Feeding device of strip sticking machine

A feeding device and sticking machine technology, which is applied in the direction of sending objects, thin material processing, transportation and packaging, etc., can solve the problems of low efficiency, achieve the effect of accurate position, improve production efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

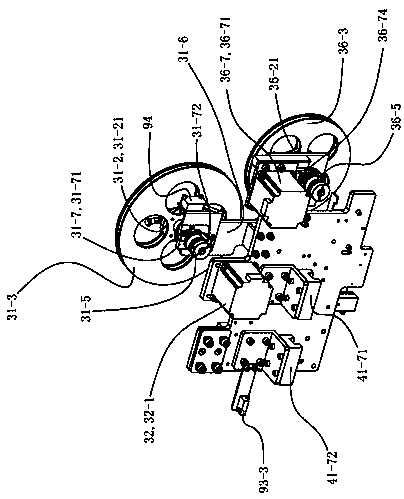

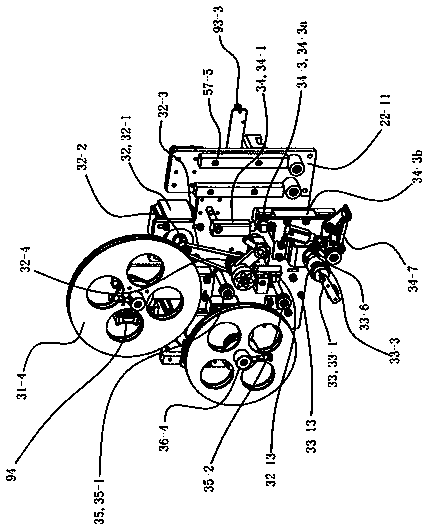

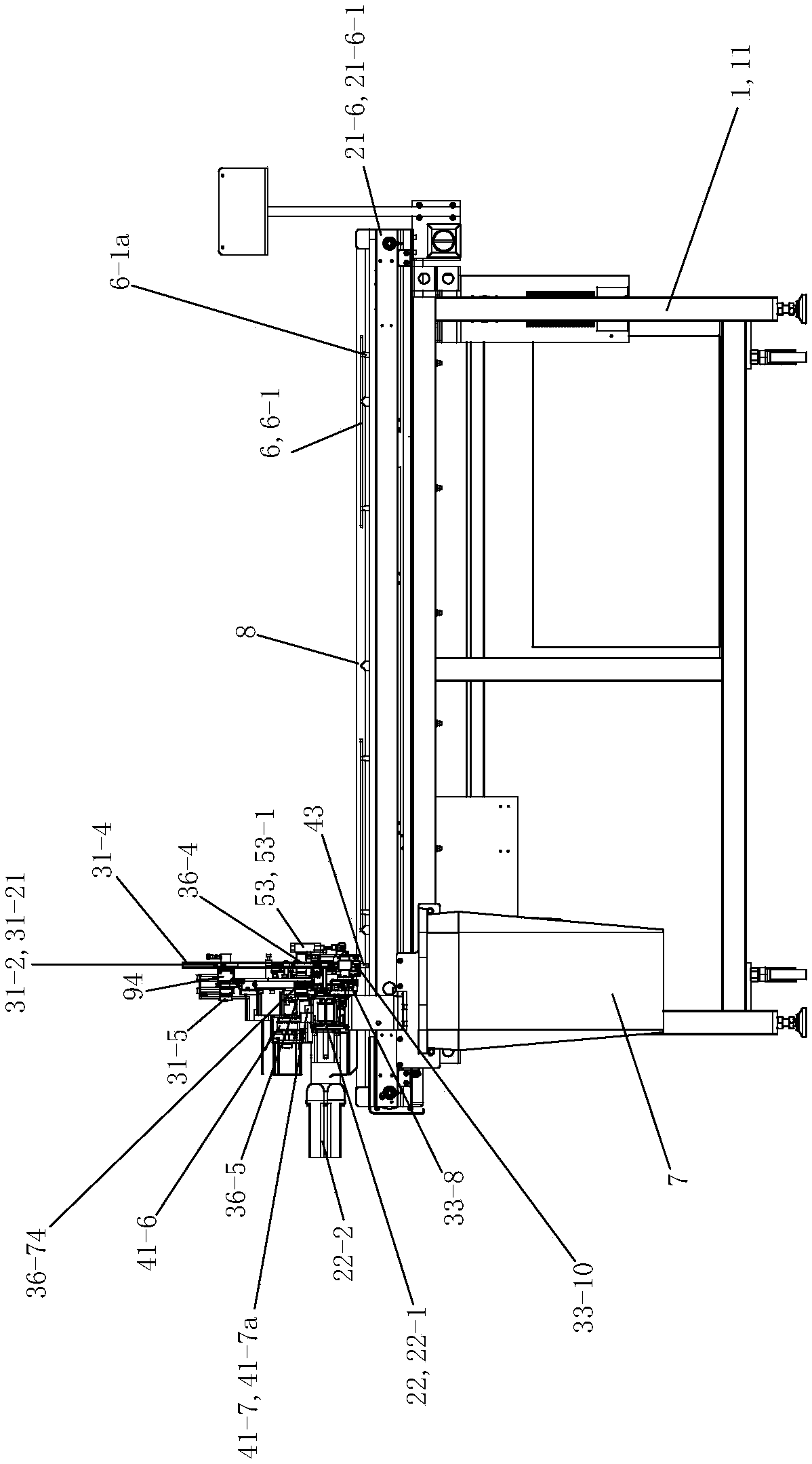

[0078] See Figure 1 to Figure 8 and Figure 14 to Figure 22 , The feeding device 3 includes a discharge tray assembly 31 , an active feeding assembly 32 , a feeding detection assembly 33 , a clamping assembly 34 , a guide wheel assembly 35 and a waste collection assembly 36 .

[0079] The discharge tray assembly 31 includes a discharge tray support shaft 31-1, a discharge tray bottom plate 31-2, a left stop tray 31-3, a right stop tray 31-4, and a first adjustable damping coupling 31-5 , The discharge tray mounting seat 31-6 and the first limiting device 31-7. The discharge tray mounting seat 31-6 is fixedly arranged on the middle upper part of the Y-axis first mounting seat plate 22-11 of the Y-axis module 22 of the tape sticking machine. The discharge tray support shaft 31-1 is arranged on the top of the discharge tray mounting seat 31-6 along the left and right rotation through corresponding bearings and bearing seats. The middle part of the bottom plate 31-2 of the dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com