Patents

Literature

53results about How to "Optimized section" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

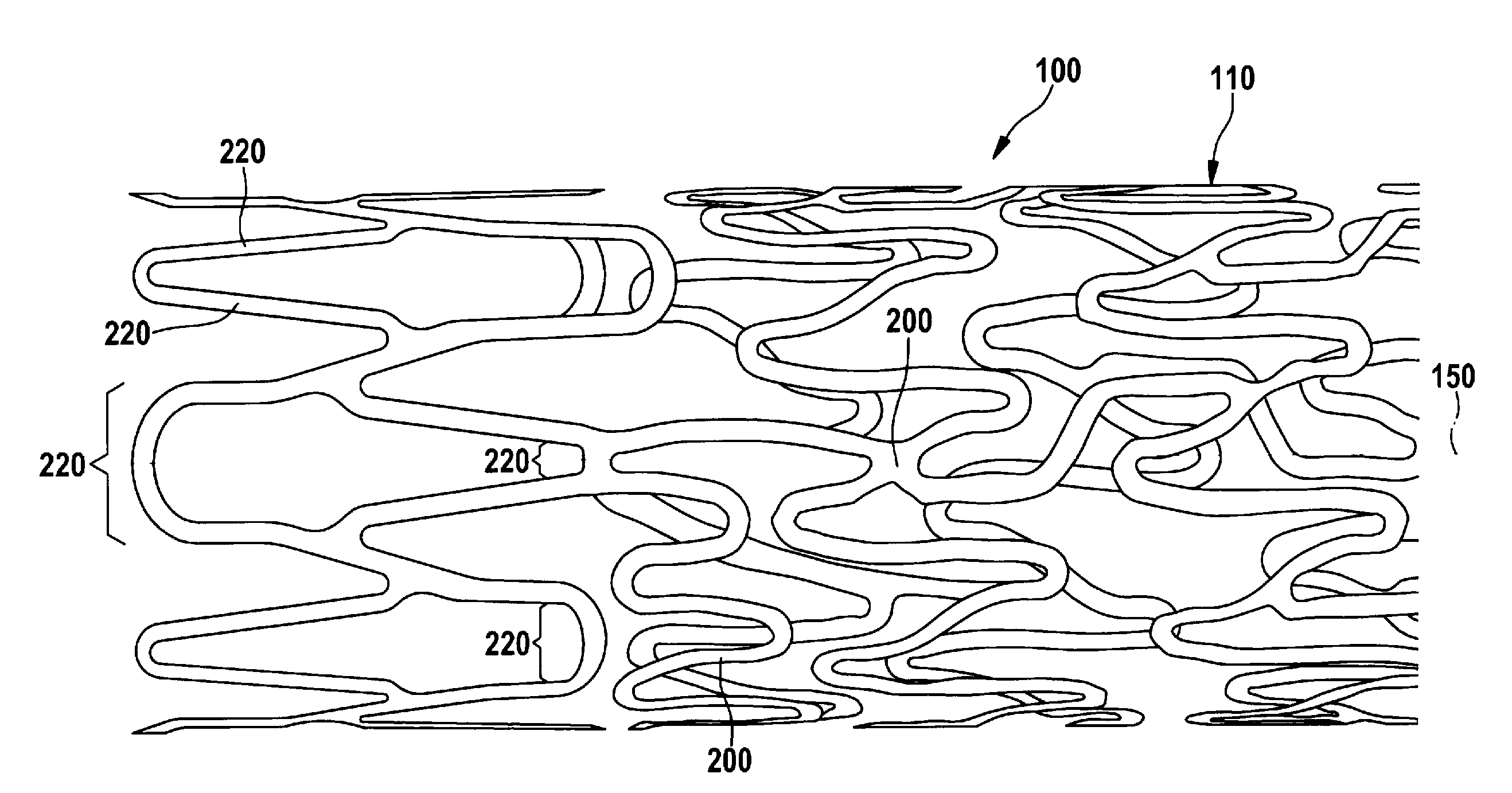

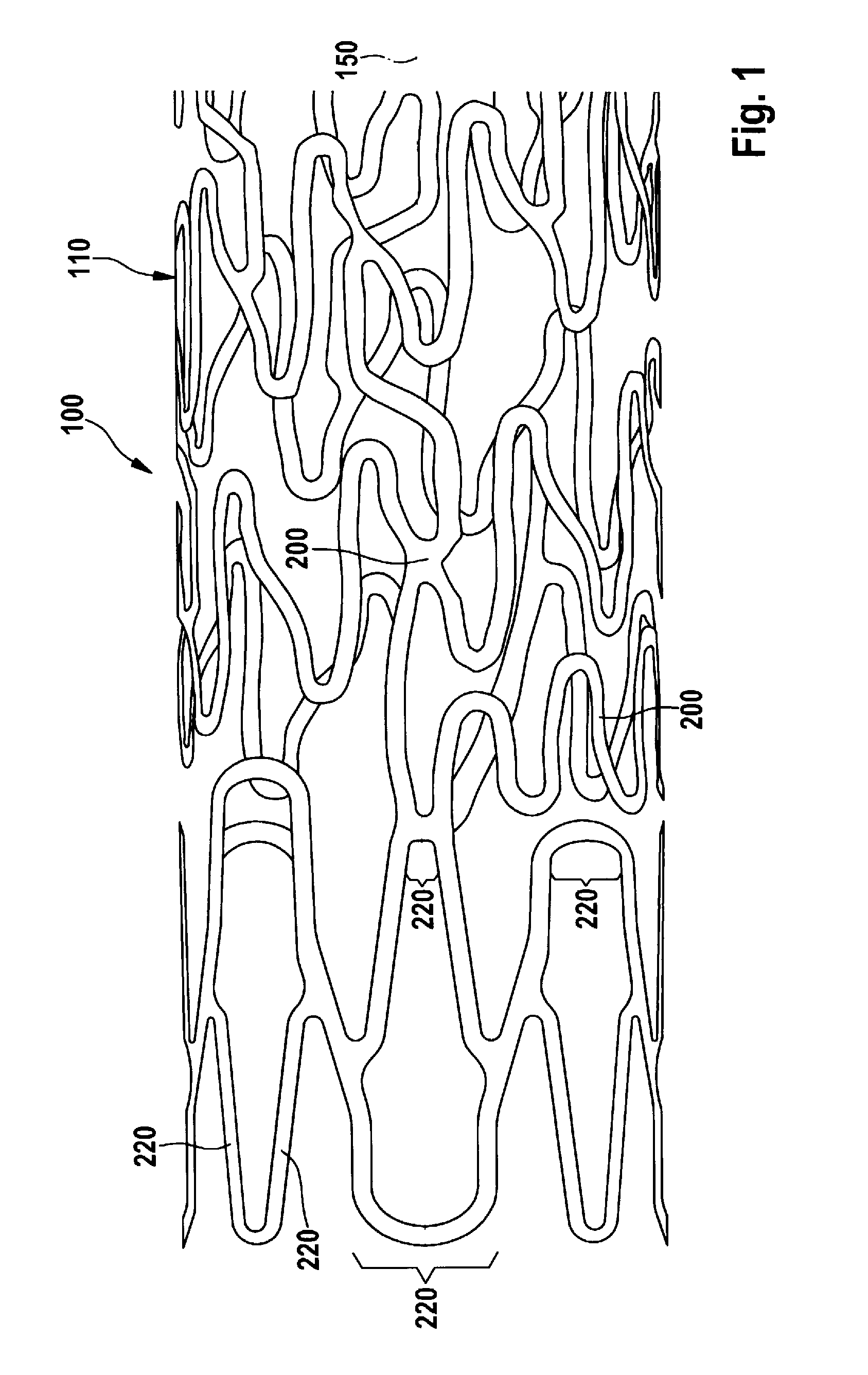

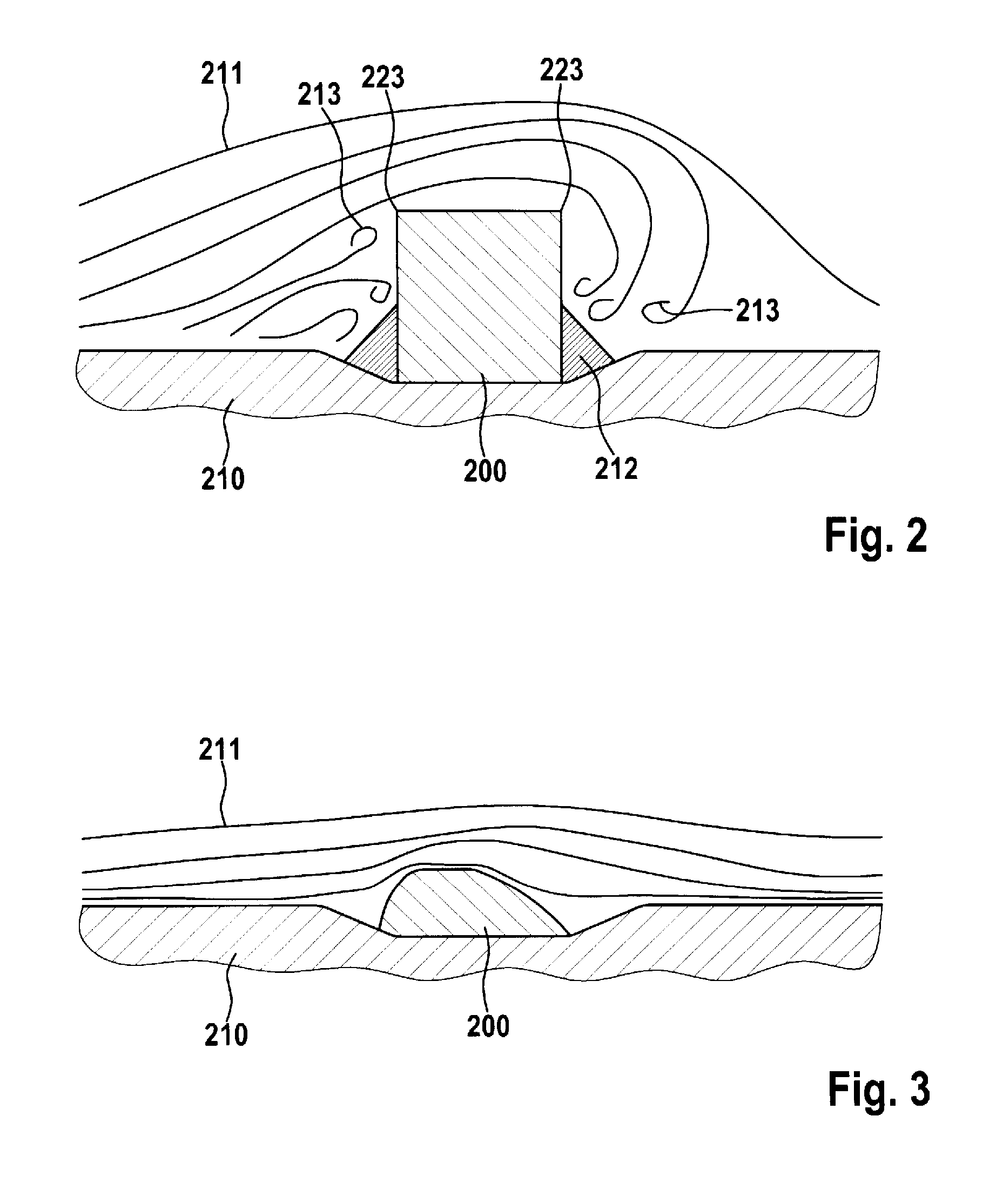

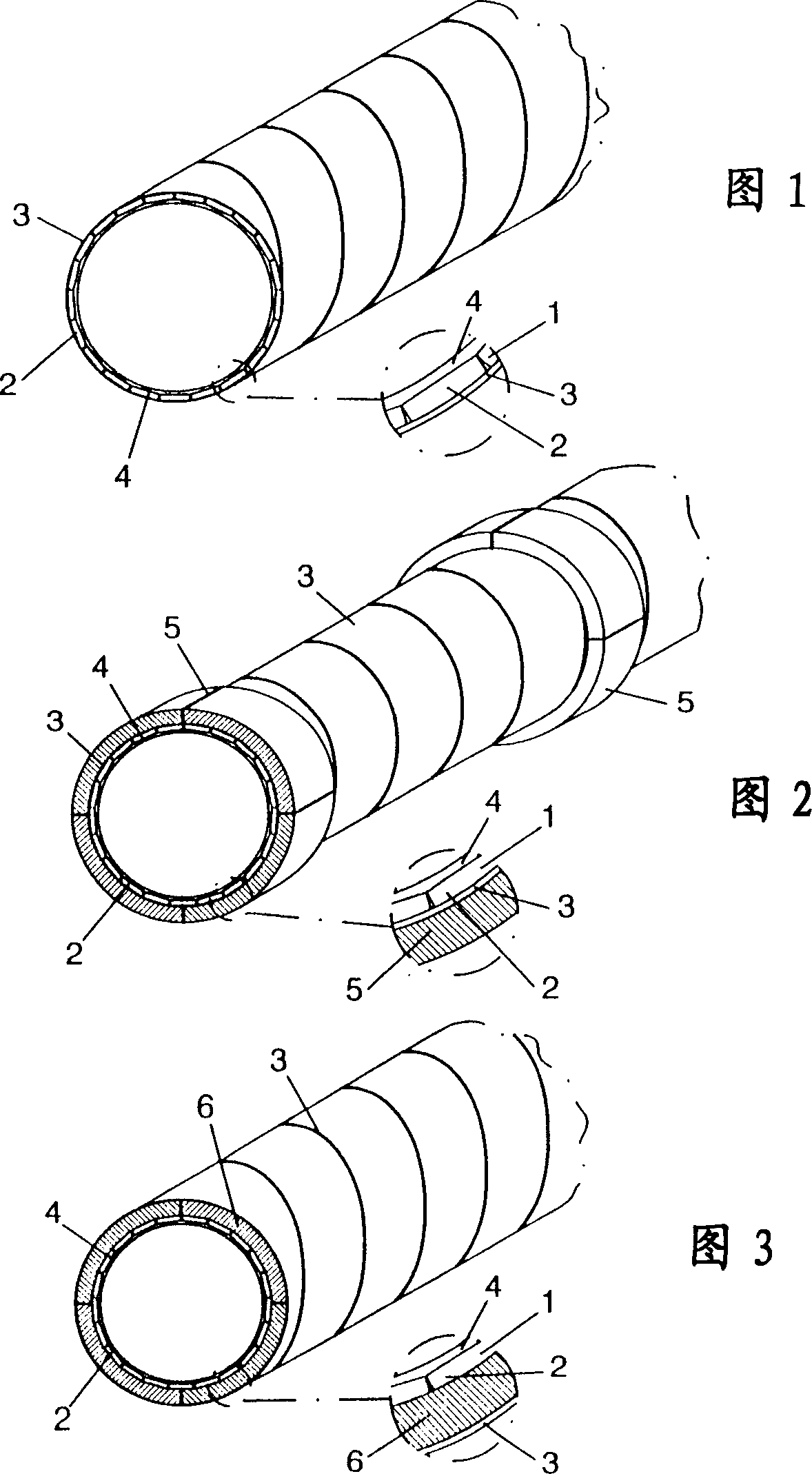

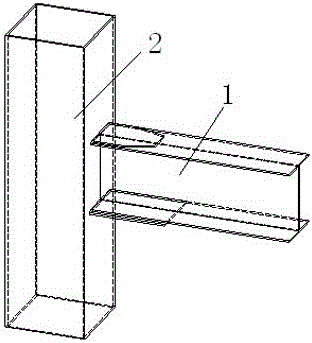

Stent and Method and Device for Fabricating the Stent

ActiveUS20100049300A1Stress minimizationAvoid injuryStentsElectrolysis componentsInsertion stentBiomedical engineering

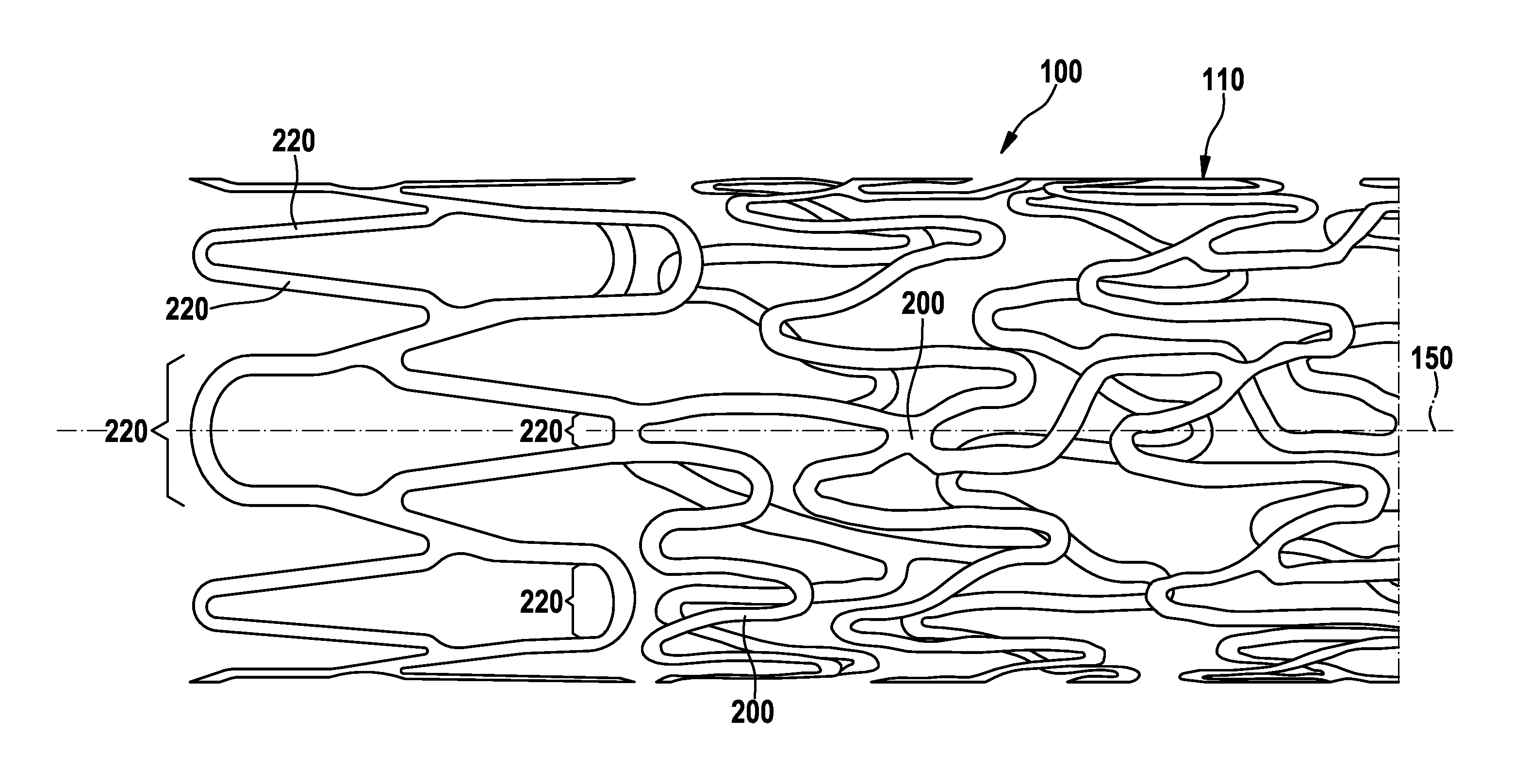

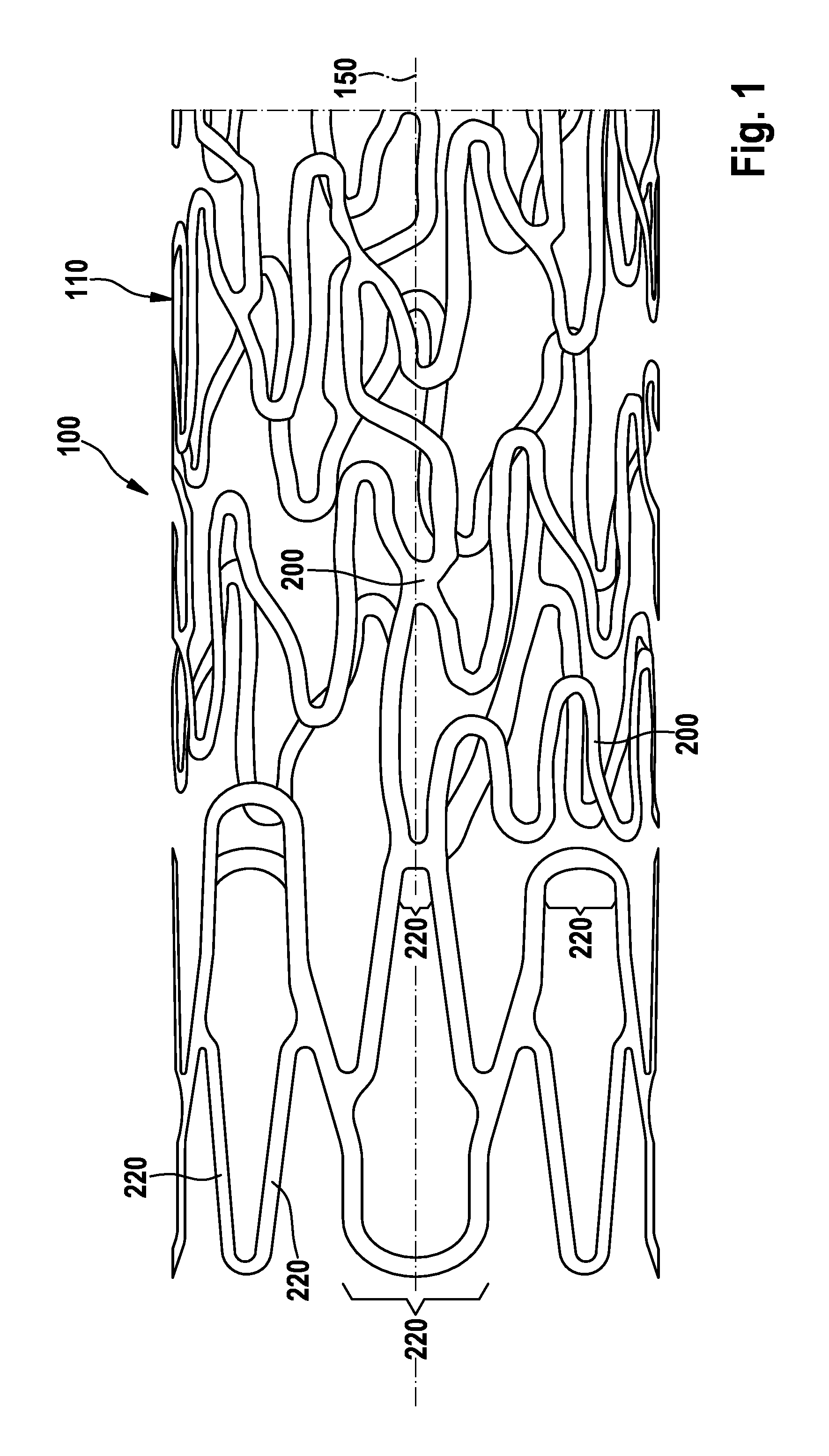

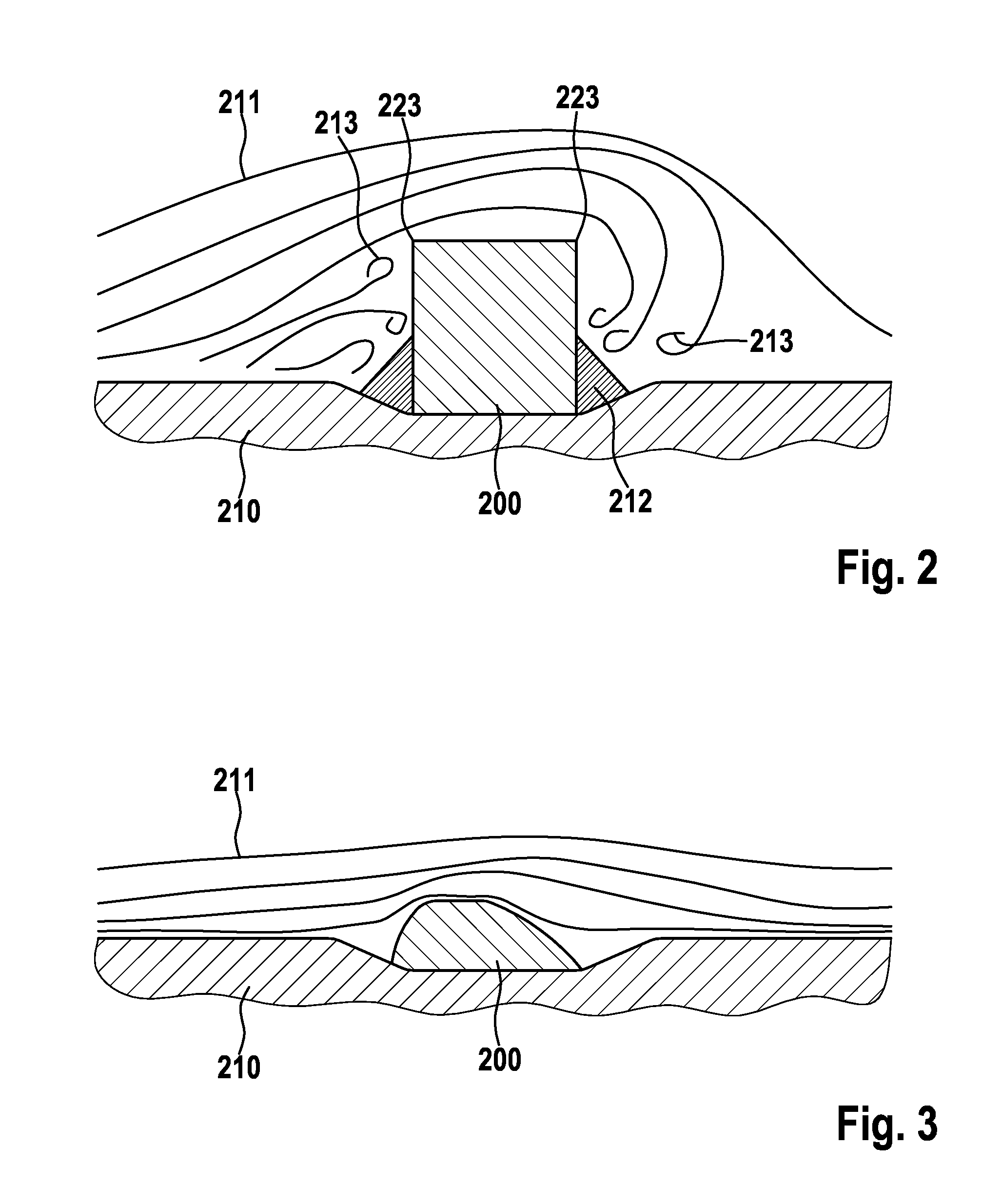

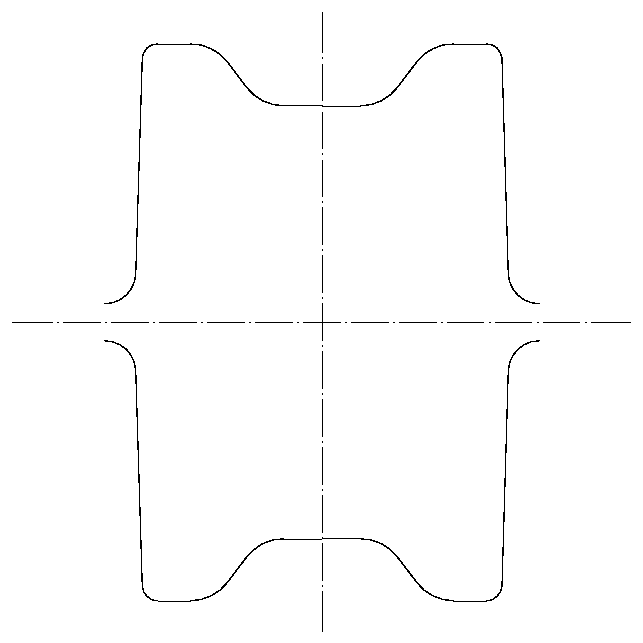

Stent, as well as a method and device for fabricating the stent, wherein the stent has a tubular lattice structure comprising individual struts and at least one strut of which at least one longitudinal section runs with at least one directional component in the radial circumferential direction of the stent, wherein the surface of the longitudinal section facing the outside of the stent is curved only about the longitudinal axis of the stent. According to the invention, the surface of longitudinal section of the strut, which surface faces the inside of the stent, has such a curvature that the strut cross section is fluidically optimized.

