Particle screening device for mechanical production

A screening device and particle technology, which is applied in the direction of filter screen, solid separation, grid, etc., can solve the problems of unsatisfactory screening effect and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

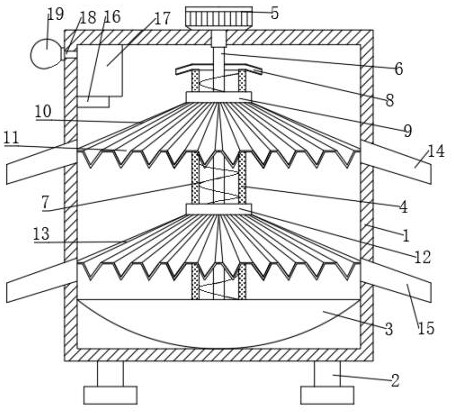

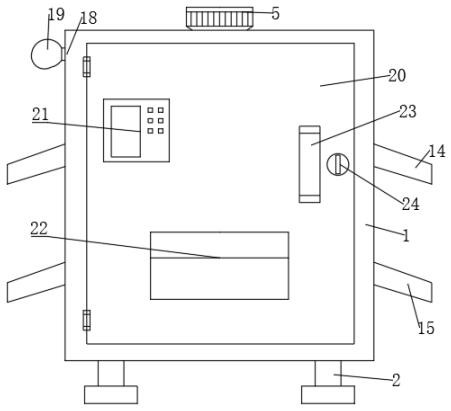

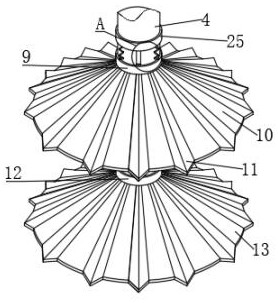

[0025] refer to Figure 1-4 , a particle screening device for mechanical production, including a box body 1, a plurality of pillars 2 are symmetrically fixed by bolts on both sides of the bottom of the box body 1, a motor 5 is fixed on the top of the box body 1 by bolts, and the output shaft of the motor 5 runs through the box body 1 is connected with a straight shaft 6, and the bottom of the inner wall of the box body 1 is fixed with a collection basin 3 by bolts. Inside the guide tube 4, the bottom of the straight shaft 6 is rotatably connected to the bottom of the inner wall of the guide tube 4, and the outer wall of the straight shaft 6 is welded with jiaolong blades 7, and the top of the guide tube 4 is fixed with a guide plate 8 by bolts, and the guide plate 8 and the guide tube 4 is connected, the straight shaft 6 and the material guide plate 8 are connected through, the outer wall of the guide pipe 4 is fixed with bolts to the first fixed ring 9 and the second fixed ri...

Embodiment 2

[0029] refer to Figure 1-5 , a particle screening device for mechanical production, the top of the first screen plate 10 is welded with a plurality of deceleration discs 29, the plurality of deceleration discs 29 are arranged in an annular array distribution, and the plurality of deceleration discs 29 are equally divided into a plurality of guide grooves 11, the cross-section of the deceleration plate 29 is arranged in a silkworm shape, and the deceleration plate 29 in the guide groove 11 is arranged in an arrangement from dense to sparse from inside to outside.

[0030] When in use, the deceleration plate 29 can block and decelerate the small particles at the bottom of the guide groove 11, prolong the movement time of the small particles on the first screen plate 11, and make the small particles move on the first screen plate 11. The path is completely screened to prevent small particles and large particles from being discharged from the first discharge plate 14 together. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com