Patents

Literature

33results about How to "Achieve constant tension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

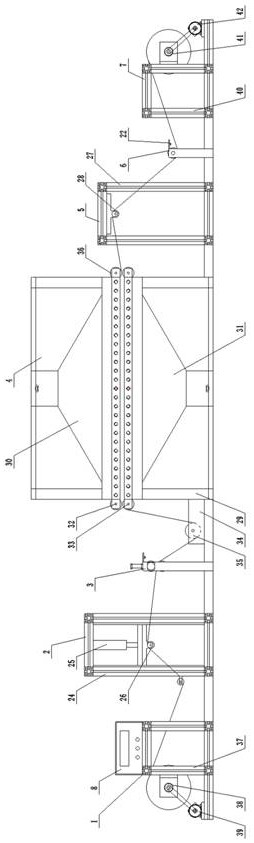

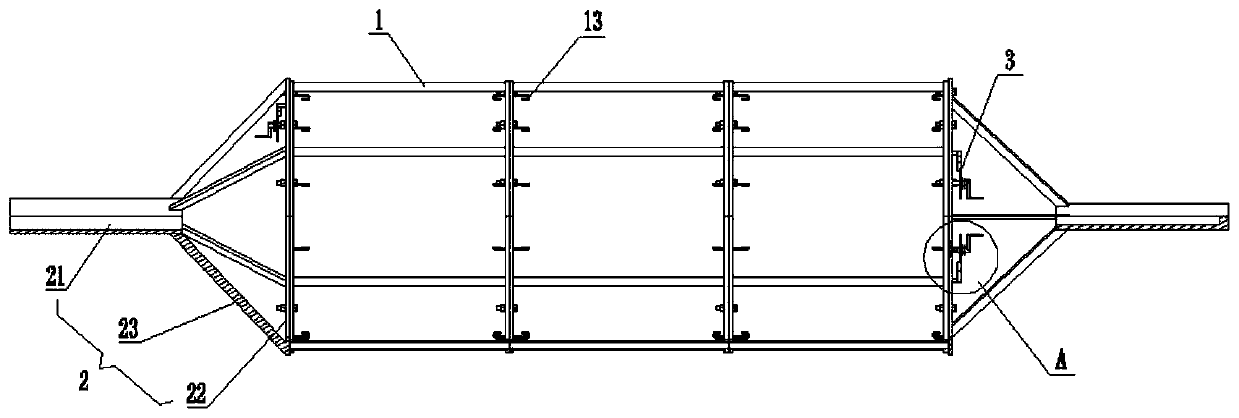

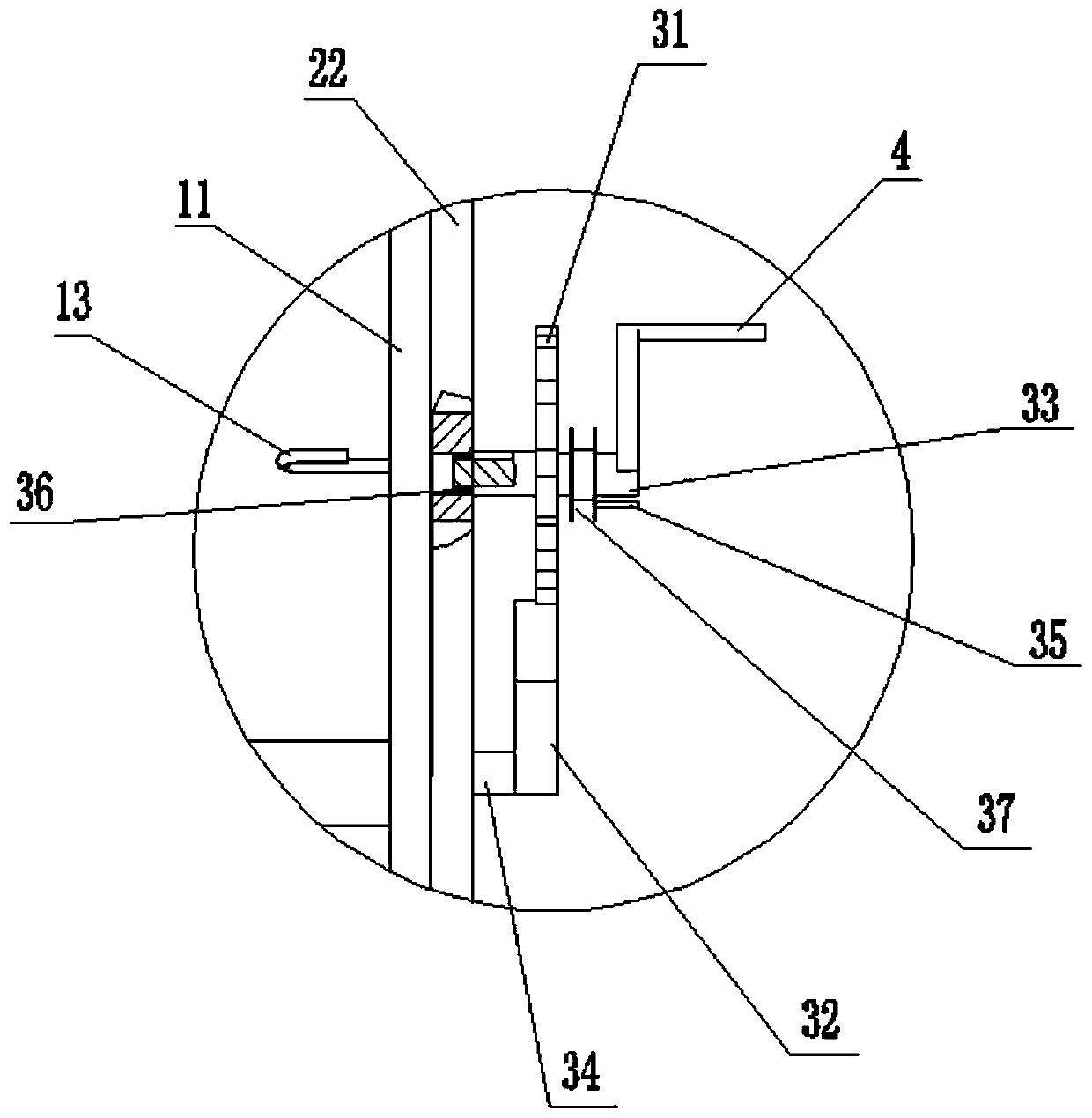

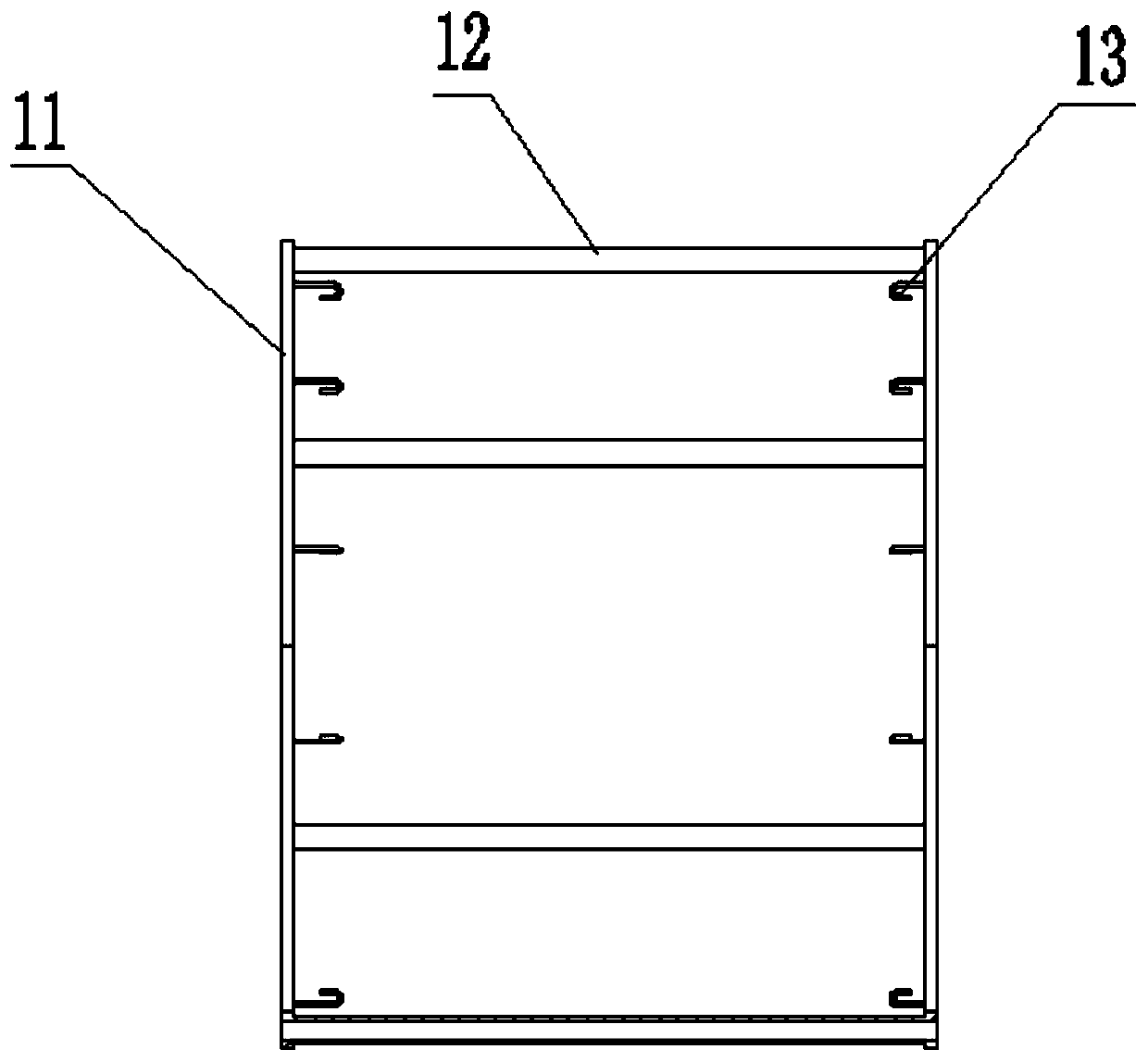

Large-caliber thermoplastic composite long-distance transportation pipe and manufacturing method and device thereof

ActiveCN107081922AHigh precisionAchieve constant tension3D object support structuresRigid pipesManufacturing technologyEngineering

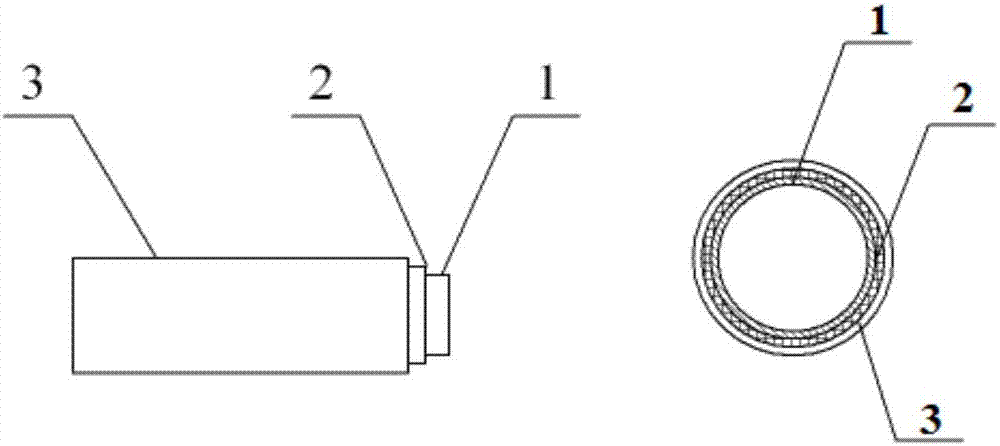

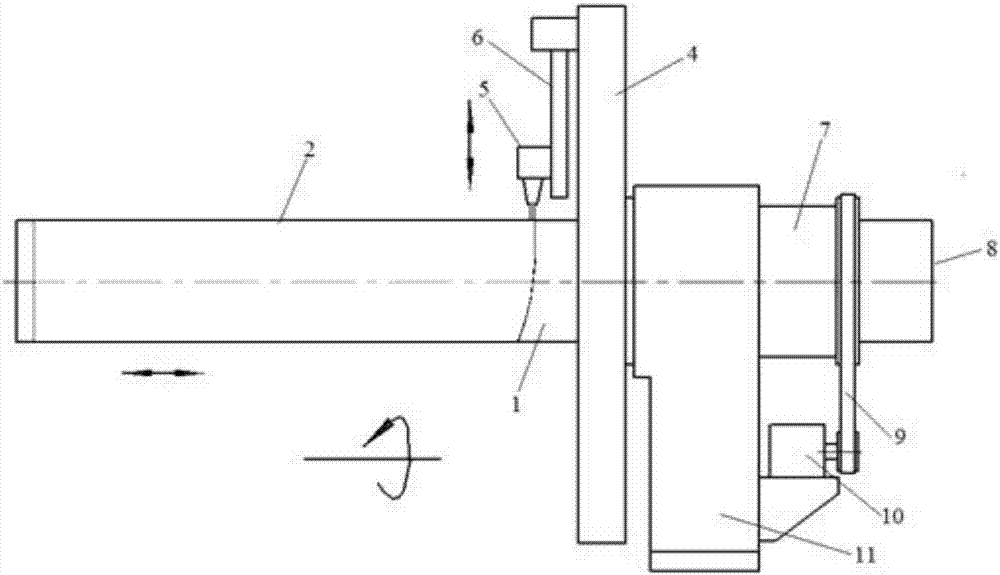

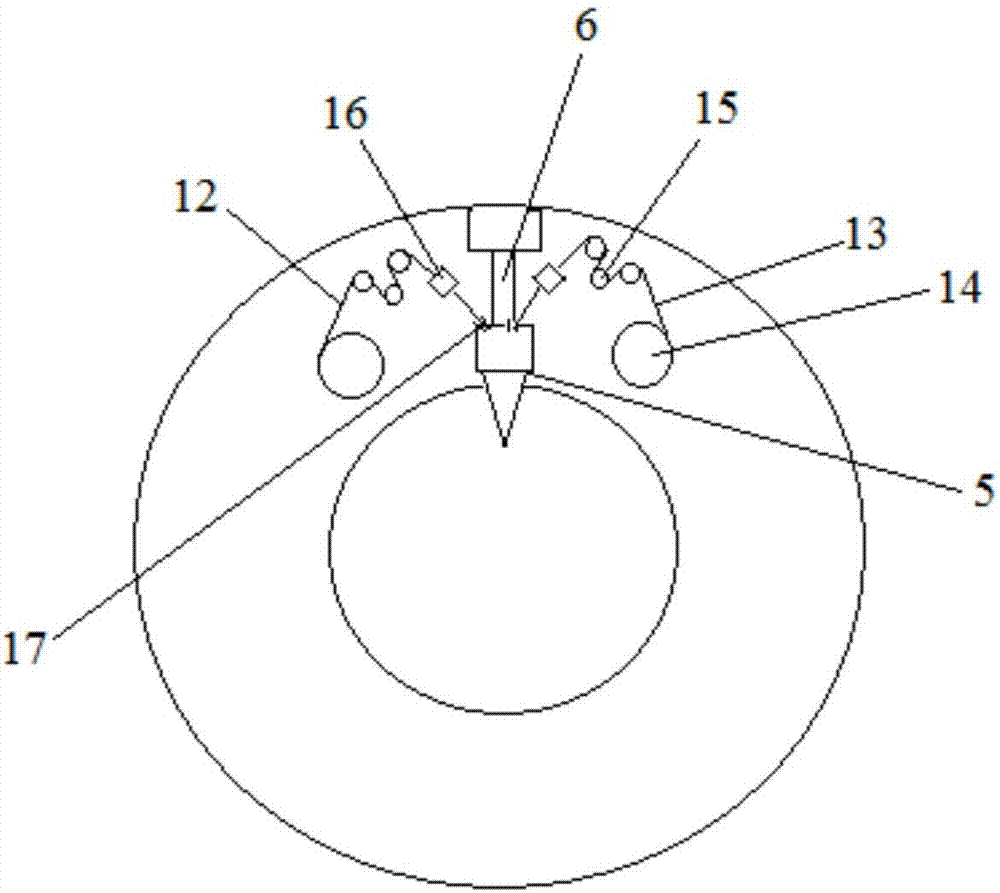

The invention relates to the technical field of manufacturing of thermoplastic composite pipelines, in particular to a large-caliber thermoplastic composite long-distance transportation pipe manufactured through a 3D printing forming technology and a manufacturing method and device of the large-caliber thermoplastic composite long-distance transportation pipe. The large-caliber thermoplastic composite long-distance transportation pipe structurally and sequentially comprises a lining layer, a fiber reinforced layer and an outer protective layer from inside to outside. The length of the thermoplastic composite long-distance transportation pipe is 8-10 m, the pipe diameter of the thermoplastic composite long-distance transportation pipe is 1000-1500 mm, the lining layer is 10-50 mm thick, the reinforced layer is 50-200 mm thick and the outer protective layer is 10-50 mm thick. The large-caliber thermoplastic composite long-distance transportation pipe has the outstanding advantages of being light in weight, resistant to high temperature, resistant to corrosion, good in flexibility and air impermeability, high in internal and external pressure rating, convenient to install and the like. Because of the smooth inner wall, the large caliber and the high internal and external pressure rating, the large-caliber thermoplastic composite long-distance transportation pipe can obtain a higher fluid speed and a higher fluid flow and is particularly suitable for being applied on the aspect of long-distance oil and gas transportation pipelines.

