High-performance horizontal yarn carrying spindle for knitting special fibers of knitting machine

A high-performance knitting machine technology, applied in the direction of knitting, textiles and paper making, can solve problems such as insufficient weaving stroke, unstable pay-off tension, uncontrollable pay-off tension, etc., to ensure product stability, save manpower, Good cognition and the effect of development and innovation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

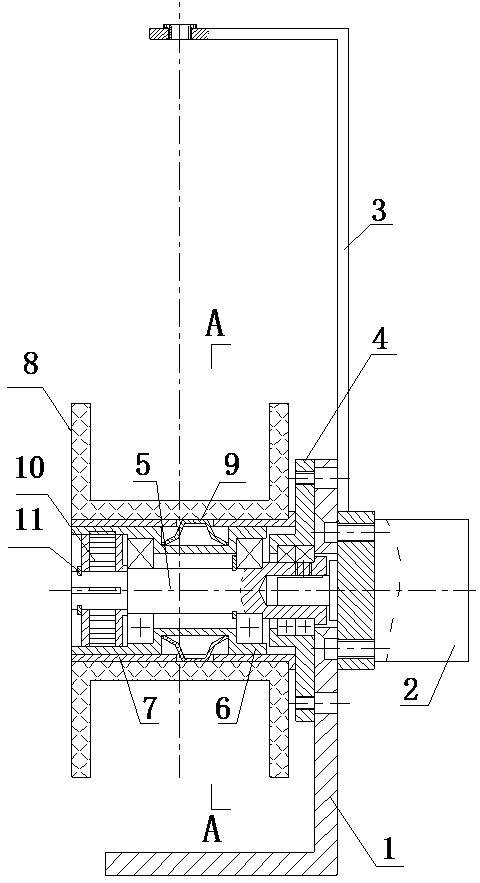

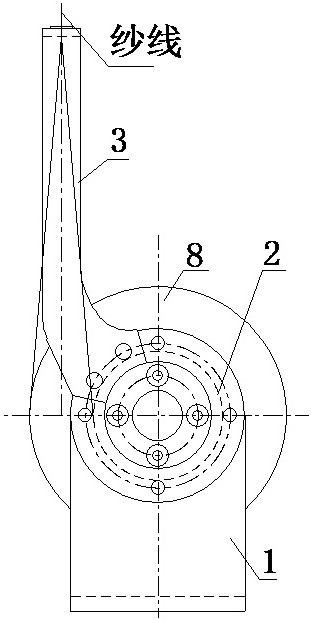

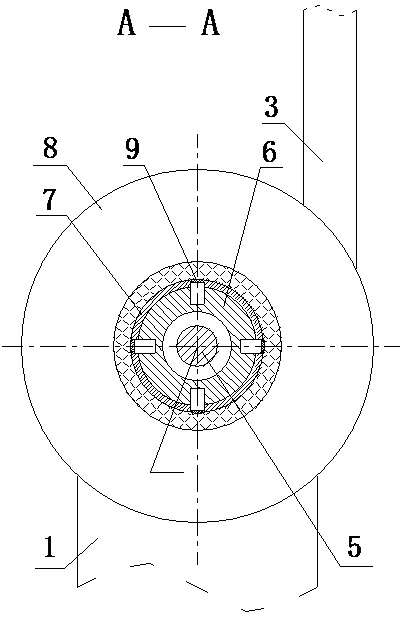

[0022] Embodiment 1: A high-performance horizontal bobbin carrying spindle includes: base 1, constant tension mechanism 2, outlet support 3, bearing flange 4, mandrel 5, bearing sleeve 6, sheath 7, bobbin 8, elastic Shrapnel 9, scroll spring device 10 and jump ring 11.

[0023] Install the bearing flange 4, outlet bracket 3 and constant tension mechanism 2 on the base 1; the mandrel 5 passes through the center of the bearing flange 4, one end of the mandrel 5 is installed on the constant tension mechanism 2 through the bearing, and the bearing sleeve 6 passes through The bearing is sleeved outside the mandrel 5, and a sheath 7 is fixedly sleeved outside the bearing sleeve 6. Elastic shrapnel 9 are installed on the bearing sleeve 6 and the sheath 7, and the yarn tube 8 is installed outside the sheath 7. The flange 4 and the bearing sleeve 6 perform circular motion; the other end of the mandrel 5 is connected with a scroll spring device 10 and a circlip 11; one end of the scroll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com