Environmental-friendly mercuric chloride metal catalyst and preparation method thereof

A metal catalyst and mercuric chloride technology, applied in physical/chemical process catalysts, hydrogen halide addition preparation, chemical instruments and methods, etc., can solve the problems of cumbersome catalyst preparation process, cumbersome catalyst preparation, and low catalytic efficiency, and achieve It is beneficial to control production, the catalyst releases smoothly, and is easy for industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) 30g of styrene-acrylic acid copolymer (weight-average molecular weight Mw=11300, molecular weight distribution MWD=1.31, glass temperature of 125°C, melting point of 215°C) was added to 300ml of tetrahydrofuran (THF) and stirred to make styrene-acrylic acid The copolymer is completely dissolved to obtain a polymer solution;

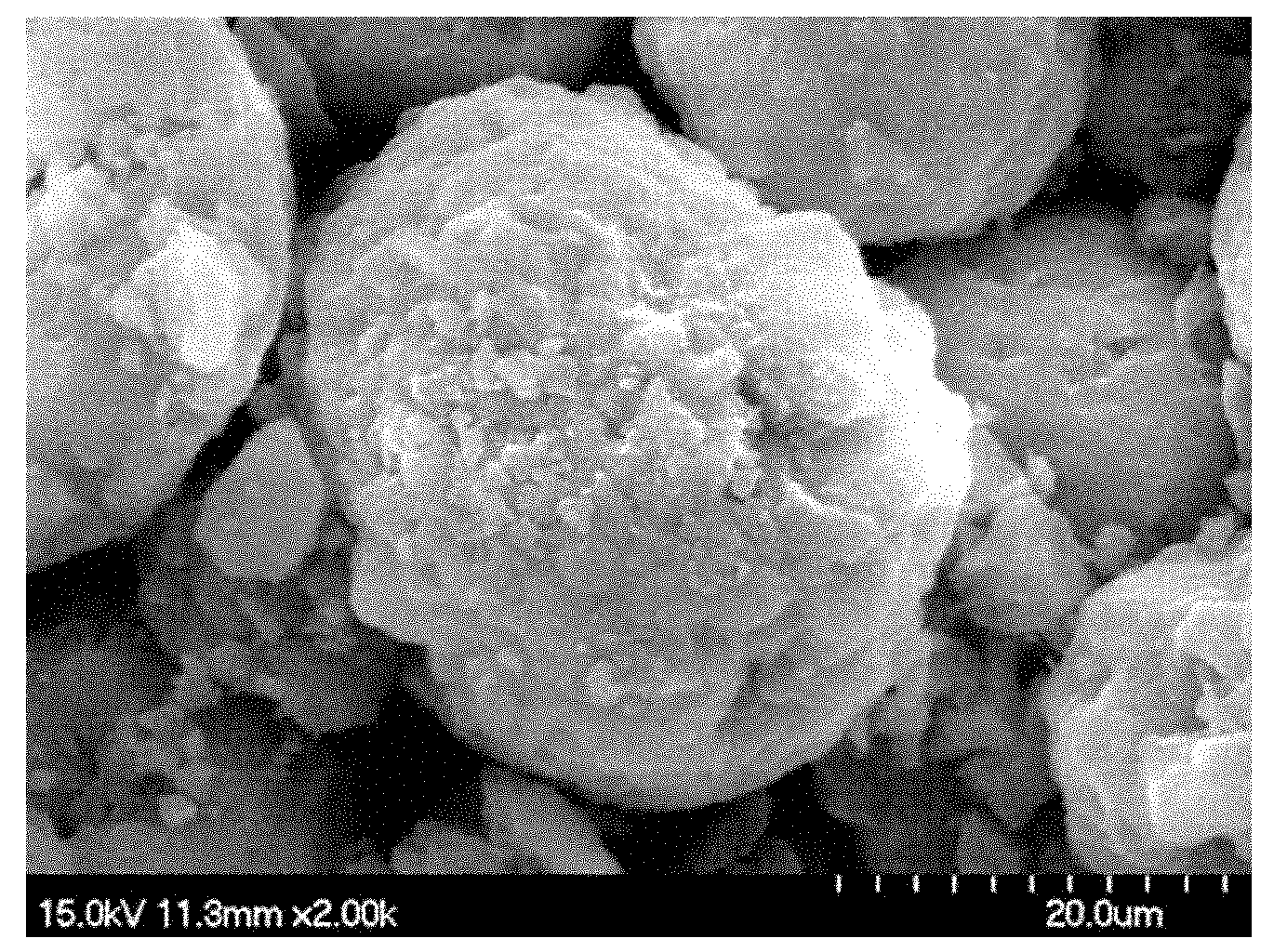

[0030] (2) Add 30g of HgCl adsorbed by activated carbon 2 Catalyst (wherein Hg weight percent content is 13.1%, SEM picture is as figure 1 ) into the polymer solution, mixed uniformly to form a slurry-like catalyst;

