Strip sticking machine

A sticker, Y-axis technology, applied in the direction of sewing tools and other directions, can solve problems such as low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

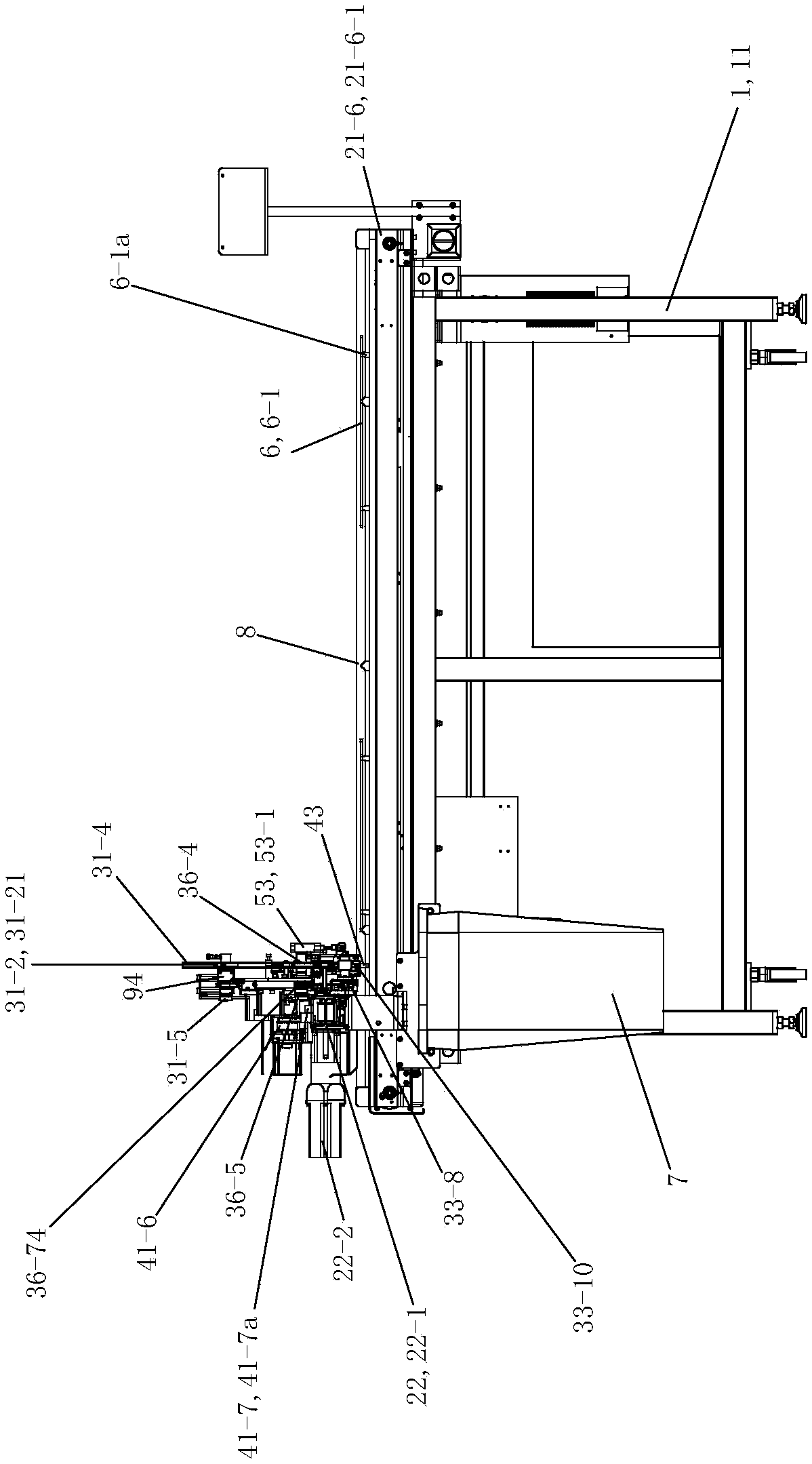

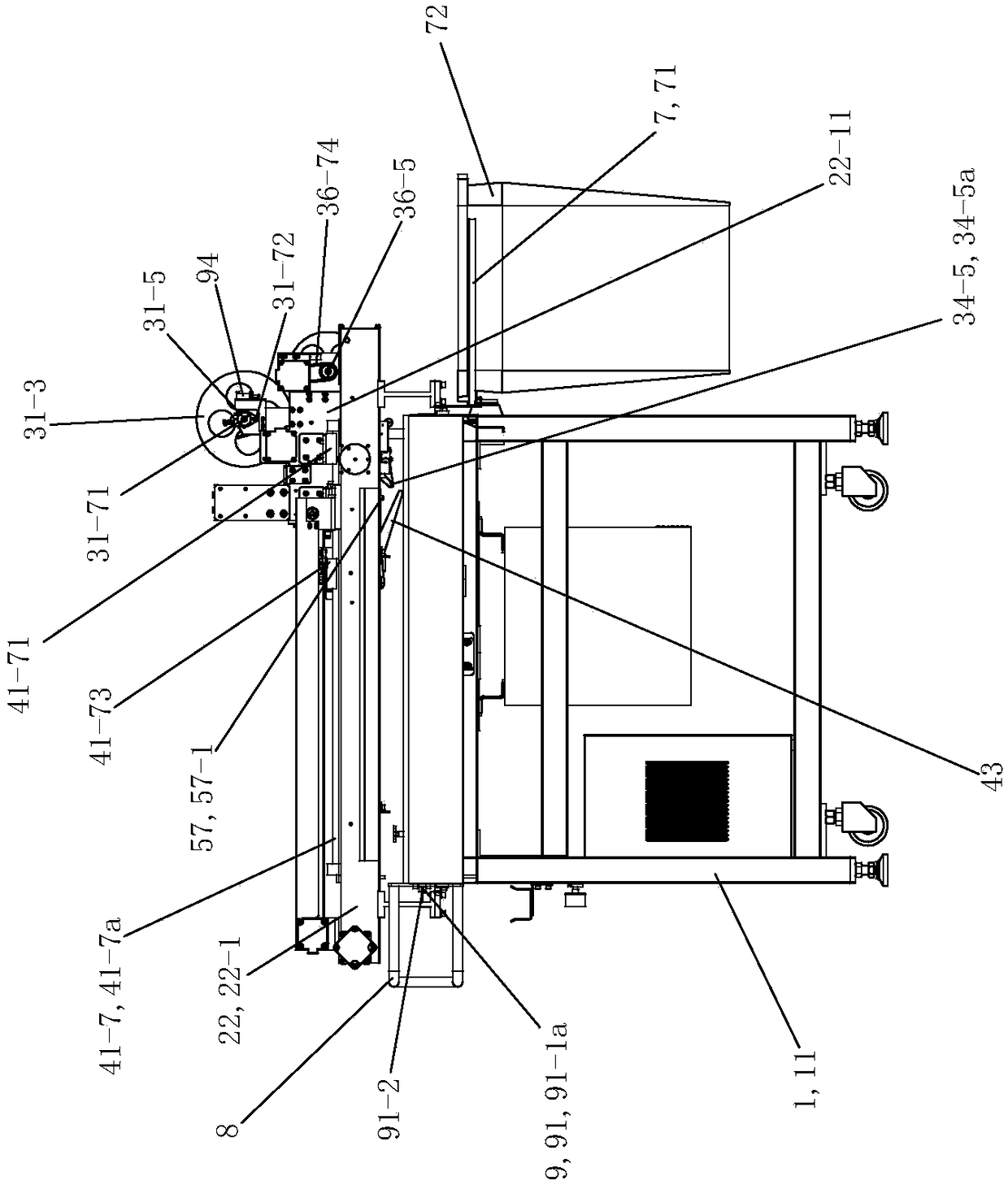

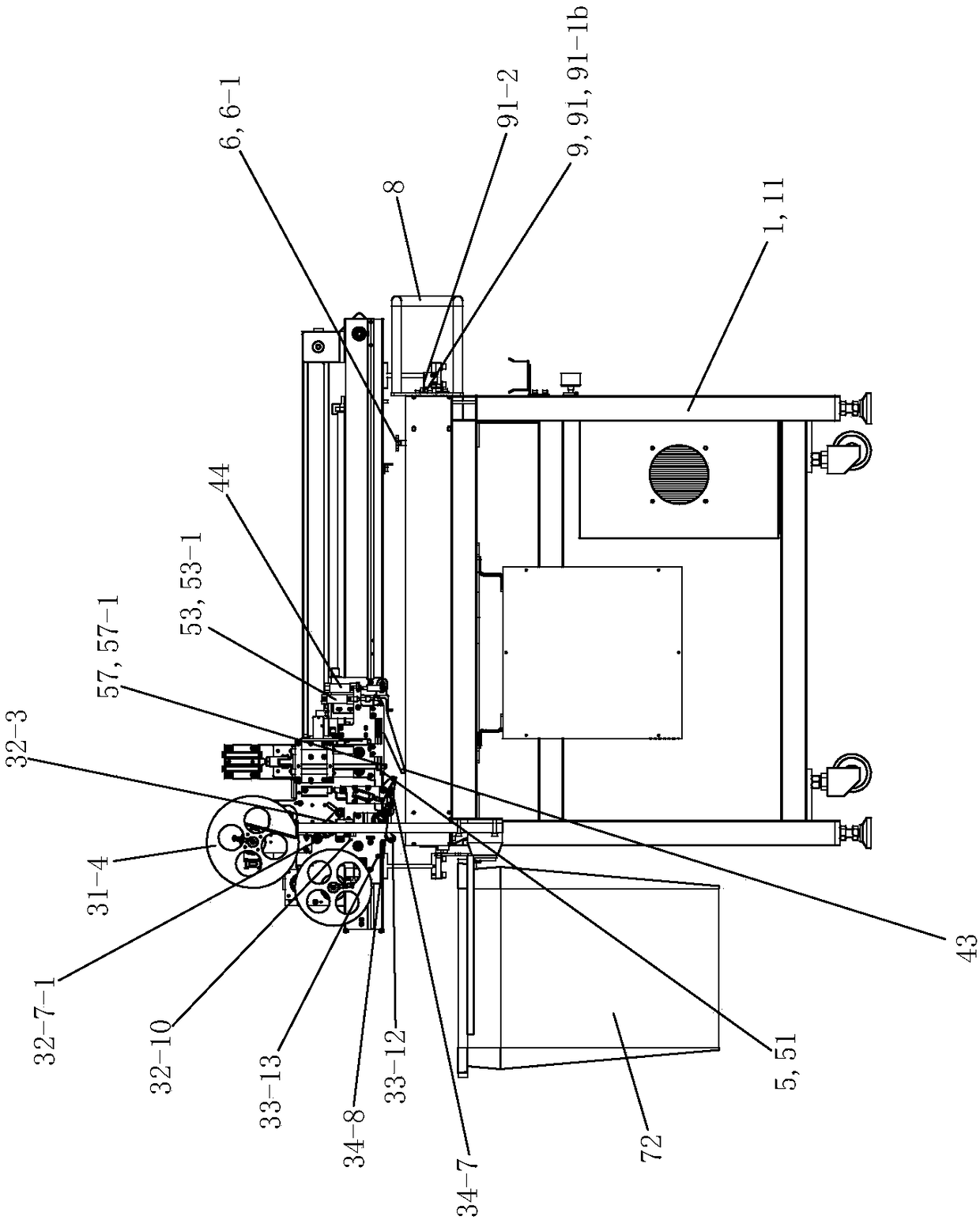

[0102] See Figure 1 to Figure 22 , The sticking machine of the present invention includes a workbench 1, an X-axis module 21, a Y-axis module 22, a feeding device 3, a pressing device 4, a shearing device 5, a positioning device 6, a feeding assembly 7, and a protective frame 8 and positioning component 9.

[0103] See Figure 1 to Figure 10 , the workbench 1 includes a main frame body 11 and a platen assembly 12 arranged on the main frame body 11 . The deck assembly 12 includes a work deck 12-1 and a work panel 12-2. There are two working panels 12-2, and the two working panels 12-2 are arranged side by side along the left and right directions on the working table 12-1. Two work panels 12-2 all adopt stainless steel plate.

[0104] See Figure 1 to Figure 10 , there are 2 groups of positioning devices 6, and the structures of the 2 groups of positioning devices 6 are the same, including 2 positioning up and down drive cylinders 6-1 and positioning pressure plates 6-2. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com