Owner:WEIHAI NACHUAN PIPE FITTINGS

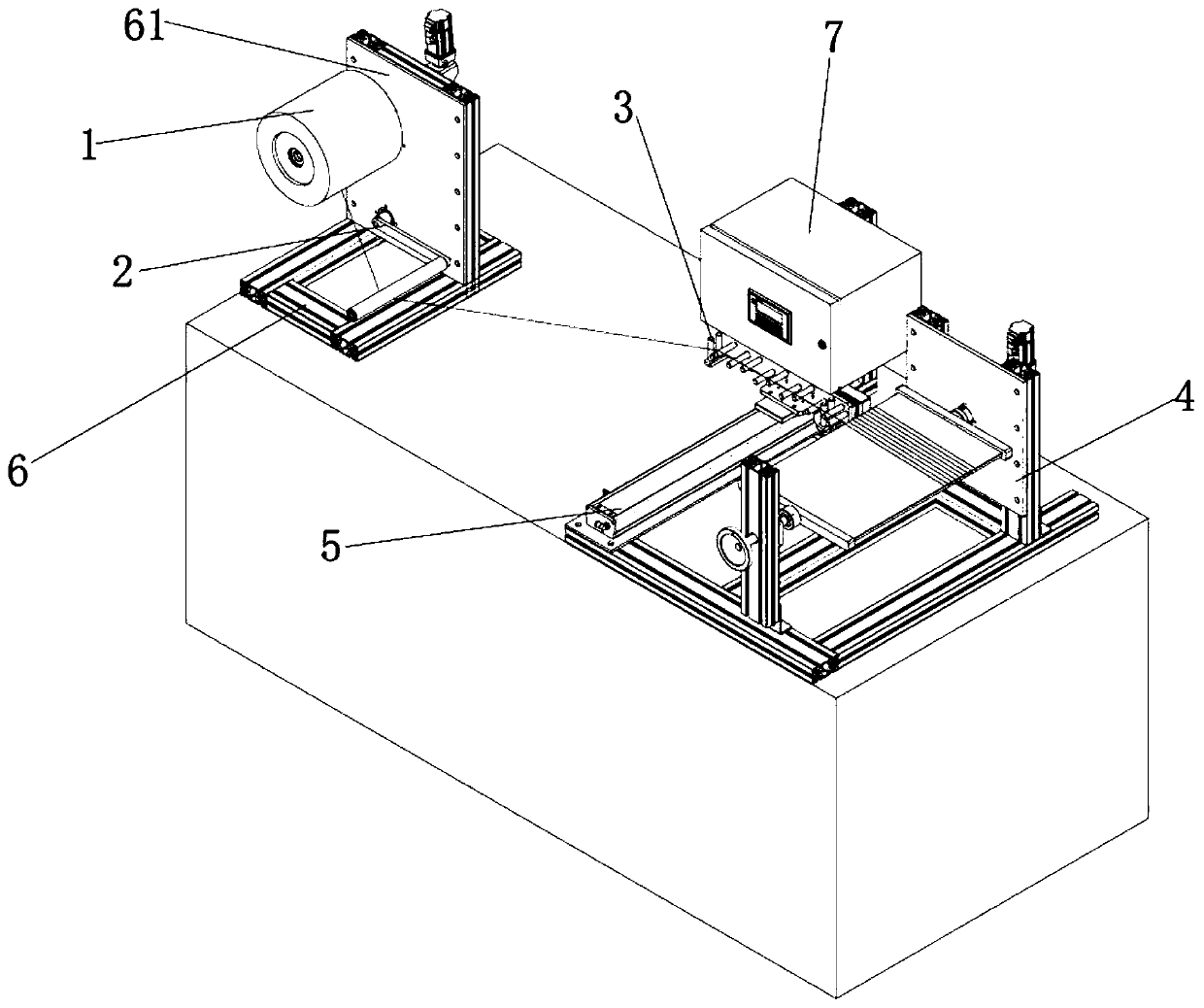

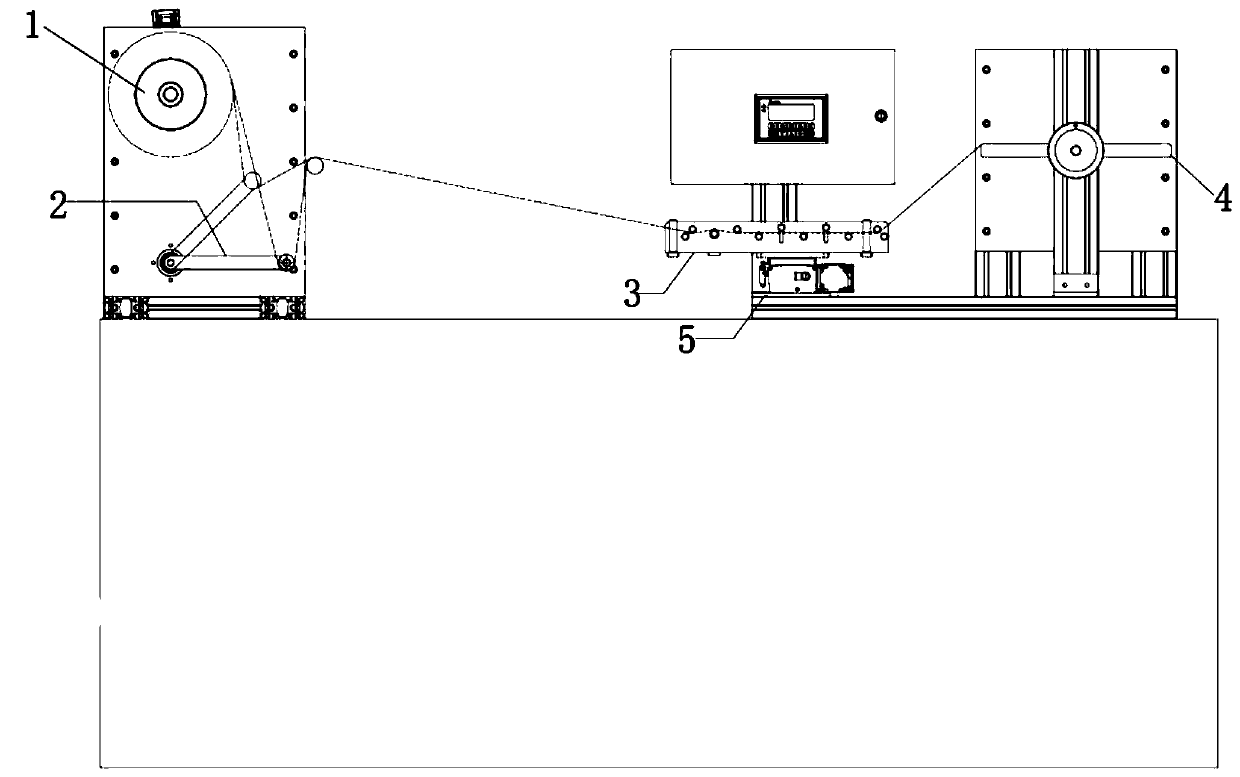

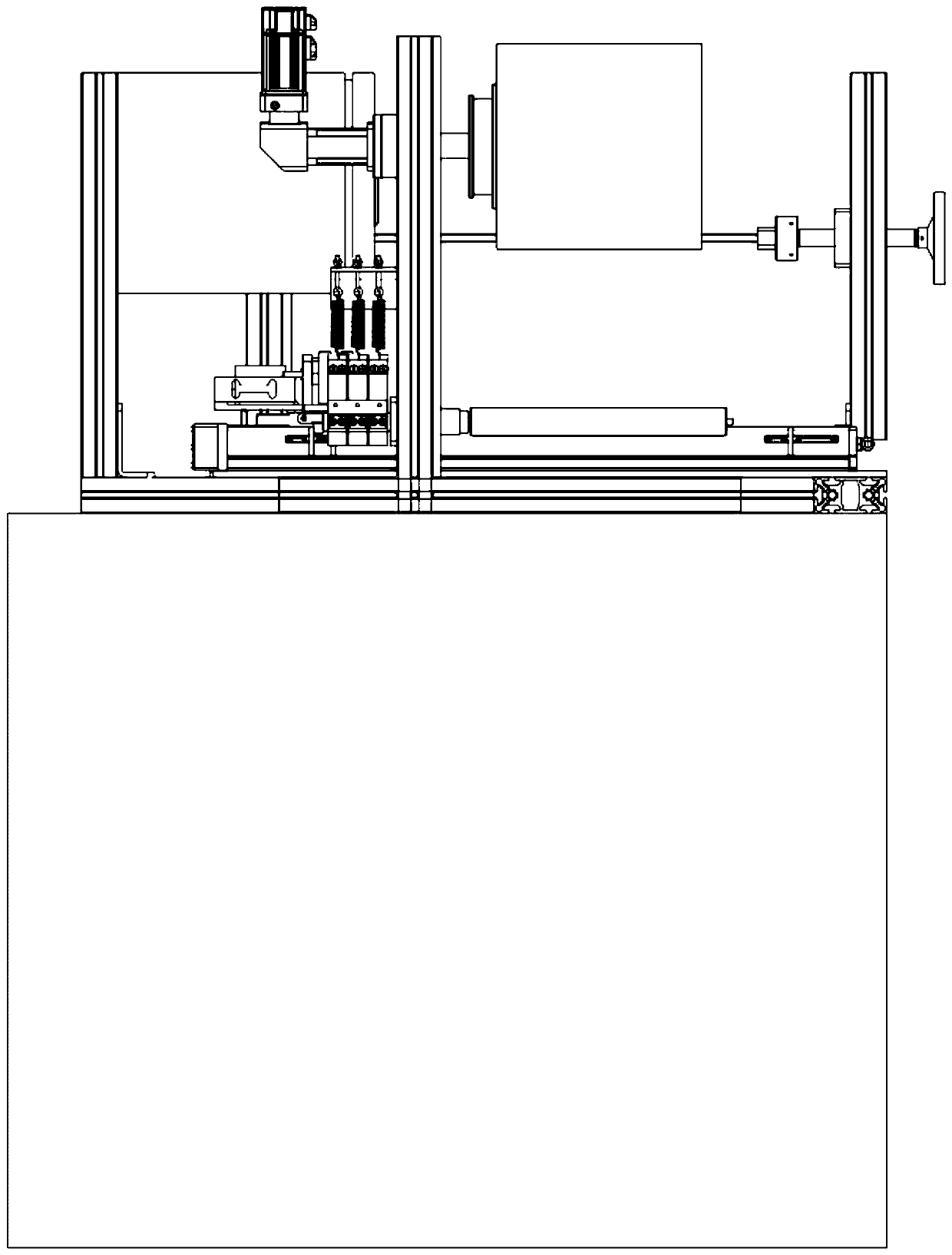

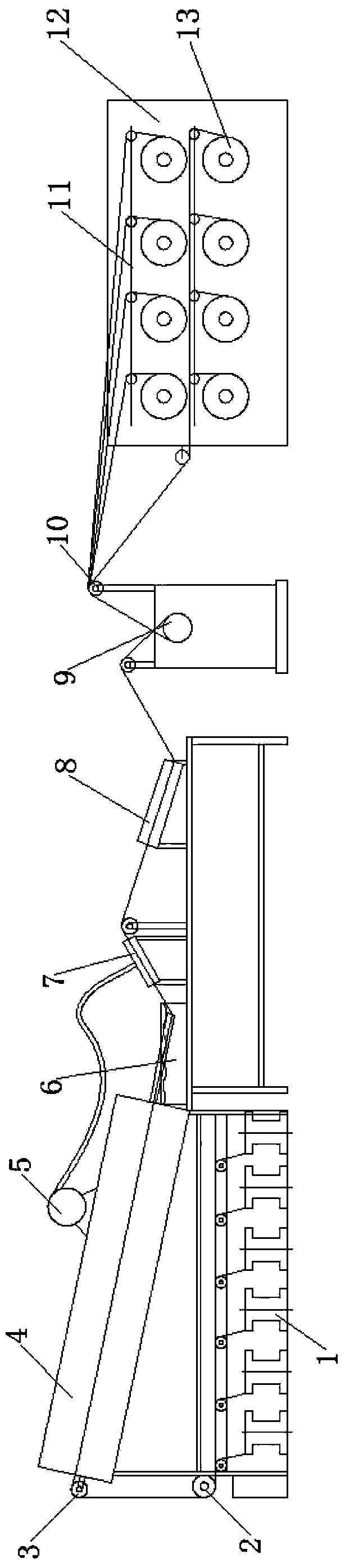

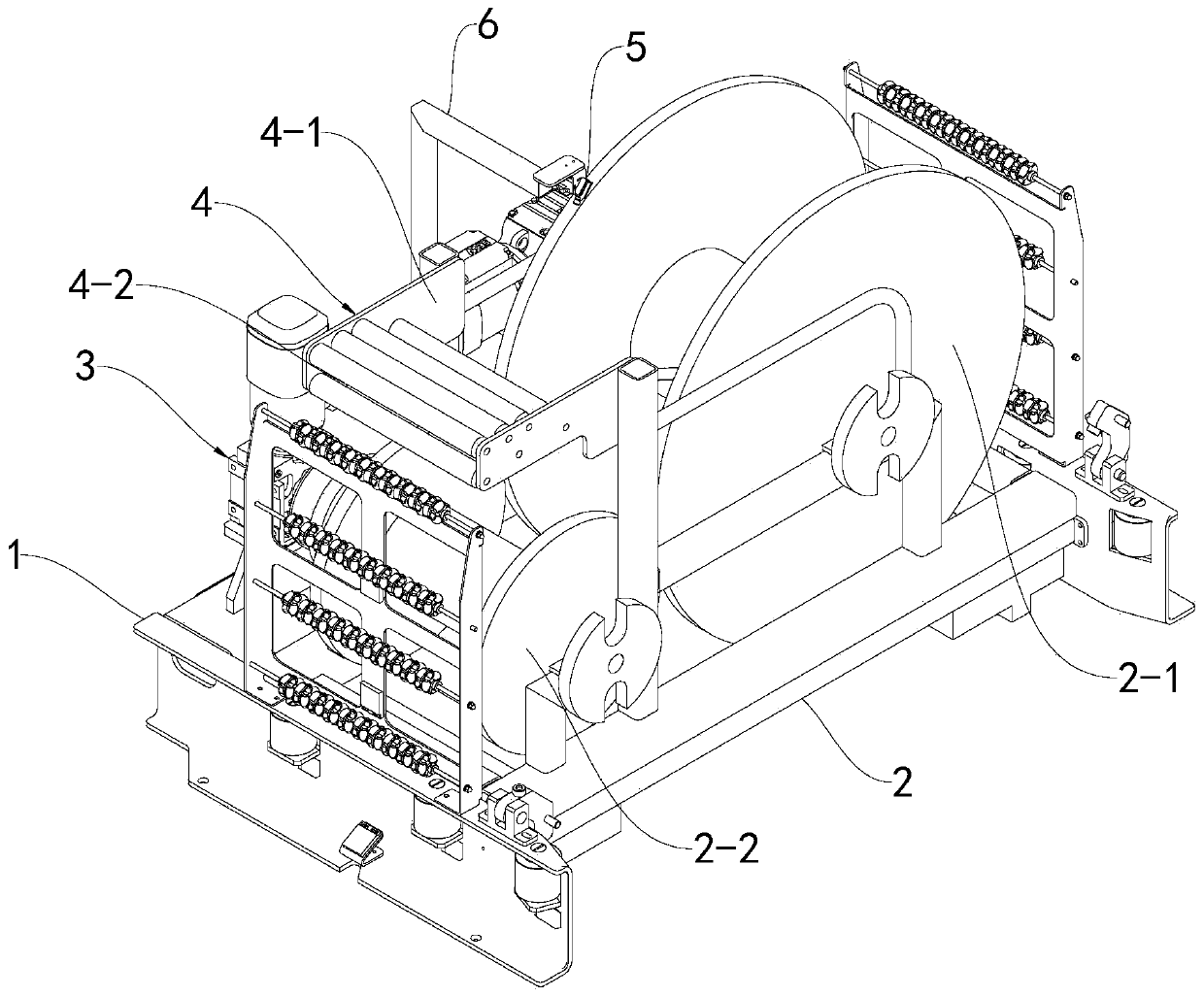

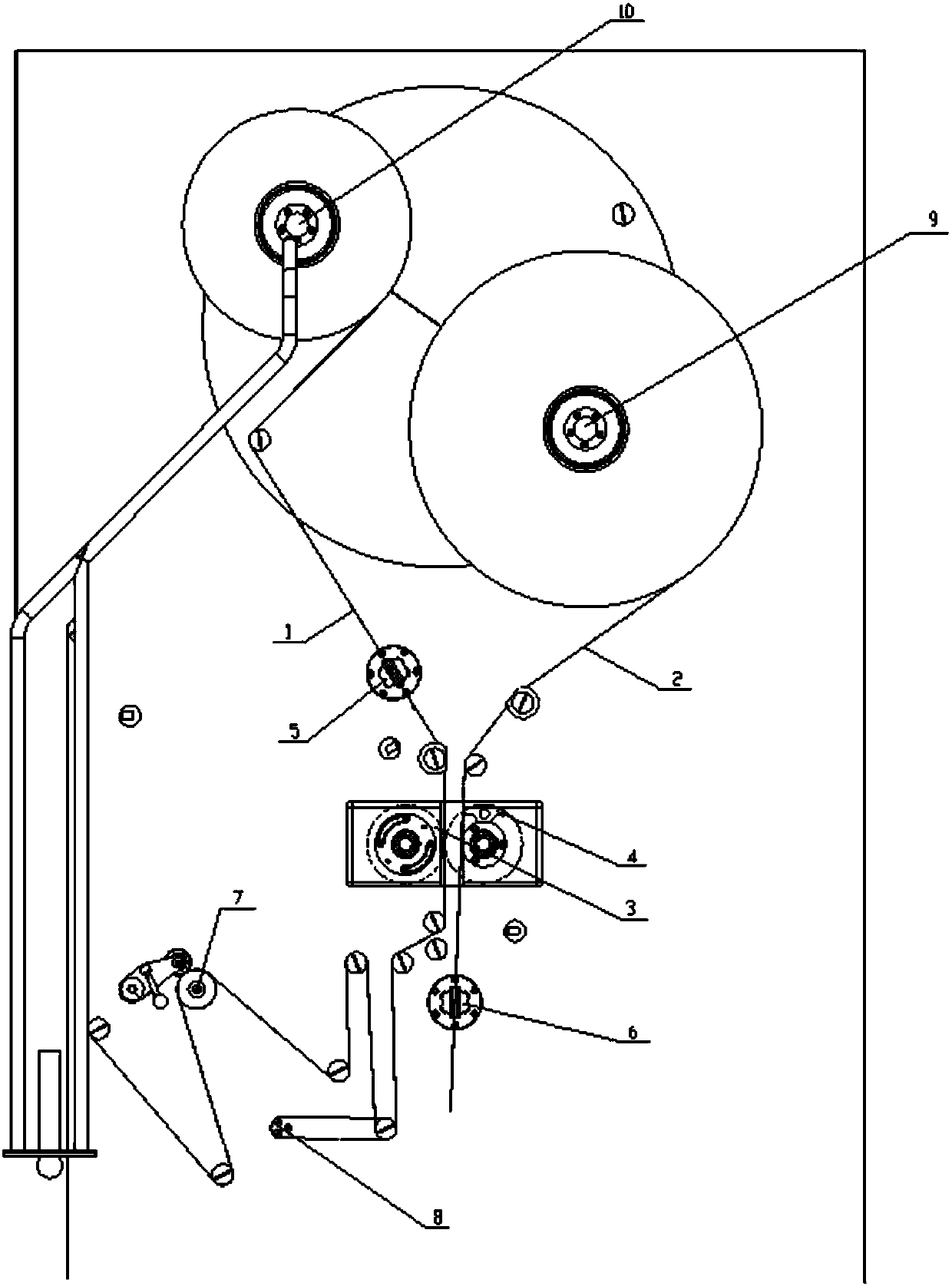

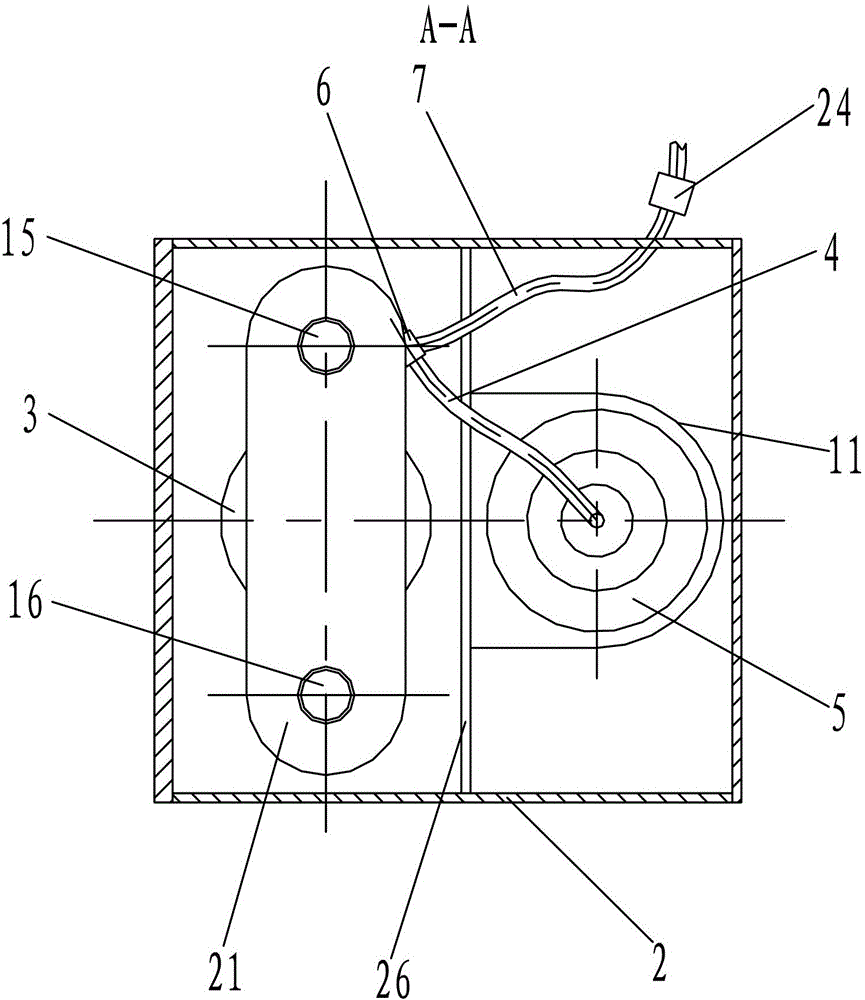

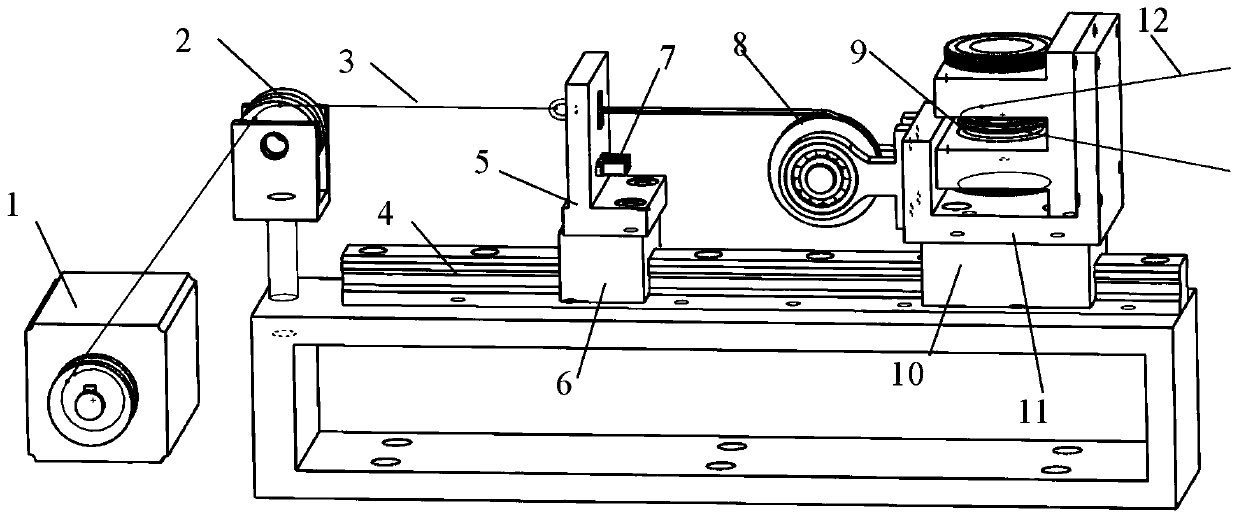

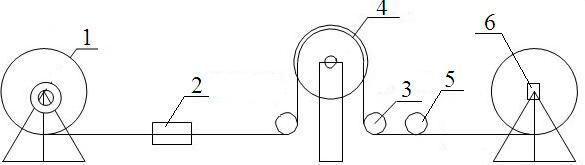

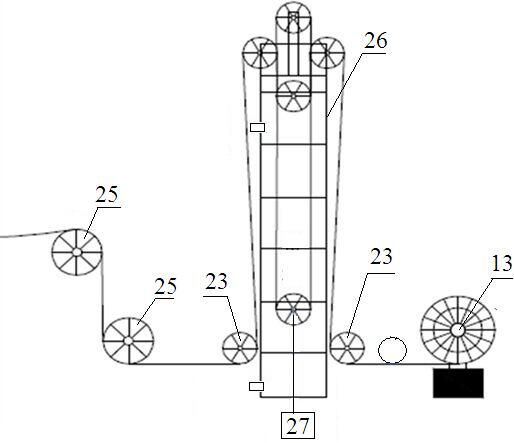

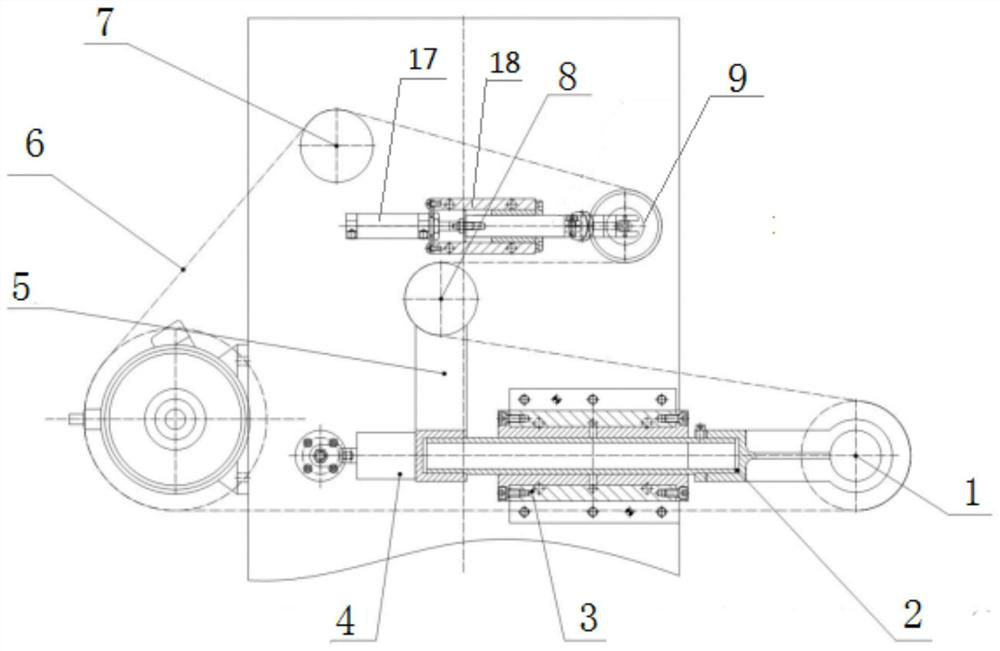

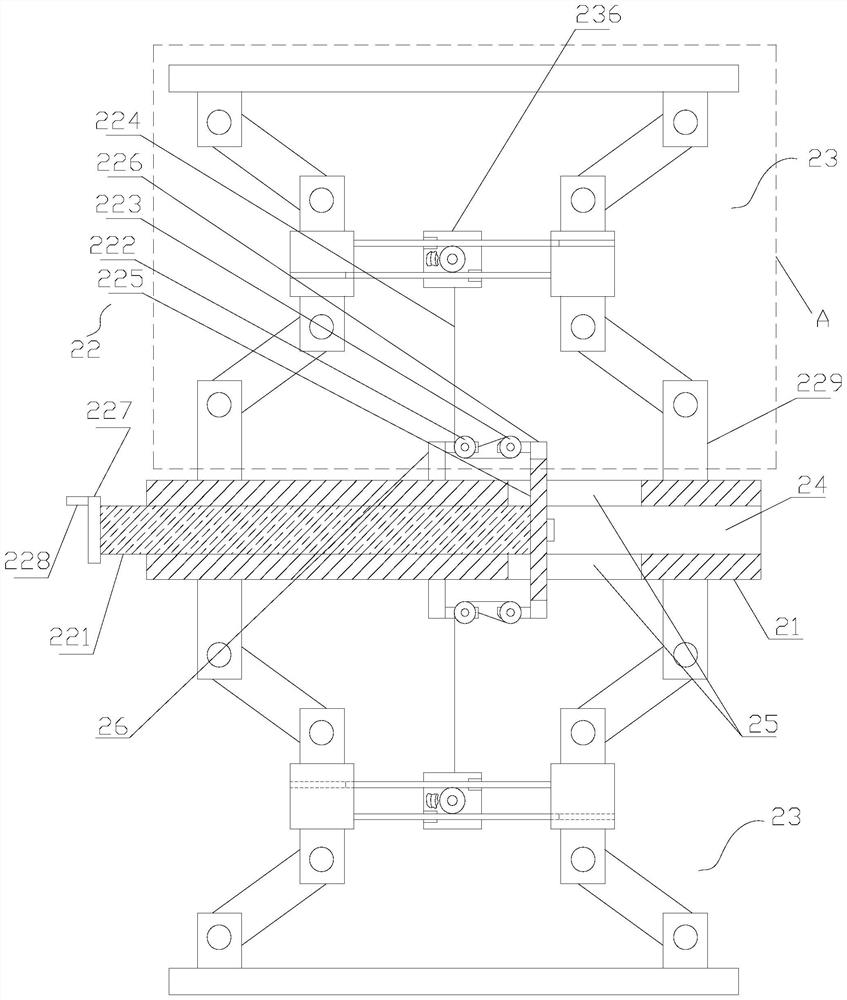

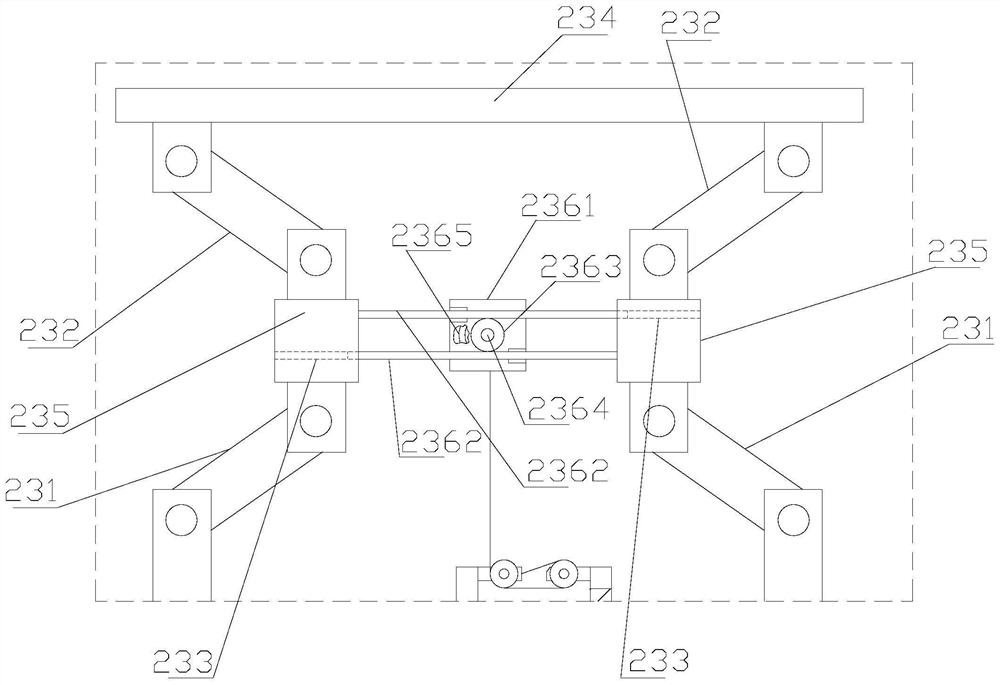

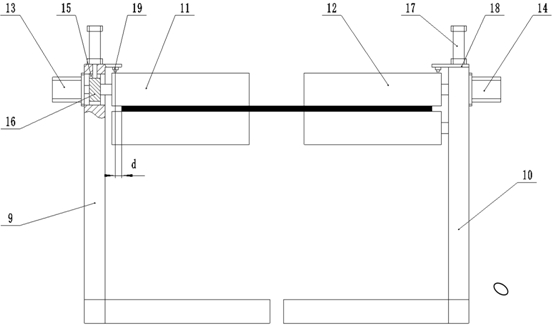

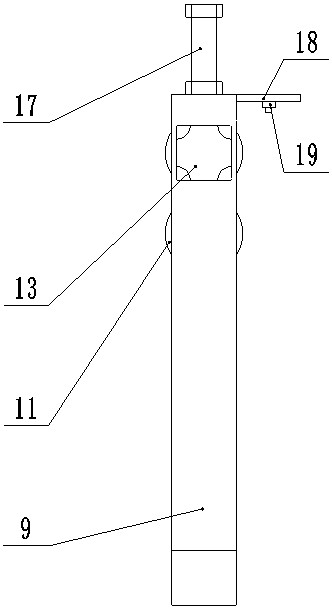

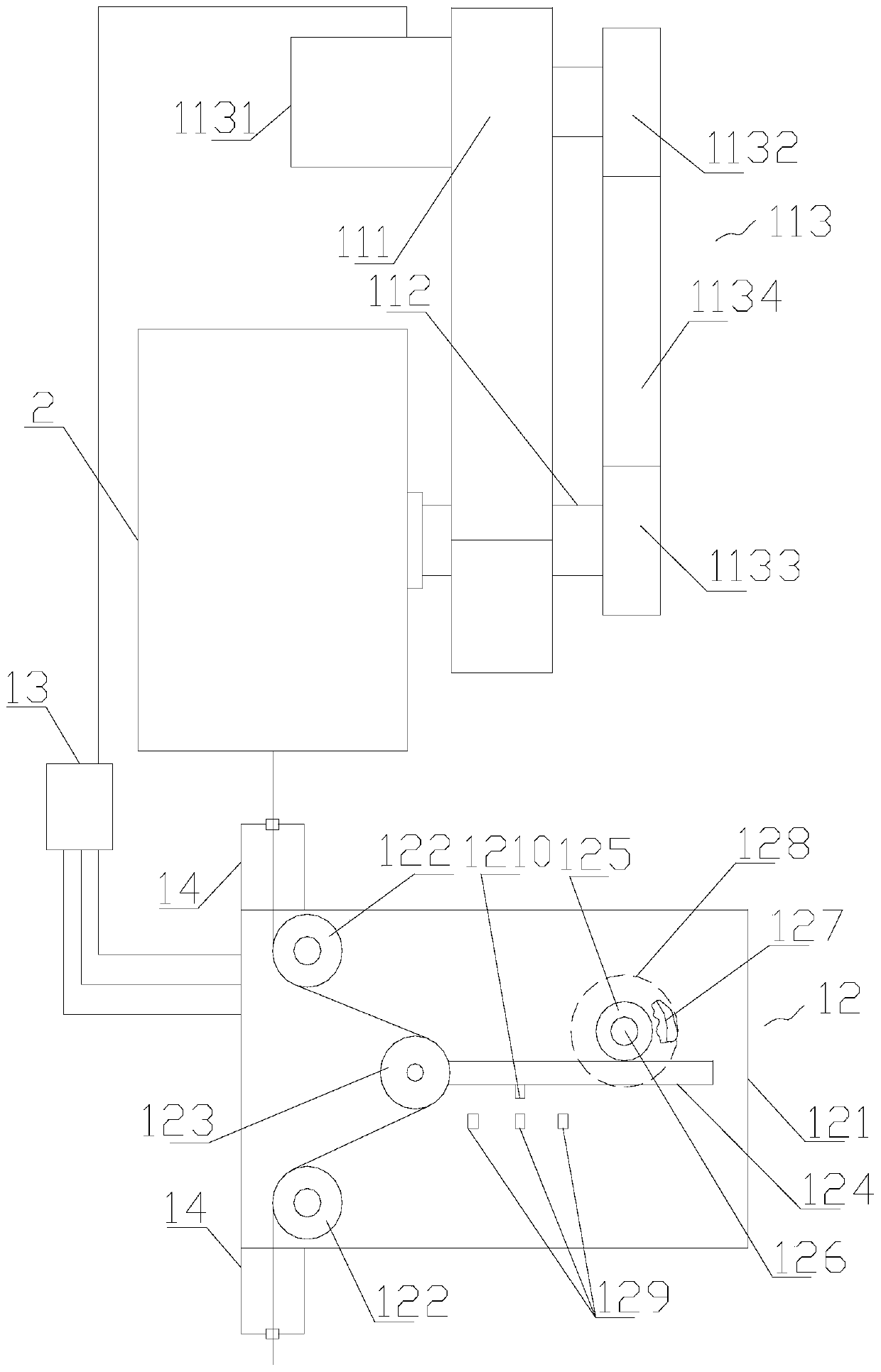

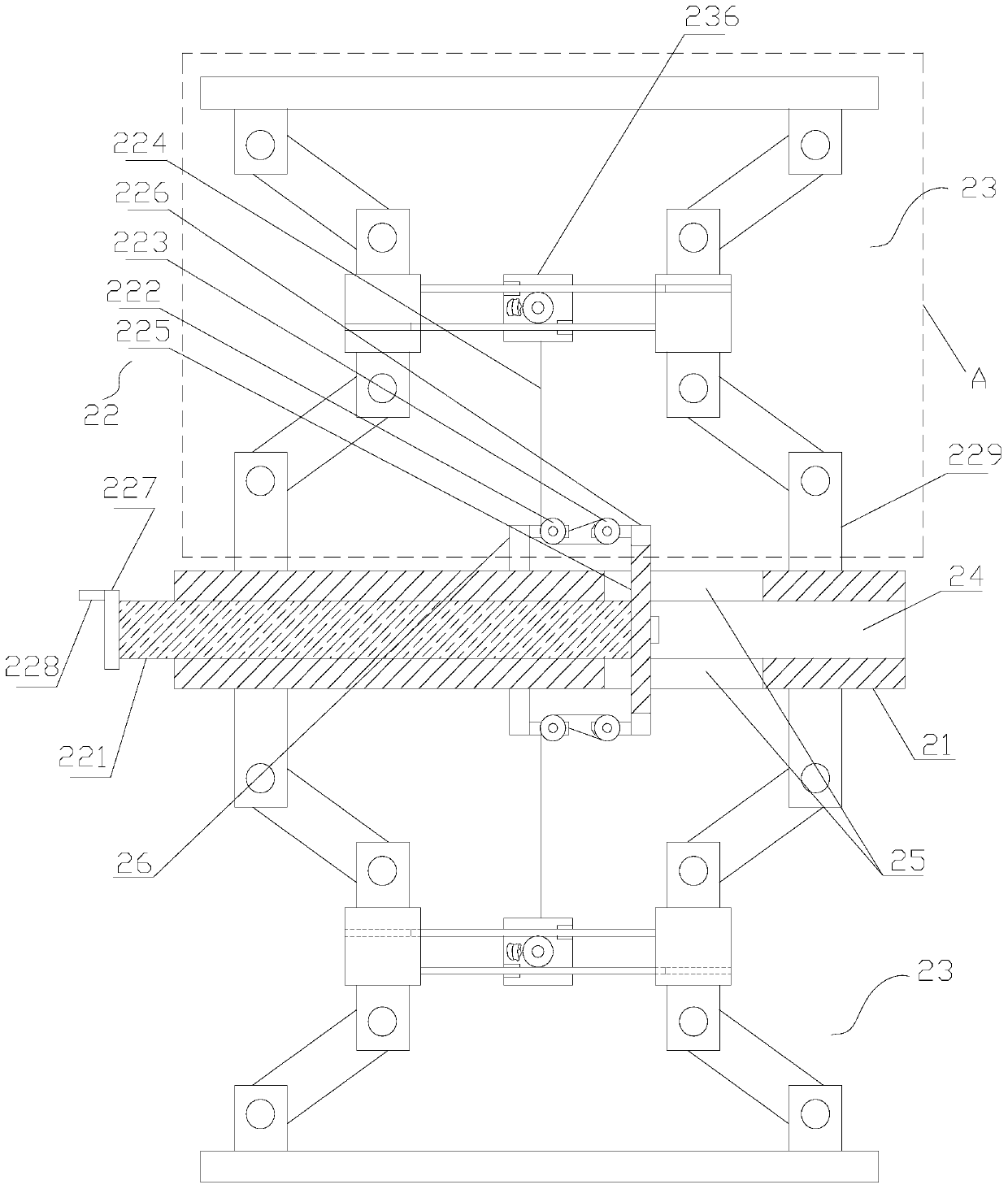

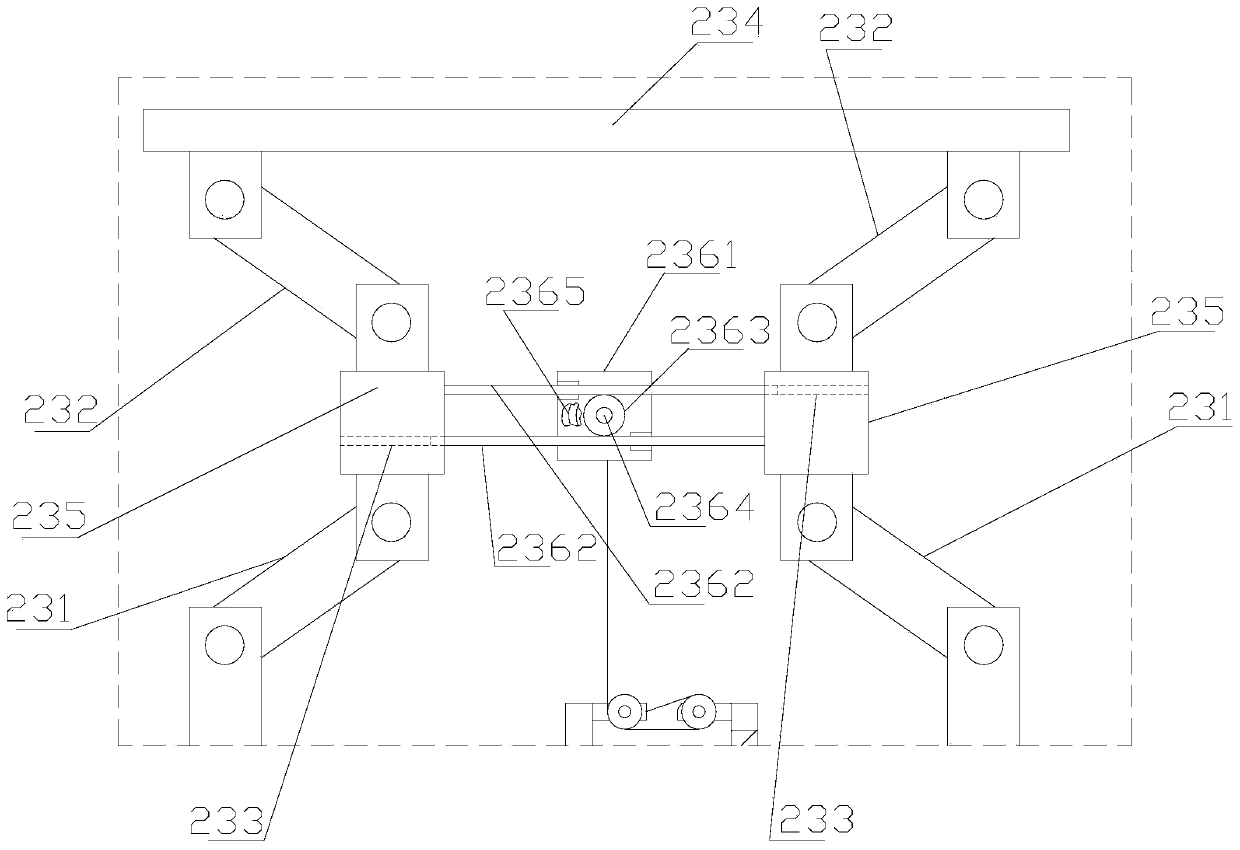

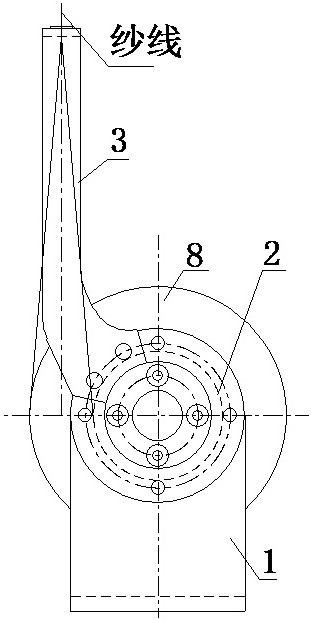

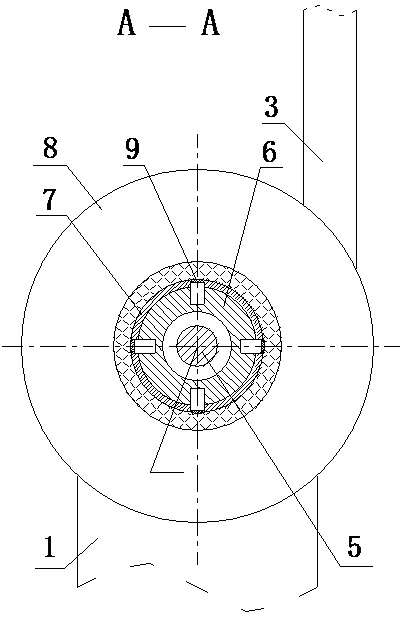

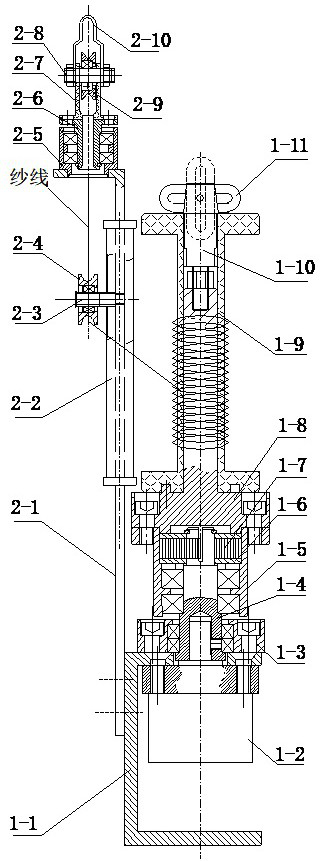

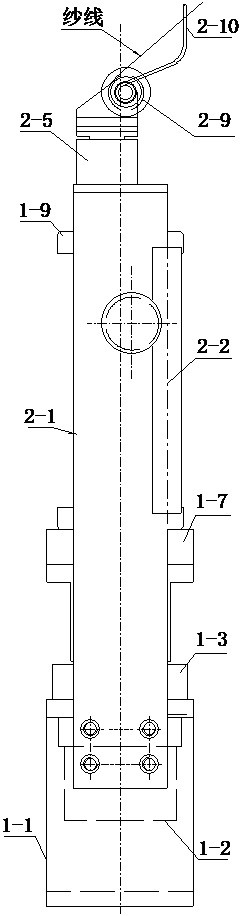

Constant-tension zero-twist fiber unfolding and winding device and operation method thereof

ActiveCN110054024ACompact structureImprove processing efficiencyFilament handlingTextiles and paperFiberYarn

The invention relates to a constant-tension zero-twist fiber unfolding and winding device. An active unwinding device, a yarn guiding and buffering device, a zero-twist fiber unfolding device, a winding device and a reciprocating device are included. The active unwinding device conducts unwinding operation on yarn on a spool. The yarn guiding and buffering device conducts the guiding movement on the yarn and provides buffering power, and the yarn is prevented from being snapped. The zero-twist fiber unfolding device conducts guiding and fiber unfolding operation on the yarn. The winding devicewinds the yarn obtained after fiber unfolding. The reciprocating device drives the zero-twist fiber unfolding device to reciprocate. The active unwinding device and the yarn guiding and buffering device are connected, the zero-twist fiber unfolding device is connected with the yarn guiding and buffering device and loaded on the end face of the reciprocating device, and the winding device is connected with the zero-twist fiber unfolding device. By means of the constant-tension zero-twist fiber unfolding and winding device, yarn unwinding, fiber unfolding and winding are finished in one device,and practicability and work efficiency of the constant-tension zero-twist fiber unfolding and winding device are improved. Meanwhile, the invention further relates to an operation method of the constant-tension zero-twist fiber unfolding and winding device.

