System and method for intelligently controlling tube continuous annealing furnaces

An intelligent control system, technology of continuous annealing furnace, applied in the direction of heat treatment process control, furnace, heat treatment furnace, etc., can solve the problems of elongation, inability to realize remote monitoring and intelligent control, low automation level, etc., to eliminate residual stress, realize The effect of automatic annealing without wasting energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

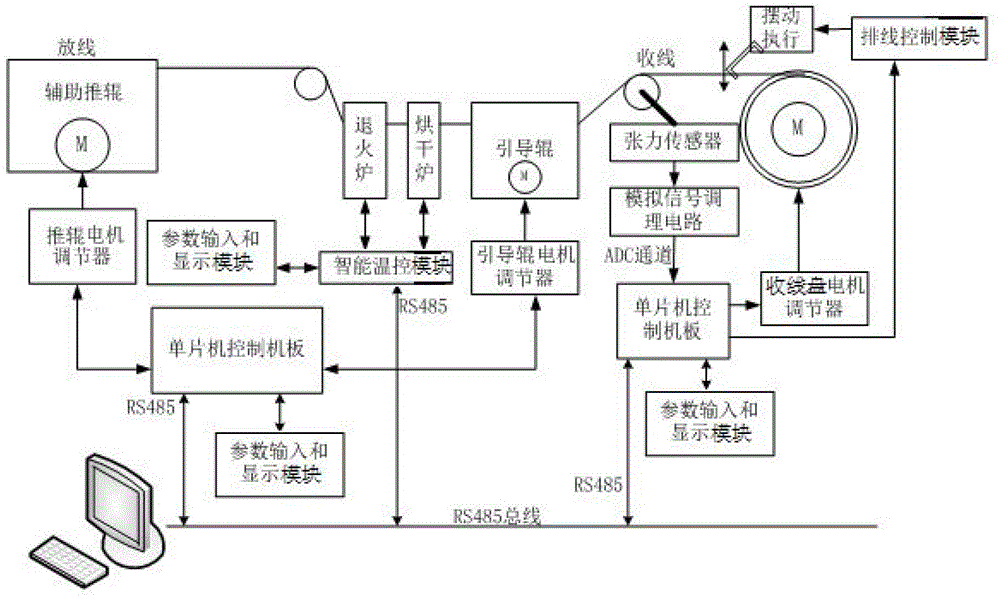

[0040] An intelligent control system for a tubular continuous annealing furnace in this embodiment includes a pay-off control unit, a temperature control unit, a guide unit, a tension monitoring unit, a take-up control unit, a single-chip microcomputer control board, and a parameter input and display module, wherein :

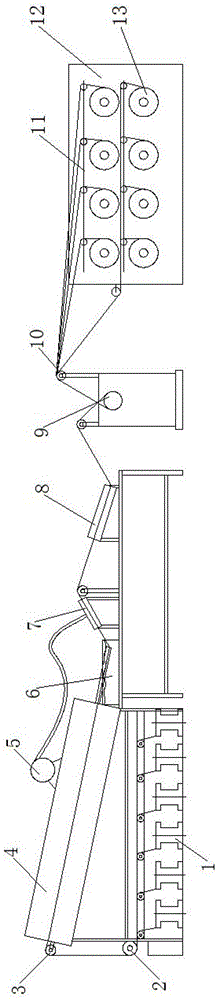

[0041] The pay-off control unit includes auxiliary push roller 2, auxiliary push roller drive motor and auxiliary push roller motor regulator. The auxiliary push roller motor regulator is connected with the auxiliary push roller drive motor through the control line. Connected with the auxiliary push roller 2, the auxiliary push roller motor regulator is connected with the single-chip control board through the control line, the auxiliary push roller drive motor is a three-phase asynchronous motor with a power of 0.55KW, and the auxiliary push roller 2 is used to send the wire into the annealing furnace 4 ;

[0042] The temperature control unit includes a temper...

Embodiment 2

[0055] The basic structure of the intelligent control system of a tubular continuous annealing furnace in this embodiment is the same as in embodiment 1, the difference is that the tension monitoring unit is replaced by a tension monitoring unit in the intelligent control system of a tubular continuous annealing furnace in this embodiment It is a torque motor controlled by a computer, which can be used as a take-up reel drive motor to take up the wire with a constant torque, thereby ensuring a constant tension of the wire and simplifying the structure of the system. The speed information of the torque motor is fed back to the cable control module by the single-chip microcomputer control board to ensure that the cable control module is adjusted synchronously. In addition, the parameter input and display modules in the intelligent control system of a tubular continuous annealing furnace in this embodiment are replaced by a computer. The single-chip microcomputer control board and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com