Internal heating type reduction activated carbon production converter

A technology of activated carbon production and internal heating, applied in the direction of inorganic chemistry, non-metallic elements, carbon compounds, etc., can solve problems such as unstable quality, blockage of furnace body, waste of heat source, etc., achieve stable product quality, prevent furnace tail blanking, good activation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

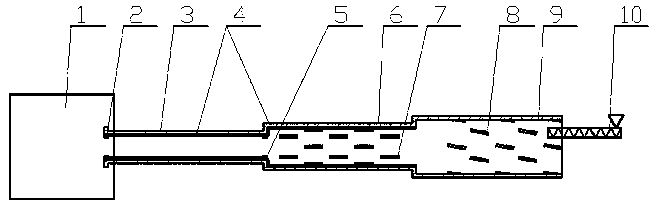

[0019] in the attached figure 1 Among them, the internal heating variable diameter activated carbon production converter includes combustion chamber 1, retaining ring 1 2, activation chamber 3, heat preservation and energy storage refractory brick 4, retaining ring 2 5, carbonization chamber 6, multi-inclination lifting plate 7, pusher type The multi-inclination lifting plate 8, the drying and plasticizing chamber 9, and the feeding auger 10; the drying and plasticizing chamber 9, the carbonization chamber 6, the activation chamber 3 and the combustion chamber 1 are sequentially connected, and the drying and plasticizing chamber 9. The inner diameters of the carbonization chamber 6 and the activation chamber 3 are successively reduced; the entrance of the drying and plasticizing chamber 9 is provided with a feed auger 10, and a push-type multi-inclination lifting plate 8 is provided in the chamber; the carbonization chamber 6 A multi-inclination lifting plate 7 is arranged in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com