Patents

Literature

134results about How to "Constant torque" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

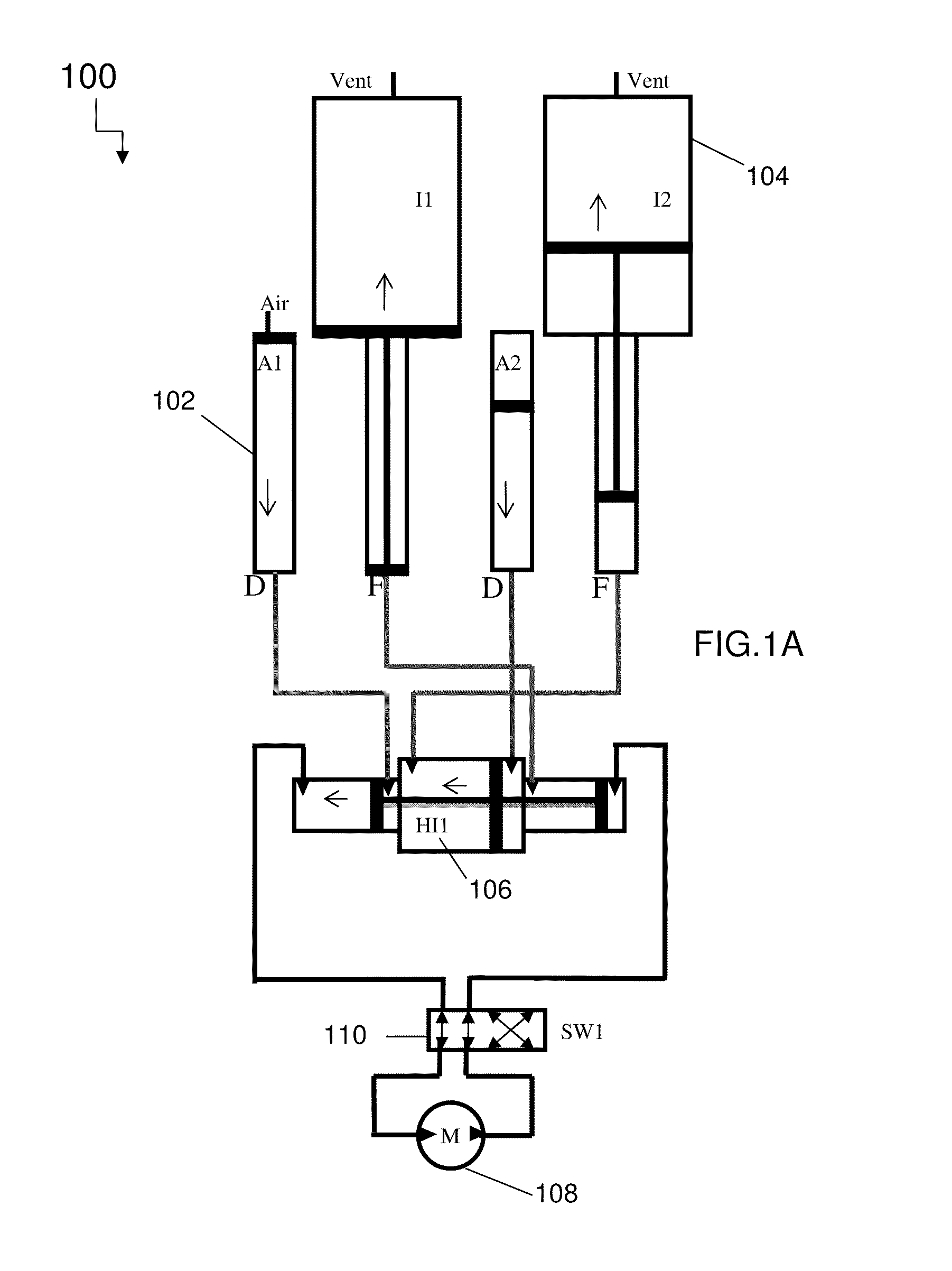

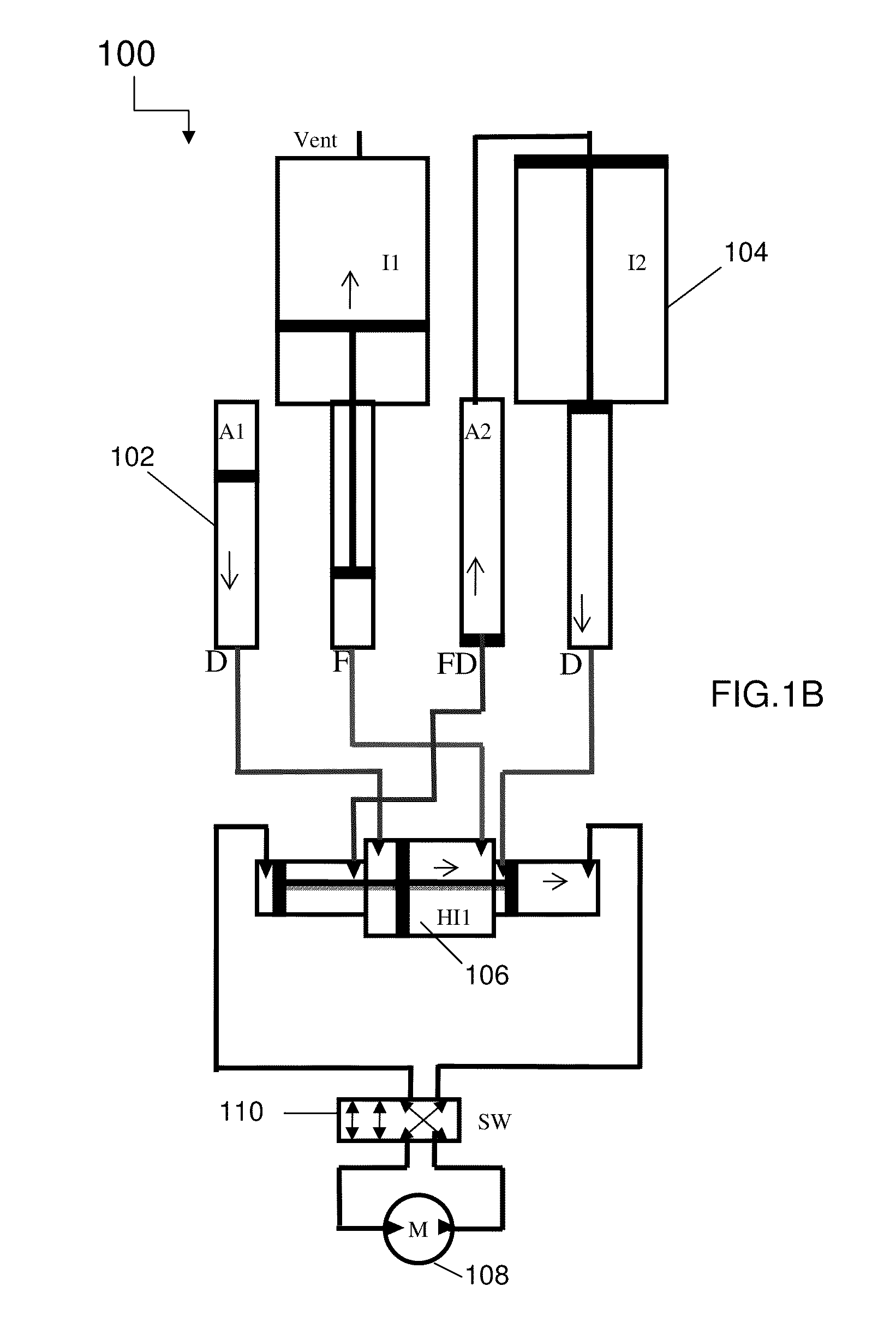

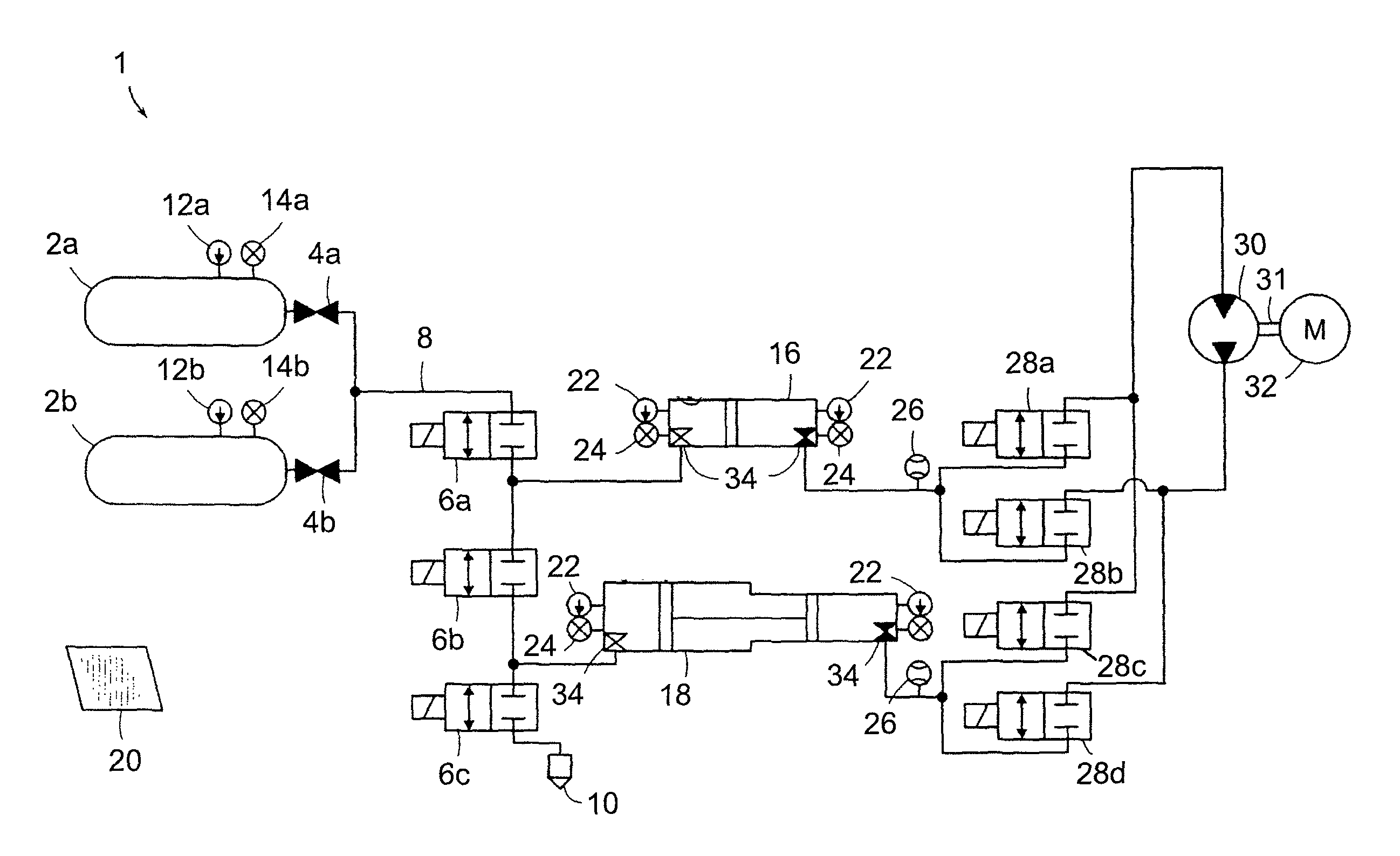

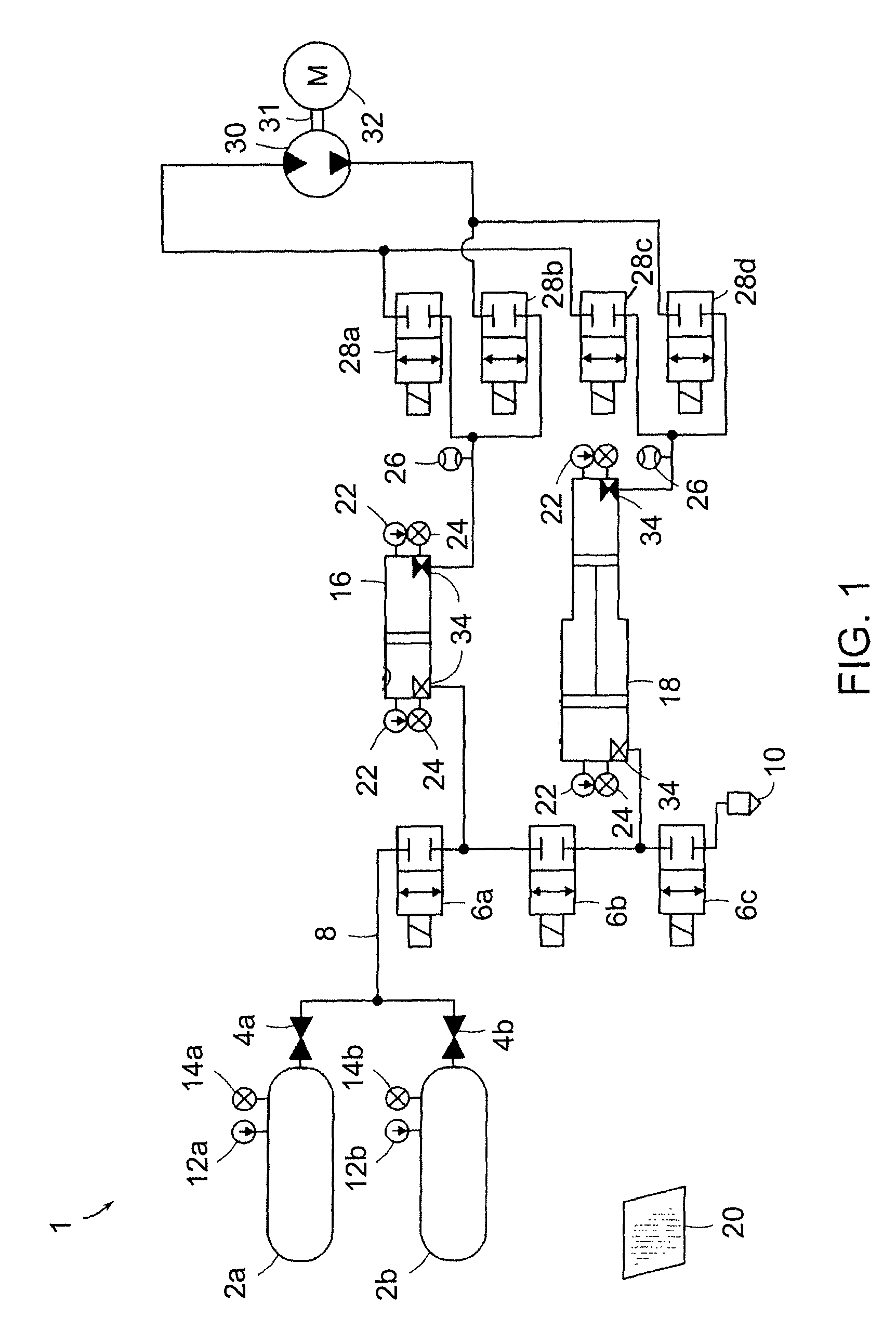

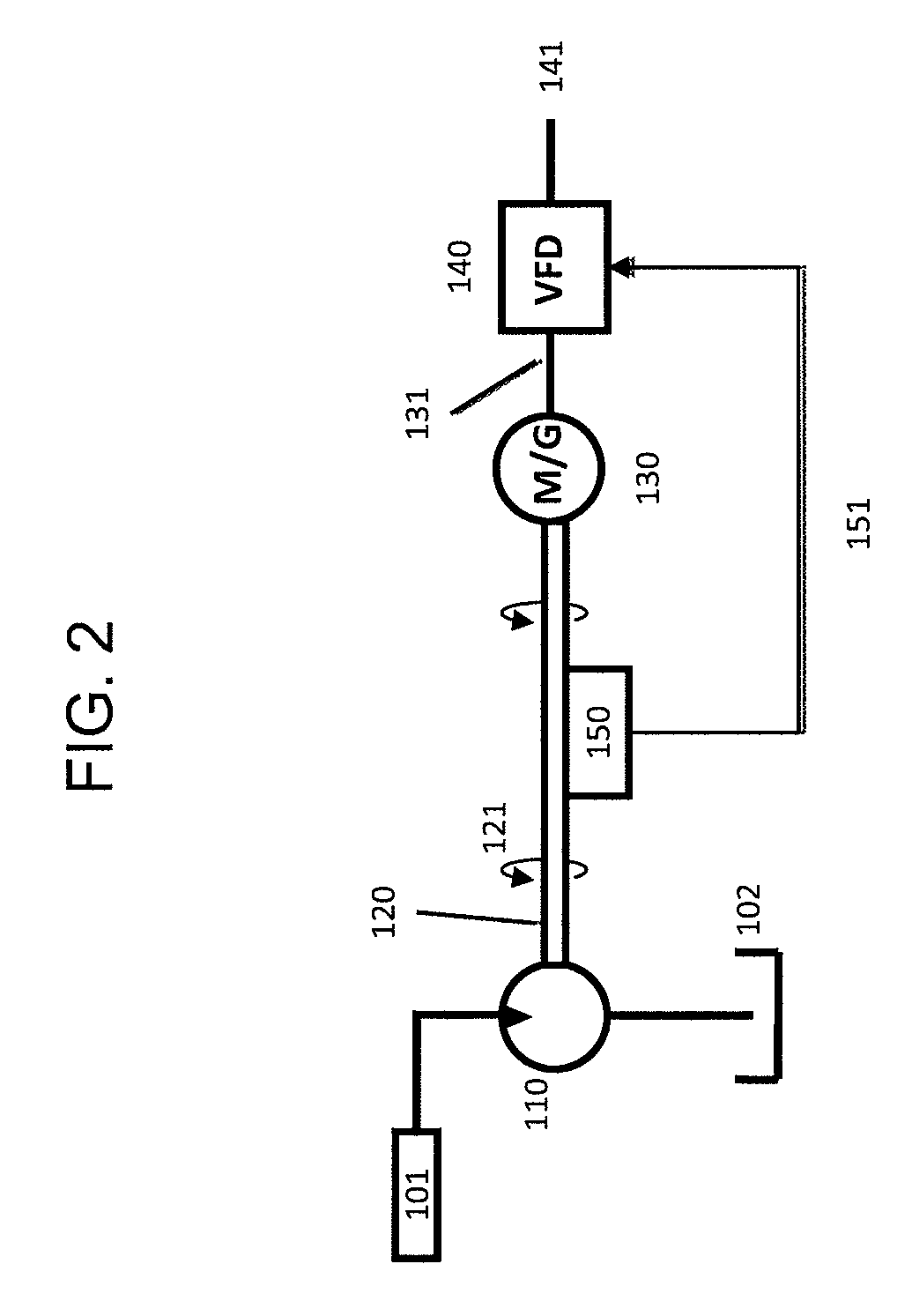

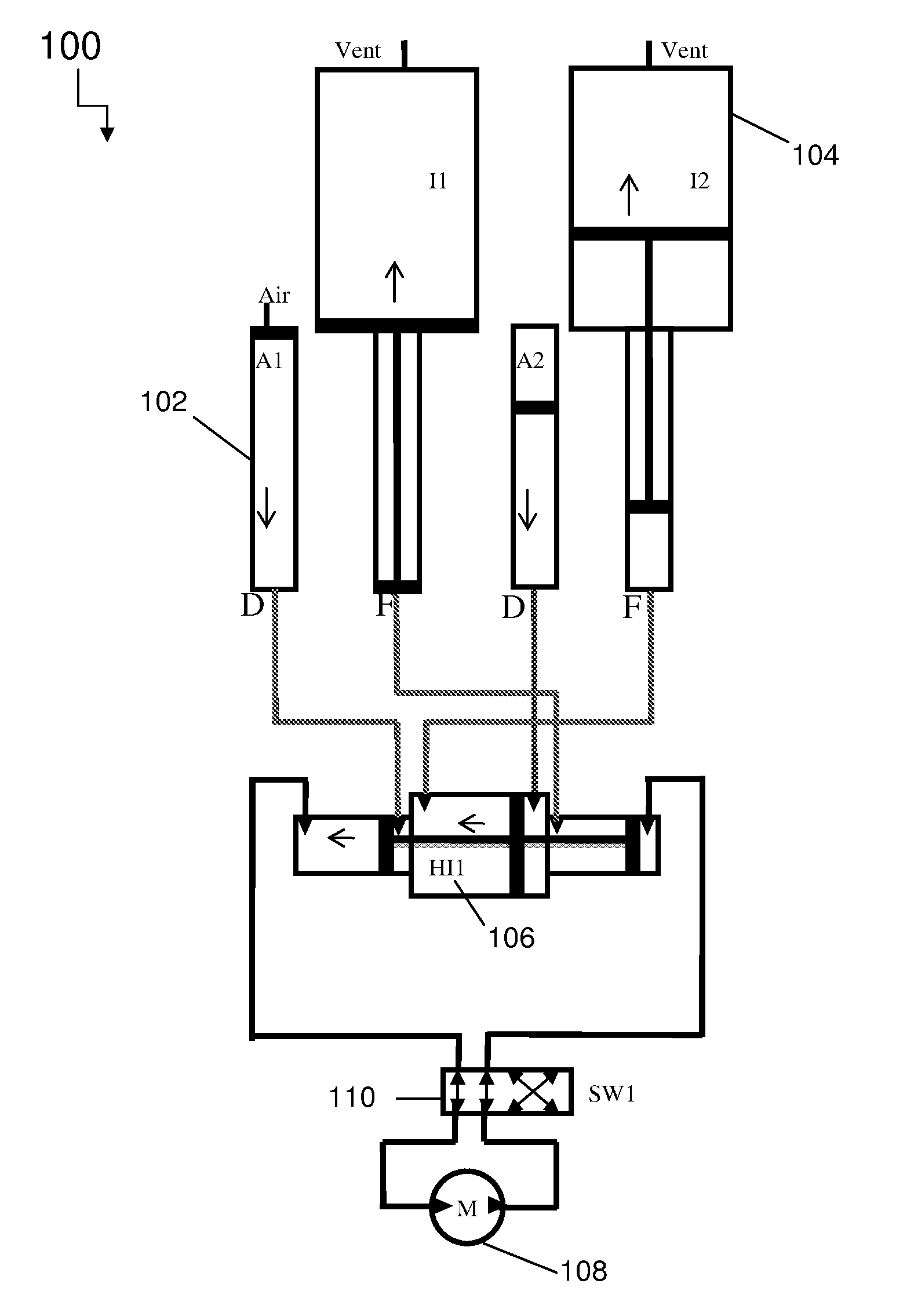

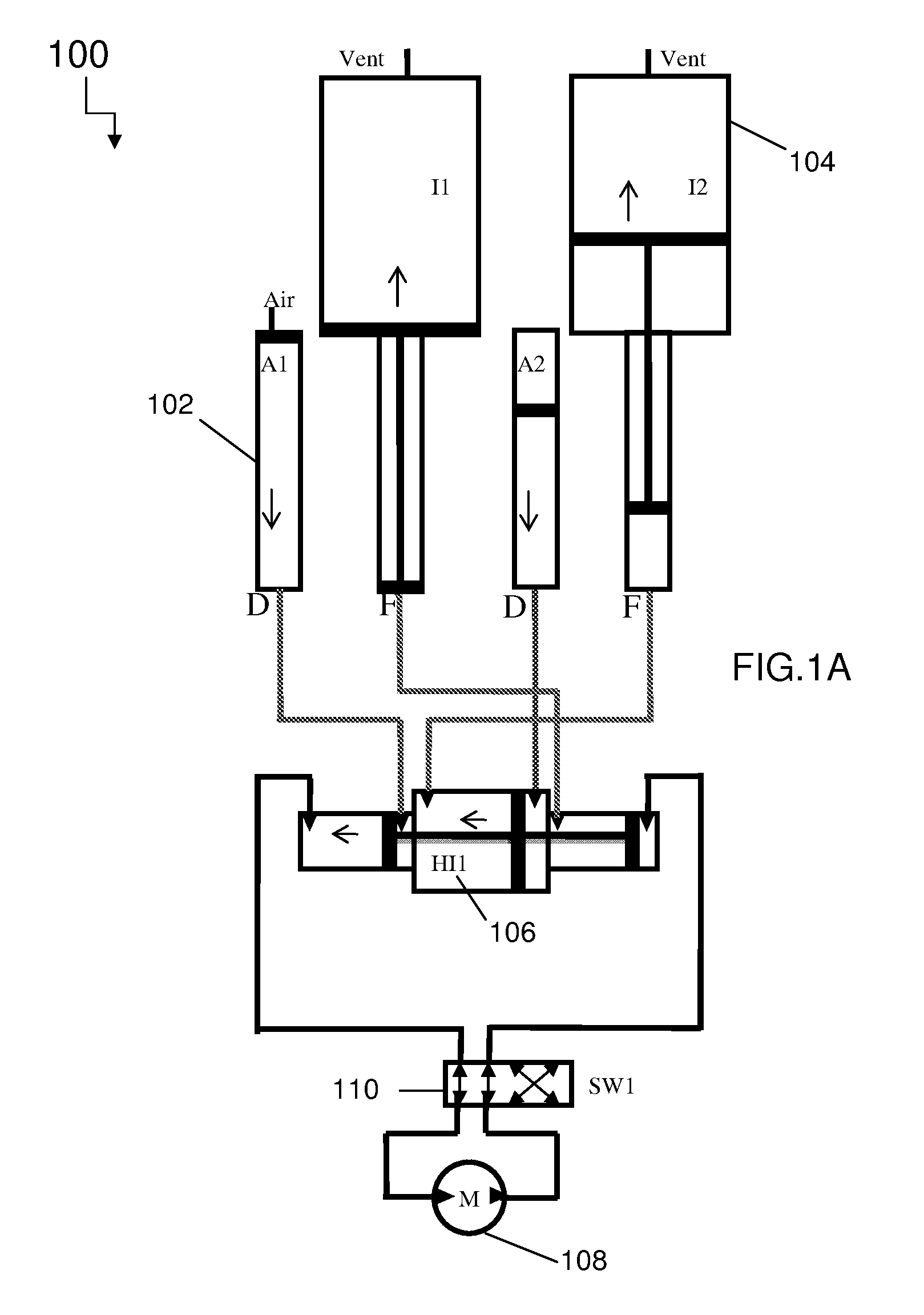

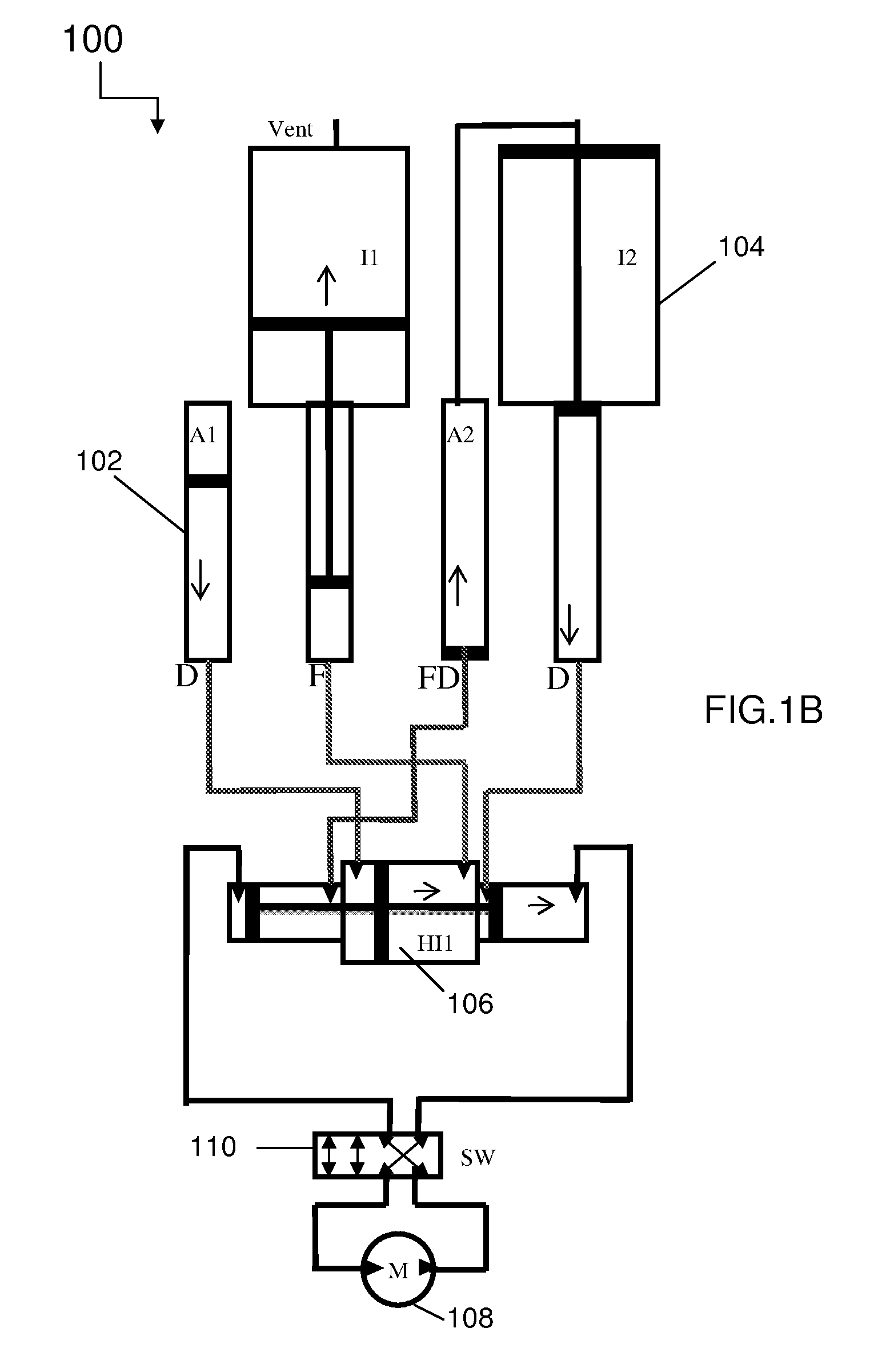

Systems and Methods for Improving Drivetrain Efficiency for Compressed Gas Energy Storage and Recovery Systems

InactiveUS20100307156A1Easy to testLow costElectrical storage systemGas turbine plantsHydraulic motorDrivetrain

The invention relates to power generation and energy storage and recovery. In particular, the invention relates to compressed gas energy storage and recovery systems using staged pneumatic conversion systems for providing narrow pressure ranges to a hydraulic motor.