Owner:BIOTRONIK AG

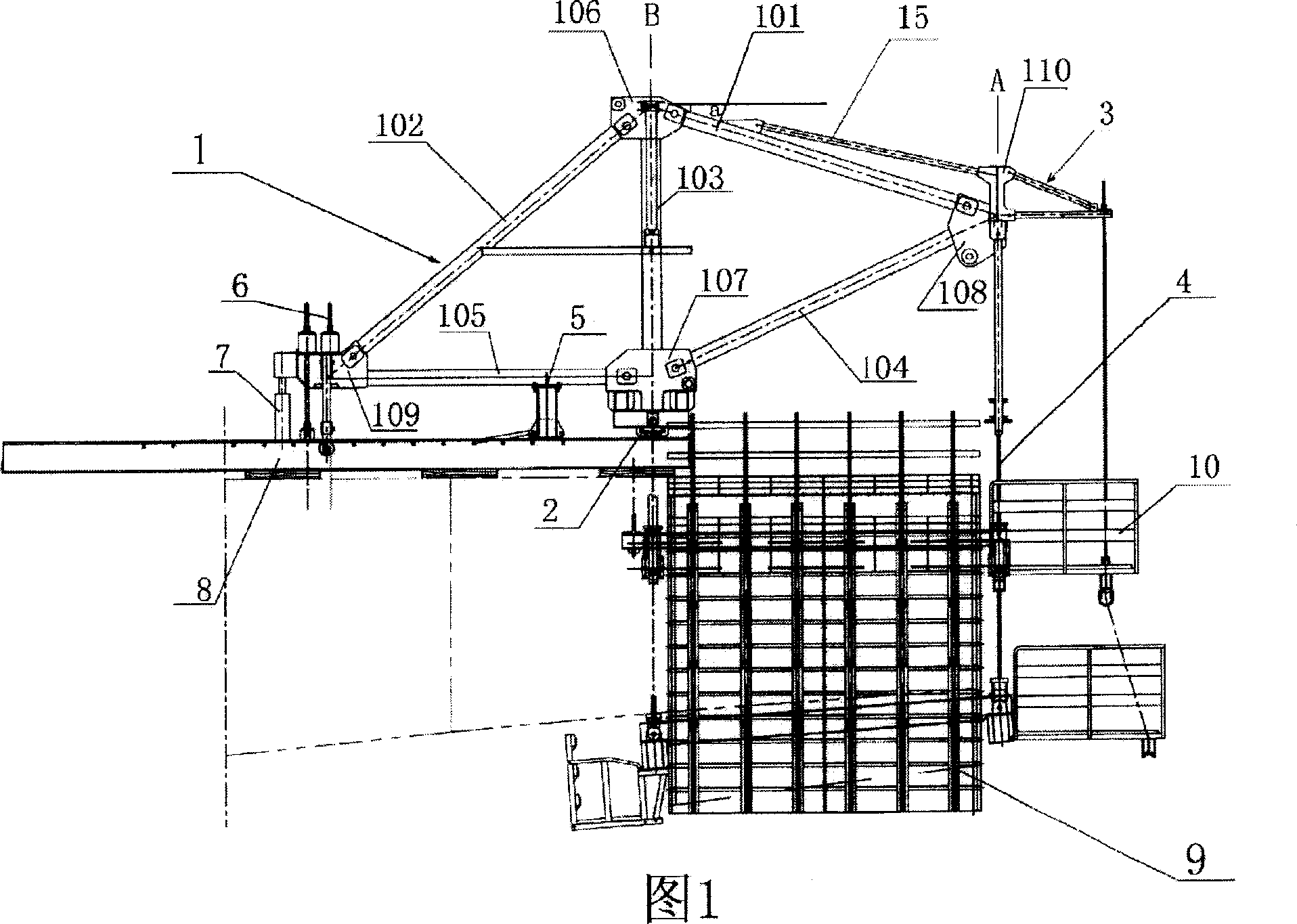

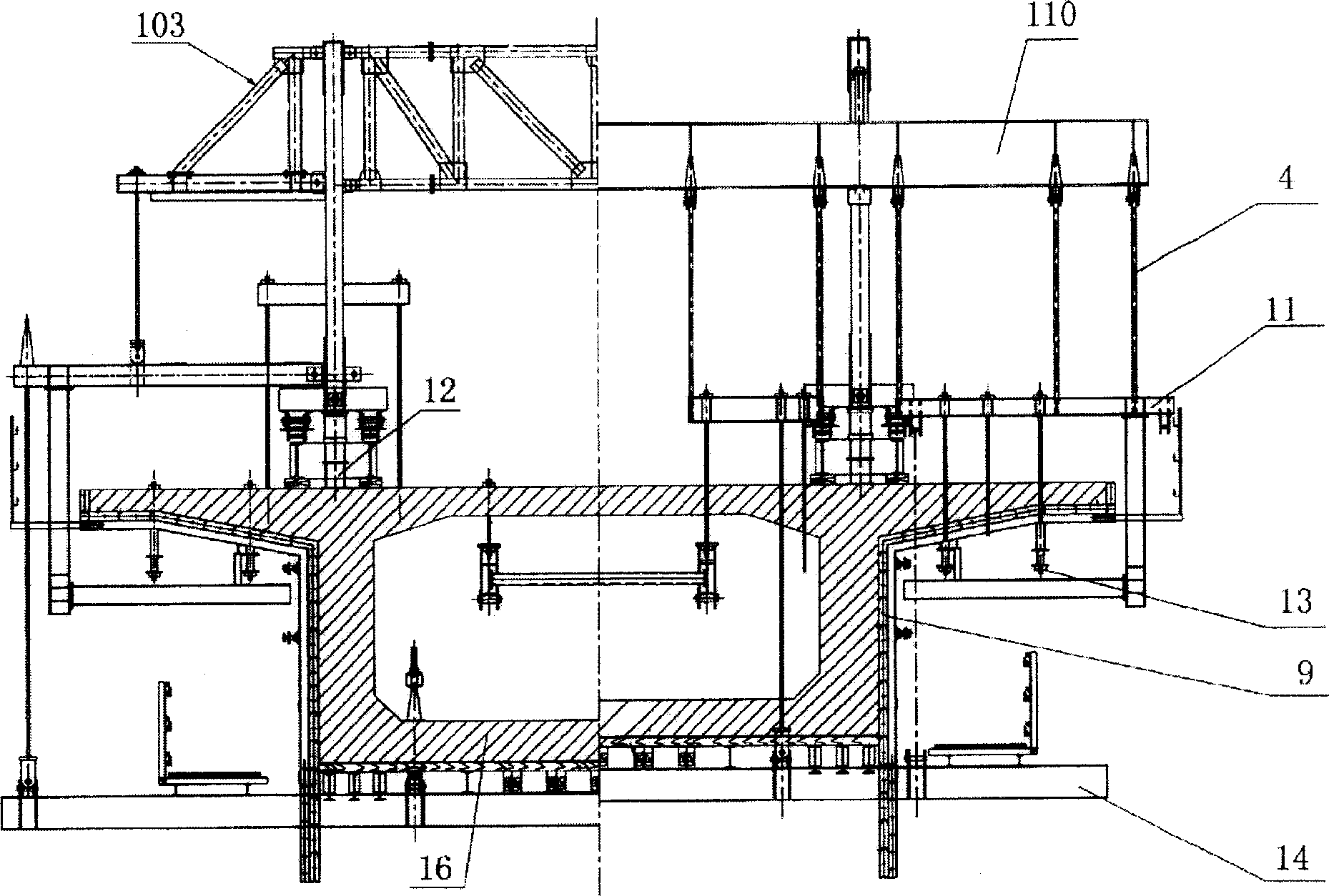

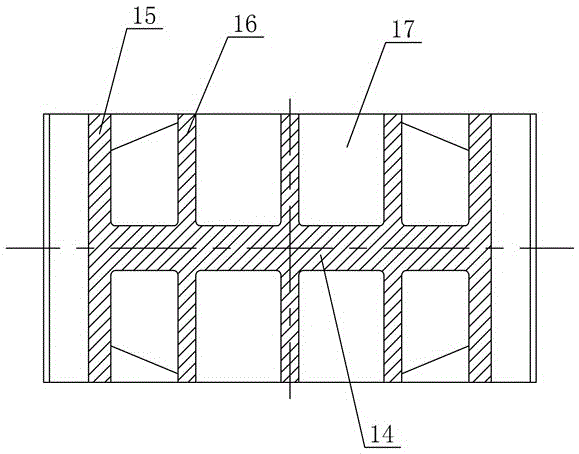

Diamond shaped cradle in truss type

InactiveCN1916289AReasonable forceOptimized sectionBridge erection/assemblyRebarAgricultural engineering

The present invention relates to a diamond trussed traveling form. Said diamond main truss is formed from upper frame, lower frame, front frame and rear frame which are connected together and formed into diamond shape. Said upper frame is inclined towards front-lower side, the front end of upper frame and front end of front frame are fixed on the front support abutment, its upper frame and upper end of rear frame are fixed on the upper support abutment, its rear frame and rear end of lower frame are fixed on the rear support abutment, the front end of its lower frame and rear end of front frame are fixed on the lower support abutment; between lower support abutment and upper support abutment a door-shaped rear hanger frame is connected, on the front support abutment a front hanger beam is fixedly connected; the front hanger beam and the door-shaped rear hanger frame are connected with a suspended mechanism, front end of said front hanger beam is connected with an auxiliary hanger frame, between the rear end of front hanger beam and upper frame a tie rod is connected, front end of the auxiliary hanger frame is connected with a hanger rod, and said hanger rod is connected with a working platform.