Owner:NEWTRY COMPOSITE

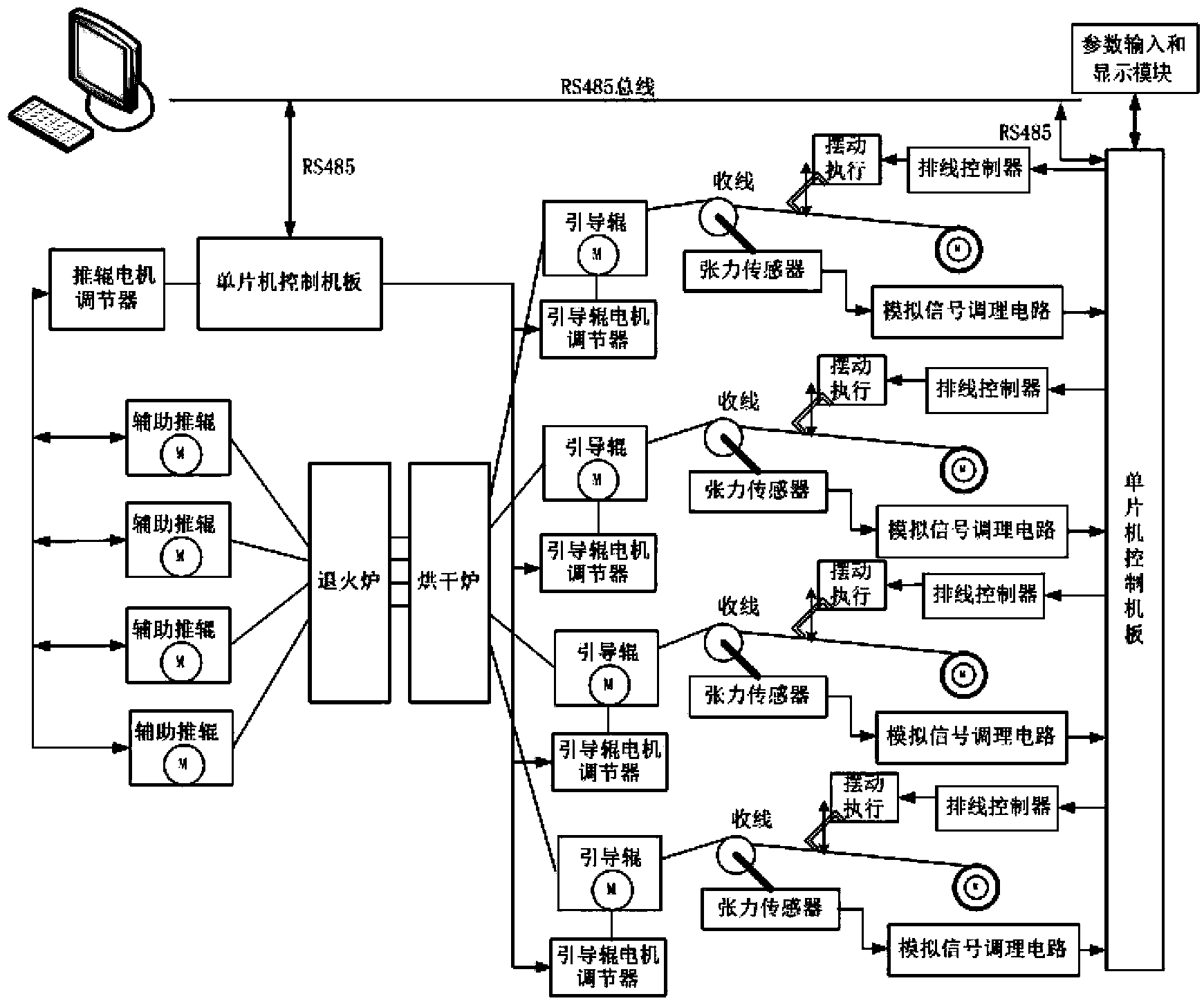

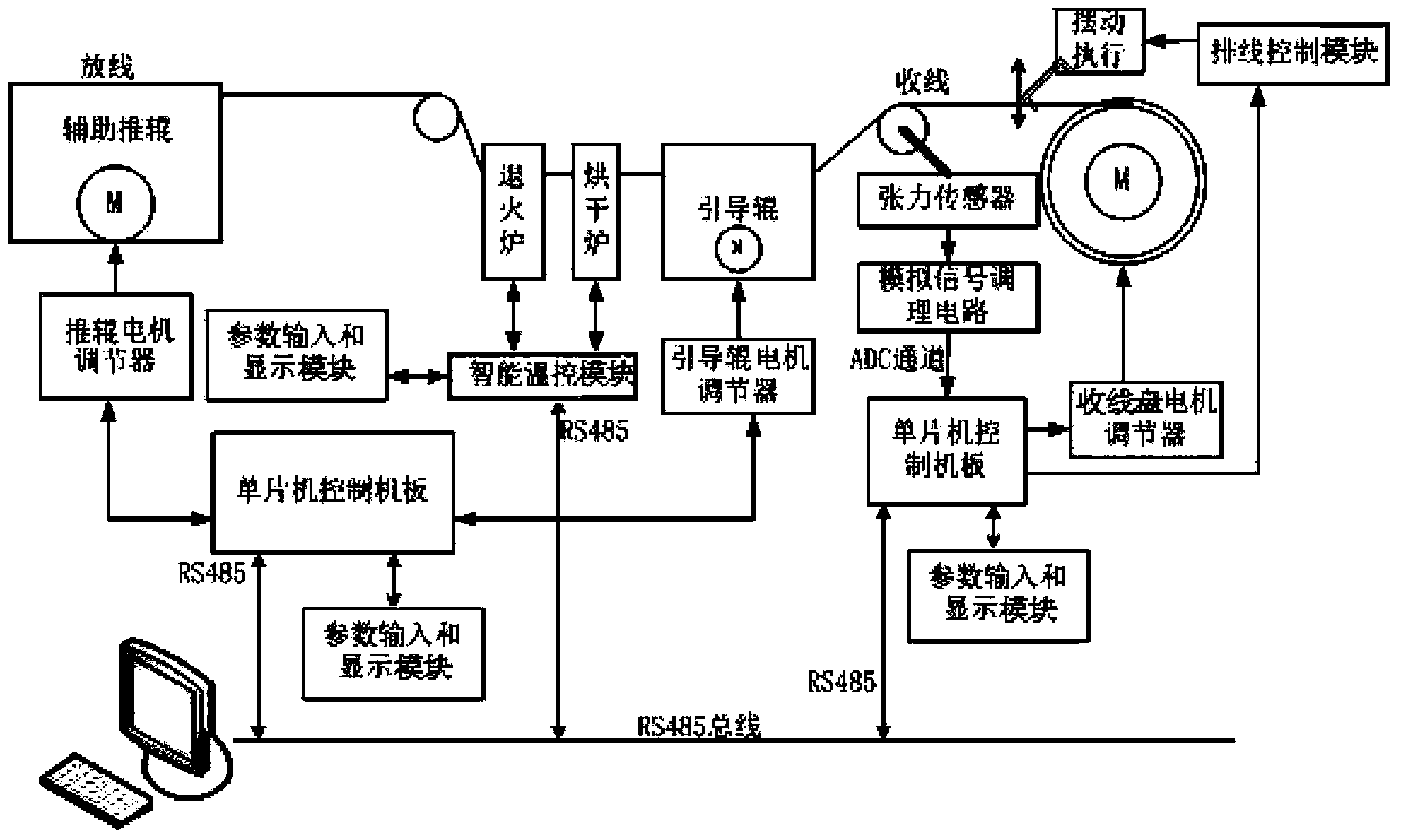

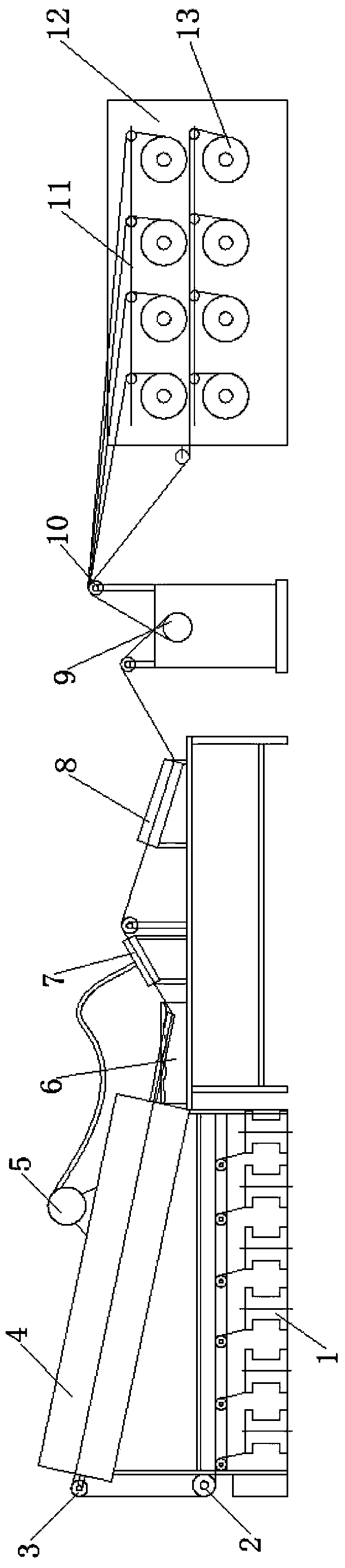

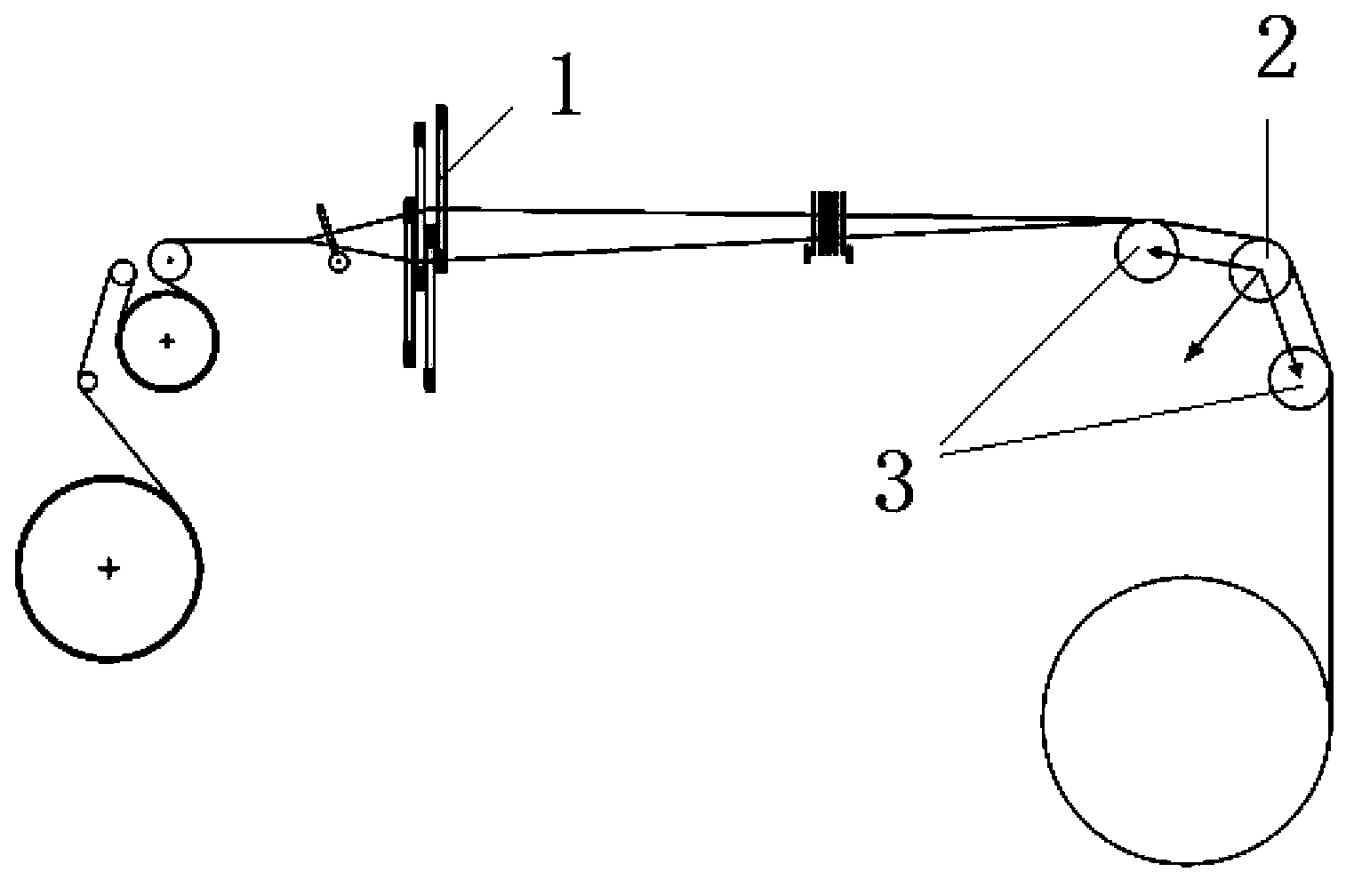

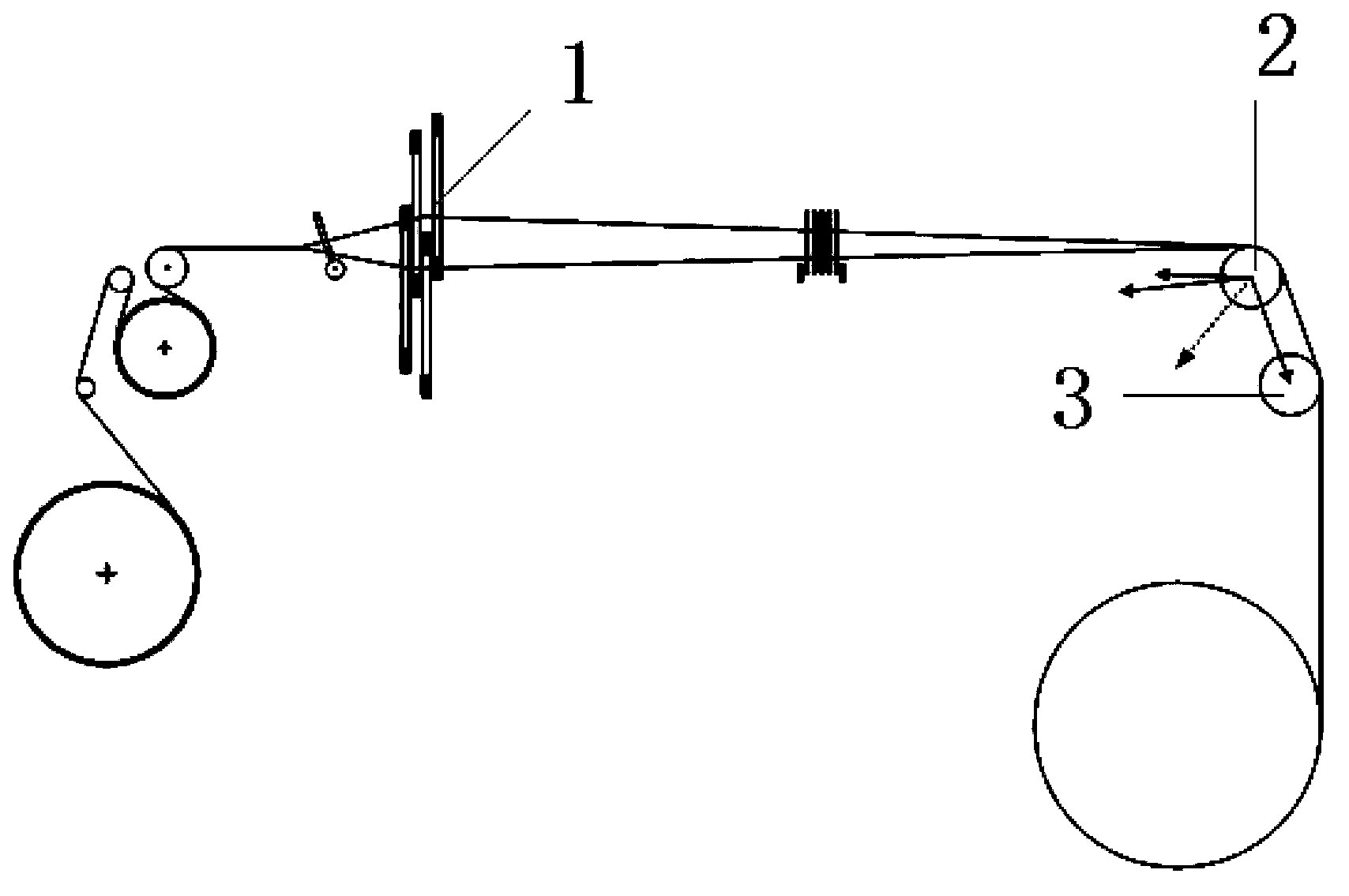

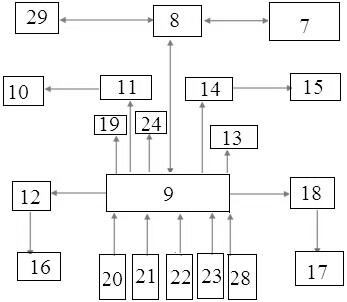

Intelligent control system and method of multi-specification tubular continuous annealing furnace

ActiveCN103436682AAvoid stretchingStable wire diameterFurnace typesHeat treatment process controlProduction lineContinuous annealing

The invention discloses an intelligent control system and an intelligent control method of a multi-specification tubular continuous annealing furnace, belonging to the technical field of intelligent control. Technical analysis and improvement are performed on the conventional continuous annealing furnace device; original single devices are rationally disassembled respectively; a plurality of groups of auxiliary push rollers, guide rollers, wire separation wheels and wire arrangement rods are additionally arranged on one set of equipment to form a continuous annealing production line capable of realizing simultaneous treatment and production of wires of multiple specifications; the annealing production line is intelligently controlled; temperature sensors are additionally arranged on the annealing furnace and a drying furnace to intelligently control the annealing and drying temperature. According to the system and the method, the annealing treatment on various wires of different specifications can be simultaneously completed on the same set of annealing equipment, and zero-tension annealing of the wires in the annealing furnace can be kept, so that the wires are prevented from being lengthened after being heated and softened, stable linear diameter is guaranteed, the equipment investment is reduced and the production cost is reduced; meanwhile, the automation degree is high, and remote monitoring and intelligent control can be realized.

Owner:江苏华旺新材料有限公司

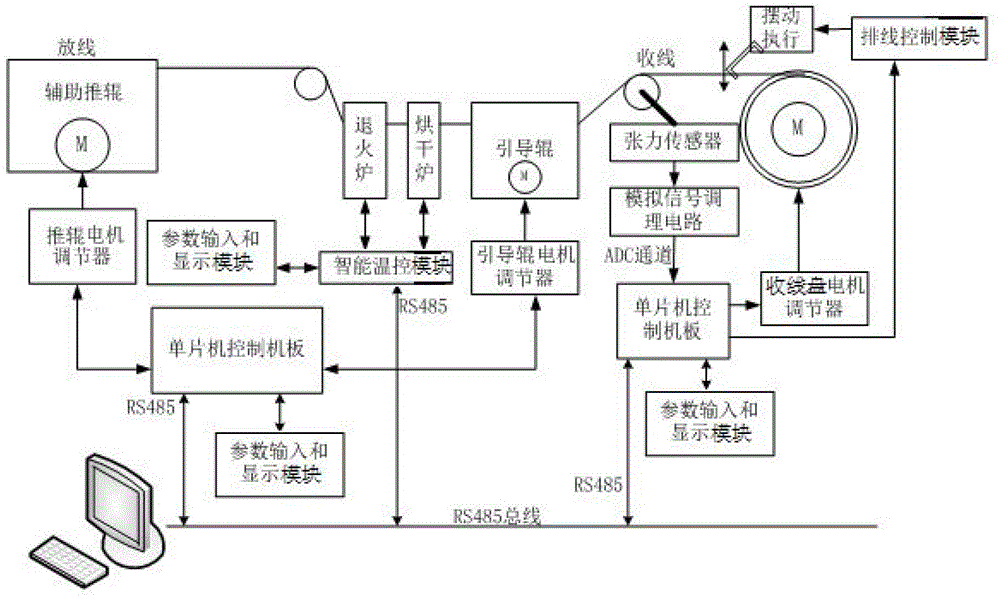

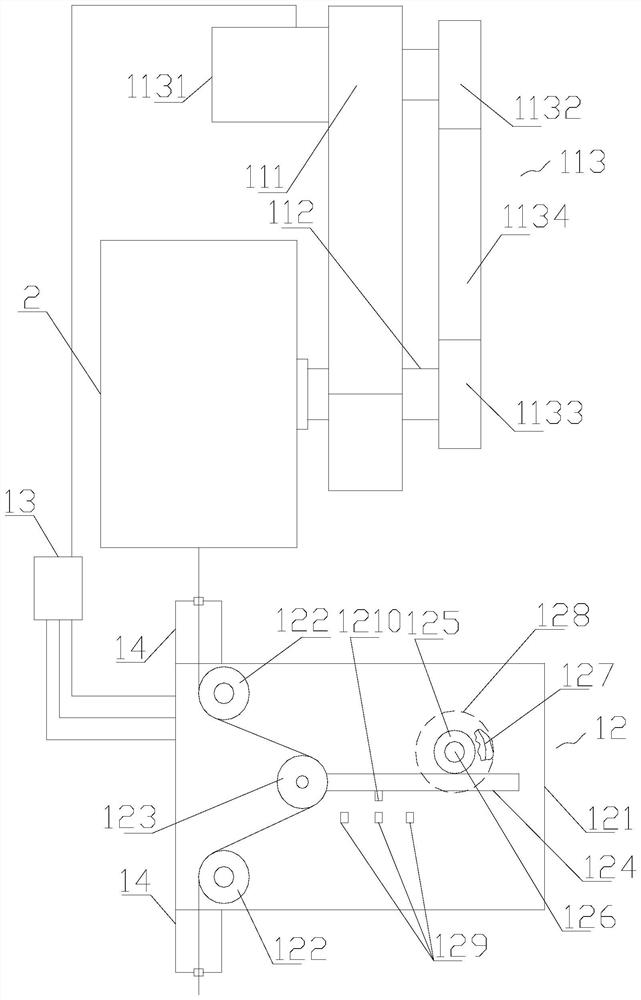

System and method for intelligently controlling tube continuous annealing furnaces

ActiveCN103436683AAvoid stretchingStable wire diameterFurnace typesHeat treatment process controlTemperature controlComputer module

The invention discloses a system and method for intelligently controlling tube continuous annealing furnaces, belonging to the technical field of intelligent control. The system disclosed by the invention is formed through carrying out a technical improvement on an existing annealing device, and respectively carries out intelligent control on an auxiliary push roller drive motor, a guide roller drive motor, a take-up reel drive motor and a winding displacement control module; a temperature sensor is respectively added on an annealing furnace and a drying furnace so as to intelligently control the annealing and drying temperatures; and the control processes are all implemented by parameter input, a display module or a computer, thereby achieving the purpose of remote monitoring and control. According to the invention, a situation that wires run in zero tension in the annealing furnace can be ensured, thereby avoiding that the wires are stretched after being softened by heating; the wires subjected to annealing can achieve an effect of constant-tension take-up, and the temperature control precision of the drying furnace and the annealing furnace is high, therefore, a situation that the wires running in the furnaces are always in an optimal recrystallization state is ensured, and the energy-saving effect is good; and the system and method disclosed by the invention are high in degree of automation, and realize remote monitoring and intelligent control.

Owner:江苏华旺新材料有限公司

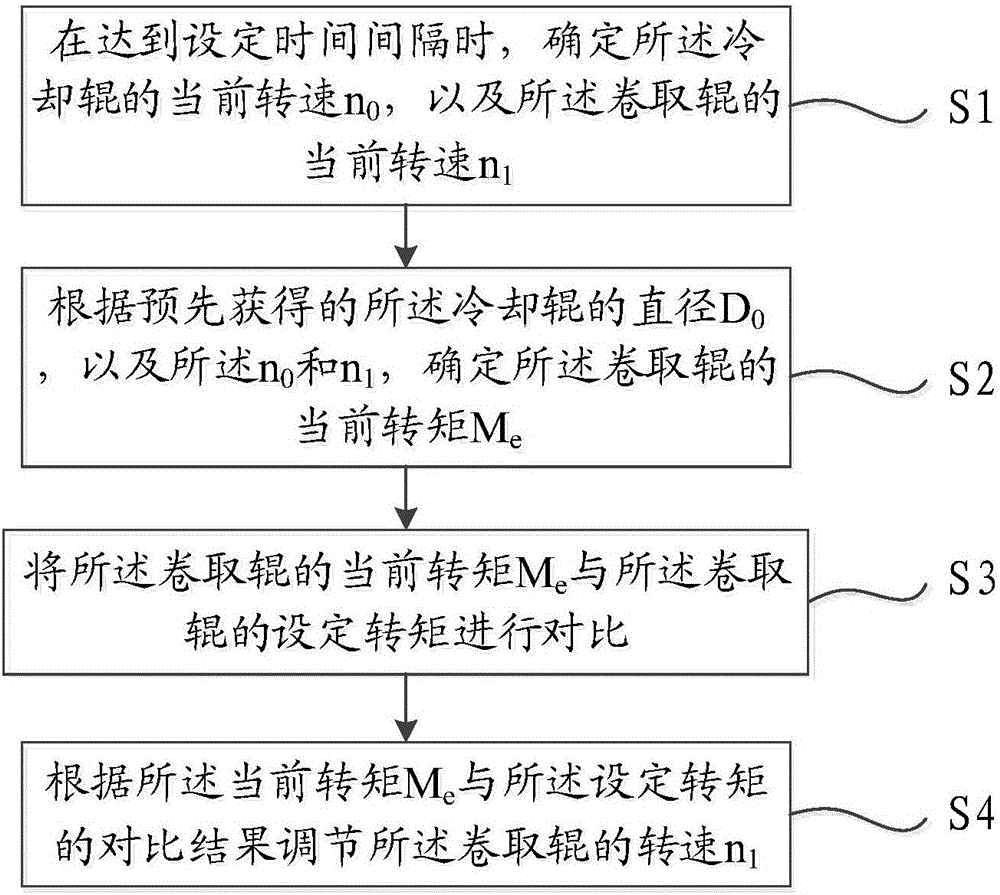

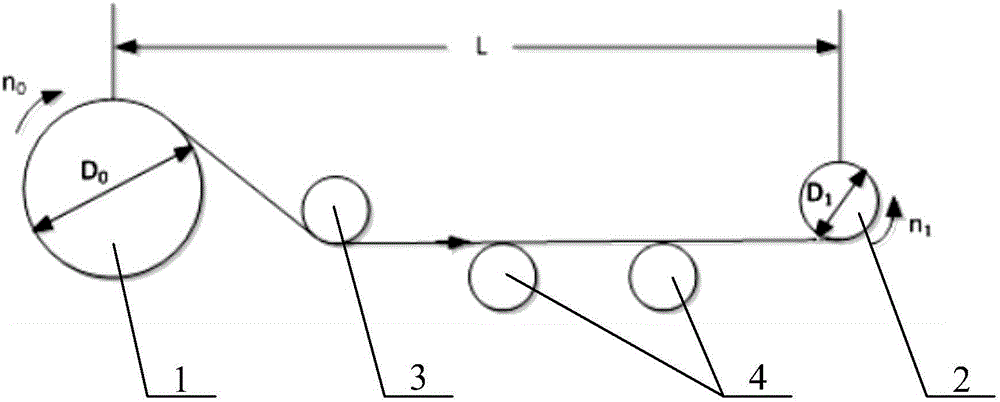

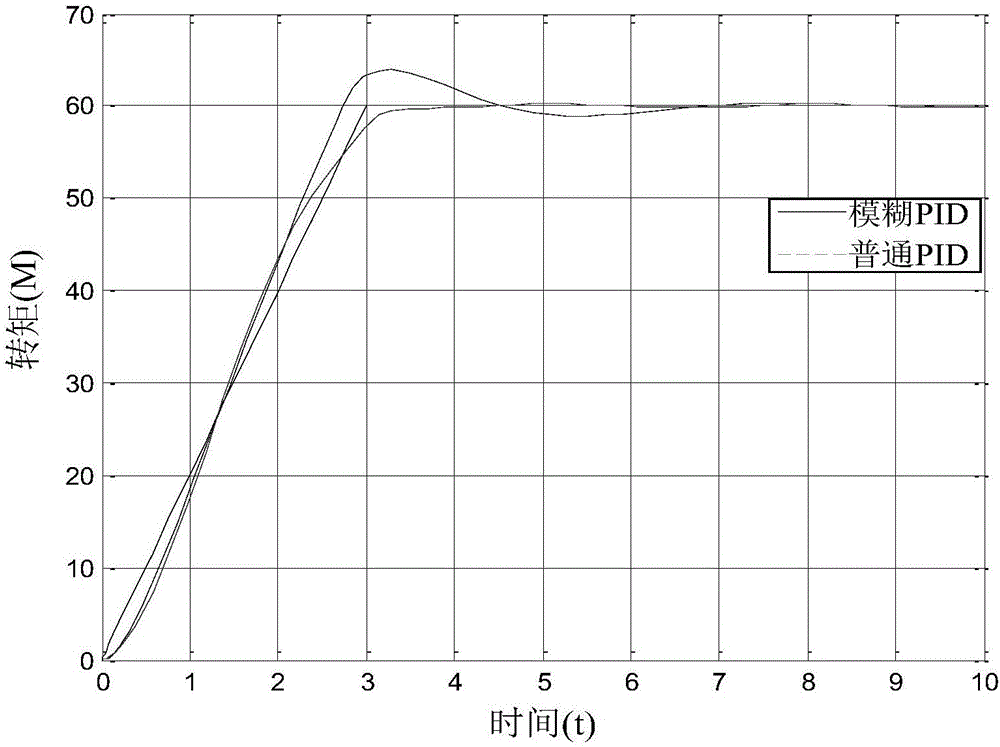

Coiling tension control method and device for amorphous strip

InactiveCN106743903AAchieve constant tensionSolve the problem of tension fluctuationFunction indicatorsWebs handlingEngineeringControl theory

The invention discloses a coiling tension control method and device for an amorphous strip. The method comprises the steps as follows: when the set time interval is reached, the current rotating speed n0 of a cooling roller and the current rotating speed n1 of a coiling roller are determined; the current torque Me of the coiling roller is determined according to the diameter D0, which is obtained in advance, of the cooling roller, the current rotating speed n0 and the current rotating speed n1; the current torque Me of the coiling roller is compared with the set torque of the coiling roller; and the rotating speed n1 of the coiling roller is adjusted according to the comparison result of the current torque Me with the set torque. With the method, the torque Me of the coiling roller is close to the set torque by adjusting the rotating speed n1 of the coiling roller, then the tension of the amorphous strip is constant, the problem of the tension fluctuation in the coiling process of the amorphous strip is effectively solved, constant tension control in the coiling process is realized, and thus the coiled strip coil is tight and neat.

Owner:GUANGDONG UNIV OF TECH

Wire tension controller of multi-strand spring digital control lathe

The invention discloses a wire tension controller of a multi-strand spring digital control lathe, comprising a shell, a tension control assembly and a tension collection assembly. The tension control assembly comprises a magnetic powder brake and a damping part; the tension collection assembly comprises a cutting fiber wheel and a pressure sensor; the signal output end of the pressure sensor and the magnetic powder brake are respectively connected with an automatic control system of the lathe; and wires are led out from a wire box arranged in the shell to wind a circular cutting fiber groove before being led out of the shell by the cutting fiber wheel. The wire tension controller of the multi-strand spring digital control lathe automatically controls the tension of the wires in the production process, monitors and controls the tension of each strand of wires in a multi-strand spring processing process by the tension collection assembly and a data acquisition and control system, realizes the constant tension of each strand of wires and the uniform and constant tension among various strands of wires, monitors the tension in real time by an application program of an upper computer and fully realizes a self-tuning system of the tension so as to ensure the quality of a finished product of a multi-strand spring.

Owner:CHONGQING UNIV

Material unwinding system and material unwinding control method

InactiveCN110385871AReal-time speed controlReal-time control of output torqueTyresMechanical engineeringControl unit

The invention discloses a material unwinding system and a material unwinding control method. The system comprises an unwinding trolley, a drive mechanism and an unwinding support. The unwinding trolley comprises a material roller and a mat cloth roller, wherein the material roller and the mat cloth roller are supported on the unwinding trolley in a rotating manner. The drive mechanism comprises amaterial unwinding motor connected with the material roller in a transmission manner, and a mat cloth rolling motor connected with the mat cloth roller in a transmission manner. The material unwindingsystem further comprises a distance measuring sensor and a control unit. The control unit can obtain the cumulative remaining thickness of materials wound around the material roller in real time based on measuring data of the distance measuring sensor, according to the material cumulative remaining thickness obtained in real time, the control unit can calculate the length of the materials currently wound around the material roller and the cumulative rolling thickness of mat cloth rolled on the mat cloth roller in real time, and according to the cumulative rolling thickness of the mat cloth rolled on the mat cloth roller, the control unit can control output torque of the mat cloth rolling motor. The system and the method can achieve constancy of tension of the mat cloth in the material unwinding process.

Owner:SAFE RUN & HISCENT MACHINERY SUZHOU

Method for controlling stability of rolling and unrolling of coating machine

InactiveCN103293999AExtended processing methodReduce instabilityProgramme control in sequence/logic controllersData signalControl theory

The invention discloses a method for controlling stability of rolling and unrolling of a coating machine. The method includes the four steps of roll diameter detection achieved through a sensor, data signal conversion, PLC operation and frequency control. Signal anti-shaking processing is carried out before the step of frequency control. A roll diameter input value is judged in a PLC, and when a1-an<30-80mm and b1-bn<30-80mm, the PLC transmits the value of an and the value of bn to a speed regulation device so that speed regulation calculation can be carried out, and a rotating speed value can be respectively fed back to a rolling motor and an unrolling motor. According to the method for controlling the stability of rolling and unrolling of the coating machine, shaking signals can be effectively prevented from being transmitted, and rolling and unrolling of the coating machine are more stable.

