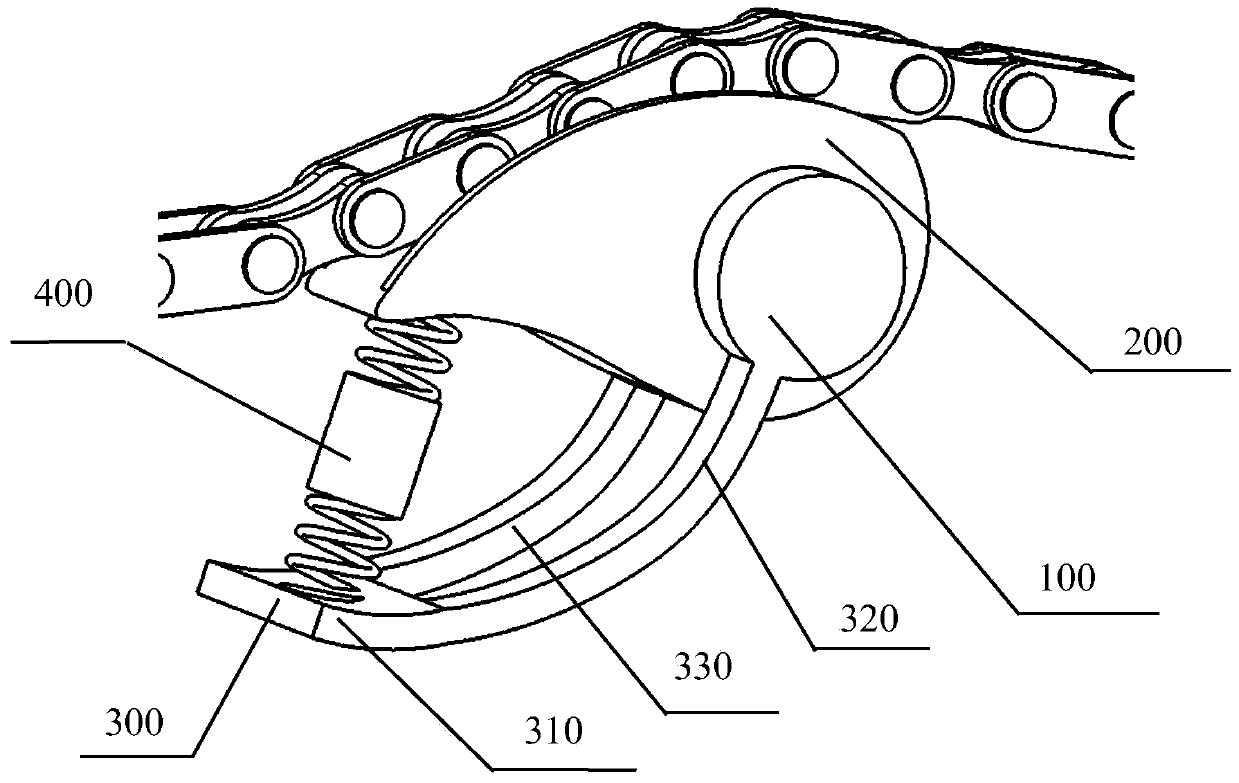

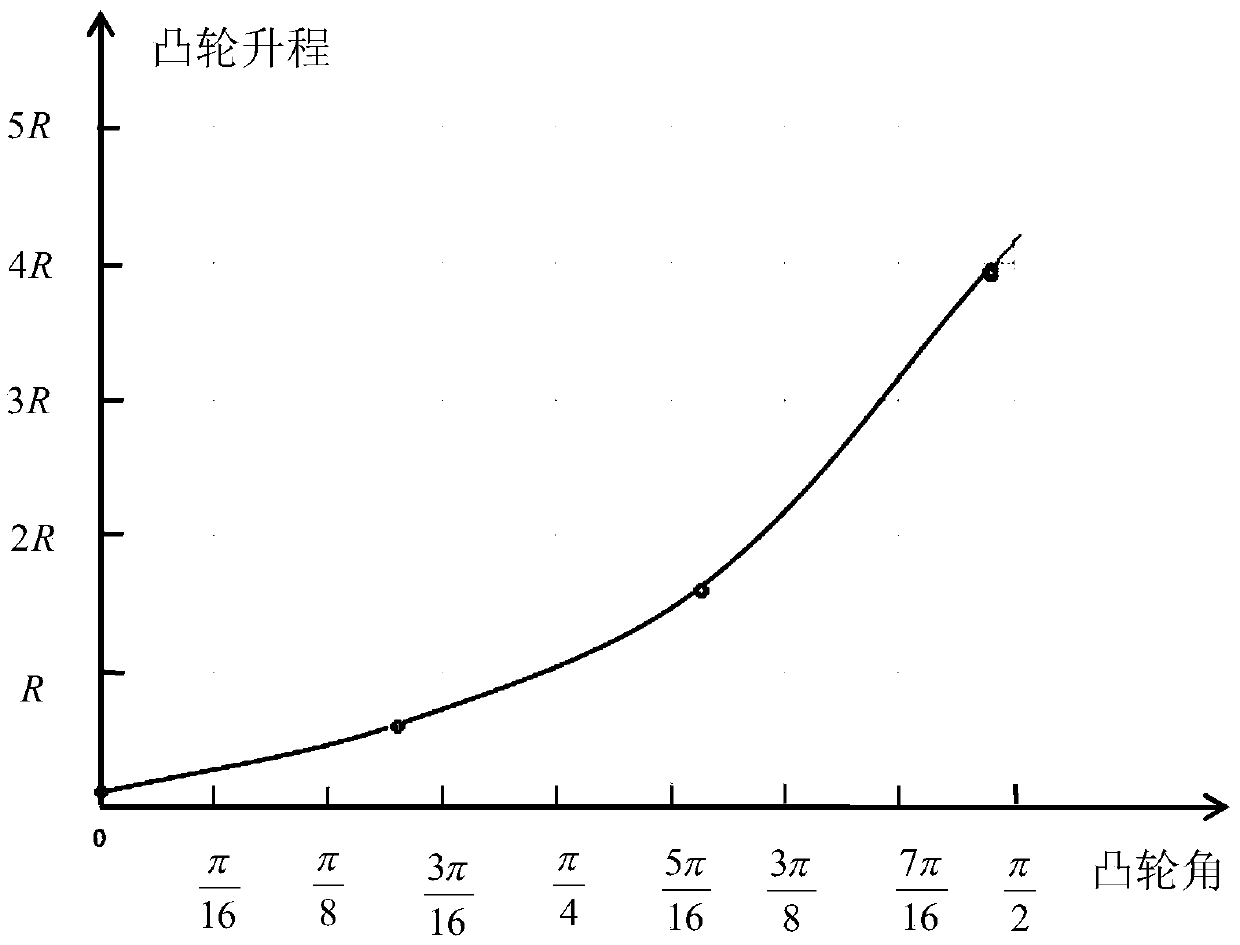

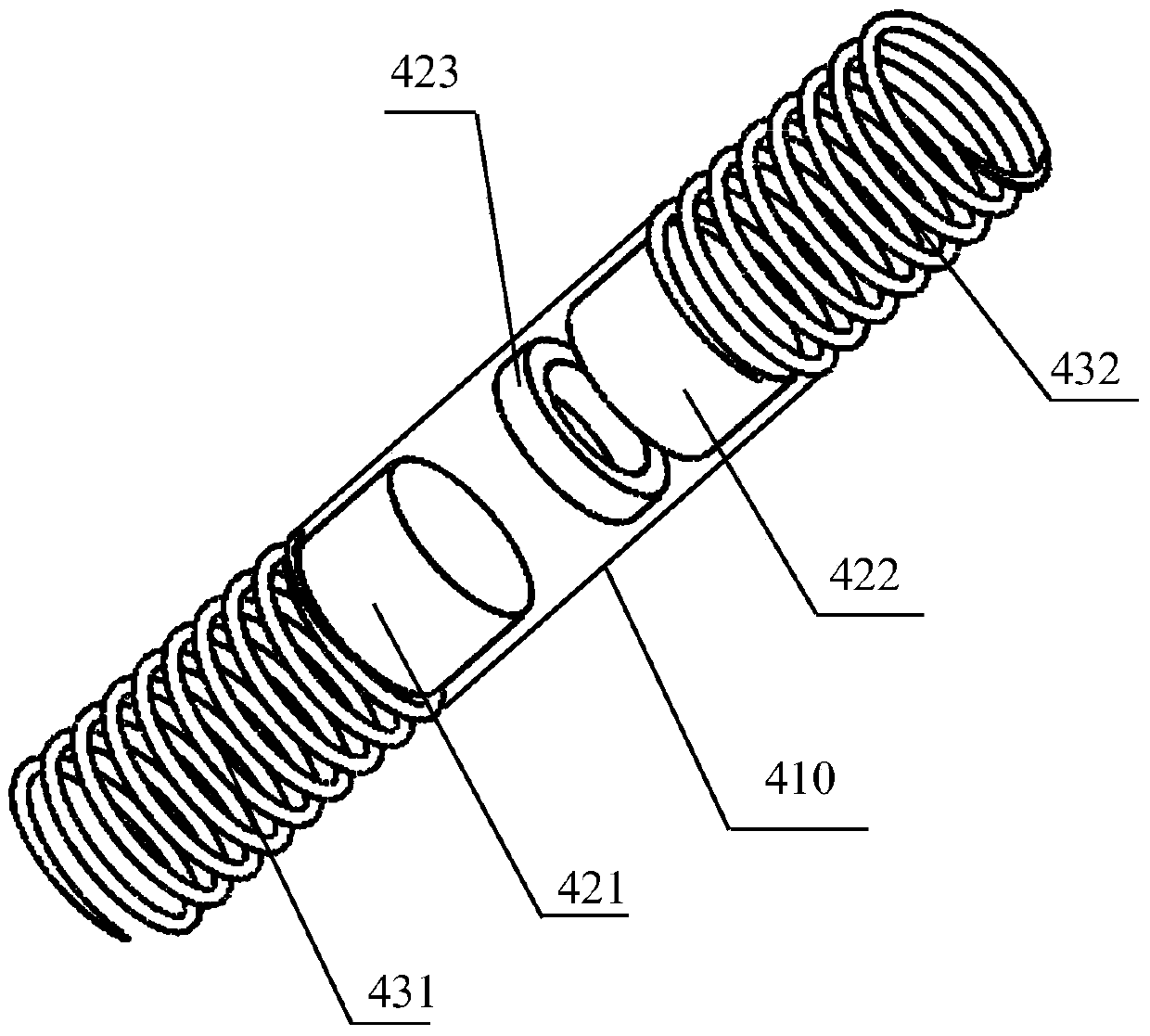

Chain tensioner based on cam, and control method thereof

The invention discloses a chain tensioner based on a cam. The chain tensioner comprises a fixing shaft, the tensioning cam, a supporting arm, a first extending arm, a second extending arm, and a shock absorption supporting device, wherein the tensioning cam is arranged on the fixing shaft in a sleeving manner and can swing around the fixing shaft, and a smooth groove is formed in the periphery of the tensioning cam and used for containing a chain; the supporting arm comprises a common terminal; the first extending arm and the second extending arm which are both connected to the common terminal are symmetrically arranged, and the first extending arm and the second extending arm are fixed to the two ends of the fixing shaft; and one end of the shock absorption supporting device is supported on the common terminal of the supporting arm, and the other end of the shock absorption supporting device is supported at the far end of the tensioning cam and used for flexible supporting to the tensioning cam. The invention further provides a control method of the chain tensioner based on the cam. By changing the current intensity of an electromagnetic body, the chain is made in an optimal tensioned state.