Owner:杨秋利

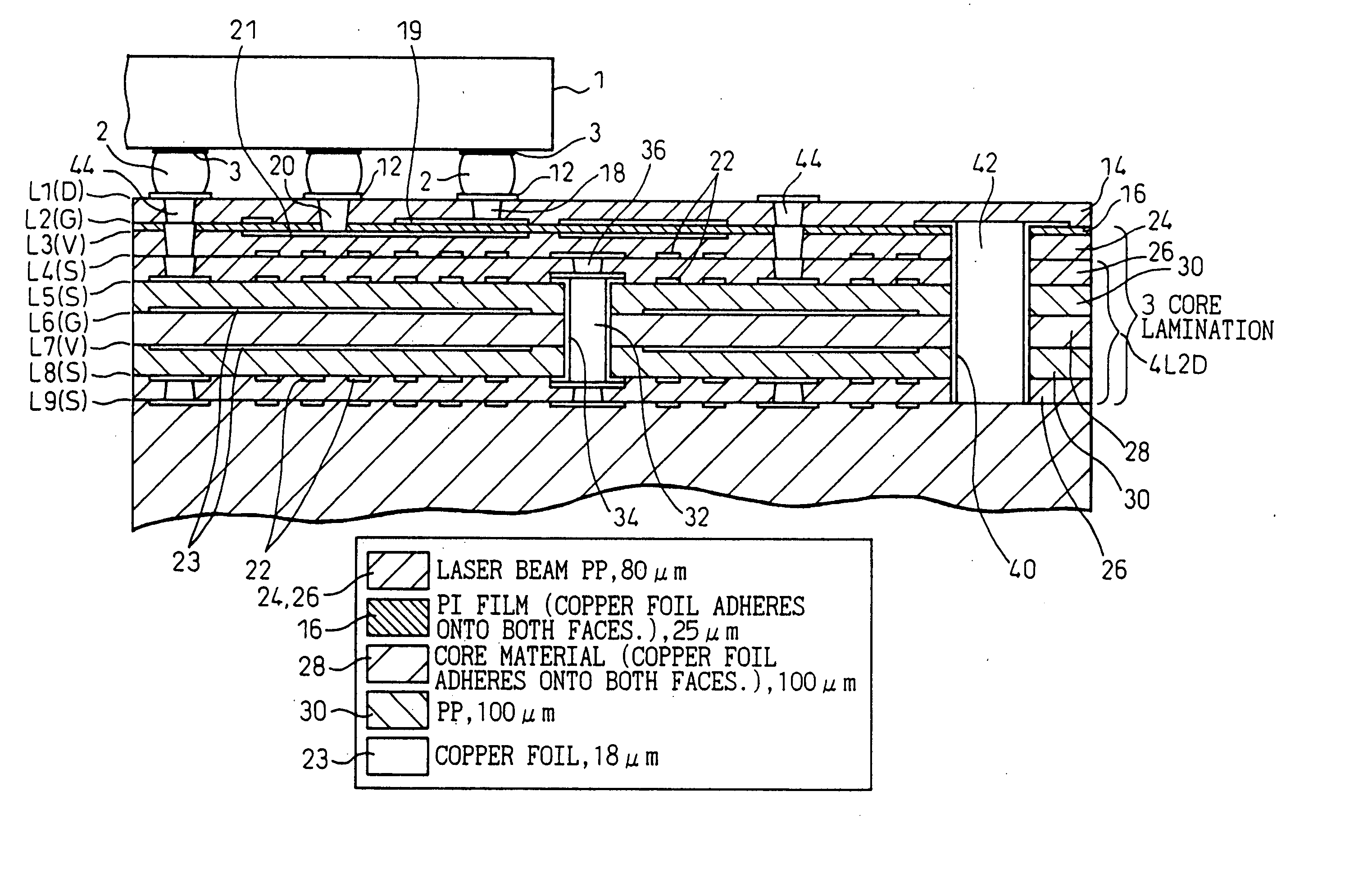

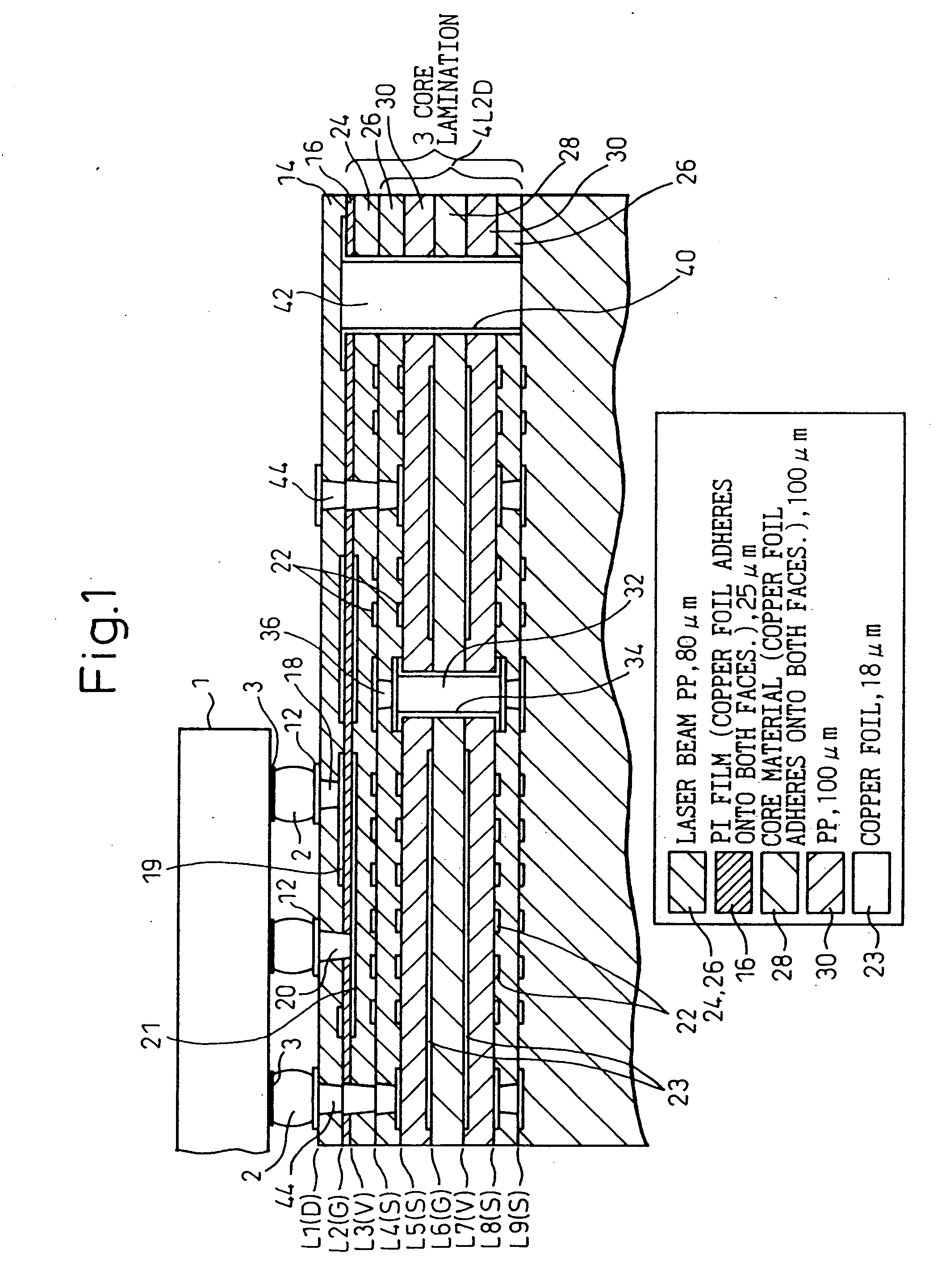

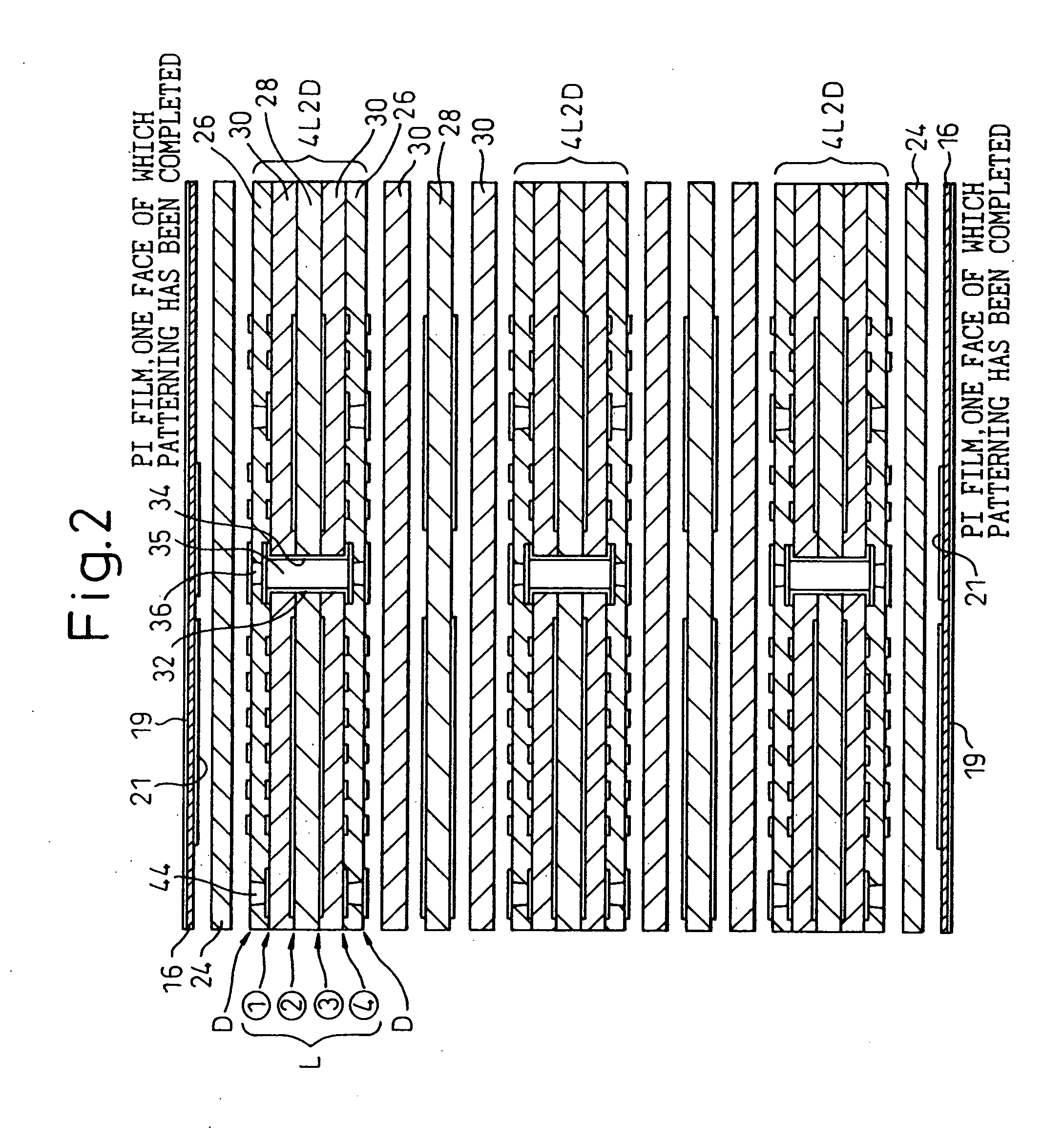

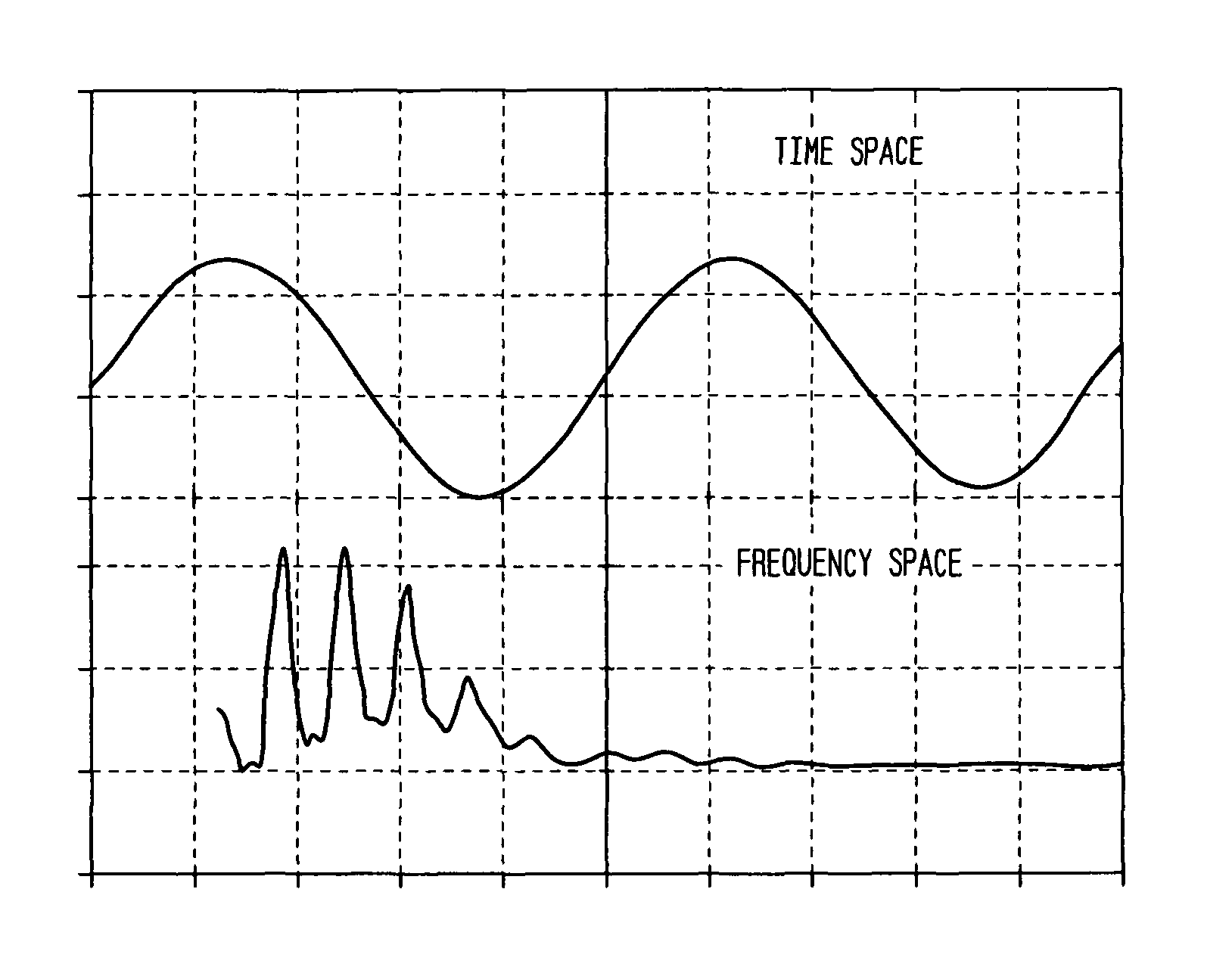

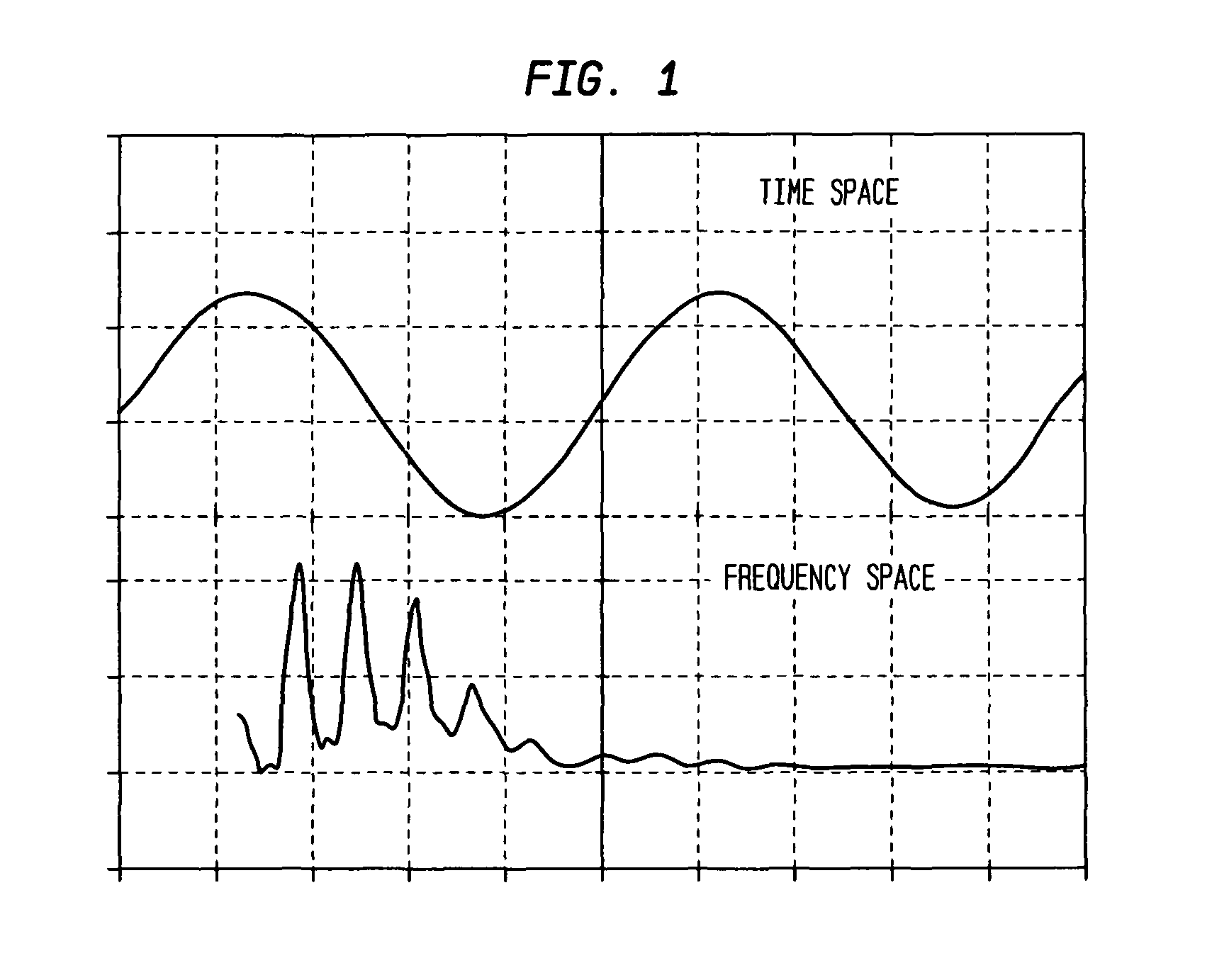

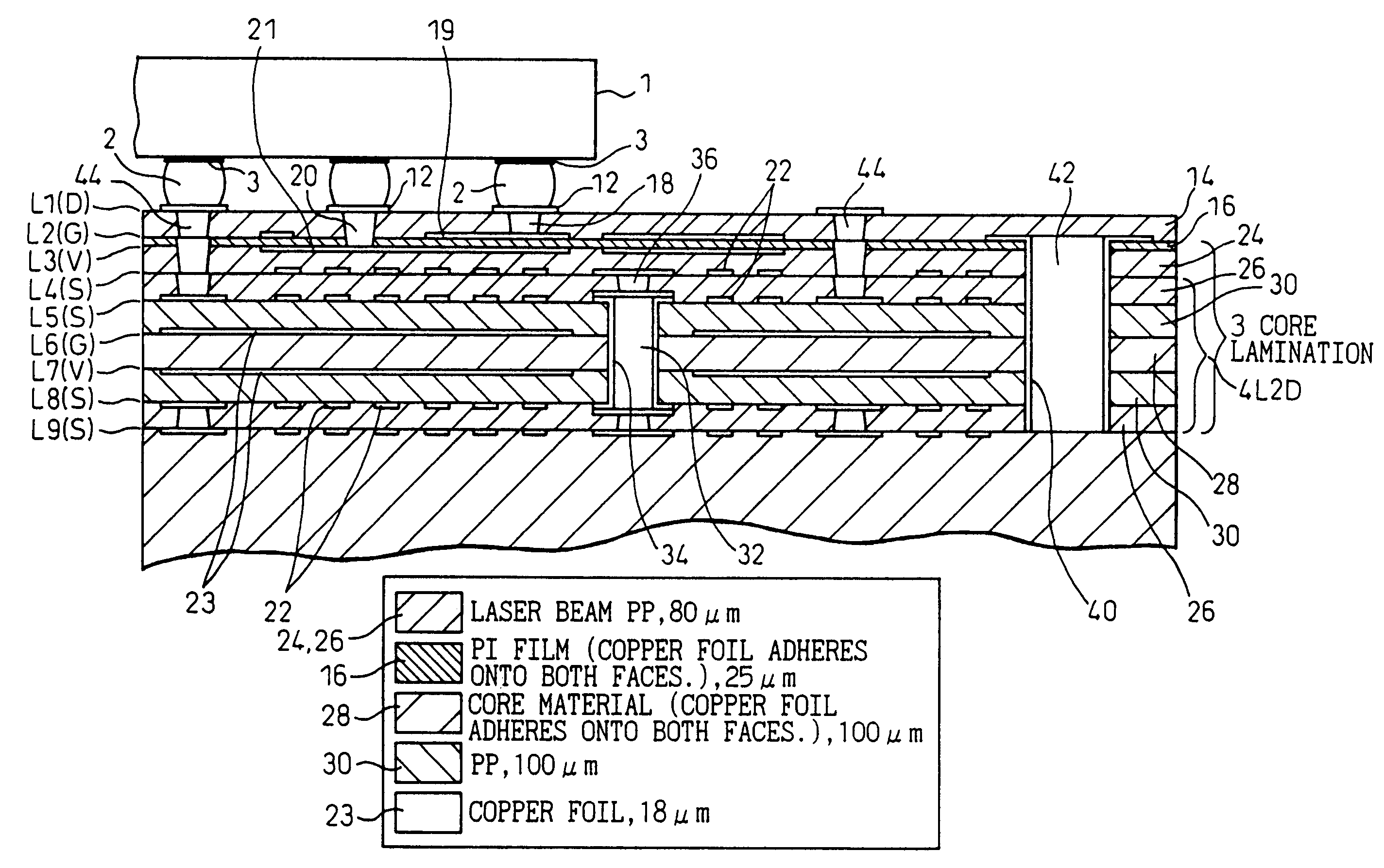

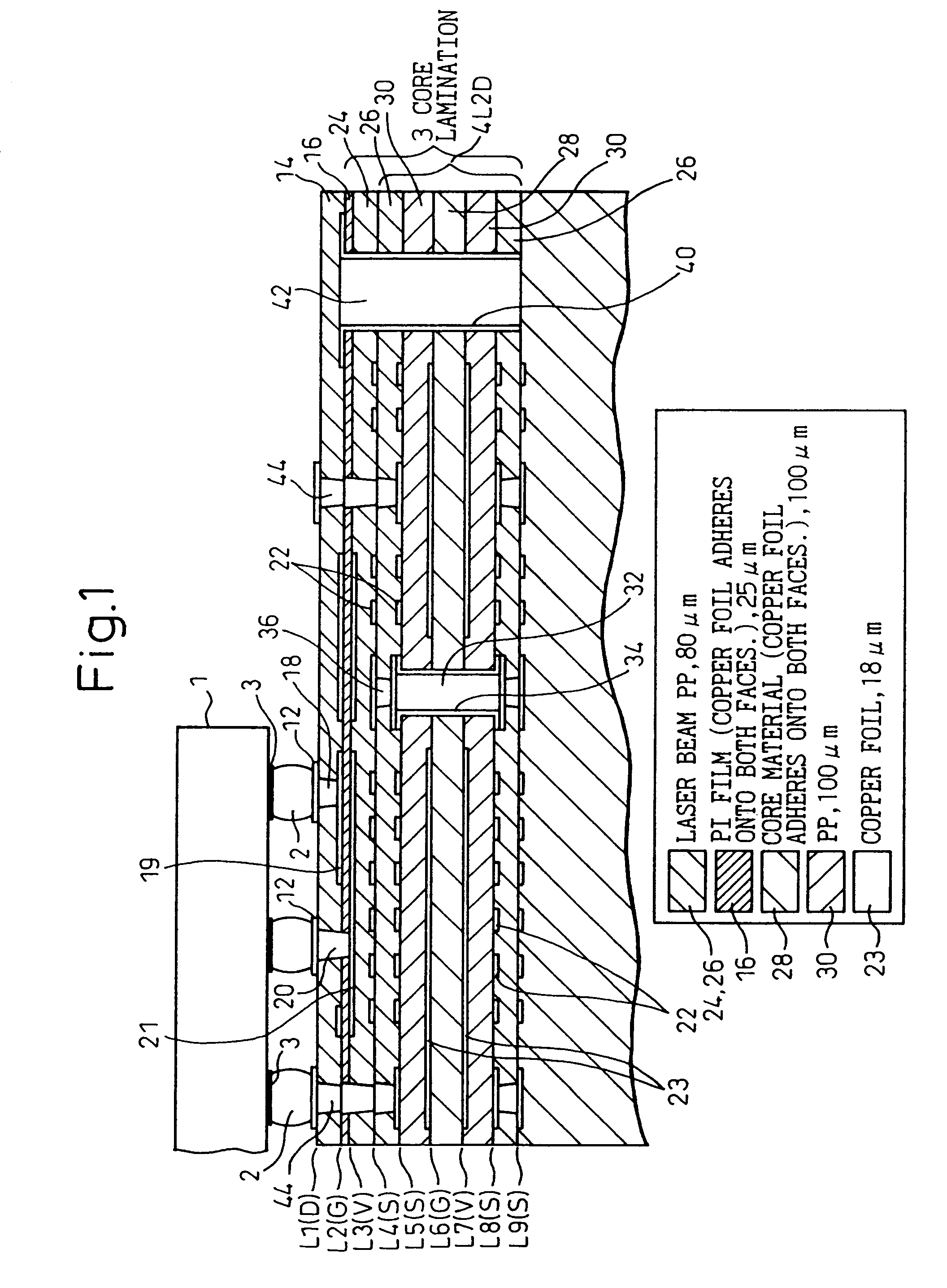

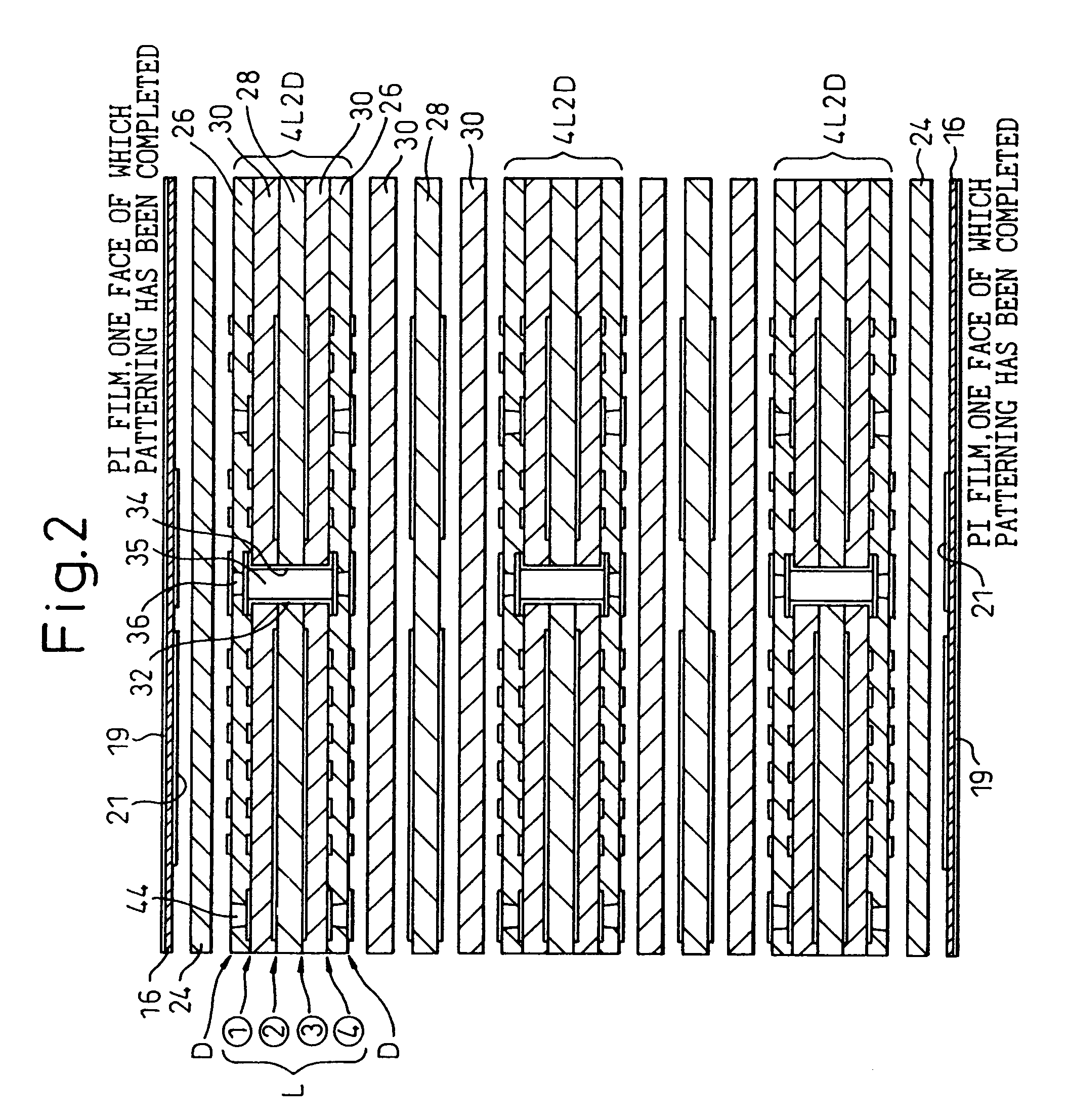

Multilayer wiring circuit board

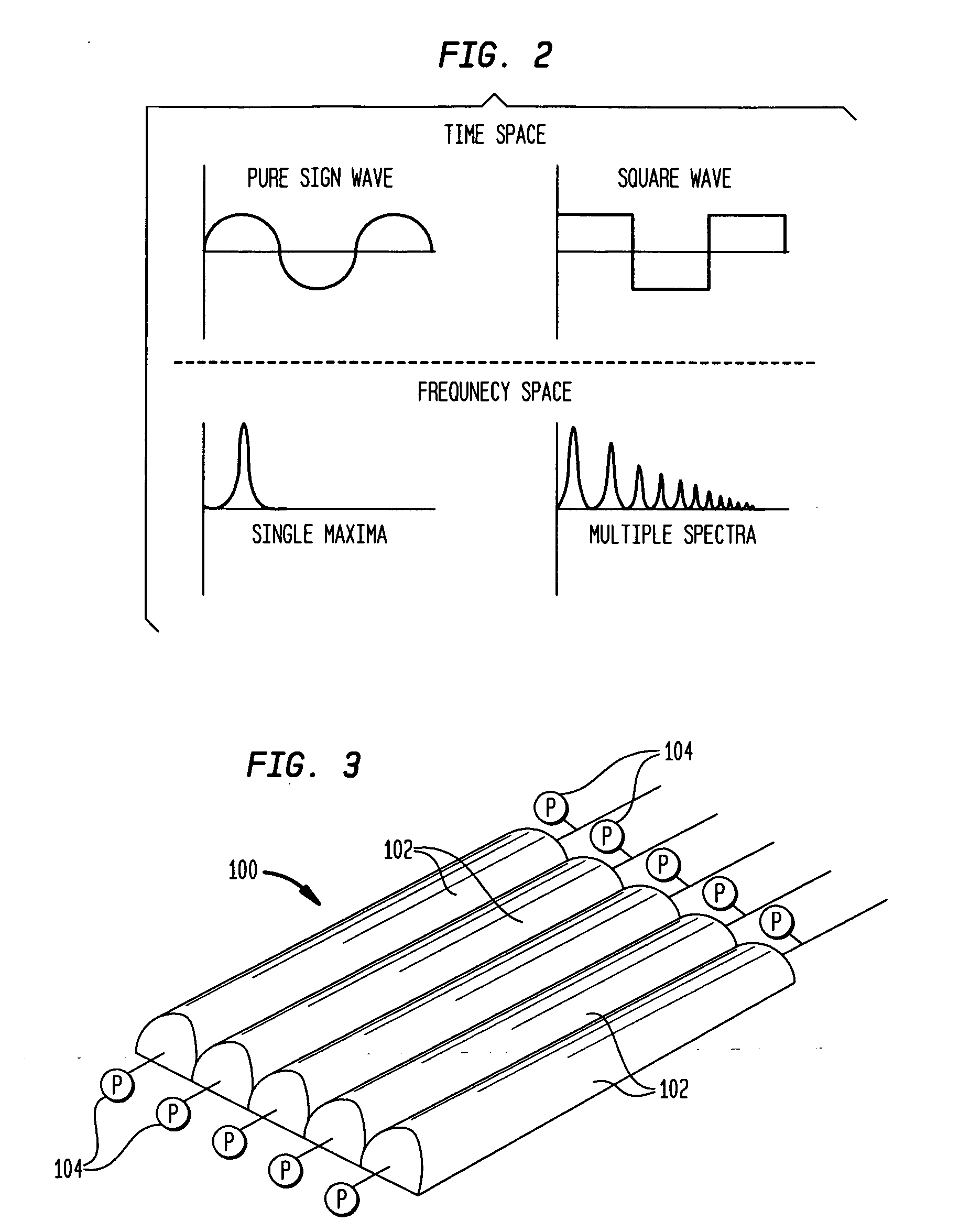

InactiveUS20050098882A1High frequency switching operationGeneration of high-frequency noise being suppressedSemiconductor/solid-state device detailsCross-talk/noise/interference reductionInductanceElectric power

An inexpensive multilayer wiring circuit board capable of conducting high frequency switching operation on the circuit while the generation of high frequency noise is being suppressed by reducing the inductance of the circuit in provided. A multilayer wiring circuit board comprising: an uppermost layer designated as a first layer on which parts are mounted; a second layer on which one of a ground layer and an electric power source layer is arranged; a third layer on which the other is arranged; and an insulating layer arranged between the ground layer and the electric power source layer. A resin layer having a thermoplastic adhesion property on both faces is used as material of the insulating layer arranged between the electric power source layer and the ground layer.

Owner:FUJITSU LTD

Method for preparing carbon fiber reinforced thermoplastic composite material

The invention discloses a method for preparing a carbon fiber reinforced thermoplastic composite material, which comprises the following steps: 1)alternatively paving carbon fiber and thermoplastic resin in a die, wherein a bottom layer and a top layer of the die are thermoplastic resin, closing the die and applying pressure; 2)accessing power supply to a carbon fiber layer, rapidly heating under current effect, when the temperature is higher than the melting point of thermoplastic resin, fusing thermoplastic resin, dipping carbon fiber under pressure; and 3)breaking power, cooling the die, and then opening the die to obtain the carbon fiber reinforced thermoplastic composite material. The method takes carbon fiber as a heat-generating body, the electrothermal conversion efficiency can reach as high as more than 90%, and the energy saving effect is obvious; simultaneously, carbon fiber is capable of melting thermoplastic resin and completing dipping, and has the advantages of short moulding time and good dipping effect, formation of good cross section of thermoplastic resin and fiber can be realized, composite material performance is increased, and processing of product with large thickness can be realized in short time.

Owner:蓝星纤维(北京)有限公司

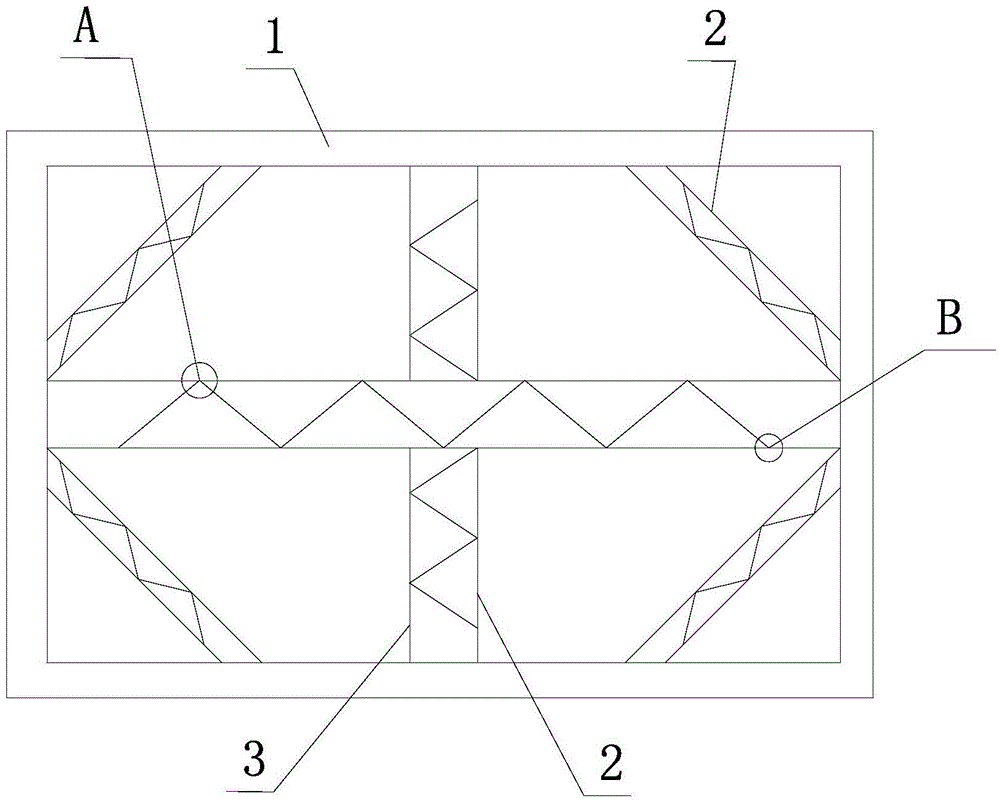

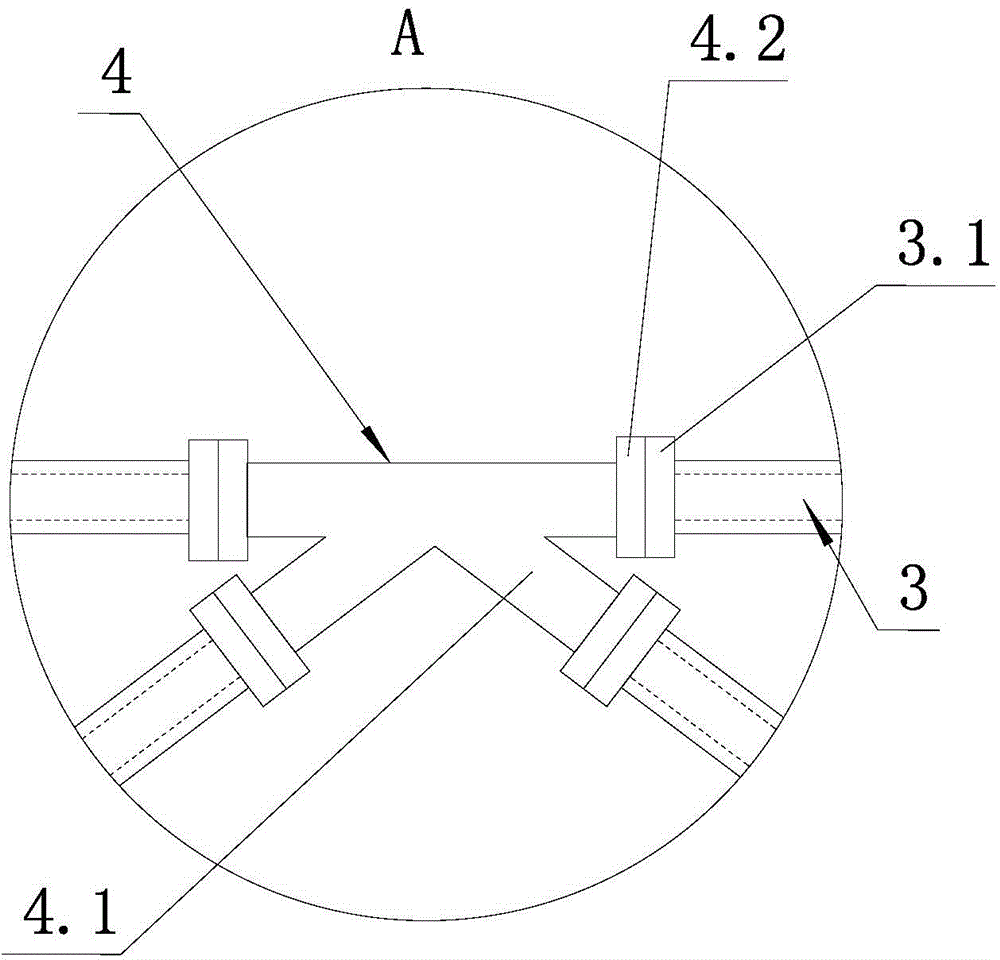

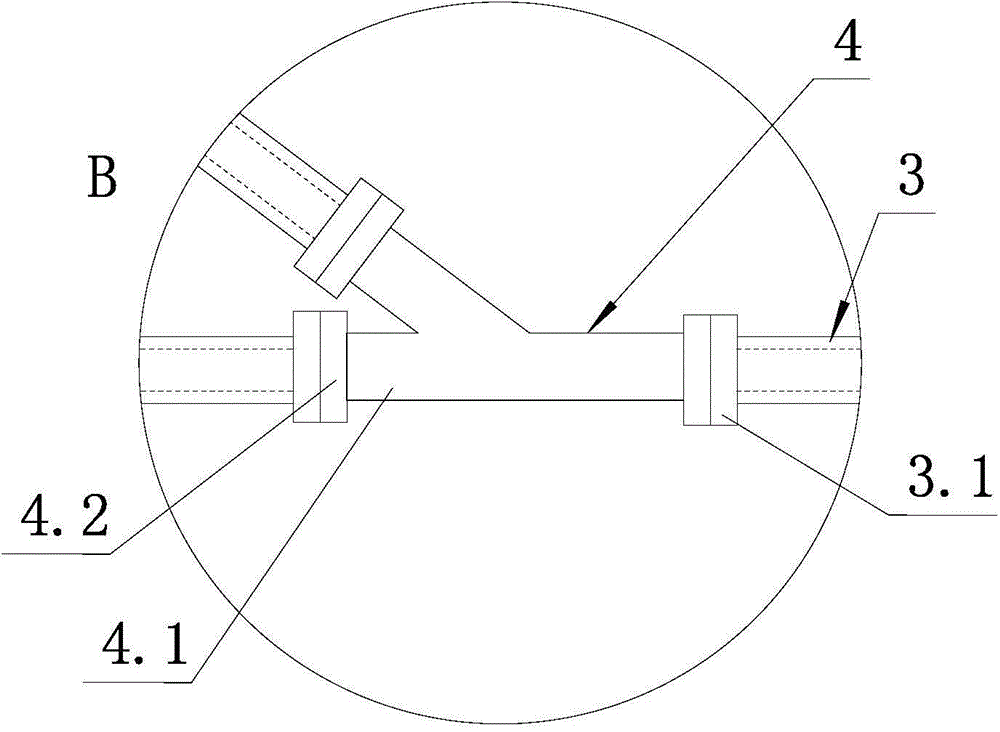

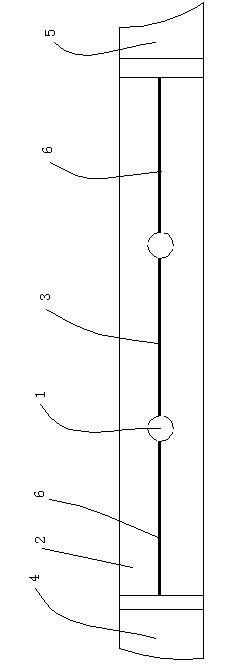

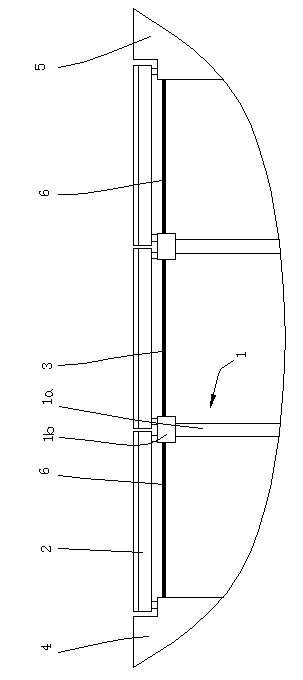

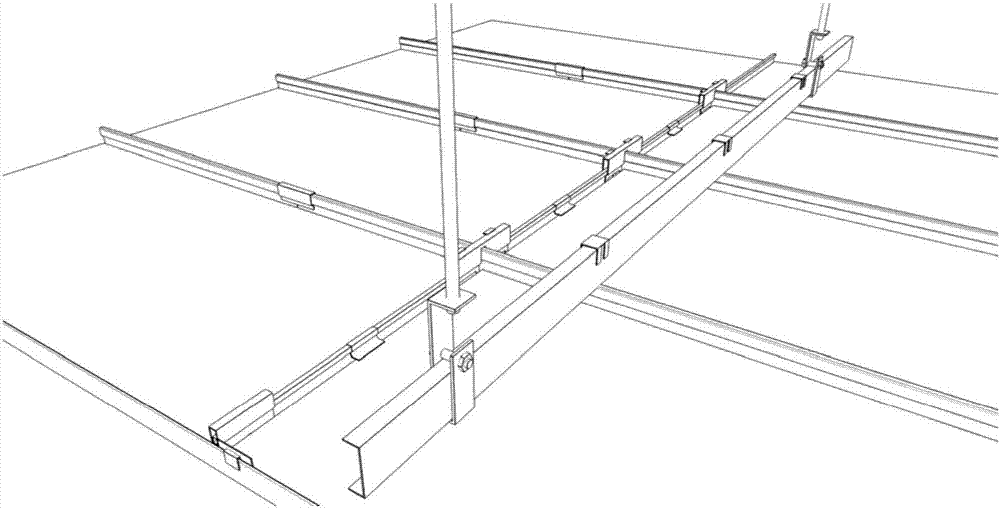

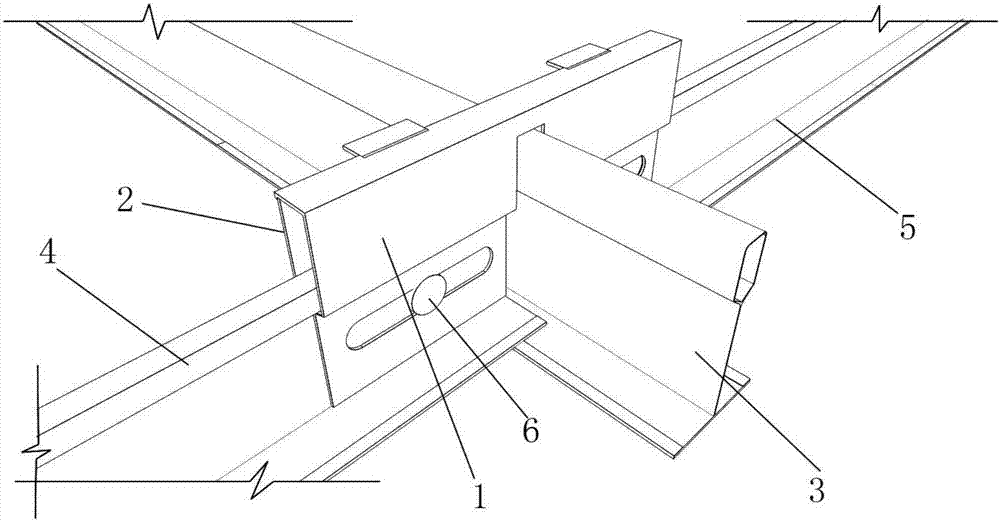

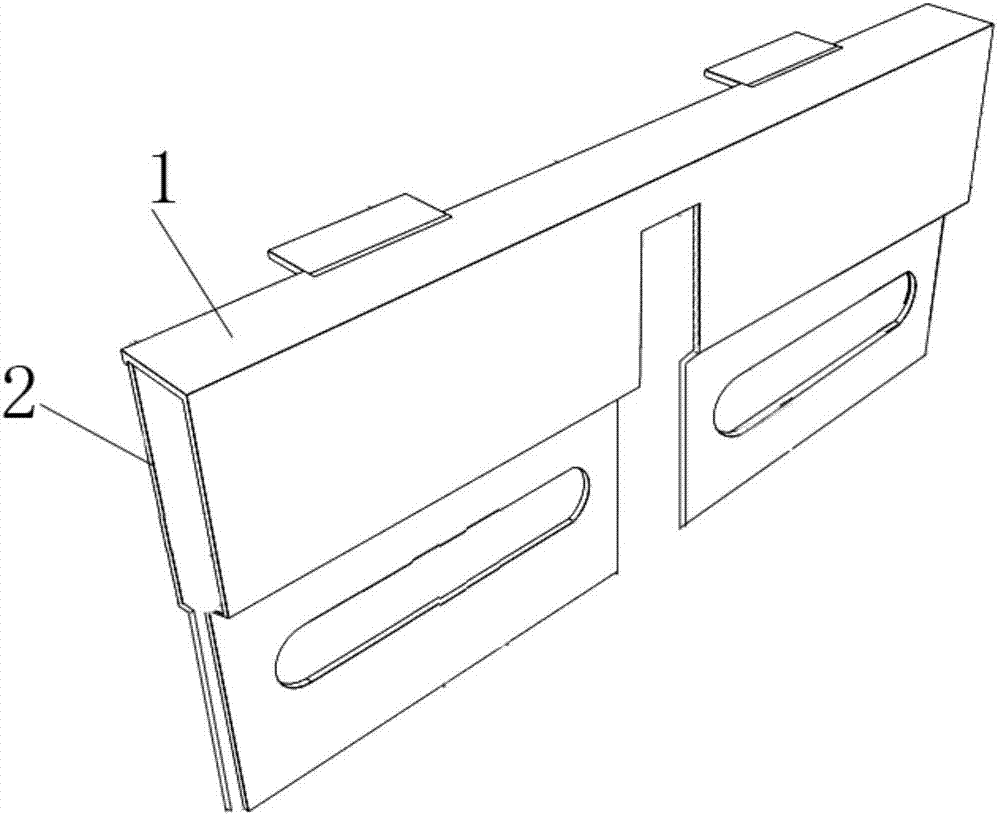

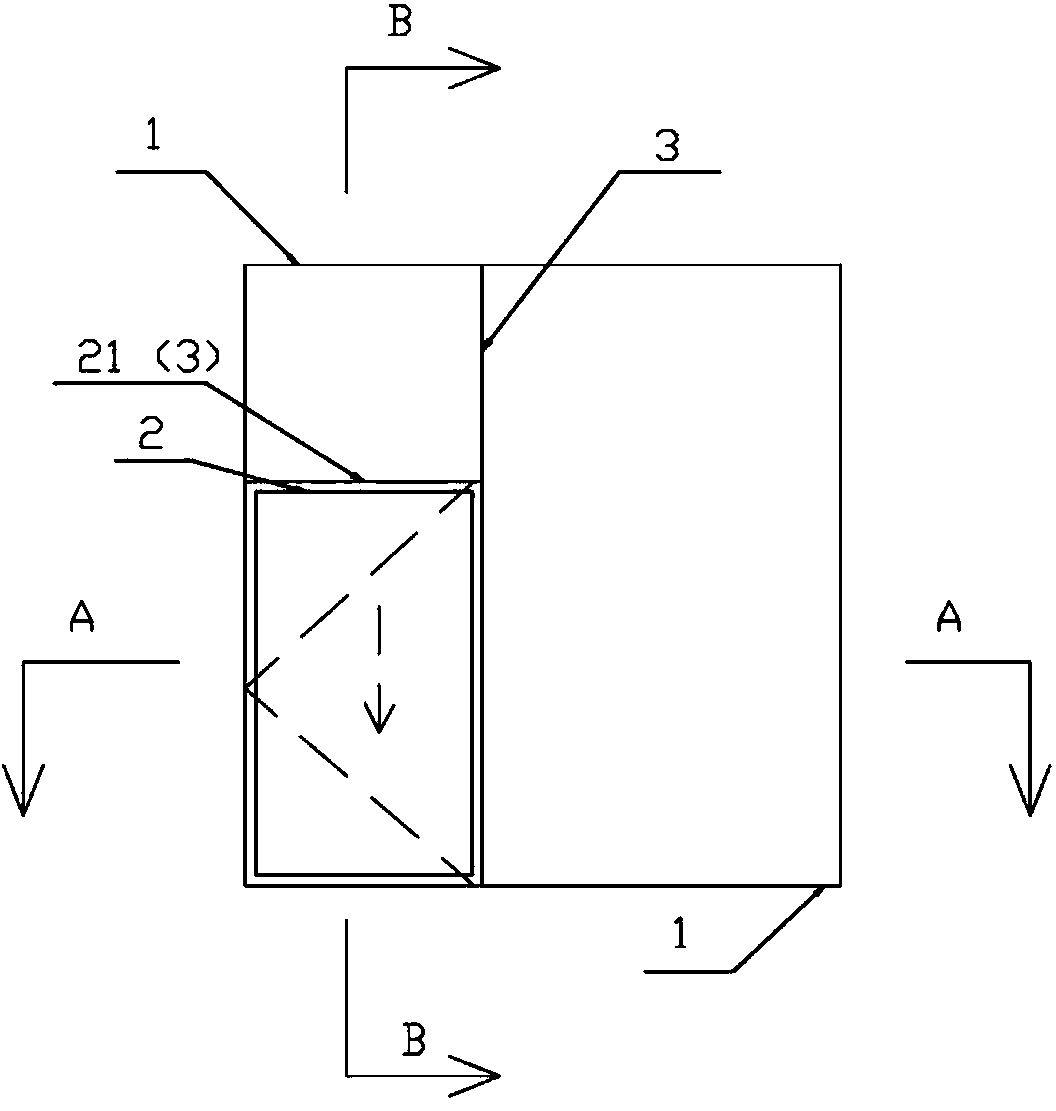

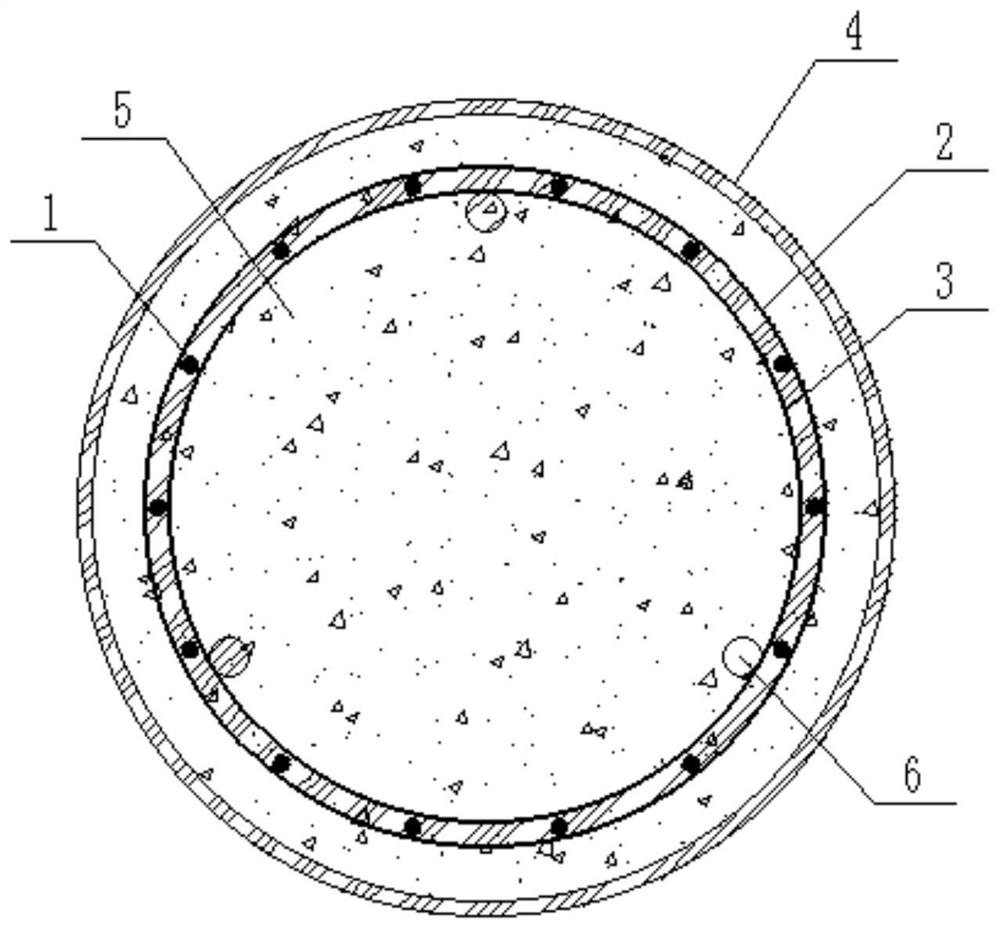

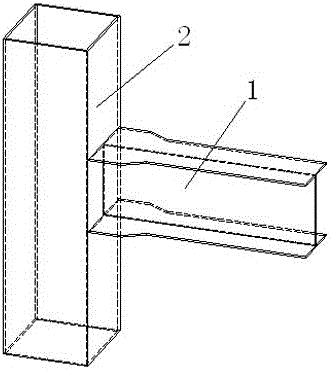

Prefabricated internal support system and construction method for foundation pit support system

The invention discloses a prefabricated internal support system and a construction method for a foundation pit support system. The prefabricated internal support system comprises a top beam (1), an enclosing purline and an inner support (2), wherein the inner support (2) is a truss type inner support (2) assembled by splicing a pre-stressed hollow square pile (3) and a node connecting piece; first end plates on the two ends of the truss type inner support (2) are in screwed connection with a connecting plate on the top beam (1), and the rest of the first end plates are in screwed connection with second end plates of the node connecting piece; the construction method comprises the key points that the pre-stressed hollow square pile (3) and the node connecting piece are assembled into the truss type inner support (2) in a splicing manner, and the two ends of the truss type inner support (2) are connected with the top beam (1). The prefabricated internal support system and the construction method for the foundation pit support system has the advantages that the system and the method are convenient and efficient, the construction speed is high, the construction period is short, the follow-up earth cutting and earth discharging are convenient, the dismounting process is also convenient, efficient and labor-saving, no safety potential hazard is caused, the system can be recycled, and the material is saved.

