Patents

Literature

42results about How to "Pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

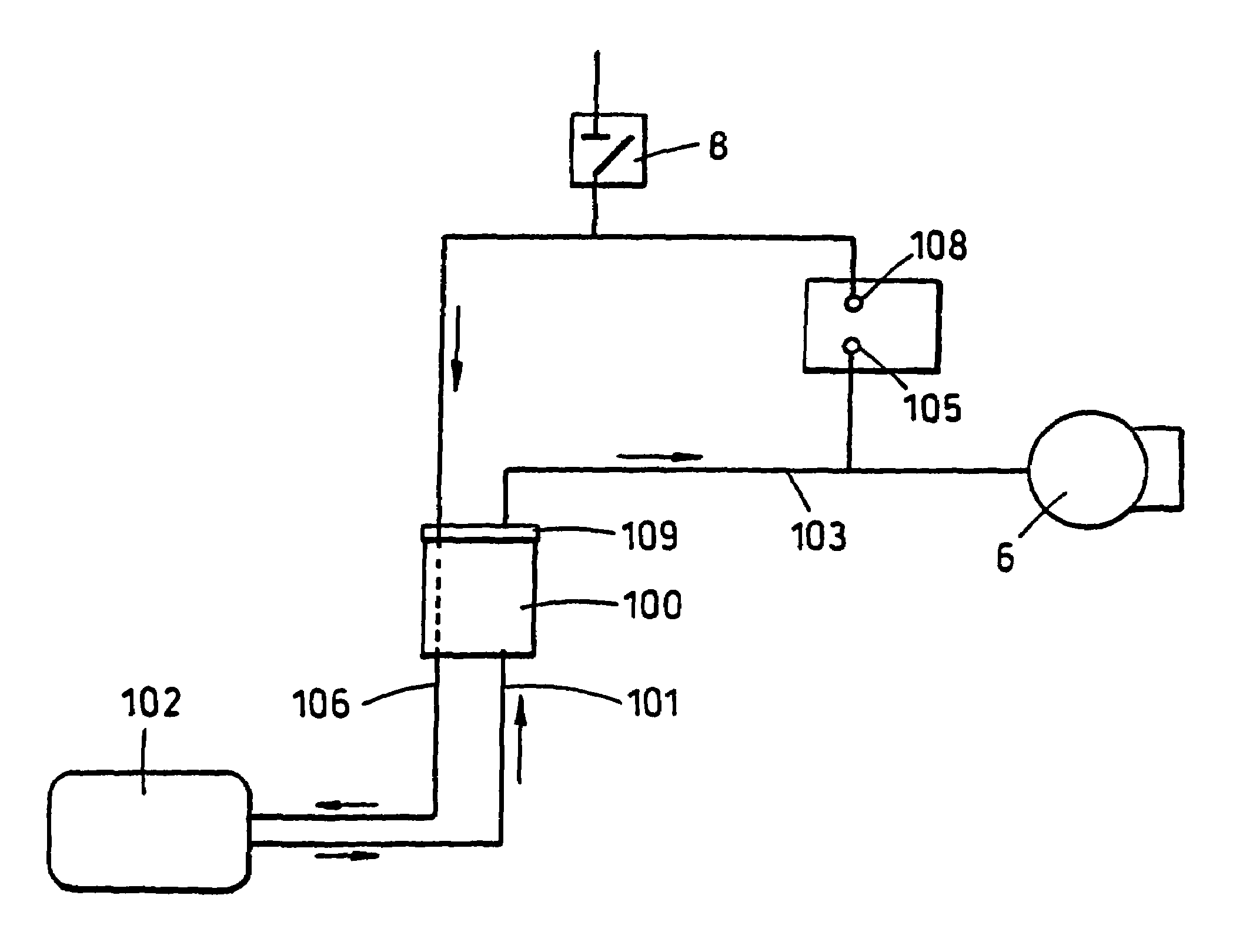

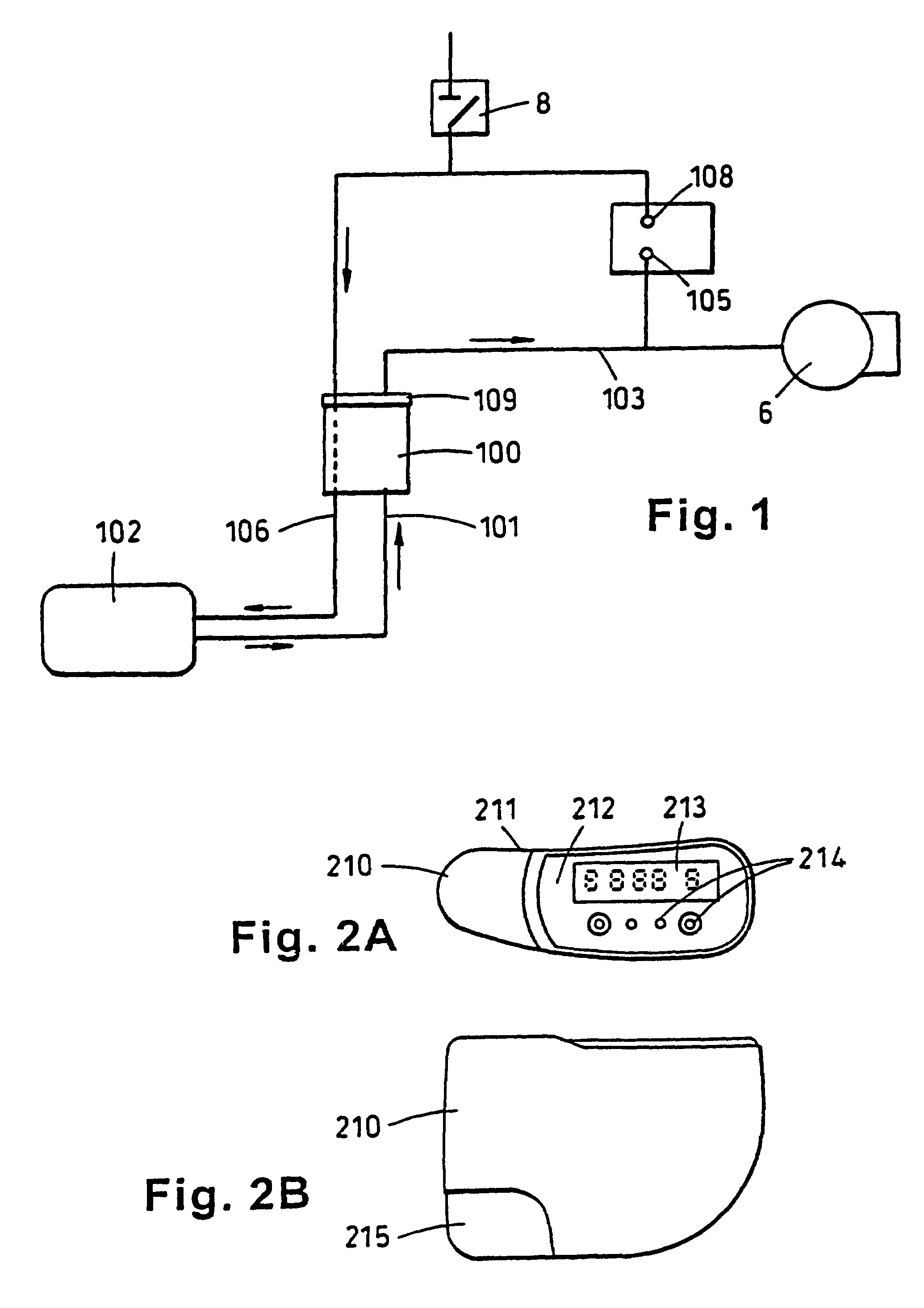

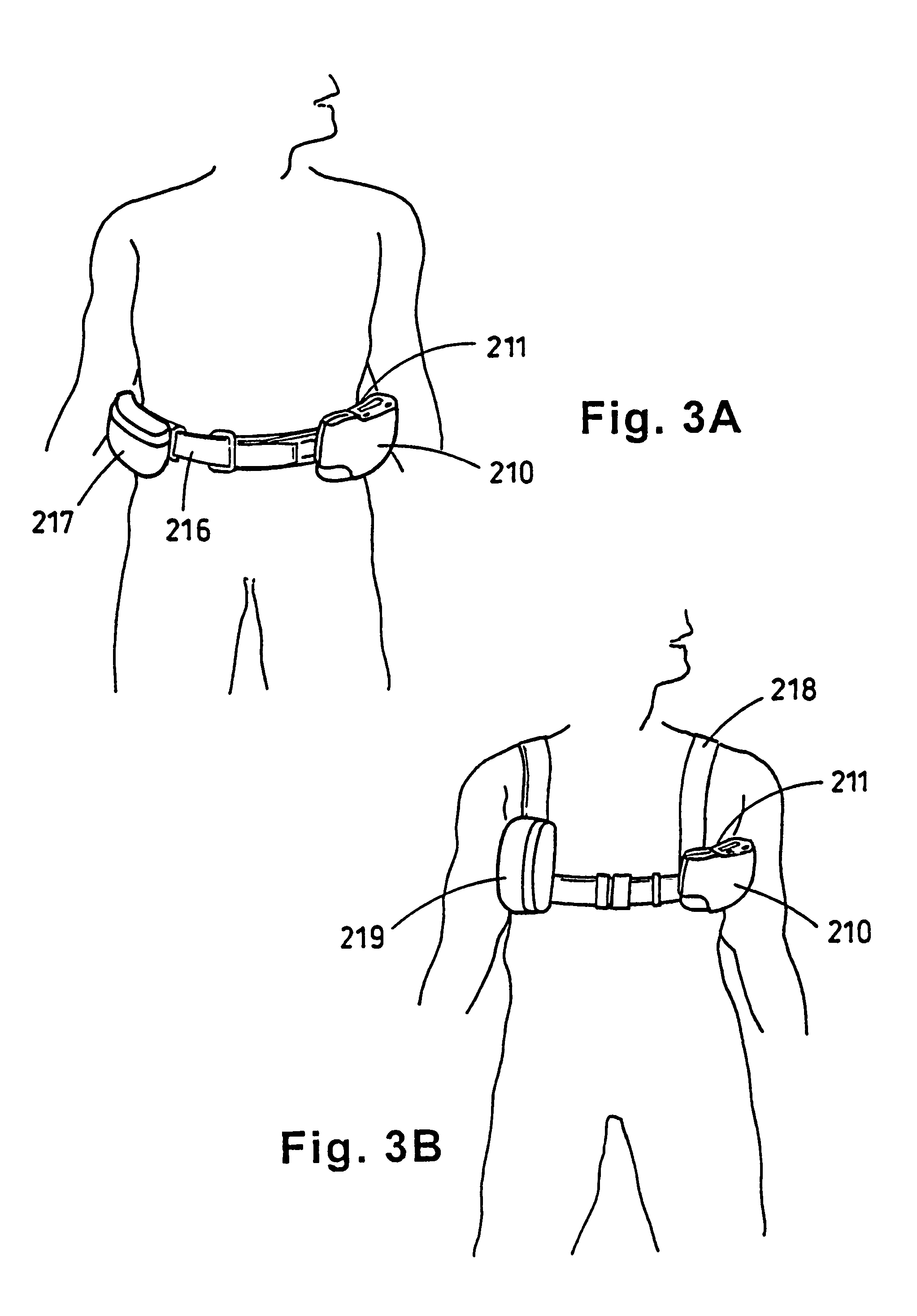

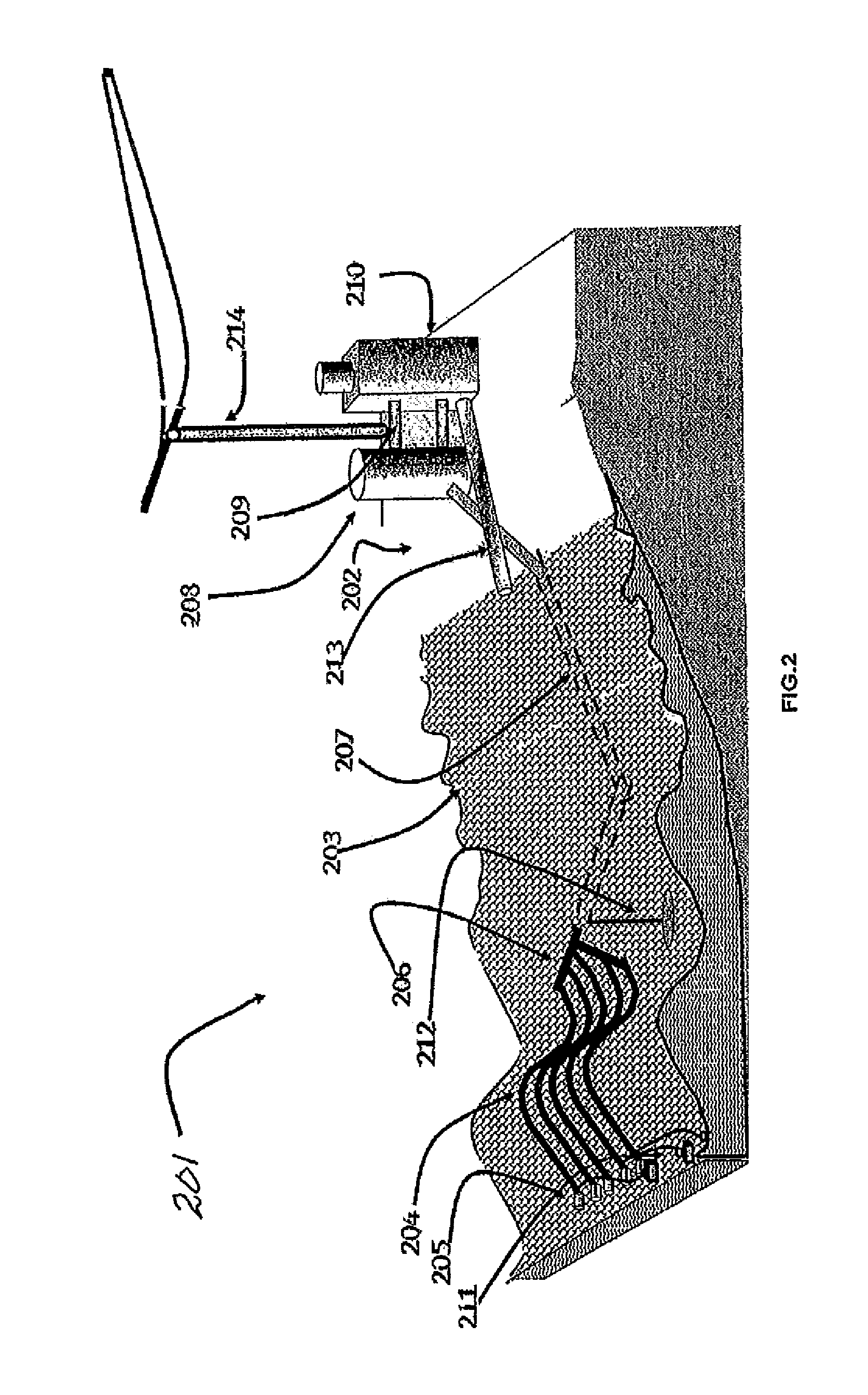

Portable wound treatment apparatus

A portable wound treatment apparatus, for stimulating the healing of superficial wounds, comprises a housing containing a suction pump and a canister for containing fluids drawn from the wound. The housing is supported on a harness or belt worn by the patient. The canister is connected to a porous wound dressing at the wound site via a plurality of tubes, a multi-lumen tube or a combination thereof. A rechargeable battery pack may be incorporated within the housing or externally thereto. The external battery pack may be shaped to balance the housing on the harness or belt. Pressure transducers are provided to monitor and report pressures at the wound site or internal to the canister. Monitored pressures may also be utilized to determine the filled state of the canister and, thereafter, either report this state to the operator or automatically discontinue suction from the wound, or both.

Owner:KCI LICENSING INC

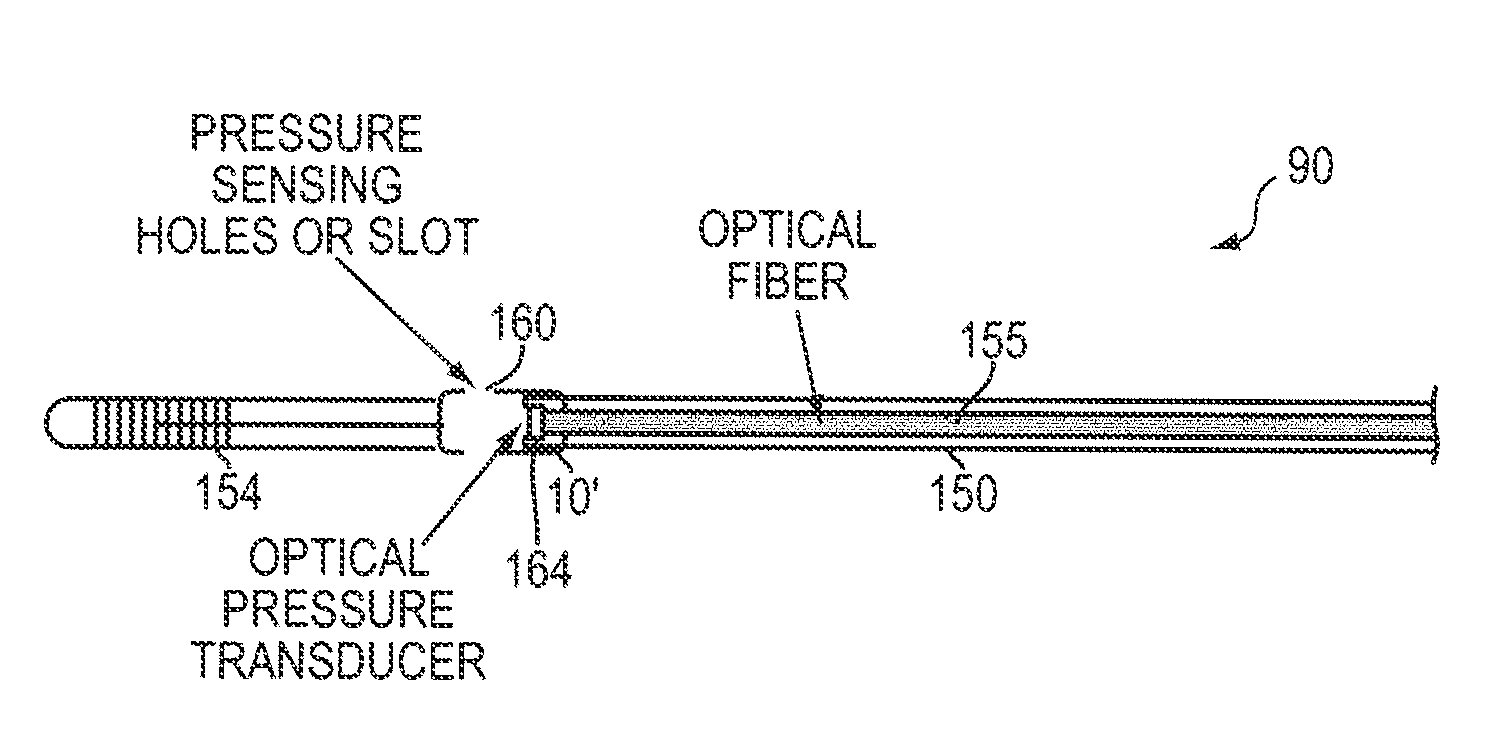

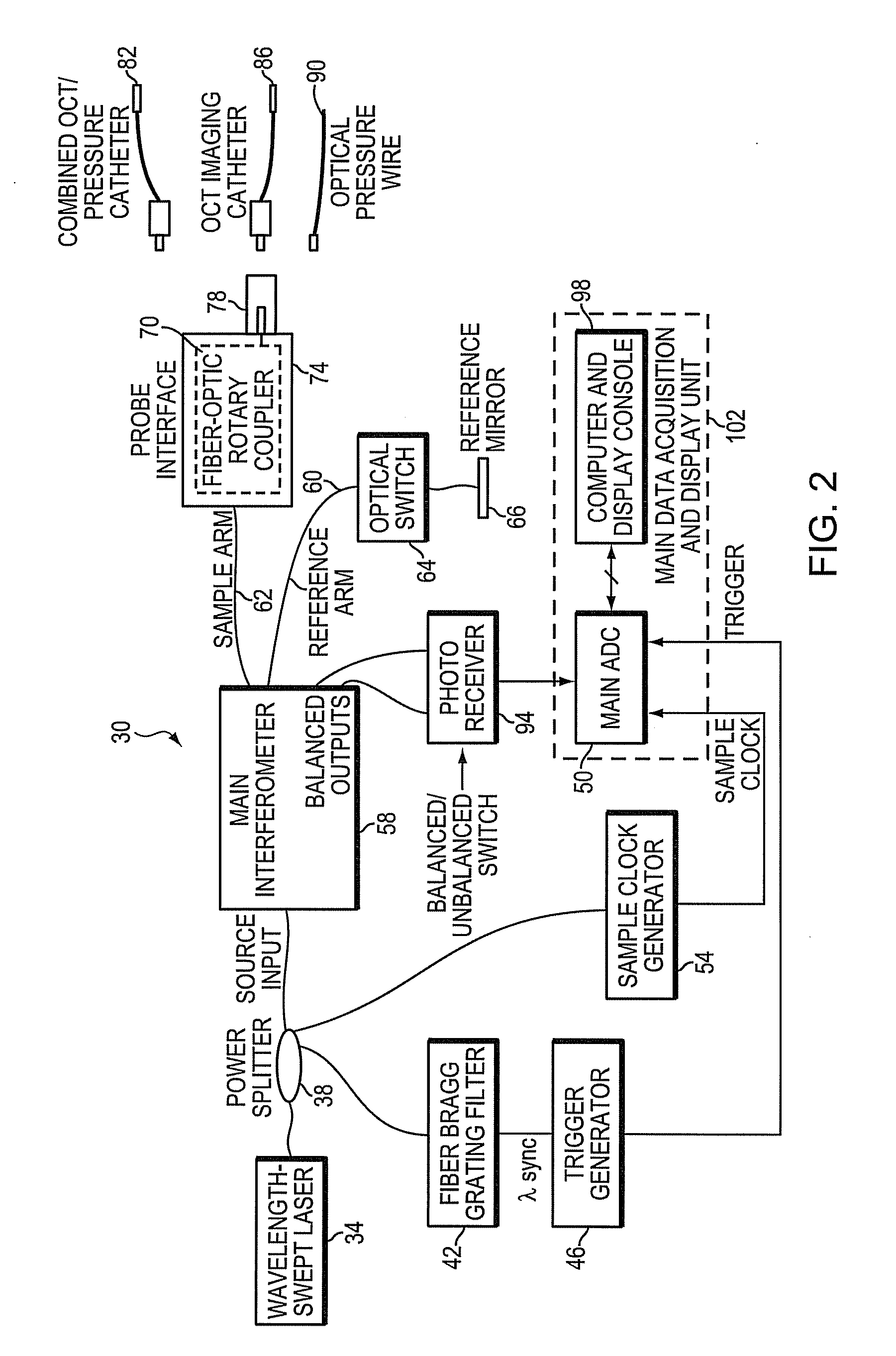

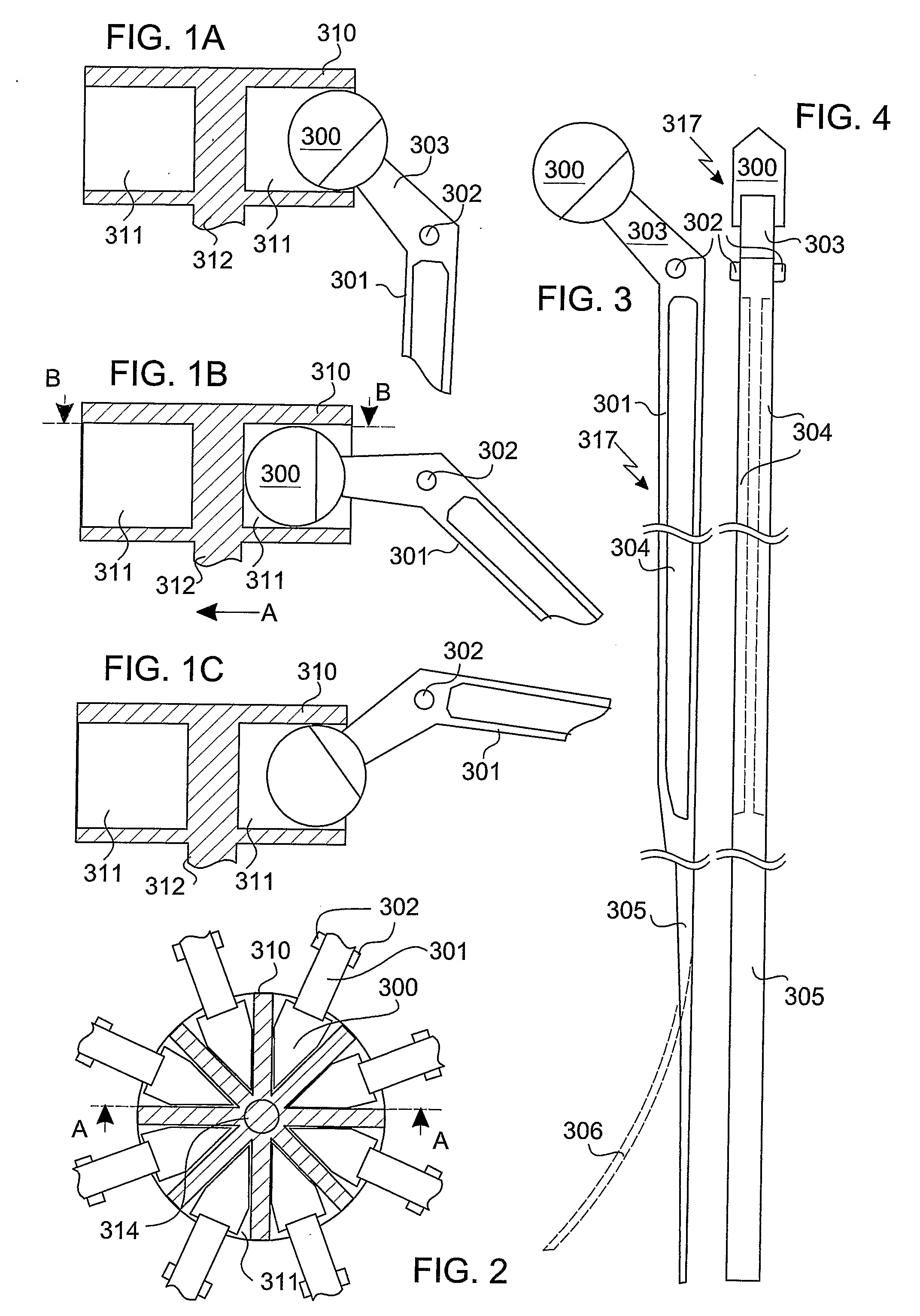

Intravascular Optical Coherence Tomography System with Pressure Monitoring Interface and Accessories

ActiveUS20120238869A1PressureEasy to useDiagnostics using spectroscopyCatheterPhotovoltaic detectorsPhotodetector

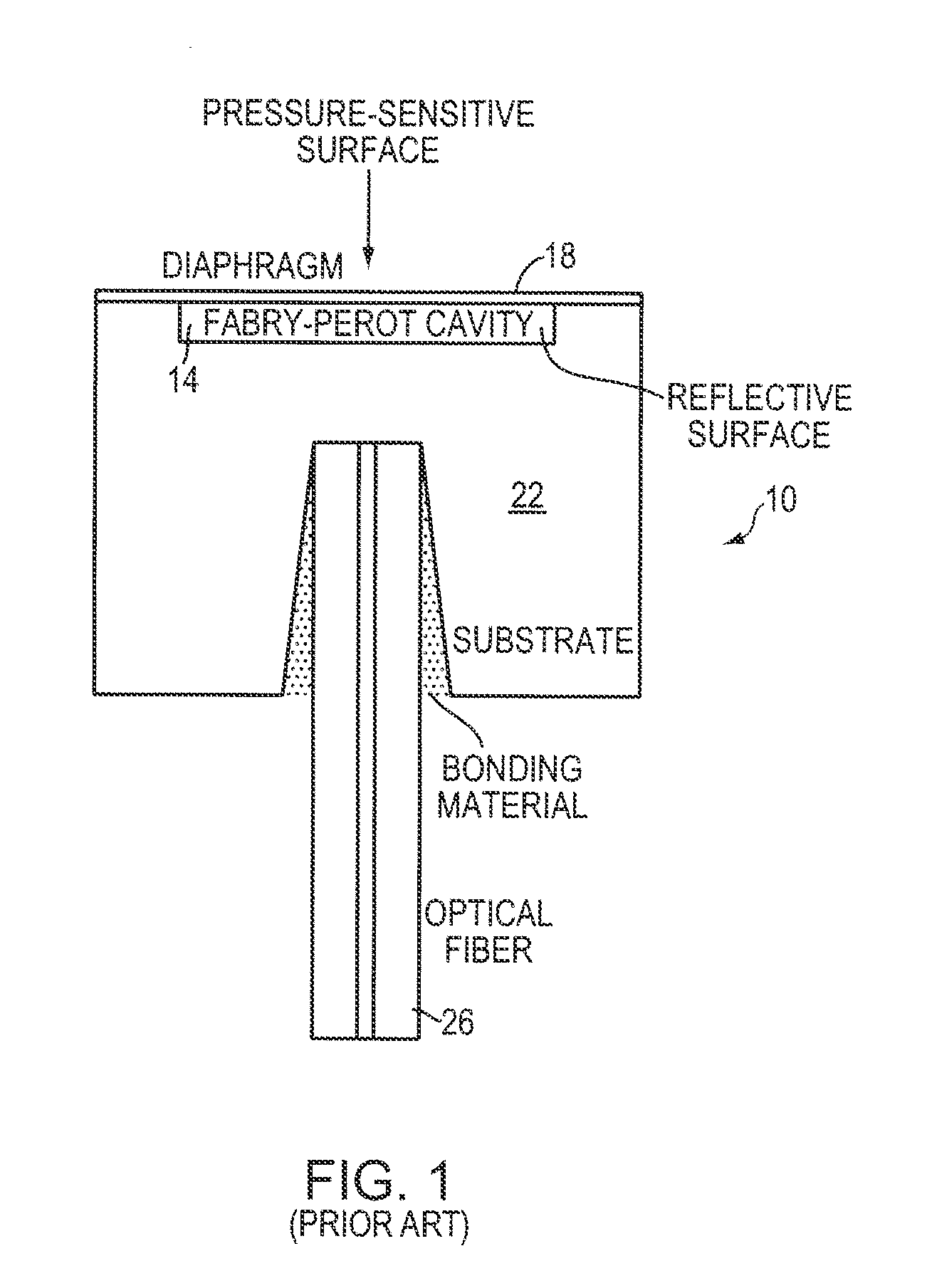

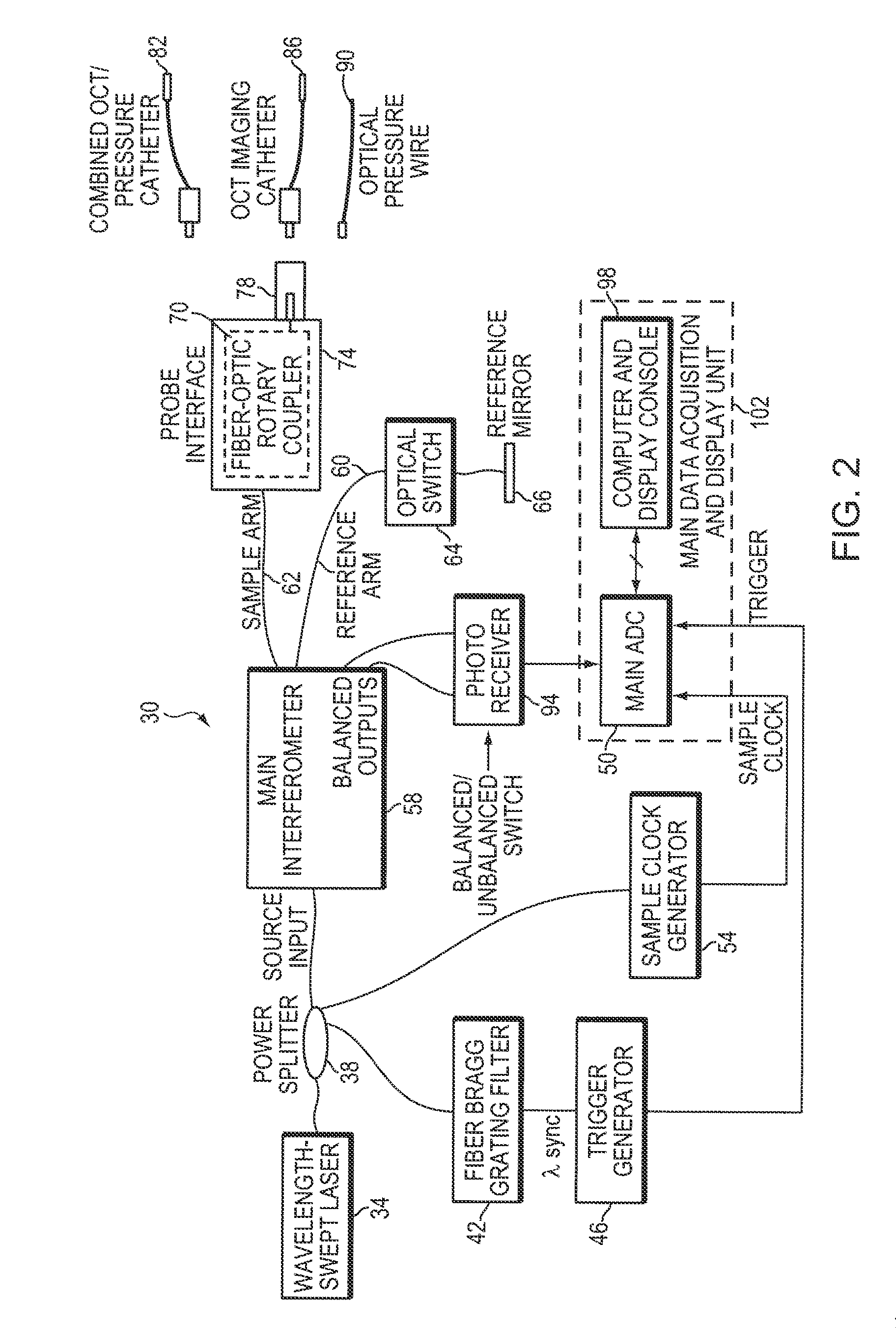

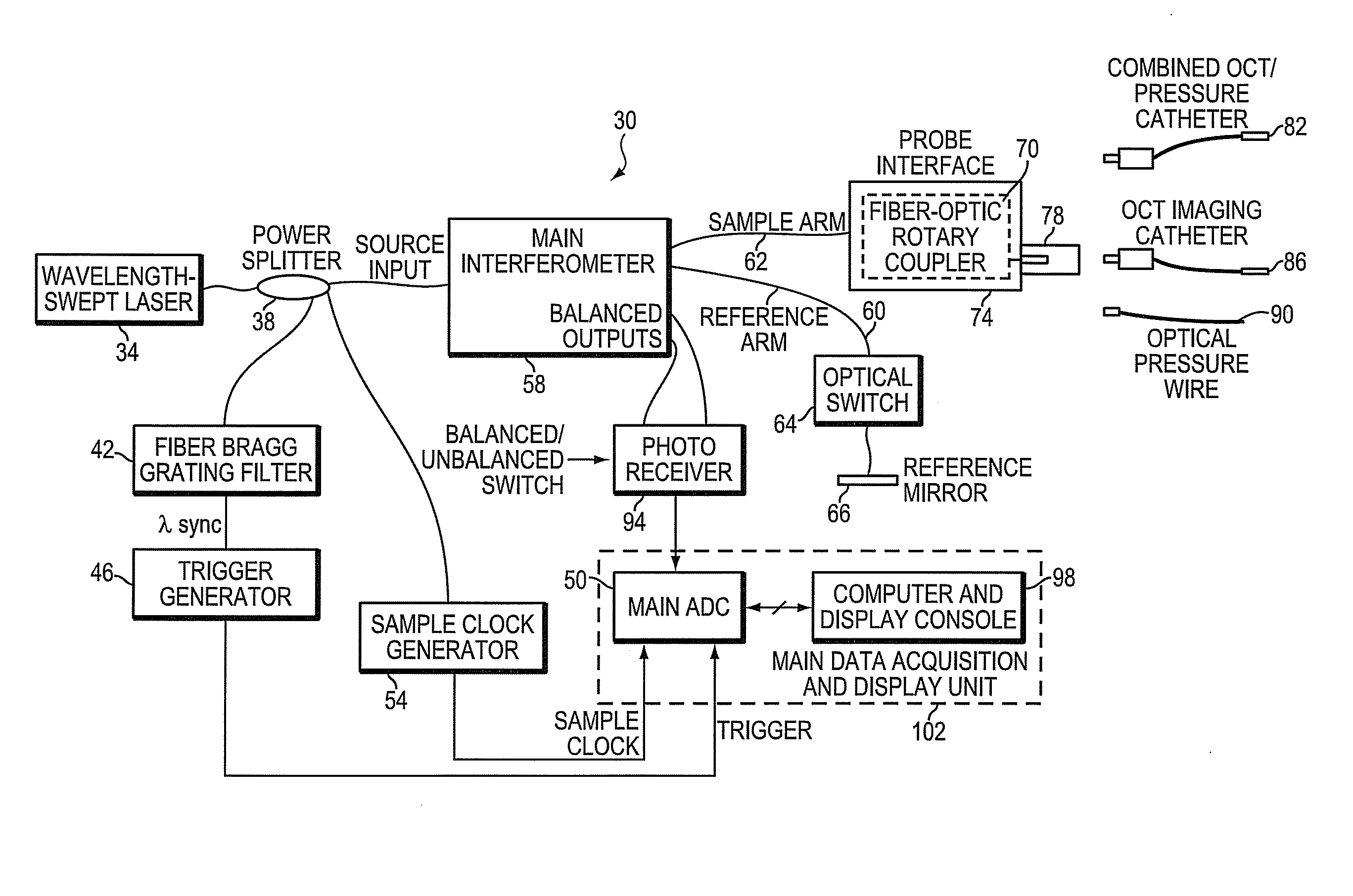

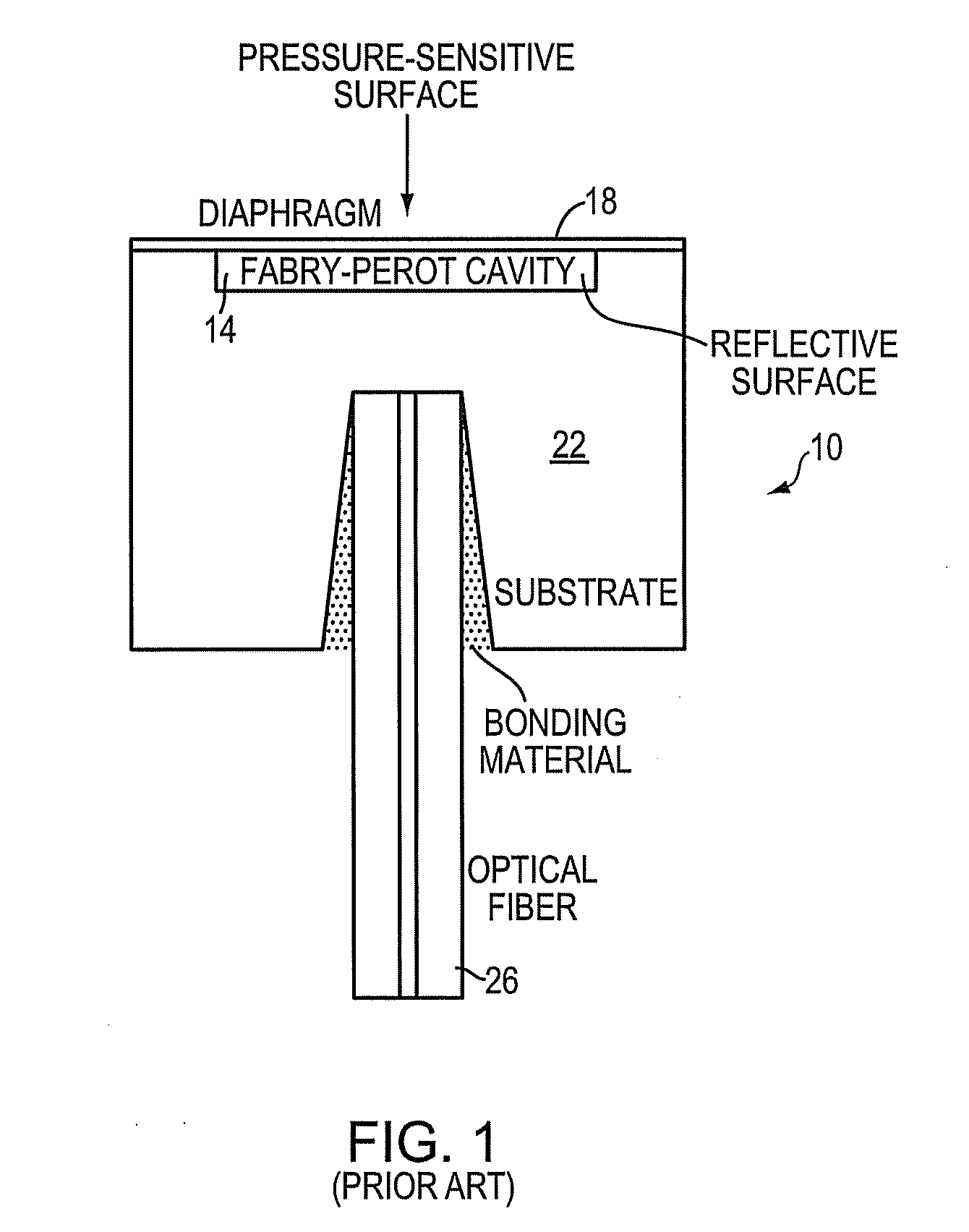

An optical coherence tomography system and method with integrated pressure measurement. In one embodiment the system includes an interferometer including: a wavelength swept laser; a source arm in communication with the wavelength swept laser; a reference arm in communication with a reference reflector; a first photodetector having a signal output; a detector arm in communication with the first photodetector, a probe interface; a sample arm in communication with a first optical connector of the probe interface; an acquisition and display system comprising: an A / D converter having a signal input in communication with the first photodetector signal output and a signal output; a processor system in communication with the A / D converter signal output; and a display in communication with the processor system; and a probe comprising a pressure sensor and configured for connection to the first optical connector of the probe interface, wherein the pressure transducer comprises an optical pressure transducer.