Owner:LIAONING UNIVERSITY OF TECHNOLOGY

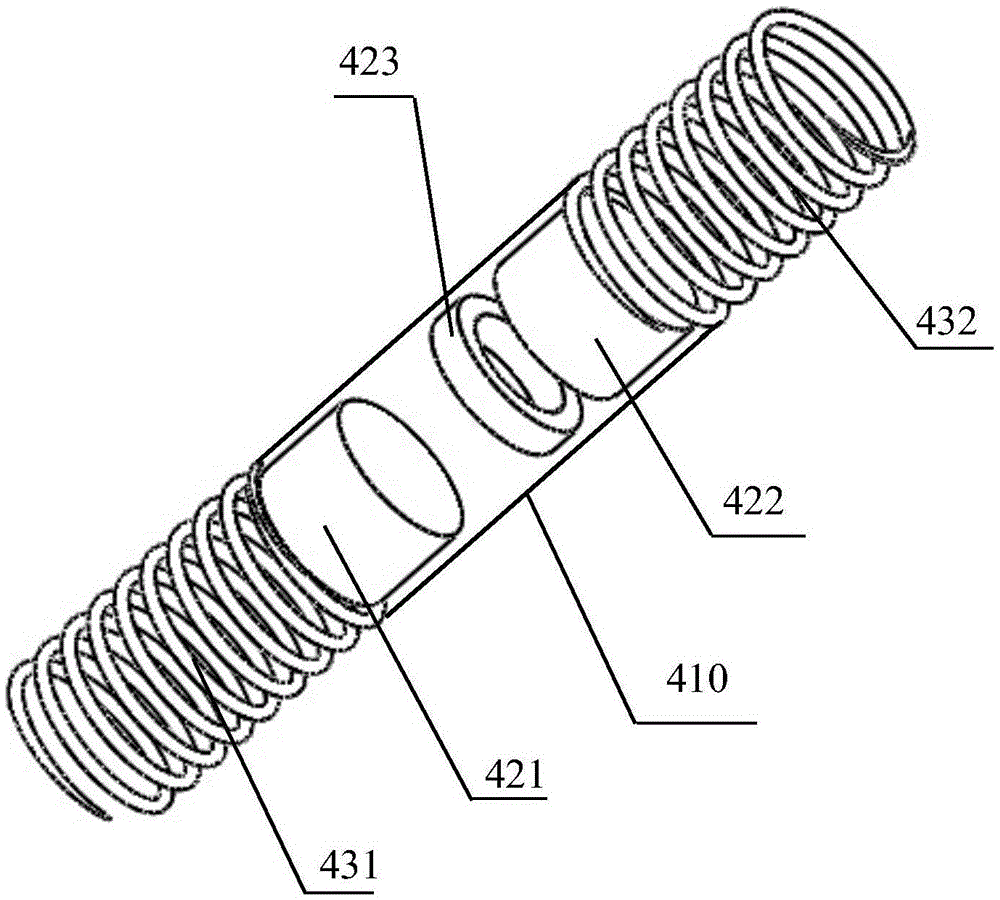

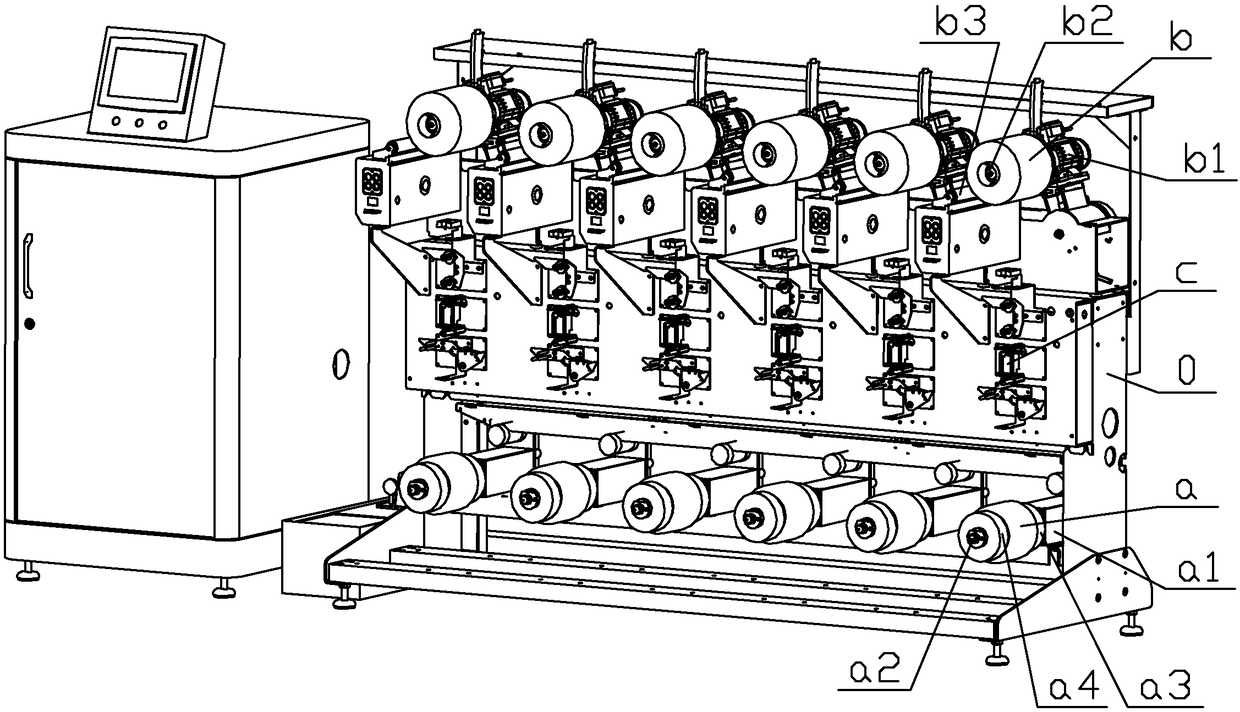

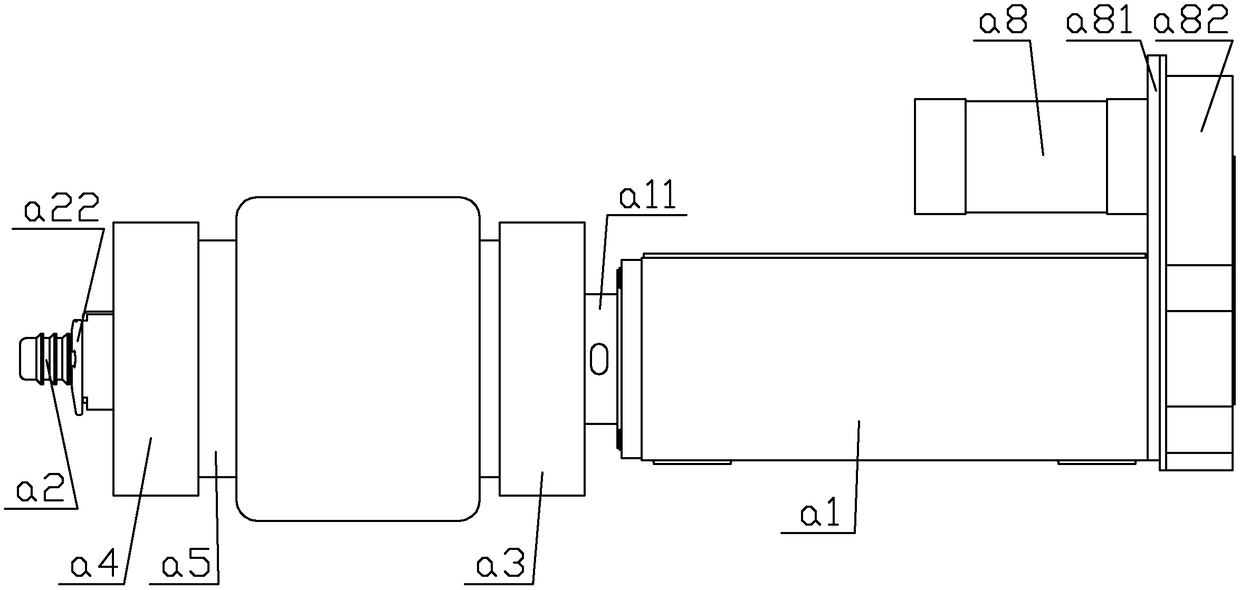

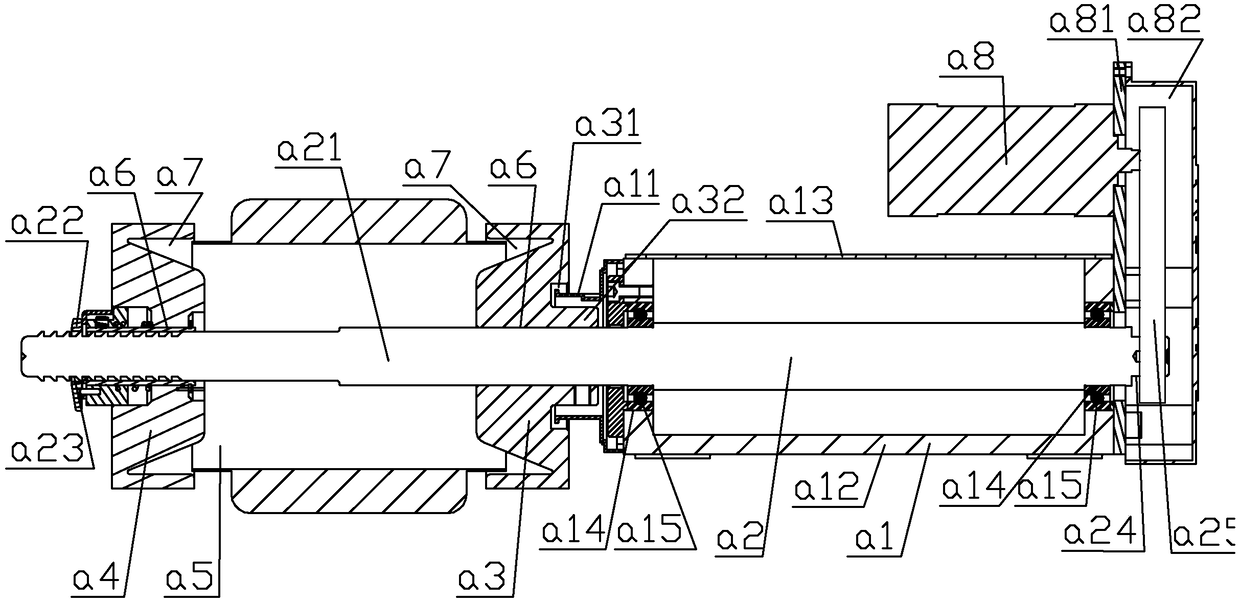

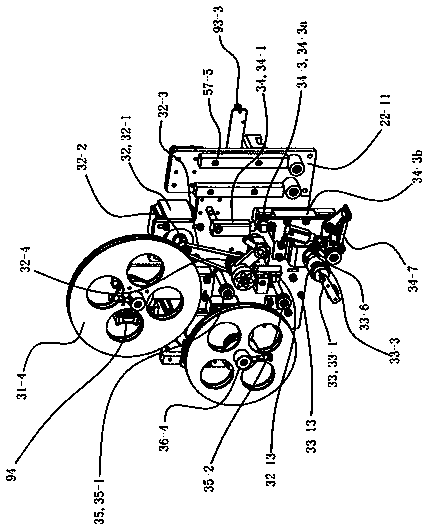

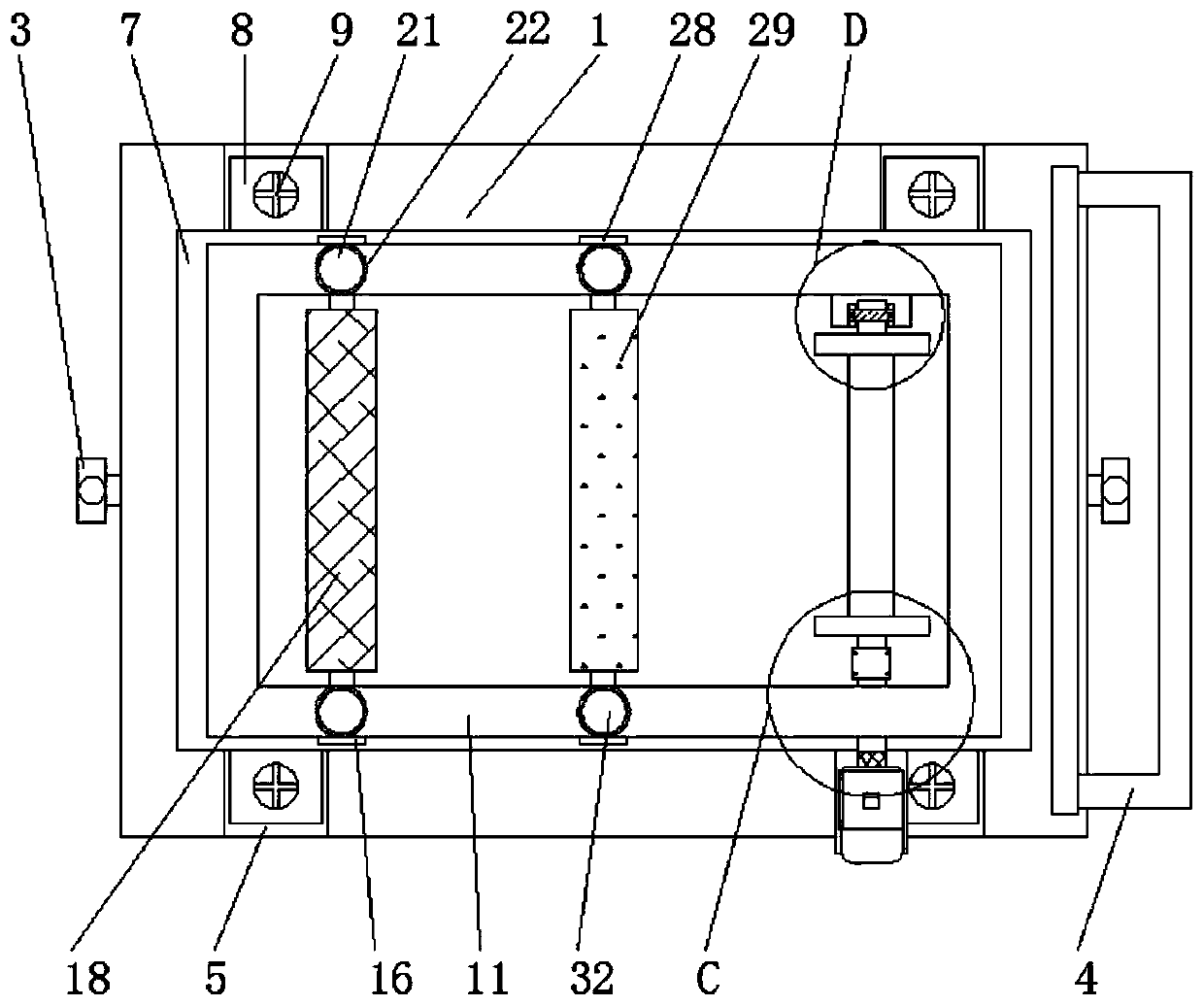

Viscose filament whole machine mechanism

PendingCN108892001AAvoid knotsImproved positioning and stabilityFilament handlingViscose fiberFilament yarn

The invention discloses a viscose filament whole machine mechanism. The surface of an abutting wheel on an active winding mechanism of the viscose filament whole machine mechanism has a slight inclination angle; by means of the inclination angle, the shape of a main reel and the elasticity of yarn after winding, the yarn can be well kept clamped and wound by the abutting wheel and the main reel, the phenomenon of winding loosening of some positions caused by insufficient matching of an original columnar abutting wheel is avoided, and the net conditions of the well wound yarn are reduced. A unwinding mechanism can deform well through a columnar elastic lining plate, and is distracted after reeled yarn is sleeved, an inner pressing disc and an outer pressing disc are sleeved in a front-rearmode to form a stable structure, the inner pressing disc and the outer pressing disc sleeve a rotating shaft and can drive the rotation to achieve yarn unwinding; if the yarn becomes loosened in the unwinding process, the elastic lining plate can be further distracted by means of elasticity, so that the yarn keeps a good tensioned state, the knotting and winding caused by yarn loosening are avoided, a yarn reeling mode such as the positioning and stabilization of viscose filaments is improved, and quick unwinding is achieved.

Owner:XINCHANG WANSHIFA TEXTILE MACHINERY

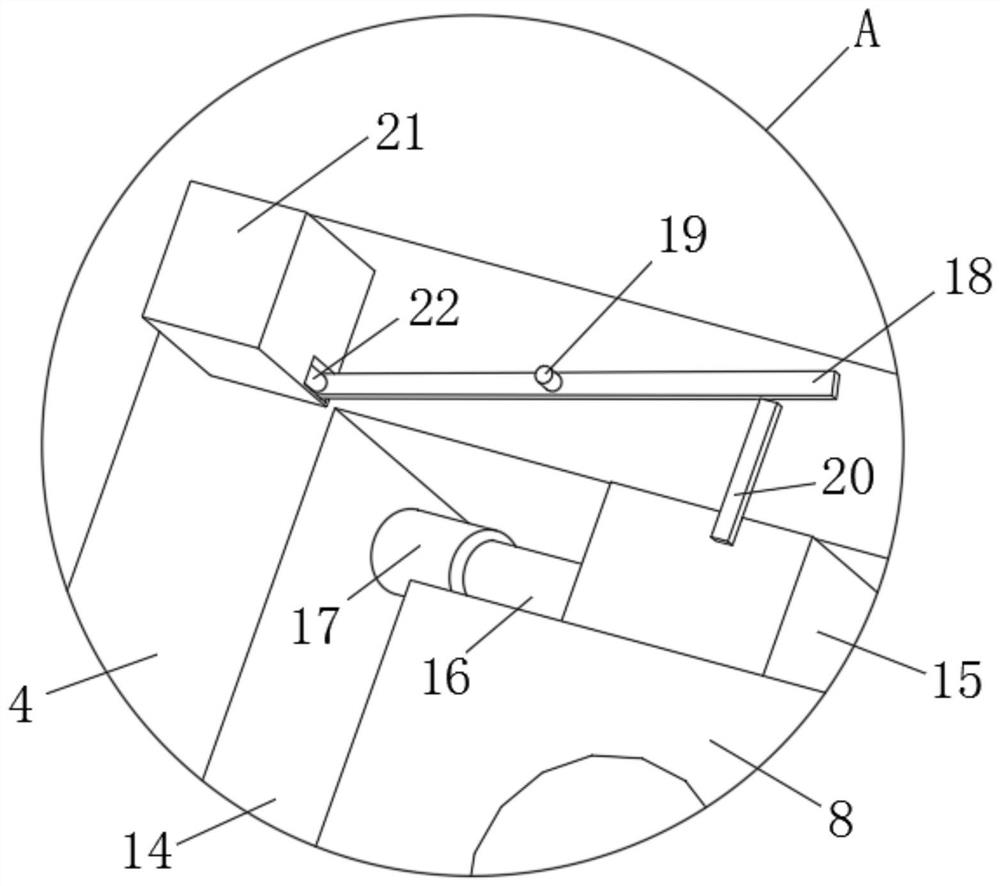

IMT in-mold transfer printing device and method

The invention discloses an IMT in-mold transfer printing device. A bearing base and an injection molding framework base arranged on the upper surface of the bearing base are included; a base materialfeeding mechanism is arranged at the upper end of the injection molding framework base; a waste film winding mechanism for reeling base material waste subjected to injection molding cutting is arranged in the bearing base, and a material receiving tensioning mechanism is further arranged above the waste film winding mechanism; and the upper surface and the lower surface of the injection molding framework base are each provided with an injection molding base material compensating mechanism for compensating for the mold closing extruding length of a base material. The invention further relates to a transfer printing method. A base material passes through the injection molding framework base in the vertical direction; the injection molding framework base performs mold closing, and the injection molding base material compensating mechanisms provide a pressed movement amount of the base material; the injection molding framework base performs mold opening, and the injection molding base material compensating mechanisms automatically return. Due to the scheme, the base material movement amount can be compensated for in the injection molding extruding process, the transfer printing qualityproblem caused by the fact that the surface tension of the base material at the injection molding position is too large is solved, the production quality of in-mold transfer printing is improved, using is convenient and fast, the control principle is simple, and the production quality is improved.

