Patents

Literature

75results about How to "Avoid blanking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

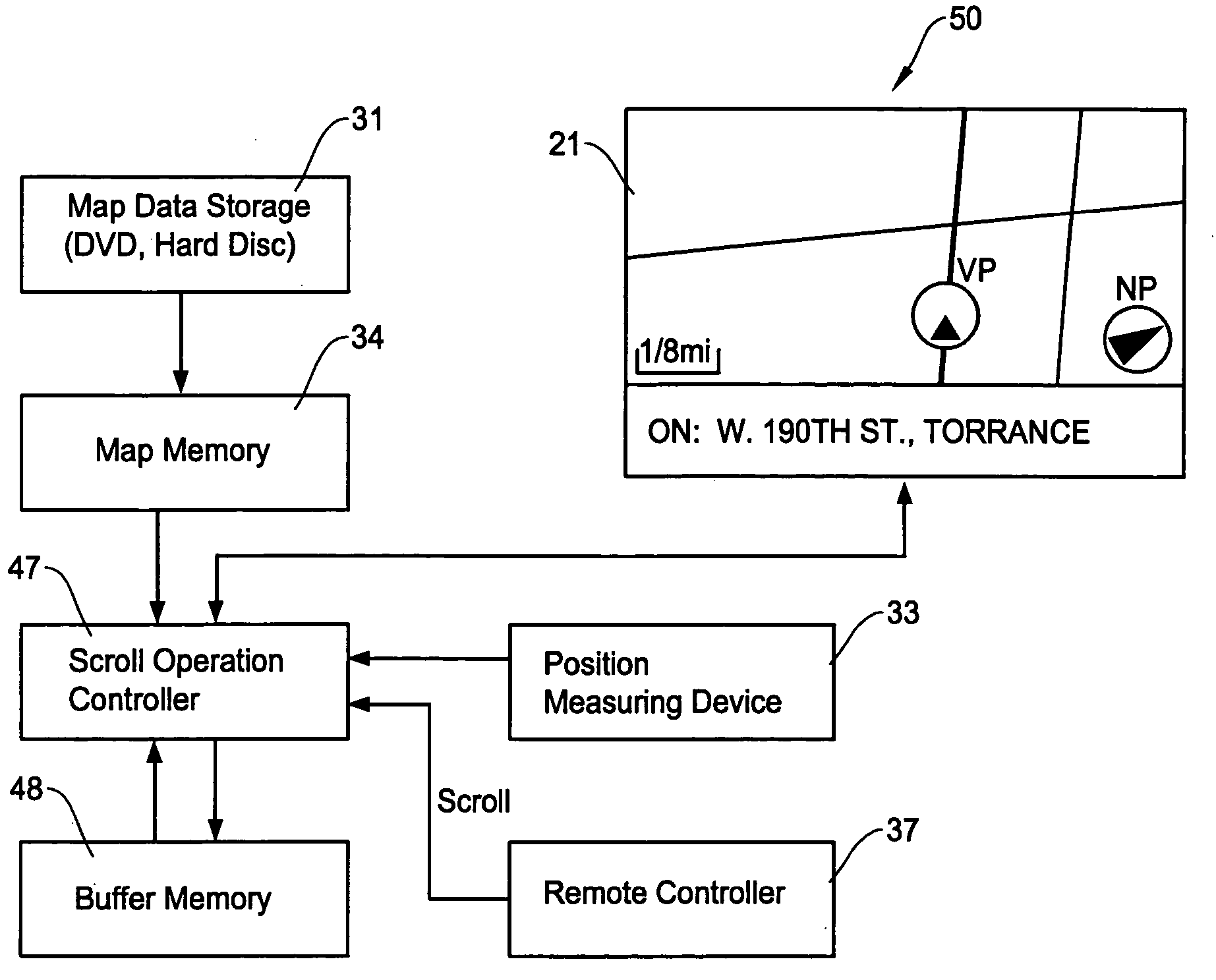

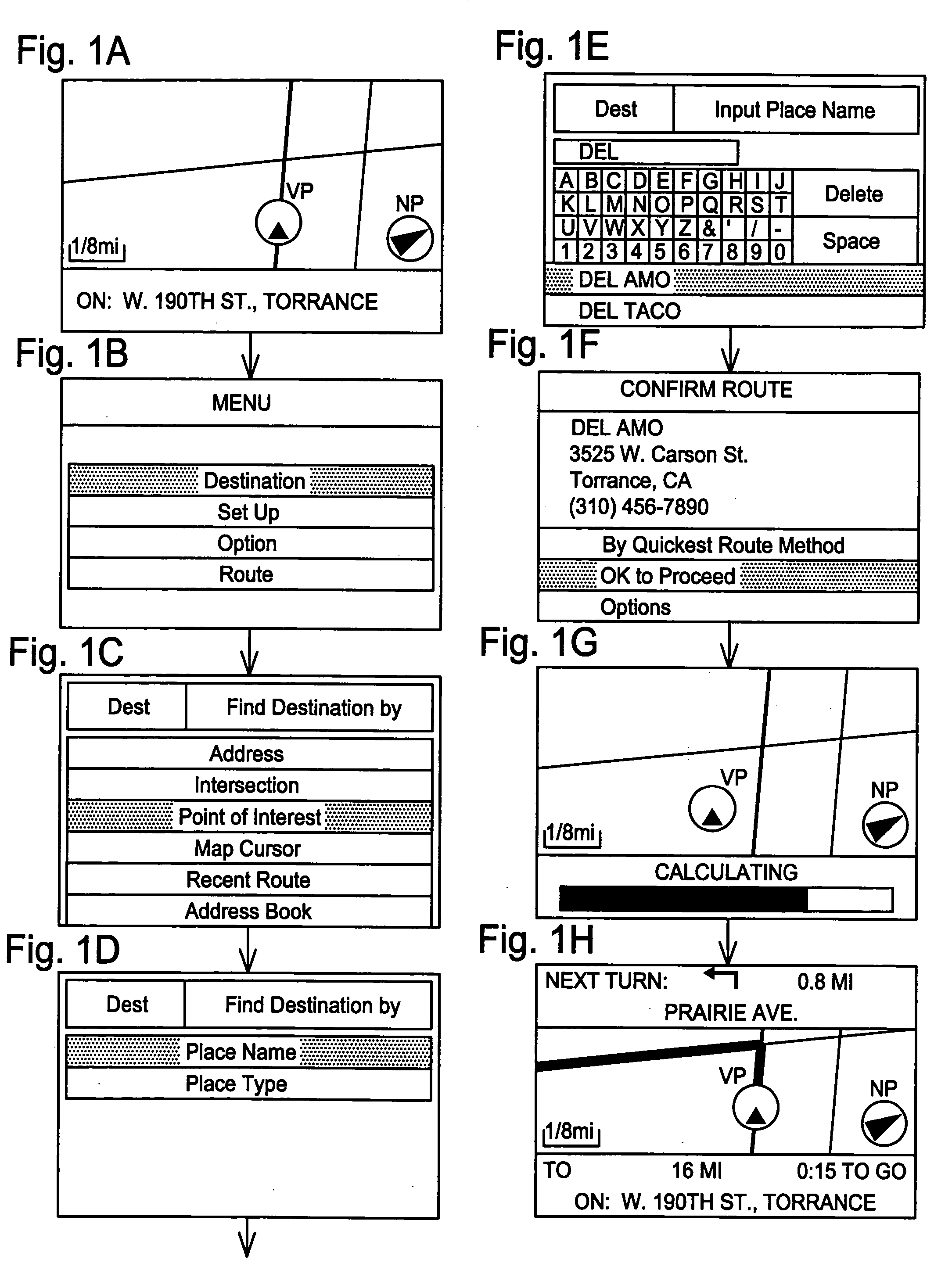

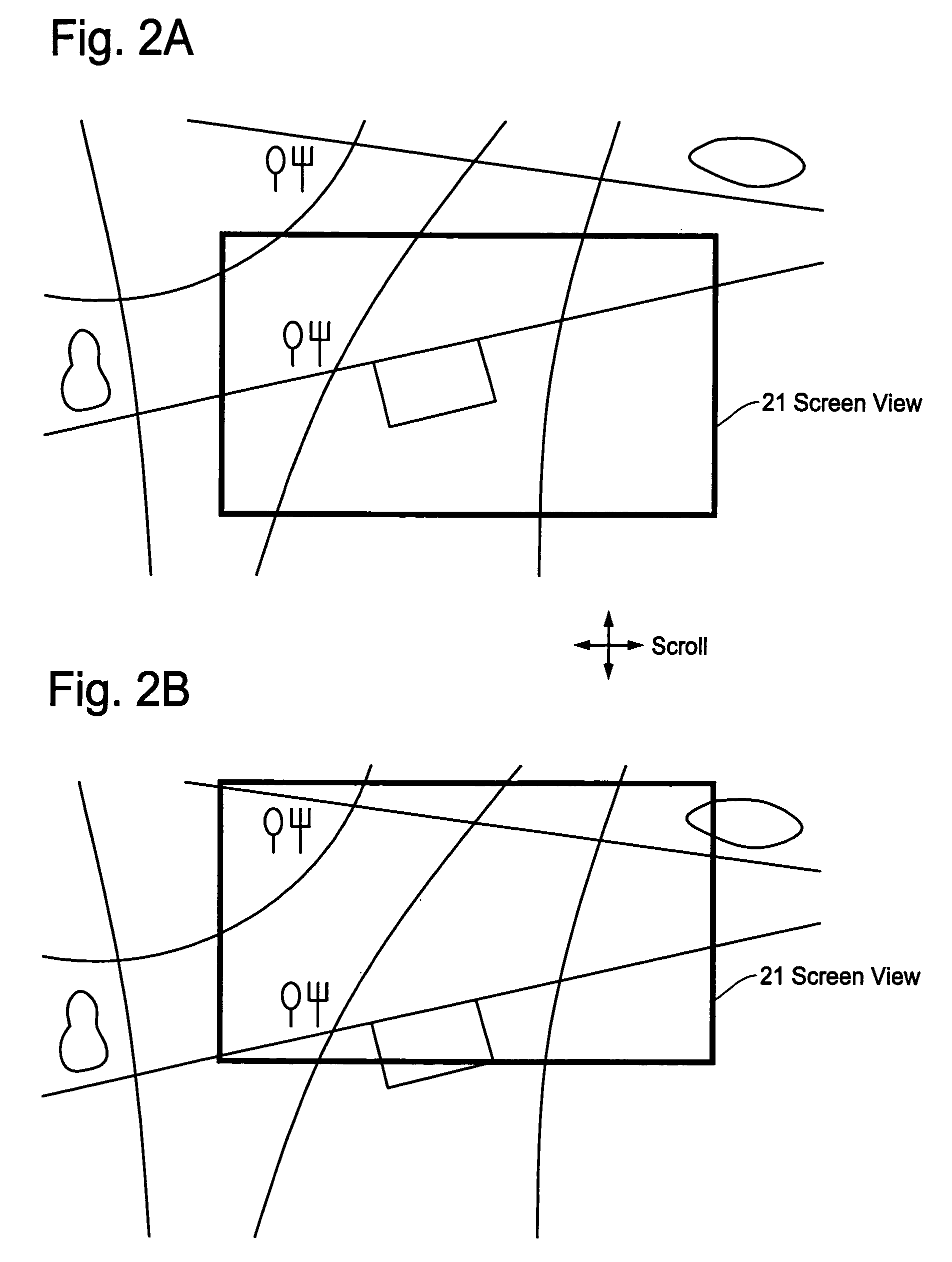

Display method and apparatus for navigation system

InactiveUS20050177305A1Avoid blankingEasy to operateInstruments for road network navigationRoad vehicles traffic controlFelt UneasyNavigation system

A display method and apparatus for a navigation system which is capable of preventing blank scroll of a display screen when there is no visible objects within a display range when the screen is scrolled and immediately jumping to the screen where a visible object exists. When a display screen is scrolled, if there is no visible object within a display range of the scroll for a relatively long period of time, the display screen just shows a blank screen, which may confuse the user or make the user feel uneasy. The display method and apparatus avoids the blank scrolling by automatically scrolling to a screen where a visible object is shown.

Owner:ALPINE ELECTRONICS INC

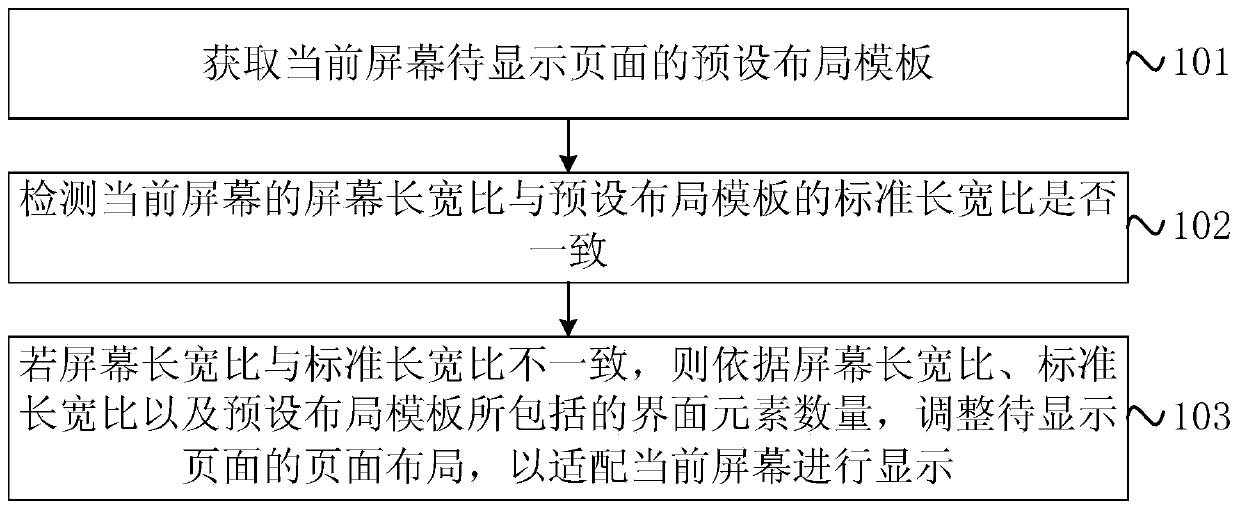

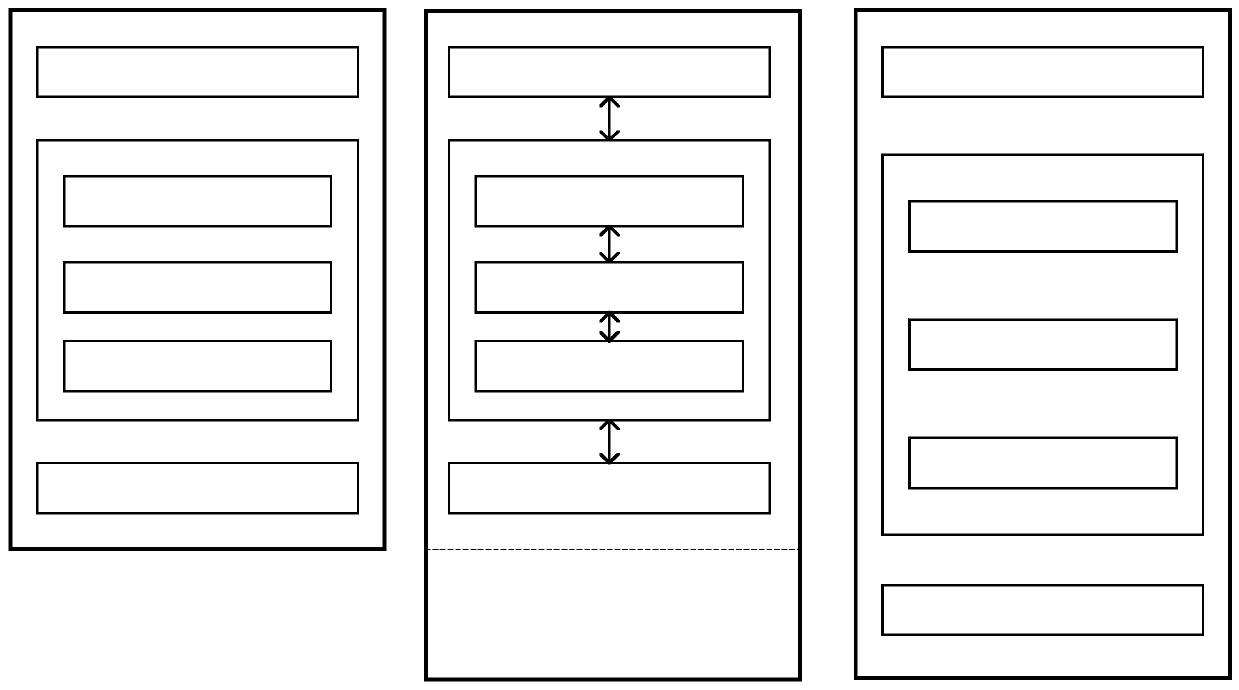

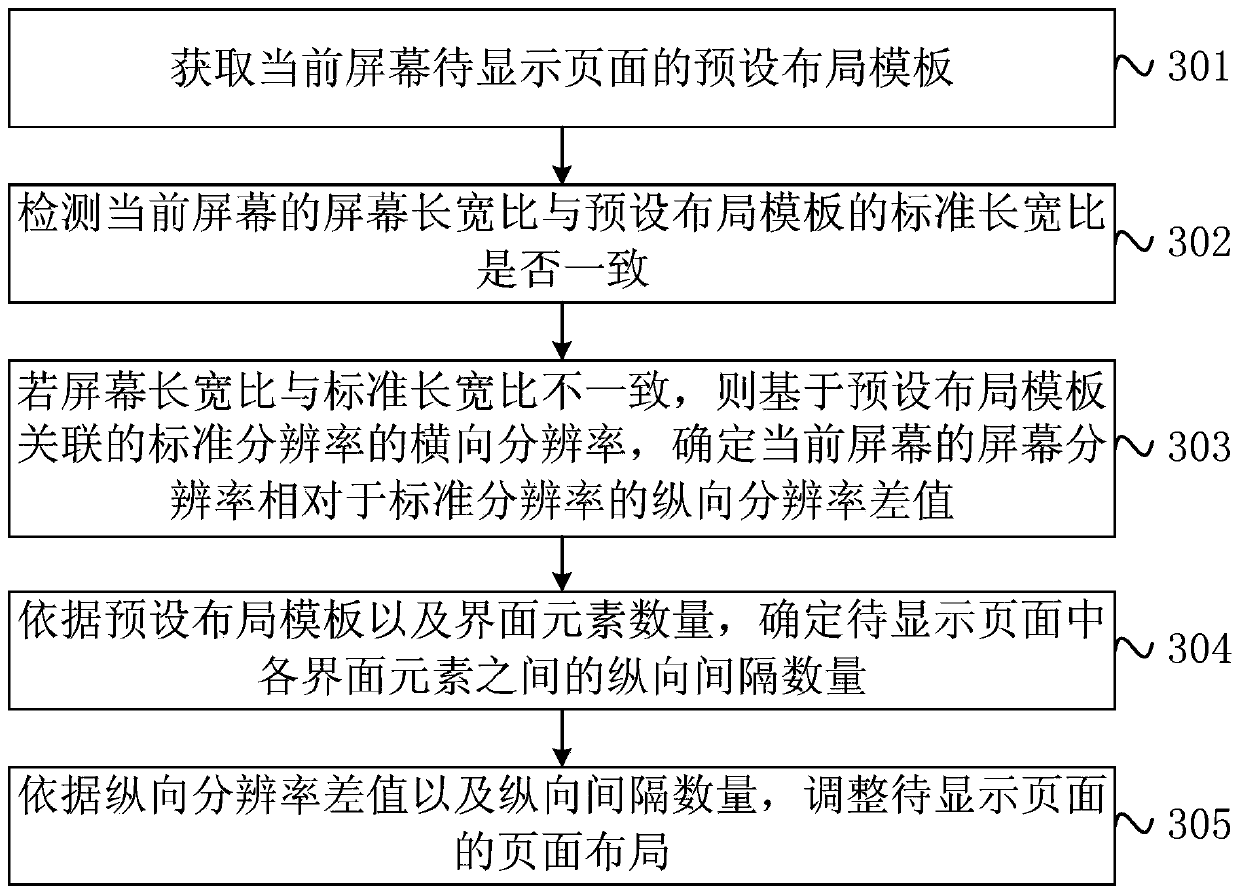

Screen adaptive display method, electronic device and computer storage medium

ActiveCN109783181AImprove aestheticsImprove effectivenessExecution for user interfacesInput/output processes for data processingOn-screen displayWidth ratio

The embodiment of the invention discloses a screen adaptive display method, an electronic device and a computer storage medium. The screen adaptive display method is used for adjusting page layout tobe adaptive to screen display. The method comprises: acquiring a preset layout template of a current screen to-be-displayed page; detecting whether the screen length-width ratio of the current screenis consistent with the standard length-width ratio of the preset layout template or not; and if the screen length-width ratio is inconsistent with the standard length-width ratio, adjusting the page layout of the to-be-displayed page according to the screen length-width ratio, the standard length-width ratio and the number of the interface elements included in the preset layout template so as to adapt to the current screen for display. So visible, According to the scheme, adaptive display of the to-be-displayed page on the current screen can be achieved by adjusting the page layout, the phenomenon that a large number of blank spaces exist in the page or the page cannot be completely displayed is avoided, and therefore the page information display effectiveness, the page display attractiveness and the user experience of users to which intelligent devices of different screen specifications belong are improved.