Owner:SUSTAINX

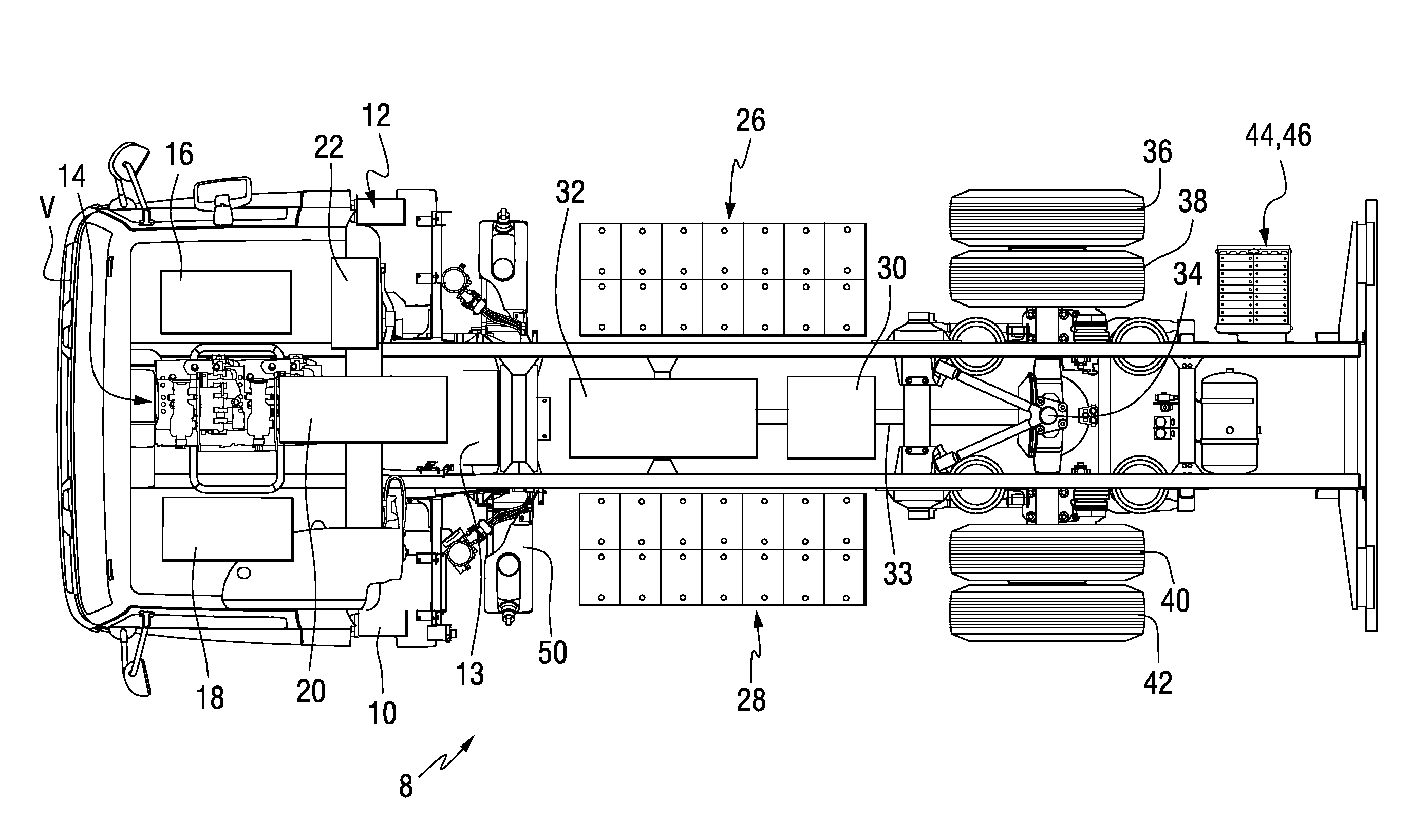

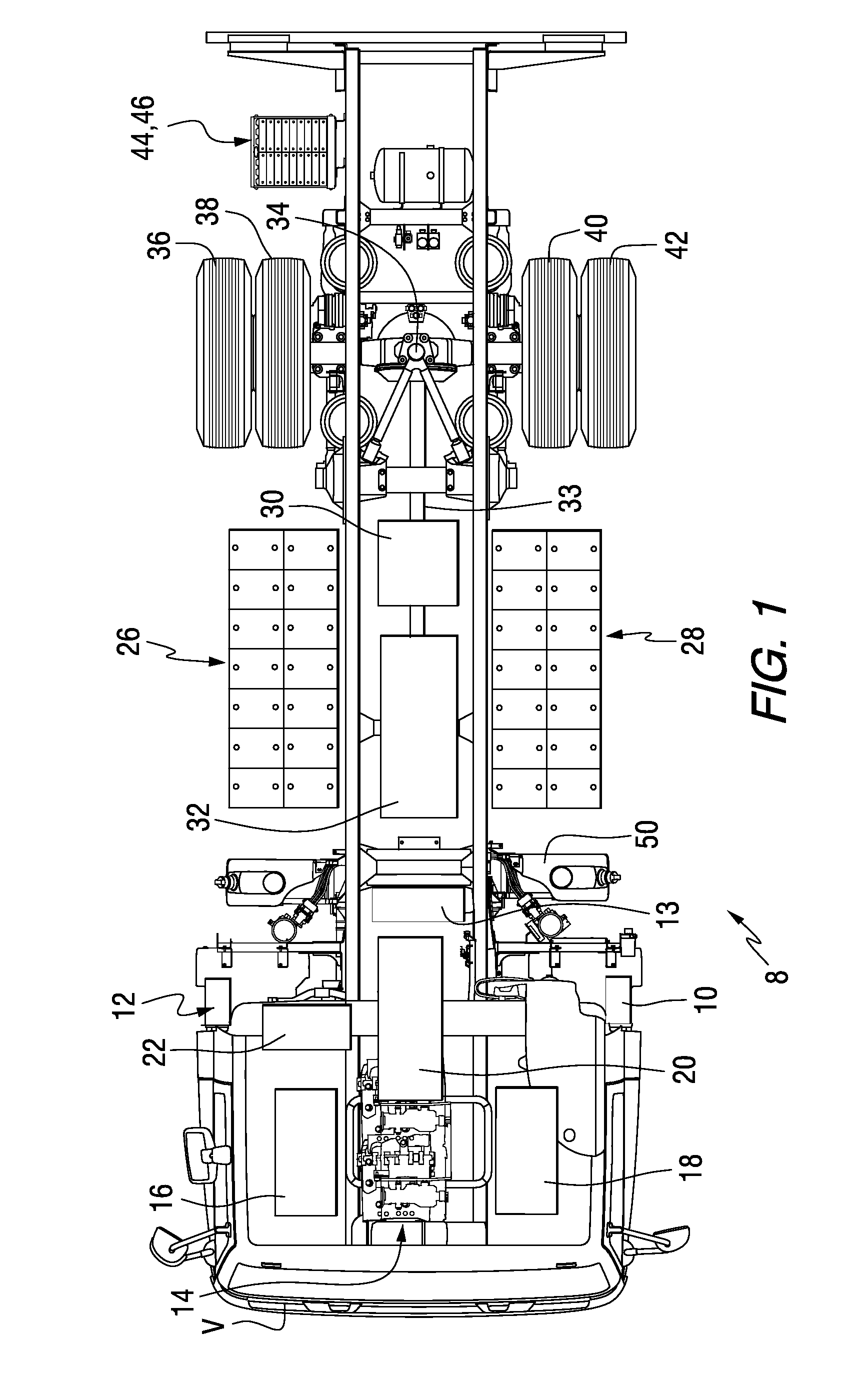

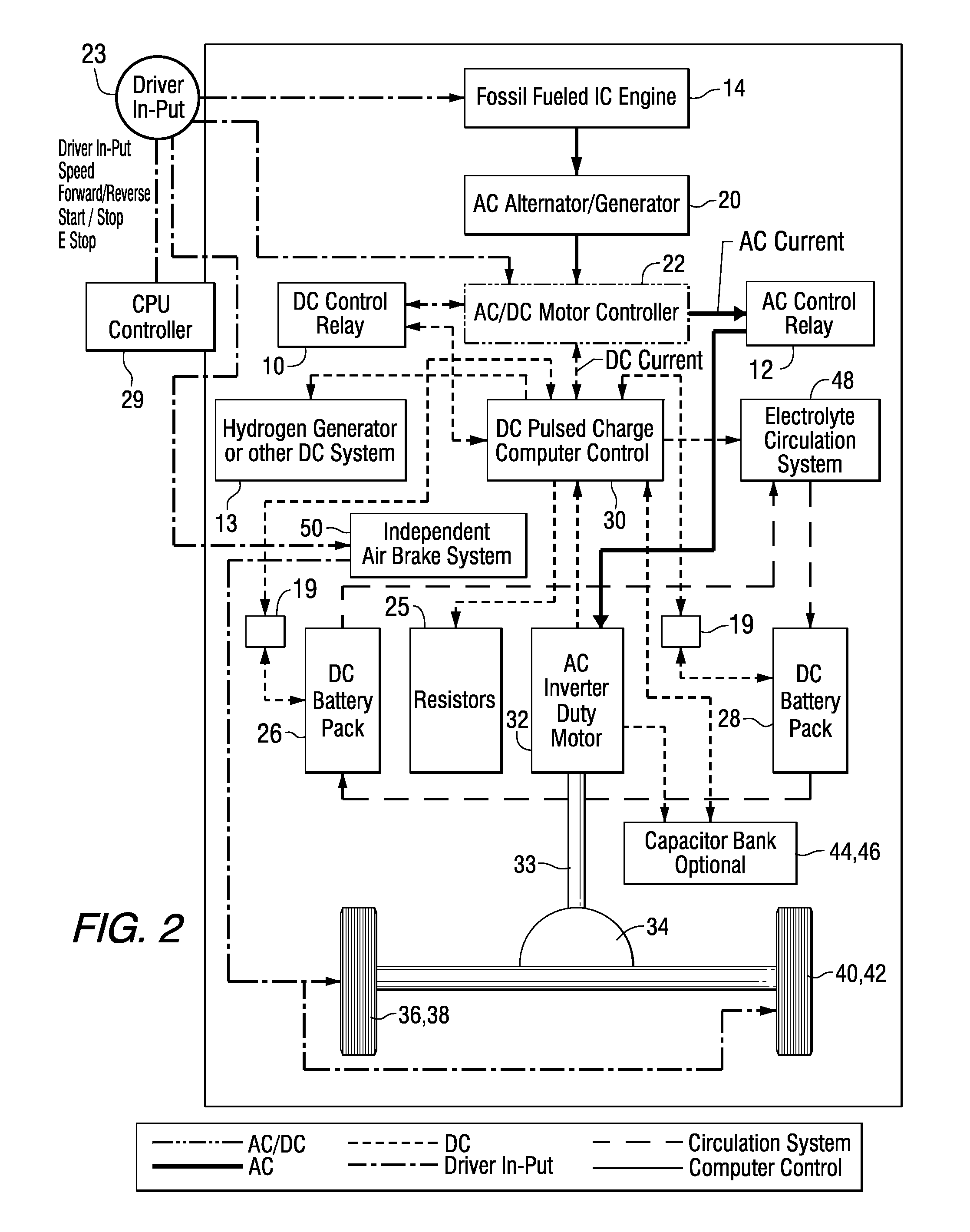

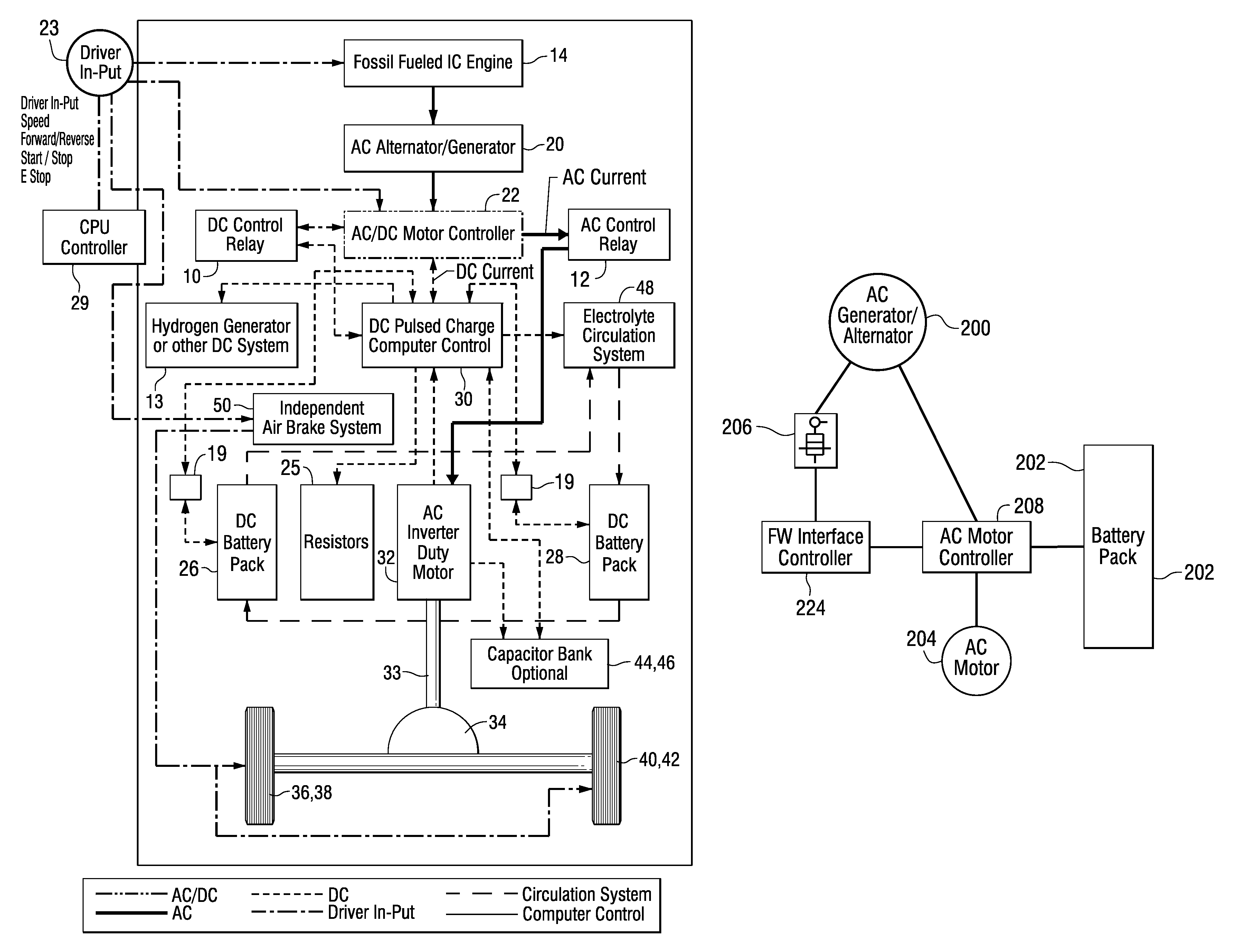

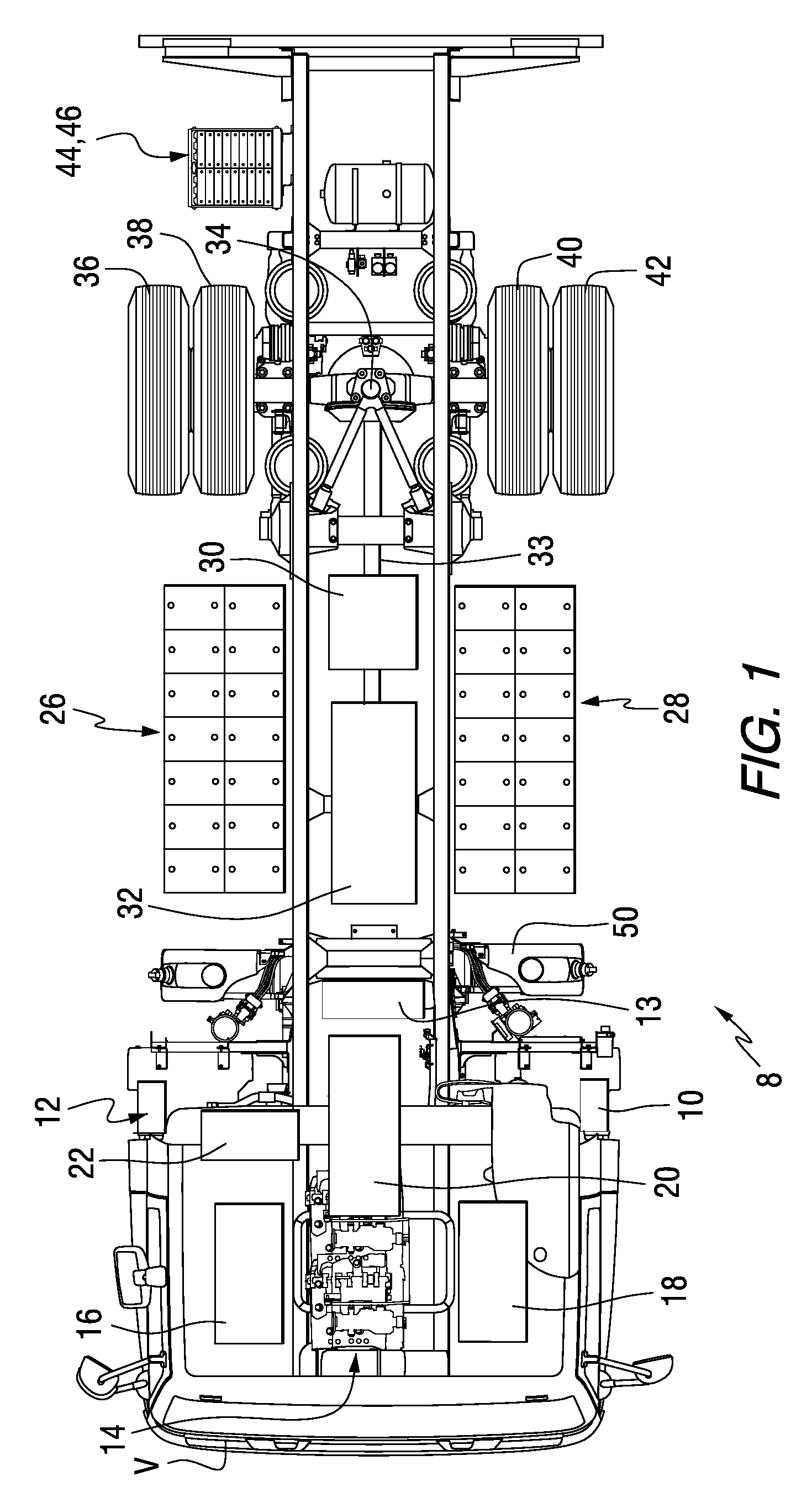

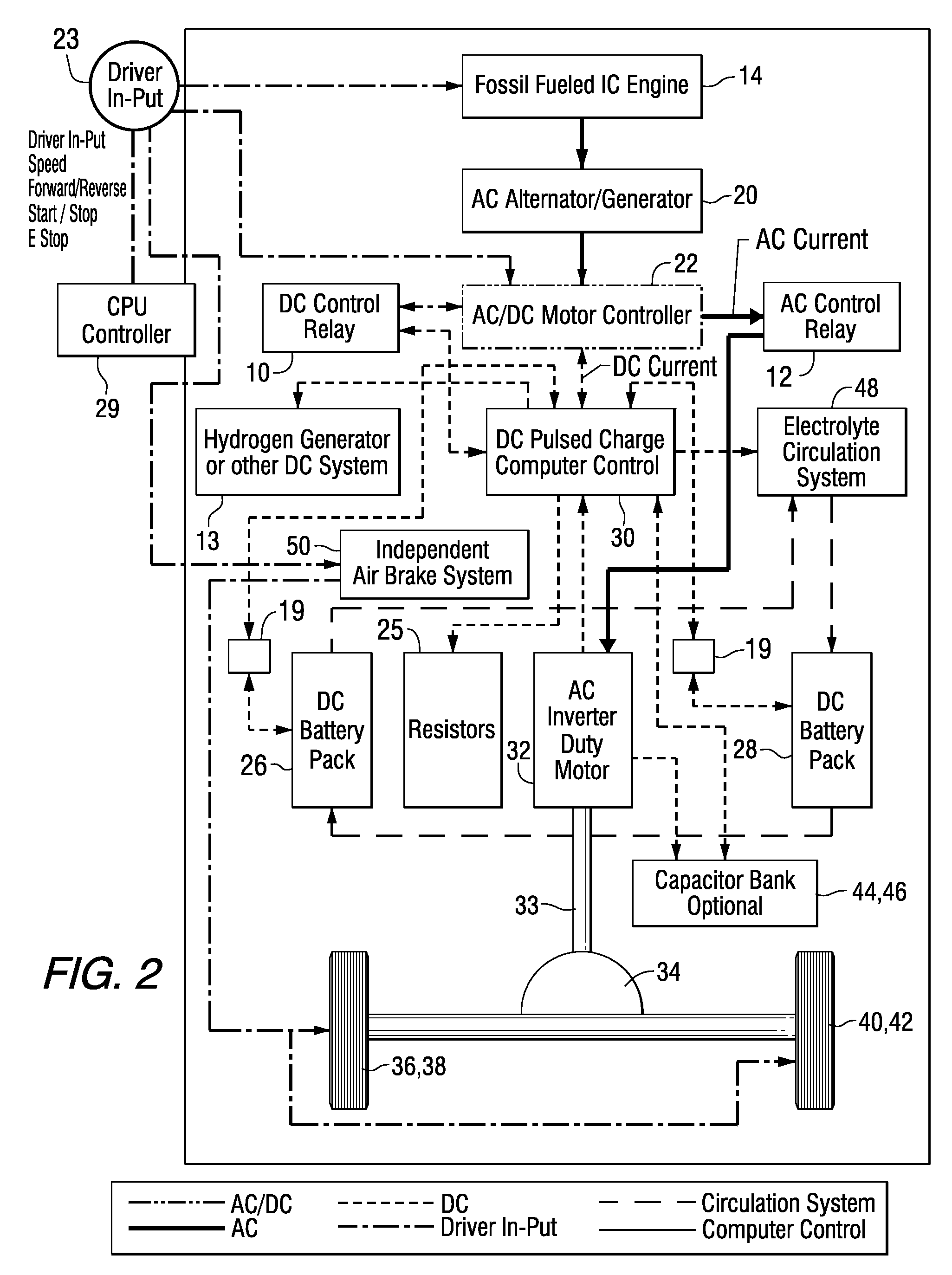

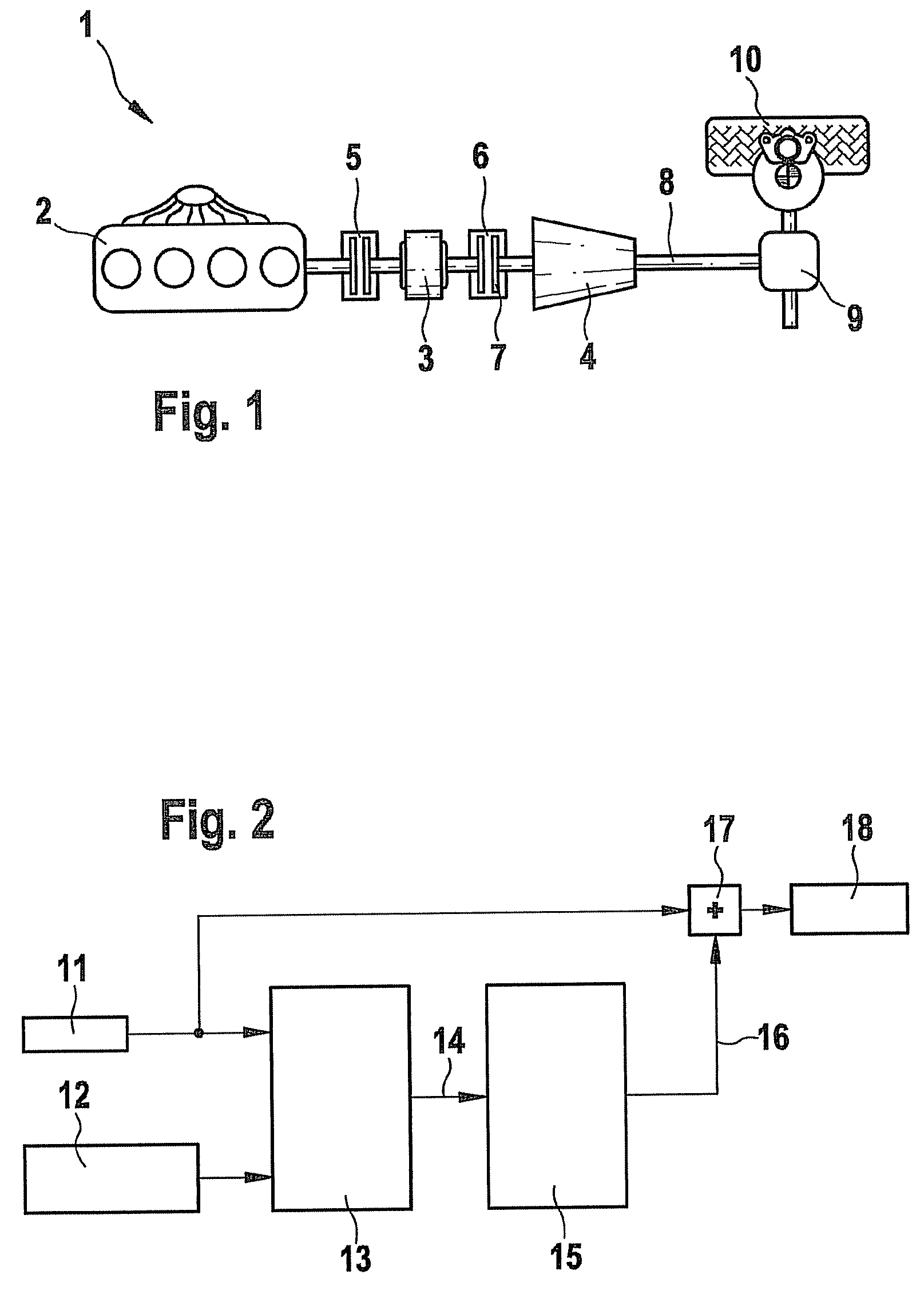

Hydrocarbon Fueled-Electric Series Hybrid Propulsion Systems

ActiveUS20110174561A1Efficiently usImproves mileage performanceCell temperature controlPlural diverse prime-mover propulsion mountingElectricityNormal load

A hybrid propulsion system for powering vehicles such as class 8 DOT classified semi-tractor trucks under normal load conditions and at highway speeds comprises an internal combustion engine, an AC generator powered by the engine, DC battery packs, an AC / DC controller, and an AC electric motor driving the drive train of the vehicle. The AC generator and the DC battery packs provide input to the AC / DC controller, which, in turn, converts the DC input from the DC battery packs via a DC circuit to AC so that the output from the AC / DC controller to the electric motor is AC for powering the vehicle. The DC battery packs may comprise thin plate flooded lead acid cells and may be connected in series, in parallel or a combination thereof. Vehicles may be retrofitted to incorporate the propulsion system.

