Patents

Literature

37results about How to "Tension real-time monitoring" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

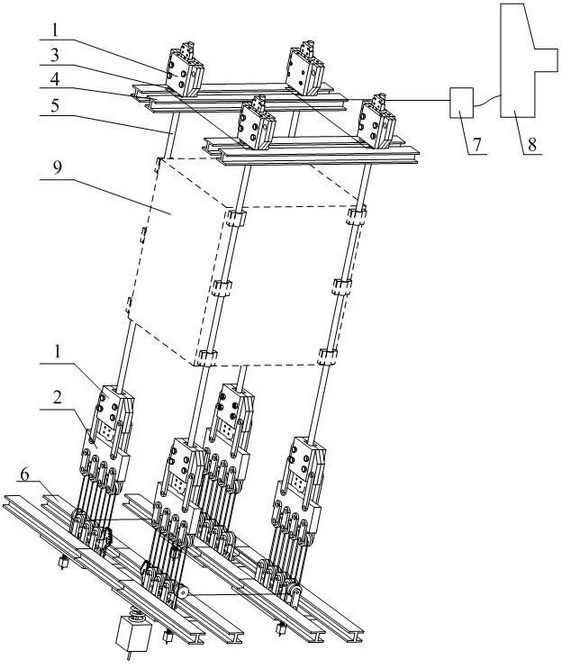

Wire rope guide rail tensioning device for mining elevator

ActiveCN102020162AFixed, safe and reliableTension real-time monitoringElevatorsMine liftsEngineeringPersonal computer

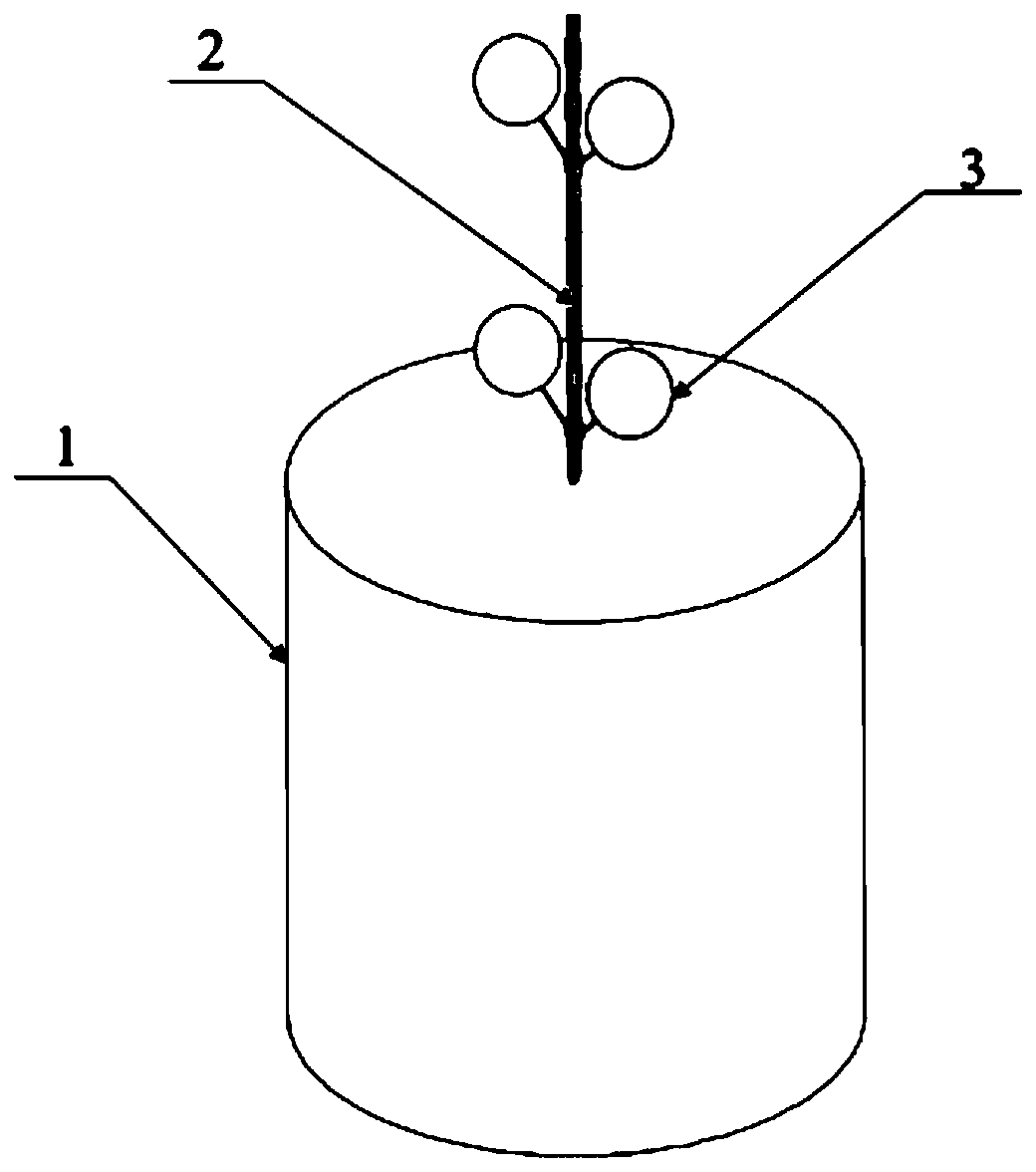

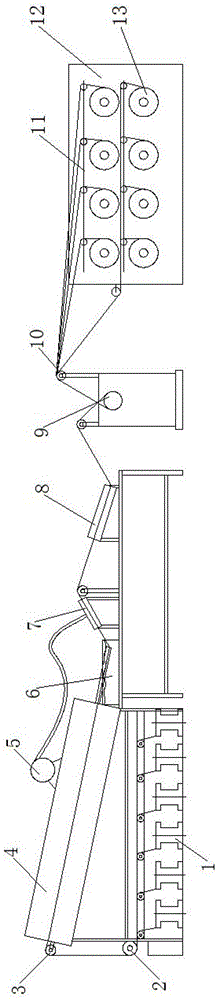

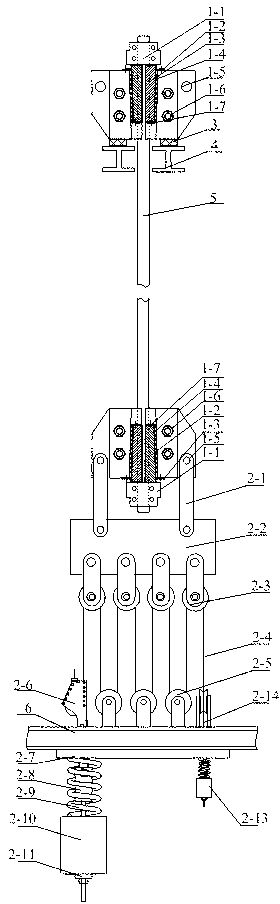

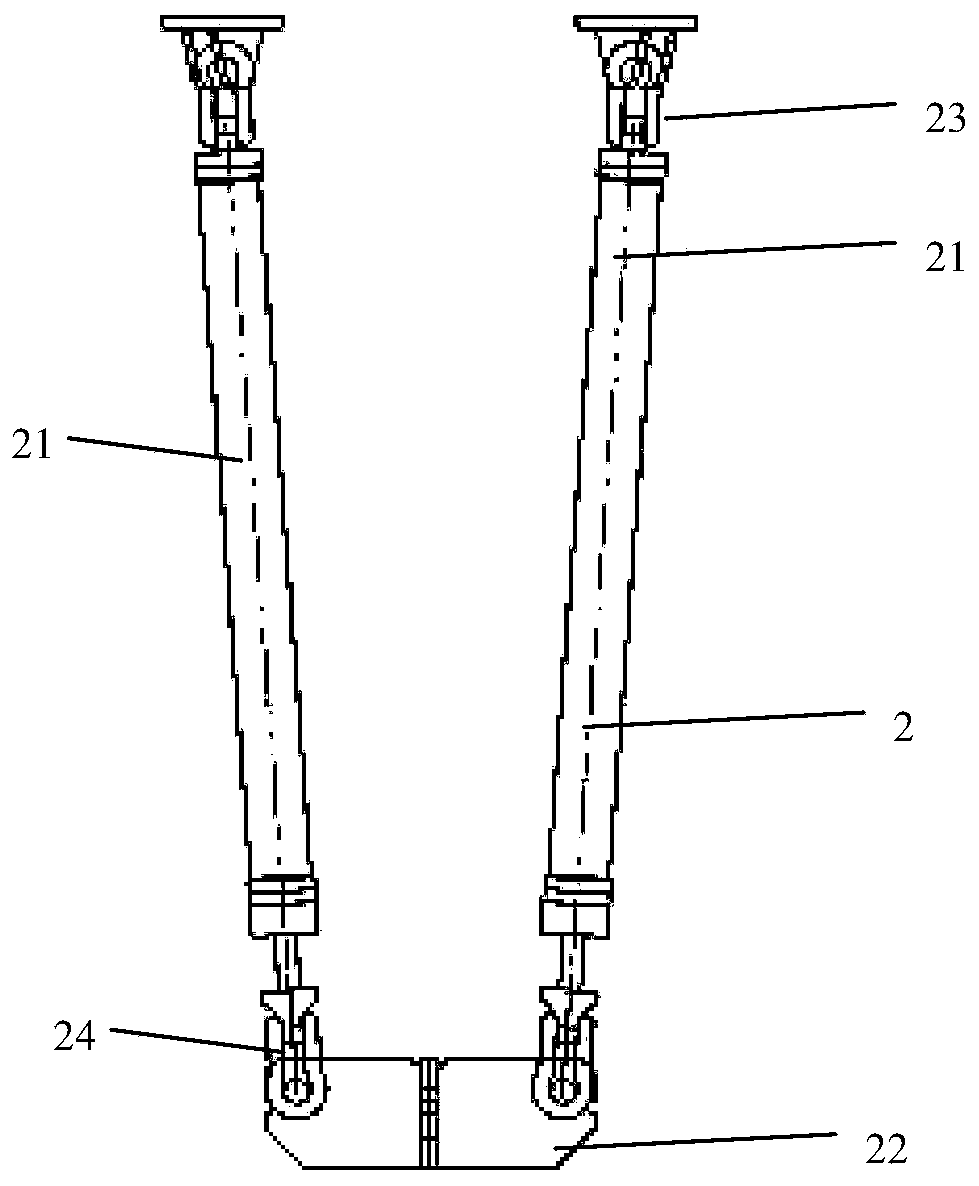

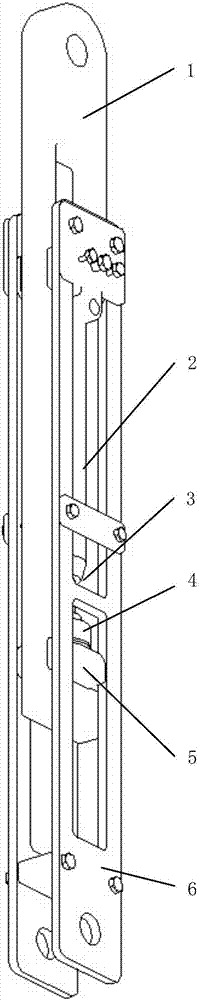

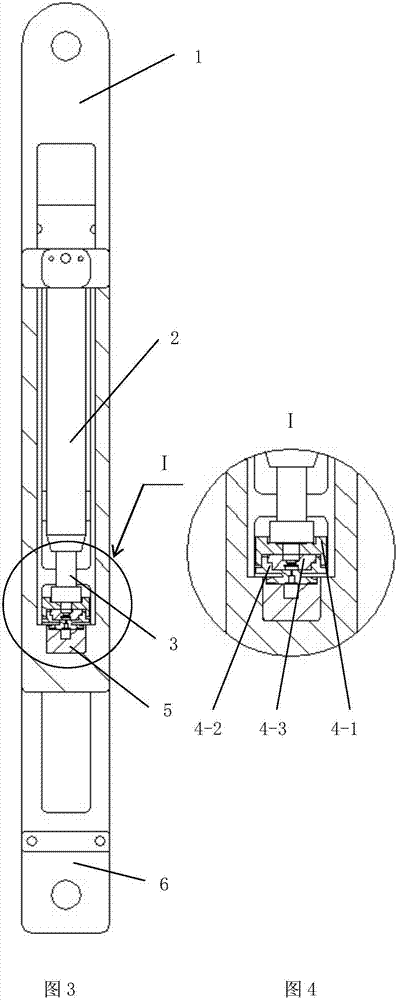

The invention discloses a wire rope guide rail tensioning device for a mining elevator, which comprises an industrial personal computer, a signal acquirer, wire rope guide rails, counterweight devices and a rope regulation device. Reversely symmetrically arranged wire rope fixing devices are arranged at the upper and lower ends of the wire rope guide rails. Upper wire rope fixing devices are fixed on upper carrier bars. Pressure sensors connected with the signal acquirer are arranged between the upper wire rope fixing devices and the upper carrier bars. Tensioning devices fixed on lower carrier bars are connected to lower wire rope fixing devices. The wire rope fixing devices arranged at the upper and lower ends of wire ropes can safely and reliably fix the wire rope guide rails, and tensioning forces are applied to the wire ropes by the tensioning devices and the counterweight devices arranged on a lower part so as to realize the longitudinal guide and transverse swing restraint of acage in a lifting running process. The wire rope guide rail tensioning device has a compact structure and reliable performance, is easy to machine and simple in installation and maintenance, can monitor the tensioning forces of the guide rails in real time and give an alarm online according to the monitored tensioning forces, and improves the taking safety and reliability of the cage.

Owner:CHINA UNIV OF MINING & TECH +1

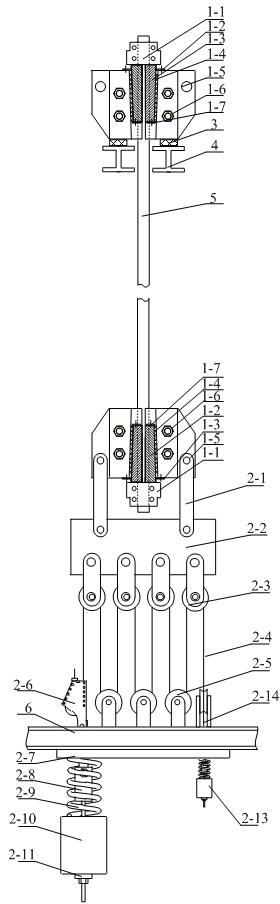

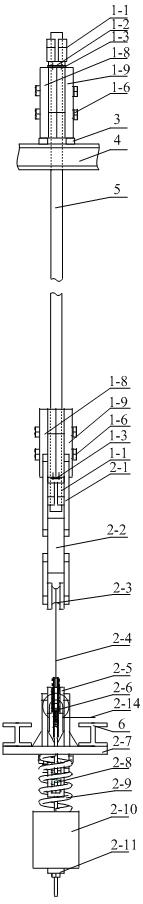

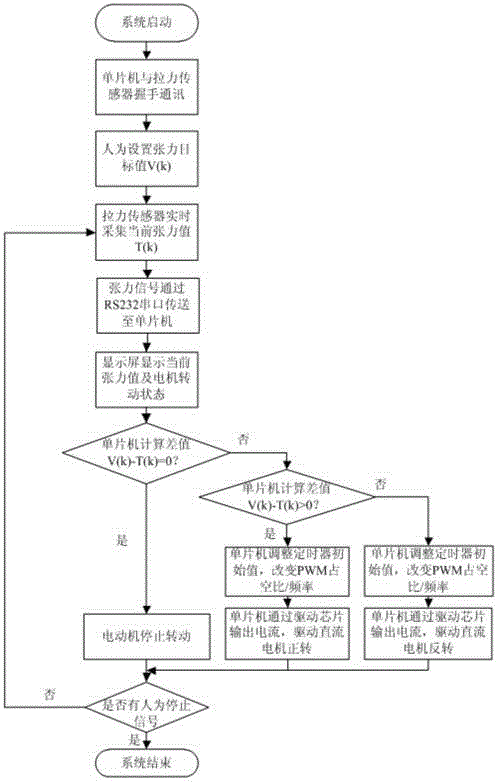

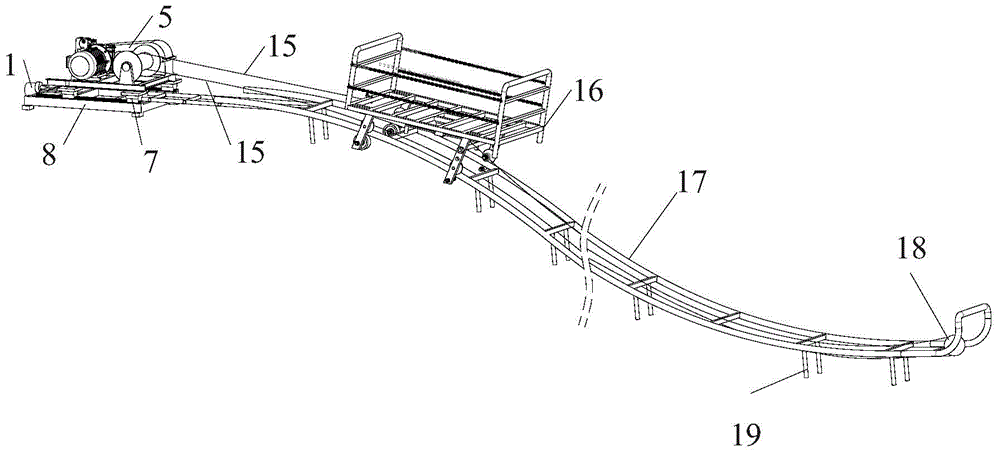

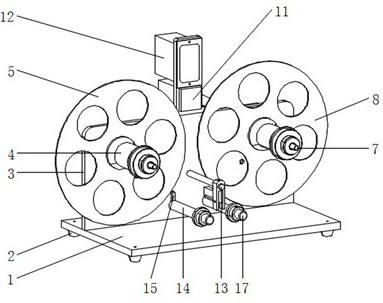

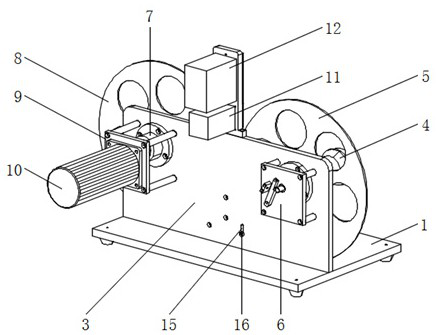

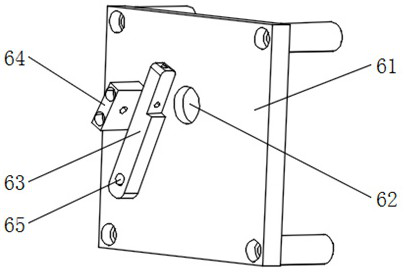

Tension adjusting device and method for steel wire ropes of bidirectional traction type rail transport machine

InactiveCN104692273AGuaranteed traction effectExtended service lifeWinding mechanismsEngineeringWire rope

