Material filling technology for prolonging crisp keeping period of crisp cone

A crispy tube and filling technology, which is applied in the field of filling technology for new crispy tube products, can solve the problems of crispy tubes not being brittle, prolonging the crispness period of crispy tubes, etc., to achieve crispness guarantee, extended crispness period, thickness and Guaranteed effect of coating surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to illustrate the present invention more clearly, the present invention will be further described below in conjunction with preferred embodiments and accompanying drawings. Similar parts in the figures are denoted by the same reference numerals. Those skilled in the art should understand that the content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention.

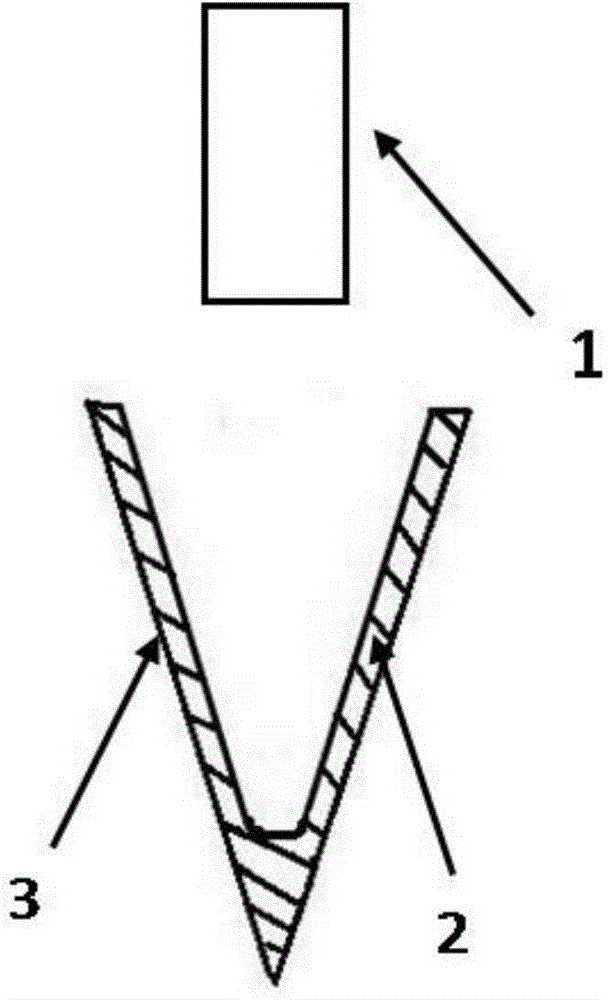

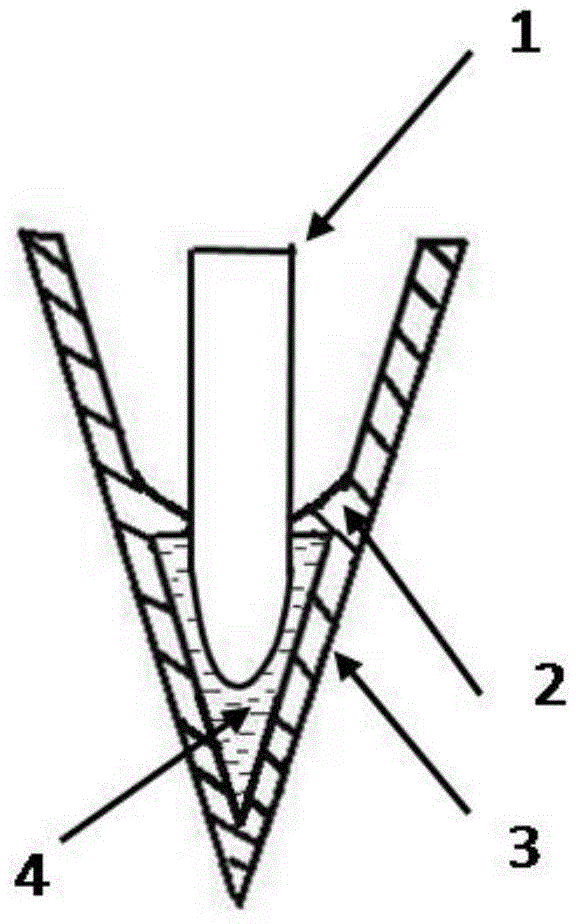

[0043] The section diagram of the filling process of the existing crispy tube products is as follows figure 1 shown. figure 1 The middle feeding pipe 1 is located on the top of the crisp tube 3, and the inner wall of the crisp tube 3 is sprayed with a chocolate layer 2. Since the front-stage process is to spray chocolate inside, such a blanking process will wash down the chocolate on the inner wall of the crispy tube, and a large amount of chocolate will accumulate at the bottom, while there will be no chocolate and insuf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com