Owner:ZHANGYUE TECH CO LTD

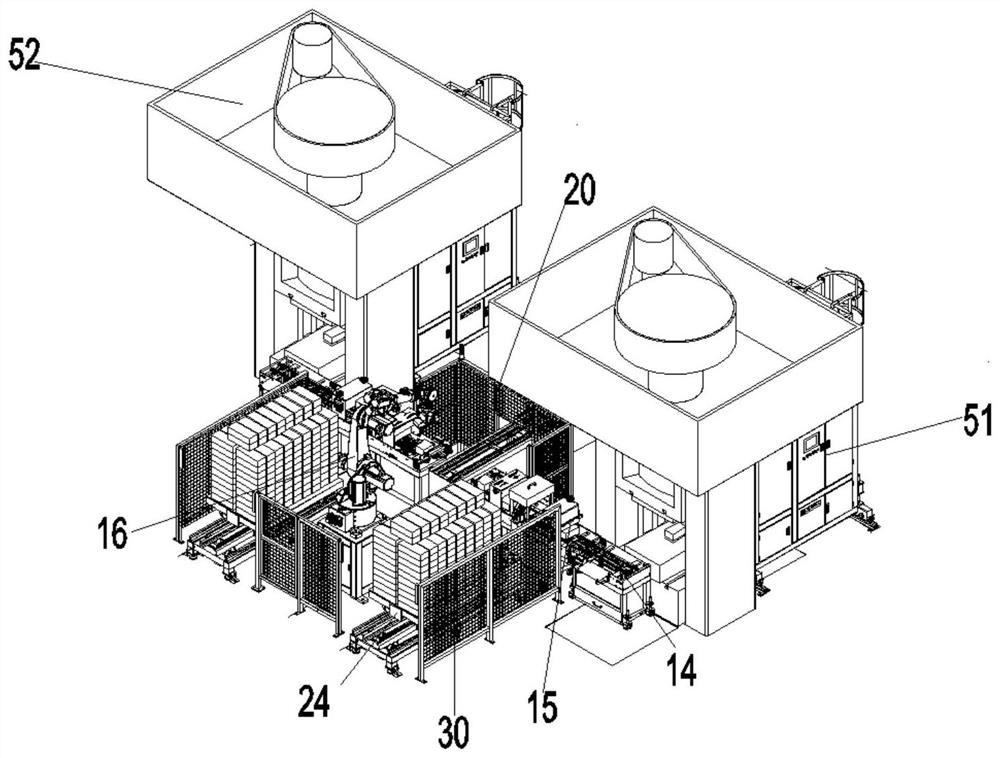

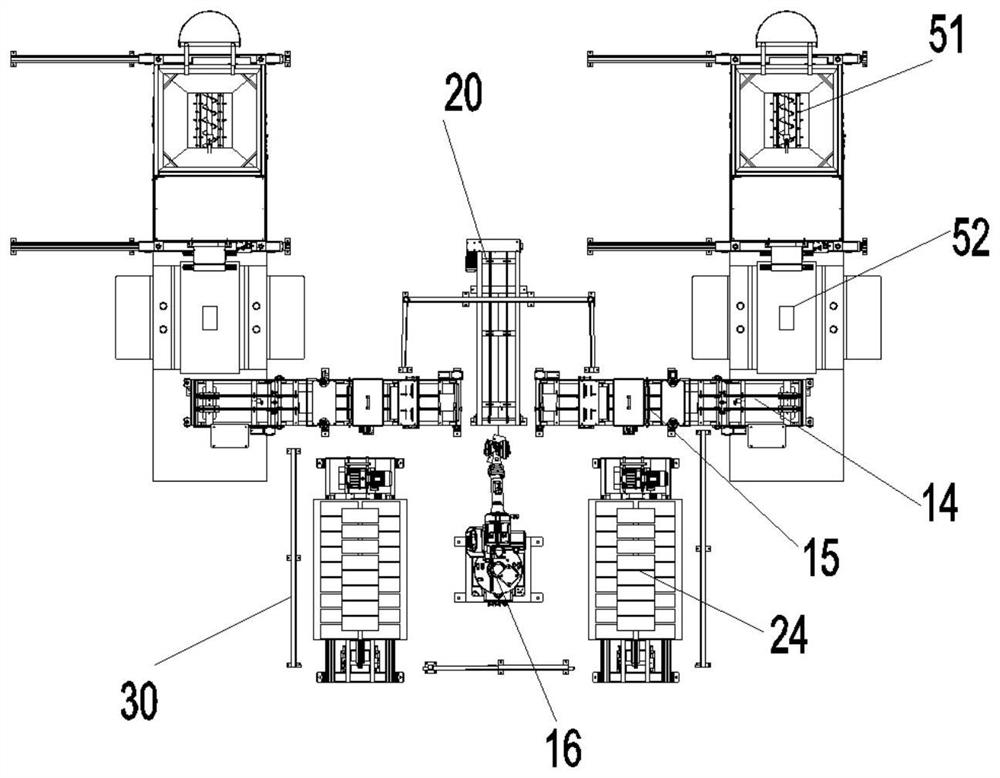

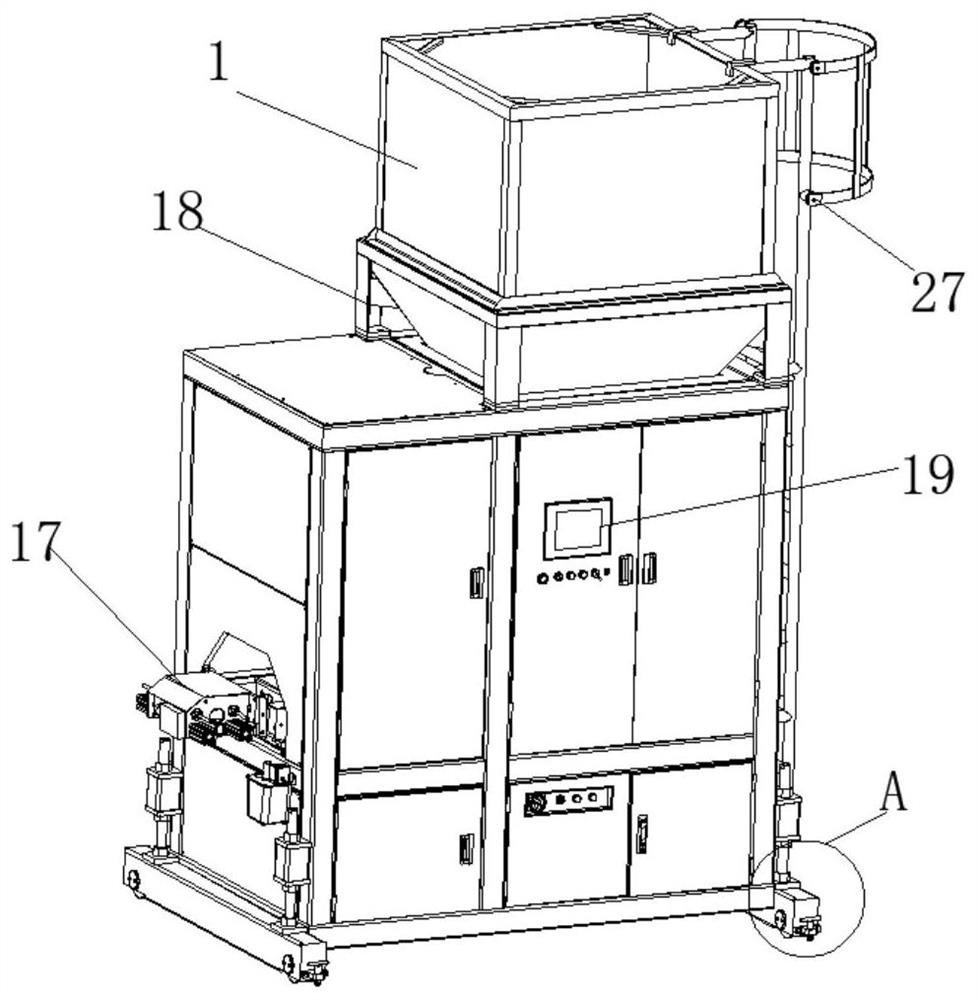

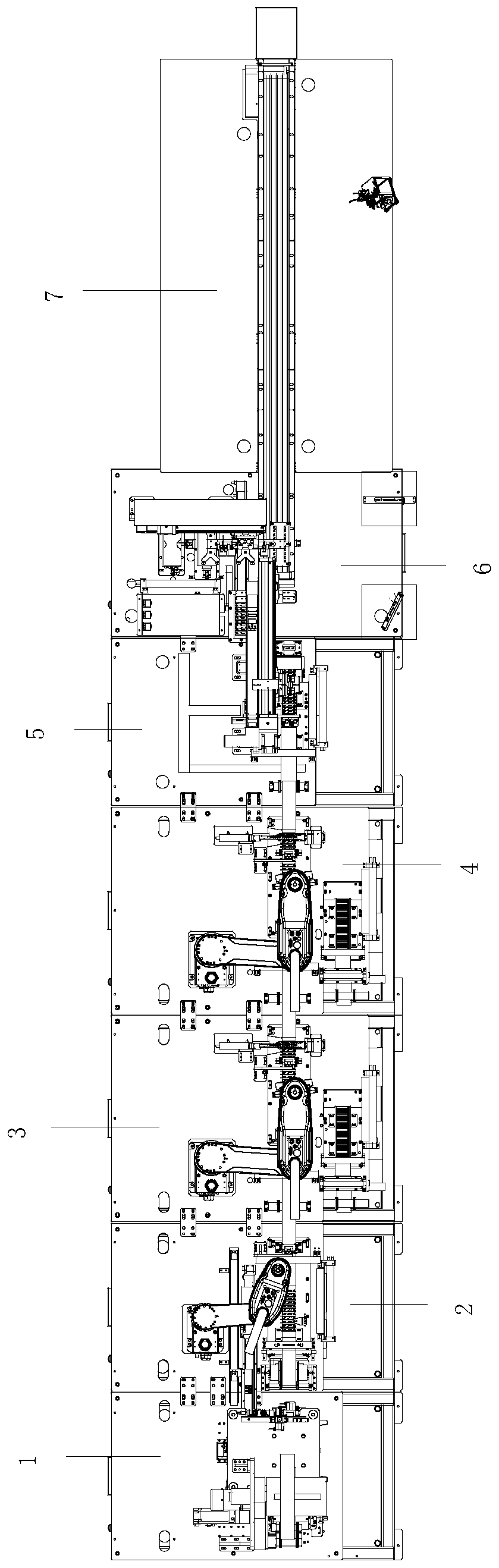

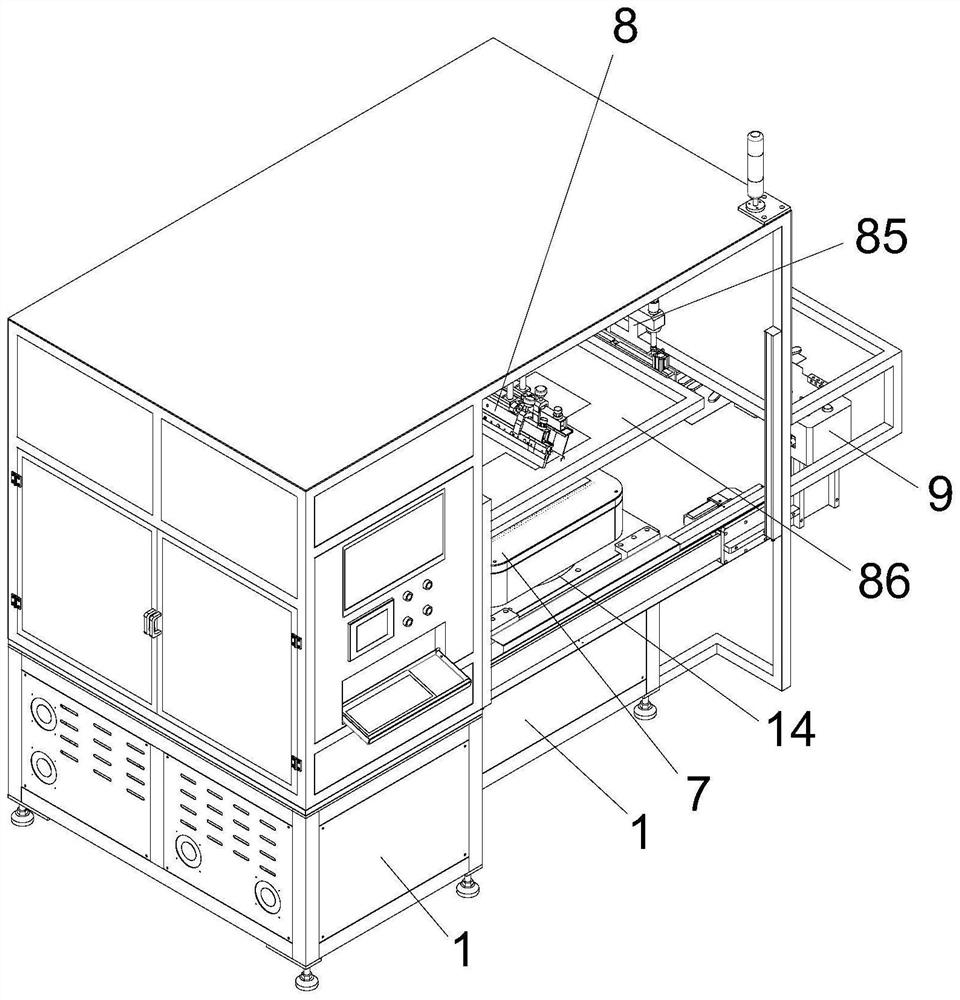

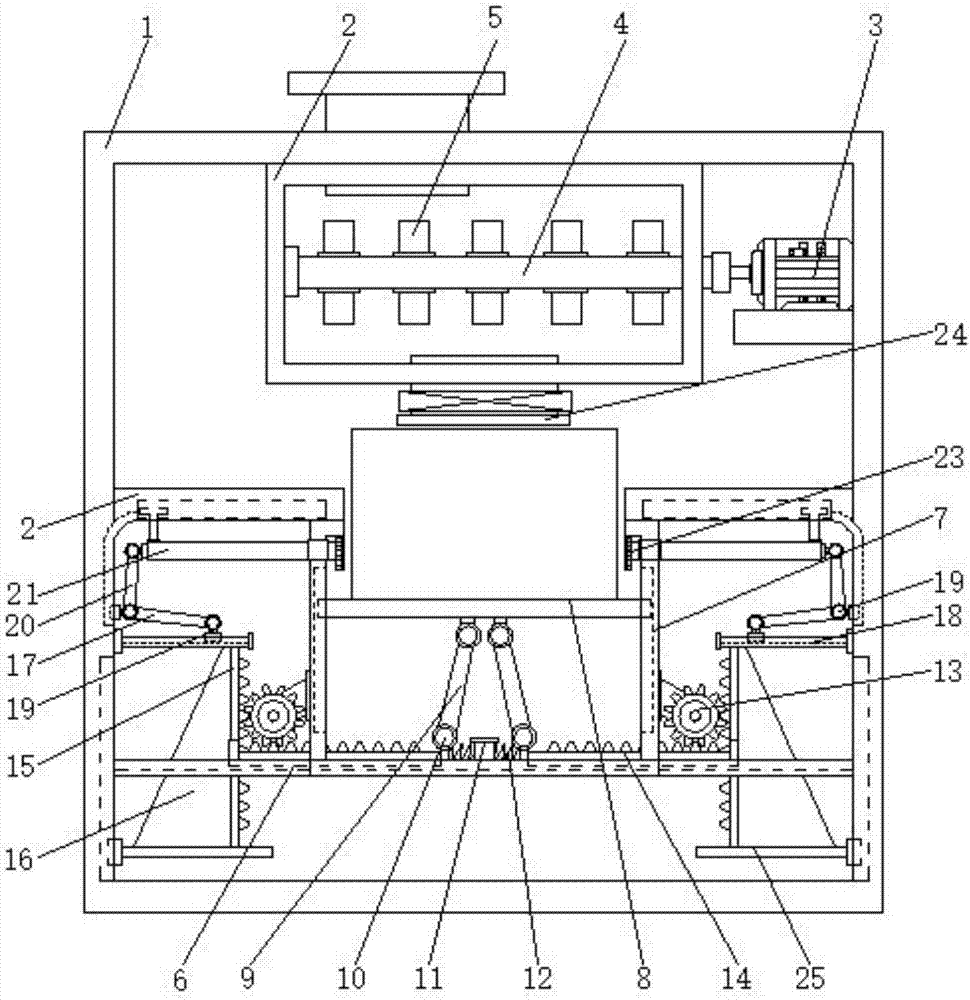

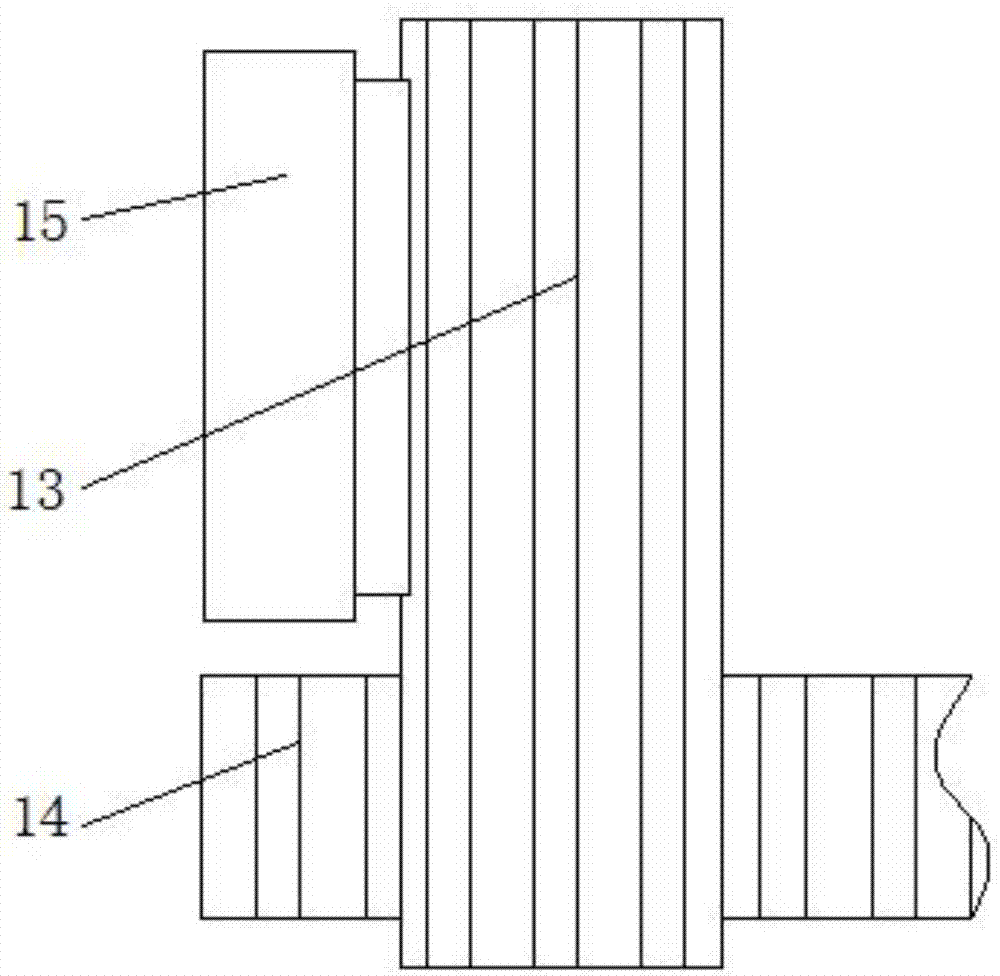

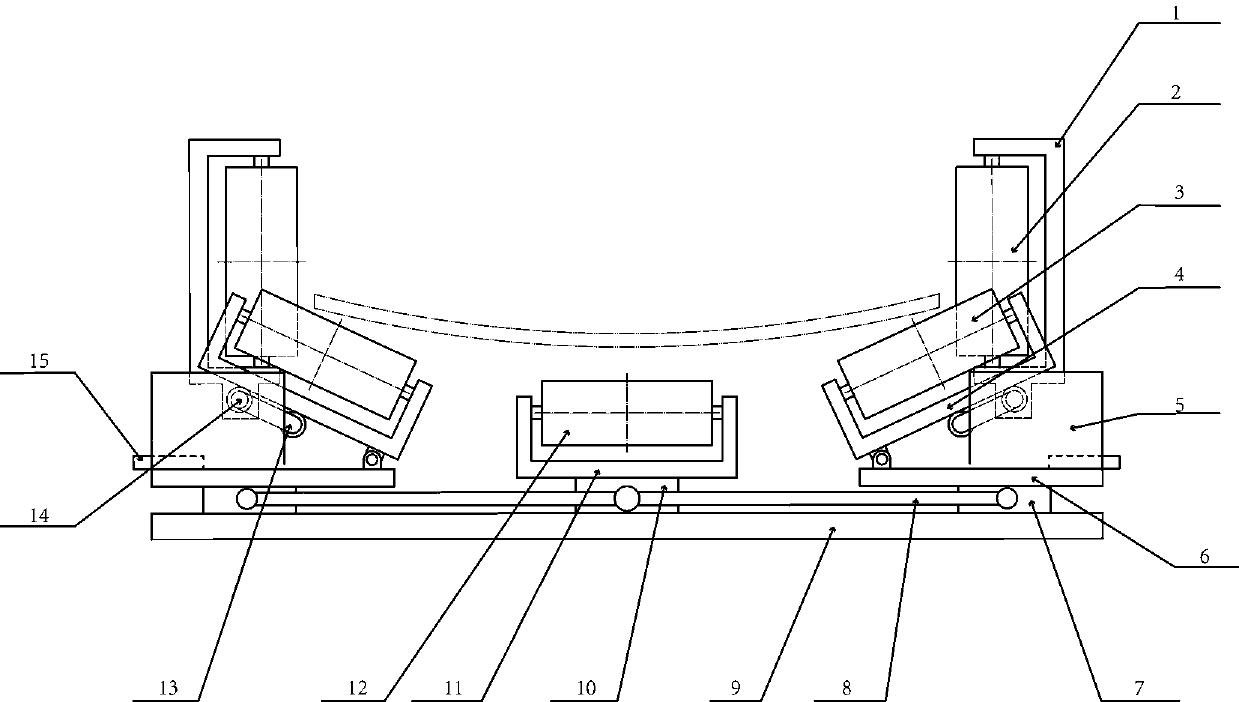

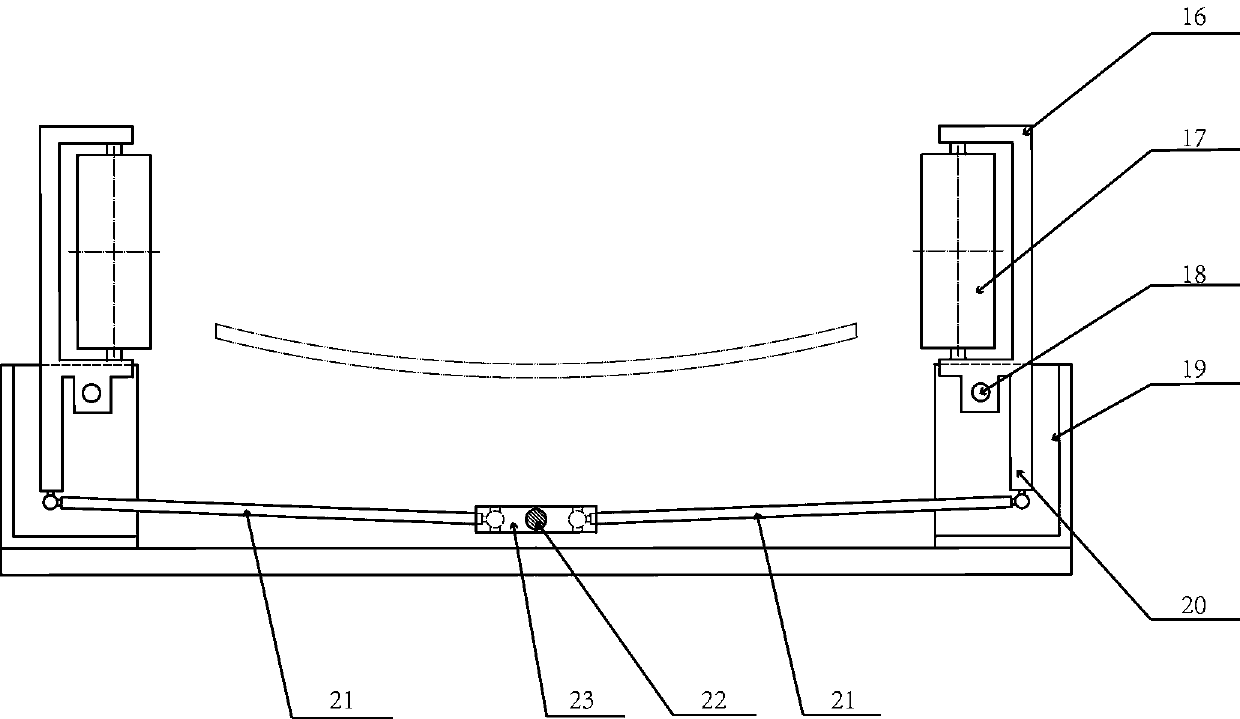

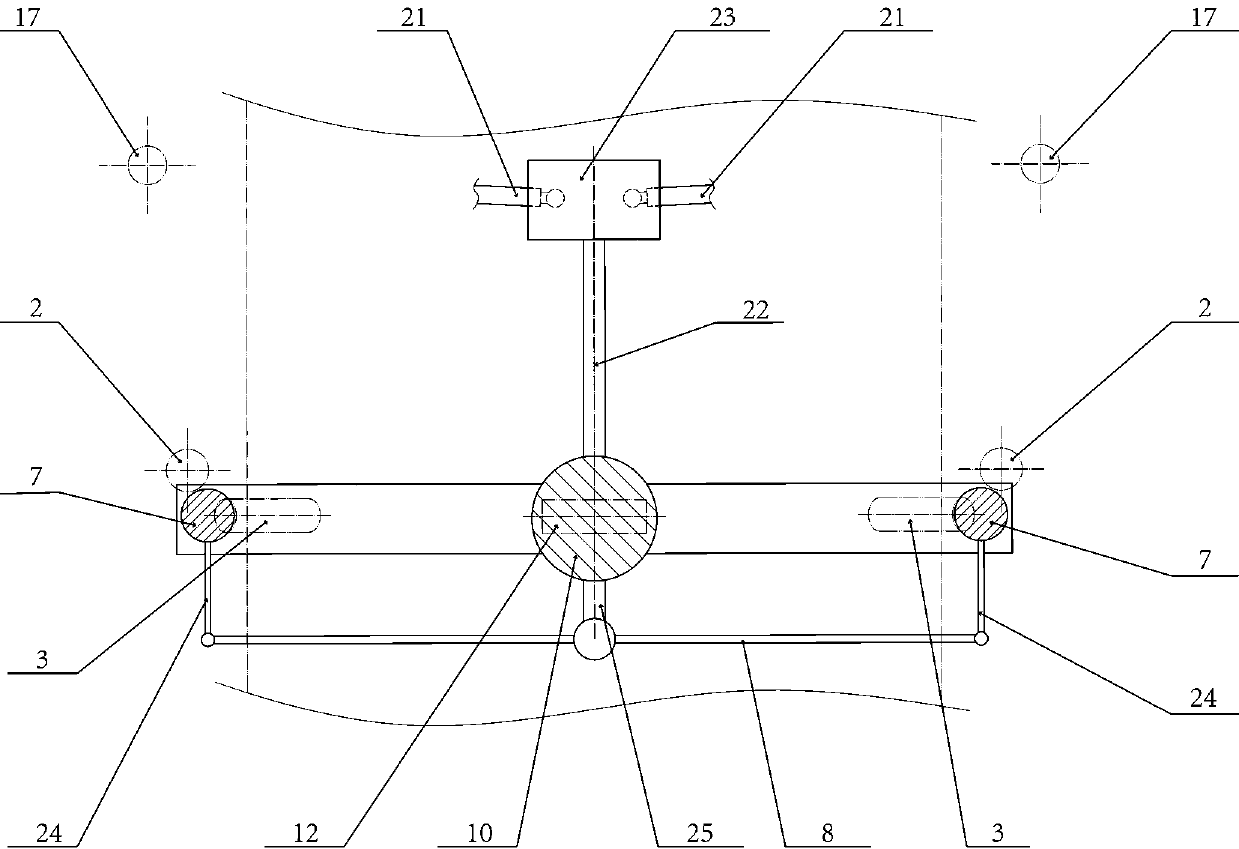

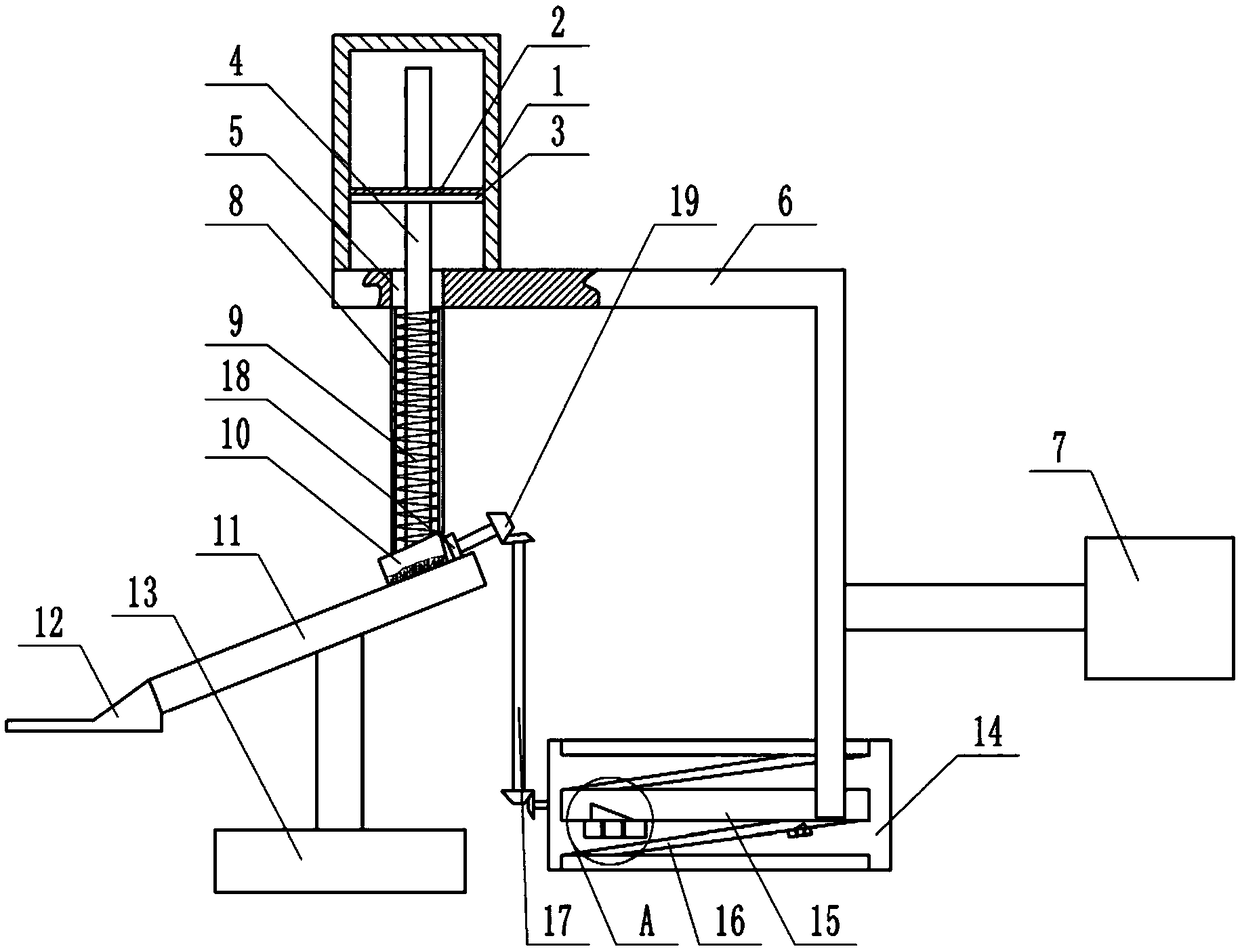

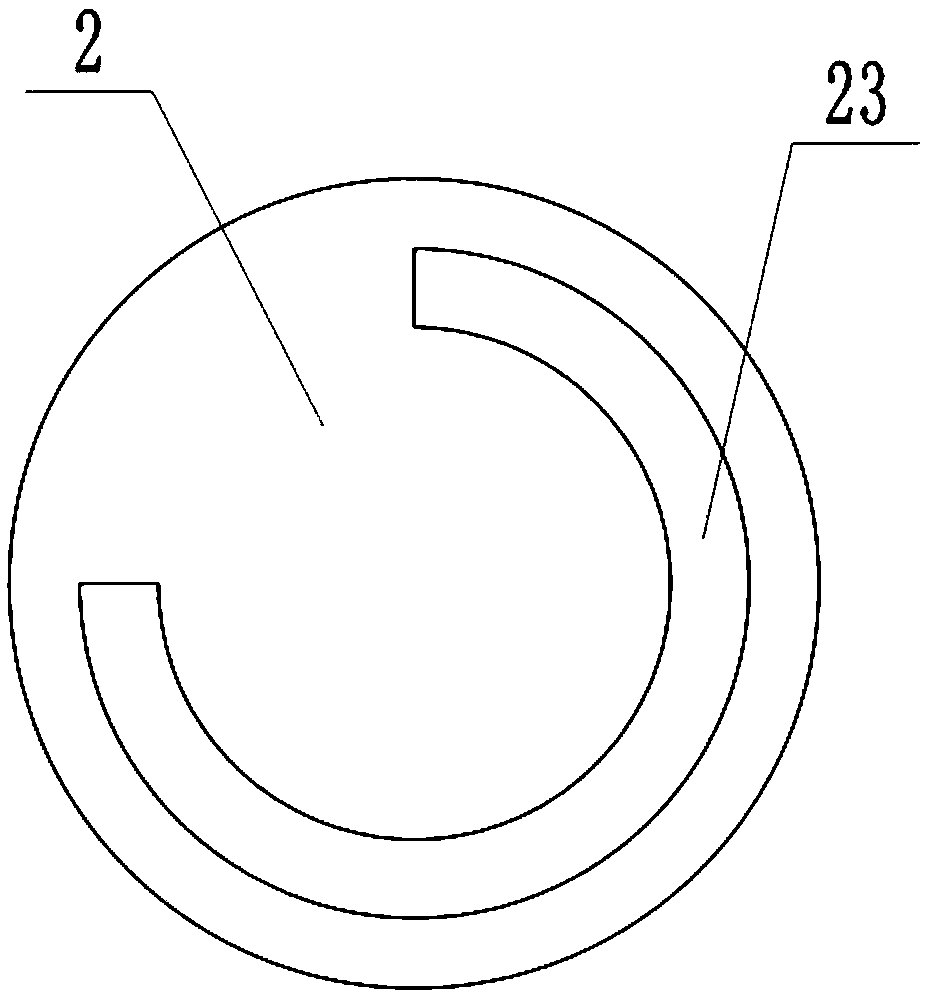

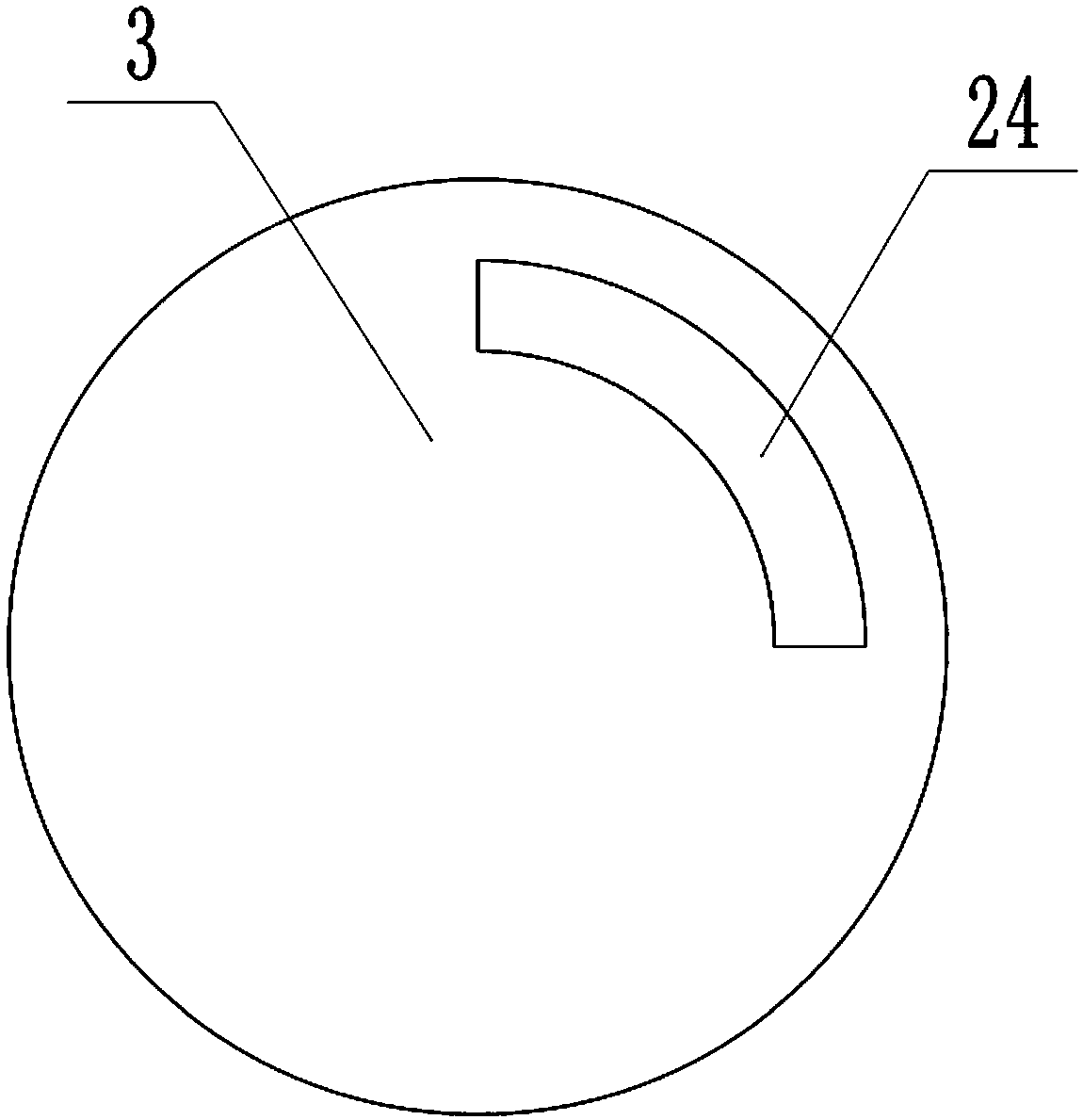

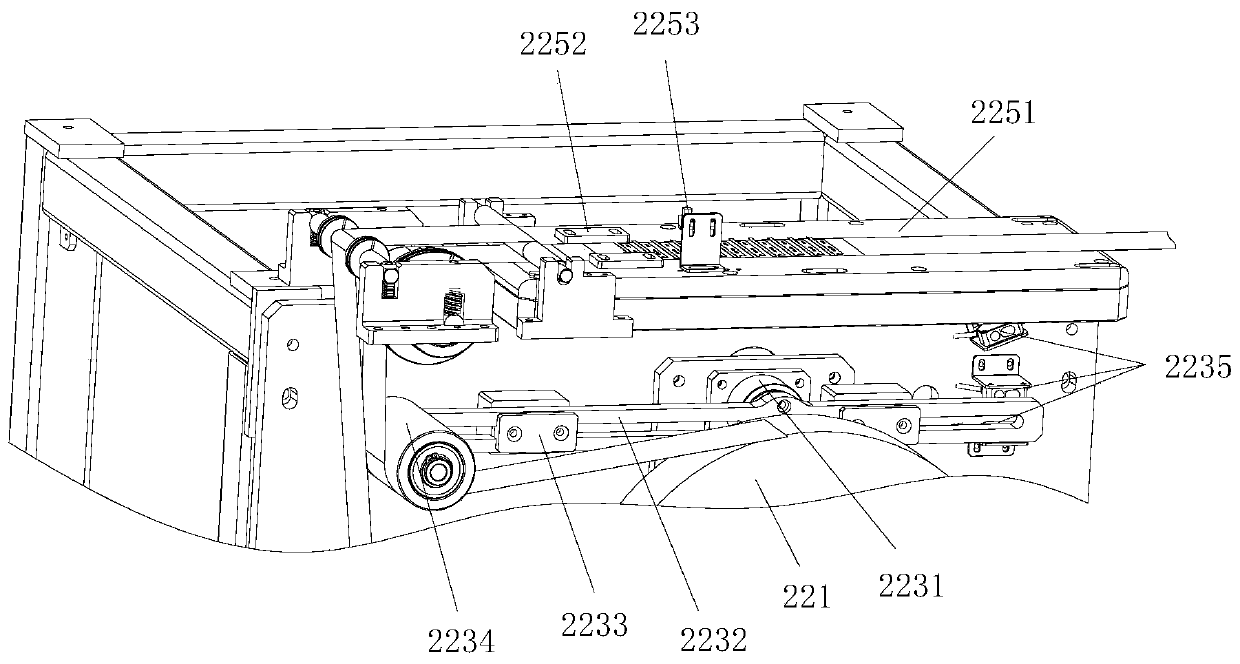

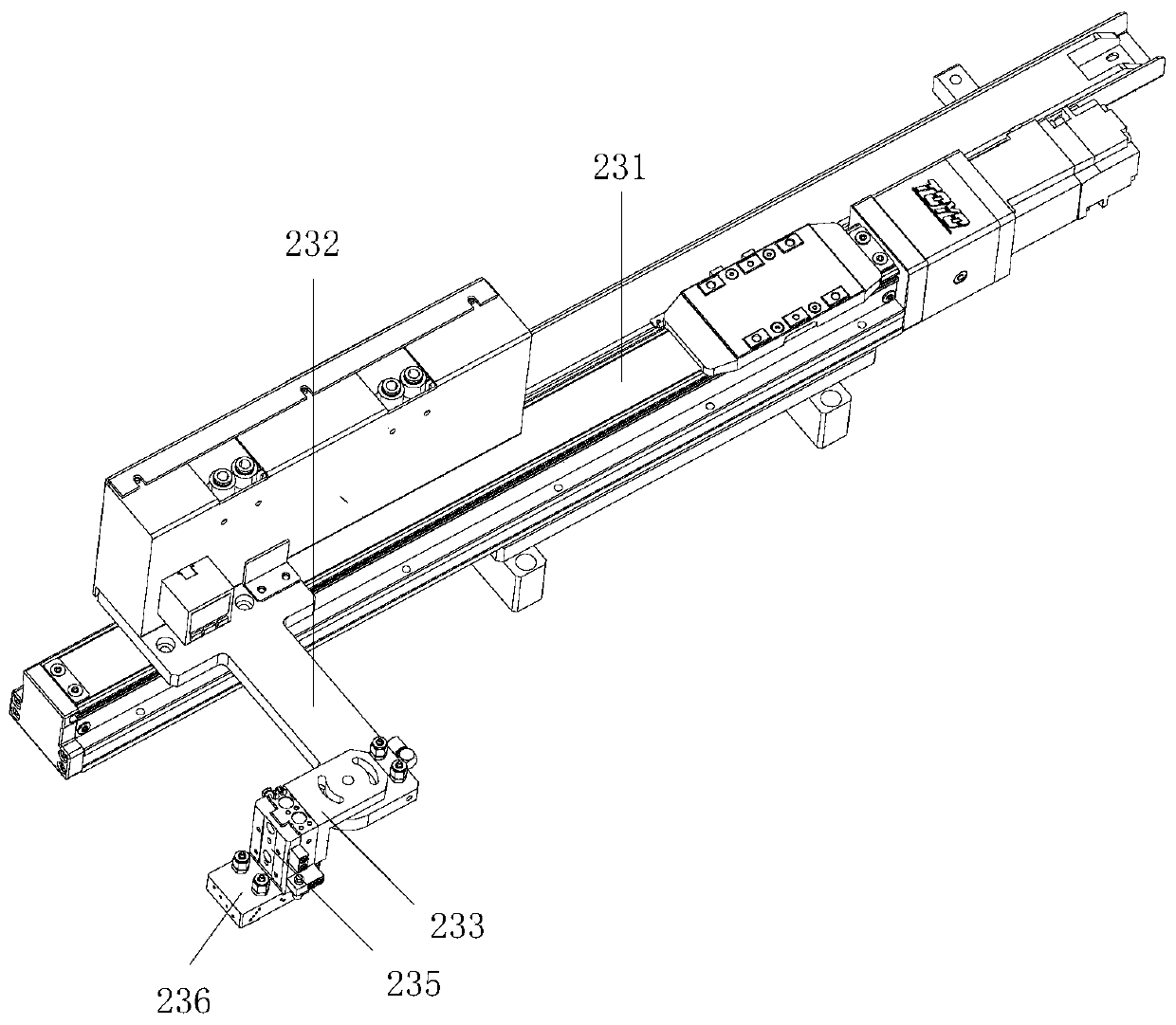

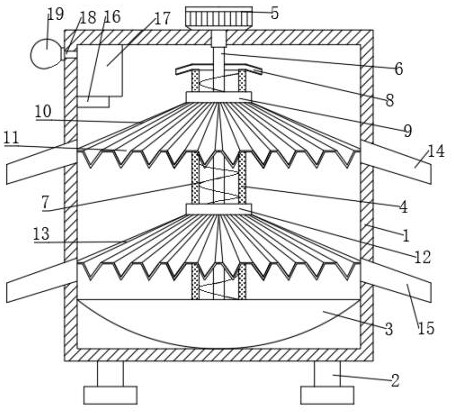

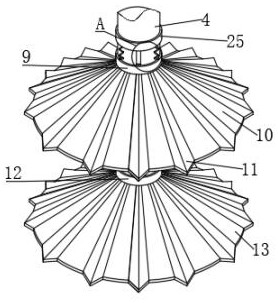

Full-automatic production system for refractory bricks

ActiveCN111702949AOvercoming automationOvercome efficiencyDischarging apparatusMixing operation control apparatusFire brickProcess engineering

The invention discloses a full-automatic production system for refractory bricks. The system is sequentially provided with automatic weighing and distributing devices, pressing machines, brick receiving and conveying tables, detecting machines, a defective product conveying table, a brick taking and stacking device and kiln car positioning areas according to refractory brick forming procedures. According to the system, raw materials are automatically detected and screened after being pressed and formed through the automatic weighing and distributing devices and the pressing machines, the bad bricks are automatically removed, the qualified bricks are stacked and loaded into a kiln car through the brick taking and stacking device, and finally, the kiln car full of the qualified bricks is fedinto a kiln through an intelligent control system for firing, and the finished bricks are