Owner:SNTO TECH GRP

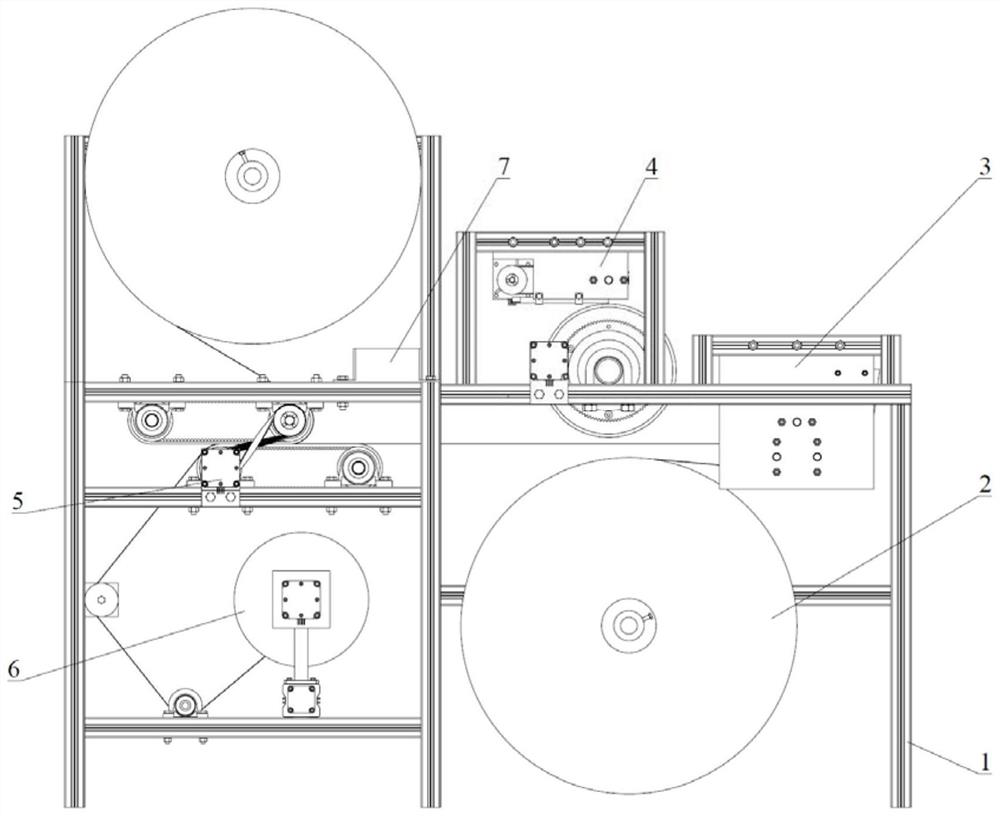

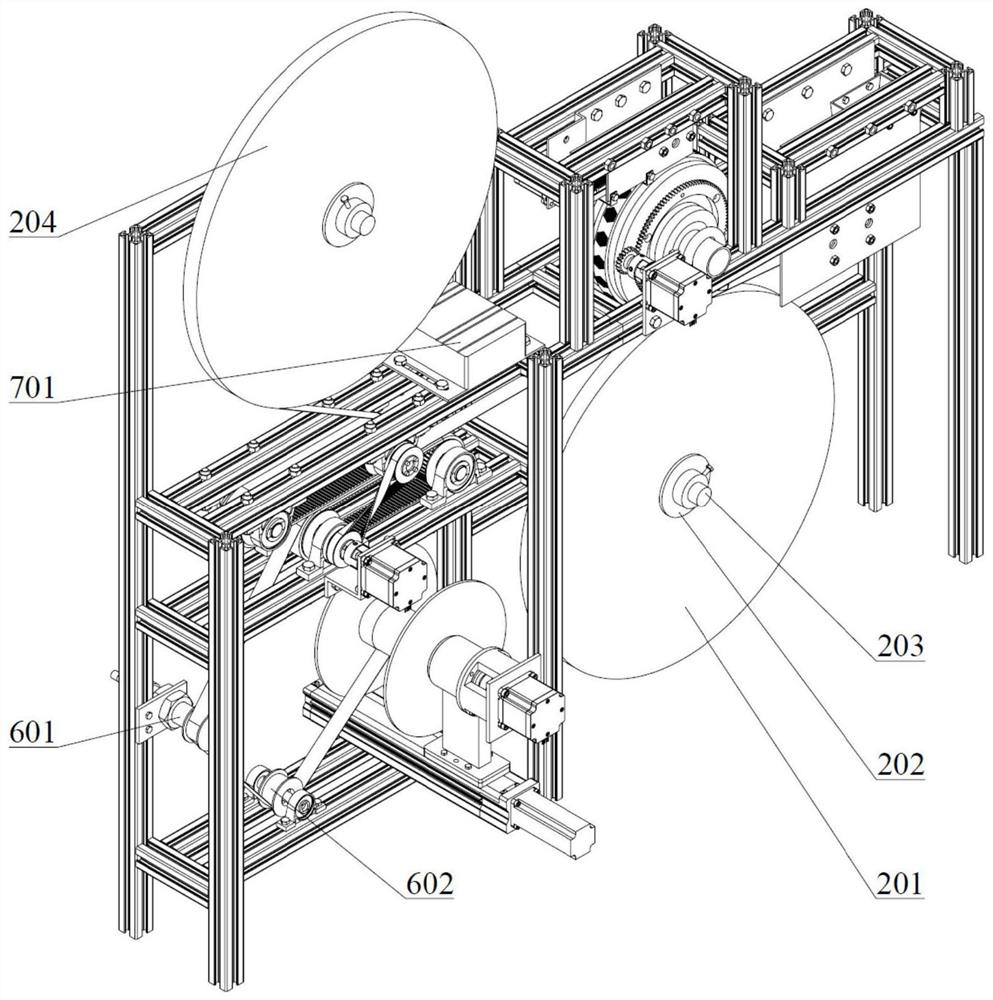

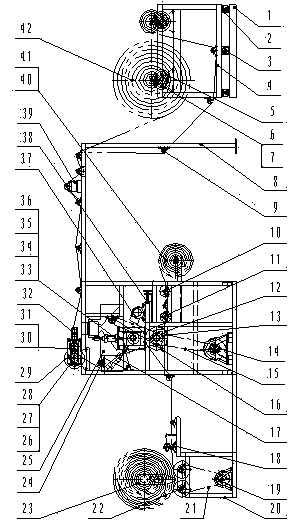

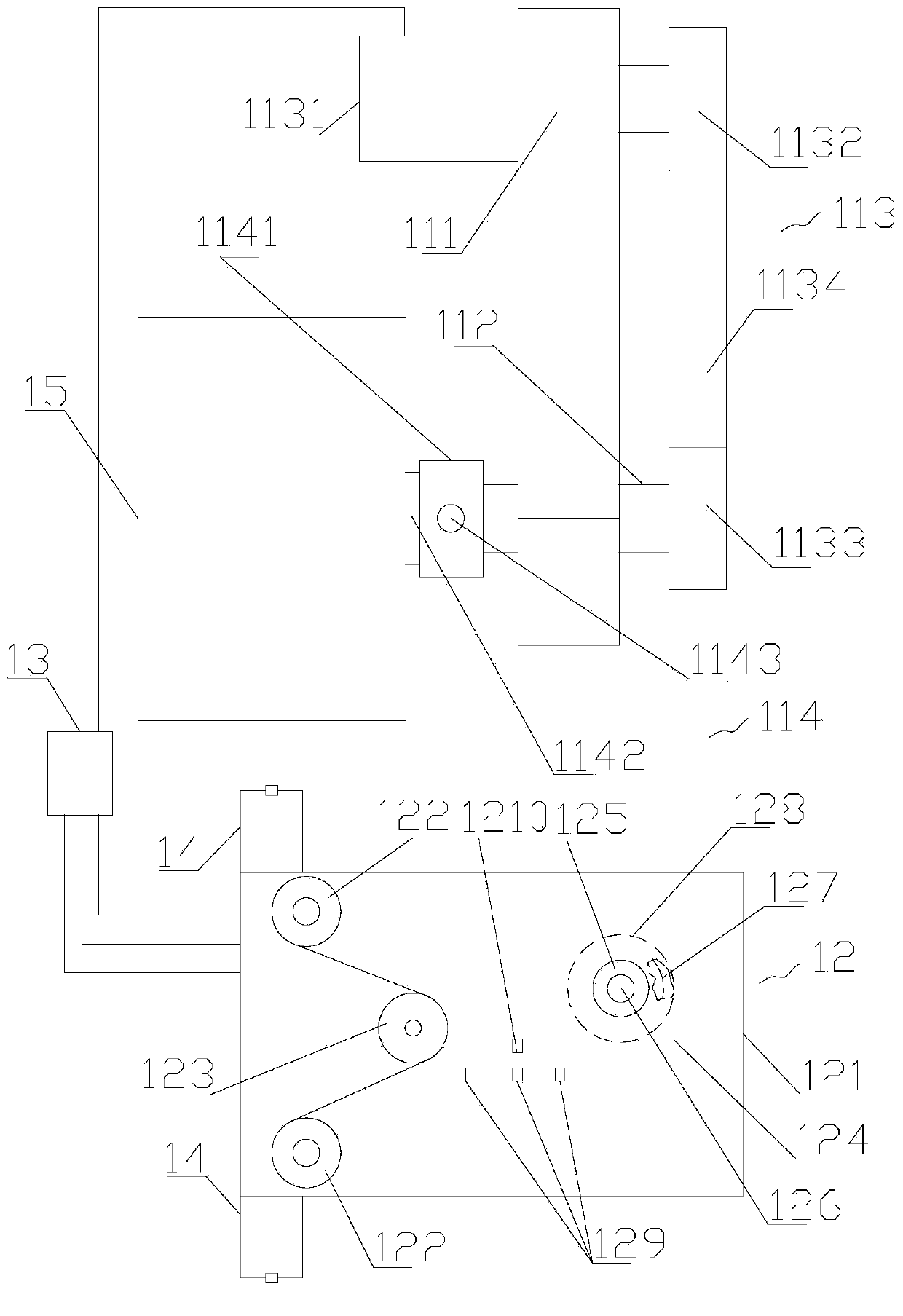

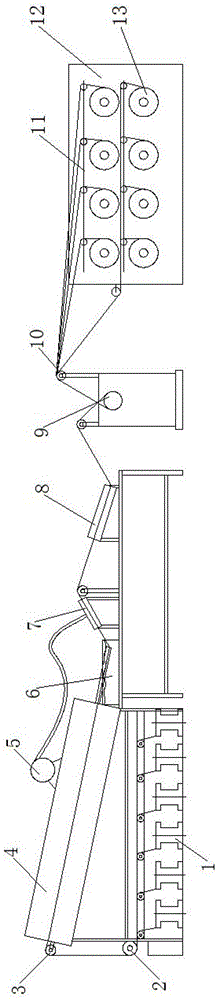

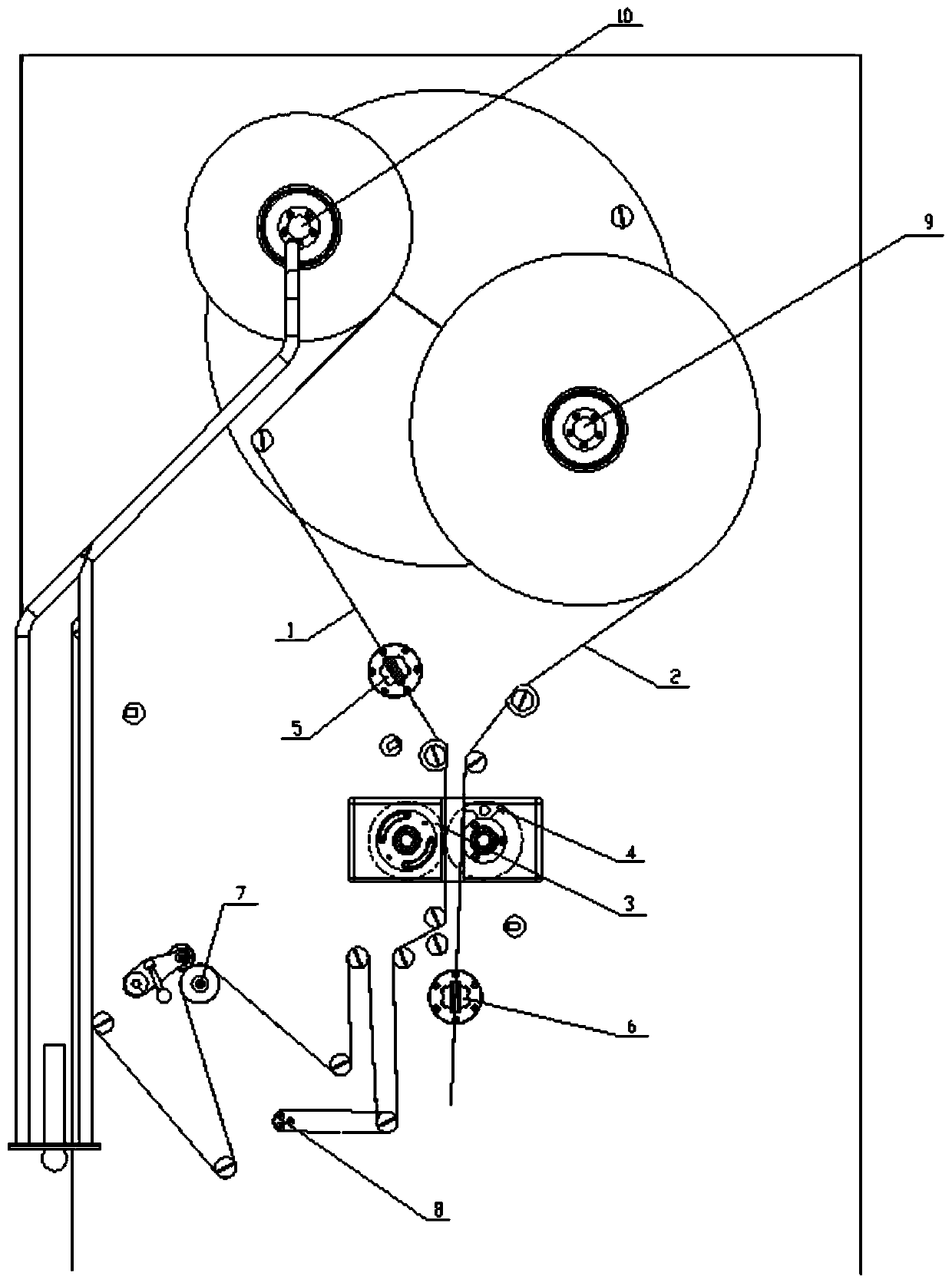

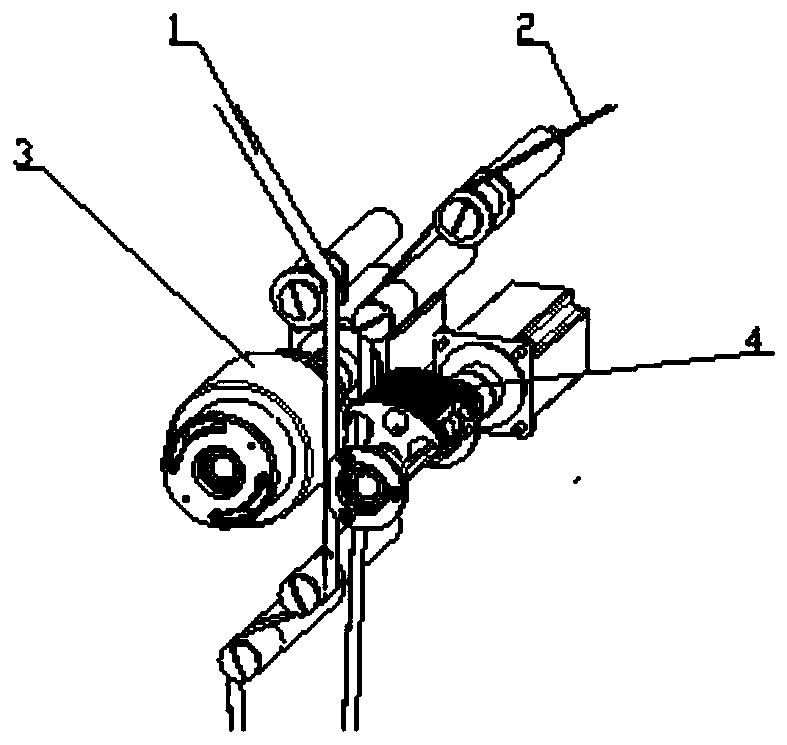

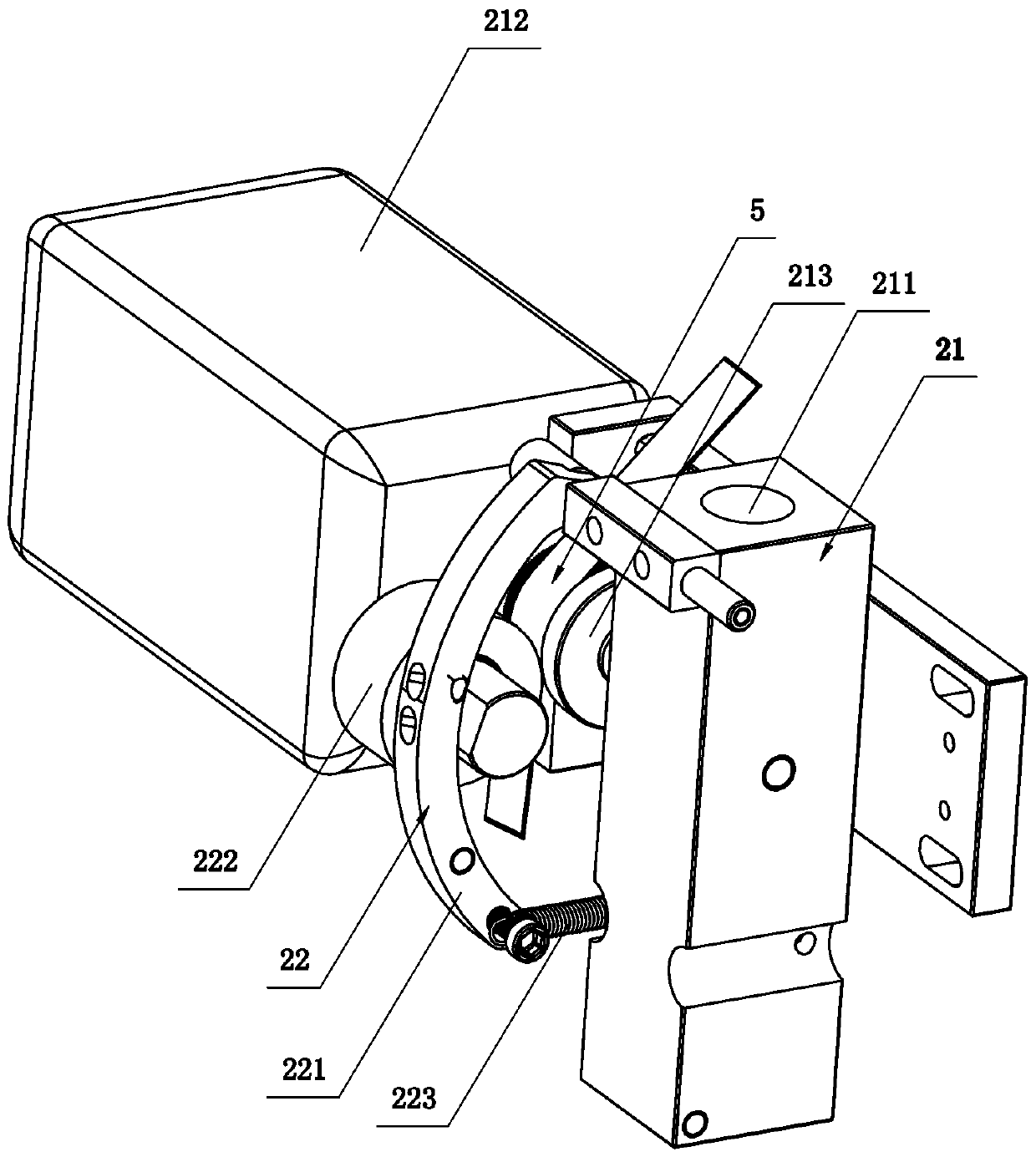

Seed tape preparation device for directional seeding corns

The invention discloses a seed tape preparation device for directional seeding corns. The seed tape preparation device for directional seeding corns comprises a working rack, a paper tape unwinding mechanism, a gluing mechanism, a directional zero-speed seed feeding mechanism, an upper and lower paper tape bonding mechanism, a winding mechanism and a control system; the working rack is formed by splicing a plurality of aluminum profiles; The paper tape unwinding mechanism comprises a lower paper tape, two material blocking disks, two optical shafts I and an upper paper tape; the upper paper tape is concentrically arranged on one optical shaft I through the material blocking disk, one optical shaft I is arranged on an upper left side of the working rack, the lower paper tape is concentrically arranged on the other optical shaft I through the material blocking disk, and the other optical shaft I is arranged on a lower right side of the working rack; and the gluing mechanism is arranged on an upper right side of the working rack, the directional zero-speed seed feeding mechanism is arranged on an upper middle part of the working rack, the upper and lower paper tape bonding mechanism is arranged on a middle part of a left side of the working rack, the winding mechanism is arranged on a lower part of the left side of the working rack and located below the upper and lower paper tape bonding mechanism, and the control system is arranged on an upper middle part of the working rack.

Owner:CHINA AGRI UNIV

Constant-tension flame compound machine

InactiveCN104057685AAchieve constant tensionQuality improvementLaminationLamination apparatusEngineeringTension control

The invention provides a constant-tension flame compound machine. The constant-tension flame compound machine comprises an automatic constant-tension sponge edge alignment and uncoiling mechanism, a coil alternation constant-tension control mechanism, a flame compound mechanism and a coiling mechanism. The constant-tension flame compound machine is characterized in that the automatic constant-tension sponge edge alignment and uncoiling device comprises an uncoiling base, a linear guide rail pair, an automatic centering mechanism, an uncoiling frame, a magnetic powder brake and a force meter; the coil alternation constant-tension control mechanism comprises a small magnetic powder brake, an auxiliary steel roller, a bearing with a seat, a slide seat support, an auxiliary glue roller, a slide seat bearing and an auxiliary air cylinder. The constant-tension flame compound machine provided by the invention is reasonable in structure, is simple and convenient to operate, ensures the constant tension of a sponge in the whole flame compound process, improves the flame compound quality greatly, reduces the running cost, and improves the production efficiency.

Owner:YANCHENG XUHUA MACHINERY

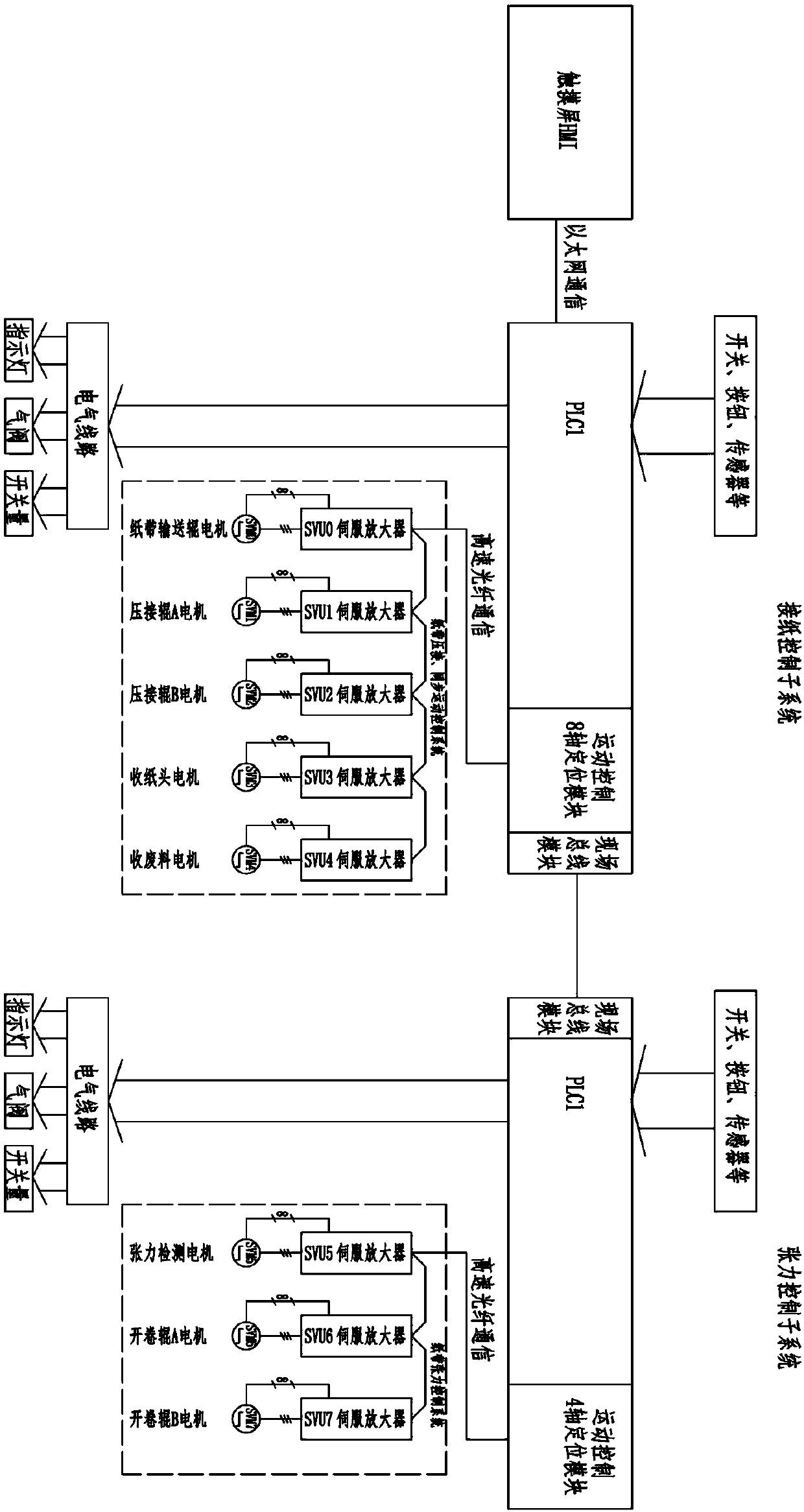

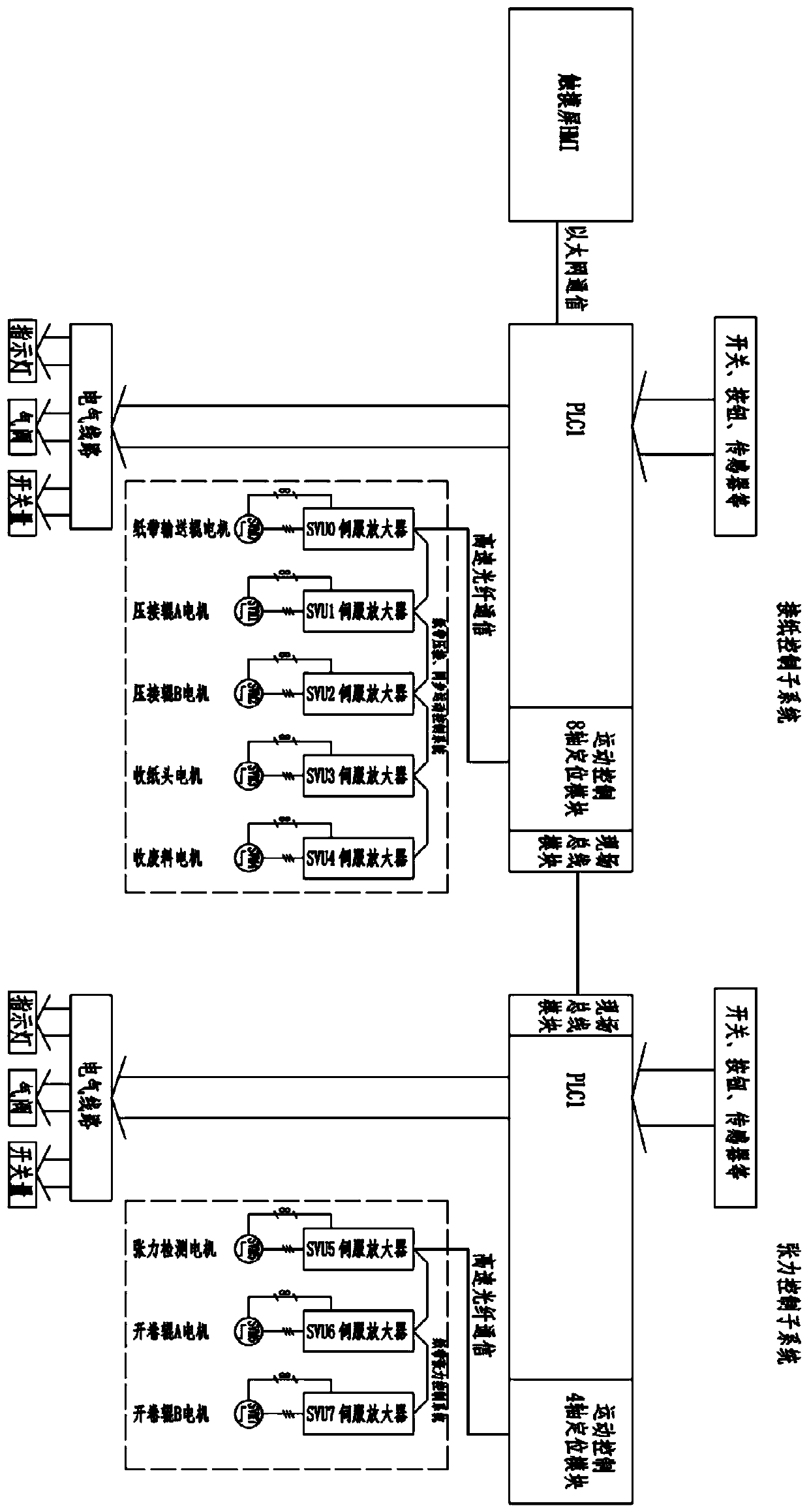

Paper connecting machine control system and method

ActiveCN108046013AGuaranteed high-speed transmissionReduce complexityWebs handlingAudio power amplifierMachine control

The invention discloses a paper connecting machine control system and method. The paper connecting machine control system comprises a paper connecting control system and a paper tape tension control system, and the paper connecting control system and the paper tape tension control system both include a PLC and a motion control positioning module connected with the PLC; a first motion control positioning module is connected with a synchronous motion control system or the paper tape tension control system of a paper tape pressing connecting machine through cables, and the synchronous motion control system and the paper tape tension control system of the paper tape pressing connecting machine both include a plurality of servo amplifiers and servo motor units connected with the servo amplifiers; and the paper connecting machine control method includes a paper connecting control method and a tension control method. According to the paper connecting machine control system and method, the paper connecting control system and the paper tape tension control system are separately independent systems, so that the system complexity is lowered and system links are reduced; and servo motors are used for detecting the tension, and the coarse and fine control of the torque is combined, thereby achieving the tension constant in the conveying process of paper tapes of a paper connecting machine.