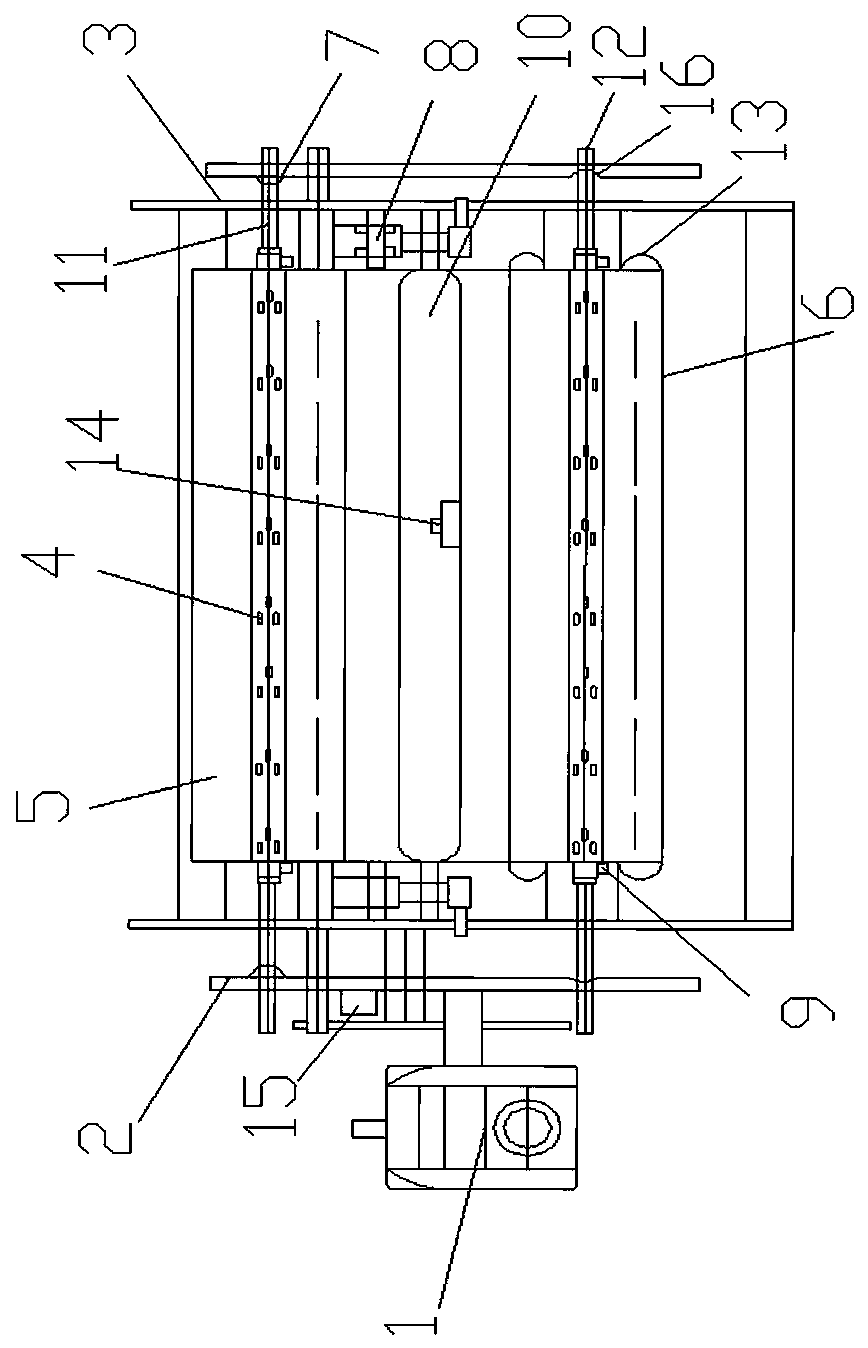

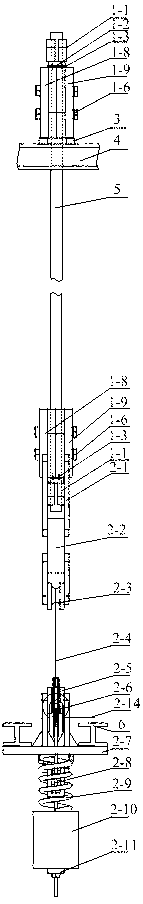

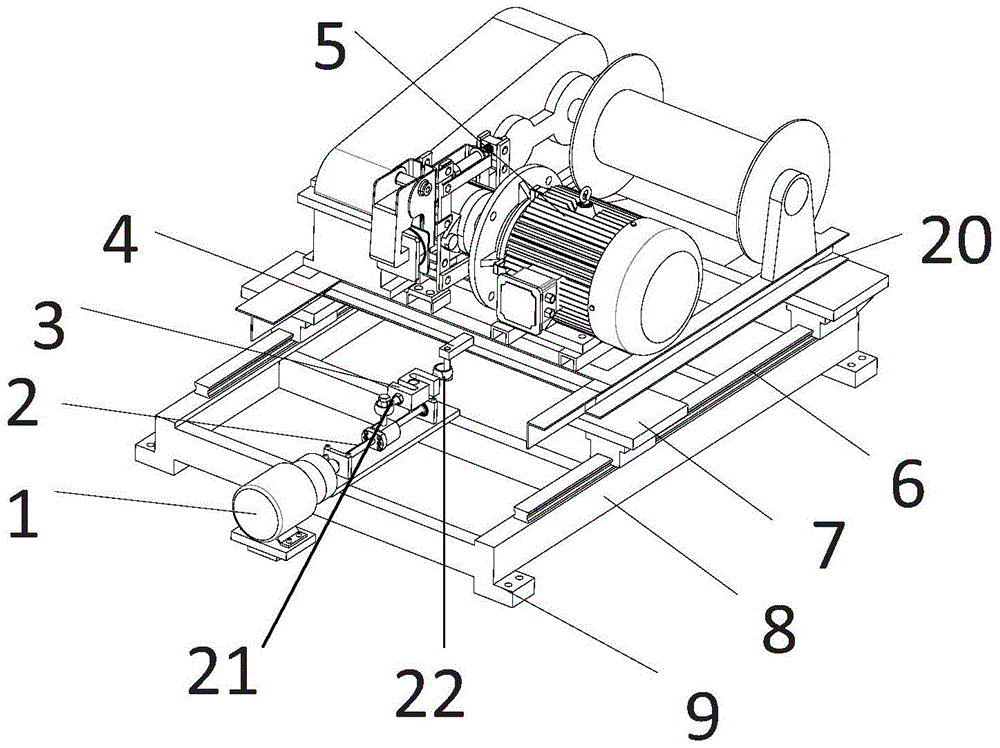

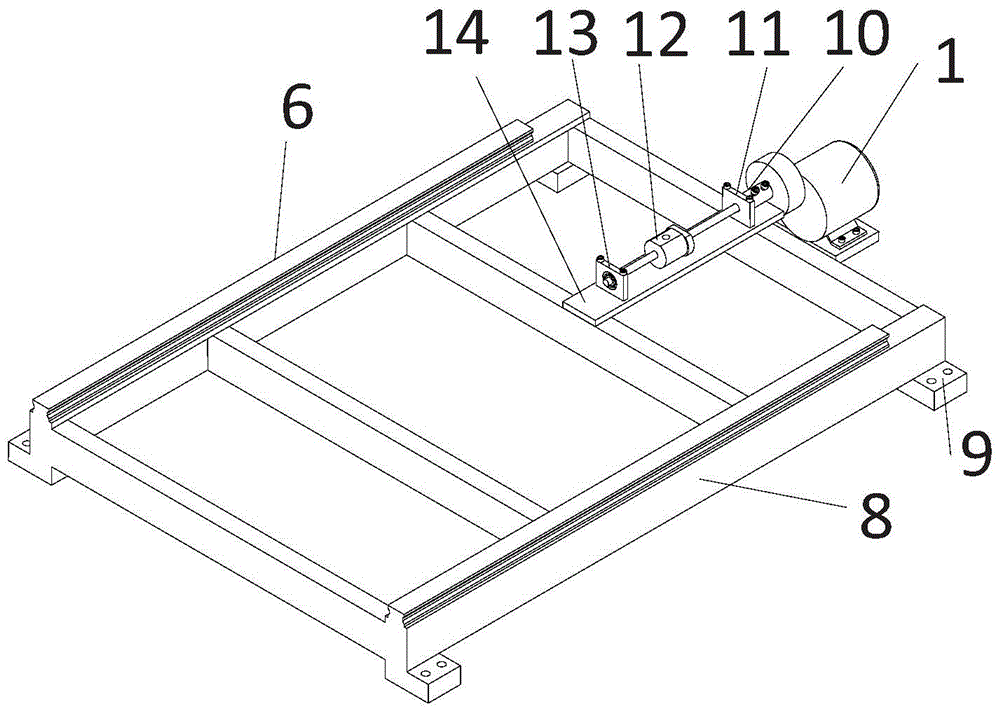

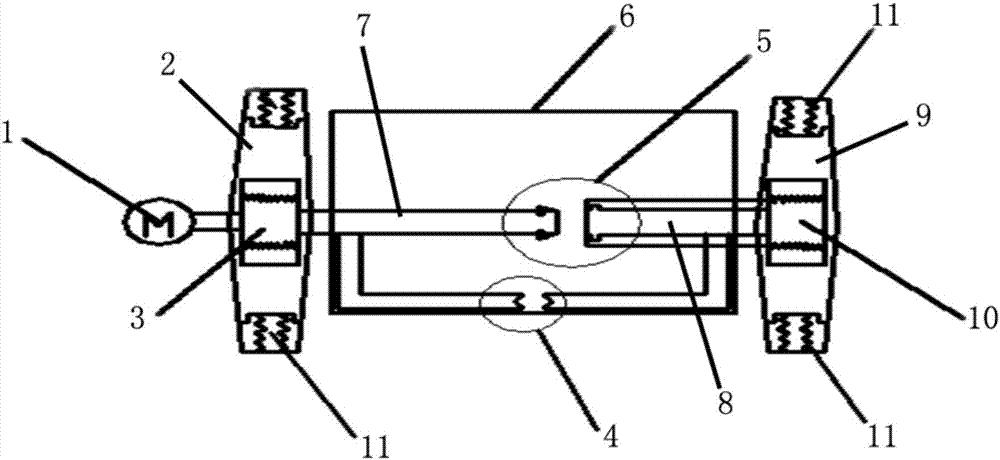

The invention relates to a tension adjusting device and method for steel wire ropes of a bidirectional traction type rail transport machine. The adjusting device comprises a tension adjusting mechanism and a control system, wherein the tension adjusting mechanism comprises a motor, a lead screw, a lead screw nut and a tension sensor, an output shaft of the motor is connected with the lead screw, the lead screw nut is connected onto the lead screw, one end of the tension sensor is connected with the lead screw nut, the other end of the tension sensor is connected with a mounting base of a winch in the bidirectional traction type rail transport machine, and the mounting base is connected with a supporting frame fixed on the ground through a linear sliding mechanism; the control system comprises a signal feedback unit, a control unit, an execution unit and a power supply, the signal feedback unit consists of the tension sensor, and the execution unit consists of the motor. With the adoption of the adjusting device, the tension of the steel wire ropes can be adjusted automatically in real time, so that the steel wire ropes are in the optimal tensioned state all the time.

Owner:SOUTH CHINA AGRI UNIV +1

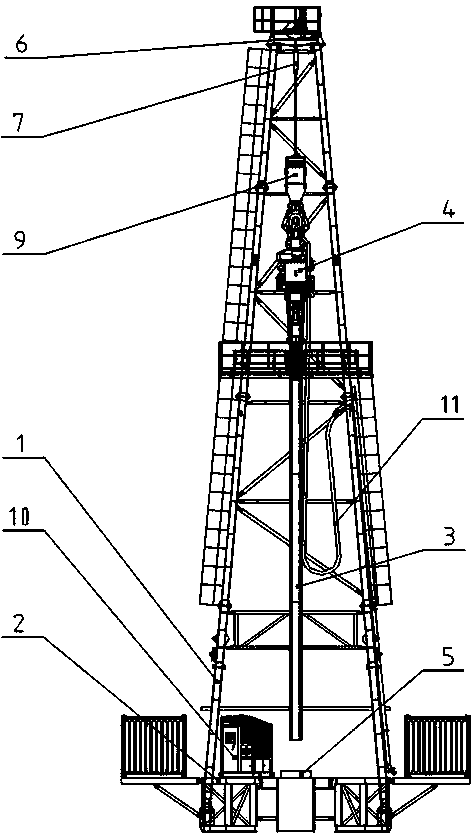

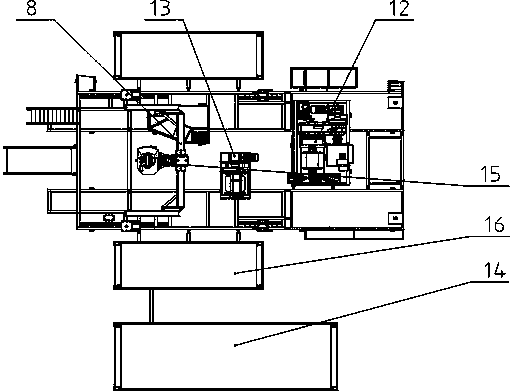

Variable-frequency electrically-driven top drive type core drill used for geological coring exploration

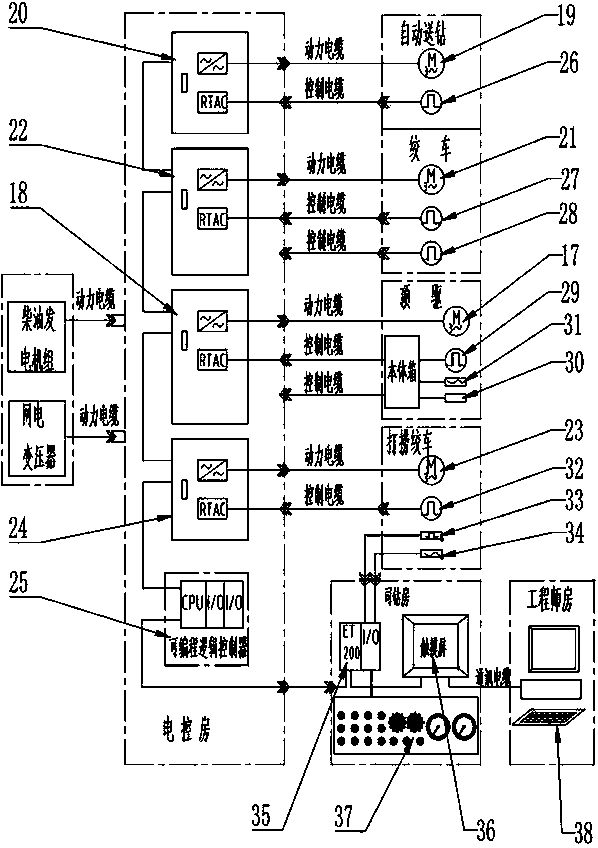

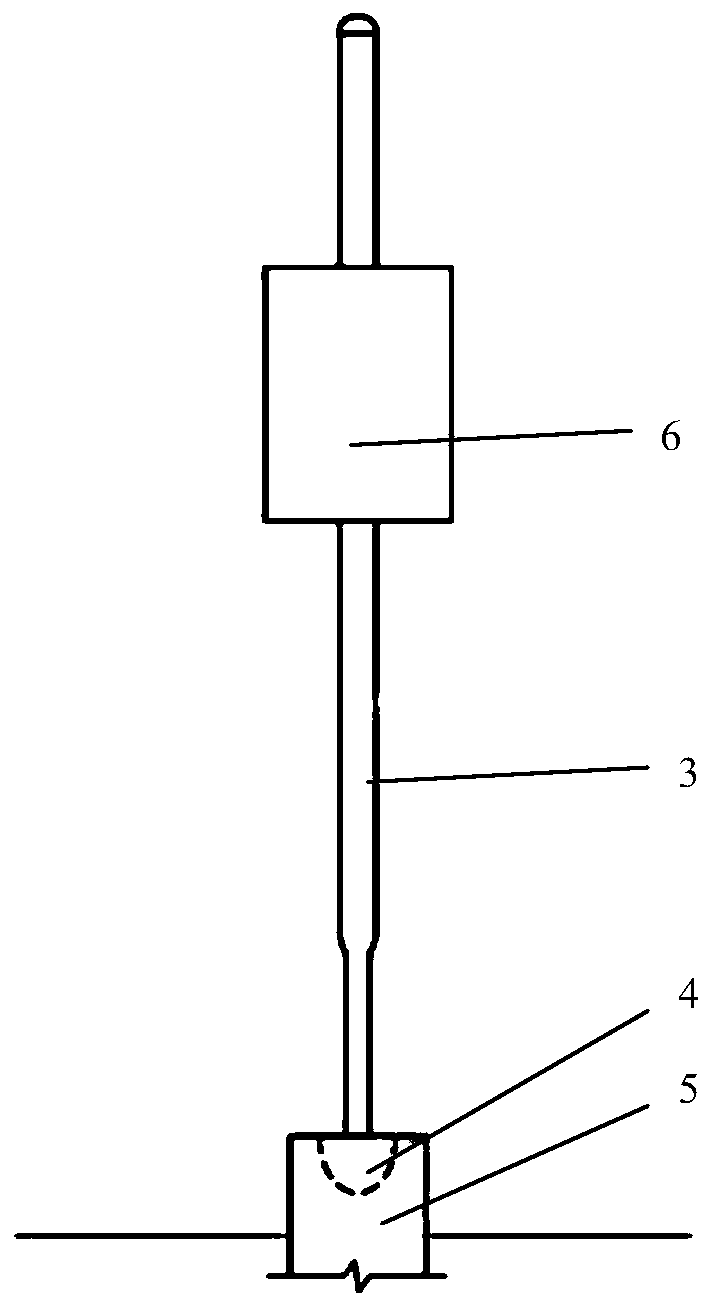

InactiveCN103711431ARealize stepless flexible controlTension real-time monitoringConstructionsRotary drillingFrequency changerTop drive

The invention discloses a variable-frequency electrically-driven top drive type core drill used for geological coring exploration. The drill comprises a platform and a vertical derrick arranged on the platform, wherein an electrically-driven winch and a salvage winch are arranged on the platform and are used for reeling and unreeling a rope, an electrically-driven turn plate is further arranged on the platform and located at the lower end of the derrick, a guide rail parallel to the derrick is arranged on the derrick and is connected with a top driver through a bracket pulley, the top driver is directly connected with a drill rod through a connecting shaft by means of a variable-frequency motor, a motor of the top driver, a motor of the electrically-driven winch, a motor of the salvage winch and a motor of the electrically-driven turn plate are driven by a frequency converter in an electric control room, the frequency converter controls the motors to work in the electric control room, the drill is further provided with an engineer room used for monitoring the work of the drill, and a rope tension and rope speed detection device is further arranged at the top end of the derrick. According to the variable-frequency electrically-driven top drive type core drill used for geological coring exploration, the drill is driven by an alternating-current variable-frequency motor to achieve rotating, rising, feeding, salvaging and the like, the long-stroke guide rail is provided, the rope speed and tension detection function is achieved, and high efficiency and low energy consumption drilling operation is achieved under the control of the frequency converter.