Owner:东莞华誉精密技术有限公司

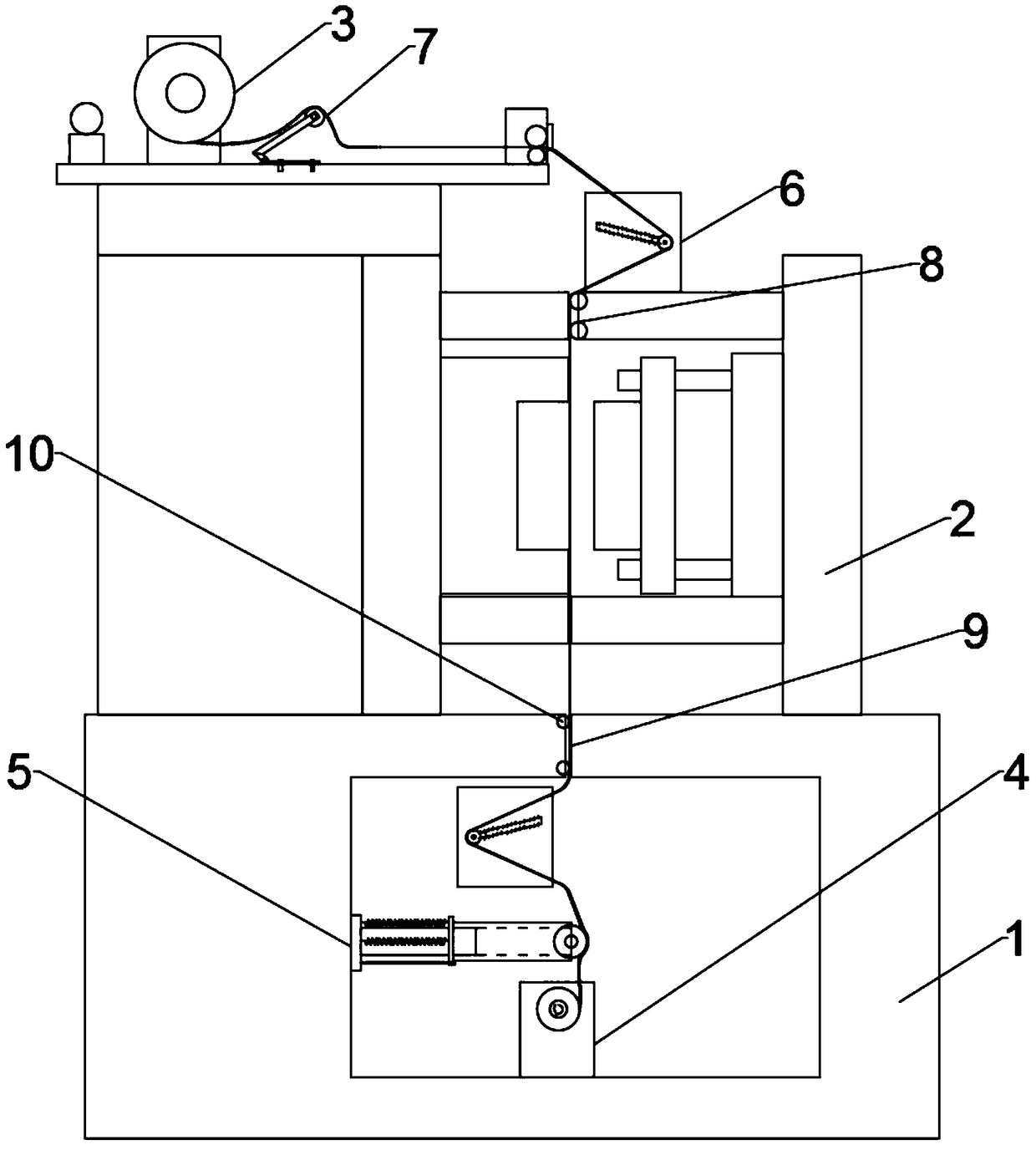

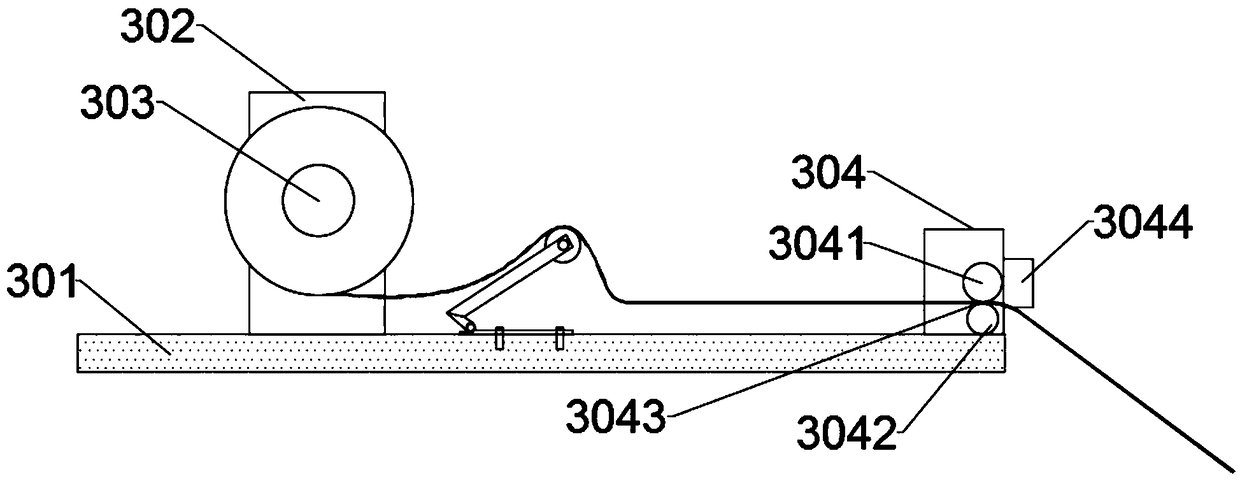

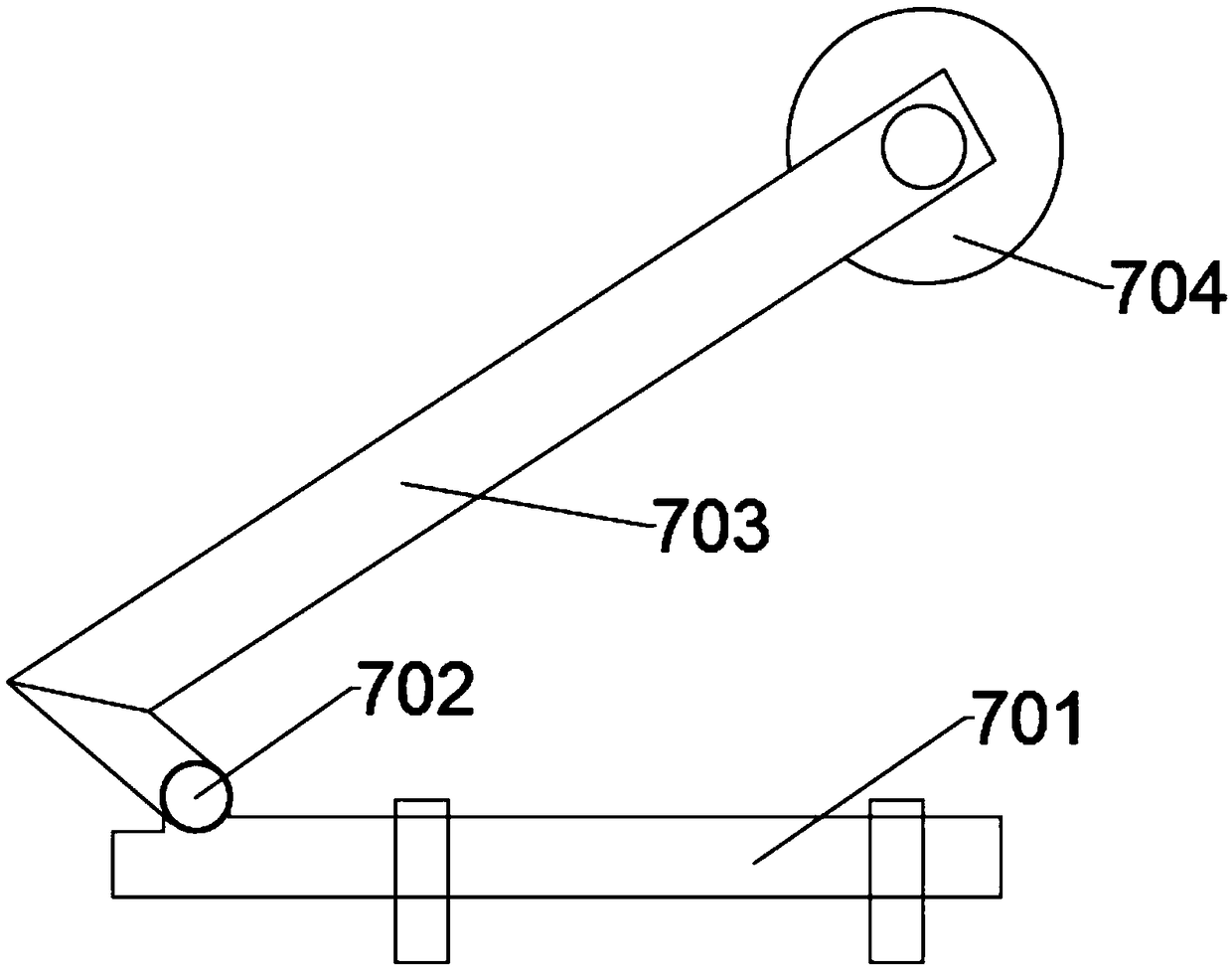

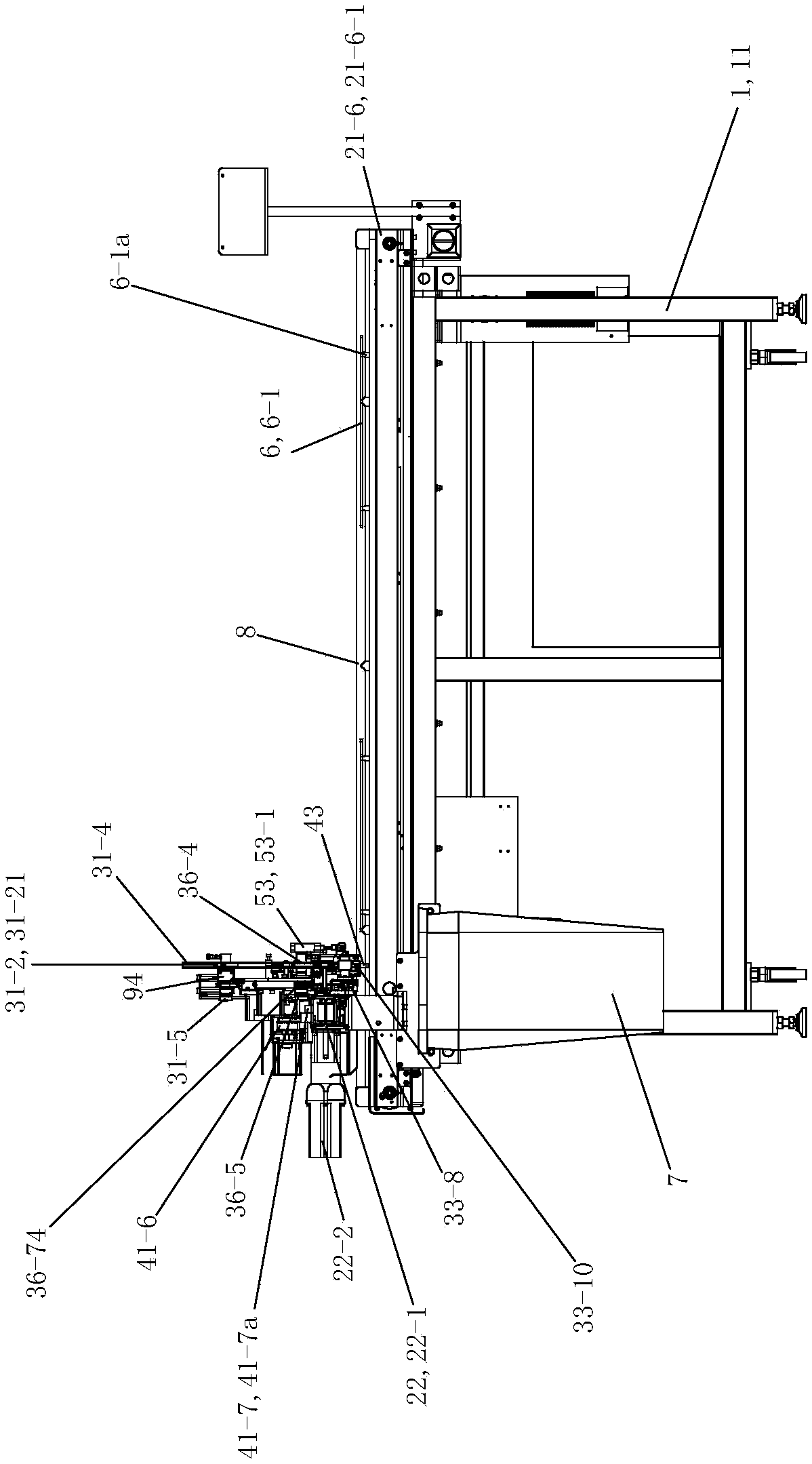

Feeding device of strip sticking machine

PendingCN108936925AIncrease productivitySimple structureArticle deliveryClothes making applicancesEngineeringHot-melt adhesive

The invention discloses a feeding device of a strip sticking machine, which is characterized in that the feeding device comprises an active feeding component, a material clamping component and a wastematerial receiving component. The material clamping component is used for clamping or loosening the hot melt adhesive film strip. The active feeding component carries out the conveying and feeding ofthe hot melt adhesive film strip, and the waste material receiving component is used for collecting the isolating paper layer of the hot melt adhesive film strip.

Owner:CHANGZHOU ZHIGU ELECTROMECHANICAL TECH CO LTD

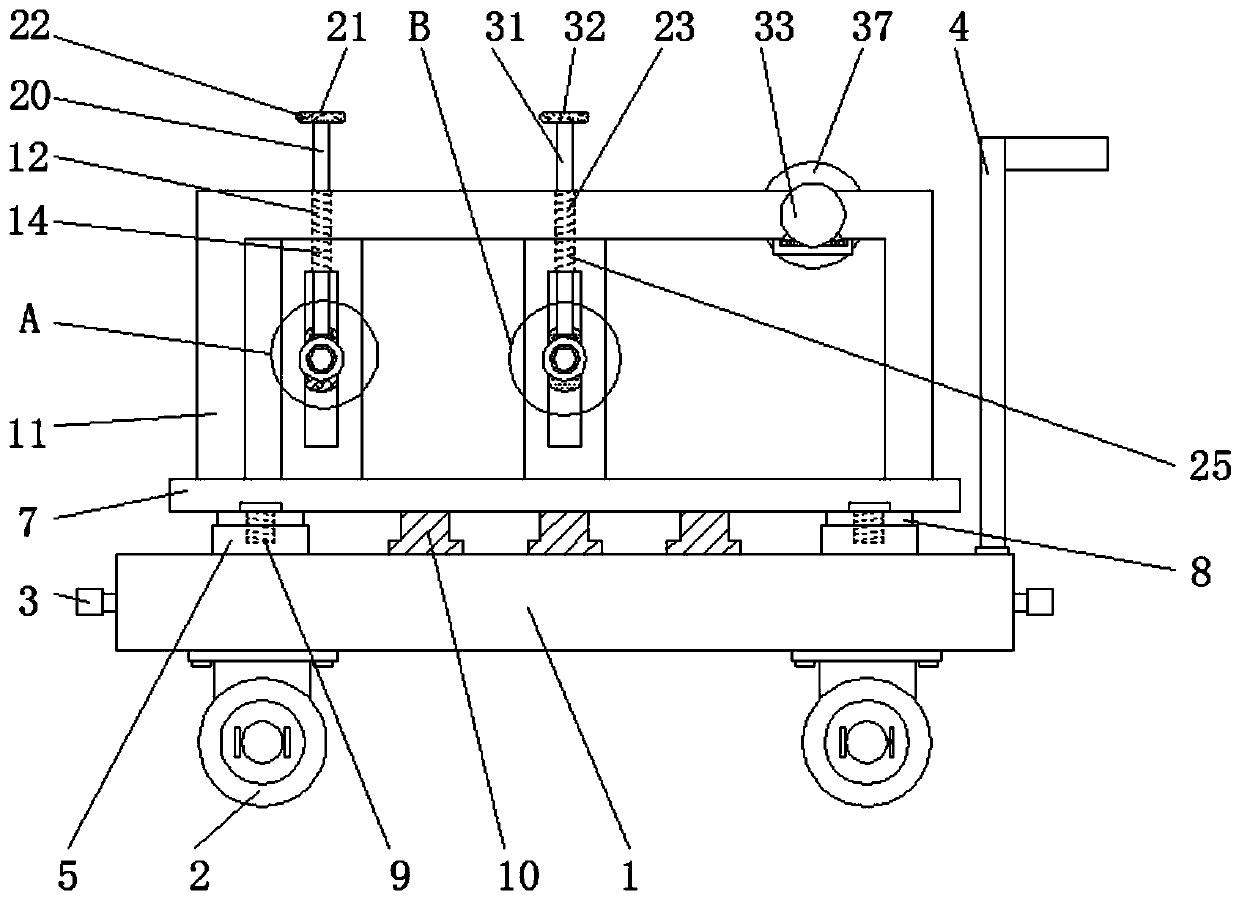

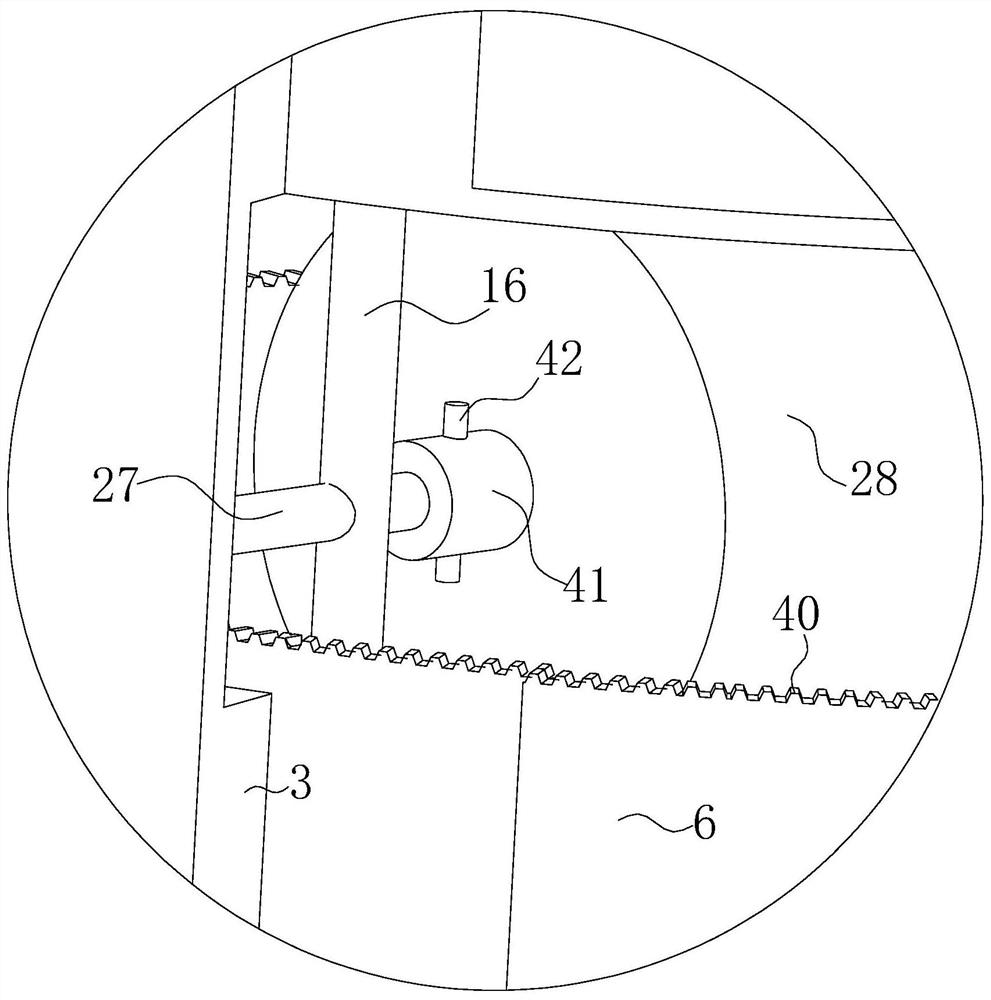

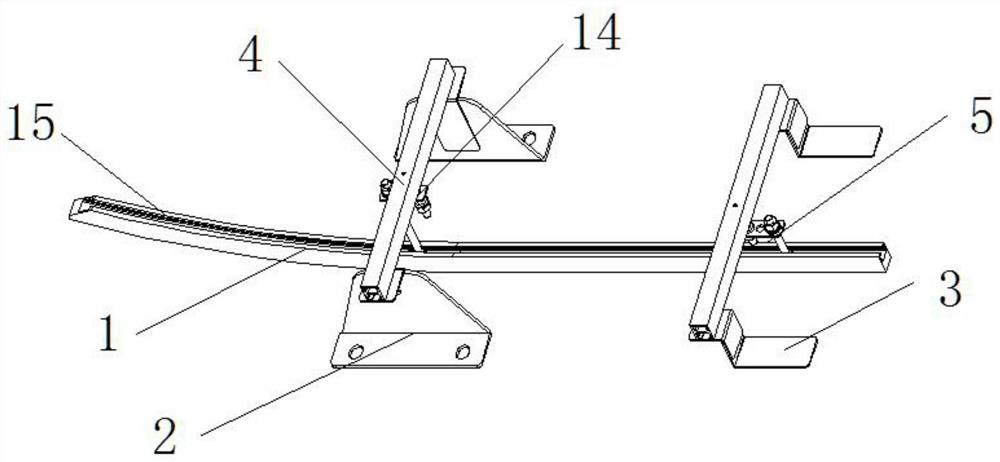

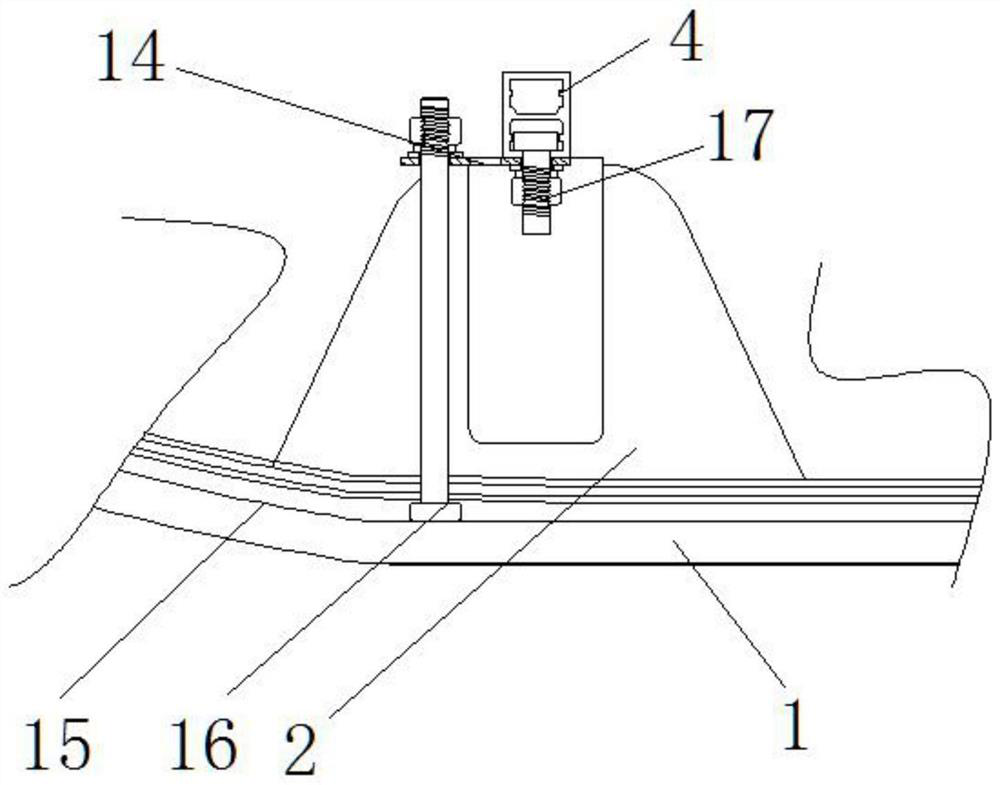

Hydraulic power station rubber pipe collecting device facilitating tensioning degree adjustment

ActiveCN110775119AGood tensionGood effectHand carts with multiple axesHand cart accessoriesPower stationStructural engineering

The invention discloses a hydraulic power station rubber pipe collecting device facilitating tensioning degree adjustment. An installing plate, a first sliding column and a third inner threaded hole are included. A fixing frame is arranged on the upper side face of the installing plate. A first inner threaded hole is formed in the upper side face of the fixing frame, meanwhile, a first fixing plate is arranged on the lower side face in the fixing frame, a second inner threaded hole is formed in the upper side face of the first fixing plate, a first sliding hole is formed in the front side of the first fixing plate, and meanwhile the upper end of the first sliding hole is in penetrating connection with the second inner threaded hole. The hydraulic power station rubber pipe collecting devicefacilitating tensioning degree adjustment is provided with a first outer threaded rod and a second outer threaded rod, meanwhile, a first rotation handle and a second rotation handle are rotated, thefirst outer threaded rod and the second outer threaded rod rotate and drive the first sliding column and a second sliding column for height adjustment, the height of a first limiting roller and a second limiting roller is adjusted, the first limiting roller and the second limiting roller support a rubber pipe, and the tensioning degree of the rubber pipe is adjusted.

