A heat-modified anti-deformation home door panel and its production process

A production process and anti-deformation technology, applied in the field of board production and manufacturing, can solve the problems of poor inner carbonization effect, uneven heating of wood, difficult production operation, etc., and achieve the effect of improving dimensional stability, maintaining mechanical properties, and reducing brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

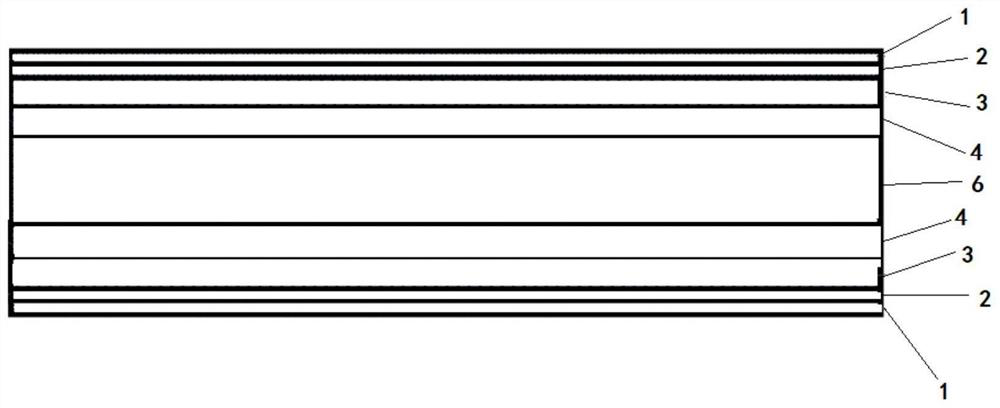

Image

Examples

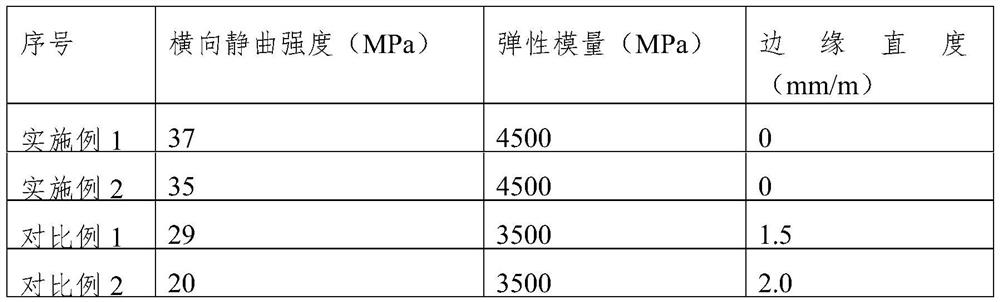

Embodiment 1

[0029] A production process of a thermally modified anti-deformation home door panel, comprising the following steps of implementation:

[0030] 1) Saw fir with a length of 25cm, a width of 6cm, and a core slat of a height of 1.2cm; the eucalyptus wood is cut into a middle board of 127mm*63mm, and the thickness is a middle board of 2.6mm;

[0031] 2) Use MJB-TF wood stabilizer to treat core slats and middle boards;

[0032] 3) Put the core slats and middle plates treated with the stabilizer in step 2) into the microwave drying kiln, and carry out dehydration of hemicellulose at a medium temperature of 150°C, with a power of 250w: the microwave drying kiln is maintained at a temperature of 150°C for 30min, keeping The microwave power is 1kw; after that, the water vapor is re-moisturized to a moisture content of 15%, and then kept at 150 °C for 3 minutes, and the microwave power is 150w, repeated twice; finally, the gradient cooling is carried out at a rate of 2 °C / h, and the te...

Embodiment 2

[0040] A production process of a thermally modified anti-deformation home door panel, comprising the following steps of implementation:

[0041] 1) Saw Chinese fir to 25cm long, 6cm wide, and 1.2cm high core slats; spin eucalyptus into 127mm*63mm medium boards, with a thickness of 2.6mm;

[0042] 2) Use MJB-TF wood stabilizer to treat core board and middle board;

[0043] 3) Put the core slats and middle plates treated with the stabilizer in step 2) into a microwave drying kiln, carry out dehydration of hemicellulose at a medium temperature of 150°C, and a power of 250w: raise the temperature of the microwave drying kiln to 150°C for 30 minutes, and keep the microwave The power is 1kw; after that, the water vapor is reconditioned to a moisture content of 15%, then carbonization is carried out at 150 °C for 3 minutes, and the microwave power is 150w, repeated twice; finally, the gradient cooling is carried out at a rate of 2 °C / h, and the temperature is maintained for 7 days. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com