Owner:LIGHTLAB IMAGING

Intravascular optical coherence tomography system with pressure monitoring interface and accessories

ActiveUS20110178413A1PressureEasy to useRadiation pyrometryInterferometric spectrometryPhotovoltaic detectorsPhotodetector

An optical coherence tomography system and method with integrated pressure measurement. In one embodiment the system includes an interferometer including: a wavelength swept laser; a source arm in communication with the wavelength swept laser; a reference arm in communication with a reference reflector; a first photodetector having a signal output; a detector arm in communication with the first photodetector, a probe interface; a sample arm in communication with a first optical connector of the probe interface; an acquisition and display system comprising: an A / D converter having a signal input in communication with the first photodetector signal output and a signal output; a processor system in communication with the A / D converter signal output; and a display in communication with the processor system; and a probe comprising a pressure sensor and configured for connection to the first optical connector of the probe interface, wherein the pressure transducer comprises an optical pressure transducer.

Owner:LIGHTLAB IMAGING

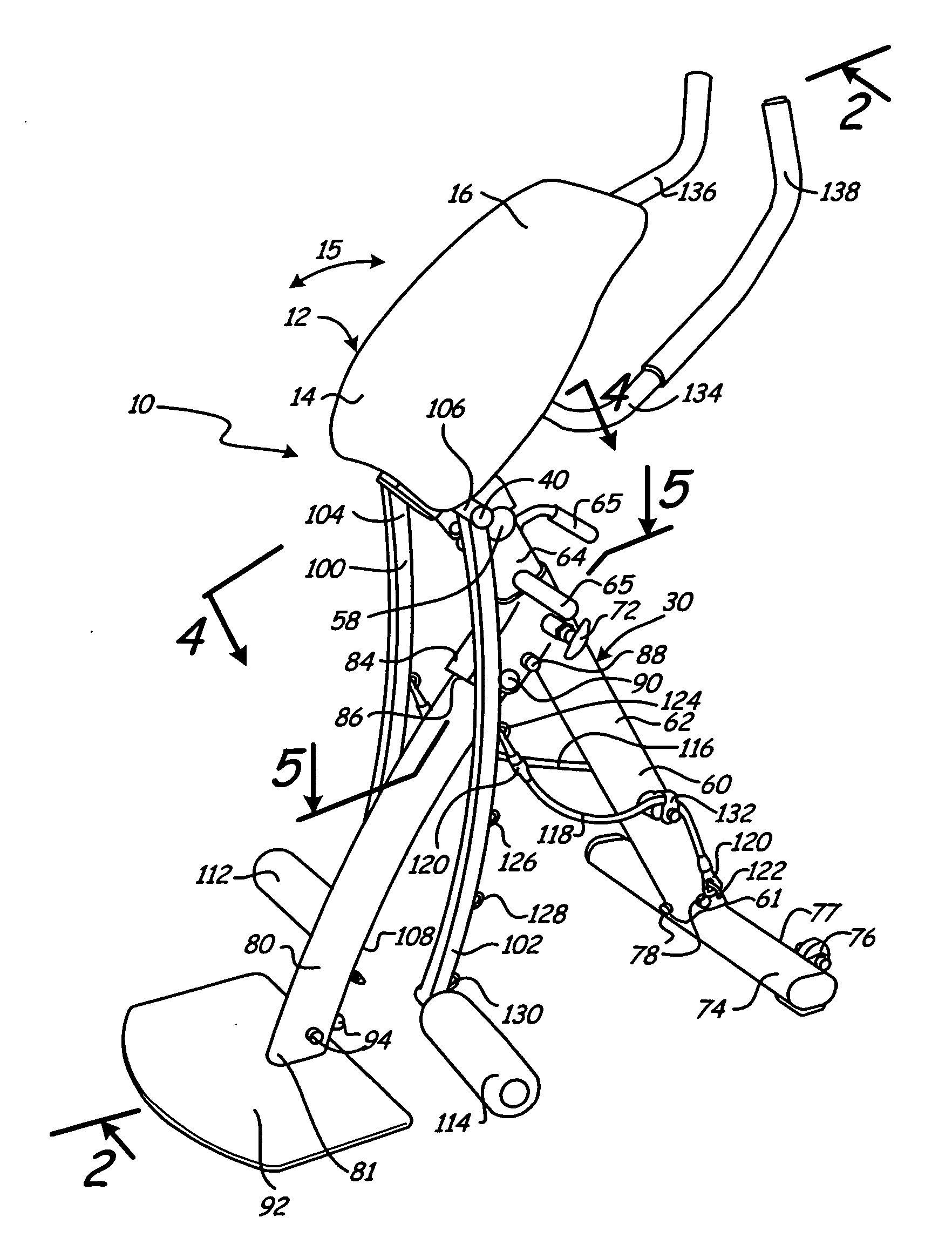

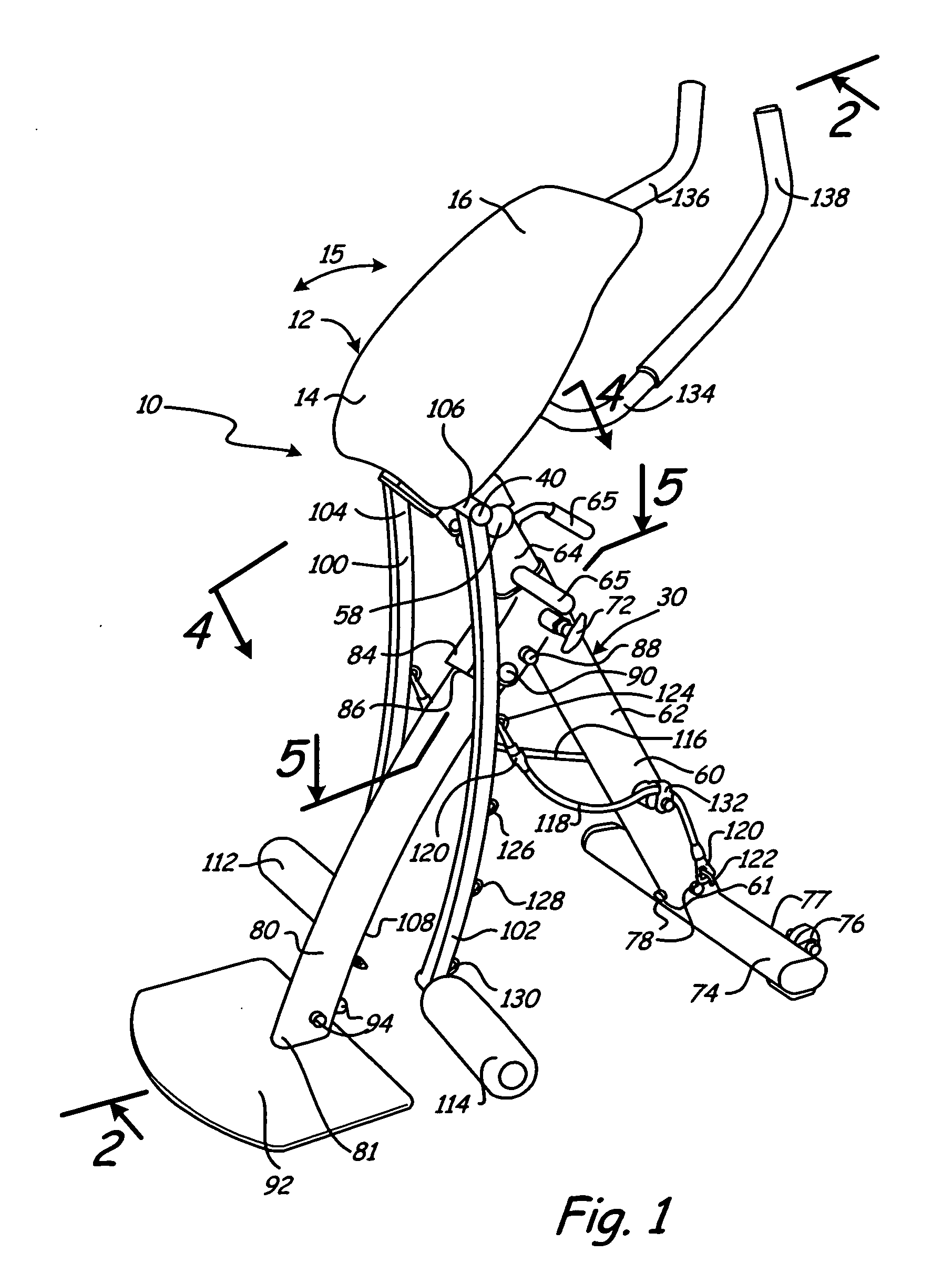

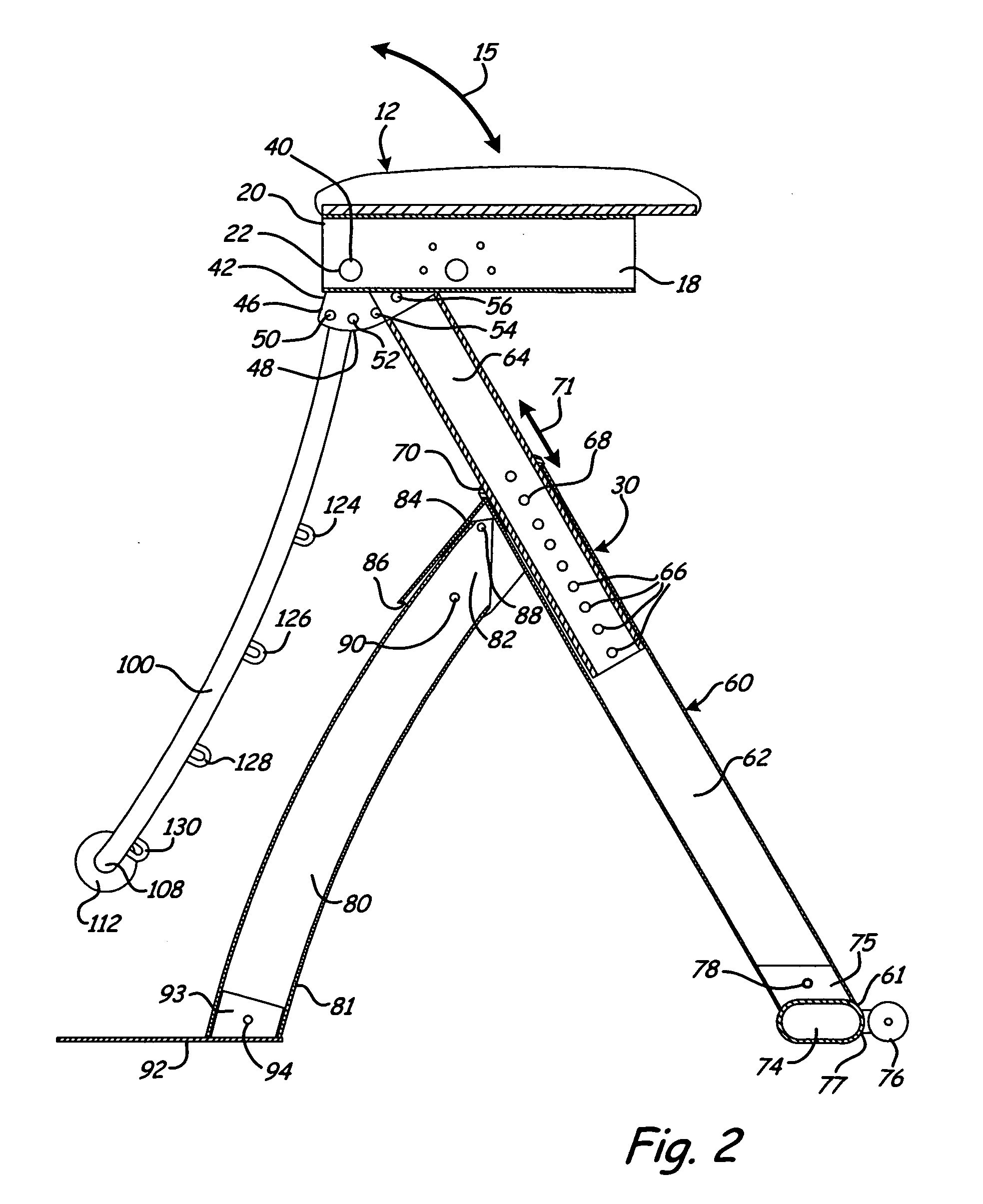

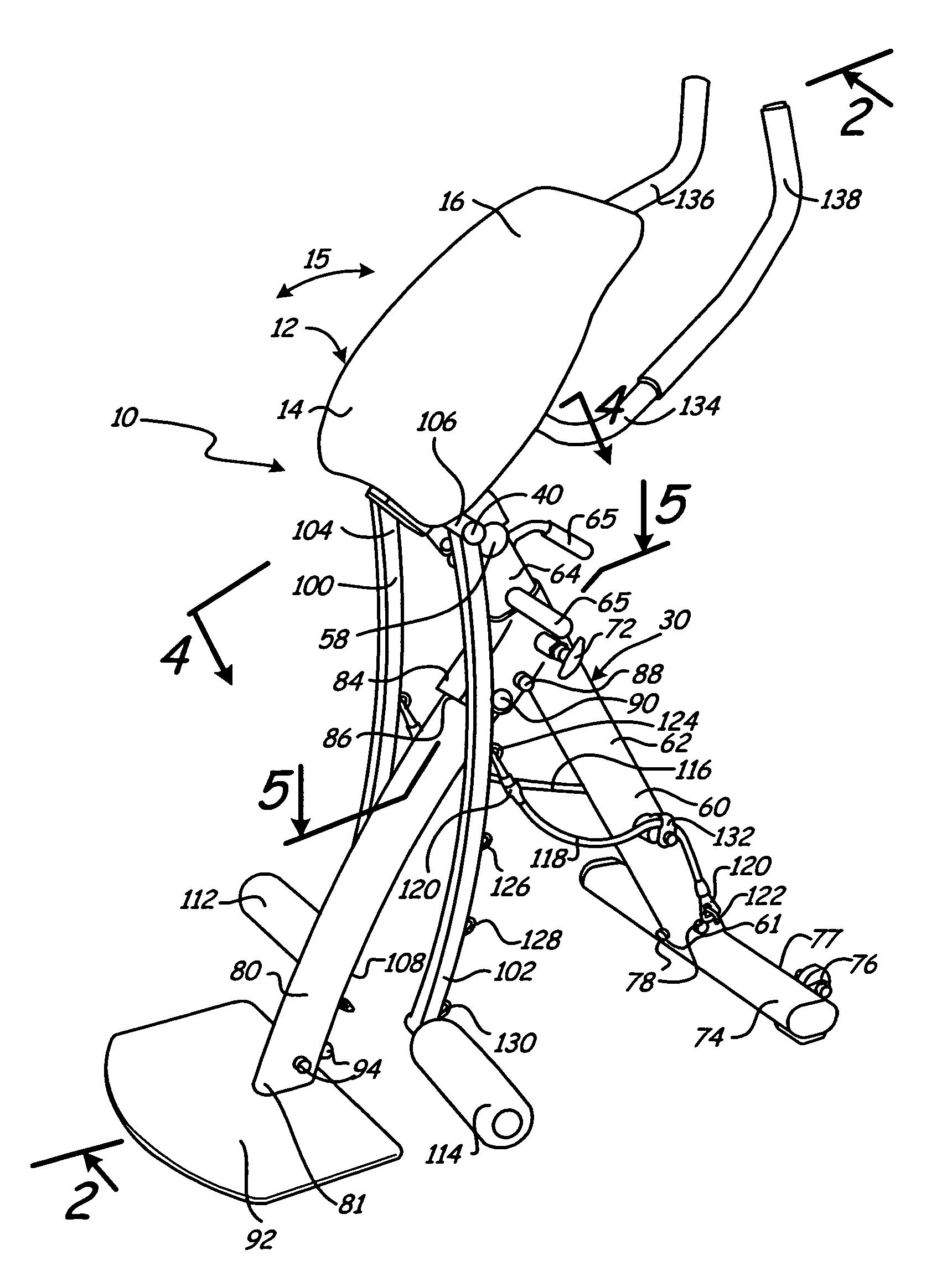

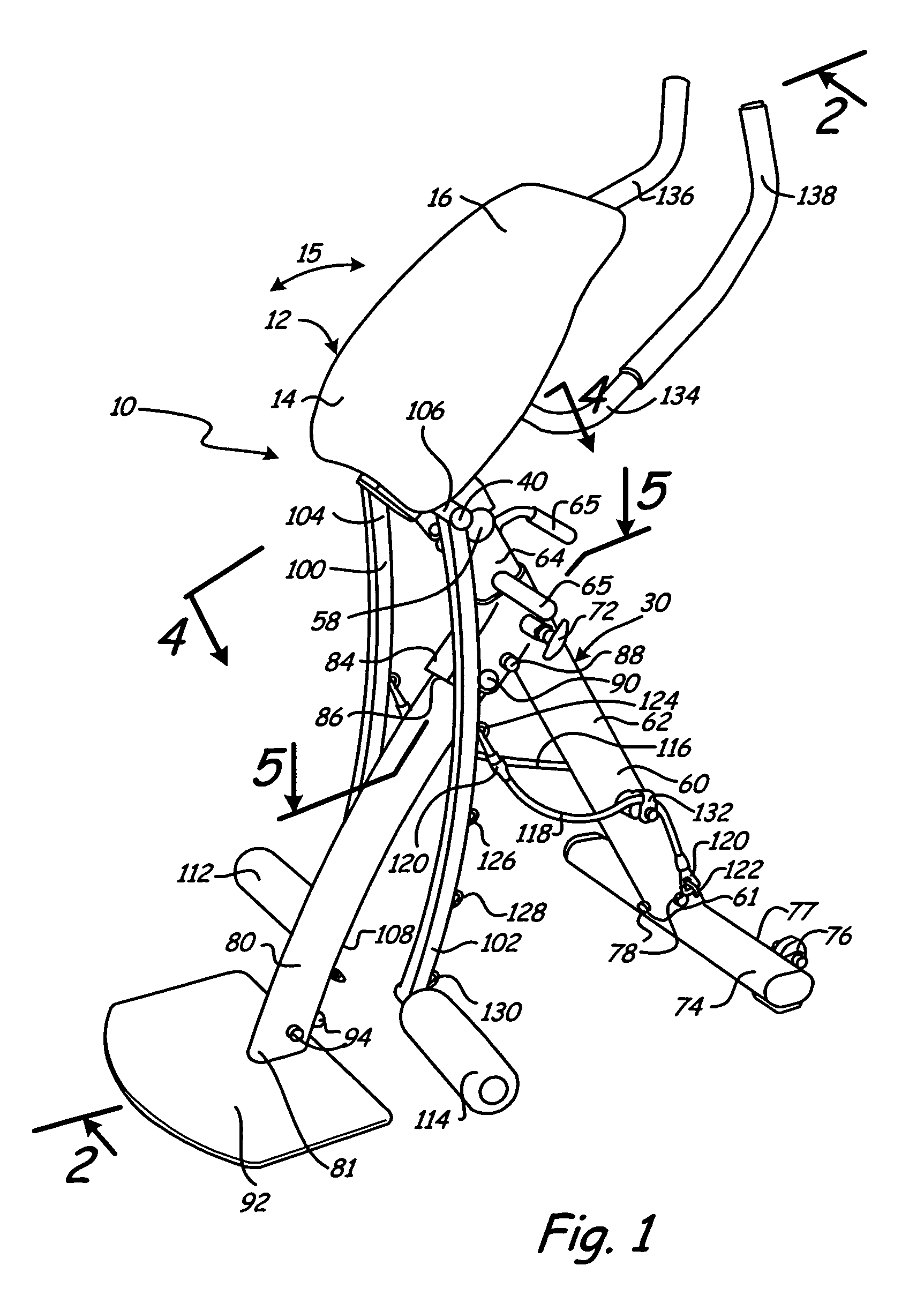

Exercise machine

An exercise device includes an upper body rest pivotally attached to a base. A first leg swing is pivotally attached to the base for engaging a first leg of an exerciser to perform a first leg raise. A second leg swing is pivotally attached to the base for engaging a second leg of an exerciser to perform a second leg raise. The upper body rest supports the spinal column and torso of an exerciser when performing the first and second leg raises.

Owner:ABDO JOHN S

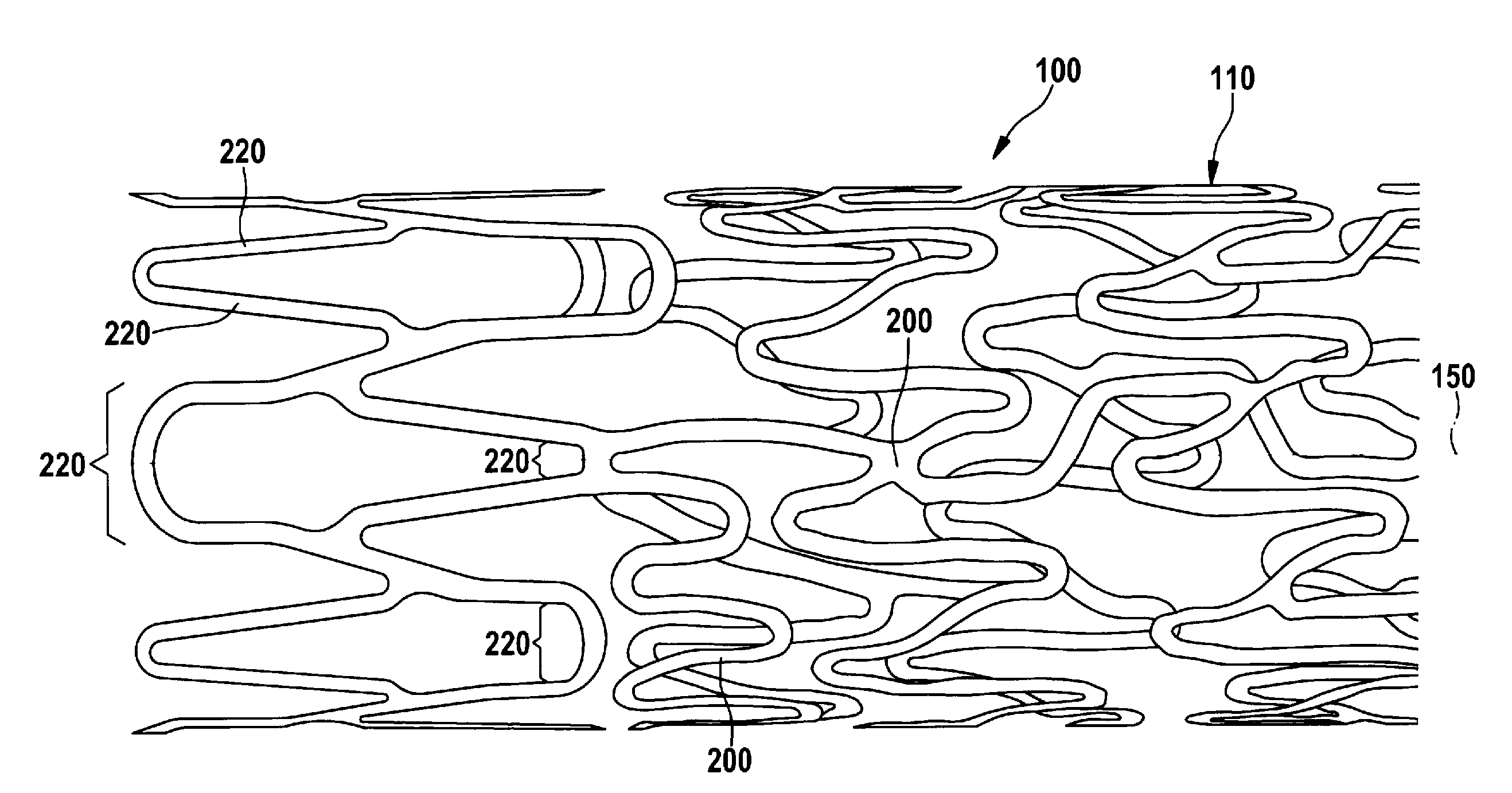

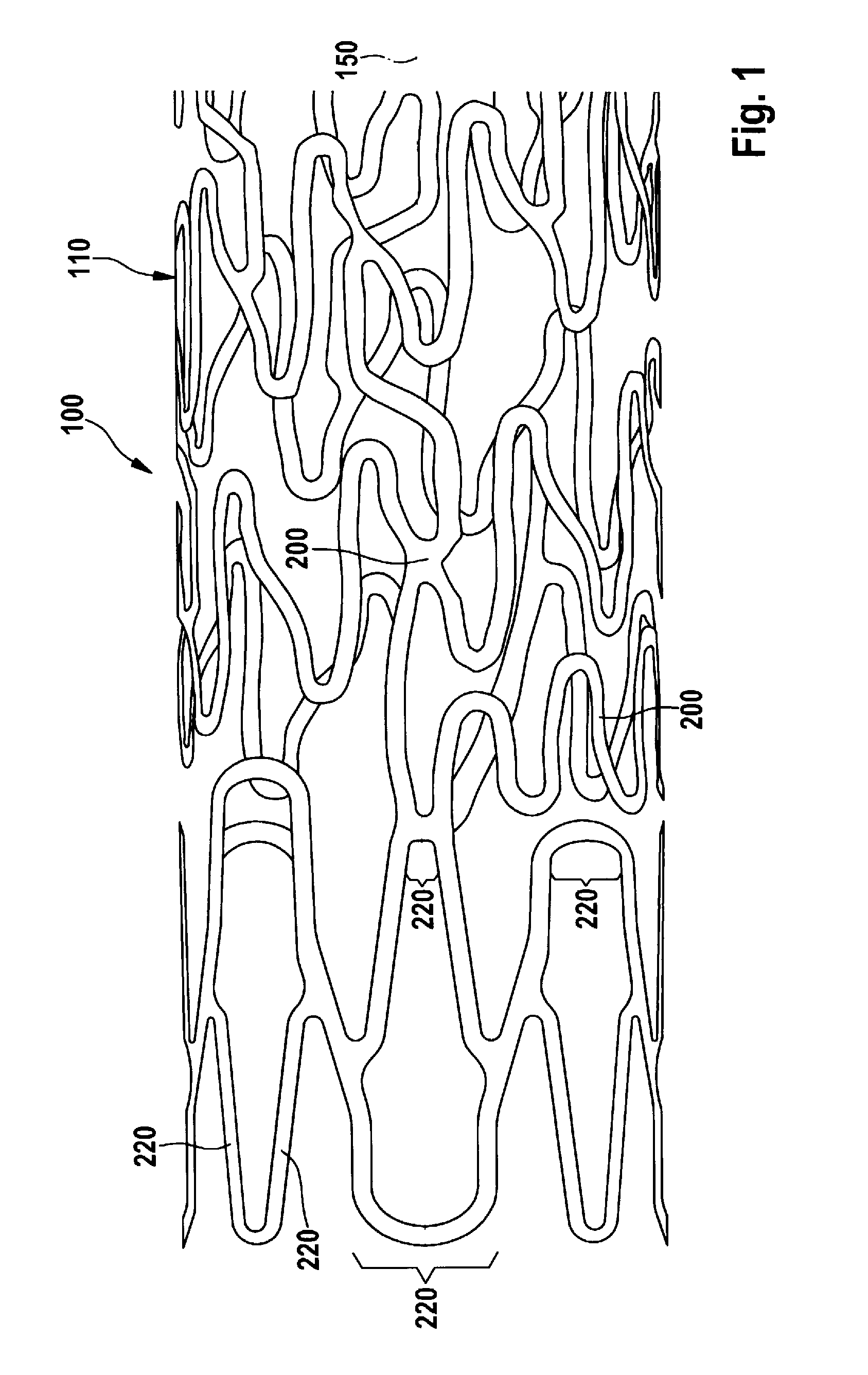

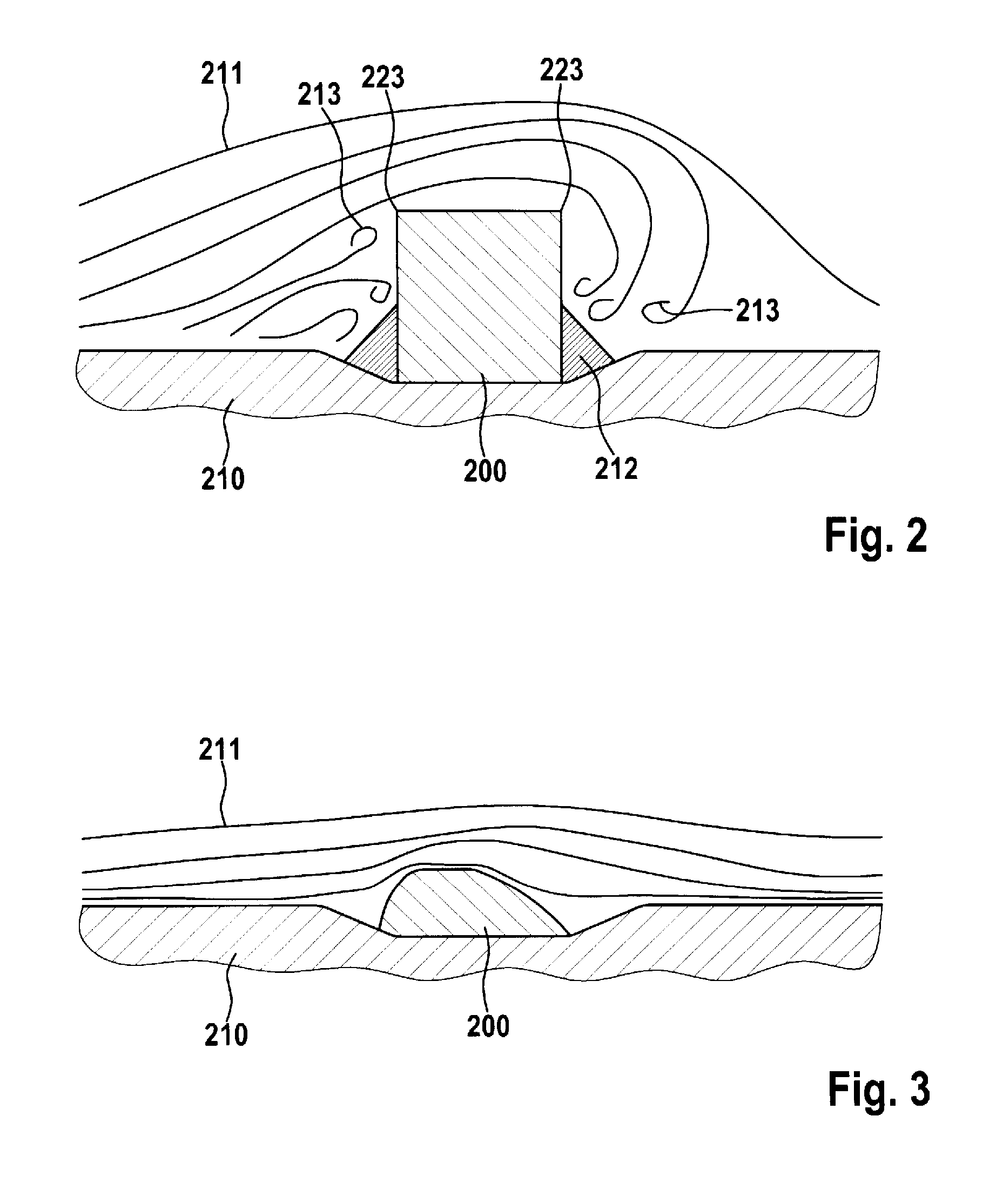

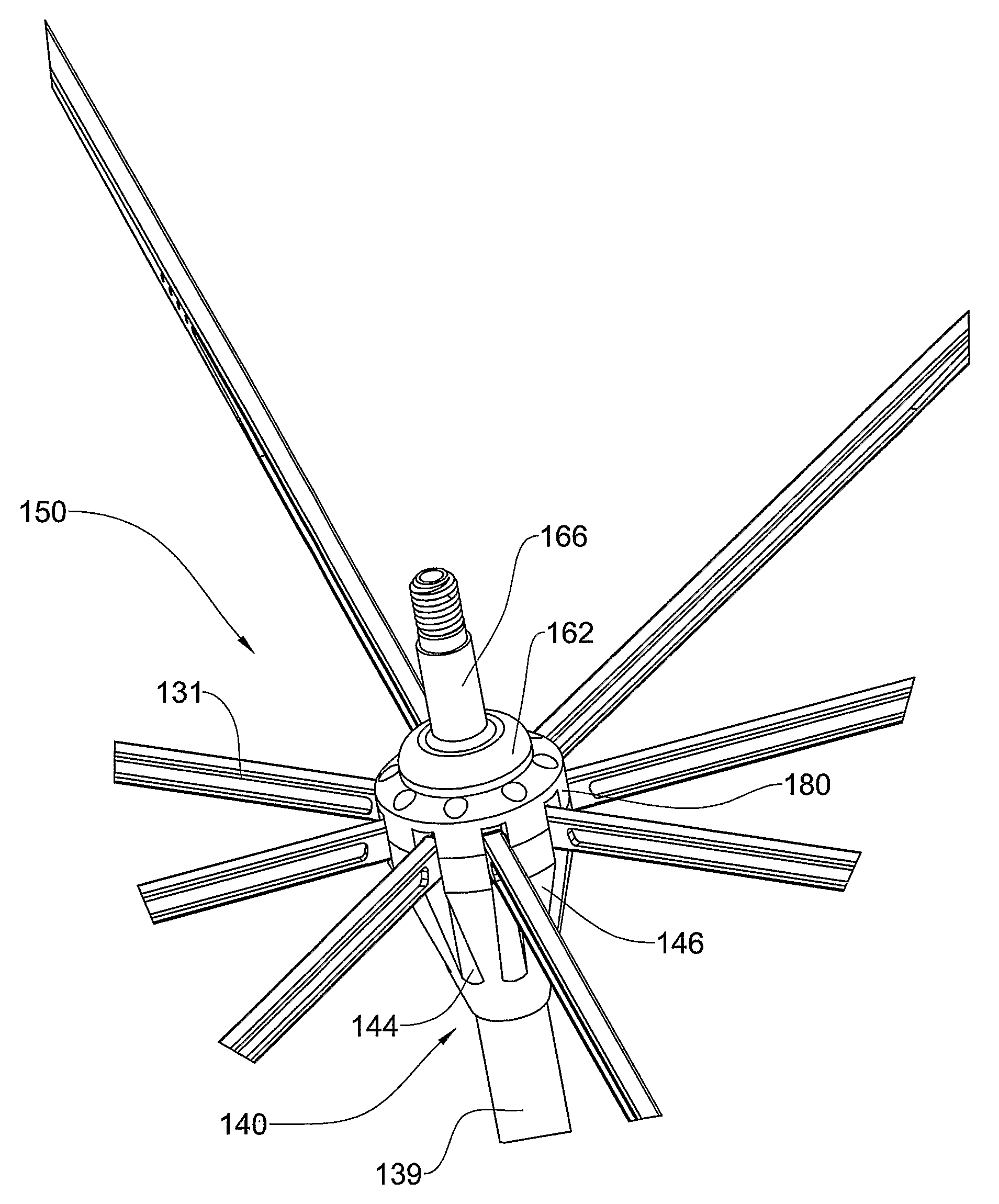

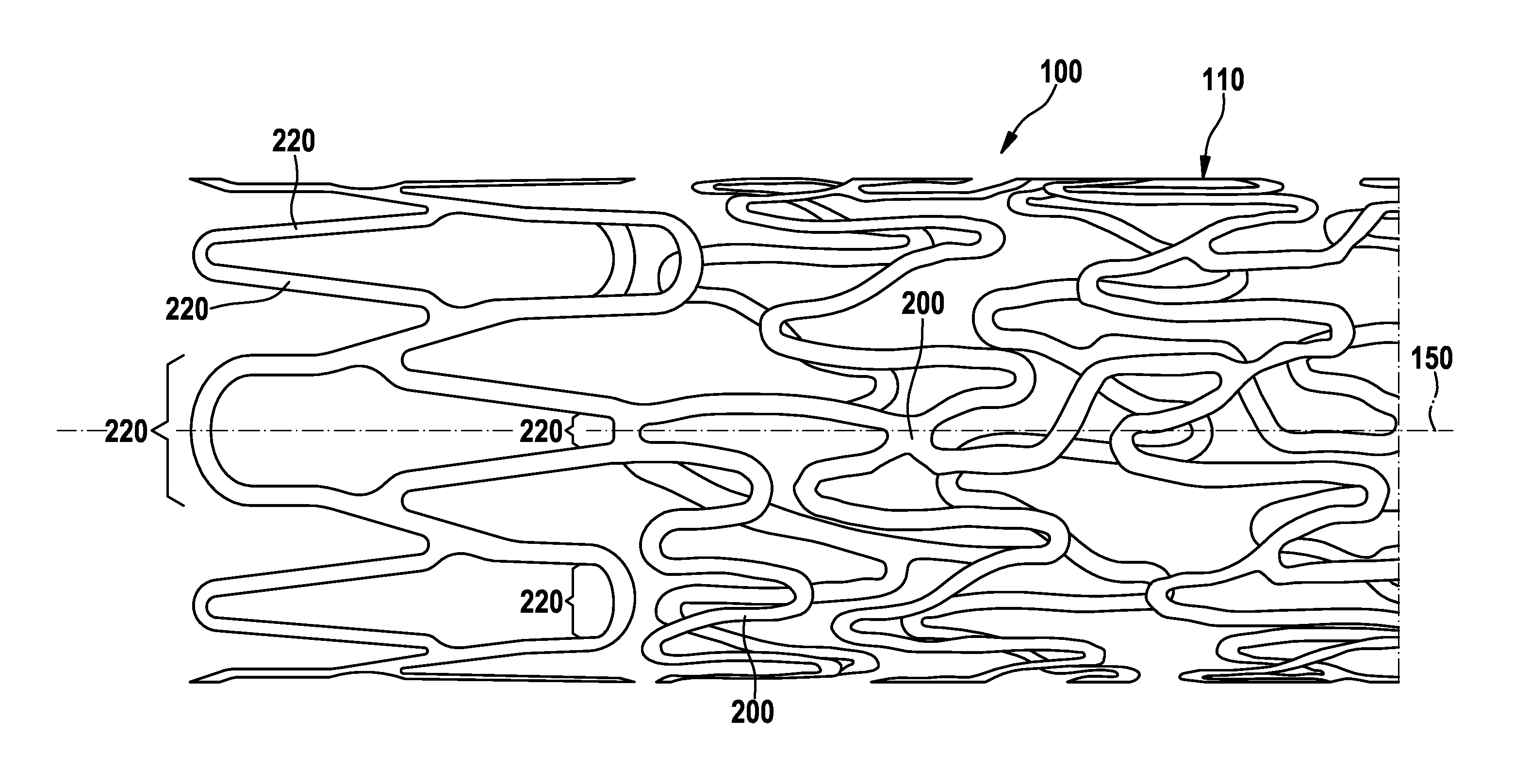

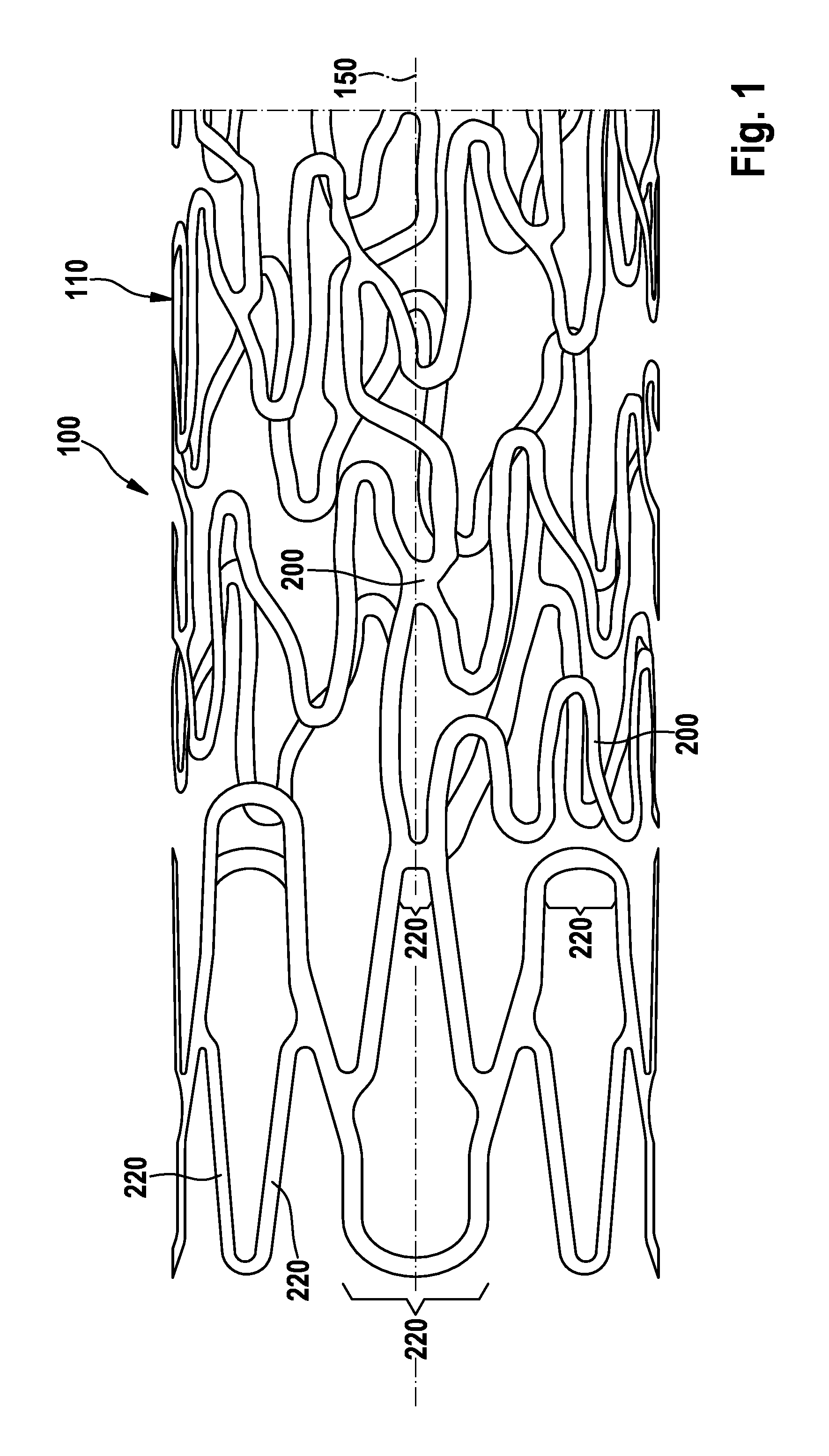

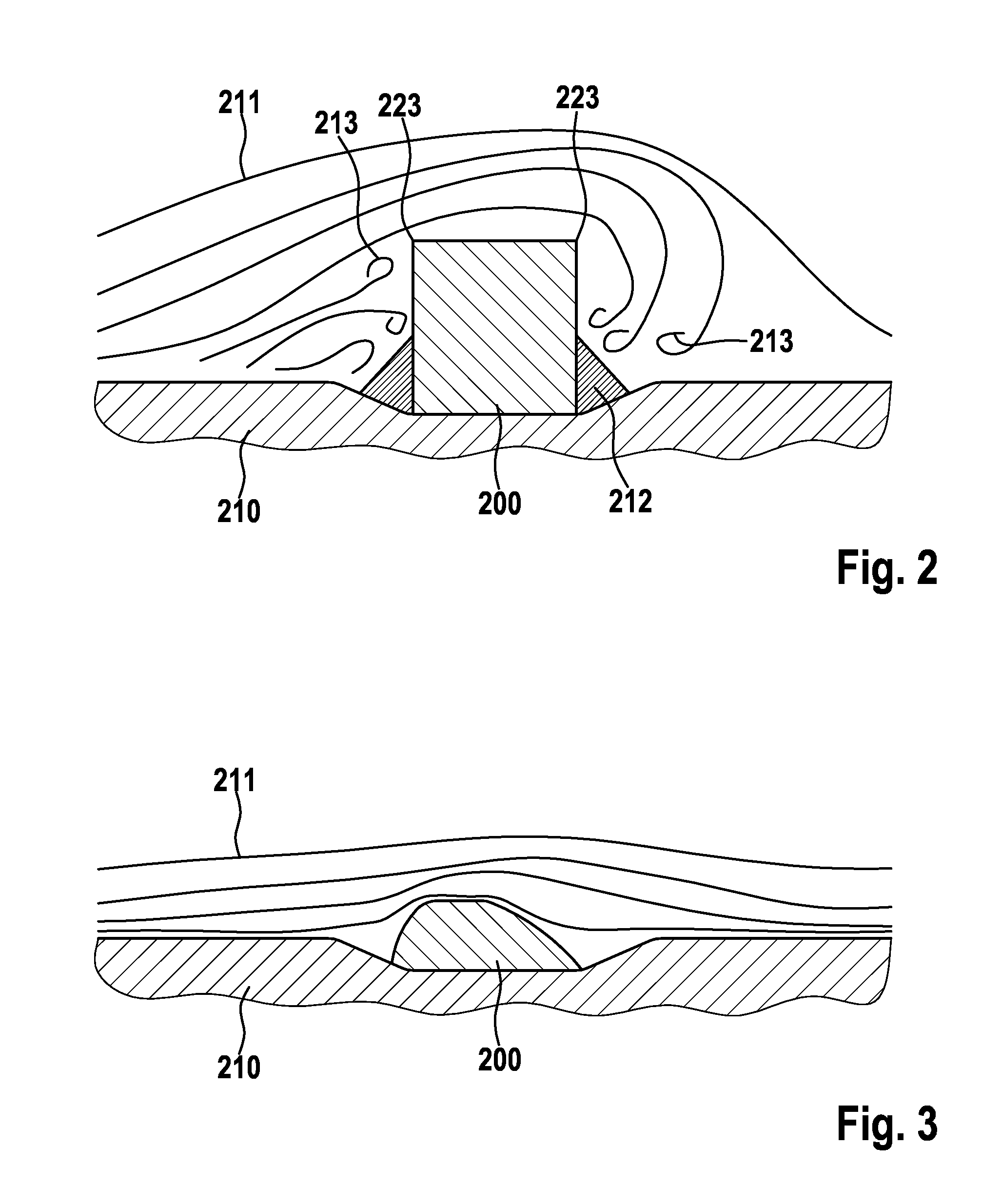

Stent and Method and Device for Fabricating the Stent

ActiveUS20100049300A1Stress minimizationAvoid injuryStentsElectrolysis componentsInsertion stentBiomedical engineering

Stent, as well as a method and device for fabricating the stent, wherein the stent has a tubular lattice structure comprising individual struts and at least one strut of which at least one longitudinal section runs with at least one directional component in the radial circumferential direction of the stent, wherein the surface of the longitudinal section facing the outside of the stent is curved only about the longitudinal axis of the stent. According to the invention, the surface of longitudinal section of the strut, which surface faces the inside of the stent, has such a curvature that the strut cross section is fluidically optimized.