obtained; and the full-automatic operation is achieved, the defects that refractory brick manufacturing in the prior art is low in automation degree, low in manufacturing efficiency and the like are overcome, and therefore, the labor cost is reduced, the working efficiency is improved, and meanwhile, the safety risk is greatly reduced, the life safety of people is guaranteed, the influence of dust on the health of people in the brick pressing process is reduced, the labor intensity is reduced, and the problem of difficulty in recruiting workers is solved.

Owner:CHANGXING RONGLI MACHINERY

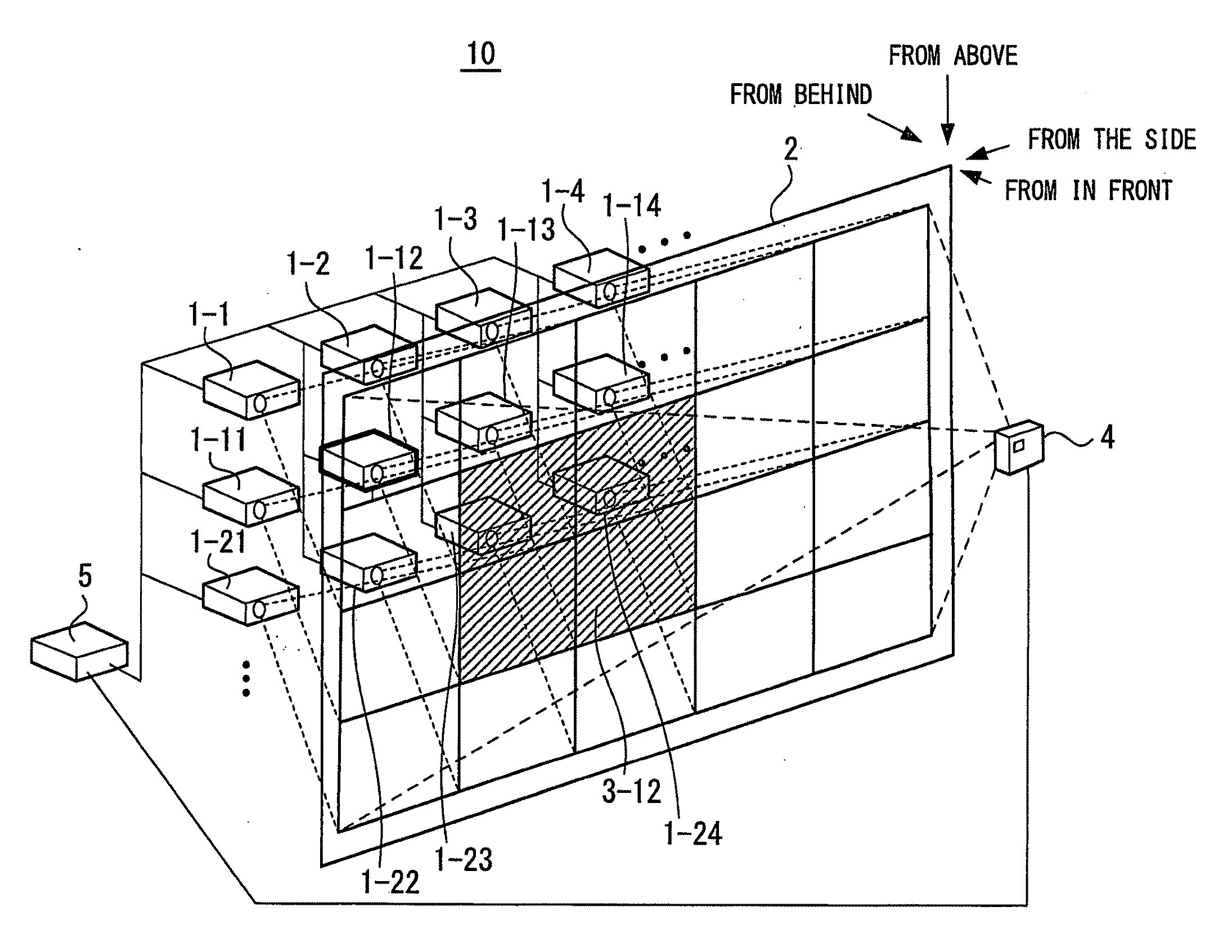

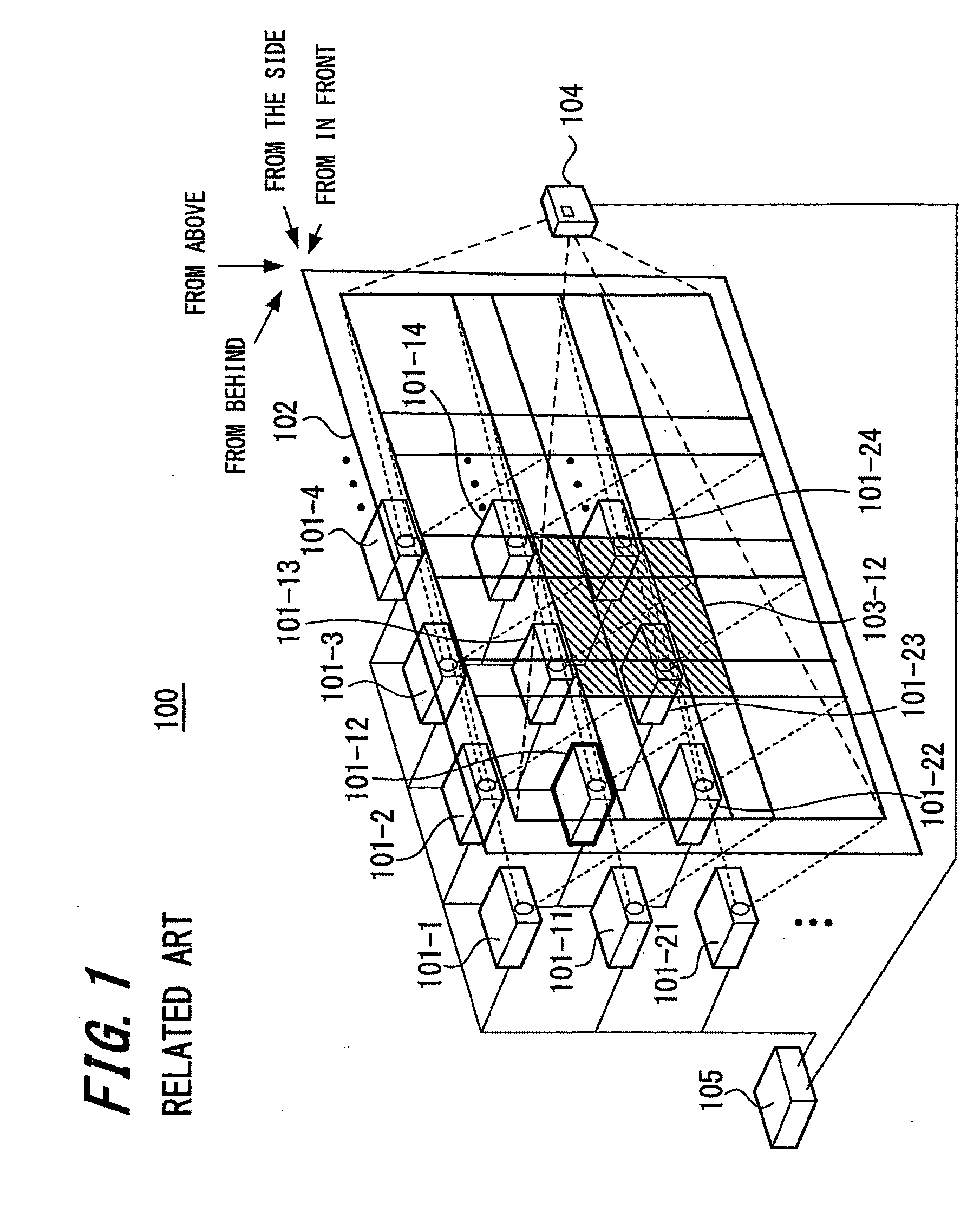

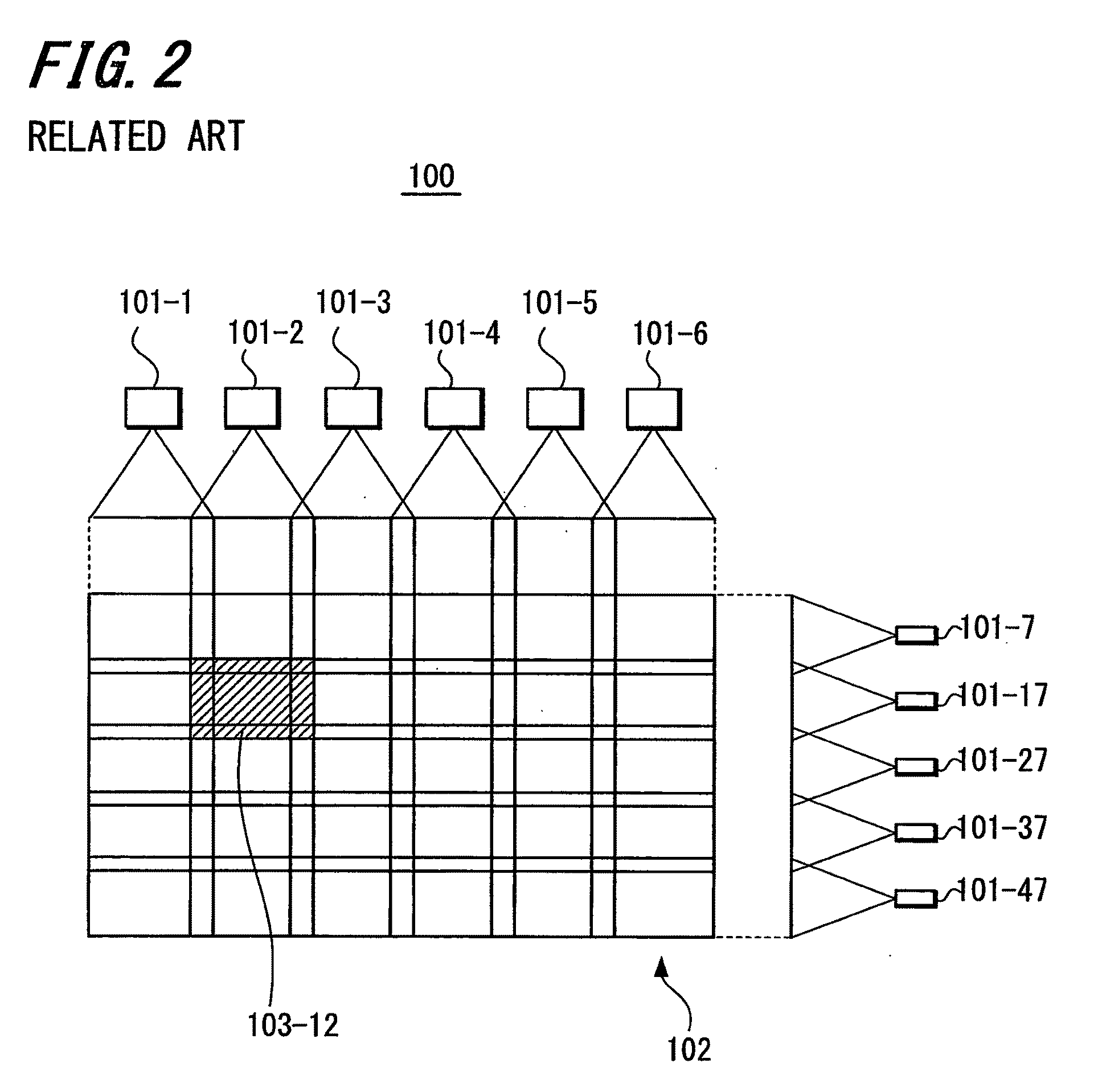

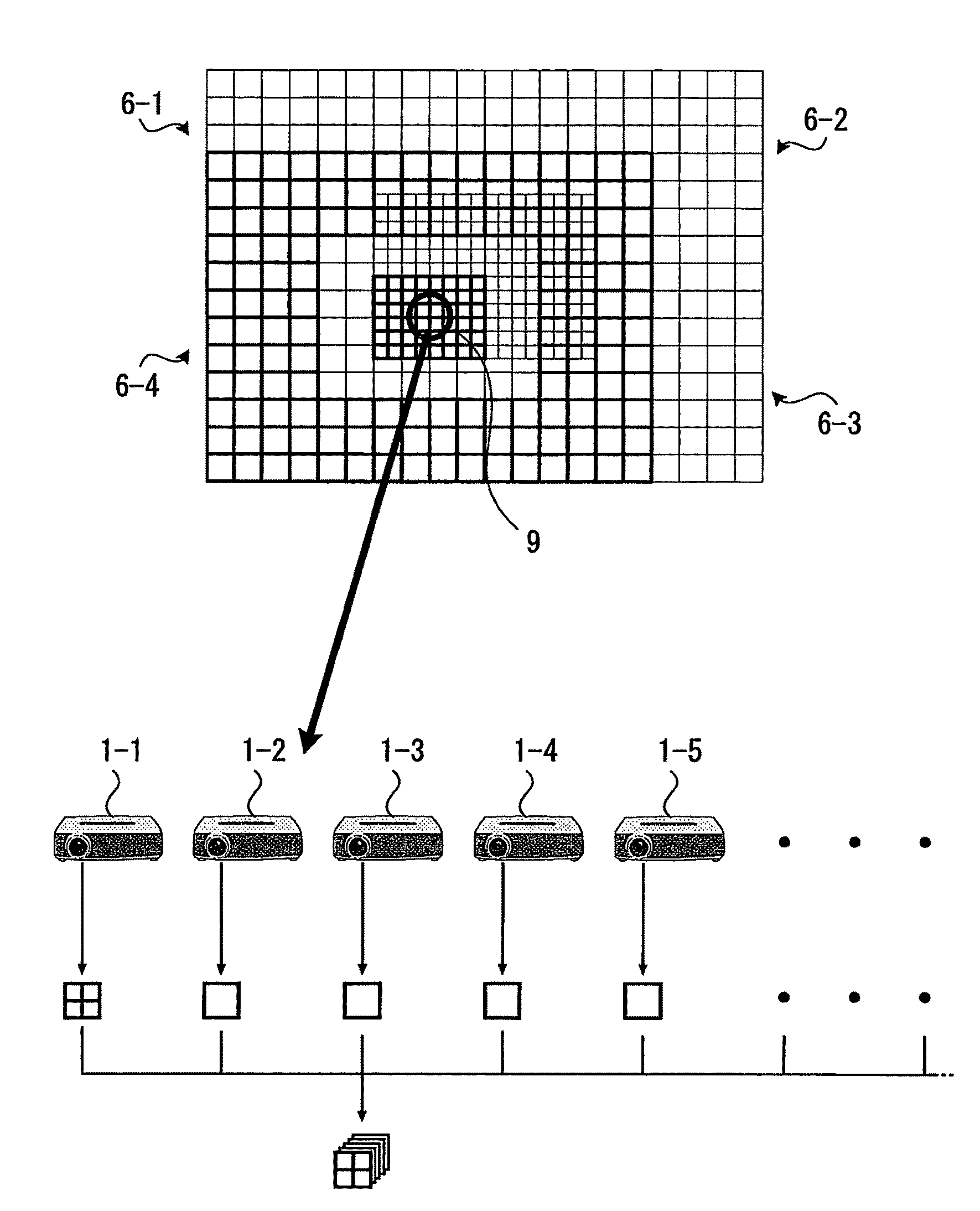

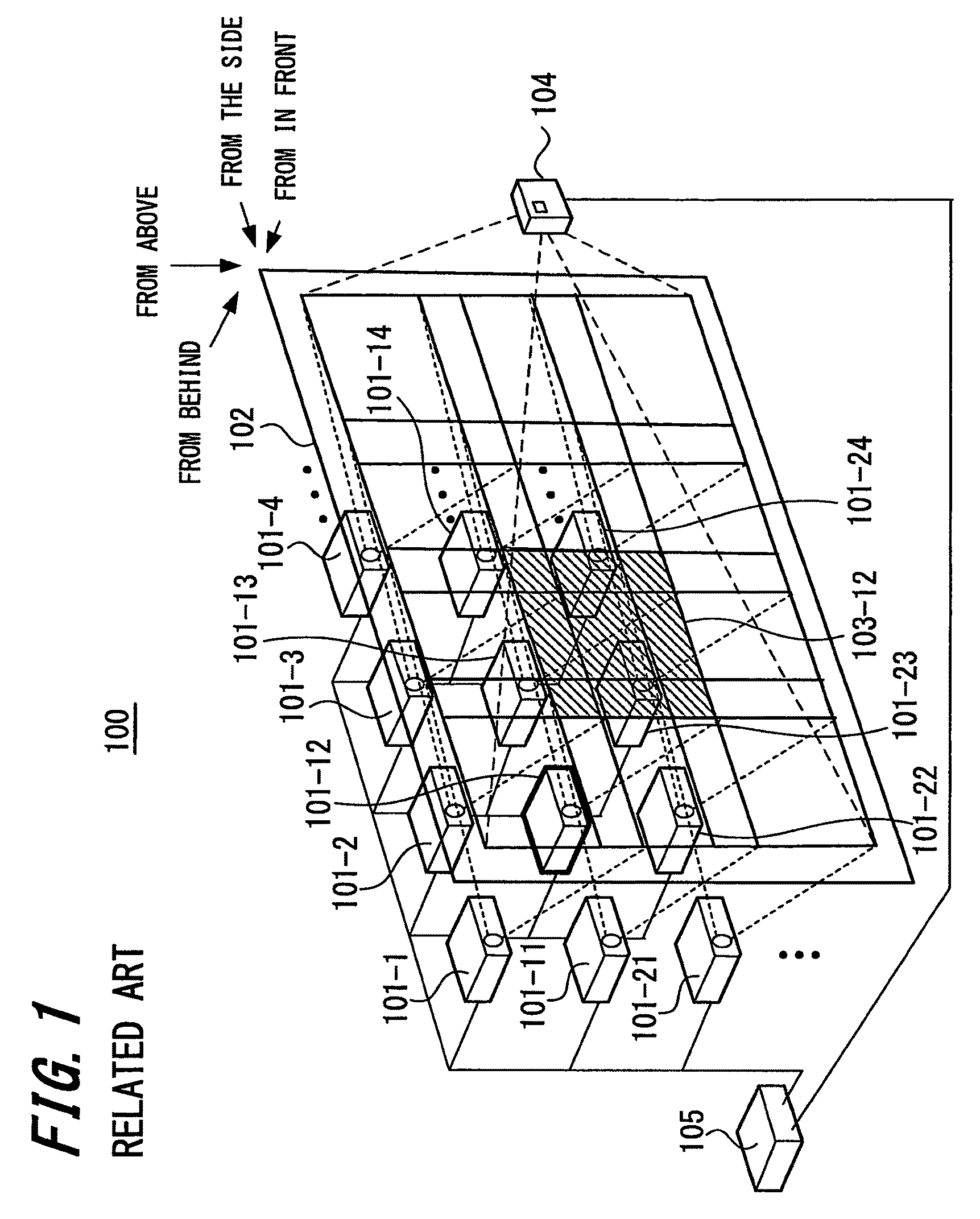

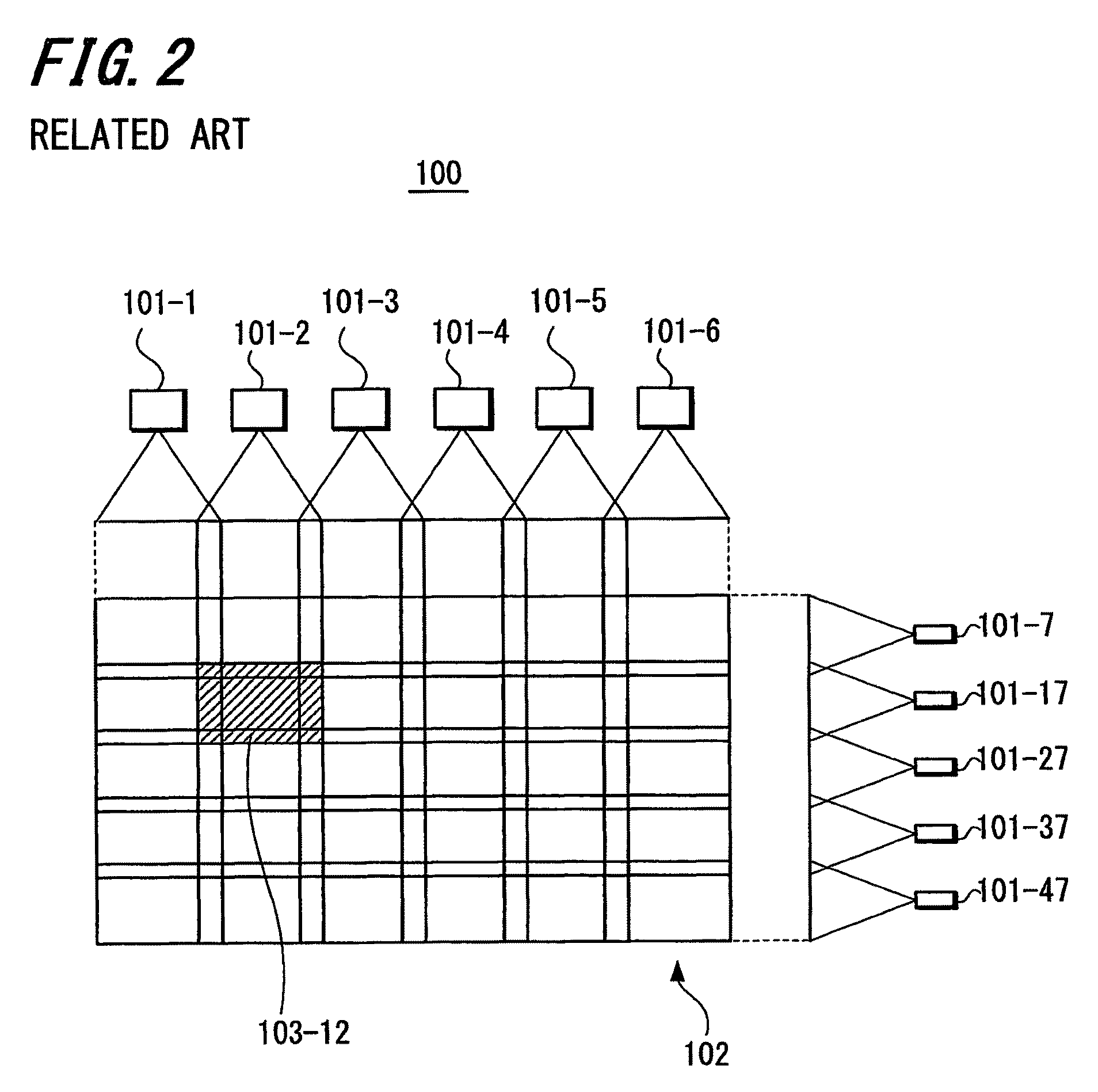

Image projecting system, image projecting method, computer program, and recording medium

InactiveUS20090213335A1Uniform brightnessAvoid blankingProjectorsColor television detailsProjection systemImage signal

An image projecting system is provided. The image projecting system includes a plurality of projector apparatuses, an observation apparatus, and a control apparatus. The projector apparatuses project images based on inputted image signals onto a screen so that the images are displaced relative to one another by a predetermined amount and superimposed. The observation apparatus observes luminance of an image region composed of a plurality of images projected onto the screen by the plurality of projector apparatuses. The control apparatus supplies the plurality of projector apparatuses with the image signals having an adjusted luminance value of each pixel for an image projected by each projector apparatus based on an observation result of the observation apparatus.

