Rope traction mechanism and push-pull window with same

A traction mechanism and rope technology, applied in the field of sliding windows, can solve problems such as large spaces, and achieve the effect of not easy to slip and good tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

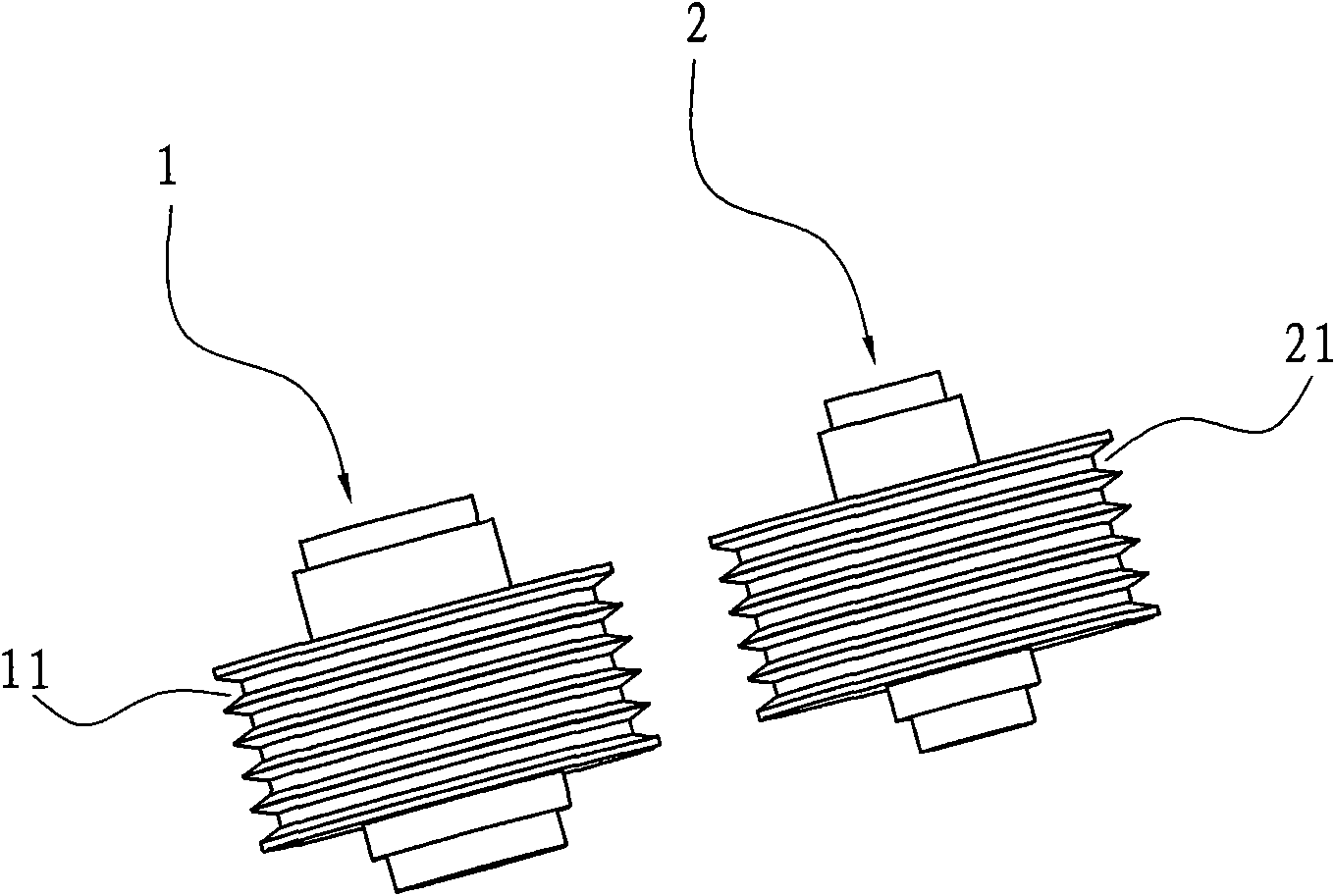

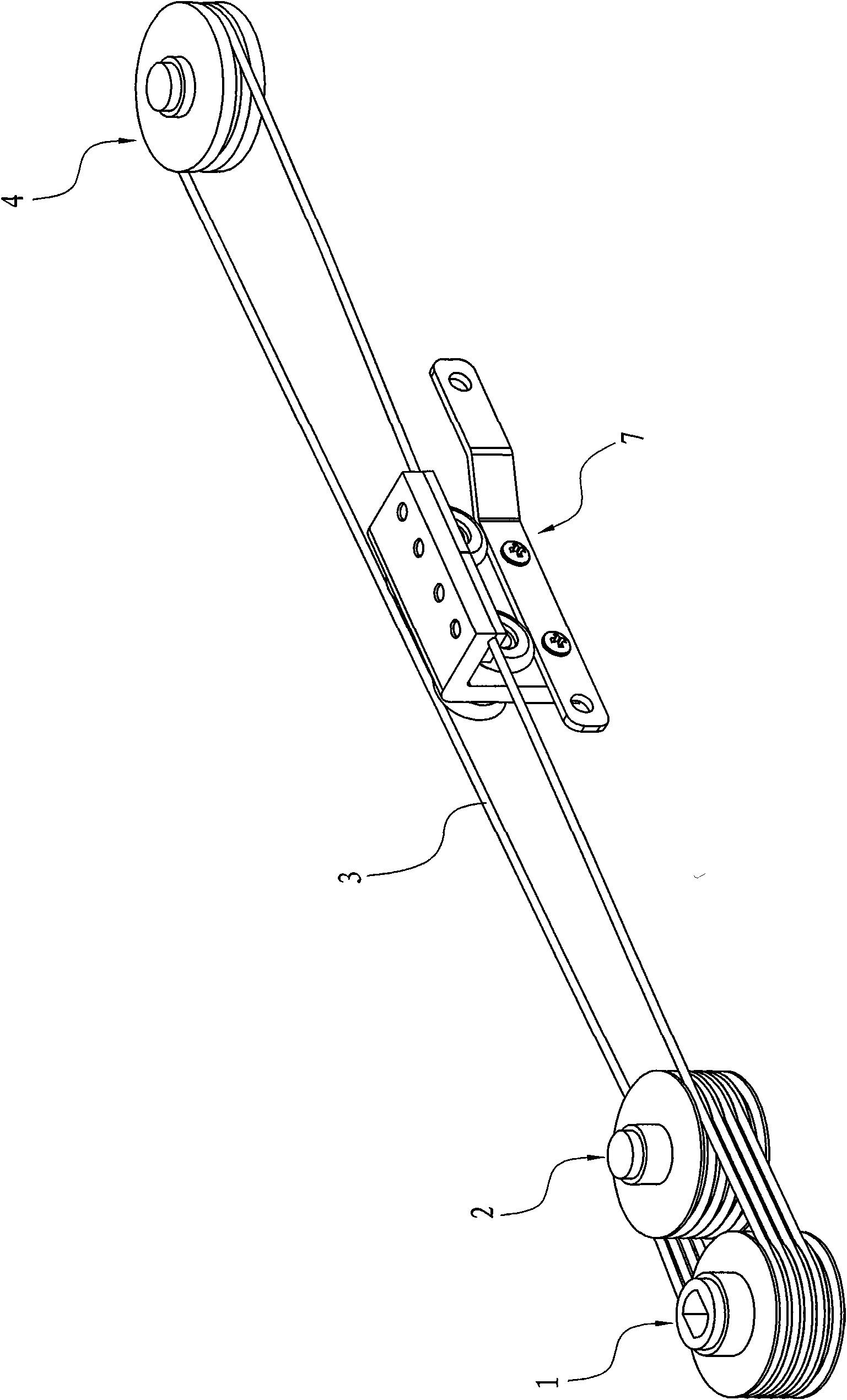

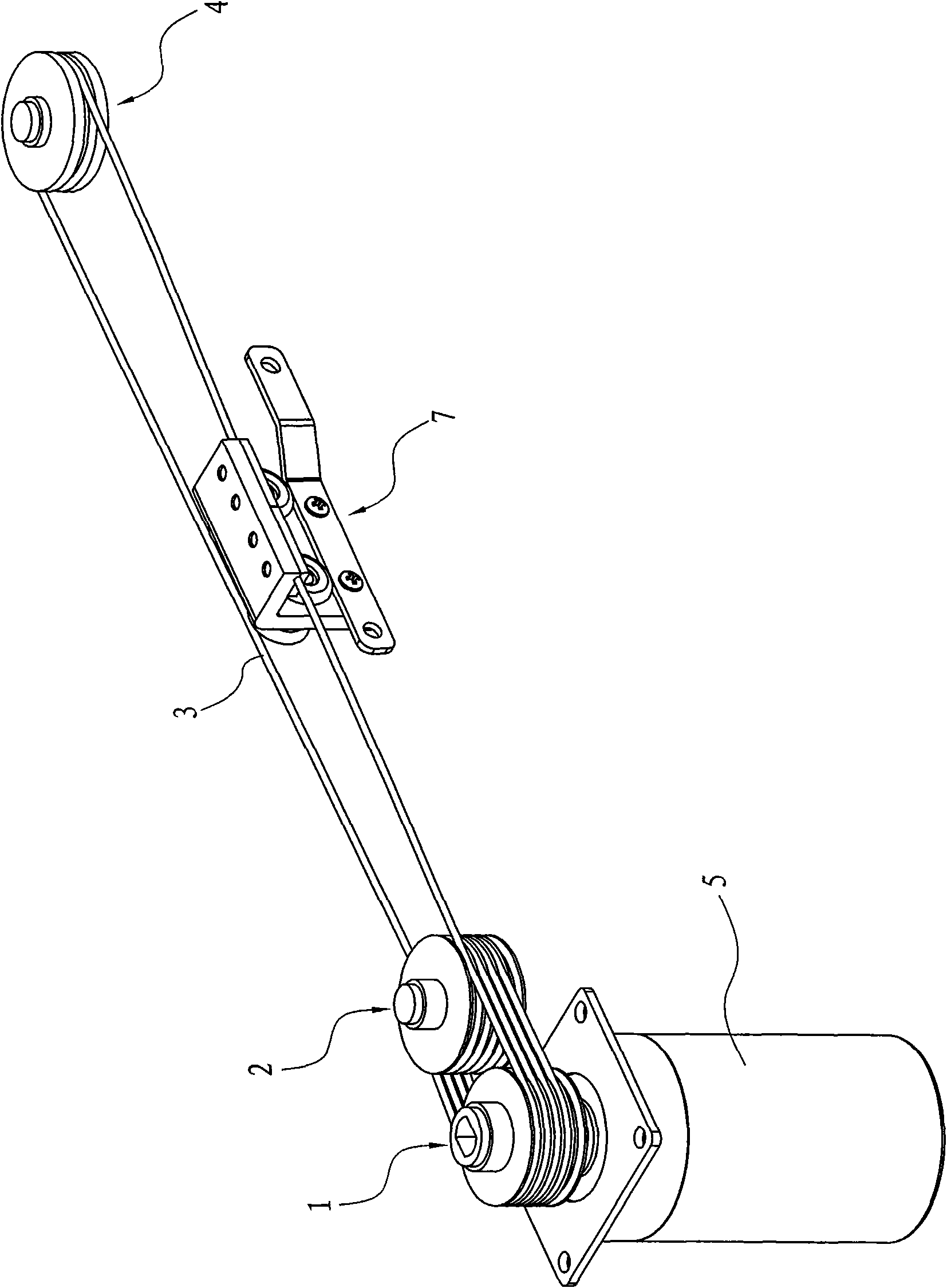

[0057] like figure 1 and 2 The rope traction mechanism shown uses the rope as the traction power to drive the external load to move, and it includes a first tension pulley 1, a second tension pulley 2, a rope 3, and a steering pulley 4, wherein the first tension pulley 1 The outer peripheral wall is provided with five annular grooves 11 arranged at intervals, and the outer peripheral wall of the second tensioning wheel 2 is also provided with five annular grooves 21 arranged at intervals; and the first tensioning wheel 1 and the second tensioning wheel 2 Adjacent to each other and arranged