Owner:EPOWER ENGINE SYST

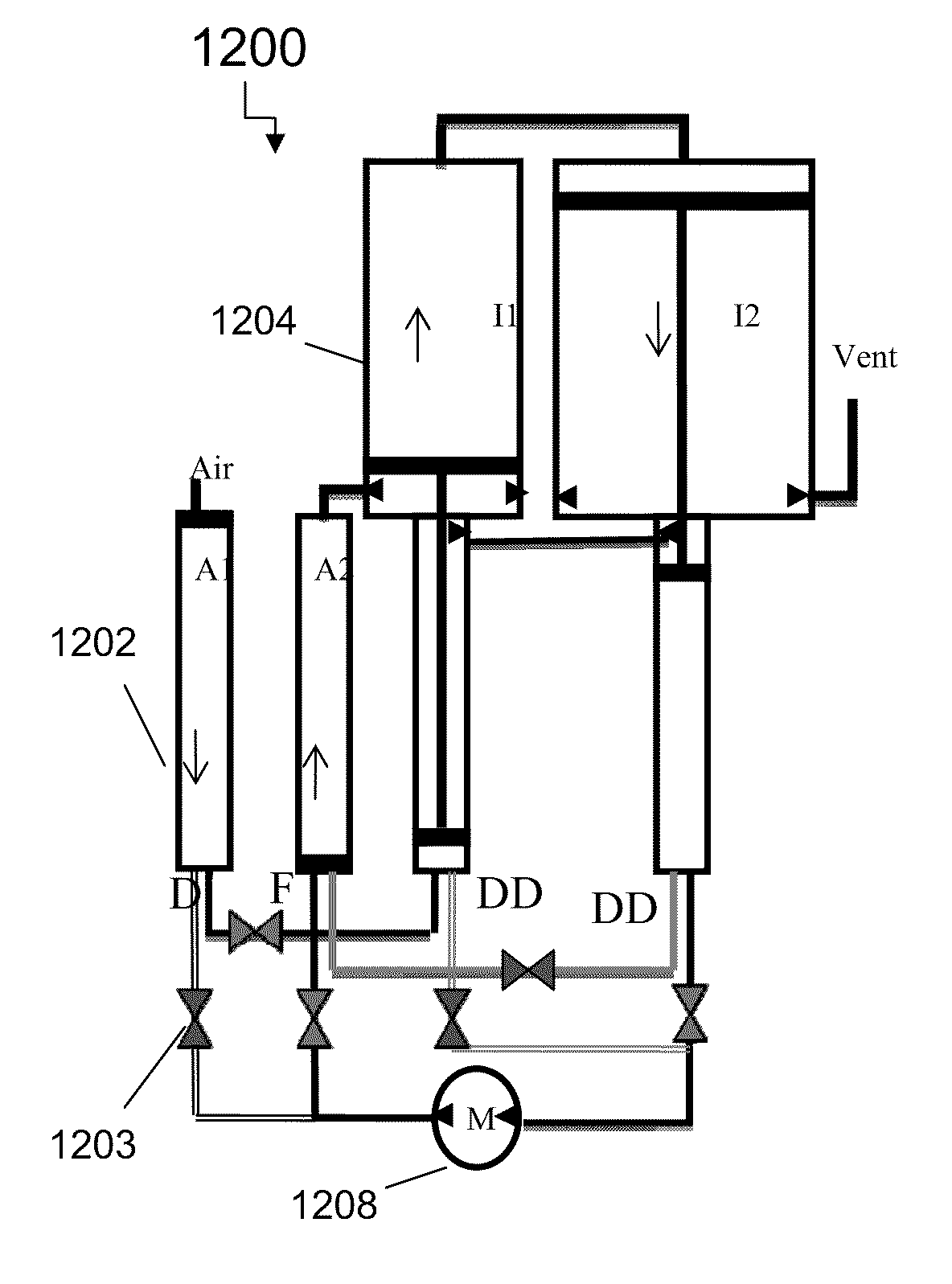

Systems and methods for improving drivetrain efficiency for compressed gas energy storage

InactiveUS7963110B2RPM increaseReduce loadElectrical storage systemFluid couplingsHydraulic motorPower flow

Owner:SUSTAINX

Hydrocarbon fueled-electric series hybrid propulsion systems

ActiveUS8783396B2High efficiency rangeImprove efficiencyPlural diverse prime-mover propulsion mountingPropulsion by batteries/cellsElectricityNormal load

A hybrid propulsion system for powering vehicles such as class 8 DOT classified semi-tractor trucks under normal load conditions and at highway speeds comprises an internal combustion engine, an AC generator powered by the engine, DC battery packs, an AC / DC controller, and an AC electric motor driving the drive train of the vehicle. The AC generator and the DC battery packs provide input to the AC / DC controller, which, in turn, converts the DC input from the DC battery packs via a DC circuit to AC so that the output from the AC / DC controller to the electric motor is AC for powering the vehicle. The DC battery packs may comprise thin plate flooded lead acid cells and may be connected in series, in parallel or a combination thereof. Vehicles may be retrofitted to incorporate the propulsion system.

Owner:EPOWER ENGINE SYST

Systems and methods for improving drivetrain efficiency for compressed gas energy storage and recovery systems

InactiveUS20110138797A1Easy to testLong lastingElectrical storage systemFluid couplingsHydraulic motorDrivetrain

The invention relates to power generation and energy storage and recovery. In particular, the invention relates to compressed gas energy storage and recovery systems using staged pneumatic conversion systems for providing narrow pressure ranges to a hydraulic motor.

Owner:SUSTAINX

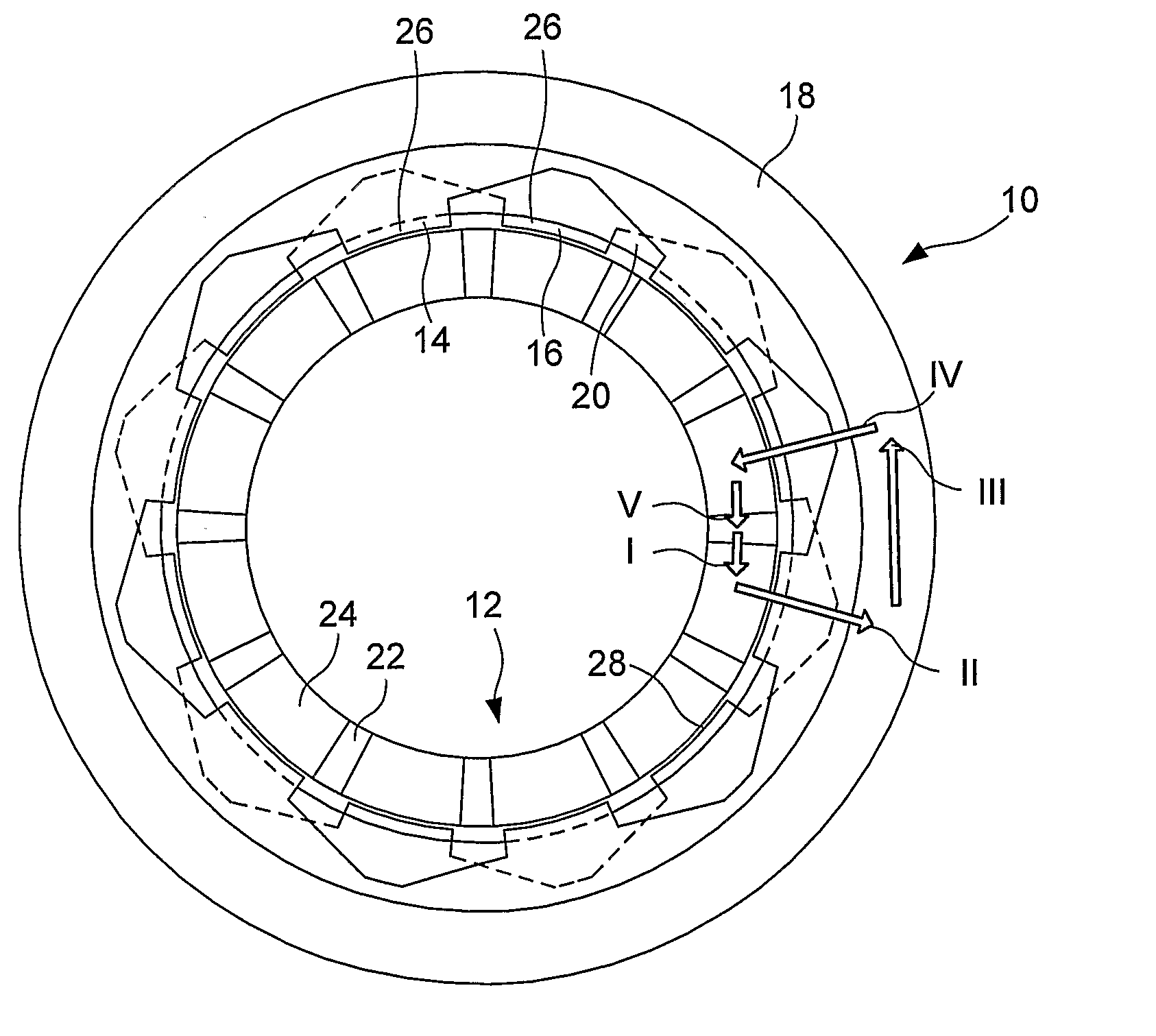

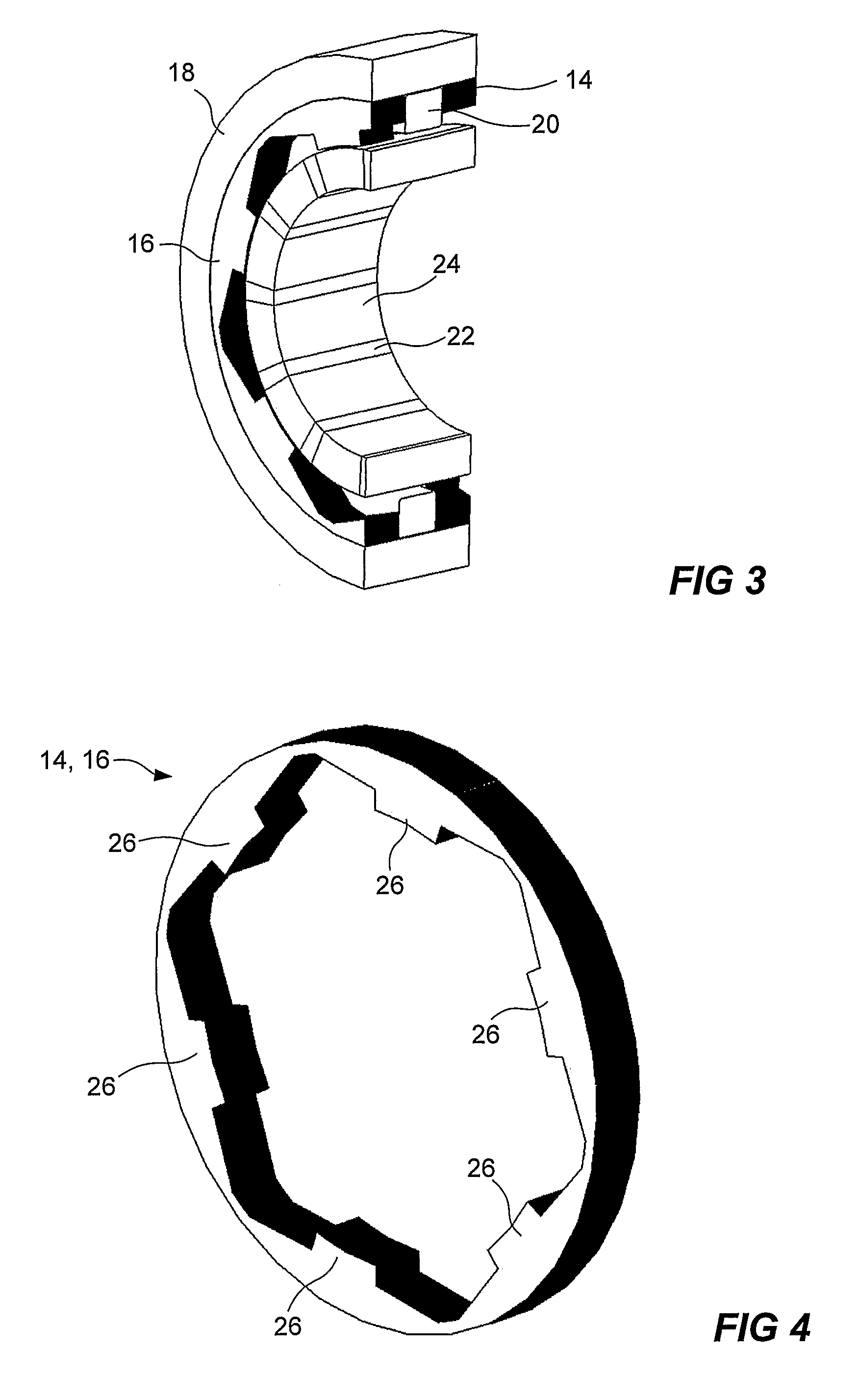

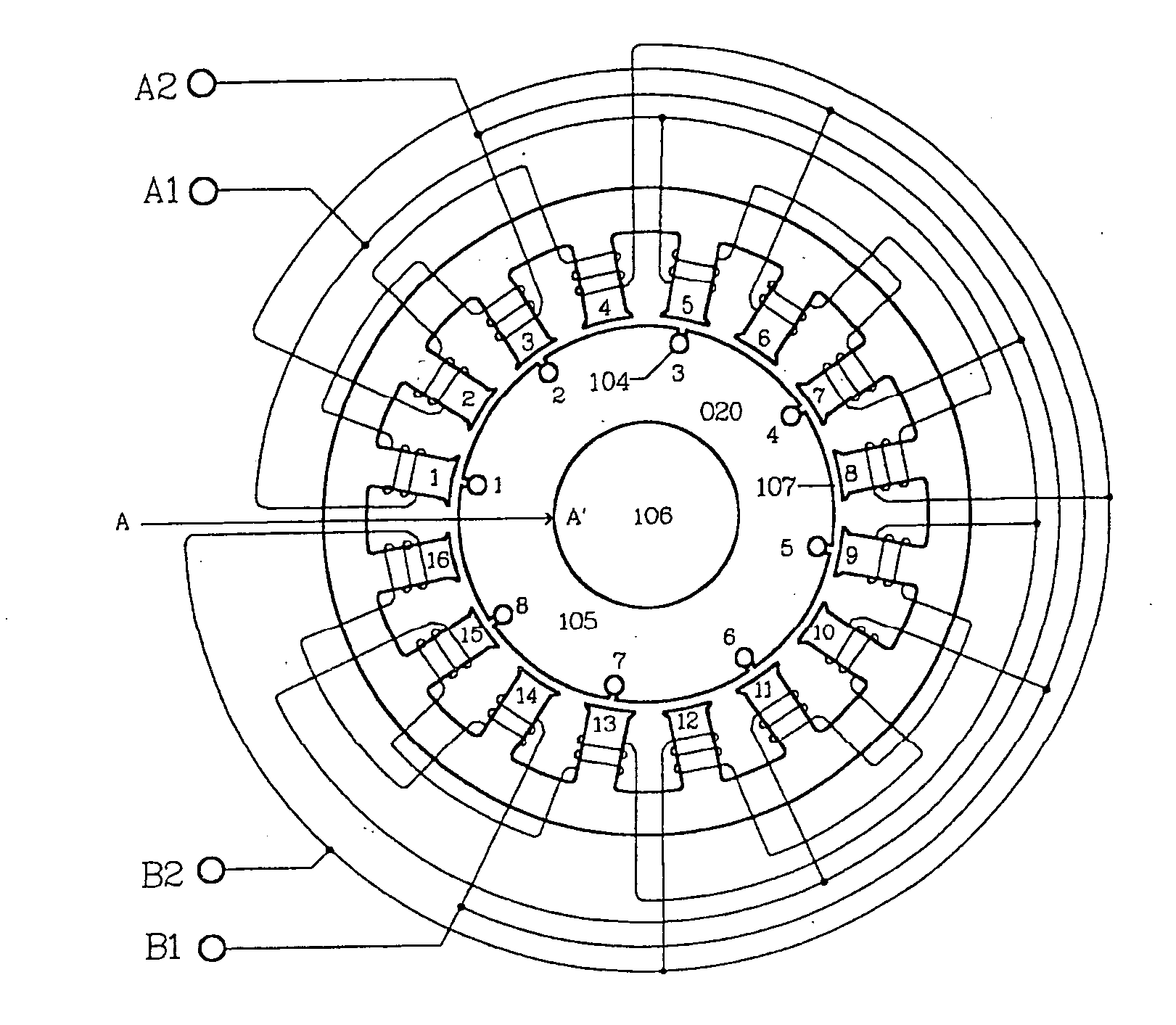

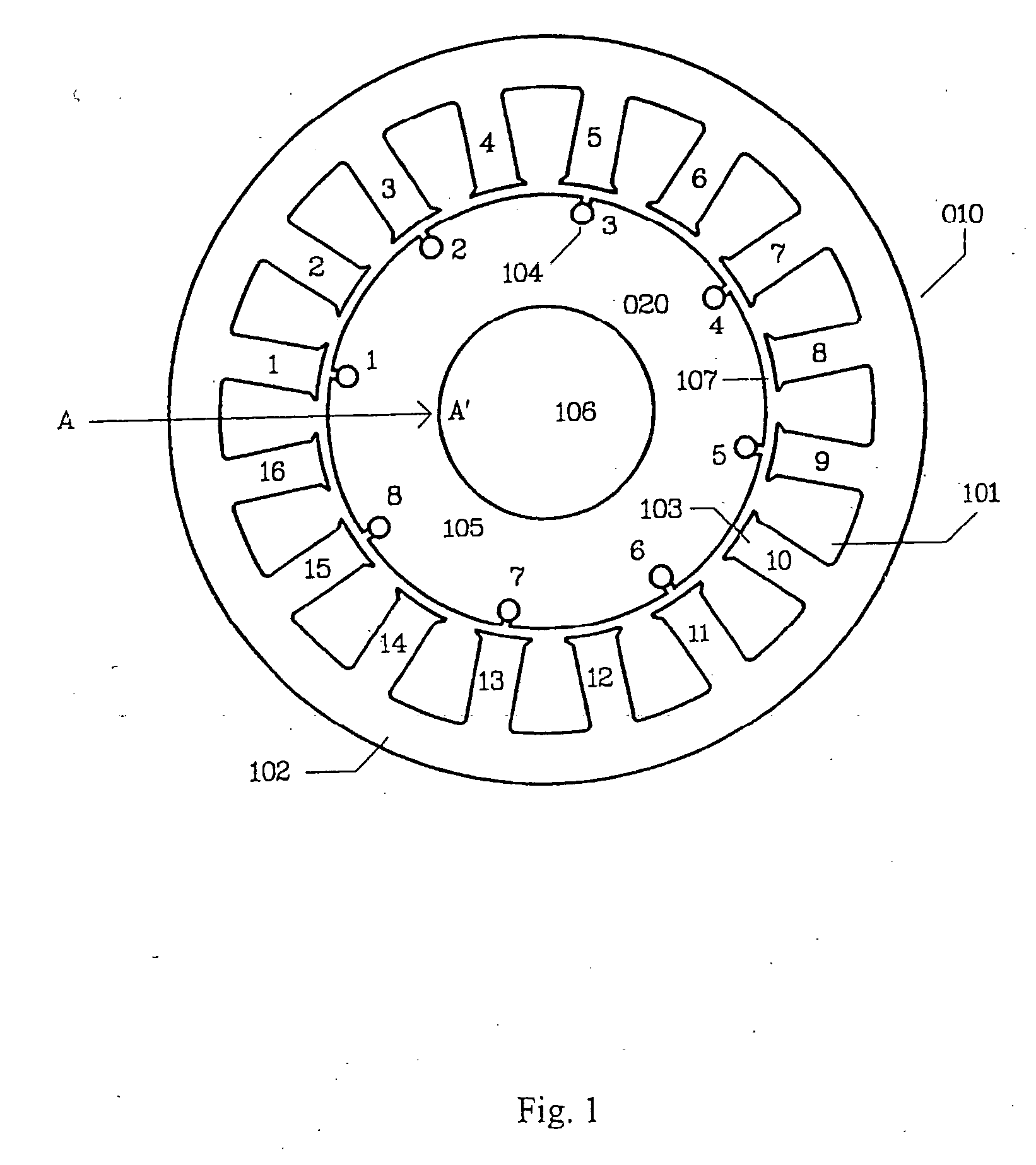

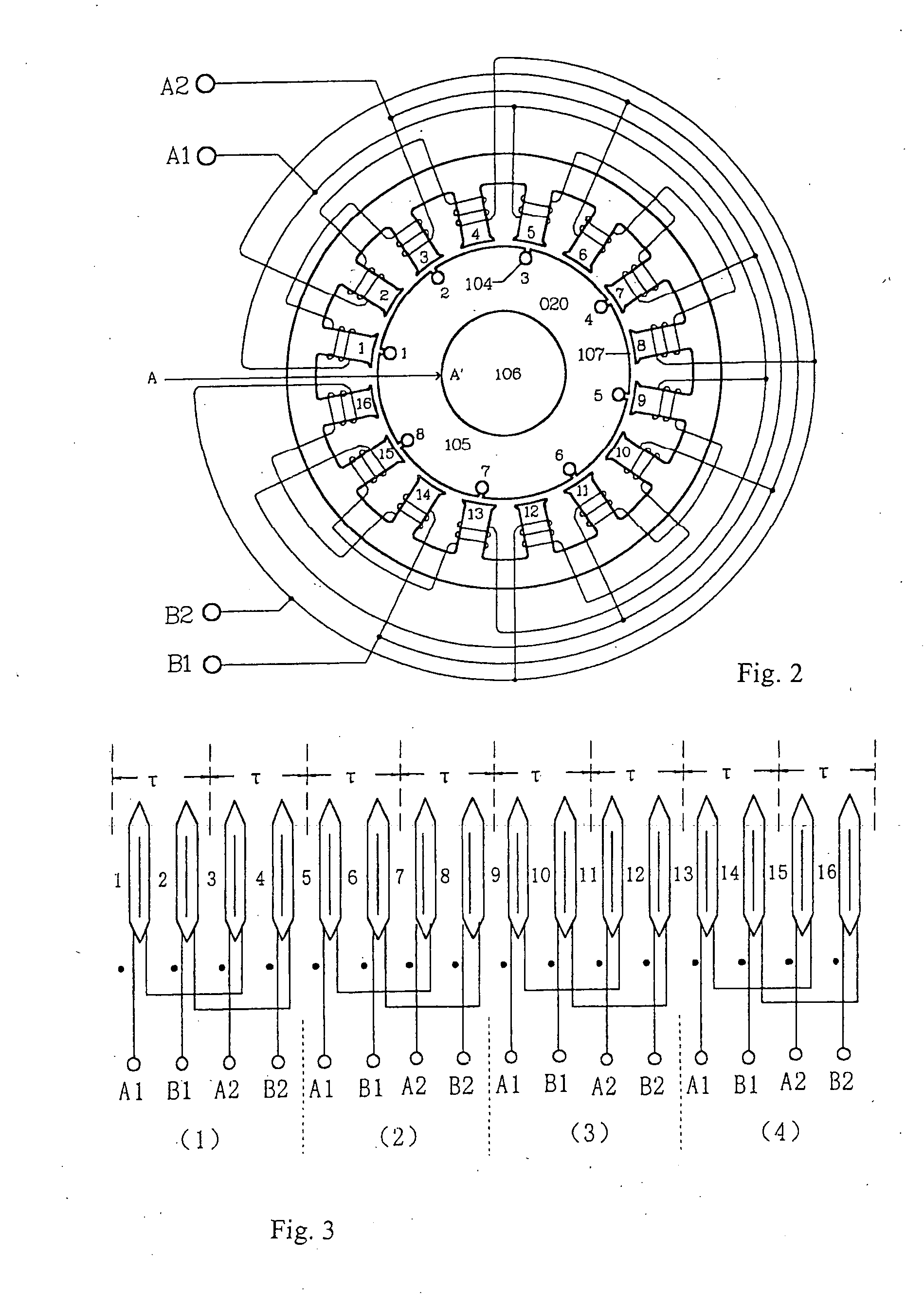

Electric Machine Assembly

InactiveUS20090243406A1Improve performanceEasy to useMagnetic circuit stationary partsManufacturing dynamo-electric machinesElectric machineEngineering

An electrical rotary machine is provided comprising a first stator core section being substantially circular and including a plurality of teeth, a second stator core section being substantially circular and including a plurality of teeth, a coil arranged between the first and second circular stator core sections, and a rotor including a plurality of permanent magnets. The first stator core section, the second stator core section, the coil and the rotor are encircling a common geometric axis, and the plurality of teeth of the first stator core section and the second stator core section are arranged to protrude towards the rotor. Additionally, the teeth of the second stator core section are circumferentially displaced in relation to the teeth of the first stator core section, and the permanent magnets in the rotor are separated in the circumferential direction from each other by axially extending pole sections made from soft magnetic material.