Owner:SONY CORP

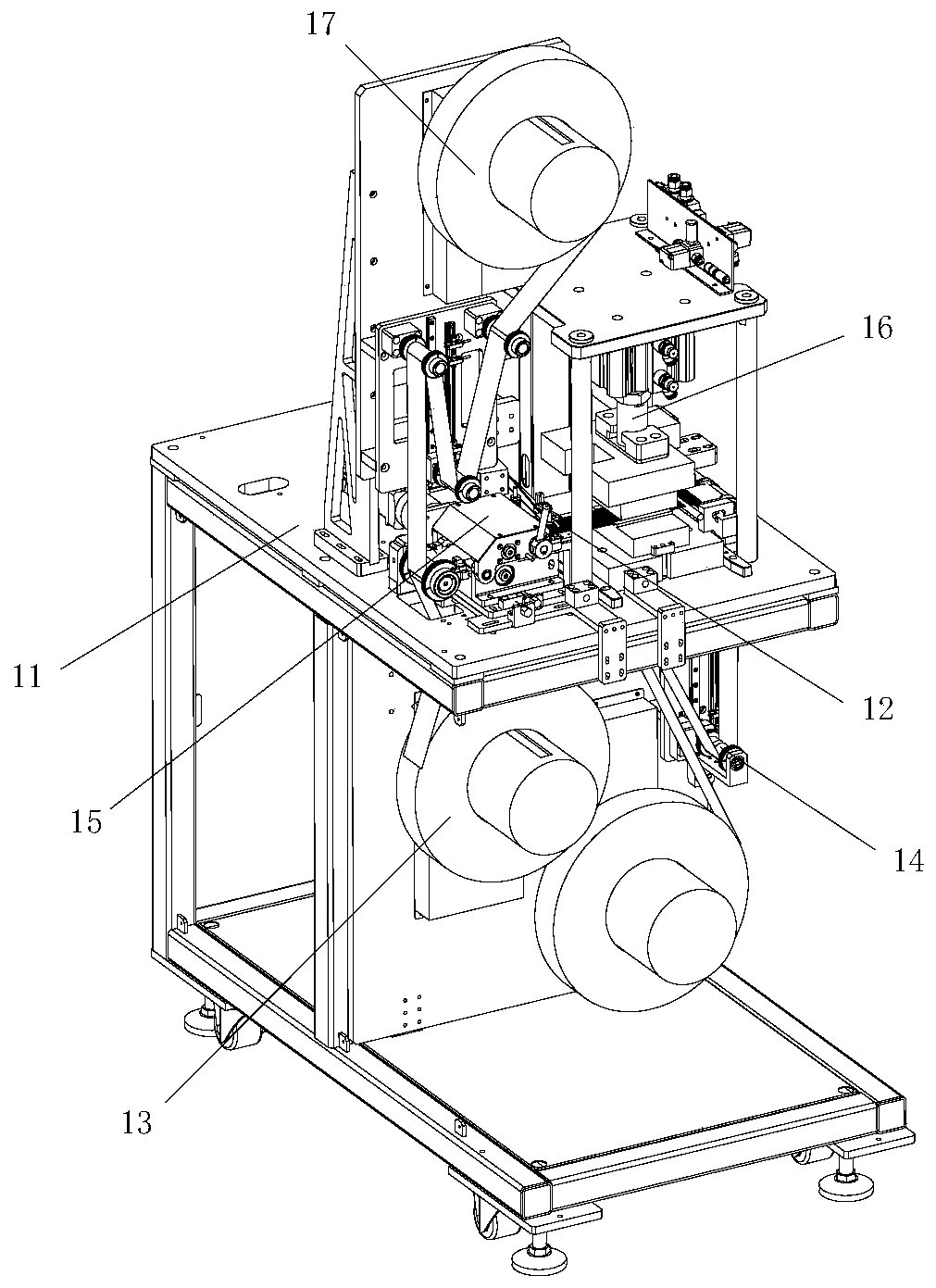

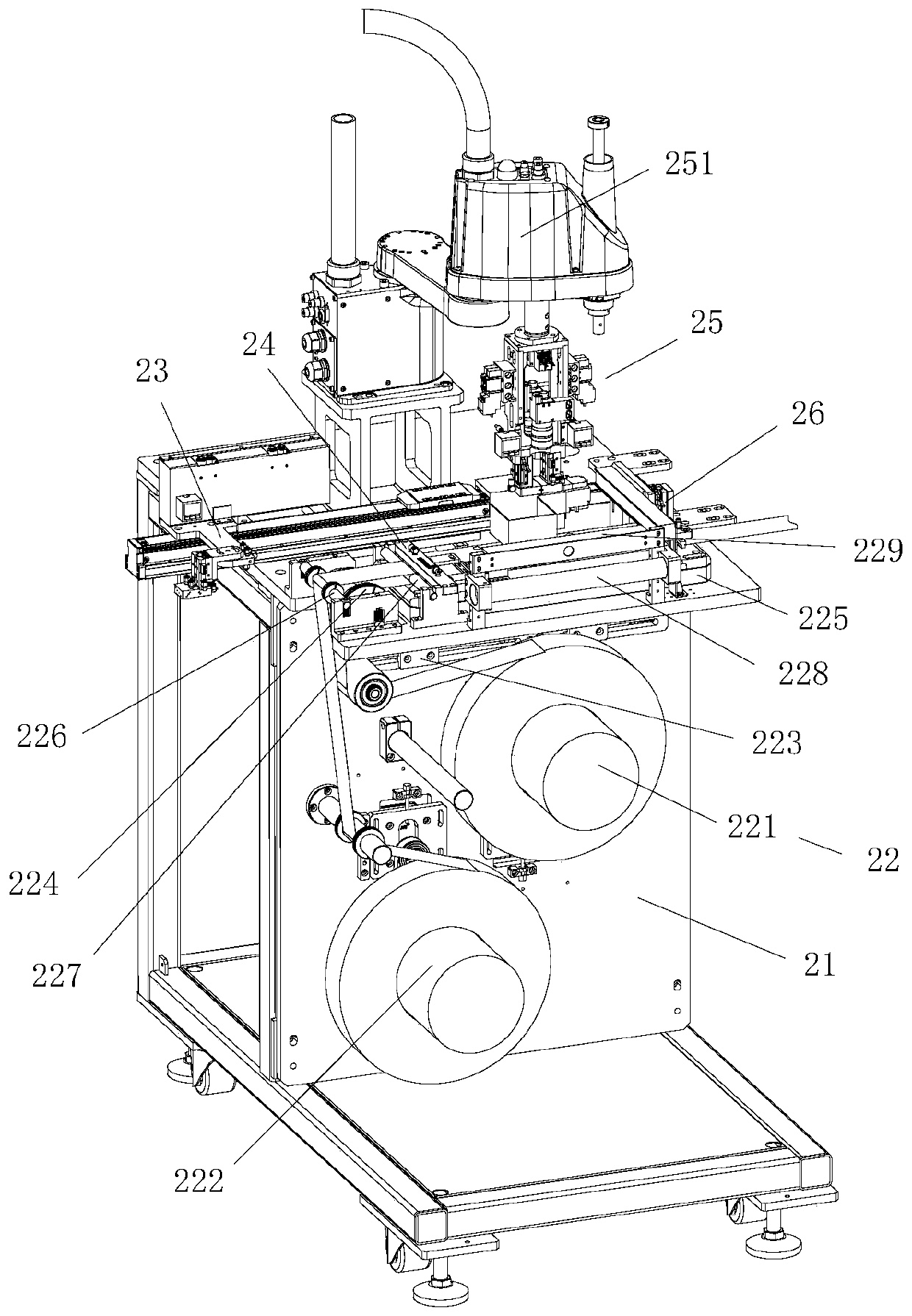

Full-automatic production line for attaching and laminating 3C product steel sheet

PendingCN111331998AGuaranteed flatnessAvoid damageLamination ancillary operationsLaminationAdhesiveManufacturing engineering

The invention discloses a full-automatic production line for attaching and laminating a 3C product steel sheet. The full-automatic production line for attaching and laminating the 3C product steel sheet comprises a steel sheet punching device, a steel sheet attaching device, a black adhesive laminating device, a back adhesive laminating device, a product detecting and stripping device, a finishedproduct collecting device and a manual detection table which are sequentially arranged in a butt joint manner, the cut steel sheet is grabbed by the steel sheet punching device and then is conveyed toa PC film at the steel sheet attaching device, the PC film is attached with black glue after passing through the black glue attaching device, the PC film is attached with back glue after passing through the back glue attaching device, the PC film is detected and stripped by the product detecting and stripping device, a stripped product is attached with a carrier film at the finished product collecting device, and a finished product is manually detected on the manual detection table. The full-automatic production line is compact in structure, stable in operation, capable of integrating steel sheet cutting, steel sheet laminating, back gum laminating, black gum laminating, product stripping and carrier film laminating, capable of replacing manpower and high in automation degree.

Owner:SUZHOU LANGKUN AUTOMATION EQUIP CO LTD

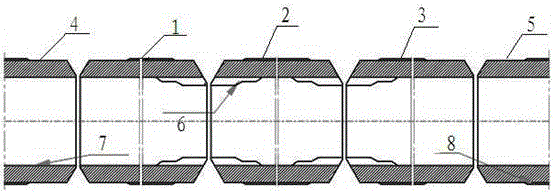

Surfacing welding method for enclosed connection of long-distance pipeline without mending

InactiveCN105983755AGuaranteed continuityAvoid anti-corrosion layer gapsWelding/cutting auxillary devicesArc welding apparatusCarbon steelWeld seam

Owner:胜利油田金岛工程安装有限责任公司 +1

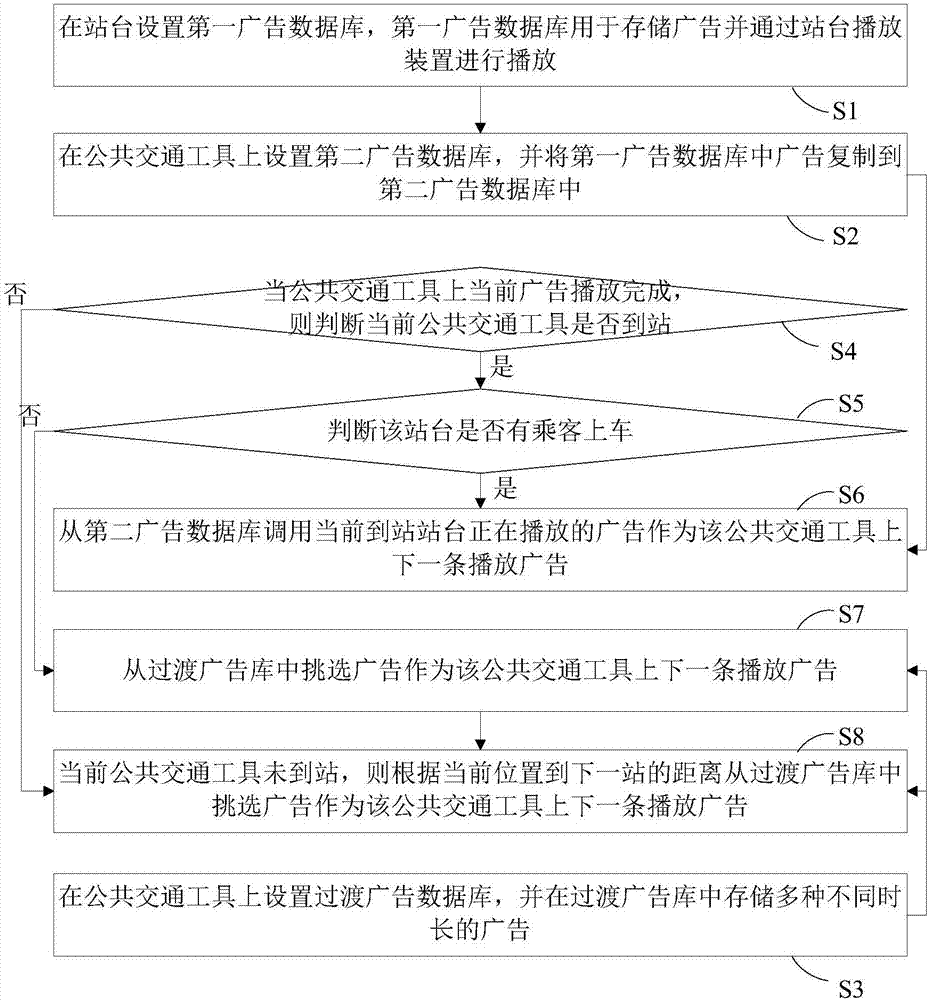

Advertising method for public transport means

ActiveCN107195260AIncrease acceptance rateReduce riskMobile visual advertisingMarketingPublic transportWorld Wide Web

The invention discloses an advertising method for public transport means. The advertising method includes the step that according to a playing advertisement of a current arrival platform, a corresponding advertisement is taken from a second advertisement database and serves as the next advertisement played on the public transport means. In this way, not only is playing of the current advertisement on the public transport means not affected, but also passengers who need to get aboard from the platform see complete advertisement information through a replay on the public transport means, the situation is avoided that only half of an platform advertisement is watched all the time, and then the acceptance rate of the platform advertisement is increased. Through the advertising method for the public transpiration means, the advertisement which is played on the platform and taken from the second advertisement database serves as the next advertisement for being played on the public transport means, thus the platform advertisement is replayed at first time, and the risk is avoided that it is too late for the passengers to watch the replayed advertisement because of rapid passenger flow on the public transport means.

Owner:蚌埠市麦沃特信息科技有限公司

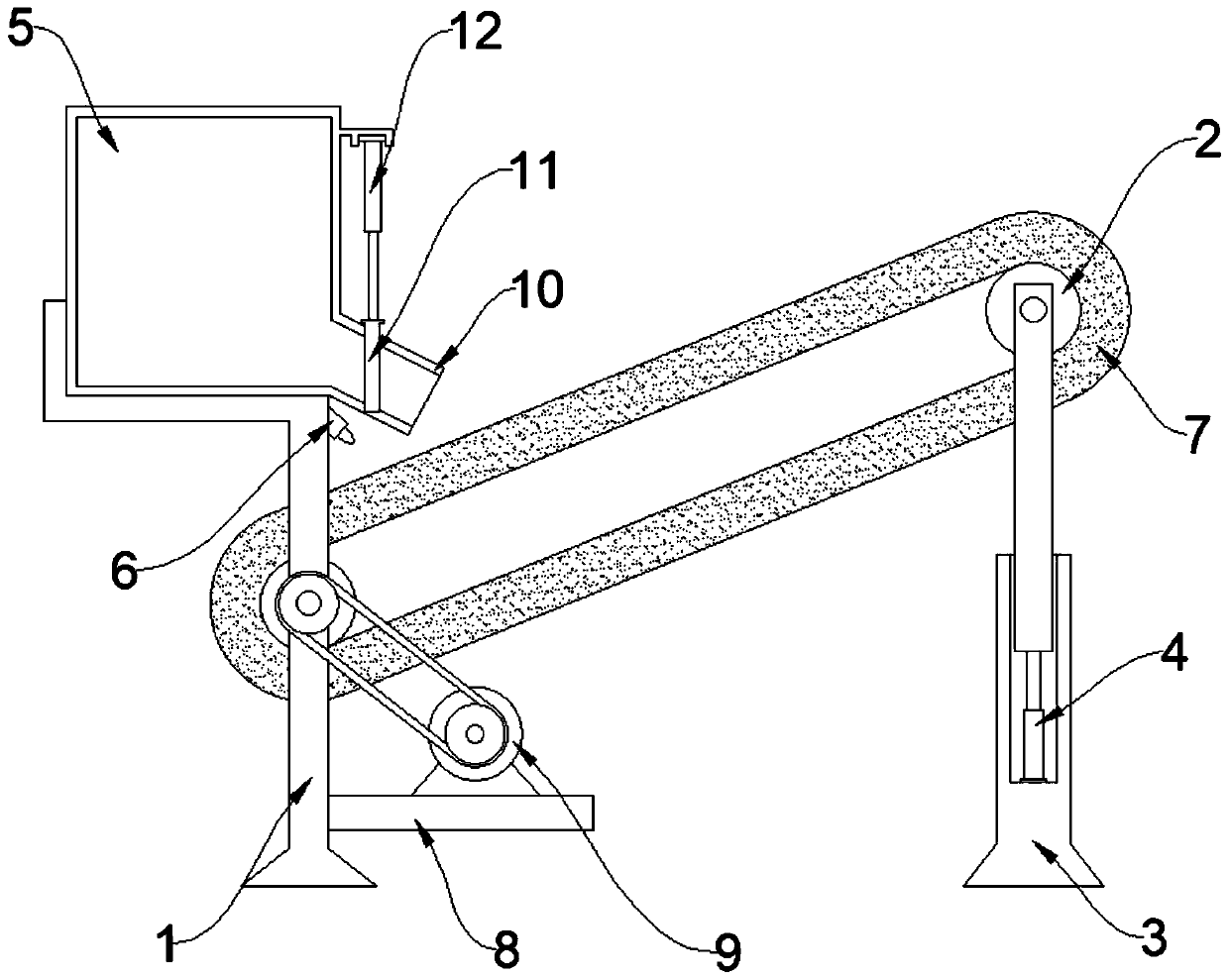

Automatic control device of belt conveying device

InactiveCN110803485AReduce deliveryRealize fixed-point feeding and conveyingConveyorsControl devices for conveyorsDrive wheelAutomatic control

The invention discloses an automatic control device of a belt conveying device and relates to the technical field of automatic control conveying. The automatic control device aims at solving the problems that an existing belt conveying device cannot ensure that a conveying groove is located below a discharging pipe during discharging, materials are not placed in a standard manner or disengage fromthe conveying belt during feeding, and conveying is affected. A lifting seat is arranged below one supporting frame, conveying rollers are arranged between the supporting frames, a conveying belt isarranged between the two conveying rollers, a supporting plate is arranged on one side of one supporting frame, a servo motor is arranged above the supporting plate, a driven wheel is arranged on oneside of the conveying roller, and a rotating shaft is arranged on one side of the output end of the servo motor. A drive wheel is arranged on one side of the rotating shaft, a discharging bin is arranged above the supporting frame, a discharging pipe is arranged on one side of the discharging bin, and a second electric telescopic rod is arranged on one side of the discharging bin. Limiting platesare arranged at the outer portion of the conveying belt, and a dividing plate is arranged between the two limiting plates.

Owner:SUZHOU DESIMIER SMART TECH CO LTD

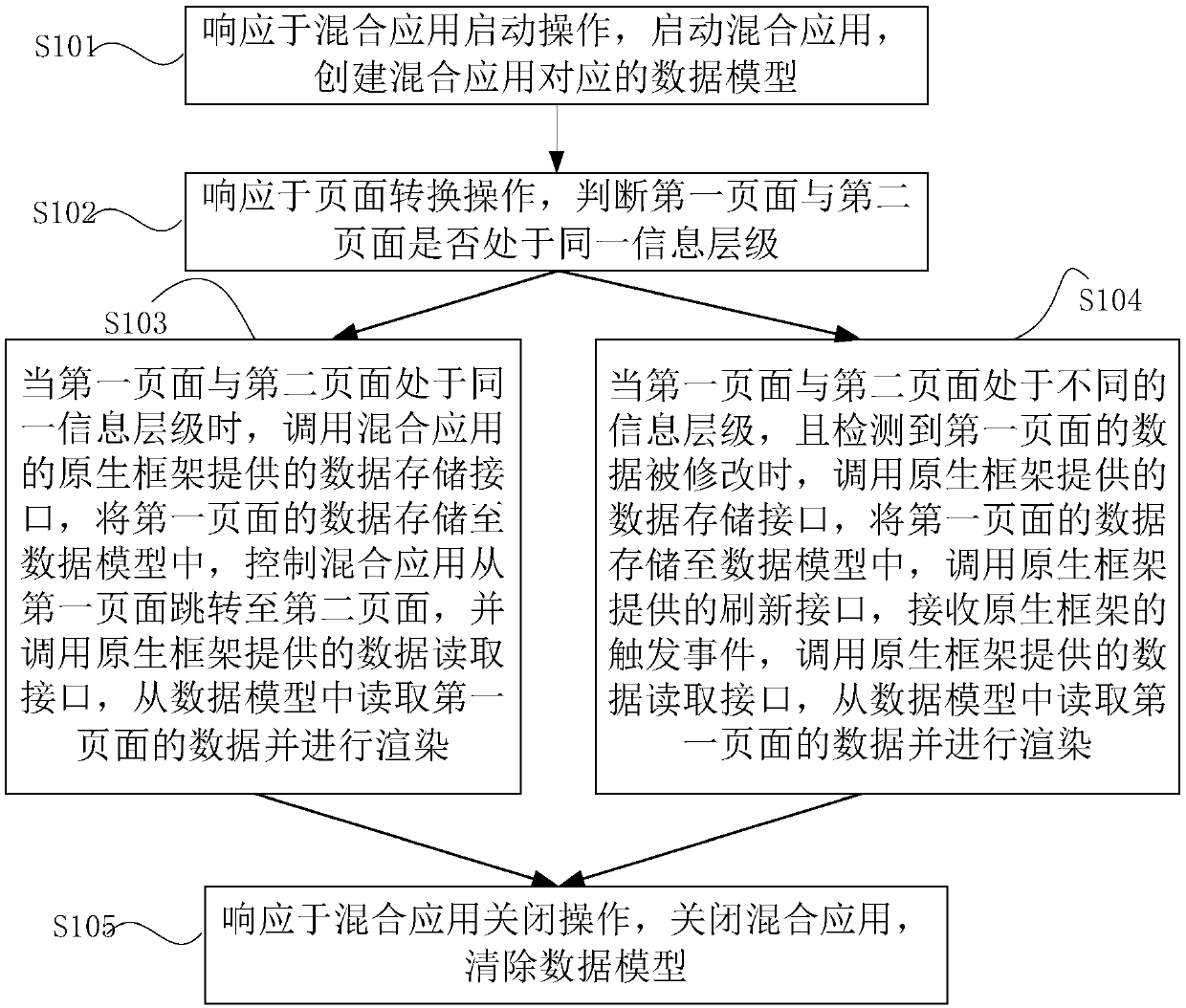

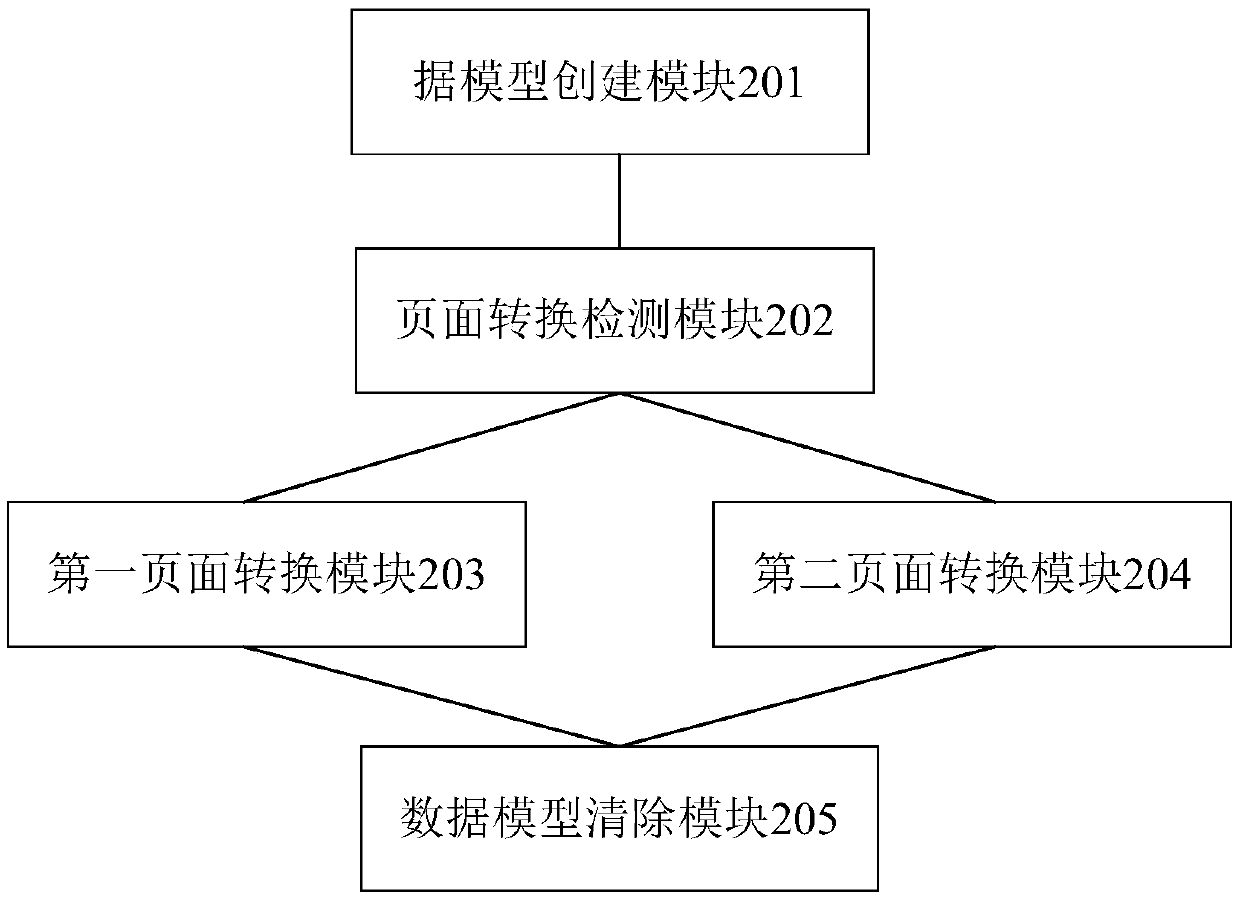

Page switching method of hybrid application, framework, computer device and storage medium

ActiveCN110020323AEasy to operateAvoid blankingWebsite content managementEnergy efficient computingInformation levelJumping

The invention provides a page switching method of a hybrid application, a frame, a computer device and a storage medium. The method comprises the steps of creating a data model when the hybrid application is started; when the pages are converted, judging whether the two pages are located at the same information level or not, and when the two pages are located at the same information level, callinga data storage interface, storing the data of a front page to a data model, controlling the jumping of the hybrid application page, calling a data reading interface, and reading the data of an original page from the data model and rendering; at different information levels, when it is detected that the data of the original page is modified, calling a data storage interface, storing the data of the original page into the data model, calling a refreshing interface, receiving a trigger event of the original framework, calling a data reading interface provided by the original framework, reading the data of the original page from the data model and rendering, and clearing the data model when the hybrid application is closed. According to the present invention, the page can be quickly reloadedduring page conversion, and the data is safe.