side by side at intervals and the two shafts are parallel; and the steering wheel 4 is set away from the first tensioning pulley 1 and the second tensioning pulley 2; The steering pulley 4 comes and walks around the first annular groove of the first tension pulley 1 in the direction close to the first tension pulley 1, and then moves away from the first tension pulley 1 and close to the se...

Embodiment 2

[0066] Different from Embodiment 1, the present invention also includes at least one guide wheel 9, and the guide wheel 9 is also set away from the two tension pulleys. The rope section between is used to connect the external load traction frame 7 of the external connection, and the rope section between the guide wheel 9 and the second tensioning wheel 2 is also used to connect the external load traction frame of the external connection, see Figure 6 shown. In this way, the movement direction of the external load can be adjusted freely.

Embodiment 3

[0068] Different from Embodiment 1, the number of turns of the rope on the first tensioning pulley and the second tensioning pulley is 1 turn or between 1 turn and 2 turns, such as 1.5 turns. And the annular groove on the outer peripheral wall of the second tensioning wheel can have only one, also can be multiple, but the rope is only wound once on the second tensioning wheel, and its specific winding method is: the rope enters the first tensioning wheel The wire inlet comes from the steering pulley and walks around the first annular groove of the first tension pulley in the direction close to the first tension pulley, and then moves away from the first tension pulley and close to the second tension pulley. Go around the annular groove on the second tensioning wheel in the direction of the second tensioning wheel, and then go around the second annular groove of the first tensioning wheel in a direction away from the second tensioning wheel and close to the first tensioning whee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com