Owner:中核大地勘察设计有限公司 +2

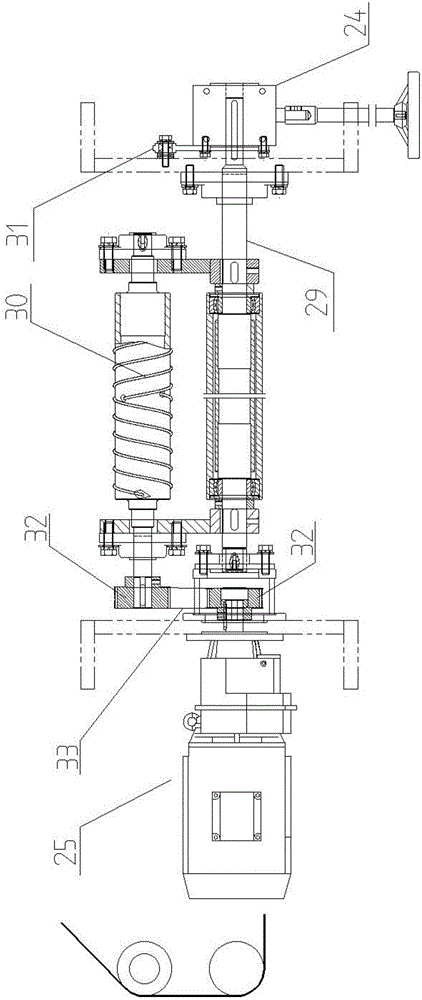

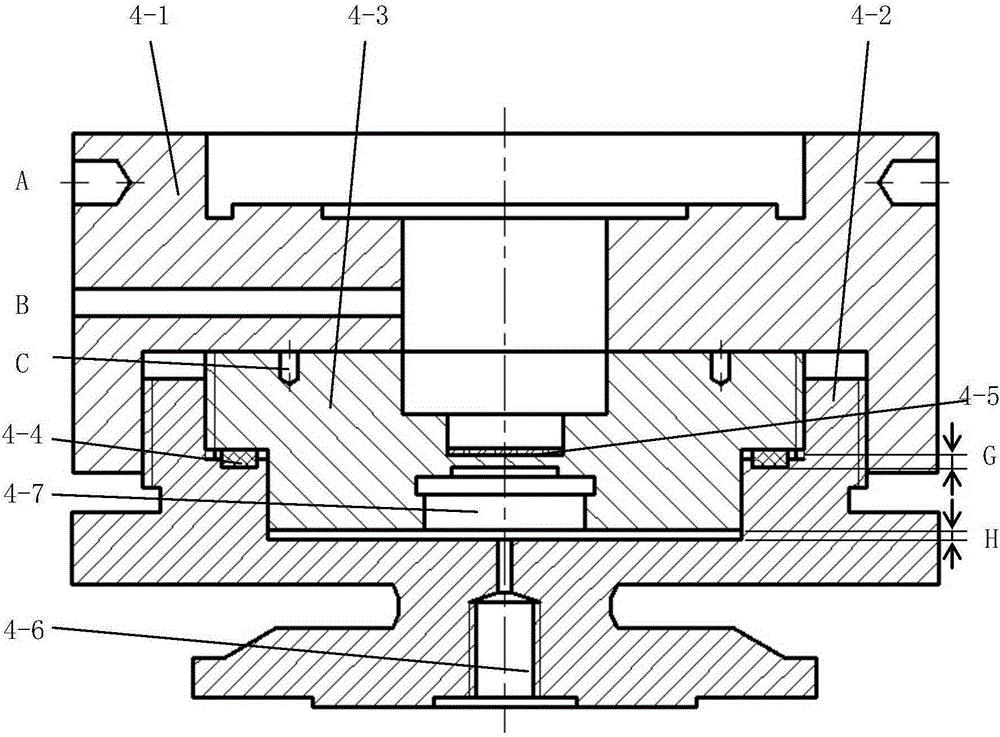

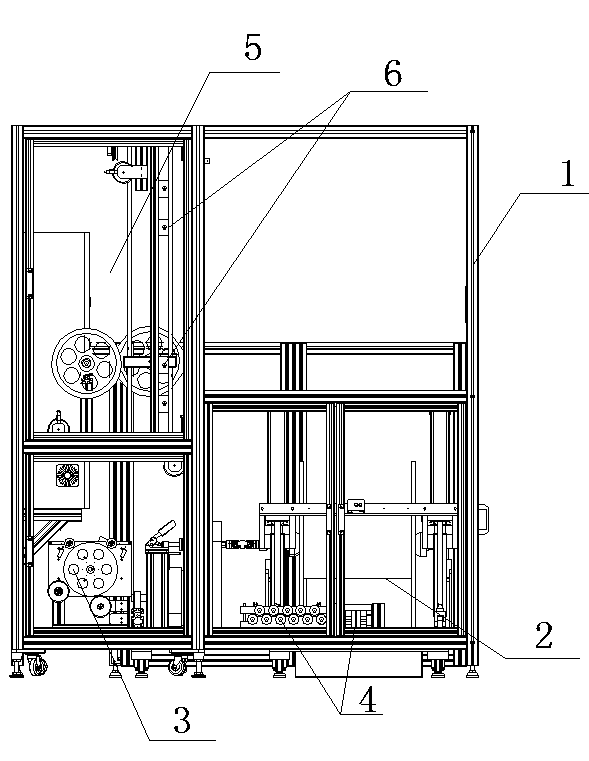

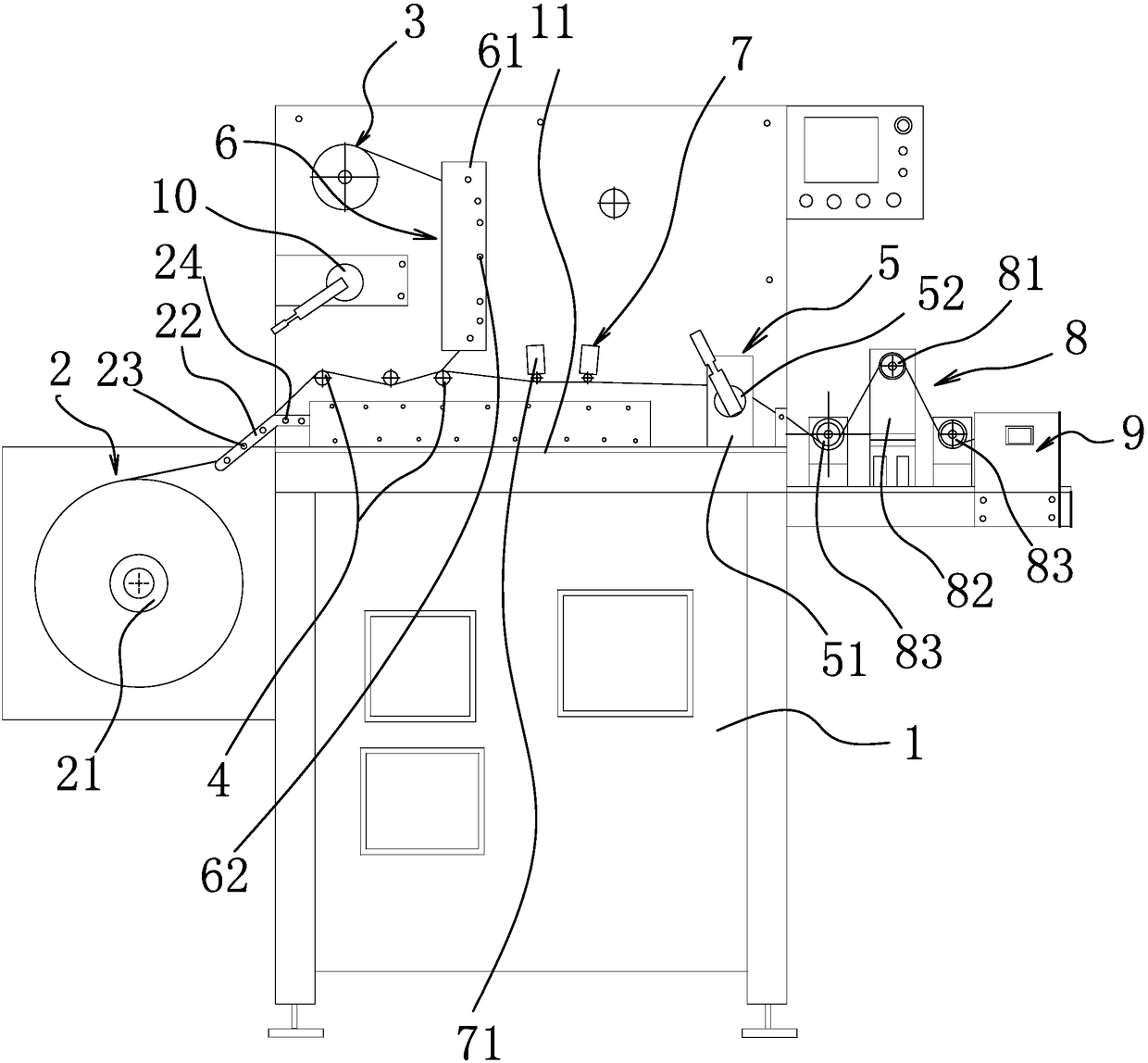

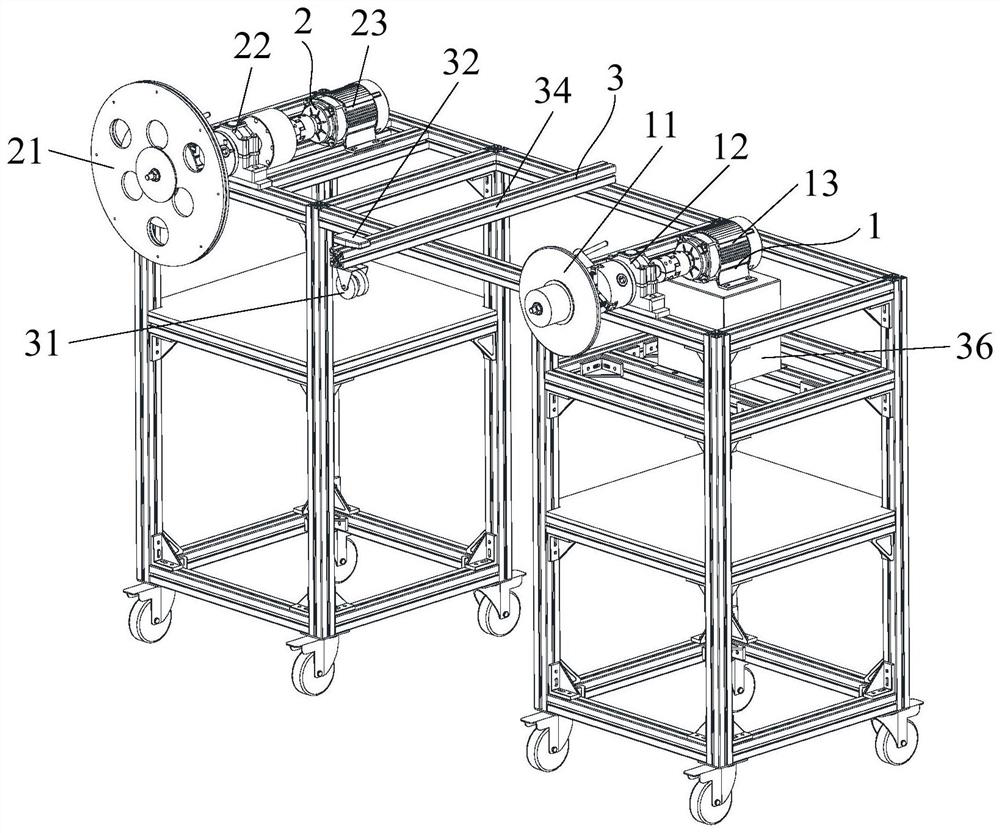

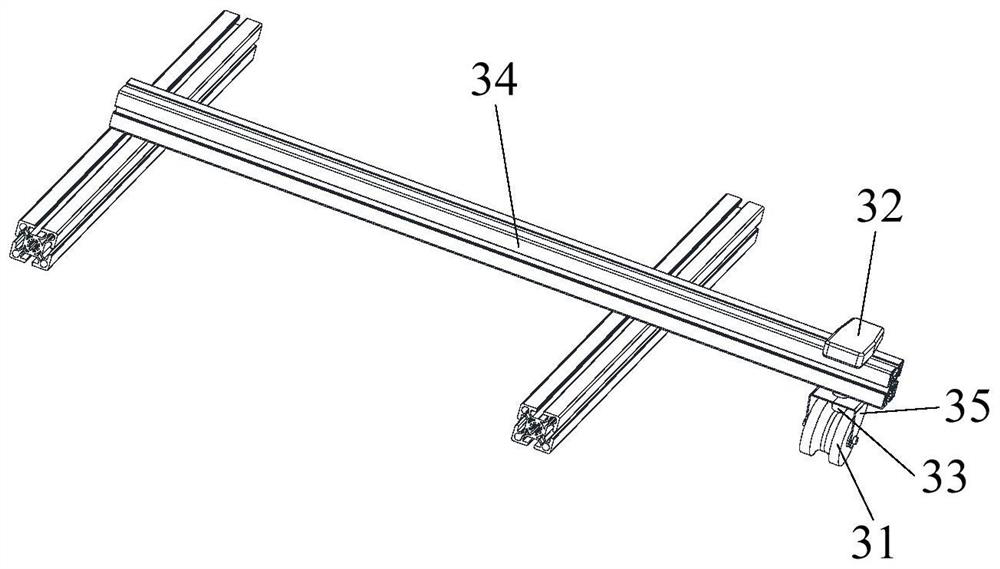

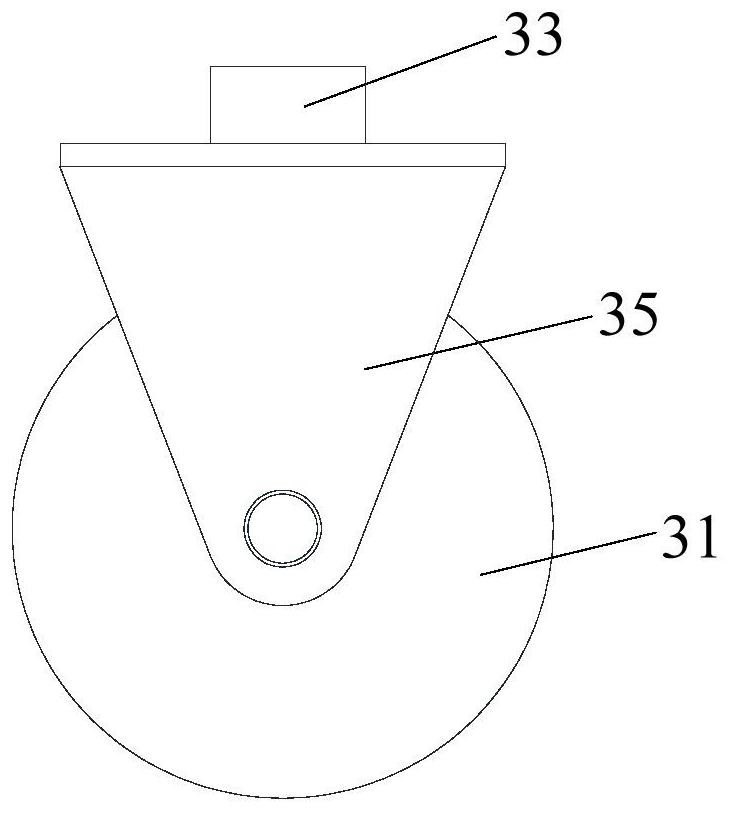

Tension control device for zero-degree belt layer winding process

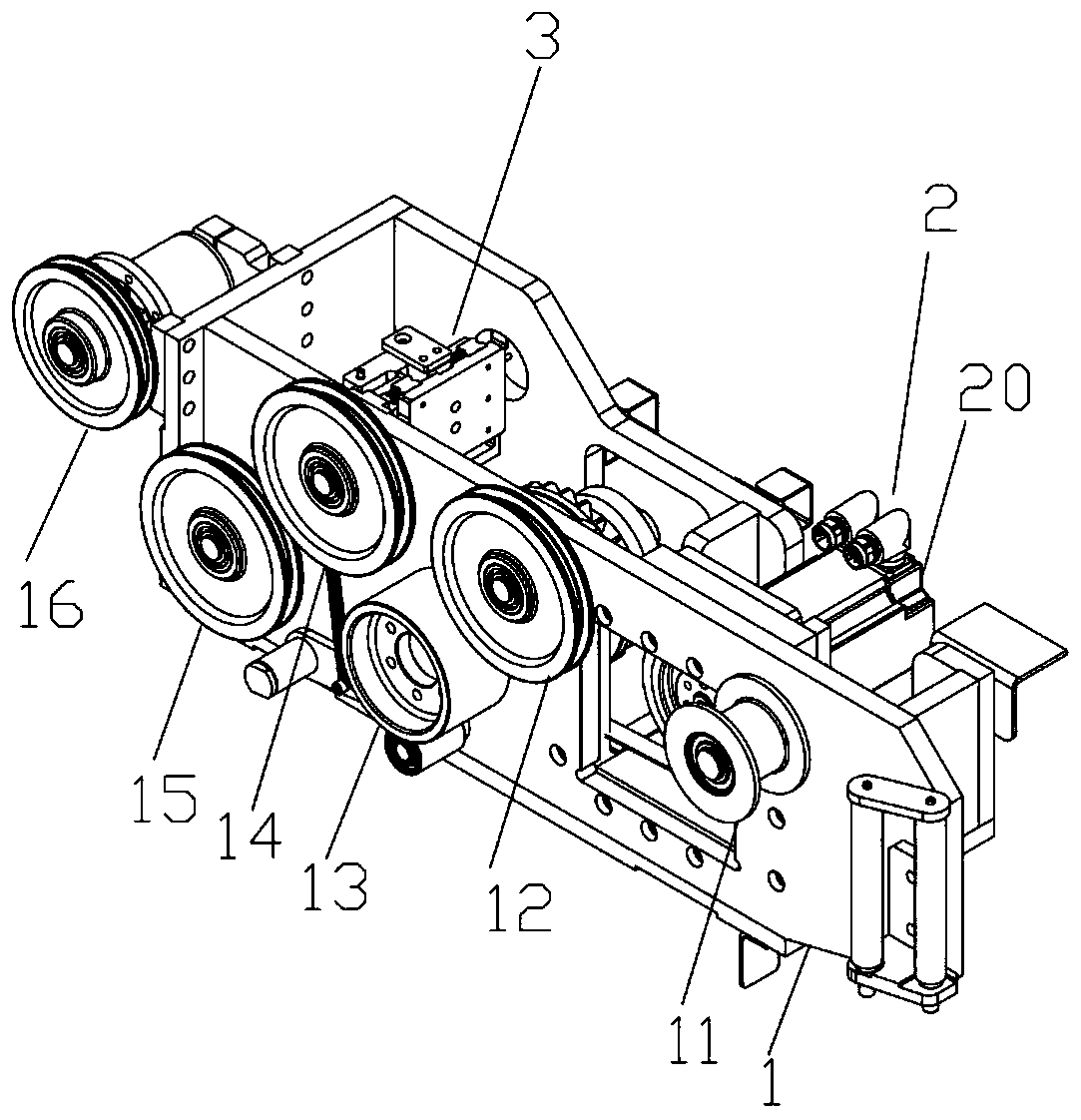

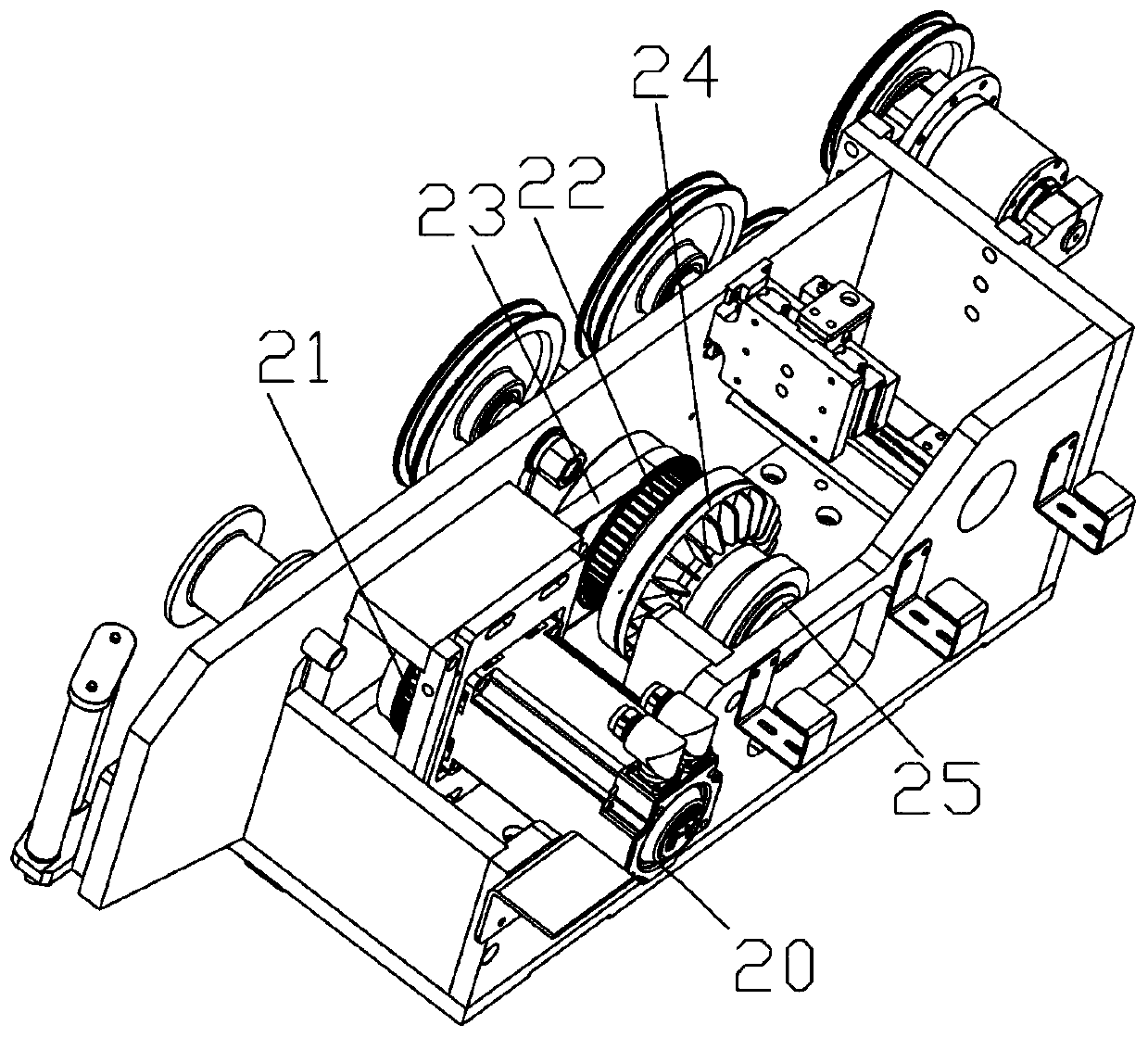

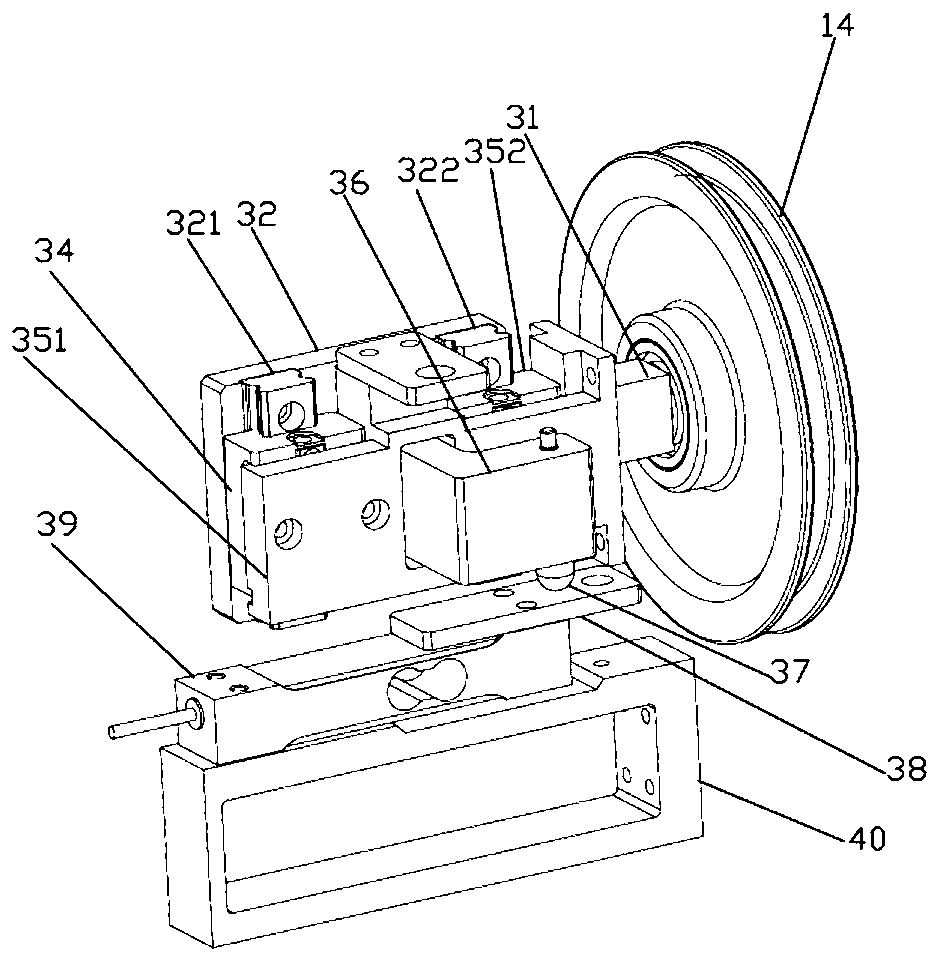

PendingCN109911678ATension real-time monitoringAvoid breakingWebs handlingRubber materialMotor drive

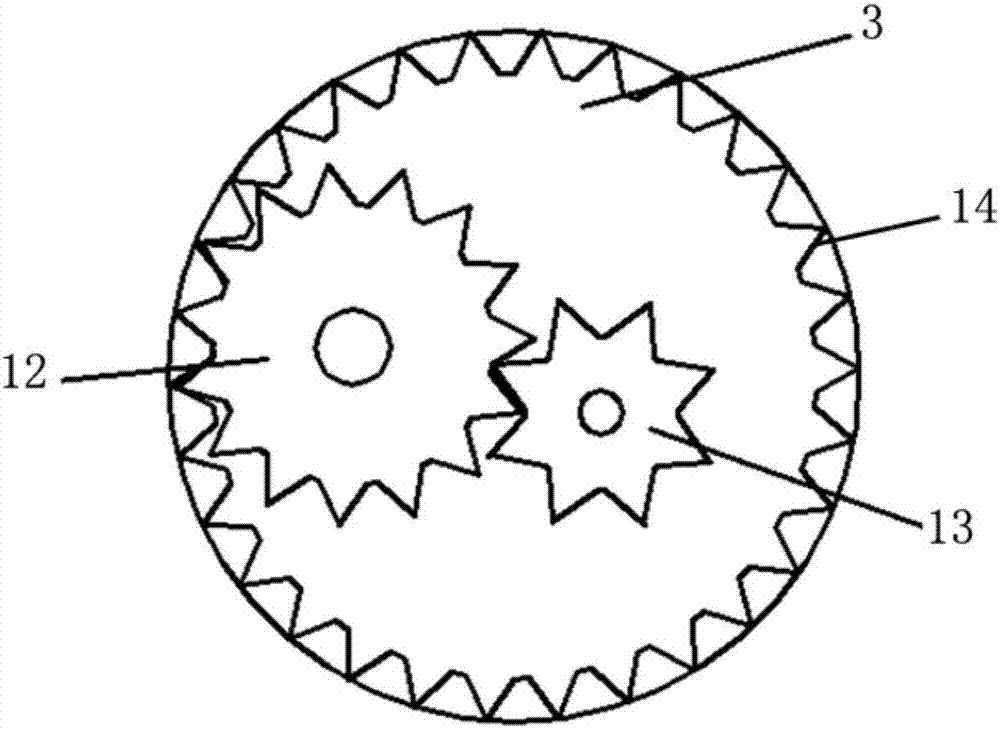

The invention provides a tension control device for a zero-degree belt layer winding process. The tension control device comprises a winding displacement assembly, a driving system and a tension detecting system. The winding displacement assembly comprises a winding displacement frame, and the winding displacement frame is sequentially provided with a guide wheel, a first transition wheel, a powerwheel, a tension wheel, a second transition wheel and a third transition wheel from a rubber material inlet. The first transition wheel, the tension wheel and the third transition wheel are distributed on the upper area of the front side of the winding displacement frame, and the power wheel and the second transition wheel are distributed on the lower area of the front side of the winding displacement frame. A rubber material passes through the lower side of the guide wheel, is wound around the first transition wheel, goes out from the lower side of the power wheel, then is wound around the upper side of the power wheel, passes out from the lower side of the second transition wheel, and finally passes out from the upper side of the third transition wheel and enters a winding head. The driving system comprises a servo motor and a transmission assembly, and the servo motor drives the power wheel to run through the transmission assembly. The tension detection system comprises a sensing assembly and a detecting assembly, and the sensing assembly is connected with the tension wheel so as to be stressed in the vertical direction. The detecting assembly comprises a base plate and a sensor, the upper surface of the base plate abuts against the sensing assembly, the sensor is fixed to the lower surface of the base plate, and the sensing assembly applies vertical stress to the sensor through the base plate.

Owner:HANGZHOU CHAOYANG RUBBER

Vertical single-/double-surface napping machine

ActiveCN106835588ATension real-time monitoringRealize automatic controlRougheningProgrammable logic controllerAgricultural engineering

The invention discloses a vertical single- / double-surface napping machine, which comprises a frame, wherein the frame is provided with a cloth feeding mechanism and a cloth discharging mechanism; front and rear napping mechanisms are arranged between the cloth feeding mechanism and the cloth discharging mechanism; each napping mechanism consists of six napping roller components. The single-surface or double-surface napping operation on a textile can be completed through adjusting a cloth threading route; traction roller components and tension roller components are arranged; adjustable single cloth spreading mechanisms and an integral rotary swing double cloth spreading mechanism are arranged, and the textile is sufficiently spread in an advancement process, and cannot crinkle; a PLC (Programmable Logic Controller) system is arranged, and the PCL system automatically regulates and controls the running speed of a raising machine according to a received feedback signal of a tension sensor; single-surface napping and double-surface napping functions are integrated by the vertical single- / double-surface napping machine; further, the vertical single- / double-surface napping machine has the advantages of being high in degree of automation, high in efficiency and good in napping effect.