Owner:宁波冶金勘察设计研究股份有限公司

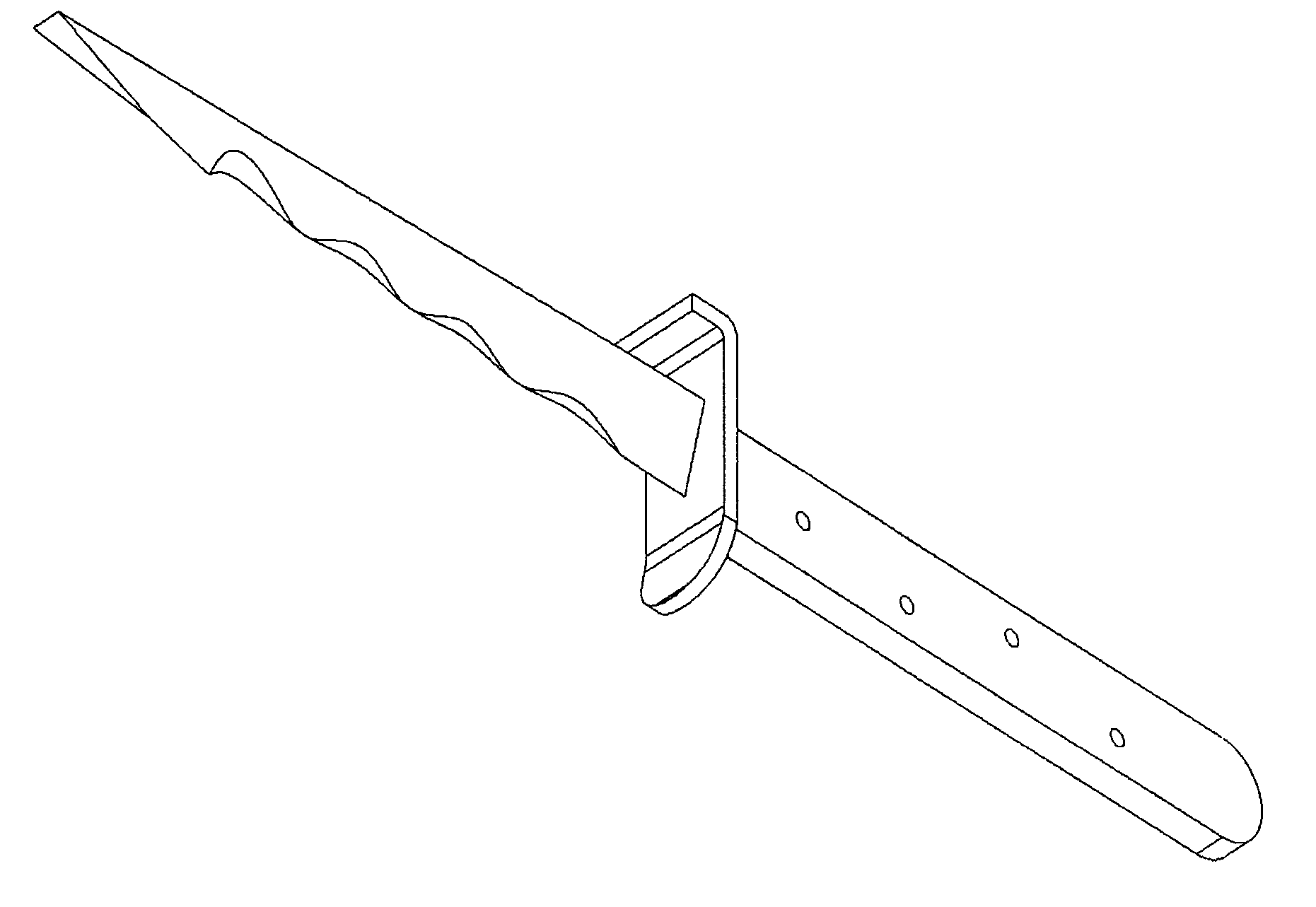

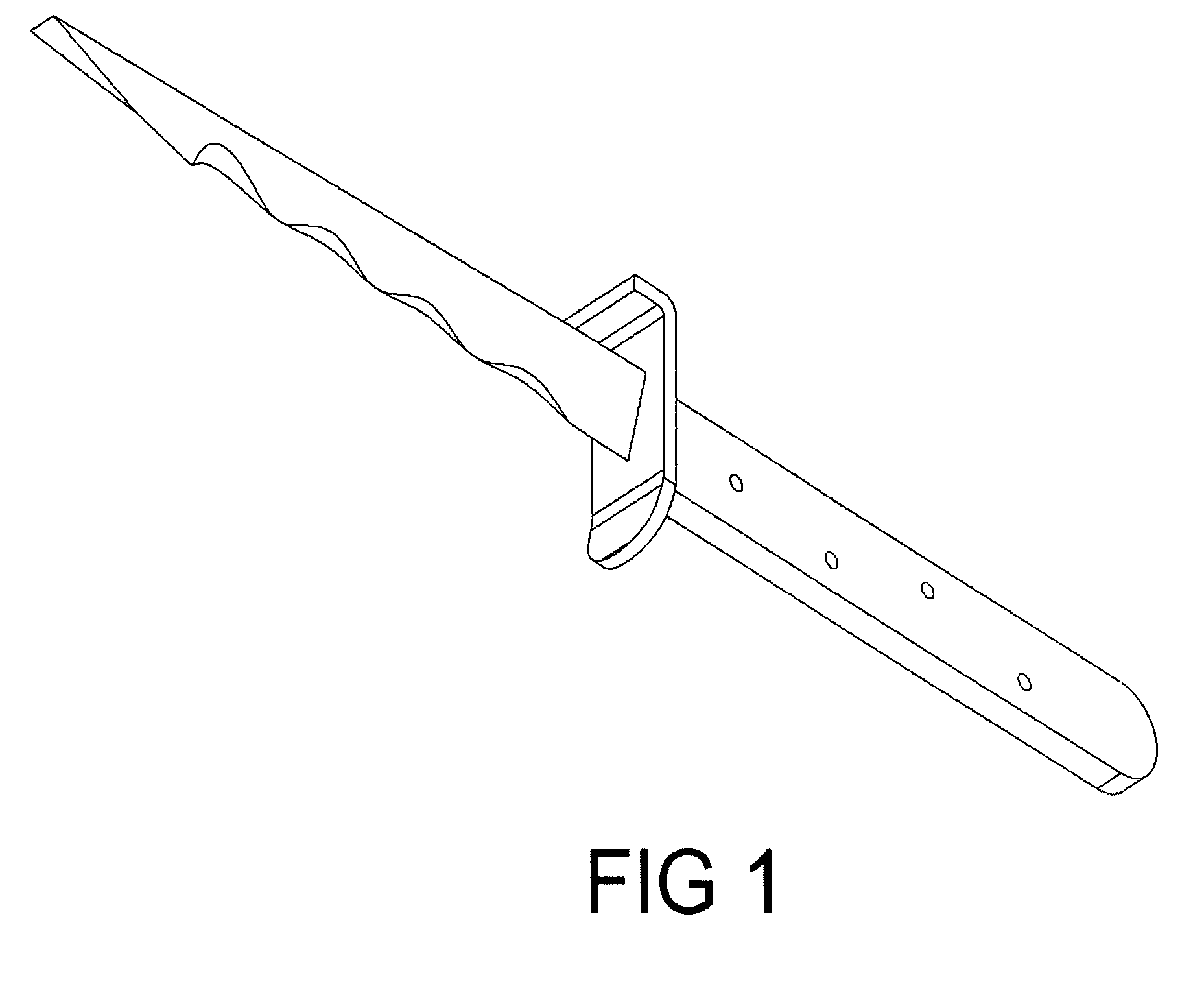

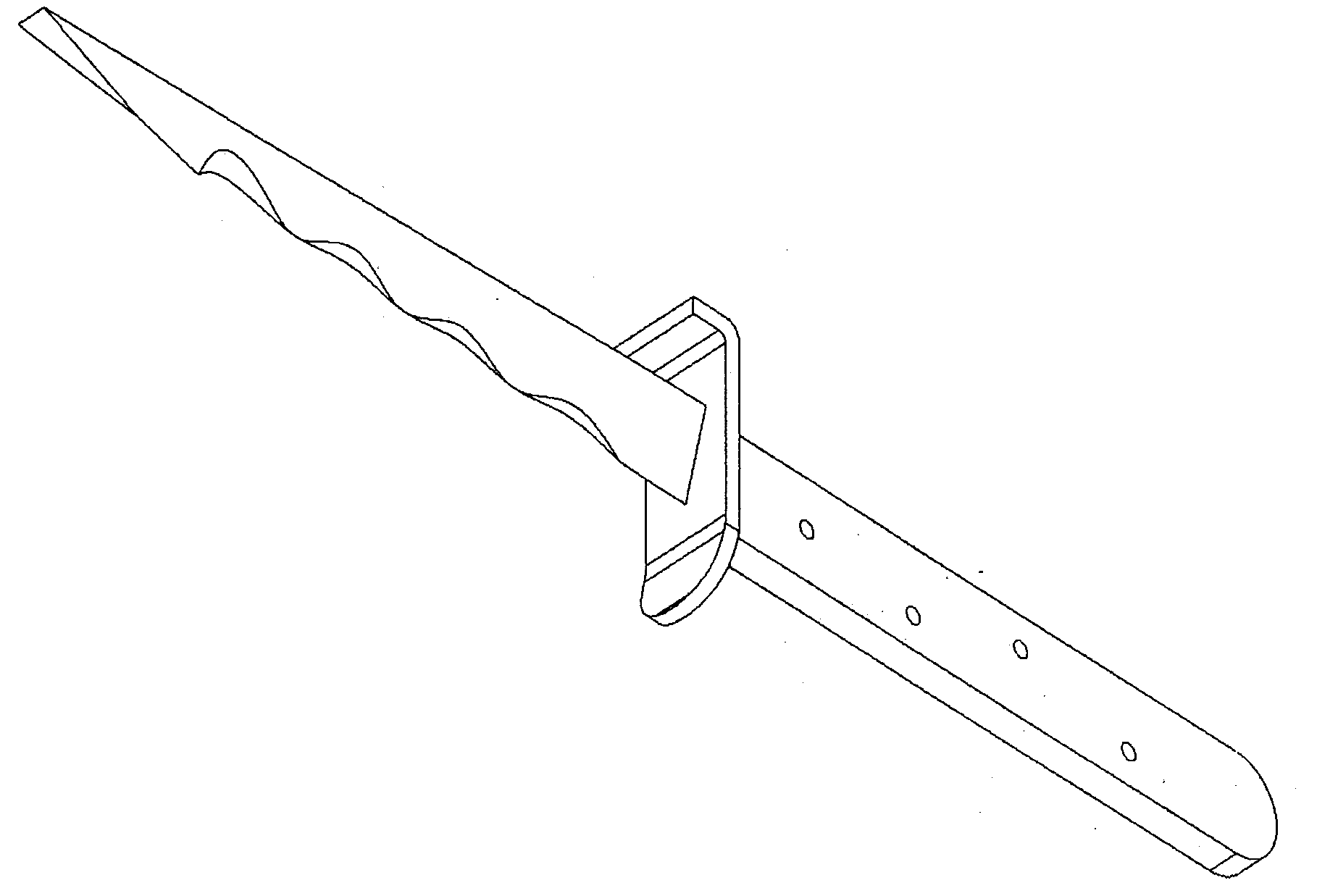

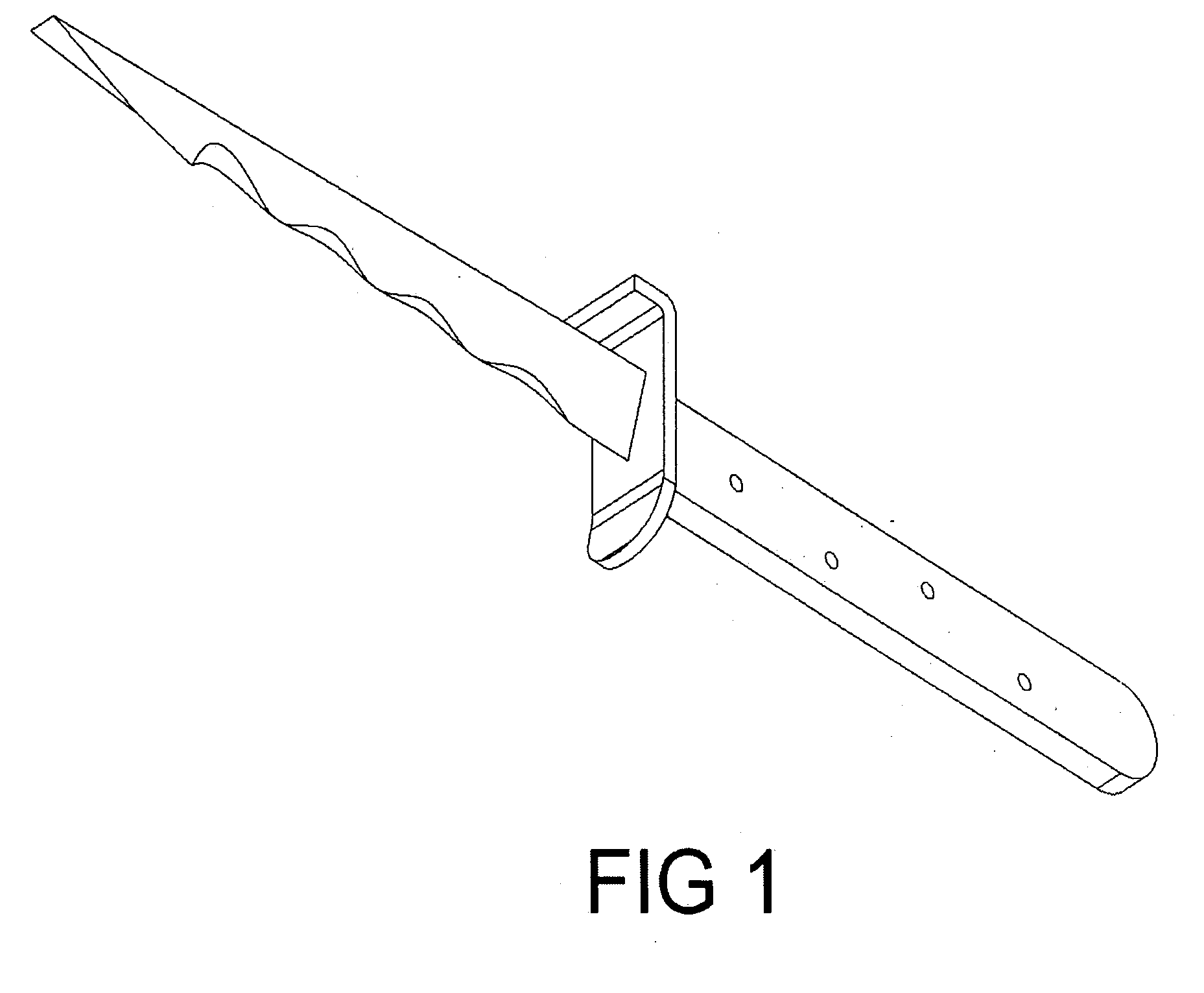

Handheld tactical knife

ActiveUS8037612B2Reduce the possibilityIncrease loadThrusting weaponsMetal working apparatusHand heldEngineering

A handheld tactical knife comprising a hilt and an elongated knife blade with a substantially triangular cross section. A spine runs on the top of said elongated knife blade, and tapers from the hilt to a tip of the blade. A main cutting edge is located on the bottom of said elongated knife blade, and at least one scallop is cut into the main cutting edge. At least one scallop transitions into a gut hook with a gut hook tip, and a flat spreading surface is located between the gut hook tip and the tip of the blade. The substantially triangular cross section of the elongated knife blade transitions to a substantially trapezoidal cross section at the flat spreading surface.

Owner:HANSEN JEREMIAH +1

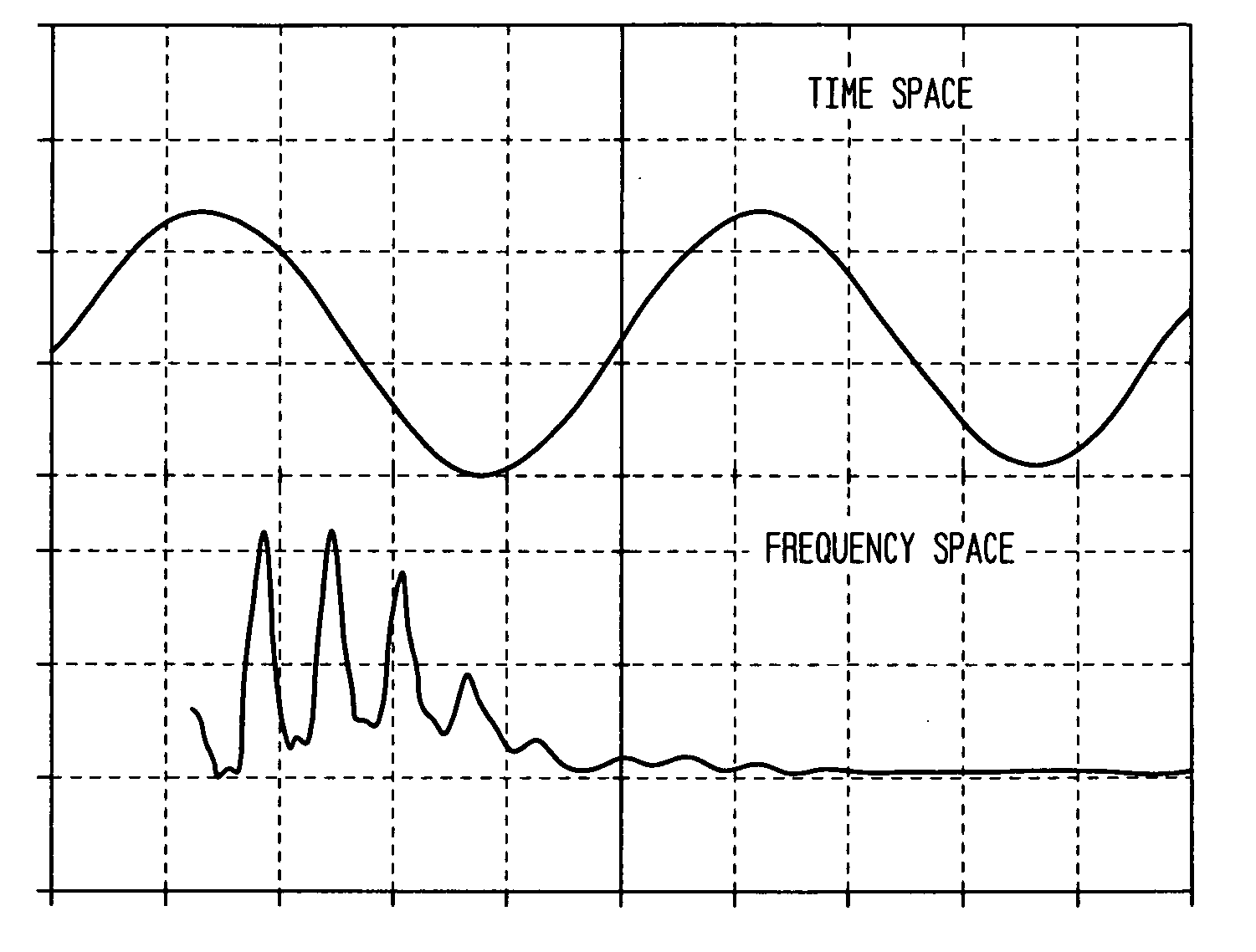

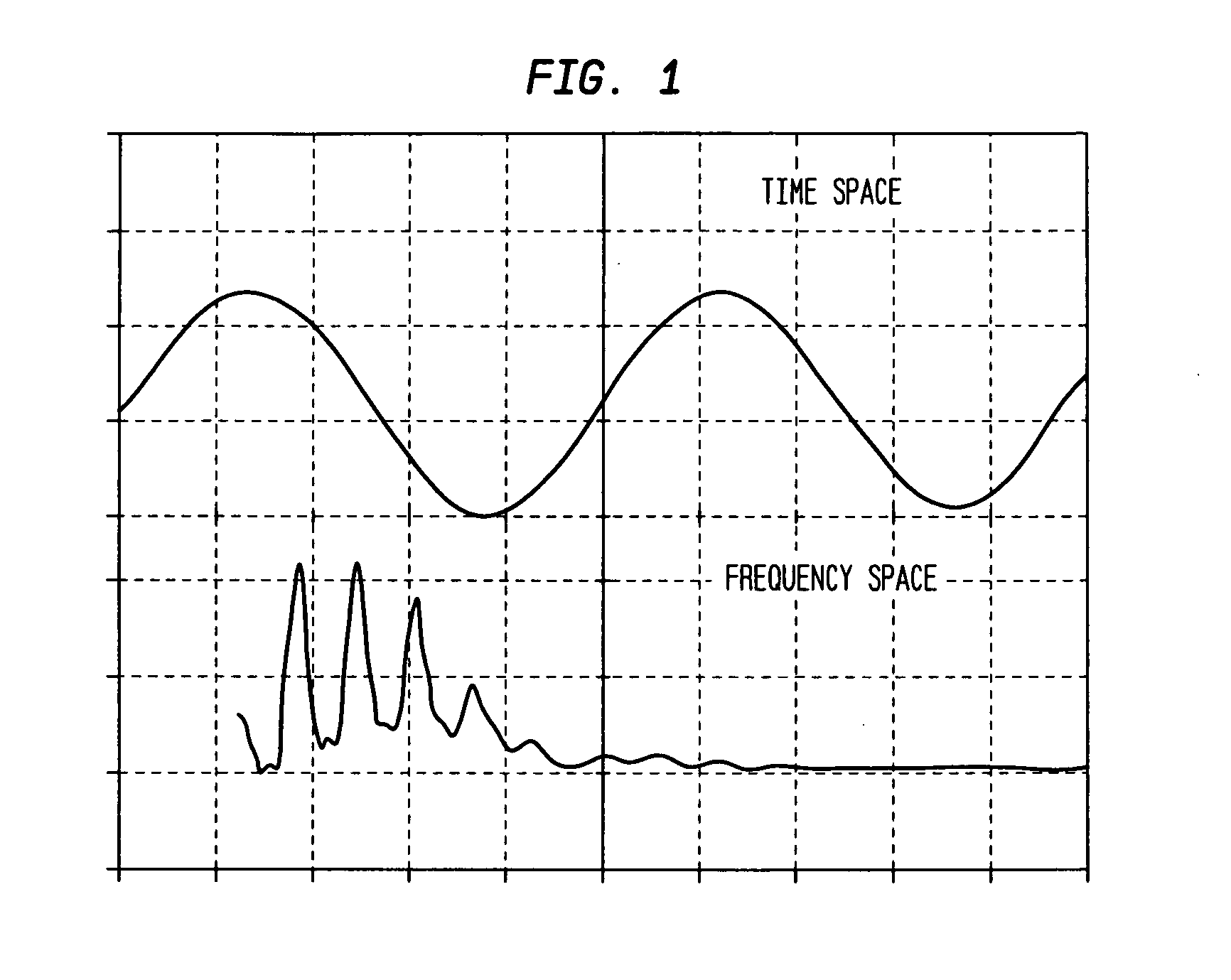

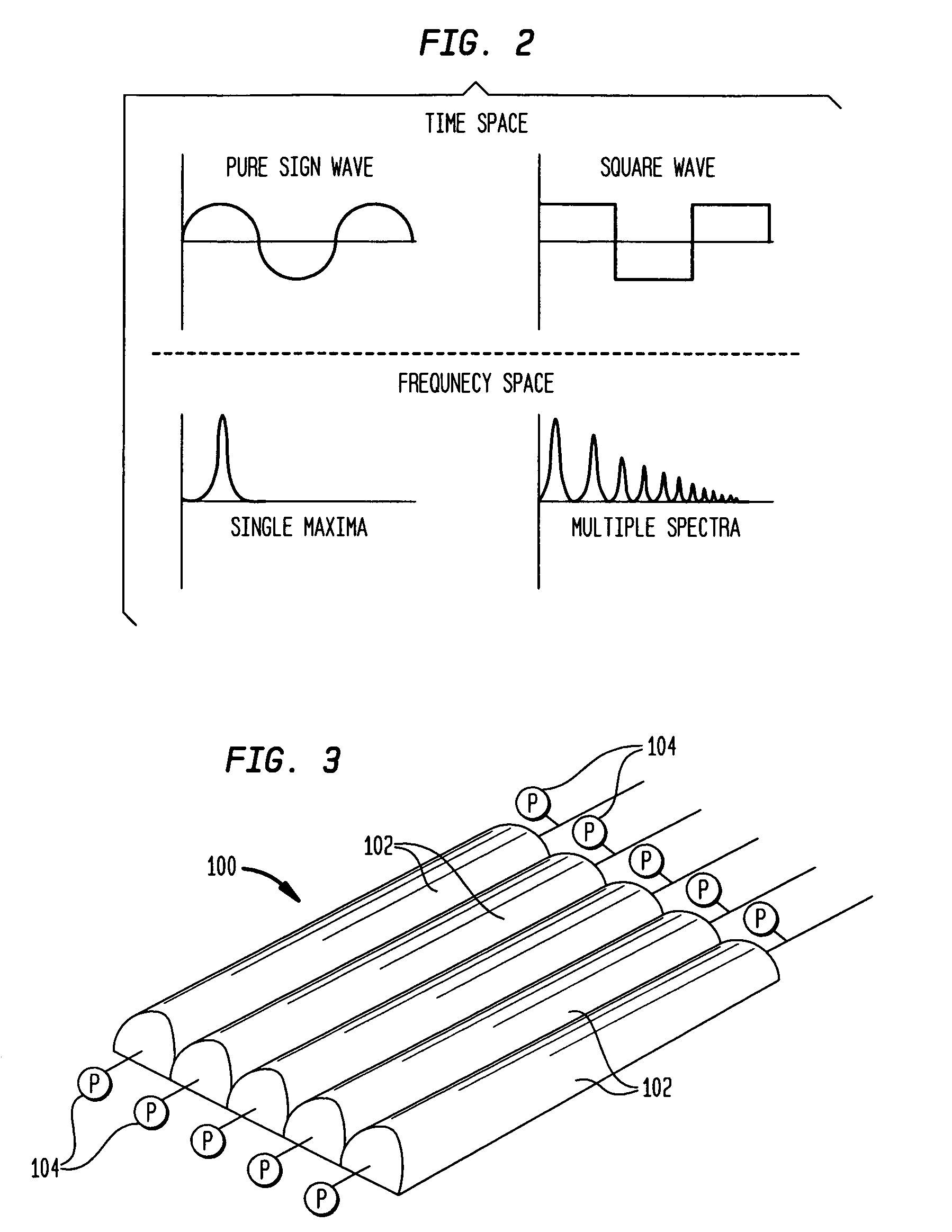

Adjustable pneumatic supporting surface

ActiveUS20100094175A1Provide controlConvenient treatmentDiagnostics using pressurePerson identificationTissues typesHumans tissues

An apparatus and method are adapted for characterizing human tissue type. A plurality of inflatable bladders enable the application of kinetic energy to the human tissue. Collected data responsive to the applied kinetic energy differentiates between different tissue types and patient loading. The data can be routed via a network to a remote location.

