Fabricated prestressed long-span beam structure

A prestressed, large-span technology, used in truss structures, girders, joists, etc., can solve the problems of large body size and components, weakened seismic performance, and huge material consumption, and achieves simple and convenient assembly and operation, reducing steel consumption. The effect of high volume, high spatial flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to have a clearer understanding of the technical solutions, objectives and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

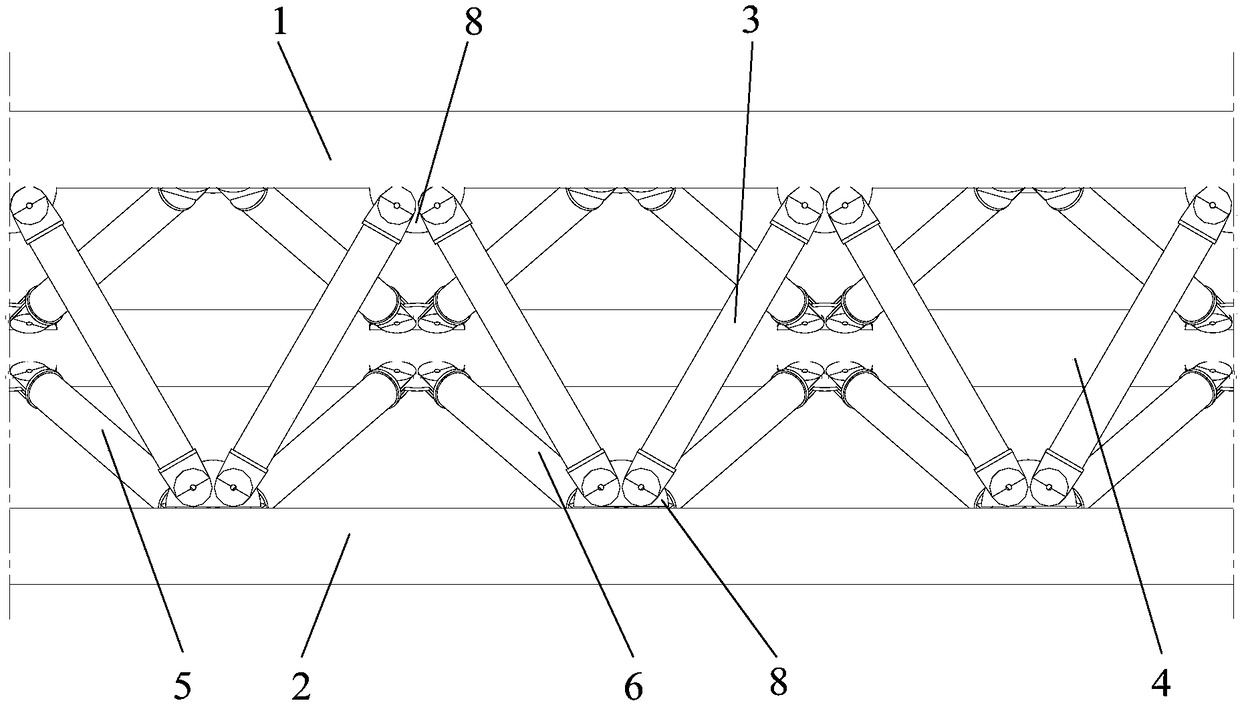

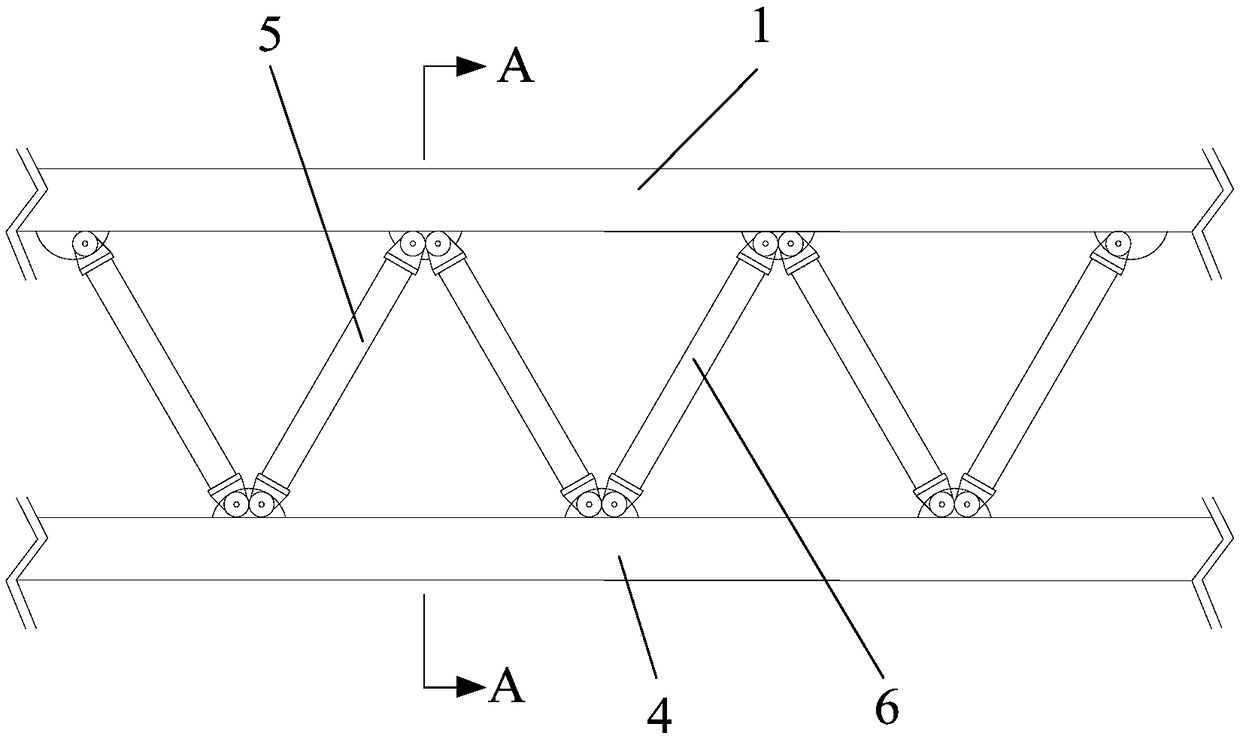

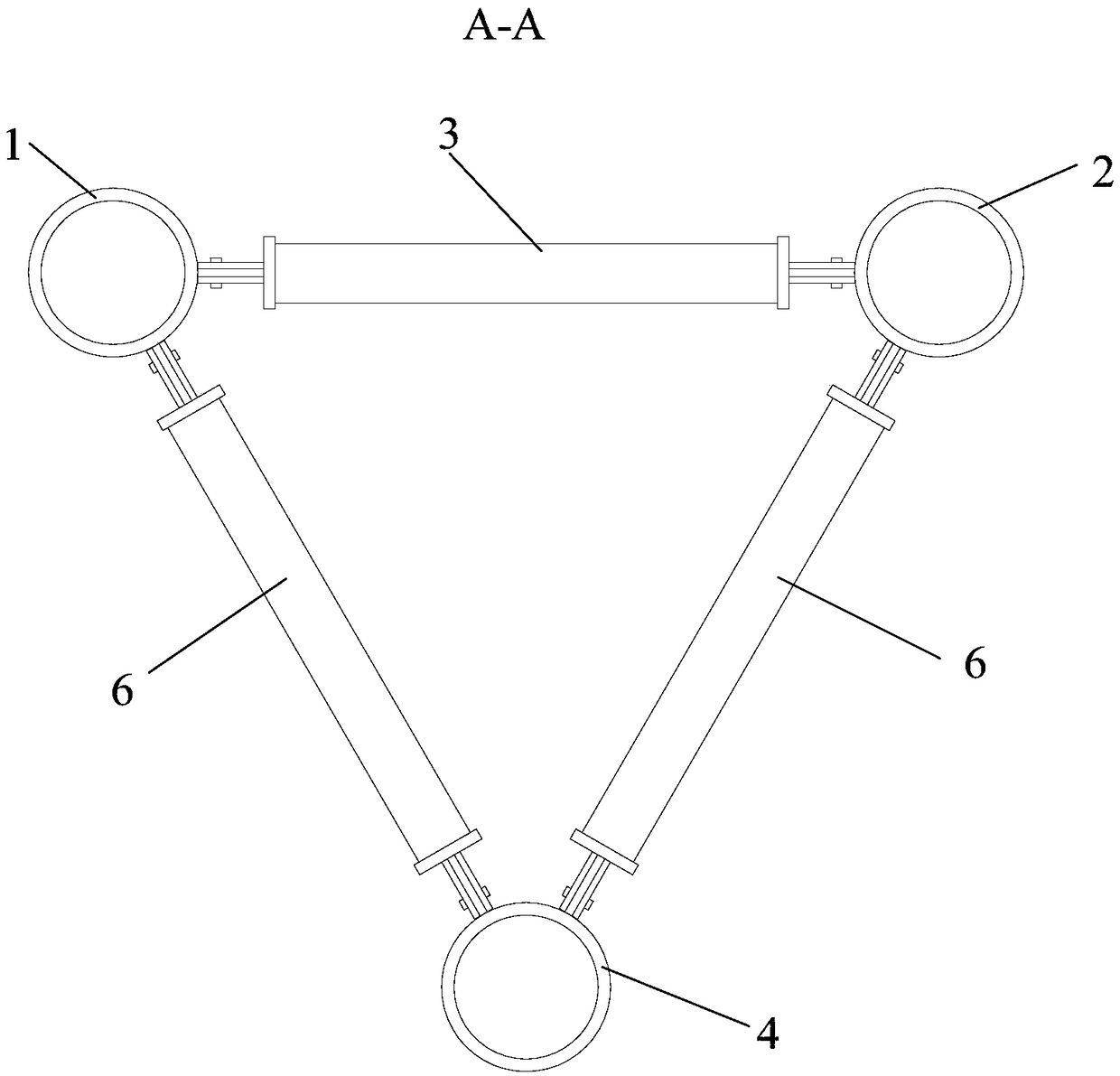

[0045] Such as figure 1 , figure 2 and image 3 As shown, the present invention provides an assembled prestressed long-span beam structure, which includes a truss girder 100, and the truss girder 100 includes an upper chord, a lower chord 4 and a plurality of assembly units, wherein the upper chord includes parallel and spaced The first support rod 1 and the second support rod 2 are all made of steel pipes with a circular cross section. The torsional performance is good and the anti-seismic performance is good. The first strut 1 is connected to the second strut 2 through the connecting piece, and the relative position of the first strut 1 and the second strut 2 is fixed through the connecting piece, so that the first strut ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com