Owner:苏州茂泰精密机械有限公司

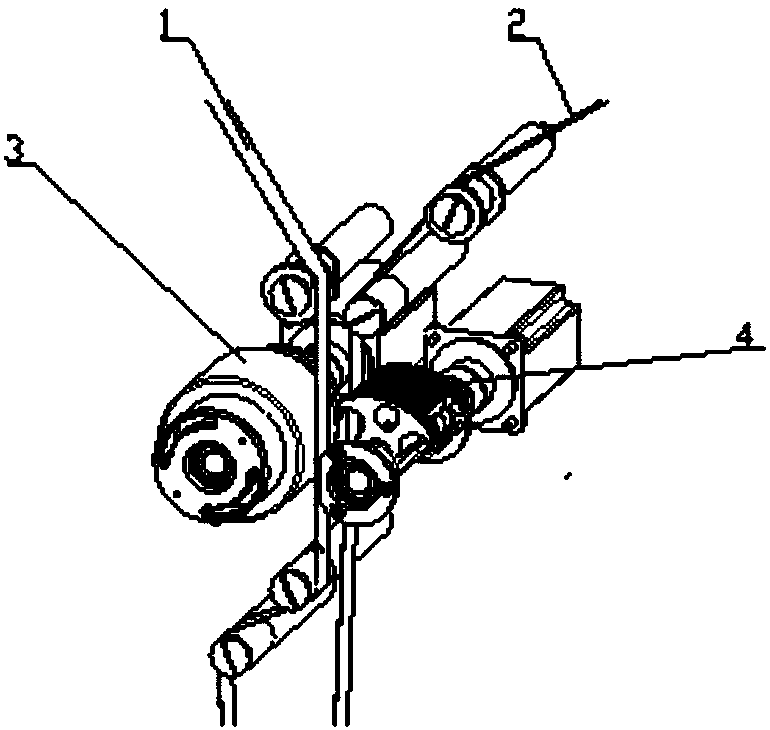

Driving device of hank yarn shed frame

InactiveCN110713073AReduce wire breakage or loose wireSimple structureFilament handlingYarnClockwork

The invention discloses a driving device of a hank yarn shed frame. The driving device comprises a driving mechanism, a tension monitoring mechanism which is located below the driving mechanism, and acontroller. The driving mechanism and the tension monitoring mechanism are controlled with the controller. The tension monitoring mechanism comprises a mounting seat, two fixed guide wheels, a movable guide wheel, a sliding rack, a driving gear, a driving shaft, a constant-force clockwork spring, a shell, three sensors and a sensed body. The two fixed guide wheels and the sliding rack which is capable of being slideably mounted are disposed on the outer side of the mounting seat; the movable guide wheel which is located in the rear of the middle of the two fixed guide wheels is disposed at the front end of the sliding rack; the sensors which are located below the sliding rack are disposed on the outer side of the mounting seat; and the three sensors are arranged in sequence from front toback. Compared with the prior art, the phenomenon of yarn breaking or loosening can be greatly reduced, the structure is simple, and constant-force tensioning can be achieved.

