Strutless type umbrella

a technology of umbrellas and struts, applied in umbrellas, walking sticks, clothing, etc., can solve the problems of not being able to meet the requirements easily, and achieve the effect of reducing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

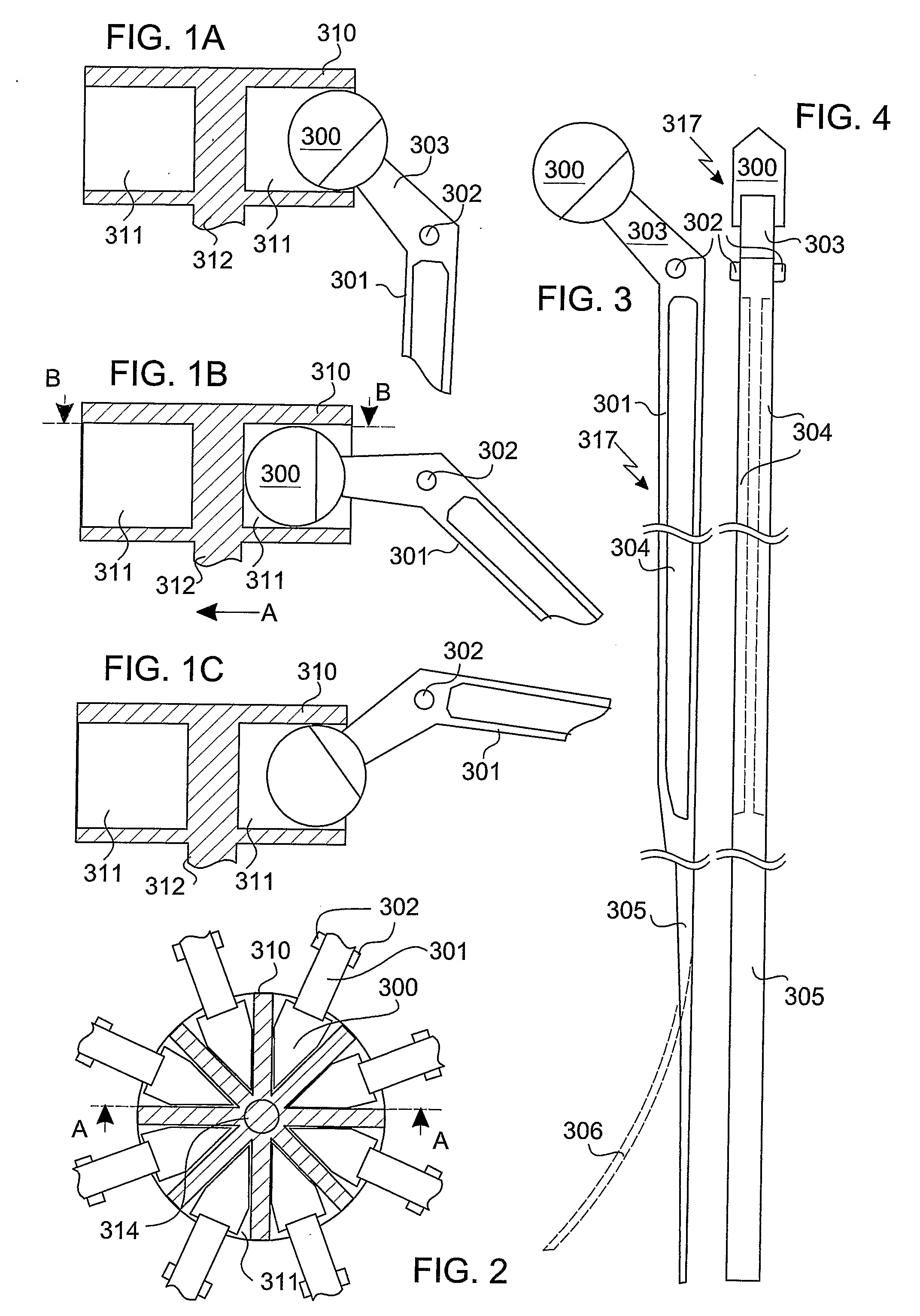

[0036]Referring to FIGS. 1A-1C and 2, there is illustrated an example of a canopy conducting mechanism of the present invention, which in the present example is based on a pin-and-slide joint. The latter is of the type defining an elongated contact region between a pin (i.e., a cylindrically-like element with circular or other rounded base surfaces) and a slide plane, the contact region thus being a line along the cylinder-like generator. FIGS. 1A-1C show, in partial vertical cross section view (taken at A-A of FIG. 2), three operational states, respectively, of the mechanism, and FIG. 2 shows a partial lateral cross section view (taken at B-B of FIG. 1B) of the canopy conducting mechanism in its state of FIG. 1B.

[0037]In the illustrated embodiment, a pin 300 of the pin-and-slide joint is actually the end portion of a rib lever 303 of an umbrella rib body 301. Pin 300 is also referred to in the context of the present invention as “the free end of the rib lever”. In this example, pin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com