Method for preparing soft aluminum conductor and molding device

A molding device and conductor technology, which is applied in the direction of cable/conductor manufacturing, electrical components, circuits, etc., can solve the problems that soft aluminum conductors cannot be obtained at the same time, conductors cannot form continuous connections, and large-length aluminum conductors cannot be obtained. The effect of simplicity, stable conductor quality, and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

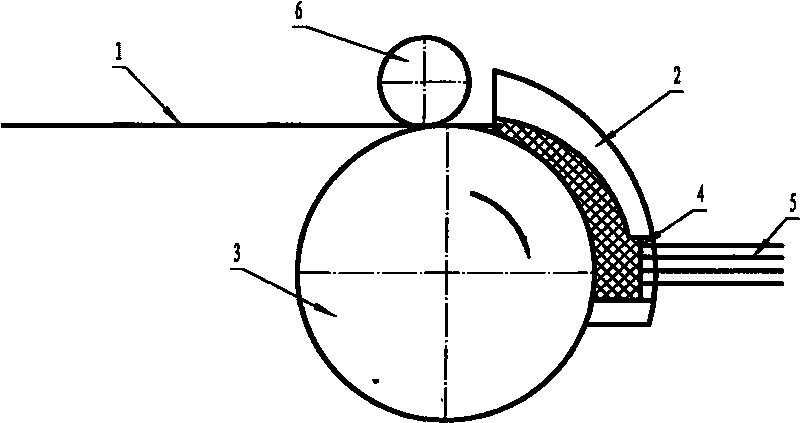

[0025] Embodiment 1: see figure 1 , the soft aluminum conductor forming device of the present invention includes a rotating friction runner 3, which surrounds about 1 / 4 of the arc length of the runner and has a shoe-shaped arc cover 2 with an enlarged area at the end. The friction runner and the arc cover enter The opening of the material end is slightly smaller than the cross-section of the feed aluminum rod. The boot-shaped arc cover surrounds the runner space and gradually expands from the feed port to the shoe sole. The forming die 4, the die discharge port is roughly parallel to the aluminum rod feed, and the die is designed with 4 parallel forming die holes, which can extrude 4 conductors 5 at the same time. There are grooves (not shown in the figure) on the peripheral surface of the friction runner, floating pressure roller 6 is arranged on the front part of the arc cover and above the friction runner 3, and grooves are also arranged on the peripheral surface of the pre...

Embodiment 2

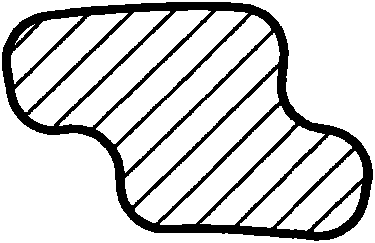

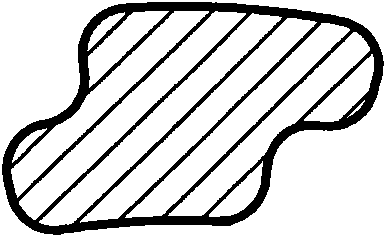

[0027] Example 2: see Figure 2-7 , as mentioned above, by changing the extruding mold, various shaped wire conductors can be extruded as shown in the figure, where the figure shows a hollow conductor.

[0028] By changing the speed of the runner and the extrusion ratio (ratio of aluminum entering and exiting), the temperature and pressure of aluminum in the molten cavity can be controlled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com