Wormwood non-woven fabric and manufacturing method thereof

A technology of non-woven fabrics and production methods, applied in textiles and papermaking, non-woven fabrics, adhesives, etc., can solve the problems of lack, development and application are not perfect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

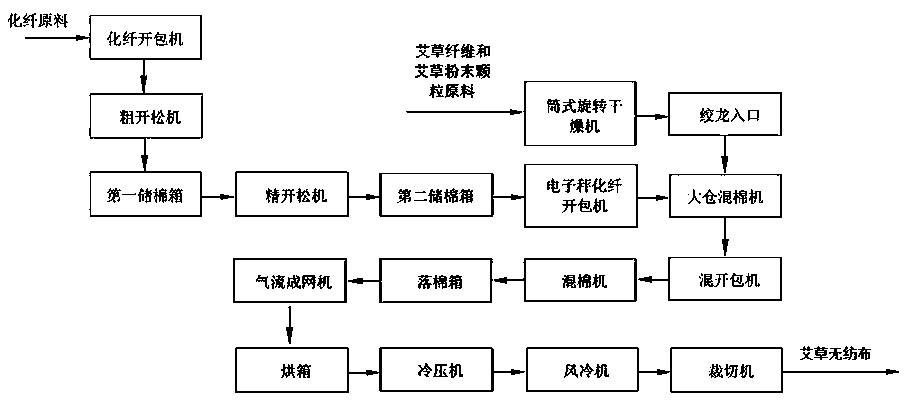

Image

Examples

Embodiment 1

[0029] Embodiment 1: a kind of wormwood non-woven fabric, comprises following composition by weight percentage content: 65% polypropylene fiber, 15% wormwood fiber and 5% wormwood powder particle, the wormwood fiber length is controlled at 1mm, fineness 3D; the length of the low-melting chemical fiber is controlled at 10mm, and the fineness is 3D; the wormwood powder particles are 100 mesh; the components are mixed, intertwined, interwoven and filled to form a continuous fiber network structure, and the 0.2mm wormwood is obtained by melting and cold pressing Grass non-woven fabric, the temperature of the hot-melt oven is 130°C, and the density of the tested wormwood non-woven fabric is 0.05g / cm 3 .

Embodiment 2

[0030] Embodiment 2: a kind of wormwood non-woven fabric, comprises following weight composition by percentage content: 70% polypropylene fiber, 17% wormwood fiber and 8% wormwood powder particle, wormwood fiber length is controlled at 20mm, fineness 20D; the length of the low melting point chemical fiber is controlled at 50mm, and the fineness is 5D; the wormwood powder particles are 30 mesh; the components are mixed, intertwined, interwoven and filled to form a continuous fiber network structure, and the 3mm wormwood is obtained by melting and cold pressing For non-woven fabrics, the temperature of the hot-melt oven is 150°C, and the density of the tested wormwood non-woven fabric is 0.1g / cm 3 .

Embodiment 3

[0031]Embodiment 3: a kind of wormwood non-woven fabric, comprises following weight composition by percentage content: 75% polypropylene fiber, 18% wormwood fiber and 10% wormwood powder particle, wormwood fiber length is controlled at 50mm, fineness 30D; the length of the low-melting chemical fiber is controlled at 80mm, and the fineness is 8D; the wormwood powder particles are 50 mesh; the components are mixed, intertwined, interwoven and filled to form a continuous fiber network structure, and the 3mm wormwood is obtained by melting and cold pressing For non-woven fabrics, the temperature of the hot-melt oven is 180°C, and the density of the tested wormwood non-woven fabric is 0.3g / cm 3 .

[0032] Embodiment 3: a kind of wormwood non-woven fabric, comprises following weight composition by percentage content: 76% polypropylene fiber, 19% wormwood fiber and 13% wormwood powder particle, wormwood fiber length is controlled at 70mm, fineness 50D; the length of the low-melting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com