Owner:BIOTRONIK AG

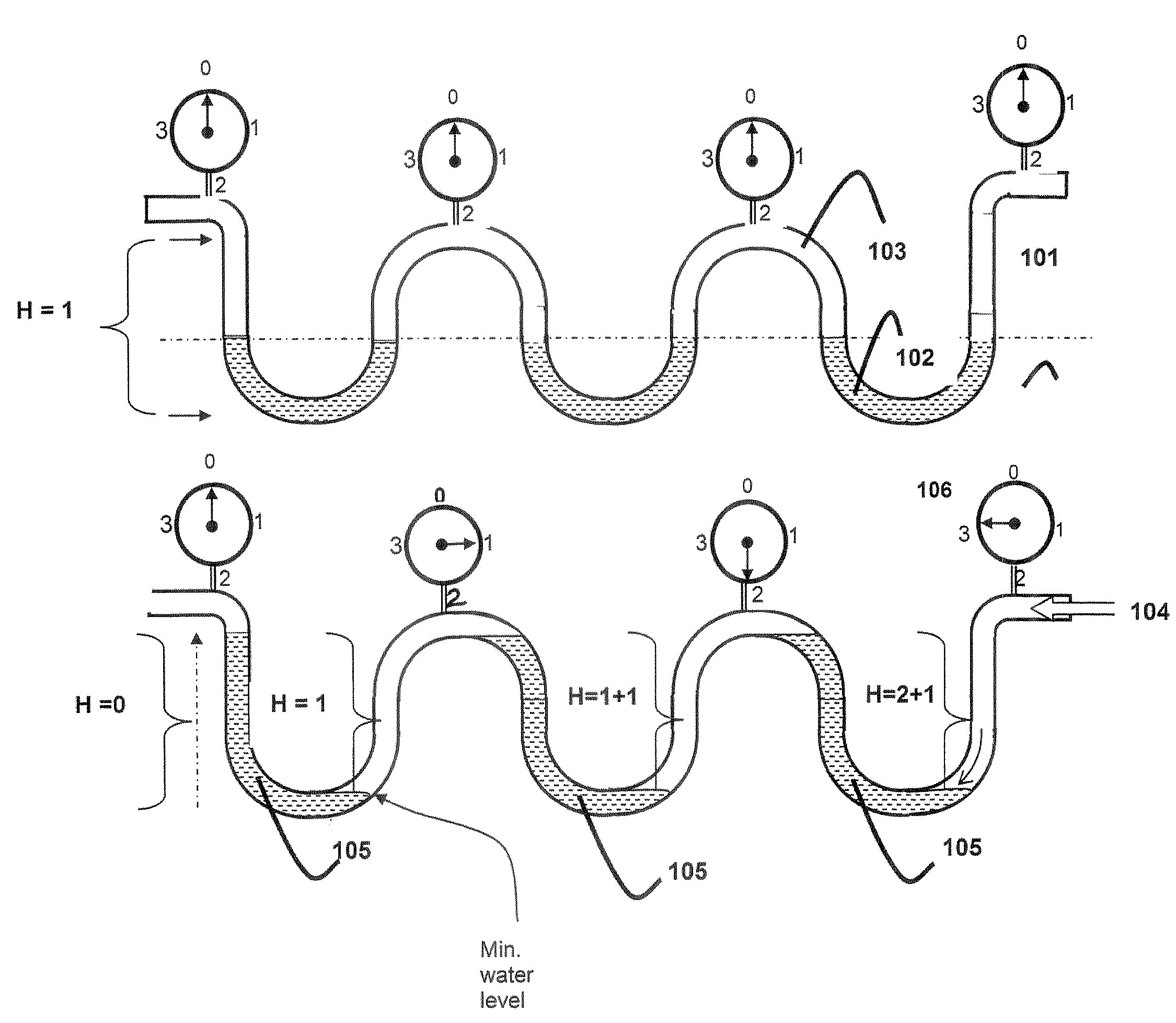

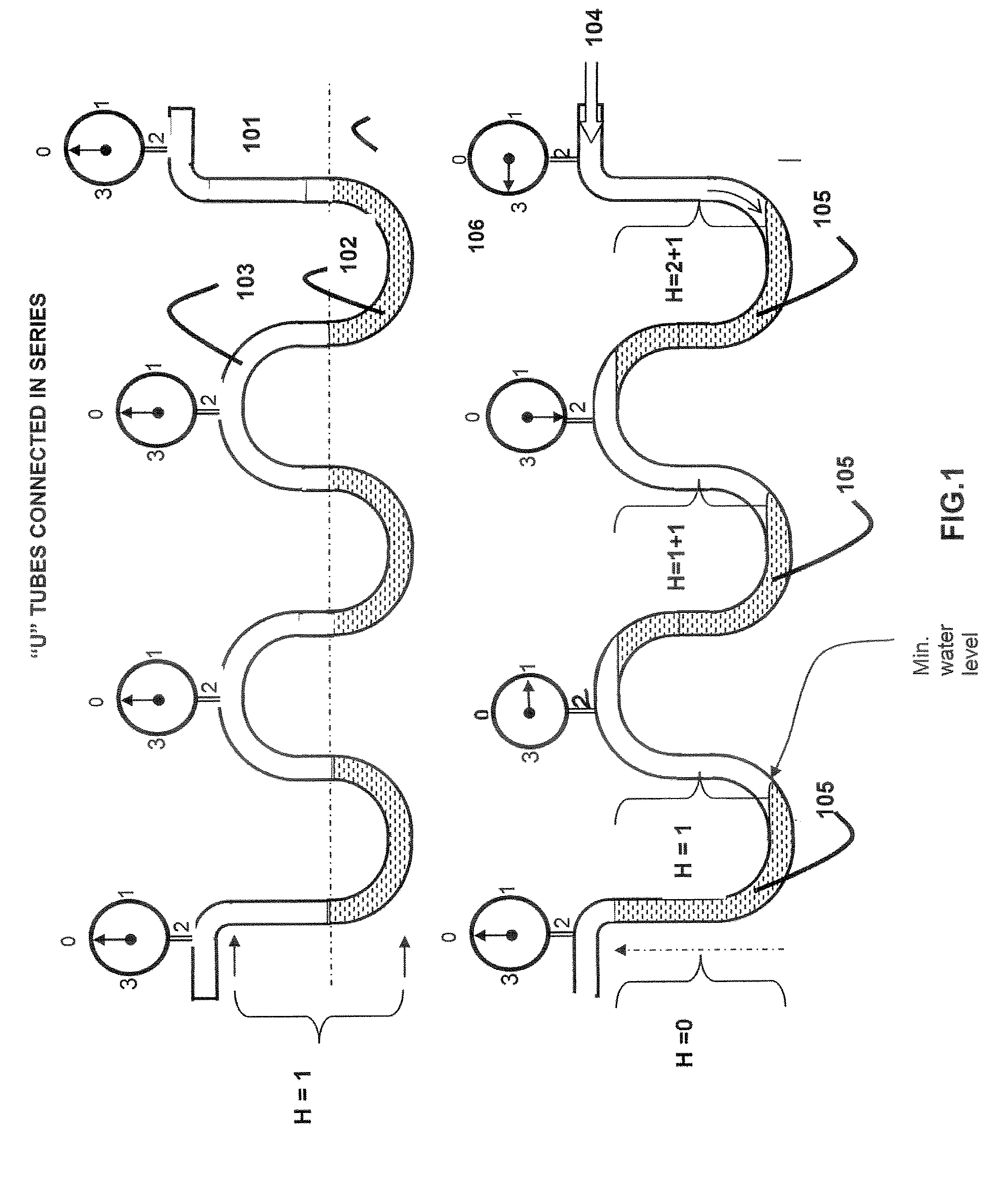

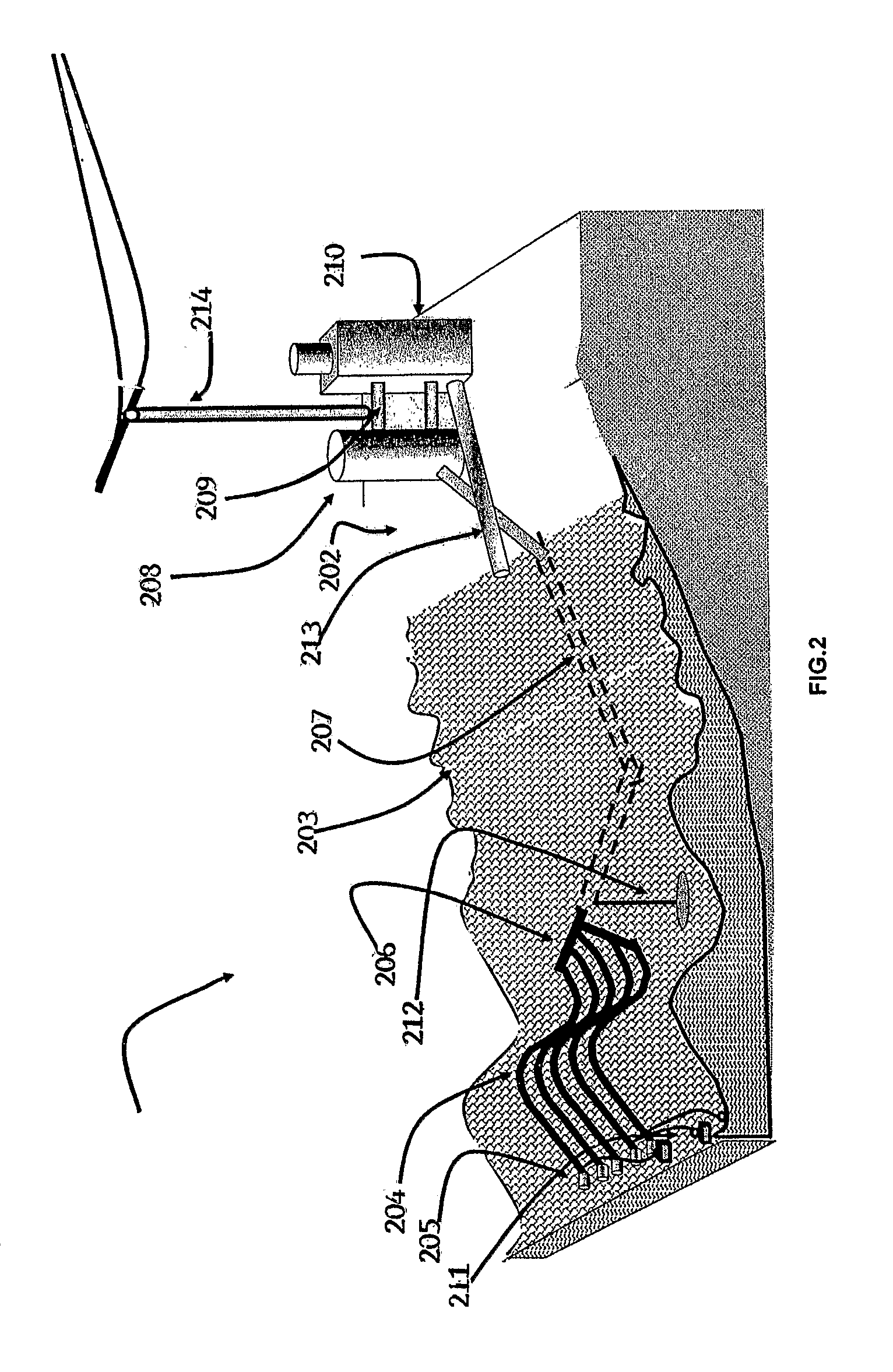

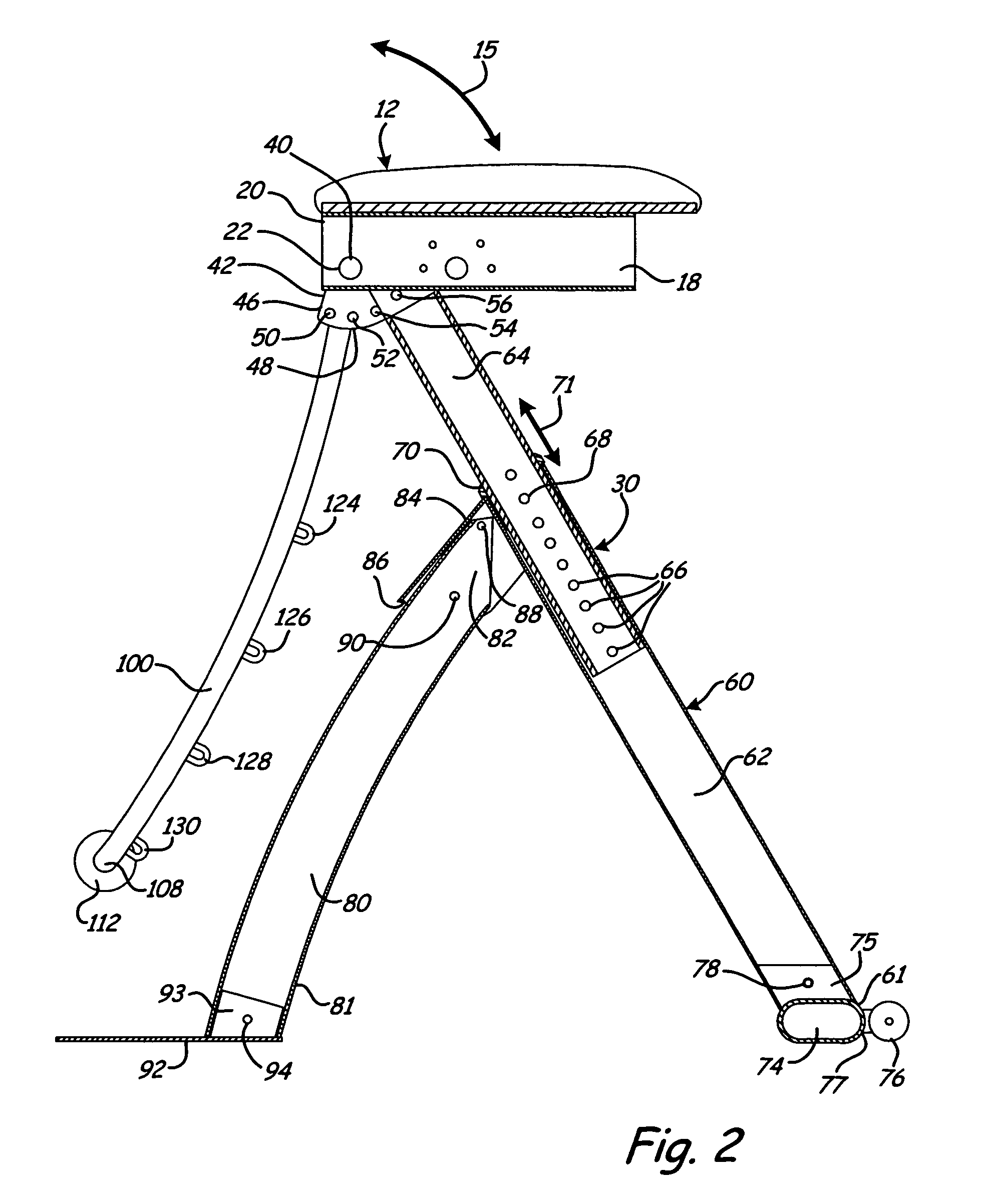

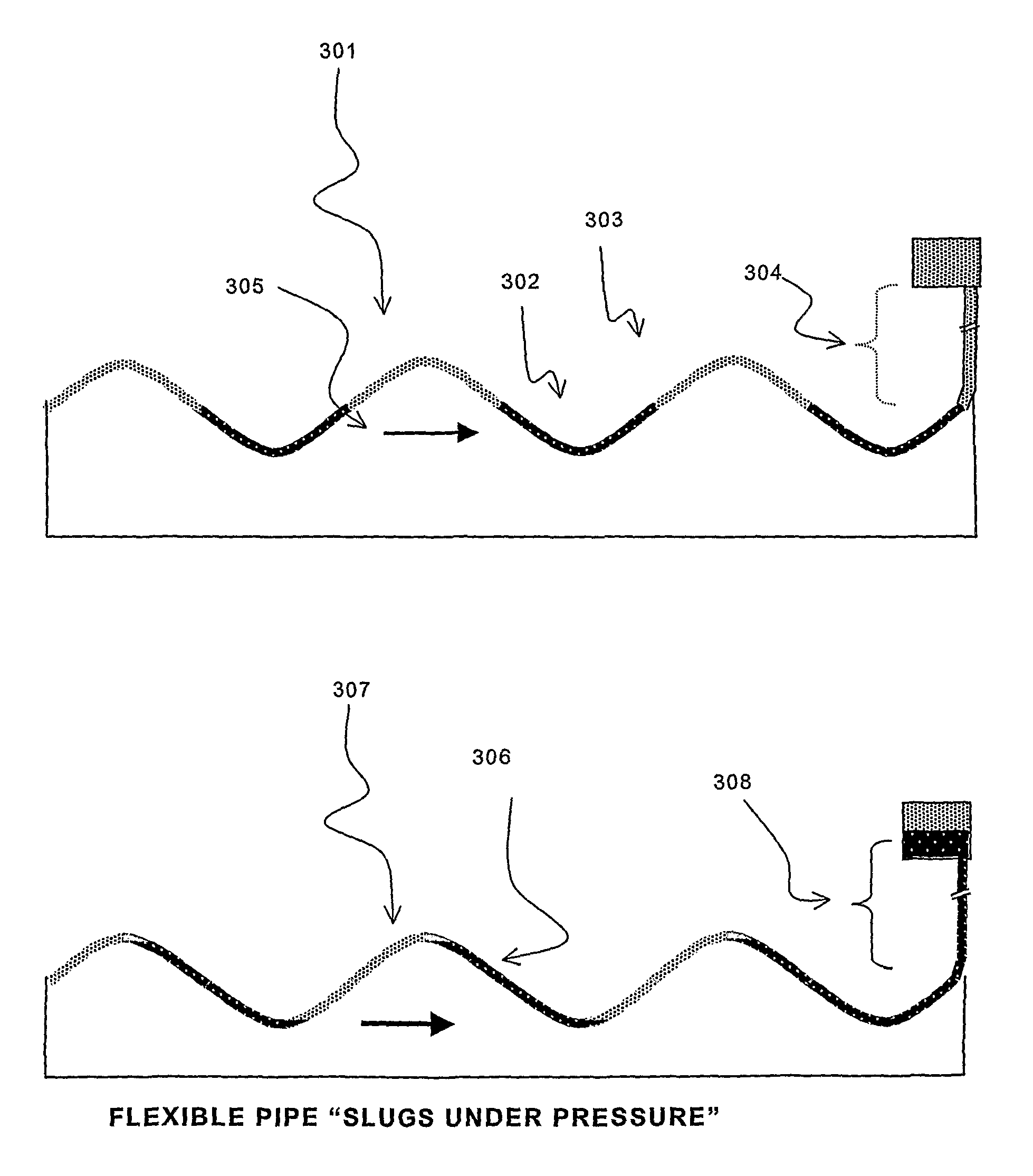

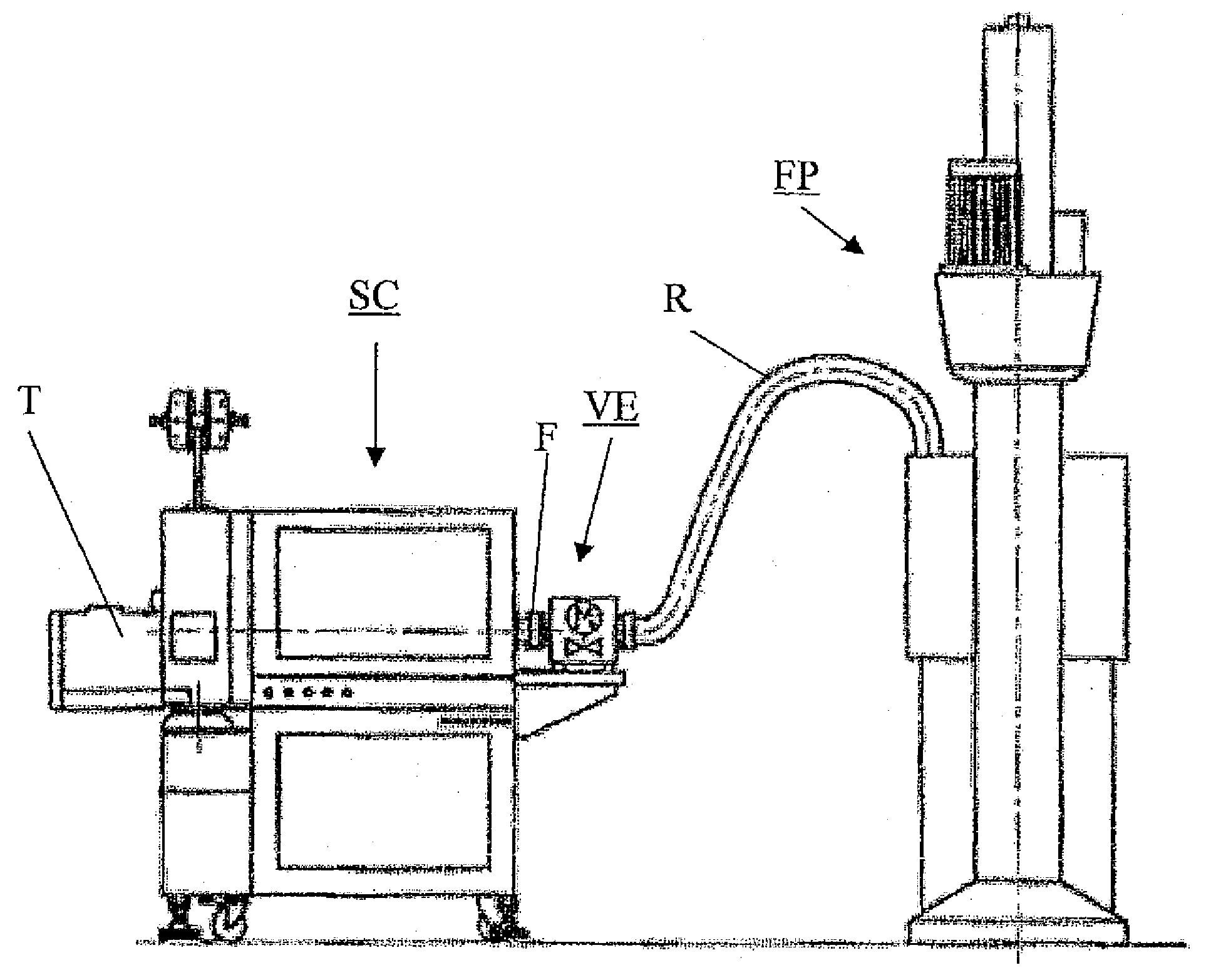

Free Floating Wave Energy Converter

InactiveUS20080229745A1Increase flow volumeIncrease pressureMachines/enginesEngine componentsVertical planeMarine engineering

A wave energy converter includes a flexible pipe and an inlet. The flexible pipe floats on the water surface, following the wave form. Slugs of water and air enter, one after the other, through the inlet. Because the flexible pipe follows the shape of the wave, water is transported through a manifold to a pressure chamber connected to a generator. The inlet consists of a hollow, inflexible pipe attached to the throat of the flexible pipe. The inflexible pipe is fixedly attached to a buoyancy tank or plurality thereof. The buoyancy tanks are arranged in a vertical plane or in tandem, with the inflexible pipe passing along the plane vertical to the fore and aft axis of the buoyancy tank and the frontward portion projecting sufficiently ahead of the buoyancy tank with the flexible pipe terminating at a singular outlet. The entire apparatus is facing the oncoming waves.

Owner:GHOUSE SYED MOHAMMED

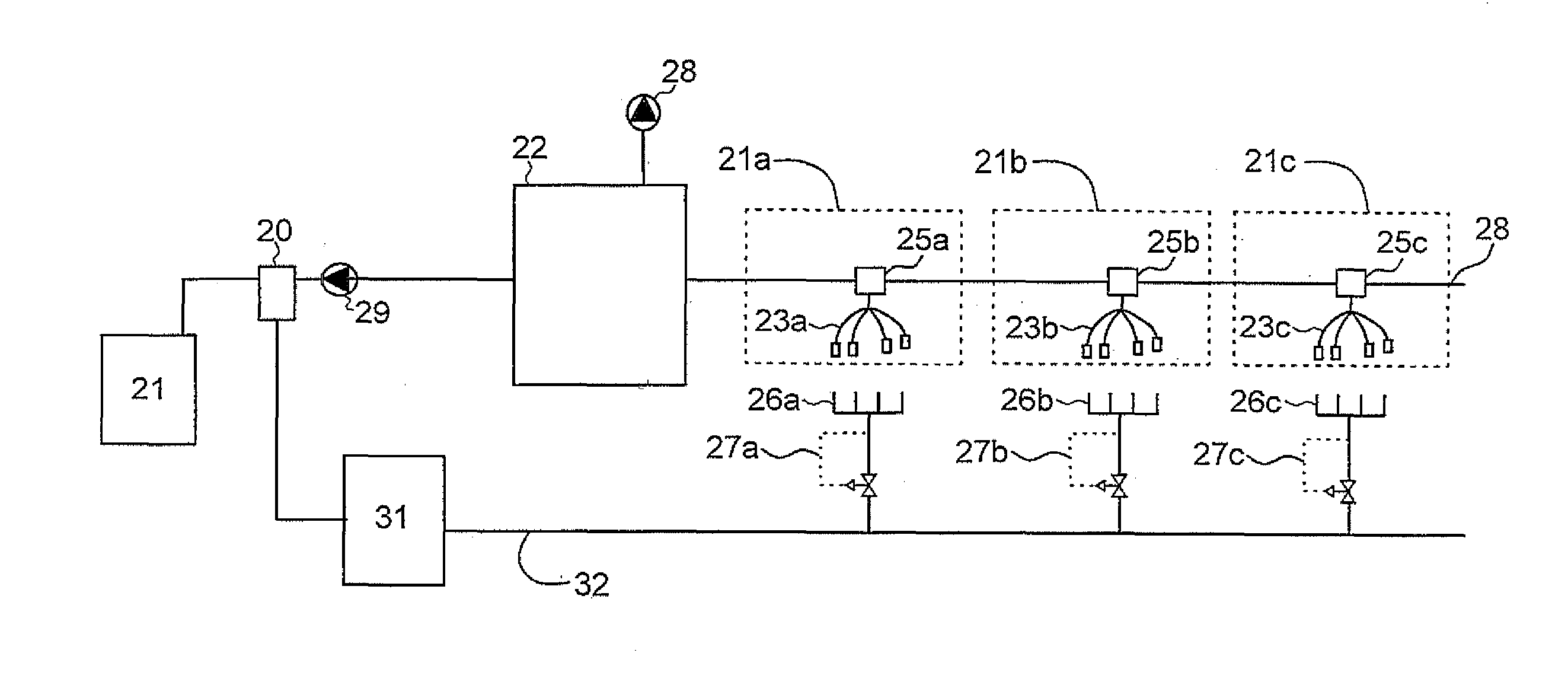

Cleaning arrangement

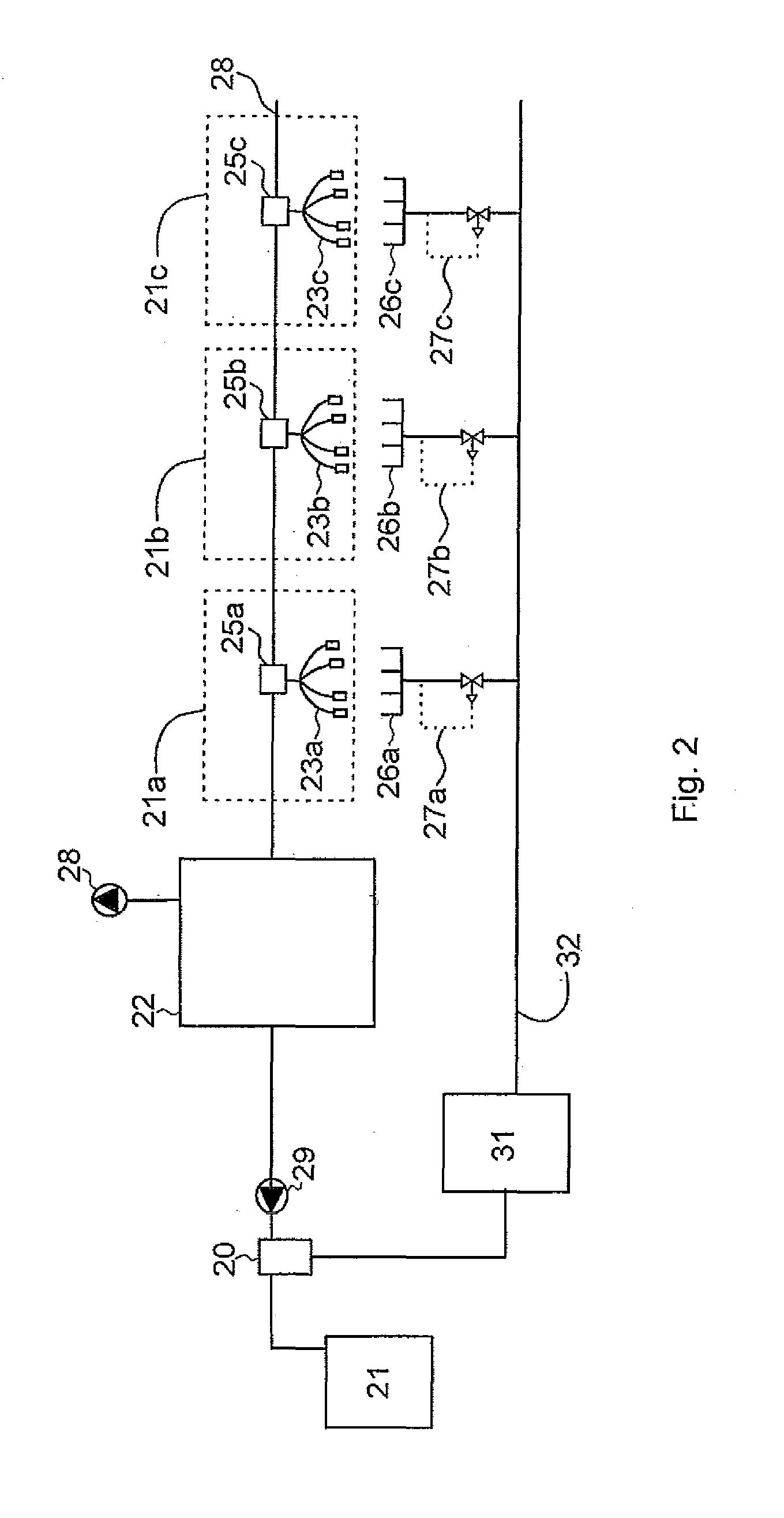

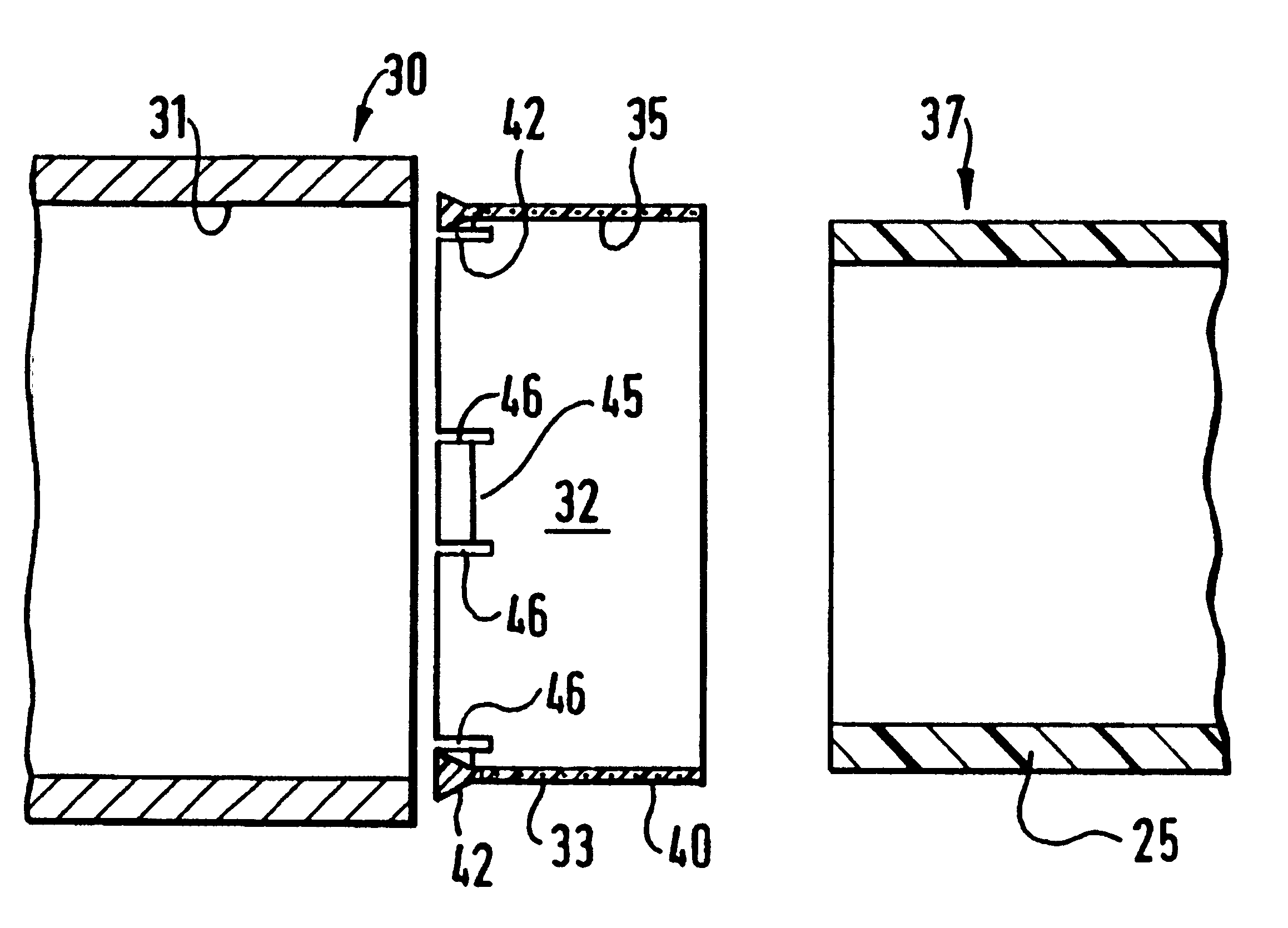

InactiveUS20110220160A1Prevent leakageOvercome disadvantagesCleaning using liquidsMilking devicesProcess engineeringAtmospheric pressure

An arrangement for controlling the supply of cleaning liquid into a milking system includes a pressurizing arrangement adapted to pressurize the cleaning liquid, a supply arrangement for selectively supplying cleaning liquid and a pressure sensing arrangement for sensing the pressure in the milking system. The pressure sensing device is operatively connected to the supply arrangement, and the supply arrangement is adapted to supply cleaning liquid into the milking system depending on the sensed pressure in the milking system. The arrangement can be adapted to supply cleaning liquid when the sensed pressure in the milking system is below the atmospheric pressure.

Owner:DELAVAL HLDG AB

Apparatus and method for fusion joining a pipe and fittings

InactiveUS6193834B1Quickly and easily field-installedImprove usabilityLamination ancillary operationsLaminationEngineeringFlange

An apparatus for fusing a pipe to a fitting includes an induction heating element wholly encased or coated with a flusible thermoplastic polymeric material, a fitting having a socket or a flange. The induction heating element is adapted to be inserted into said socket or mounted on said flange, the fitting and the element together defining a throughbore, a portion of a pipe adapted to be inserted into the throughbore or mountable on said flange. The apparatus also includes a locating and maintaining member on the induction heating element with one or more projections adapted to be snap-fitted on the fitting, the pipe or both, and capable of locating and maintaining the position of the heating element relative to the fitting or the member portion. The induction fusion element is capable of fusing the fitting and the pipe portion.

