Reinforced connecting joint of steel structure beam and steel column and construction method of reinforced connecting joint

A technology for strengthening connection and steel structure, applied in the direction of building structure, construction, etc., can solve the problems of increasing the layered tear of steel column, greatly affecting the construction effect, affecting the quality of welding seam, etc. The structure is simple and the effect of optimizing the steel beam section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

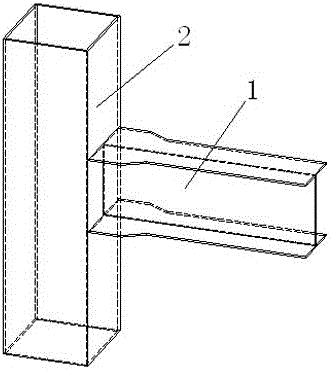

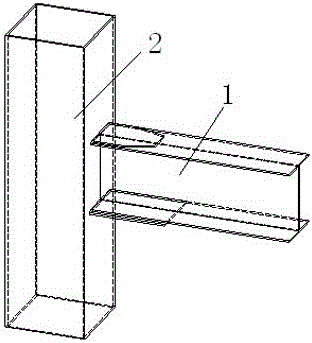

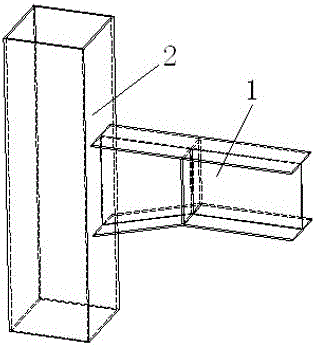

[0009] Such as Figure 4 , 5 As shown, a reinforced connection node of a steel structure beam and steel column includes a steel beam 1 and a steel column 2 connected to each other, and the steel column 2 is located at the joint with the steel beam 1 and is provided with a box girder section 7 through a sealing plate 3, and the box girder Studs 4 are distributed on the inner peripheral surface of the section 7; pouring holes 6 are arranged on the upper end surface of the box girder section 7, and concrete 5 is poured into the box girder section 7 through the pouring holes 6. Concrete 5 is poured into the steel beam 1 .

[0010] The steel girder 1 and steel column 2 can be box-shaped, or can be box-shaped by adding steel plates on both sides of the H-shaped steel, and pouring holes 6 are set on the upper flanges of the steel beam 1 and steel column 2. According to the mechanical performance It is required to determine whether the pouring hole 6 is closed with a steel plate aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com