Free Floating Wave Energy Converter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

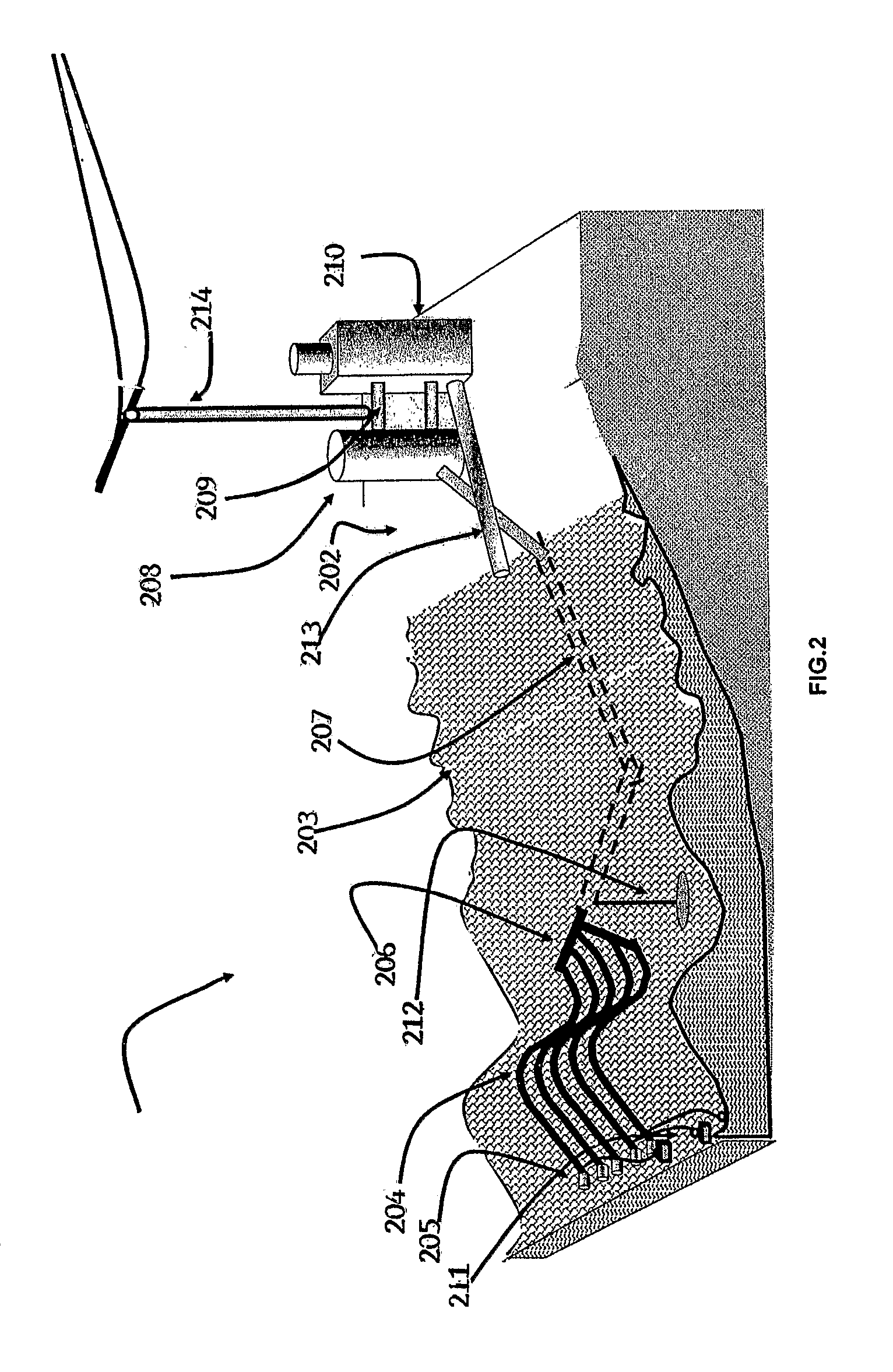

[0043]Embodiments of the present invention will be described below specifically with reference to accompanying drawings.

