Surfacing welding method for enclosed connection of long-distance pipeline without mending

A technology of long-distance pipelines and welding methods, applied in welding equipment, welding equipment, arc welding equipment, etc., can solve the problems of reducing the overall service life of pipelines, avoid blanking of anti-corrosion layers, ensure continuity, and improve overall corrosion resistance and the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

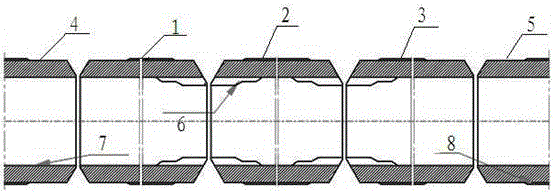

[0014] Specific implementation methods: such as figure 1 As shown, a steel pipe is divided into prefabricated pipe A1 and prefabricated pipe B3 of equal length, and a ladder-shaped corrosion-resistant alloy surfacing layer 6 is surfacing on one end of the prefabricated pipe A1 and prefabricated pipe B3 respectively, and the groove and slope are processed by plasma. The corrosion-resistant alloy surfacing layer is exposed on the inner wall of the mouth, and then trimmed and polished; the short joint 2 is prefabricated. The internal and external anti-corrosion treatment is carried out on the above-mentioned surfacing puppet 2, prefabricated pipe A1, and prefabricated pipe B3, and the internal anti-corrosion layer covers the first step of the ladder-shaped corrosion-resistant alloy surfacing layer to form a continuous internal anti-corrosion layer 7; 2 The sum of the lengths of the prefabricated pipe A1 and the prefabricated pipe B3 is slightly greater than the length of the rese...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com