Owner:PING AN TECH (SHENZHEN) CO LTD

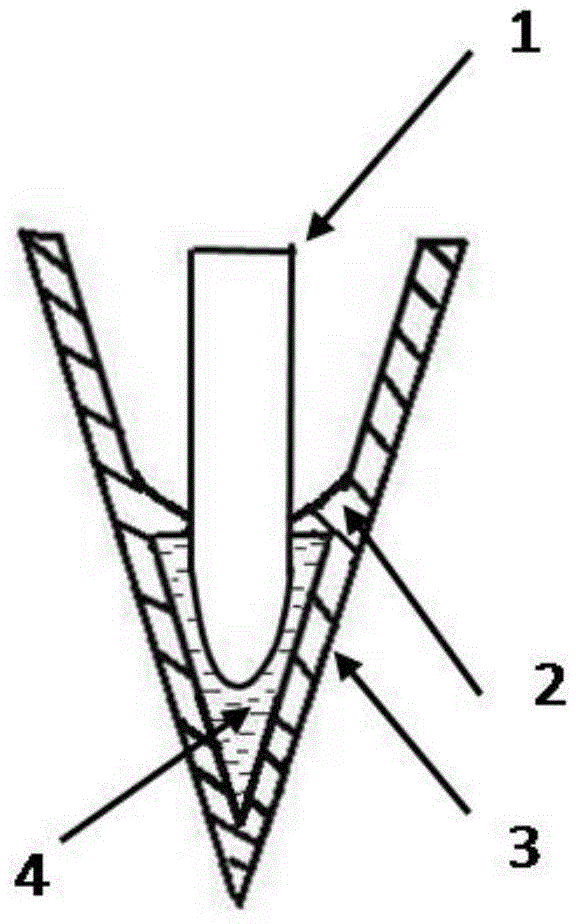

Material filling technology for prolonging crisp keeping period of crisp cone

The invention discloses a material filling technology for prolonging a crisp keeping period of a crisp cone. When a station containing the chocolate layer crisp cone sprayed on a flat line moves to a material filling station, a discharge pipe is controlled to decrease to the bottom of the crisp cone; an end of the discharge pipe is used for extruding the chocolate layer at the bottom of the crisp cone upwards; the discharge pipe is lifted, and the material is discharged when the discharge pipe is lifted, material liquid surface height is always higher than an annular gap between the discharge pipe and the crisp cone until feeding of the required material liquid is competed; the end of the discharge pipe is in an arc shape, a discharging mode of the discharge pipe is porous discharging at the side lower part of the end. The material filling technology increases the structural state of the product, the brittleness and mouthfeel of the product are improved, the crisp keeping period of the crisp cone product is greatly prolonged, sub-quality products proportion is reduced, material leakage cannot be generated, transport process is safe, technical reconstruction cost is low, and the production process is easily realized.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

PCB inner layer circuit making device and making method

InactiveCN108337825AShorten production timeReduce waiting timePrinted circuit aspectsMultilayer circuit manufactureCooking & bakingBatch processing

The invention discloses a PCB inner layer circuit making device comprising a first feeding temporary storage frame, an inner layer pre-processing grinding plate roughening line, a second feeding temporary storage frame, an inner layer printing ink coating and baking line, a third feeding temporary storage frame, a reading mechanism, an exposure mechanism, a fourth feeding temporary storage frame,a developing, etching and unwinding line and an optical detecting mechanism, which are arranged in sequence, wherein each feeding temporary storage frame is connected with a mechanical arm for grabbing material, and the devices are sequentially connected by a conveyor belt along a material processing sequence. The device improves the processing efficiency and prevents the problem of scratching andscrapping the surface of the board by manual material handling, thereby improving the product yield and reducing the production cost. The invention further discloses a PCB inner layer circuit makingmethod for reducing the manual operation steps and the production time, eliminating the manual loading and unloading, and reducing the handling operations, thereby saving manpower, reducing the laborcosts, and being suitable for industrial batch processing of PCBs.

Owner:江西景旺精密电路有限公司

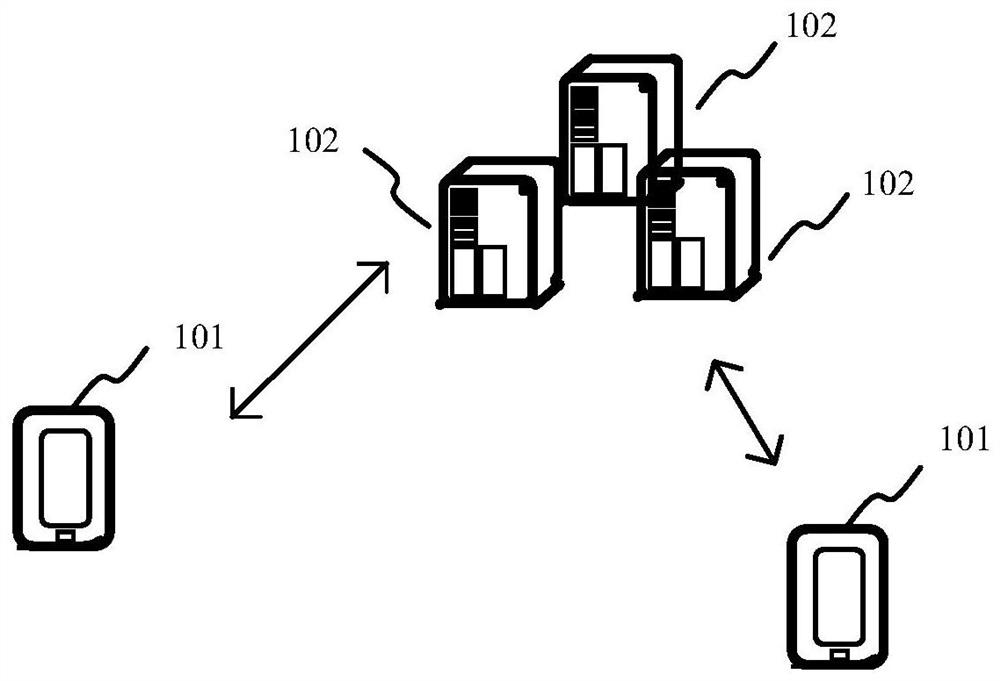

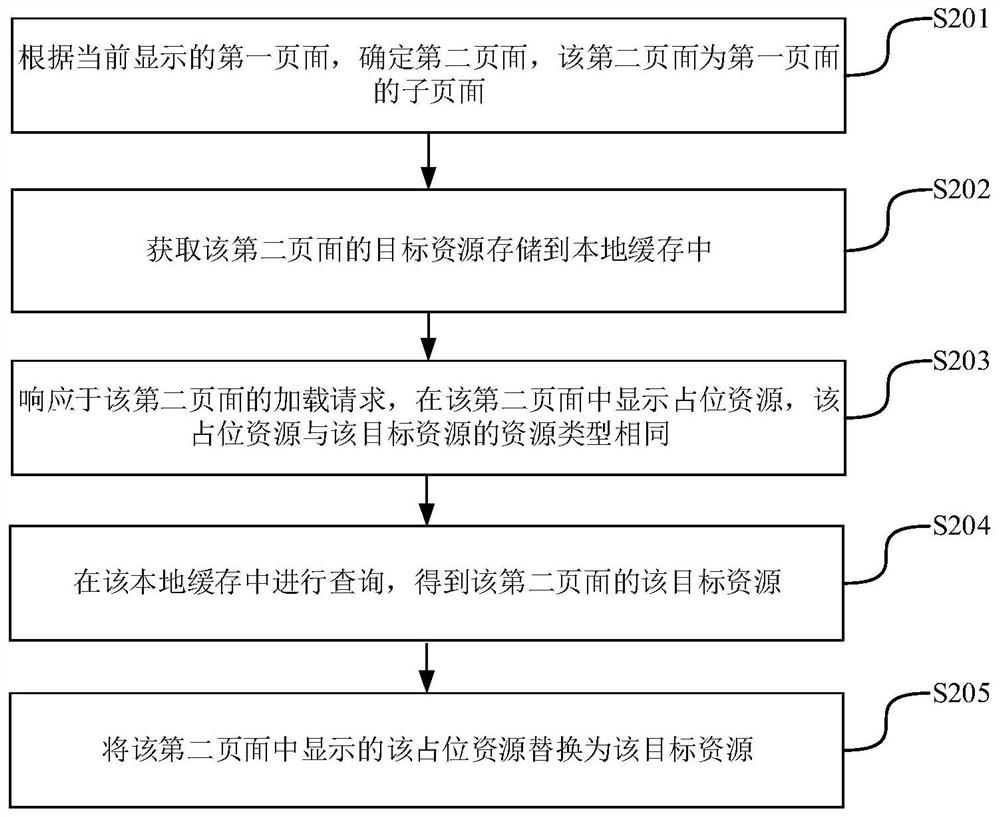

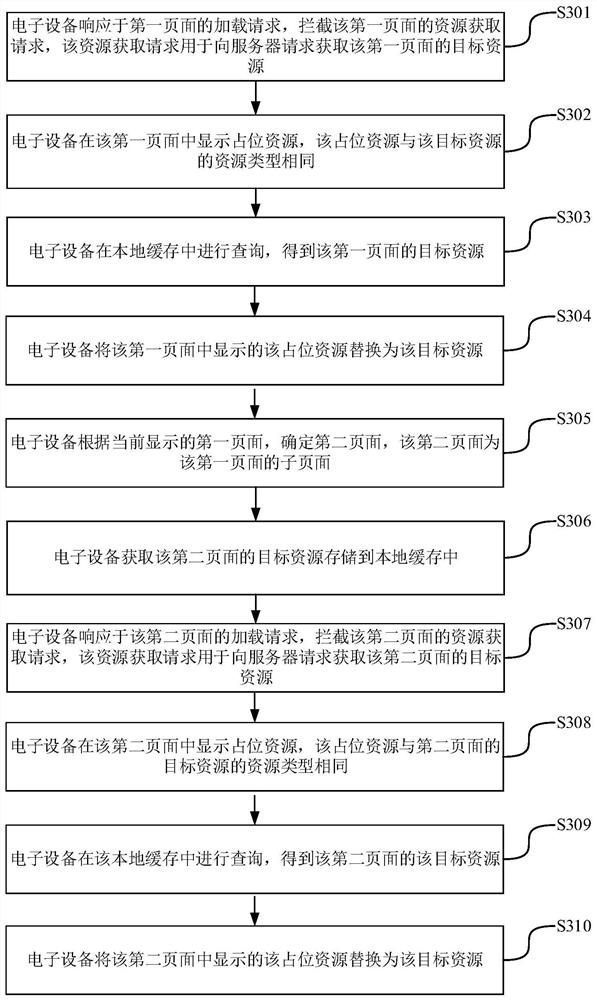

Page display method and device, electronic equipment and storage medium

PendingCN111625315AImprove display speedReduce consumptionExecution for user interfacesComputer hardwareEngineering

The invention relates to a page display method and device, electronic equipment and a storage medium, and belongs to the technical field of networks. The method comprises the steps: determining a second page according to a currently displayed first page, wherein the second page is a sub-page of the first page; obtaining a target resource of the second page and storing the target resource in a local cache; responding to a loading request of the second page, and displaying occupied resources in the second page; performing querying in a local cache to obtain a target resource of the second page;and replacing the placeholder resources displayed in the second page with the target resources. According to the invention, the flow consumption can be reduced, and the page display speed is improved.

Owner:BEIJING DAJIA INTERNET INFORMATION TECH CO LTD

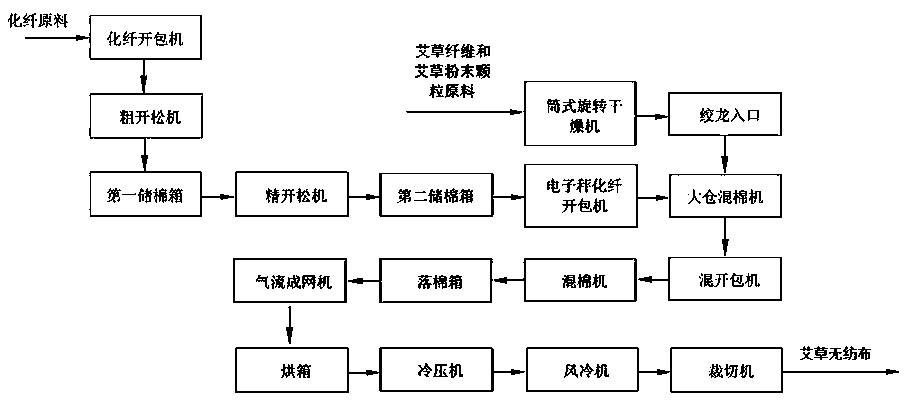

Wormwood non-woven fabric and manufacturing method thereof

InactiveCN109554825ARelease stabilityTo achieve the effect of anti-mosquito and miteNon-woven fabricsAdhesivesWoven fabricFineness

The invention discloses a wormwood non-woven fabric which is prepared from, by weight, 65-80% of chemical fiber with low melting point, 15-20% of wormwood fiber and 5-15% of wormwood particles, wherein the length of wormwood fiber ranges from 1 to 90 mm and the fineness thereof ranges from 3D to 60D, the length of chemical fiber with low melting point ranges from 10 mm to 200 mm and the fineness thereof ranges from 3D to 100D, and the wormwood particles are of grain size smaller than 80 meshes. The invention further discloses a manufacturing method of the wormwood non-woven fabric, including the steps of unpacking, coarse opening, fine opening, screening and drying, metering of chemical fiber, metering of wormwood fiber, primary mixing, uniform mixing, pre-laid process, air-laid process, heating to melt, cold pressing, and cooling. The wormwood non-woven fabric manufactured by the method has good breathability and also has functions of mosquito preventing and mite repelling.

Owner:宁波艾克本草纤维有限公司

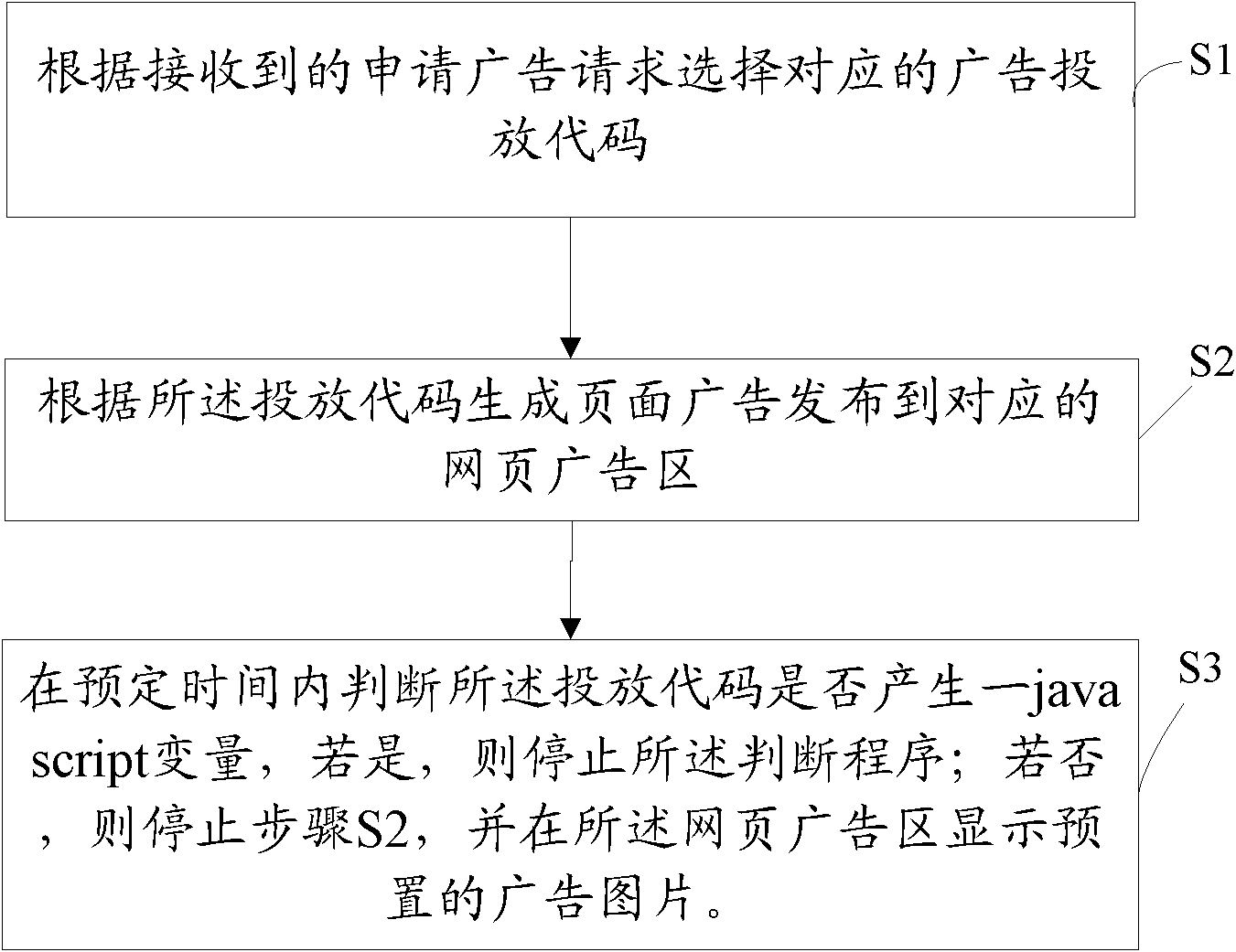

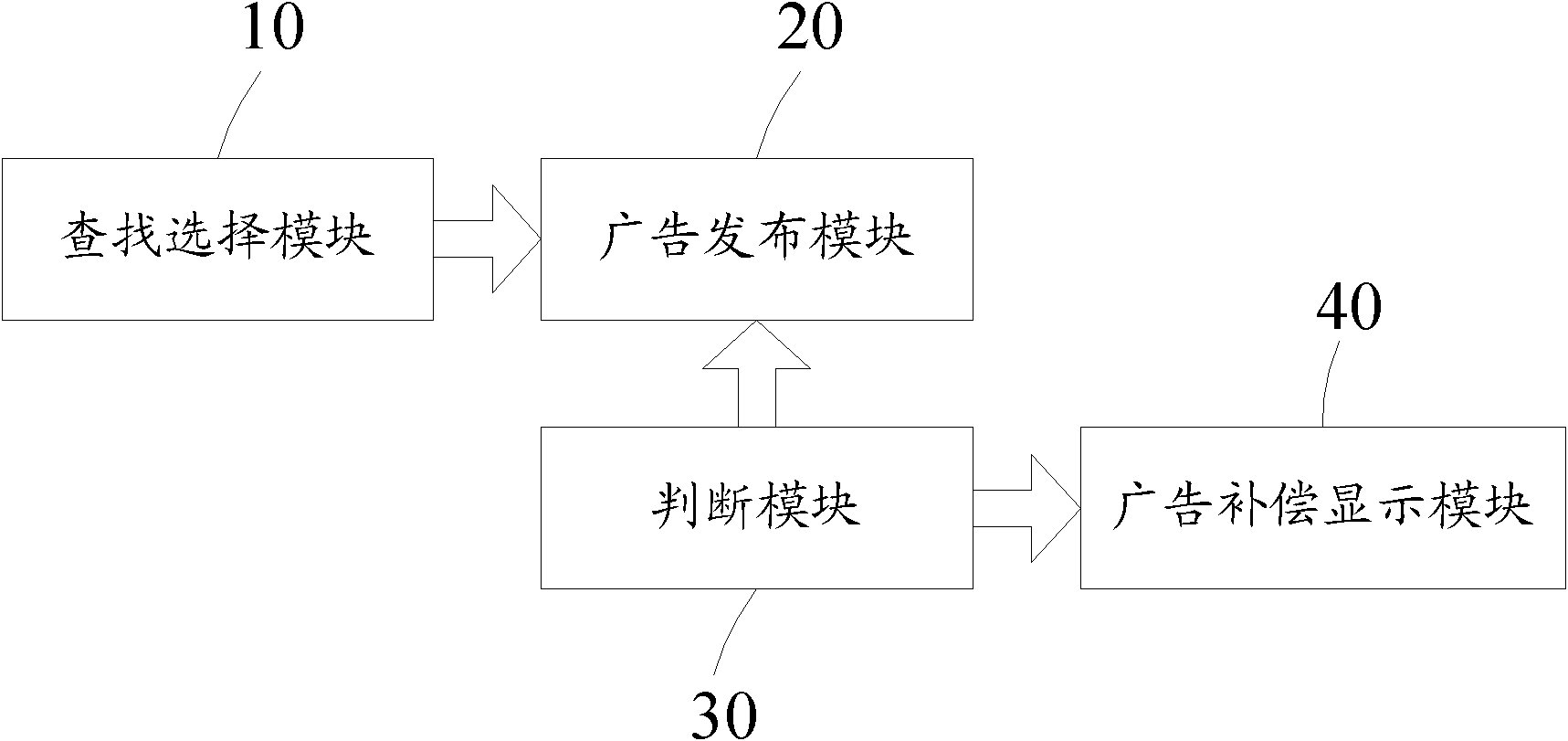

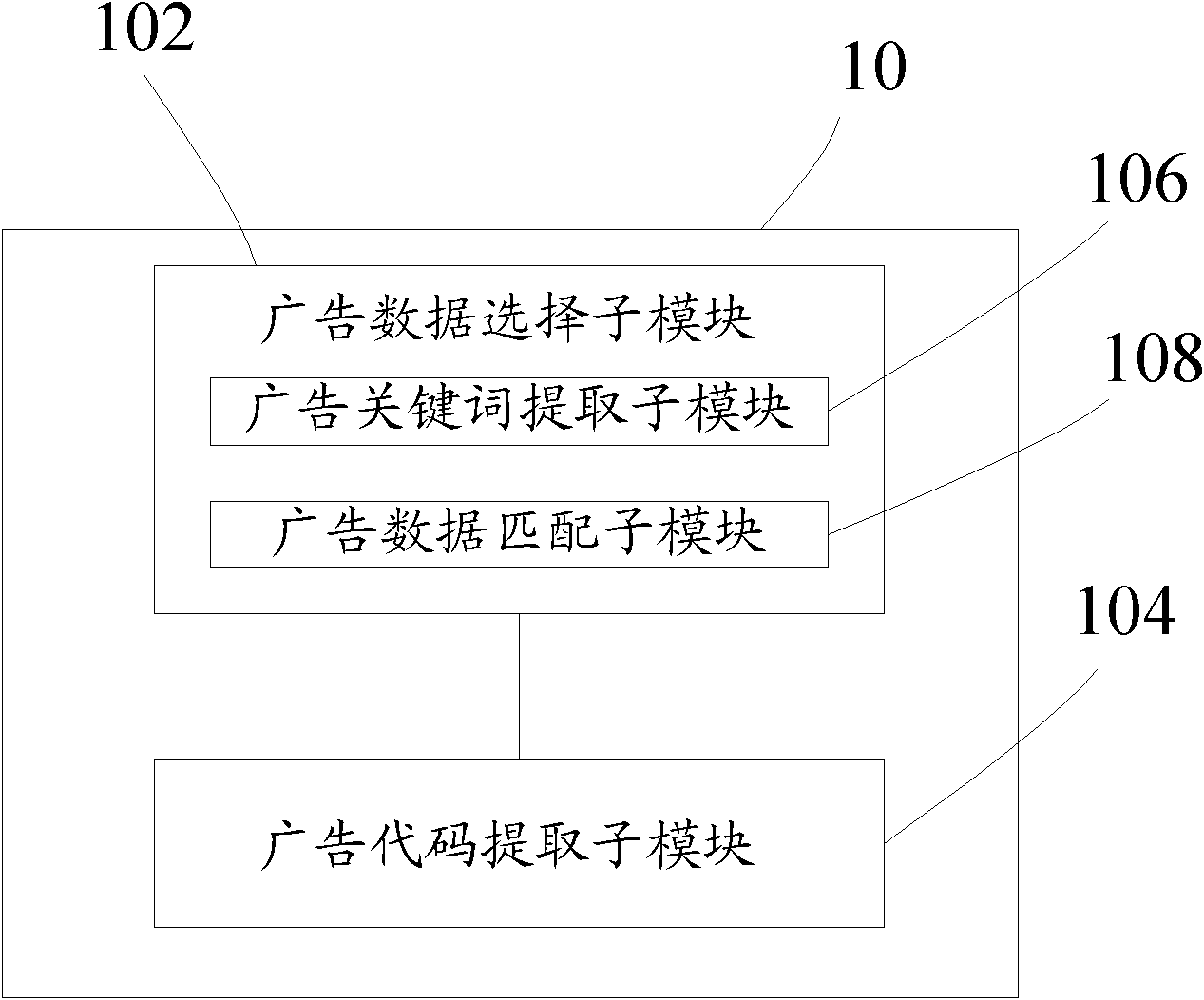

Webpage advertisement delivery method and system

The invention relates to webpage advertisement delivery method and system. The method comprises the following steps: S1, selecting a corresponding advertisement delivery code according to a received advertisement application request; S2, generating a webpage advertisement according to the delivery code and publishing the generated webpage advertisement to a corresponding webpage advertisement region; and S3, determining whether the delivery code generates a javascript variable in a preset time by a javascript determination program or not; if so, stopping the determination program; if not, stopping the step S2 and displaying a preset advertisement picture in the webpage advertisement region. The webpage advertisement delivery method and system avoid the problems of advertisement code failure and blank advertisement region due to an advertisement delivery server or network reasons.

