A kind of weather-resistance modified plastic particles of automobile headlights and its production process

A technology of plastic granules and production process, applied in the field of plastics, can solve the problems of decreased physical and mechanical properties, poor weather resistance, poor stability, etc., and achieve the effects of reducing energy consumption, prolonging thermal insulation aging, and avoiding sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A weather-resistant modified plastic particle for automobile headlights, which is composed of the following materials in parts by weight: 130 parts of polybutylene terephthalate, 25 parts of polystyrene, 12 parts of diatomite, 8 parts of nano-alumina, 6 parts of silicon powder, 8 parts of microcrystalline cellulose, 8 parts of monoglyceride stearate, 5 parts of calcium stearate, 2 parts of citrate, 25 parts of cyclohexanone.

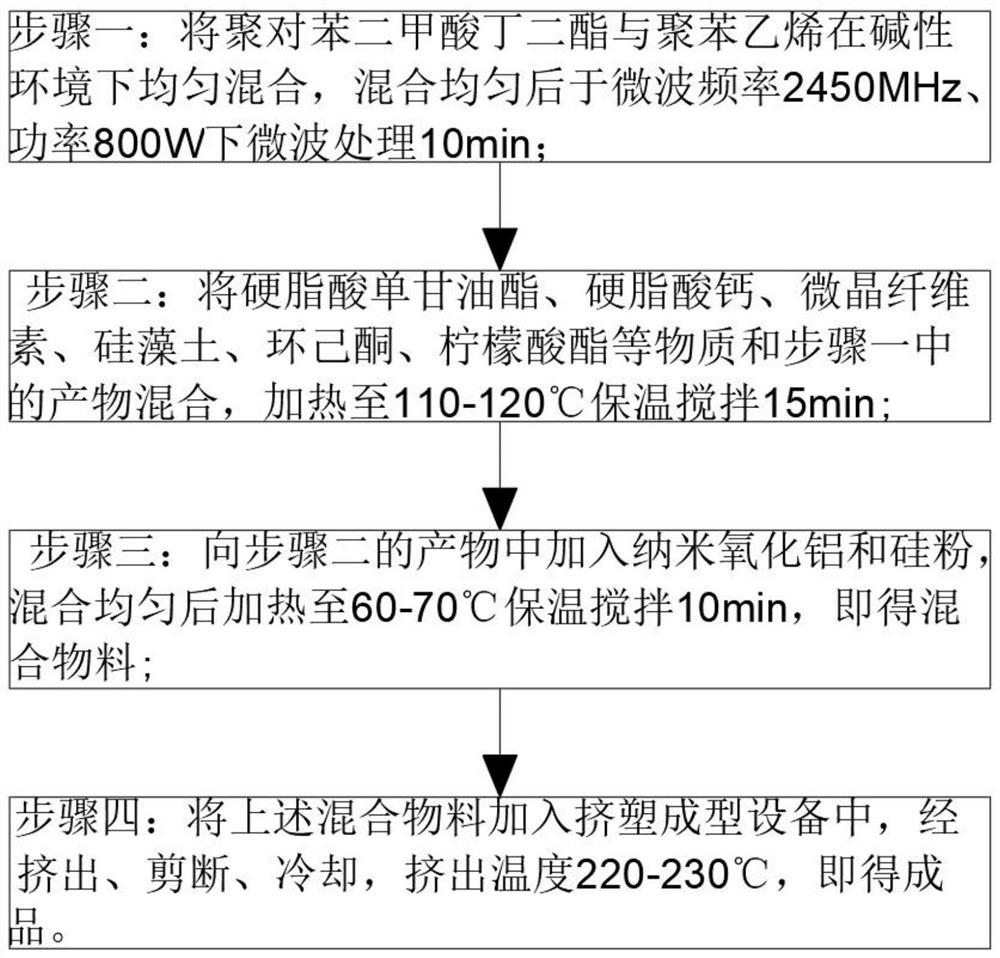

[0043] A production process of weather-resistant modified plastic particles for automobile lamps, comprising the following steps:

[0044] Step 1, uniformly mix polybutylene terephthalate and polystyrene in an alkaline environment, and after mixing evenly, microwave at a microwave frequency of 2450MHz and a power of 800W for 10 minutes;

[0045] Step 2. Stearic acid monoglyceride, calcium stearate, microcrystalline cellulose, diatomaceous earth, cyclohexanone, citric acid ester and other substances are mixed with the product in step 1, heated to 1...

Embodiment 2

[0049] A weather-resistant modified plastic particle for automobile headlights, which is composed of the following materials in parts by weight: 150 parts of polybutylene terephthalate, 30 parts of polystyrene, 16 parts of diatomite, 12 parts of nano-alumina, 8 parts of silicon powder, 12 parts of microcrystalline cellulose, 12 parts of monoglyceride stearate, 8 parts of calcium stearate, 5 parts of citrate, and 30 parts of cyclohexanone.

[0050] A production process of weather-resistant modified plastic particles for automobile lamps, comprising the following steps:

[0051] Step 1, uniformly mix polybutylene terephthalate and polystyrene in an alkaline environment, and after mixing evenly, microwave at a microwave frequency of 2450MHz and a power of 800W for 10 minutes;

[0052] Step 2. Stearic acid monoglyceride, calcium stearate, microcrystalline cellulose, diatomaceous earth, cyclohexanone, citric acid ester and other substances are mixed with the product in step 1, heat...

Embodiment 3

[0056] A weather-resistant modified plastic particle for automobile headlights, which is composed of the following materials in parts by weight: 140 parts of polybutylene terephthalate, 27 parts of polystyrene, 14 parts of diatomite, 10 parts of nano-alumina, 7 parts of silicon powder, 10 parts of microcrystalline cellulose, 10 parts of monoglyceride stearate, 6.5 parts of calcium stearate, 3 parts of citrate, and 27.5 parts of cyclohexanone.

[0057] The production process of a weather-resistant modified plastic granule for automobile lamps according to claim 1, comprising the following steps:

[0058] Step 1, uniformly mix polybutylene terephthalate and polystyrene in an alkaline environment, and after mixing evenly, microwave at a microwave frequency of 2450MHz and a power of 800W for 10 minutes;

[0059] Step 2. Stearate monoglyceride, calcium stearate, microcrystalline cellulose, diatomaceous earth, cyclohexanone, citric acid ester and other substances are mixed with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com