Mining plow

A recovery planer and planer technology, which is applied in the direction of slitting machinery, earthwork drilling and mining, etc., can solve the problems of time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

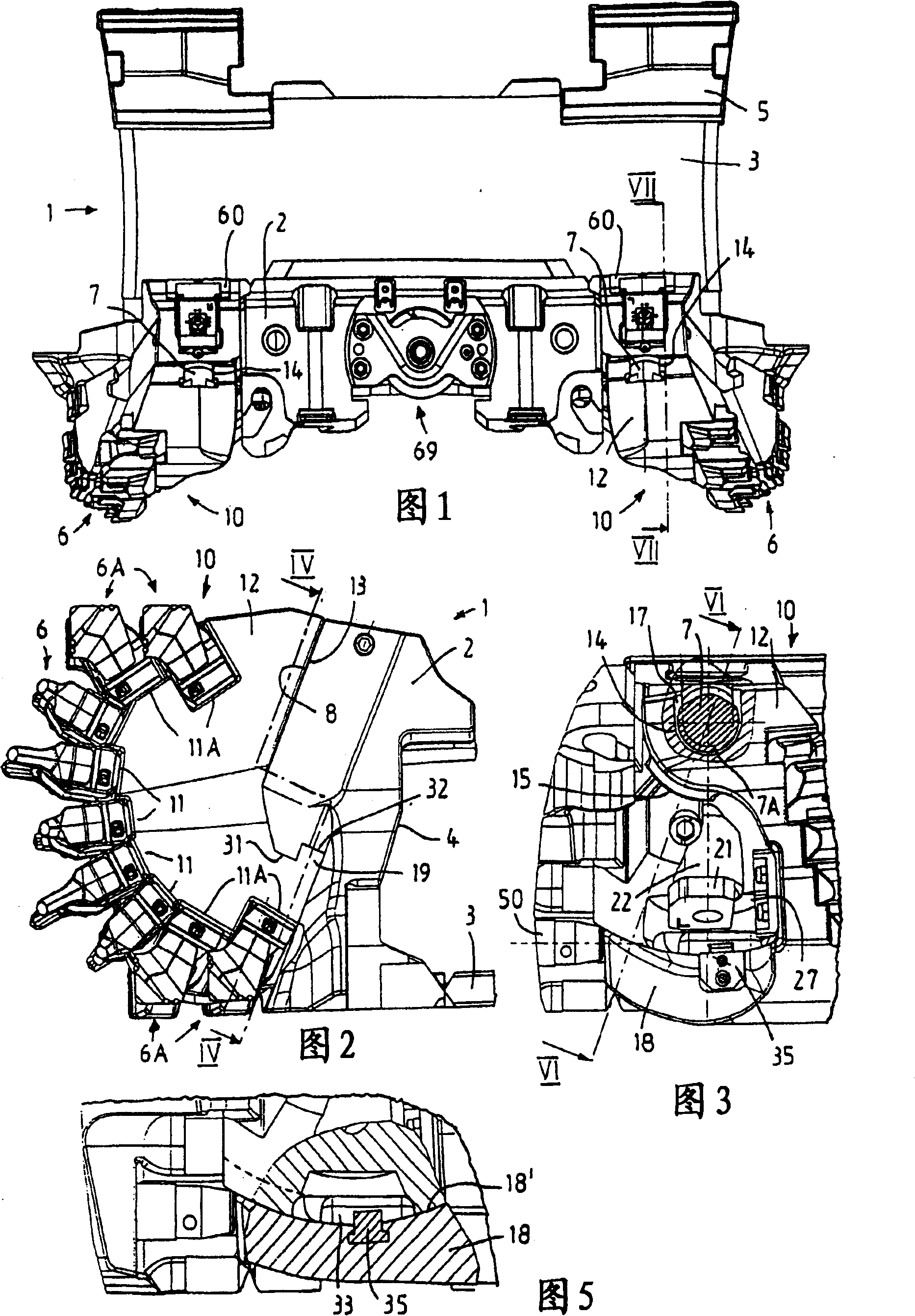

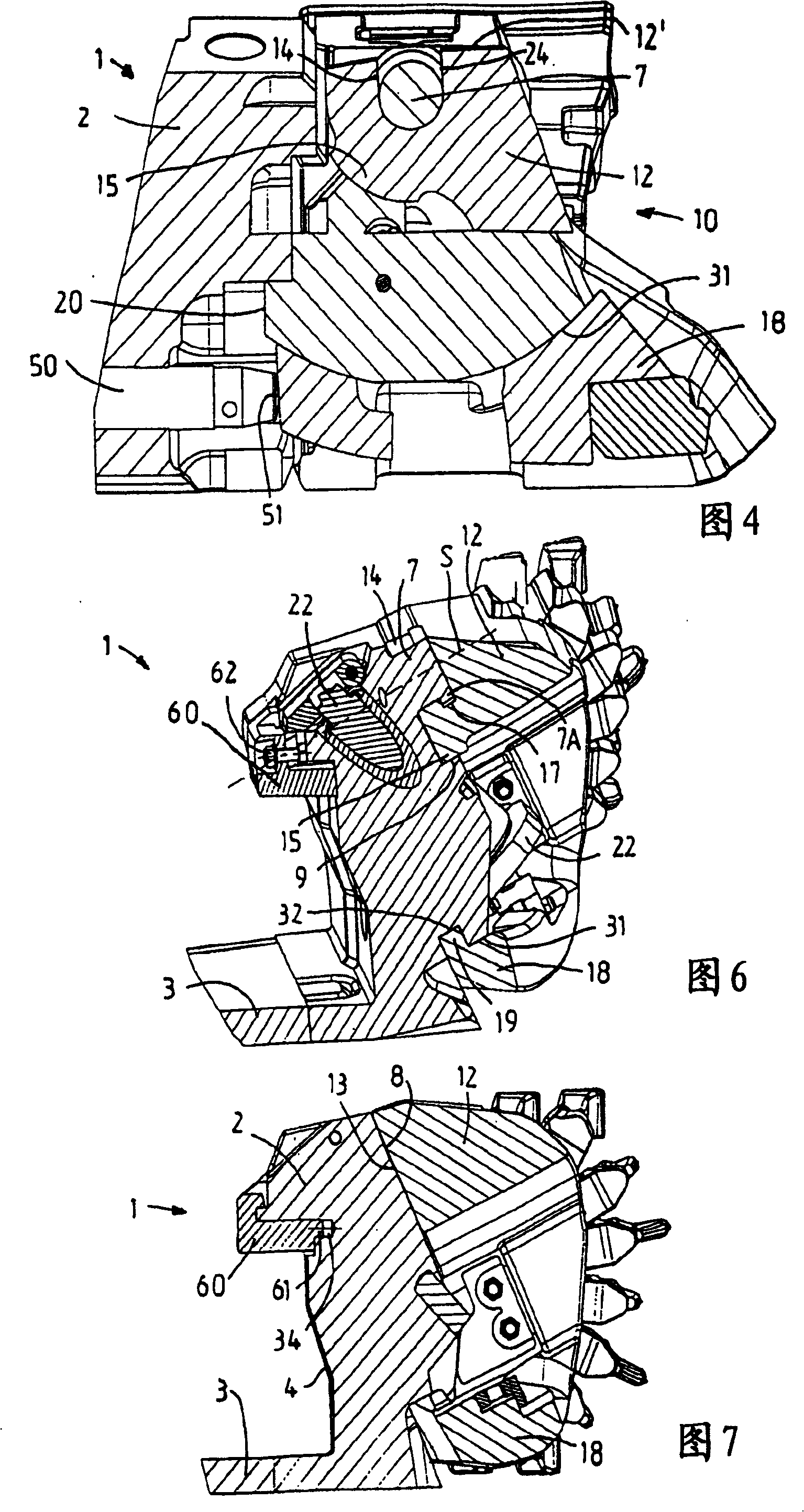

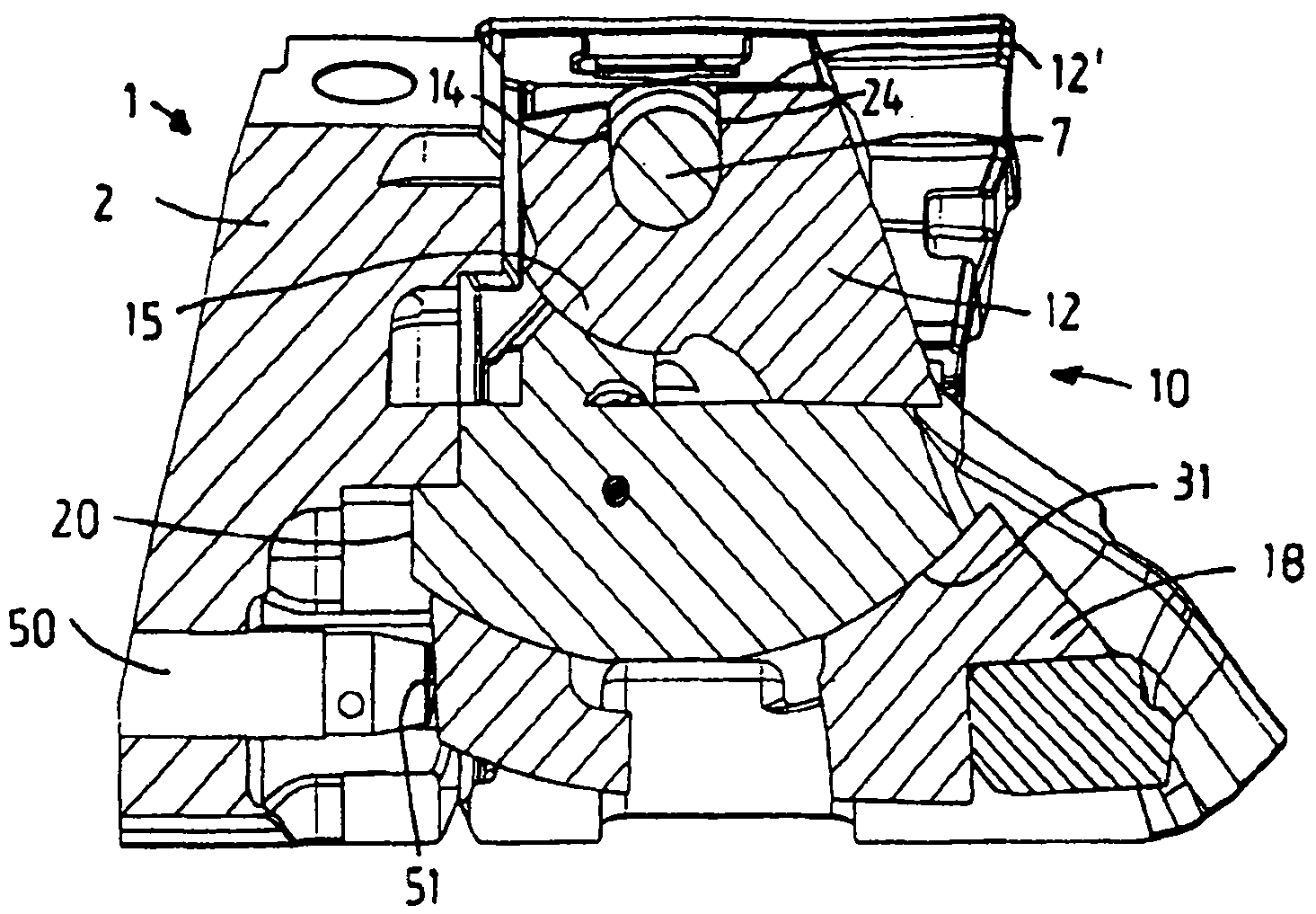

[0021] The planing mechanism, which is generally marked by the reference 1 in each figure, becomes the implementation form of the tow-hook planer and has a planer base body 2 formed as a casting, on which a multi-piece planer support plate is rigidly fixed. ) The planer support plate in the center. The back side 4 of the filling side of the planer base body 2 is configured so that the planer base body 2 can be guided by its planer base body 2 on a guide plate on the working surface side of another conveyor, not shown. At the same time, the planer uses its planer support plate 3 to embed the two branches of the conveyor from below, and a guide ear 5 on the end of the filling side of the planer support plate 3 is embedded with a planer for moving the planer 1 In the chain guide channel of the machine traction chain, in order to use the mining planer 1 to excavate coal in the underground working face, a tool holder 10 is swingably fixed on the planer base 2 for each movement direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com