Owner:UPONOR LTD

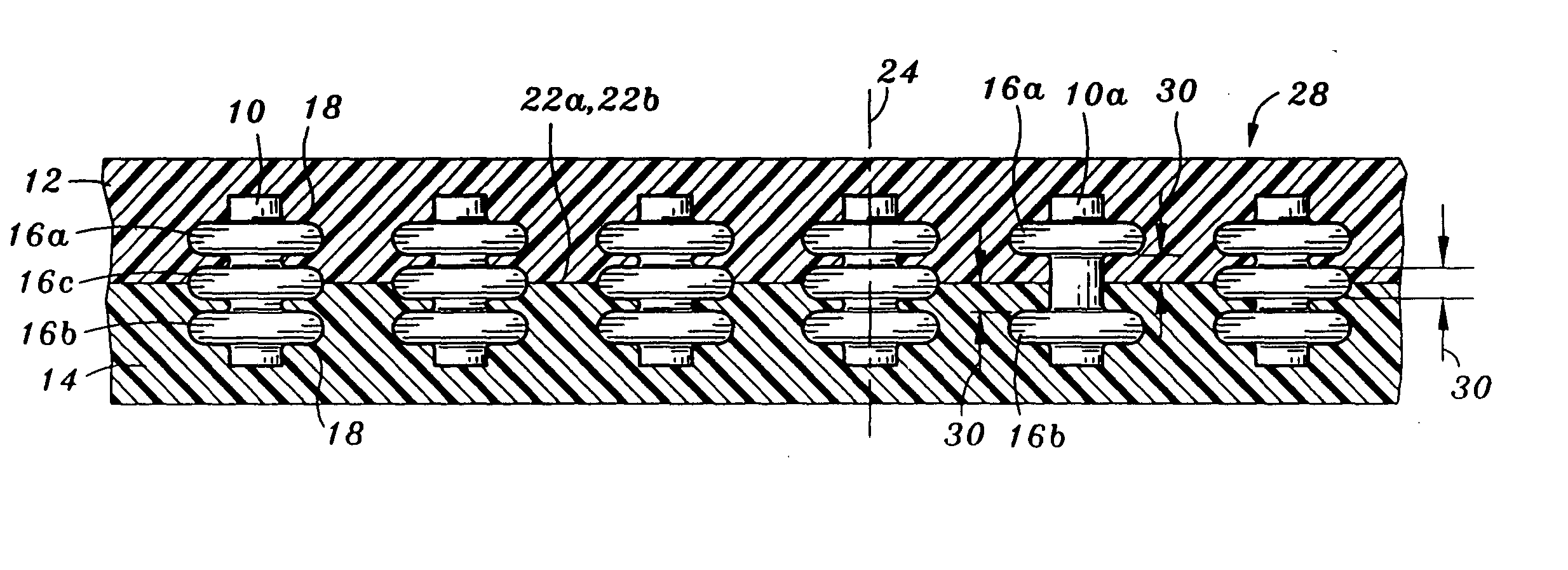

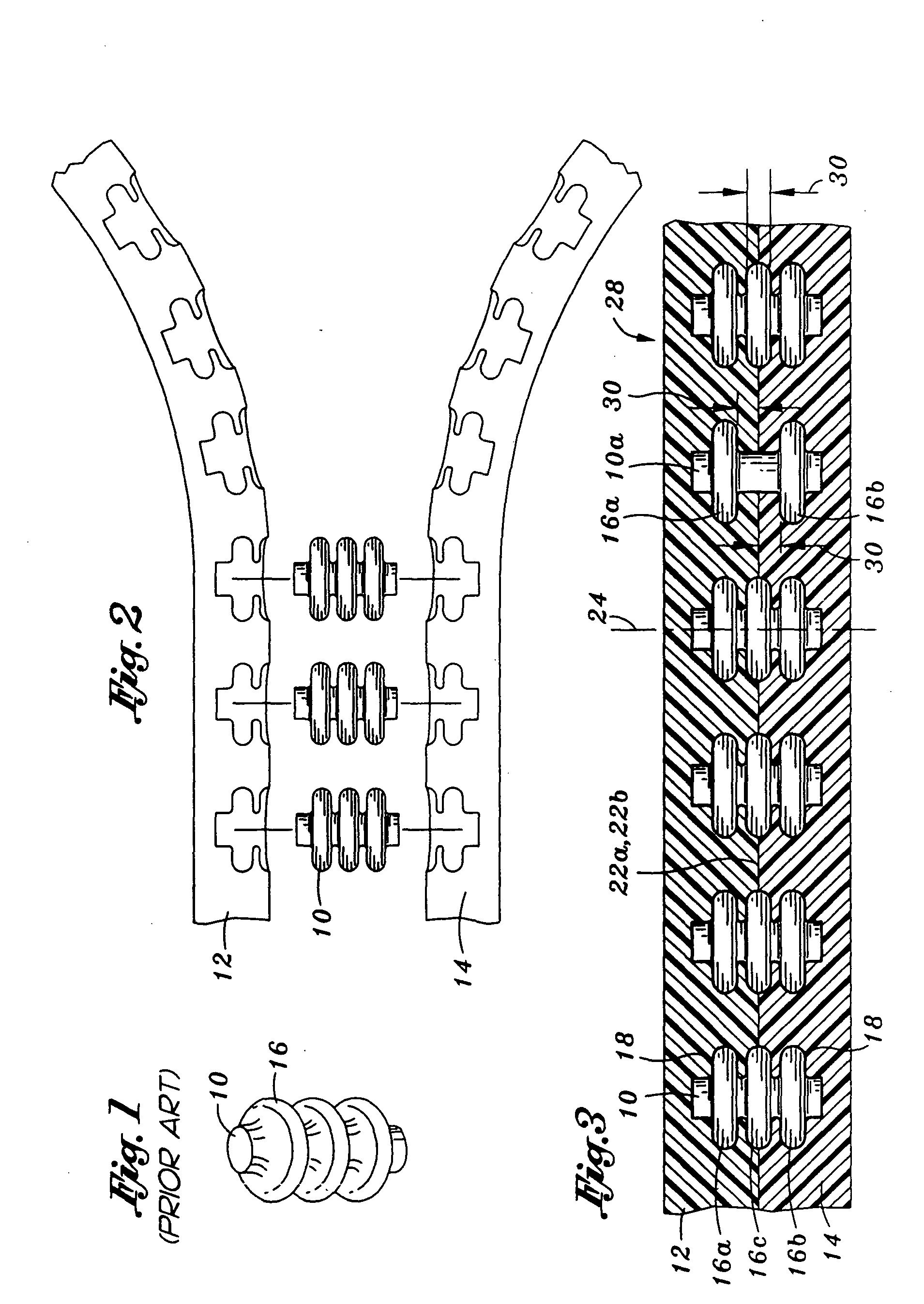

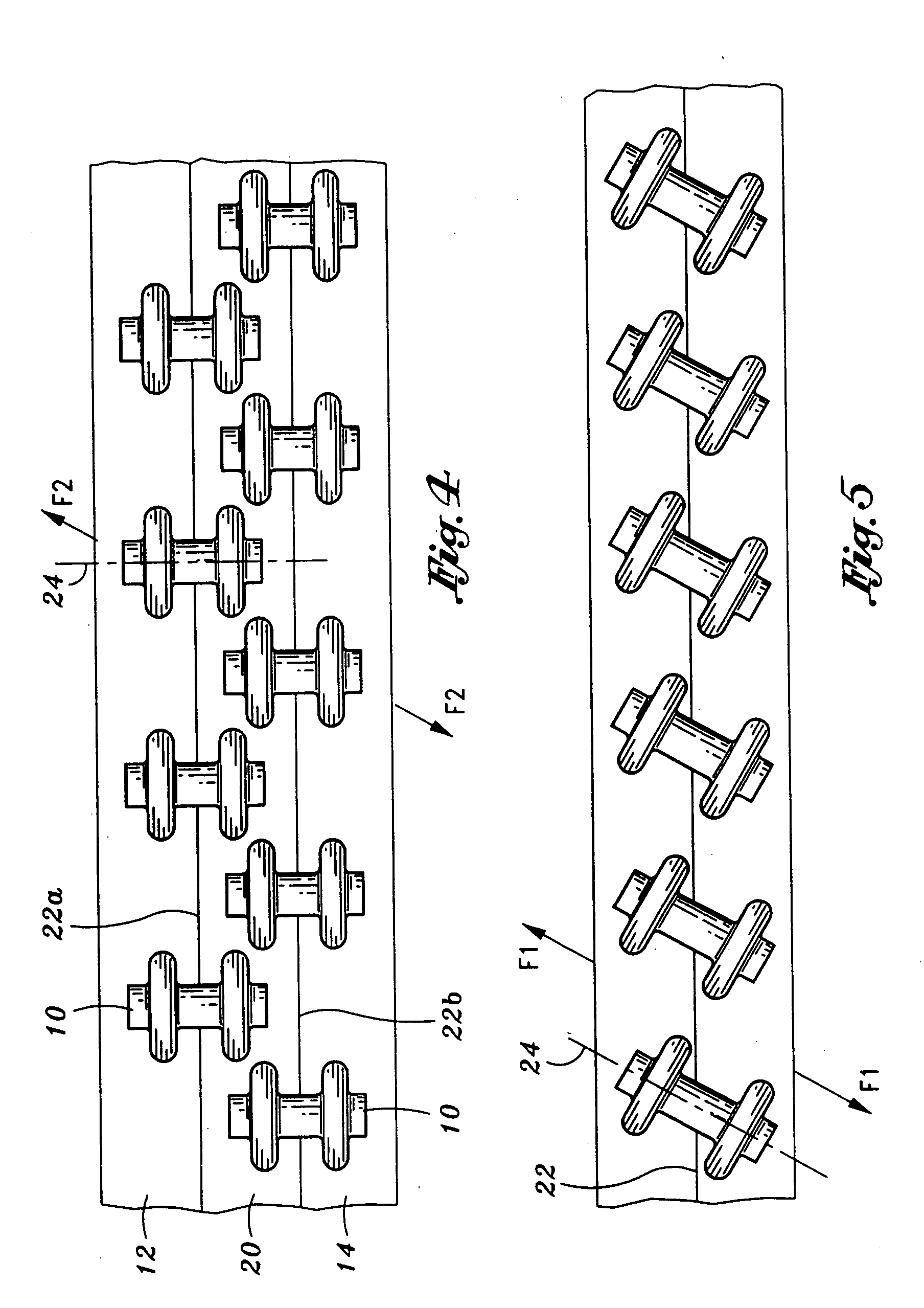

Structural assemblies using integrally molded, and welded mechanically locking z-pins

InactiveUS20050042023A1Reduce stress concentrationAbility to controlMaterial gluingSheet joiningEngineeringHardness

A structure is provided which includes first and second layers. The first and second layers are attached to each other by embedding or otherwise attaching at least one mechanically locking z pin to the first layer and then subsequently joining the protruding portion of the z pin to the second layer prior to the second layer being processed to a fully cured state. Alternatively, the z pin material is injected into a cavity formed in the first and second layer and then brought to a fully cured state. The z pin may have physical characteristics such as orientation, melting point and hardness as a function of the physical characteristics of the first and second layer and the forces subjected upon the first and second layers. For example, the z pin may define a longitudinal axis and be embedded within the first and second layers in alignment with an applied force subjected on the first and second layers. This ensures that the z-pin is subjected primarily to tensile forces which allows designs to better control the failure mode of the attached first and second layers.

Owner:NORTHROP GRUMAN CORP

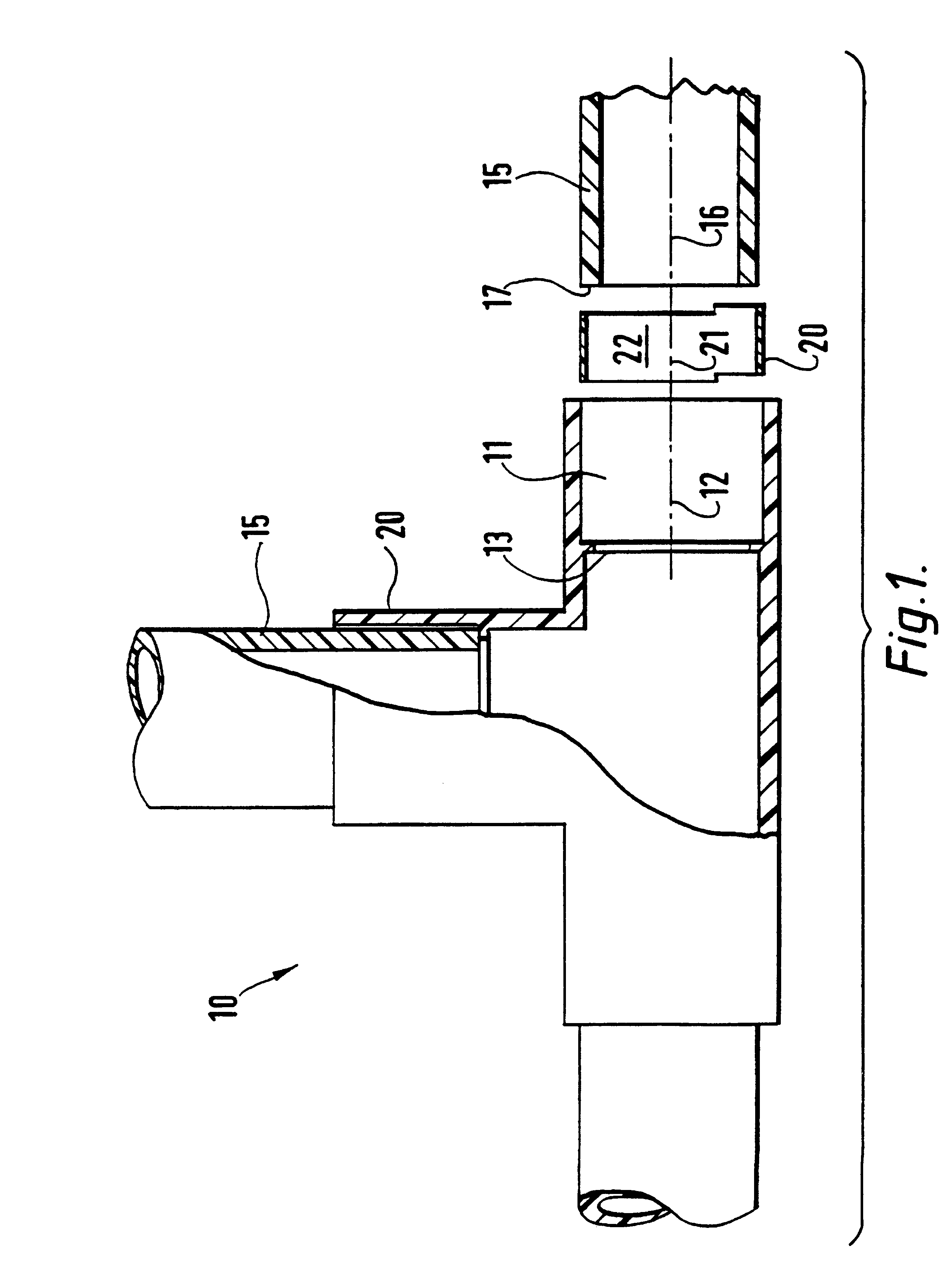

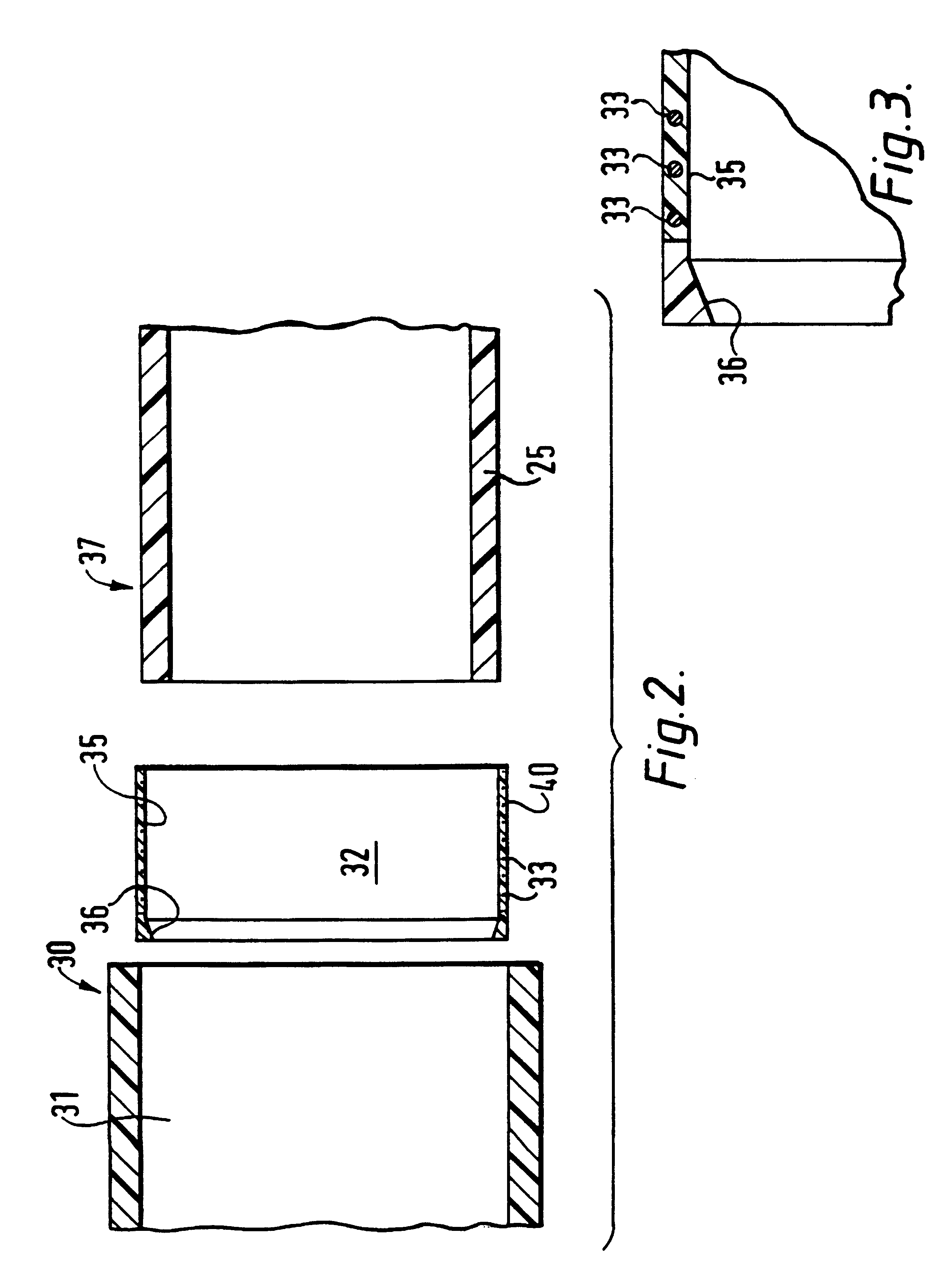

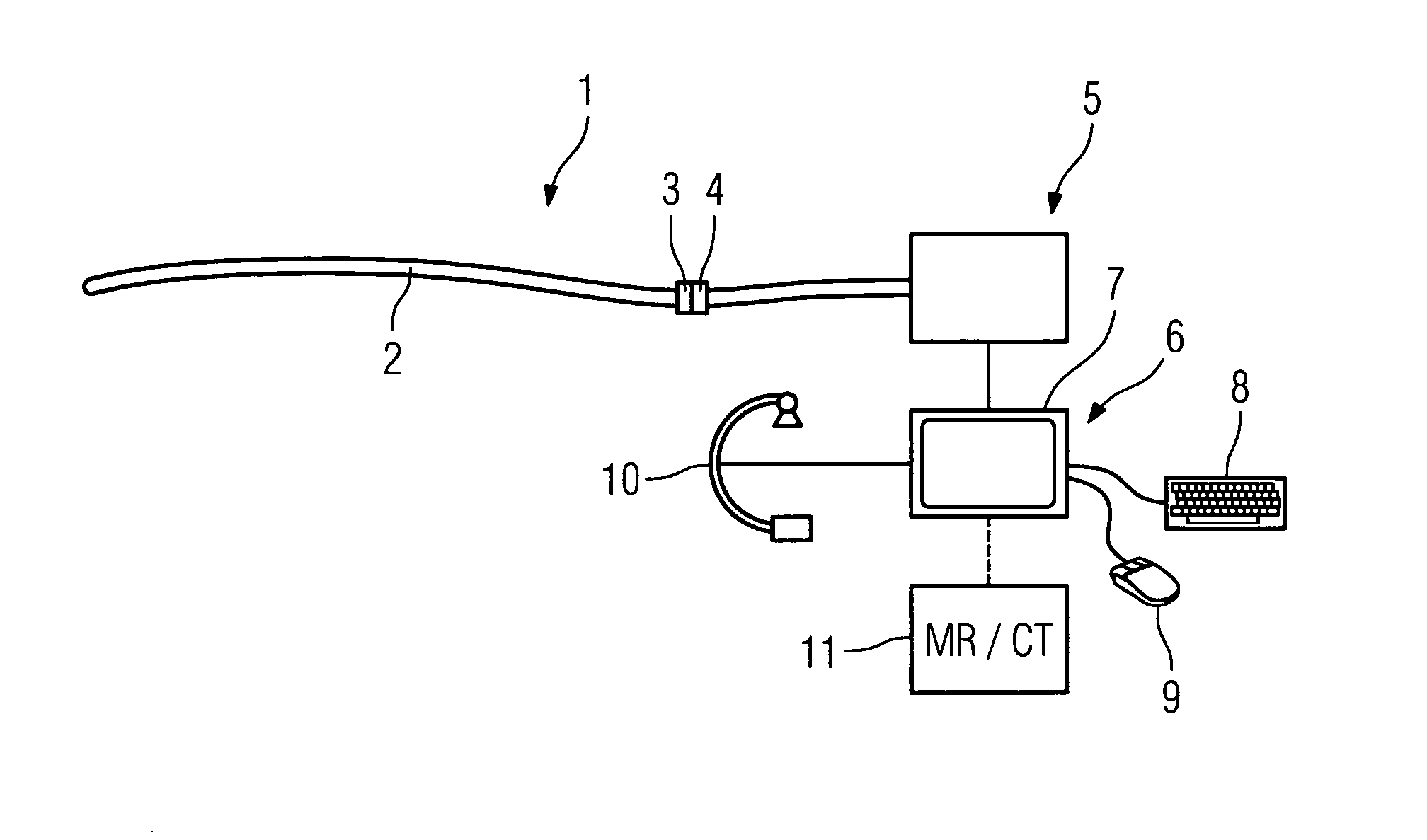

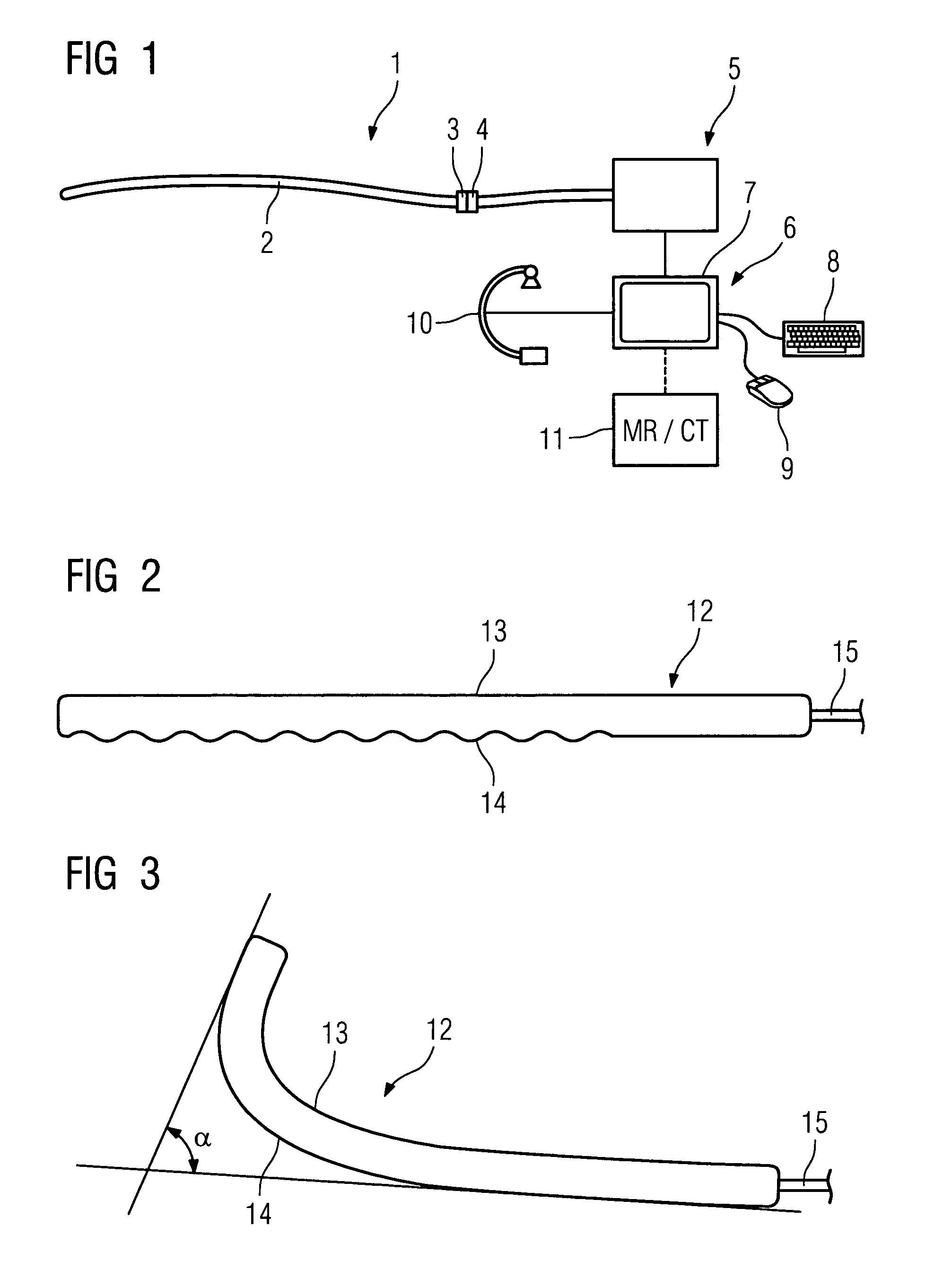

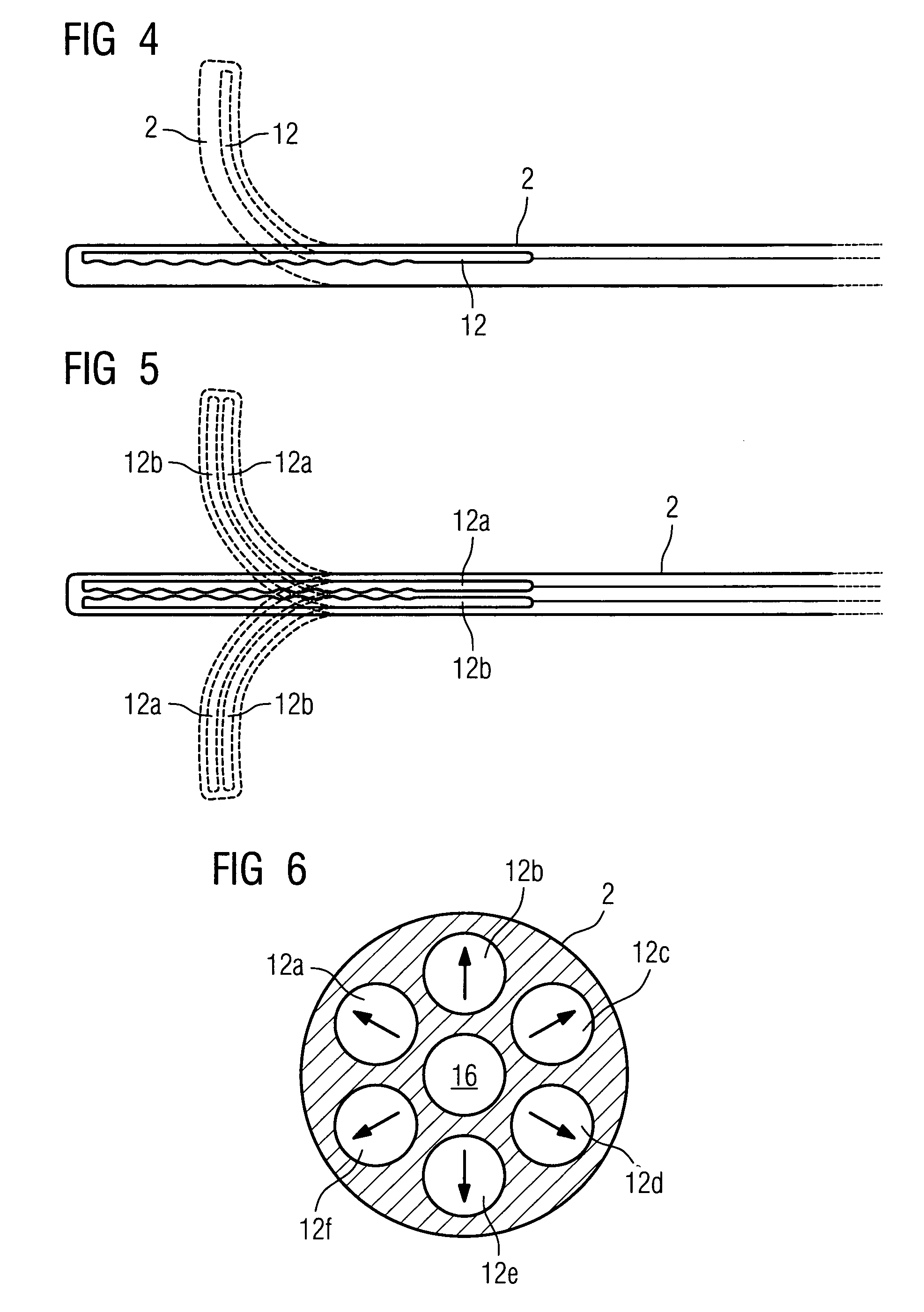

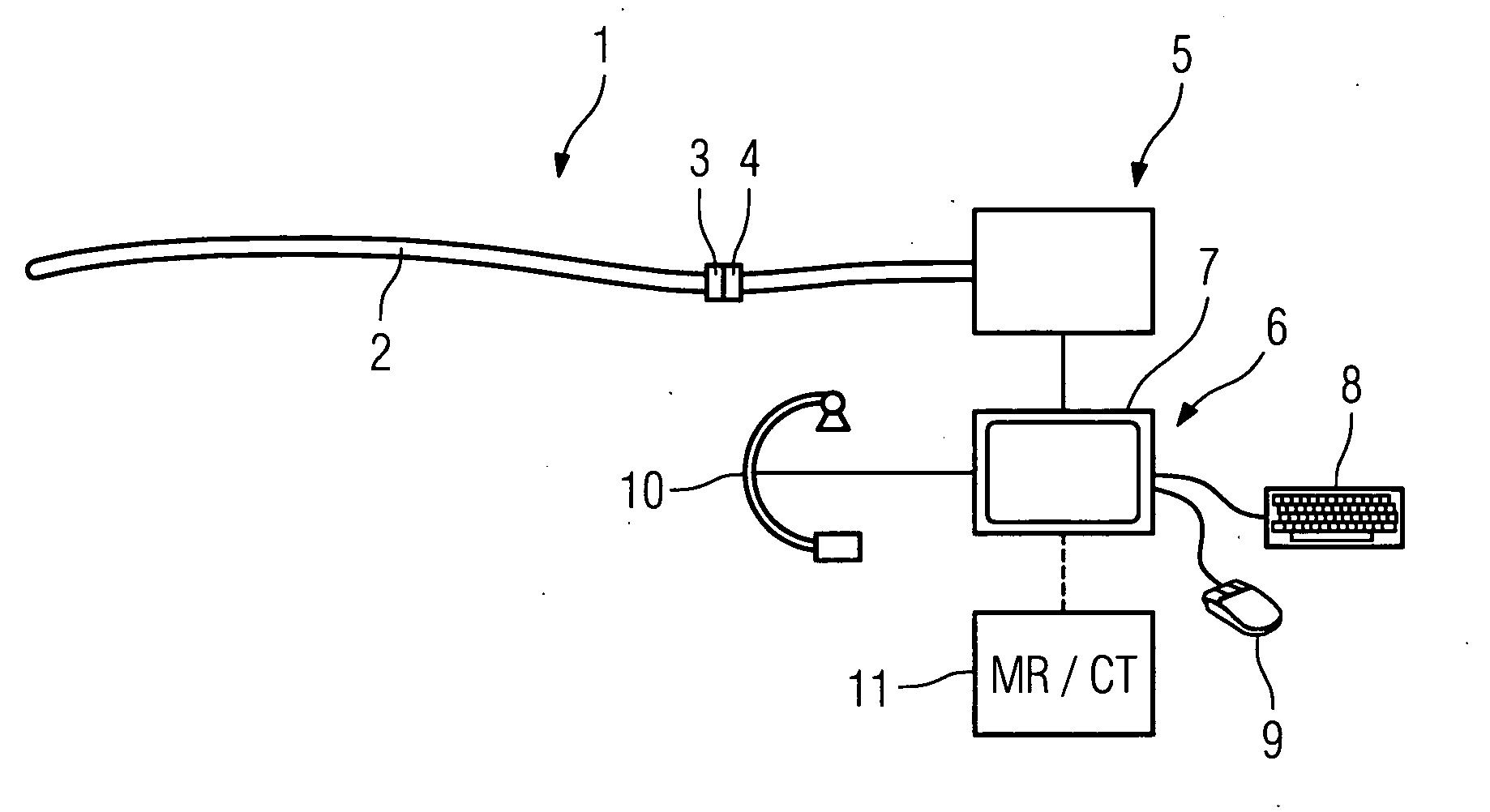

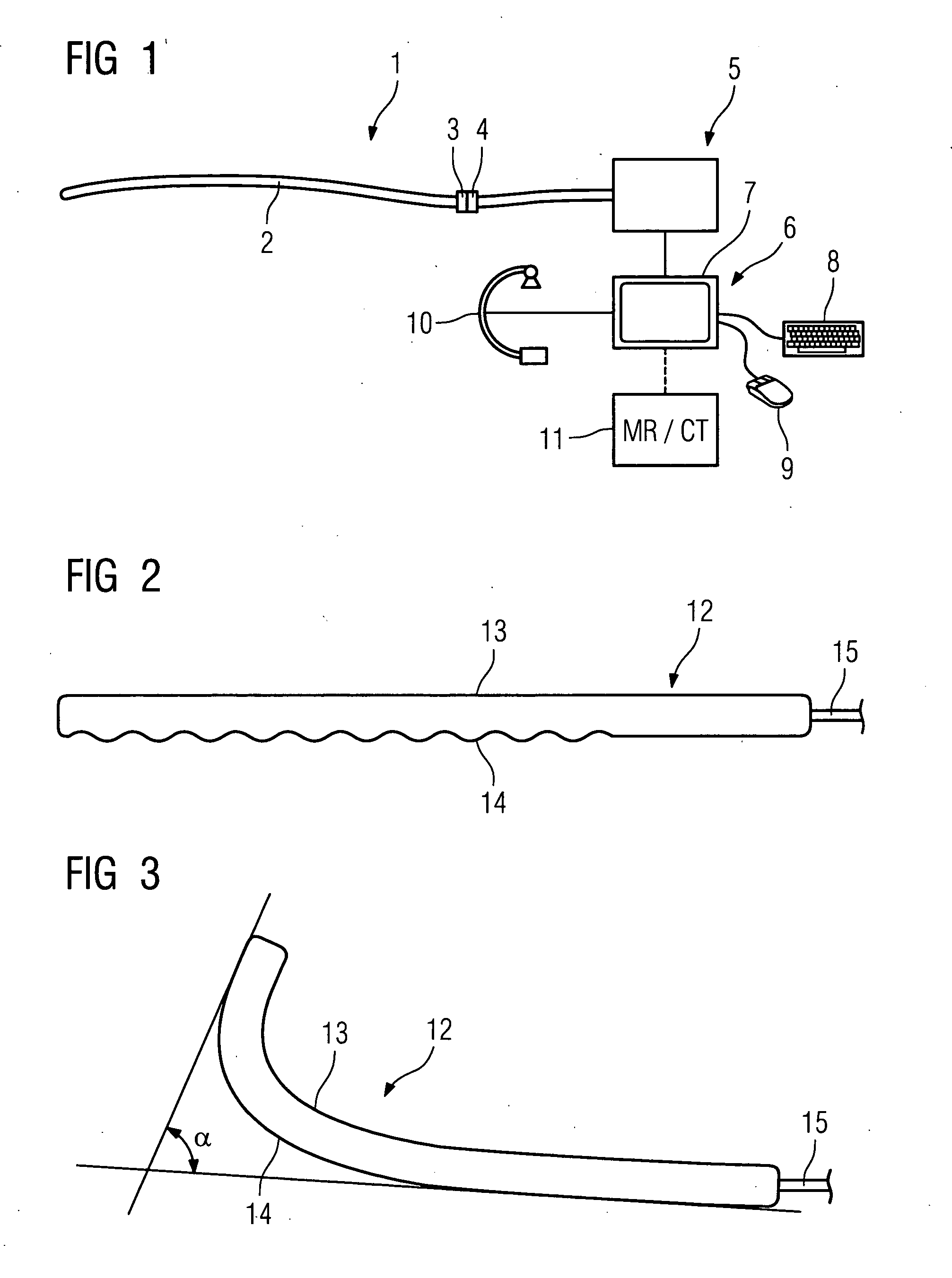

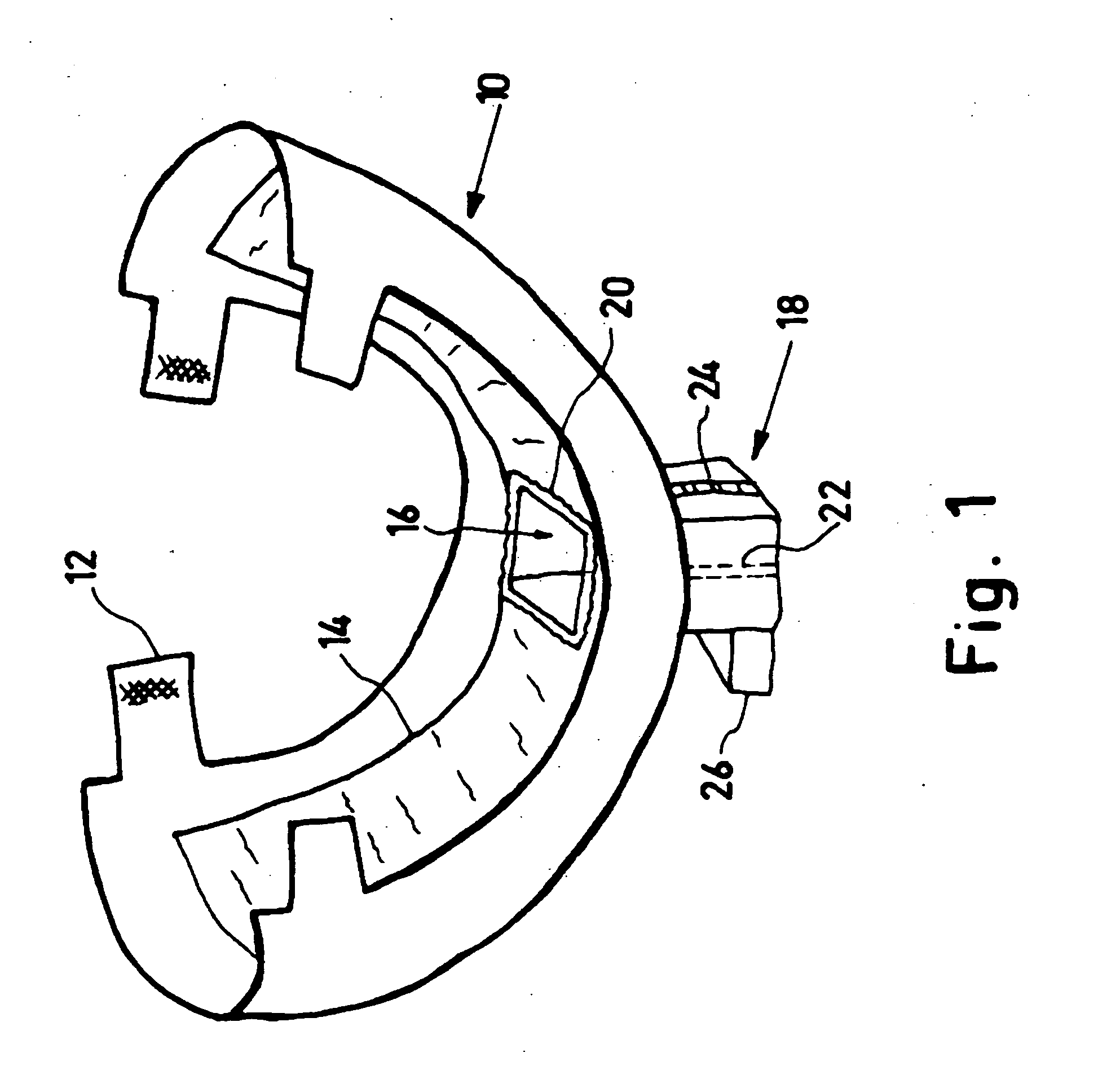

Catheter

Catheter for inserting into a hollow organ, in particular a blood vessel, wherein at least one tube- or balloon-like flexural element (12, 12a, . . . , 12l) which can be filled with a filling medium is provided inside the catheter, which flexural element is flexible in the non-pressurized state and stiffens as a result of pressure buildup internally and assumes a predetermined curved shape.

Owner:SIEMENS HEALTHCARE GMBH

Strutless type umbrella

InactiveUS20090071518A1Reduce thicknessReduce number and weightWalking sticksUmbrellasMechanical engineering

Umbrella rib assembly is presented for use in strutless umbrella having a pin and slide canopy conducting mechanism. The rib assembly comprises a longitudinal rib body having a pivot member at its end, and a rib lever extending from the rib body, and being characterized in that the pivot member and the rib body together with the rib lever present a single piece of material, and the pivot member is located in a corner formed between the rib body and the rib lever.