Owner:徐州天睿地机械有限公司

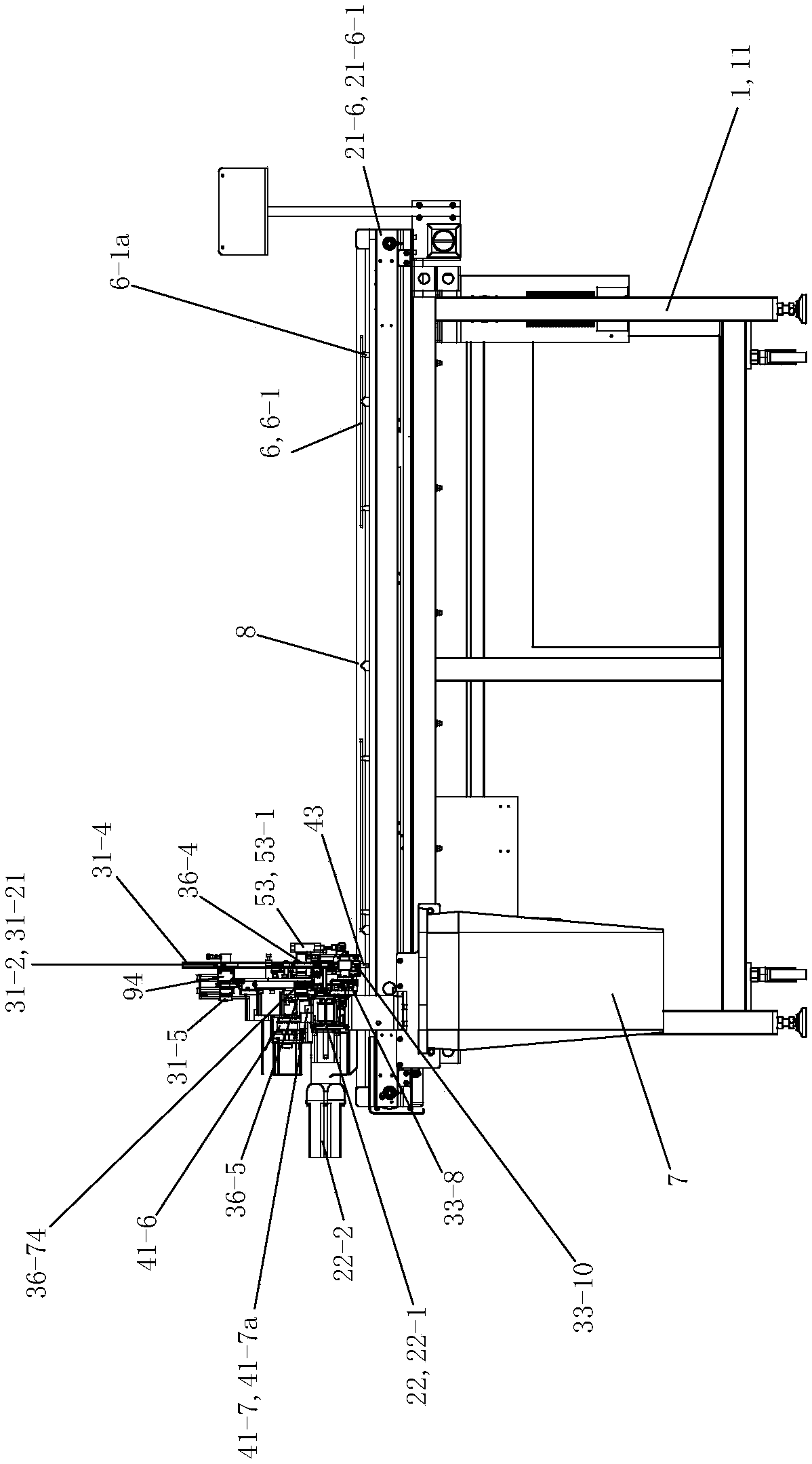

Strip sticking machine

PendingCN108936926ASimple structureImprove work efficiencyClothes making applicancesEngineeringHot-melt adhesive

The invention discloses a strip sticking machine, and is characterized by comprising a worktable, an X-axis module, a Y-axis module, a feeding device, a pressing device, a shearing device and a discharging component. The discharging component is used for placing the hot melt adhesive film strip. The X-axis module is arranged on the worktable and is used for driving the Y-axis module to move left and right along the X-axis direction on the upper side of the worktable. The Y-axis module drives the feeding device to move back and forth in the Y-axis direction on the upper side of the worktable. The feeding device comprises an active feeding component, a material clamping component and a waste material receiving component. The material clamping component is used for clamping or loosening the hot melt adhesive film strip. The active feeding component carries out the conveying and feeding of the hot melt adhesive film strip, and the waste material receiving component is used for collecting the isolating paper layer of the hot melt adhesive film strip. The pressing device is arranged on the Y-axis module, can move back and forth in the Y-axis direction, and is used for pressing the corresponding part of the adhesive film layer of the hot melt adhesive film strip, so that the adhesive film layer of the pressing hot melt adhesive film strip is pasted on the corresponding cloth. The shearing device is used for cutting the hot melt adhesive film strip.

Owner:CHANGZHOU ZHIGU ELECTROMECHANICAL TECH CO LTD

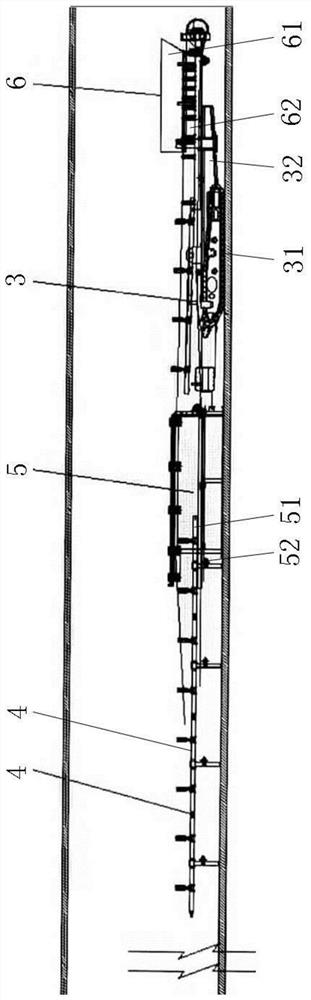

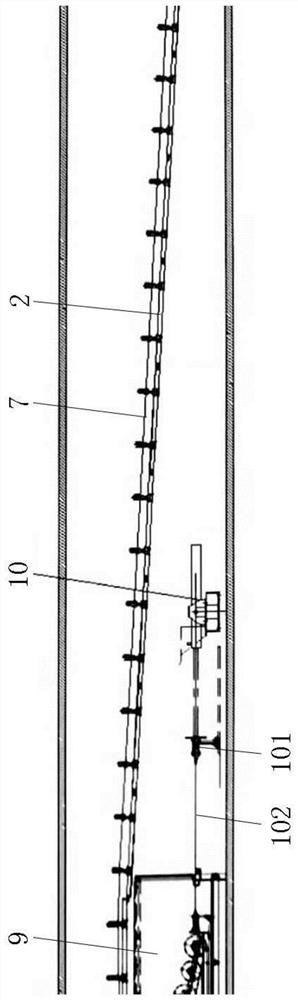

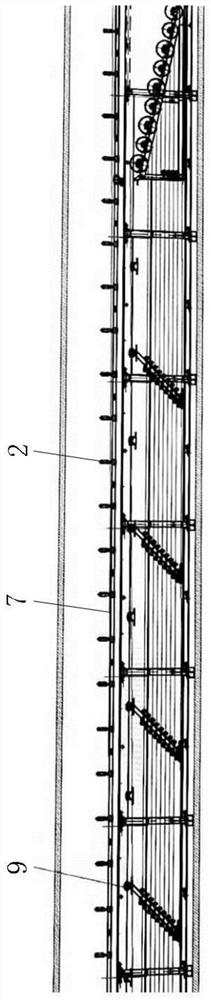

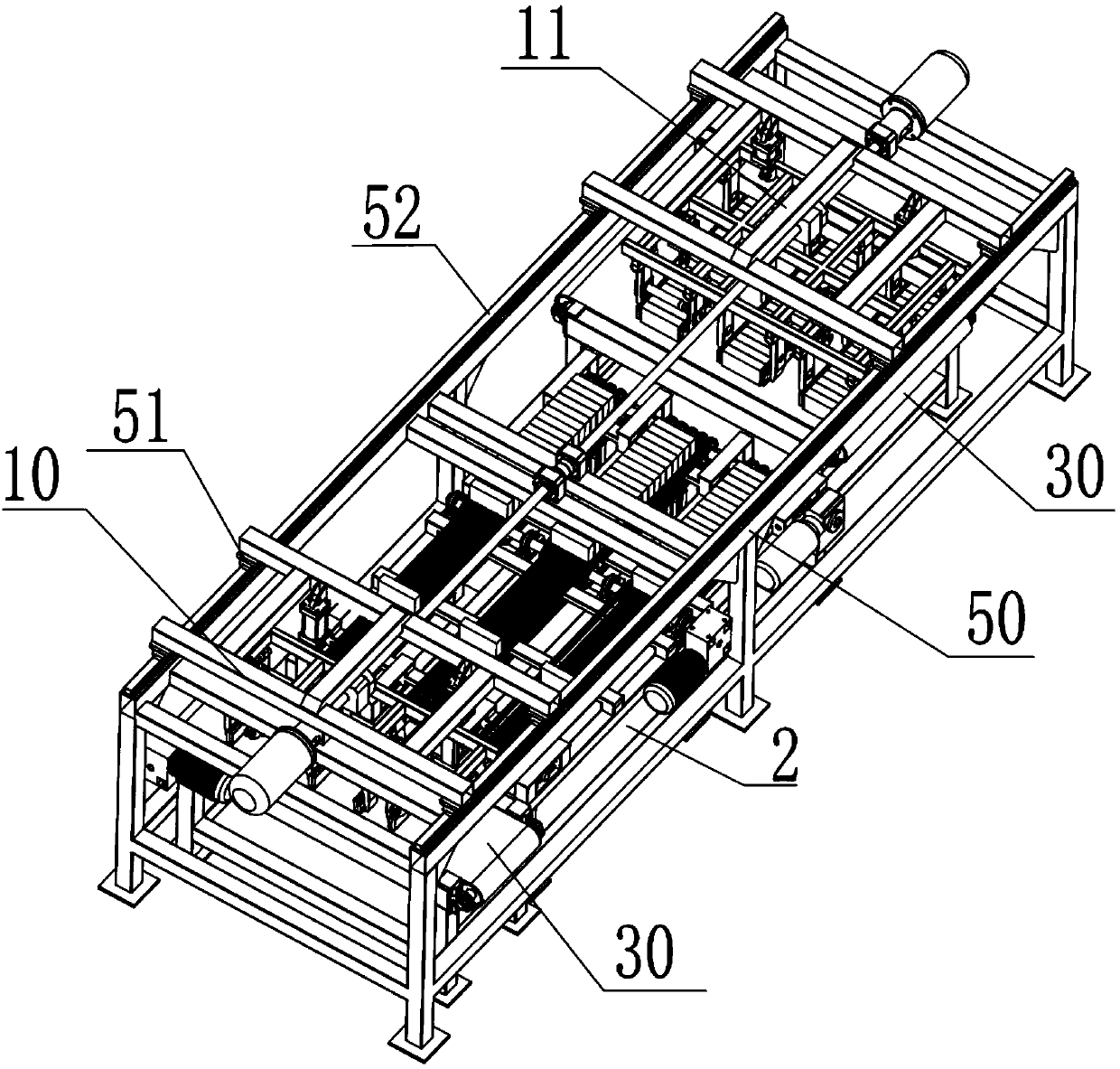

Synchronous self-moving transshipment transportation system

InactiveCN111689130AIncrease transport distanceExtended shipping lengthConveyorsEarth drilling and miningTransit systemEngineering

The invention discloses a synchronous self-moving transshipment transportation system. The synchronous self-moving transshipment transportation system comprises a discharging mechanism, a plurality offixed racks which are laid in a roadway, a walking mechanism, a tail extension mechanism, a material receiving mechanism, a conveying belt, a driving mechanism, a belt storage bin and a tensioning adjusting mechanism, wherein the discharging mechanism is arranged at an opening of the roadway and used for discharging outwards, the walking mechanism is arranged at the inner end of the roadway and synchronously moves with tunneling equipment, the tail extension mechanism is arranged on the outer end face of the walking mechanism and is used for laying a plurality of movable racks in a dismountable manner, the material receiving mechanism is arranged on the inner end face of the walking mechanism and used for receiving mining materials of the tunneling equipment, the conveying belt is wound on all the fixed racks and the movable racks, the driving mechanism is arranged in the roadway and used for driving the conveying belt to run, the belt storage bin is arranged in the roadway and used for storing the conveying belt with the preset length, and the tensioning adjusting mechanism is arranged in the roadway and used for adjusting the tensioning state of the conveying belt when the movable racks are disassembled and assembled. According to the synchronous self-moving transshipment transportation system, the continuous coal mining and transportation operation in the roadway can be realized, the shutdown waiting time is saved, and the operation efficiency is improved.

Owner:CHINA RAILWAY CONSTR HEAVY IND

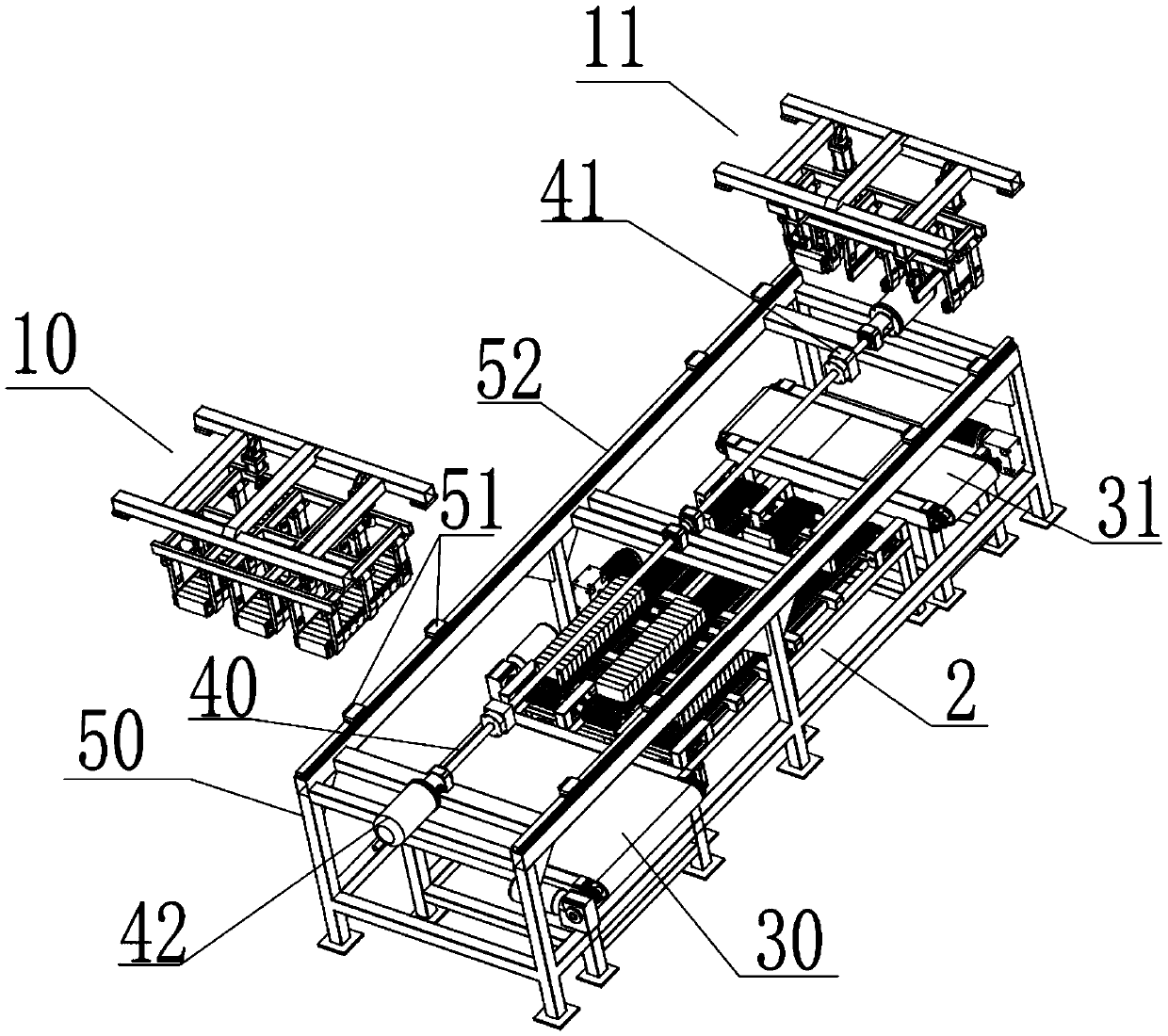

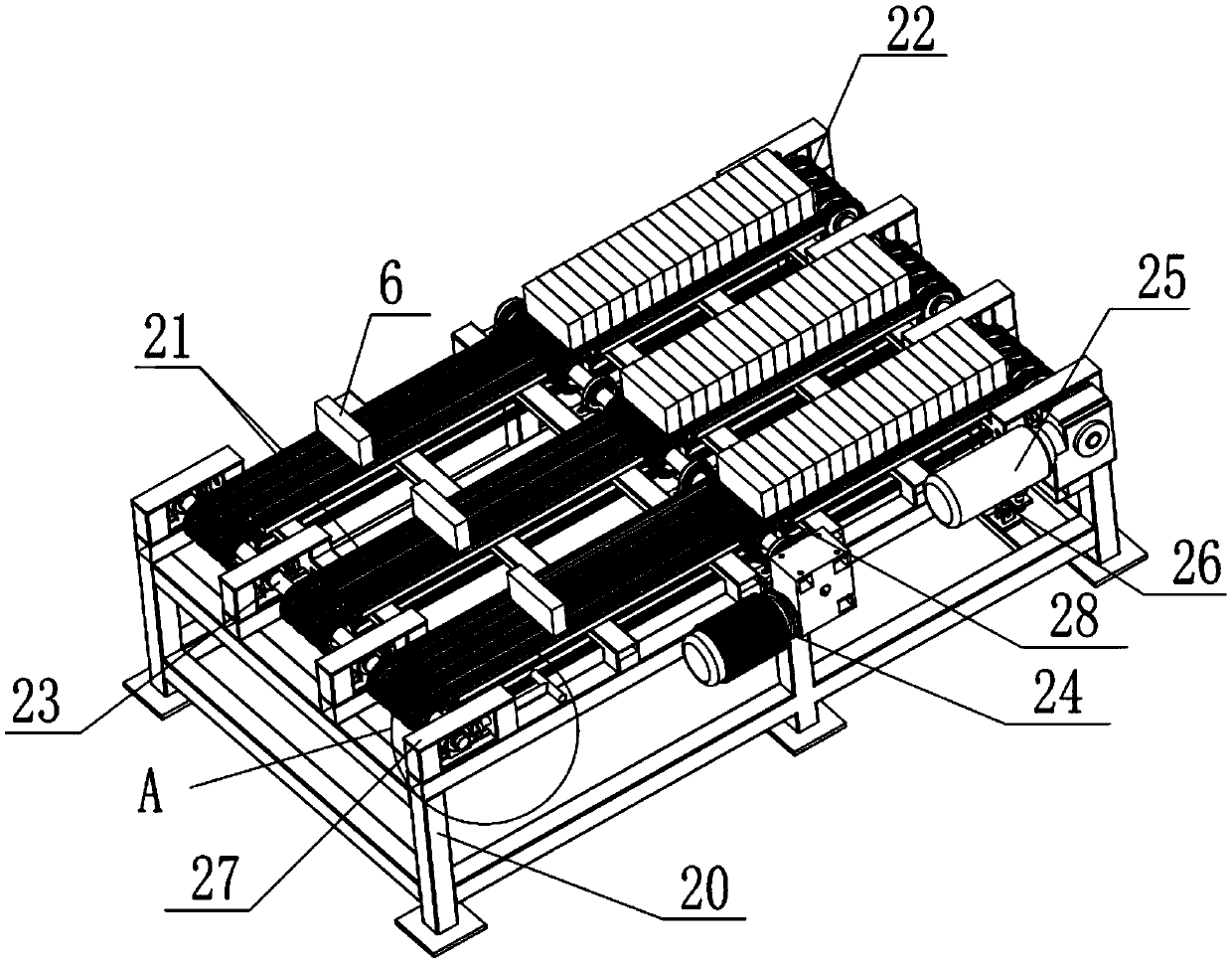

Chain type green brick grouping device

PendingCN110654817APrevent fallingHigh degree of automationConveyorsControl devices for conveyorsBrickIndustrial engineering

The invention relates to the technical field of green brick grouping equipment and discloses a chain type green brick grouping device which comprises carrying units, a grouping unit and two transmitting units, wherein the two transmitting units are arranged at the two ends of the grouping unit separately; the carrying units are arranged above the two transmitting units in a sliding and hanging manner; the grouping unit comprises a conveying component, a collecting and arranging component and a plurality of groups of sensors; the conveying component and the adjacent end of the collecting and arranging component are in seamless connection; and the sensors are arranged on the conveying component and the collecting and arranging component. Through mutual cooperation of the carrying units, thegrouping unit and the two transmitting units, full-automatic grouping carrying operation of green bricks can be realized; in addition, during the actual using process, the green bricks can be groupedaccording to the specifications needed by stacking; and through the structural design, the chain type green brick grouping device can completely replace traditional manual operation to carry and groupgreen bricks, the green bricks with various specifications can be grouped and arranged efficiently and precisely, and the automation degree and the working efficiency are high.