Owner:JIANGSU YINGYOU TEXTILE MACHINERY

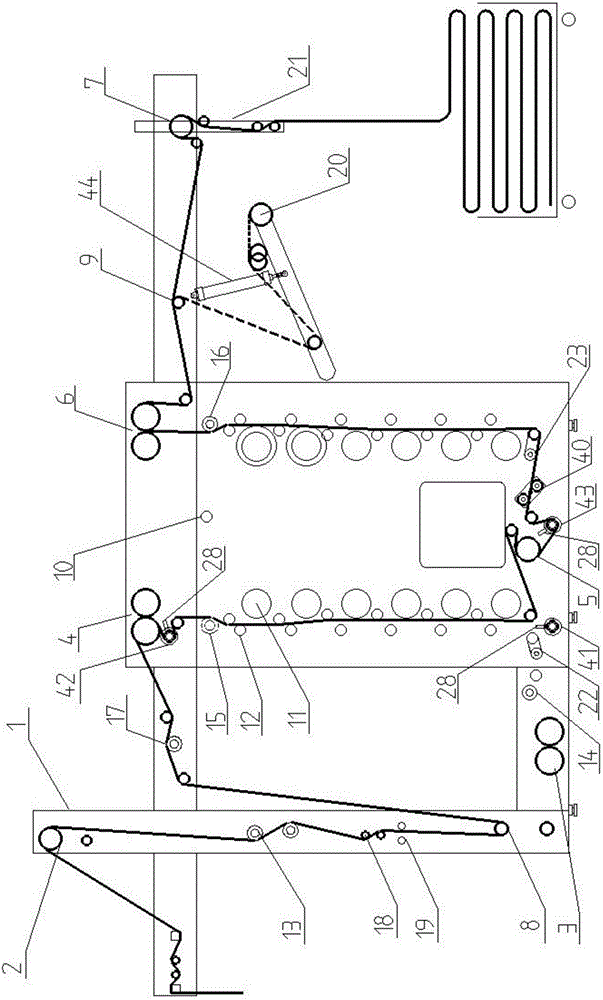

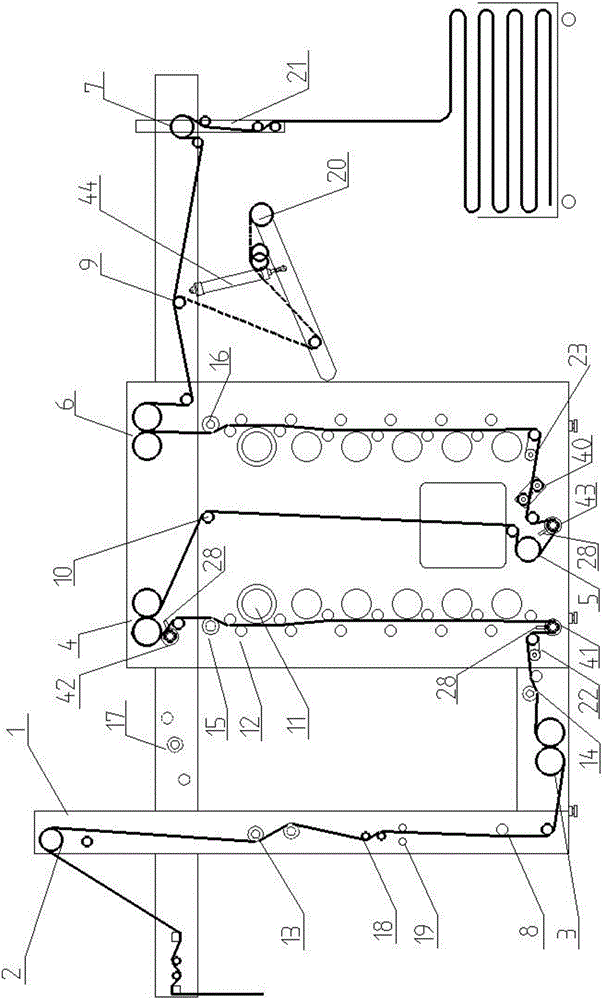

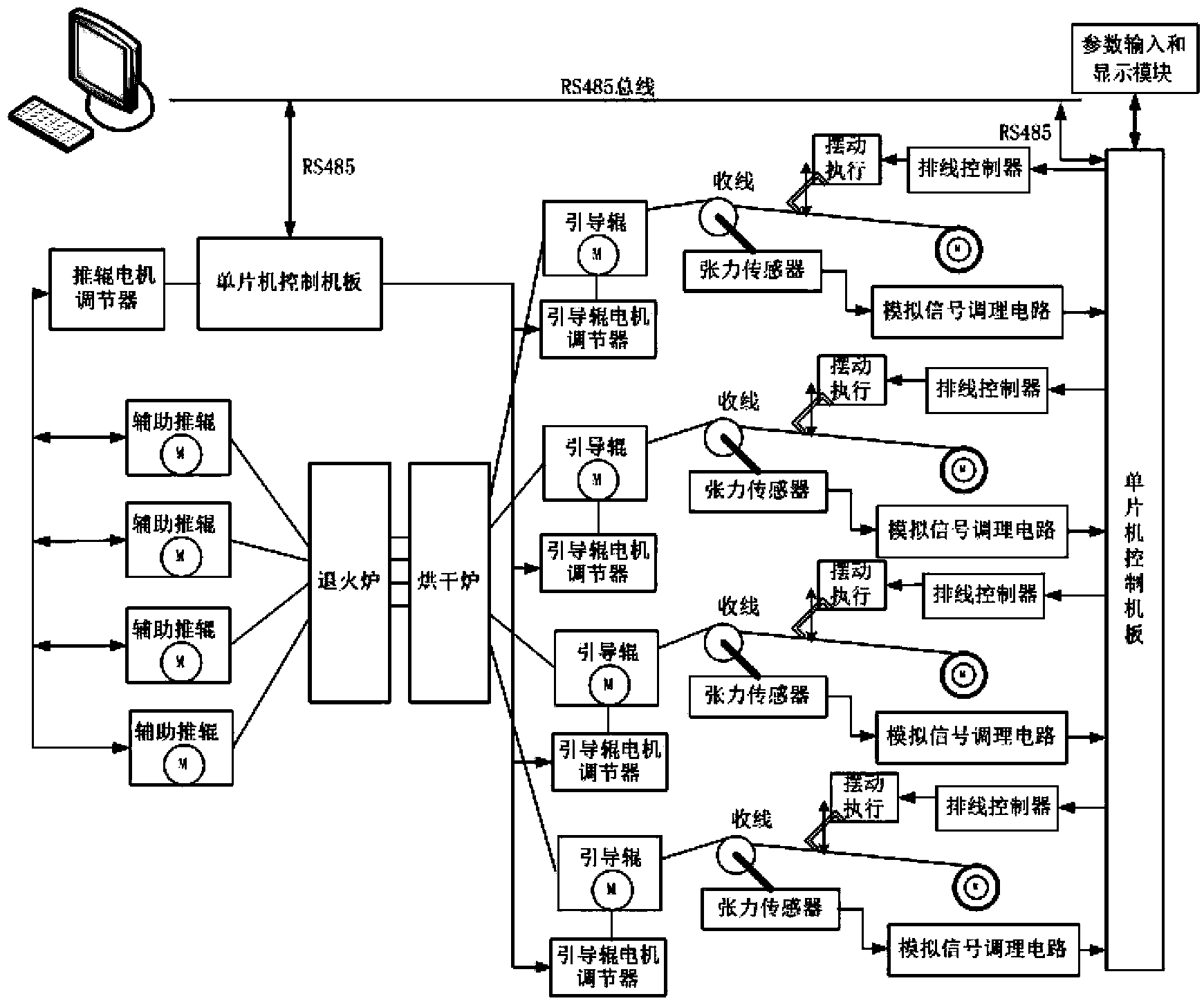

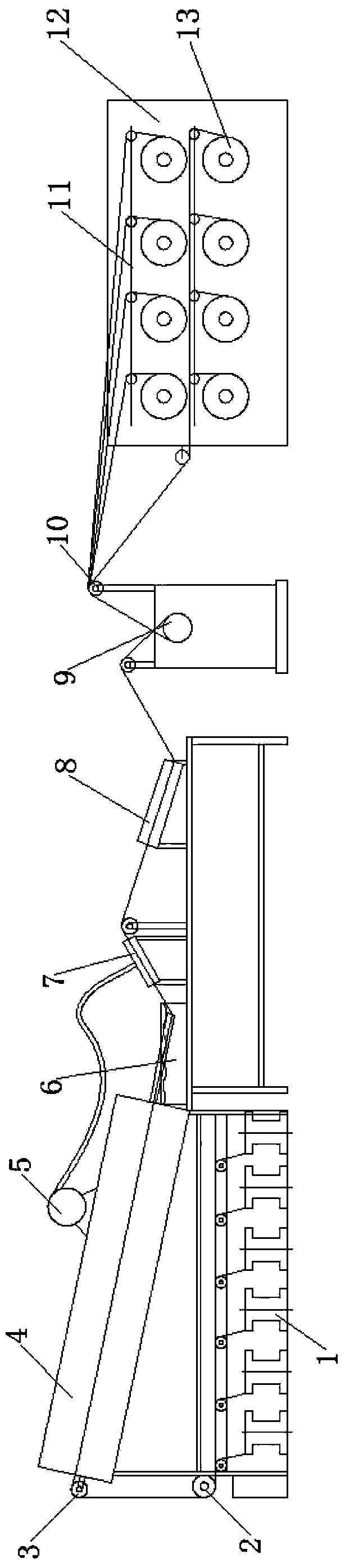

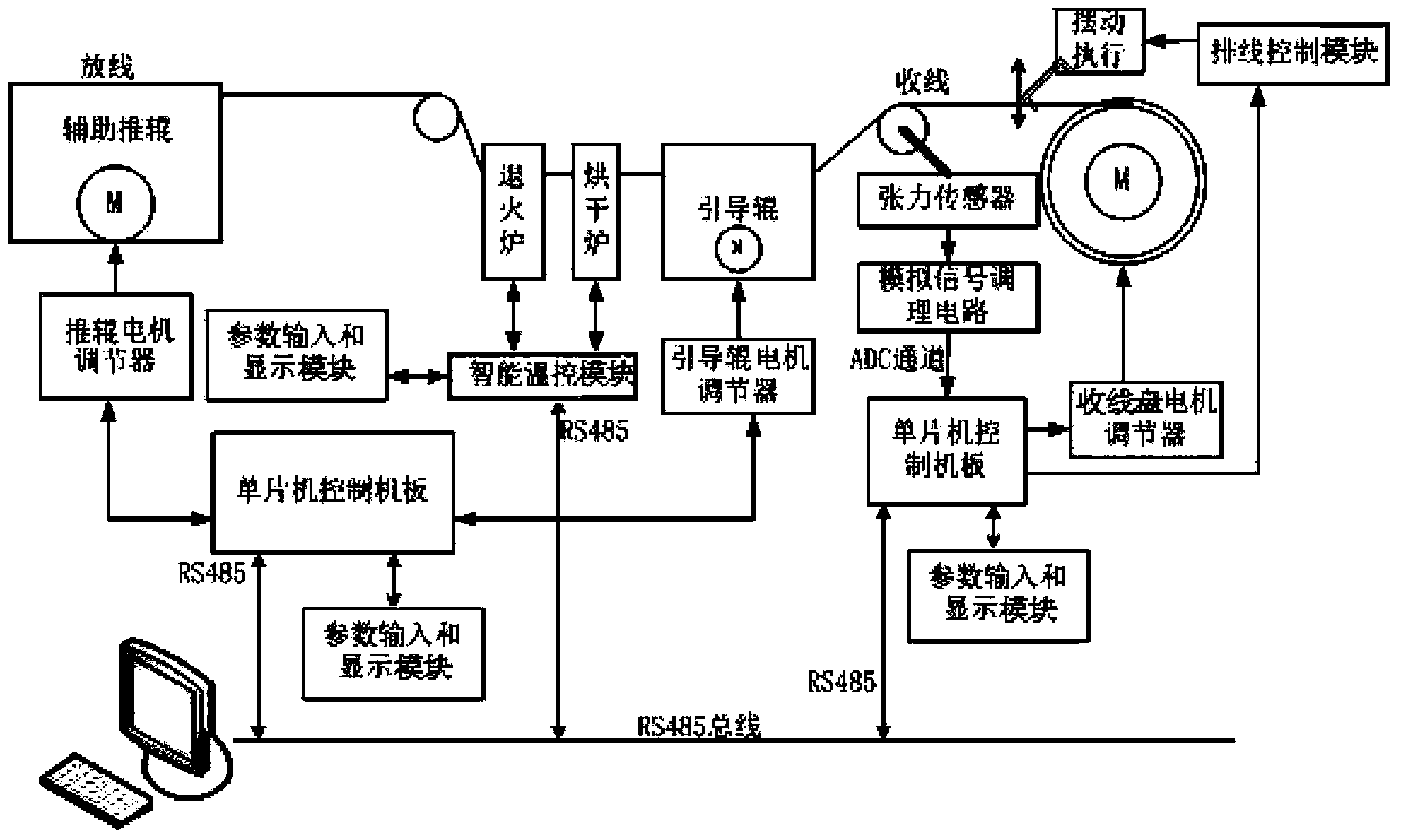

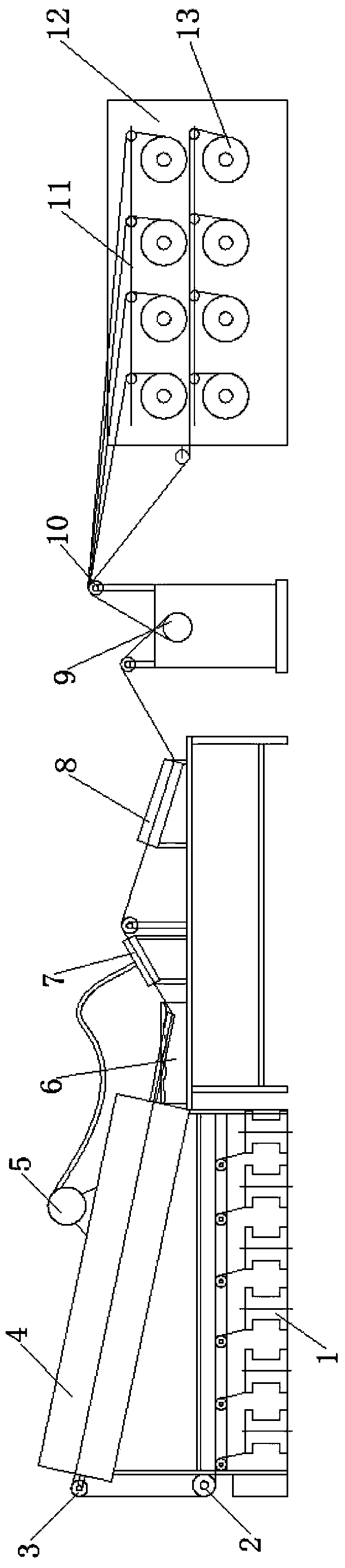

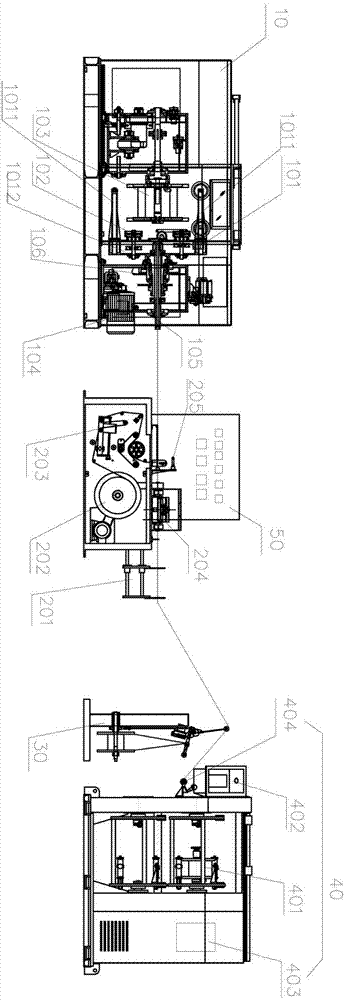

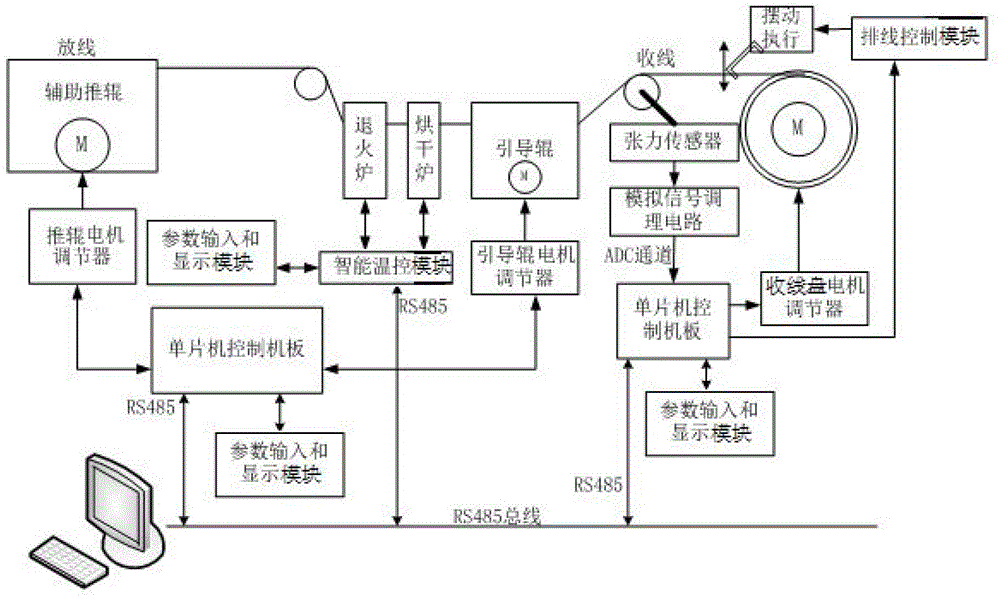

Intelligent control system and method of multi-specification tubular continuous annealing furnace

ActiveCN103436682AAvoid stretchingStable wire diameterFurnace typesHeat treatment process controlProduction lineContinuous annealing

The invention discloses an intelligent control system and an intelligent control method of a multi-specification tubular continuous annealing furnace, belonging to the technical field of intelligent control. Technical analysis and improvement are performed on the conventional continuous annealing furnace device; original single devices are rationally disassembled respectively; a plurality of groups of auxiliary push rollers, guide rollers, wire separation wheels and wire arrangement rods are additionally arranged on one set of equipment to form a continuous annealing production line capable of realizing simultaneous treatment and production of wires of multiple specifications; the annealing production line is intelligently controlled; temperature sensors are additionally arranged on the annealing furnace and a drying furnace to intelligently control the annealing and drying temperature. According to the system and the method, the annealing treatment on various wires of different specifications can be simultaneously completed on the same set of annealing equipment, and zero-tension annealing of the wires in the annealing furnace can be kept, so that the wires are prevented from being lengthened after being heated and softened, stable linear diameter is guaranteed, the equipment investment is reduced and the production cost is reduced; meanwhile, the automation degree is high, and remote monitoring and intelligent control can be realized.

Owner:江苏华旺新材料有限公司

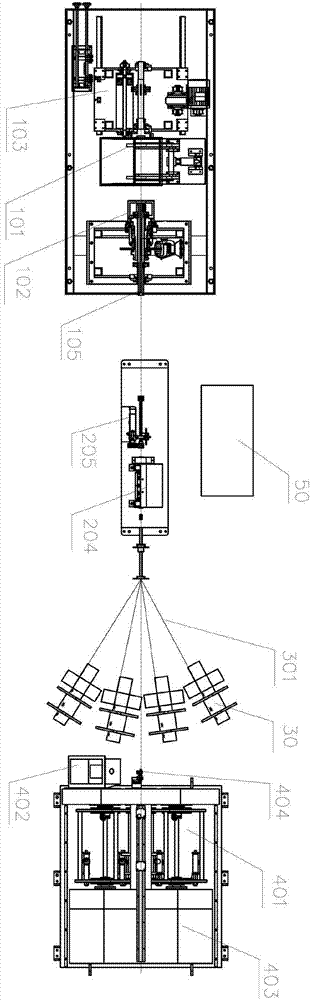

System and method for intelligently controlling tube continuous annealing furnaces

ActiveCN103436683AAvoid stretchingStable wire diameterFurnace typesHeat treatment process controlTemperature controlComputer module

The invention discloses a system and method for intelligently controlling tube continuous annealing furnaces, belonging to the technical field of intelligent control. The system disclosed by the invention is formed through carrying out a technical improvement on an existing annealing device, and respectively carries out intelligent control on an auxiliary push roller drive motor, a guide roller drive motor, a take-up reel drive motor and a winding displacement control module; a temperature sensor is respectively added on an annealing furnace and a drying furnace so as to intelligently control the annealing and drying temperatures; and the control processes are all implemented by parameter input, a display module or a computer, thereby achieving the purpose of remote monitoring and control. According to the invention, a situation that wires run in zero tension in the annealing furnace can be ensured, thereby avoiding that the wires are stretched after being softened by heating; the wires subjected to annealing can achieve an effect of constant-tension take-up, and the temperature control precision of the drying furnace and the annealing furnace is high, therefore, a situation that the wires running in the furnaces are always in an optimal recrystallization state is ensured, and the energy-saving effect is good; and the system and method disclosed by the invention are high in degree of automation, and realize remote monitoring and intelligent control.

Owner:江苏华旺新材料有限公司

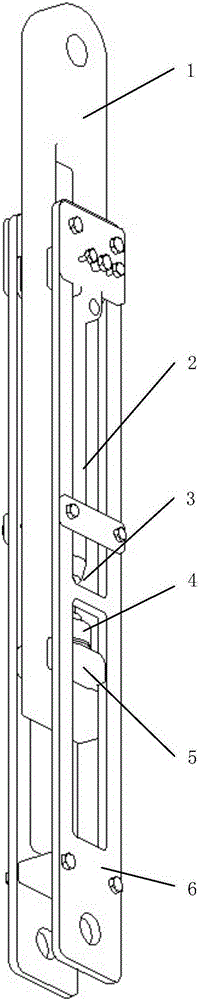

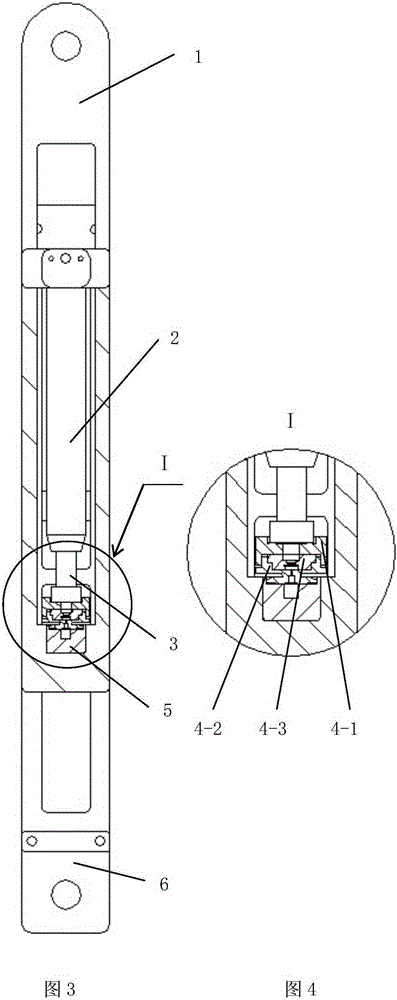

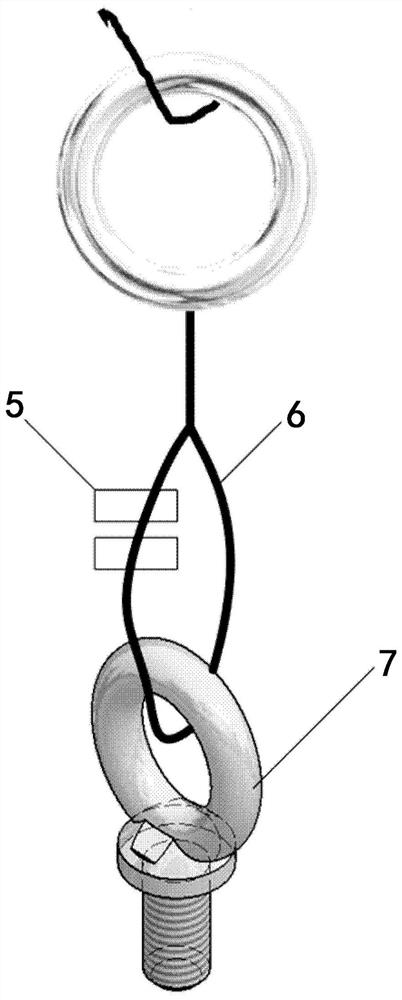

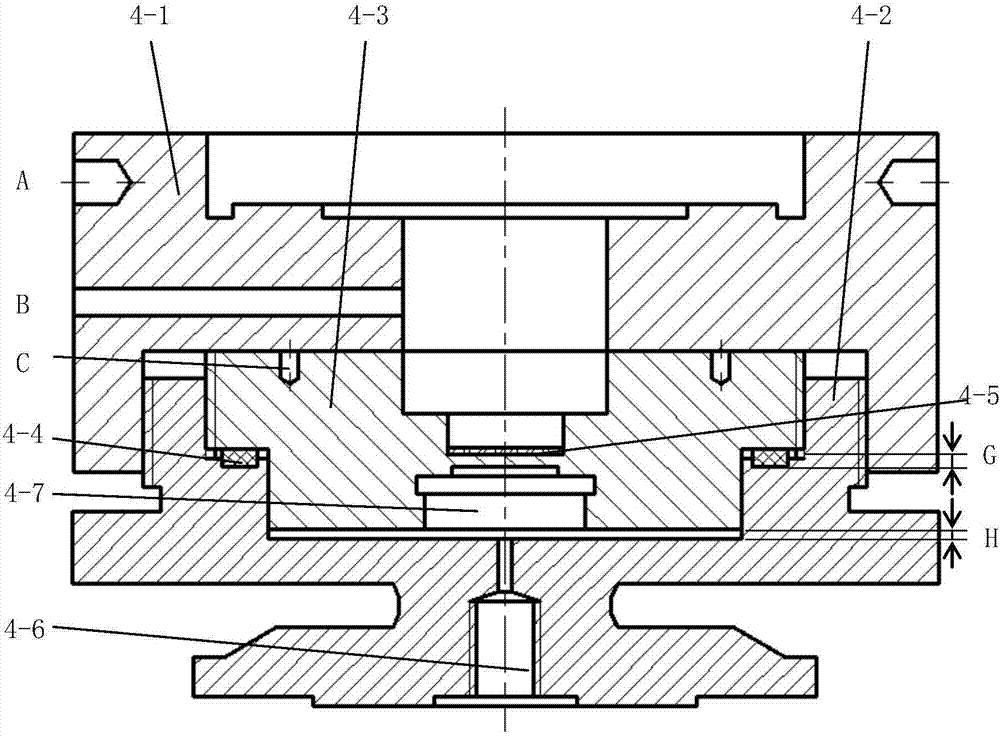

Tension monitoring sensor for eliminating vibration peak value of elevator steel wire ropes

ActiveCN105347132AReasonable structural designEliminate jitter flutterElevatorsPeak valueStrain gauge

The invention discloses a tension monitoring sensor for eliminating a vibration peak value of elevator steel wire ropes. The tension monitoring sensor comprises an upper cover which is in movable fit with a telescopic pole of a hydraulic oil cylinder, a disk body which is in movable fit with a slide block, an oil cavity cylinder which is packaged by the upper cover and the disk body, wherein the upper cover is in threaded connection with the disk body and covers the disk body; the oil cavity cylinder is in threaded connection in the disk body; and a ring of copper rings used for sealing oil is arranged between the disk body and the oil cavity cylinder. The sensor is mounted between the slide block of a balancing and suspending device of a friction type elevator oil cylinder and the telescopic pole of the hydraulic cylinder; under the action of the tension of the steel wire ropes, the part, pasted with a strain gage, of the sensor generates elastic deformation to measure tension of each steel wire rope; and sum of tension of all steel wire ropes is total load hoisted by the elevator. The sensor is reasonable in structural design; influence of kick of stress caused by shaking, vibrating and the like of the steel wire ropes in an elevator working process can be eliminated, and tension of the steel wire ropes can be stably and accurately monitored in real time.

