Efficient material evening and canning device for cosmetic production

A high-efficiency technology for cosmetics, which is applied in the field of high-efficiency leveling and canning equipment, can solve the problems of empty bottles and uneven cosmetics, and achieve the effect of preventing fixed-point accumulation and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

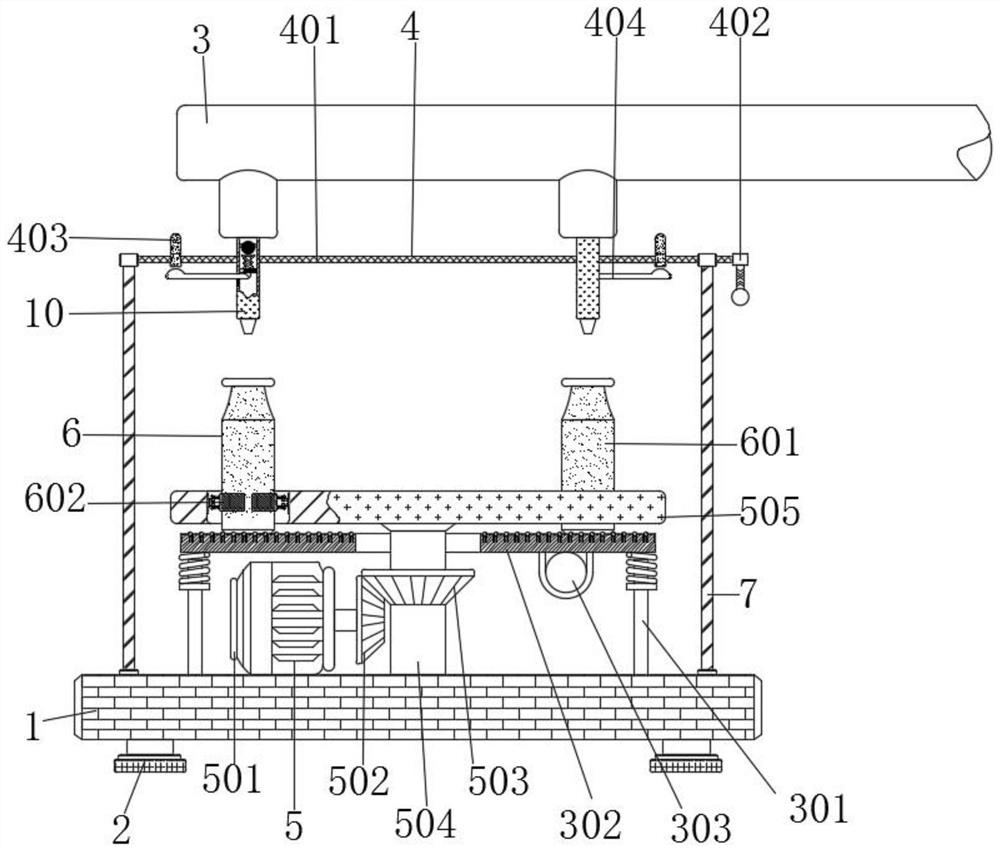

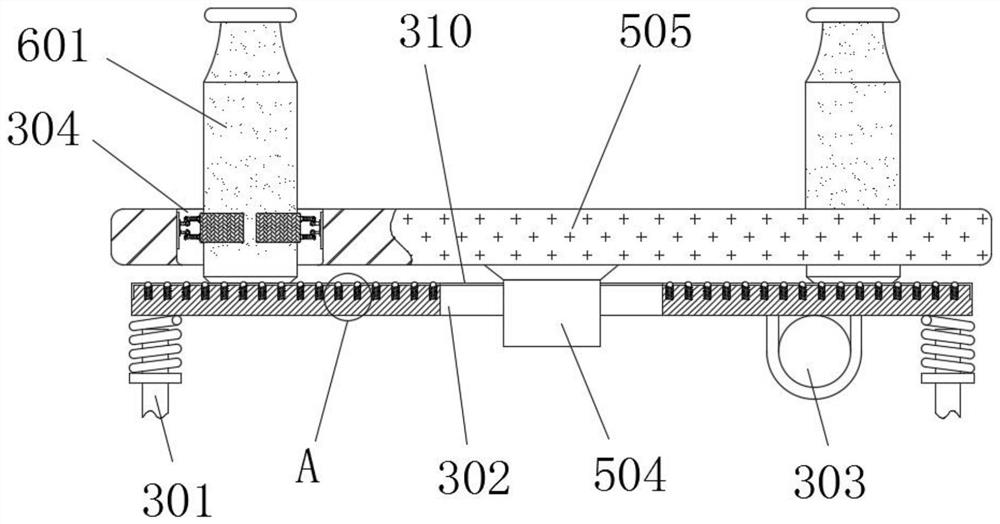

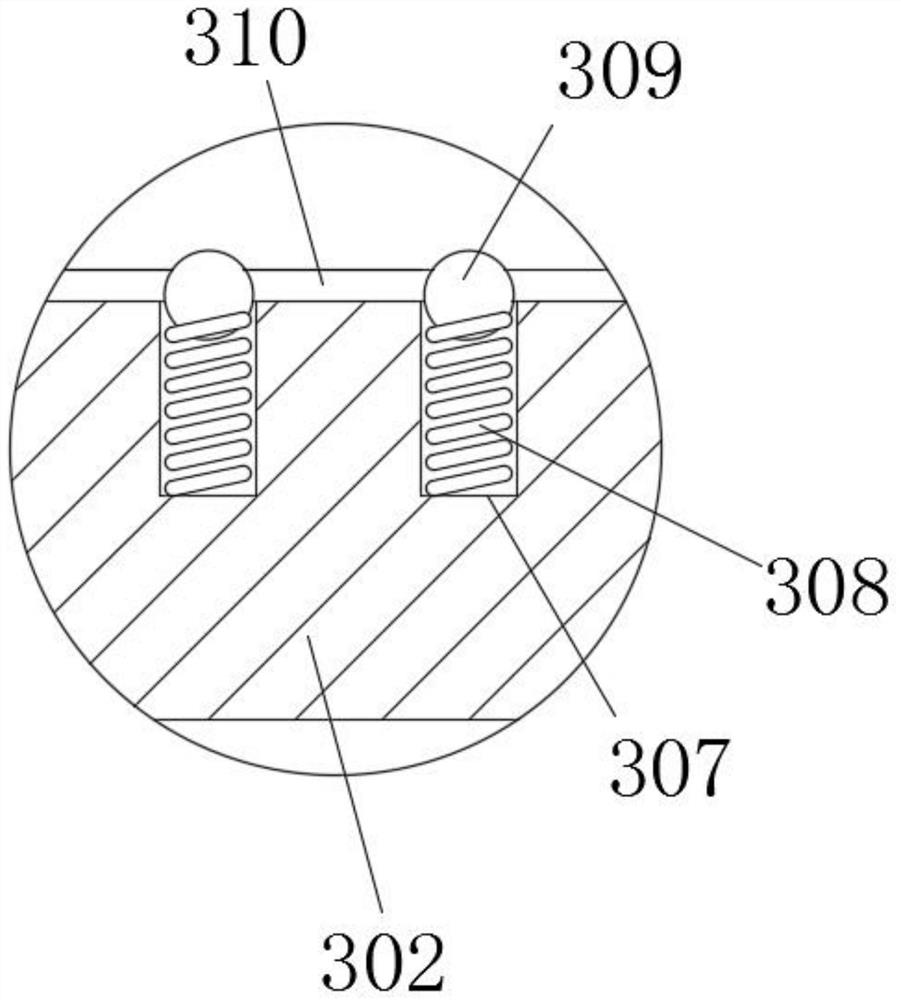

[0033] see Figure 1-5, the present invention provides a technical solution: a high-efficiency leveling and canning equipment for cosmetics production, including a base plate 1; a rotating mechanism 5 is installed above the base plate 1, and the rotating mechanism 5 includes a servo motor 501, a first gear 502, The second gear 503, the second rotating shaft 504 and the turntable 505, the bottom end of the servo motor 501 is fixedly connected with the top left side of the base plate 1, the output end of the servo motor 501 is fixedly connected with the middle of the left end of the first gear 502, the servo motor 501 The output end drives the first gear 502 to rotate, the teeth of the first gear 502 mesh with the teeth of the second gear 503, and the second gear 503 rotates through the meshing force between the first gear 502 and the second gear 503. The middle inner wall of the second gear 503 is fixedly connected to the upper outer wall of the second rotating shaft 504, and t...

Embodiment 2

[0036] see Figure 1-8 , the present invention provides a technical solution: a high-efficiency leveling and canning equipment for cosmetics production, including an external output port 3, support rods 7 are provided on the left and right sides below the external output