Owner:天津市隆达工业自动化设备有限公司

Moon cake processing molding equipment

The invention discloses moon cake processing molding equipment, which comprises a dough making device, a stuffing filling device, a molding device and an automatic dish arrangement device, wherein thedough making device, the stuffing filling device, the molding device and the automatic dish arrangement device are sequentially connected, one side of the stuffing filling device is provided with a stuffing filling mixing breaking device, the dough making device comprises a base, a flour storage box and a dough making cylinder fixedly connected above the base, one end of the base is provided witha motor, a stirrer is arranged in the dough making cylinder, the top portion of the dough making cylinder is provided with a water sprinkling mechanism, the water sprinkling mechanism comprises a water inlet pipe and a water sprinkling tray, the stuffing filling mixing breaking device comprises a breaking mixing box, a first separation plate and a second separation plate, one side wall of the opposite inner side walls of the breaking mixing box is hinged to the first separation plate, the other side wall is hinged to the second separation plate, and when the first separation plate and the second separation plate are positioned in the same horizontal plane, the first separation plate and the second separation plate form a baffle to sequentially divide the breaking mixing box into a pounding chamber and a mixing chamber from top to bottom. With the moon cake processing molding equipment of the present invention, the multiple processes can be completed by the same equipment.

Owner:天伦食品集团有限公司

Preparation process of infantile diarrhea ointment

InactiveCN112043764ALow costAvoid loss of potencyAnthropod material medical ingredientsDigestive systemInfantile diarrheaOfficinalis

The invention discloses a preparation process of infantile diarrhea ointment, and relates to the technical field of ointment. The preparation process comprises the following steps that S1, raw materials are prepared, wherein the infantile diarrhea ointment comprises the following raw materials of, by weight, 30-35 parts of cinnamon, 20-23 parts of radix aucklandiae, 20-28 parts of folium artemisiae argyi, 15-20 parts of radix bupleuri, 12-15 parts of gallnut, 10-13 parts of cortex magnoliae officinalis, 12-14 parts of golden cypress and 7-10 parts of mint; and S2, the radix aucklandiae, the folium artemisiae argyi, the radix bupleuri, the golden cypress and the mint are crushed and are sieved with a 110-mesh sieve to obtain radix aucklandiae fine powder, folium artemisiae argyi fine powder, radix bupleuri fine powder, golden cypress fine powder and mint fine powder to be stored for later use. According to the preparation process, the antidiarrheic ointment is low in cost and free of side effects, peculiar smells of the ointment can be shielded through the mint powder, discomfort to children is prevented, when the ointment is used, a cool and comfortable feeling is achieved, and irritant side effects of the ointment on the children can be prevented.

Owner:安徽宝华药业有限公司

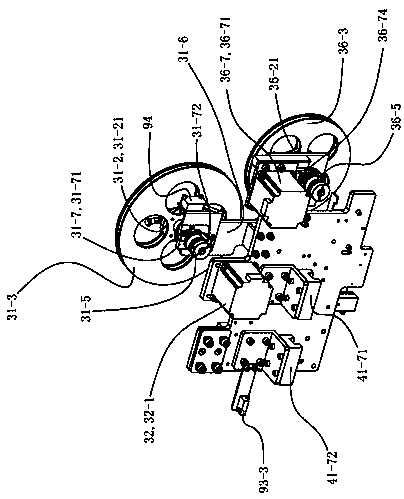

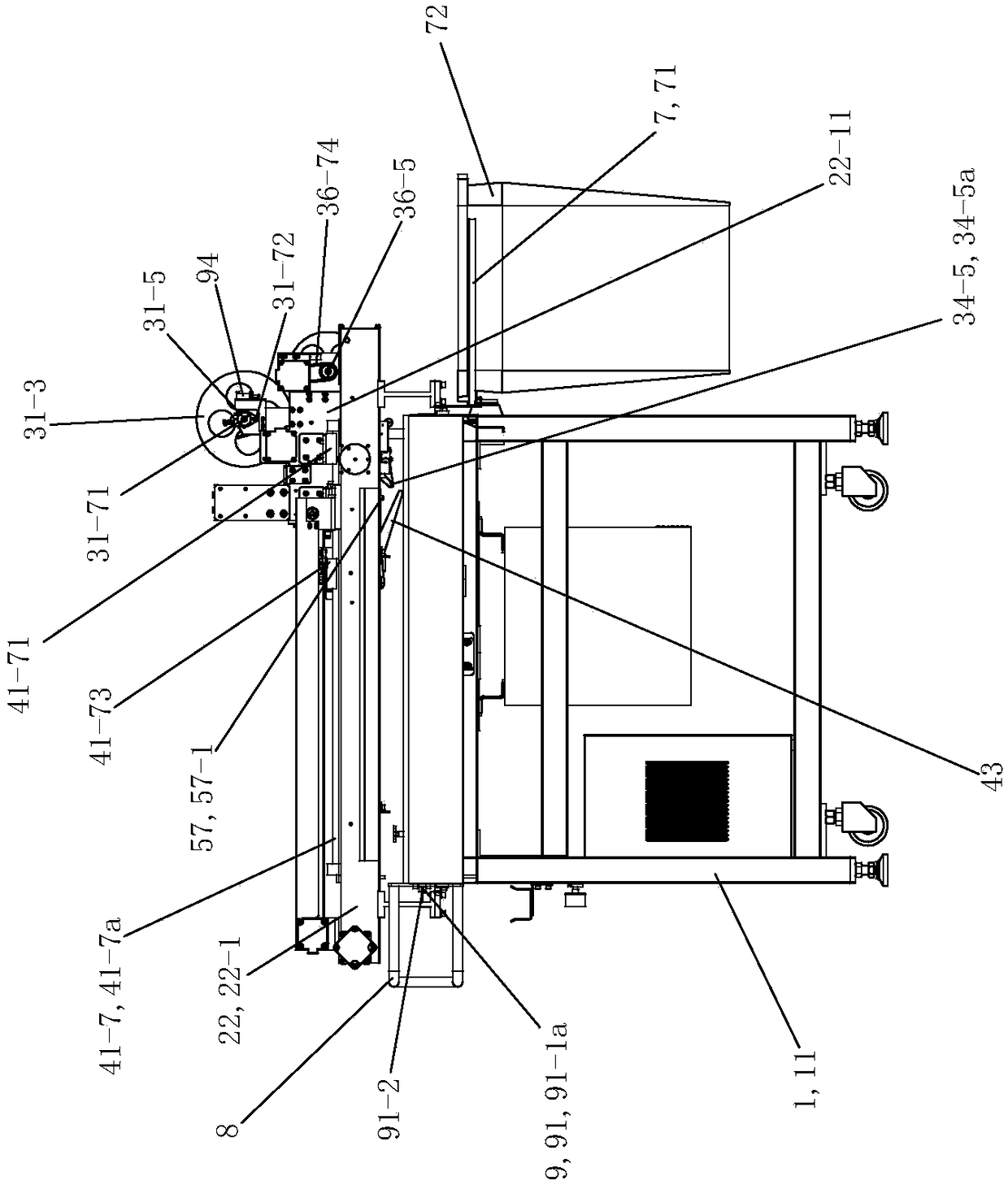

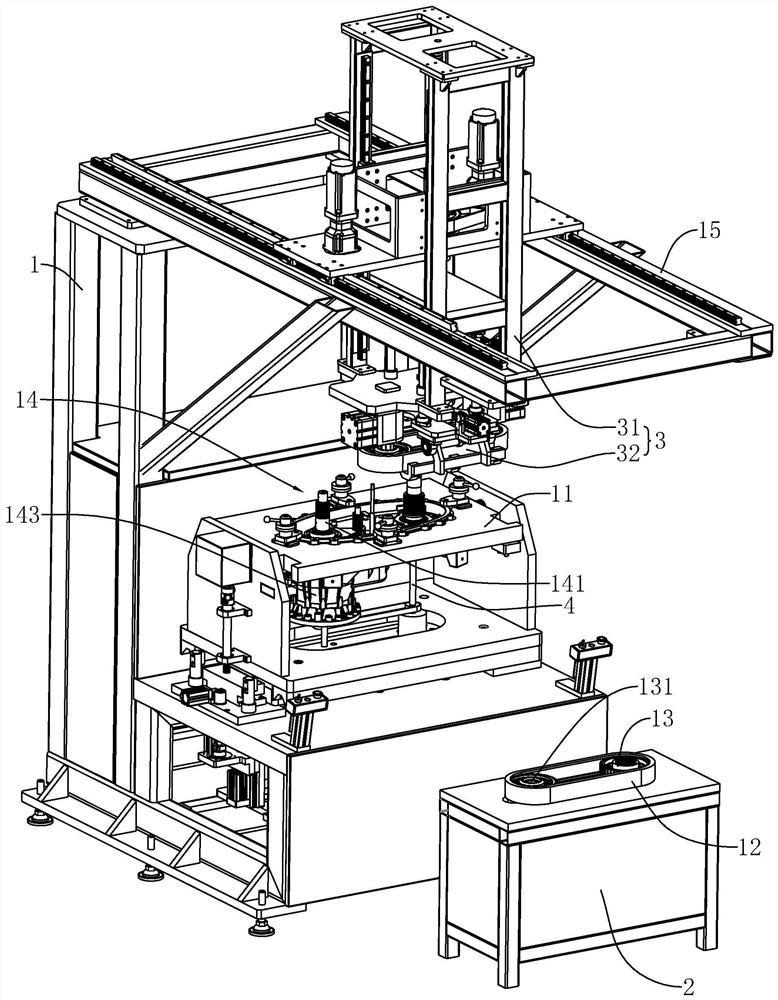

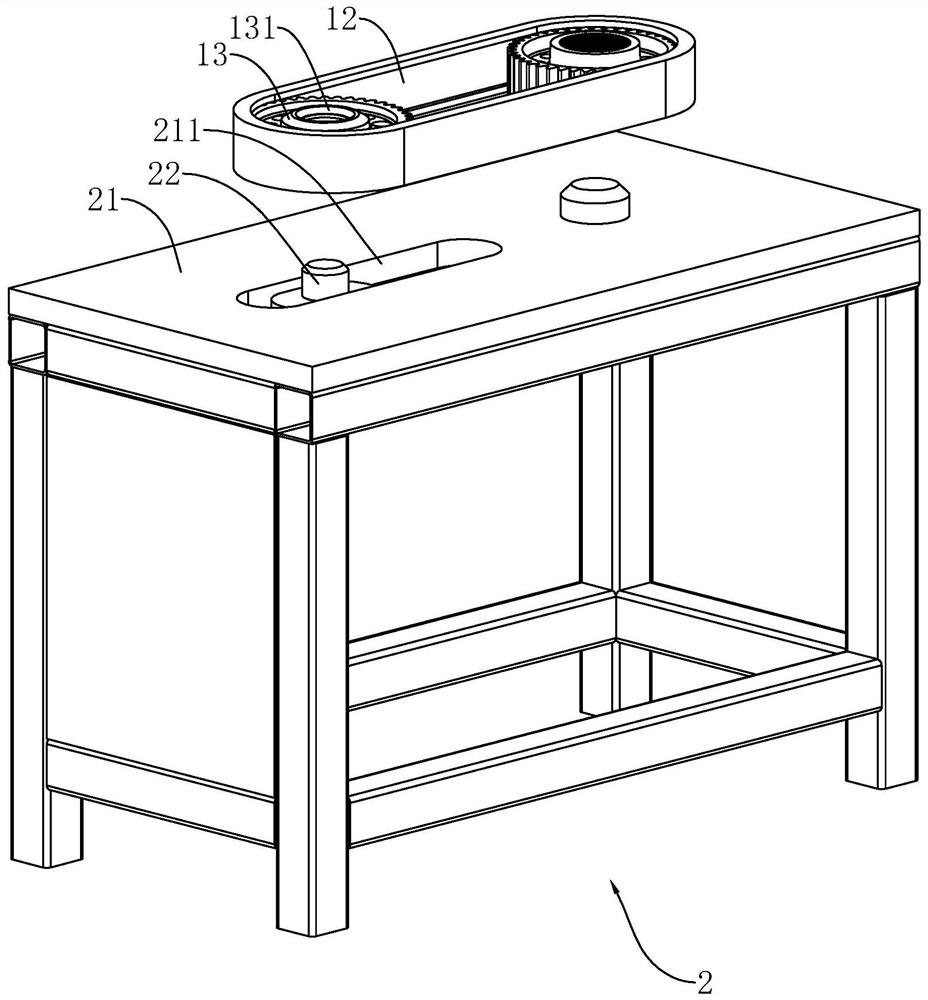

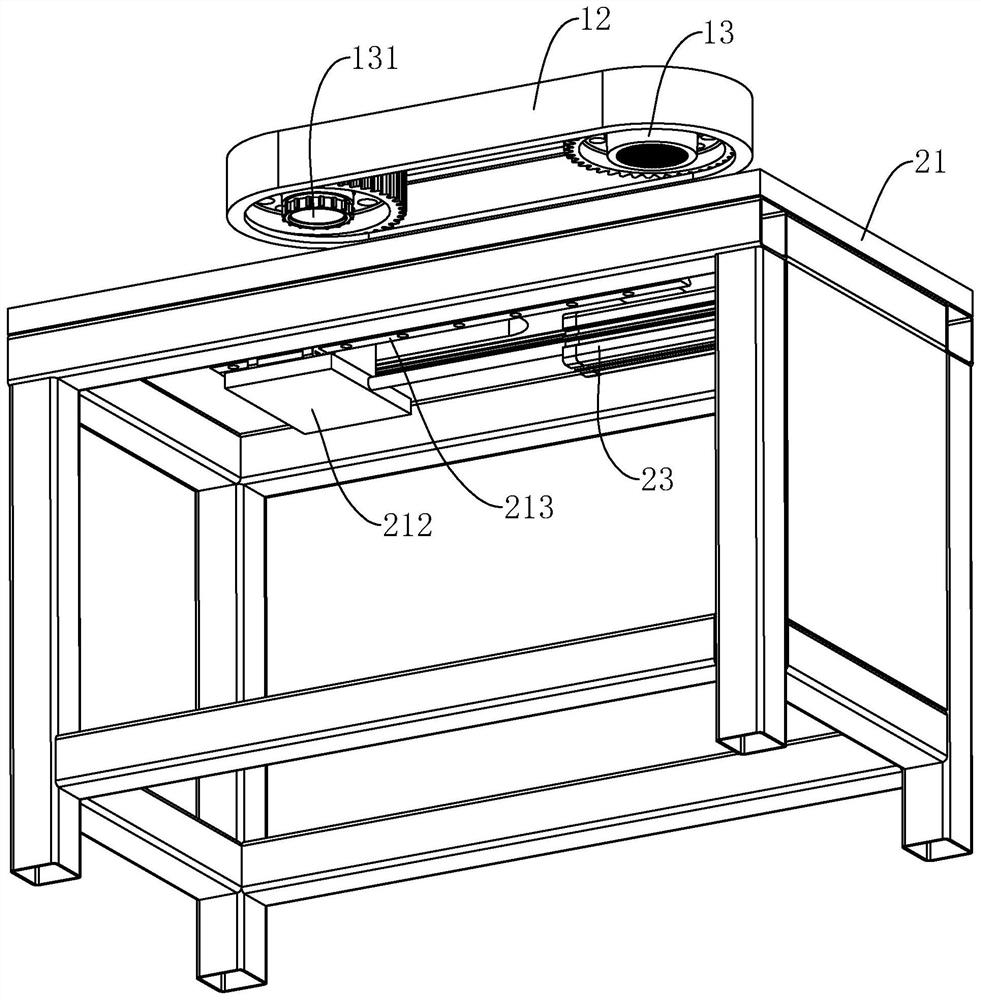

Automatic clamping and mounting equipment for synchronous chain wheel assembly

ActiveCN113146212AImplement automatic installationEasy to installGearingMetal working apparatusControl engineeringMachine

The invention relates to automatic clamping and mounting equipment for a synchronous chain wheel assembly, and relates to the technical field of chain assembly. The automatic clamping and mounting equipment is used for assembling a workpiece, and the workpiece comprises a module A and a module B; the module A comprises two chain wheels and a chain tensioned on the two chain wheels, and each chain wheel is coaxially provided with a shaft hole; the module B comprises a base and two rotating shafts rotationally connected to the base, and the two rotating shafts are in one-to-one correspondence with the shaft holes of the chain wheels and are used for mounting the shaft holes of the chain wheels; and a machine frame and a machine shell for bearing the chain wheels and the chain are included, the machine frame is provided with an objective table for bearing the base, and the machine frame is provided with a grabbing device for clamping the chain wheels tensioned by the chain from the machine shell and mounting the chain wheels on the rotating shafts. According to the automatic clamping and mounting equipment, a tensioning device and the grabbing device are arranged, the chain is arranged on the chain wheels in a sleeving manner through the tensioning device to be in a tensioning state, the chain and the chain wheels in the tensioning state are installed on the rotating shafts under driving of the grabbing device, the chain and the chain wheels are automatically installed on the rotating shafts, and therefore the advantage that the chain wheels and the chain are conveniently installed is achieved.