Owner:HOGANAS AB

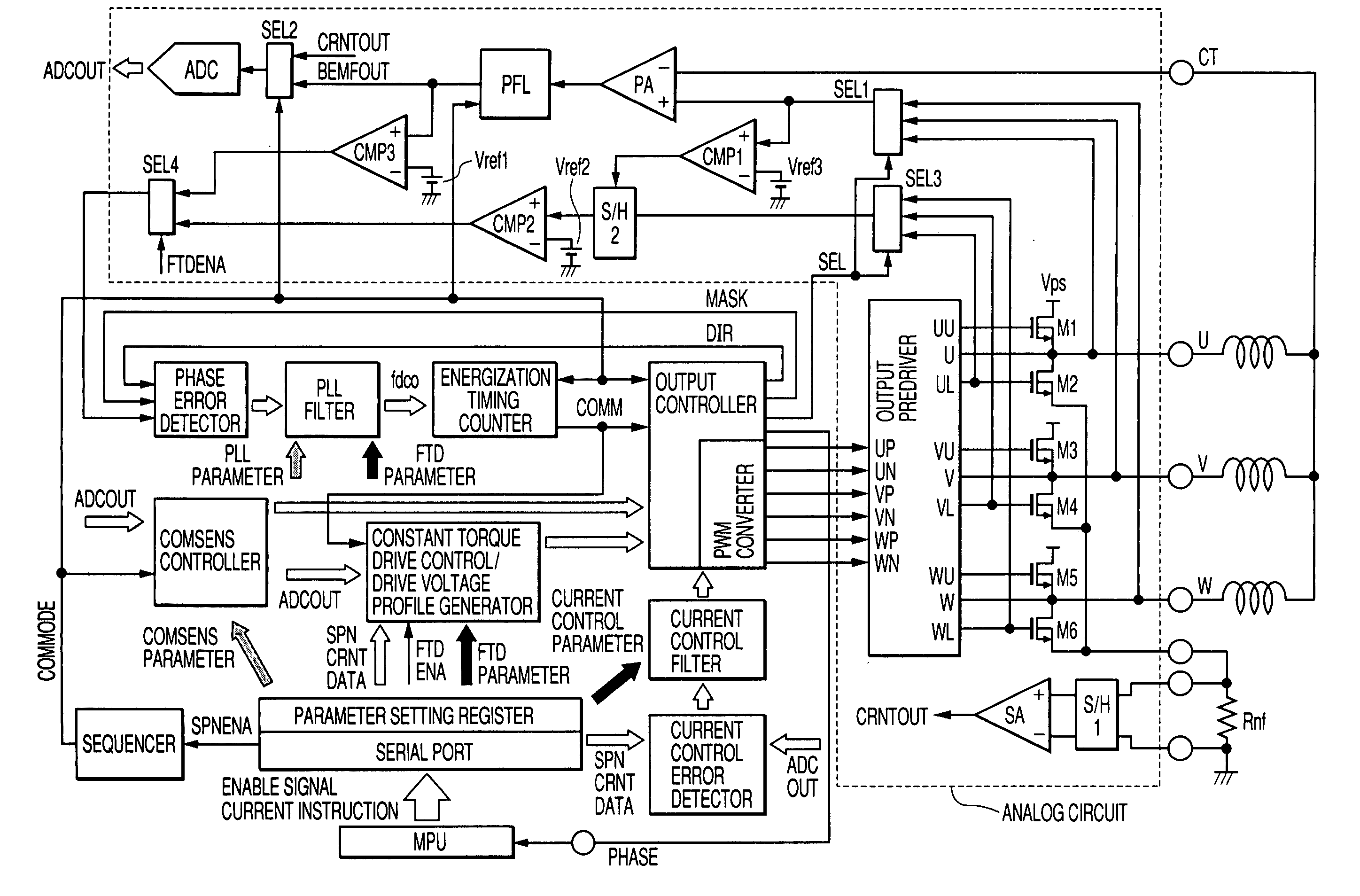

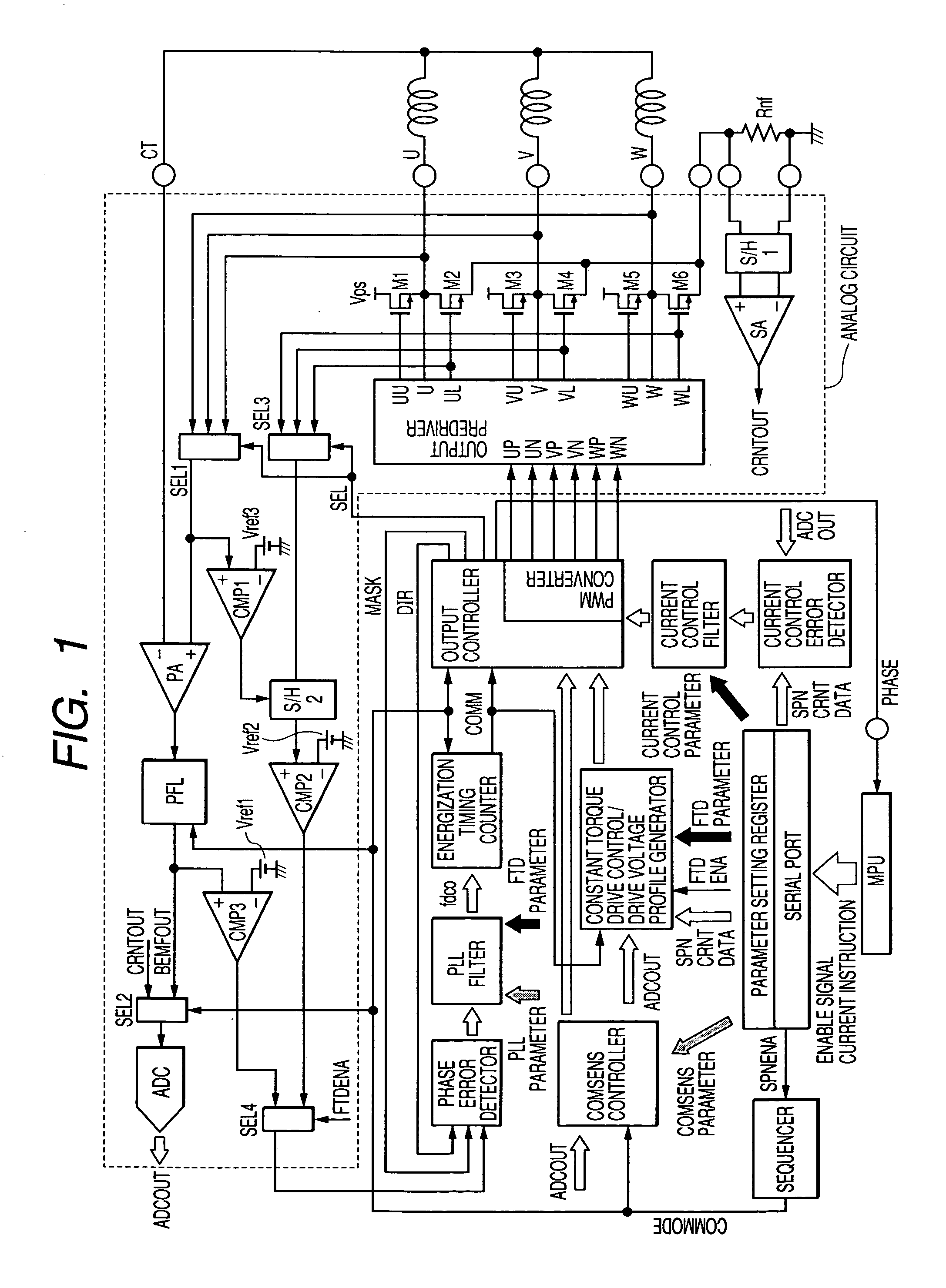

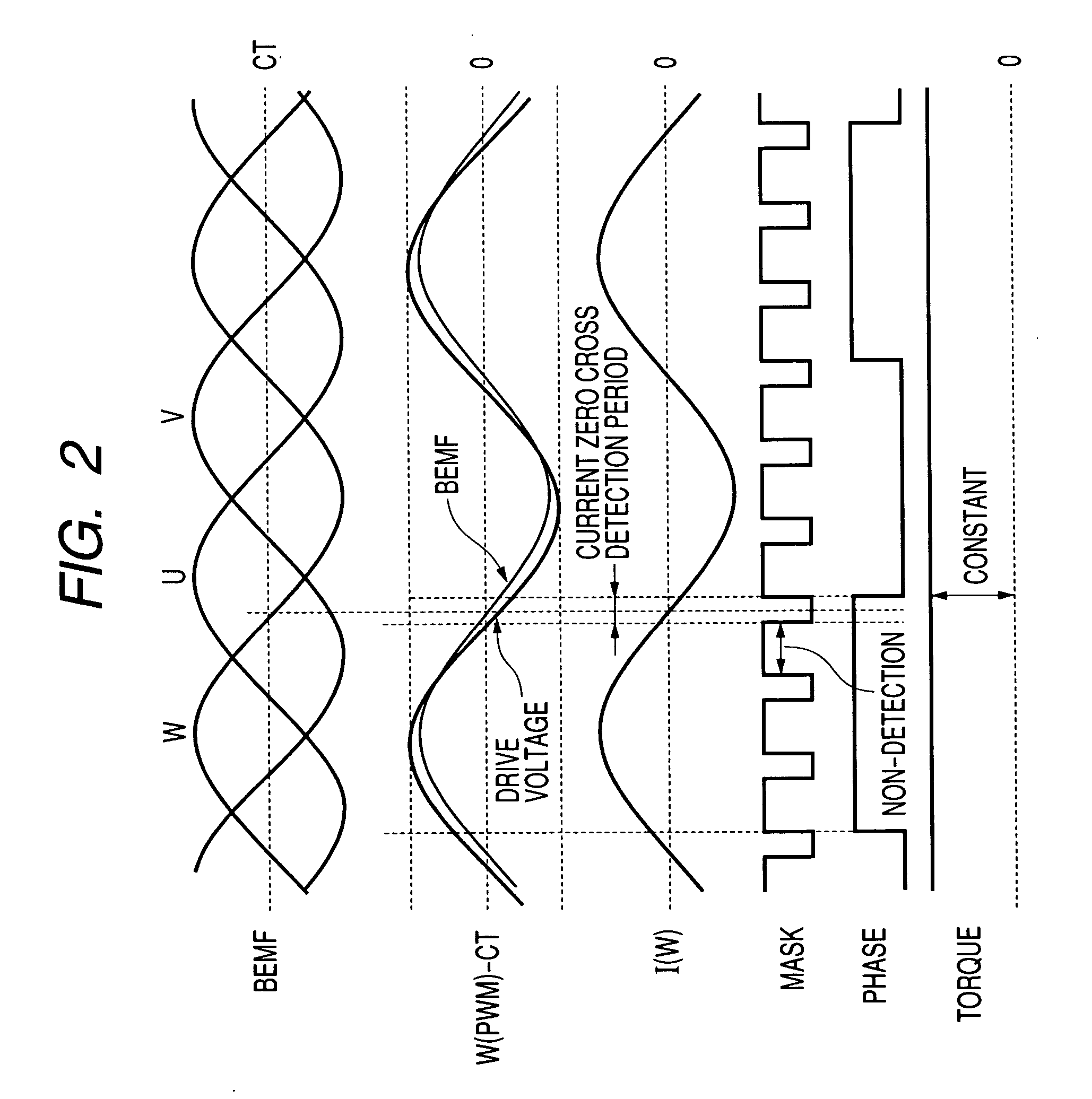

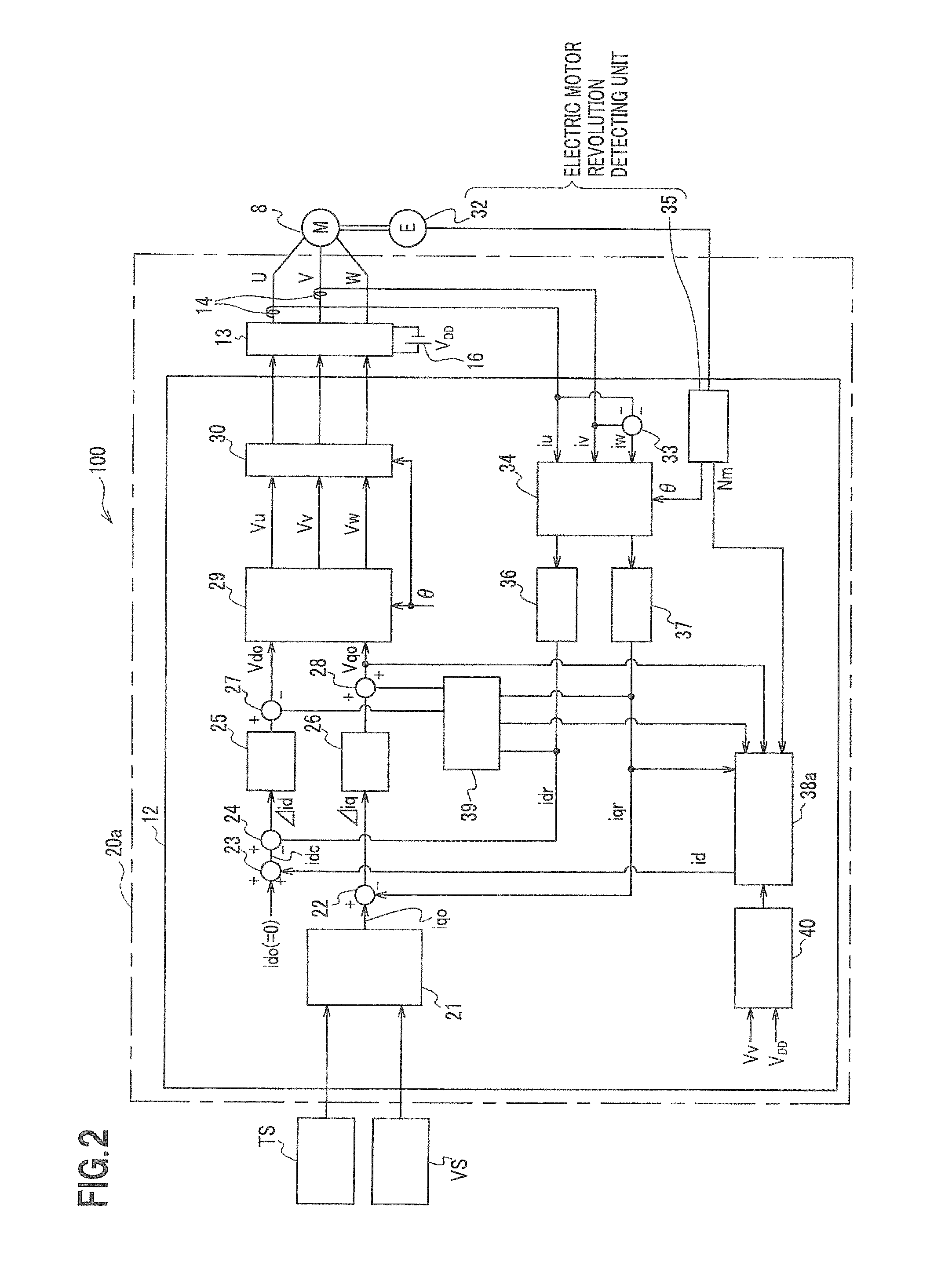

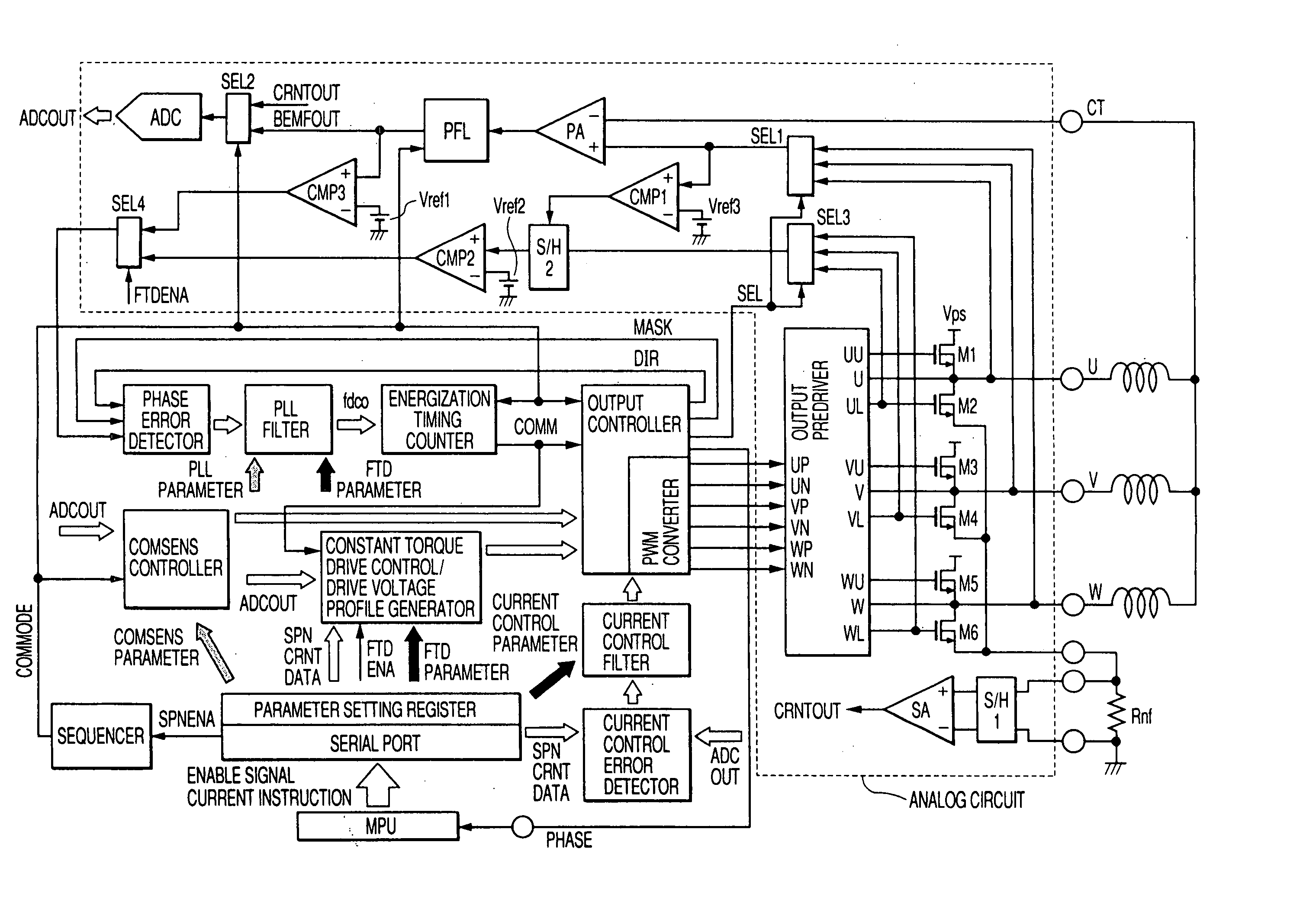

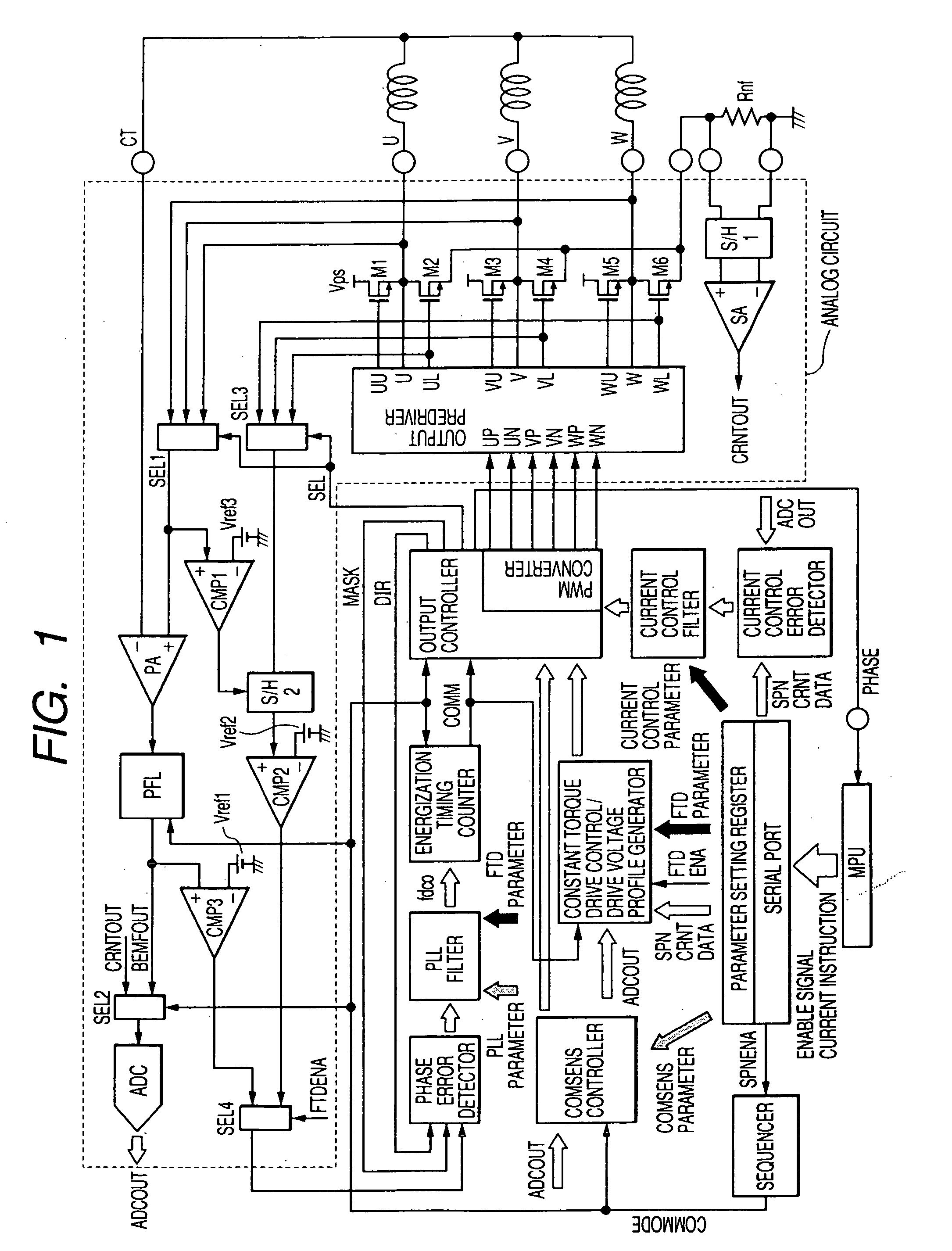

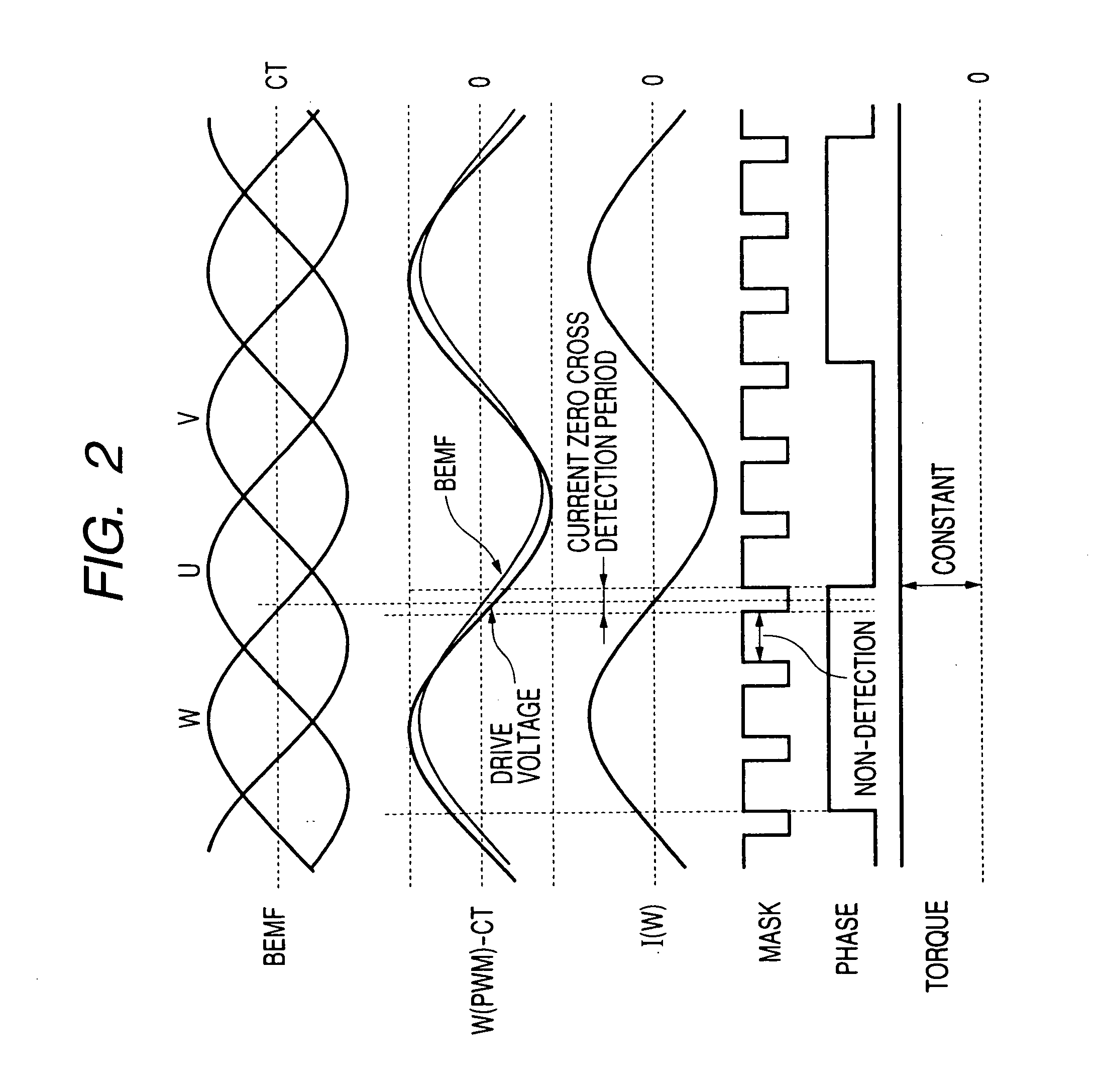

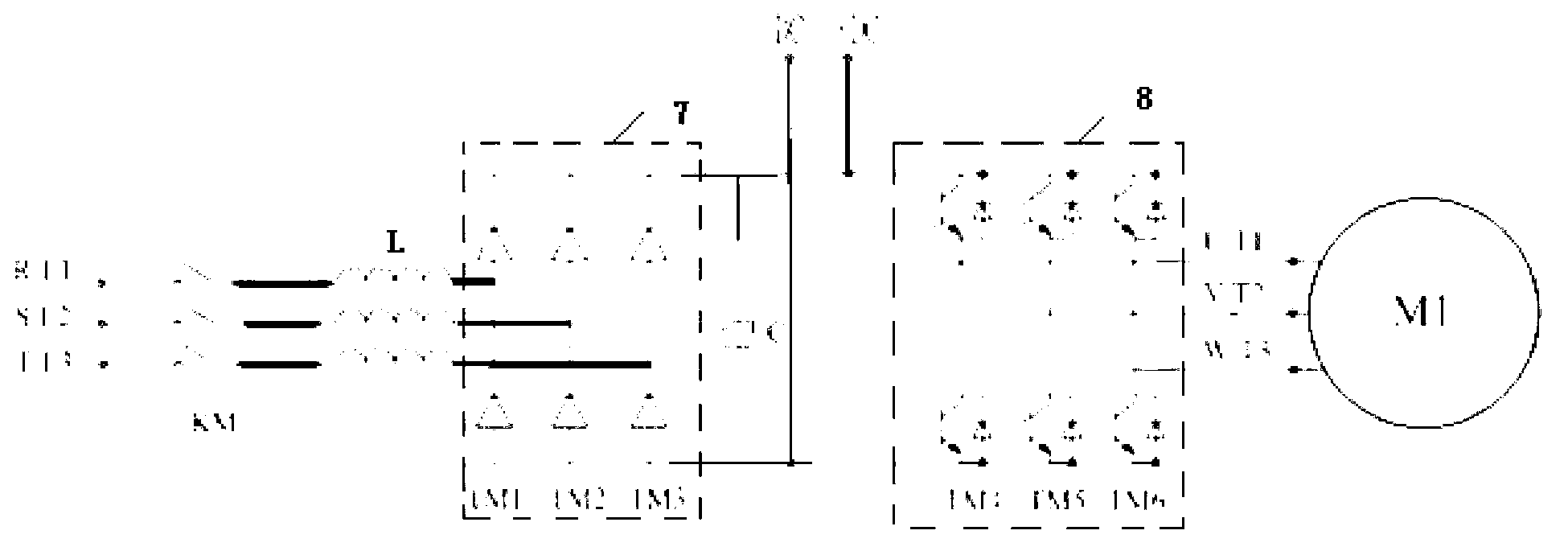

Motor drive device and integrated circuit device for motor driving

InactiveUS20050067986A1Improve accuracySimple configurationTorque ripple controlSynchronous motors startersMotor driveThree-phase

A three-phase DC motor output stage including a predriver that supplies drive voltages to power MOSFETs supplies output voltages to three-phase coils, monitors whether each of gate-to-source voltages of the power MOSFETs is greater than or equal to a predetermined voltage and thereby detects a current zero cross, and employs the output of such current zero cross detection in PLL control for controlling energization switching timing and thereby forms drive voltages of 180-degree energization. Lower hooks with a voltage minimum phase as GND and upper hooks with a voltage maximum phase as a source are set as patterns alternately repeated for every electrical angle of 60 degrees. The patterns are expressed in linear approximation to generate sine wave-like drive voltages, thereby causing sine wave-like currents to flow into the three-phase coils.