Owner:HLZ INNOVATION

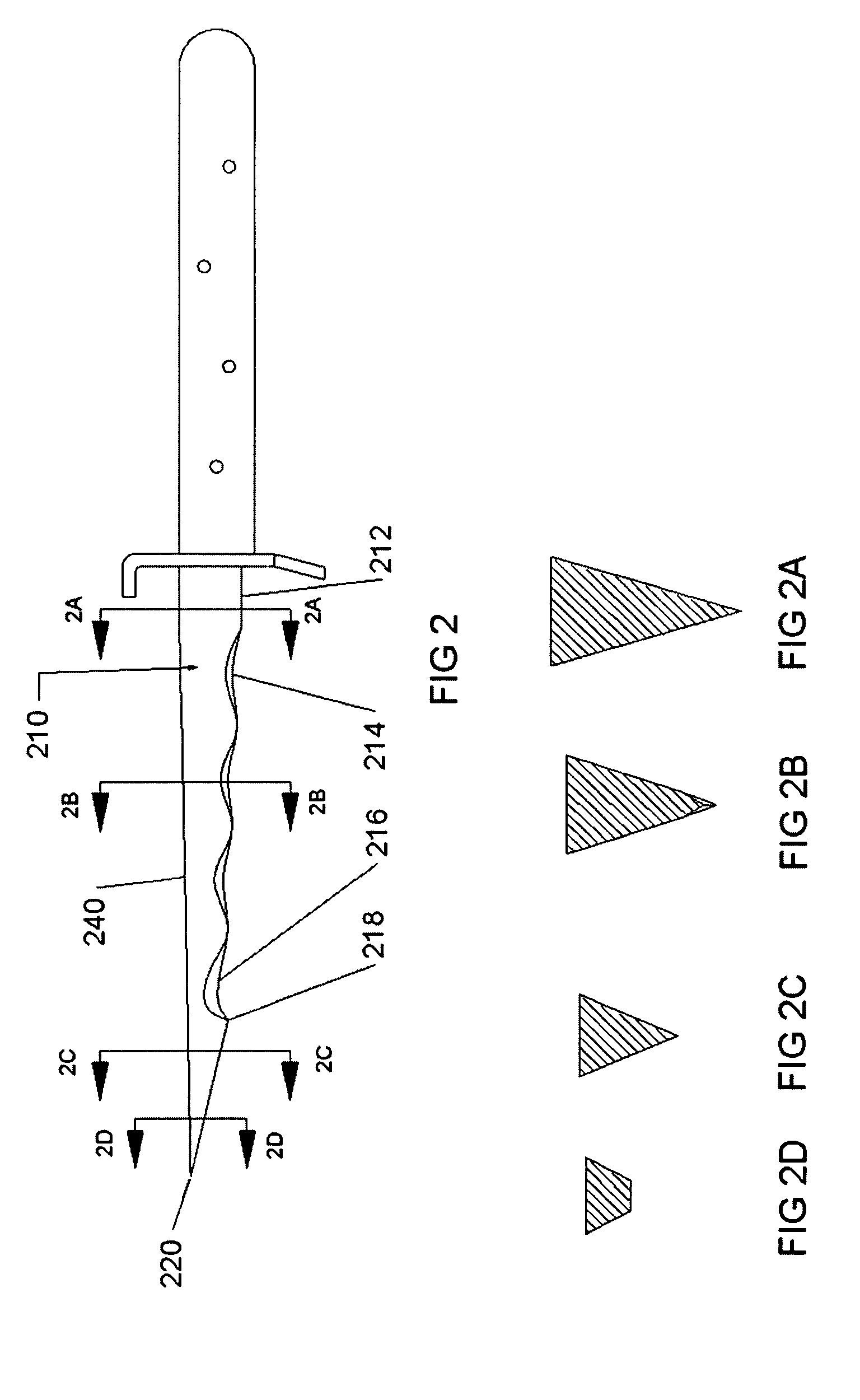

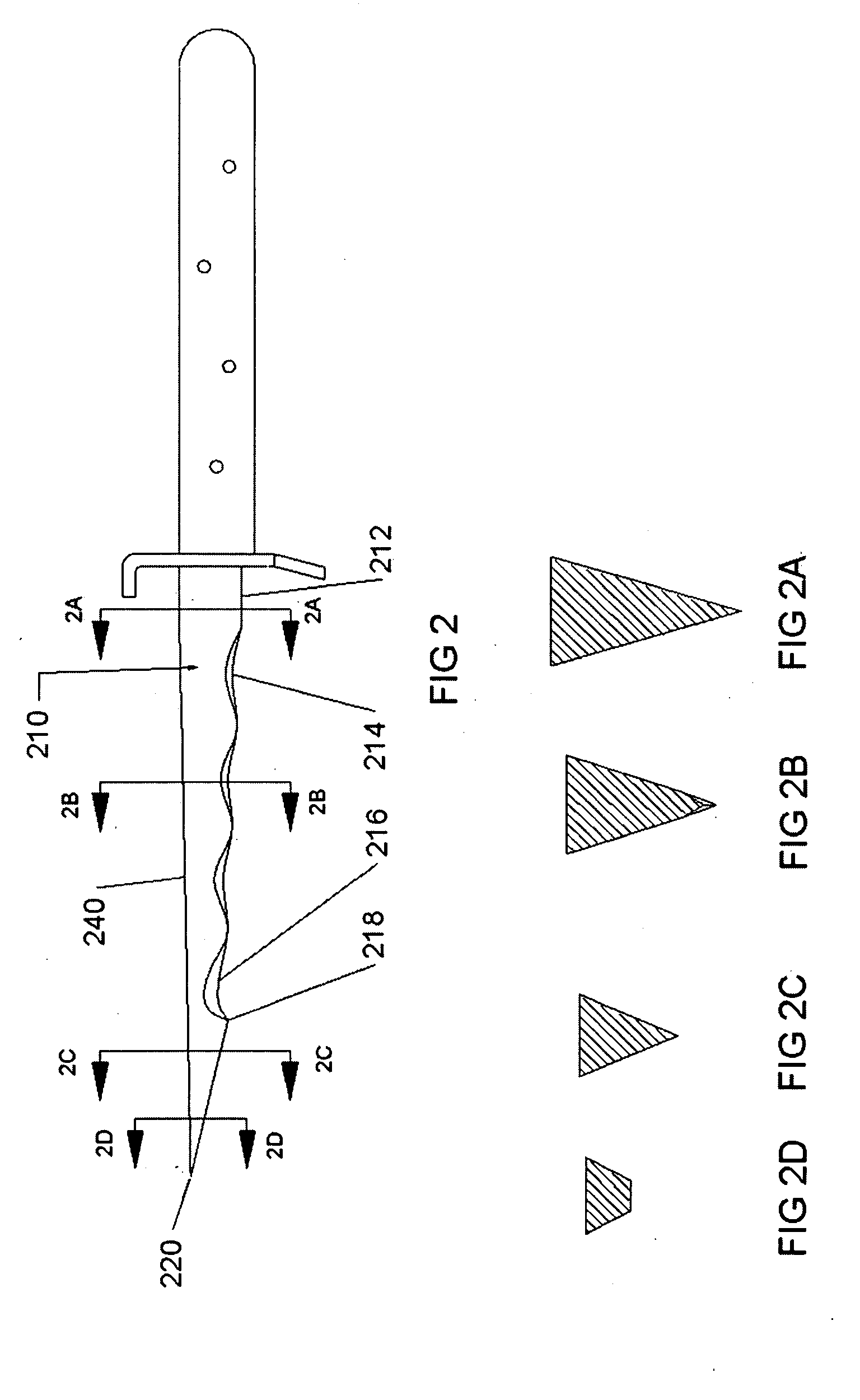

Handheld Tactical Knife

ActiveUS20100101100A1Effective cutting edgeMore woundThrusting weaponsMetal working apparatusEngineeringHand held

Handheld tactical knife combining structural features of a structurally advantageous and stress distributing base cross section (FIG. 2A), a penetrating tip (220), tapers in perpendicular axis along the blade length (FIG. 2, FIG. 3), and a cutting edge (212). The preferred embodiment contains scallops (214), a gut hook (218), and a penetrating chisel-type tip (220).

Owner:HANSEN JEREMIAH +1

Adjustable pneumatic supporting surface

ActiveUS8801635B2Provide controlOptimized sectionStuffed mattressesSurgeryTissues typesHumans tissues

An apparatus and method are adapted for characterizing human tissue type. A plurality of inflatable bladders enable the application of kinetic energy to the human tissue. Collected data responsive to the applied kinetic energy differentiates between different tissue types and patient loading. The data can be routed via a network to a remote location.

Owner:HLZ INNOVATION

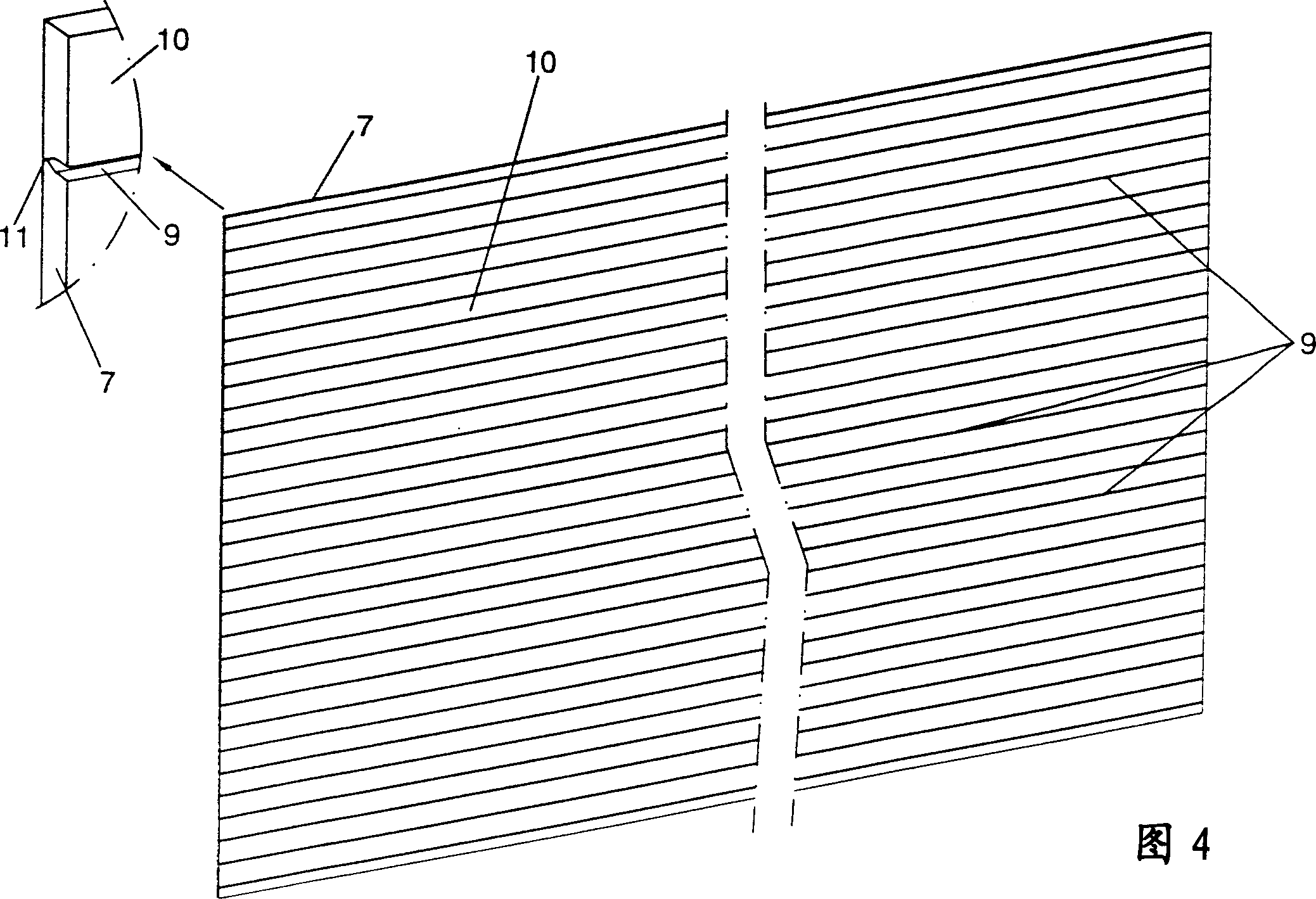

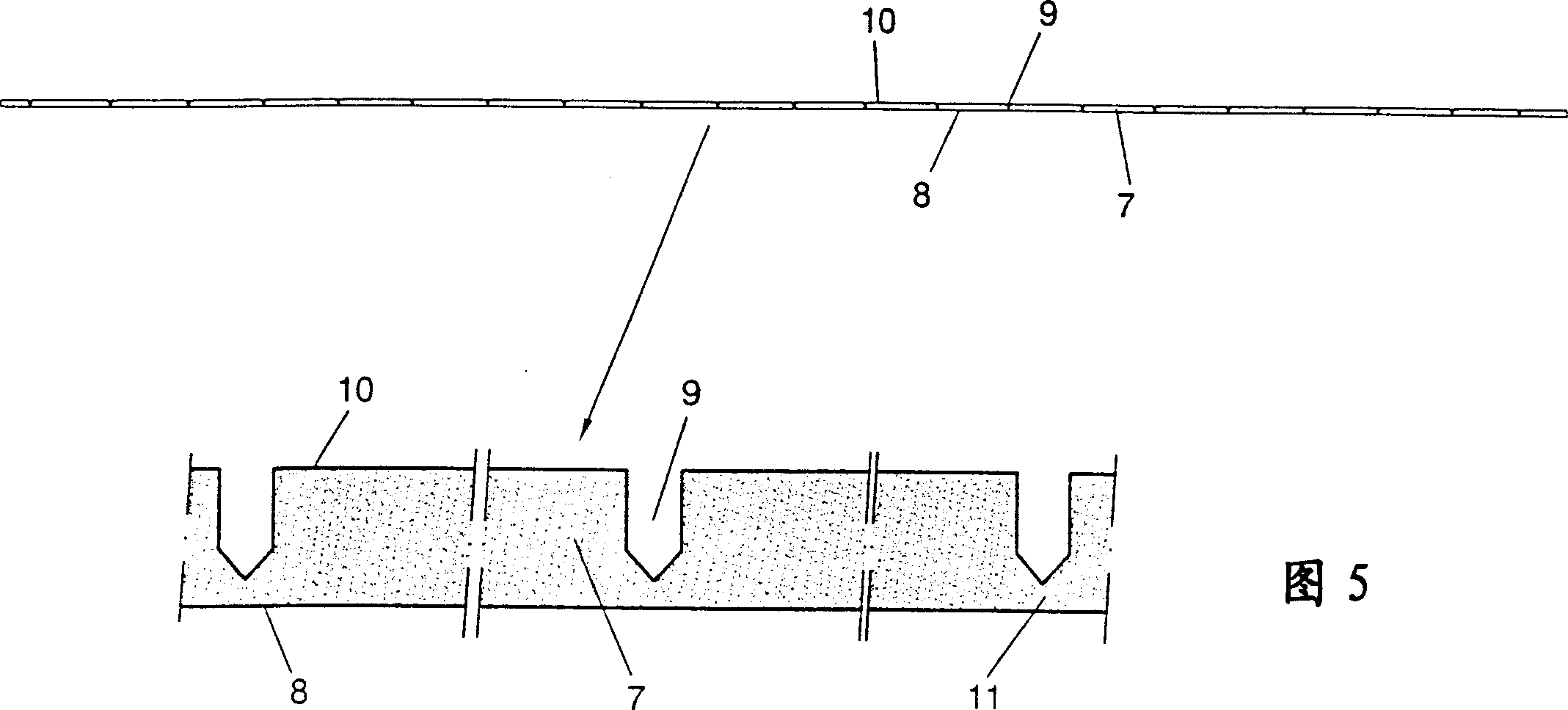

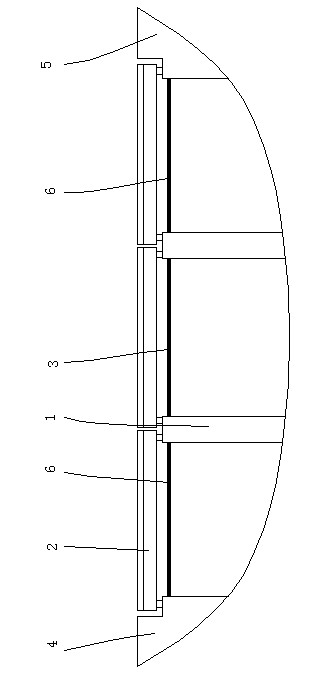

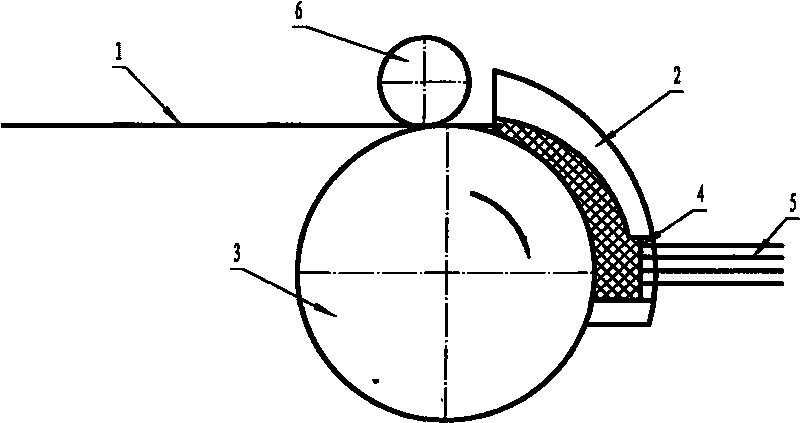

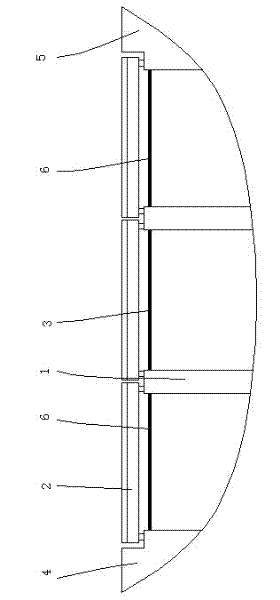

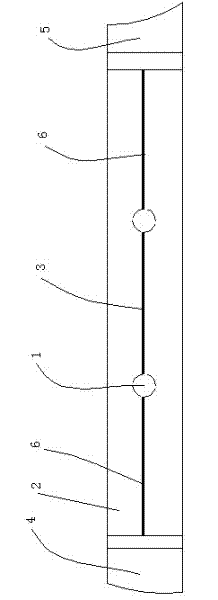

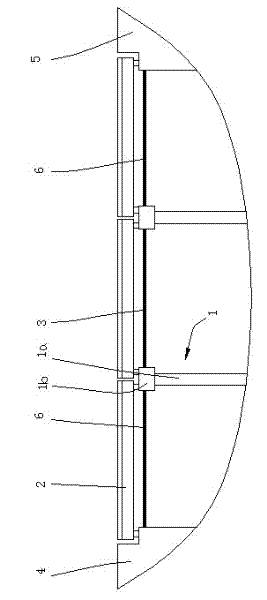

Formwork for cylindrical columns

Said formwork consists of a plurality of narrow laminae (2) made of plastified wood or rigid plastic, which are joined to form a tubular body (1) and are fixed with the aid of an outer envelope (3) consisting of a helicoidally wound glassfiber mesh while the inside of said tubular body (1) receives a self-adhesive film (4). Optionally, the formwork may be provided with stiffeners to preserve its cylindrical configuration, said stiffeners being adequately distributed collars (5) or a tubular body (6) made of stretched polystyrene that is placed between the body (1) and the outer envelope (3). The tubular body (1) can be a single plate (7) that is initially flat and whose width matches the diameter of the desired column. Said plate (7) has a plurality of longitudinal cuts (9) on the outer face thereof, which define weakening areas (11) enabling its deformation for the purpose of forming a cylindrical element.

Owner:约瑟曼纽尔巴莱罗萨利纳斯

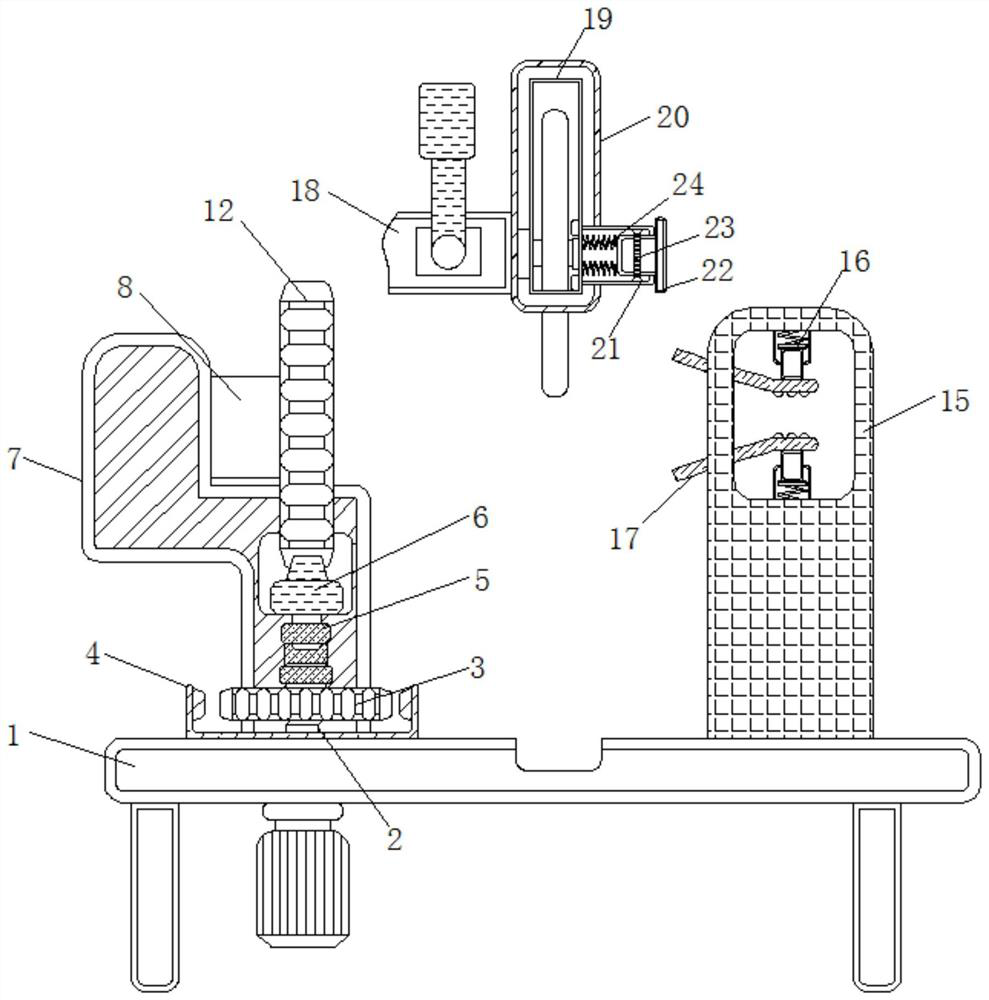

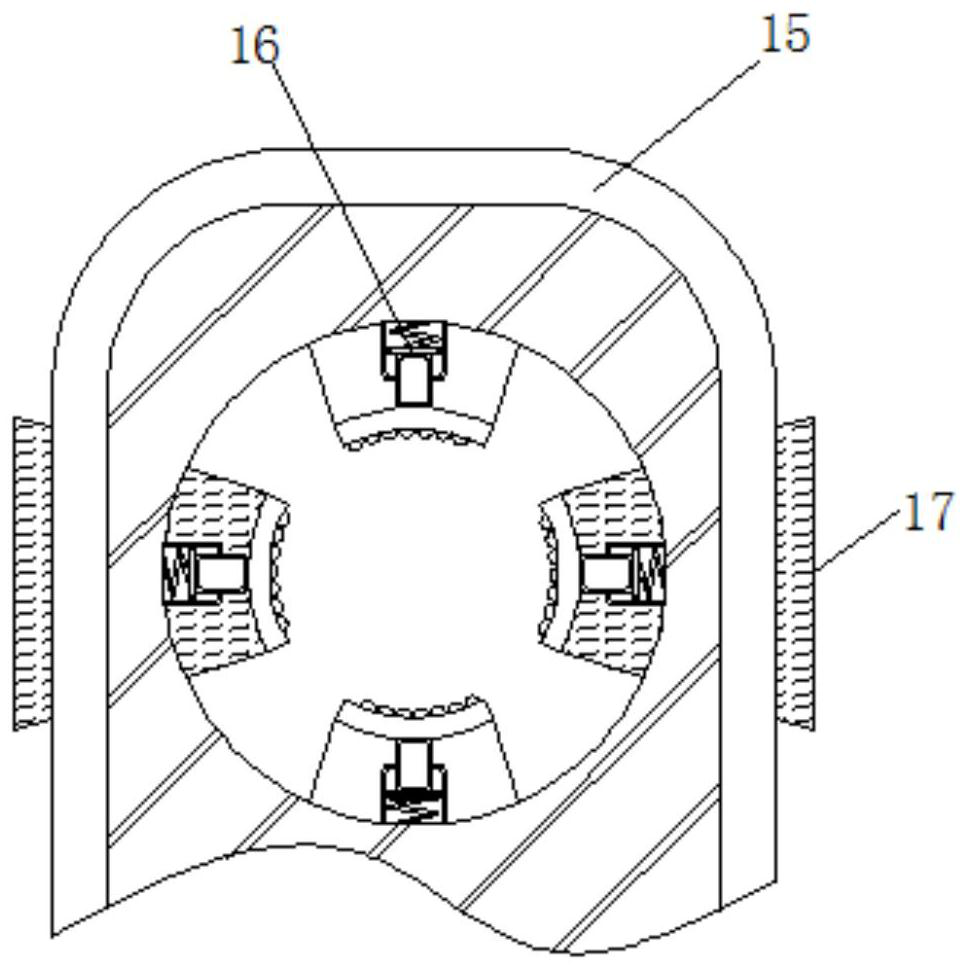

Multifunctional circular pipe metal cutting machine

InactiveCN112388058ANo tiltingOptimized sectionMetal sawing devicesMaintainance and safety accessoriesGear wheelMetal machining

The invention relates to the field of metal processing, and discloses a multifunctional circular pipe metal cutting machine which comprises a base. A first rotating rod is rotatably connected to the interior of the base, a first gear is fixedly connected to the surface of the first rotating rod, and a second rotating rod is fixedly connected to the top end of the first rotating rod; and a foundation support is fixedly connected to the upper surface of the first rotating rod, a first stand column is fixedly connected to the top end of the base, a sliding strip is slidably connected into the first stand column, and a fixing block is fixedly connected to the side, close to the sliding strip, of the first stand column. By arranging a telescopic rod, a clamping plate, a rotating wheel, a connecting rod, the rotating rod and the sliding strip, a double clamping device is formed, metal pipes with different diameters can be clamped, the stable clamping effect can be well achieved, the situation that the metal pipes incline during cutting is avoided, the sections of the cut metal pipes are more perfect, and the practicability of the machine is enhanced.