Owner:海盐县梦芝舟毛纺厂

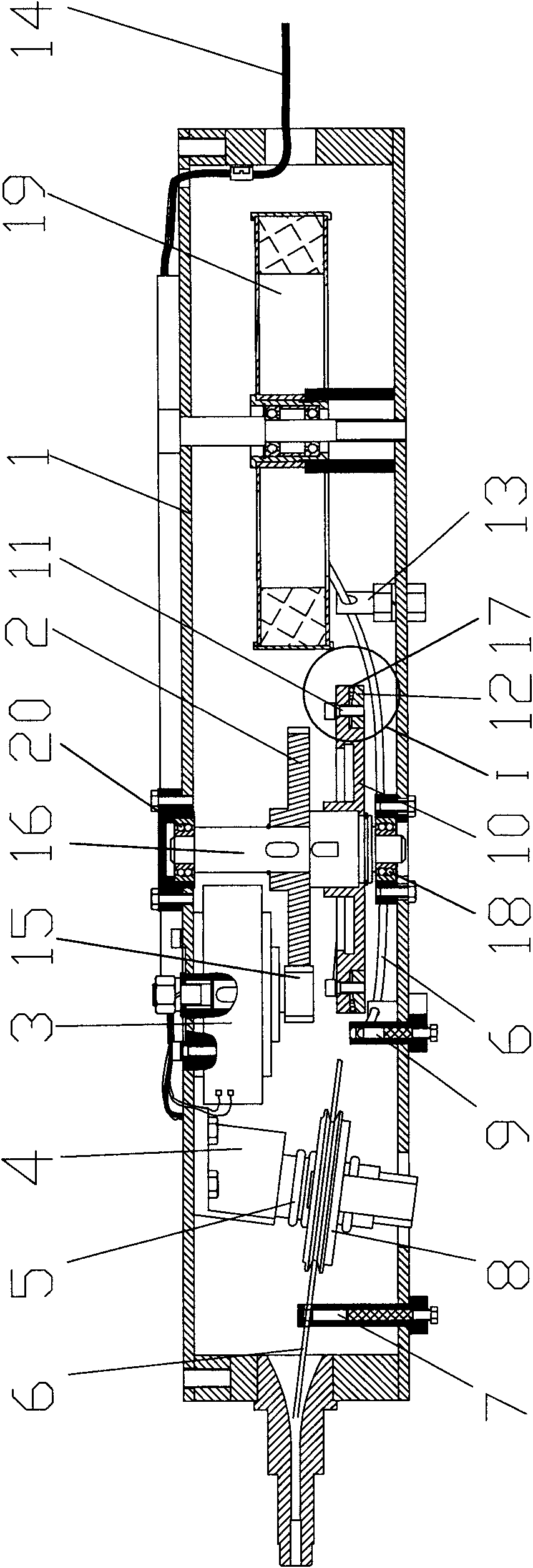

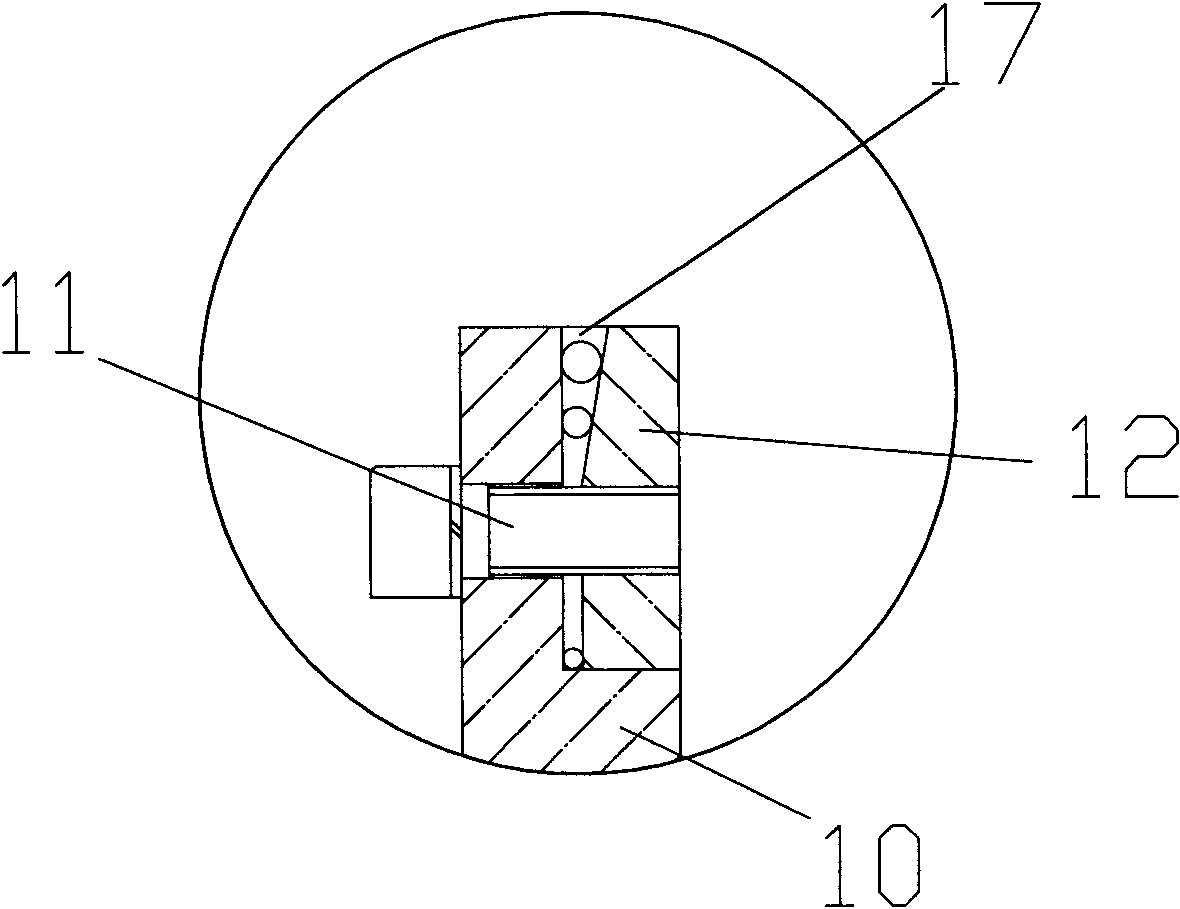

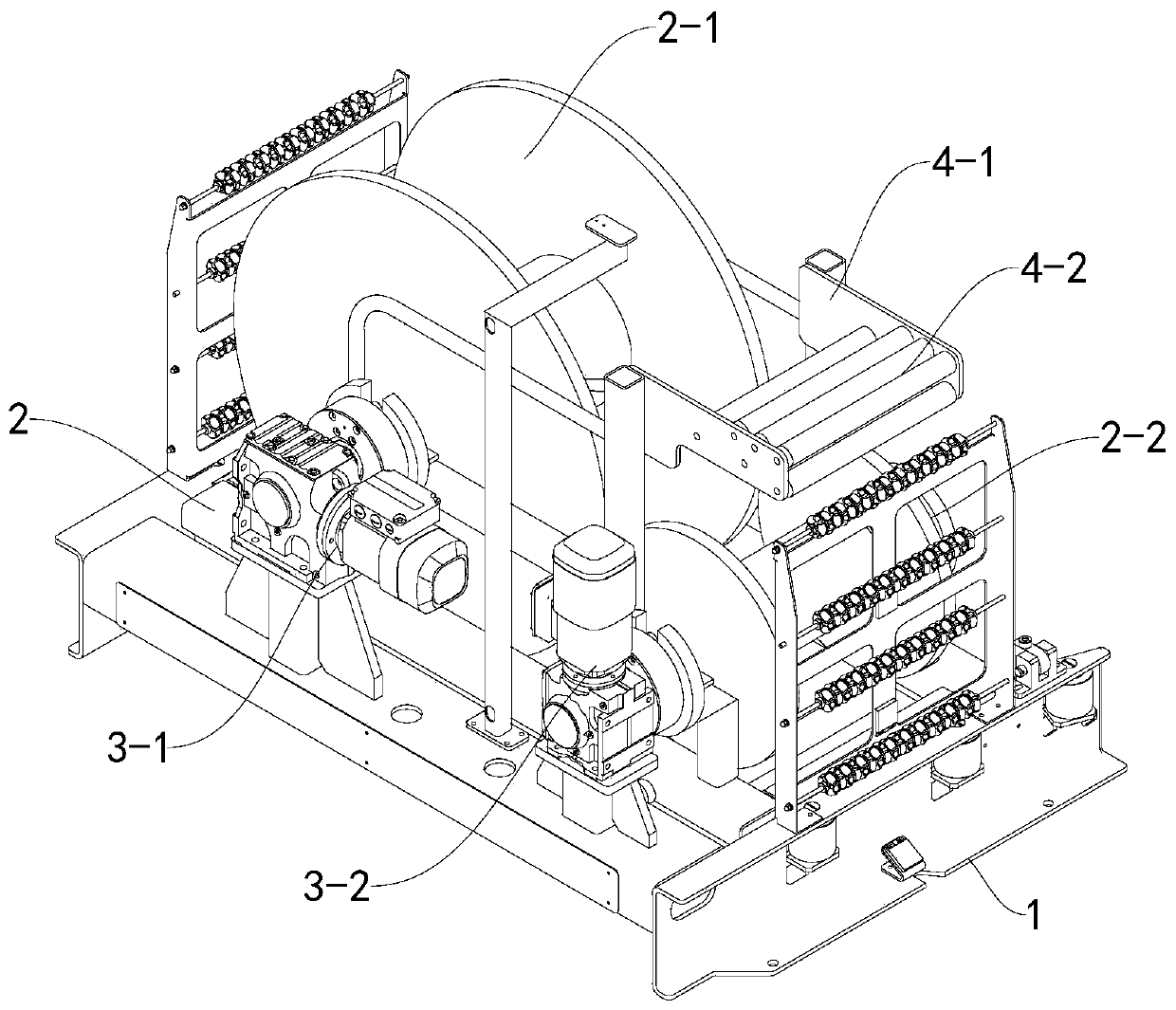

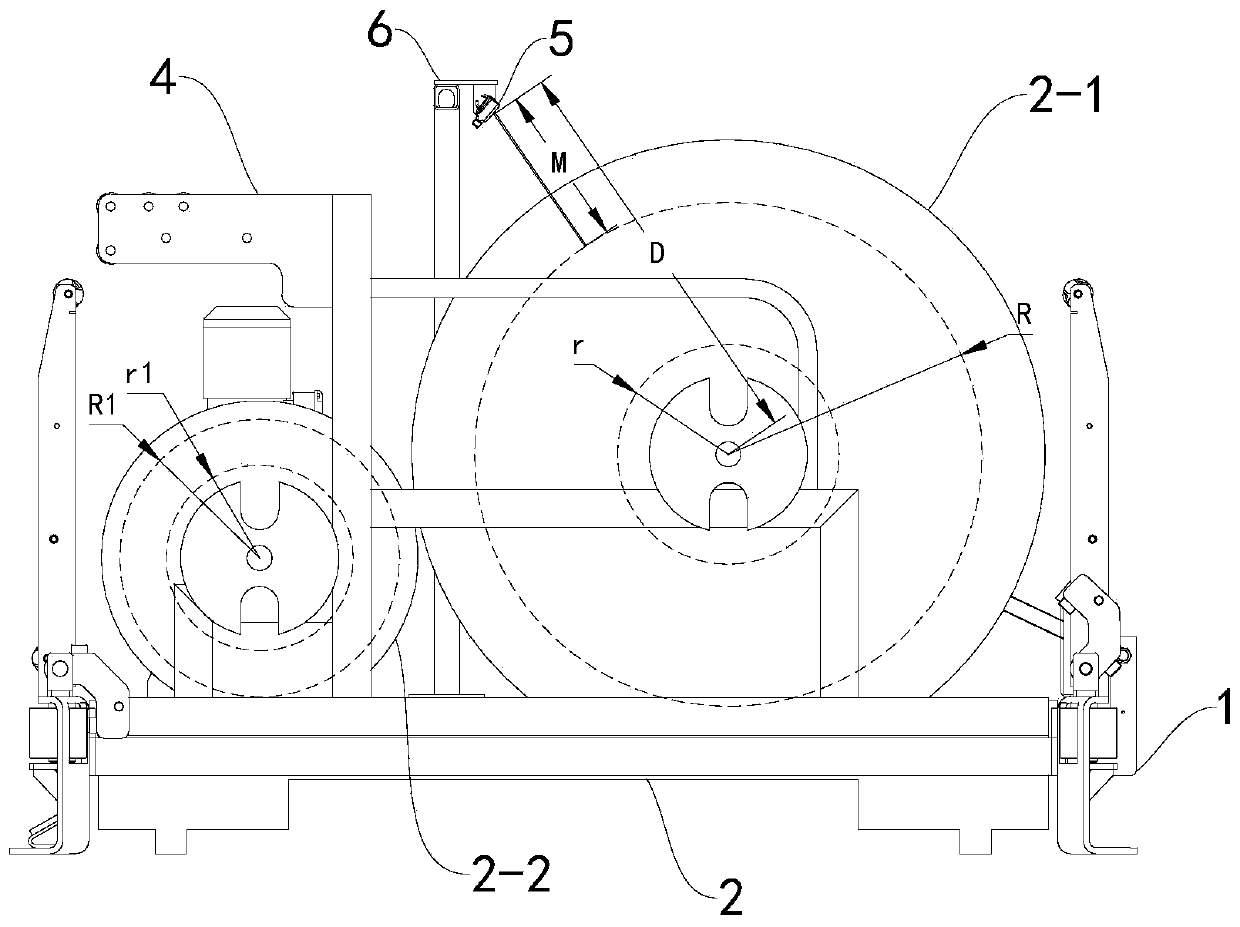

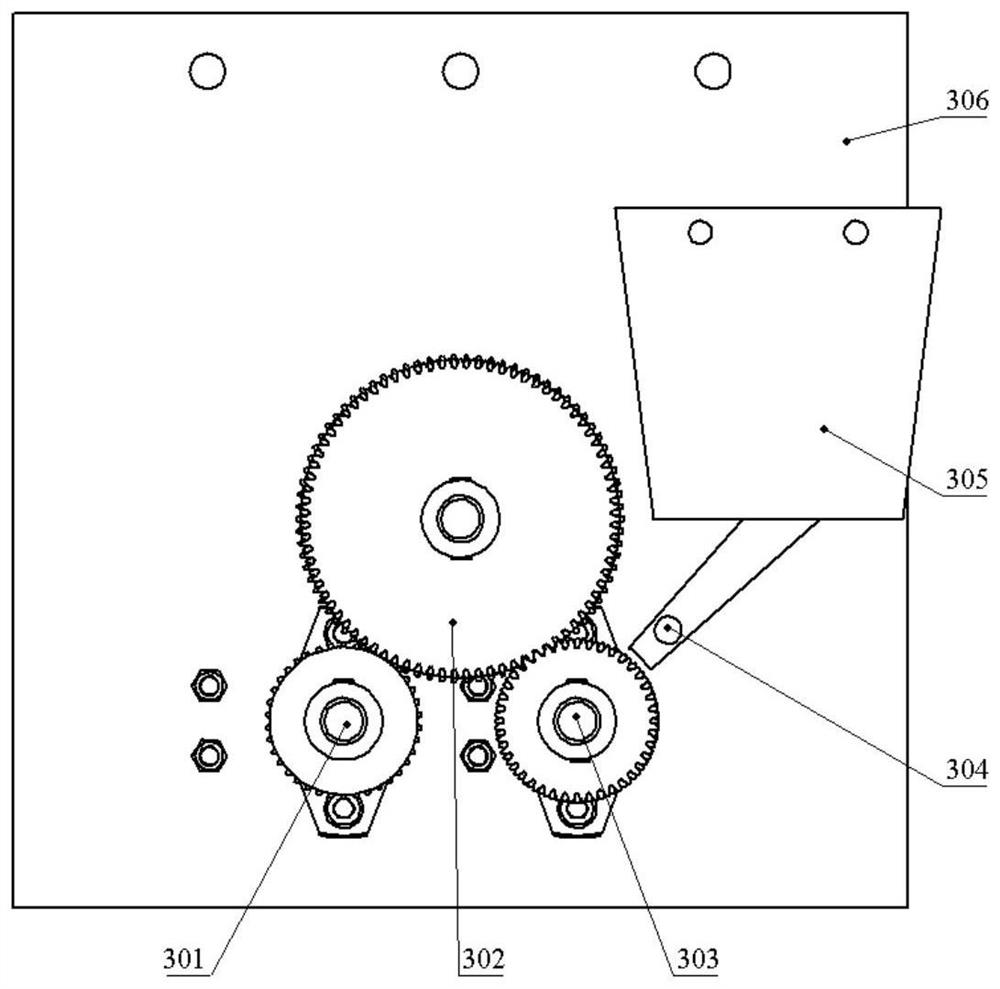

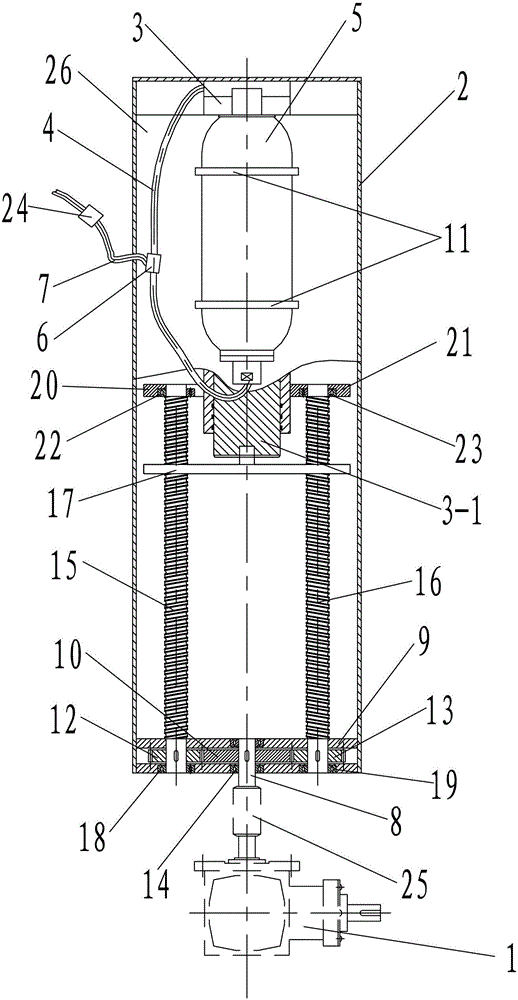

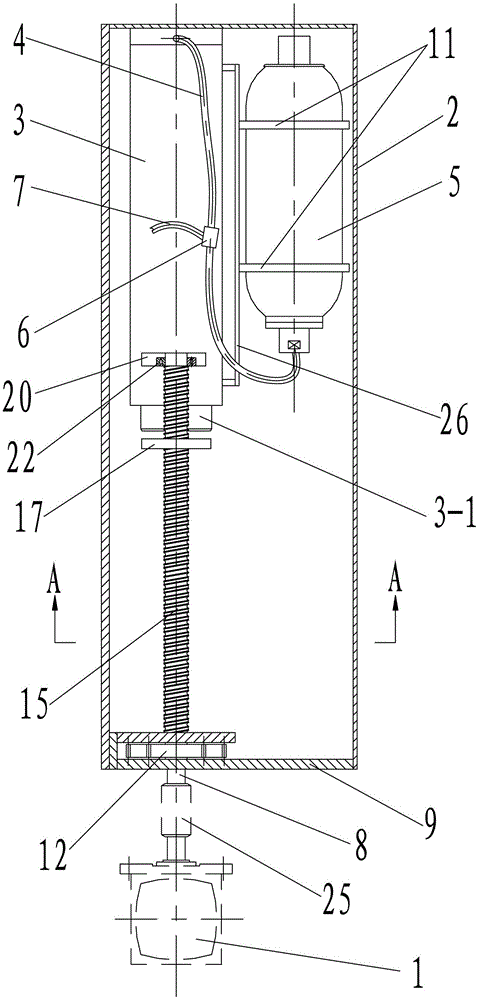

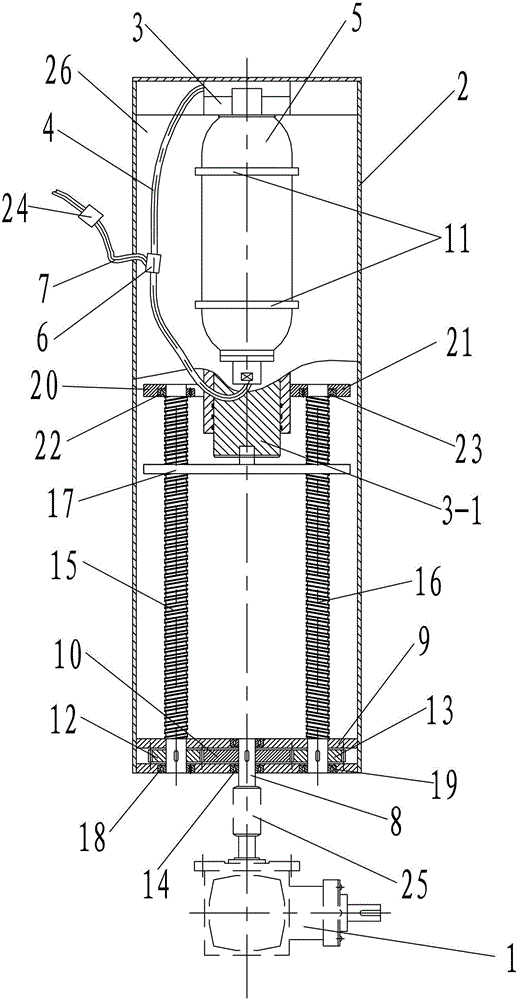

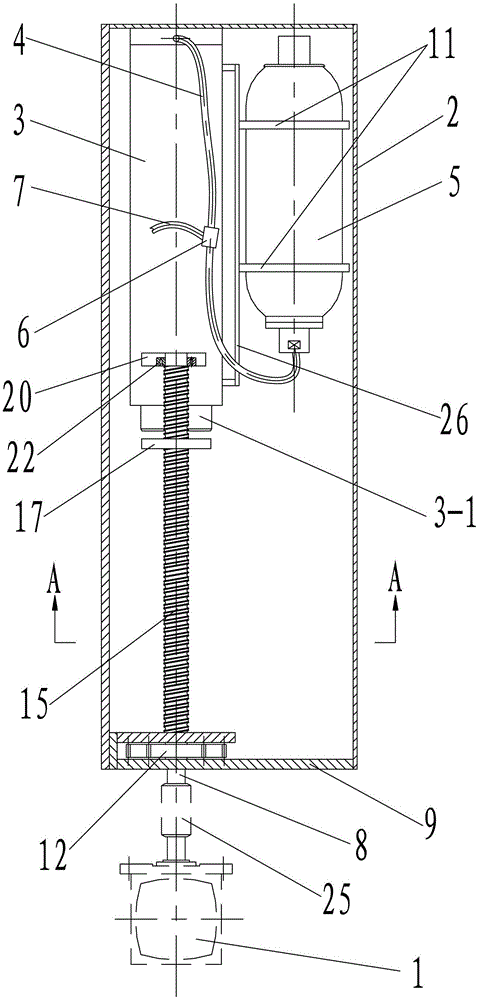

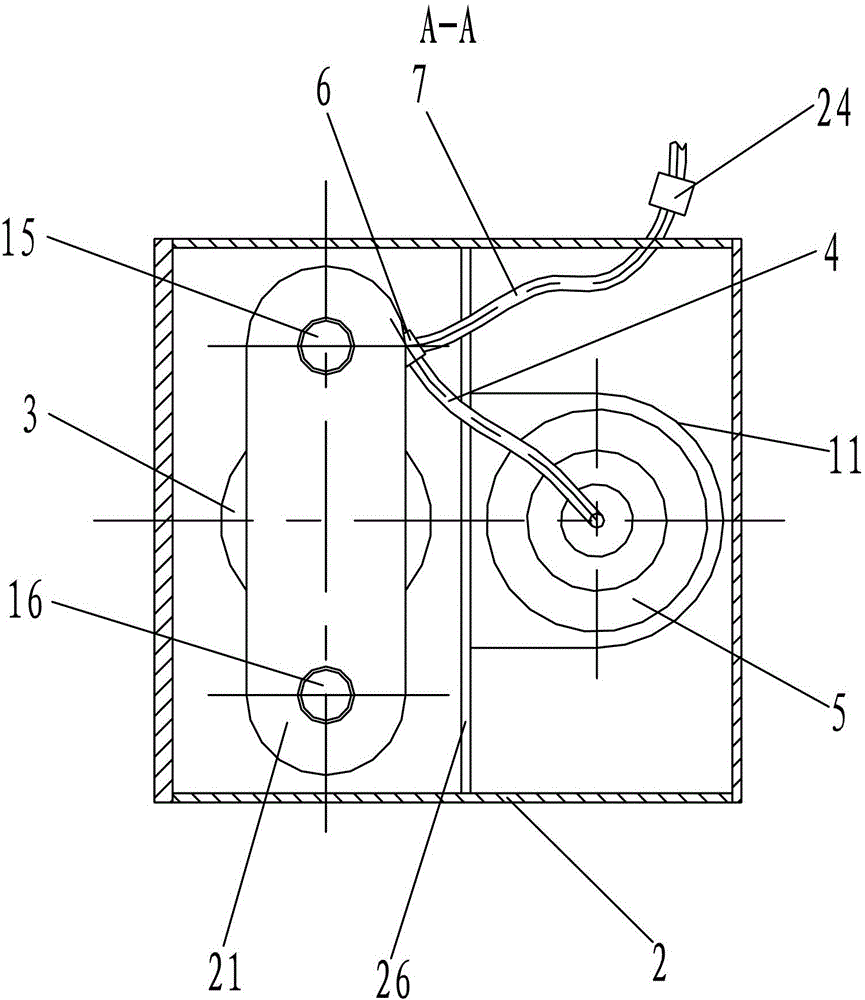

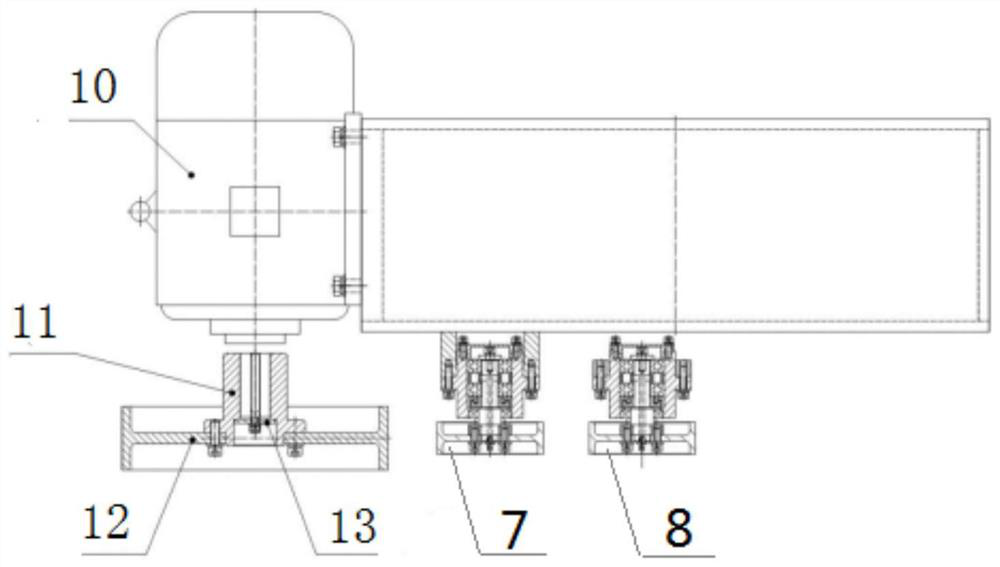

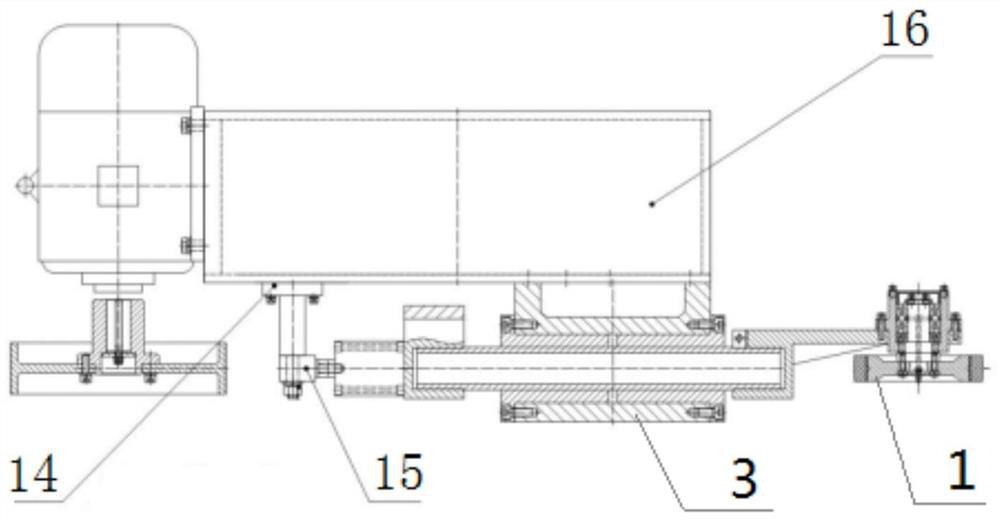

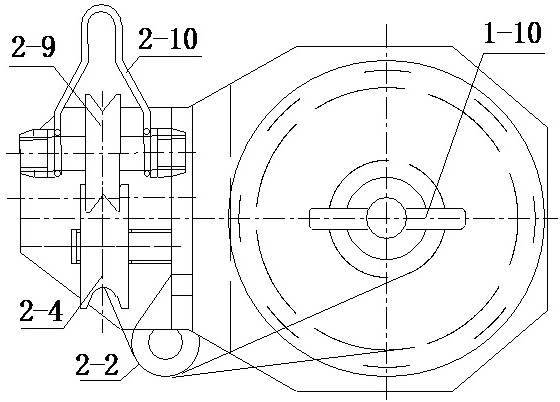

Servo device of trenching machine pipe coiling system

ActiveCN102979129ACompact structureNovel and reasonable designSoil-shifting machines/dredgersGear driveDrive shaft

The invention discloses a servo device of a trenching machine pipe coiling system. The device comprises a speed reducer, a constant tension control mechanism and a driving mechanism, wherein the constant tension control mechanism is used for providing constant tension to a hydraulic rubber pipe in a trenching machine; the driving mechanism is used for transmitting the power output by the speed reducer to the constant tension control mechanism; the constant tension control mechanism comprises a plunger type hydraulic oil tank and an energy accumulator connected with the plunger type hydraulic oil tank through a first oil pipe; a second oil pipe is connected with the first oil pipe through a tee joint; the driving mechanism comprises a driving shaft, a gear driving mechanism and a screw rod driving mechanism; the driving shaft is connected with the speed reducer; the gear driving mechanism is connected with the driving shaft; and the screw rod driving mechanism is connected with the gear driving mechanism, used for converting the rotary movement of the gear driving mechanism into the linear movement of a plunger rod in the plunger type hydraulic oil tank and is connected with the plunger rod in the plunger type hydraulic oil tank. The servo device is compact in structure, reasonable in design, convenient to mount and use, complete in function, good in servo performance, good in constant tension control effect, stable and reliable in performance and high in popularization and application value.

Owner:中铁二十局集团西安工程机械有限公司

Tension control method and device

The invention discloses a tension control method. Specific number values of warp tension are accurately acquired according to a heald frame, beating-up, dropper shake and weaving machine vibration in the running process of a weaving machine, calculated by means of a data processing algorithm to obtain a real warp tension value, a detection value in the running process of the weaving machine is not influenced by measurement errors caused by rear beam movement and heald frame opening and closing through a tension control device, constant tension is achieved, and even and consistent upper weft threads of a fabric are kept.

Owner:刘文化

System and method for intelligently controlling tube continuous annealing furnaces

ActiveCN103436683BAvoid stretchingStable wire diameterFurnace typesHeat treatment process controlTemperature controlComputer module

Owner:江苏华旺新材料有限公司

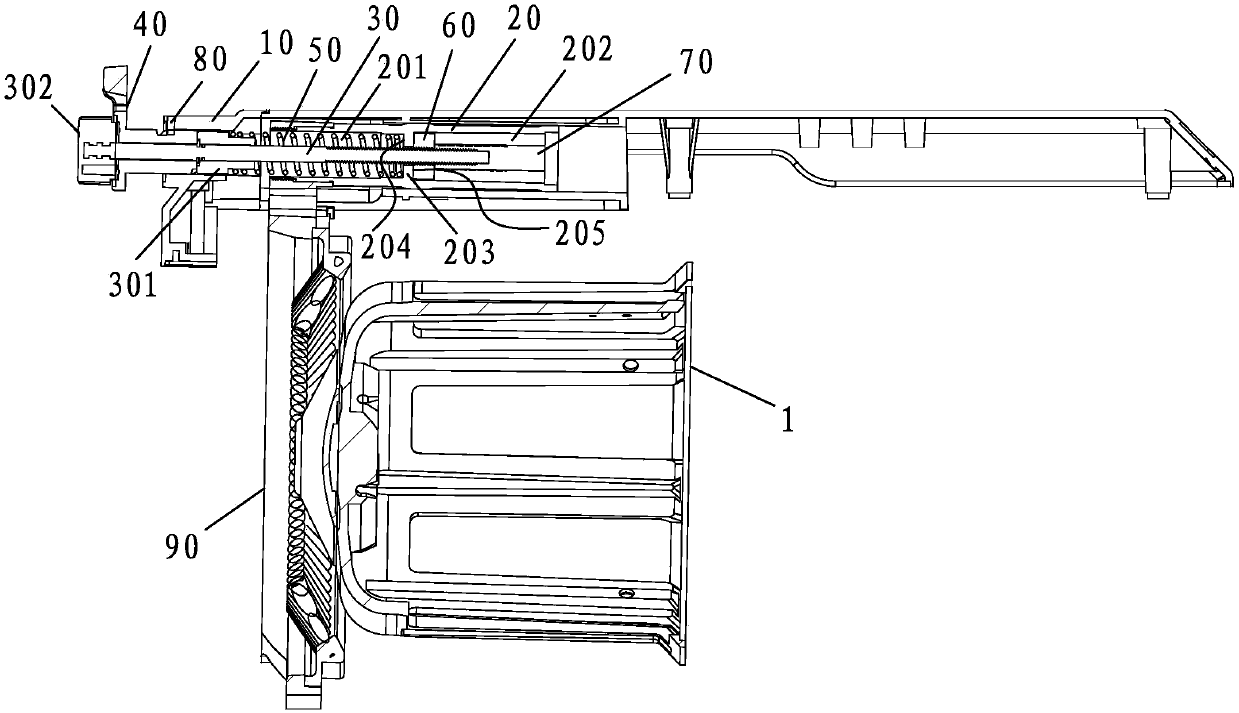

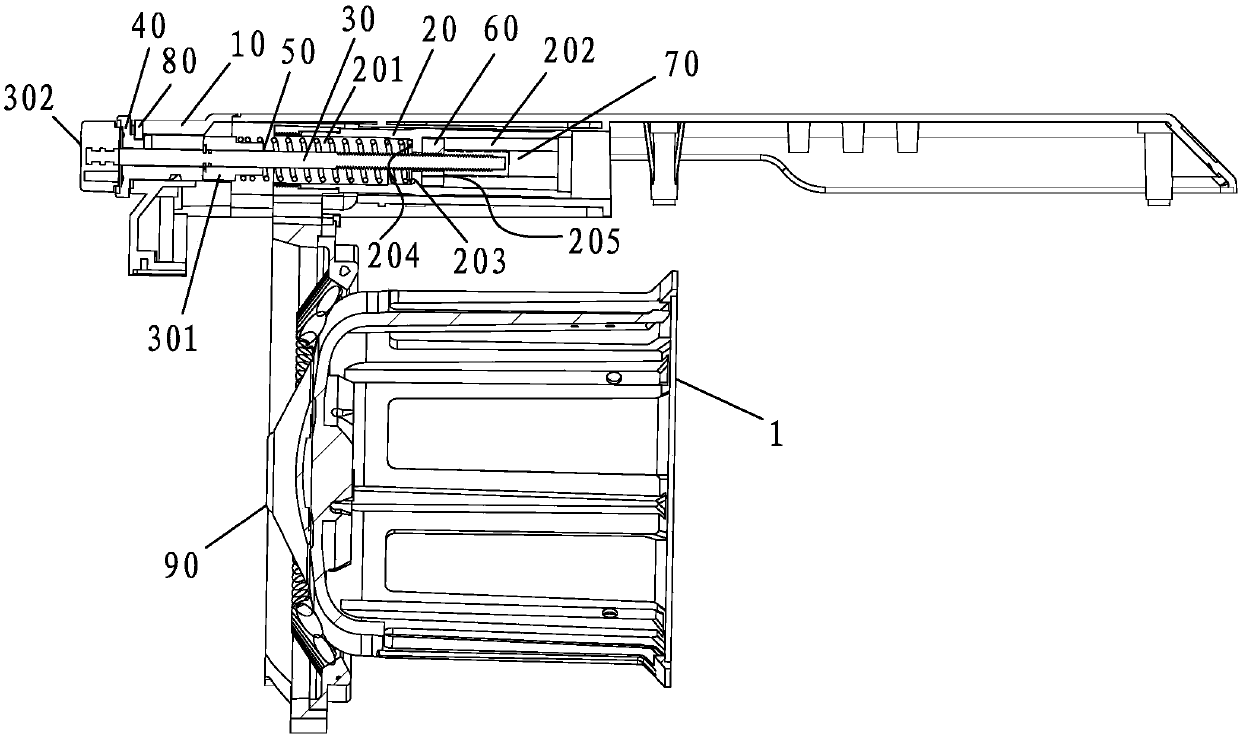

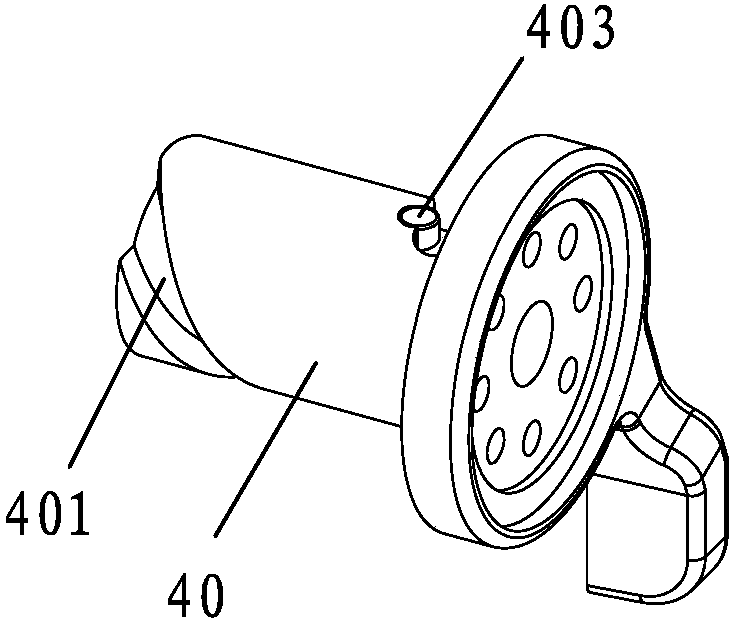

A Constant Force Quick Adjustment Device for Weft Feeder

The invention relates to the field of textile machinery, in particular to a constant-force fast adjusting device of a weft feeder, which includes a casing, an inner tube fixed inside the casing and fixed to a fixed brush frame, and a screw; There is a wrench head assembly, and the inner end extends into the inner tube; there is a rib on the inner wall of the inner tube that divides the inner tube into an outer chamber and an inner chamber; A nut pressing block is matched with the inner wall of the outer chamber without rotation, and the tension spring sleeved on the screw rod is supported between the outer end faces of the ribs of the first nut pressing block; The nut pressing block is matched with the inner wall of the inner chamber without rotation, and the return spring sleeved on the screw rod is supported on the second nut pressing block and the inner end surface of the housing. The invention realizes stable and constant tension adjustment, and at the same time is simpler, convenient to process and low in cost.

Owner:ZHEJIANG SANHE INTELLIGEN TECH CO LTD

Servo device of trenching machine pipe coiling system

ActiveCN102979129BCompact structureNovel and reasonable designSoil-shifting machines/dredgersGear driveGear wheel

Owner:中铁二十局集团西安工程机械有限公司

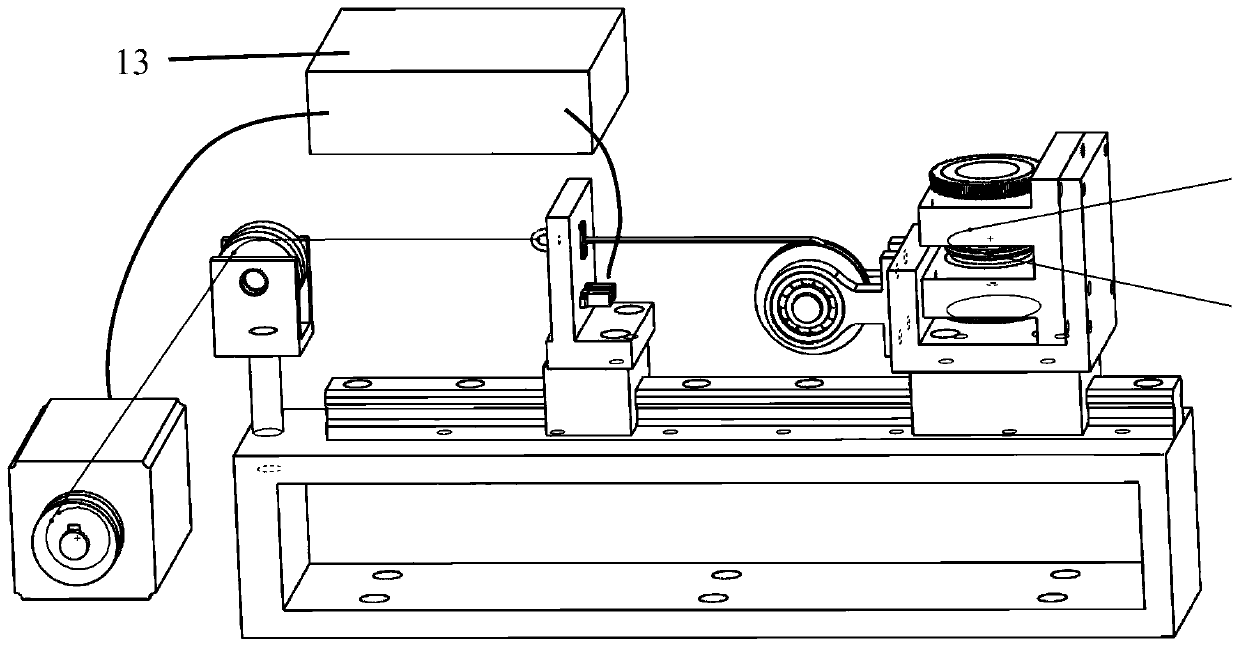

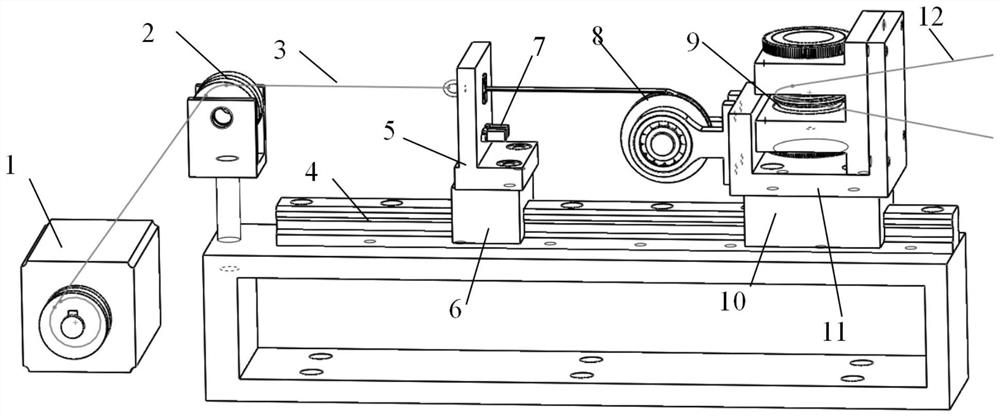

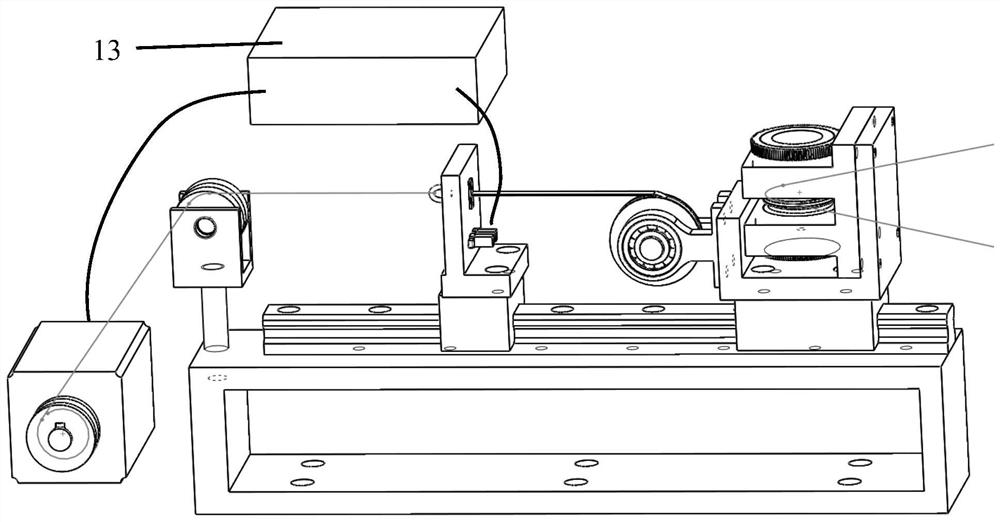

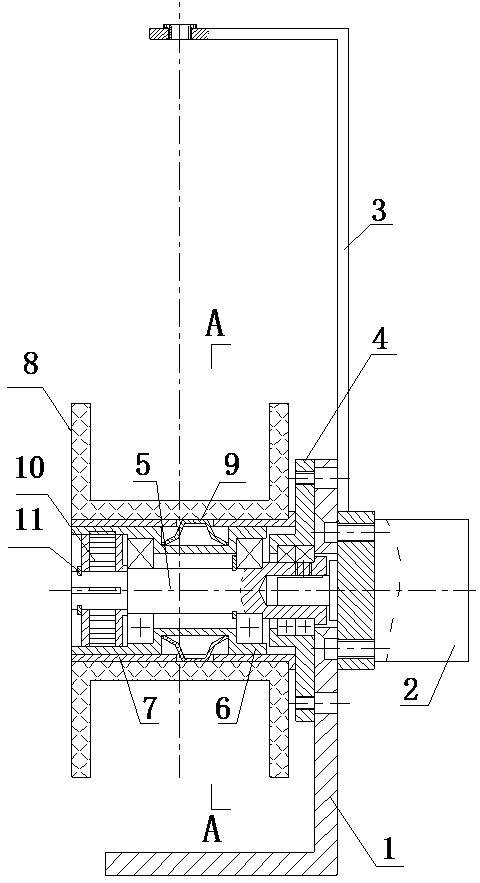

Electrode wire tightness adjustment mechanism for electrical spark linear incising machine tool