Owner:HITACHI HIGH-TECH CORP +1

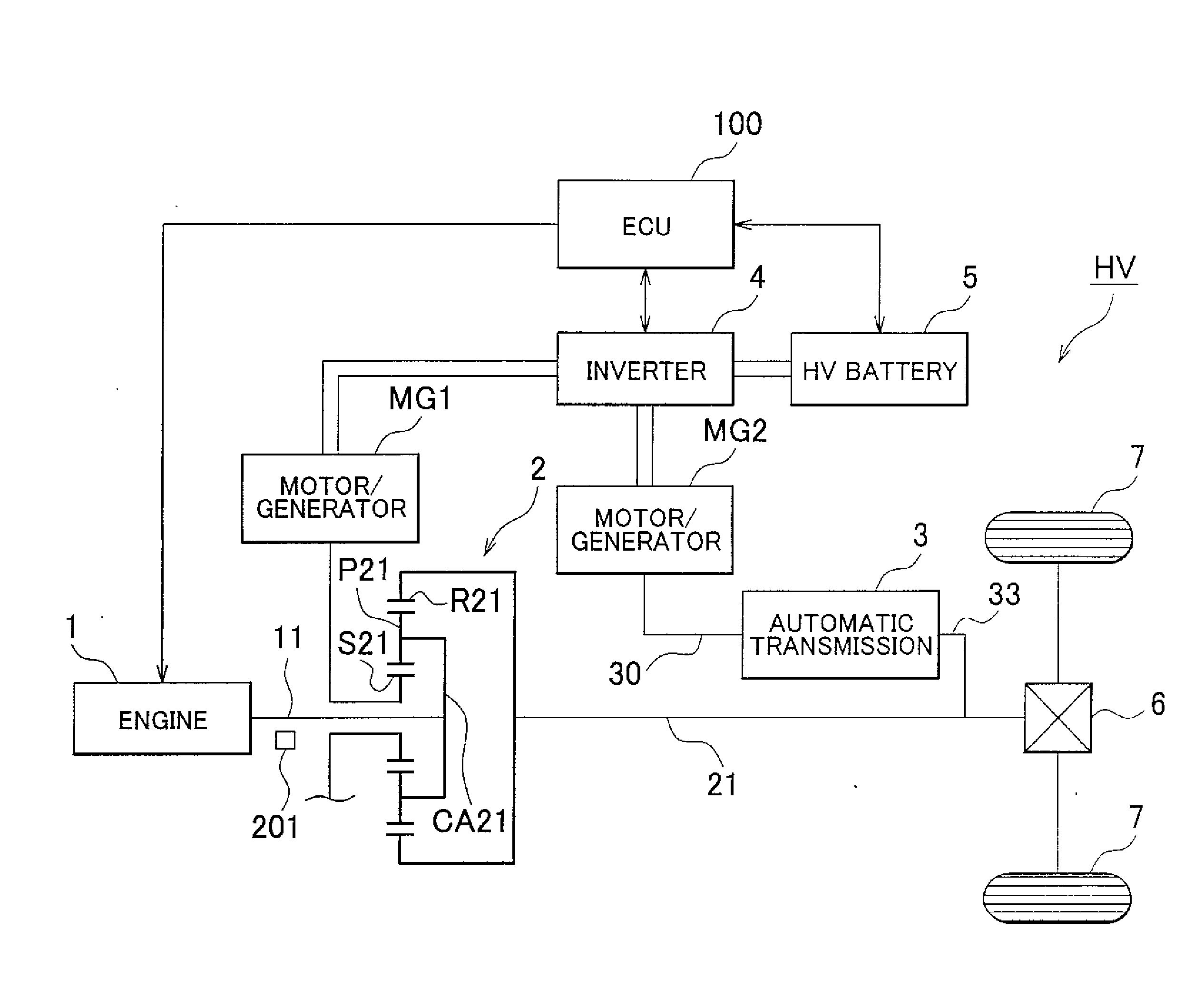

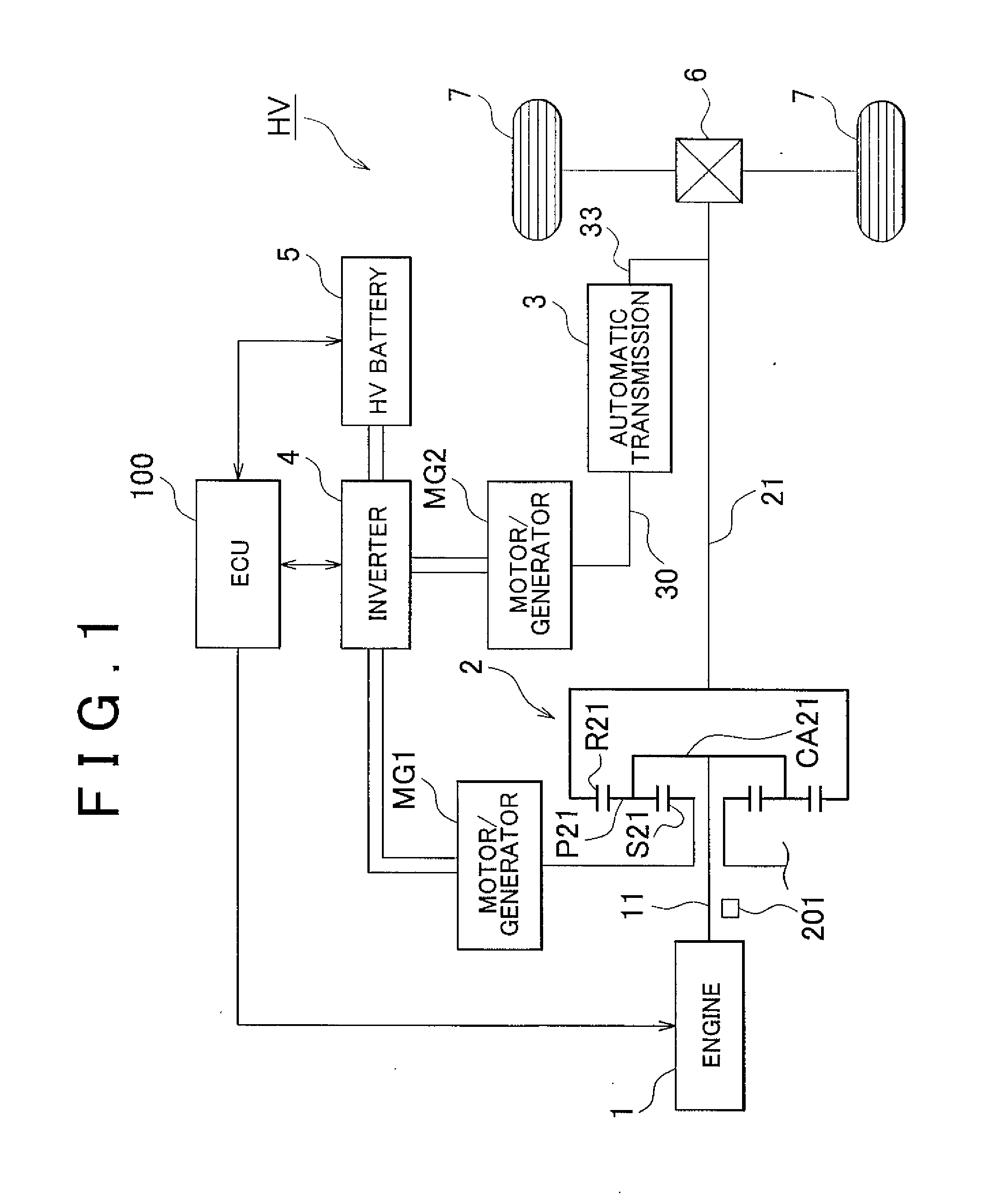

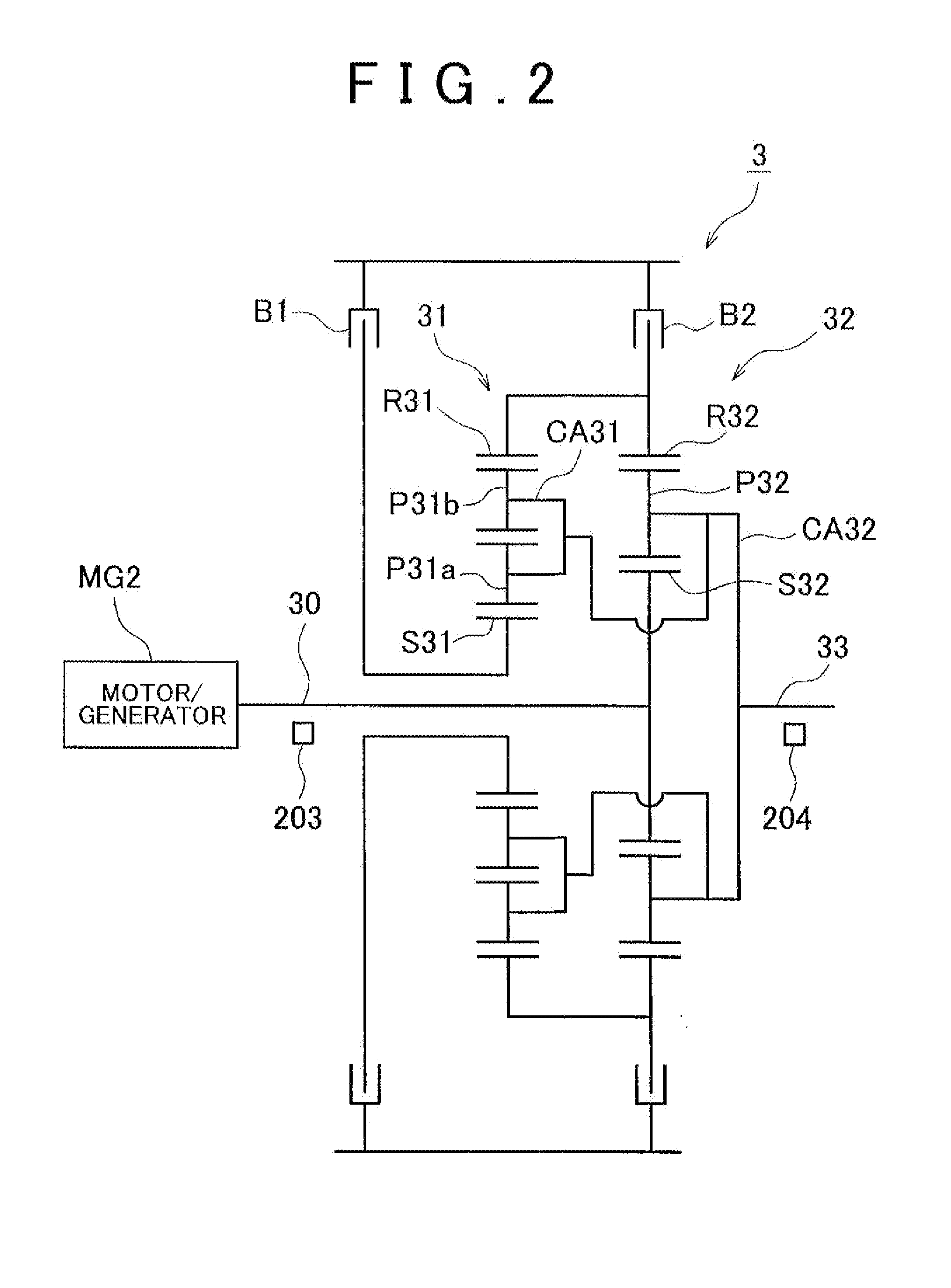

Vehicular control apparatus and control system

InactiveUS20080220933A1Reduce shockCutting synchronizationHybrid vehiclesSpeed controllerAutomatic transmissionTransmitted power

A control apparatus for a vehicle is provided with an electric motor that outputs driving force for running the vehicle; an automatic transmission that establishes a plurality of gears by selectively applying and releasing a plurality of friction apply elements in a predetermined combination for each gear among the plurality of gears, and transmits power from the electric motor to an output shaft of the vehicle; and a torque controlling portion which, when there is a demand for a power-off downshift, controls output torque of the electric motor such that input torque of the automatic transmission becomes constant torque during an inertia phase of that shift, and controls the output torque of the electric motor such that the output torque of the automatic transmission comes to match the torque required after the shift, after rotation synchronization by an apply-side friction apply element is complete.

Owner:TOYOTA JIDOSHA KK

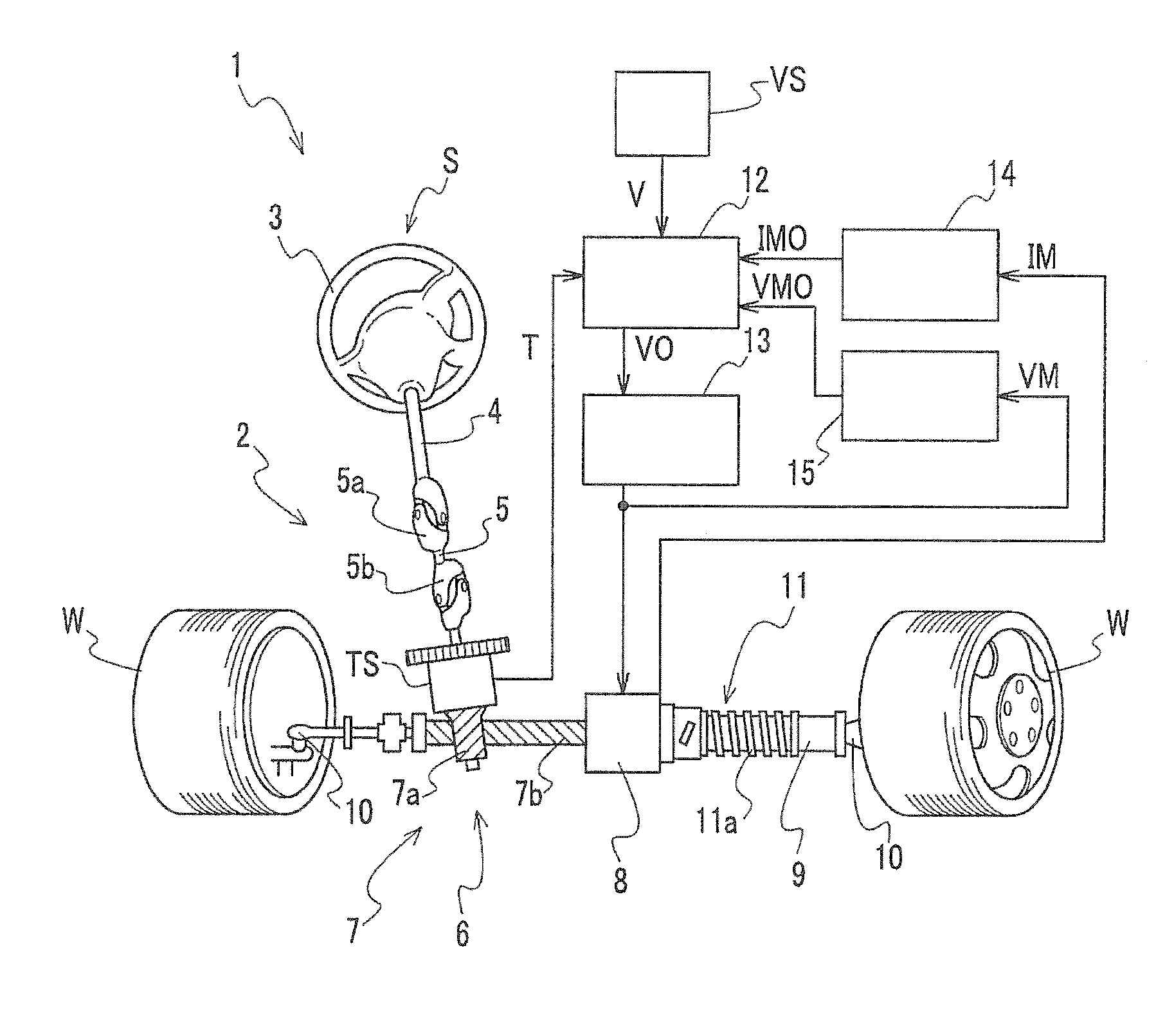

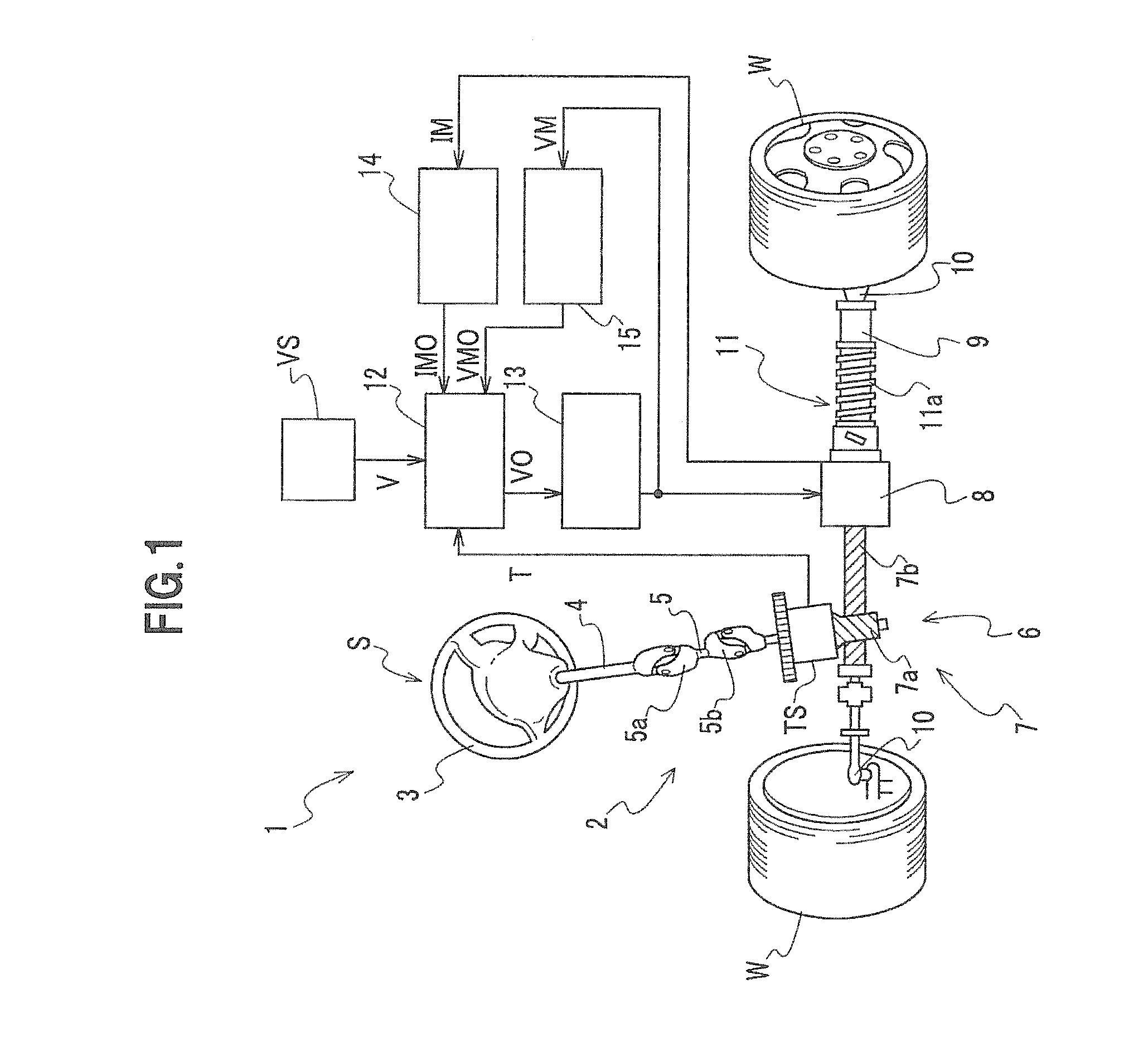

Electric power steering apparatus and electric motor driving controller used for the apparatus

InactiveUS20110231066A1Suppressing torque rippleIncrease rotation speedDigital data processing detailsSingle motor speed/torque controlElectric power steeringPower flow

A q-axis target current setting unit generates a q-axis current command value based on a steering input signal from a steering torque sensor and a vehicle speed signal from a vehicle speed sensor. An electric motor generates a predetermined torque based on the q-axis current command value and a q-axis current (a torque current) to which a fed back q-axis real current is added. On the other hand, a d-axis correction current setting unit sets a field weakening current (a d-axis current) in response to a voltage saturation (duty ratio=driving voltage of electric motor / power supply voltage) output from a voltage saturation calculating unit. For this reason, when the voltage saturation becomes high, distortion (harmonics component) in current can be decreased by decreasing the voltage saturation while keeping the torque constant using a predetermined torque current, and a torque ripple can be suppressed.

Owner:HONDA MOTOR CO LTD

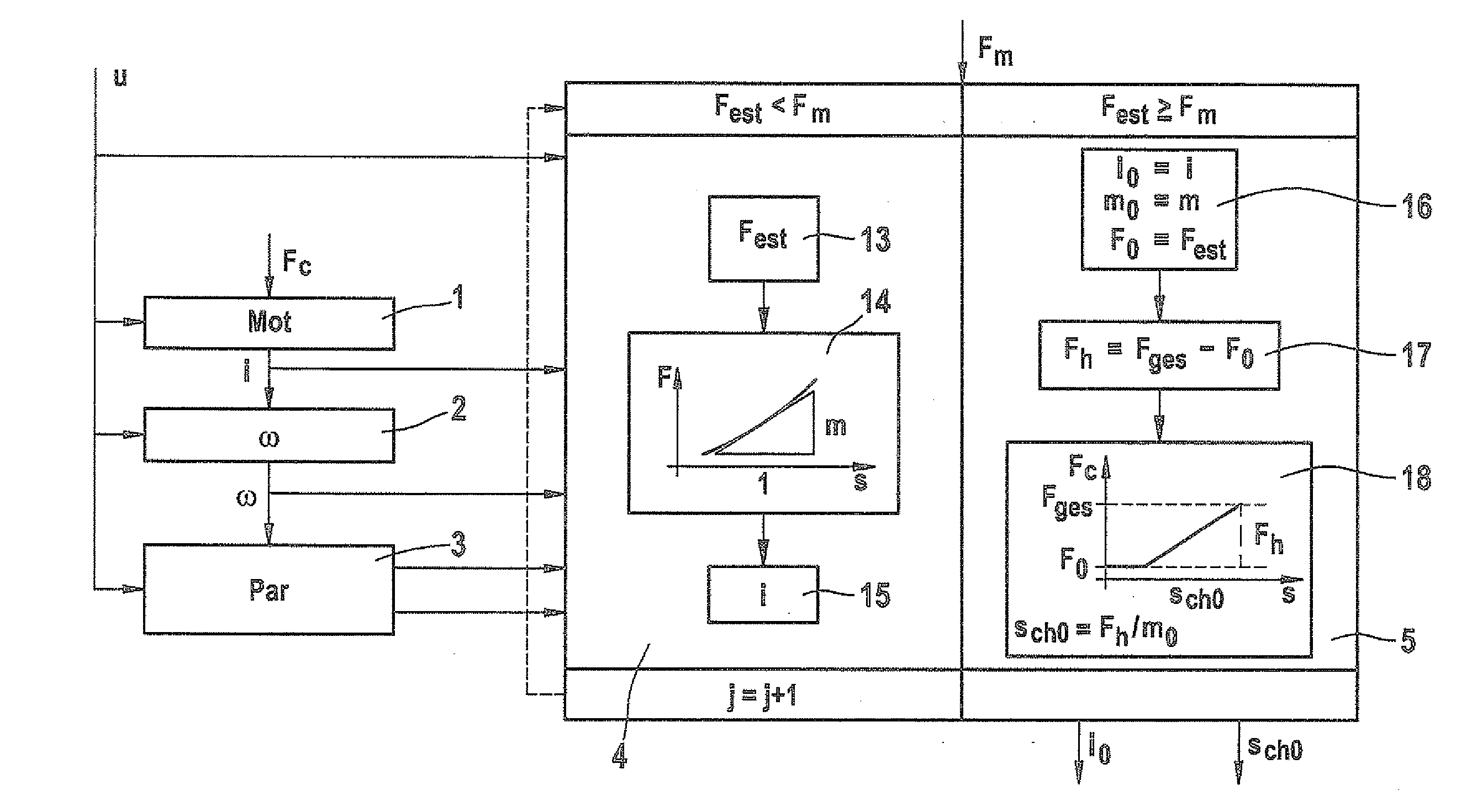

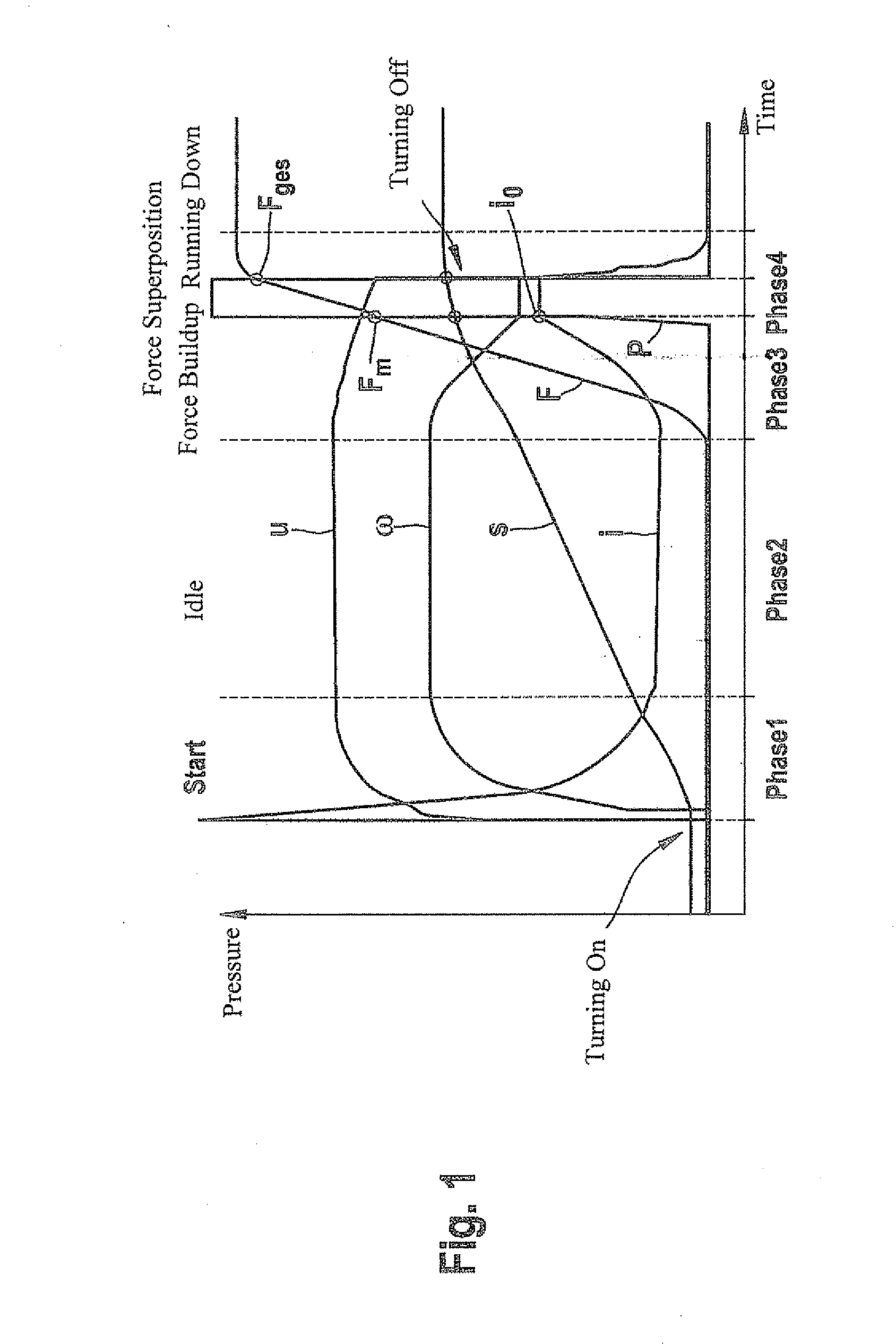

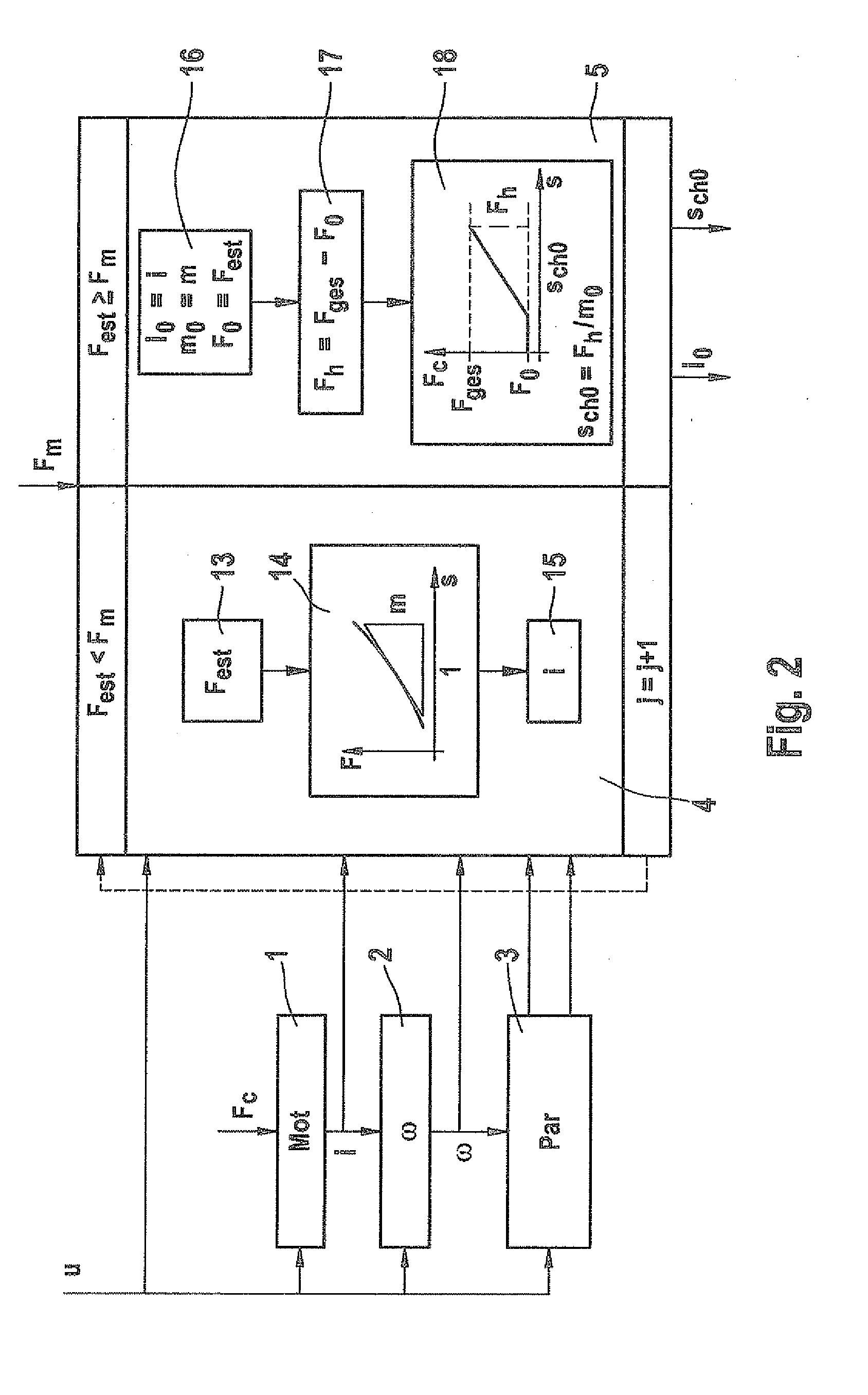

Method for setting the clamping force of a hydraulically supported electric motor-driven parking brake

ActiveUS20120205202A1Constant torqueAccurate calculationBraking action transmissionBrake actuating mechanismsApplication procedureEngineering

A method for setting the clamping force acting on a wheel brake, a part of the clamping force being provided using an electromechanical brake device and simultaneously another part of the clamping force being provided using a hydraulic brake device. During an application procedure, the power consumption of the electric motor-driven brake device is regulated to an essentially constant value in an operating phase (phase 4), in which both brake devices simultaneously exert force, so as to set the clamping force of the parking brake very precisely.

Owner:ROBERT BOSCH GMBH

Motor drive device and integrated circuit device for motor driving

ActiveUS20060158142A1Simple configurationImprove performanceTorque ripple controlAC motor controlMotor driveEngineering

A three-phase DC motor output stage including a predriver that supplies drive voltages to power MOSFETs supplies output voltages to three-phase coils, monitors whether each of gate-to-source voltages of the power MOSFETs is greater than or equal to a predetermined voltage and thereby detects a current zero cross, and employs the output of such current zero cross detection in PLL control for controlling energization switching timing and thereby forms drive voltages of 180-degree energization. Lower hooks with a voltage minimum phase as GND and upper hooks with a voltage maximum phase as a source are set as patterns alternately repeated for every electrical angle of 60 degrees. The patterns are expressed in linear approximation to generate sine wave-like drive voltages, thereby causing sine wave-like currents to flow into the three-phase coils.