Owner:LASIES INVESTMENTS & ENTERPRISES

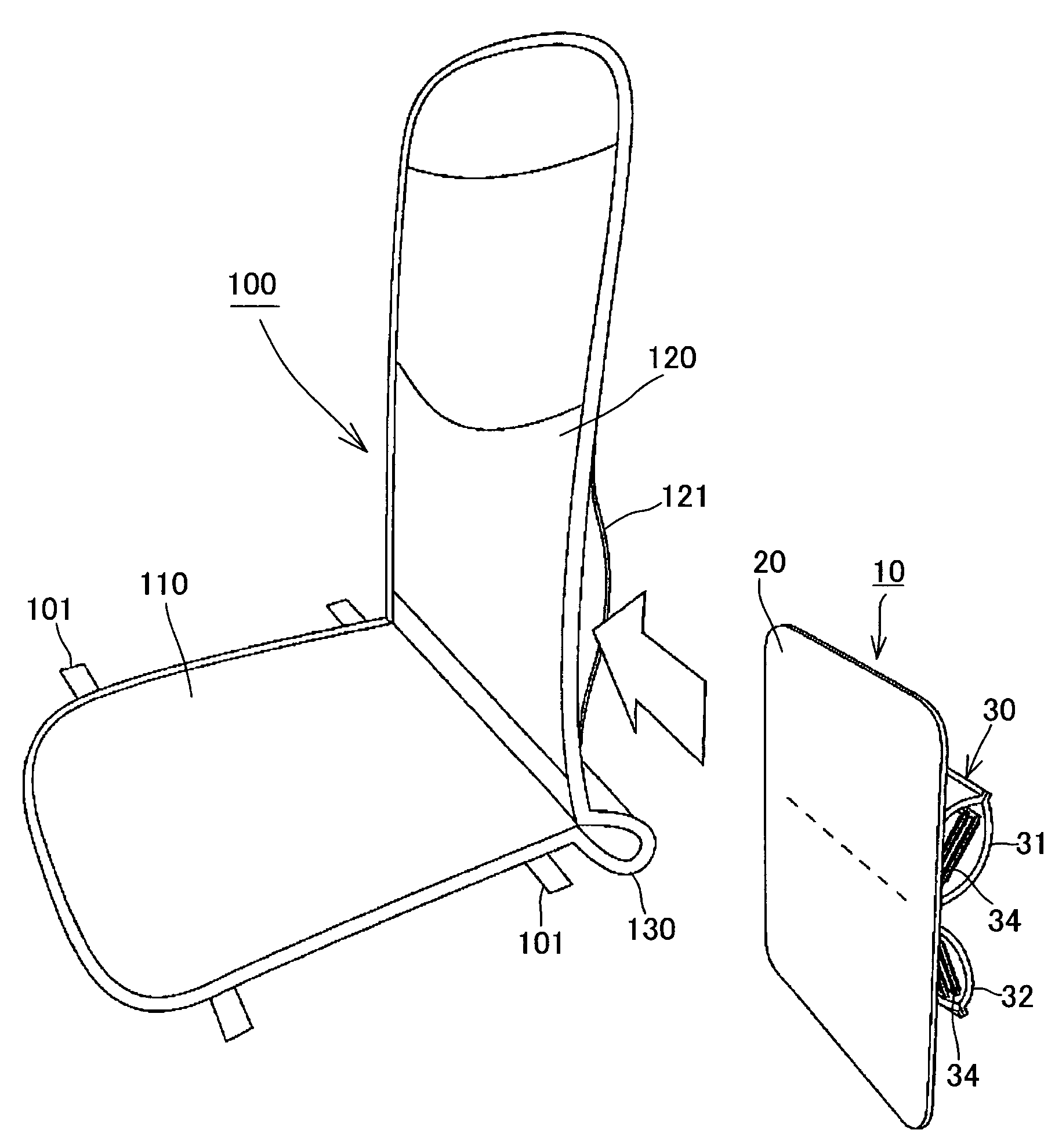

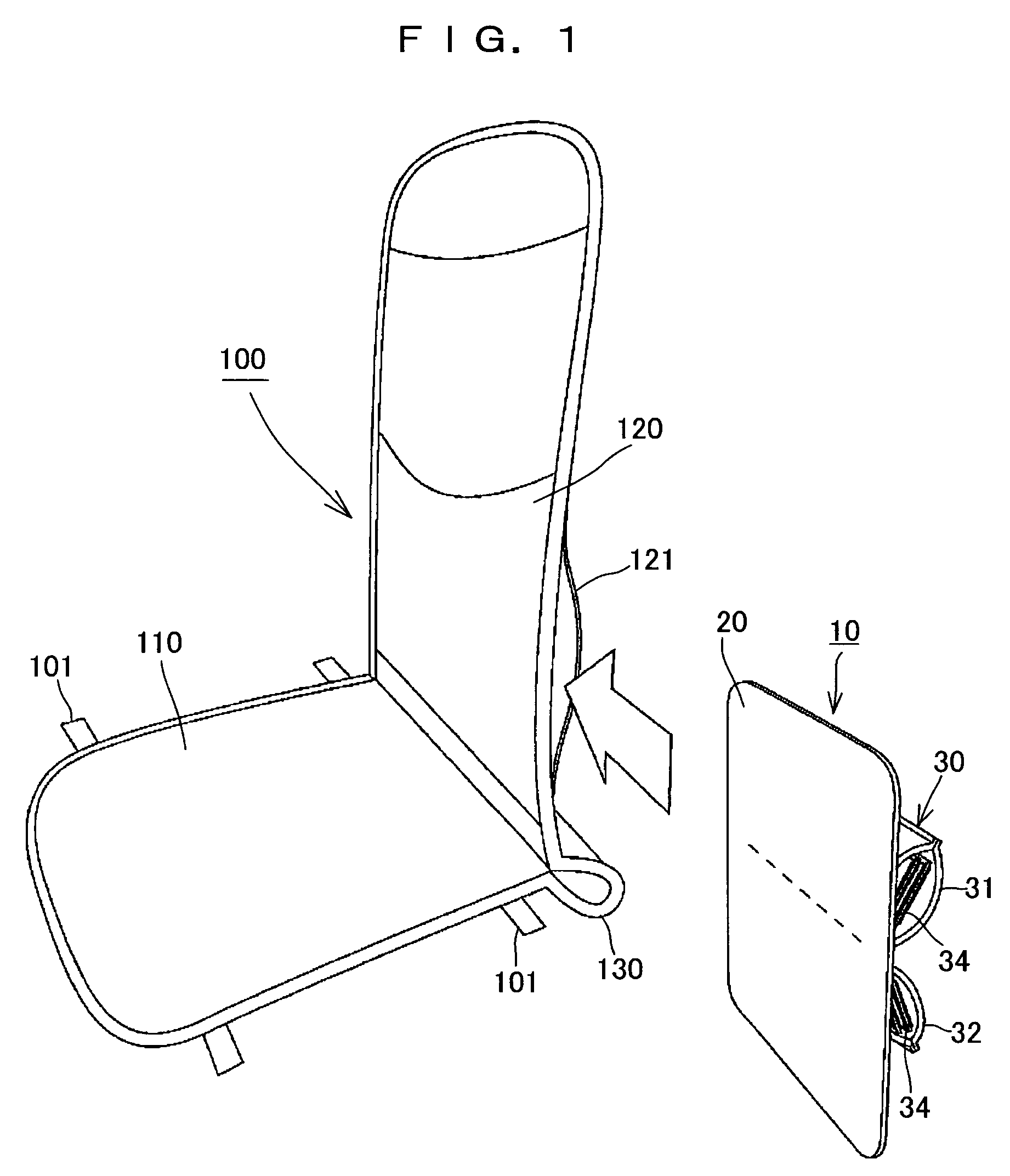

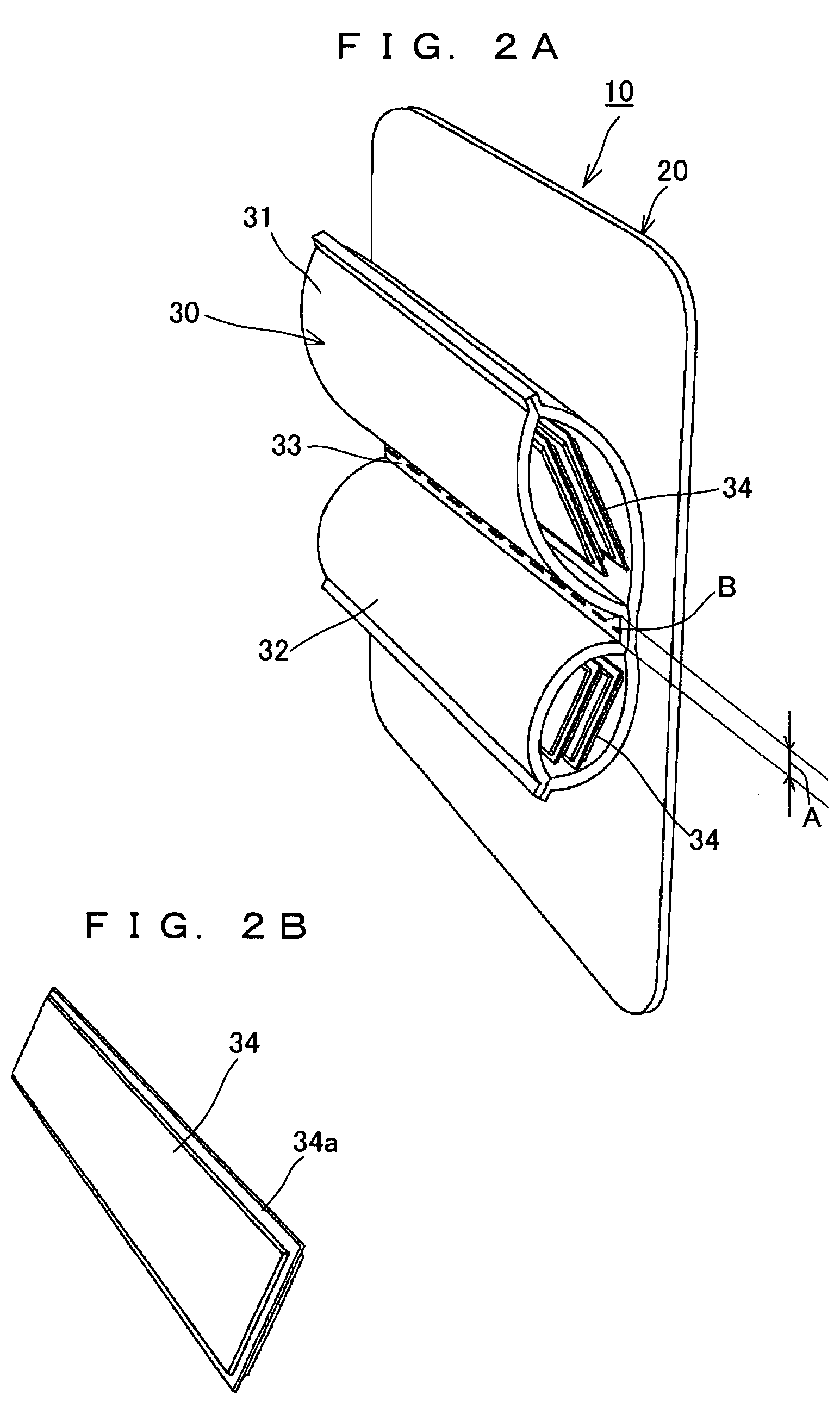

Lumbar support, cushion for seat, and seat structure

Owner:DELTA TOOLING CO LTD

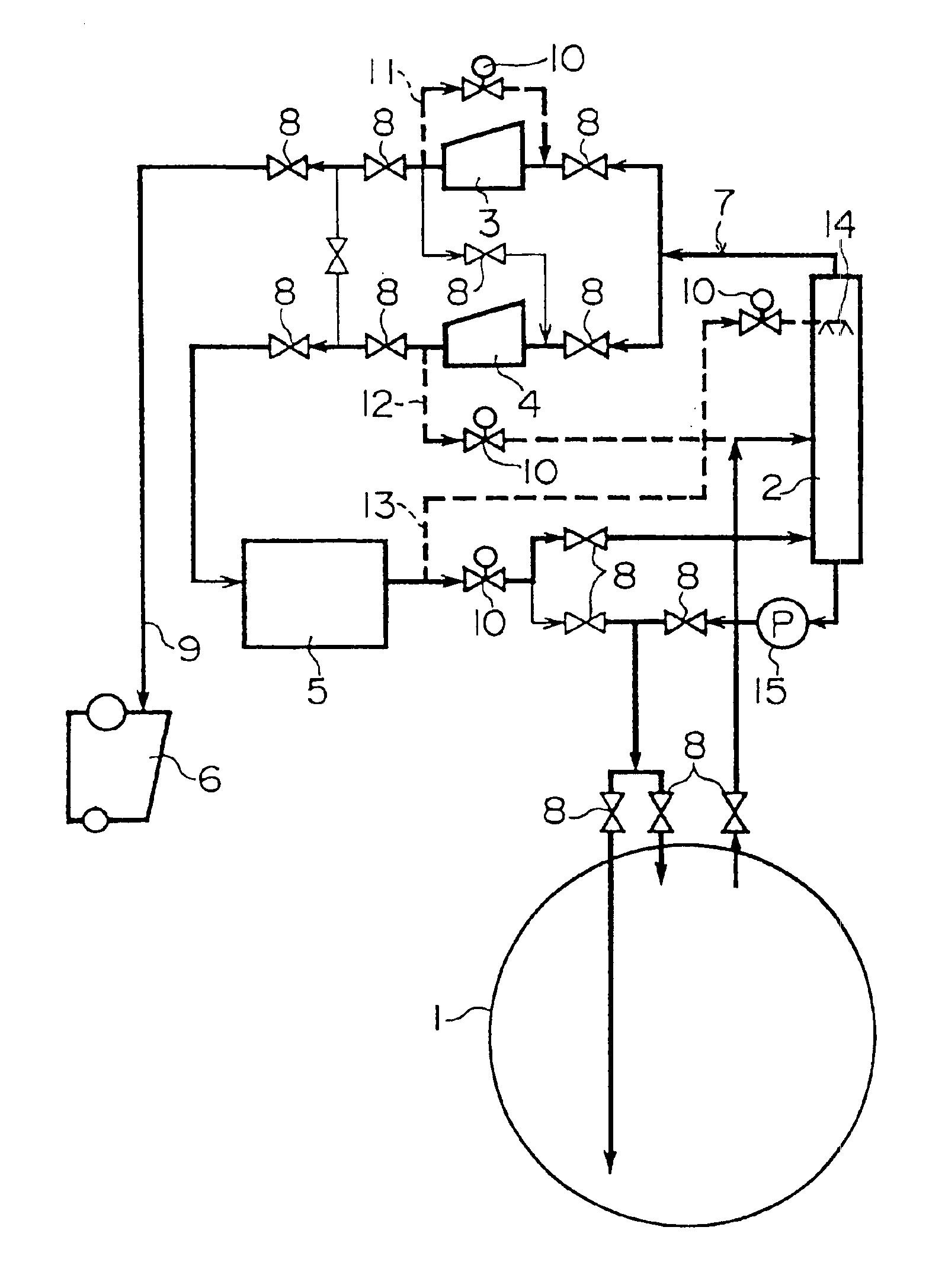

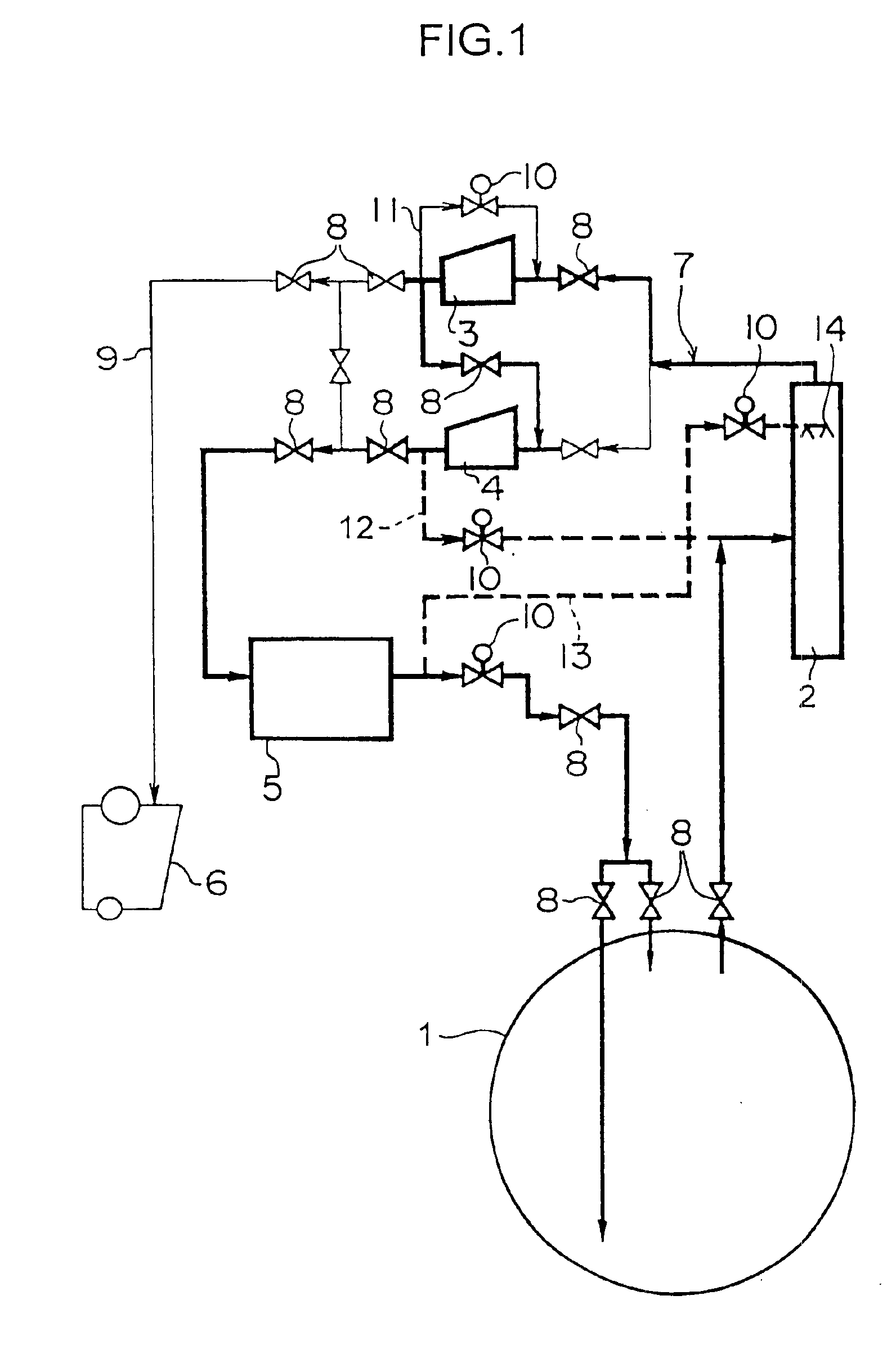

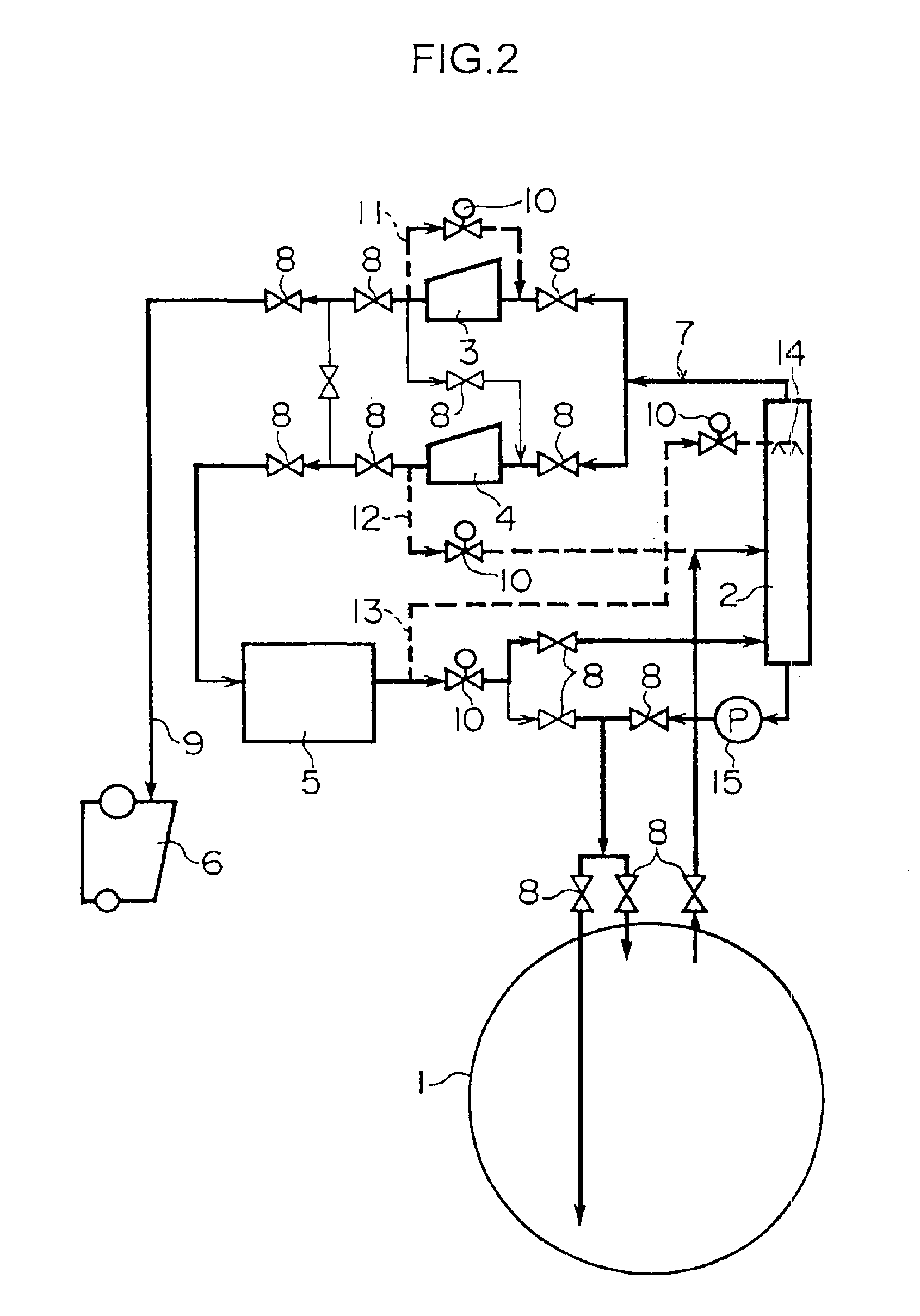

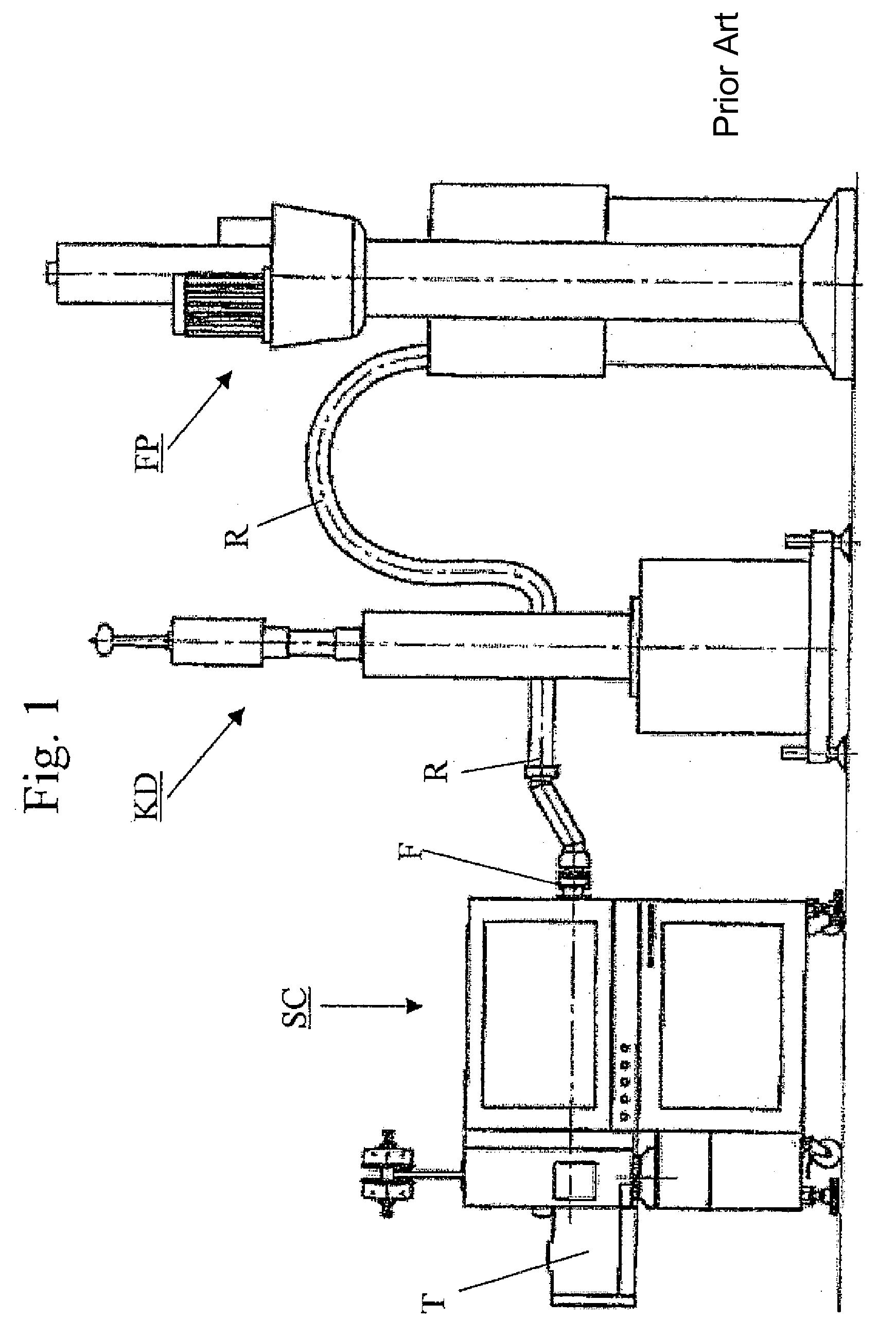

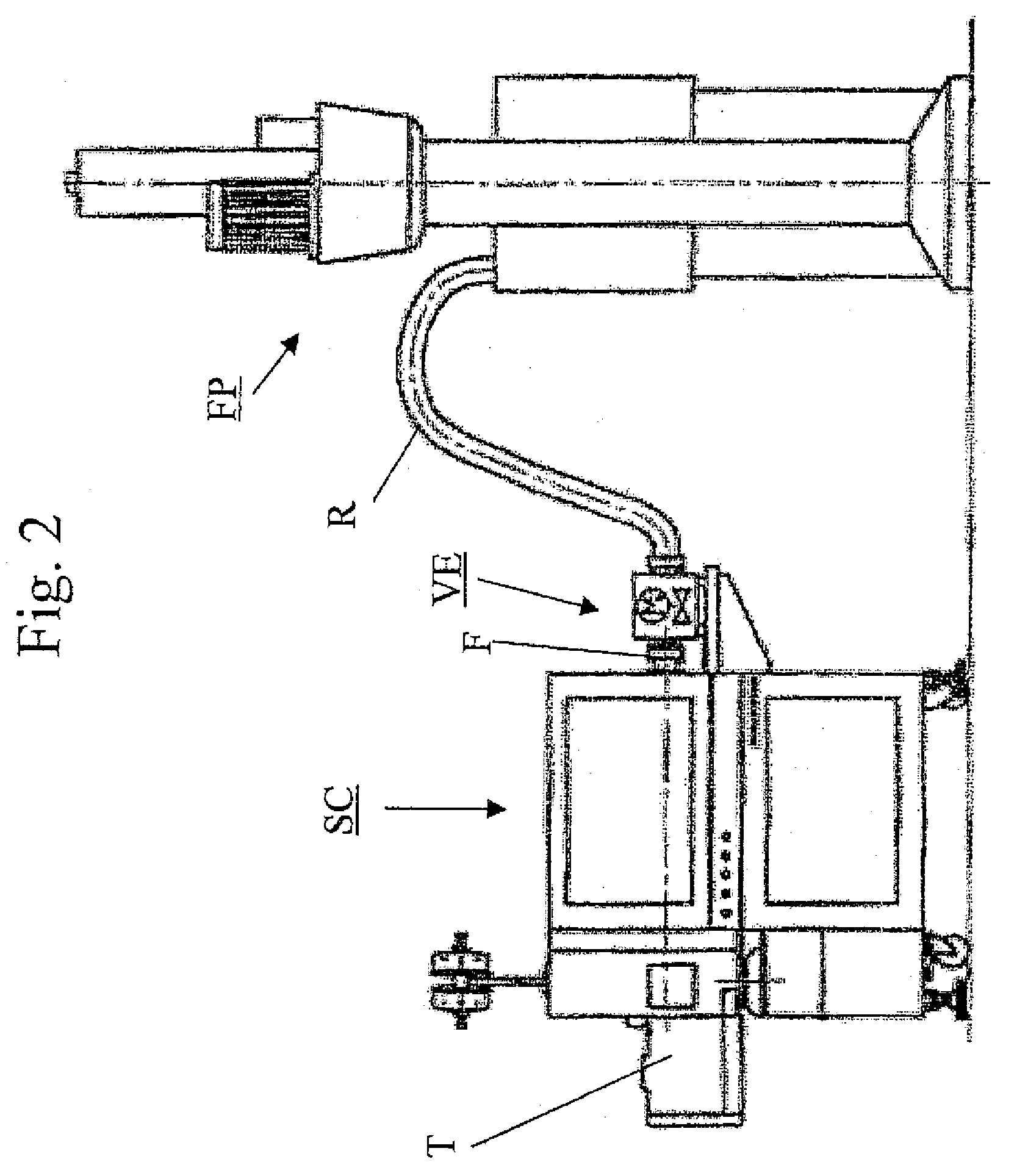

Device and method for pressure control of cargo tank of liquefied natural gas carrier

InactiveUS6901762B2Guaranteed uptimeLow costSolidificationLiquefactionEngineeringPressure controlled ventilation

An apparatus for controlling the pressure in a cargo tank 1 supplies BOG generated from liquefied natural gas stored in the cargo tank 1 to a burning system 6 through a compressor. In this apparatus, a reliquefaction plant 5 is disposed on the downstream side of first and second compressors 3 and 4 and on the upstream side of the cargo tank 1 so that BOG discharged from the second compressor 4 is liquefied by the reliquefaction plant 5 and the liquefied fluid is returned again into the cargo tank 1.

Owner:MITSUBISHI SHIPBUILDING CO LTD +3

Exercise machine

Owner:ABDO JOHN S

Free floating wave energy converter

InactiveUS7823380B2PressureIncrease the number ofMachines/enginesEngine componentsVertical planeMarine engineering

A wave energy converter includes a flexible pipe and an inlet. The flexible pipe floats on the water surface, following the wave form. Slugs of water and air enter, one after the other, through the inlet. Because the flexible pipe follows the shape of the wave, water is transported through a manifold to a pressure chamber connected to a generator. The inlet consists of a hollow, inflexible pipe attached to the throat of the flexible pipe. The inflexible pipe is fixedly attached to a buoyancy tank or plurality thereof. The buoyancy tanks are arranged in a vertical plane or in tandem, with the inflexible pipe passing along the plane vertical to the fore and aft axis of the buoyancy tank and the frontward portion projecting sufficiently ahead of the buoyancy tank with the flexible pipe terminating at a singular outlet. The entire apparatus is facing the oncoming waves.

Owner:GHOUSE SYED MOHAMMED

Catheter

Catheter for inserting into a hollow organ, in particular a blood vessel, wherein at least one tube- or balloon-like flexural element (12, 12a, . . . , 12l) which can be filled with a filling medium is provided inside the catheter, which flexural element is flexible in the non-pressurized state and stiffens as a result of pressure buildup internally and assumes a predetermined curved shape.

Owner:SIEMENS HEATHCARE GMBH

Two-For-One Twisting Spindle Having a Pneumatically Actuated Threading Device

InactiveUS20100018178A1Easy to produceReduce weightPiercing arrangementsDrafting machinesRotational axisEngineering

Two-for-one twisting spindle having a pneumatically actuated threading device, with a spindle shaft rotatable about a vertical axis partially configured as a hollow shaft with a lower feed bore extending coaxially to the rotational axis, and with an injector element opening into a thread guide channel of a thread guide ring temporarily connectable during threading to a compressed air source. Part of the compressed air feed to the injector element is formed by the feed bore. The compressed air feed comprises a connection element (27) with a curved air channel (26), which connects the feed bore (24) to the injector element (16). The connection element (27) is configured as a separate component and the air channel (26) is adapted to the flow requirements.

Owner:SAURER TECH GMBH & CO KG

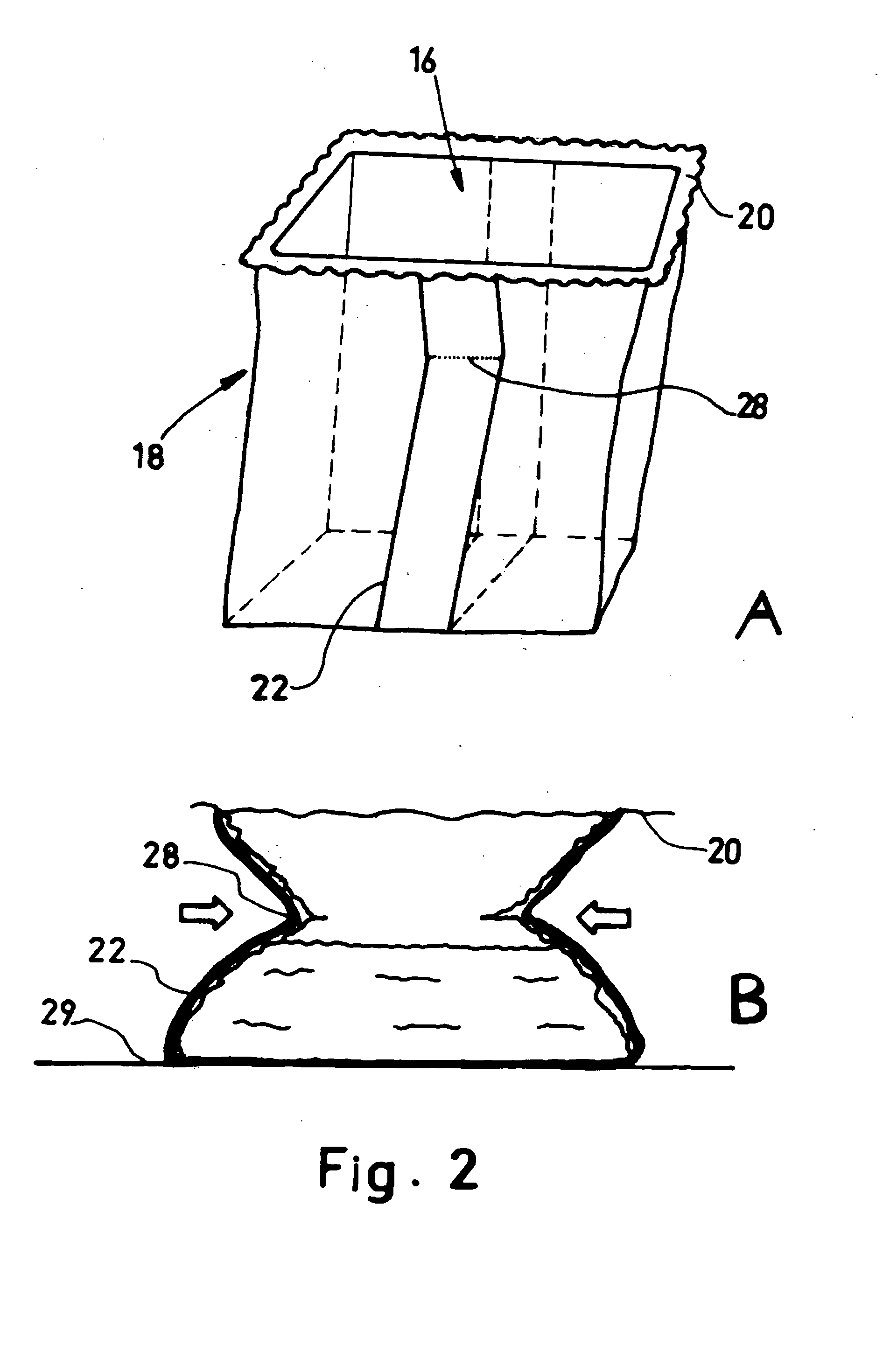

Anti-irritant disposable diaper

InactiveUS20060004340A1Skin irritation and discomfortEasy to separateBaby linensTamponsEngineeringCrotch

An improved, anti-irritant, disposable diaper. The diaper is comprised of a front portion, a crotch area, a rear portion, closing tabs for securing the diaper upon a wearer, waste containment means for collecting and isolating body wastes; attachment means for detachably attaching said containment means to the crotch area of the interior said diaper. The improvement comprises a reinforced, semi-rigid ribbing disposed contiguous to at least one surface of the containment means, for restoring the containment means to its original shape after being compressively deformed, and closure means provided on the containment means, to ensure closure of the containment means when the wearer is seated.

Owner:BEN NATAN CHAIM

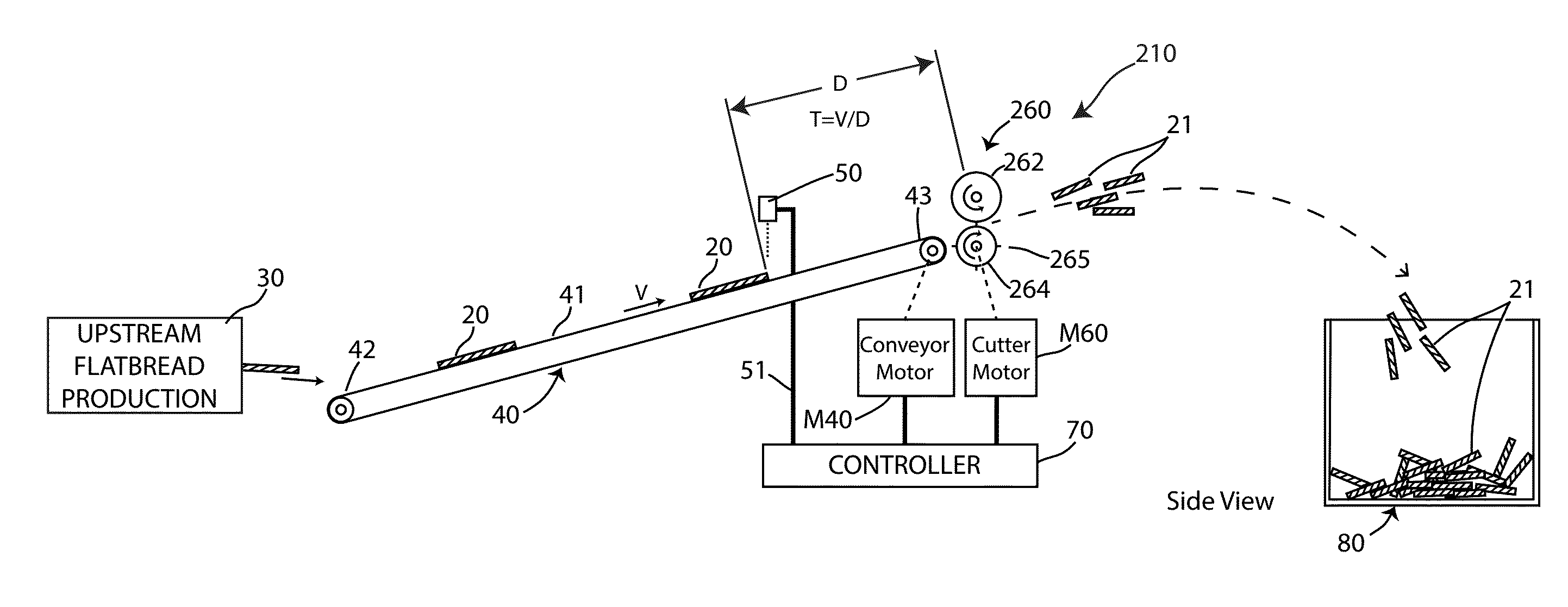

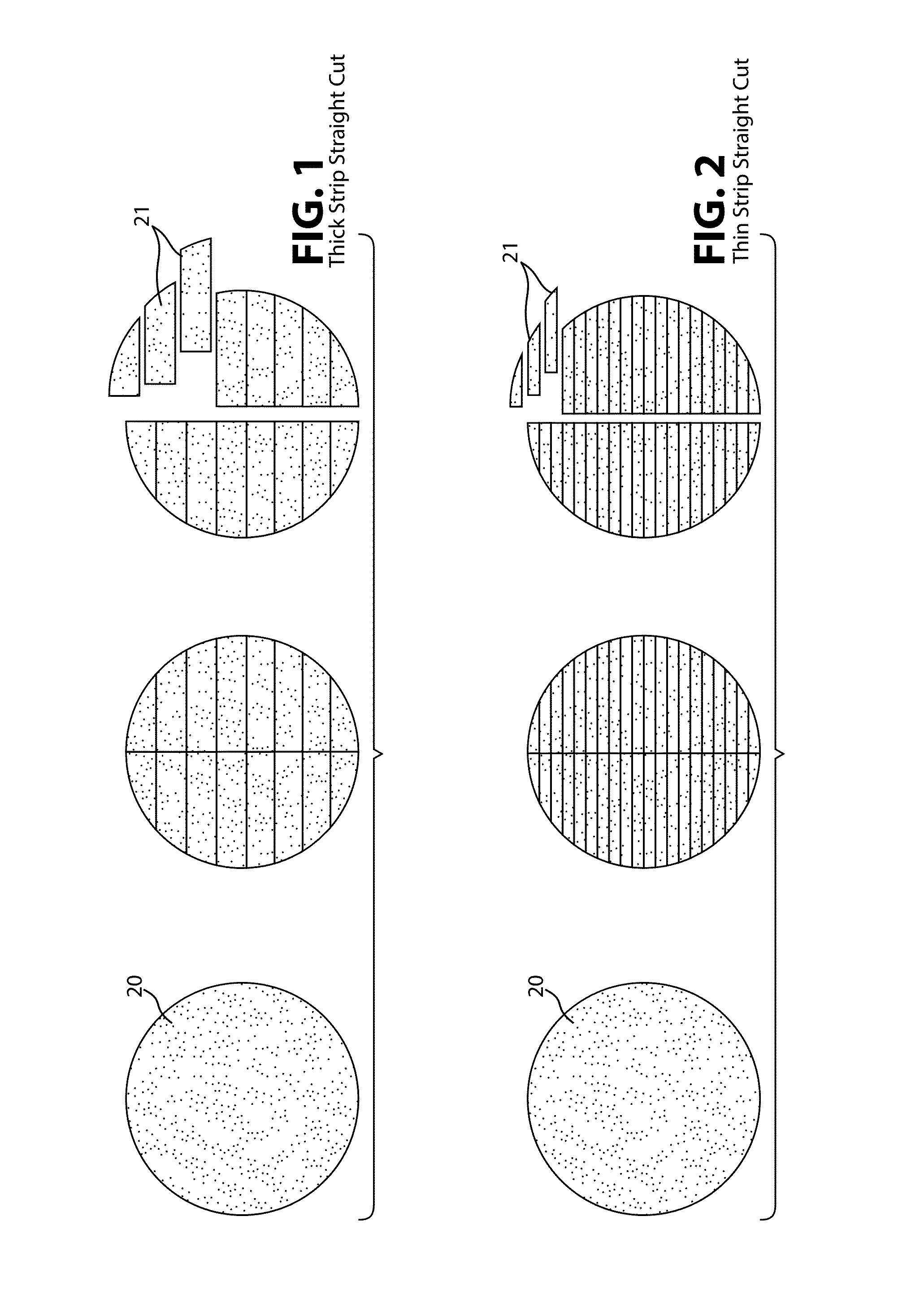

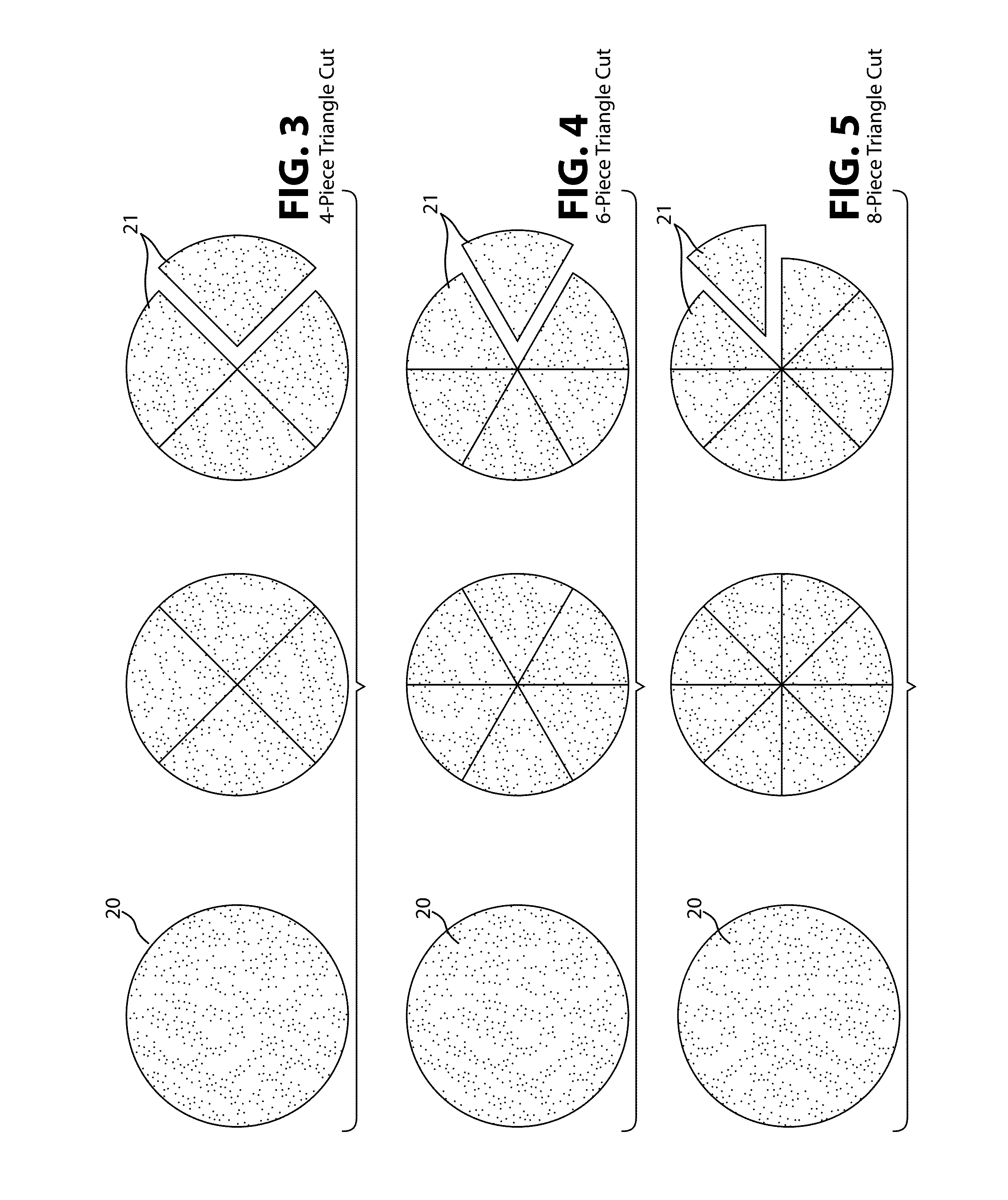

Continuous Tortilla Chip Cutter

InactiveUS20150135921A1PressureEffortMetal working apparatusFood preparationTortilla chipsProgrammable logic controller

A continuous tortilla chip cutting system where tortilla carried on a conveyor are continuously divided by a cutting mechanism into pre-cuts for frying into chips. A programmable controller drives a servo motor that moves an upper surface of the conveyor at a known velocity V, and a detector located above the conveyor at a known distance D from the cutting mechanism alerts the controller to the imminent arrival of the tortilla. The controller also controls a servo motor that actuates the cutting mechanism in a stop / start fashion. Based on the detection of the tortilla, the controller drives the servo motor associated with the cutting mechanism at just the right time and at just the right speed so that the cutter mechanism cuts each arriving tortilla into predictable sub-units called “pre-cuts” based on the velocity V of the conveyor belt, the detection of the flat bread unit carried by the conveyor, and the known distance between the moving flat bread unit and the cutter assembly.