Owner:JUYUE INFORMATION TECH SHANGHAI

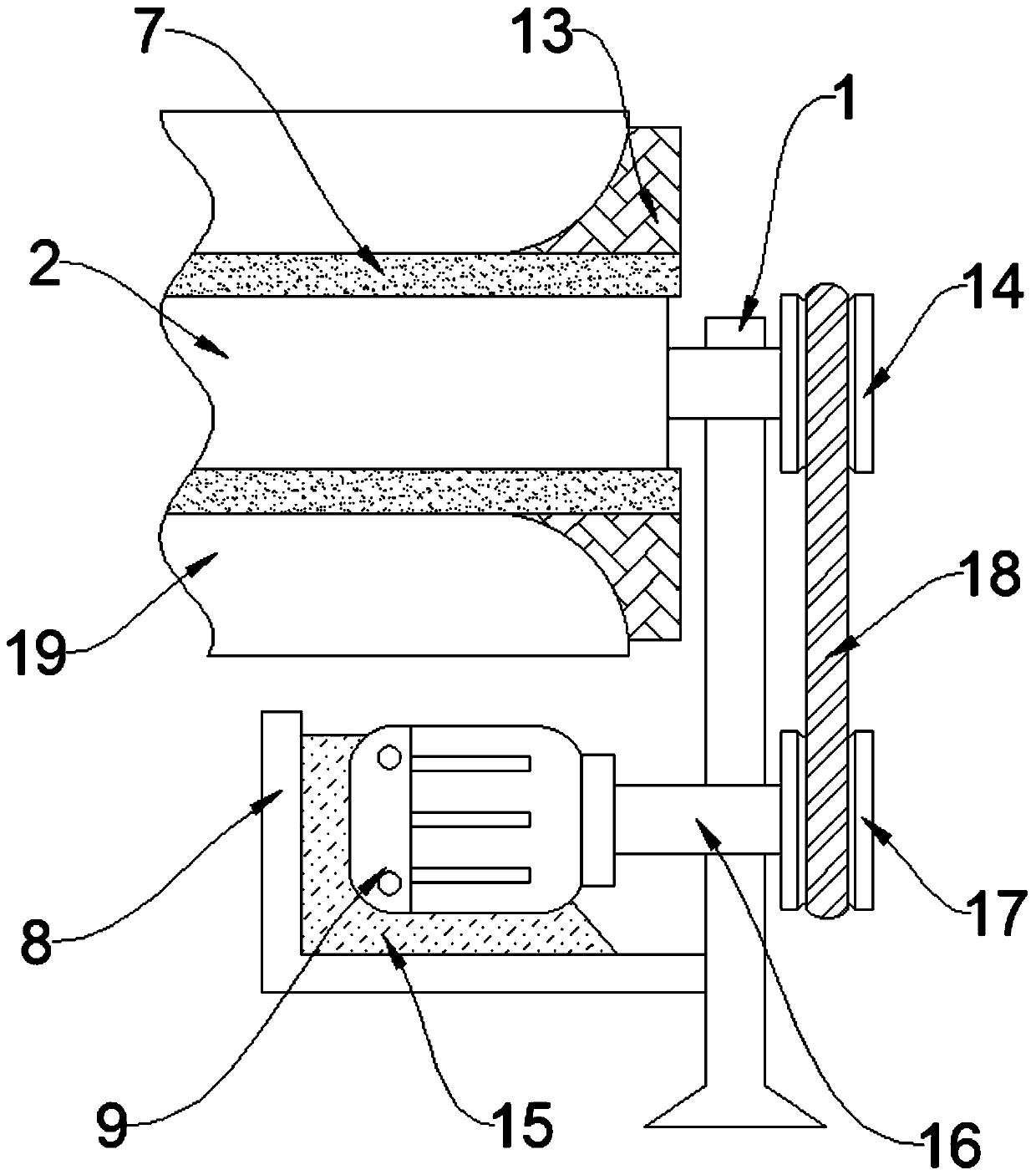

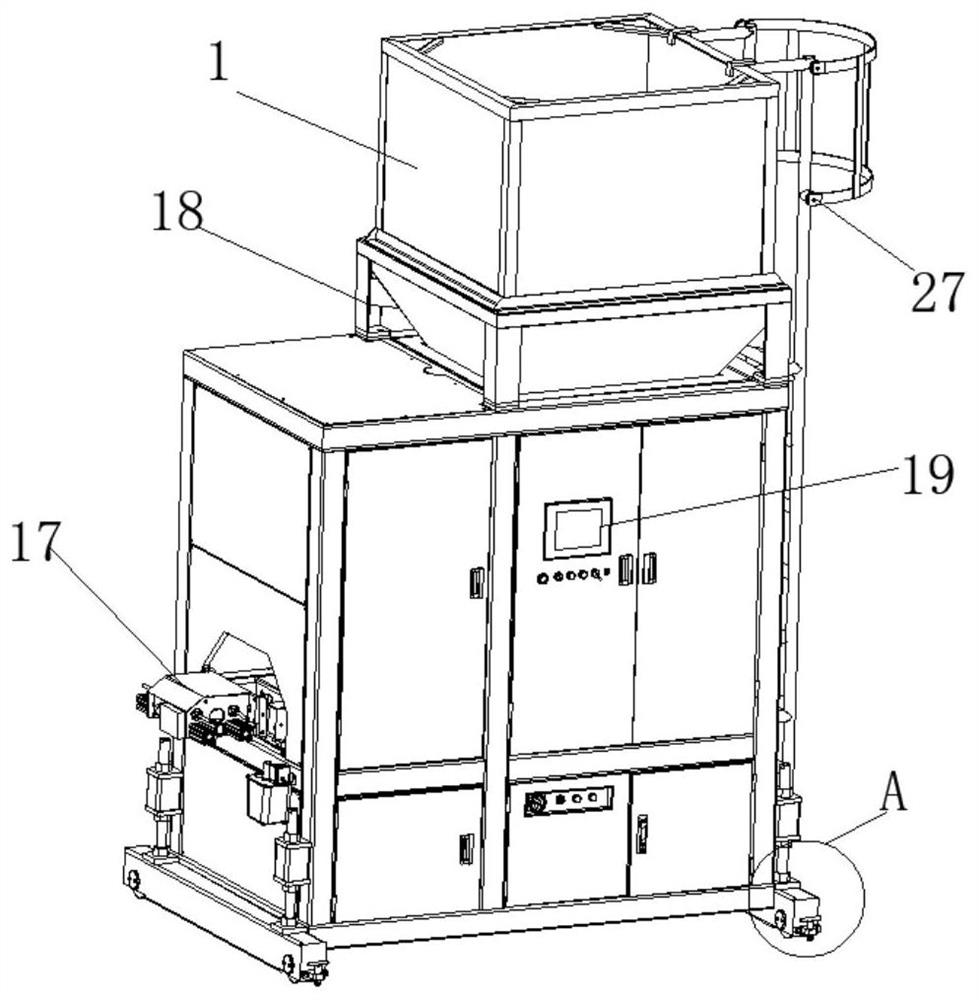

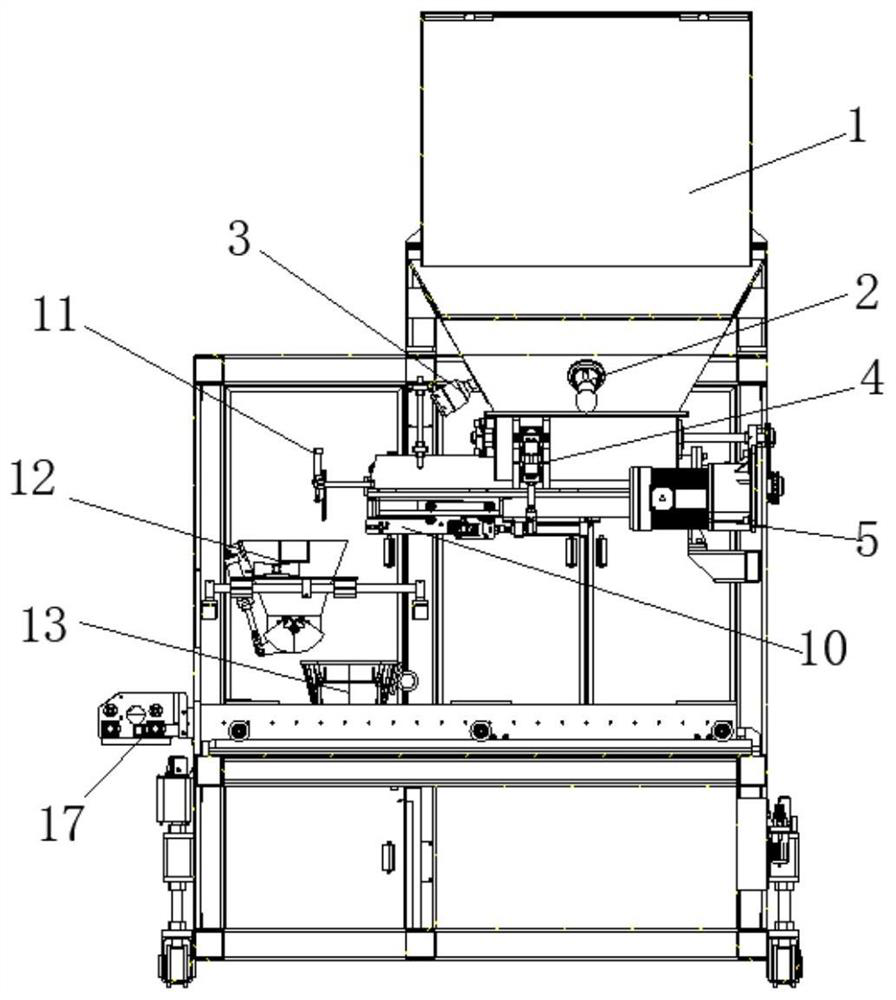

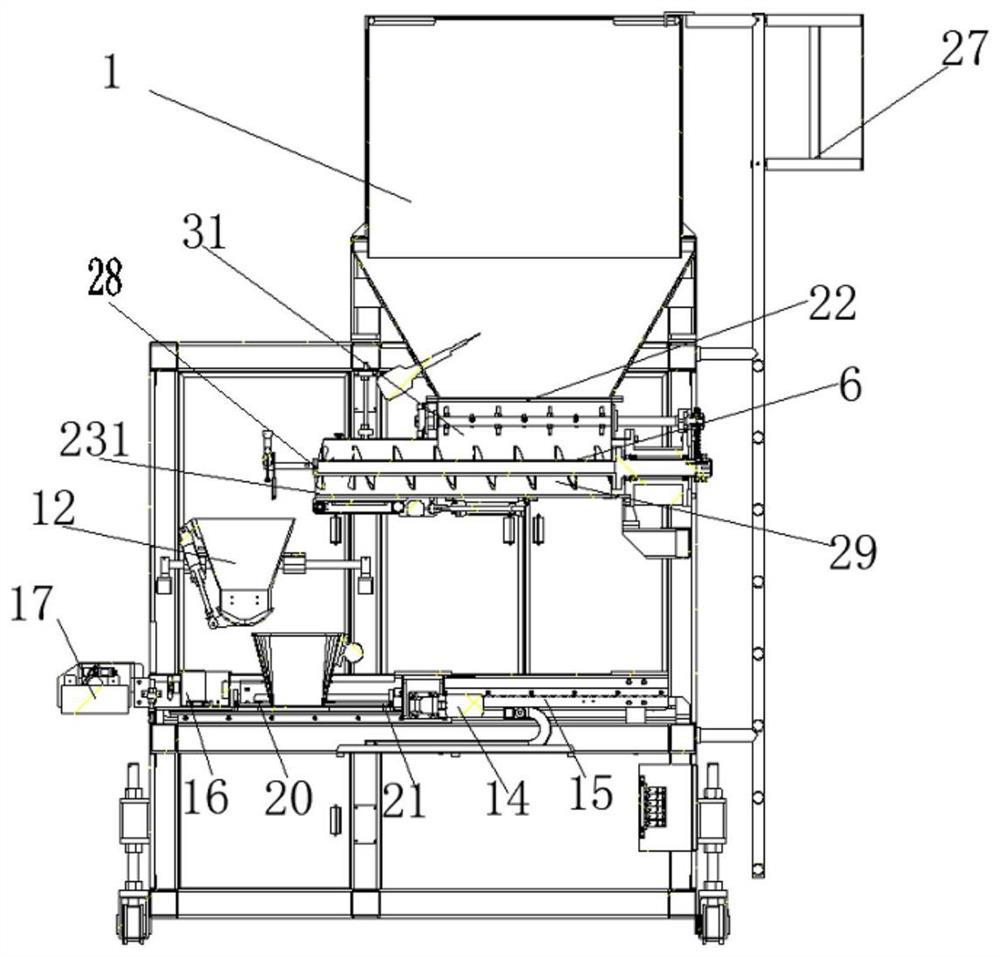

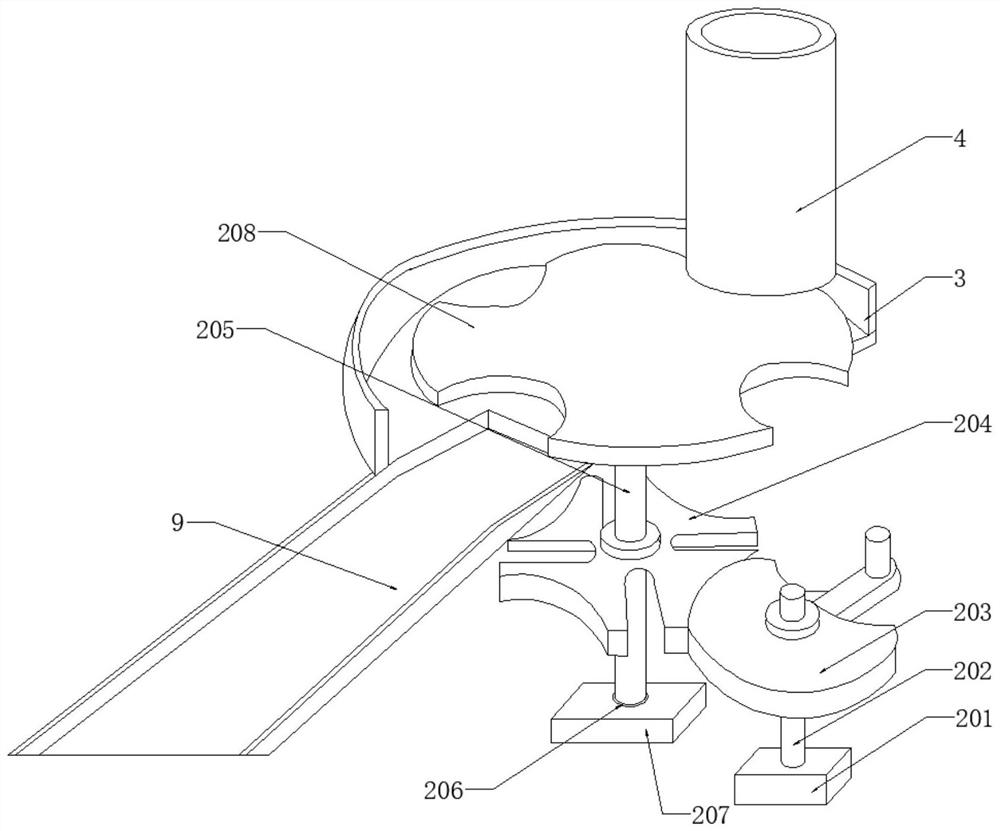

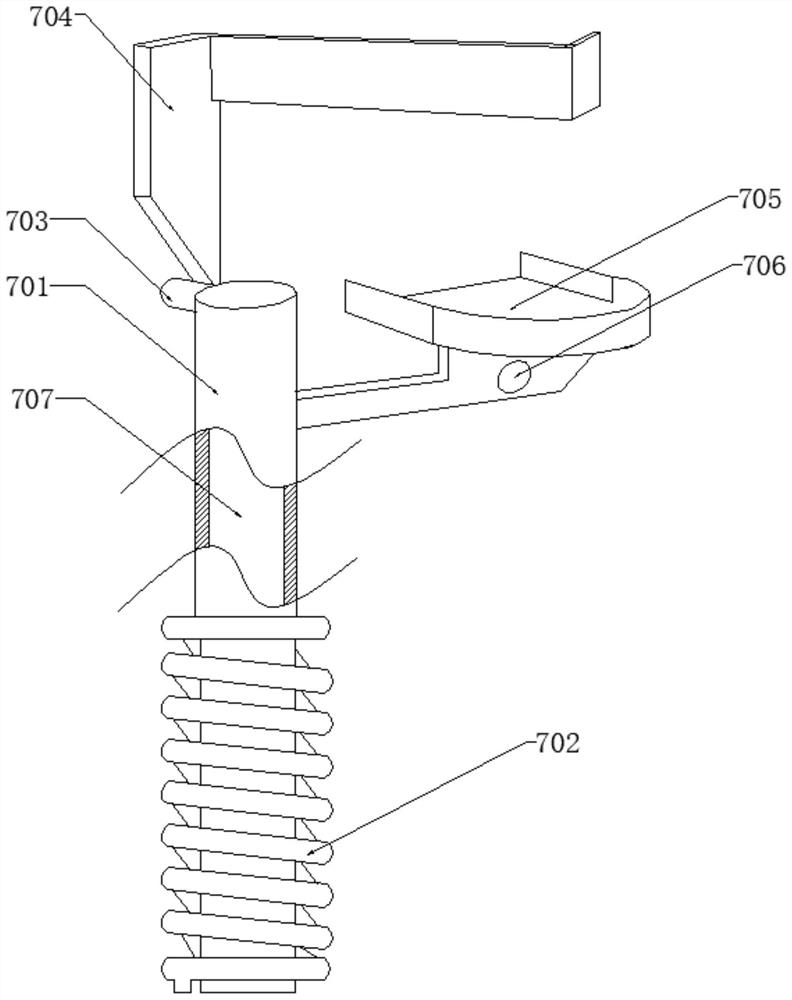

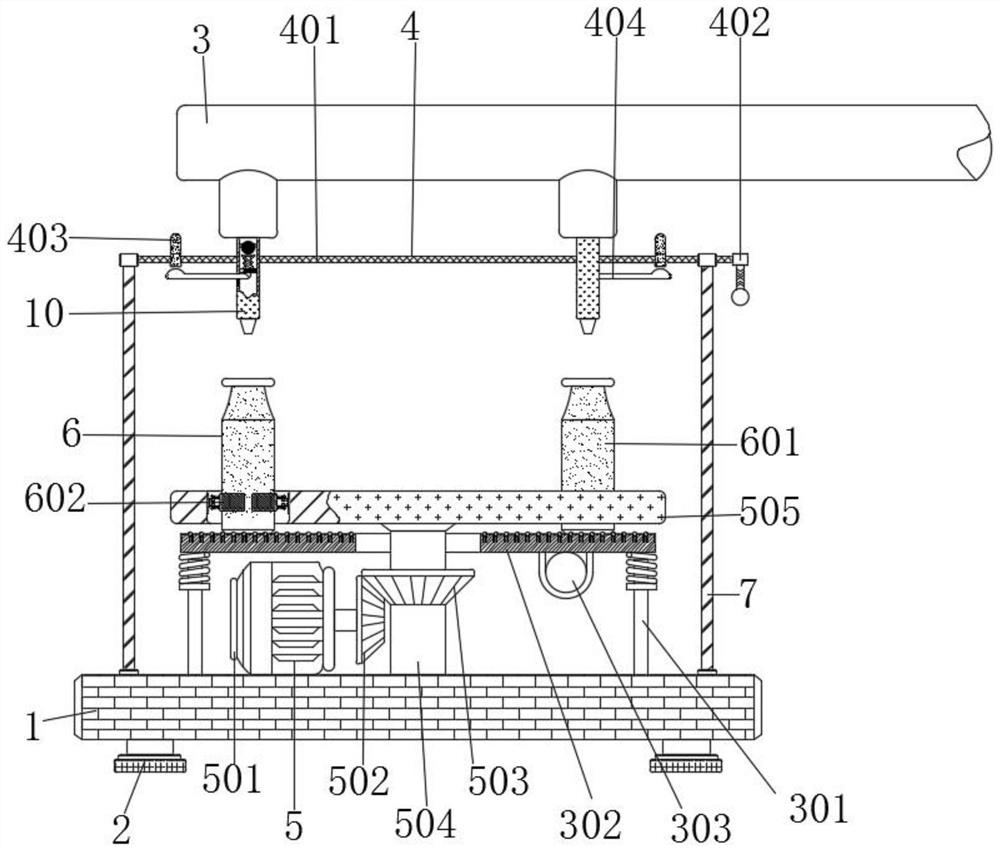

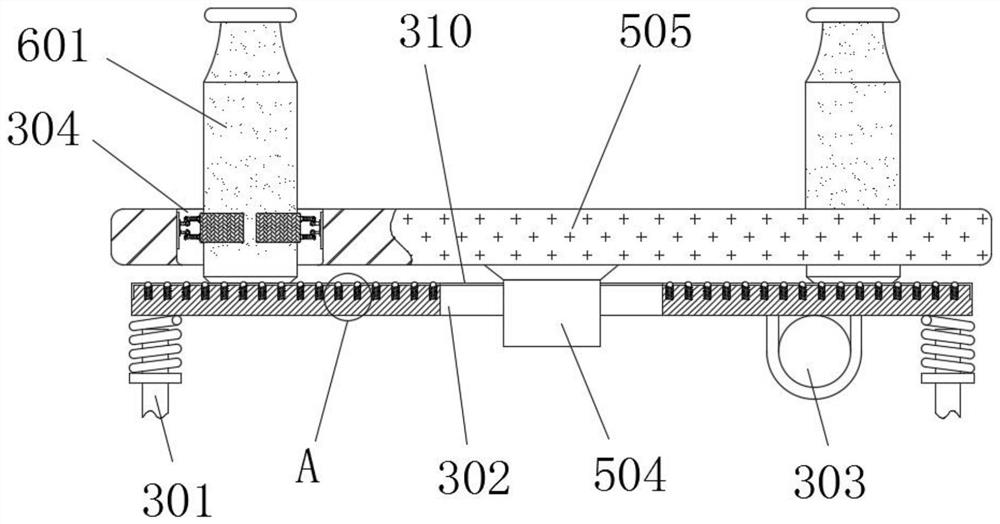

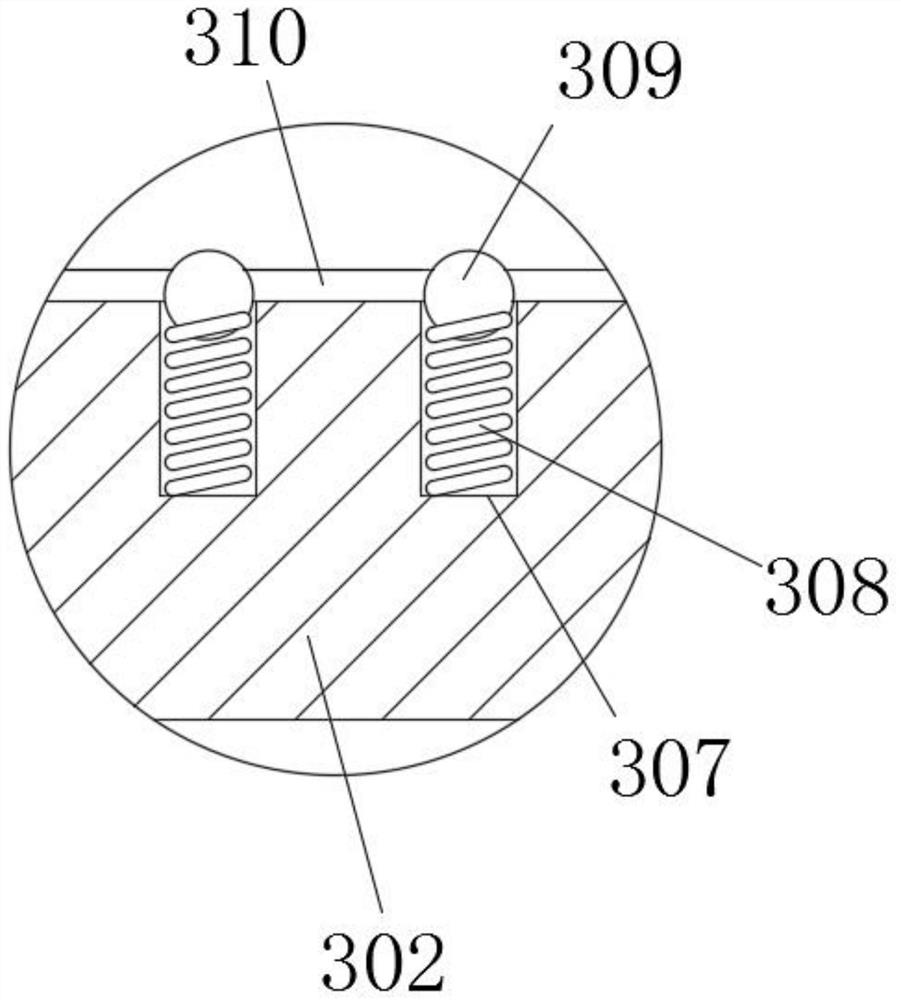

Automatic refractory brick weighing and distributing system

InactiveCN111633785AStop fallingAccurate weighingCeramic shaping plantsFeeding arrangmentsFire brickStructural engineering

The invention discloses an automatic refractory brick weighing and distributing system. The automatic refractory brick weighing and distributing system comprises a rack, a stock bin and a spiral conveying mechanism, wherein a feeding channel is horizontally arranged above a spiral channel, a stirring device is rotationally connected in the feeding channel, a fine supplementing mechanism is horizontally fixed to the bottom of the spiral conveying mechanism in a sliding mode, a switch blade mechanism cooperating with the fine supplementing mechanism is fixed to the position, close to a discharging port, of the rack, and an overturning mechanism is fixed to the bottom of the spiral conveying mechanism. According to the automatic refractory brick weighing and distributing system, the combination of a switch blade and a conveyor is adopted so that raw material fine compensation be realized, and the accuracy of weighing each time can be ensured; and meanwhile, a brick taking machine head isarranged on a material distributing machine, so that products pressed by a pressing machine can be taken and placed while automatic material distribution is completed, unmanned operation from materialdistribution to brick taking is achieved, more labor cost is saved, and meanwhile the life safety of workers is guaranteed.

Owner:CHANGXING RONGLI MACHINERY

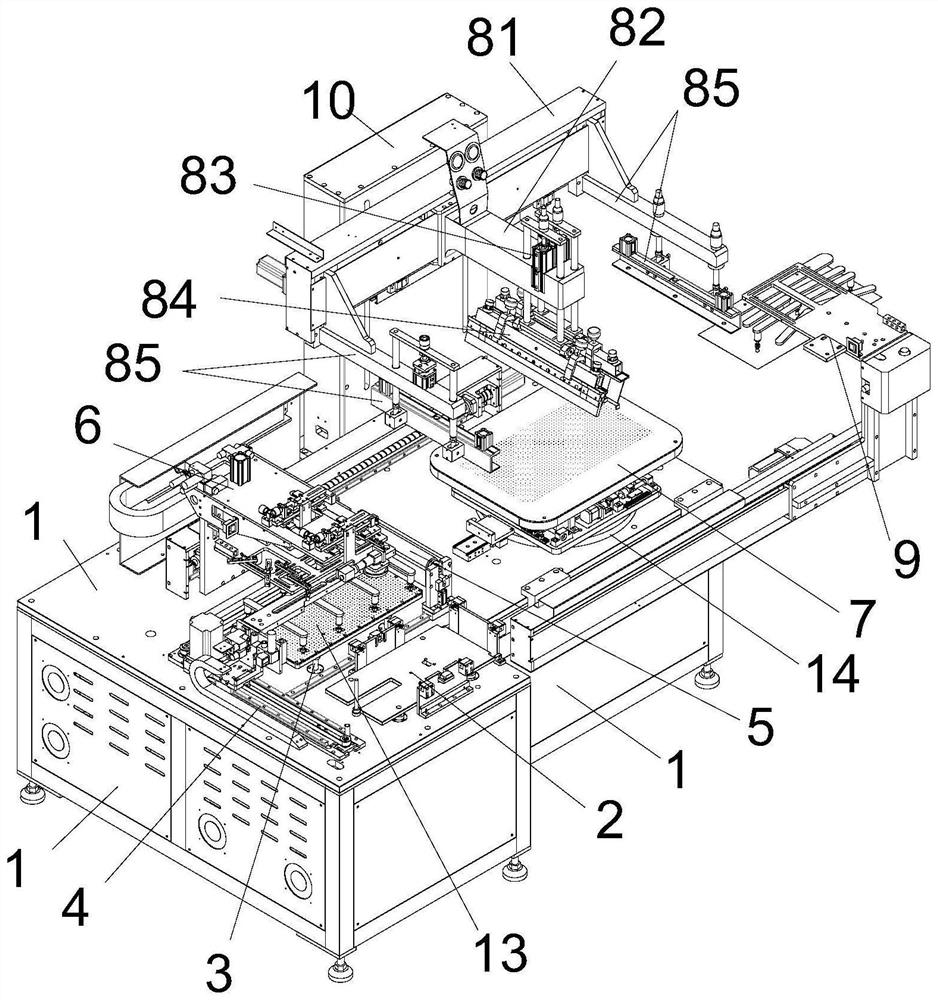

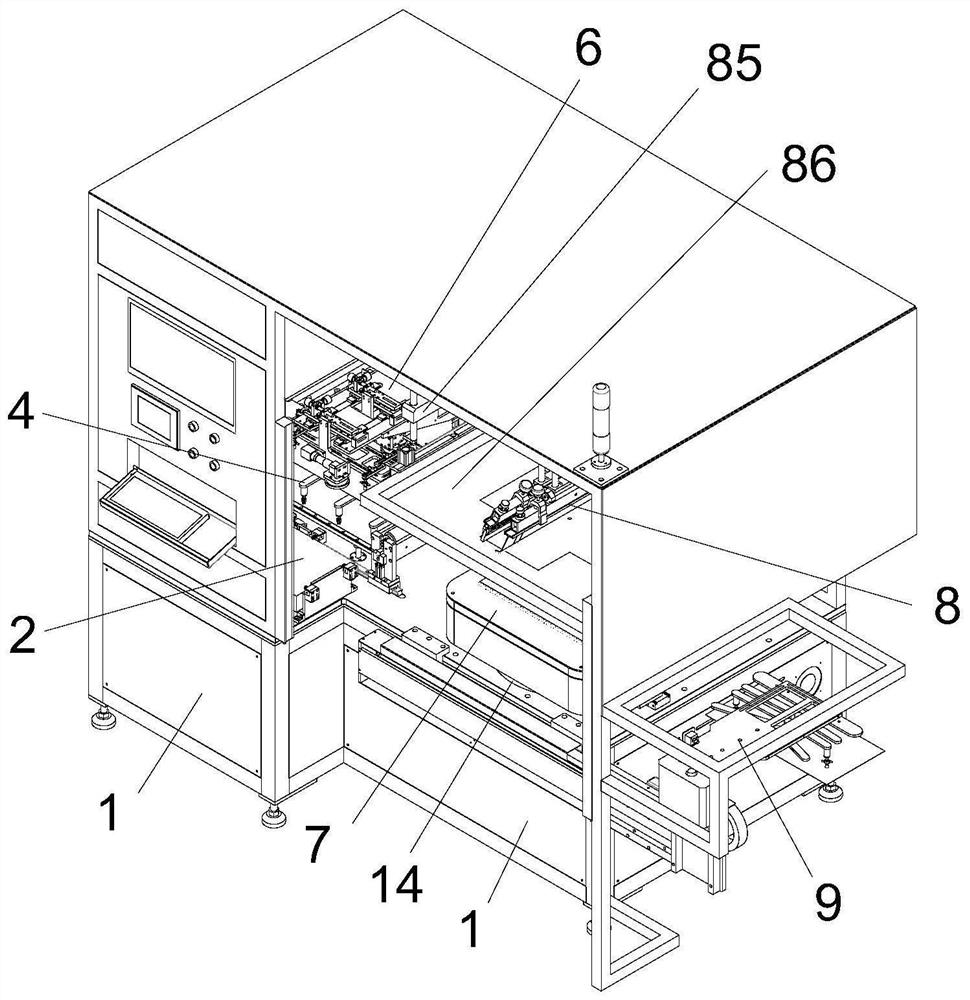

Automatic CCD printing machine

PendingCN111823703ARealize automatic printingAvoid manual loadingScreen printersConductive pattern formationDust controlPrinting press

The invention discloses an automatic CCD printing machine and relates to the technical field of printing. A machine cabinet is included; a lifting material stack mechanism, a feeding turning connection table, a first feeding mechanism, a dust removing mechanism, a second feeding mechanism, a printing platform, a printing mechanism and a discharging mechanism are installed above the machine cabinet; the lifting material stack mechanism is arranged in front of the feeding turning connection table; the first feeding mechanism is arranged on the left of the feeding turning connection table and thelifting material stack mechanism; the feeding turning connection table is arranged on the middle portion of the dust removing mechanism; the printing platform is arranged on the right of the feedingturning connection table; the second feeding mechanism is arranged behind the printing platform and the feeding turning connection table; the rear portion of the printing mechanism is fixedly providedwith a lifting mechanism; the lower end of the lifting mechanism is fixedly installed on the rear portion of the machine cabinet; the printing mechanism is arranged above the printing platform; the discharging mechanism is arranged in front of the printing platform; and the right end of the discharging mechanism extends out of the machine cabinet to be arranged. Manual feeding and discharging areavoided, and the positioning precision and the overall printing efficiency are improved.