Owner:武海星

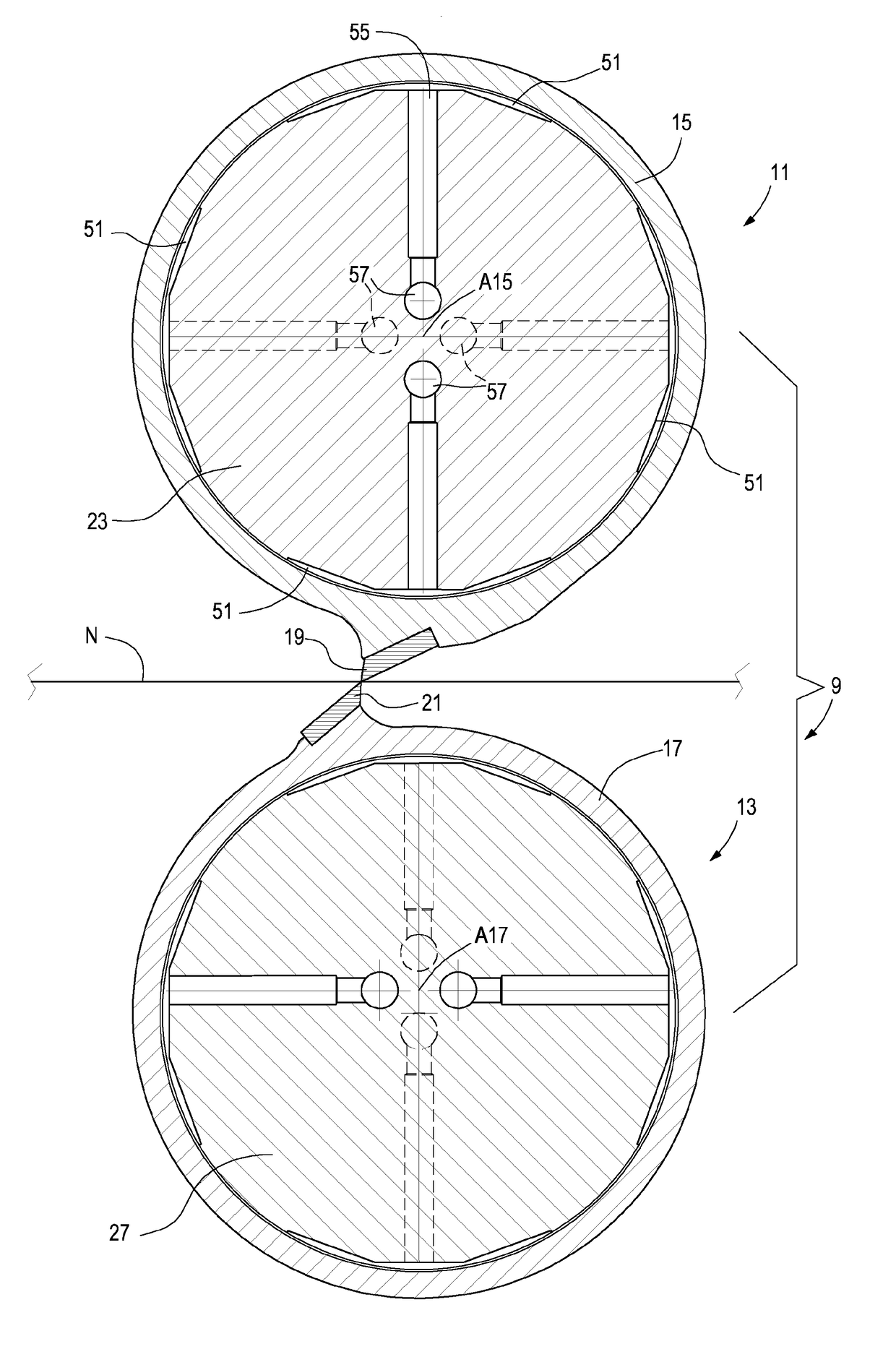

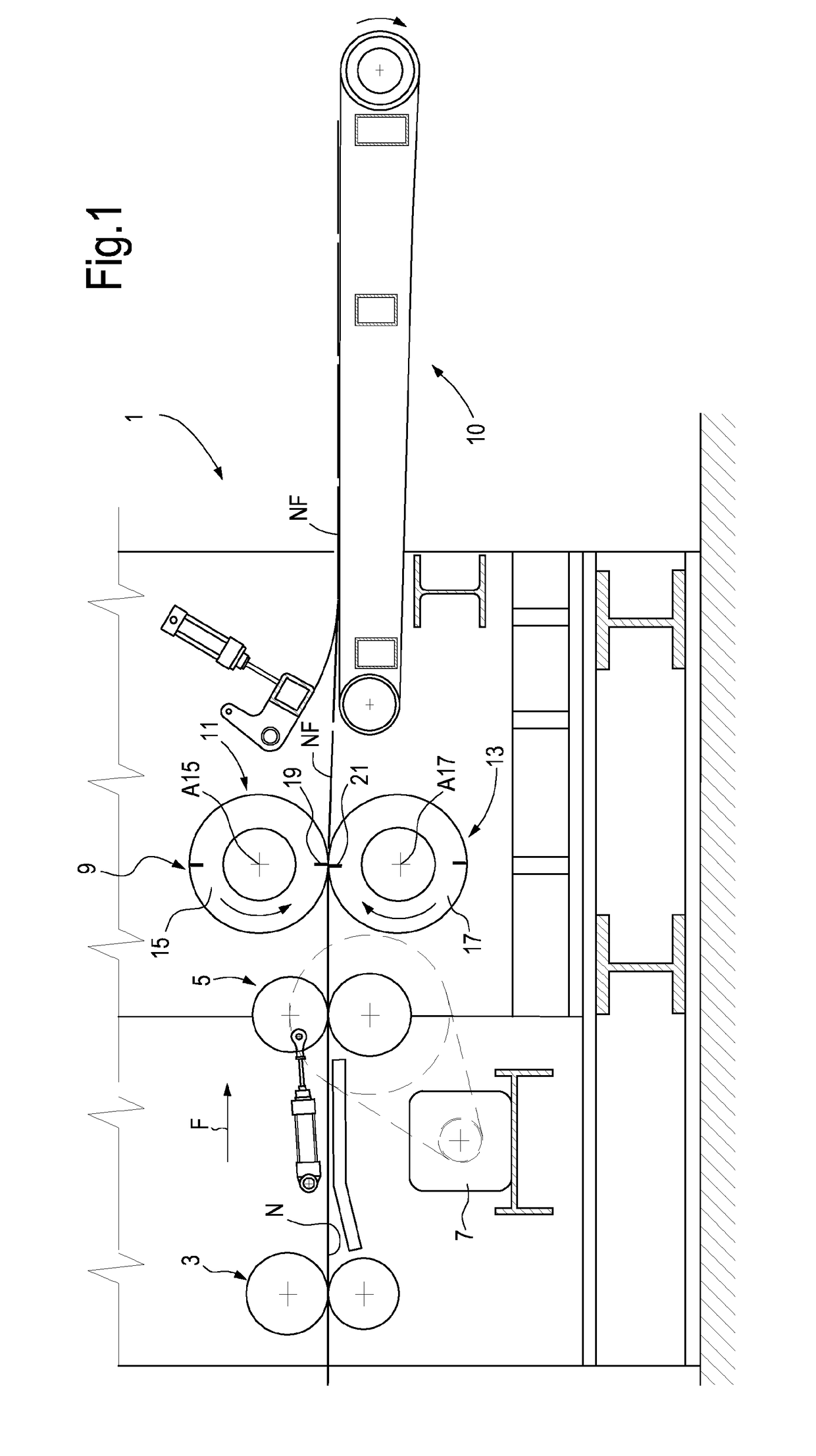

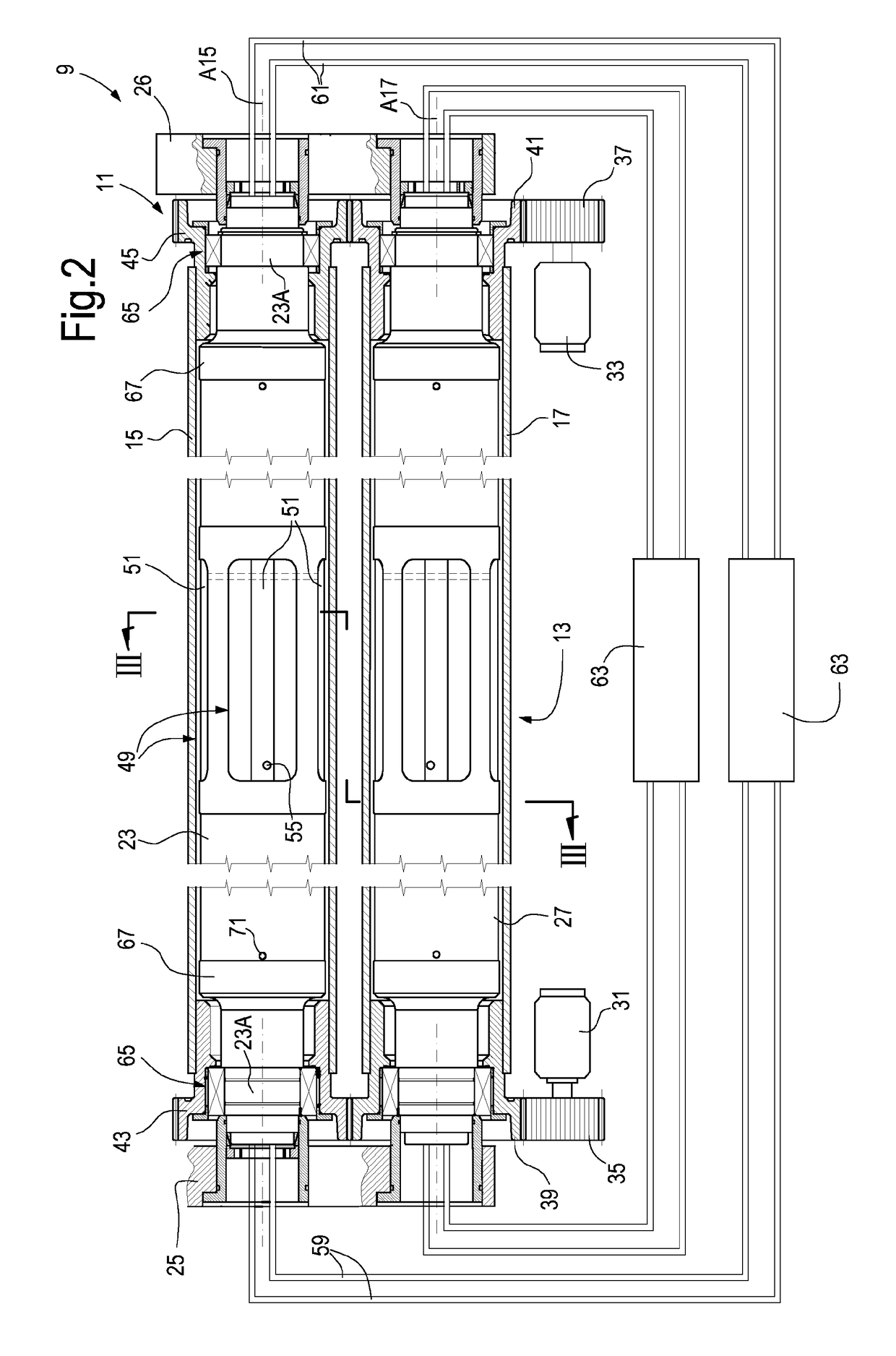

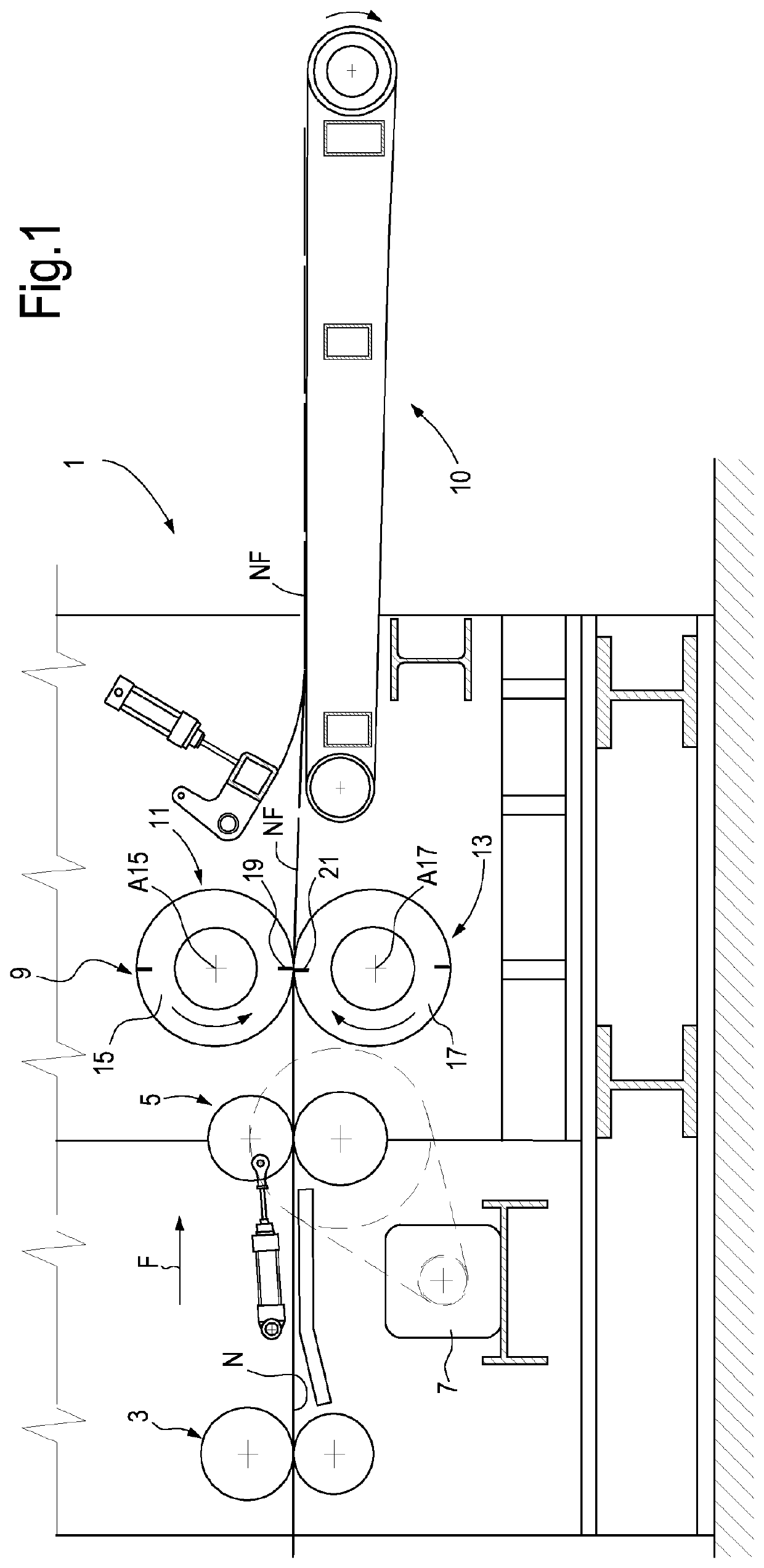

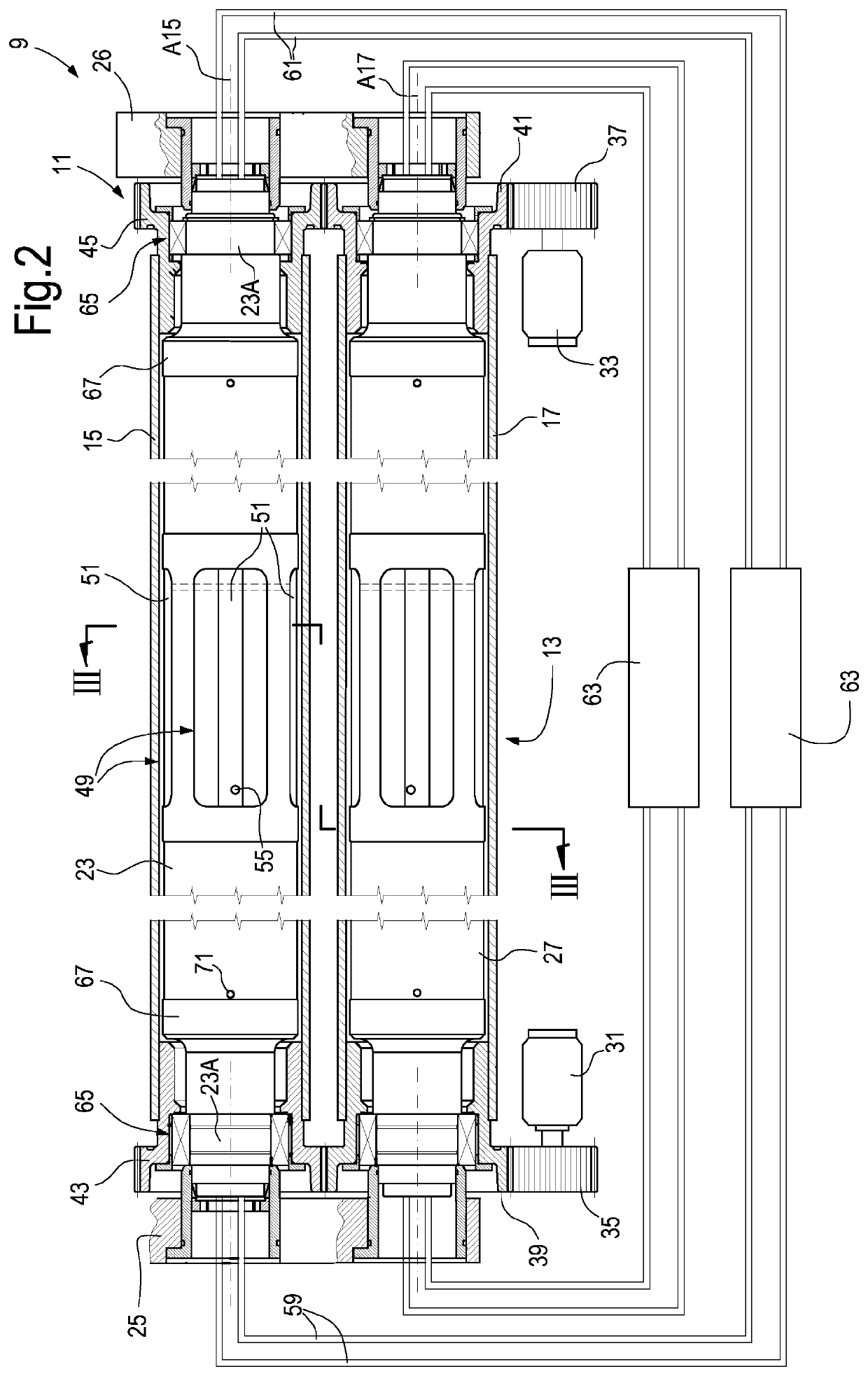

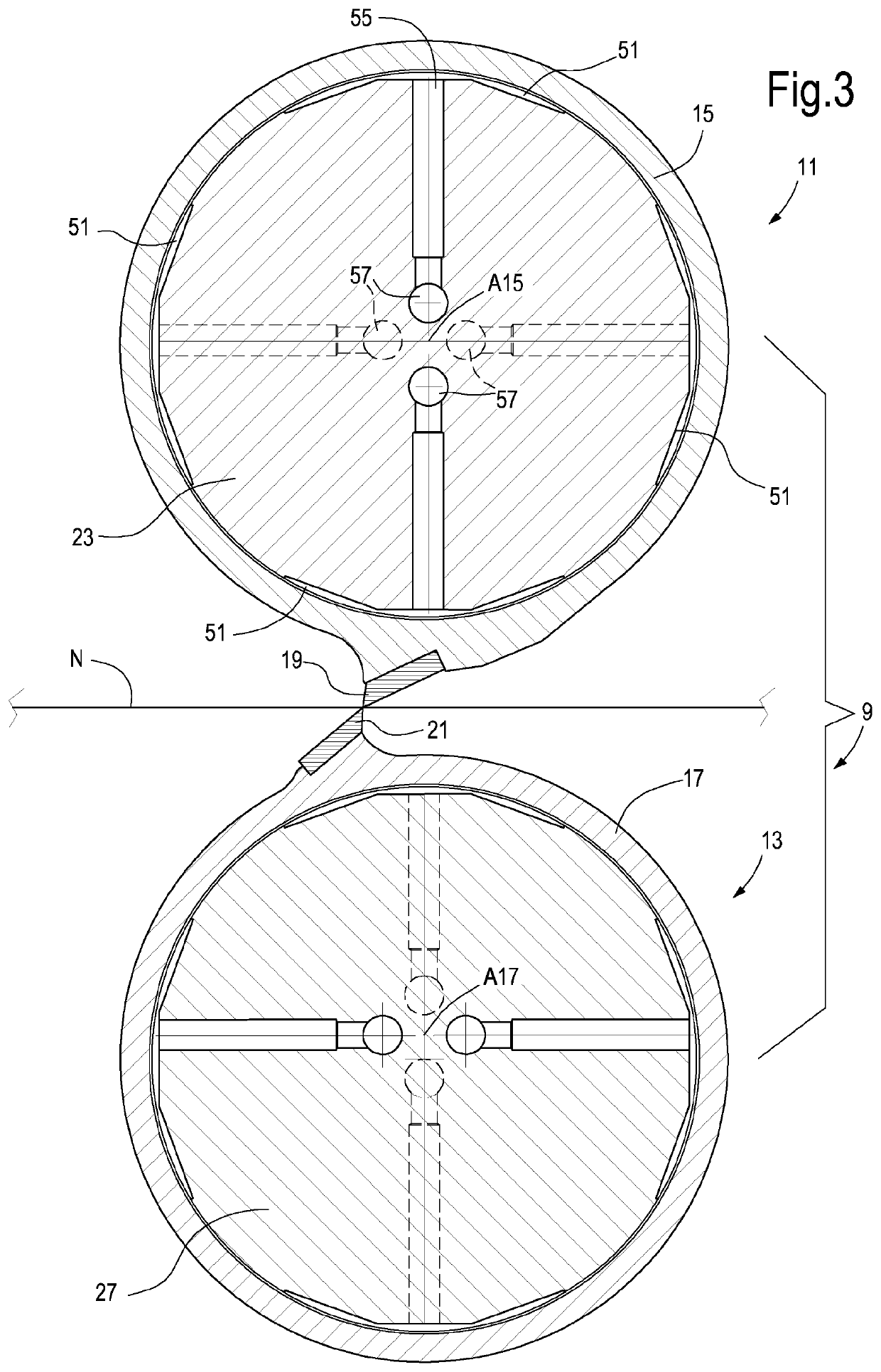

Device for transverse cutting of a web material and machine containing said device

The device includes a hollow cutting roller with a blade attached to the outer surface of the hollow roller. A stationary shaft is also provided, arranged inside the hollow roller and coaxial therewith. The stationary shaft is connected to a supporting structure and the hollow roller is rotatably supported onto the stationary shaft). A motor drive is provided to rotate the hollow roller around the stationary shaft. The hollow roller is supported onto the stationary shaft by at least a hydrostatic bearing arranged in an intermediate position between the ends of the stationary shaft.

Owner:FOSBER

Stent and Method and Device for Fabricating the Stent

ActiveUS20120214384A1Easy to cutReduce risk of damageStentsBlast gunsInsertion stentBiomedical engineering

Stent, as well as a method and device for fabricating the stent, wherein the stent has a tubular lattice structure comprising individual struts and at least one strut of which at least one longitudinal section runs with at least one directional component in the radial circumferential direction of the stent, wherein the surface of the longitudinal section facing the outside of the stent is curved only about the longitudinal axis of the stent. According to the invention, the surface of longitudinal section of the strut, which surface faces the inside of the stent, has such a curvature that the strut cross section is fluidically optimized.

Owner:BIOTRONIK AG

Cable restraint pier anti-seismic structure

InactiveCN101942797AReduce your own internal strengthControl displacementBridge structural detailsEngineeringAbutment

The invention discloses a cable restraint pier anti-seismic structure, which comprises at least one pier which is longitudinally arranged, a left bridge abutment and a right bridge abutment at the left end and the right end and a superstructure which is supported on the piers and the left and right bridge abutments, a first cable is connected between two adjacent piers, the left and right bridge abutments and the piers close to the left and right bridge abutments are all fixed by a second cable, and connecting ends of the first cable and the second cable are both connected in the upper part of the piers. The cable restraint pier anti-seismic structure has simple and novel structure and can solve the problems that the piers generate too large displacement under earthquakes which leads to the damage of the superstructure, the piers generate too large internal force at the bottom of the piers to be damaged under earthquakes, and a foundation generates too large interface force to be damaged under earthquakes.

Owner:CHINA MERCHANTS CHONGQING COMM RES & DESIGN INST

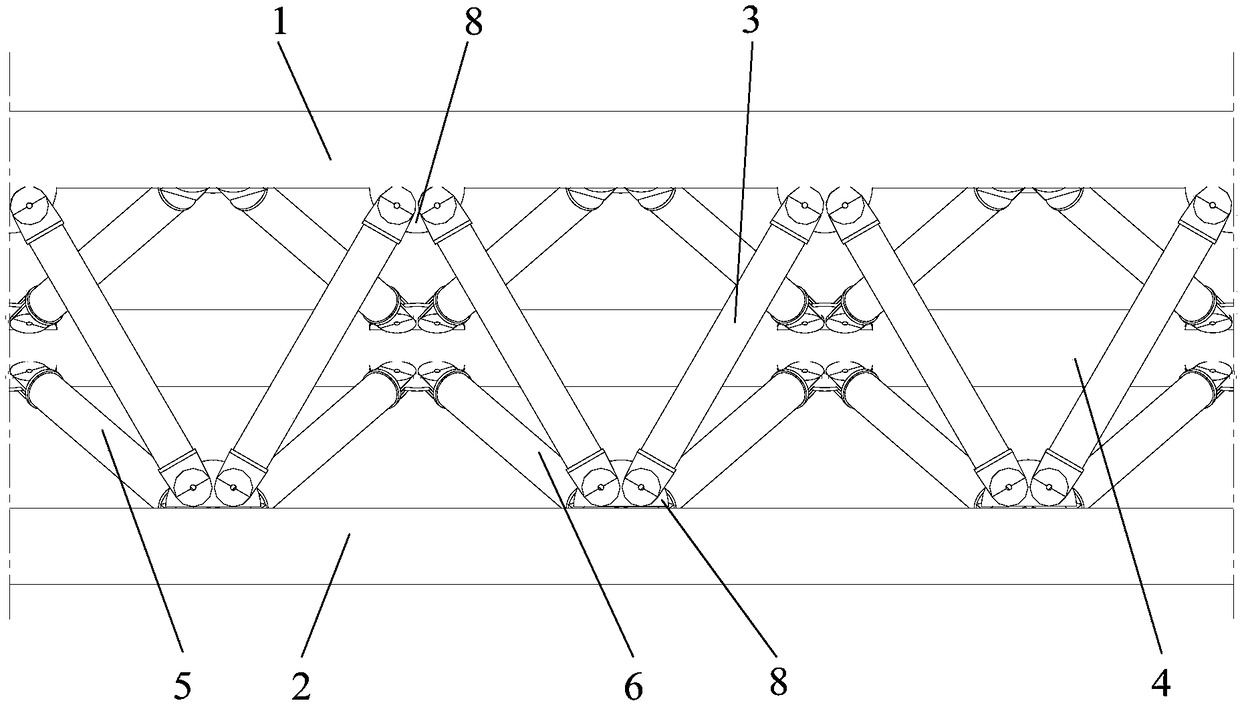

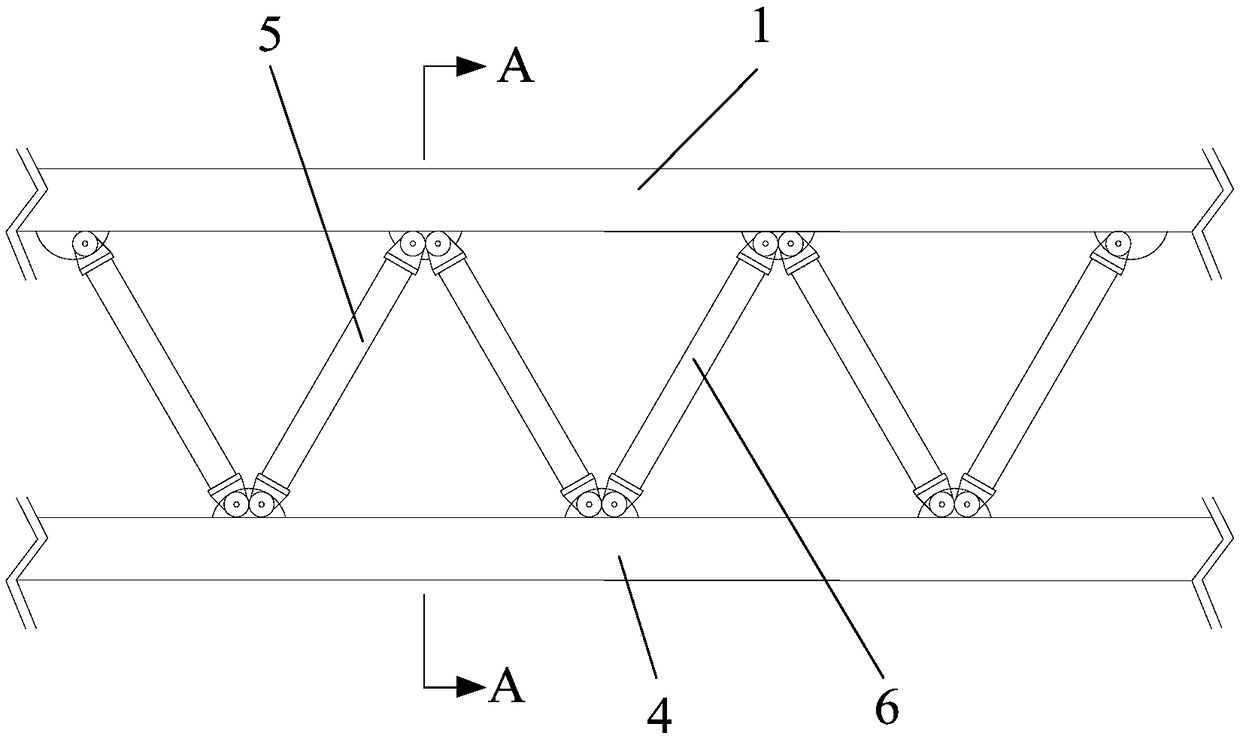

Fabricated prestressed long-span beam structure

The invention provides a fabricated prestressed long-span beam structure. The fabricated prestressed long-span beam structure comprises trussed beams, and the trussed beams comprise upper chords, lower chords and a plurality of assembled-connecting units. The upper chords comprise first supporting rods and second supporting rods arranged in parallel at intervals, and the first supporting rods areconnected with the second supporting rod through connecting pieces. The lower chords are arranged under the upper chords and located between the first supporting rods and the second supporting rods, and the lower chords and the upper chords are arranged in parallel. The assembled-connecting units comprise a plurality of web rods, the lower ends of the web rods are arranged adjacent to each other and hinged to the lower chords, the first supporting rods are hinged to the upper ends of part of the web rods, and the second supporting rods are hinged to the upper ends of the other part of the webrods. The web rods connected to the first supporting rods are arranged at intervals, and the web rods connected to the second supporting rods are arranged at intervals. The fabricated prestressed long-span beam structure can be fabricated on site according to the use demand, construction is convenient and quick, costs are reduced, a hinged method is adopted at joints, it is ensured that the shaftof the web rods is not subject to the action of bending moment, green construction is achieved, and maintenance is convenient.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

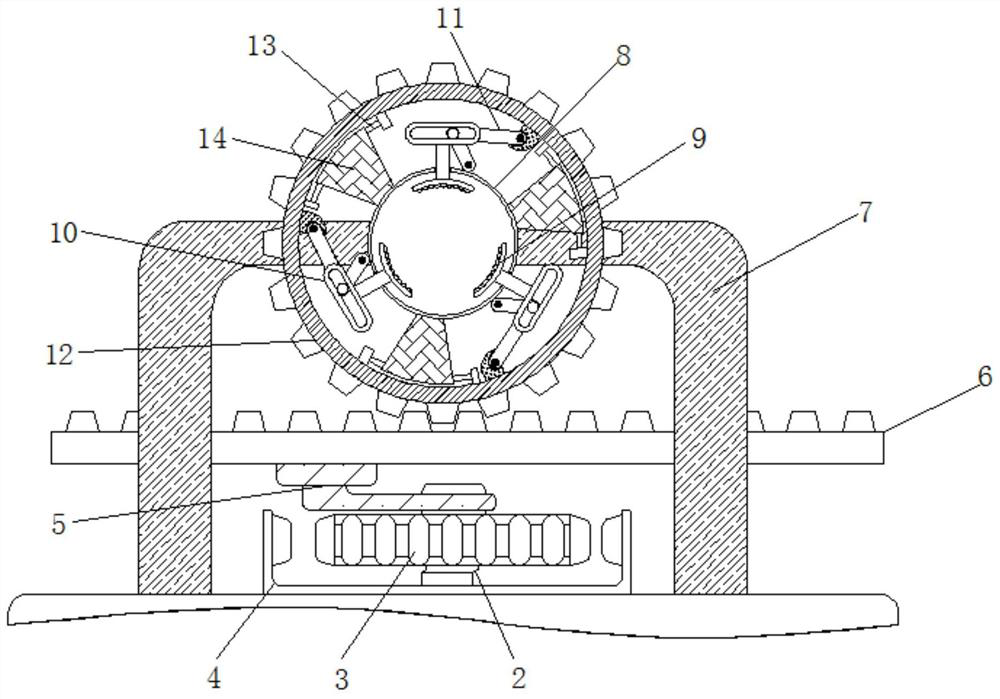

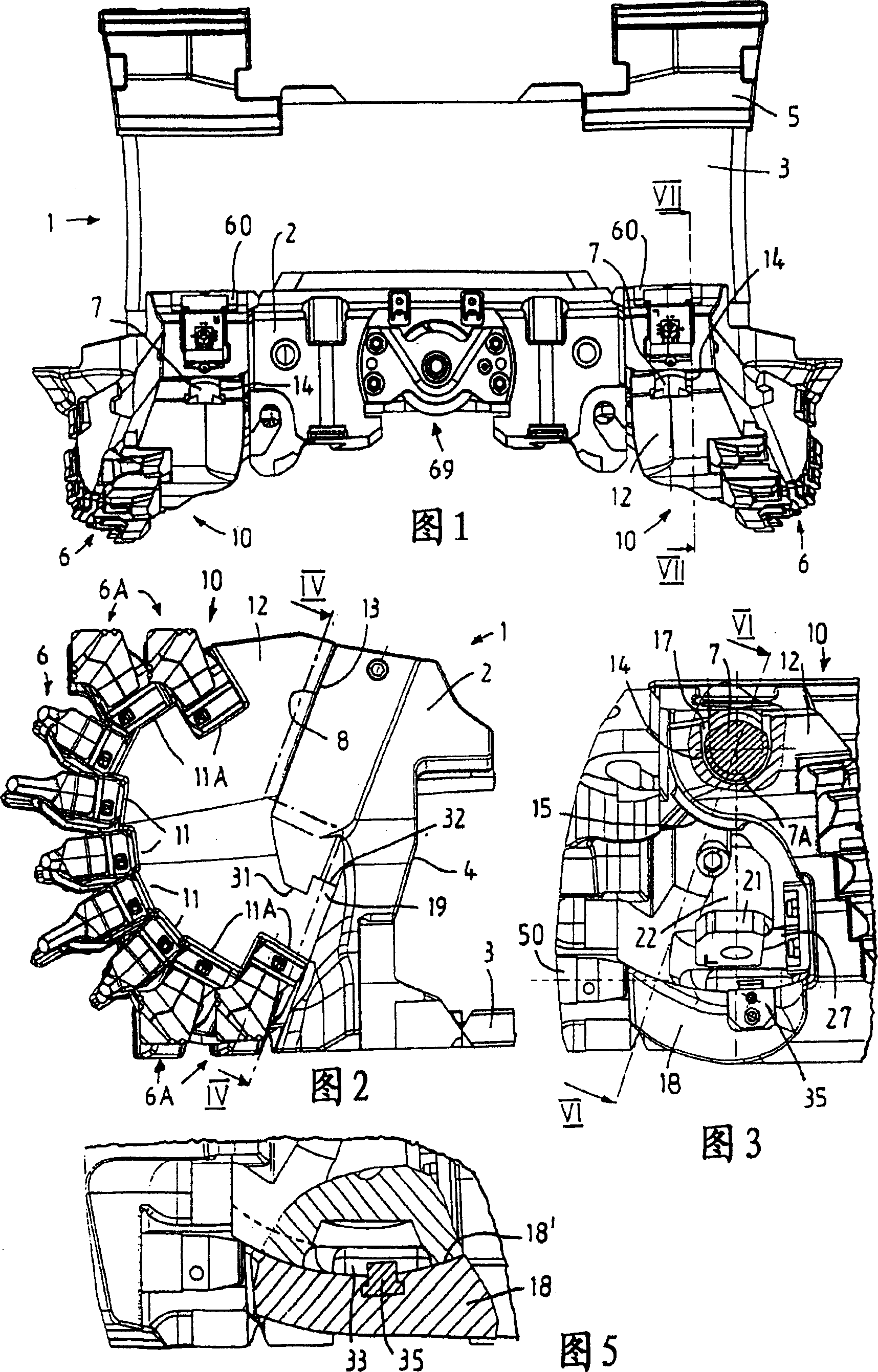

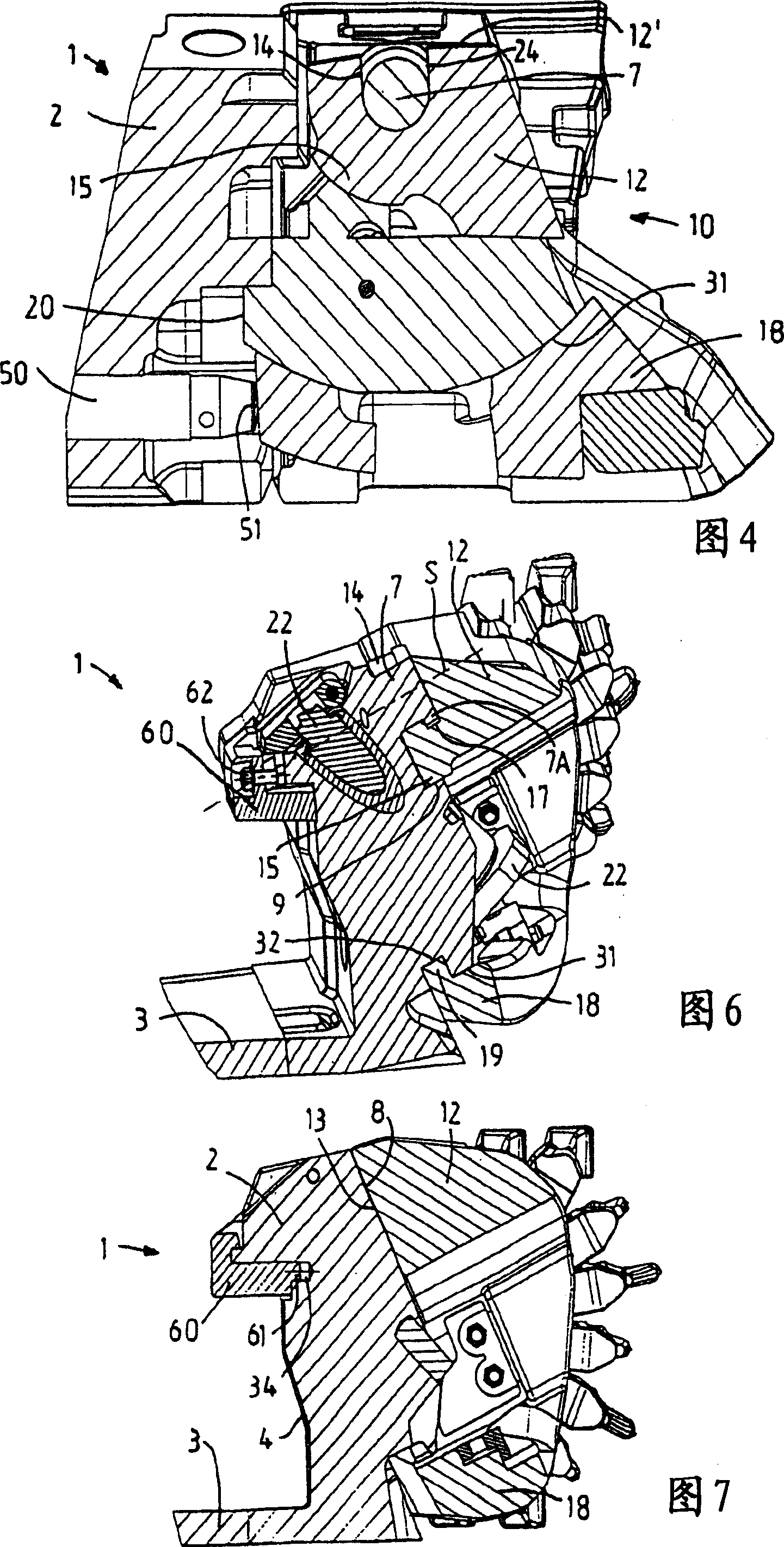

Mining plow

ActiveCN1952348ANo problem to install/removeEasy to installSlitting machinesEngineeringSupport surface

