Prefabricated internal support system and construction method for foundation pit support system

A technology of prefabricated assembly and foundation pit support, which is applied in the direction of infrastructure engineering, excavation, construction, etc., can solve the problems of extended working hours, large internal support cross-sectional area, time-consuming and labor-intensive problems, so as to reduce labor intensity, increase support span, Easy and fast operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

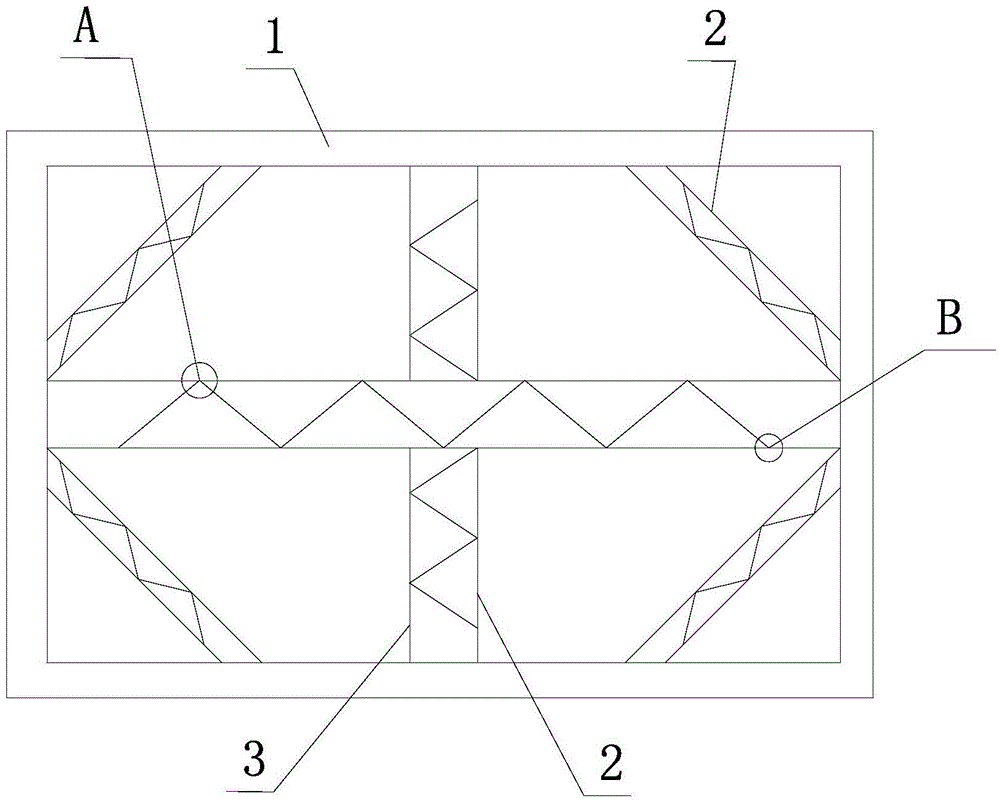

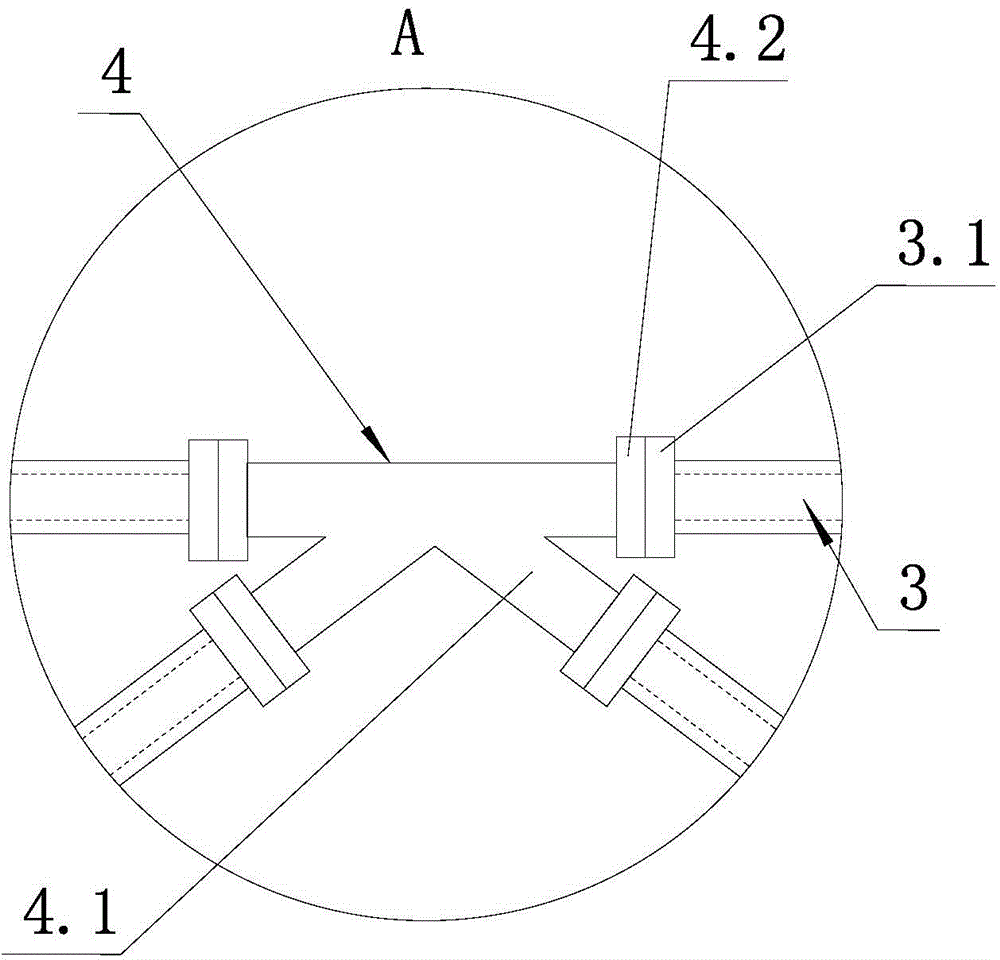

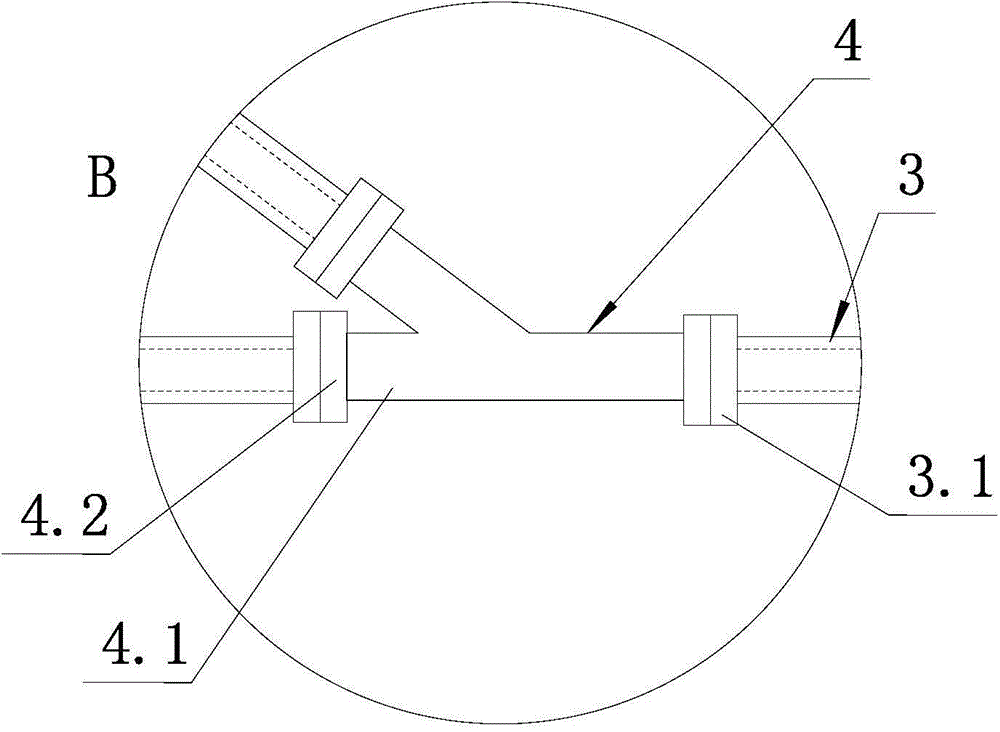

[0025] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, the prefabricated internal support system of the foundation pit support system of the present invention includes a top beam 1, multiple purlins of different elevations and a horizontal internal support 2. The top beam 1 and the surrounding purlins are all cast-in-place reinforced concrete structures. The horizontal inner support 2 is a truss-type inner support 2 assembled by splicing and assembling a plurality of prefabricated prestressed hollow square piles 3 and node connectors 4 . Both ends of each prestressed hollow square pile 3 are fixed with a first end plate 3.1 with threaded holes. The node connector 4 is provided with the same number of ends 4.1 as the number of prestressed hollow square piles 3 that meet at the node. In other words, if...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com