Owner:CASA HERRARA

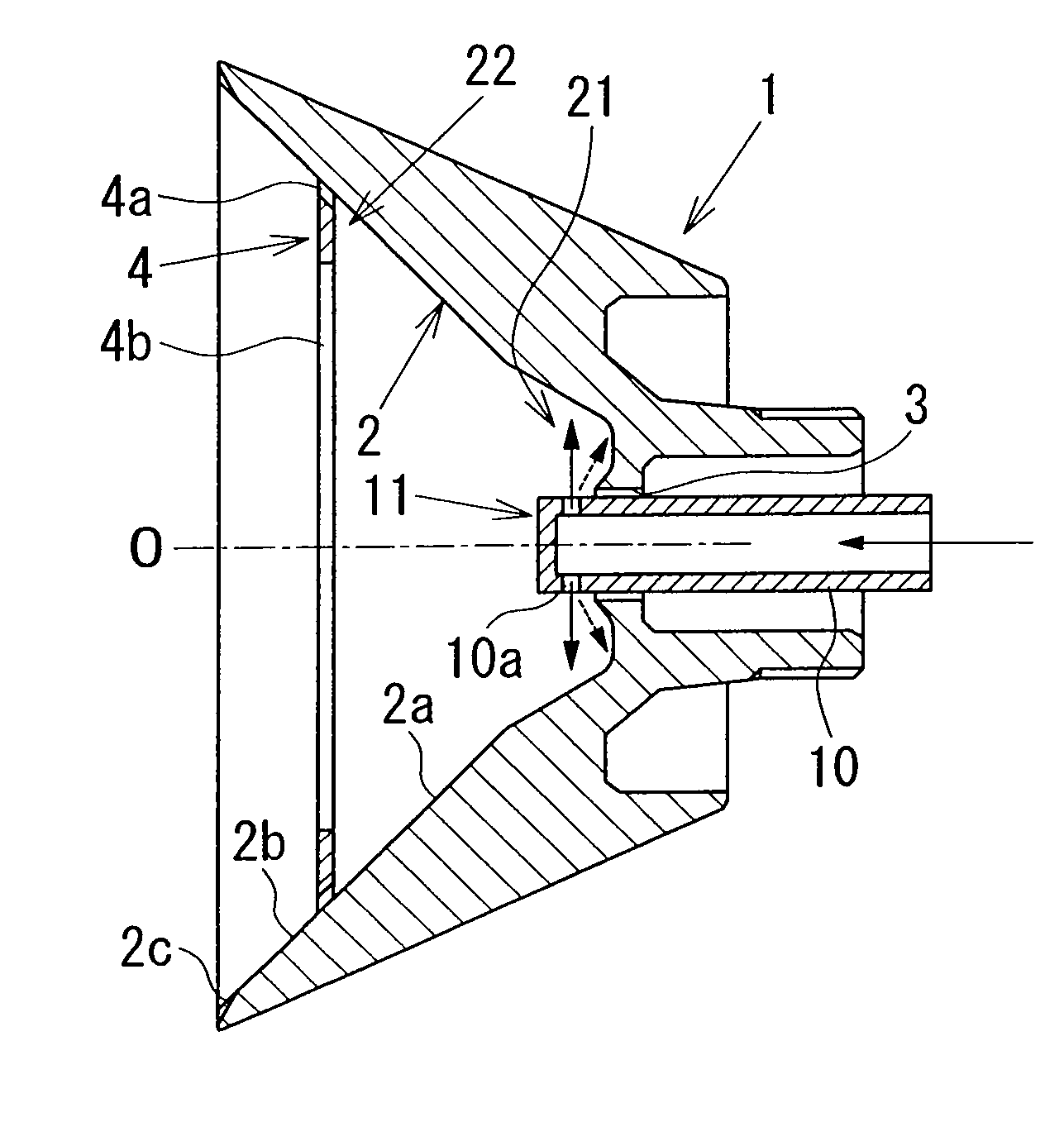

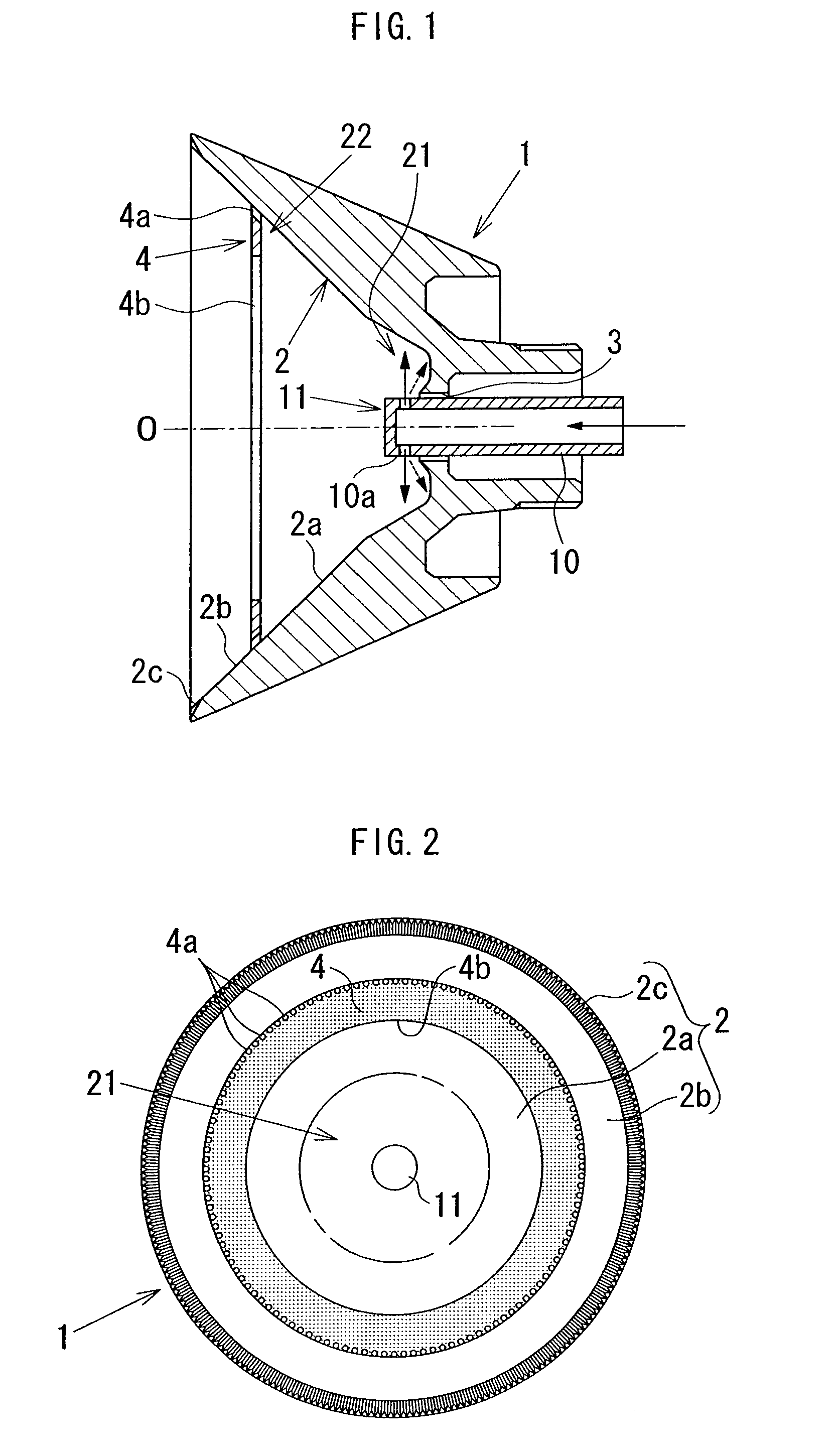

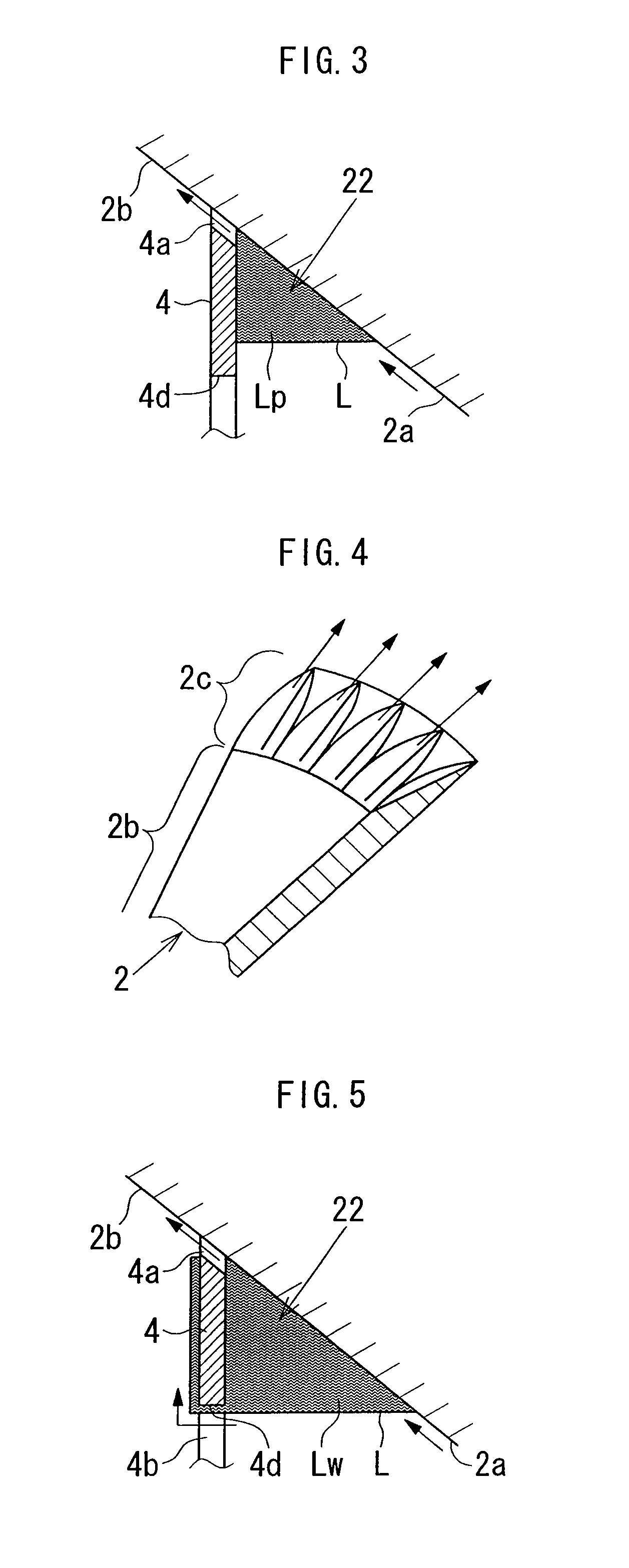

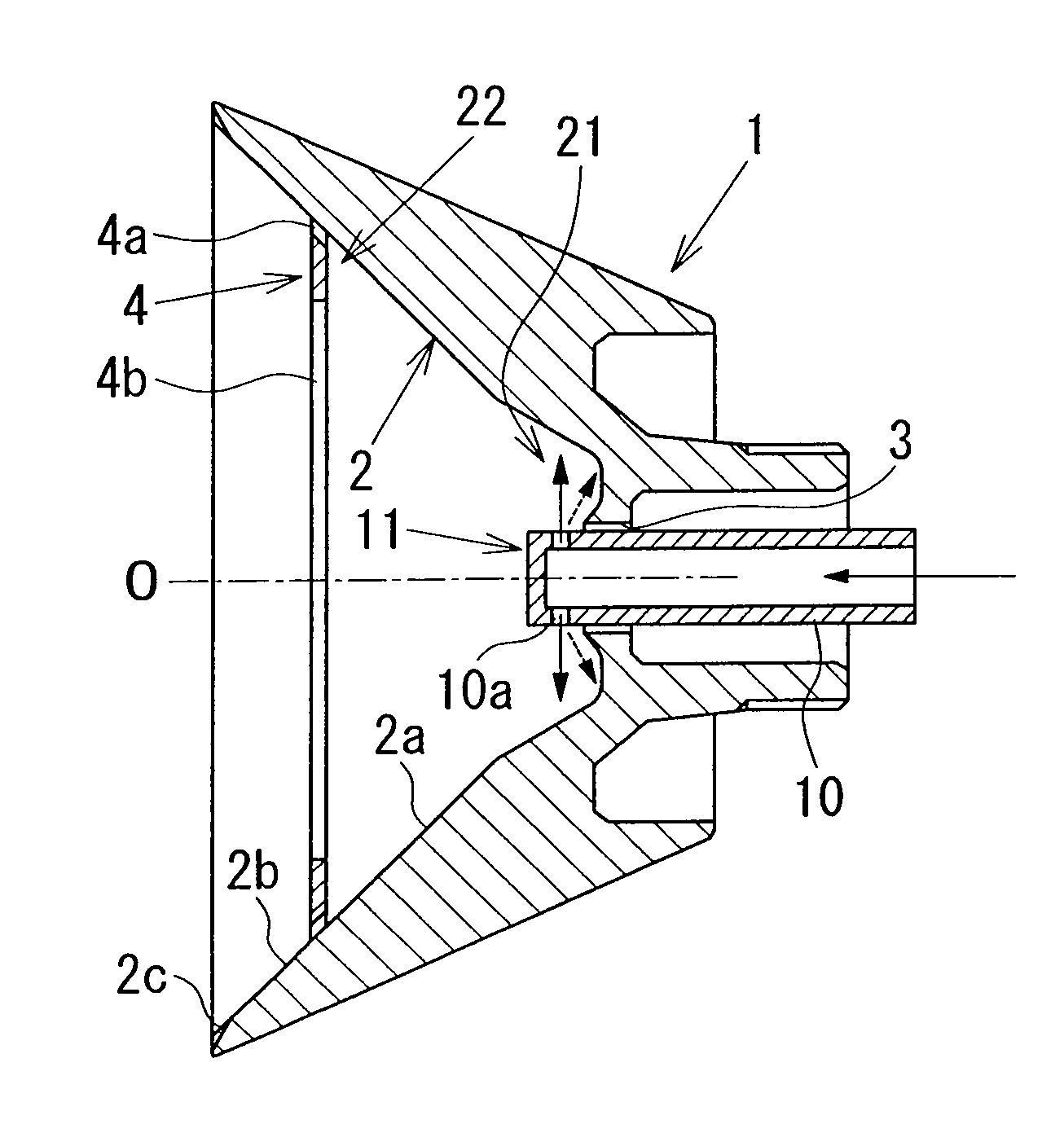

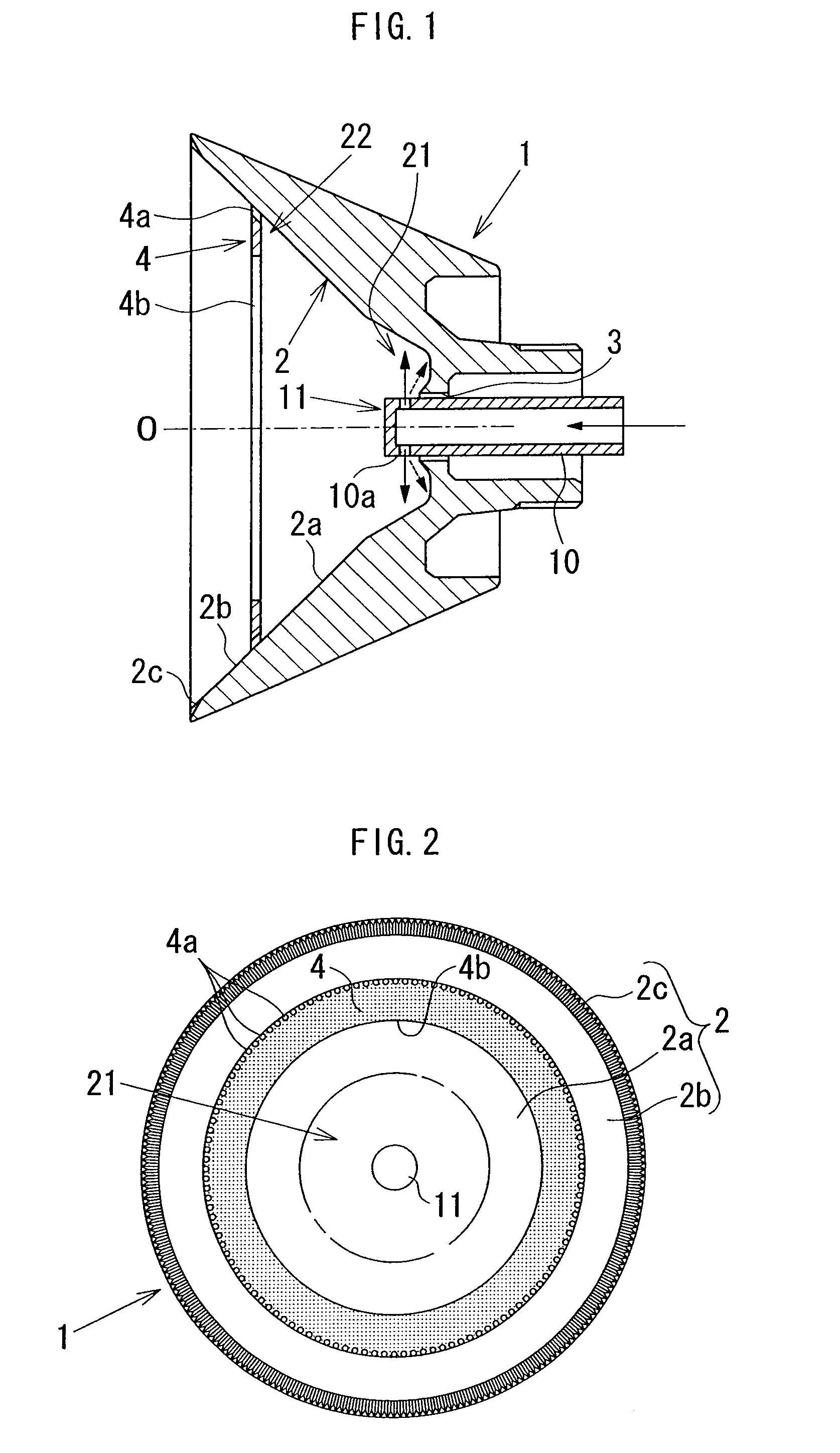

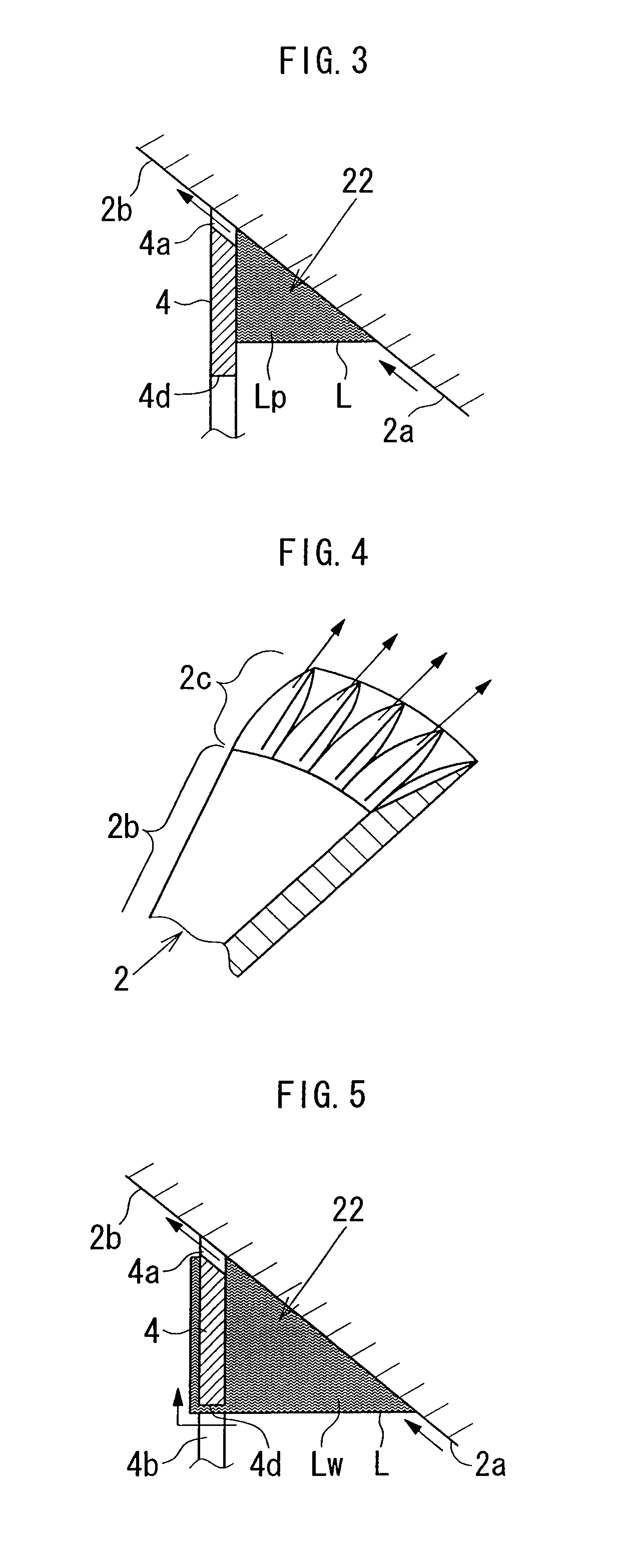

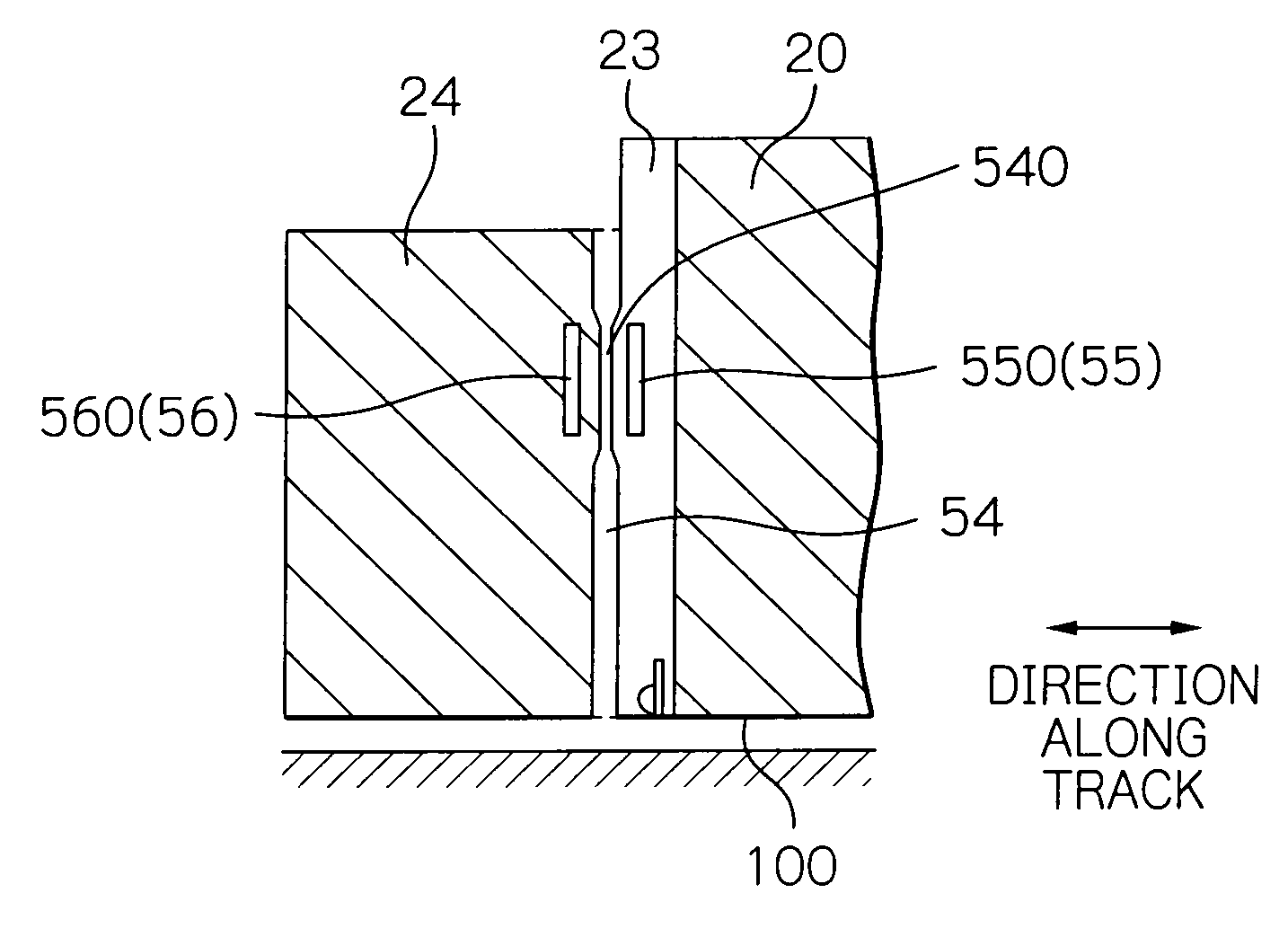

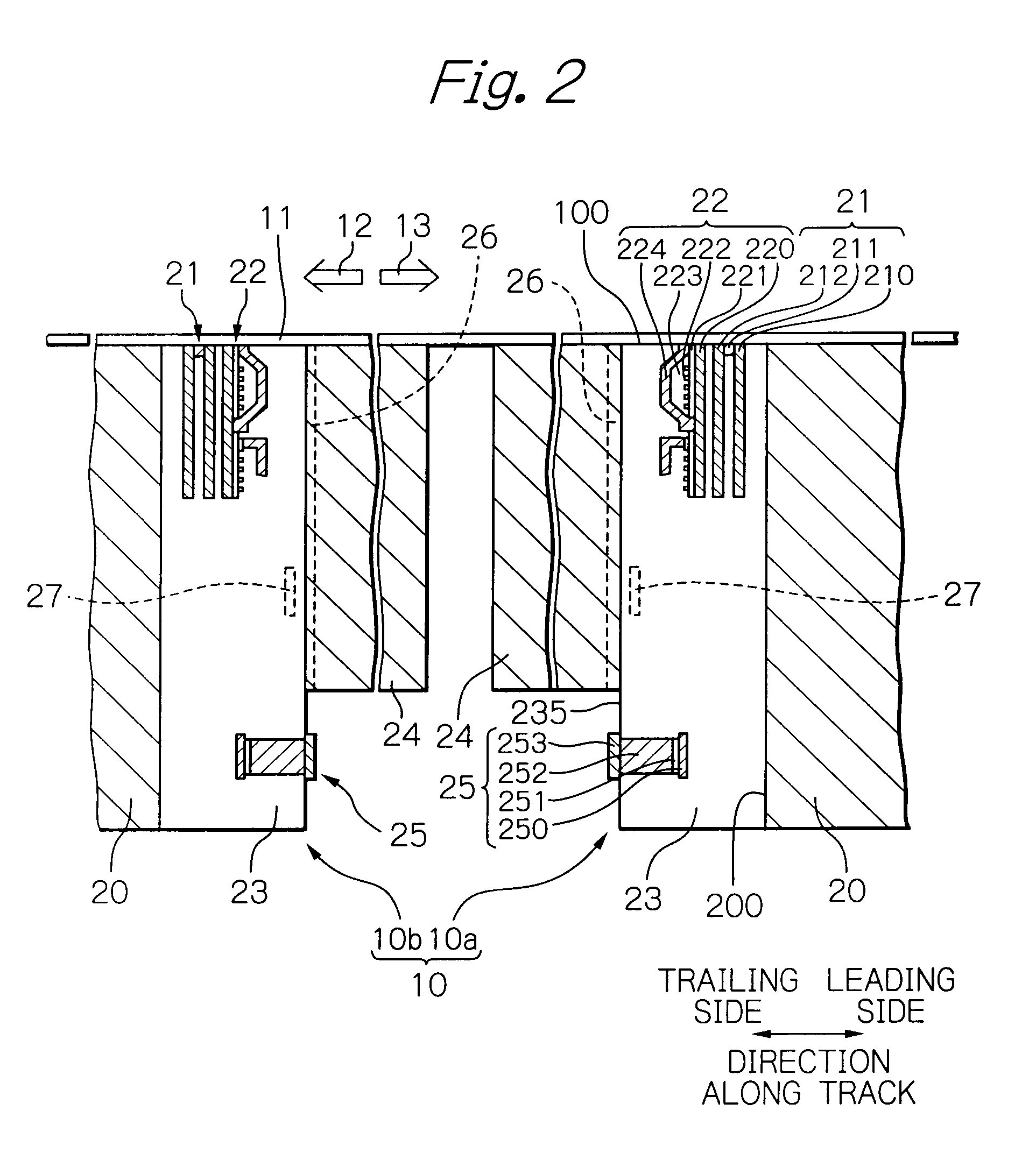

Rotary atomizing head, rotary atomization coating apparatus, and rotary atomization coating method

A rotary atomizing head 1, which has an inner peripheral surface 2 whose diameter increases from a bottom 21 of the inner peripheral surface toward a tip thereof, and atomizes and releases paint by applying a centrifugal force generated by rotation to the paint supplied to the bottom of the inner peripheral surface, includes a paint supply nozzle 11 for supplying the paint and a cleaning solution to the bottom of the inner peripheral surface, and the paint supply nozzle has a nozzle hole 10a for discharging the paint and the cleaning solution from a rotation center O portion of the rotary atomizing head in a direction substantially perpendicular to a rotation axis of the rotary atomizing head. The rotary atomizing head 1 also includes a dam portion 4 that is provided in an intermediate portion between the bottom and the tip of the inner peripheral surface and dams the paint and the cleaning solution supplied from the paint supply nozzle to the bottom and flow along the inner peripheral surface toward the tip.

Owner:TOYOTA JIDOSHA KK +1

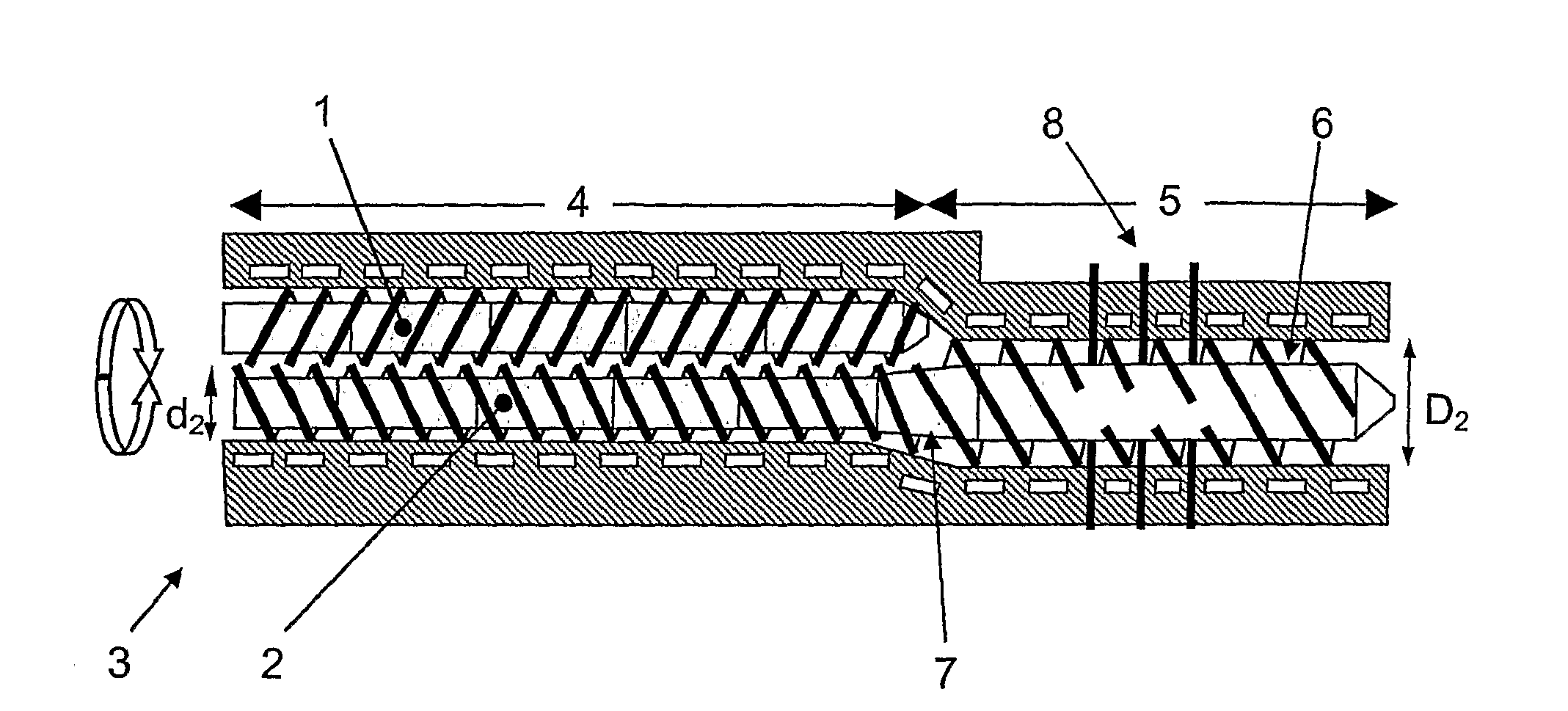

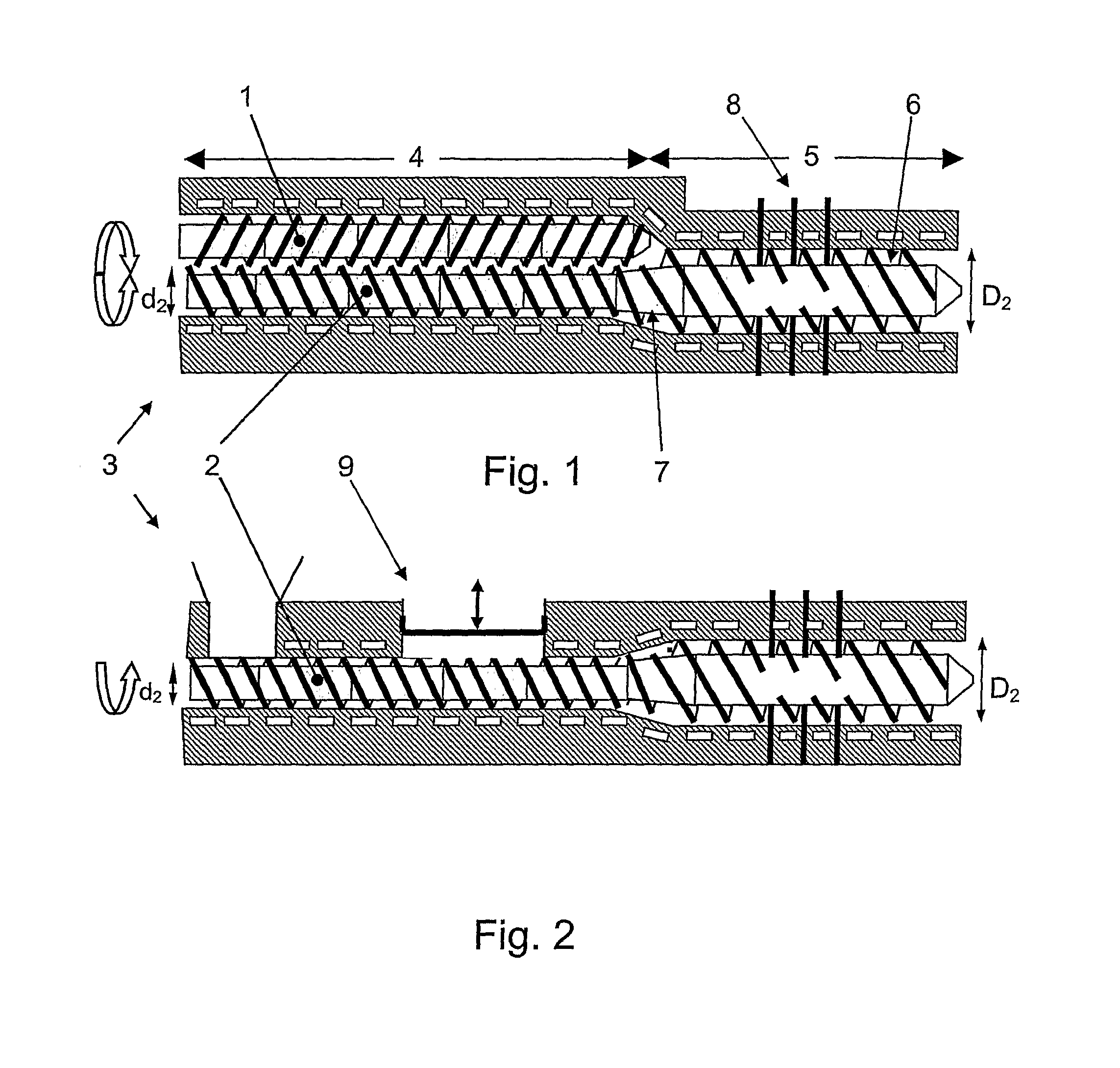

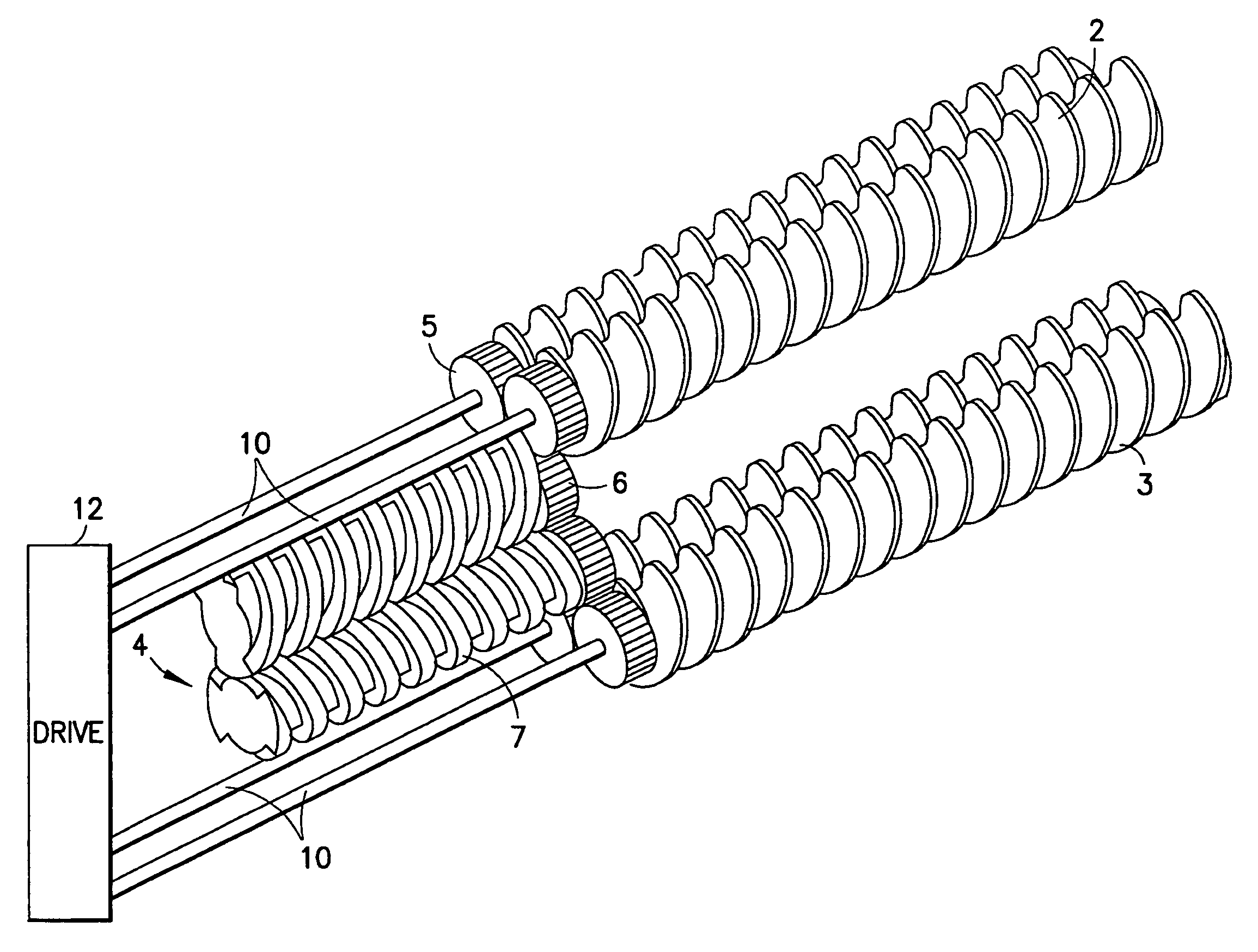

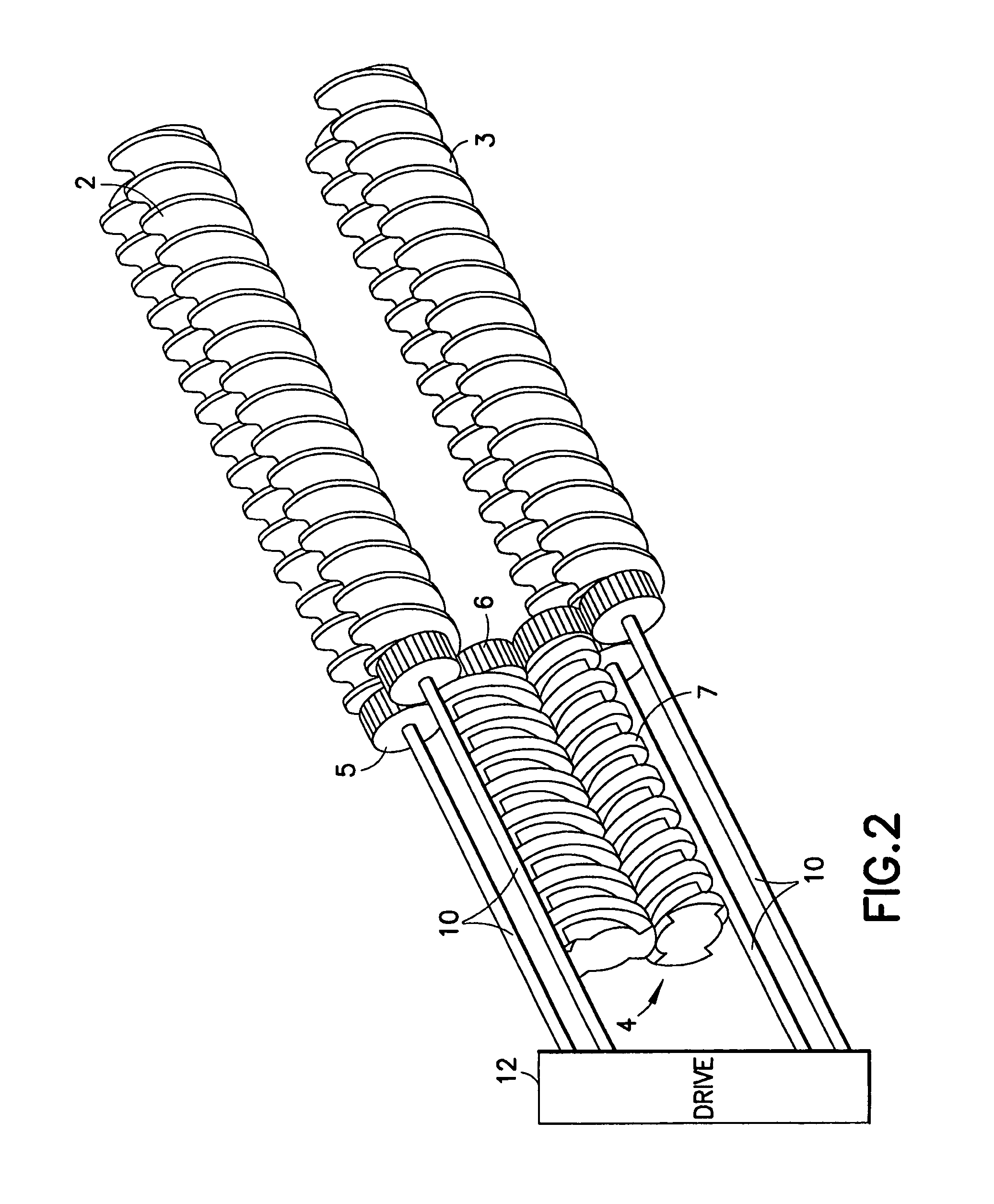

Device and method for processing of polymer materials

InactiveUS20100238759A1PressureMinimal temperature increaseRotary stirring mixersMixing/kneading with horizontally-mounted toolsRotation velocityEngineering

A device for processing a polymer material including a first screw having a first length; and a second screw having a second length different from the first length, wherein the first screw is configured to be rotated at one of a direction and a speed of rotation that is independent from a respective speed or rotation of the second screw.