Owner:CHINA UNIV OF MINING & TECH +1

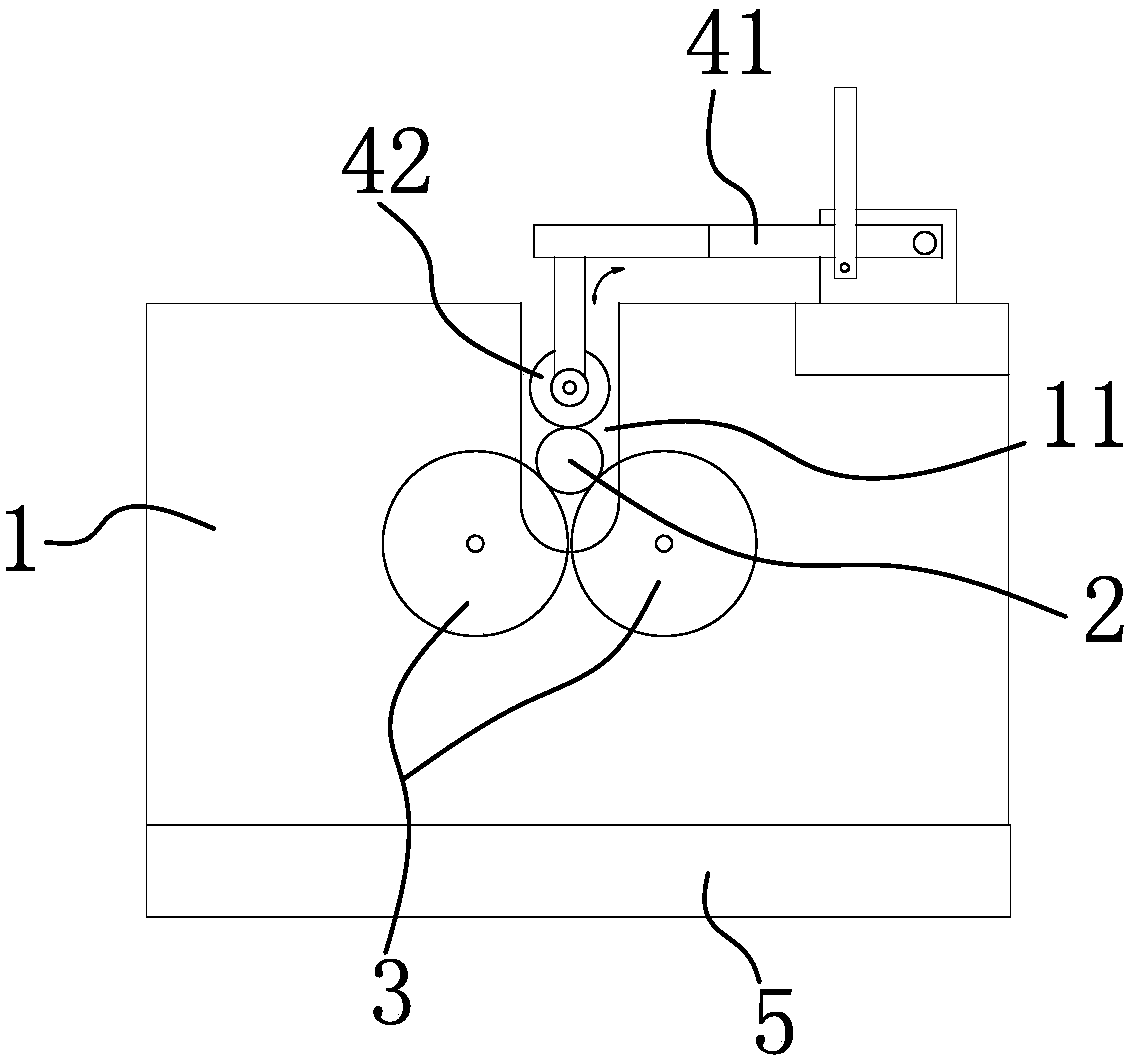

Paying-off machine

InactiveCN103426563AGuaranteed normal operationAvoid damageCable/conductor manufactureEngineeringMechanical engineering

The invention discloses a paying-off machine which comprises a machine frame, a wire coil located on the machine frame, a traction mechanism driving the wire coil to be paid off and a guide mechanism guiding the output of a wiring harness. The traction mechanism comprises a traction wheel and a driving mechanism driving the traction wheel to operate. The paying-off machine further comprises a feedback mechanism used for detecting the tension of the wiring harness and outputting and feeding back a signal. The feedback mechanism comprises a tension sensor arranged at one side of the traction wheel. The tradition mode that the wire coil is driven to be paid off is changed to the mode that paying-off is achieved through the traction of the traction mechanism, the traction wheel is driven to operate through the driving mechanism so that paying-off conducted at an even speed can be achieved. Meanwhile, the tension sensor is arranged, so that the tension of the wiring harness on the portion of the traction wheel is monitored in real time, the signal is fed back in time, the phenomenon that the wiring harnesses are stacked due to over paying-off or the machine is blocked due to insufficient paying-off is avoided, the normal operation of the paying-off machine is guaranteed, the work efficiency is improved, damage to the paying-off machine is reduced, and repair and use cost is reduced.

Owner:苏州启成精密工业有限公司

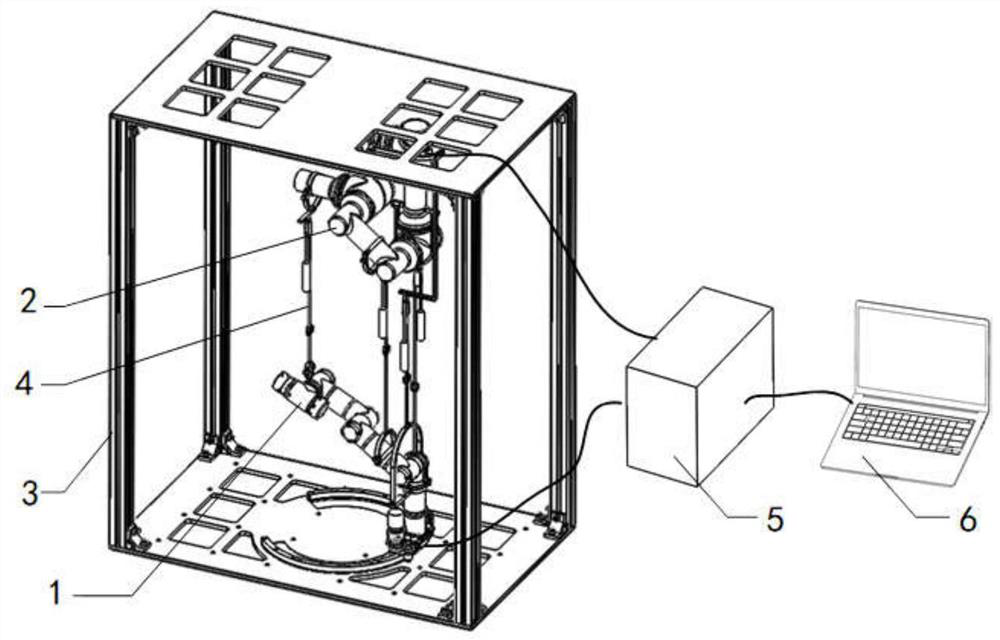

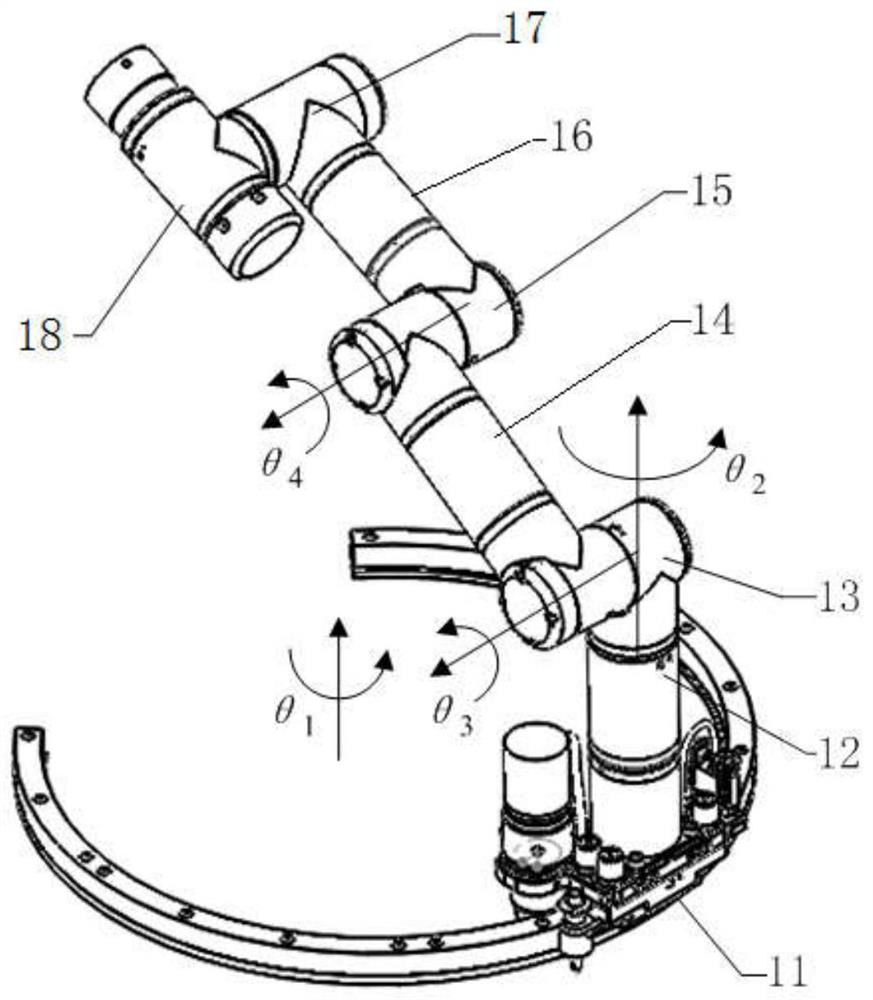

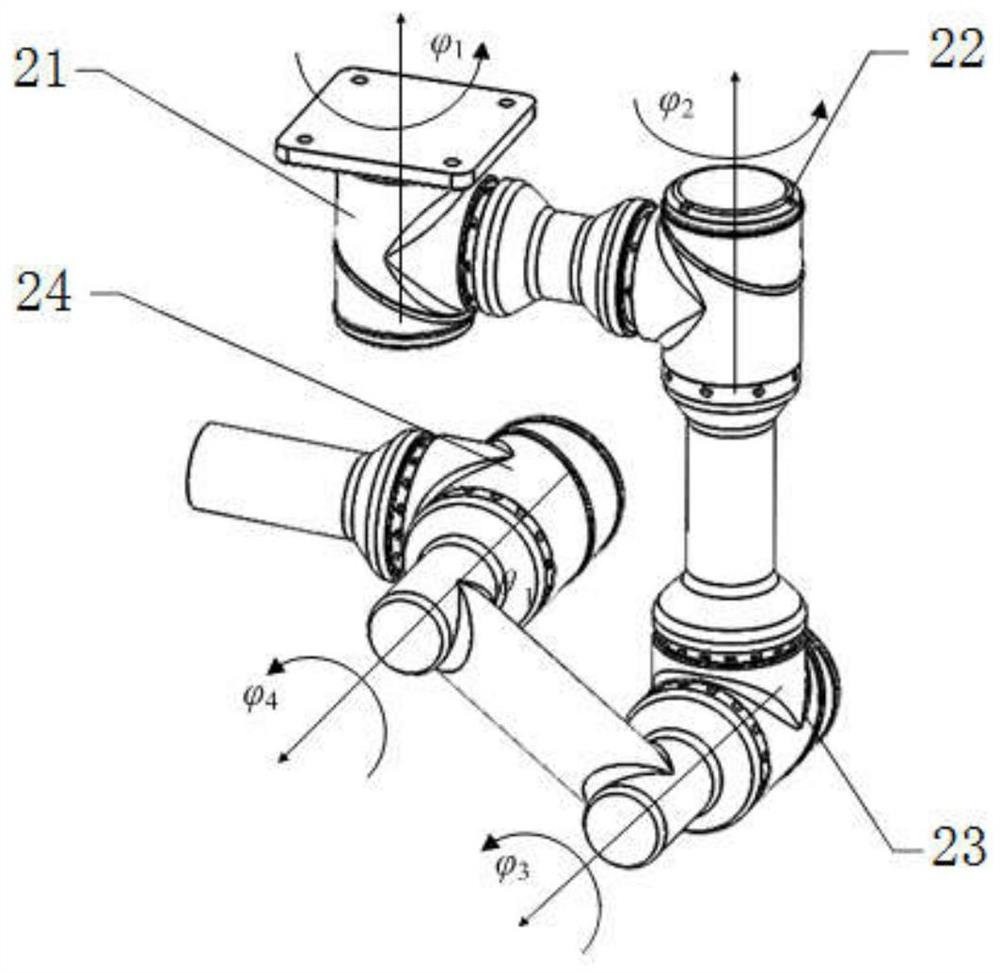

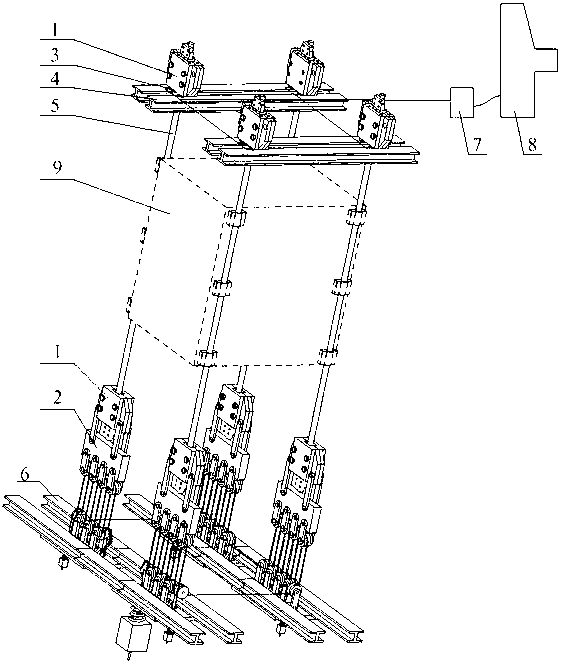

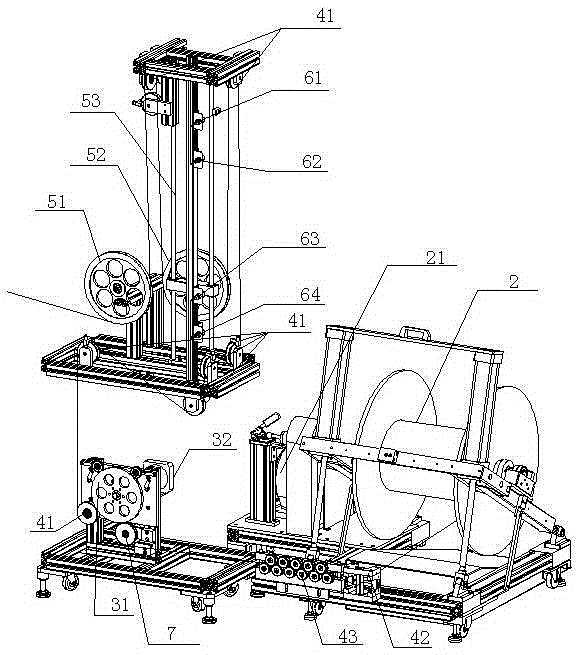

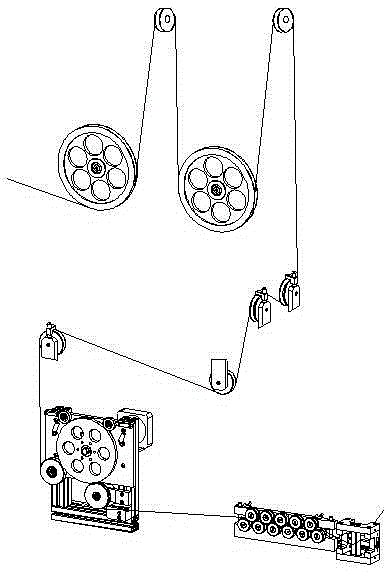

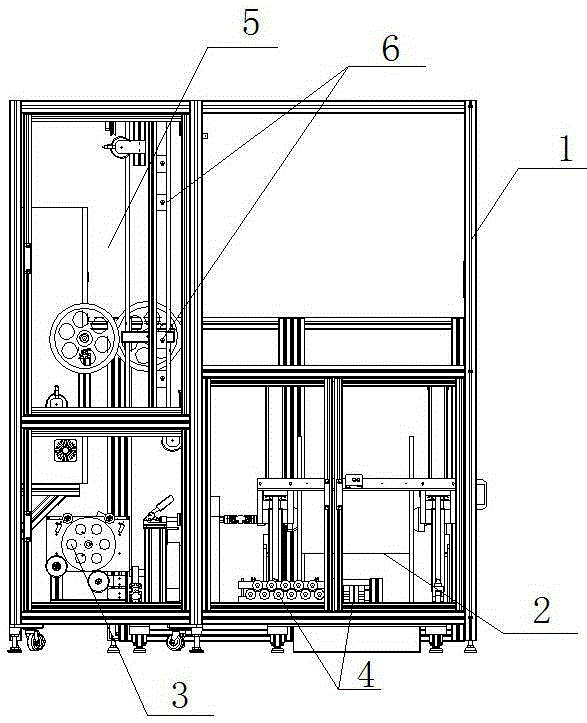

Three-dimensional motion gravity compensation system for space manipulator

PendingCN113071721AAchieve gravity compensationVersatileCosmonautic condition simulationsSynchronous controlGround testing

The invention relates to the technical field of aerospace engineering ground test equipment, in particular to a three-dimensional motion gravity compensation system for a space manipulator. The system comprises a compensated mechanical arm, a follow-up mechanism, a support and a hanging spring suspension system, the compensated mechanical arm is arranged at the bottom of the support, and the follow-up mechanism is arranged at the top of the support and connected with the compensated mechanical arm through the hanging spring suspension system; the compensated mechanical arm and the follow-up mechanism are the same in structure, and three-dimensional motion gravity compensation of the compensated mechanical arm is achieved by synchronously controlling motion of the compensated mechanical arm and the follow-up mechanism. Multi-axis and three-dimensional motion gravity compensation is carried out on the compensated mechanical arm, and the purpose of simulating the space microgravity working state on the ground is achieved.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

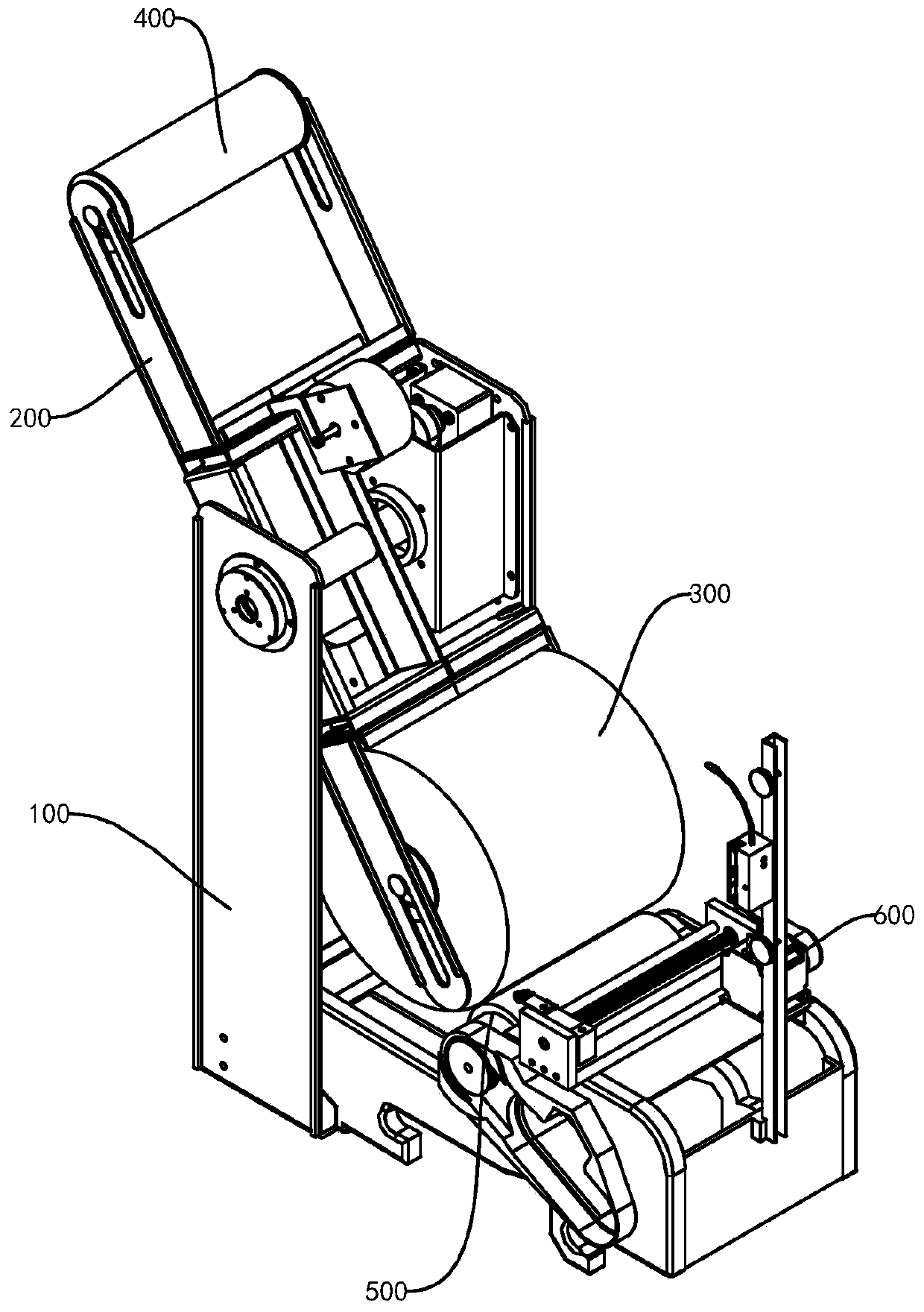

Automatic laminating labeling machine

PendingCN108216819AAchieve separationIncrease productivityLabelling machinesWebs handlingTension control

The invention belongs to the technical field of labeling, and particularly relates to an automatic laminating labeling machine. The problem that design is unreasonable in the prior art is solved. Theautomatic laminating labeling machine comprises a rack with a conveying table, a feeding mechanism is arranged at the feeding end of the conveying table, and a label unrolling device located above thefeeding mechanism is further arranged on the conveying table. A plurality of guide rolls arranged in a scattered manner in the length direction of the conveying table are arranged on the conveying table, and a rolling device is arranged at the discharging end of the conveying table. A label locating mechanism located above any guide roll is arranged on the conveying table. A label detecting device located in front of the rolling device is arranged on the conveying table, and a control mechanism and a rolling mechanism which are located behind the rolling device and arranged in sequence are further arranged on the conveying table. The automatic laminating labeling machine has the beneficial effects of being capable of being suitable for labeling at different intervals and improving labeling efficiency.