Owner:RENESAS ELECTRONICS CORP

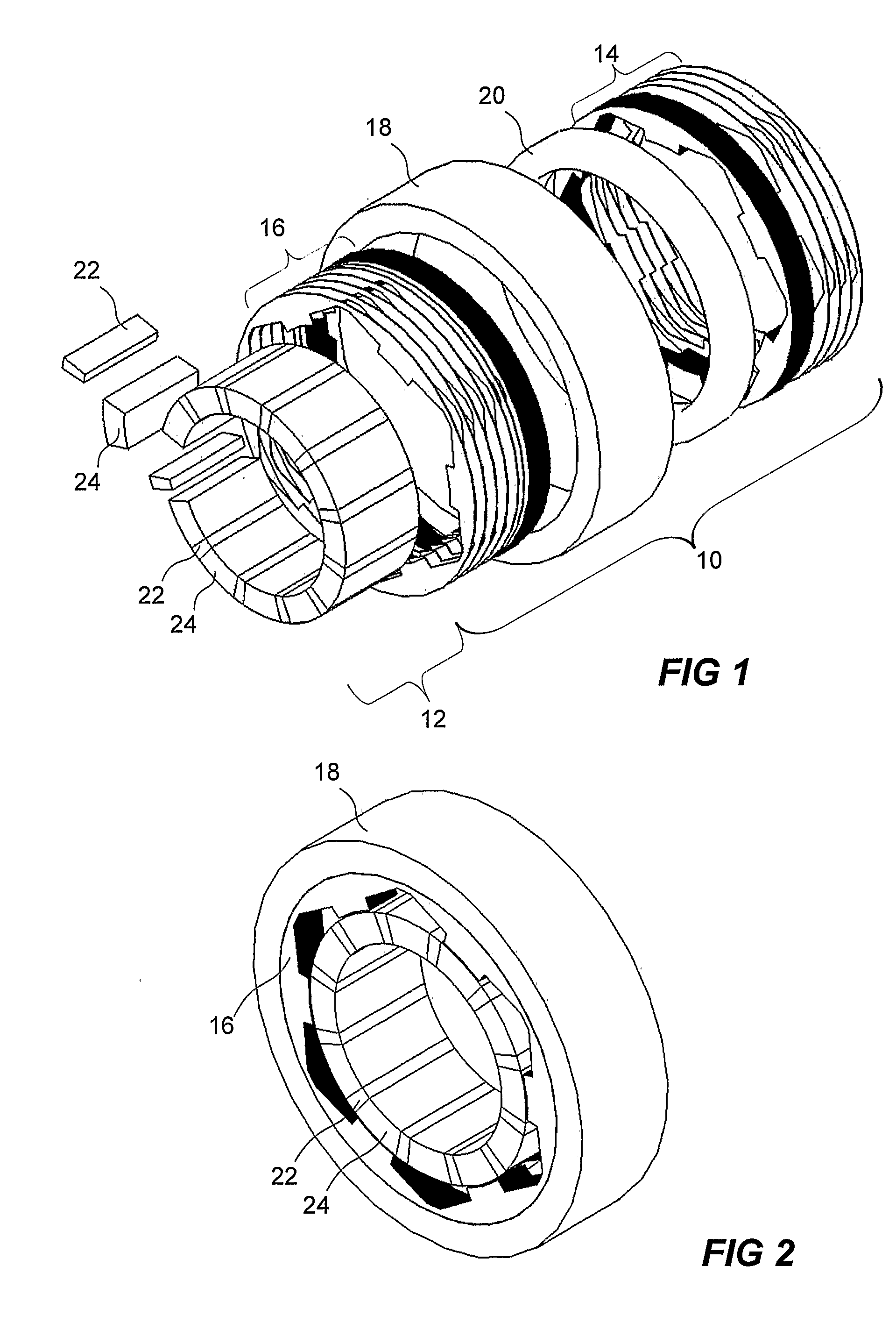

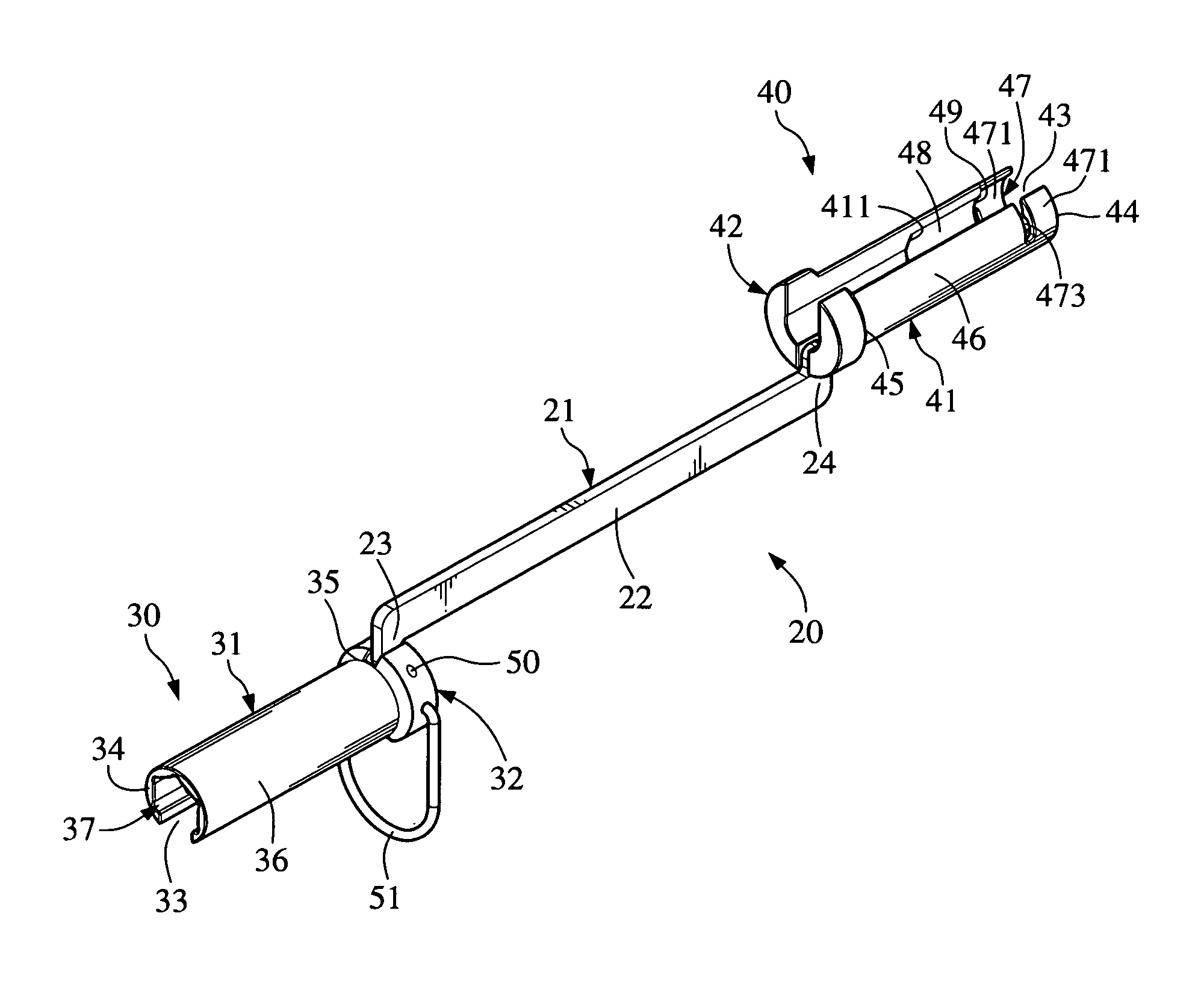

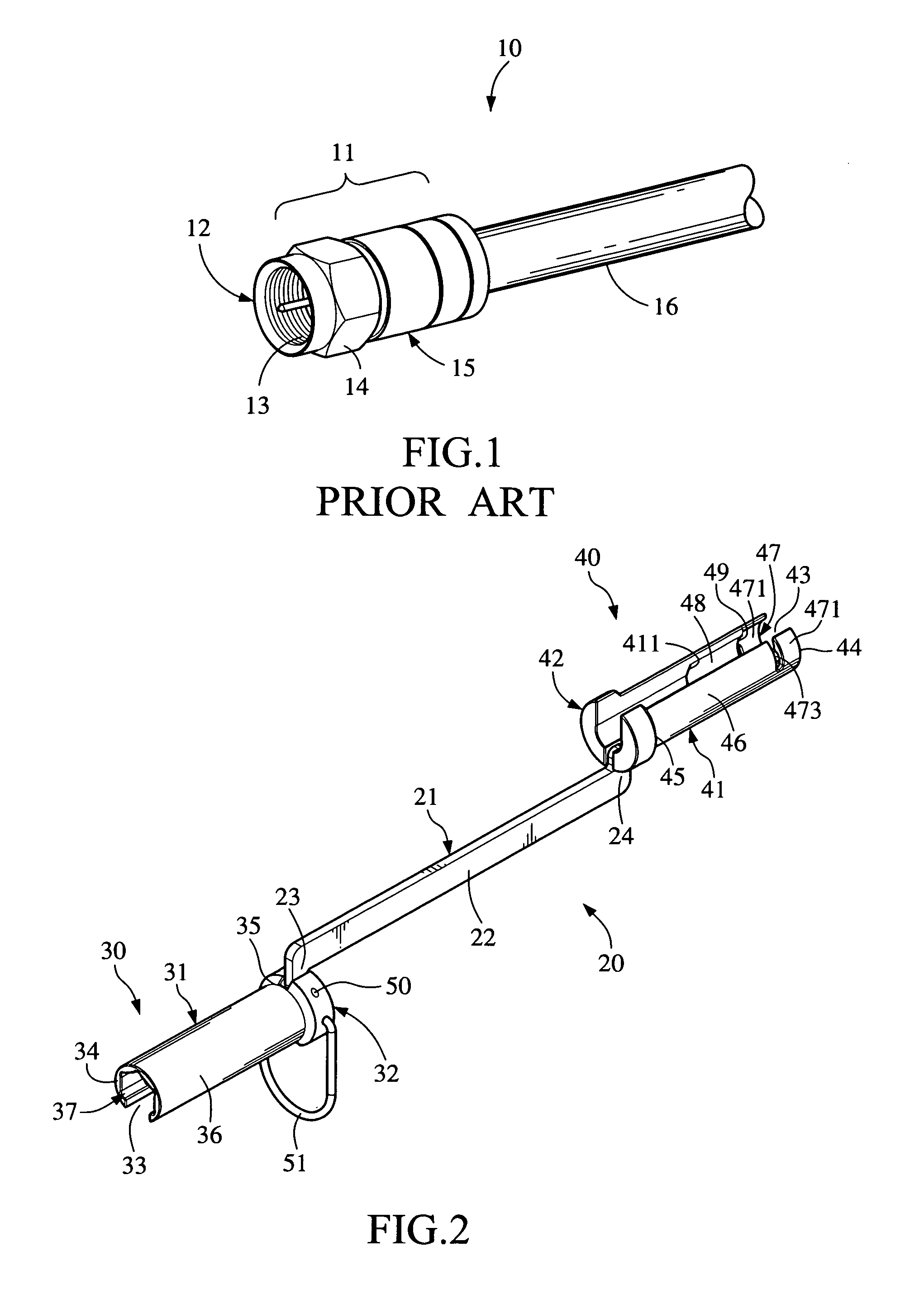

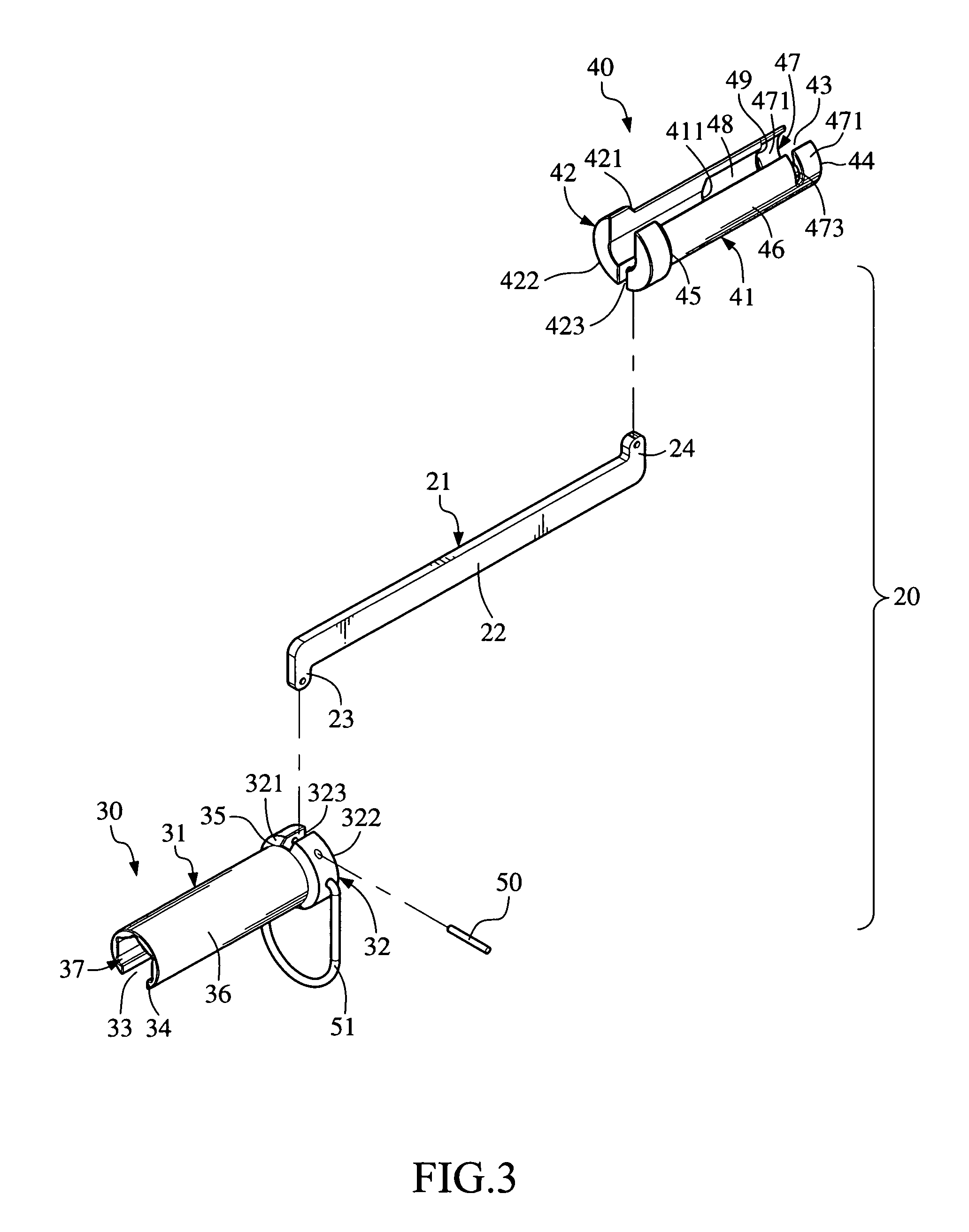

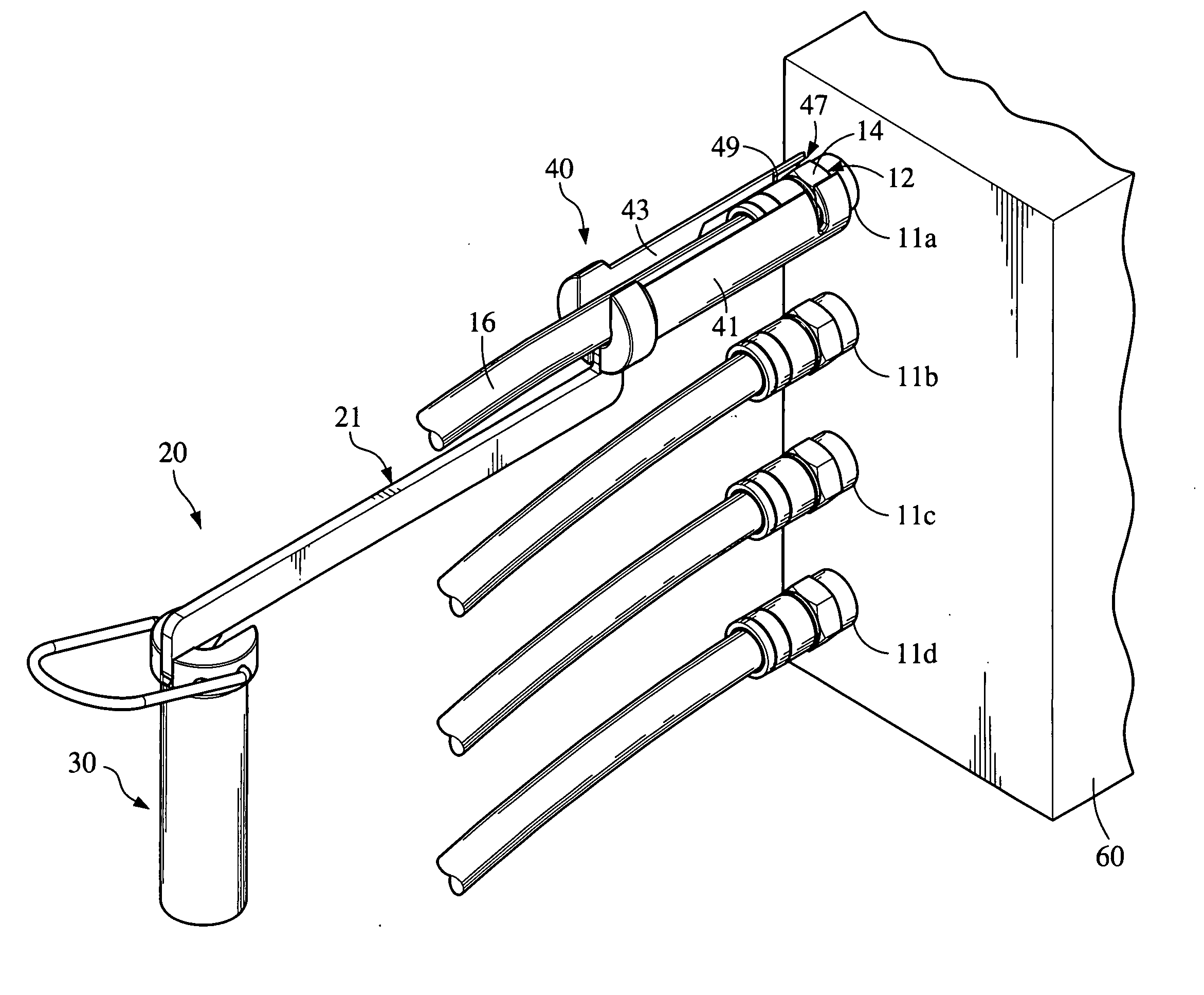

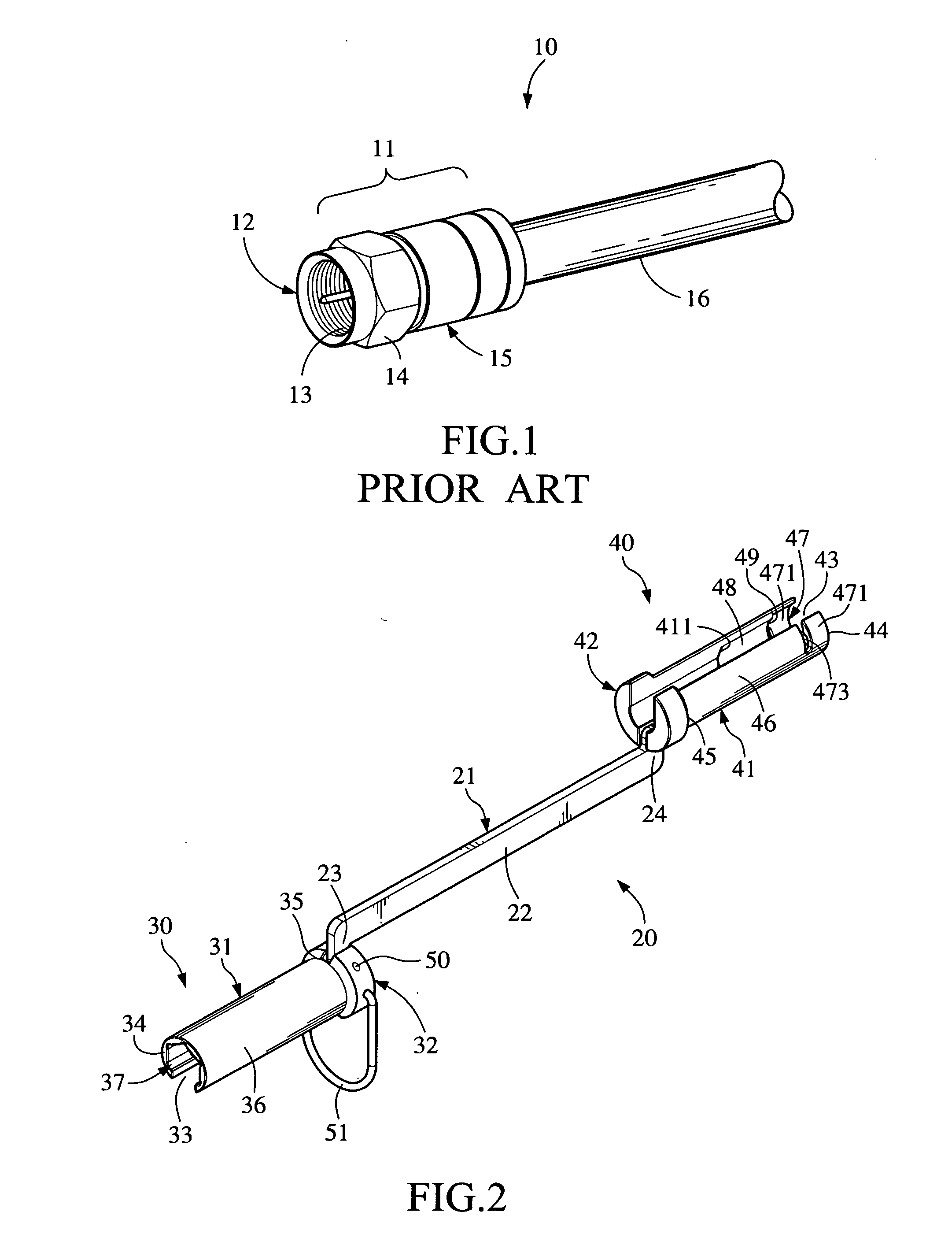

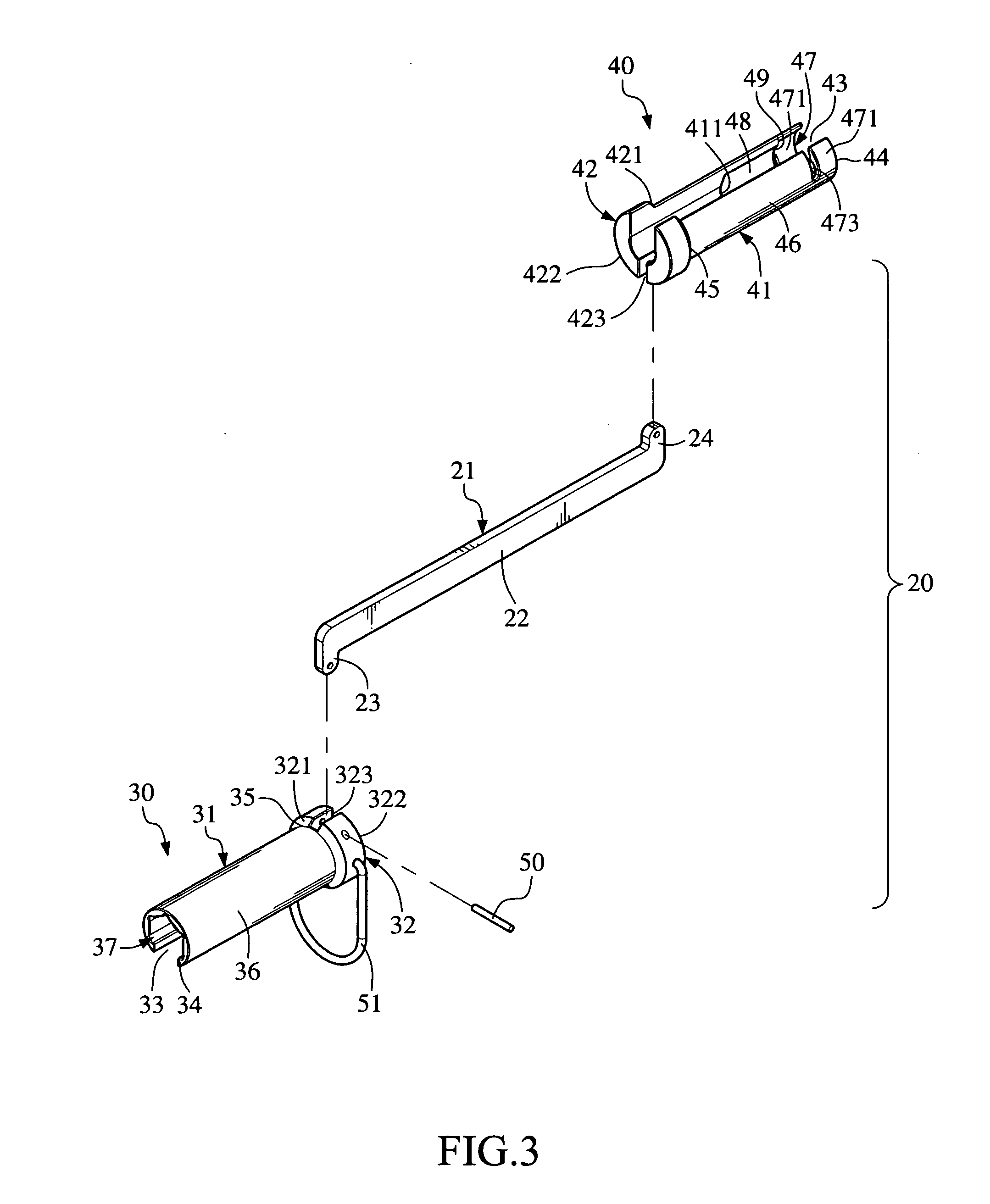

Tool for installing and removing male F-type coaxial cable connector

InactiveUS7975578B2Constant torqueSimply usedCoupling device engaging/disengagingTwo-part coupling devicesEngineeringElectric cables

A tool includes a first and a second socket wrench pivotally turnably connected to two ends of a link. Each of the first and second socket wrenches includes a wrench portion and a circular end portion having an axial slot extended through them. The wrench portion of the first socket wrench is internally formed of a hexagonally shaped portion for fitting around a hexagonally-shaped outer surface of a connecting ring of a male F connector to tighten or loosen the connecting ring to or from a female F connector, and the wrench portion of the second socket wrench is internally formed of a constant-torque shaped portion for fitting around the hexagonally-shaped outer surface of the connecting ring to prevent the tool from applying an excessive torque on the connecting ring when turning the same. The tool can be used without being hindered by bent or closely arranged cables.

