Mining plow

A recovery planer and planer technology, which is applied in the direction of slitting machinery, earthwork drilling and mining, etc., can solve the problems of time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

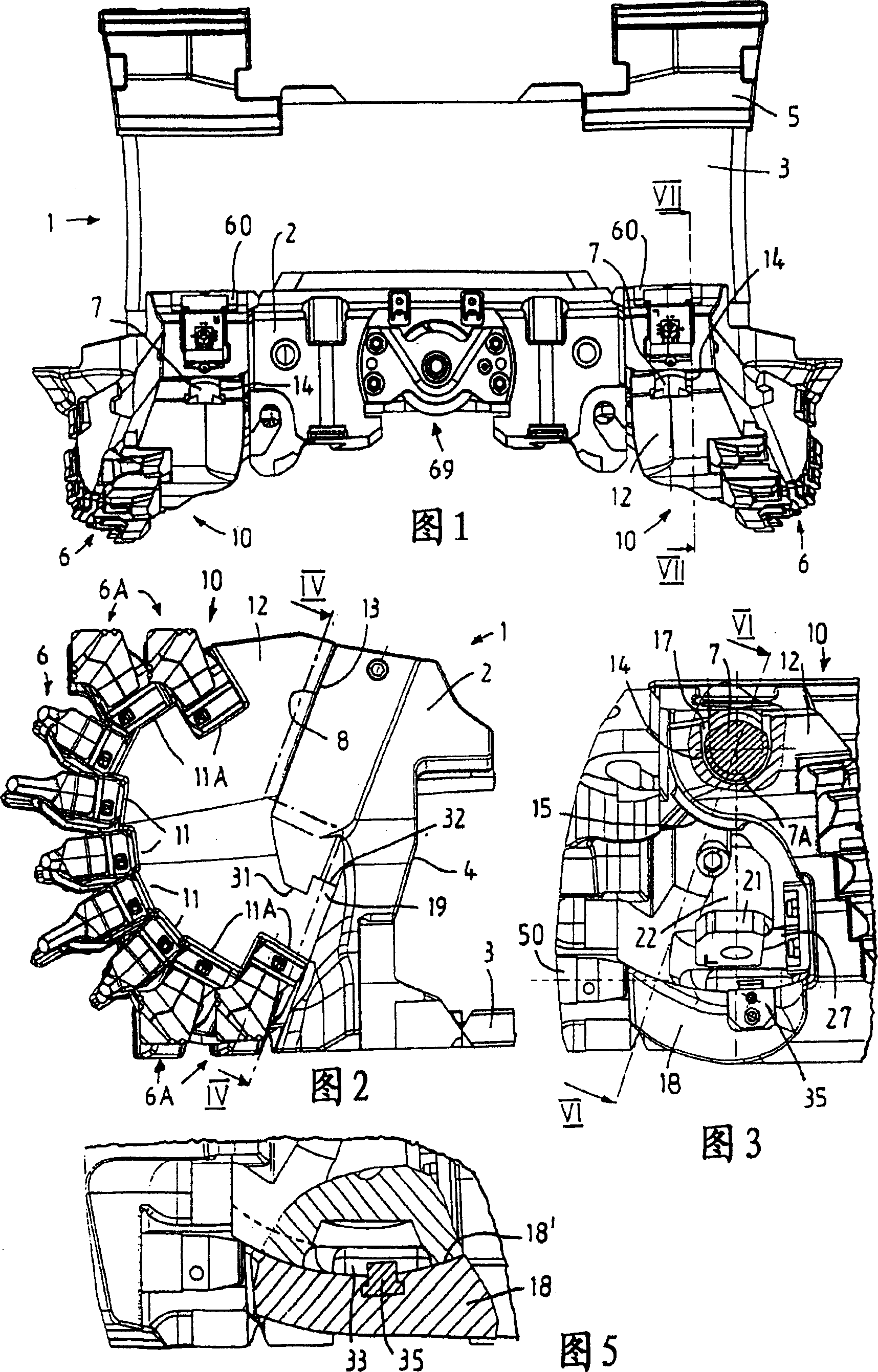

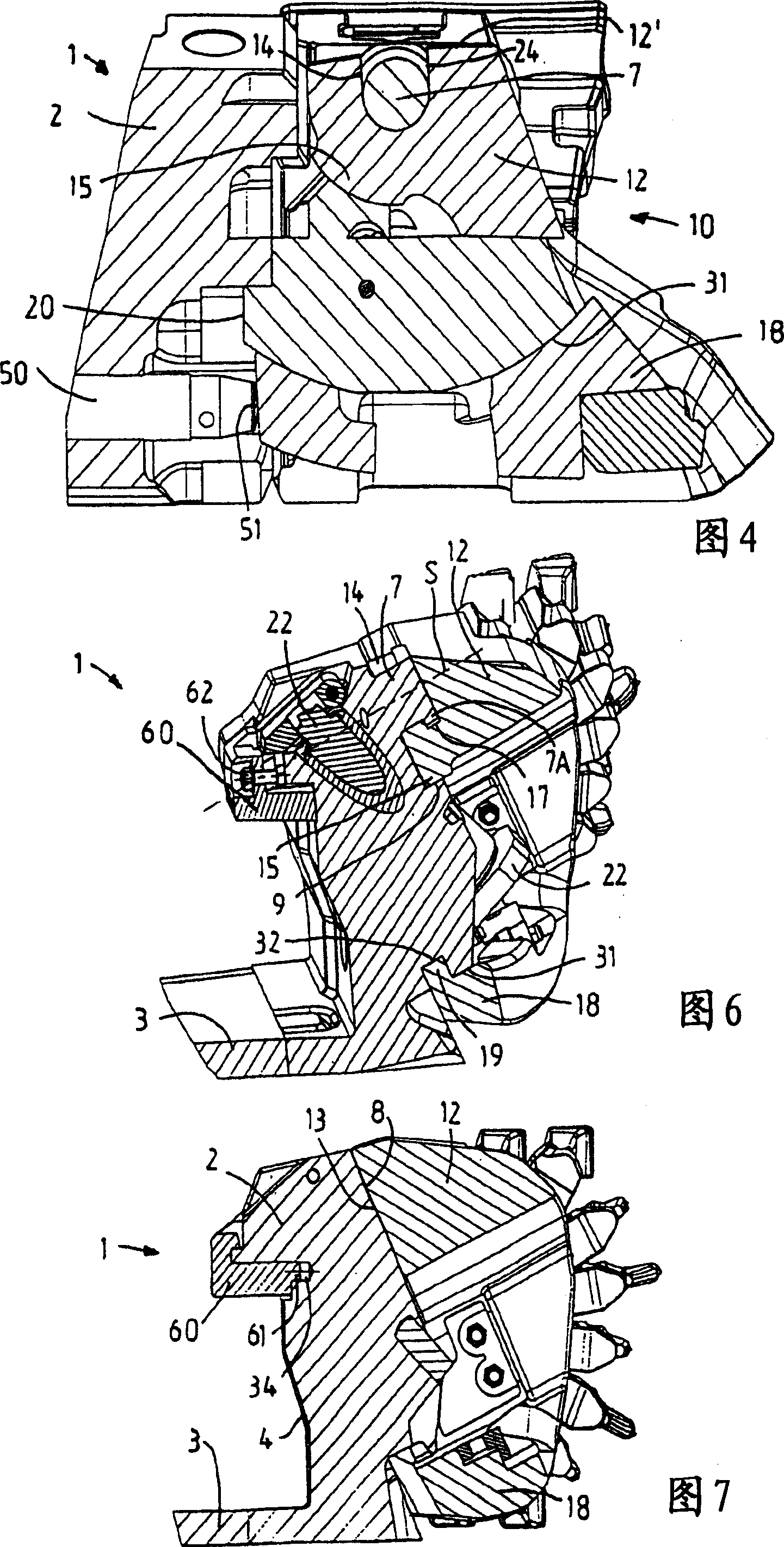

[0021] The recovery planing mechanism indicated generally by 1 in the figures is an embodiment of a tow hook planer and has a planer base body 2 designed as a casting, to which a multi-part planer support plate (Hobelschwert ) planer support plate part 3 in the center. The filling-side back 4 of the planer base body 2 is designed such that the planer 1 can be guided by its planer base body 2 in a supported manner on a guide plate on the working surface side of a further conveyor, not shown. At the same time the recovery planer engages with its planer strut 3 the two feed lines of the conveyor from below, and a guide lug 5 on the filling-side end of the planer strut 3 engages a planer for moving the planer 1 In the chain guide channel of the traction chain of the machine, in order to use the recovery planer 1 to mine coal in the working face in the underground, a tool holder 10 is fixed on the planer base 2 to swing for each moving direction of the recovery planer 1, and two of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com