[0044]A good example of the “Flexible Pipe” WEC is surfing. As a surfer rides down a wave, it follows him, but not the water. In another example, say, if a thin and flexible sheet of impermeable material is spread out on a wave train and some water is poured on it, the water will immediately get collected in the troughs and start flowing along with the waves. Now, instead of the sheet above, let us use a hollow flexible pipe, as described in paragraph below:

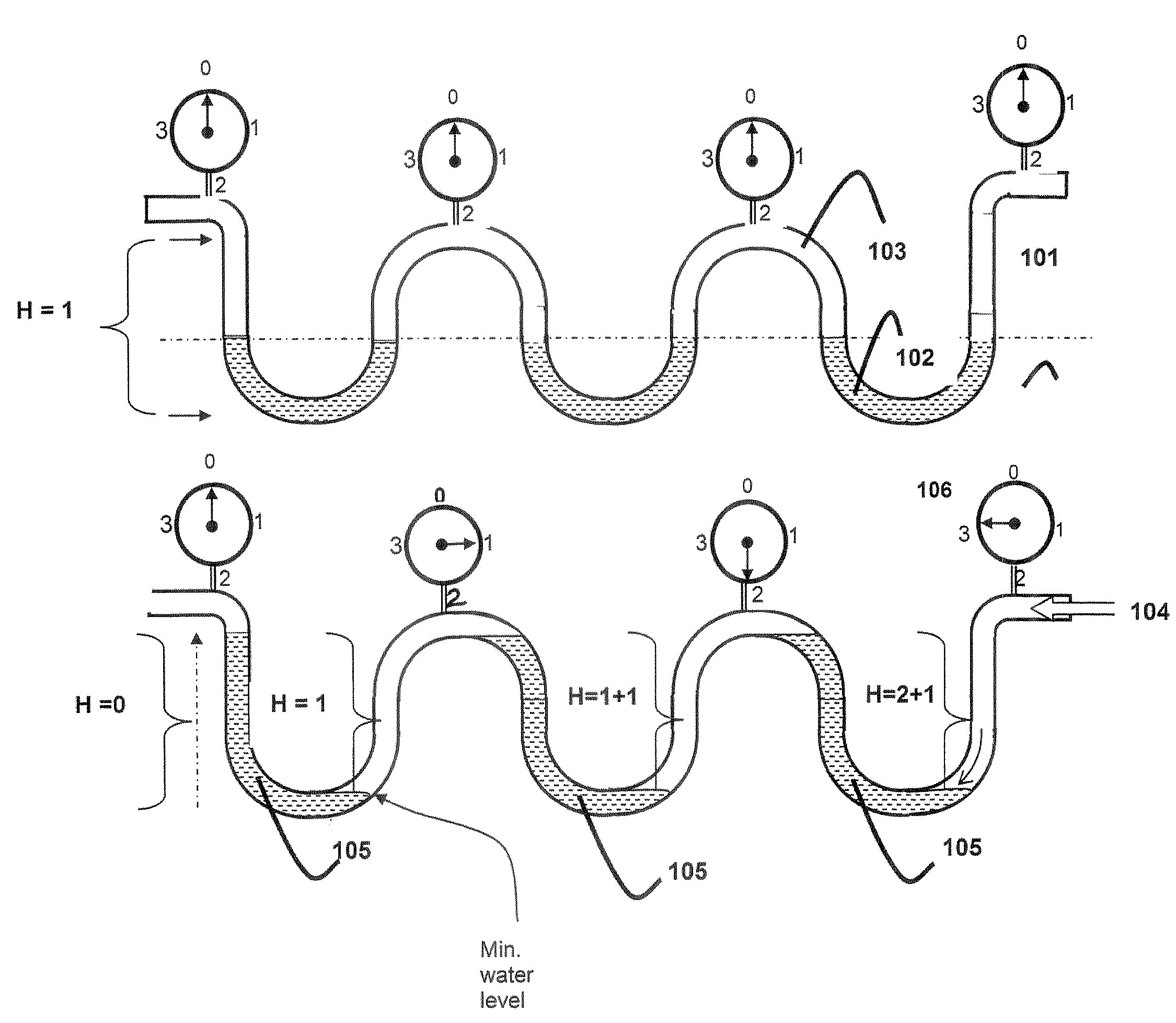