The invention relates to a recovery planer comprising a planer base (2) guided on a conveyor, which has a pivot pin on an inclined support surface (8) for any direction of movement of the planer (7) a swingable support for a knife rest (10), and includes two knife rests (10), each knife rest is supported swingably on the corresponding swing pin (7) by means of a swing support and has A base (18), by means of which the base tool holder (10) is guided on a pivoting surface (31) formed on the planer base below the bearing surface and oriented concentrically to the axis of rotation of the associated pivoting pin (7) . According to the invention, the swivel support of the tool holder (10) is formed as a groove (14) with open edges, by means of which the tool holder (10) can be pushed parallel to the support surface (8) onto the swivel pin (7) in a mounting swivel position. superior. Mounting of each tool holder can then be carried out relatively simply from below.

Owner:CATERPILLAR INC

Method for preparing soft aluminum conductor and molding device

InactiveCN101733297AQuality improvementNot easy to wearCable/conductor manufactureElectrical conductorMaterials science

The invention relates to the improvement of a method for preparing a soft aluminum conductor for an electrician and a molding device. The method is characterized by comprising the following steps of: delivering and filling an aluminum rod in a seal friction smelting space by continuous feeding and carrying out continuous friction on the space filled aluminum so that the aluminum is heated above the recrystallization temperature to a semi-smelting state; and continuously extruding under continuous feed and extrusion through a molding die in a tail end area of the smelting space. The molding device comprises a rotary friction rotating wheel and a shield, wherein the shield surrounds the periphery of part of rotating wheel and forms the seal friction smelting space; and a conductor extrusion molding die is arranged at the tail end area of the shield. Compared with the prior art, the invention has small extrusion power consumption and high production efficiency and can simultaneously extrude a plurality of soft aluminum conductors; the obtained conductor has good section consistency and stable quality and can realize continuous infinite length extrusion and finish aluminum softening modification and conductor extrusion once; and the molding device has simple structure.

Owner:FAR EAST CABLE +2

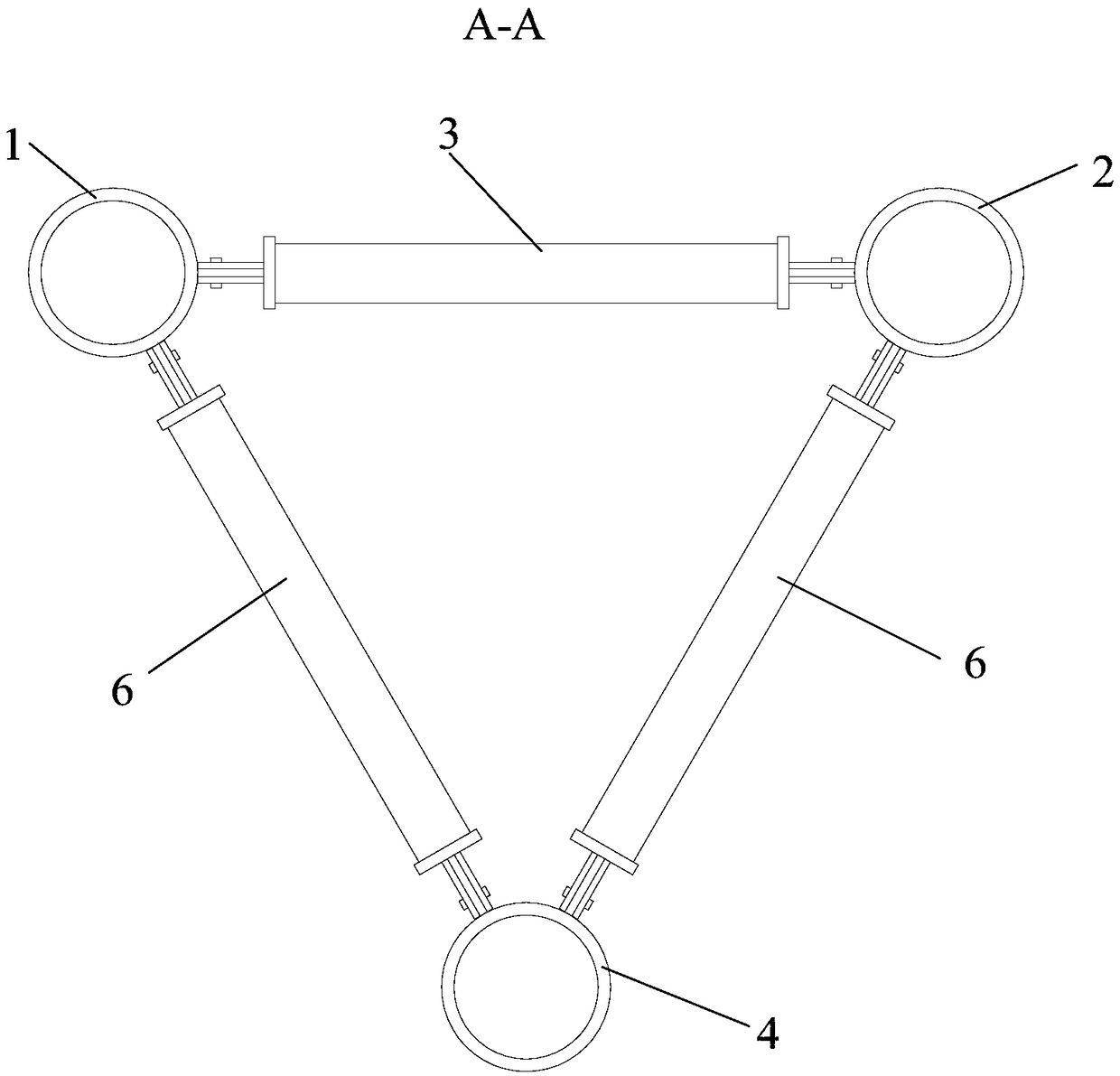

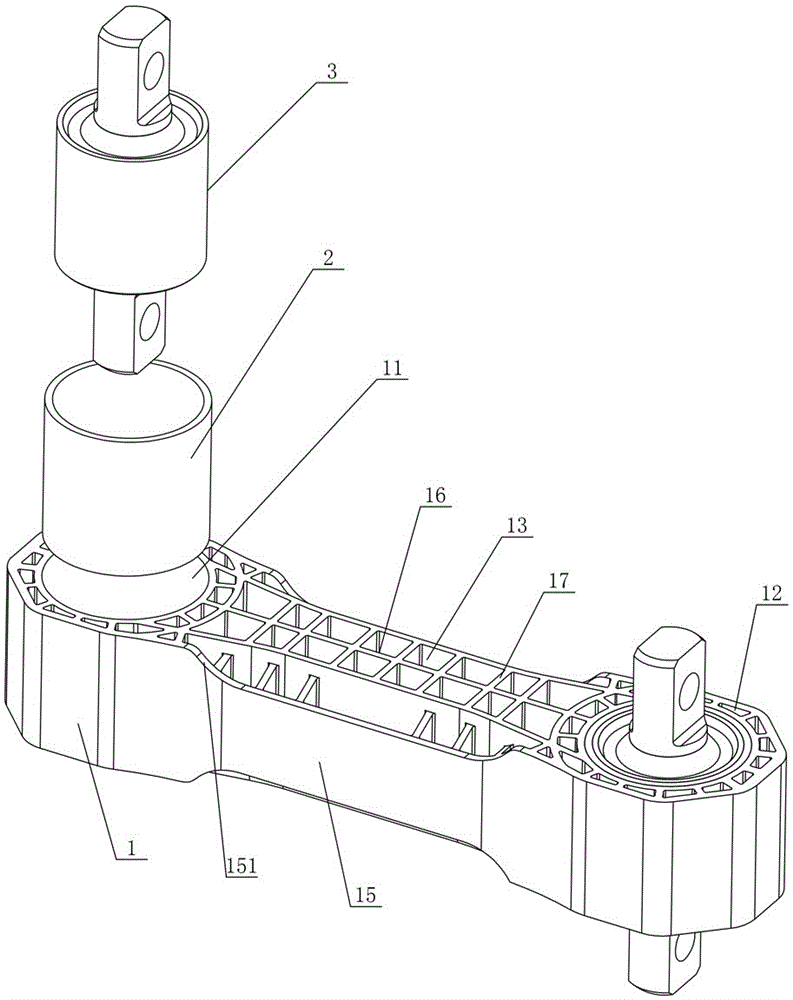

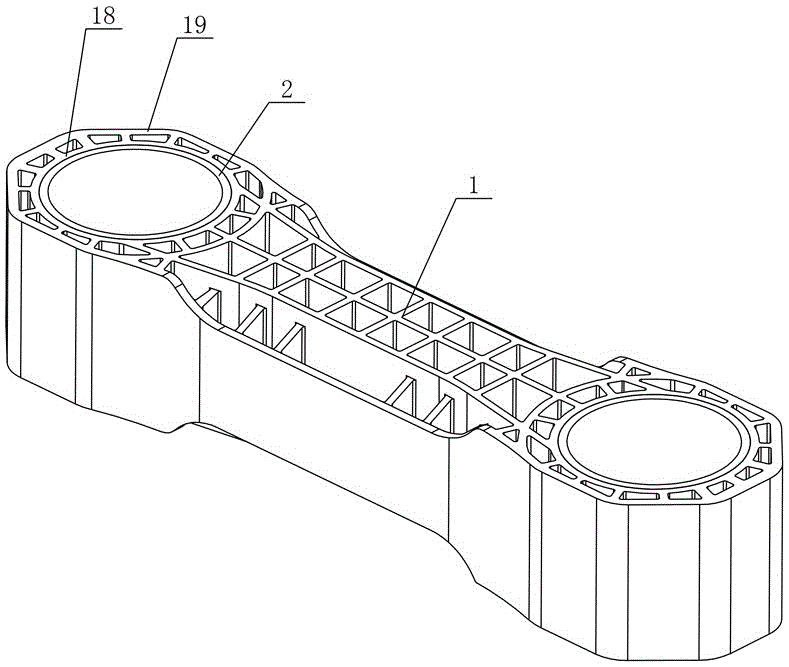

Lightweight traction rod for urban rail vehicle

InactiveCN106828532AReduce operating energy consumptionReduce load weightDraw-gearInterference fitFiber

The invention discloses a lightweight traction rod for an urban rail vehicle. The lightweight traction rod for the urban rail vehicle comprises a rod body, two metal mounting rings and two elastic joints. The rod body is formed by fiber reinforced plastic, and the two elastic joints are formed by steel and vulcanization. Mounting holes are formed in two ends of the rod body; the two metal mounting rings are matched with the two mounting holes correspondingly in an integral molding mode; the two elastic joints are in interference fit with the two metal mounting rings correspondingly; a plurality of first hollow portions which are consistent with the mounting holes in the axial direction are arranged at the rod body along the periphery of the mounting holes; and a plurality of second hollow portions consistent with the mounting holes in the axial direction are arranged at the part, between the two mounting holes, of the rod body. The traction rod has the advantages of being high in strength, capable of being produced in batches, and capable of reducing the weight of the vehicle performance load and vehicle operating energy consumption.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Multilayer wiring circuit board

InactiveUS7253023B2High frequency switching operationGeneration of high-frequency noise being suppressedSemiconductor/solid-state device detailsCross-talk/noise/interference reductionInductanceElectric power

Owner:FUJITSU LTD

Ceiling board damping structure

Owner:BEIJING NEW BUILDING MATERIALS PLC

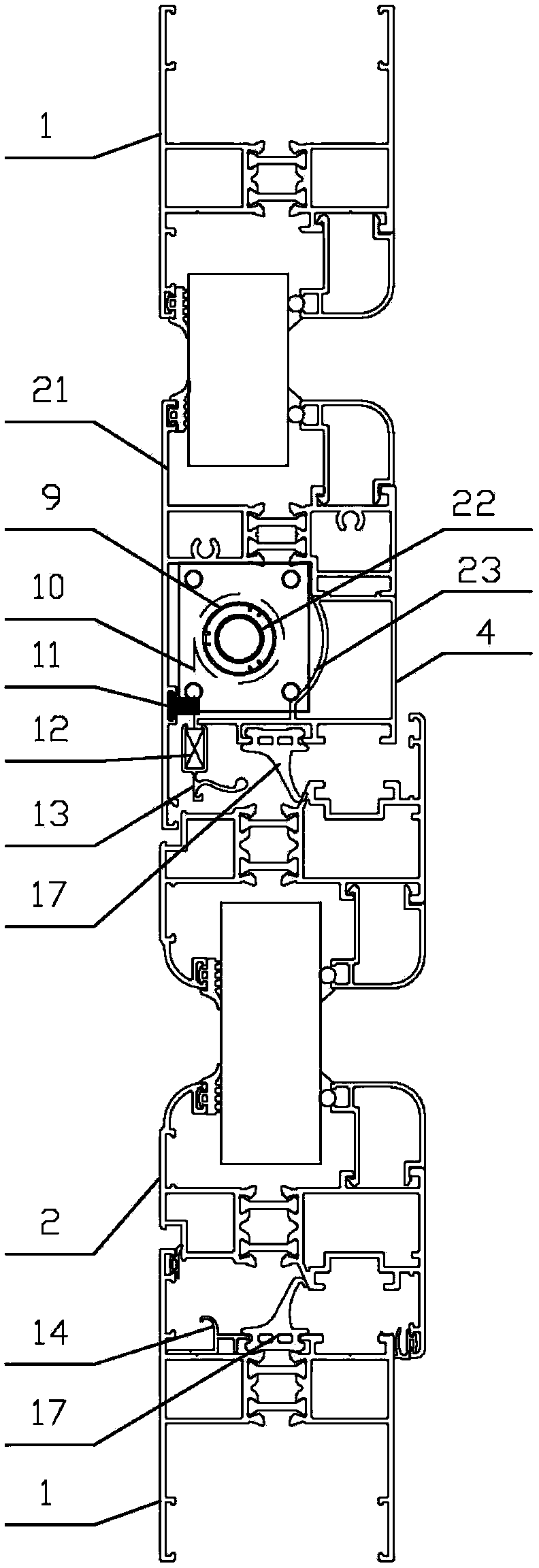

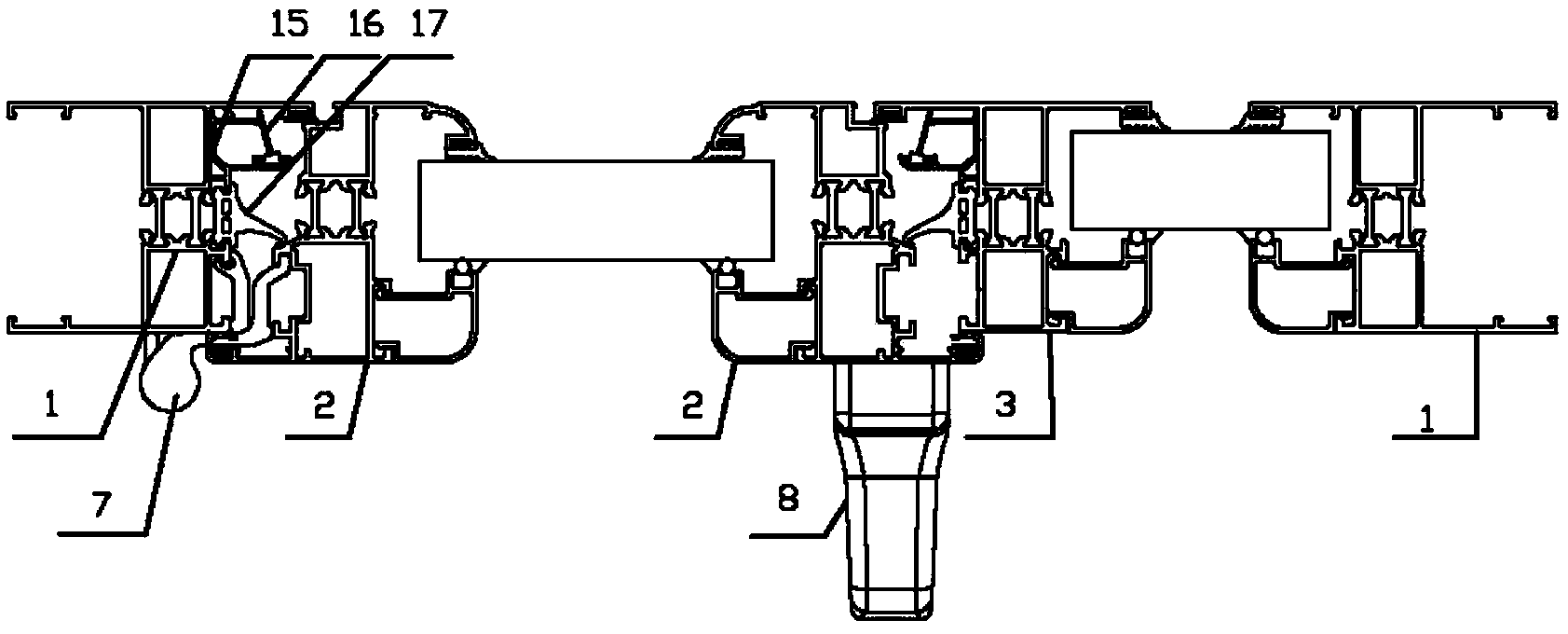

Window with integral invisible screen window

ActiveCN104074431AOptimized sectionReduce the amount of aluminum usedInsect protectionWindow/door framesWindow screenPressure resistance

The invention discloses a window with an integral invisible screen window for optimizing the matching of the window and the screen window in the prior art. The window is characterized in that on the basis of basic structures of a window side frame, a window sash, window glass and window middle beams, a screen winding pipe, a torsional spring, a piece of screen, a window screen pull handle and a screen hook are added, wherein the screen winding pipe is arranged in the window middle beams; the torsional spring is arranged in the screen winding pipe and is used for winding the screen; the screen is wound on the screen winding pipe in a non-use state; the window screen pull handle is arranged at the tail end of the screen and extends out of the window middle beams; and the screen hook is arranged on the window side frame at the opposite end to the screen winding pipe in a way of being matched with the window screen pull handle. Through the integral design of the screen window and a window main body, the function of the screen window is realized in an invisible mode; the screen window is applicable to various kinds of window types; the cross sections of the window and the screen window are greatly reduced and optimized; the cost is reduced; the screen window and the screen are in integral invisible design, and the integral appearance of building door and window engineering is not influenced; when the window sash is closed, the screen is wound back, the outwards exposed time of the screen is reduced, and the service life is prolonged; when the screen window is not used for a long time, the dismounting is not needed; and the properties such as wind pressure resistance, airtightness and watertightness of the whole window are not influenced.

Owner:LANZHOU MINGDI ALUMINUM

Device for transverse cutting of a web material and machine containing said device

ActiveUS10744664B2Optimized sectionReduce distortionMetal working apparatusElectric machineryEngineering

The device includes a hollow cutting roller with a blade attached to the outer surface of the hollow roller. A stationary shaft is also provided, arranged inside the hollow roller and coaxial therewith. The stationary shaft is connected to a supporting structure and the hollow roller is rotatably supported onto the stationary shaft. A motor drive is provided to rotate the hollow roller around the stationary shaft. The hollow roller is supported onto the stationary shaft by at least a hydrostatic bearing arranged in an intermediate position between the ends of the stationary shaft.

Owner:FOSBER

Etching solution

PendingCN113981447AFinely craftedSlow etch rateConductive material chemical/electrolytical removalBenzeneIntegrated circuit manufacturing

The invention discloses an etching solution formula, and relates to the field of printed circuit board manufacturing and the field of integrated circuit manufacturing. According to the invention, the etching solution can be provided for reducing the copper thickness and forming the circuit, can improve the poor pinholes in the copper surface and optimize the rectangular circuit section, and meanwhile, improves the etching speed and improves the efficiency. The etching solution is characterized by being composed of sulfuric acid, hydrogen peroxide, an alcohol accelerant and a benzene ring stabilizer, the mass ratio of hydrogen peroxide to sulfuric acid in unit volume is larger than 8: 1, the hydrogen peroxide accounts for 8-30% by mass, the sulfuric acid accounts for 0.3-15% by mass, the alcohol accelerant accounts for 5-20% by mass, and the benzene ring stabilizer accounts for 0-2% by mass.

Owner:纳然电子技术(苏州)有限公司

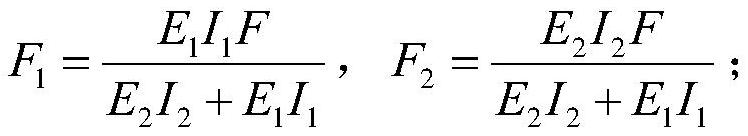

Novel steel pipe cast-in-place pile and bearing capacity and internal force calculation method thereof

InactiveCN113006054AOptimized sectionLow costFoundation testingComplex mathematical operationsReinforced concreteArchitectural engineering

The invention discloses a novel steel pipe cast-in-place pile. A structural form that a steel pipe subjected to anti-corrosion design is internally provided with a reinforcement cage and is poured with concrete is adopted to form a steel pipe and reinforced concrete combined structure. The invention further discloses a bearing capacity and internal force calculation method of the novel steel pipe cast-in-place pile. The bearing capacity calculation of the novel steel pipe cast-in-place pile foundation can be combined with the calculation method of the steel pipe pile and the cast-in-place pile, the side friction resistance refers to the steel pipe pile, and the end resistance refers to the cast-in-place pile; and under the condition that the steel pipe cast-in-place pile meets the elastic long pile condition, the ratio of the steel pipe to the concrete pile core resisting horizontal force is the same as the bending rigidity ratio of the two materials. The novel steel pipe cast-in-place pile and the bearing capacity and internal force calculation method thereof have the advantages that material waste is reduced, the section of a pile foundation is optimized, compared with a steel casing which is about to achieve the elastic long pile condition and only serves as a temporary facility, the engineering cost can be reduced by about 40% or even 50%, and the horizontal force resistance of the cast-in-place pile under the same pile diameter is improved by about 80%.