Owner:深圳市欣荣自动化智能设备有限公司

Image projecting system, method, computer program and recording medium

InactiveUS8267523B2Uniform luminanceUniform brightnessProjectorsColor television detailsImage resolutionProjection system

A plurality of projector apparatuses project images based on inputted image signals onto a screen so that the images are displaced relative to one another by a predetermined amount and superimposed. The luminances of an image region composed of a plurality of projected images that have been projected onto the screen are observed. Luminance values of pixels that construct an image to be projected by each projector apparatus are adjusted based on an observation result and are supplied to the plurality of projector apparatuses. The image region composed of the plurality of projected images is presented by superimposing a first projected image and a second projected image that has a higher resolution than the first projected image. Predetermined pixels in the image region are presented by superimposing corresponding pixels in the projected images from n adjacent projector apparatuses.

Owner:SONY CORP

Box filling machine with quantifying function

InactiveCN107985645AReduce the burden onEasy to packRotary stirring mixersWrapper twisting/gatheringEngineeringElectromagnetic valve

The invention discloses a box filling machine with a quantifying function. The machine comprises a box; the top of the inner wall of the box is fixedly connected with a stirring box; the top of the right side of the inner wall of the box is fixedly connected with a motor through a motor base; an output shaft of the motor is fixedly connected with a stirring shaft through a coupling; the end, far from the motor, of the stirring shaft penetrates through the stirring box, and extends into the stirring box; the left end of the stirring shaft is rotationally connected with the left side of the inner wall of the stirring box; a vertical pipe penetrates through the bottom of the inner wall of the stirring box; an electromagnetic valve is arranged on the vertical pipe; a support plate is fixedly connected between the two sides of the inner wall of the box; the top of the support plate is fixedly connected with a quantifying box; and the machine relates to the technical field of box filling machines. The box filling machine with the quantifying function can effectively fill boxes, can determine if requirements are met according to the box filling weight in the box filling process, has no need to manually observe all the time, and relieves the burden of workers.

Owner:黄涛

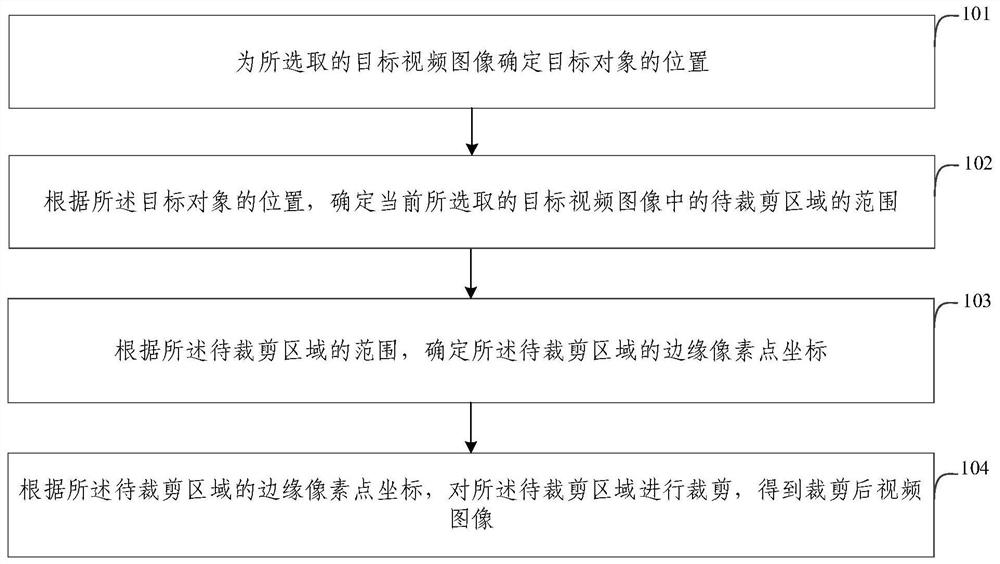

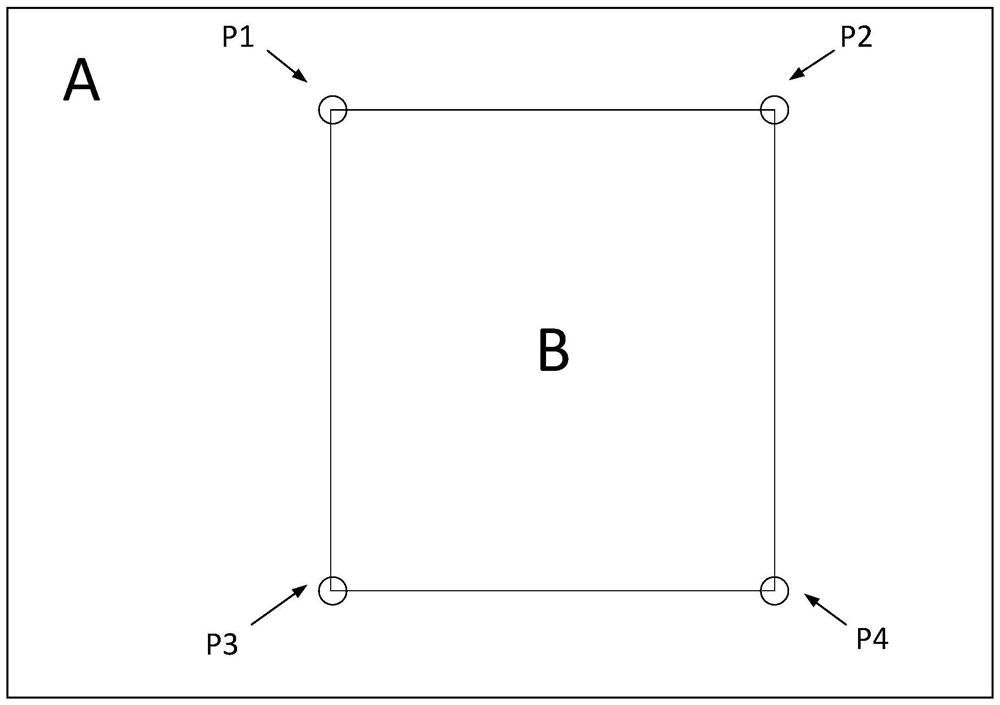

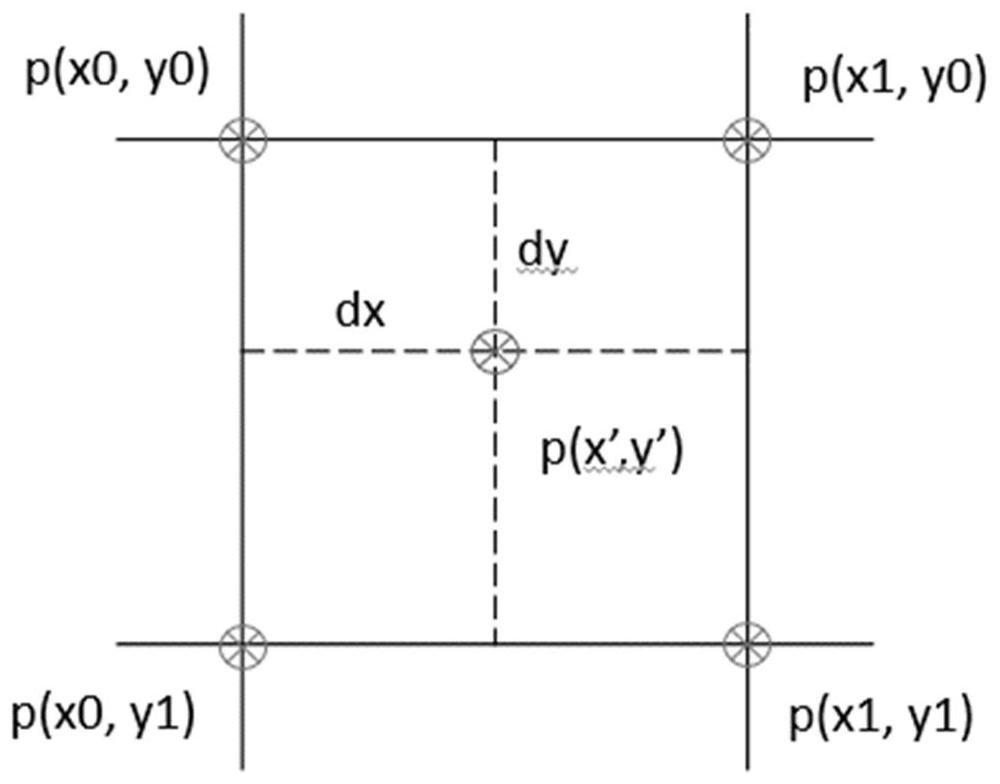

Video image cutting method and device, electronic equipment and storage medium

The embodiment of the invention provides a video image cutting method and device, electronic equipment and a storage medium. The method comprises the following steps: determining the position of a target object for a selected target video image; wherein the target object is an object to be contained in the cut target video image; determining the range of a to-be-cut area in the currently selectedtarget video image according to the position of the target object; determining edge pixel point coordinates of the to-be-cut area according to the range of the to-be-cut area; and cutting the to-be-cut area according to the edge pixel point coordinates of the to-be-cut area to obtain a cut video image. According to the video image cutting method and device, the electronic equipment and the storagemedium provided by the embodiment of the invention, the range of the to-be-cut area is determined by identifying the target object in the target video image, so that the target object is located at arelatively fixed position in the video image obtained after cutting; and the blank condition of the cut video image is avoided.

Owner:MIGU CO LTD +1

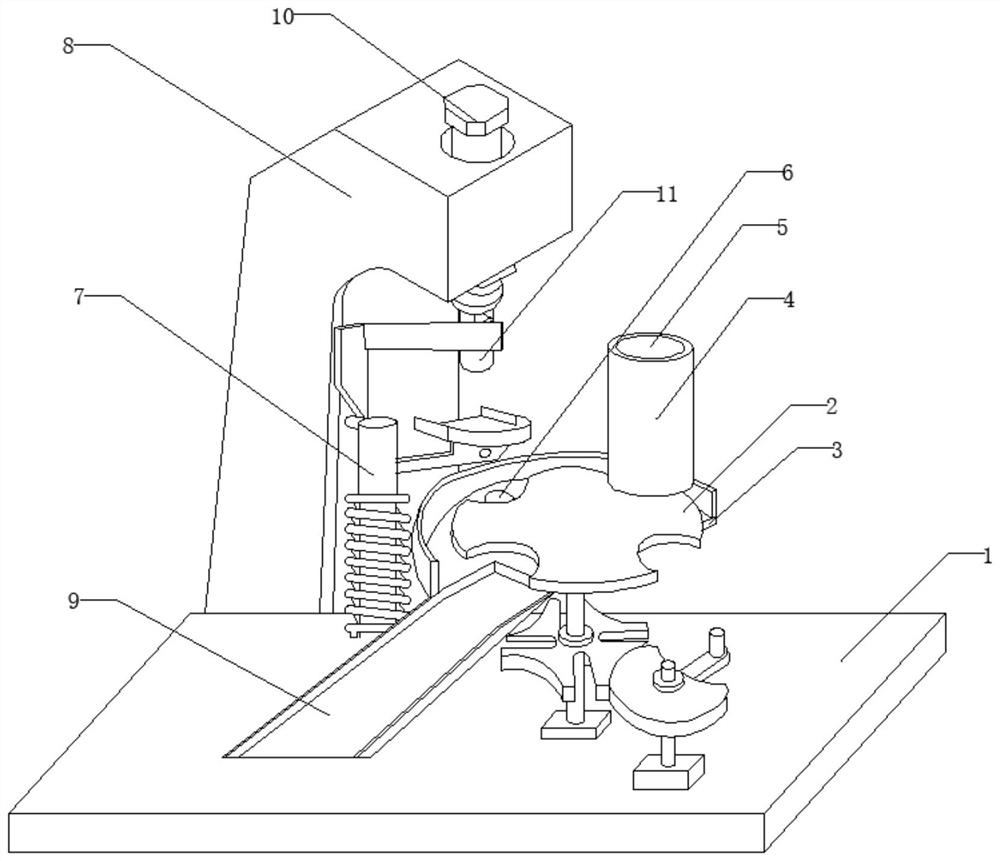

Belt automatic deviation adjusting device

The invention relates to a belt automatic deviation adjusting device comprising a lifting and deviation correcting device. The lifting and deviation correcting device comprises two bases located on the two sides of a belt, skew roller assemblies and first vertical roller assemblies, the skew roller assemblies and the first vertical roller assemblies are mounted on the bases, each skew roller assembly comprises a skew roller base and a skew roller, and each skew roller base is hinged to the corresponding base. Each first vertical roller assembly includes a first bracket, a first vertical rollerbase and a supporting module, wherein the lower end of the first bracket is fixedly connected with the corresponding base, the upper end is rotationally provided with a first rotating shaft, the first vertical roller base is fixedly connected with the first rotating shaft, and a first vertical roller is mounted on the first vertical roller base. The outer end of each supporting module is fixedlyconnected to the corresponding first rotating shaft, and the inner end of each supporting module is in contact with the lower end surface of the corresponding skew roller base. According to the belt automatic deviation adjusting device, a lifting deviation correcting device and a steering deviation correcting device are arranged on the two sides of the transport belt, two-way self-swinging deviation adjusting of the belt in running can be achieved through carrier rollers, the deviation correcting speed is high, the deviation adjusting effect is good, the wear of the transport belt is reduced,and the manpower of a mine material transportation site is saved.

Owner:山东黄金矿业(莱州)有限公司焦家金矿

Automobile part stamping device

PendingCN112893590AHigh precisionGood effectMetal-working feeding devicesCleaning using gasesStructural engineeringStamping press

The invention discloses an automobile part stamping device which comprises a bottom plate, an adjusting mechanism is arranged at the top end of the bottom plate, a feeding disc is arranged on one side of the top end of the adjusting mechanism, a discharging groove is formed in the top end of the feeding disc, a feeding port is formed in the top end of the discharging groove, a lower die is arranged at the top end of the feeding disc, and a sweeping mechanism is arranged on one side of the adjusting mechanism. A punching machine is arranged on the side, away from the adjusting mechanism, of the sweeping mechanism, the sweeping mechanism and the punching machine are arranged at the top end of the bottom plate, and a discharging plate is arranged at the bottom end of the feeding disc. The automobile part stamping device has the beneficial effects that under the action of the adjusting mechanism, the discharging groove can evenly discharge materials at a constant speed, so that the working efficiency is improved, an obtained die can be directly discharged from the discharging plate under the action of a punching head of the punching machine and the lower die, and therefore collection of automobile parts is completed, and under the action of the sweeping mechanism, and after each time of stamping is finished, the sweeping mechanism is used for blowing and cleaning the surface of the lower die, so that sweeps of the lower die are cleaned away.

Owner:重庆大江国立精密机械制造有限公司

Efficient material evening and canning device for cosmetic production

InactiveCN112141982AImprove work efficiencyPrevent spot accumulationLiquid bottlingElectric machineryBottle

The invention discloses an efficient material evening and canning device for cosmetic production. The device comprises a bottom plate, and a rotating mechanism is mounted above the bottom plate; the rotating mechanism comprises a servo motor, a first gear, a second gear, a second rotating shaft and a rotary disc; and supporting seats are installed on the bottom plate, a vibration disc is installedon the supporting seats, a vibration motor is installed at the bottom of the vibration disc, the rotary disc is located on the upper portion of the vibration disc, and through installation grooves are formed in the rotary disc in an annular array mode. In the filling process, the vibration motor drives the vibration disc to vibrate, the bottoms of packaging bottles contact the vibration disc, sothat the packaging bottles vibrate, then a cosmetic filling the packaging bottles is laid flat into bottle bodies due to vibration of the bottle bodies, thus fixed-point accumulation of the cosmetic is prevented, and that the interior of the bottle bodies is empty is avoided.

Owner:贾影丽

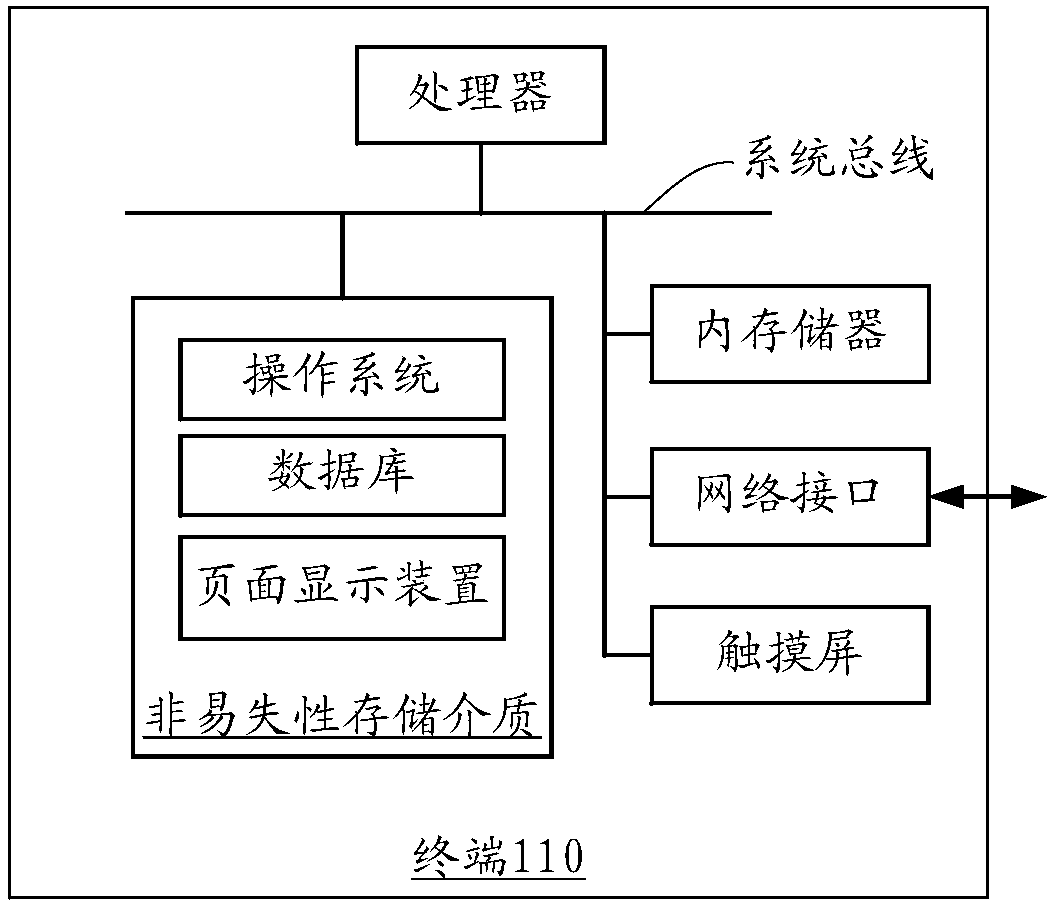

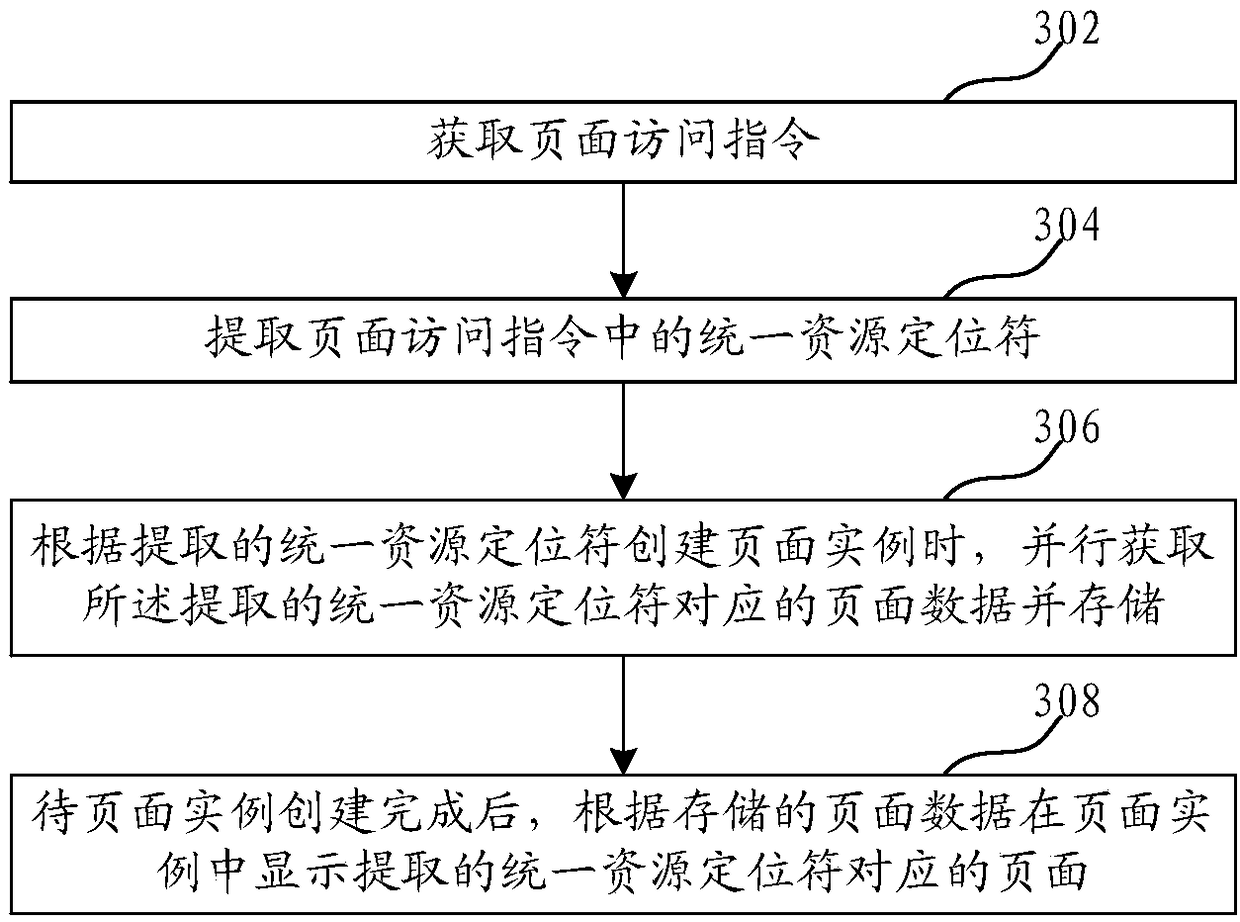

Page display method and device

ActiveCN108255898AImprove display speedAvoid blankingSpecial data processing applicationsWeb data browsing optimisationUniform resource locatorTime-Consuming

The invention relates to a page display method and device. The method comprises the following steps that: obtaining a page access instruction; extracting a uniform resource locator in the page accessinstruction; according to the extracted uniform resource locator, creating a page living example, and obtaining page data corresponding to the extracted uniform resource locator, and storing the obtained page data; after the page living example finishes being created, according to the stored page data, displaying a page corresponding to the extracted uniform resource locator in the page living example. By use of the page display method and device provided by the invention, the page data can be obtained without waiting for the completion of the creating of the page living example. After the page living example finishes being created, the page can be directly displayed in the created page living example according to the stored page data, time consumed for waiting for creating the page livingexample is saved, page display speed is improved, and a situation that page margins are in the presence for a long time is avoided.

Owner:PING AN TECH (SHENZHEN) CO LTD

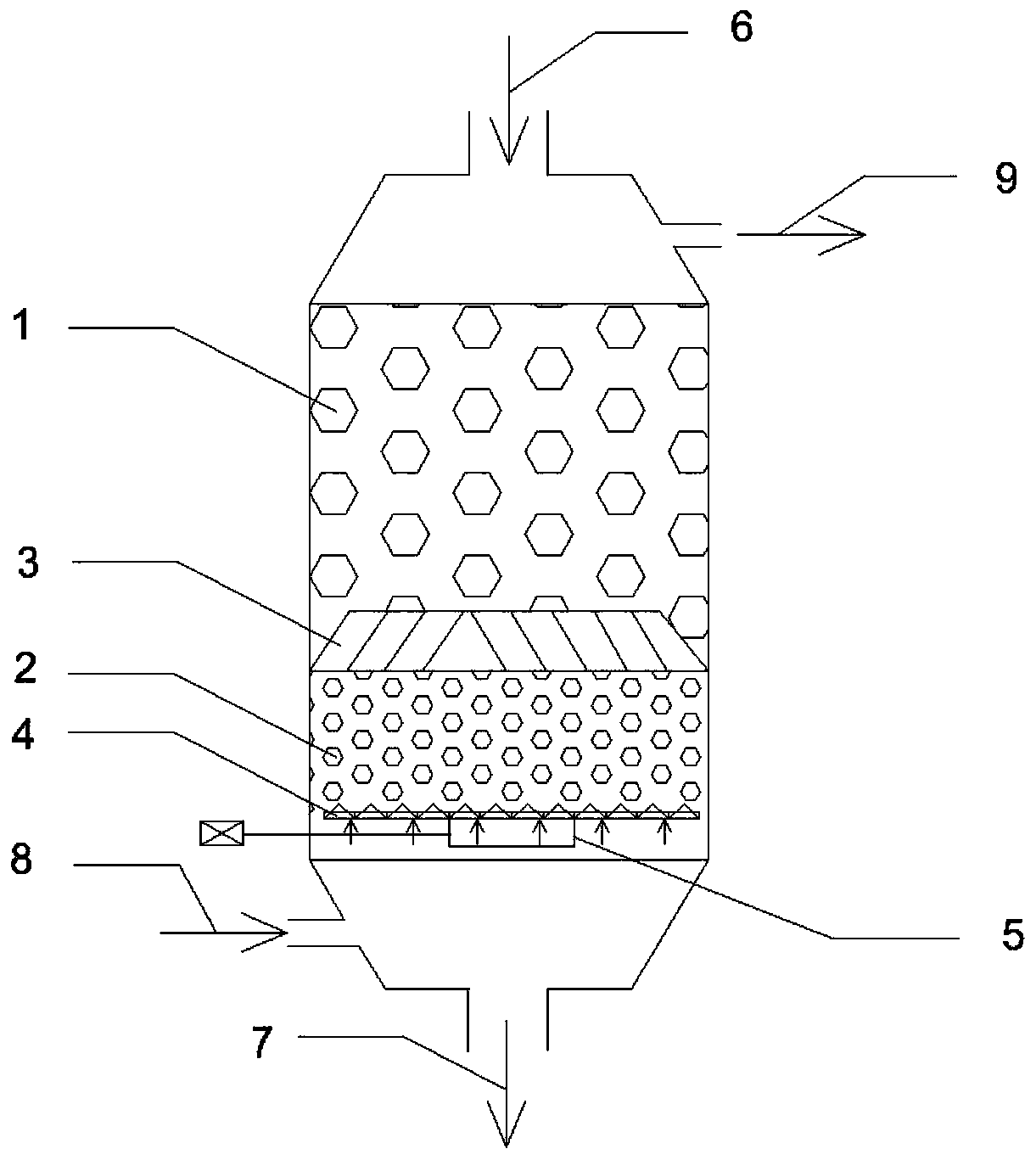

Method and device for desulfurization of high-temperature flue gas through forced grinding and on-line decomposition CaCO3

ActiveCN110639355ASimple processLow costGas treatmentDispersed particle separationThermodynamicsFlue gas

The invention discloses a method and a device for desulfurization of high-temperature flue gas through forced grinding and on-line decomposition CaCO3. According to the invention, CaCO3 is adopted asa desulfurizing agent and is decomposed into CaO on line through heat energy of high-temperature flue gas, and CaO reacts with SO2; and in the desulfurization process, a grinding disc is adopted for rotary grinding so as to break a CaSO3 product shell layer wrapping the surfaces of CaO particles, so obstruction in the further reaction of CaO and SO2 is eliminated. A desulfurization reaction is carried out in an integrated reactor which comprises a CaCO3 decomposition zone, a desulfurization section, a grate bridge and the grinding disc; high-temperature flue gas which is not desulfurized enters the desulfurization section for the desulfurization reaction; and the desulfurized high-temperature flue gas enters the CaCO3 decomposition zone to continue decomposition of CaCO3 and then is discharged through a flue gas outlet to enter a subsequent process link. According to the invention, online decomposition of CaCO3 is carried out by utilizing the high-temperature flue gas, and surface updating of CaO is realized by utilizing forced grinding, so the desulfurizing agent, namely CaCO3 is fully utilized, desulfurization efficiency is greatly improved, the purity of the desulfurization product gypsum is guaranteed, and desulfurization cost is reduced; and the device is simple in structure and convenient to implement.

