Flow passage structure of regenerative pump

A regenerative, flow channel technology, applied in non-variable pumps, non-volume pumps, pumps, etc., can solve problems affecting pump performance and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

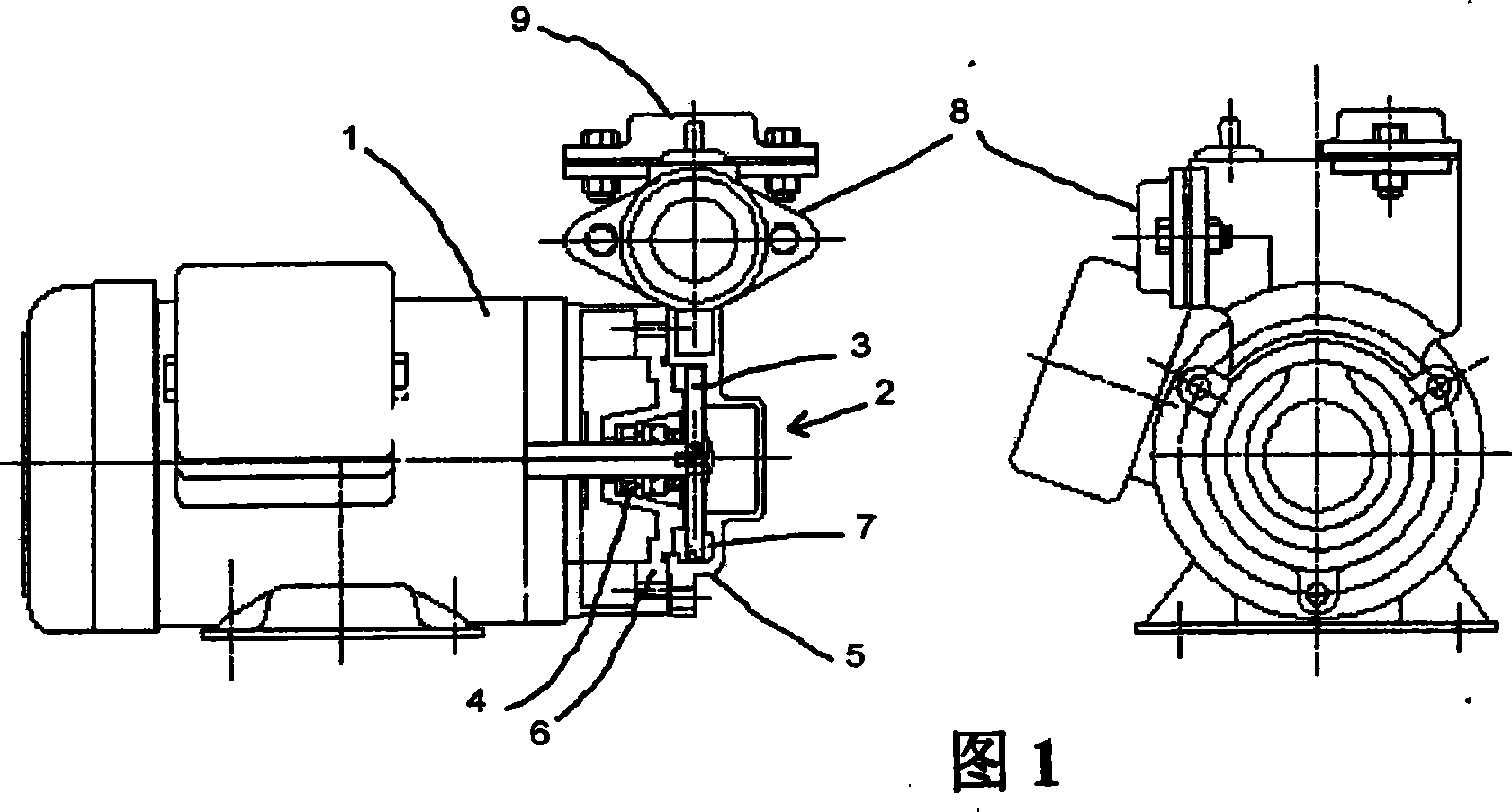

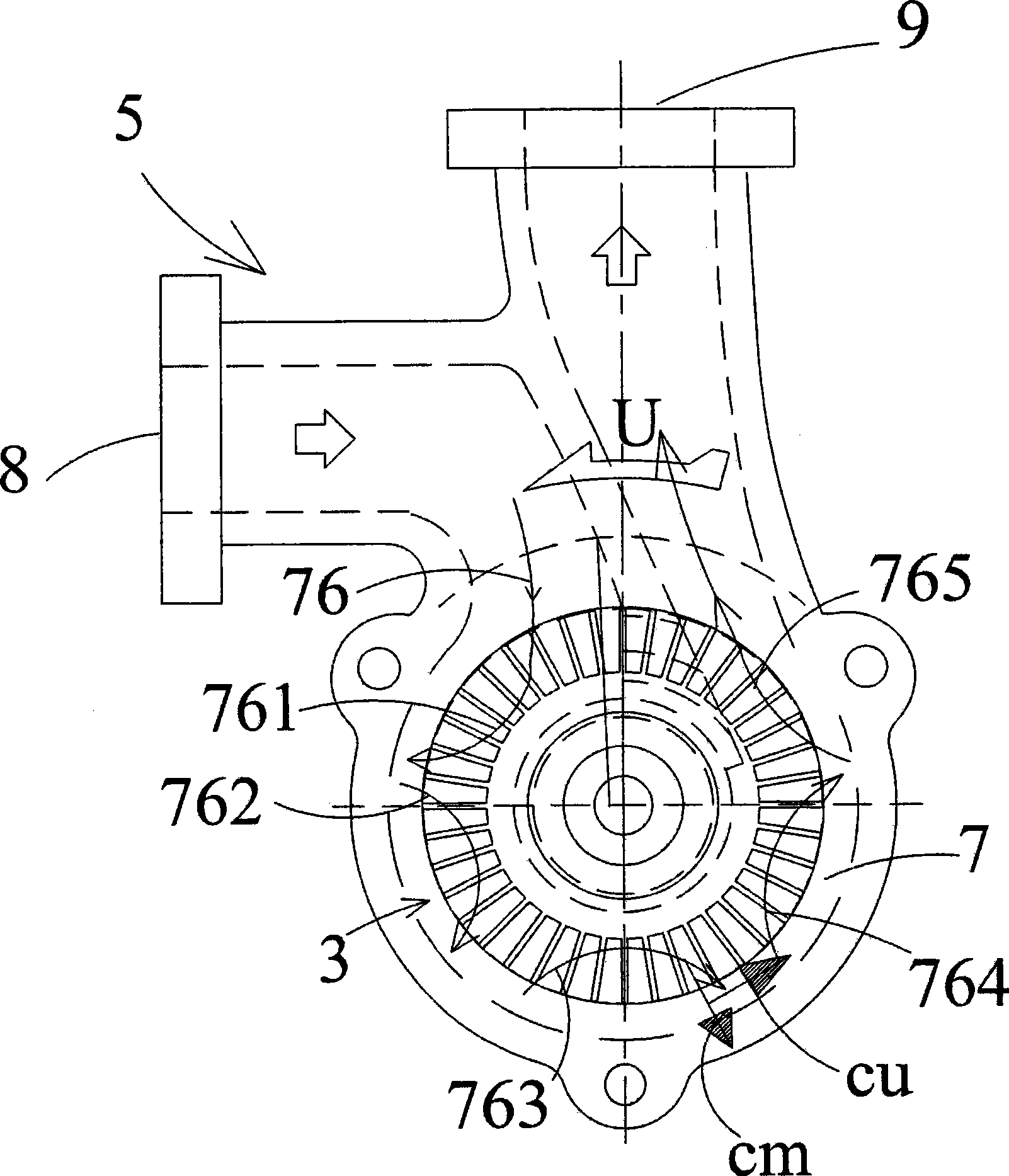

[0040] In order to further understand and understand the features, purposes and functions of the present invention, a detailed description is given below with reference to the drawings:

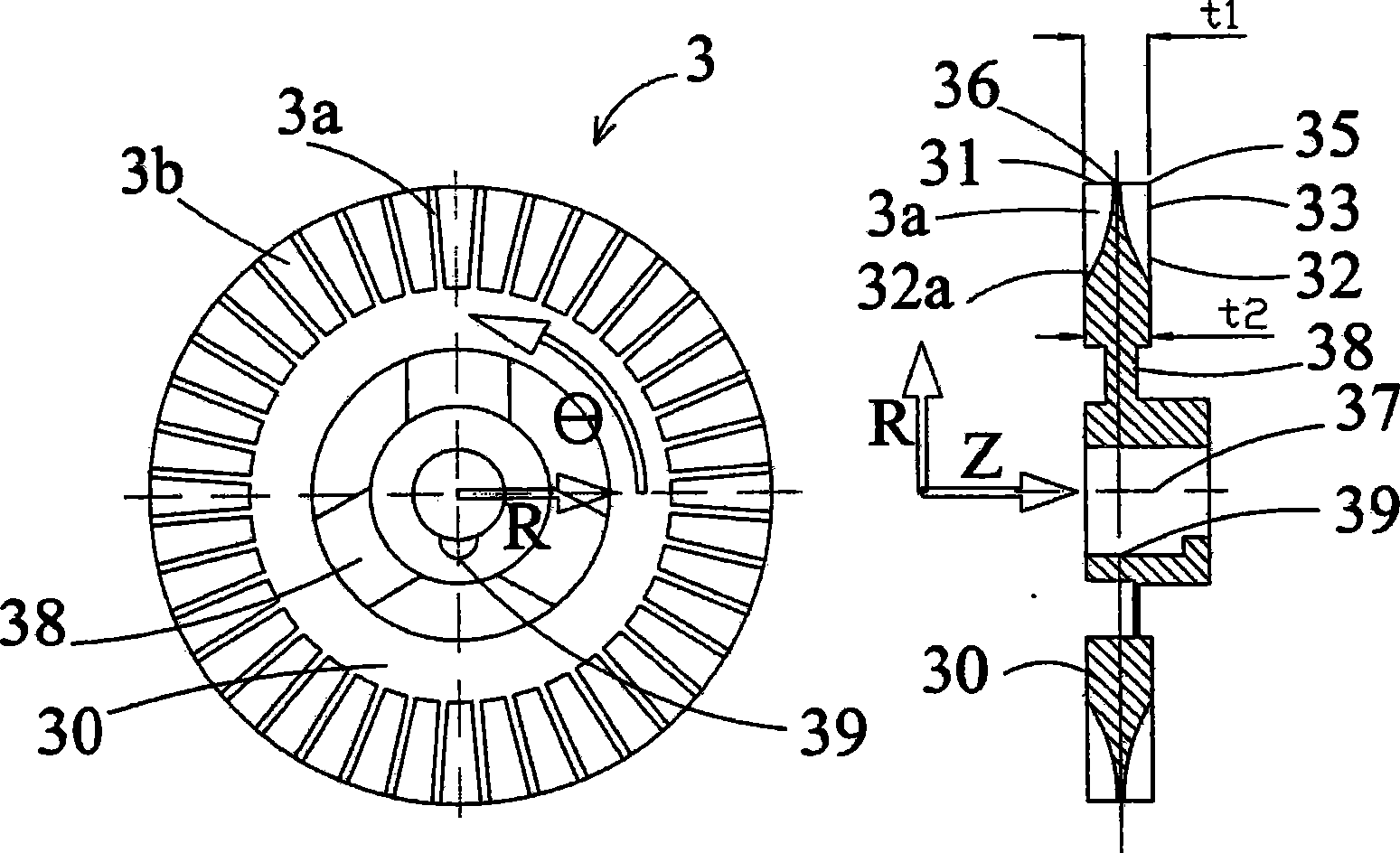

[0041] Please refer to Fig. 5, it is one of the embodiments of the present invention in the closed impeller, and the impeller 3 is a disc-shaped structure, and several radial blades are arranged on both sides of the outer edge of the disc, and the corresponding blades on the same side The space between two adjacent blades constitutes a radial channel, and the structure of the blades includes a blade inlet 32, a blade side plate 34, a blade outlet 31 and a blade hub plate 36, and the shaft hole 37 of the central hub of the impeller 3 is provided with The keyway 39 is used to smoothly connect the motor shaft, and several ribs 38 are connected between the hub and the disc at the root of the blade 30. The axial coordinate of the impeller structure is the z axis, the radial coordinate is the r axis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com