Owner:PHOENIX COMM TECH INT

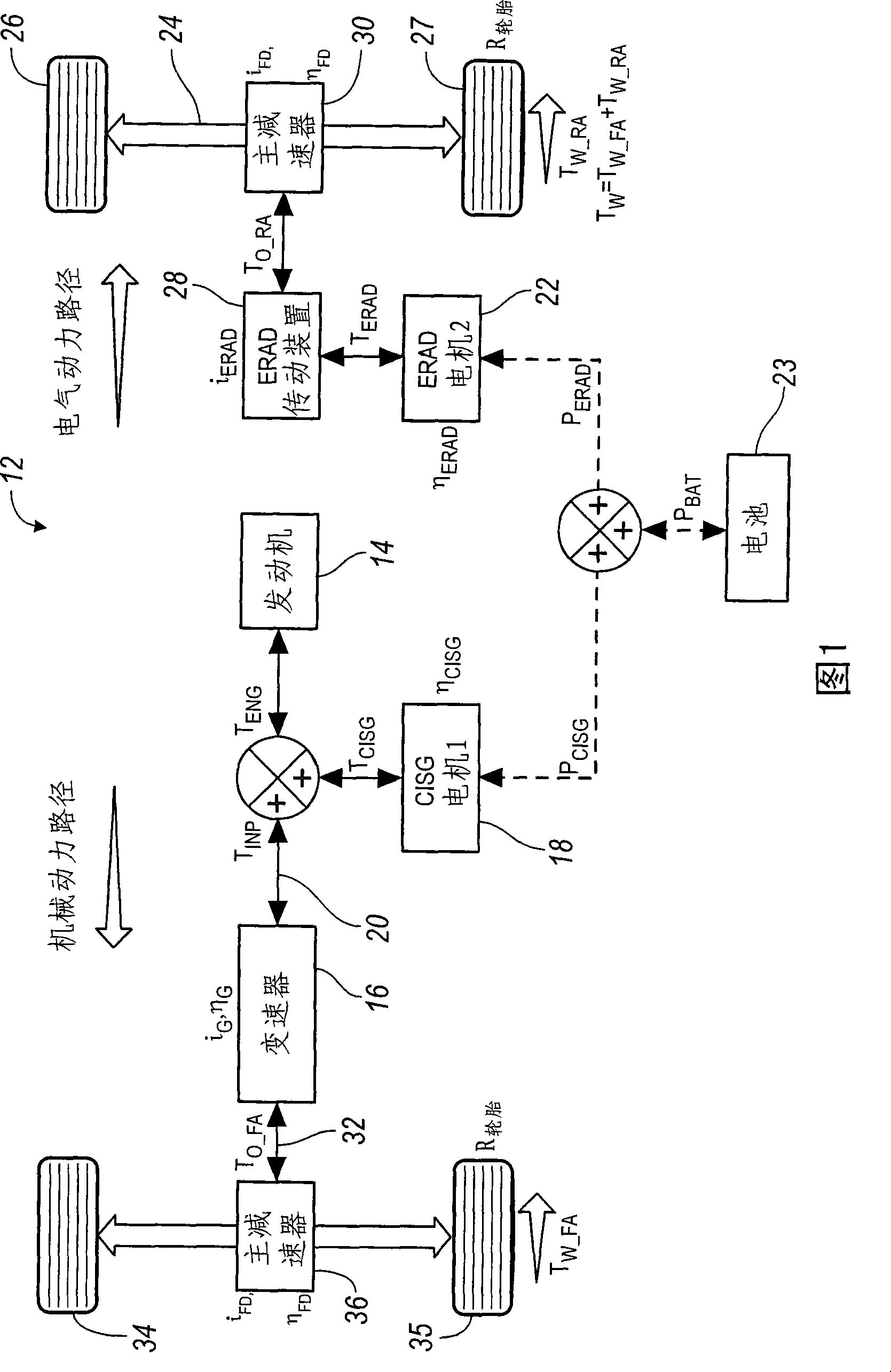

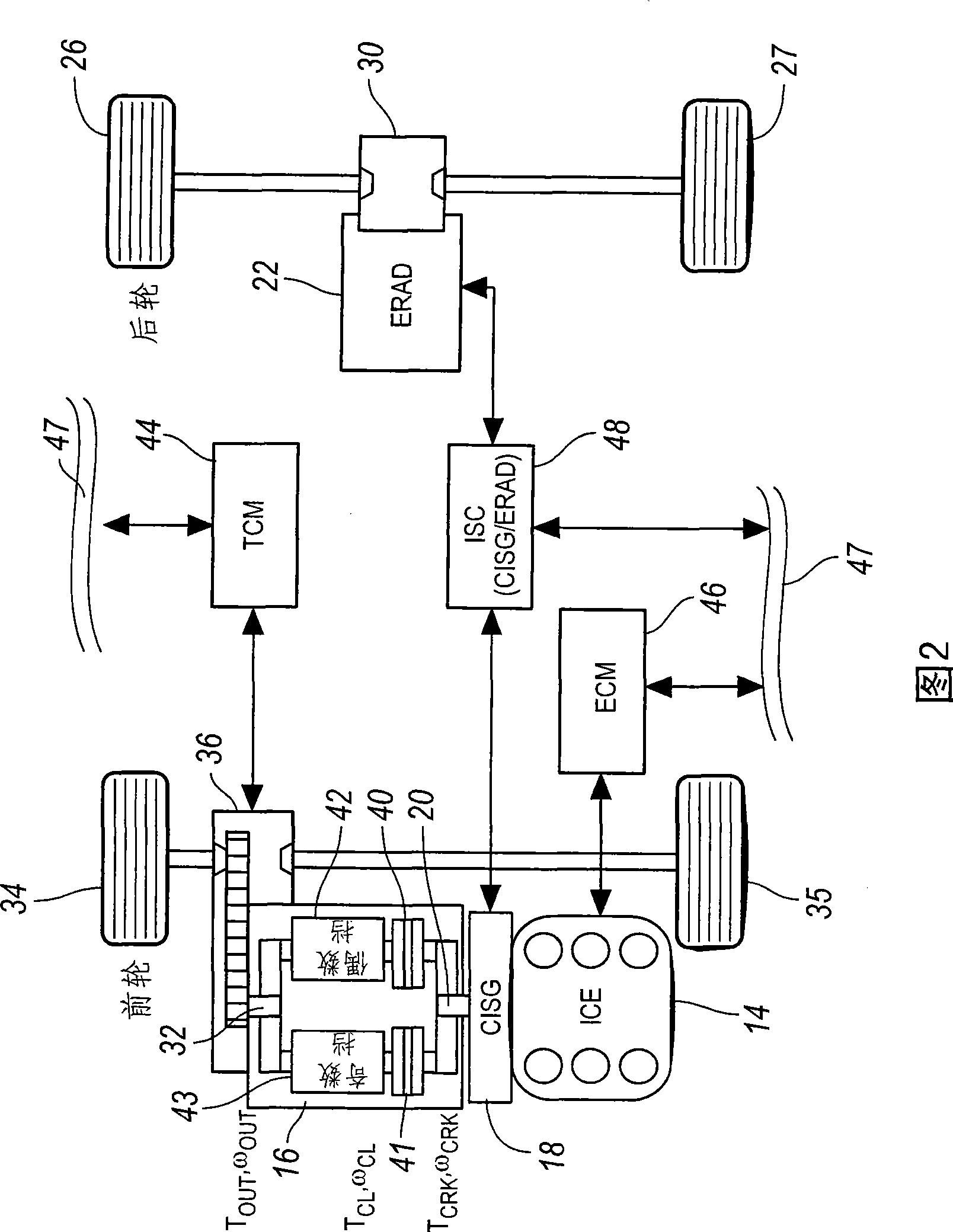

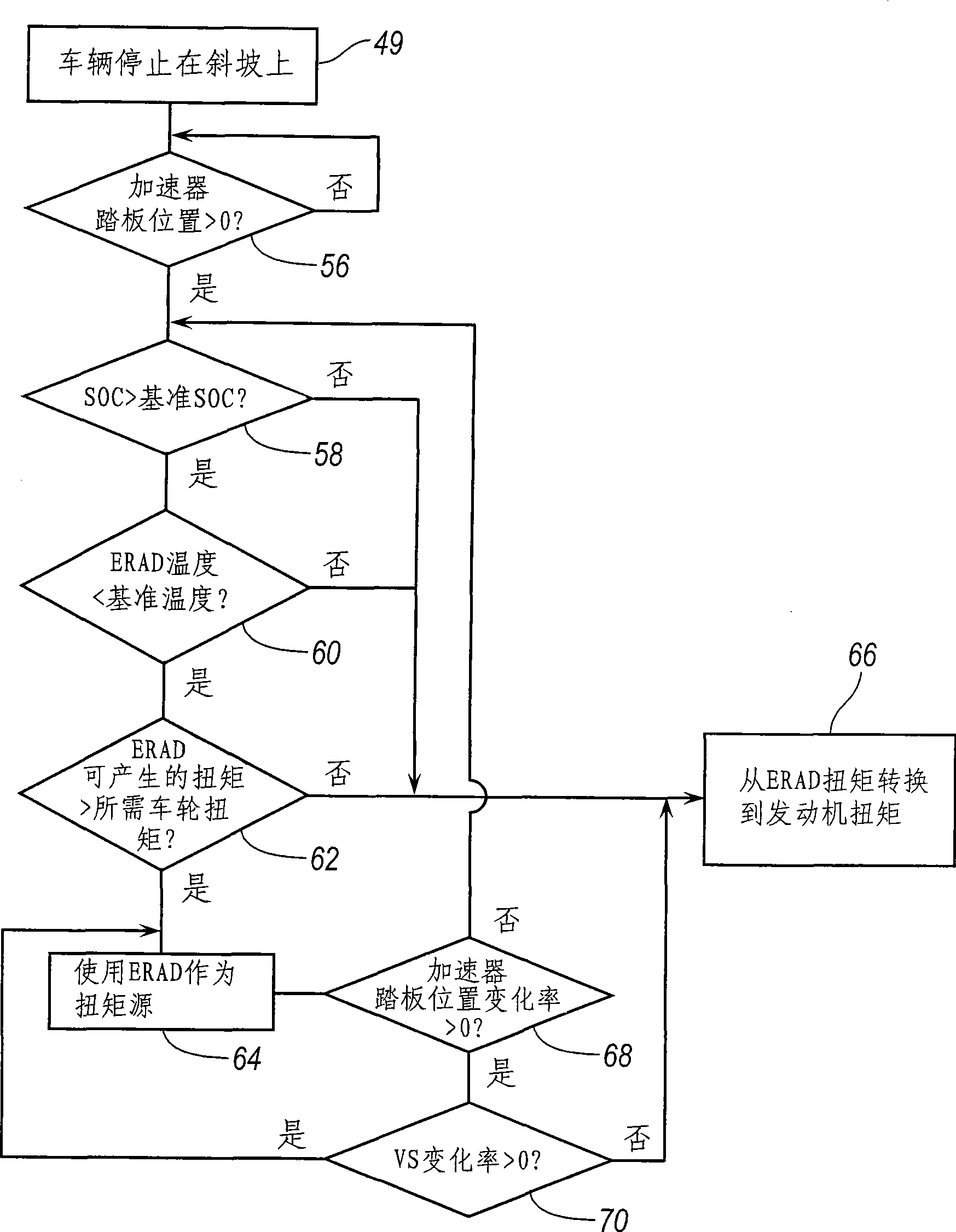

Rollback control of a hybrid electric vehicle

InactiveCN101367339AConstant torquePrevent slippingVehicle sub-unit featuresEngine controllersElectric machineDrivetrain

Owner:FORD GLOBAL TECH LLC

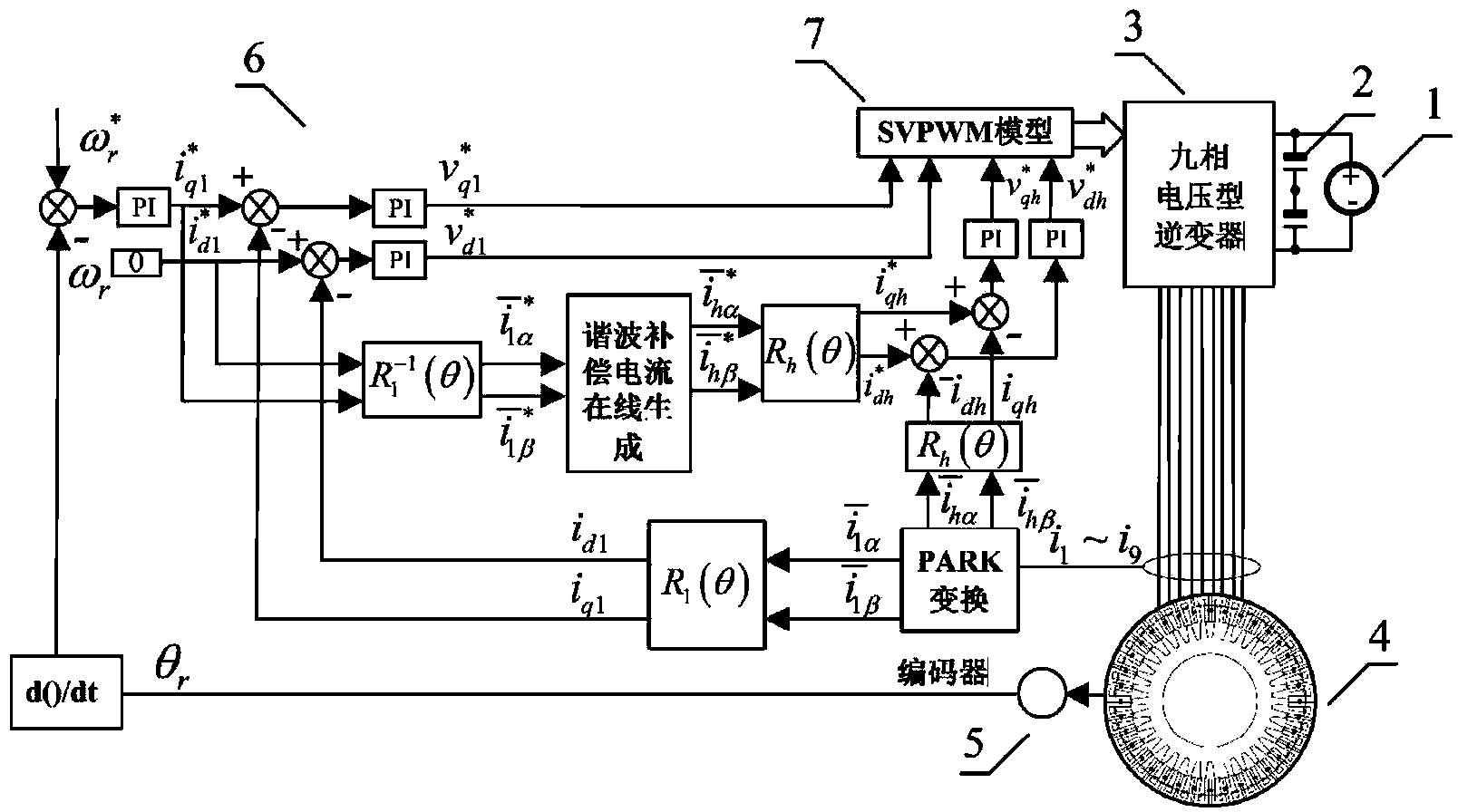

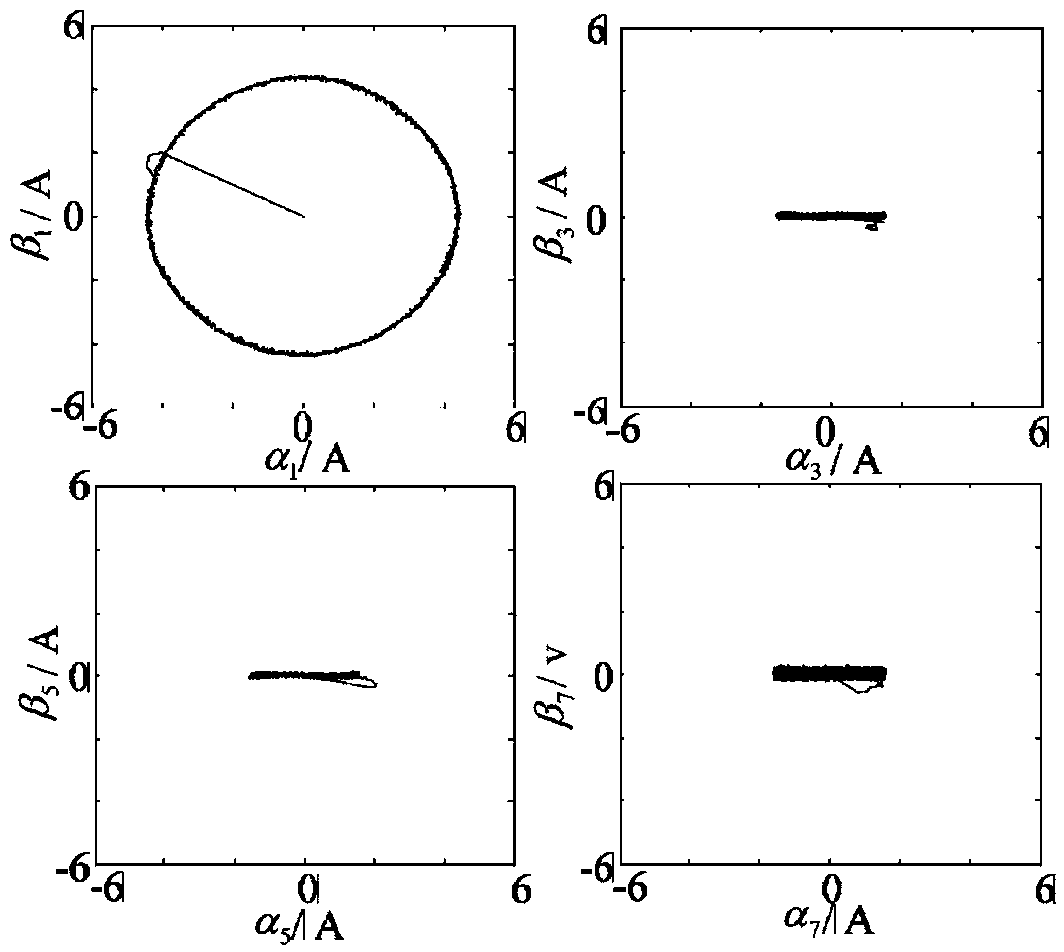

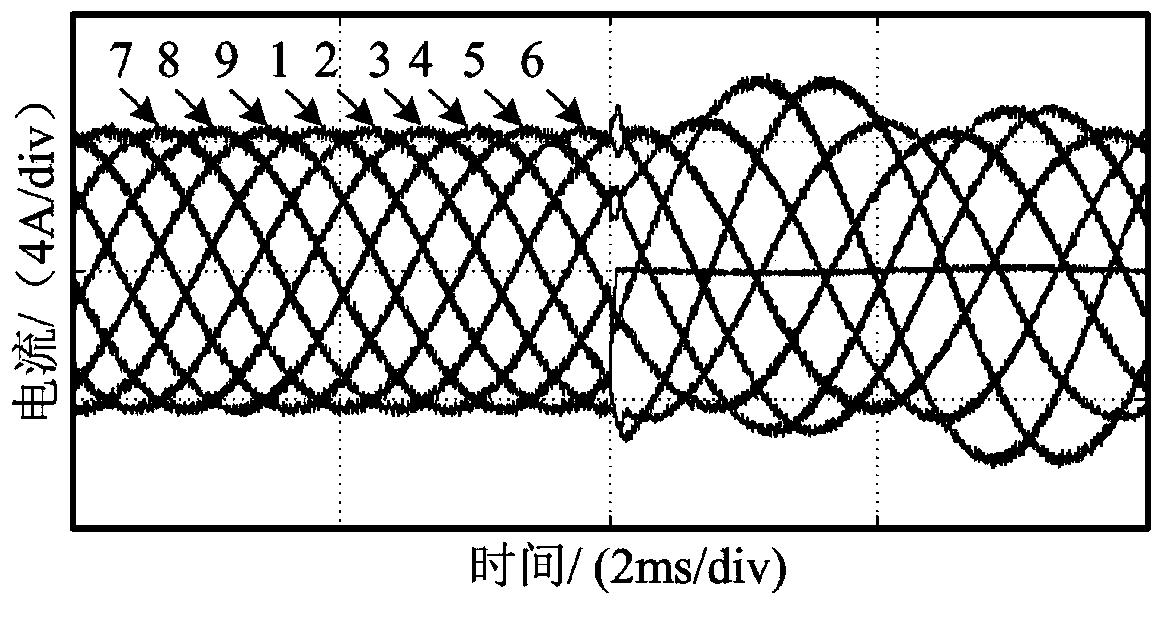

Default phase fault-tolerant control method of nine-phase flux-switching permanent magnetic motor

ActiveCN103973191ARealize no static difference adjustmentThe output speed does not changeElectronic commutation motor controlVector control systemsHarmonicElectric machine

The invention discloses a default phase fault-tolerant control method of a nine-phase flux-switching permanent magnetic motor. The default phase fault-tolerant control method includes that redundancy characteristics and harmonic current of a nine-phase system are utilized to compensate a fault-tolerant control strategy; when a motor winding or a driving system is in a default-phase failure caused by one-phase circuit breaking or circuit shorting, by online calculating third, fifth and seventh harmonic current momentary values under copper loss minimum boundary conditions in real time and performing closed-loop decoupling control on the harmonic current, the motor can be smoothly transited from a nine-phase normal state to an eight-phase fault state and maintain both output rotating speed and rotating torque to be unchanged, undisturbed running of the driving system is realized, and requirements, of high-reliability application fields like track traffic and electromobiles, on system continuous running capability are met; during designing of the nine-phase flux-switching permanent motor, electromagnetic torque pulsation rate is lowered while high torque density of the special motor is retained.

Owner:SOUTHEAST UNIV

Tool for installing and removing male F-type coaxial cable connector

ActiveUS20100282030A1Easy to useConstant torqueCoupling device engaging/disengagingTwo-part coupling devicesEngineeringElectric cables

A tool includes a first and a second socket wrench pivotally turnably connected to two ends of a link. Each of the first and second socket wrenches includes a wrench portion and a circular end portion having an axial slot extended through them. The wrench portion of the first socket wrench is internally formed of a hexagonally shaped portion for fitting around a hexagonally-shaped outer surface of a connecting ring of a male F connector to tighten or loosen the connecting ring to or from a female F connector, and the wrench portion of the second socket wrench is internally formed of a constant-torque shaped portion for fitting around the hexagonally-shaped outer surface of the connecting ring to prevent the tool from applying an excessive torque on the connecting ring when turning the same. The tool can be used without being hindered by bent or closely arranged cables.

Owner:PHOENIX COMM TECH INT

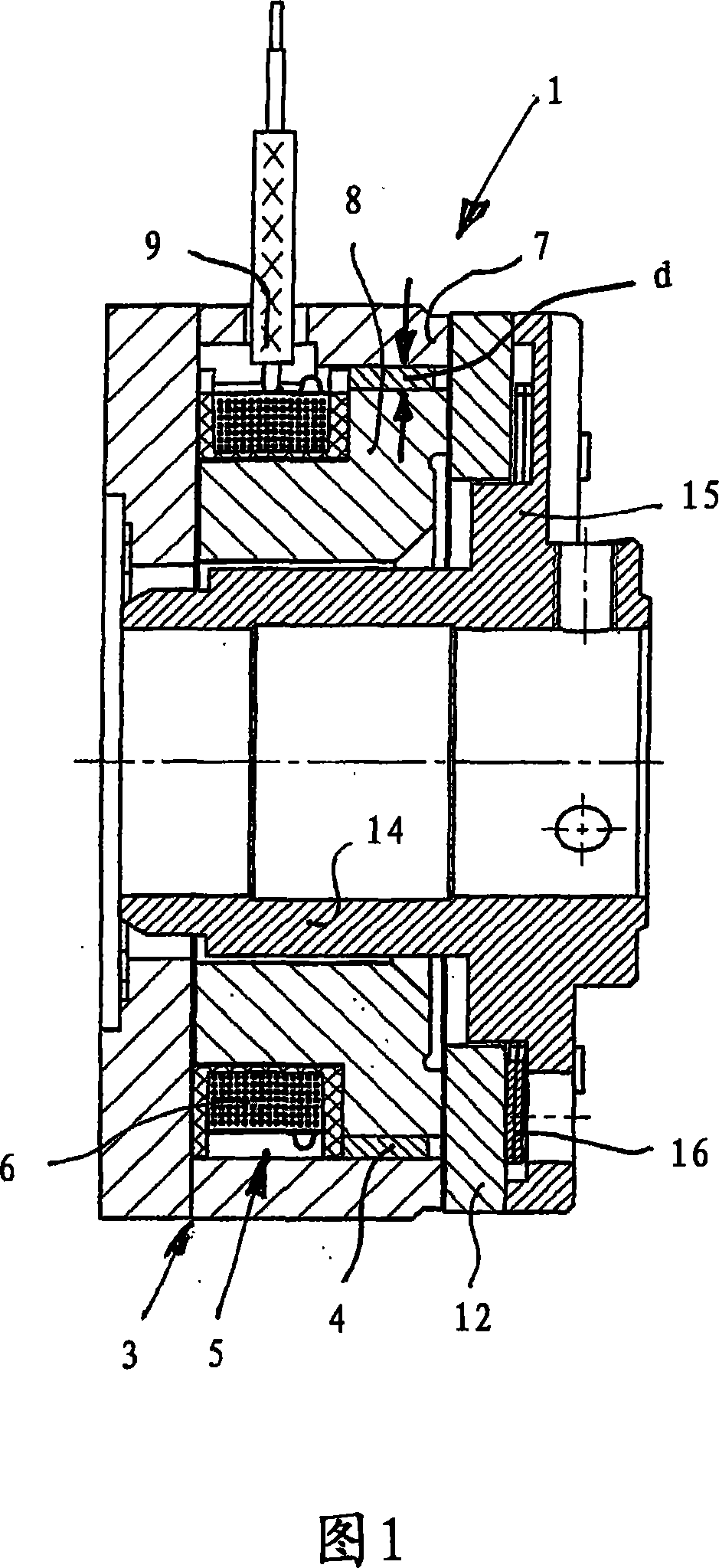

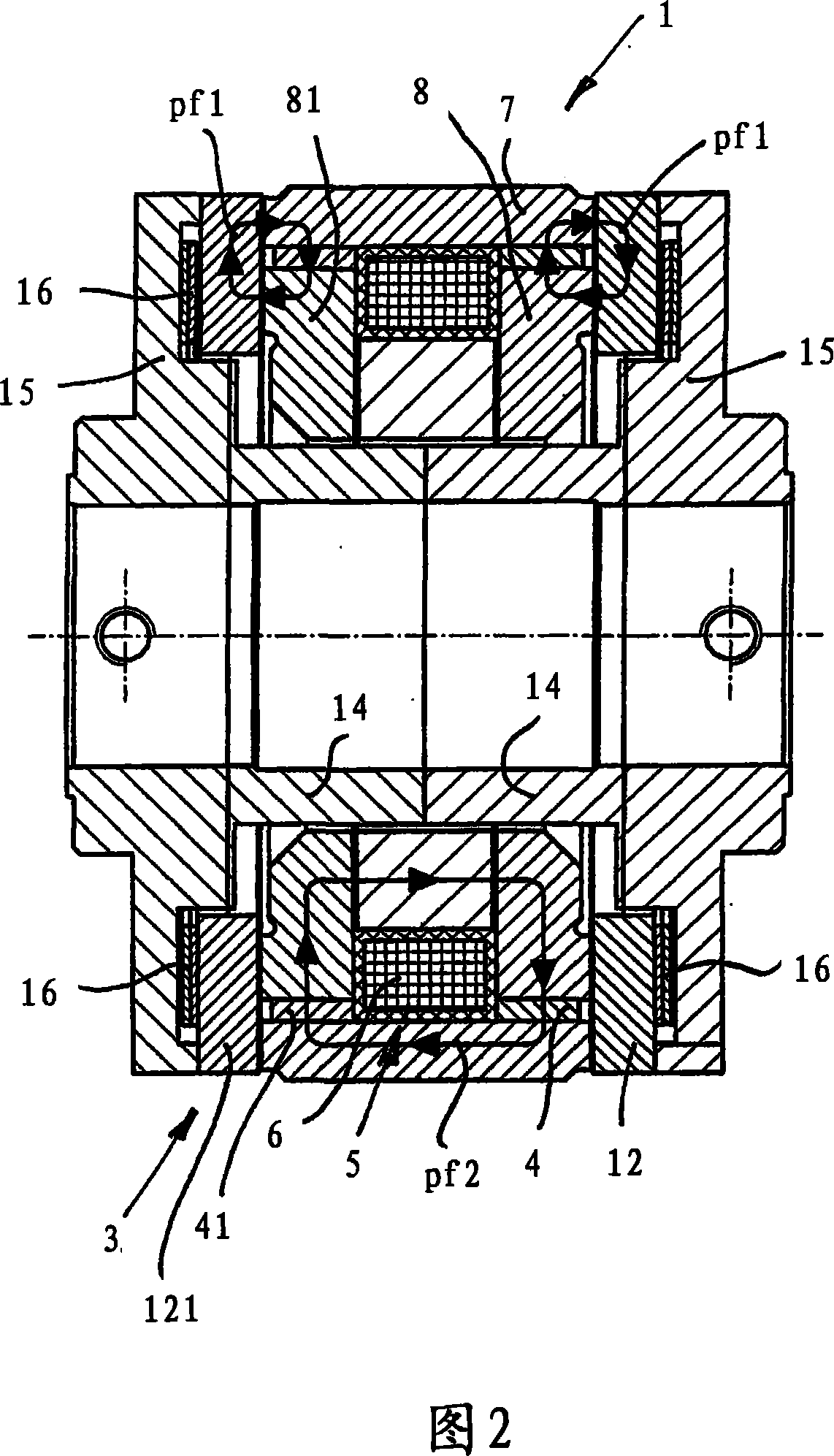

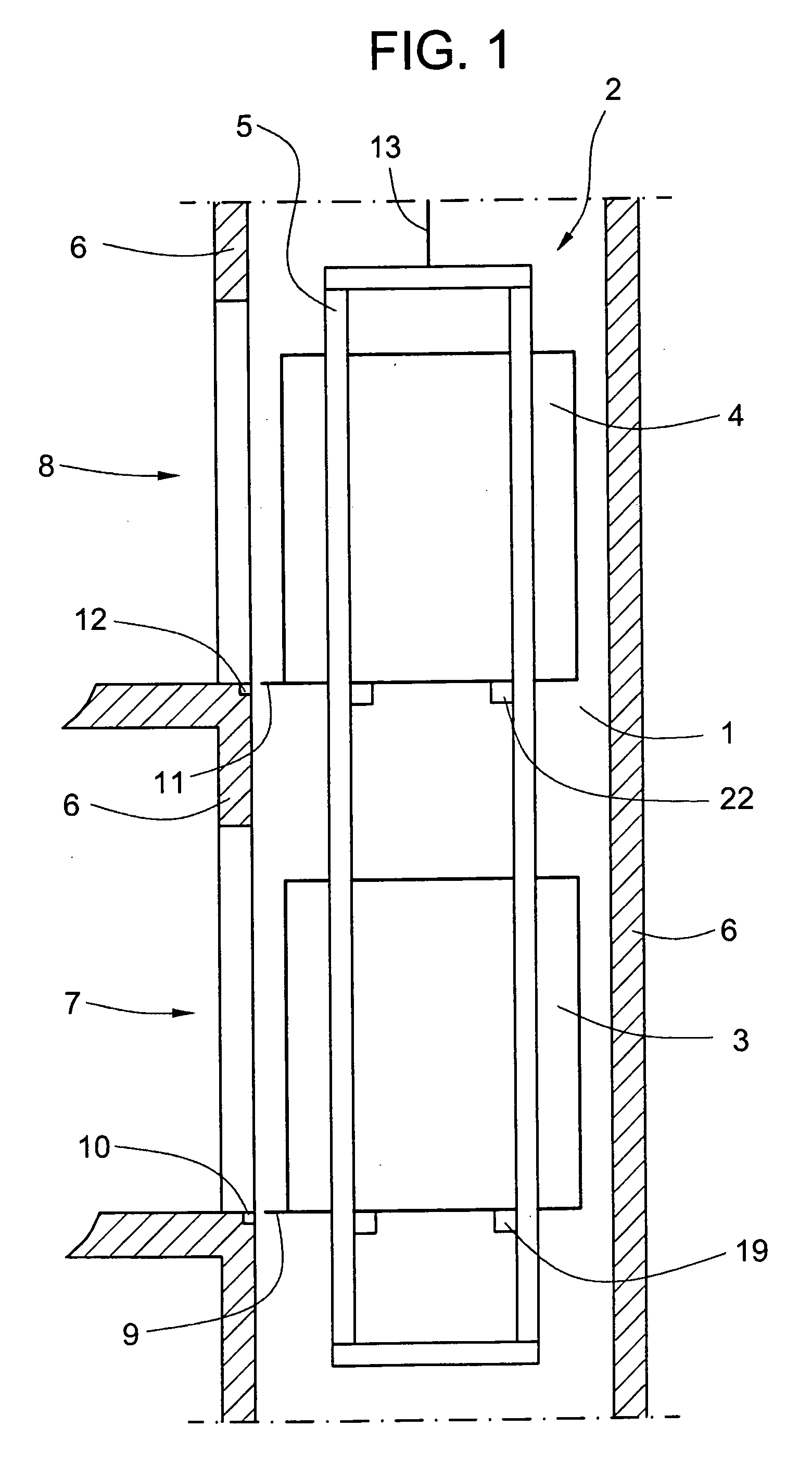

Electromagnetic permanent magnet brake

ActiveCN101115937AConstant torqueRaise or enlarge the magnet surfaceAxially engaging brakesBrake actuating mechanismsMagnetic tension forceSpring force

An electromagnetic brake (20), in particular for an electric drive is provided, having a brake body (3), which is provided with a sleeve-shaped permanent magnet (4), an electromagnet (5) with an exciting coil (6), an external ring in the form of an external pole and an internal ring (8) in the form of an internal pole, wherein an armature disc (12) rotatably connected to a shaft is attractable against the brake body (3) or the external or internal ring surfaces by the permanent magnet (4) force acting against a return spring force. When the exciting coil is powered, the permanent magnet (4) magnetic field is compensated in such a way that the armature disc (12) is lifted up from the brake body (3) by the spring force, thereby allowing the brake to be released. A radial cross-sectional dimension or cross-sectional thickness d of the permanent magnet (4) is smaller than the axial dimension thereof and a spatial arrangement, viewed in the axial direction, is provided between the armature disc (12) and the exciting coil (6) in the area radially external with respect to the exciting coil (6) or the housing thereof.