Owner:TROESTER

Rotary atomizing head, rotary atomization coating apparatus, and rotary atomization coating method

InactiveUS8720797B2Easy to cleanEasy to removeBurnersMovable spraying apparatusEngineeringCentrifugal force

A rotary atomizing head 1, which has an inner peripheral surface 2 whose diameter increases from a bottom 21 of the inner peripheral surface toward a tip thereof, and atomizes and releases paint by applying a centrifugal force generated by rotation to the paint supplied to the bottom of the inner peripheral surface, includes a paint supply nozzle 11 for supplying the paint and a cleaning solution to the bottom of the inner peripheral surface, and the paint supply nozzle has a nozzle hole 10a for discharging the paint and the cleaning solution from a rotation center O portion of the rotary atomizing head in a direction substantially perpendicular to a rotation axis of the rotary atomizing head. The rotary atomizing head 1 also includes a dam portion 4 that is provided in an intermediate portion between the bottom and the tip of the inner peripheral surface and dams the paint and the cleaning solution supplied from the paint supply nozzle to the bottom and flow along the inner peripheral surface toward the tip.

Owner:TOYOTA JIDOSHA KK +1

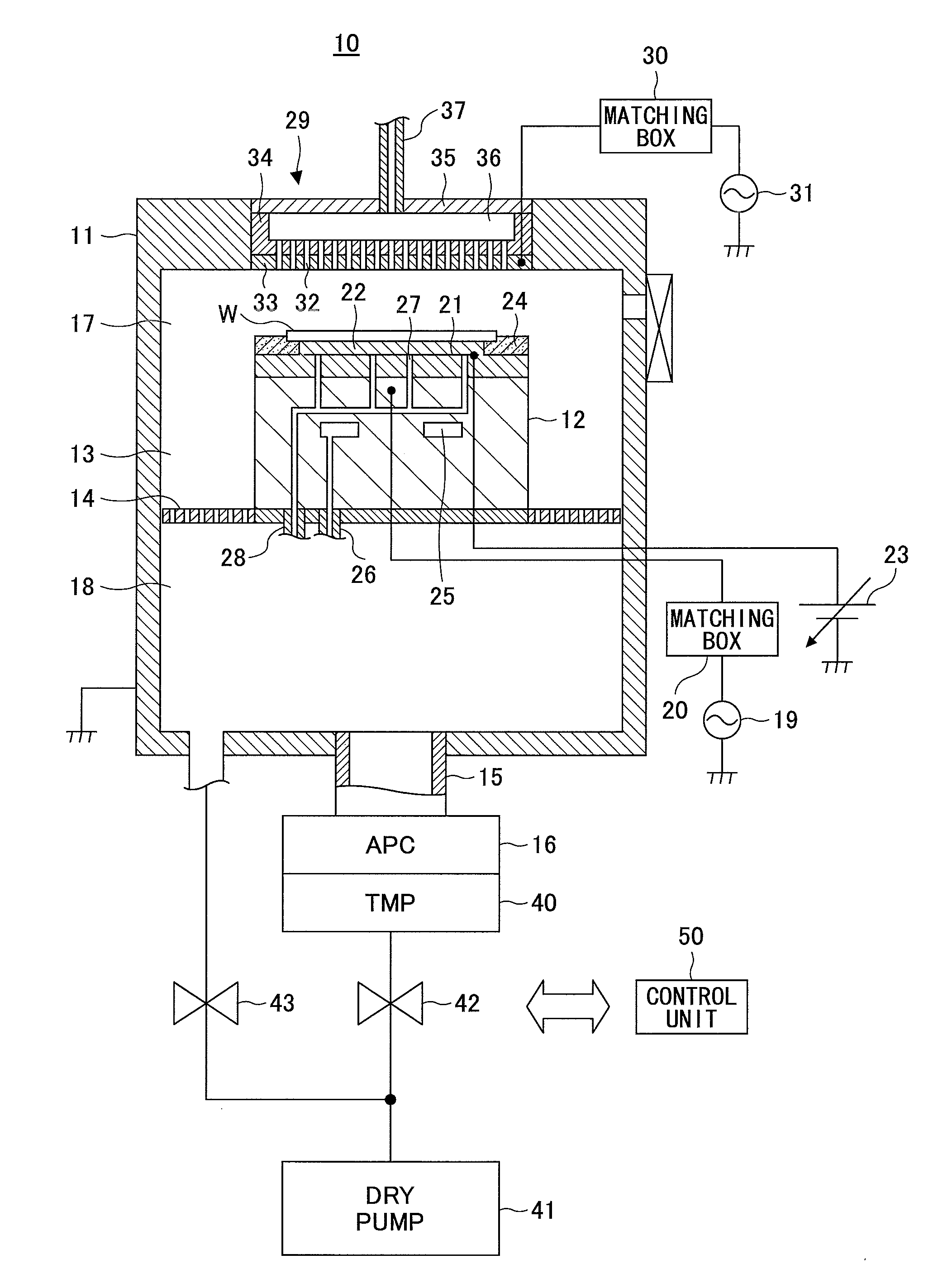

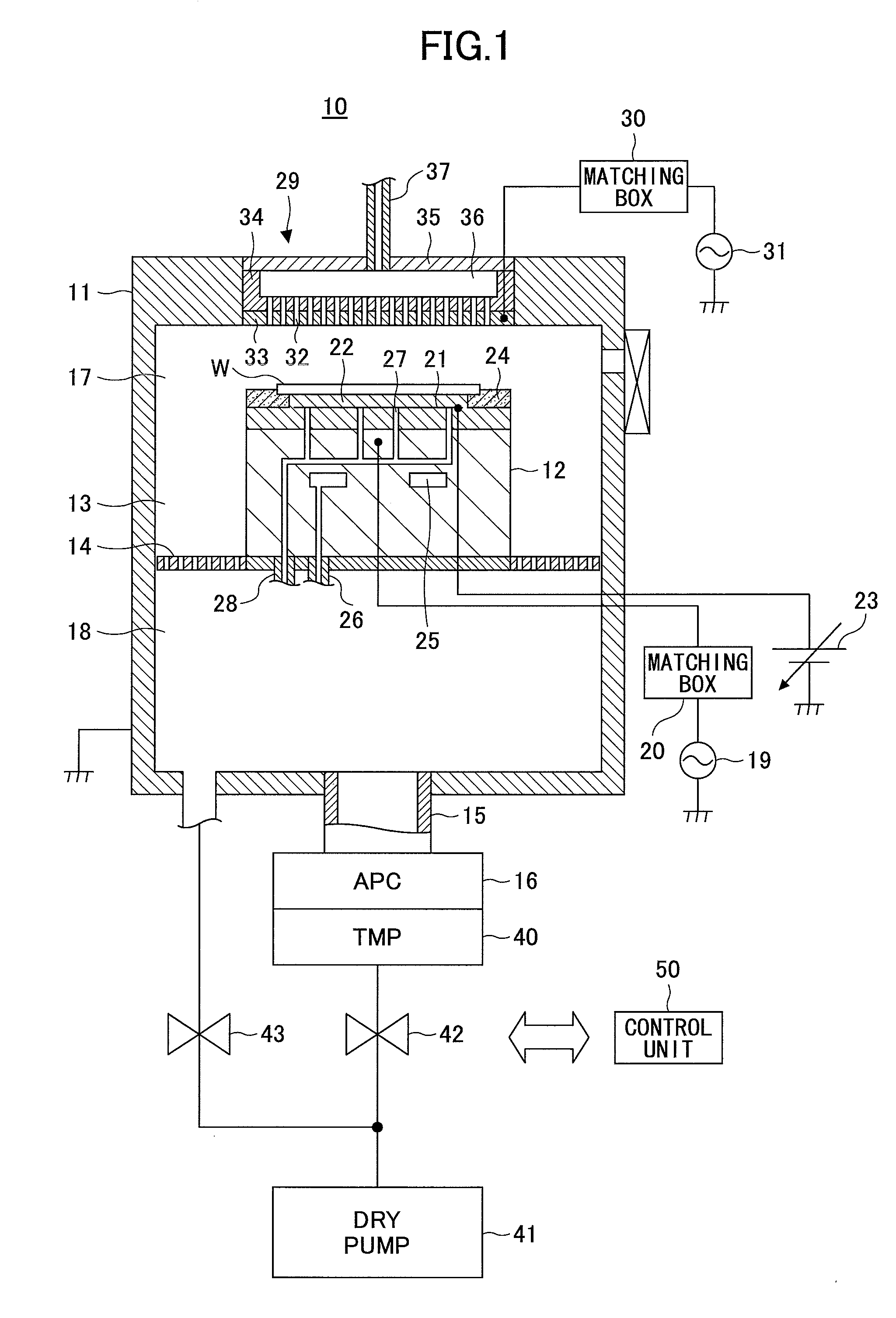

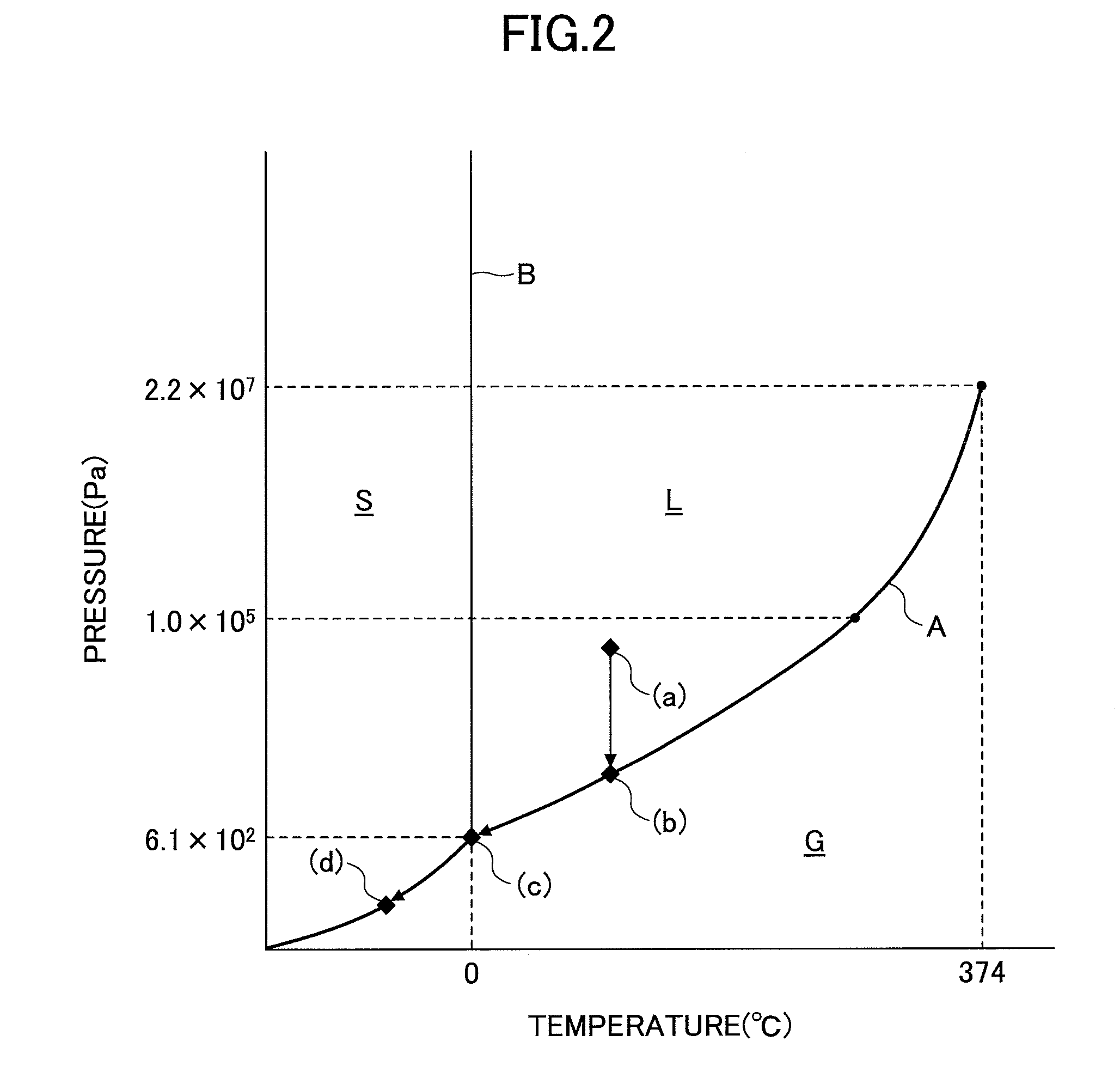

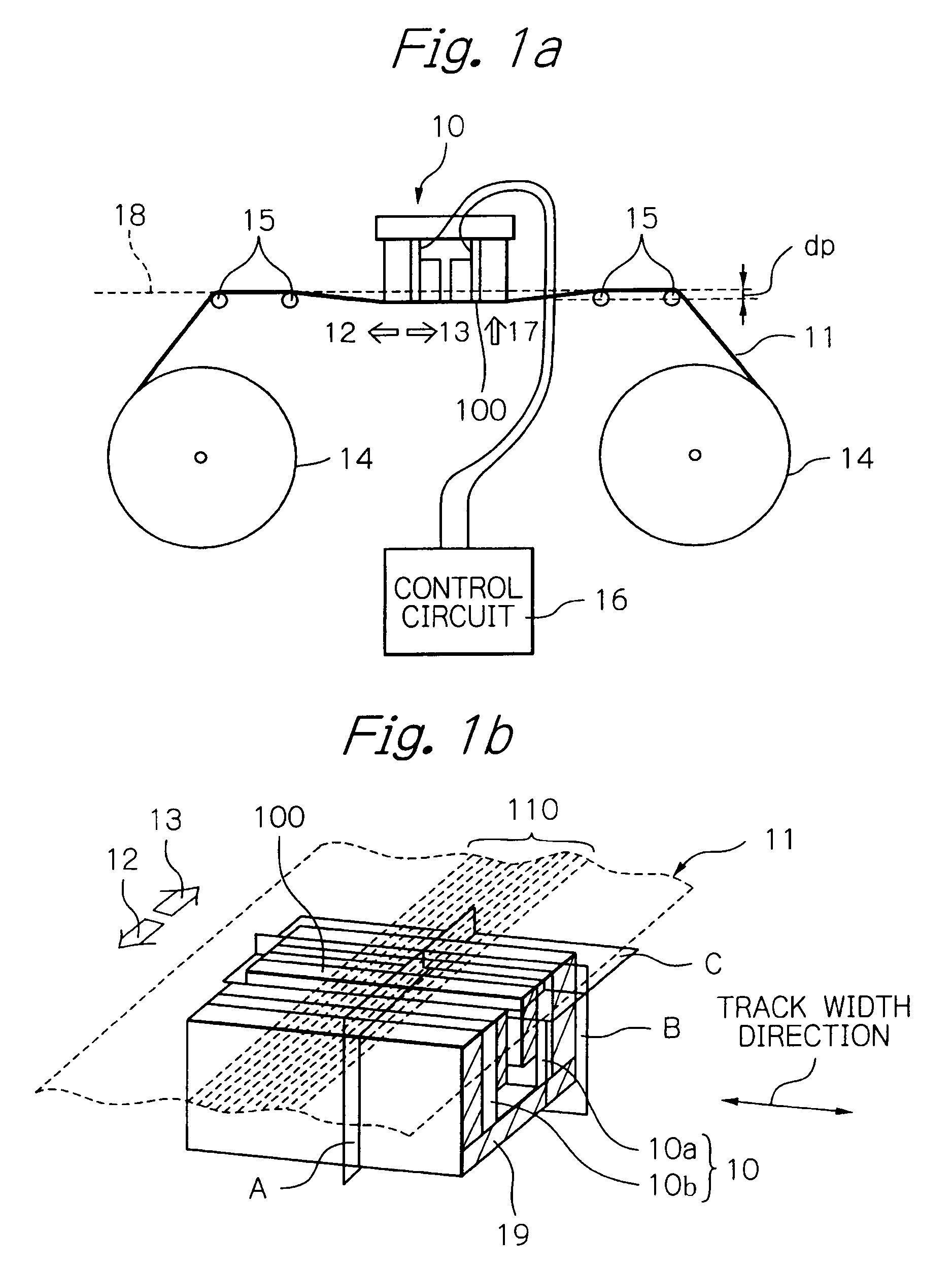

Evacuation method and vacuum processing apparatus

ActiveUS20160189988A1Reduce pressurePreventing moisture inside the vacuum chamber from freezingOperating means/releasing devices for valvesElectric discharge tubesEngineeringMechanical engineering

An evacuation method used for a vacuum processing apparatus including a vacuum processing chamber is provided. The vacuum processing chamber is evacuated by an exhaust device for a first predetermined period of time by opening a valve connecting the exhaust device with the vacuum processing chamber. A pressure in the vacuum processing chamber is urged to increase by closing the valve and leaving the valve closed for a second predetermined period of time after evacuating the vacuum processing chamber. Evacuating the vacuum processing chamber and urging the pressure in the vacuum processing chamber to increase are performed so as to reduce the pressure in the vacuum processing chamber to a pressure between 6.7 Pa and 13.3×102 Pa (between 5 Torr and 10 Torr) without freezing moisture in the vacuum processing chamber.

Owner:TOKYO ELECTRON LTD

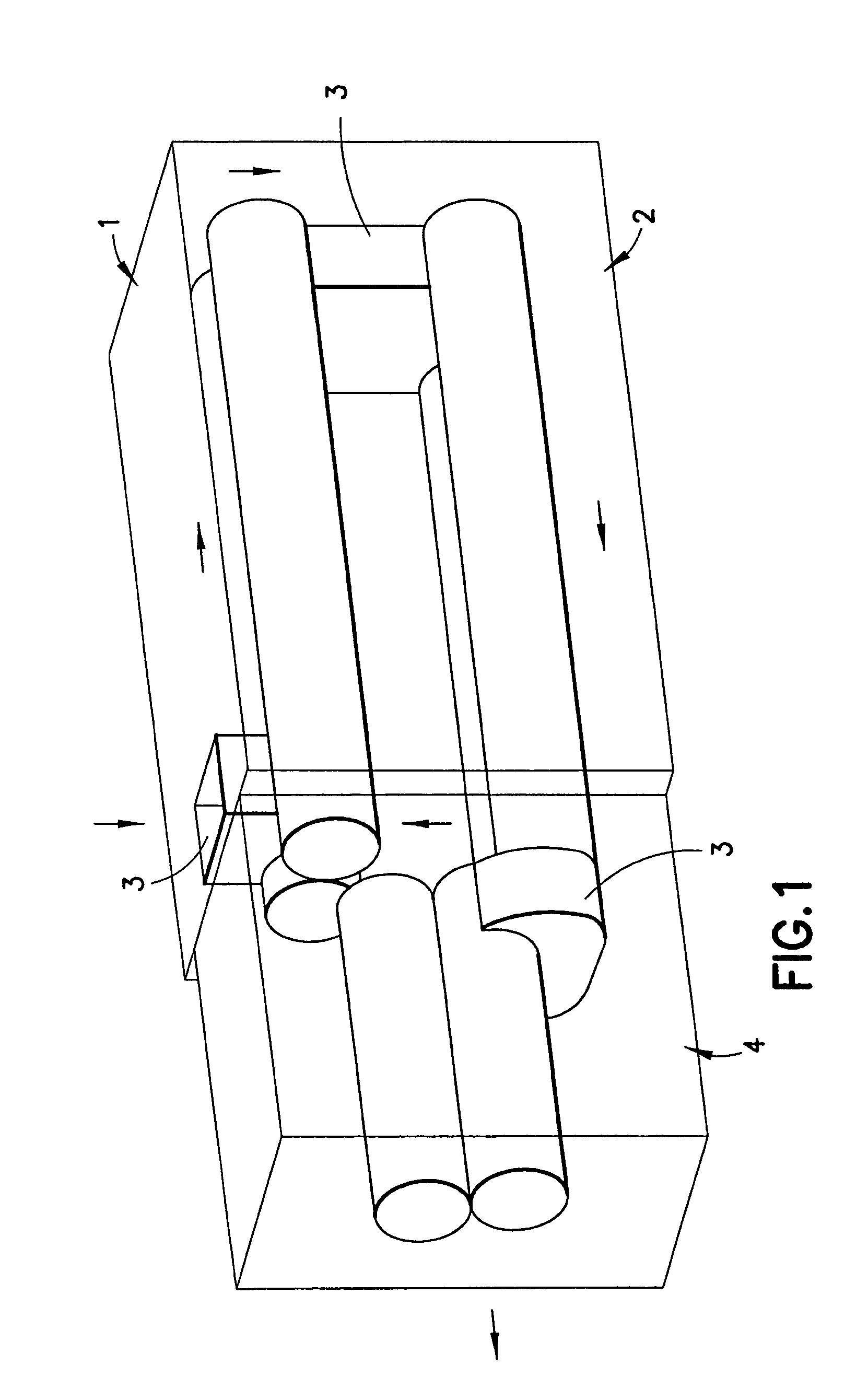

Multiple extruder configuration

InactiveUS7017732B2High mean residence timeHigh torqueRotary stirring mixersMixing/kneading with horizontally-mounted toolsBiomedical engineeringTwin screw extruder

The invention concerns a multiple-extruder configuration in which two co-rotating twin-screw extruders and a counter-rotating twin screw extruder are connected to each other with respect to the flow of material.

Owner:BERSTORFF GMBH

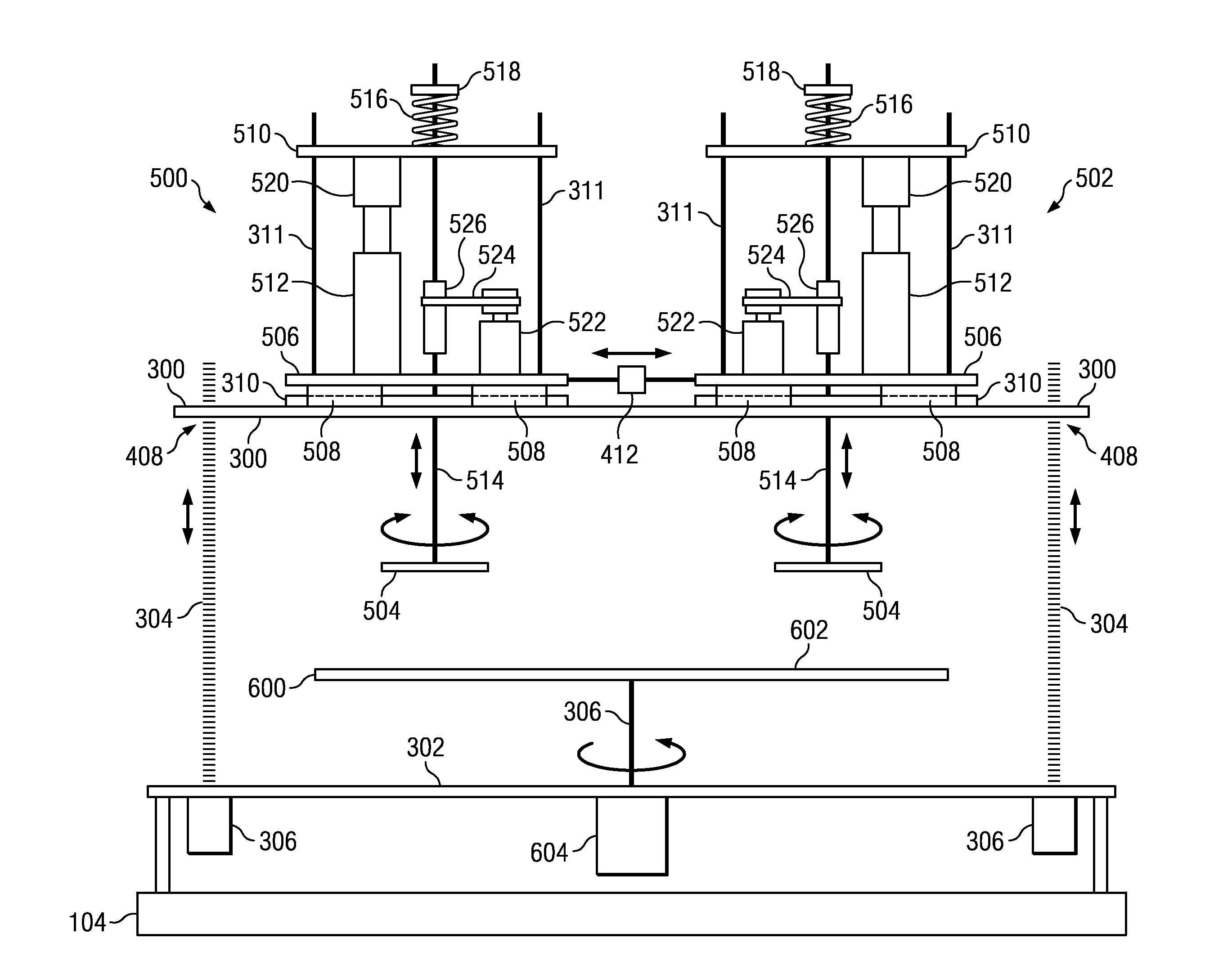

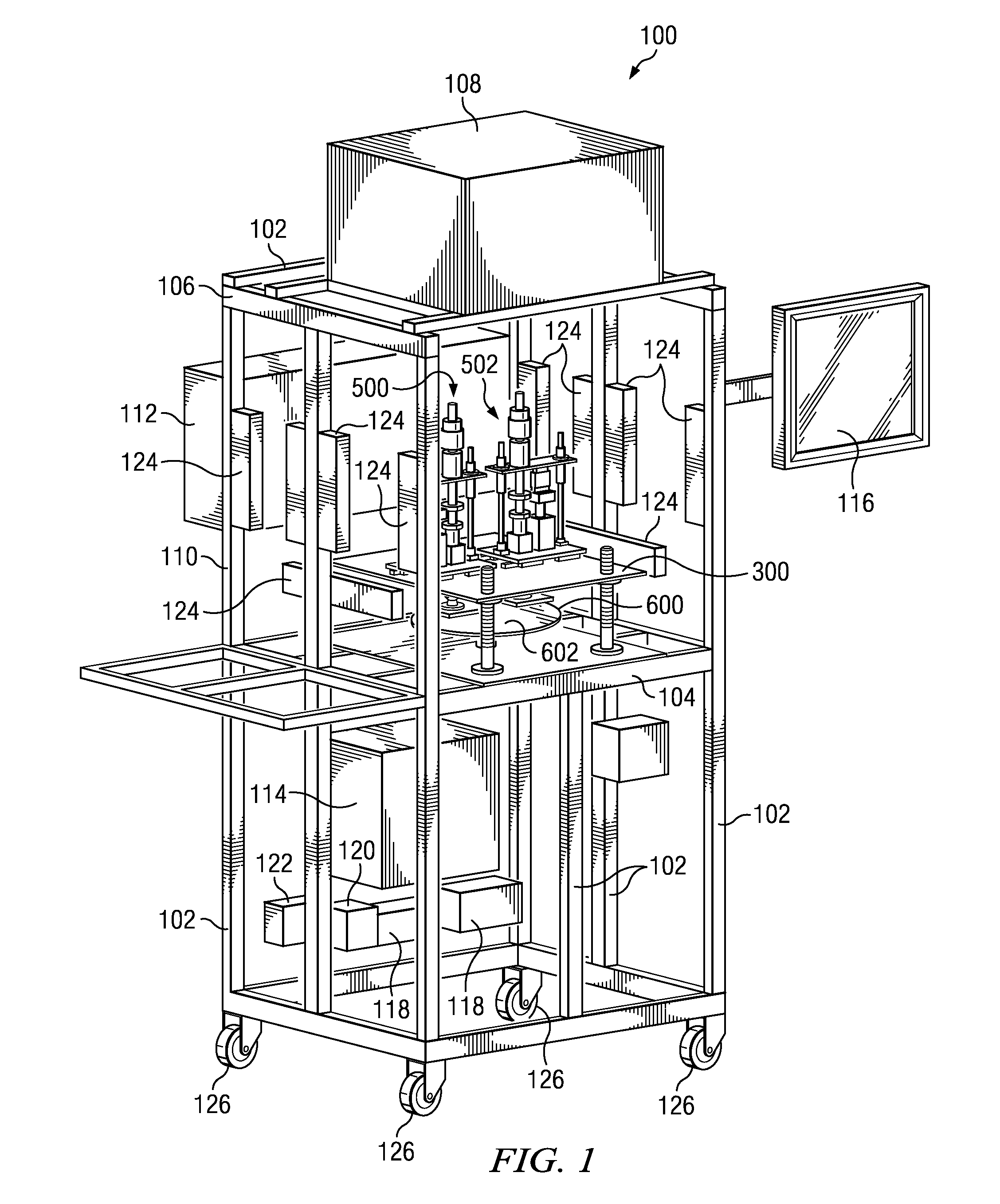

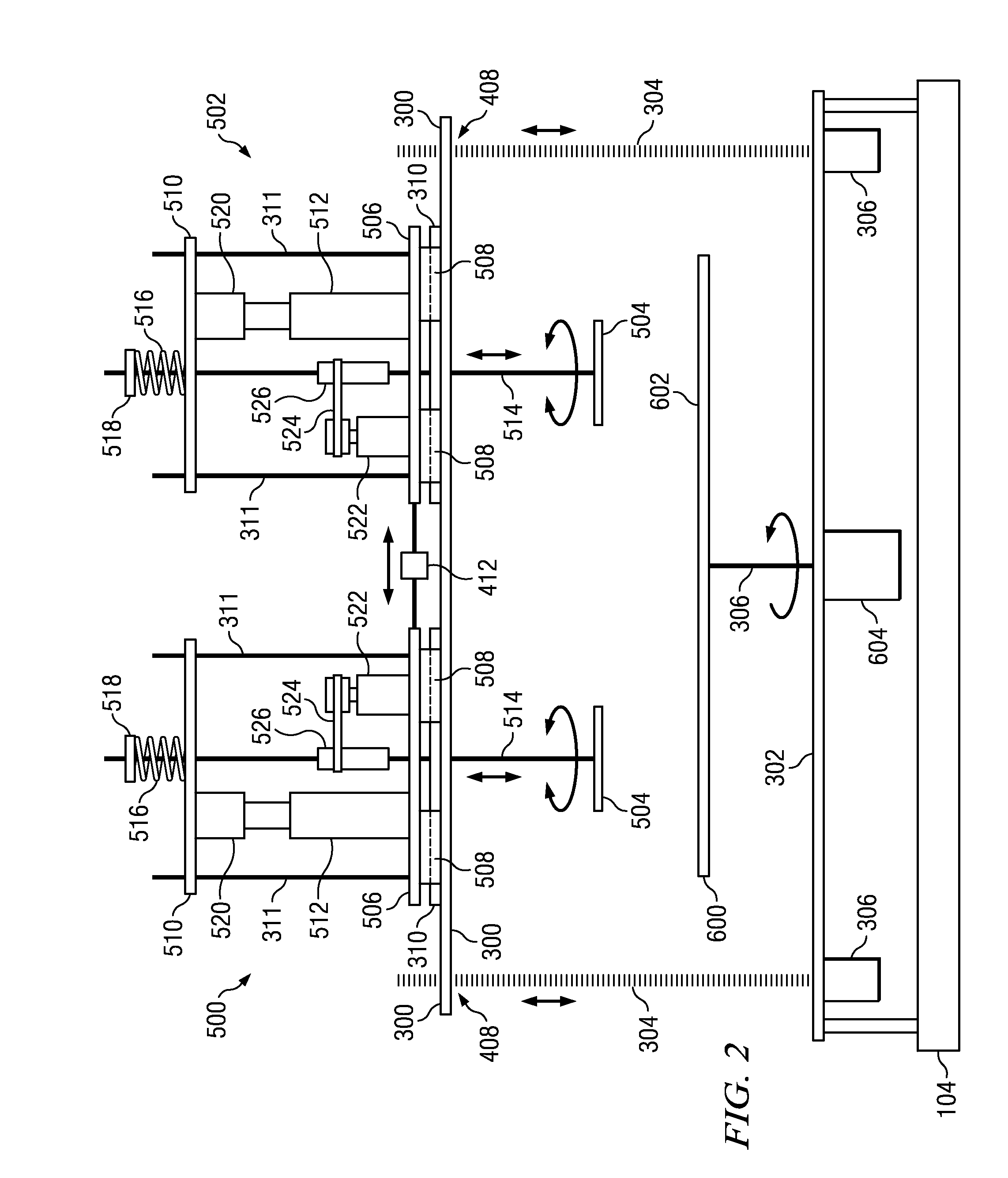

Automated chemical polishing system adapted for soft semiconductor materials

ActiveUS20100120334A1PressureRegulate the amount of pressurePolishing machinesRevolution surface grinding machinesSemiconductor materialsControl theory

At least one wafer is suspended on a respective jig shaft above a polishing platen. The degree of parallelism between the wafer and the polishing platen is controlled using a three-point suspension, which allows for planar pitch adjustments using vertical actuation algorithms. As the wafer is lowered into contact against the polishing platen, a load cell senses how much of the weight of the jig shaft, wafer mount and wafer continues to be supported by the jig. The vertical displacement of the wafer is controlled using a linear actuator responsive to a signal from the load cell. Vertical actuation of the wafer serves to increase or decrease this amount of supported weight, in turn decreasing or increasing the amount of applied down-force exerted between the wafer and the platen. A compression spring is used to increase the resolution of the pressure control. Finally, system components exposed to the work environment are encapsulated by chemically resistive components to prevent corrosion of system components.