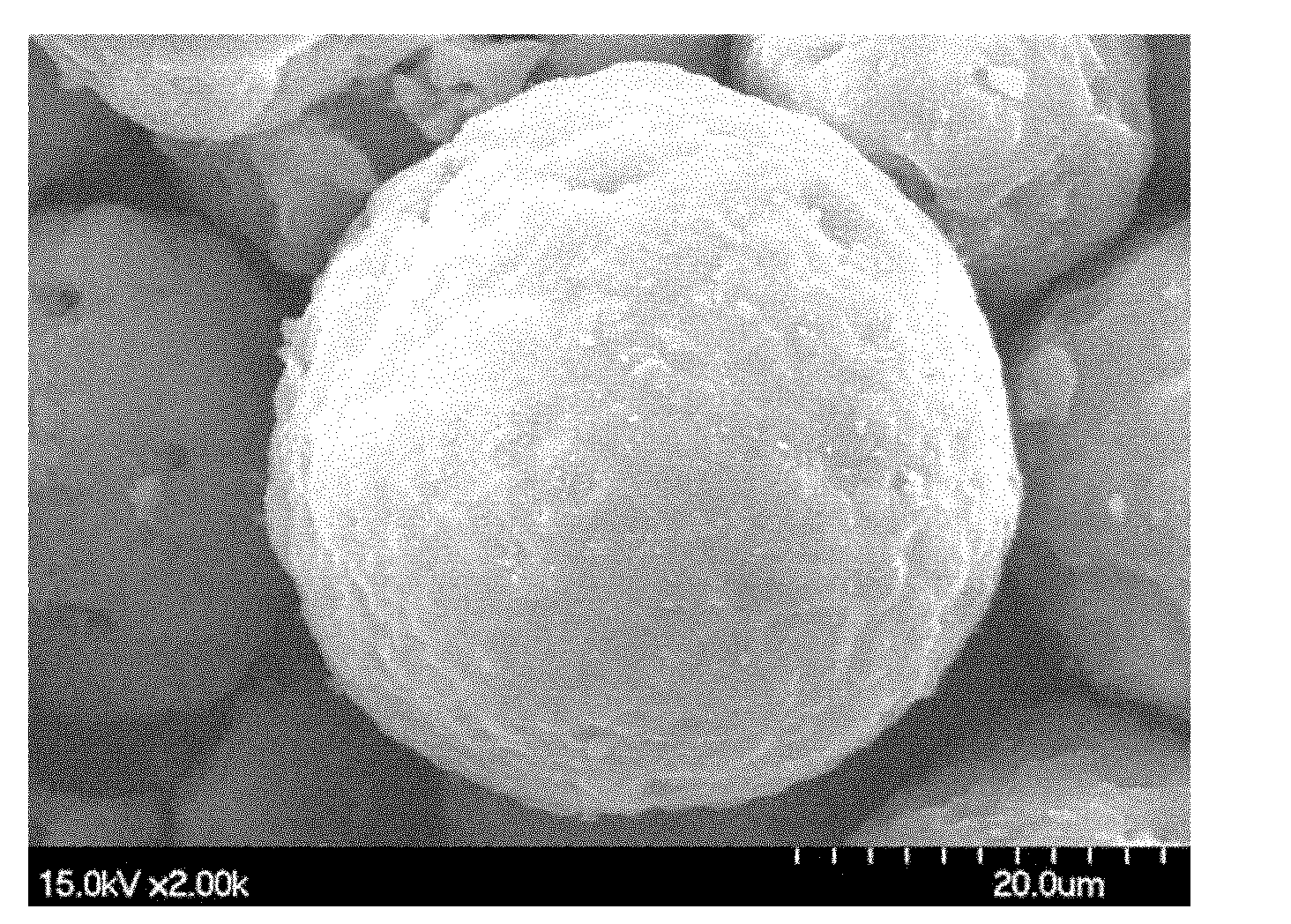

[0031] (3) Evaporate 4000ml of normal hexane at 66°C, and completely pass it into the slurry-like catalyst prepared in step (2) of the stirring state in the form of gas phase normal hexane (the addition rate of normal hexane is 1ml / min), and then stop Stir, precipitate the solid matter, extract the suspended liquid, and wash the precipitated solid matter with n-hexane for 3 times to obtain an environment-friendly mercuric chlori...

Embodiment 2

[0034] (1) Add 3g of styrene-acrylic acid copolymer (weight average molecular weight Mw=11300, molecular weight distribution MWD=1.31, glass temperature is 125°C, melting point is 215°C) into 300ml tetrahydrofuran (THF) and stir to make styrene-acrylic acid The copolymer is completely dissolved to obtain a polymer solution;

[0035] (2) Add 30g of HgCl adsorbed by activated carbon 2 Catalyst (wherein Hg weight percent content is 13.1%) in polymer solution, mixes and forms slurry-like catalyst;

[0036] (3) Evaporate 4000ml of normal hexane at 66°C, and completely pass it into the slurry-like catalyst prepared in step (2) of the stirring state in the form of gas phase normal hexane (the addition rate of normal hexane is 1ml / min), and then stop Stir, precipitate the solid matter, extract the suspended liquid, and wash the precipitated solid matter with n-hexane for 3 times to obtain an environment-friendly mercuric chloride metal catalyst, totaling 32.7 g.

[0037] (4) 32.5g o...

Embodiment 3

[0039] (1) Add 300g of styrene-acrylic acid copolymer (weight-average molecular weight Mw=11300, molecular weight distribution MWD=1.31, glass temperature of 125°C, melting point of 215°C) into 500ml of tetrahydrofuran (THF) and stir to make styrene-acrylic acid The copolymer is completely dissolved to obtain a polymer solution;

[0040] (2) Add 30g of HgCl adsorbed by activated carbon 2 Catalyst (wherein Hg weight percent content is 13.1%) in polymer solution, mixes and forms slurry-like catalyst;

[0041] (3) Evaporate 4000ml of normal hexane at 66°C, and completely pass it into the slurry-like catalyst prepared in step (2) of the stirring state in the form of gas phase normal hexane (the addition rate of normal hexane is 1ml / min), and then stop Stir, precipitate the solid matter, draw out the suspended liquid, and wash the precipitated solid matter with n-hexane for 3 times to obtain an environment-friendly mercuric chloride metal catalyst, totaling 328.5 g.

[0042] (4) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com