Owner:QIANDA NEW MATERIAL CO LTD

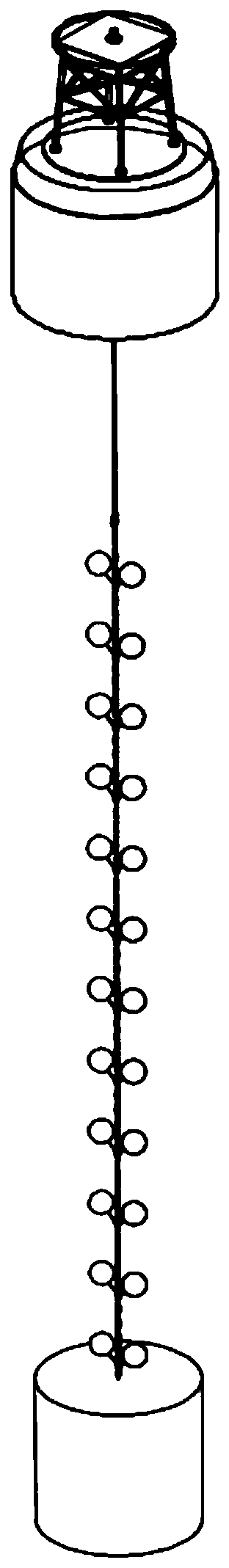

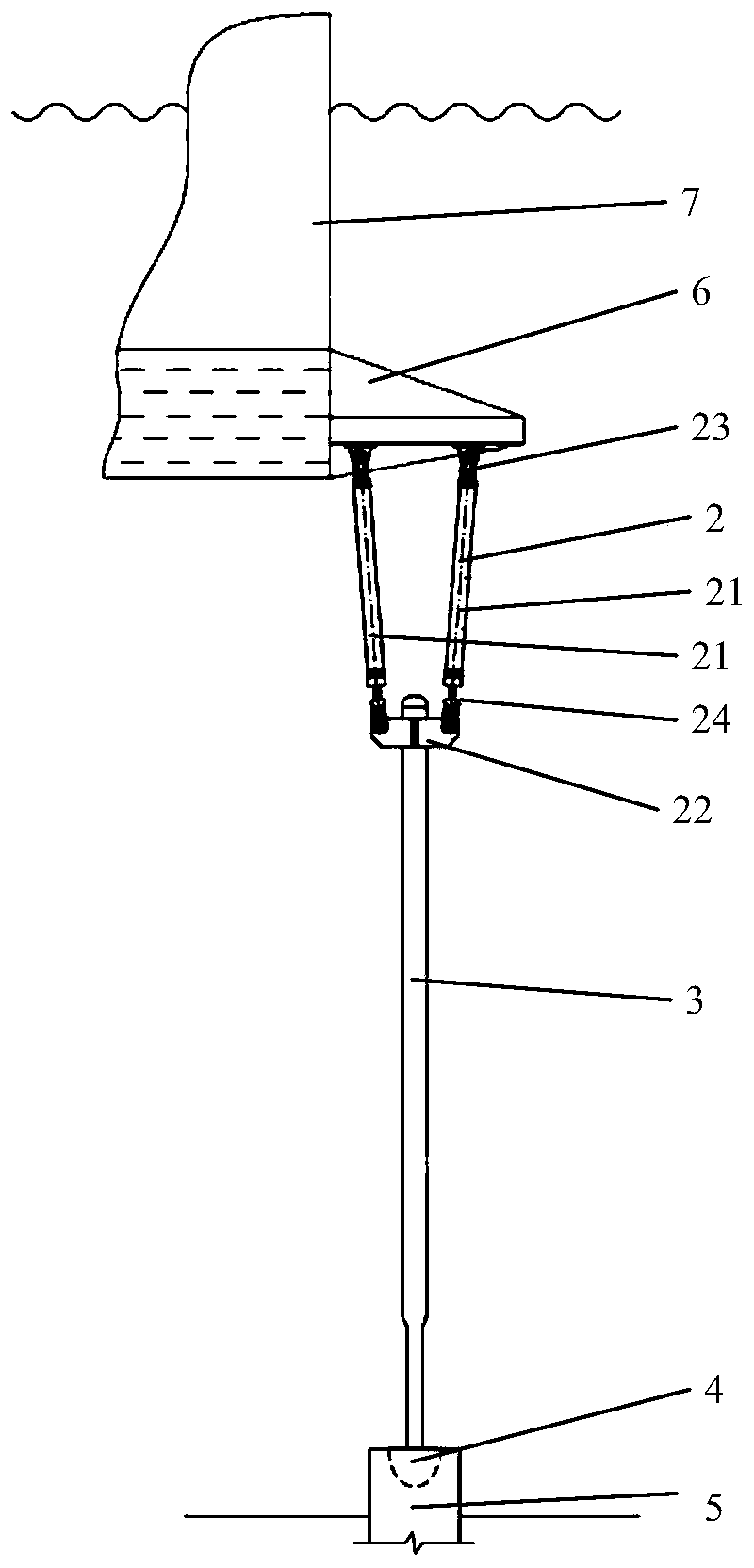

Accurate positioning buoy device for suspension anchor cable based on constant tension control

PendingCN110203334APrecise positioningOptimize the length ratioWaterborne vesselsBuoysBuoyEngineering

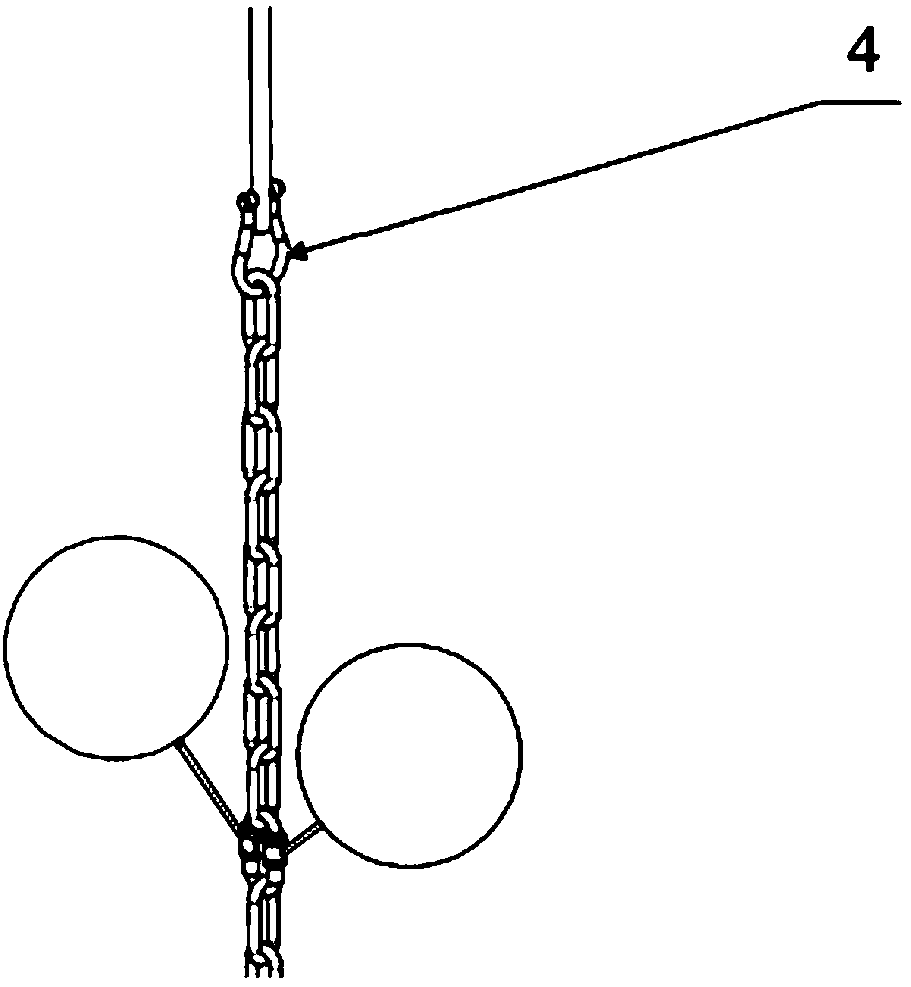

The invention discloses an accurate positioning buoy device for a suspension anchor cable based on constant tension control. The device comprises an anchorage, an anchor chain, a plurality of buoyancyballs, a buoy and a buoy lamp bracket; one end of the anchor chain is located in the middle of the upper end of the anchorage, the plurality of buoyancy balls are distributed along the anchor chain,and the buoy lamp frame is positioned at the upper end of the buoy; a winding drum and a driving device used for driving the winding drum to rotate are arranged at the upper end of the inner cavity ofthe buoy, a cable is wound on the winding drum, the free end of the cable penetrates out of a cable guide hole in the inner cavity of the buoy and is connected with the other end of the anchor chain;and a tension sensor used for detecting tension of the cable is further arranged at the upper end of the inner cavity of the buoy. According to the accurate positioning buoy device, the anchor chainis perpendicular to the horizontal plane through the arrangement of the buoyancy balls, the buoy can be kept at the working position all the time, and the positioning is accurate; through the arrangement of the tension sensor and the positioning device, when the buoy is deviated, the buoy can return to in-situ; the length ratio of the anchor chain and the cable is optimized, so that the required power of the winding drum for driving the reeling and unreeling cable is the minimum.

Owner:DALIAN MARITIME UNIVERSITY +1

Novel automatic winding machine device

InactiveCN107585615ADoes not move radiallyAppropriate tensionWebs handlingWinding machinePressure sensor

The invention discloses a novel automatic winding machine device in the field of textile machinery. The novel automatic winding machine device comprises a winding device axially arranged on a windingmachine frame, and further comprises side plates longitudinally installed on a first bearing and a second bearing, a driving device speed reduction motor. The winding device comprises a first wheel, asecond wheel and a heating roller which are transversely arranged. The first wheel is fixed to the side plates through bayonets. A group of symmetrical pressure sensors are arranged outside the two sides of the first wheel. The second wheel is movably arranged on the side plates in a penetrating mode, and a group of symmetrical pressure sensors are arranged at the two ends of the second wheel. The heating roller is of a hollow structure. A temperature sensor for collecting temperature in real time and transmitting data is placed in the heating roller. The novel automatic winding machine device has the advantages that the heating roller can automatically heat cloth to make the cloth smooth, and the cloth has certain tension and is more closely wound through the two wheels.

Owner:YIZHENG NO 3 TEXTILE MACHINERY FACTORY

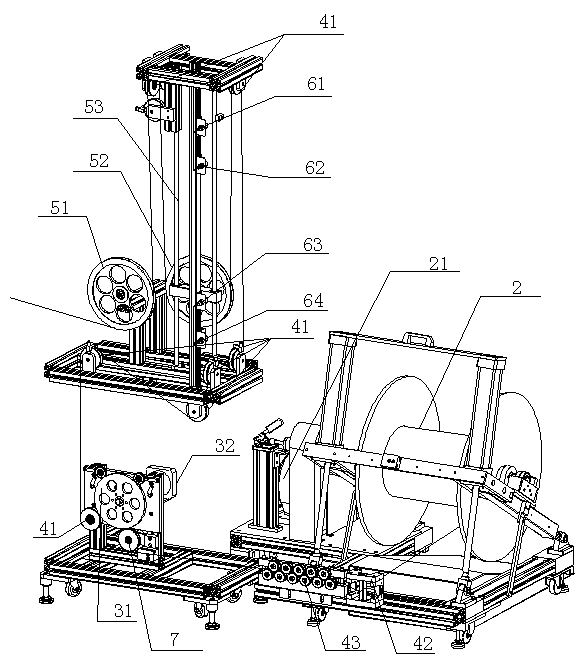

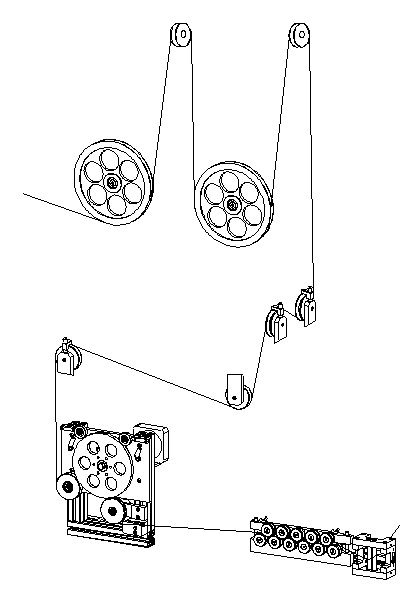

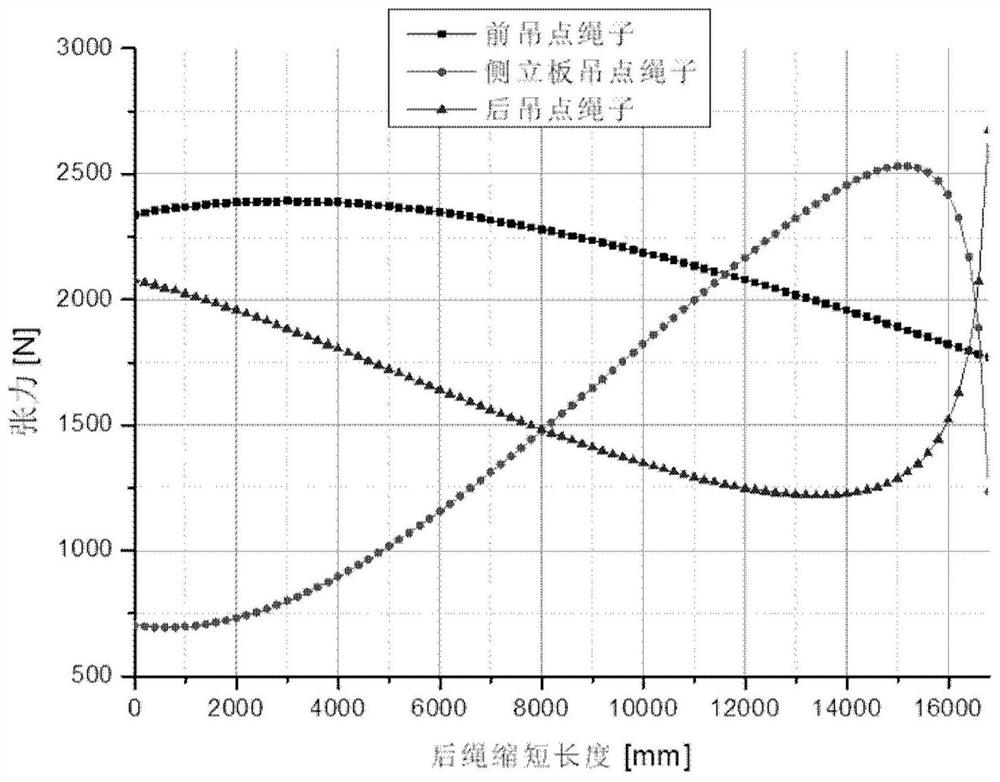

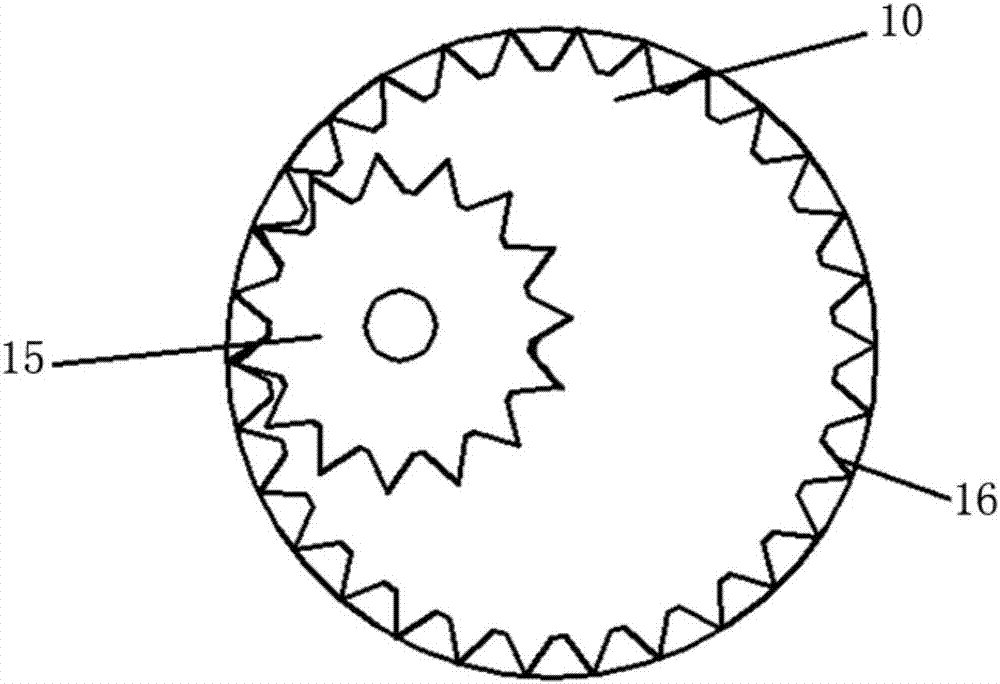

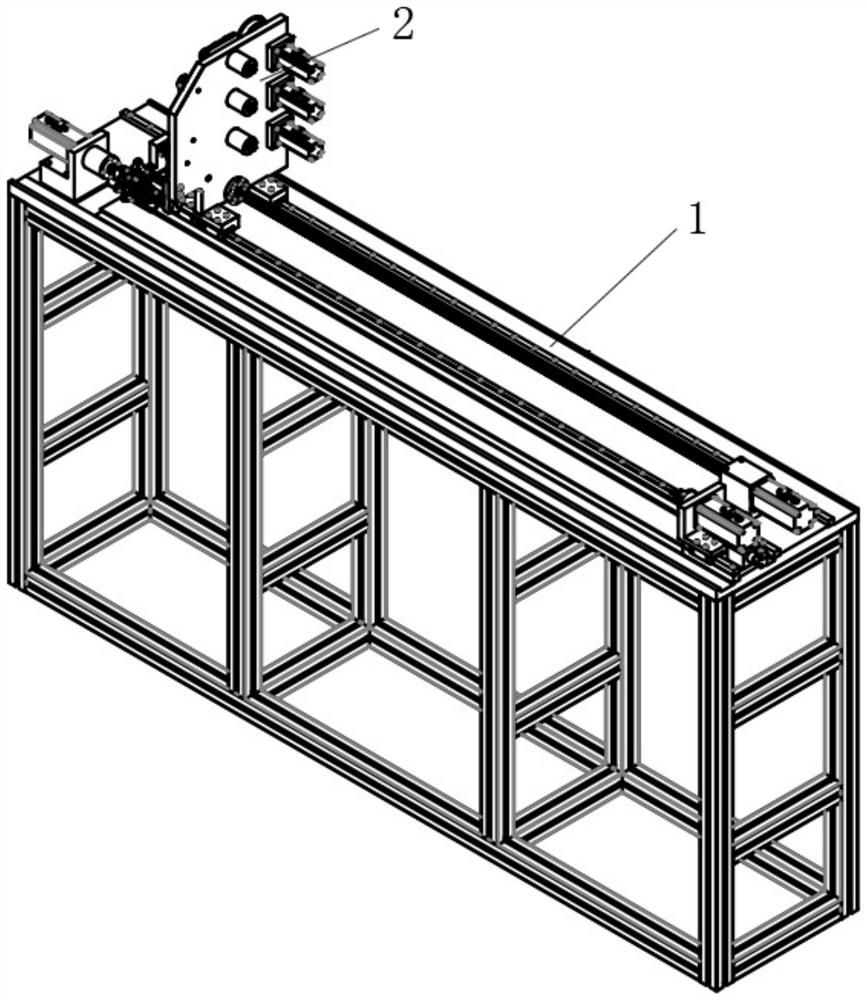

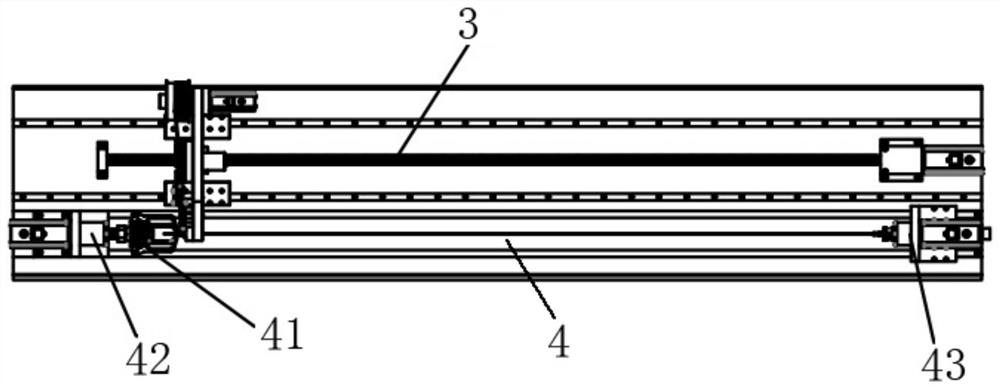

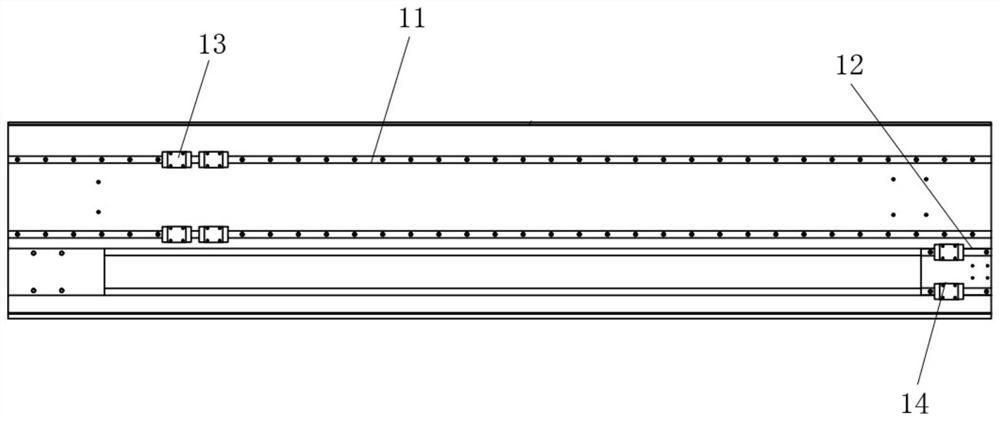

Hoisting flight attitude adjustment throwing device for aircraft

PendingCN112249359AImprove flight performanceSave some toolingLaunching/towing gearFlight vehicleClassical mechanics

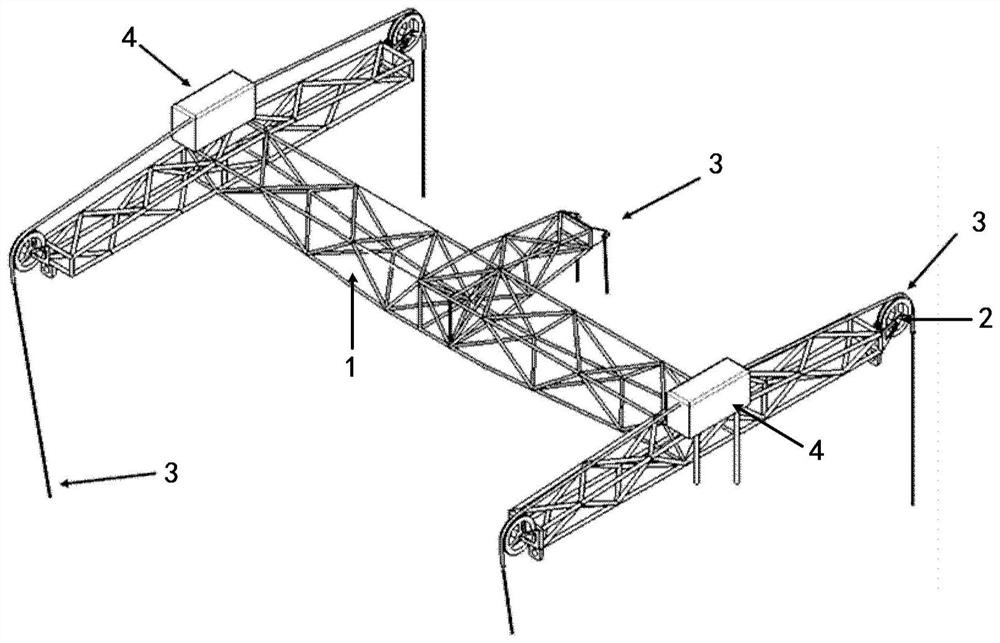

A hoisting flight posture adjusting throwing device for an aircraft comprises a hoisting frame (1), wherein a plurality of pulley blocks (2) are arranged on the hoisting frame in a distributed mode, ahoisting rope system (3) being arranged on each pulley block, and the hoisting rope systems (3) being connected to different positions of the aircraft; a posture adjusting driving device (4) connected with one end of each lifting rope system (3) and used for winding and unwinding the lifting rope system (3); and a throwing separation device used for cutting off the connection between the liftingrope systems (3) and the aircraft. The device can support zero consumption of energy in the lift-off stage of aircrafts of different size levels, meanwhile, posture adjustment in the lift-off processof the aircrafts can be achieved, the flight performance is improved, separation safety and reliability can be guaranteed, and risks caused by structural damage and failure due to clamping stagnationand other problems are avoided.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