Owner:XIANGTAN UNIV

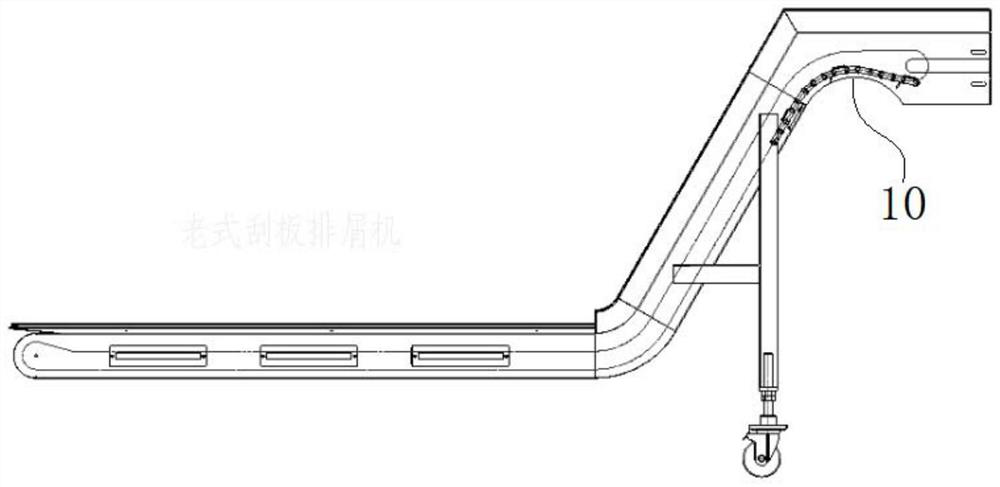

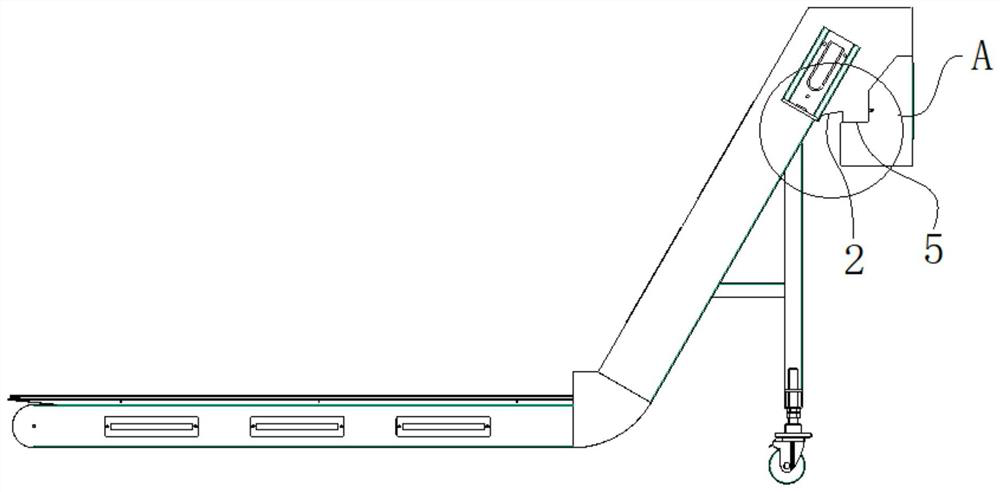

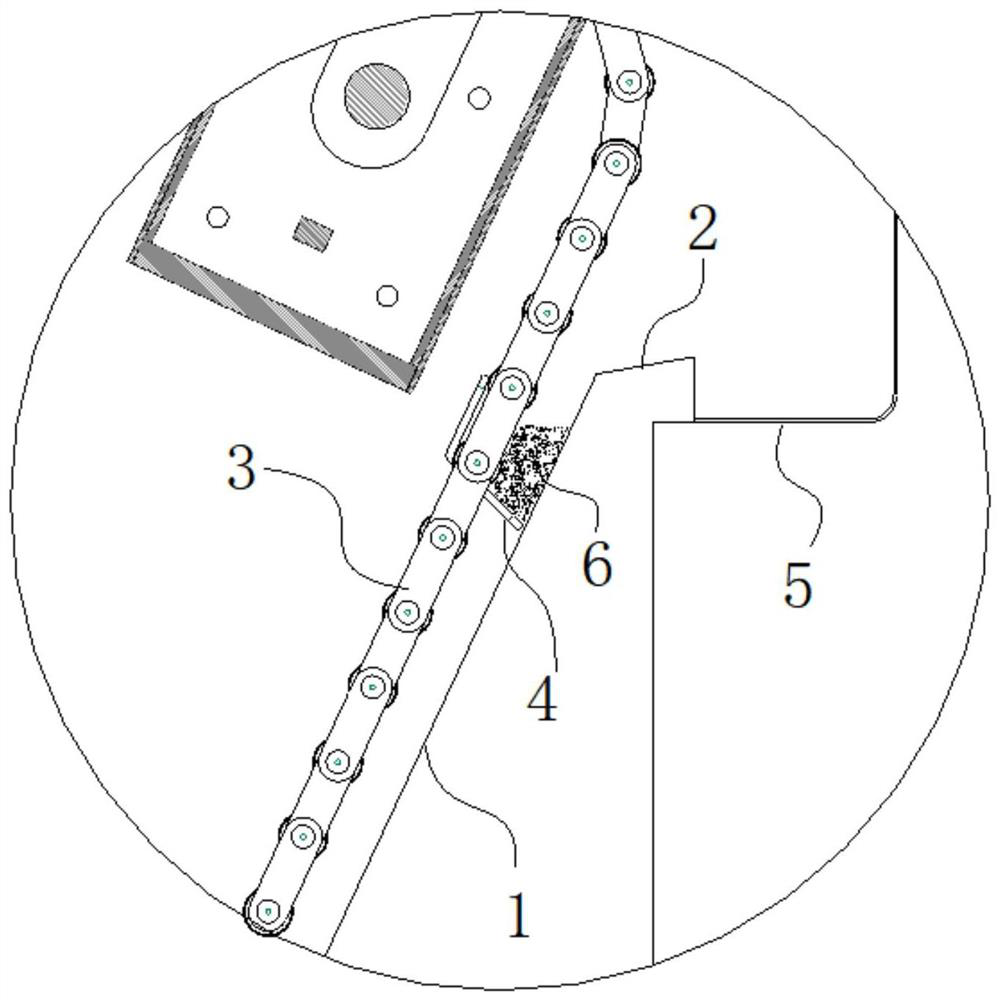

Scraper type chip removal device and chip removal method

PendingCN113103056AReduce carryAvoid churnMaintainance and safety accessoriesStructural engineeringProcess engineering

The invention discloses a scraper type chip removal device and a chip removal method, and belongs to the technical field of machine tool machining matched equipment. The scraping plate type chip removal device comprises a circulating type scraper chain and a plurality of scrapers, wherein one ends of the scrapers are fixedly connected to the circulating type scraper chain, and the other ends of the scrapers are tightly attached to a chip removal climbing section; and a chip removal retention section is arranged between the chip removal climbing section and a chip removal discharging port. By fully utilizing the poor adhesive force between cutting fluid and scrap iron and the inclination angle of the scrapers in the conveying process, the cutting fluid is separated from the scrap iron under the action of the gravity of the cutting fluid and then flows back into a cutting fluid pool along the chip removal climbing section, the carrying amount of the cutting fluid during scrap iron falling is reduced, and therefore loss and waste of the cutting fluid are avoided, and the pollution to soil or environment caused by chemical components contained in the cutting fluid is also avoided.

Owner:马鞍山昇工智能科技有限公司

Preserved meat processing equipment

ActiveCN108813699AImprove efficiencyReduce labor intensityMeat/fish preservation using solidsFood coatingPulp and paper industry

The invention relates to the field of processing of preserved meat, in particular to preserved meat processing equipment. The preserved meat processing equipment comprises a processing platform whichis obliquely arranged, wherein a clamping apparatus for clamping meat is arranged on the processing platform; a rotating mechanism for driving the clamping apparatus to rotate is connected to the clamping apparatus; a material cylinder which slides horizontally is arranged above the processing platform; a fixed discharging plate is fixedly connected to the inner part of the material cylinder, anda rotating discharging plate is rotatably connected to the inner part of the material cylinder; a first discharging hole is formed in the fixed discharging plate; a second discharging hole which is intermittently opposite to the first discharging hole is formed in the rotating discharging plate; a brush is arranged below the material cylinder; a screw rod which penetrates through the fixed discharging plate and the rotating discharging plate is rotatably connected to the brush, and is in threaded connection with the rotating discharging plate; a first pressing spring which sleeves the screw rod is connected between the brush and the material cylinder; and a discharging pipe is arranged between the brush and the material cylinder in a communicating manner. Through the adoption of the schemeof the preserved meat processing equipment disclosed by the invention, in the making course of the preserved meat, seasonings are mechanically coated on the meat, so that the making efficiency of thepreserved meat is improved.

Owner:桐梓县月亮河飞宏腊制品有限公司

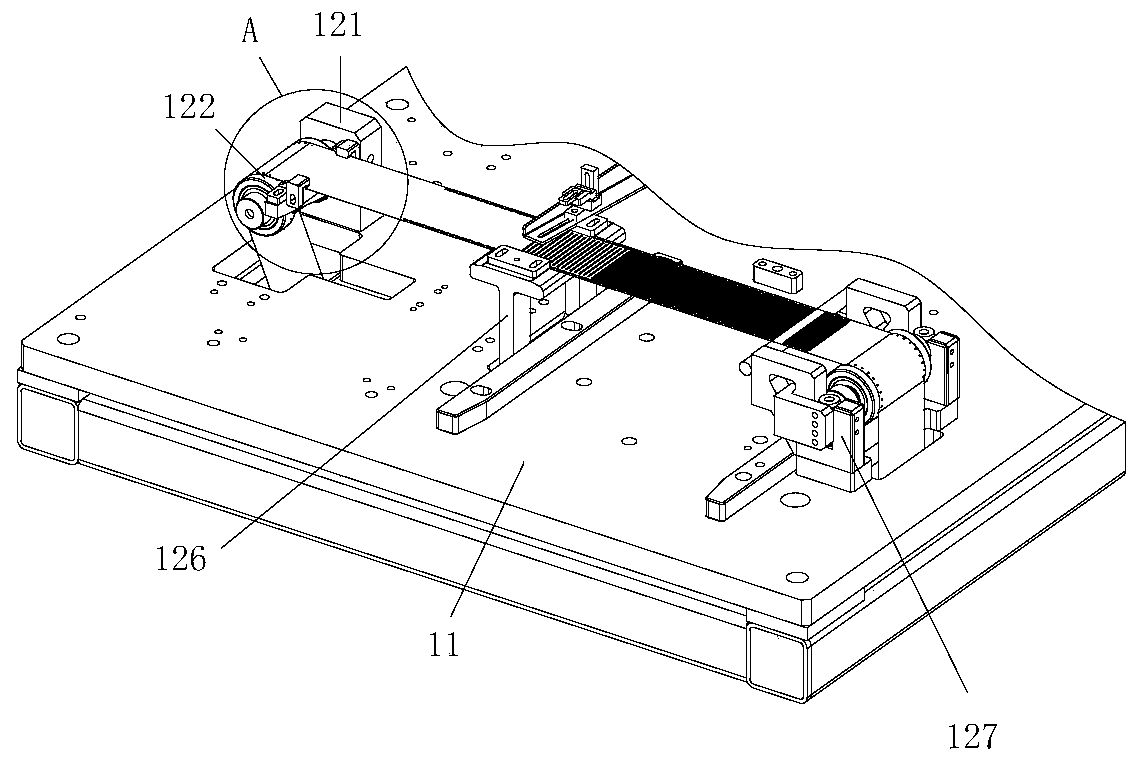

Steel sheet laminating device

PendingCN111361259AAvoid skewAutomatically adjust the feeding tightnessLamination ancillary operationsLaminationMetallurgyEngineering

The invention discloses a steel sheet laminating device. The steel sheet laminating device comprises a laminating rack, a PC film feeding unit, an adjustable steel sheet transplanting manipulator, a steel sheet positioning adsorption platform, a laminating manipulator and a pressing assembly, wherein the PC film feeding unit is mounted on the laminating rack, the adjustable steel sheet transplanting manipulator, the steel sheet positioning adsorption platform, the laminating manipulator and the pressing assembly are arranged on the PC film feeding unit, the adjustable steel sheet transplantingmanipulator grabs a steel sheet at a steel sheet punching device and then places the steel sheet on the steel sheet positioning adsorption platform, the laminating manipulator adsorbs and laminates the steel sheet on the PC film, and the pressing assembly presses the steel sheet on the PC film. By means of the mode, the device is compact in structure, stable in operation and capable of automatically adjusting the feeding tightness, guaranteeing the feeding stability, adjusting the levelness of the adsorption holes in the bottom face of the adsorption block, positioning and adsorbing steel sheets, facilitating subsequent steel sheet adsorption and product pressing and pasting and meanwhile avoiding product damage.

Owner:SUZHOU LANGKUN AUTOMATION EQUIP CO LTD

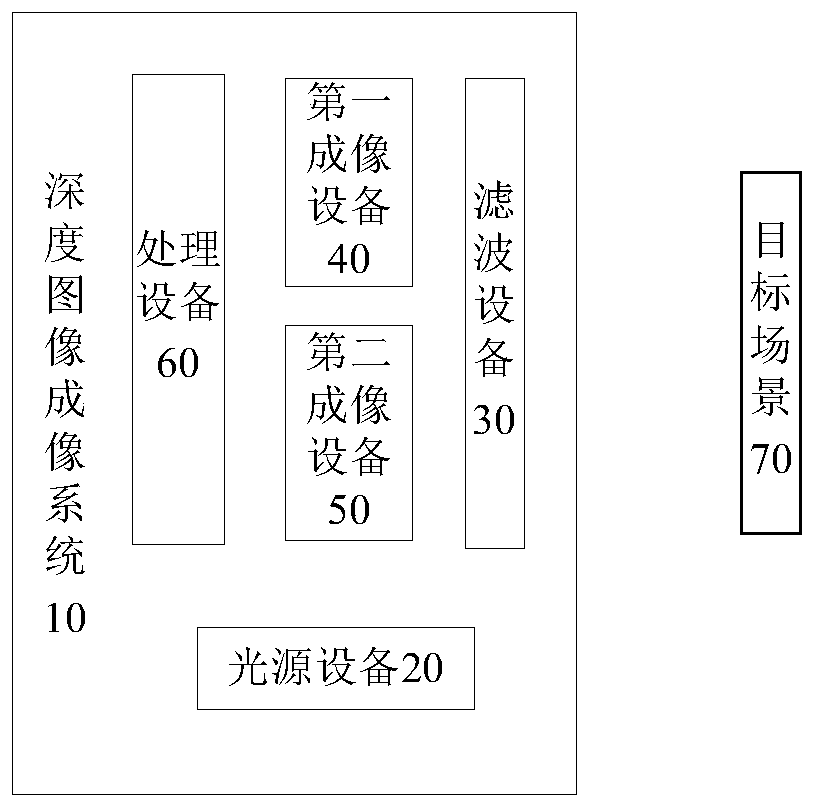

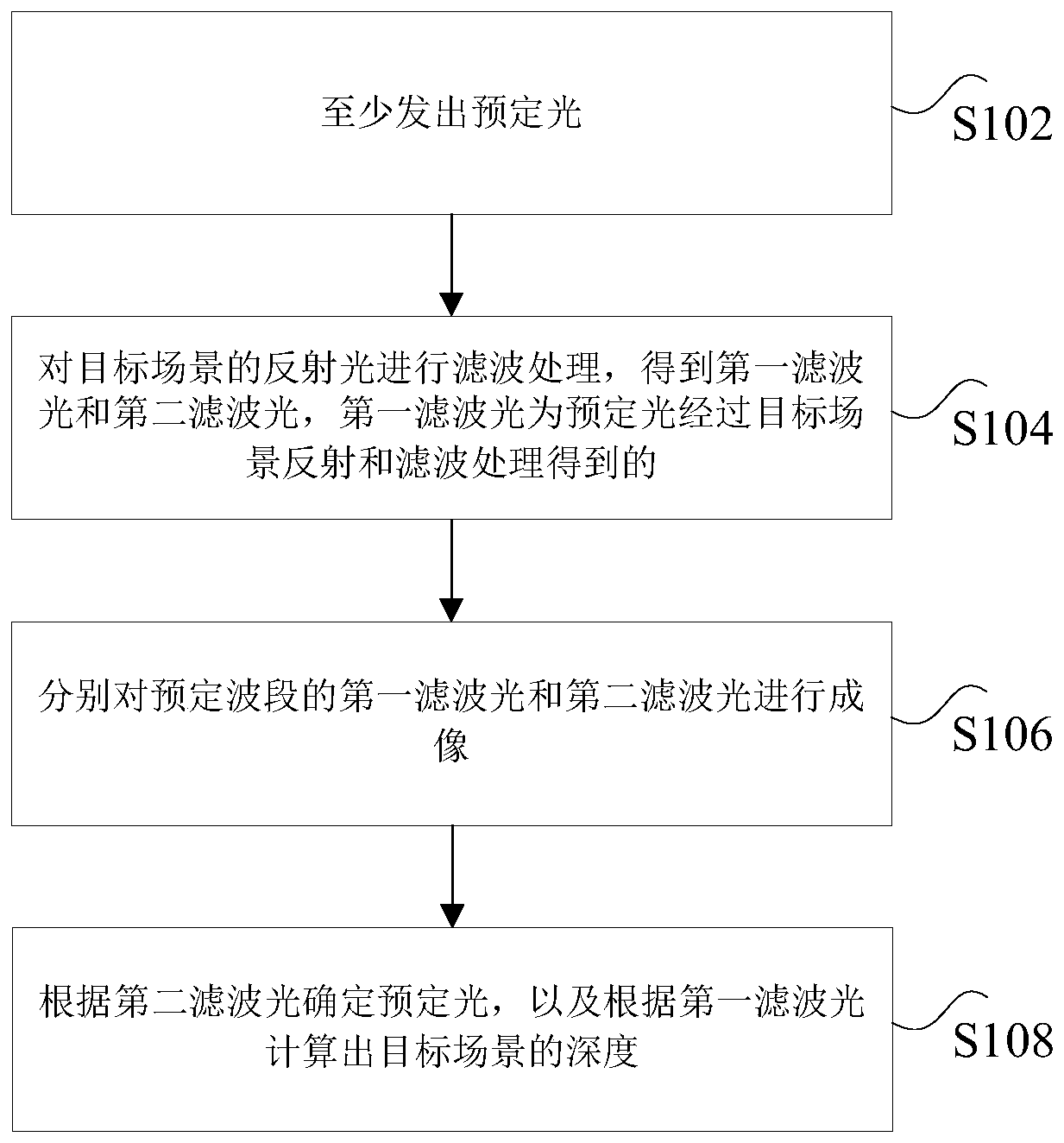

Depth image imaging system and method

PendingCN110441784AImprove accuracyImprove reliabilityElectromagnetic wave reradiationLight sourceImaging equipment

The invention provides a depth image imaging system and method. The imaging system comprises light source equipment, filtering equipment, first imaging equipment, second imaging equipment and processing equipment; the light source equipment is positioned at one side of a target scene, and used for at least sending predetermined light; the filtering equipment is positioned at one side of the targetscene, and used for filtering reflected light of the target scene, so that first filtered light and second filtered light are obtained; the first filtered light is obtained by reflecting and filtering the predetermined light through the target scene; the first imaging equipment and the second imaging equipment are positioned at the light exit side of the filtering equipment, and used for respectively imaging the first filtered light and the second filtered light in the predetermined band; and the processing equipment is used for determining the predetermined light according to the second filtered light, and calculating the depth of the target scene according to the first filtered light. The imaging system can measure the depth of the target scene more accurately.

Owner:ZHEJIANG SUNNY OPTICAL CO LTD

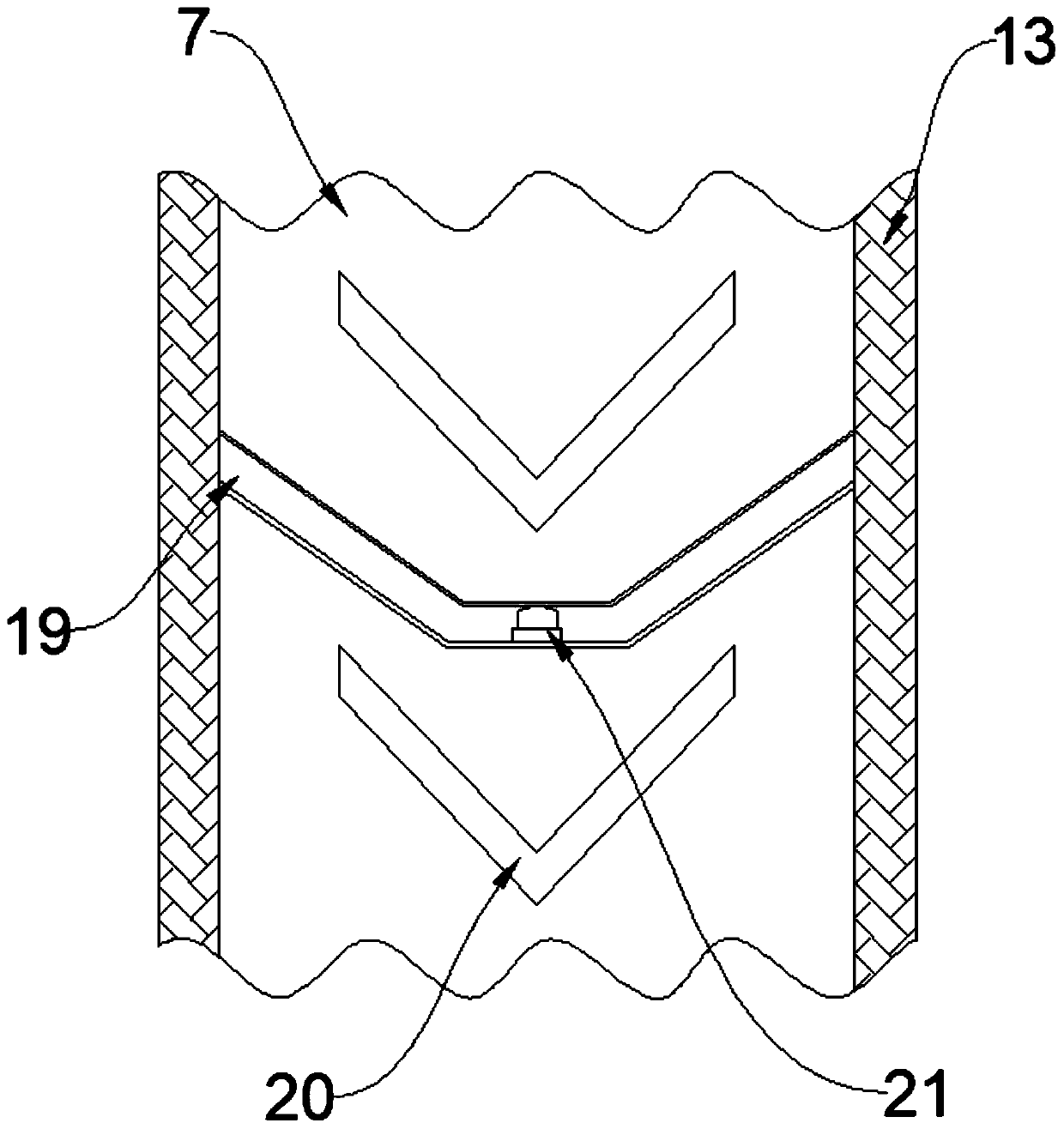

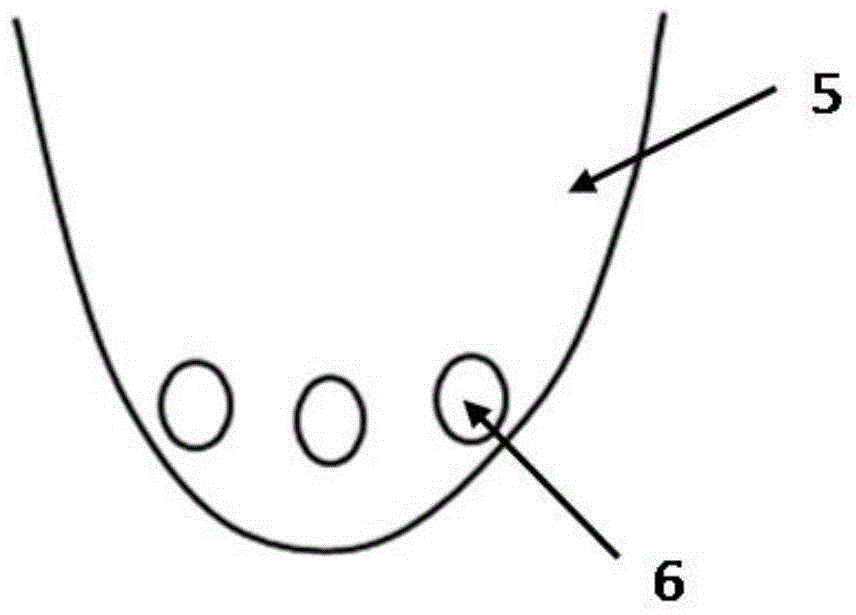

Particle screening device for mechanical production

InactiveCN111790604AUniform Stratified ScreeningIncrease contact areaSievingScreeningPhysicsElectric machinery

The invention belongs to the technical field of machining, particularly relates to a particle screening device for mechanical production. The particle screening device aims to solve the problem that an existing device is not ideal in screening effect. According to the scheme, the particle screening device comprises a box body, wherein a motor is fixed to the top of the box body, and an output shaft of the motor is connected with a straight shaft; a collecting basin is fixed to the bottom of the inner wall of the box body, a guide pipe is fixed to the bottom of the inner wall of the collectingbasin, and a first fixing ring and a second fixing ring are fixed to the outer wall of the guide pipe; and a first screen plate and a second screen plate are fixed to the bottom of the first fixing ring and the bottom of the second fixing ring respectively, and the first screen plate and the second screen plate are arranged to be of hollow circular truncated cone structures. According to the particle screening device for mechanical production, the first screen plate is arranged to be of the hollow circular truncated cone structure, a plurality of guide grooves are formed in the first screen plate, and the sections of the guide grooves are arranged in V shapes, so that the contact area and capacity are effectively increased; and small particles are located at the bottoms of the guide grooves, large particles are located at the upper portions of the guide grooves, and the large and small particles are evenly screened in a layered mode, so that the screening effect of the device is improved.

Owner:宣城知明灯机械设计有限公司

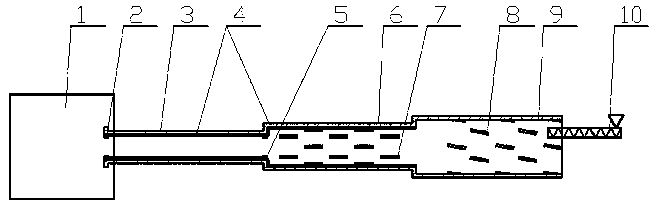

Internal heating type reduction activated carbon production converter

ActiveCN103130220AUniform carbonizationGood activation effectCarbon compoundsActivated carbonRetaining ring

The invention relates to an internal heating type reduction activated carbon production converter which comprises a combustion room, a first retaining ring, an activation chamber, heat-insulating / energy-storing refractory bricks, a second retaining ring, a carbonization chamber, a multi-inclination-angle raising plate, a push type multi-inclination-angle raising plate, a drying and plasticization chamber and a feeding spiral conveyer, wherein the drying and plasticization chamber, the carbonization chamber, the activation chamber and the combustion room are sequentially communicated and connected; the inner diameters of the drying and plasticization chamber, the carbonization chamber and the activation chamber are sequentially reduced; the feeding spiral conveyer is arranged at the inlet of the drying and plasticization chamber; the push type multi-inclination-angle raising plate is arranged in the drying and plasticization chamber; the multi-inclination-angle raising plate is arranged in the carbonization chamber; the inner walls of the carbonization chamber and the activation chamber are respectively provided with a layer of heat-insulating / energy-storing refractory bricks; and the retaining rings are respectively arranged at discharge ports of the carbonization chamber and the activation chamber. The internal heating type reduction activated carbon production converter can prevent the material from falling at the tail part of the converter, realizes uniform carbonization, achieves favorable activation effect, can maximize the activated carbon yield and fully utilize heat in the converter, and is stable in product quality, energy-saving and environment-friendly.

Owner:徐州天正活性炭厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com