Owner:湖北宏博汽车工业智能装备有限公司

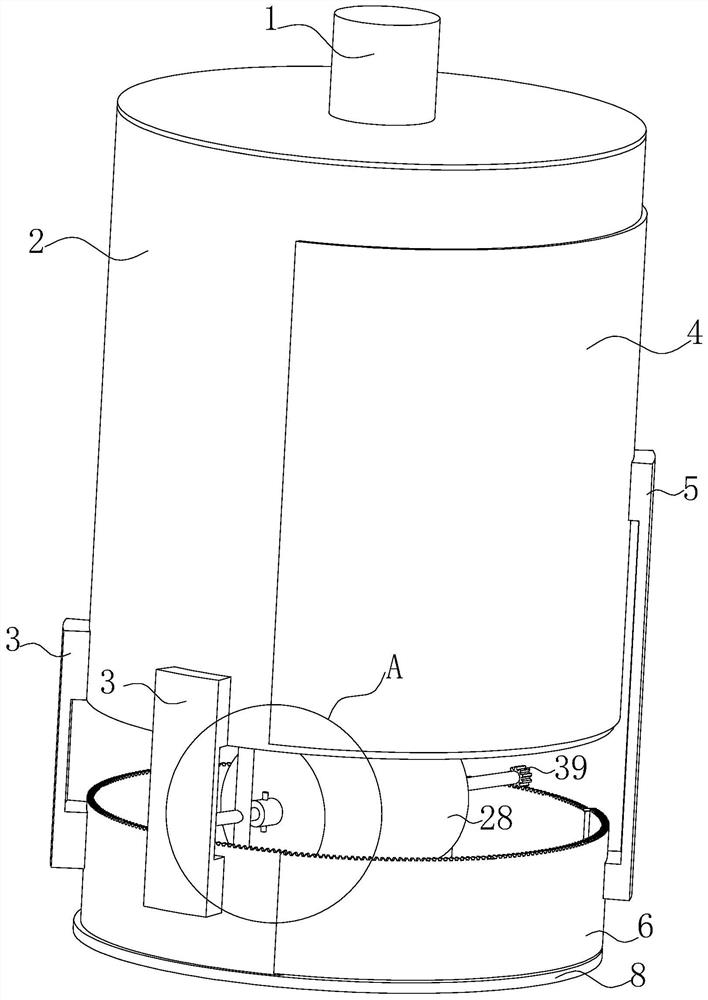

Apparatus used for manufacturing non-woven fabric through blended fiber solution

The invention discloses an apparatus used for manufacturing a non-woven fabric through a blended fiber solution. The apparatus includes a pre-blending drum, a forming pipe and a water pump; the blended fiber water solution is blended in the pre-blending drum, and the pre-blending drum is provided with a horizontal stirring device and a vertical blending device; the horizontal stirring device is used for horizontally stirring the blended fiber water solution; the vertical blending device is used for vertically stirring the blended fiber water solution; the lower end of the forming pipe is inserted deep into the water solution, the upper end of the forming pipe is exposed in the air, and multiple forming holes are formed in the lower end of the forming pipe; the water pump includes a water pipe, and the water pipe is disposed in the lower end of the forming pipe and used for pumping water in the forming pipe. By adopting the apparatus, a high-strength non-woven fabric product can be easily and quickly obtained.

Owner:长沙云聚汇科技有限公司

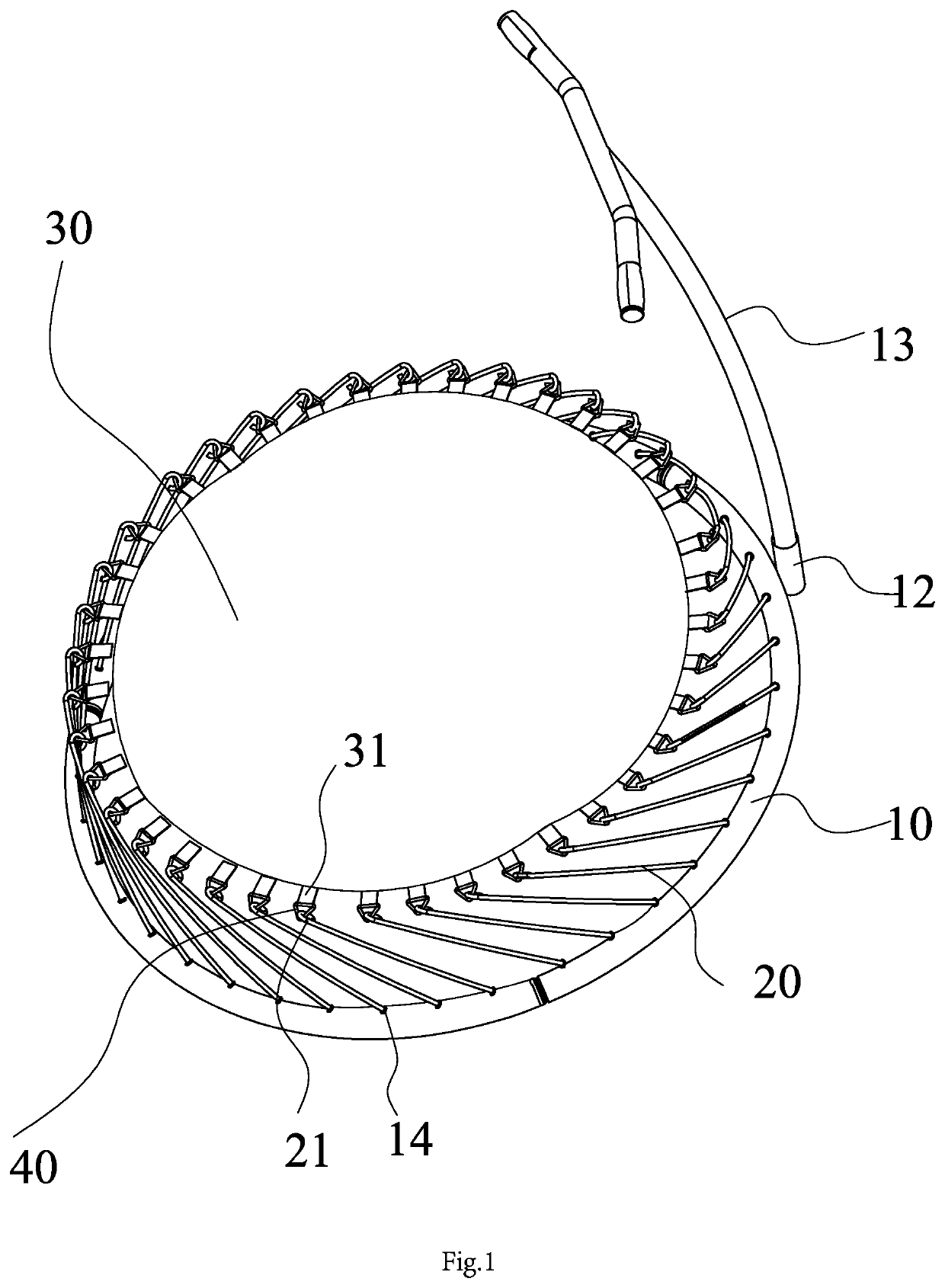

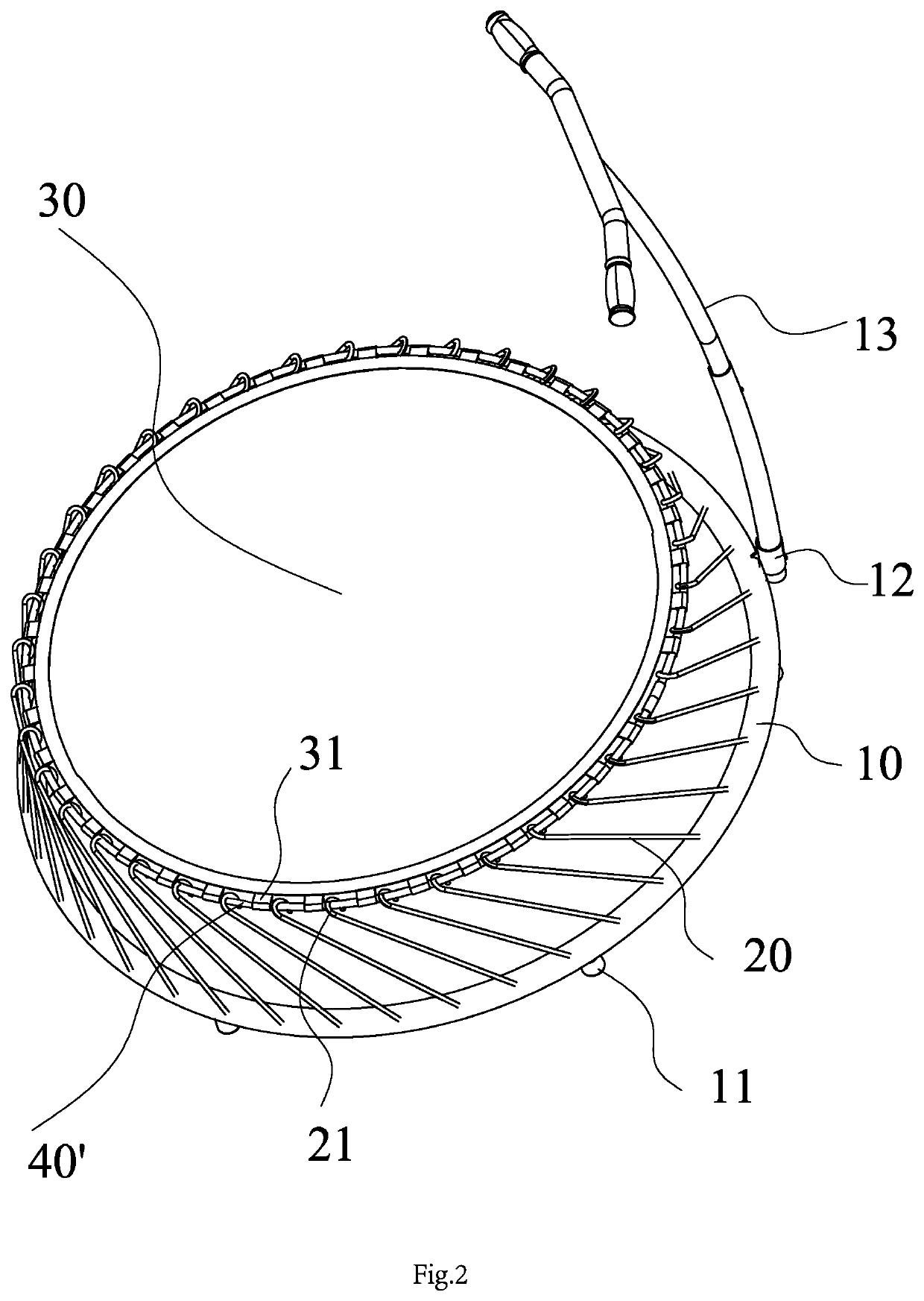

Stable basin-shaped trampoline

ActiveUS20210197005A1Increase stabilityGood tensionResilient force resistorsSpring boardsStructural engineeringMechanical engineering

Owner:WANG SIQI

Metal coiled material surface embossing device based on same-side arrangement of rolling and discharging

PendingCN110978870AEasy to tightenReduce space consumptionEmbossing decorationsStructural engineeringEmbossing

The invention relates to a metal coiled material surface embossing device based on same-side arrangement of rolling and discharging. The device is used for performing embossing on a plate, and comprises a bracket, wherein an upper embossing roller and a lower embossing roller are arranged on the bracket; and the device further comprises a rack, and according to the feeding sequence, a first tensioning roller, a feeding roller, a second tensioning roller, a third tensioning roller and a rolling roller are sequentially arranged on the rack, wherein the feeding roller and the rolling roller are located on the same side of the bracket, the axis of the feeding roller and the axis of the rolling roller are not located on the same vertical line, the feeding roller is located above the rolling roller, and the rotating direction of the feeding roller is opposite to that of the rolling roller. According to the device, on the basis of feeding and rolling integral formation and arrangement, compared with an original device, the tensioning state is better, and the embossing effect is improved.