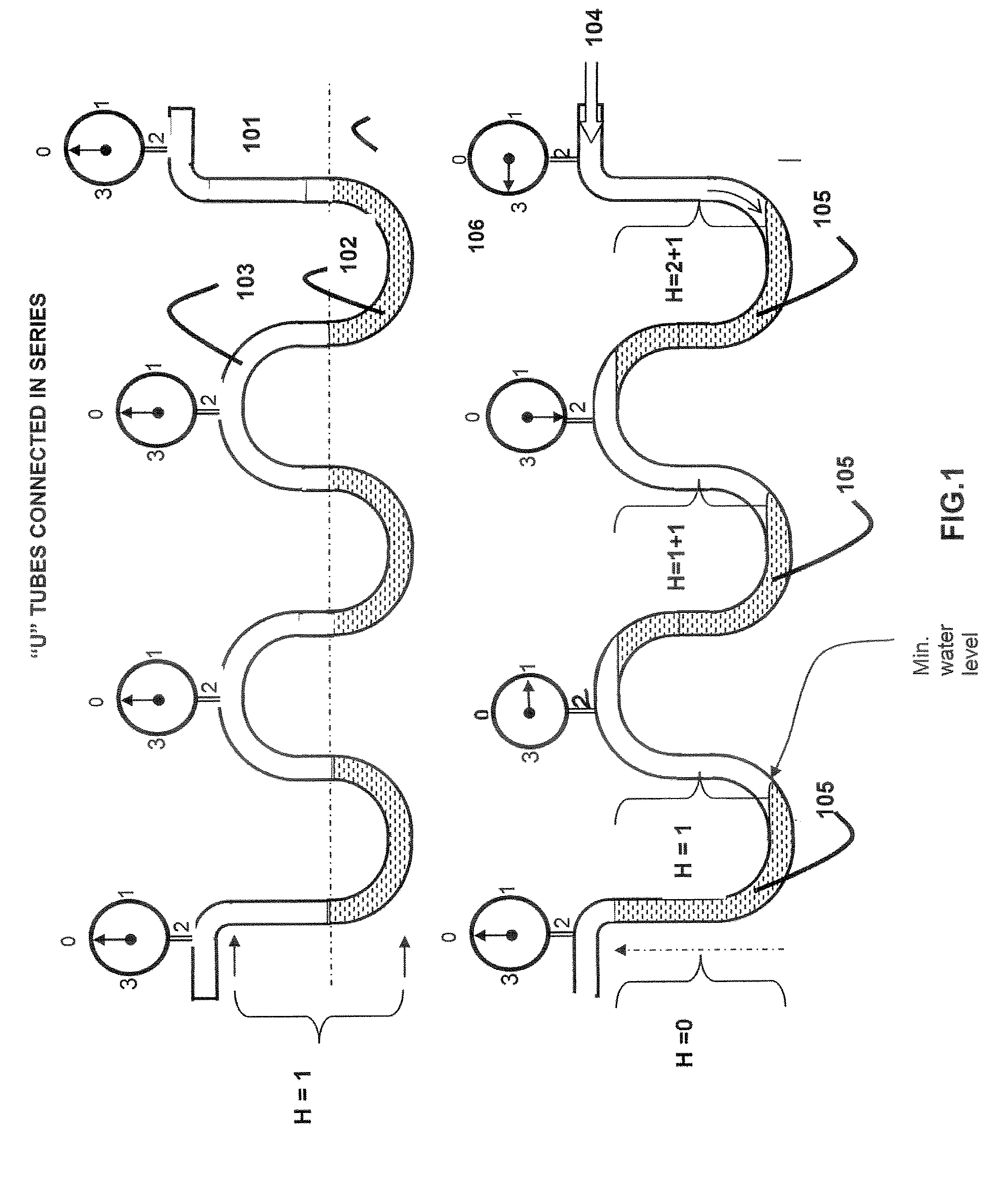

[0045]When the FFWEC is idling, i.e., with no load applied at the outlet, the water slugs remain in the trough part of the waves as it progresses. Whereas, under operating load the water slugs get pushed up the crest of the preceding wave all along the Flexible Pipe. This aspect has been illustrated at FIGS. 1 (a) and (b), respectively.

[0046]FIG. 1 of the accompanying drawings illustrates the behavior of the air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com