Owner:DRS NETWORK & IMAGING SYST

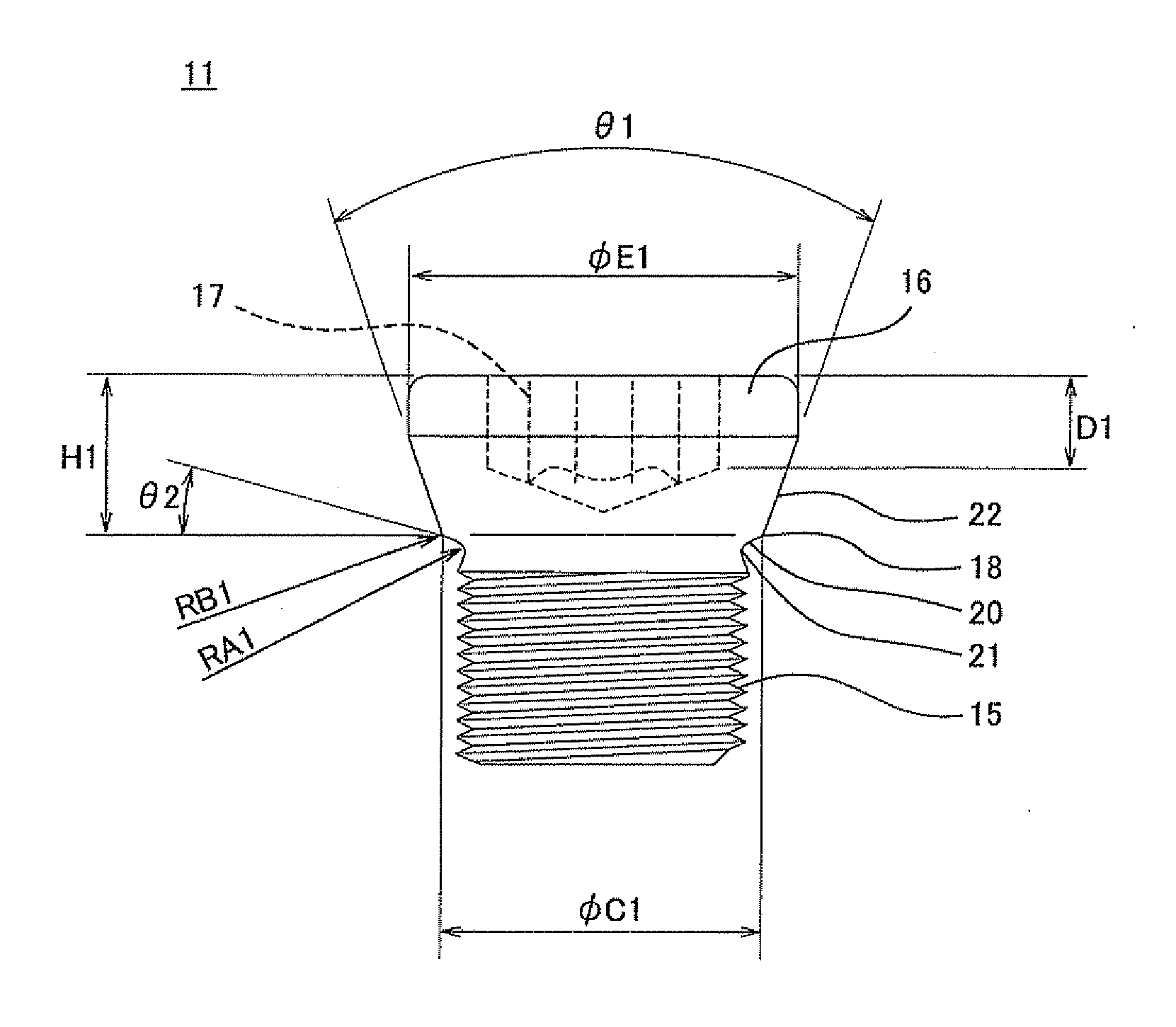

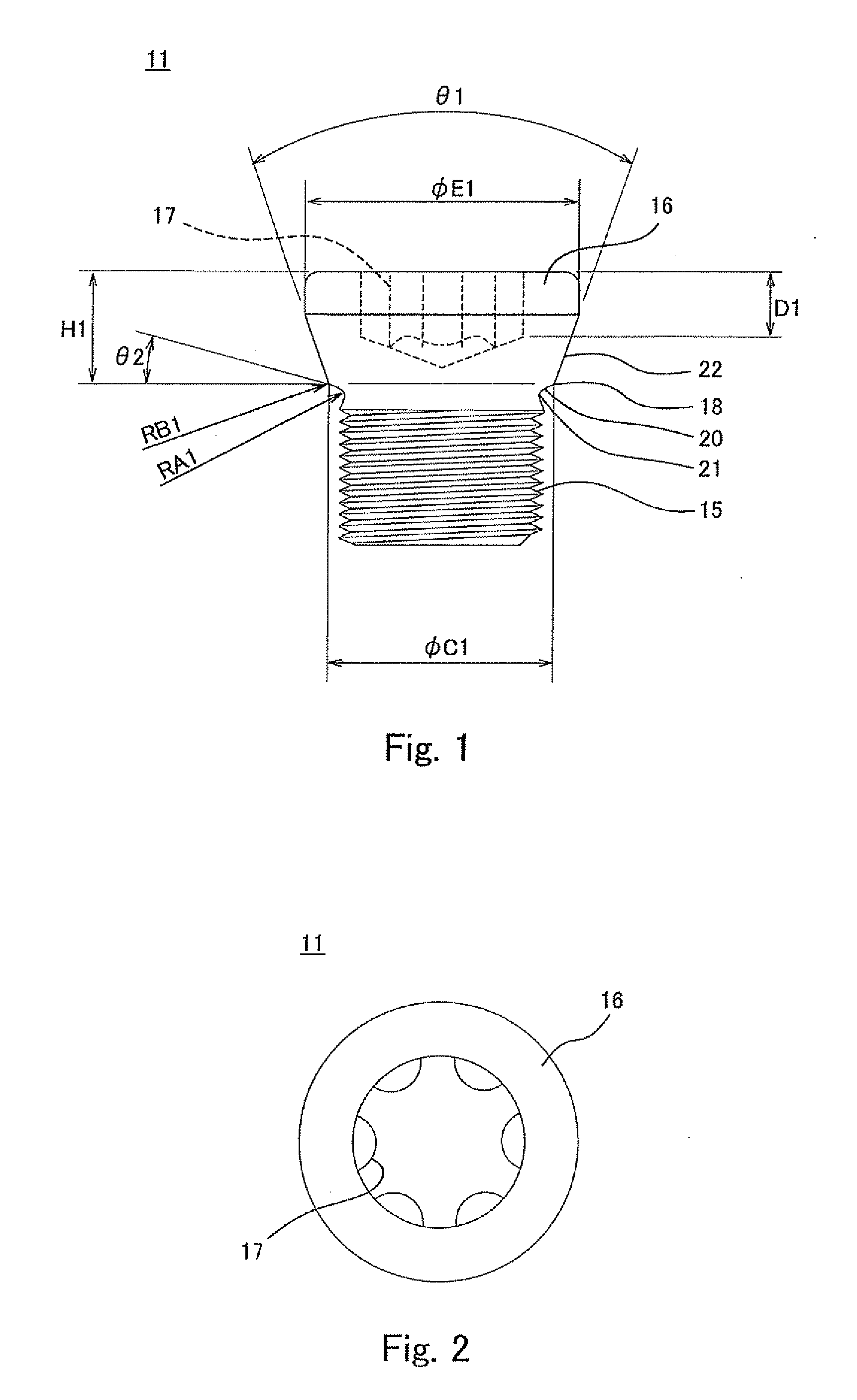

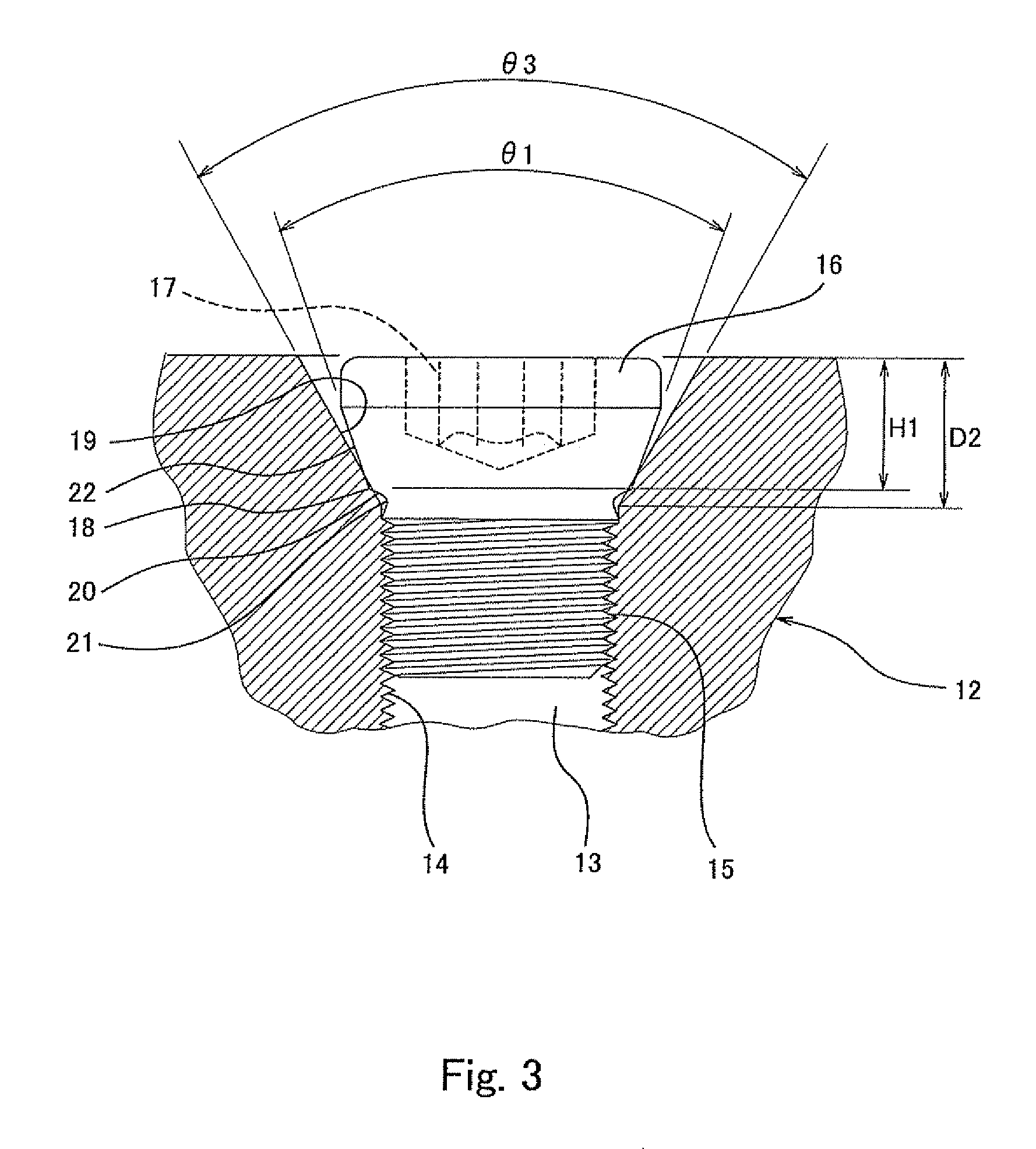

Filler plug for hydraulic device

A filler plug is configured such that: a head portion is formed on an upper end of an external thread; a sealing portion formed at the head portion strongly contacts a funnel-shaped inclined inner peripheral surface formed at one end of an internal thread of a hydraulic device oil passage by tightening the external thread with respect to the internal thread; an upper peripheral surface of the sealing portion is tapered; a circular constricted portion is formed between the sealing portion and the upper end of the external thread; and a dimensionless value of a head portion height H1 from an upper surface of the head portion to the sealing portion, that is, a dimensionless value obtained by dividing the head portion height H1 by a nominal designation value of the external thread portion, ranges from 0.4 to 0.7.

Owner:KAWASAKI HEAVY IND LTD

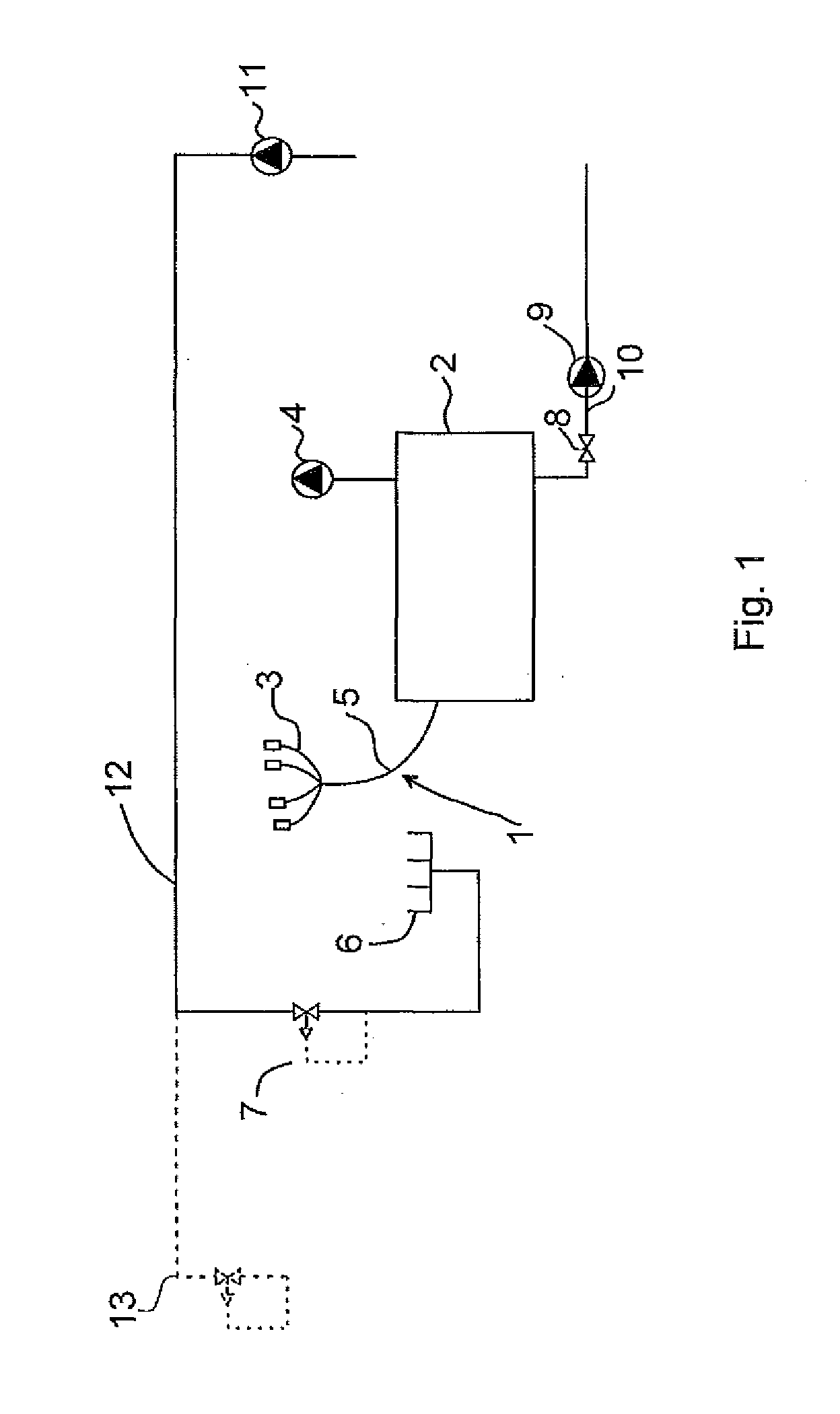

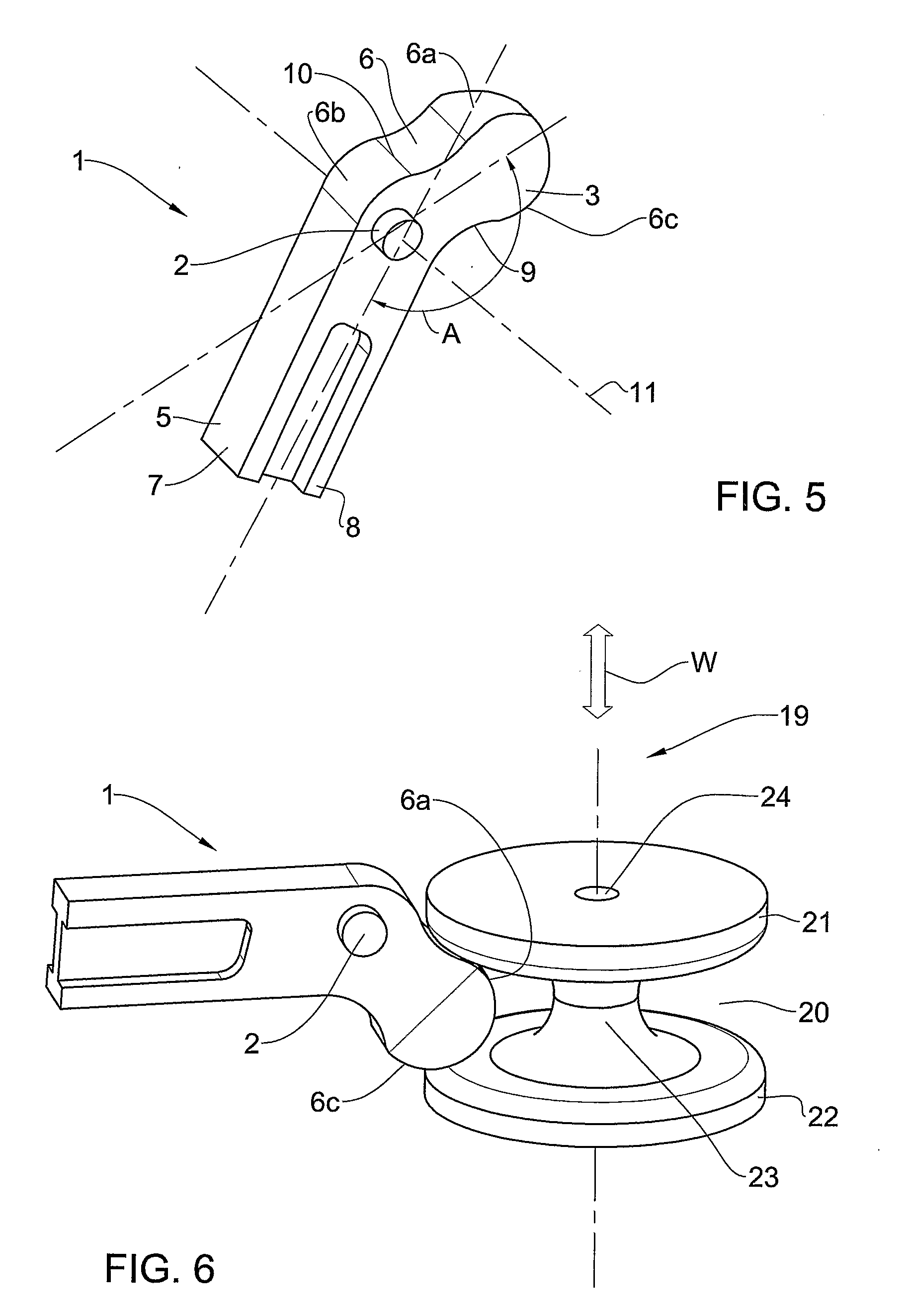

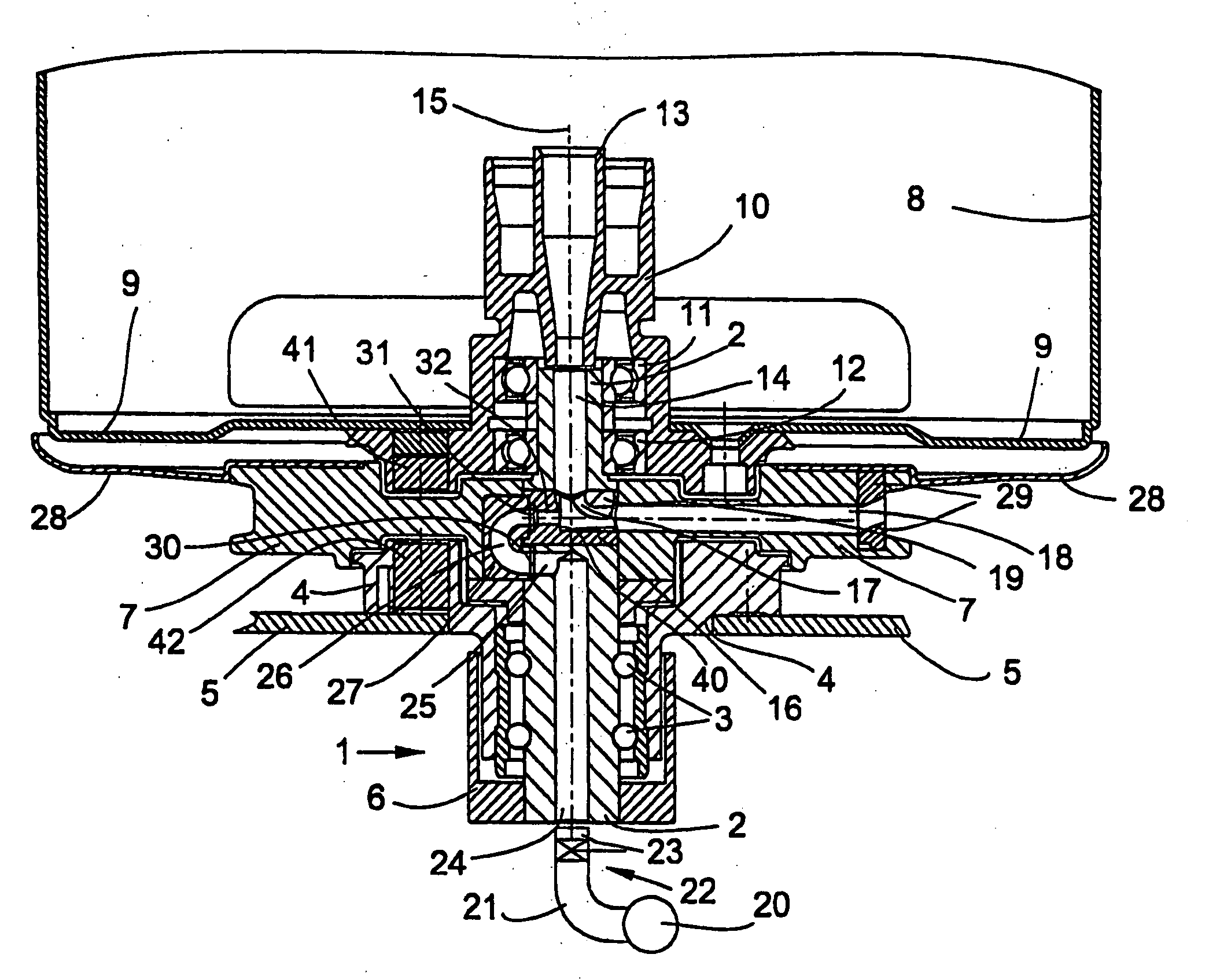

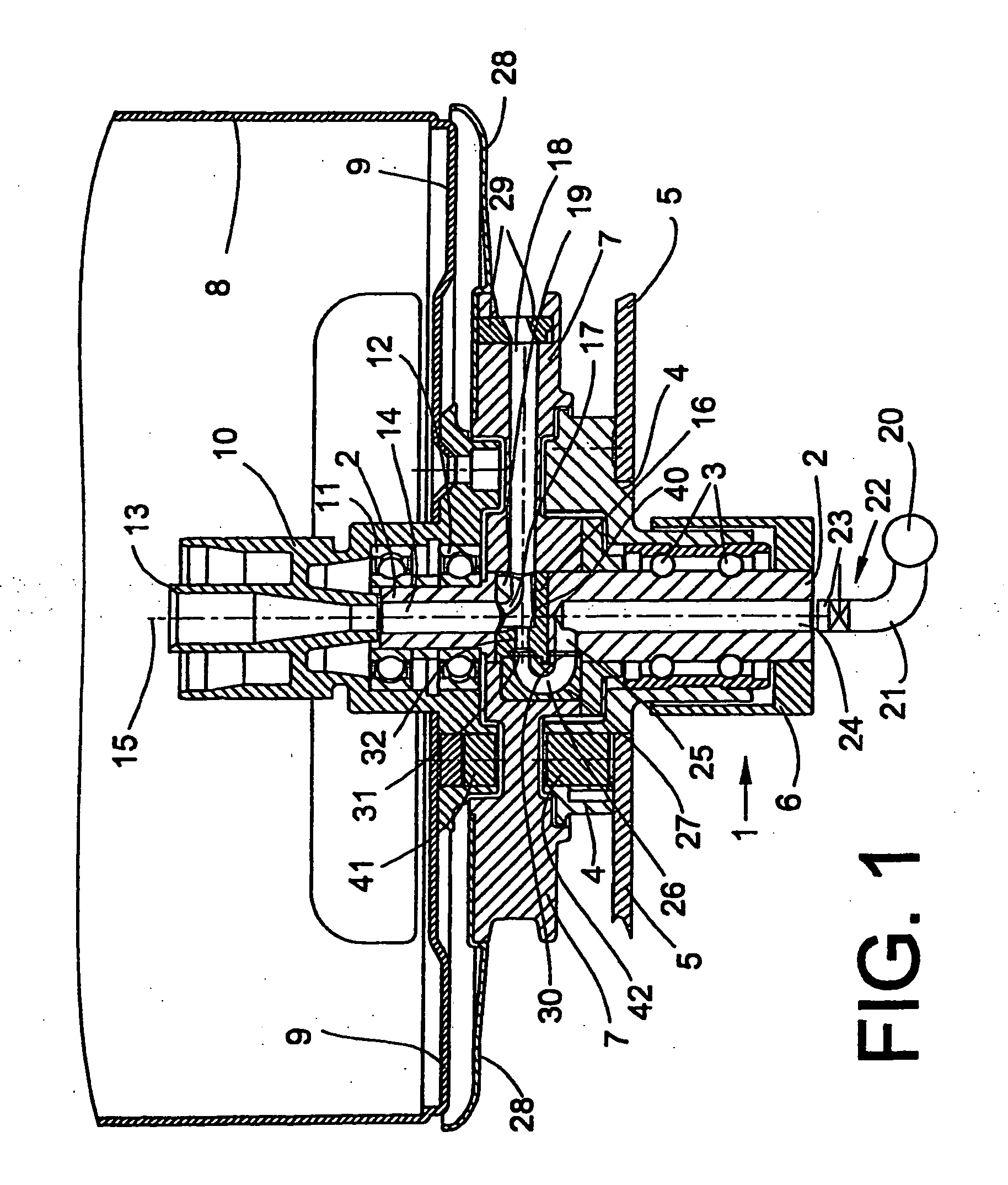

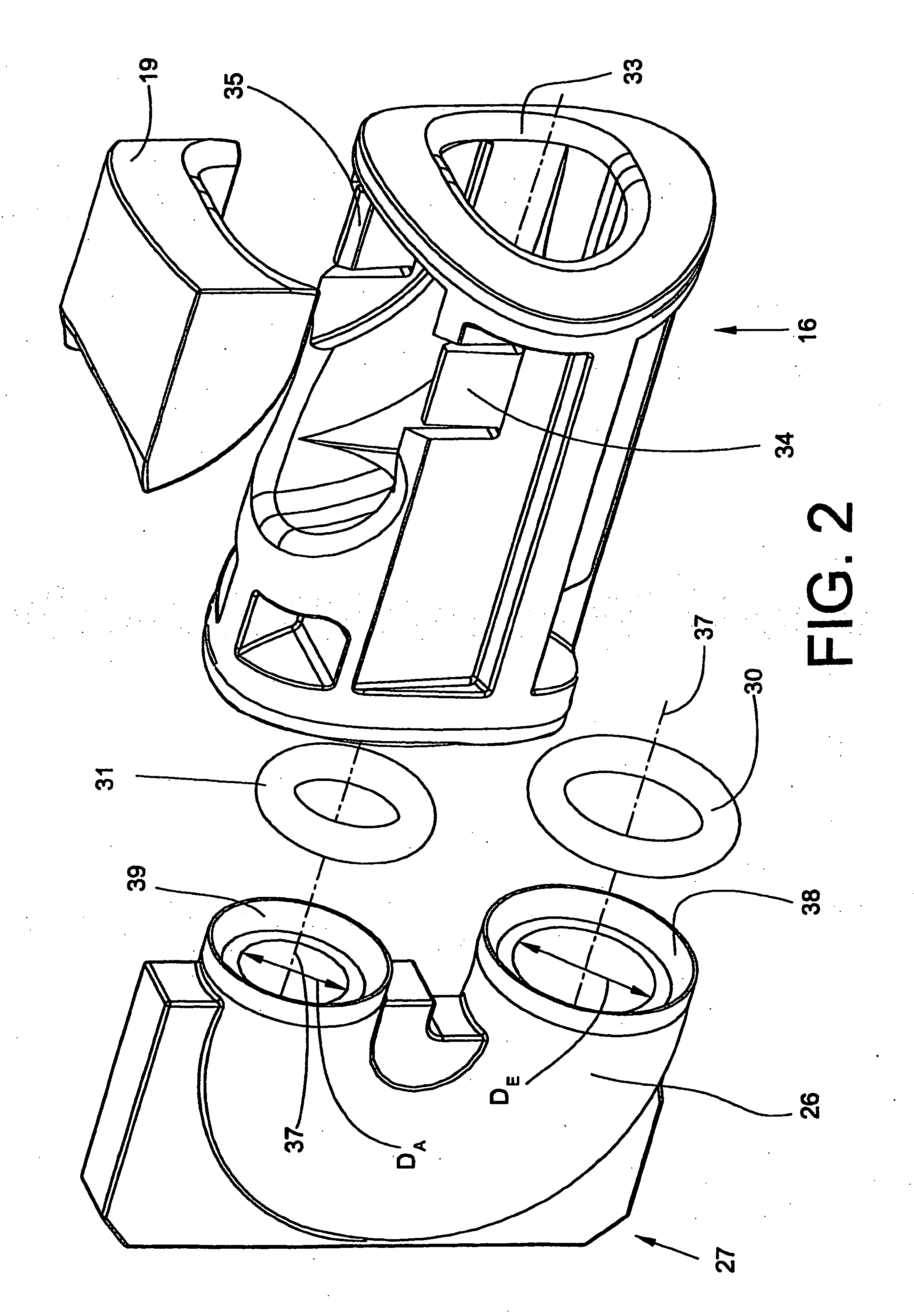

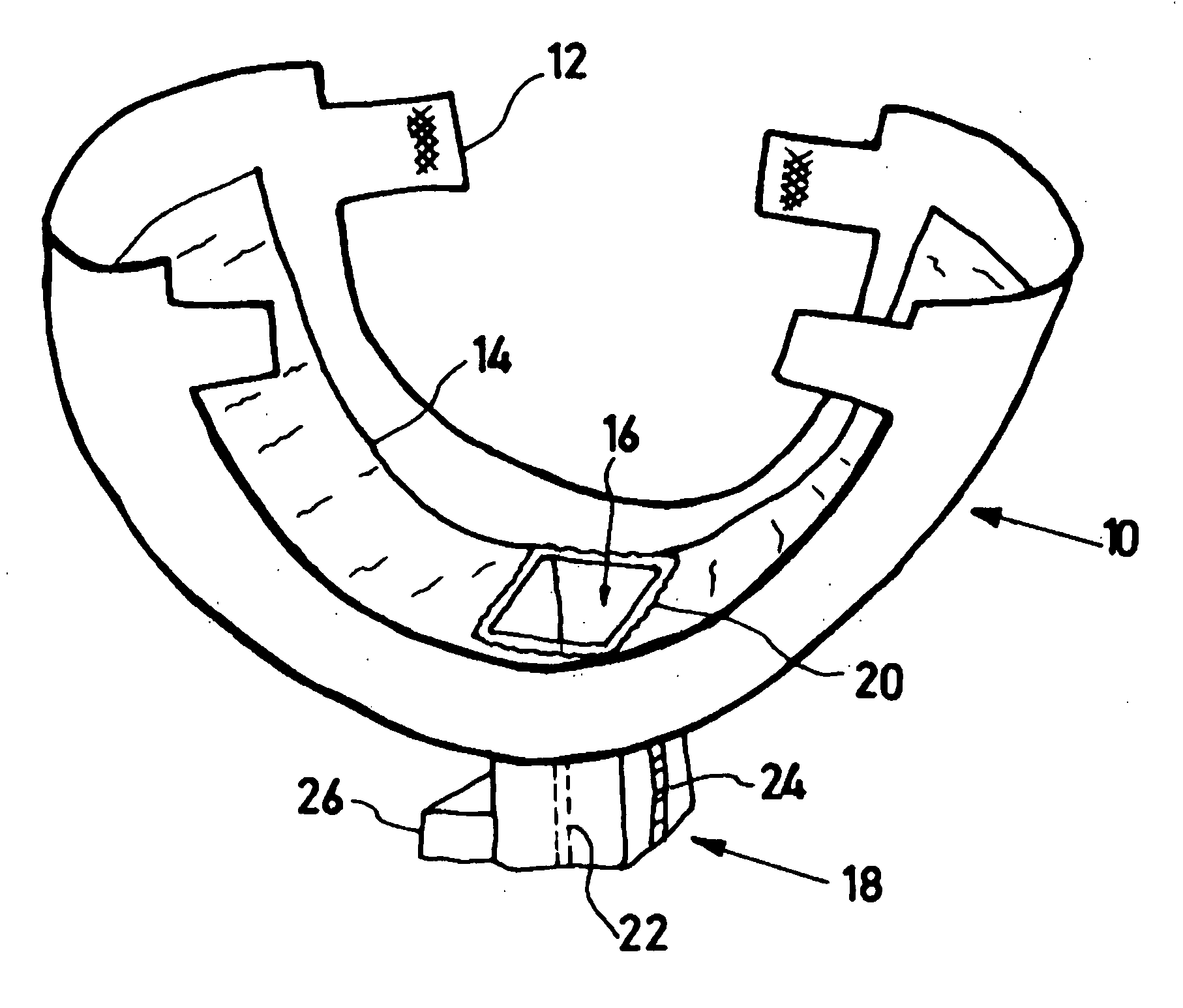

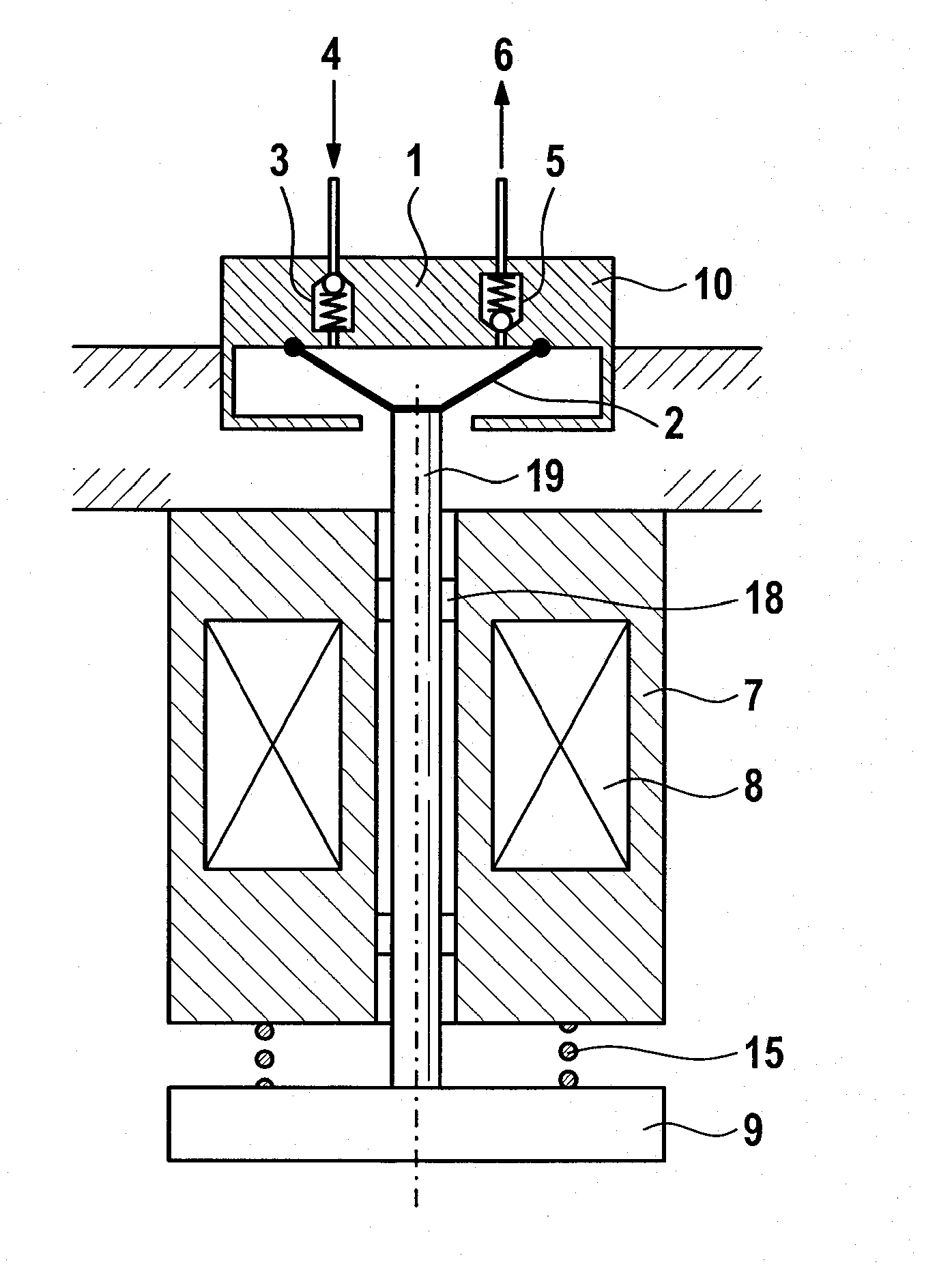

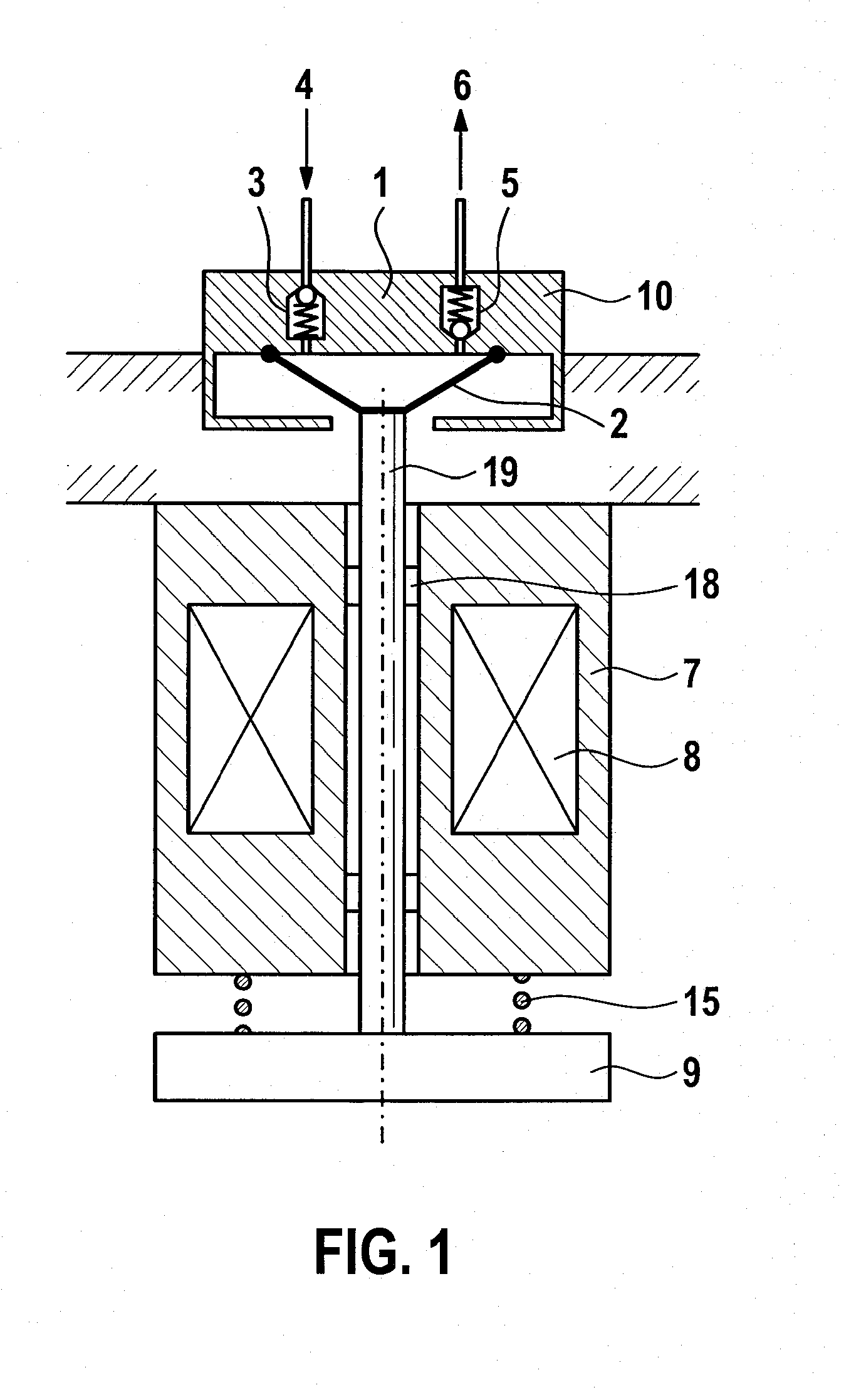

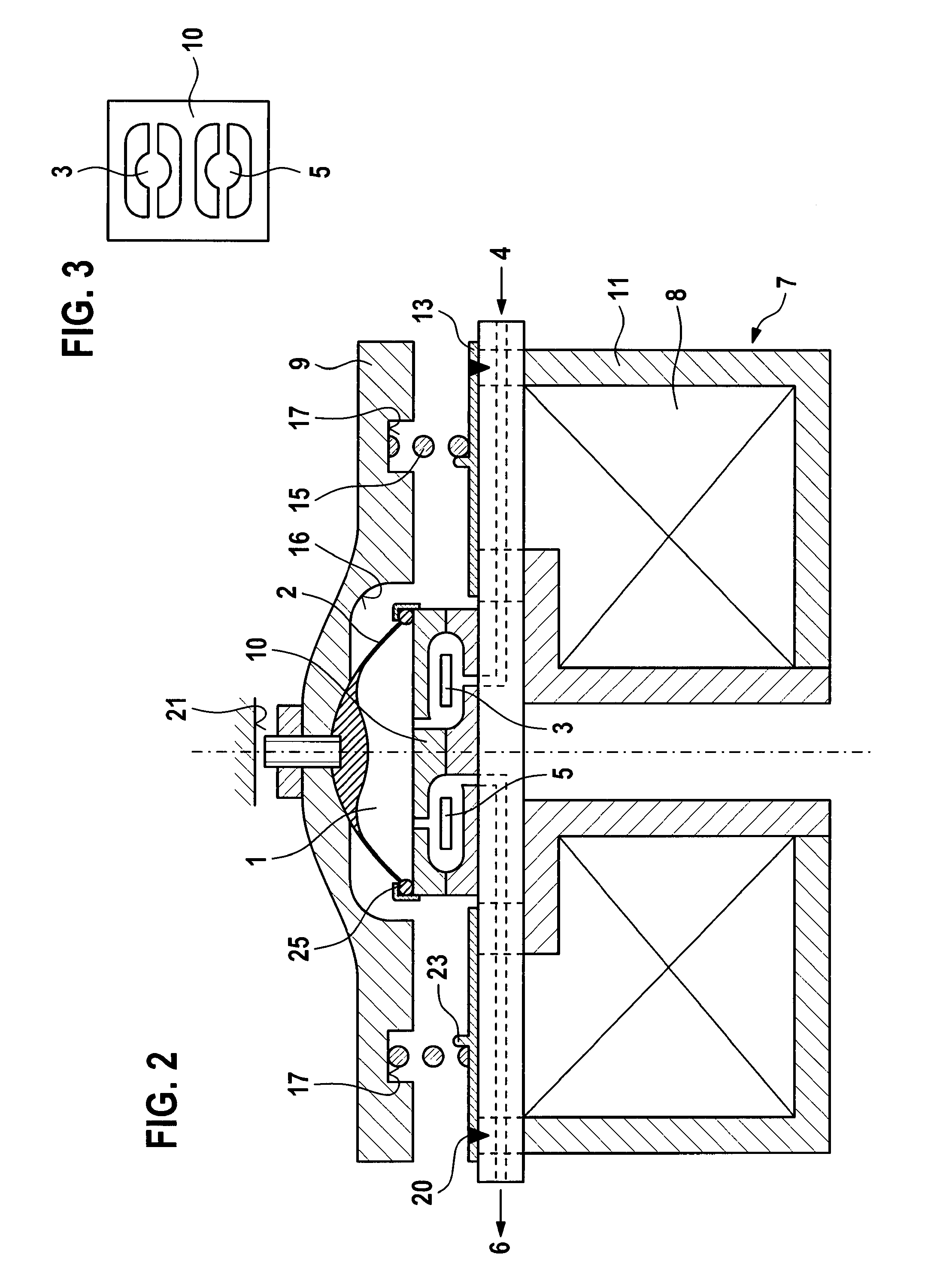

Diaphragm pump, and exhaust-gas aftertreatment system having a diaphragm pump

InactiveUS20130309108A1Reduce noiseReduce frictionFlexible member pumpsPositive-displacement liquid enginesDiaphragm pumpAqueous solution

Diaphragm pump for delivering a fluid, in particular an exhaust-gas aftertreatment medium, such as an aqueous urea solution for example, comprising a working chamber (1) which is delimited by a working diaphragm (2) and which can be connected via a first valve (3) to an inlet (4) and via a second valve (5) to an outlet (6), and an electromagnet (7) which comprises a coil assembly (8) and an armature (9) which interacts with the coil assembly (8) and is operatively connected to the working diaphragm (2). According to the invention, the valves (3, 5) are configured in a valve plate (10) which is arranged between the coil assembly (8) and the armature (9). Exhaust-gas aftertreatment system having a diaphragm pump of this type.

Owner:ROBERT BOSCH GMBH

Stent and Method and Device for Fabricating the Stent

ActiveUS20120214384A1Easy to cutReduce risk of damageStentsBlast gunsInsertion stentBiomedical engineering

Stent, as well as a method and device for fabricating the stent, wherein the stent has a tubular lattice structure comprising individual struts and at least one strut of which at least one longitudinal section runs with at least one directional component in the radial circumferential direction of the stent, wherein the surface of the longitudinal section facing the outside of the stent is curved only about the longitudinal axis of the stent. According to the invention, the surface of longitudinal section of the strut, which surface faces the inside of the stent, has such a curvature that the strut cross section is fluidically optimized.

Owner:BIOTRONIK AG

Filling device and method for filling with viscous filling material

InactiveUS20080264515A1Precise and direct mannerVast supplyPackaging meatSausage makingClip placementFilling materials

A filling device and associated method for filling viscous filling material, in particular sealants, into a tubular casing material. The filling device comprises: a shutoff valve, a filling tube disposed downstream from the shutoff valve in the direction of flow of the filling material, a clip placement and clip closing device disposed downstream from the filling tube in the direction of flow of the filling material and a supply of tubular casing material disposed at least partially on the filling tube. At least one sensor is also provided for directly or indirectly measuring the length of casing material drawn from the supply of casing material, the output signal of the sensor being able to control at least the closing of the shutoff valve through which the pressurized filling material can be fed to the filling tube.

Owner:POLY CLIP SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com