Owner:包钢钢业(合肥)有限公司

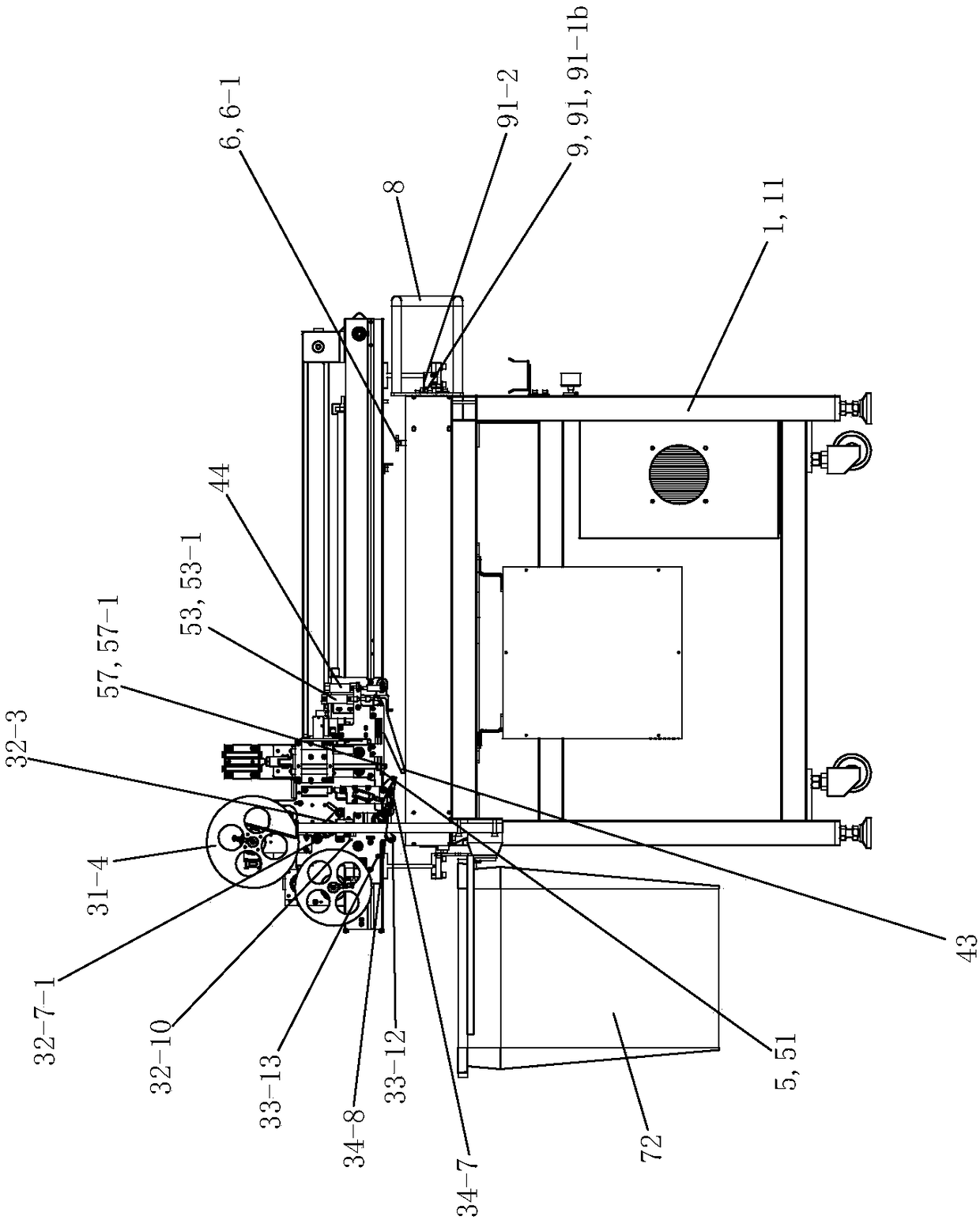

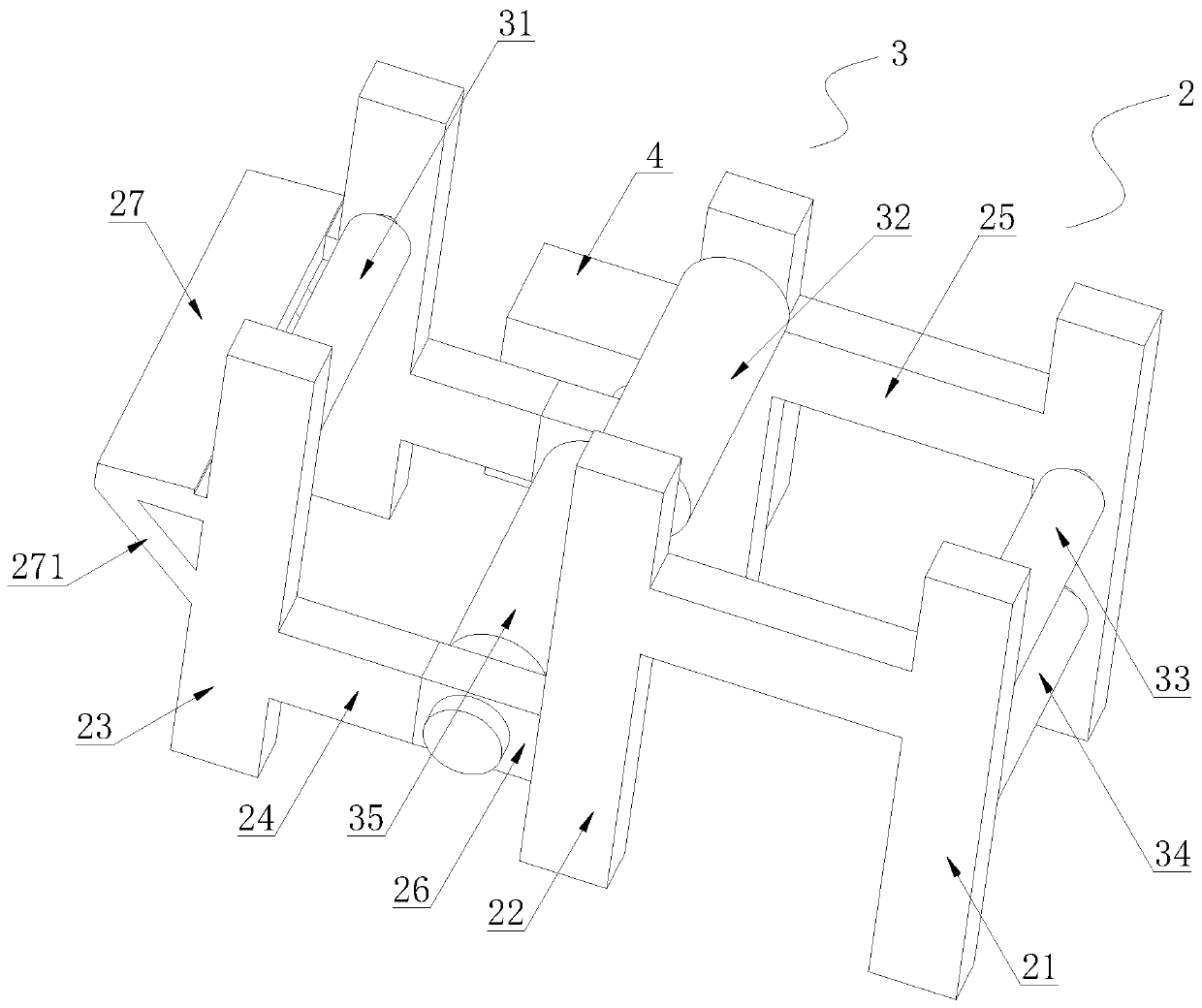

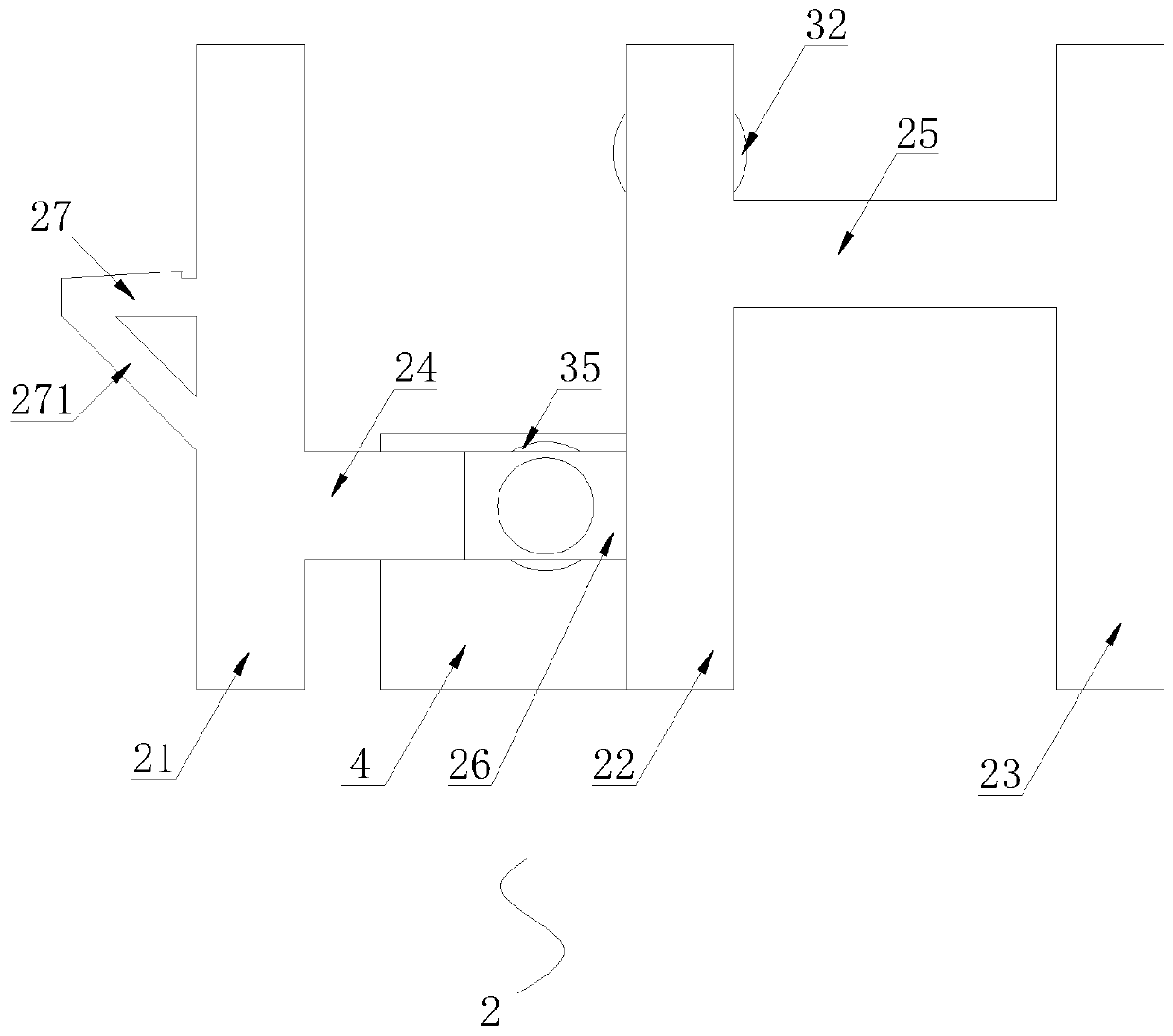

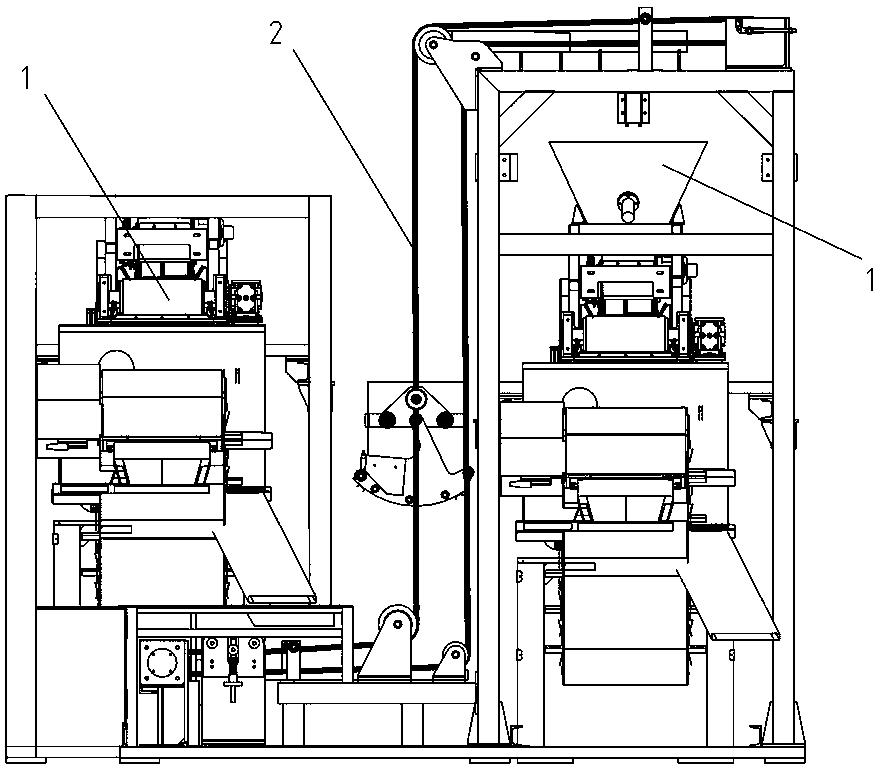

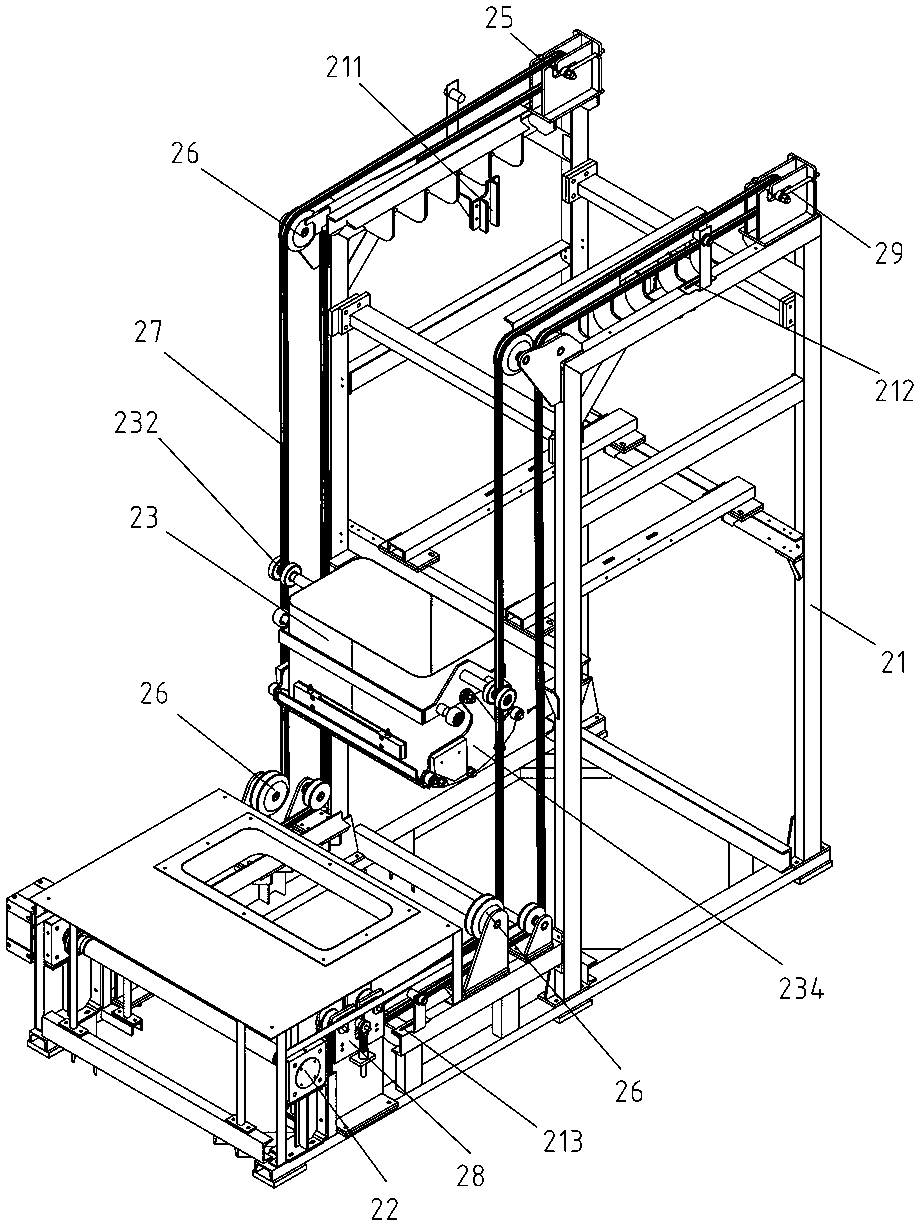

An automatic sample preparation system for sample collection and preparation

The invention discloses an automatic sample preparation system used for sampling and preparing a sample. The automatic sample preparation system used for sampling and preparing the sample comprises more than two sample preparing treatment units; a Z-shaped conveying device which is used for lifting and conveying a material is arranged between adjacent two sample preparing treatment units; the Z-shaped conveying device comprises a machine frame, a driving assembly which is arranged on the machine frame, a material conveying barrel, and two Z-shaped chain conveying channels which are formed symmetrically; each Z-shaped chain conveying channel comprises a driving wheel assembly, a driven wheel assembly, a guide wheel assembly and an annular chain which are matched with one another; the two ends of the material conveying barrel are respectively connected to the two annular chains; the driving assembly drives the two annular chains to move synchronously through the two driving wheel assemblies so as to drive the material conveying barrel to collect the material which is treated once at the previous-stage sample preparing treatment unit and lift and convey the material to the next-stage sample preparing treatment unit for unloading the material and performing automatic sample preparing operation. The automatic sample preparation system used for sampling and preparing the sample has the advantages that the operation is stable, the labour intensity can be reduced, the sample precision can be effectively ensured, and the efficiency is extremely high.

Owner:HUNAN SUNDY SCI & TECH DEV

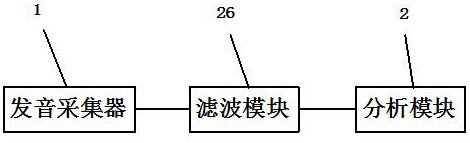

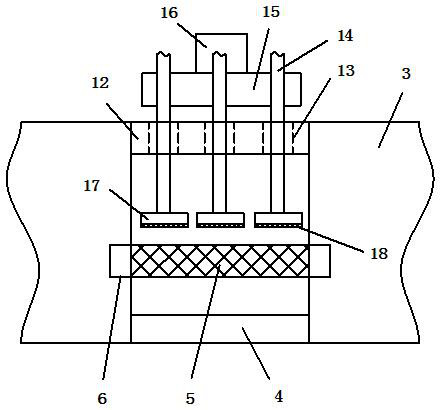

An intelligent device for teaching English

InactiveCN107871408BGood tensionImprove stretchElectrical appliancesEngineeringMechanical engineering

The invention discloses an intelligent device for English teaching. The intelligent device for the English teaching comprises a pronunciation collector and an analysis module. The pronunciation collector comprises a housing. The housing is internally provided with a backboard and a vibrating diaphragm. The edge of the vibrating diaphragm is connected with the housing. The inner wall of the housingis provided with a plurality of first grooves. The first grooves are internally provided with a first worm. The first worm is connected to a first motor through a first worm wheel. The top end of thefirst worm is in the shaft connection with a clamping block. The clamping block is used for clamping and fixing the vibrating diaphragm. The top of the vibrating diaphragm is provided with a top plate. The top plate is fixed in the housing. The top plate and the vibrating diaphragm are alternately installed. The top plate is provided with a plurality of through holes. A second worm is inserted and connected in the through holes. The second worm is connected to a second motor through a second worm wheel. The bottom of the second worm is in the shaft connection with a first metal spring sheet.The surface of the first metal spring sheet is provided with a flexible buffer layer. The intelligent device for the English teaching is capable of improving the deficiency of the prior art, improvingthe accuracy of the collector for collecting the pronunciation, and improving the judgment precision of the analysis module.

Owner:冯雯雯

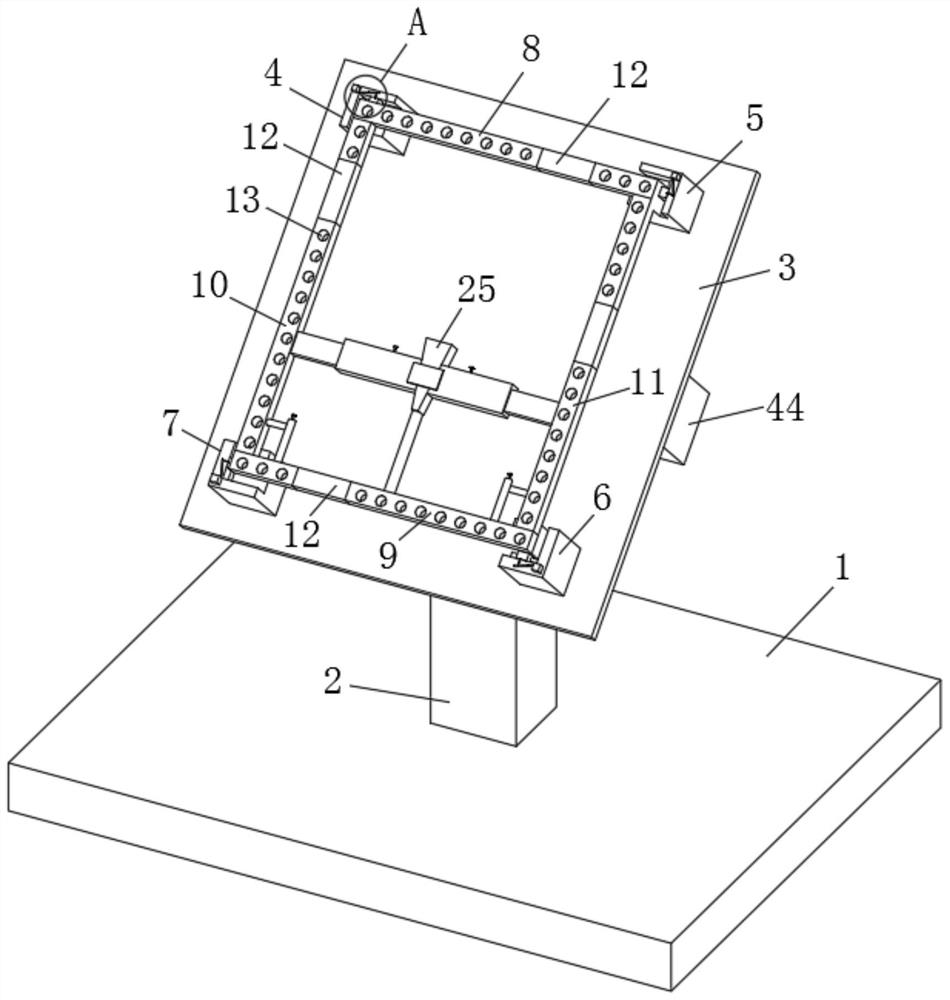

Accurate trimming device for advertisement design works

PendingCN114378876ANot easy to curlAdjustable lengthMetal working apparatusStructural engineeringPlastic film

The invention relates to the field of advertisements, in particular to a precise trimming device for advertisement design works, which comprises a bottom plate, the top of the bottom plate is rotatably connected with an iron mounting plate through a stand column, and a first cross rod, a second cross rod, a first vertical rod and a second vertical rod are arranged on one side, far away from the stand column, of the mounting plate; the first cross rod, the second cross rod, the first vertical rod and the second vertical rod form a rectangle, and four corners of the rectangle are respectively connected with the mounting plate through a first mounting block, a second mounting block, a third mounting block and a fourth mounting block in the clockwise direction. The plastic film can be fixed through the air holes, and the plastic film is not prone to curling. The first cross rod, the second cross rod, the first vertical rod and the second vertical rod can be stretched by any length within a certain range, so that the first cross rod, the second cross rod, the first vertical rod and the second vertical rod can adapt to the sizes of more plastic films.

Owner:马鞍山市棒棒贝贝教育咨询有限公司

Moving steel bench

The invention relates to a steel moving rack which is a chain drive type steel moving rack. The steel moving rack comprises a transverse moving frame and a lifting frame. The transverse moving frame comprises a supporting mechanism for supporting a chain. The supporting mechanism comprises an upper supporting structure and a lower supporting structure, wherein the upper supporting structure is used for supporting the tight side of the chain, and the lower supporting structure is used for supporting the loose side of the chain. Each supporting structure comprises two rails distributed on the two sides of the chain and a guide rail located between the two rails, wherein each guide rail is located below the corresponding tight side or the corresponding loose side of the chain. Multiple groups of rolling wheels walking on the chain are evenly installed on the chain in the circumferential direction. Because the tight side and the loose side of the chain can be supported by the supper supporting structure and the lower supporting structure, the problem that due to the length of the chain, the overhung part of the chain is too long is avoided, and normal operation of the transverse moving frame is guaranteed. In this way, the steel moving rack can effectively increase the steel moving distance and is suitable for the condition that a continuous casting hot charging roller bed and a rolled steel feeding roller way for a furnace form a large span.