ActiveCN110253099AAchieve constant tensionConstant tensionElectrical-based machining electrodesPull forceElectric machinery

The invention discloses an electrode wire tightness adjustment mechanism for an electrical spark linear incising machine tool. The electrode wire tightness adjustment mechanism for the electrical spark linear incising machine tool comprises mechanism fixing seat, a motor, a steel rope, a pulley, a pulley support, a first base, a first sliding block, a distance measuring sensor, a constant force spring, a spring support, a second base, a second sliding block, a tensioning guide wheel and a guide rail. The constant force spring is connected with the tensioning guide wheel through the second base; the free end of the constant force spring is connected with the steel rope through the first base; the distance measuring sensor is arranged on the first base and is used for measuring the distance from the constant force spring to the first base; the first base is arranged on the first sliding block; and the other end of the steel rope bypasses the pulley and is connected with the motor. Through the effective combination of the motor and the constant force spring, the constant force spring is used for microscopically regulating and controlling a tensioning force of an electrode wire, and the motor is used for macroscopically regulating and controlling the tensioning force, the characteristics of tensile force constancy and reaction rapidness of the constant force spring are reasonably utilized, and meanwhile, through the macroscopical regulation and control of the motor, the elongation of the constant force spring is changed within a certain range, so that the problem of system oscillation is well solved.

Owner:GUANGDONG UNIV OF TECH

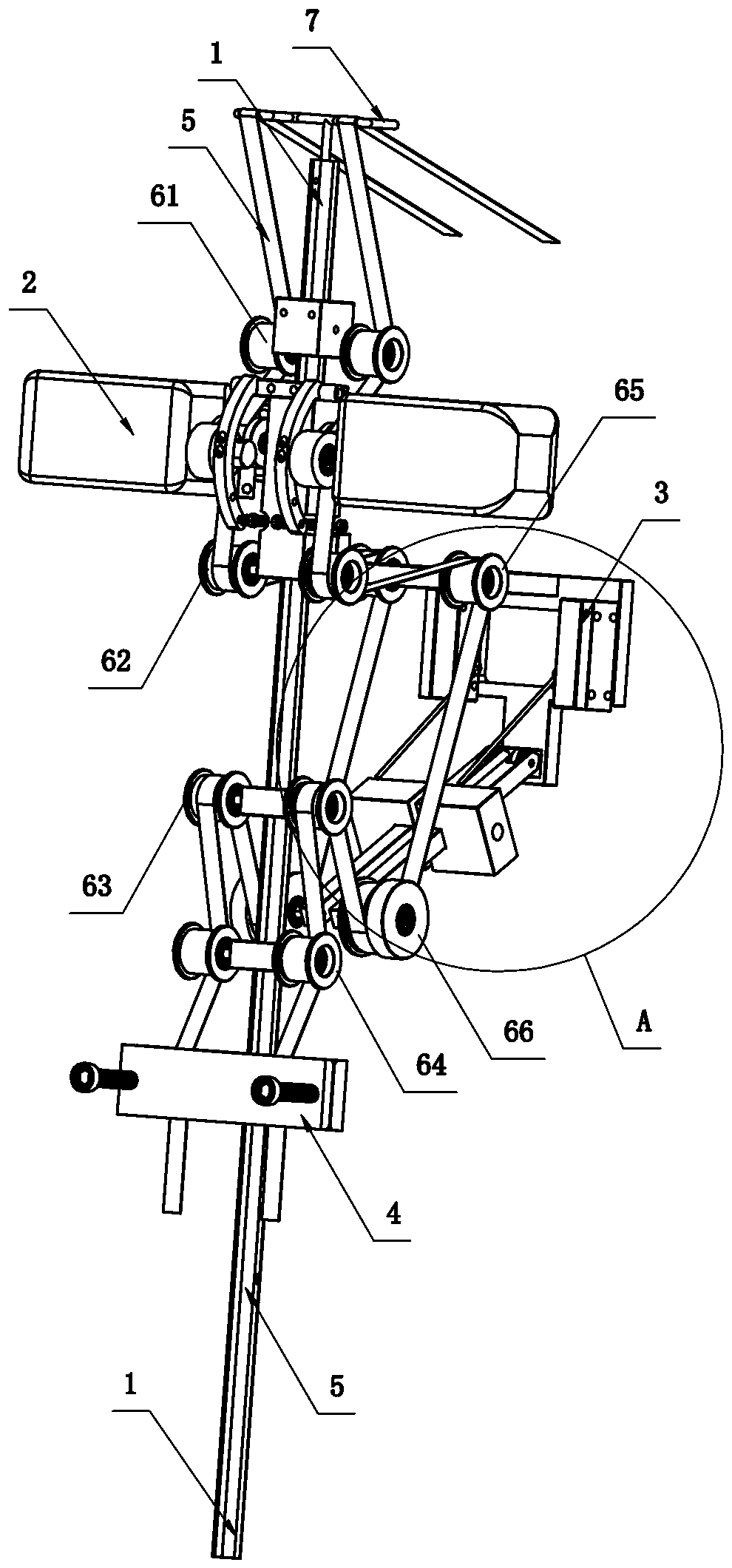

Control method for erecting main cable based on suspension bridge air spinning method

PendingCN114296386AImprove automationEasy to operateProgramme control in sequence/logic controllersVisual monitoringComputer monitor

According to the control method for erecting the main cable based on the suspension bridge aerial spinning method, in the aerial spinning process, an upper computer and a monitoring system are in real-time communication connection to monitor a construction site, and a tension device in the wire unwinding process of an unwinding mechanism or the wire winding process of a winding mechanism is controlled in real time through a lower computer; the tension measuring devices on the two sides of the tension tower are monitored at the same time and compared with a tension set value to achieve constant tension control over the main cable steel wire, the real-time winding diameter of the winding mechanism is measured through the winding diameter measuring device, the angular speed is converted into the linear speed through the lower computer, and the winding length of the winding mechanism is obtained through the length metering device. According to the system, the upper computer monitors the operation state of each device in real time, the lower computer monitors the operation state of each device in real time, control adjustment is carried out according to measurement data of each sensor, and real-time interaction between integrated control and construction site operation is realized through the visual monitoring system, so that the automation and operability of the system are improved.

Owner:CCCC SHEC SECOND ENG

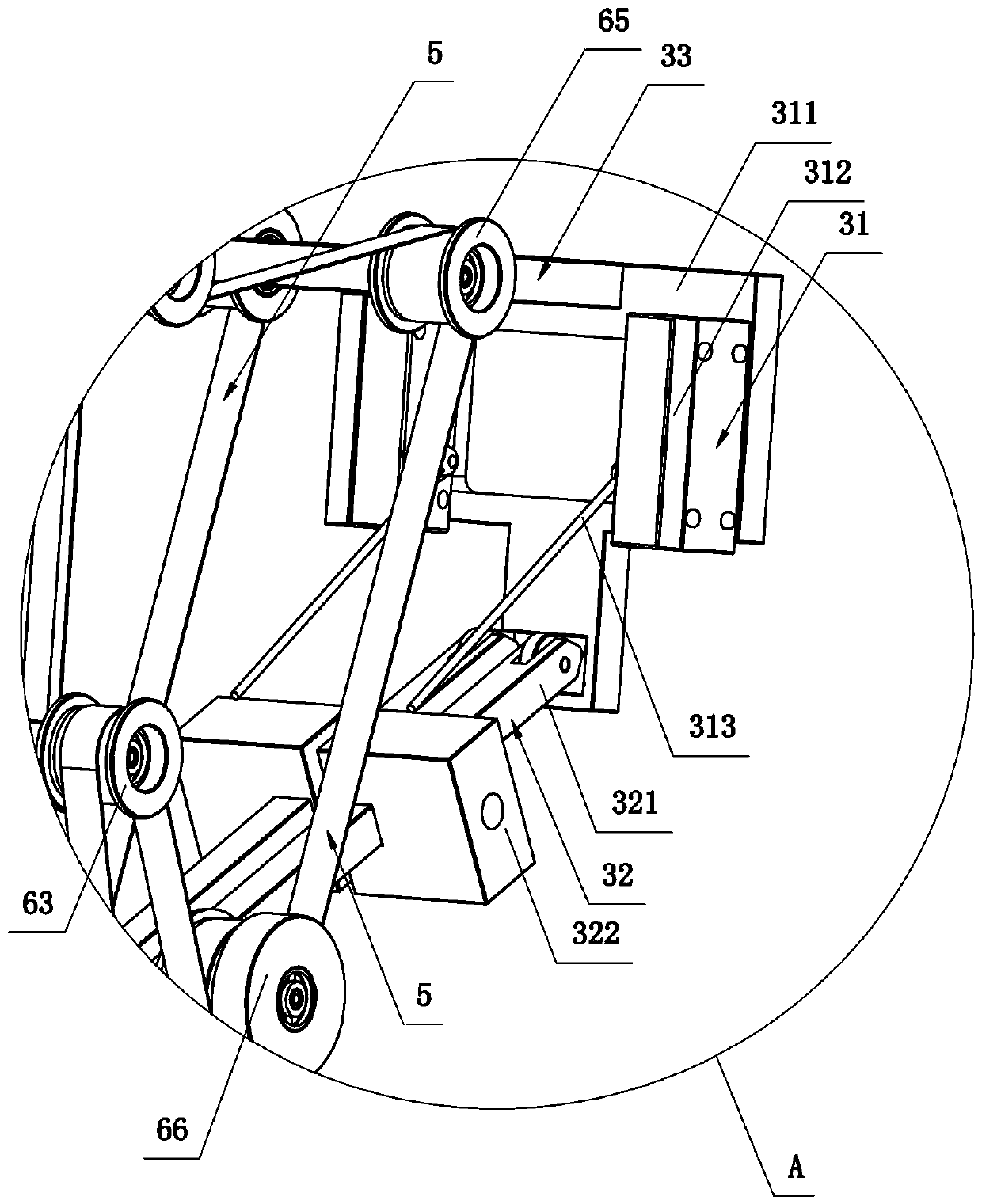

Abrasive belt grinding device with joint control of pressure and tension and its application method

ActiveCN109702611BAchieve constant tensionGuaranteed lifeBelt grinding machinesMaintainance and safety accessoriesDrive wheelMachined surface

The invention discloses a pressure and tension combined-control abrasive belt grinding device and a using method thereof. The device comprises a contact wheel assembly, a first air cylinder, a drivingwheel assembly, a tensioning wheel assembly, a second air cylinder, a second idler wheel assembly and an abrasive belt, wherein the contact wheel assembly is connected with the extending end of an air cylinder push rod of the first air cylinder, and the first air cylinder is used for adjusting the contact pressure of the contact wheel assembly; the tensioning wheel assembly is connected with theextending end of an air cylinder push rod of the second air cylinder, and the second air cylinder is used for adjusting the tensioning force of the tensioning wheel assembly; and the abrasive belt sequentially passes through a driving wheel of the driving wheel assembly and a tensioning wheel of the tensioning wheel assembly, the second idler wheel of the second idler wheel assembly and the contact wheel of the contact wheel assembly and is tensioned. According to the pressure and tension combined-control abrasive belt grinding device, the contact wheel assembly and the tensioning wheel assembly are controlled to complete corresponding displacement, and the influence of changes of the normal grinding pressure on the tension is eliminated; and the grinding force of the grinding process is kept constant, so that the vibration in the grinding process is effectively reduced, and the quality of the machined surface and the service life of the abrasive belt are guaranteed.

Owner:AECC AVIATION POWER CO LTD

Roll diameter calculation and optimization method of die-cutting machine

PendingCN112456211AOptimize volume diameter dataRoll diameter data is stableWebs handlingStructural engineeringMechanical engineering

The invention relates to a roll diameter calculation and optimization method of a die-cutting machine. The method is technically characterized by comprising the following steps: filtering a pulse in anormal fluctuation range, and calculating a roll diameter by the filtered pulse; filtering the calculated roll diameter through an array; and optimizing the filtered roll diameter data to obtain final relatively stable roll diameter data. According to the method, the pulse at the initial stage of roll diameter calculation is filtered, stability calculation is conducted in each step of calculation, the roll diameter data with good stability is finally obtained, and meanwhile, a roll diameter fluctuation value can be decreased, so that constant tension of materials on the die-cutting machine isachieved, and great help is provided for the production process of the die-cutting machine.

Owner:中融飞腾(北京)科技有限公司

A twisted gauze rolling device

The invention discloses a skein unwinding device, which comprises a driving mechanism, a tension monitoring mechanism located below the driving mechanism, a controller and a skein scaffolding, the driving mechanism and the tension monitoring mechanism are both connected to the controller, and the driving The mechanism is provided with a skein scaffolding, and the tension monitoring mechanism includes a mounting base, two fixed guide wheels, a moving guide wheel, a sliding rack, a driving gear, a driving shaft, a constant spring spring I, a casing, and three induction There are two fixed guide wheels and a slidably installed sliding rack on the outside of the mounting seat. Compared with the prior art, the phenomenon of broken or loose threads can be greatly reduced, and the structure is simple. Realize constant tension, easy to take yarn, adjustable peripheral diameter and convenient and quick adjustment.

Owner:海盐县梦芝舟毛纺厂

An electrode wire tension adjustment mechanism of a wire-cut electric discharge machine

ActiveCN110253099BAchieve constant tensionConstant tensionElectrical-based machining electrodesWire cuttingEngineering

The invention discloses an electrode wire tension adjusting mechanism of a wire electric discharge machine tool, comprising a mechanism fixing seat, a motor, a steel rope, a pulley, a pulley support, a first base, a first slider, a distance measuring sensor, a constant force spring, Spring support, second base, second slide, tensioning guide wheel and guide rail. The constant force spring is connected with the tension guide wheel through the second base, and its free end is connected with the steel rope through the first base. The distance measuring sensor is installed on the first base to measure the distance from the constant force spring to the first base. The first base Installed on the first slide block, the other end of the steel rope goes around the pulley to connect with the motor. The effective combination of the motor and the constant force spring, the constant force spring regulates the tension force of the electrode wire on the "micro level", and the "macro" level of the motor regulates the tension force, and rationally utilizes the characteristics of constant tension and rapid response of the constant force spring At the same time, the "macro" regulation of the motor makes the elongation of the constant force spring change within a certain range, which solves the problem of system oscillation very well.

Owner:GUANGDONG UNIV OF TECH

A paper splicer control system and control method

ActiveCN108046013BGuaranteed high-speed transmissionReduce complexityWebs handlingMachine controlAudio power amplifier

The invention discloses a paper connecting machine control system and method. The paper connecting machine control system comprises a paper connecting control system and a paper tape tension control system, and the paper connecting control system and the paper tape tension control system both include a PLC and a motion control positioning module connected with the PLC; a first motion control positioning module is connected with a synchronous motion control system or the paper tape tension control system of a paper tape pressing connecting machine through cables, and the synchronous motion control system and the paper tape tension control system of the paper tape pressing connecting machine both include a plurality of servo amplifiers and servo motor units connected with the servo amplifiers; and the paper connecting machine control method includes a paper connecting control method and a tension control method. According to the paper connecting machine control system and method, the paper connecting control system and the paper tape tension control system are separately independent systems, so that the system complexity is lowered and system links are reduced; and servo motors are used for detecting the tension, and the coarse and fine control of the torque is combined, thereby achieving the tension constant in the conveying process of paper tapes of a paper connecting machine.

Owner:苏州茂泰精密机械有限公司

Transmission system and method for synchronous control of textile machinery

ActiveCN114476789AAccurate realizationManufacturing precision requirements are lowInspecting textilesFunction indicatorsSynchronous controlControl engineering

The invention discloses a textile machinery synchronous control transmission system which comprises an unwinding mechanism, a first tension adjusting mechanism, an overfeeding mechanism, a setting machine, a second tension adjusting mechanism, a flattening mechanism, a winding mechanism and a controller. The unwinding mechanism, the first tension adjusting mechanism, the overfeeding mechanism, the setting machine, the second tension adjusting mechanism, the flattening mechanism and the winding mechanism are sequentially arranged in the cloth conveying direction. The overfeeding mechanism comprises a first overfeeding frame and a second overfeeding frame, a first overfeeding roller pair is installed on the first overfeeding frame, a second overfeeding roller pair is installed on the second overfeeding frame, and the two overfeeding roller pairs jointly carry out overfeeding conveying on wide cloth; the two pairs of overfeeding rollers are arranged and used for overfeeding conveying, the overfeeding rollers capable of being controlled by the controller and the controller can prevent cloth from being obliquely pulled, the overfeeding mechanism is matched with the adjusting mechanism so that automatic deviation correction of the cloth and automatic adjustment of the tension of the cloth can be achieved, constant-tension operation is kept, and the shaping effect is improved.

Owner:HANGZHOU JIE DRIVE TECH

A constant tension cloth belt guiding device on a square tooth rice discharge machine

ActiveCN106276367BSame tooth spacingSimple structureSlide fastenersWebs handlingEngineeringMechanical engineering

The invention discloses constant-tension cloth belt guide equipment of a square tooth arranger. The equipment comprises a guide column vertically arranged; and a cloth belt conveying device, a swing rod feeding device and a cloth belt clamping device are fixedly mounted on the guide column in sequence from top to bottom. As the cloth belt conveying device, the swing rod feeding device and the cloth belt clamping device are provided, when cloth belts enter the cloth belt conveying device, are conveyed on the swing rod feeding device, and penetrate through the cloth belt clamping device, the cloth belts are kept under the effect of the same one tension to achieve the constant tension effect, that is, the cloth belts are fed with the same one elastic force from an inlet to an outlet and in the outlet, the constant tension requirement in the production process is achieved, the same tooth gap of a zipper is guaranteed, and the product quality and the product assembly effect are improved.

Owner:FUJIAN SBS ZIPPER SCI & TECH CO LTD

Tool and method for winding and sample preparation of carbon fiber multifilament

InactiveCN110926892ASmooth walking trackGood expandabilityPreparing sample for investigationFiberRatchet

The invention discloses a tool and method for carbon fiber multifilament winding sample preparation, and relates to the technical field of material performance testing. The tool comprises a winding support, the winding support comprises at least one winding assembly, and each winding assembly comprises two end frames and a winding rod connected with the two end frames; a plurality of fixing hooksare arranged on the opposite sides of the two end frames in the circumferential direction, and openings of the fixing hooks face the centers of the end frames; two supporting frames which are arrangedon the two sides of the winding support respectively; a ratchet mechanism which comprises a ratchet wheel and a pawl, the ratchet wheel is rotationally connected to a supporting frame through a rotating shaft, one end of the pawl is connected to the supporting frame through a pawl shaft, and the other end of the pawl is meshed with outer edge teeth of the ratchet wheel; and a hanging needle is arranged on the ratchet wheel or the rotating shaft. According to the tool for winding and sample preparation of the carbon fiber multifilament, the winding process of an engine shell can be simulated more accurately, and the actual strength of carbon fibers applied to the engine shell can be represented more accurately.

Owner:THE GENERAL DESIGNING INST OF HUBEI SPACE TECH ACAD

Reeled yarn unwinding device

The invention discloses a reeled yarn unwinding device. The reeled yarn unwinding device comprises a drive mechanism, a tension monitoring mechanism located below the drive mechanism, a controller anda reeled yarn shed frame. The drive mechanism and the tension monitoring mechanism are connected with the controller. The reeled yarn shed frame is arranged on the drive mechanism. The tension monitoring mechanism comprises a mounting seat, two fixed guide wheels, a moving guide wheel, a sliding gear rack, a drive gear, a drive shaft, a constant-force spring I, an outer shell, three inductors andan inducted body. The two fixed guide wheels and the sliding gear rack capable of being mounted in a sliding manner are arranged on the outer side of the mounting seat. Compared with the prior art, the phenomenon of breaking or loosening can be greatly reduced, the structure is simple, constant-force tensioning is achieved, yarn can be taken easily, the peripheral diameter can be adjusted, and adjusting is convenient and rapid.

Owner:海盐县梦芝舟毛纺厂

High-performance horizontal yarn carrying spindle for knitting special fibers of knitting machine

The invention discloses a high-performance horizontal yarn carrying spindle for knitting special fibers of a knitting machine, and belongs to horizontal yarn carrying spindles of knitting machines. The horizontal bobbin yarn carrying spindle is characterized in that a bearing flange, a yarn outlet support and a constant tension mechanism are installed on a base; a mandrel penetrates through the center of the bearing flange, one end of the mandrel is installed on the constant tension mechanism through a bearing, a bearing sleeve is connected outside the mandrel in a sleeving manner through a bearing, the bearing sleeve is fixedly sleeved with a protective sleeve, elastic pieces are installed on the bearing sleeve and the protective sleeve, a bobbin is installed outside the protective sleeve, and the mandrel does circular motion on the bearing flange and the bearing sleeve; the other end of the mandrel is connected with a volute spiral spring device and a clamp spring; one end of the volute spiral spring is arranged on the mandrel, and the other end of the volute spiral spring is arranged on the bearing sleeve; and the clamp spring at the end part of the mandrel prevents the volute spiral spring device from moving. The high-performance horizontal yarn carrying spindle has the advantages that according to the high-performance horizontal yarn carrying spindle, the manpower is saved, the quality and the efficiency are improved, the product stability is ensured, and large stroke, constant tension and uniform knitting pitch of the special knitting machine are realized.

Owner:XUZHOU HENGHUI BRAIDING MACHINE

Yarn carrying spindle for controlling bobbin pay-off tension through magnetic damping for knitting machine

The invention discloses a yarn carrying spindle for controlling bobbin pay-off tension through magnetic damping for a knitting machine, and belongs to the yarn carrying spindle for controlling the bobbin pay-off tension through the magnetic damping. The yarn carrying spindle comprises a tension pay-off mechanism and a yarn outlet mechanism. The yarn outlet mechanism is fixedly installed at the upper end of one side of the tension pay-off mechanism. The tension pay-off mechanism comprises a base, a magnetic damper, a bearing flange, a mandrel, a sheath, a gasket, a volute spiral spring, a bobbin base, a bobbin, a bobbin pin shaft and a bobbin buckle. The yarn outlet mechanism comprises a vertical rod, a yarn outlet blocking rod, a third wheel shaft, a third wheel, a bearing sleeve, a rotating shaft, a yarn outlet wheel support, a yarn outlet wheel shaft, a yarn outlet wheel and a yarn outlet swing head; one side of the vertical rod is provided with the yarn outlet blocking rod, and thevertical rod is provided with the third wheel; the rotating shaft is installed at the top of the vertical rod and provided with the yarn outlet wheel support; and the yarn outlet wheel and the yarn outlet swing head are installed on the yarn outlet wheel support. The yarn carrying spindle has the advantages that manpower is saved, quality and efficiency are improved, product stability is guaranteed, and the large stroke, constant tension and even knitting pitch of a special knitting machine are achieved.

Owner:XUZHOU HENGHUI BRAIDING MACHINE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com