Steel rail clamping mechanism for hydraulically jacking or dragging heavy stuff

A clamping mechanism and rail technology, applied in hoisting devices, hoisting devices, etc., can solve the problems of troublesome switching between pushing and dragging, difficult rail disengagement, high processing costs, etc., and achieves easy on-site operation, simple structure, The effect of low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

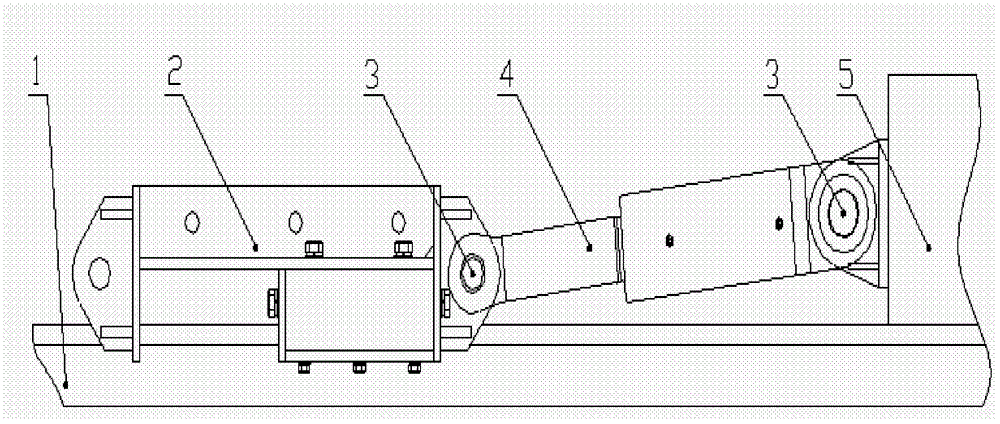

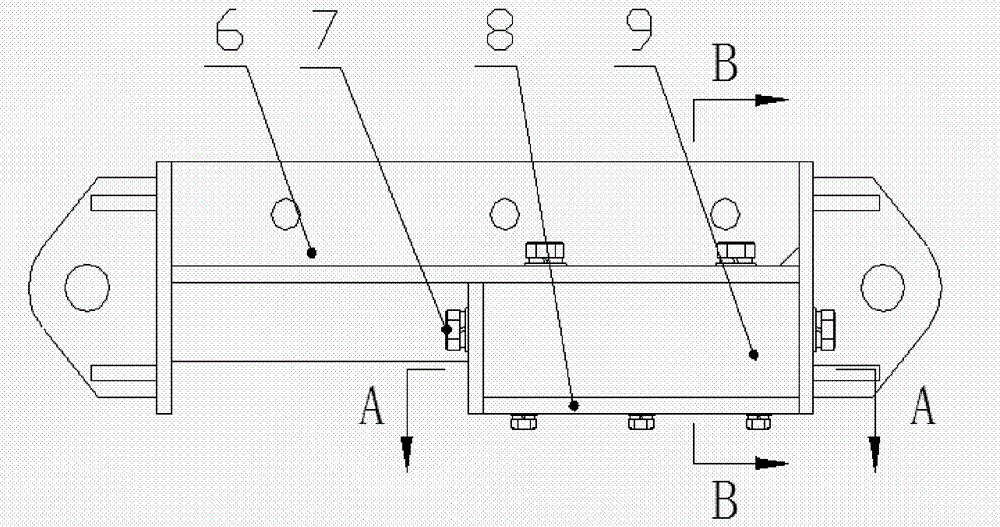

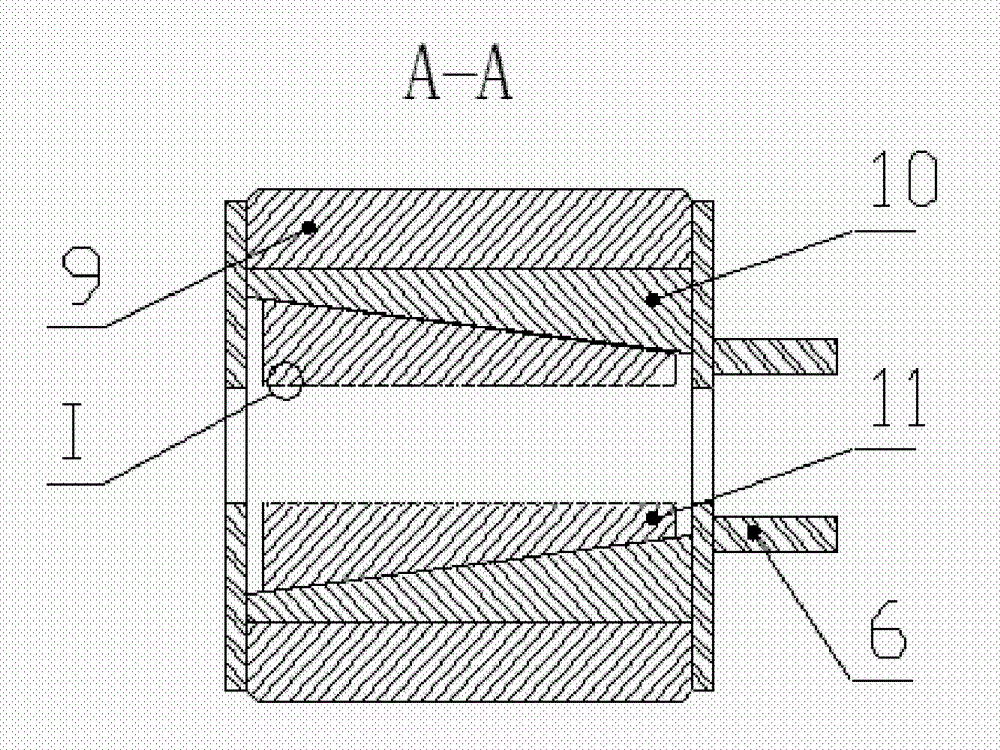

[0030] like Figure 1-5 As shown, the invention of this example is a rail clamping mechanism for hydraulically pushing or dragging heavy objects. The clamping mechanism 2 is connected with one end of the oil cylinder 4, and the other end of the oil cylinder 4 is connected with the weight 5. The clamping mechanism 2 is connected with the weight 5. The weight 5 is placed on the rail 1; the clamping mechanism 2 includes an upper cover plate 6, a lower supporting plate 8, a casing 9, an outer wedge 10 and an inner wedge 11, and the outer wedge 10 and the inner wedge 11 are arranged on the shell Inside the body 9, the slope of the outer wedge 10 is set on the slope of the inner wedge 11, and the opposite side of the slope of the inner wedge 11 is in contact with the side of the rail 1, and the side of the inner wedge 11 is provided with sharp teeth. The left and right sides of the steel rail 1 in the 9 are provided with an outer wedge 10 and an inner wedge 11;

[0031] There are b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com