Owner:WISDRI ENG & RES INC LTD

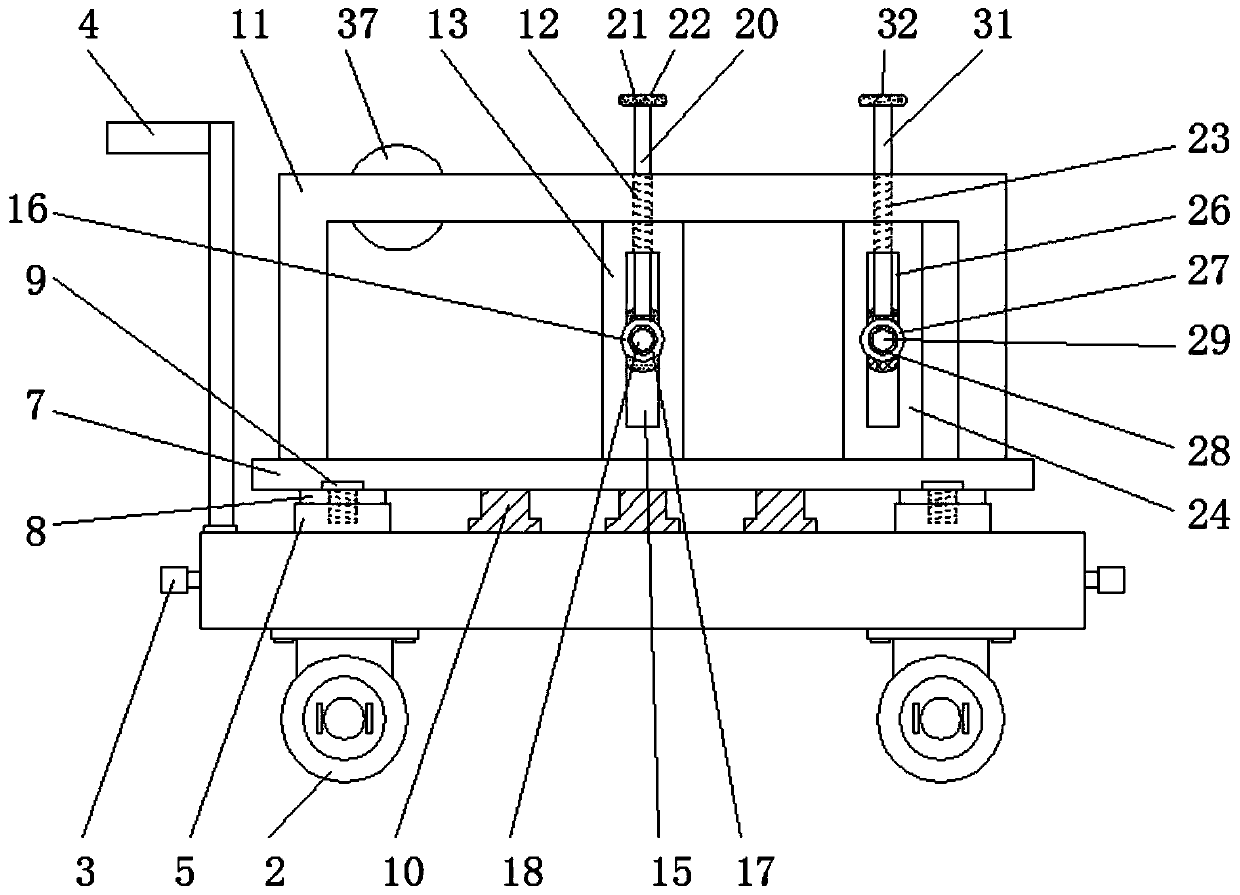

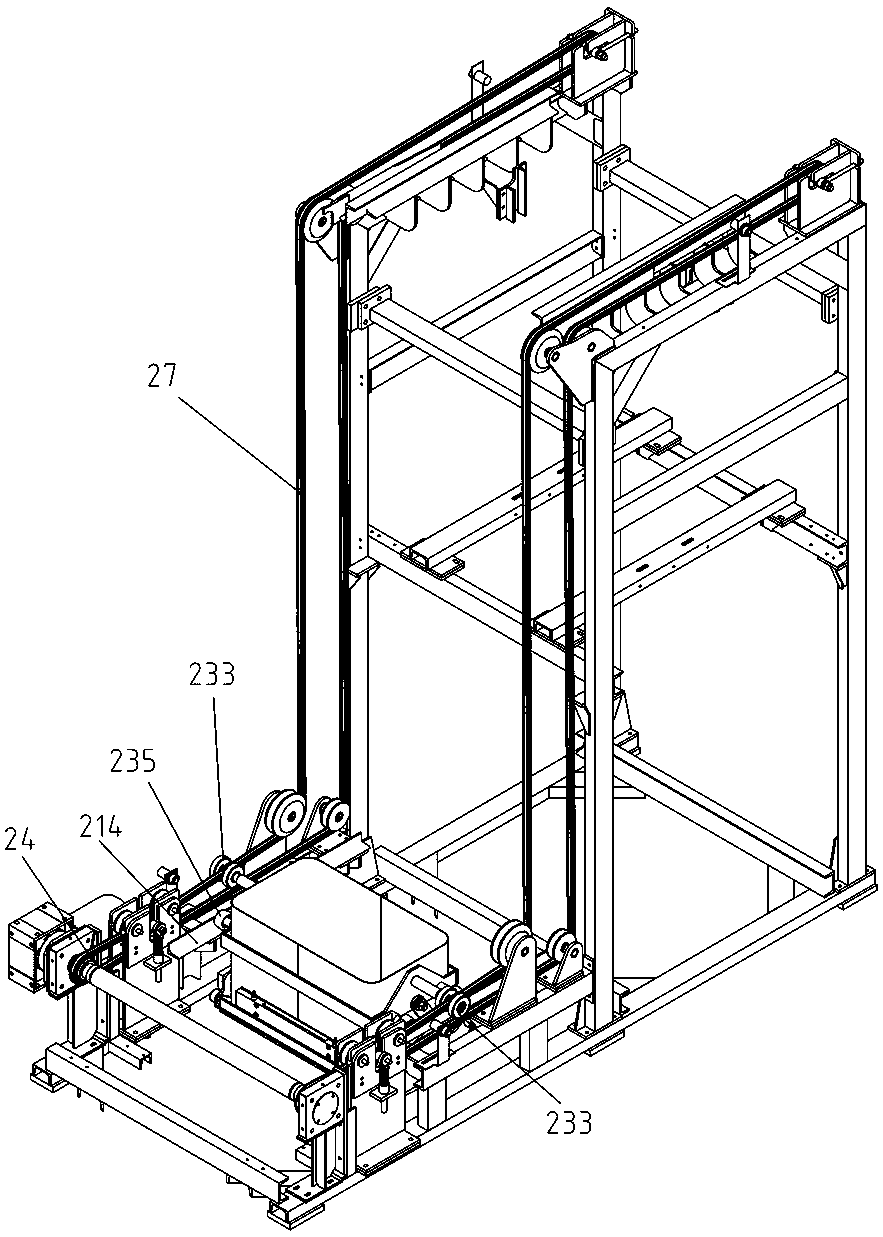

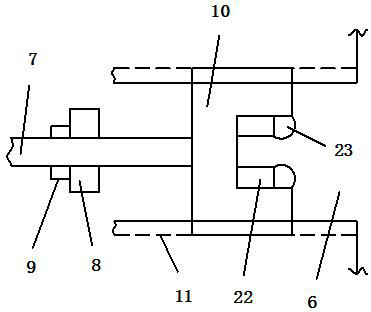

A device and method for adjusting the tension force of a wire rope of a two-way traction rail conveyor

InactiveCN104692273BTension real-time monitoringGood tensionWinding mechanismsPull forceControl system

The invention relates to a tension adjusting device and method for steel wire ropes of a bidirectional traction type rail transport machine. The adjusting device comprises a tension adjusting mechanism and a control system, wherein the tension adjusting mechanism comprises a motor, a lead screw, a lead screw nut and a tension sensor, an output shaft of the motor is connected with the lead screw, the lead screw nut is connected onto the lead screw, one end of the tension sensor is connected with the lead screw nut, the other end of the tension sensor is connected with a mounting base of a winch in the bidirectional traction type rail transport machine, and the mounting base is connected with a supporting frame fixed on the ground through a linear sliding mechanism; the control system comprises a signal feedback unit, a control unit, an execution unit and a power supply, the signal feedback unit consists of the tension sensor, and the execution unit consists of the motor. With the adoption of the adjusting device, the tension of the steel wire ropes can be adjusted automatically in real time, so that the steel wire ropes are in the optimal tensioned state all the time.

Owner:SOUTH CHINA AGRI UNIV +1

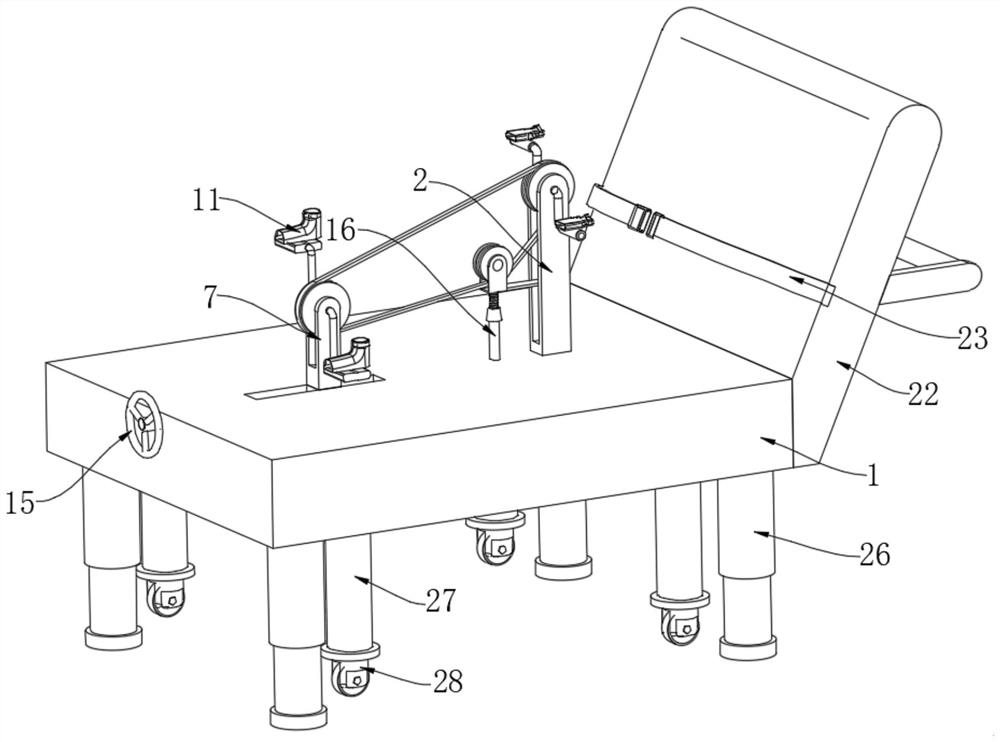

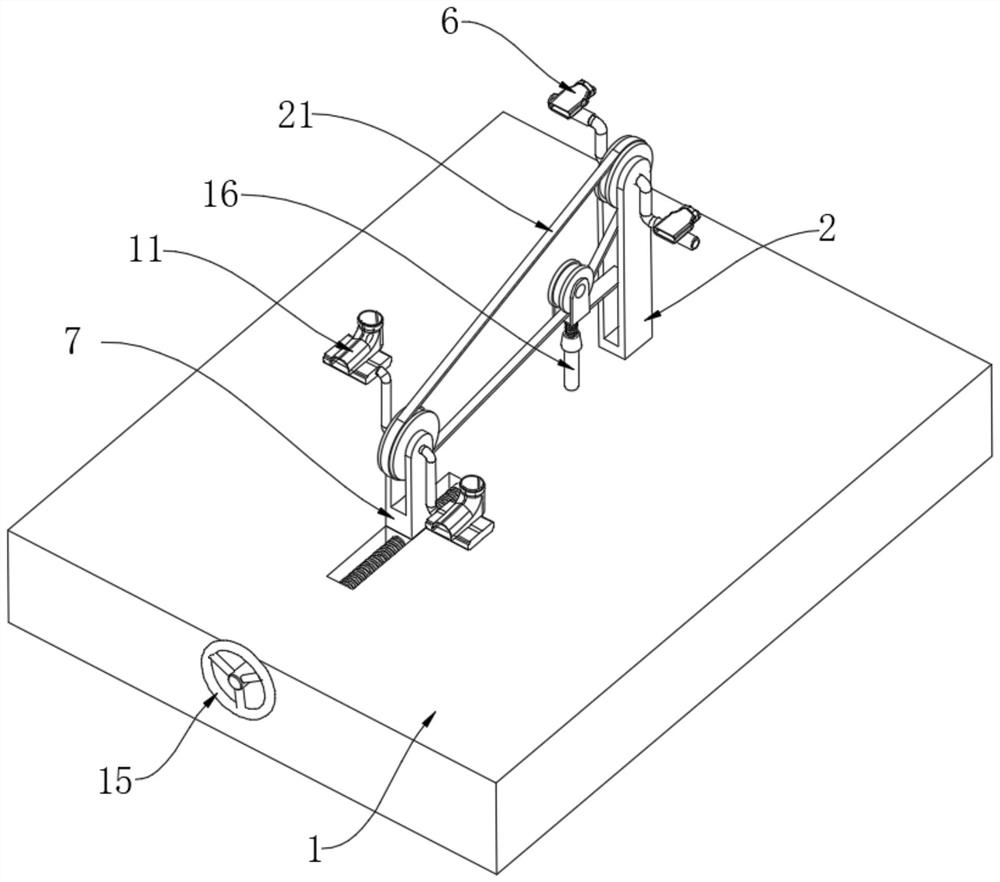

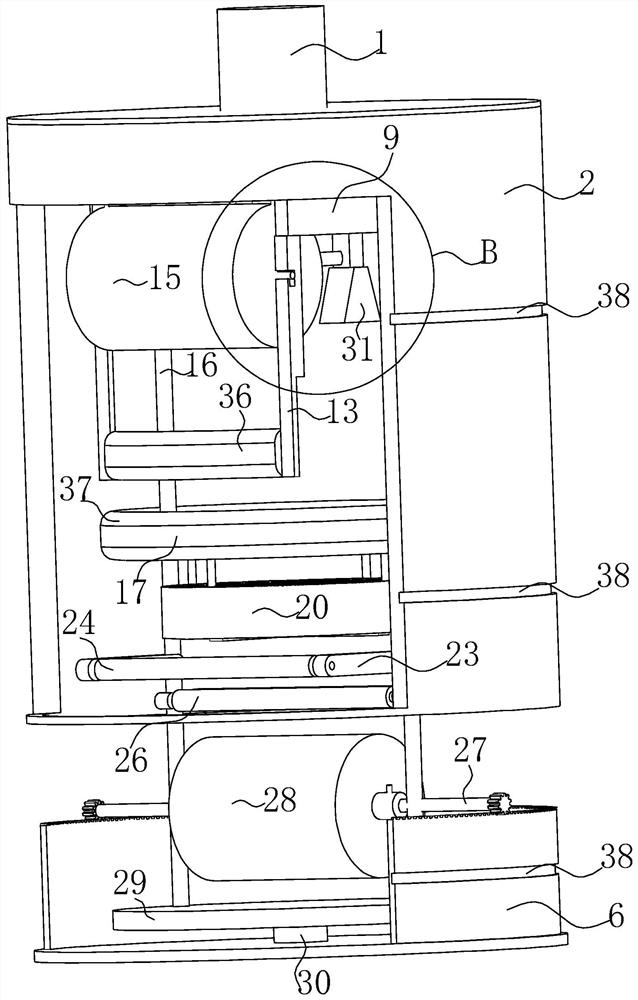

Postoperative nursing rehabilitation device for neurosurgery department

InactiveCN114642565ATo achieve the effect of rehabilitation trainingGood tensionChiropractic devicesPhysical medicine and rehabilitationNursing care

The neurosurgery postoperative nursing rehabilitation device comprises a bottom plate, a supporting frame is fixedly connected to the top of the bottom plate, a rotating rocker is rotatably connected to the inner wall of the supporting frame, and a first transmission wheel is fixedly connected to the position, located on the inner side of the supporting frame, of the outer wall of the rotating rocker; sleeves are rotationally connected to the two ends of the rotating rocker, hand fixing devices are fixedly connected to the outer walls of the sleeves, and a movable frame is arranged at the top of the bottom plate. When the patient carries out rehabilitation training on the hands, the patient shakes a rotating rocker through the hands, the rotating rocker can drive a first transmission wheel to rotate, the first transmission wheel drives a second transmission wheel to rotate through a belt, the second transmission wheel can drive a rotating foot lever to rotate along with the rotating rocker, and therefore the legs of the patient are driven to carry out rehabilitation exercise; and the rotating rocker rotates along with the rotating foot lever by treading the rotating foot lever by feet, so that the hand of the patient is subjected to rehabilitation training, and the device achieves the effect of performing rehabilitation training on the hand and the legs of the patient.

Owner:THE AFFILIATED HOSPITAL OF QINGDAO UNIV

Polyester fiber drying device

ActiveCN112556379AIncrease contactDry fastDrying gas arrangementsDrying chambers/containersPolyesterFiber

The invention discloses a polyester fiber drying device in the technical field of fiber production equipment. The polyester fiber drying device comprises a motor, the motor is fixedly arranged in thecenter of the top of a shell, two first supporting plates, three third sliding grooves and a first sliding door are fixedly arranged on the periphery of the shell, and a second supporting plate is fixedly arranged on the outer end face of the first sliding door; and a rack frame is fixedly connected to the bottom of the shell through a first supporting plate, a second sliding door is fixedly connected to the first sliding door through the second supporting plate, the rack frame is fixedly connected to a base, and a drying mechanism is arranged in the shell. Through the arrangement of the structure, the contact between fiber cloth and hot air can be increased, so that the fiber cloth is quickly dried, the drying time is shortened, no indentation is generated on the fiber cloth, fibers are prevented from being damaged due to the fact that direct contact with a heat source is avoided, the drying efficiency is improved, the fiber quality is guaranteed, and people can better use the fiber cloth conveniently.

Owner:江苏瑞恩新材料有限公司

Cam-based chain tensioner and its control method

The invention discloses a chain tensioner based on a cam. The chain tensioner comprises a fixing shaft, the tensioning cam, a supporting arm, a first extending arm, a second extending arm, and a shock absorption supporting device, wherein the tensioning cam is arranged on the fixing shaft in a sleeving manner and can swing around the fixing shaft, and a smooth groove is formed in the periphery of the tensioning cam and used for containing a chain; the supporting arm comprises a common terminal; the first extending arm and the second extending arm which are both connected to the common terminal are symmetrically arranged, and the first extending arm and the second extending arm are fixed to the two ends of the fixing shaft; and one end of the shock absorption supporting device is supported on the common terminal of the supporting arm, and the other end of the shock absorption supporting device is supported at the far end of the tensioning cam and used for flexible supporting to the tensioning cam. The invention further provides a control method of the chain tensioner based on the cam. By changing the current intensity of an electromagnetic body, the chain is made in an optimal tensioned state.

Owner:LIAONING UNIVERSITY OF TECHNOLOGY

Novel fruit cup reversing device

The invention discloses a novel fruit cup reversing device. The novel fruit cup reversing device comprises a driving wheel, wherein a fixed shaft is fixedly connected to the axis of the inner side ofthe driving wheel, a chain is movably connected to the outer side of the driving wheel in a meshed mode, a concentric disc is fixedly connected to the rear end of the driving wheel, a driven wheel isconnected to the inner side of the right end of the chain in a meshed mode, a guide tensioning device is fixedly connected to the lower side of the left end of the interior of the chain, a fruit cup is movably connected to the outer side of the chain, sorting lines are fixedly connected to the front end and the rear end of the upper end of the chain, and the concentric disc is of a cylindrical sheet structure and is coaxially distributed with the driving wheel and the driven wheel. According to the novel fruit cup reversing device, the guide tensioning device can effectively realize the guidetensioning of the chain, the turning radius of the chain is increased, the abnormal damage of chain jumping and deviation of the chain is effectively avoided, the stability of chain transmission is guaranteed, the noise in the transmission process is reduced, and the service life of the chain is prolonged.

Owner:JIANGXI REEMOON TECH HLDG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com