port 3, and the external output port 3 A control mechanism 4 is installed below, and the control mechanism 4 includes a first rotating shaft 401, a handle 402, a cam 403, a curved rod 404, a rubber pad 405, a liquid injection port 406, a first horizontal plate 407, a second horizontal plate 408, a first compression The spring 409 and the top block 410, the outer walls on the left and right sides of the first rotating shaft 401 are connected to the upper inner wall of the support rod 7 through internal bearings, and the first rotating shaft 401 rotates on the support rods 7 on both sides through the internal bearings on both sides. The right side outer wall of the first rotating shaft 401 is fixedly connected w...

Embodiment 3

[0038] As an option, see Figure 1-5 , high-efficiency leveling and filling equipment for cosmetics production, a fixing mechanism 6 is installed in a ring above the turntable 505, and the fixing mechanism 6 includes a packaging bottle 601, a fixing splint 602, a third horizontal plate 603, an installation chute 604, and a slider 605, the second compression spring 606, the third gear 607 and the support plate 608, the lower outer wall of the packaging bottle 601 is matched with the inner wall above the left side of the turntable 505, and the packaging bottle 601 is stored in the groove on the turntable 505, and the packaging bottle 601 The outer walls on the left and right sides of the bottom of the left side are all fitted with the inner side of the fixed splint 602. The fixed splint 602 on both sides fixes the packaging bottle 601 in the groove in the turntable 505, and the left end of the left fixed splint 602 is fixed on both sides up and down. There is a third horizontal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com