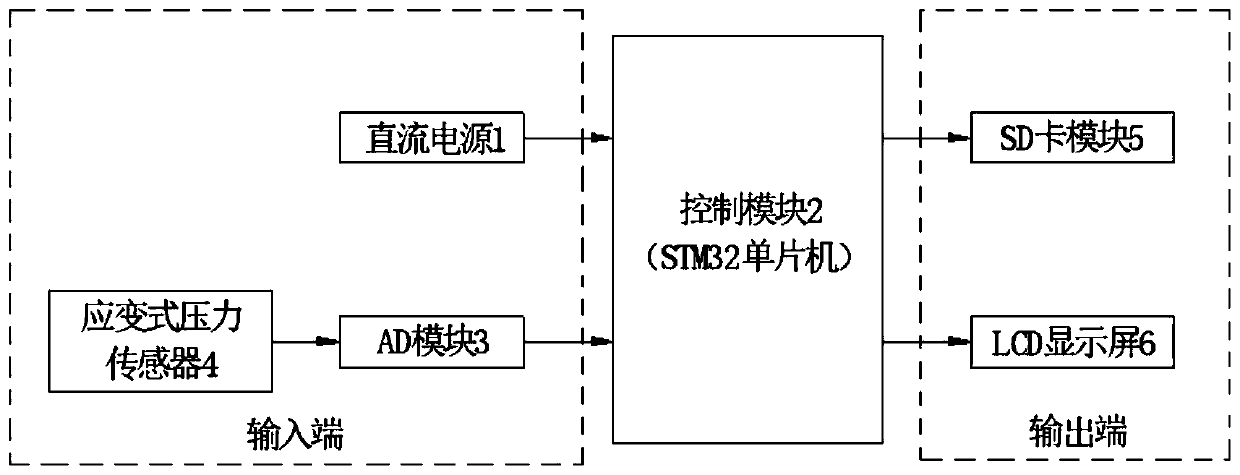

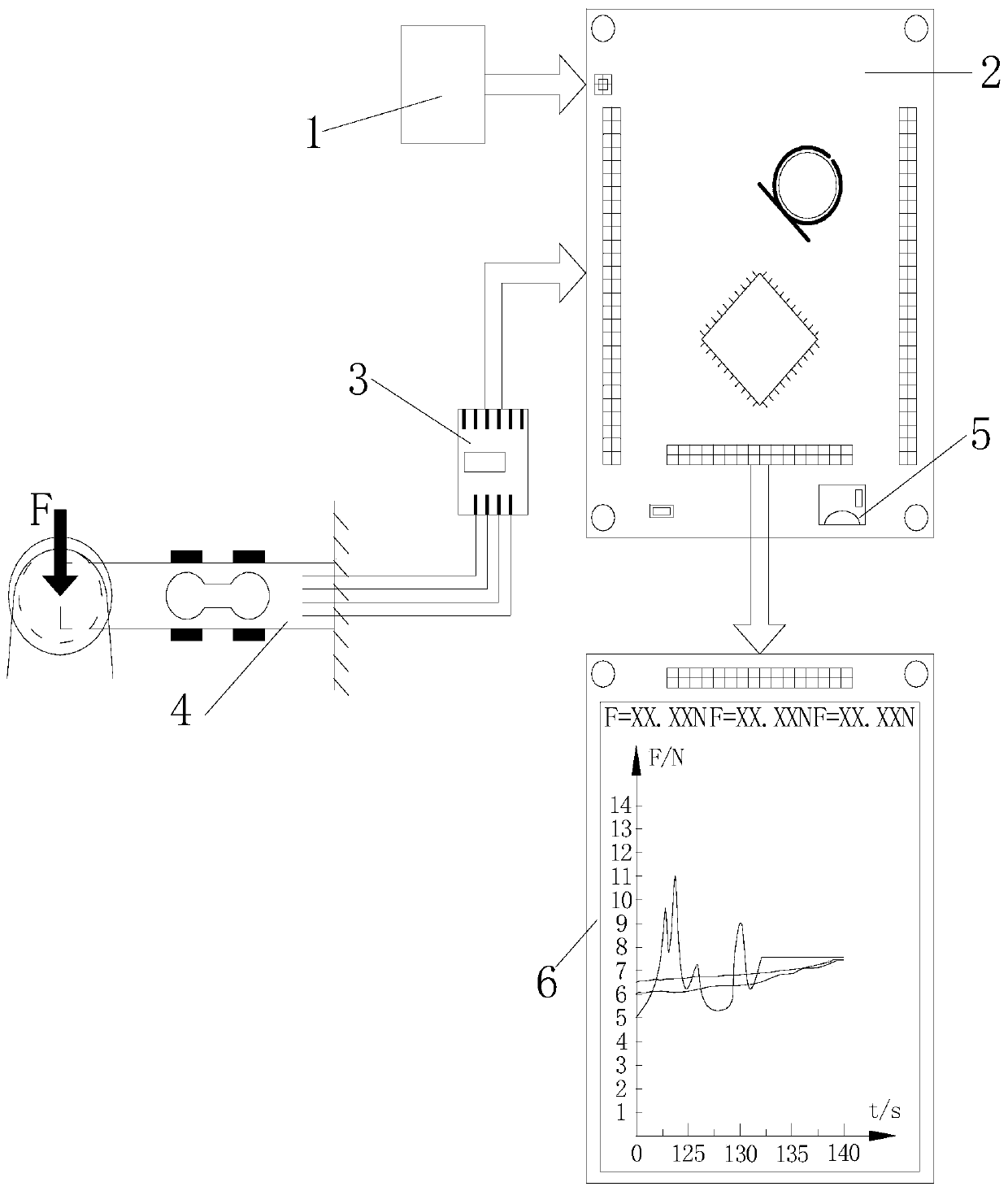

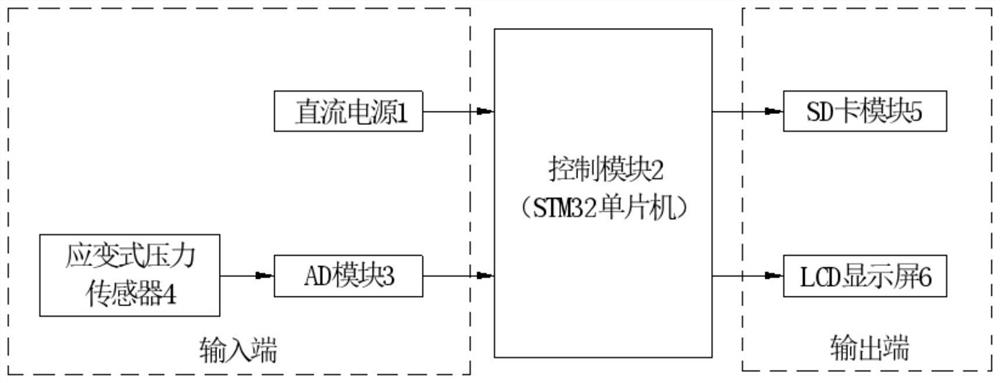

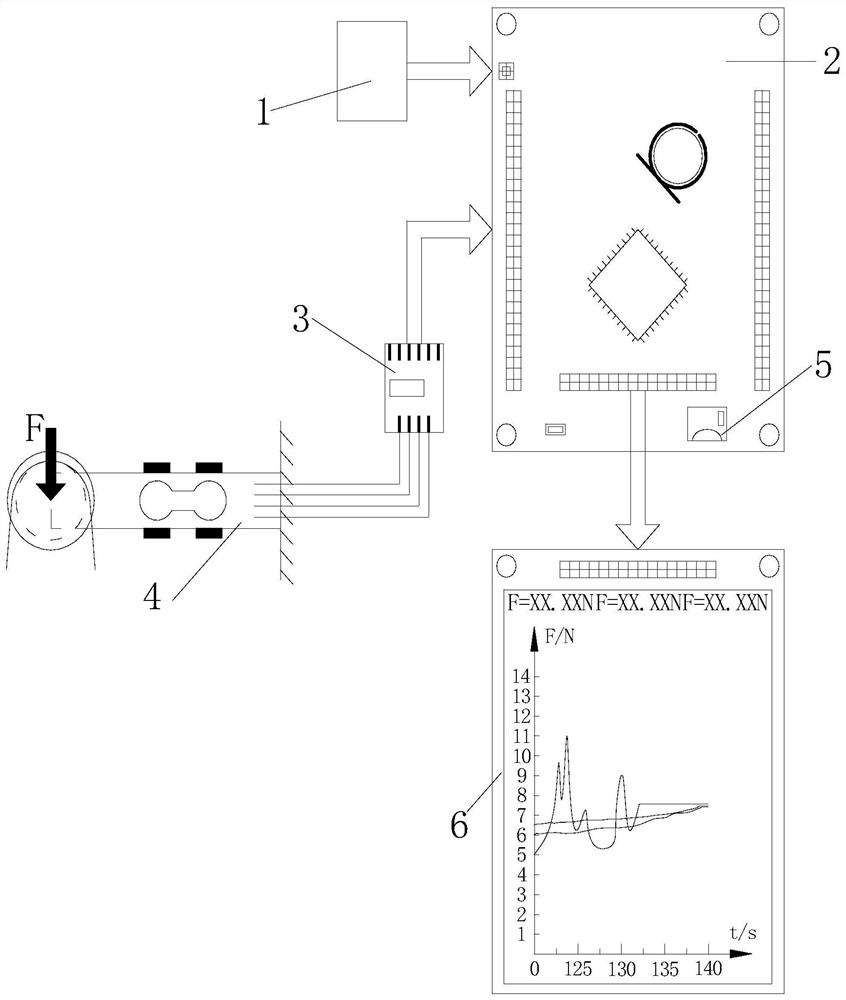

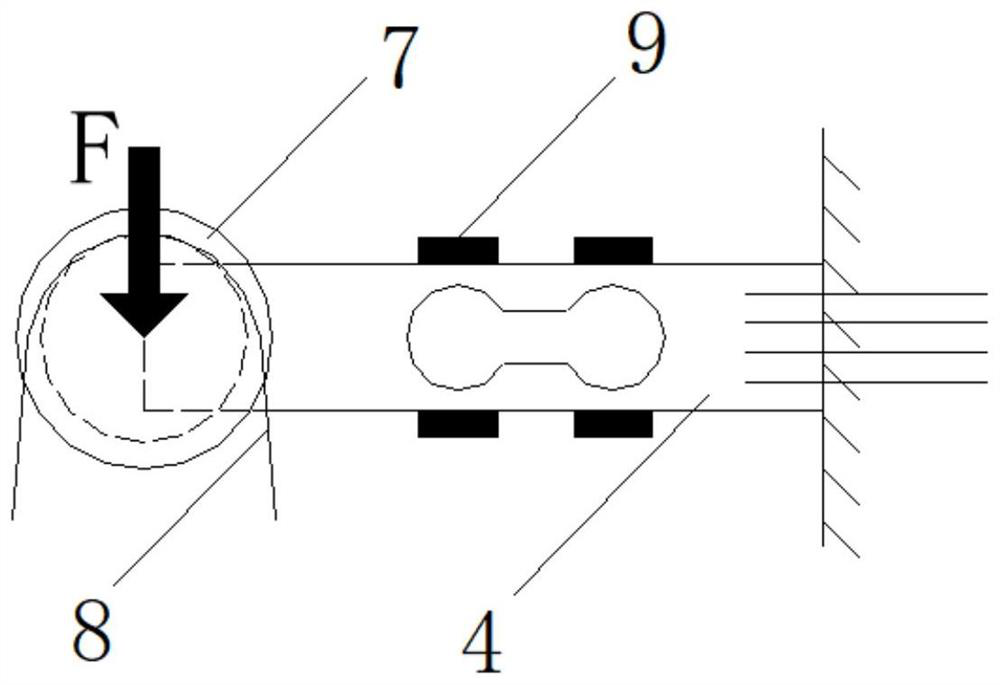

Wire electrical discharge machining electrode wire tension detection and LCD image display device

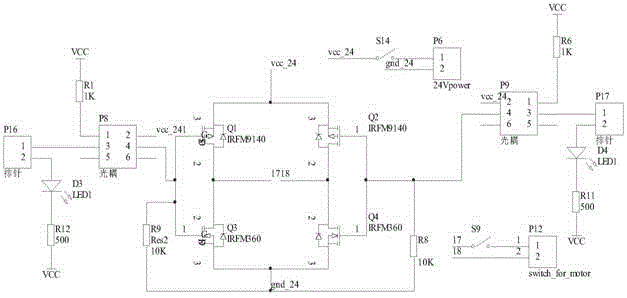

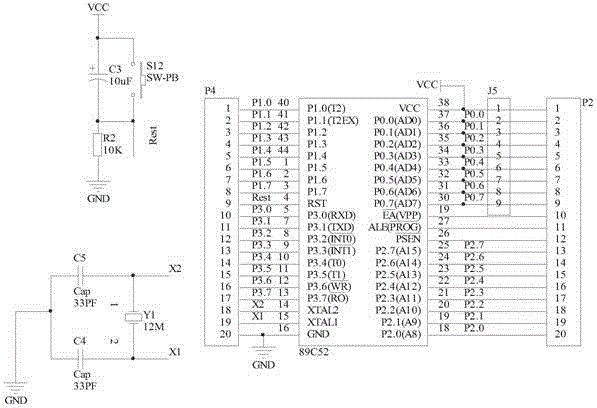

ActiveCN109967809AOvercoming the difficulty of not being able to detect wire tensionOutput graphics are stableElectrical-based machining electrodesElectrical-based auxillary apparatusTime changesWire tension

The invention discloses a wire electrical discharge machining electrode wire tension detection and LCD image display device. The device comprises a direct current power supply, a control module, an ADmodule, a strain type pressure sensor, an SD card module and an LCD screen, wherein the direct current power supply is connected with the control module, the AD module and the strain type pressure sensor are sequentially connected to form a sampling circuit, the strain type pressure sensor is used for detecting the analog quantity of the tension of an electrode wire and converting the analog quantity into a digital quantity through the AD module, the control module is used for calculating the relation between the digital quantity and the actual tension value after the digital quantity is received and correcting the relation, moreover, on the basis, an internal algorithm program processing is carried out, the image and the numerical value (including the real-time tension and the tension average value of the front n seconds) of the tension along with time changes are displayed on the LCD screen in real time, and the SD card module is used for storing the tension value in a timed mode. According to the device, the tension of the electrode wire can be detected in real time, and the change trend can be displayed in the form of the image.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +2

Winding machine

PendingCN110155803AEasy to replaceCycloidal speed adjustableFilament handlingWinding machineEngineering

The invention discloses a winding machine. The winding machine comprises a machine frame, swing arms, a master winding barrel, a slave winding barrel, a drive barrel and a wire swinging device. The swing arms are hinged to the machine frame. The master winding barrel is arranged at one ends of the swing arms. The slave winding barrel is arranged at the other ends of the swing arms. The drive barrel drives the master winding barrel to rotate. The wire swinging device is arranged on the machine frame. The winding machine has the beneficial effects that because the master winding barrel and the slave winding barrel are driven by rotation arms, replacement is convenient.

Owner:无锡旭洲智能科技有限公司

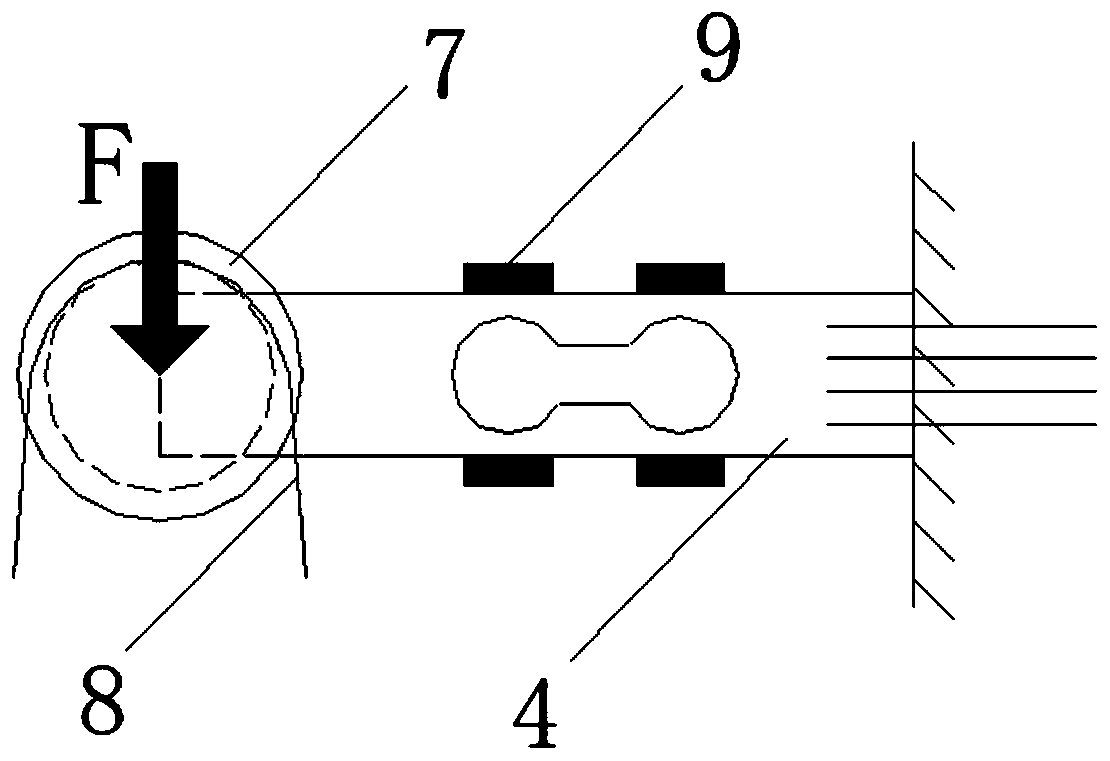

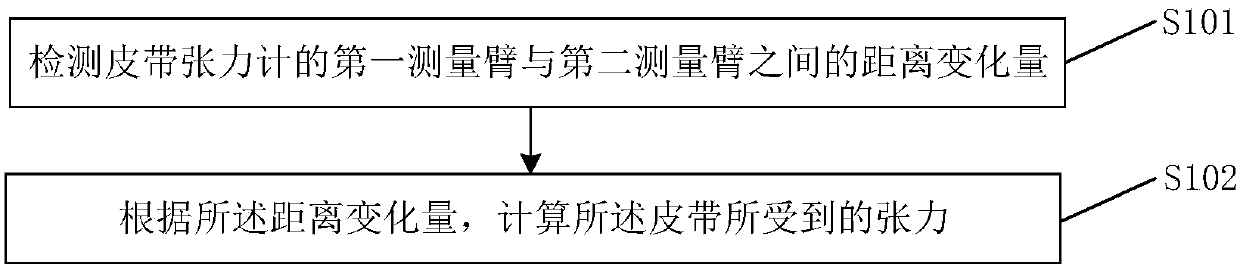

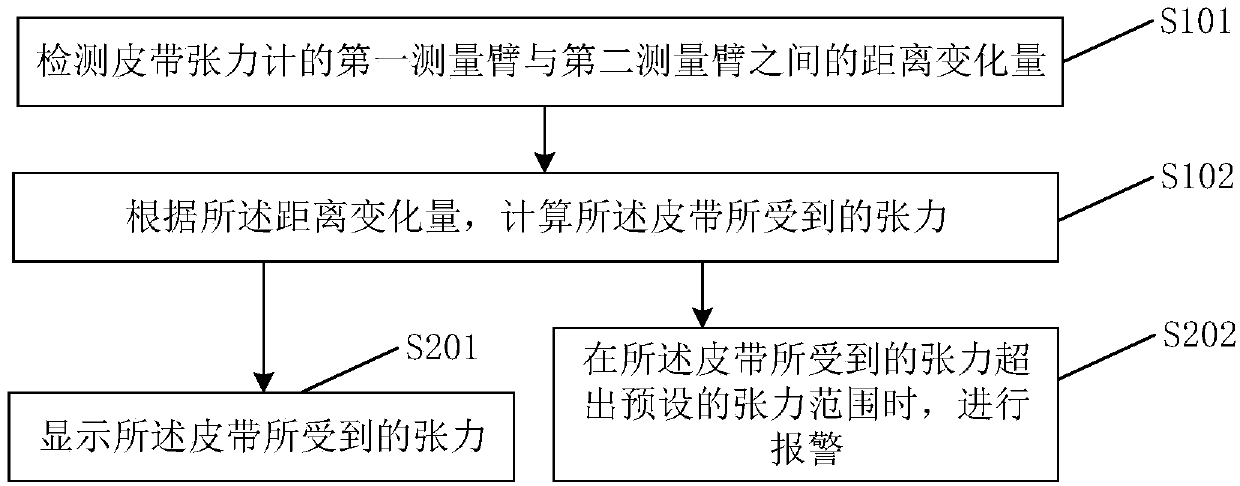

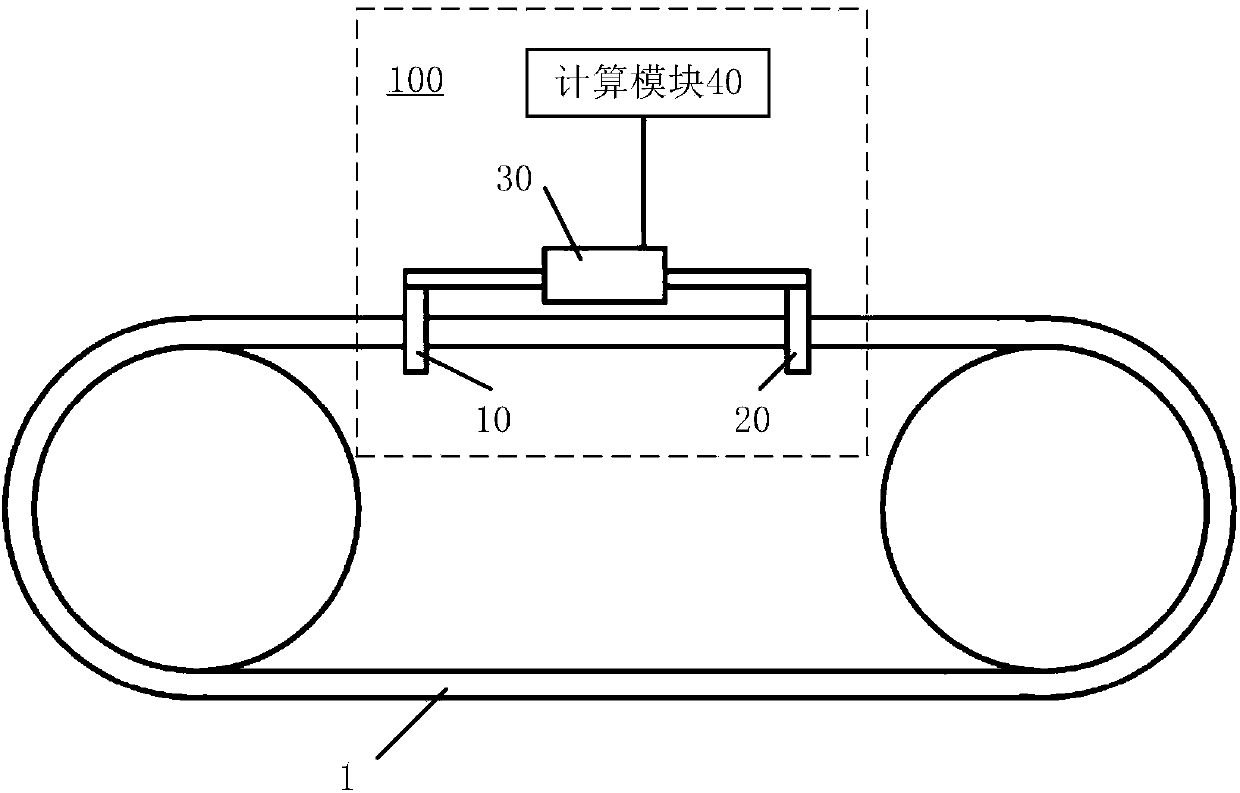

Belt tension detection method and belt tension meter

InactiveCN109764997ATension real-time monitoringGuaranteed reliabilityTension measurementEngineeringMechanical field

The invention relates to a belt tension detection method and a belt tension meter, and relates to the mechanical field. The belt tension detection method comprises the steps that the distance variation quantity between a first measuring arm and a second measuring arm of the belt tension meter is detected; and according to the distance variation quantity, the tension on a belt is calculated. According to the belt tension detection method, the belt tension to be detected can be directly obtained, and the belt tension can be monitored in real time during the belt installation process, so that thereliability of the belt installation is guaranteed, and the reliability of a transmission system provided with the belt is further guaranteed to a certain extent.