Owner:CCCC WUHAN HARBOR ENG DESIGN & RES

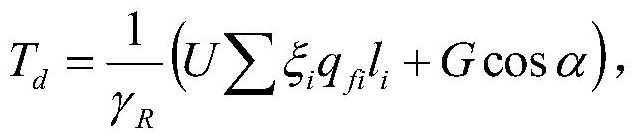

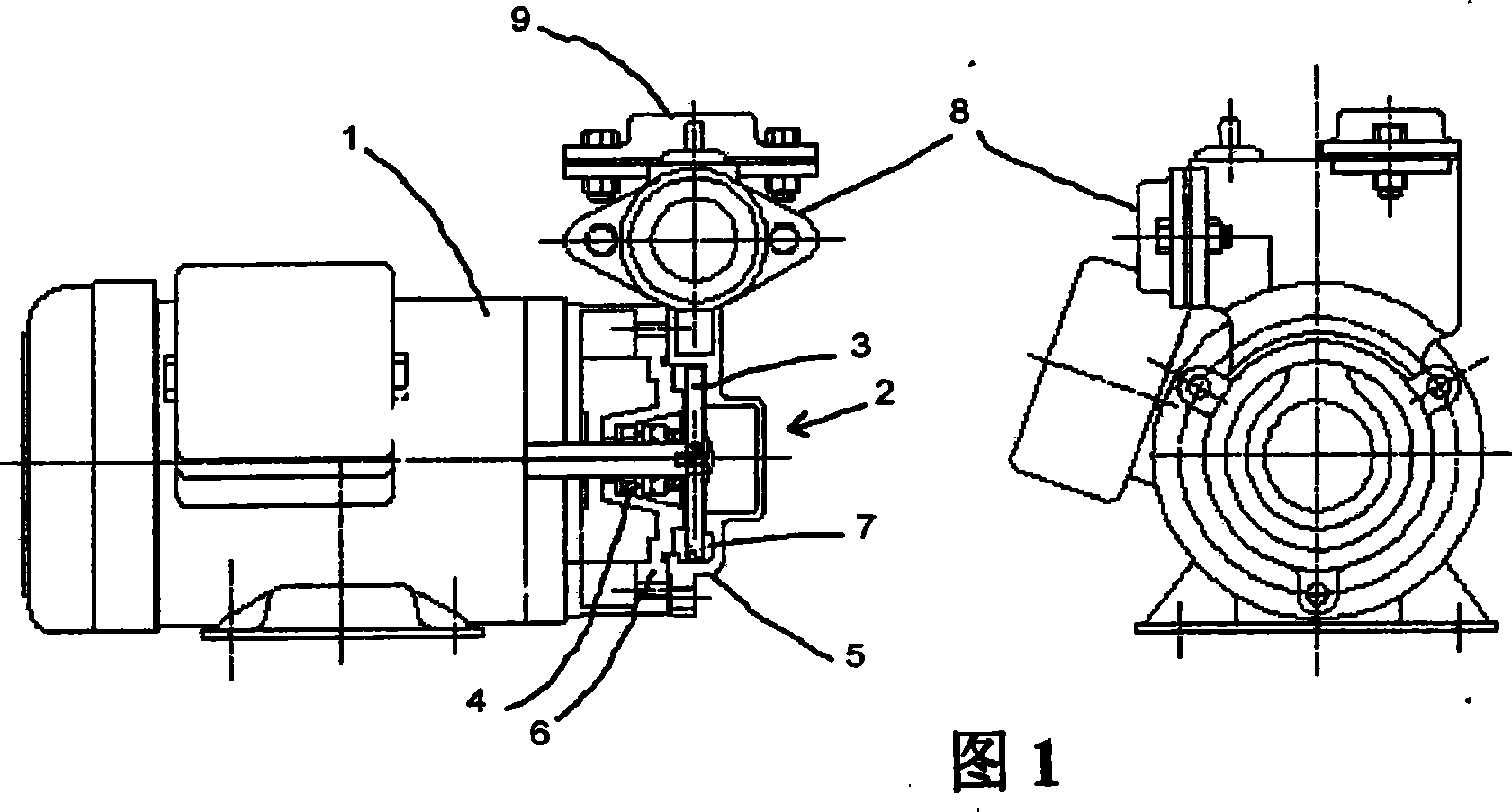

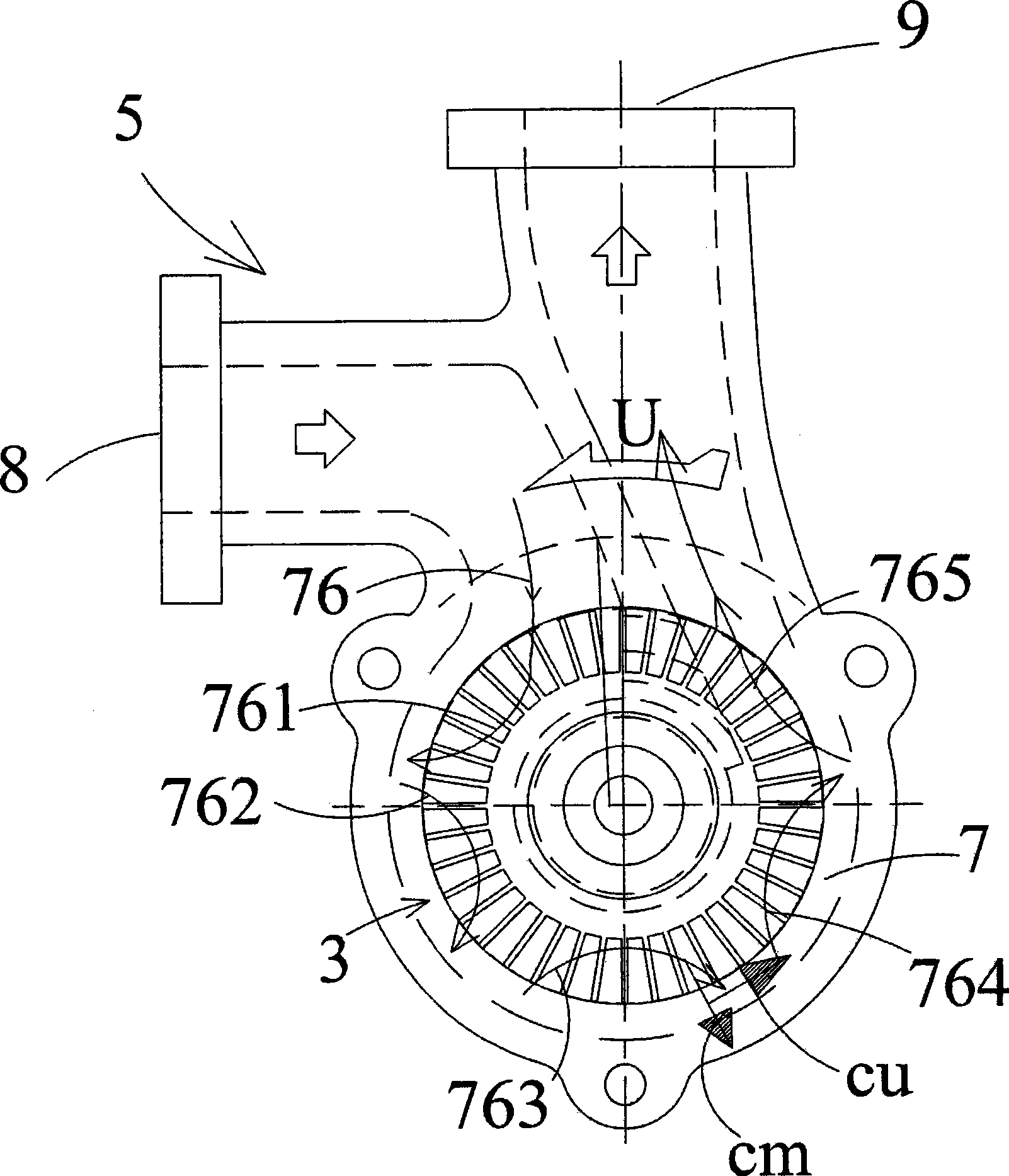

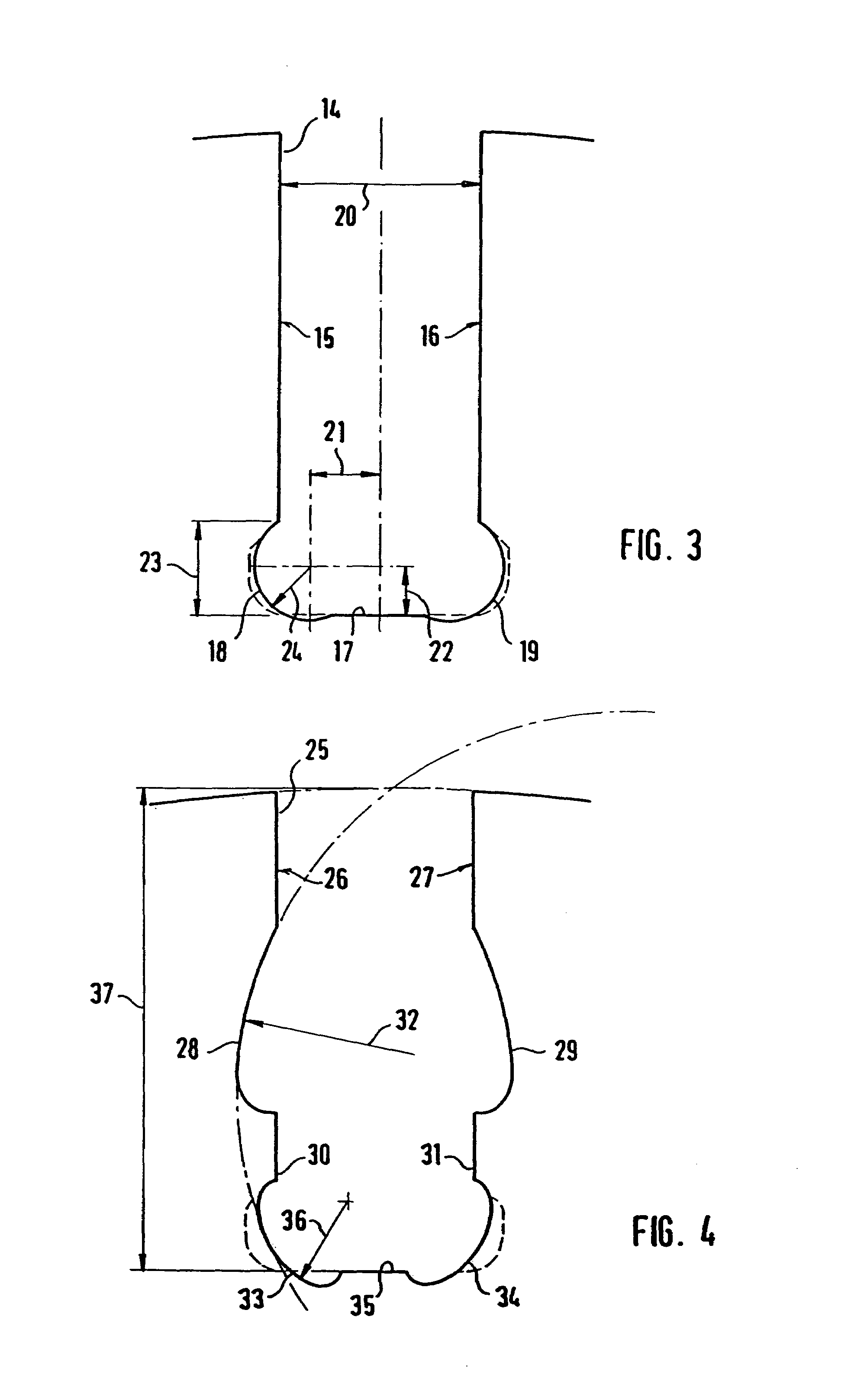

Flow passage structure of regenerative pump

ActiveCN101368578AOptimized sectionSlow down the flowCircumferential flow pumpsPump componentsImpellerStreamflow

Disclosed is the interval channel structure of a regenerative pump, which comprises the vane interval channel of a closed impeller and a pump shell interval channel; an impeller is provided with radial vanes; the space between the two vanes on the same side construct the radial vane interval channel; the vane interval channel includes a vane inlet, a vane inlet root arc, a vane lateral plate, a vane hub plate, a vane outlet and a vane root; a pump shell has an arc-shaped interval channel section; the interval channel section includes the interval channel inner wall top part, the interval channel lateral side inner wall and the interval channel bottom inner wall; the largest width of the interval channel section is close to the inlet of the vane; the interval channel inner wall top part is close to the vane outlet; the inner diameter of the interval channel inner wall top part is more than the largest outer diameter of the impeller; the corner angle of the interval channel inner wall top and the interval channel lateral side inner wall is an obtuse angle; the interval channel lateral side inner wall is extended to be open towards the section of the interval channel with the largest width and smoothly connected with the interval channel bottom inner wall; the interval channel bottom inner wall furls towards the vane inlet; the interval channel bottom inner wall maintains smooth with the vane inlet root arc. The interval channel structure of a regenerative pump can improve the noise problem of the regenerative pump and improve the output flow.

Owner:BUENO TECH

Cable restraint pier anti-seismic structure

InactiveCN101942797BFirmly connectedAvoid destructionBridge structural detailsAbutmentSuperstructure

The invention discloses a cable restraint pier anti-seismic structure, which comprises at least one pier which is longitudinally arranged, a left bridge abutment and a right bridge abutment at the left end and the right end and a superstructure which is supported on the piers and the left and right bridge abutments, a first cable is connected between two adjacent piers, the left and right bridge abutments and the piers close to the left and right bridge abutments are all fixed by a second cable, and connecting ends of the first cable and the second cable are both connected in the upper part of the piers. The cable restraint pier anti-seismic structure has simple and novel structure and can solve the problems that the piers generate too large displacement under earthquakes which leads to the damage of the superstructure, the piers generate too large internal force at the bottom of the piers to be damaged under earthquakes, and a foundation generates too large interface force to be damaged under earthquakes.

Owner:CHINA MERCHANTS CHONGQING COMM RES & DESIGN INST

Reinforced connecting joint of steel structure beam and steel column and construction method of reinforced connecting joint

The invention belongs to the field of steel structure buildings and particularly relates to a reinforced connecting joint of a steel structure beam and a steel column and a construction method of the reinforced connecting joint. The construction method comprises the steps as follows: step 1, a factory blanks a steel beam and a steel column, and studs are welded on a sealing plate required to be mounted to the steel column; step 2, the steel beam and the steel column are assembled and welded; step 3, the sealing plate is laid on the steel column on site, a box girder section is formed, and an opening is reserved in the upper sealing plate of the box girder section; step 4, concrete is poured in the steel beam and the box girder section during floor concrete pouring. The stress requirement of the connecting joint of the beam column is fully met, production and site construction are convenient and simple, and the problems caused by addition of cover plates on upper and lower flanges of beams, increase of width of flange plates, addition of knee braces and other construction measures during beam and column connection are solved. In addition, the joint is more concise and attractive in style.

Owner:ZHEJIANG JINGGONG STEEL BUILDING GRP

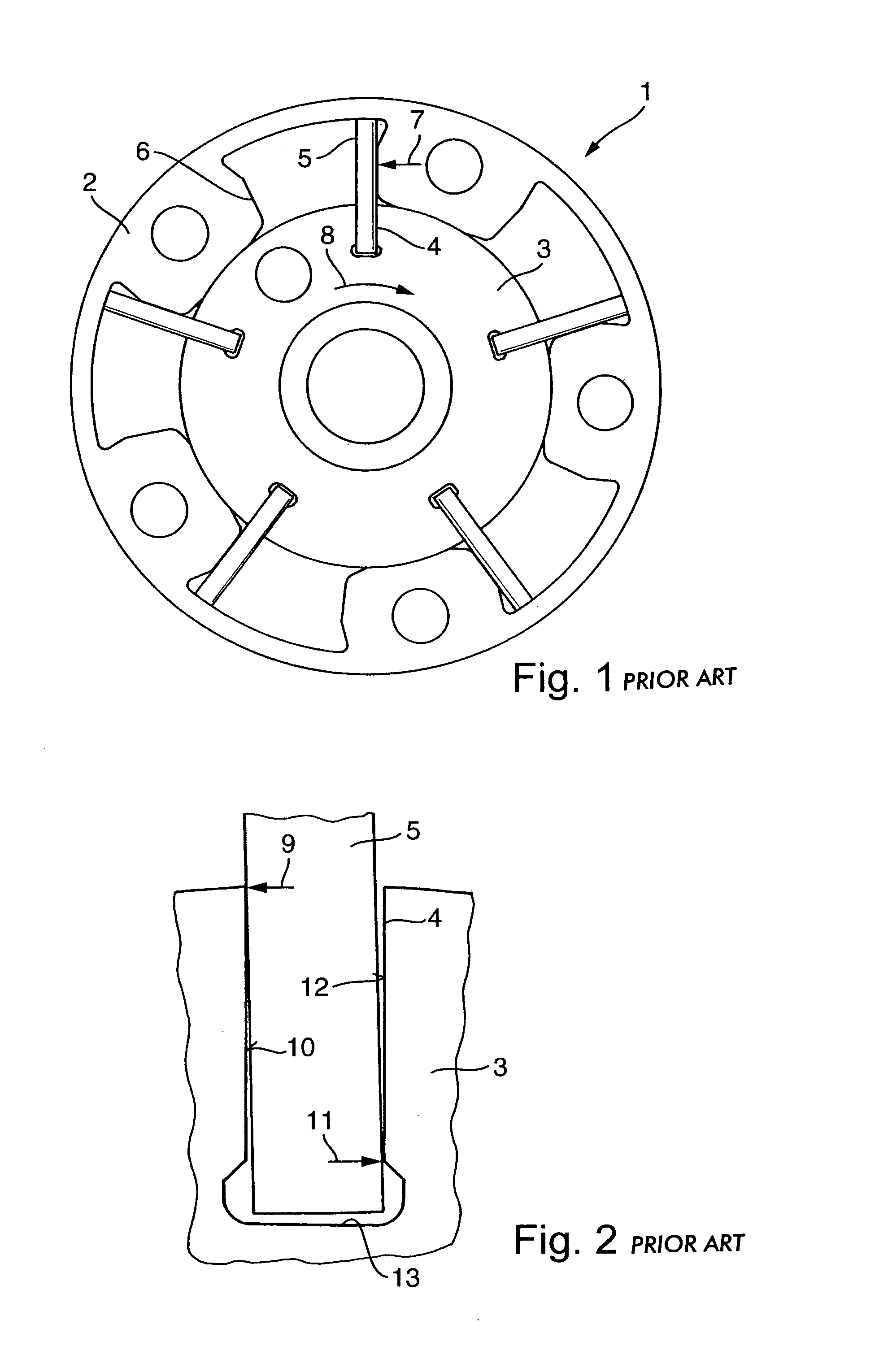

Vane-type camshaft adjuster

ActiveUS7188596B2Optimized sectionReduce loadMetal sawing devicesValve arrangementsEngineeringCamshaft

A vane-type camshaft adjuster having a stator, and a rotor connectable to a camshaft. The rotor has a plurality of radially protruding blades inserted in respective blade grooves. The blade groove has groove side faces, a groove bottom and rounded transition regions between the groove side faces and the groove bottom. The transition regions undercut the groove side faces, wherein the rounded transition regions are configured, at least in part, as circular arc segments which undercut the groove bottom.

Owner:SCHAEFFLER TECH AG & CO KG

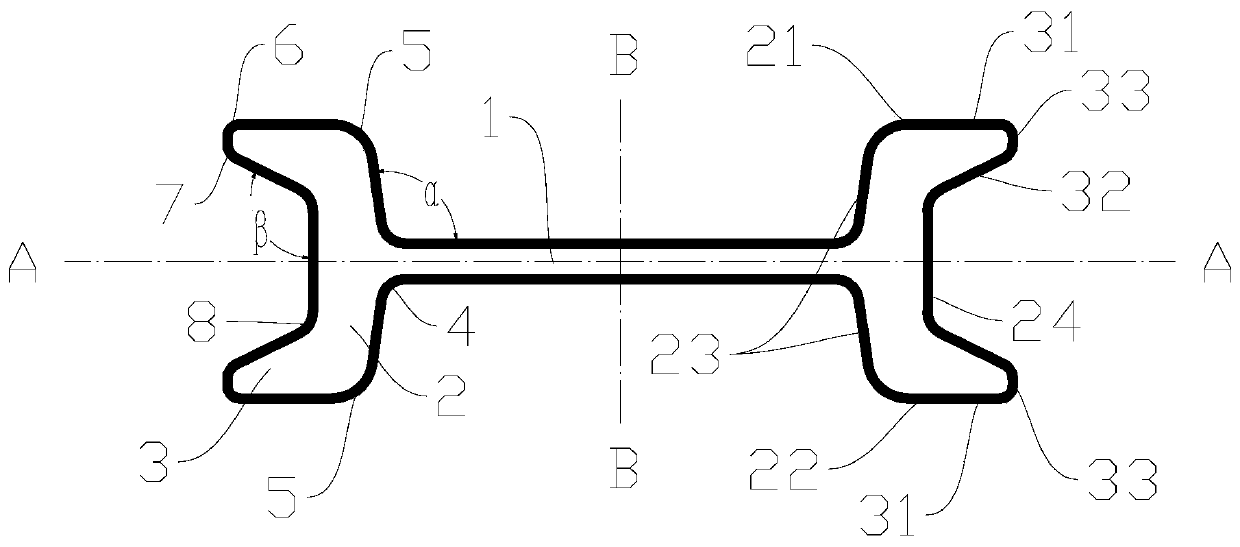

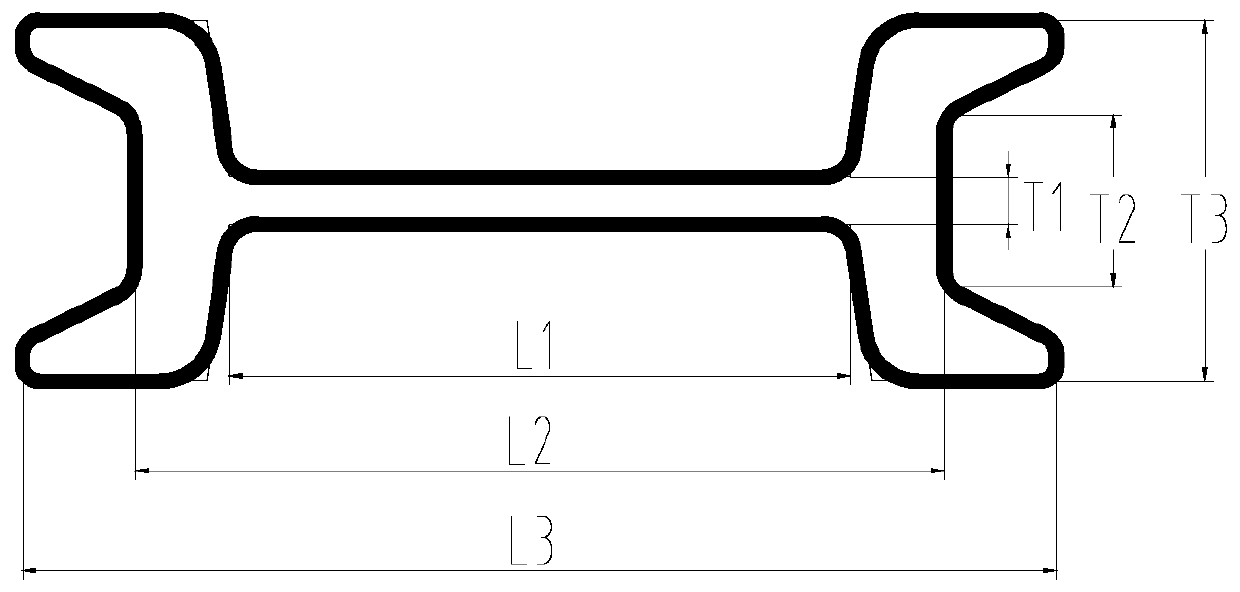

Novel section figured steel and production method thereof

ActiveCN109775560AImprove carrying capacityStable structureElongated constructional elementsMetal rolling arrangementsEngineeringLateral bending

The invention provides novel section figured steel and a production method of the novel section figured steel. The section figured steel comprises a web, flanges and corners. The left end and the right end of the web are each provided with one flange, the upper end and the lower end of each flange are each provided with one corner, and the web, the two flanges and the four corners are integrally formed. The transverse center line of the web is A-A, the vertical center line of the web is B-B, one end of each corner is connected with the corresponding flange, and the other end of each corner isextended in the direction away from B-B. By means of the technical scheme, the production efficiency and the metal utilization rate are improved, the production cost is reduced, using economy is improved, the section figured steel is obtained after strengthening I-shaped steel, lateral bending resistance is high, and compared with traditional section I-shaped steel, the section is optimized, and the bearing capacity is higher.

Owner:SHANDONG IRON & STEEL CO LTD

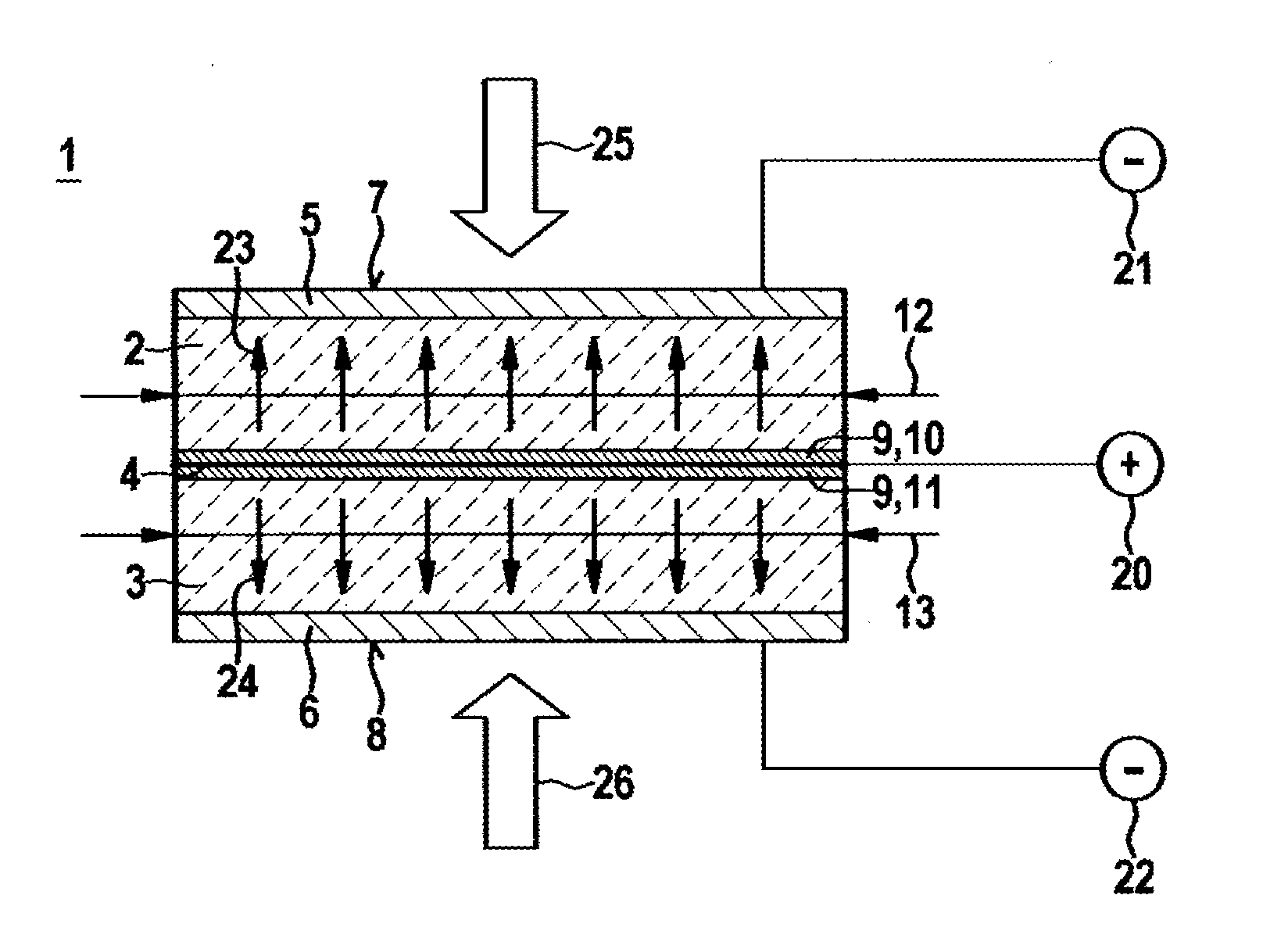

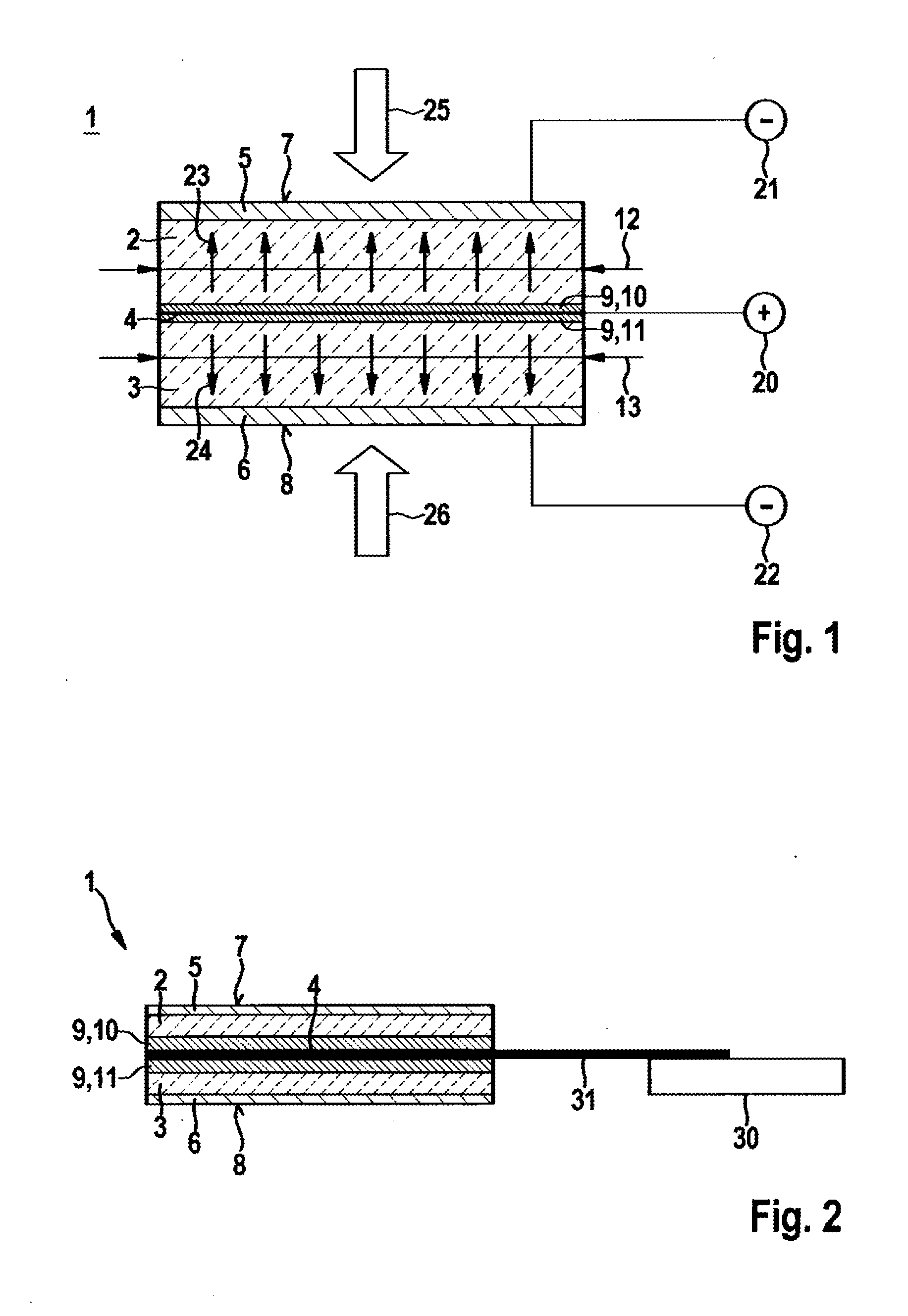

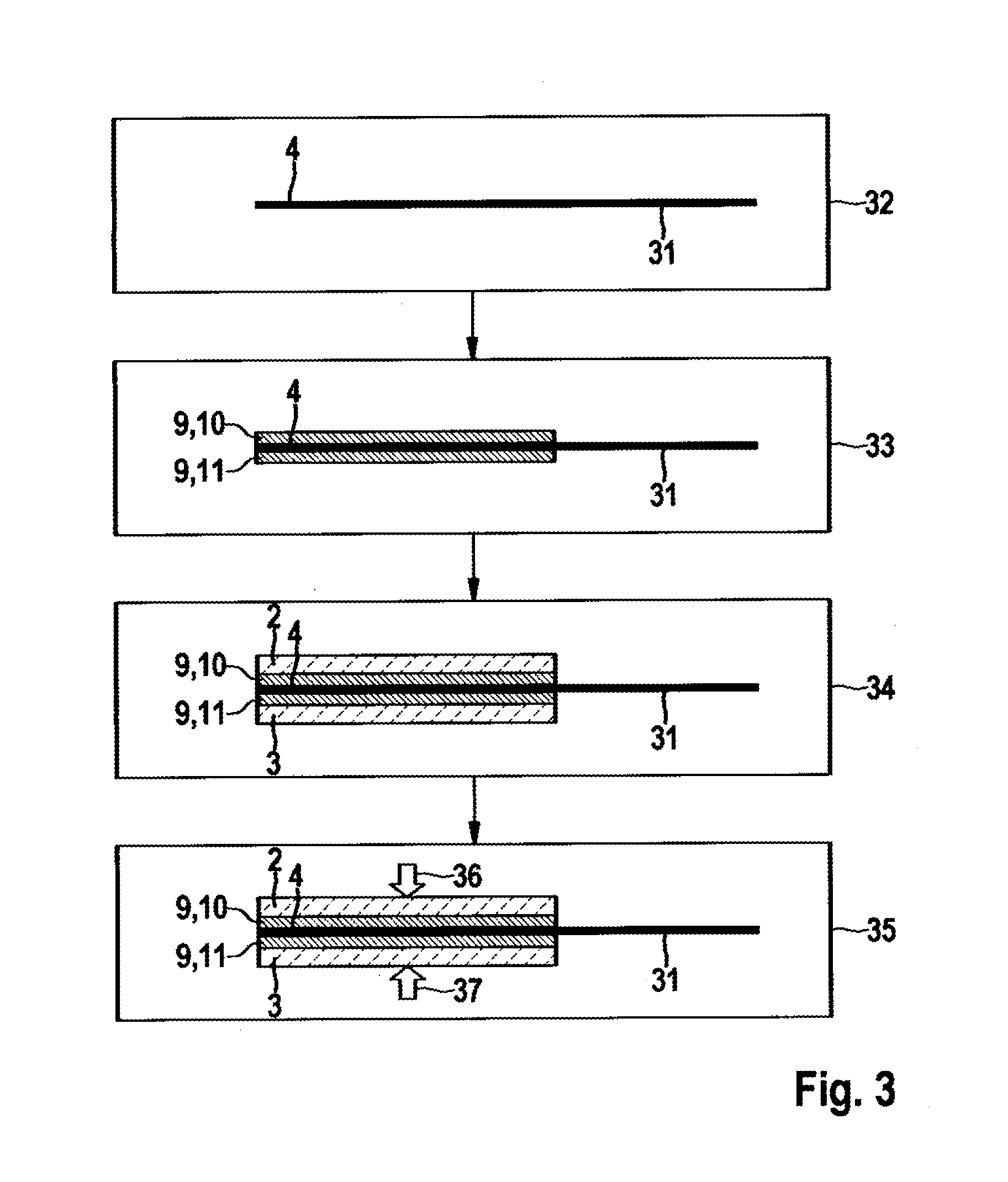

Piezoelectric component and method for producing a piezoelectric component

InactiveUS20140191620A1Improve conductivityOptimal signal generationPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesEngineeringContact layer

An electrically conductive contact layer (4) is provided with a joining material (9) during a method for producing a piezoelectric component (1), in particular a piezoelectric sensor (1). To this end, the electrically conductive contact layer (4) can be dipped into a paste that serves to form the joining material (9). The contact layer (4) provided with the joining material (9) is subsequently disposed between a first piezoceramic layer (2) and a second piezoceramic layer (3). The contact layer (4) is then inserted via the joining material (9) between the first piezoceramic layer (2) and the second piezoceramic layer (3), wherein a pressure is applied to the first piezocermaic layer (2) against the second piezoceramic layer (3).

Owner:ROBERT BOSCH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com