Owner:BEIQI FOTON MOTOR CO LTD

Single-stranding unit with return combustion and automatic tension system

InactiveCN104240855ABack twistImprove product qualityCable/conductor manufactureElectrical conductorCombustion

The invention discloses a single-stranding unit with a return combustion and automatic tension system. The single-stranding unit comprises a wire collecting device and a single strander according to the sequence of trend of wires, and the wire collecting device is used for forming of the multi-strand core wires and wrapping and forming of the multi-strand core wires and core wire outer materials; the single strander is used for machining the multi-strand wires by stranding, a wire taking and leading device, a first turning body and a take-up device are arranged inside the single strander, the wire taking and leading device is used for taking and leading the wires from the wire collecting device, and the first turning body is used for machining the wires taken and led by the wire taking and leading device by stranding; the single-stranding unit with the return combustion and automatic tension system further comprises a return combustion machine arranged in front of the wire collecting device, and a second turning body is arranged in the return combustion machine and synchronously rotates with the first turning body. The problem about damage to a conductor and the skin due to the fact that a wire is not twisted reversely in the prior art is solved, signal transmission speed of the wires is increased, and stability in signal transmission of the wires is improved as well.

Owner:SUZHOU CHAOLONG MACHINERY

System and method for intelligently controlling tube continuous annealing furnaces

ActiveCN103436683BAvoid stretchingStable wire diameterFurnace typesHeat treatment process controlTemperature controlComputer module

Owner:江苏华旺新材料有限公司

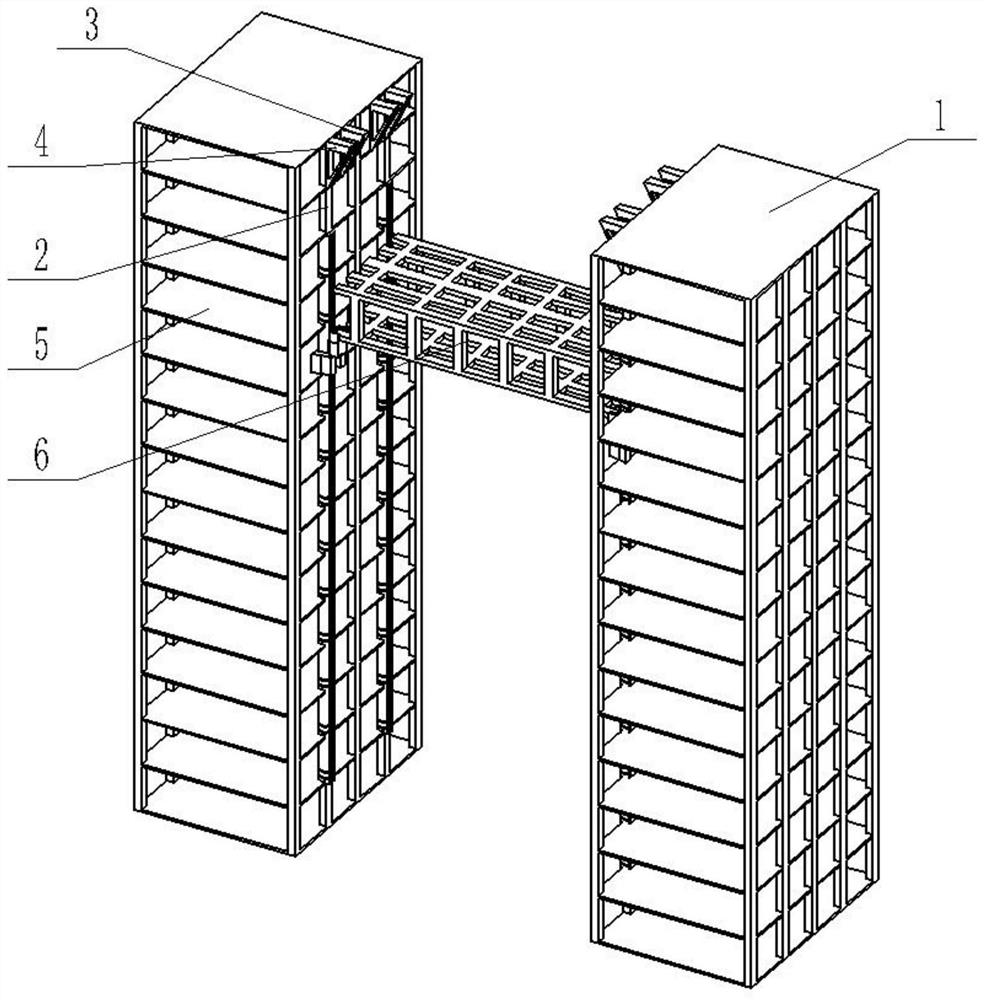

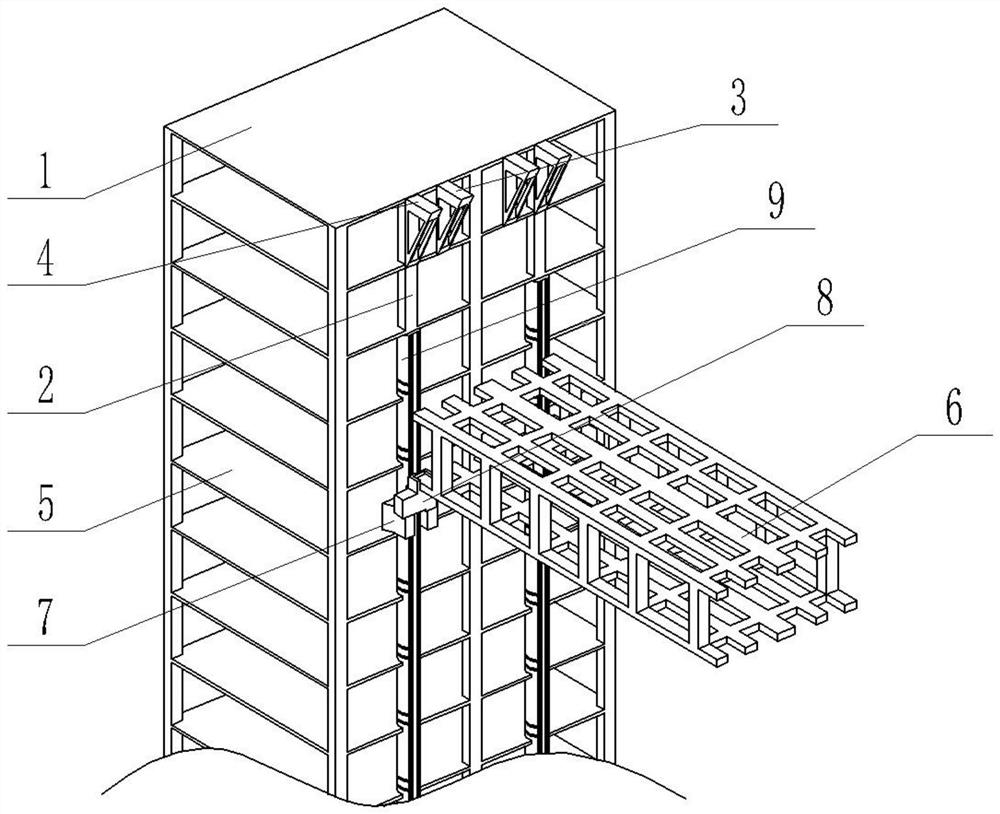

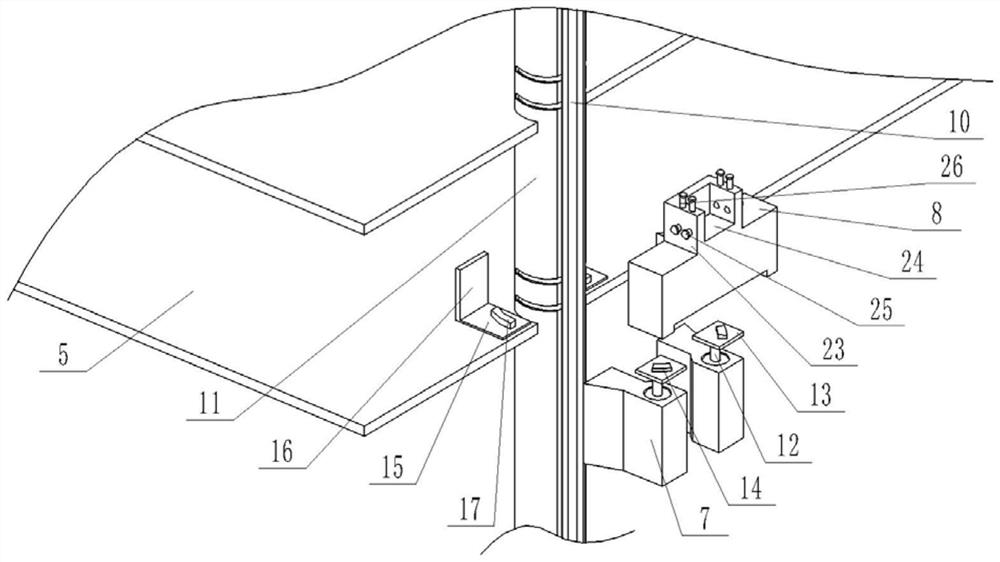

Emergency disposal equipment and use method thereof for integral lifting aerial corridor between ultra-high group towers

ActiveCN111764498AEnsure safetyPlay the role of temporarily shelving the air corridorBuilding material handlingTowerMechanical engineering

The invention relates to the field of constructional engineering, and particularly discloses emergency disposal equipment for integral lifting an aerial corridor between ultra-high group towers. The emergency disposal equipment comprises a rail, a first sliding device, a second sliding device and an auxiliary hoisting mechanism; a jacking mechanism is arranged on the second sliding device, and thefirst sliding device is movably arranged on the jacking mechanism; the rail comprises a main rail body and two auxiliary rail bodies, the auxiliary rail bodies are arranged on the two sides of an outer frame column and integrally formed with the main rail body, a main sliding groove is vertically formed in the main rail body, and the first sliding device is arranged in the main sliding groove ina sliding mode; and auxiliary sliding grooves are horizontally formed in the multiple auxiliary rail bodies, the auxiliary sliding grooves are vertically in communication with a vertical sliding groove, the vertical sliding groove penetrates through the main rail body and the auxiliary rail bodies, and the second sliding device can move upwards in the vertical sliding groove after moving to the vertical sliding groove. According to the emergency disposal equipment, the problem of emergency disposal in the lifting process of the aerial corridor between the ultra-high group towers can be solved.

Owner:SHANGHAI NO 4 CONSTR

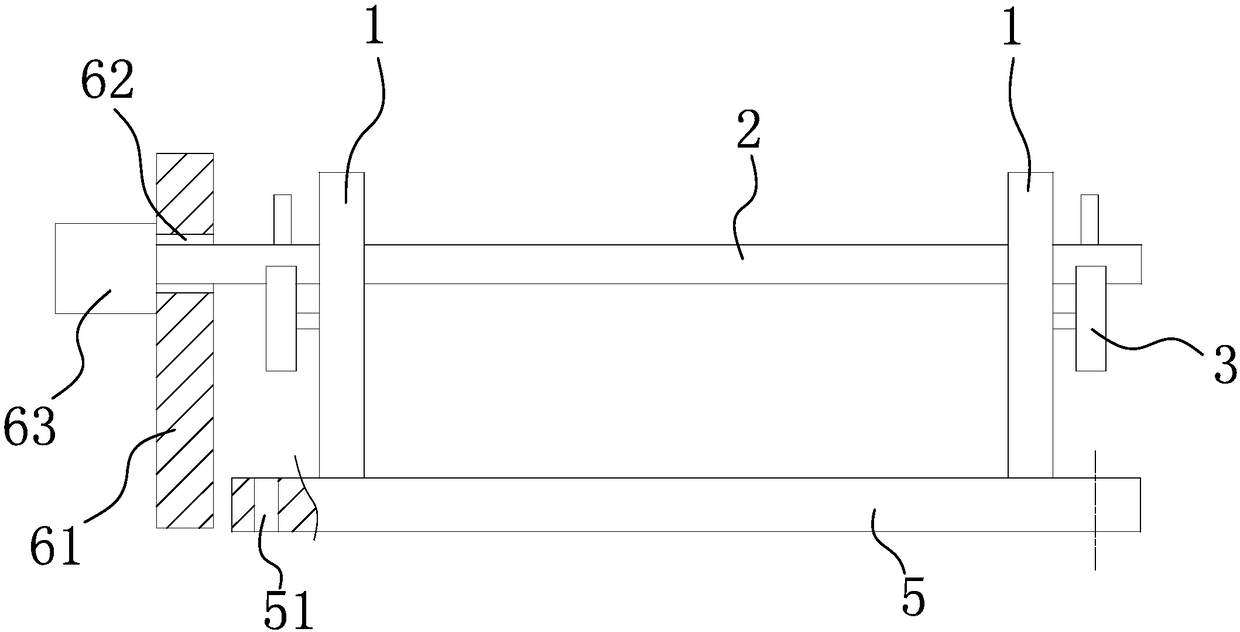

Superconducting strip winding device and control method thereof

PendingCN114538168ATight windingTension real-time monitoringSuperconductor elements usageWebs handlingLaser rangingWinding machine

The invention relates to the technical field of superconducting tape winding, in particular to a superconducting tape winding device and a control method thereof. The superconducting tape winding device comprises a pay-off mechanism, a winding mechanism and a control system, wherein the winding mechanism comprises a wire spool and a driving motor for driving the wire spool to rotate; the pay-off mechanism comprises a pay-off reel and a torsion motor for transmitting torque to the pay-off reel; the control system comprises a guide wheel, a laser range finder, a pressure sensor and a controller, the laser range finder detects the outer diameter of the superconducting tape wound on the pay-off reel in real time, and the controller regulates and controls the output torque of the torsion motor in real time according to outer diameter data fed back by the laser range finder and converts the theoretical tension value of the torsion motor acting on the superconducting tape; the pressure sensor is used for detecting the pressure of the superconducting tape acting on the guide wheel in real time, and the controller is used for converting the actual tension value borne by the superconducting tape; and the controller controls the winding of the superconducting tape according to the actual tension value and the theoretical tension value, so that the tension in the winding process is ensured to be consistent.

Owner:ENN SCI & TECH DEV

Wire rope guide rail tensioning device for mining elevator

ActiveCN102020162BFixed, safe and reliableTension real-time monitoringElevatorsMine liftsPersonal computerEngineering

The invention discloses a wire rope guide rail tensioning device for a mining elevator, which comprises an industrial personal computer, a signal acquirer, wire rope guide rails, counterweight devices and a rope regulation device. Reversely symmetrically arranged wire rope fixing devices are arranged at the upper and lower ends of the wire rope guide rails. Upper wire rope fixing devices are fixed on upper carrier bars. Pressure sensors connected with the signal acquirer are arranged between the upper wire rope fixing devices and the upper carrier bars. Tensioning devices fixed on lower carrier bars are connected to lower wire rope fixing devices. The wire rope fixing devices arranged at the upper and lower ends of wire ropes can safely and reliably fix the wire rope guide rails, and tensioning forces are applied to the wire ropes by the tensioning devices and the counterweight devices arranged on a lower part so as to realize the longitudinal guide and transverse swing restraint of acage in a lifting running process. The wire rope guide rail tensioning device has a compact structure and reliable performance, is easy to machine and simple in installation and maintenance, can monitor the tensioning forces of the guide rails in real time and give an alarm online according to the monitored tensioning forces, and improves the taking safety and reliability of the cage.

Owner:CHINA UNIV OF MINING & TECH +1

A device and method for adjusting the tension force of a wire rope of a two-way traction rail conveyor

InactiveCN104692273BTension real-time monitoringGood tensionWinding mechanismsPull forceControl system

The invention relates to a tension adjusting device and method for steel wire ropes of a bidirectional traction type rail transport machine. The adjusting device comprises a tension adjusting mechanism and a control system, wherein the tension adjusting mechanism comprises a motor, a lead screw, a lead screw nut and a tension sensor, an output shaft of the motor is connected with the lead screw, the lead screw nut is connected onto the lead screw, one end of the tension sensor is connected with the lead screw nut, the other end of the tension sensor is connected with a mounting base of a winch in the bidirectional traction type rail transport machine, and the mounting base is connected with a supporting frame fixed on the ground through a linear sliding mechanism; the control system comprises a signal feedback unit, a control unit, an execution unit and a power supply, the signal feedback unit consists of the tension sensor, and the execution unit consists of the motor. With the adoption of the adjusting device, the tension of the steel wire ropes can be adjusted automatically in real time, so that the steel wire ropes are in the optimal tensioned state all the time.

Owner:SOUTH CHINA AGRI UNIV +1

Battery foil rewinding machine lowering breakage risk

InactiveCN111960158AReduce the risk of belt breakageEasy to installWebs handlingElectrical batteryMechanical engineering

The invention relates to the technical field of rewinding machines and discloses a battery foil rewinding machine lowering breakage risk. The battery foil rewinding machine lowering the breakage riskcomprises a base. The outer surface of the upper end of the base is provided with an installation plate. The outer surface of the front end of the installation plate is provided with an unwinding roller. The surface of the back end of the unwinding roller is provided with a first limiting disk. The surface of the back end of the installation plate is provided with a brake structure corresponding to the tail end of the unwinding roller. The side end of the unwinding roller is provided with a winding roller. The surface of the back end of the winding roller is provided with a second limiting disk. The outer surface of the front end of the lower portion of the installation plate is provided with a first tension roller. The side end of the first tension roller is provided with a second tensionroller. A tension sensor is arranged between the first tension roller and the second tension roller. The battery foil rewinding machine lowering the breakage risk is provided with a winding roller enabling the battery foil to be conveniently installed, the tension of the battery foil in the rewinding process can be monitored in real time, the tension of the battery foil in the rewinding process is adjusted beneficially, and a brake function can be provided for the unwinding roller.

Owner:SUZHOU W B ROYMAX ELECTRONICS TECH

A wire electric discharge cutting electrode wire tension detection and LCD image display device

ActiveCN109967809BOvercoming the difficulty of not being able to detect wire tensionOutput graphics are stableElectrical-based machining electrodesElectrical-based auxillary apparatusWire cuttingEngineering

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +2

A self-tensioning tendon and its installation method

ActiveCN107628198BSave installation timeReduce installation riskAnchoring arrangementsHydraulic cylinderClassical mechanics

The invention discloses a self-tensioning tension tendon and its installation method, which includes: a base, which is installed on the platform body of a floating platform or on the outside of a column; a top connector, which includes a hydraulic cylinder and a Tension ring, the cylinder body of the hydraulic cylinder is fixedly connected to the base, and the piston rod of the hydraulic cylinder is fixedly connected to the upper surface of the tension ring; the main body of the tension tendon is a hollow steel pipe structure, and the upper end of the main body of the tension tendon is connected to the upper surface of the tension ring. The tension ring is fixedly connected; the bottom connector, the lower end of the tension tendon main body is fixedly connected to the upper end of the bottom connector, and the lower end of the bottom connector is inserted into the anchoring foundation. The invention utilizes the expansion and contraction of the piston rod of the hydraulic cylinder to quickly dive the platform to the installation draft, thereby saving installation time.

Owner:708TH RES INST OF CSSC

A traction wire rope protection device for air rides

The invention discloses a traction wire rope protection device for air vehicles. The traction wire rope passes through the passage of the traction wire rope. The traction wire rope is provided with several air vehicles along the direction of transporting personnel. Each air vehicle passes through the positioning bracket and the traction The wire ropes are connected, and the traction wire rope protection device includes a broken rope catching mechanism, a traction protection mechanism, a programmable logic controller PLC and a central control machine, and the programmable logic controller PLC communicates with the central control machine through industrial Ethernet, and the broken rope catching mechanism includes a tension The sensor and the gripping device arranged on one side of the traction wire rope channel, the tension sensor is connected with the traction wire rope, the tension sensor is connected with the programmable controller PLC, the traction protection mechanism includes a protective shell and a driving motor, the protective shell is connected with the gripping device, and the driving The motor is connected with the grip device through a linkage assembly. The invention can not only capture the broken steel wire rope in time, but also form secondary protection for the steel wire rope, avoiding the occurrence of secondary accidents.

Owner:SHANDONG UNIV OF SCI & TECH

Micro winding spring winding machine

ActiveCN113976768AImprove winding efficiencyPracticalMetal working apparatusWinding machineStructural engineering

The invention provides a micro winding spring winding machine. The micro winding spring winding machine comprises a lathe bed, a pay-off mechanism, a transmission mechanism and an anchoring winding mechanism. Wherein a pay-off mechanism sliding rail and a tailstock sliding rail are arranged on the lathe bed, a guide rail sliding table is installed on the pay-off mechanism sliding rail, and a tailstock guide rail sliding table is installed on the tailstock sliding rail; and the pay-off mechanism is connected to the lathe bed through the guide rail sliding table and used for paying off. The transmission mechanism is connected to the lathe bed and used for driving the pay-off mechanism to move horizontally. And the anchoring winding mechanism is arranged on one side of the pay-off mechanism and used for winding a silk thread into a winding spring. The pay-off mechanism and the anchoring winding mechanism of the micro winding spring winding machine are independently arranged on the lathe bed, the pay-off mechanism can select pay-off of one or more strands of silk threads according to the winding requirement, the adjustable main shaft tailstock component is arranged in the anchoring and winding mechanism, the position of the anchoring and winding mechanism can be adjusted according to different lengths of needed winding springs, multiple strands of silk threads can be paid off, anchored and wound at the same time, the winding efficiency of the winding spring is improved, and the practicability is higher.

Owner:SHANGHAI JIAO TONG UNIV

a pay-off machine

InactiveCN103426563BGuaranteed normal operationAvoid damageCable/conductor manufactureEngineeringMechanical engineering

Owner:苏州启成精密工业有限公司

A hoist wire rope tension monitoring sensor for eliminating vibration peaks

ActiveCN105347132BEliminate tension-kick issuesTension real-time monitoringElevatorsHydraulic cylinderEngineering

The invention discloses a tension monitoring sensor for eliminating a vibration peak value of elevator steel wire ropes. The tension monitoring sensor comprises an upper cover which is in movable fit with a telescopic pole of a hydraulic oil cylinder, a disk body which is in movable fit with a slide block, an oil cavity cylinder which is packaged by the upper cover and the disk body, wherein the upper cover is in threaded connection with the disk body and covers the disk body; the oil cavity cylinder is in threaded connection in the disk body; and a ring of copper rings used for sealing oil is arranged between the disk body and the oil cavity cylinder. The sensor is mounted between the slide block of a balancing and suspending device of a friction type elevator oil cylinder and the telescopic pole of the hydraulic cylinder; under the action of the tension of the steel wire ropes, the part, pasted with a strain gage, of the sensor generates elastic deformation to measure tension of each steel wire rope; and sum of tension of all steel wire ropes is total load hoisted by the elevator. The sensor is reasonable in structural design; influence of kick of stress caused by shaking, vibrating and the like of the steel wire ropes in an elevator working process can be eliminated, and tension of the steel wire ropes can be stably and accurately monitored in real time.

Owner:CHINA UNIV OF MINING & TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com