Owner:KENDRION VILLINGEN GMBH

Method for operating a hybrid drive system having a torque converter

ActiveUS8298117B2Constant torquePrevented from feelingSpeed controllerPropulsion using engine-driven generatorsImpellerMobile vehicle

A method for operating a hybrid drive system, in particular of a motor vehicle, having at least one electric machine and one internal combustion engine, a disconnecting clutch being provided between the electric machine and the internal combustion engine and a torque converter having a turbine wheel being provided between the electric machine and a hybrid drive output, the disconnecting clutch being engaged for starting the internal combustion engine. It is provided that, as a function of the rotational speed of the turbine wheel of the torque converter, a rotational speed is predefined for the electric machine such that no sudden torque change occurs at the hybrid drive output when the internal combustion engine is started.

Owner:ROBERT BOSCH GMBH

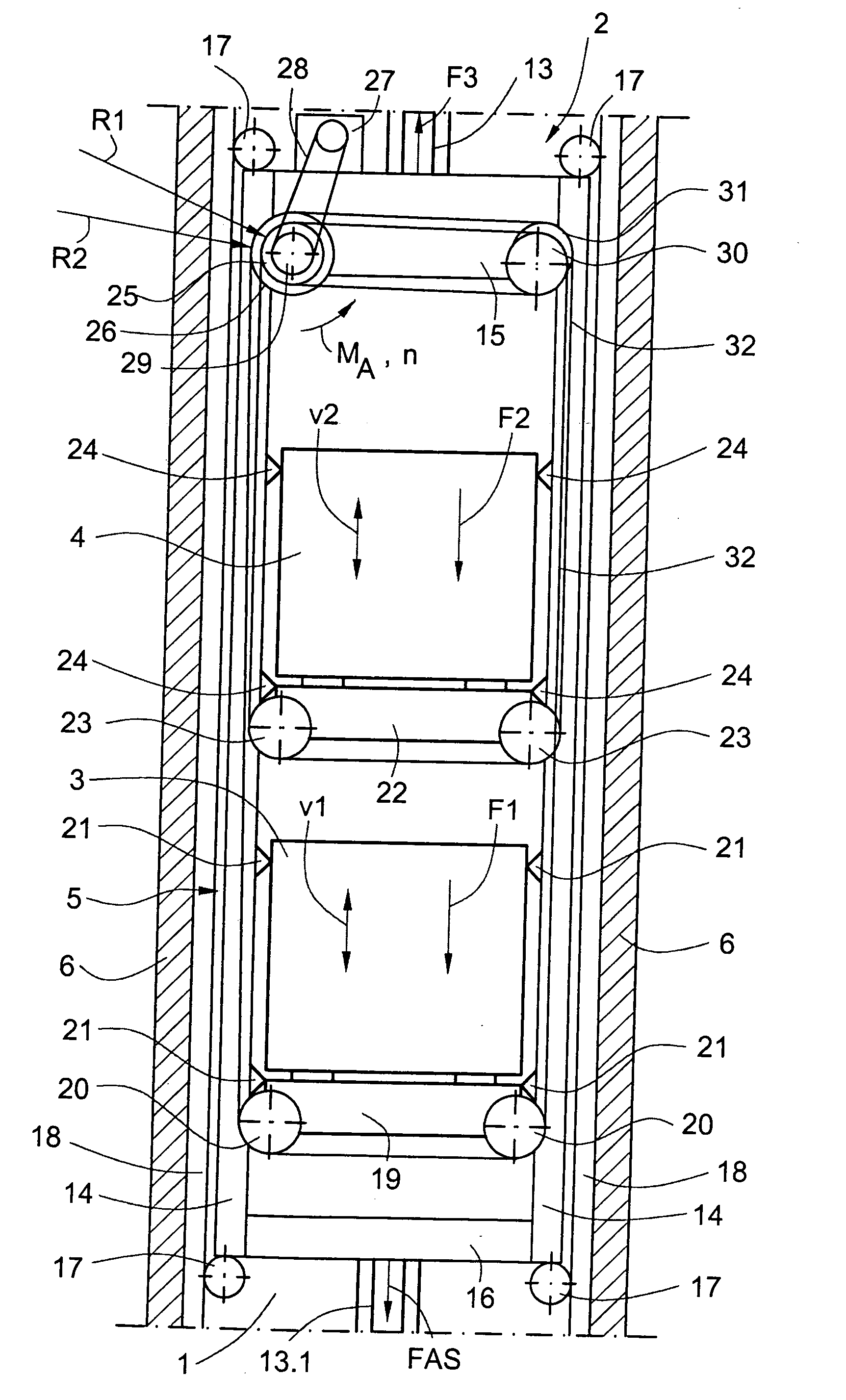

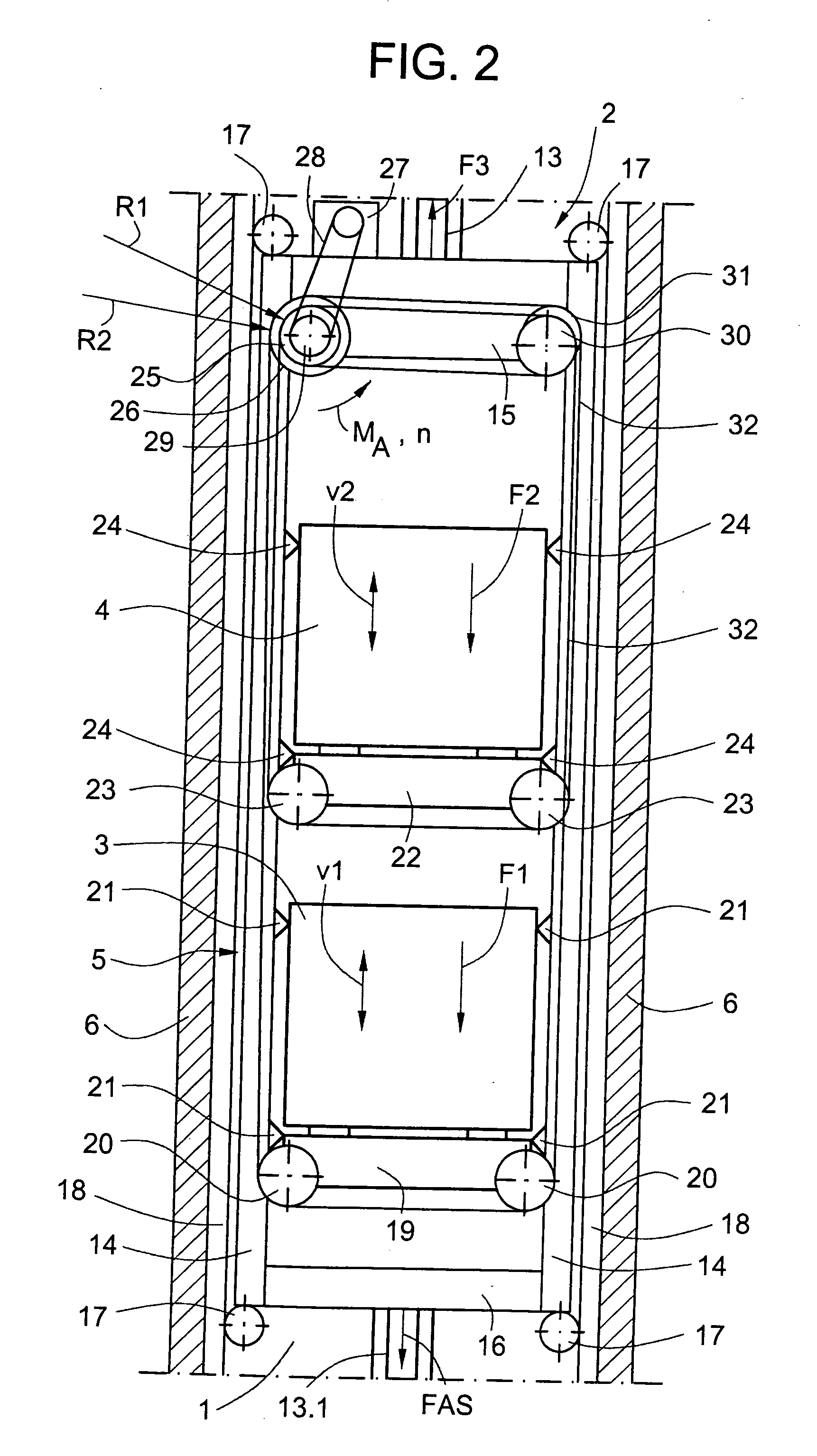

Equipment for fine positioning of the cars of a multi-stage car for an elevator

ActiveUS20060163006A1Safe boardingSafe departureLifting devicesElevatorsLocation EquipmentElectric cables

A multi-stage elevator car has equipment for fine positioning of the cars wherein the car thresholds are positionable at the level of the floor thresholds. Adjusting equipment operating on the principle of a differential block and pulley is provided for fine positioning of the cars, the equipment including an endless cable guided over deflecting rollers arranged at the main frame of the multi-stage car and over deflecting rollers arranged at the cars, wherein the cars execute vertical movements of opposite sense.

Owner:INVENTIO AG

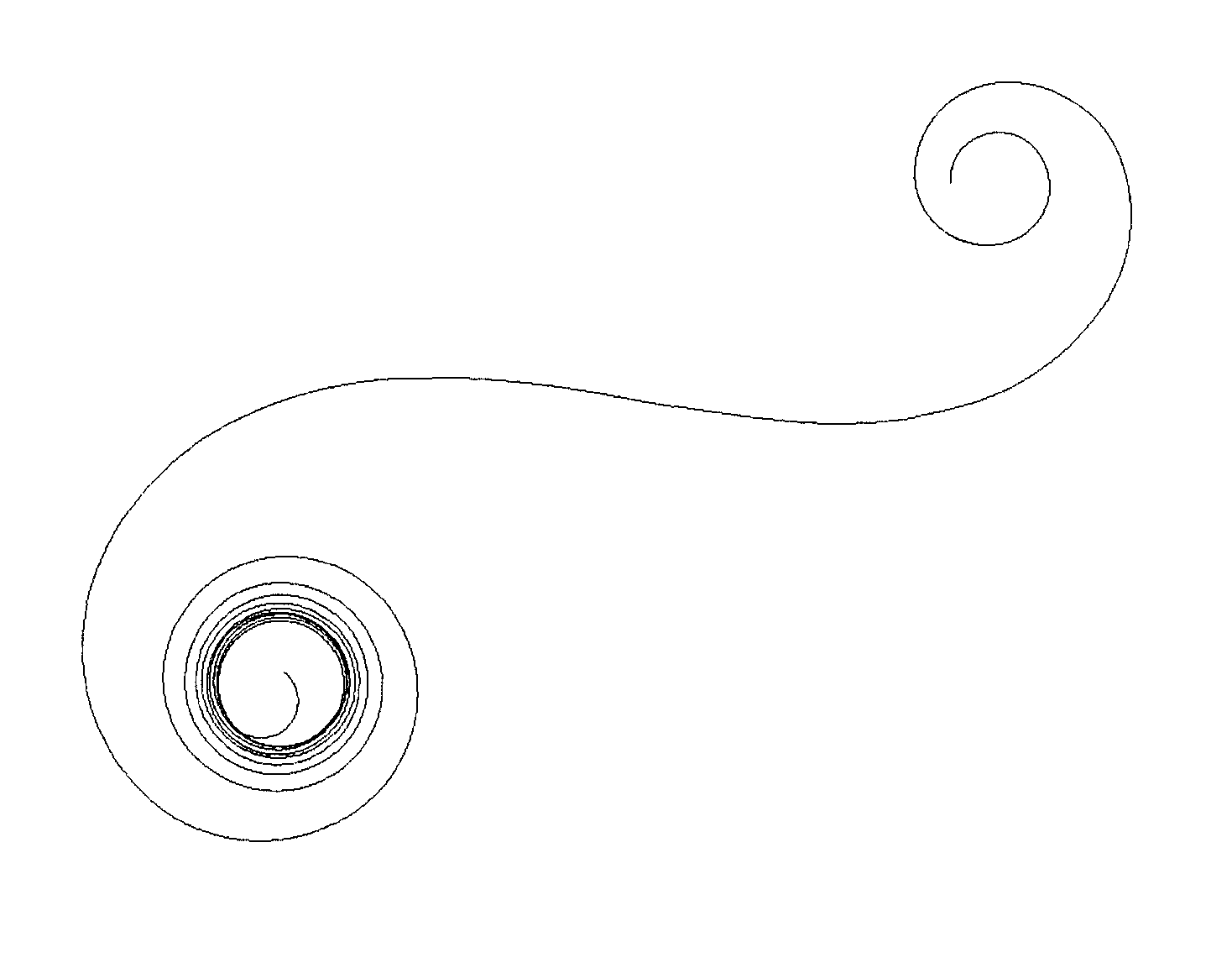

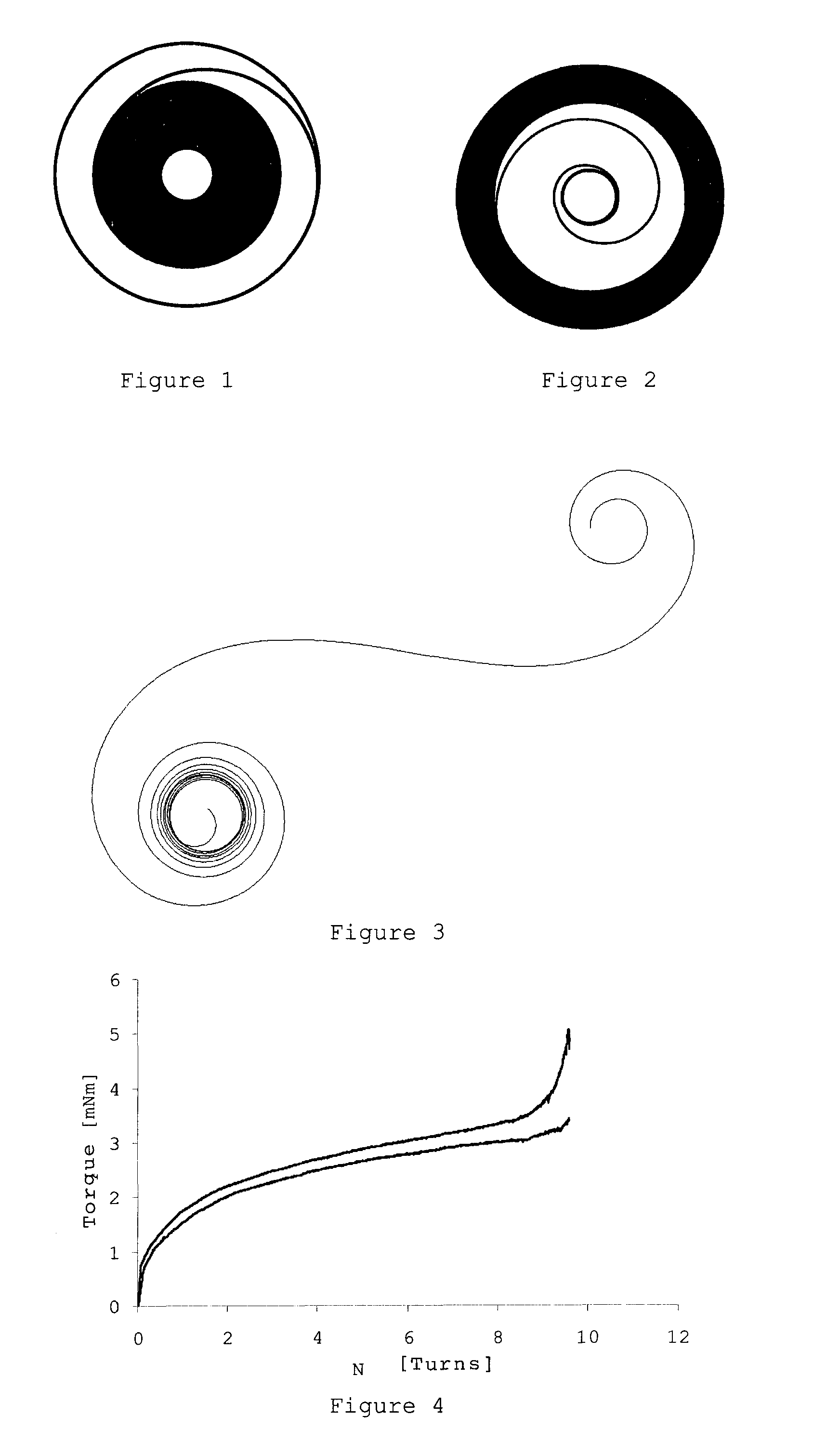

Mainspring

ActiveUS8348496B2High densityConstant torqueElectric windingClock driving mechanismsMetallic materialsEngineering

Owner:ROLEX SA

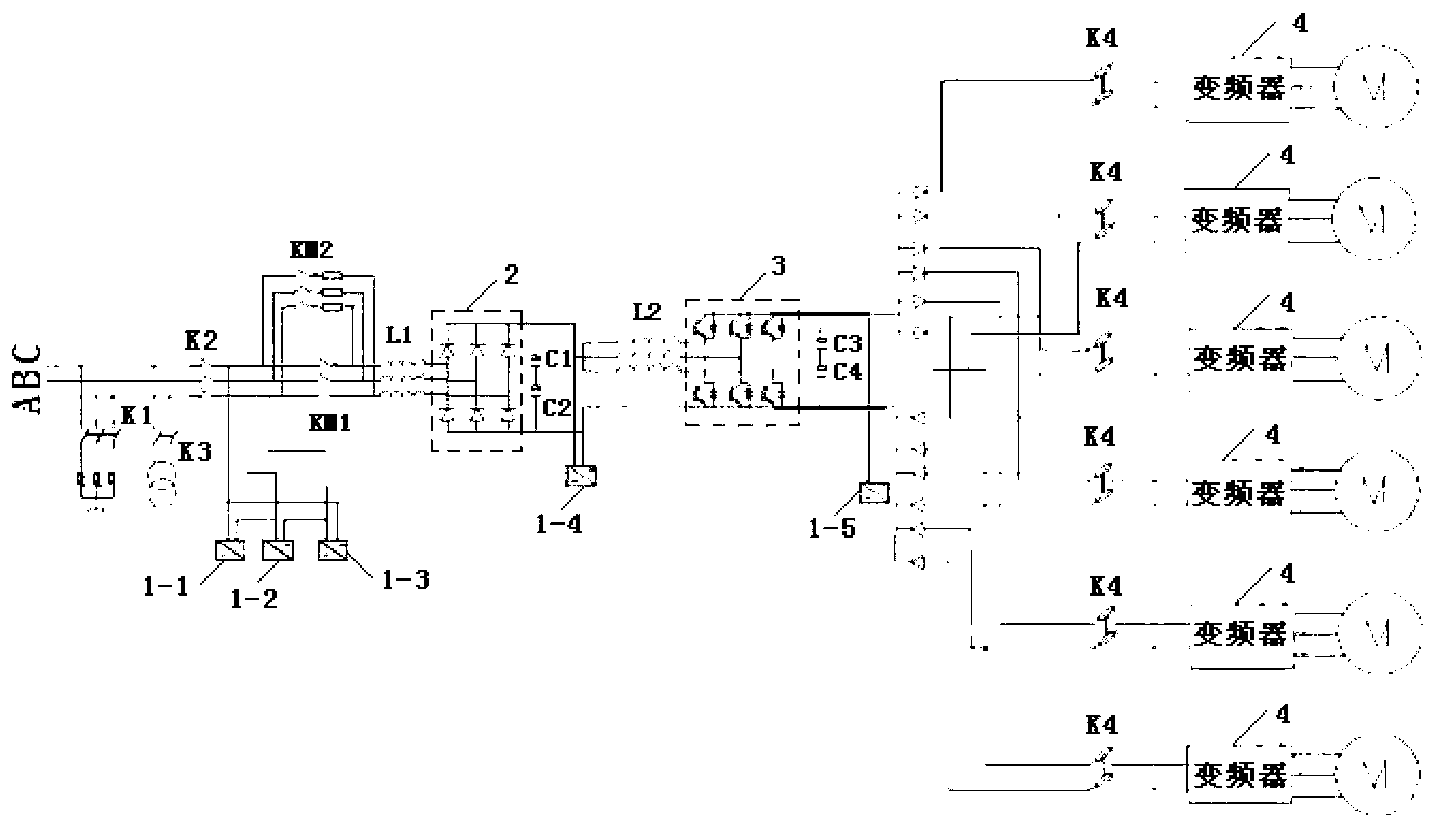

Pulverized coal feeder frequency converter control system with low voltage ride-through power supply device

ActiveCN103326385AGuaranteed output powerDC voltage risePower oscillations reduction/preventionFrequency changerCapacitance

The invention provides a pulverized coal feeder frequency converter control system with a low voltage ride-through power supply device and relates to the field of pulverized coal feeder frequency converter control. The pulverized coal feeder frequency converter control system with the low voltage ride-through power supply device aims to solve the problems that when a pulverized coal feeder frequency converter control system encounters low system voltages, a pulverized coal feeder stops running, and changes of rotating speed, changes of torque and changes of power are caused. According to the pulverized coal feeder frequency converter control system with the low voltage ride-through power supply device, three-phase alternative current power energy passes through a second three-phase switch and a first contactor and is fed into a rectification loop formed by a first three-phase inducer and a diode rectification bridge, the three-phase alternative current power energy is transformed to direct current power energy and is stored in a first capacitor and a second capacitor, a BOOST type boost chopper circuit is formed by a second three-phase inducer and a three-phase inverter circuit, the direct current power energy on the first capacitor and the second capacitor can be transformed to direct current power energy with a higher voltage class, and the direct current power energy with the higher voltage class is stored in a third capacitor and a fourth capacitor and is fed into a frequency converter. A pre-charging loop is formed by a second contactor and three resistors of another set, and stable charging for the first capacitor, the second capacitor, the third capacitor and the forth capacitor when a voltage detecting module is powered on initially is achieved. The pulverized coal feeder frequency converter control system with the low voltage ride-through power supply device is applied to pulverized coal feeder control systems of boilers.

Owner:DATANG JIXI THERMAL POWER CO LTD

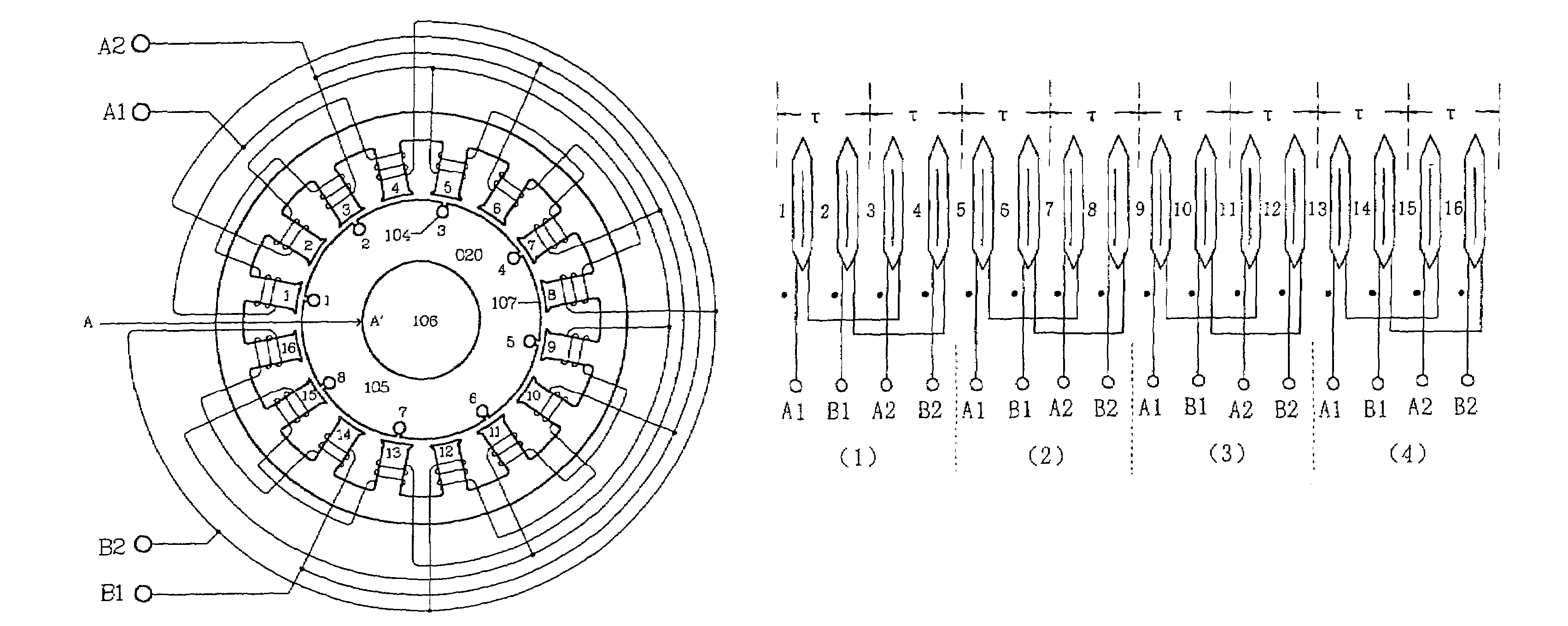

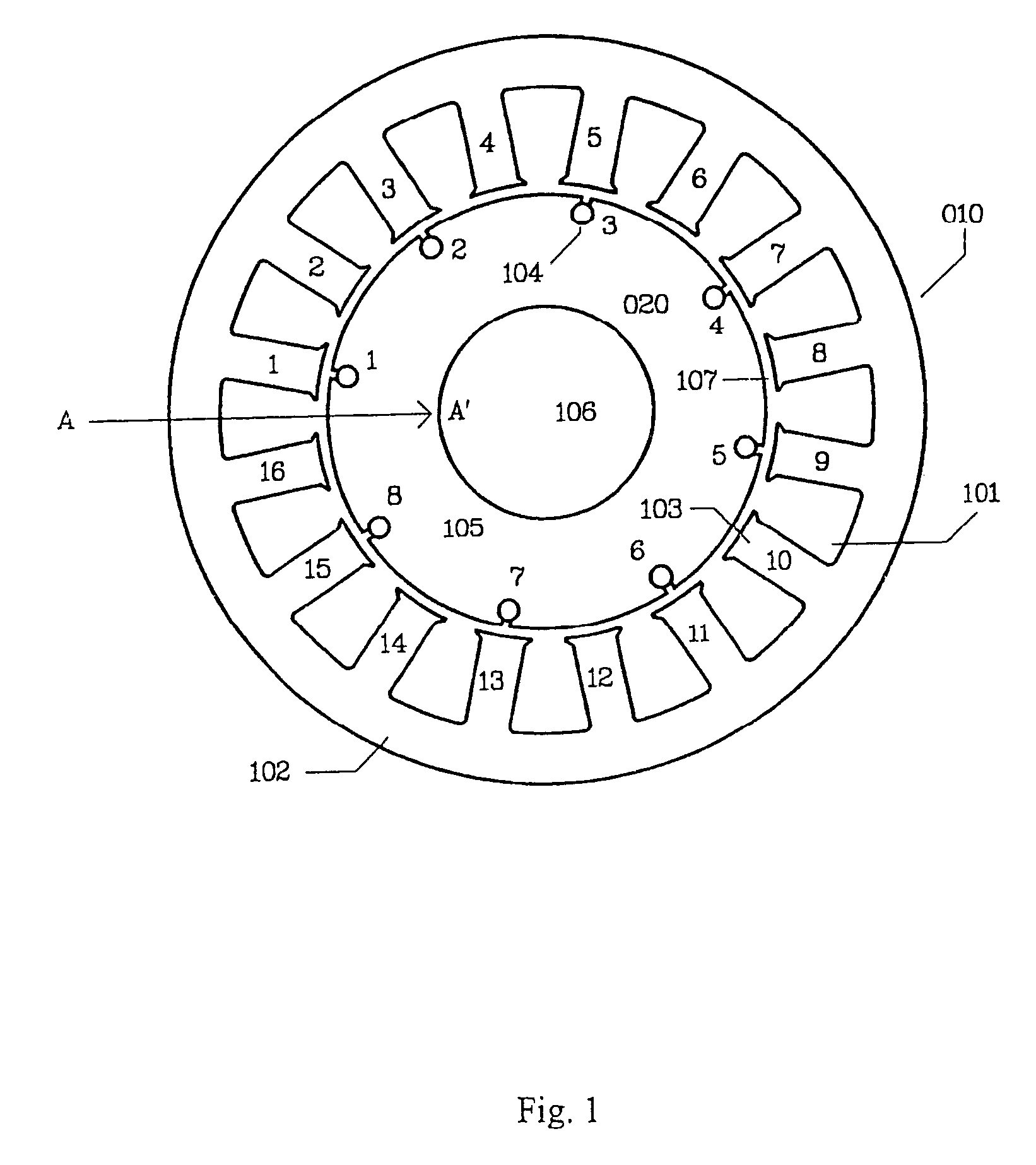

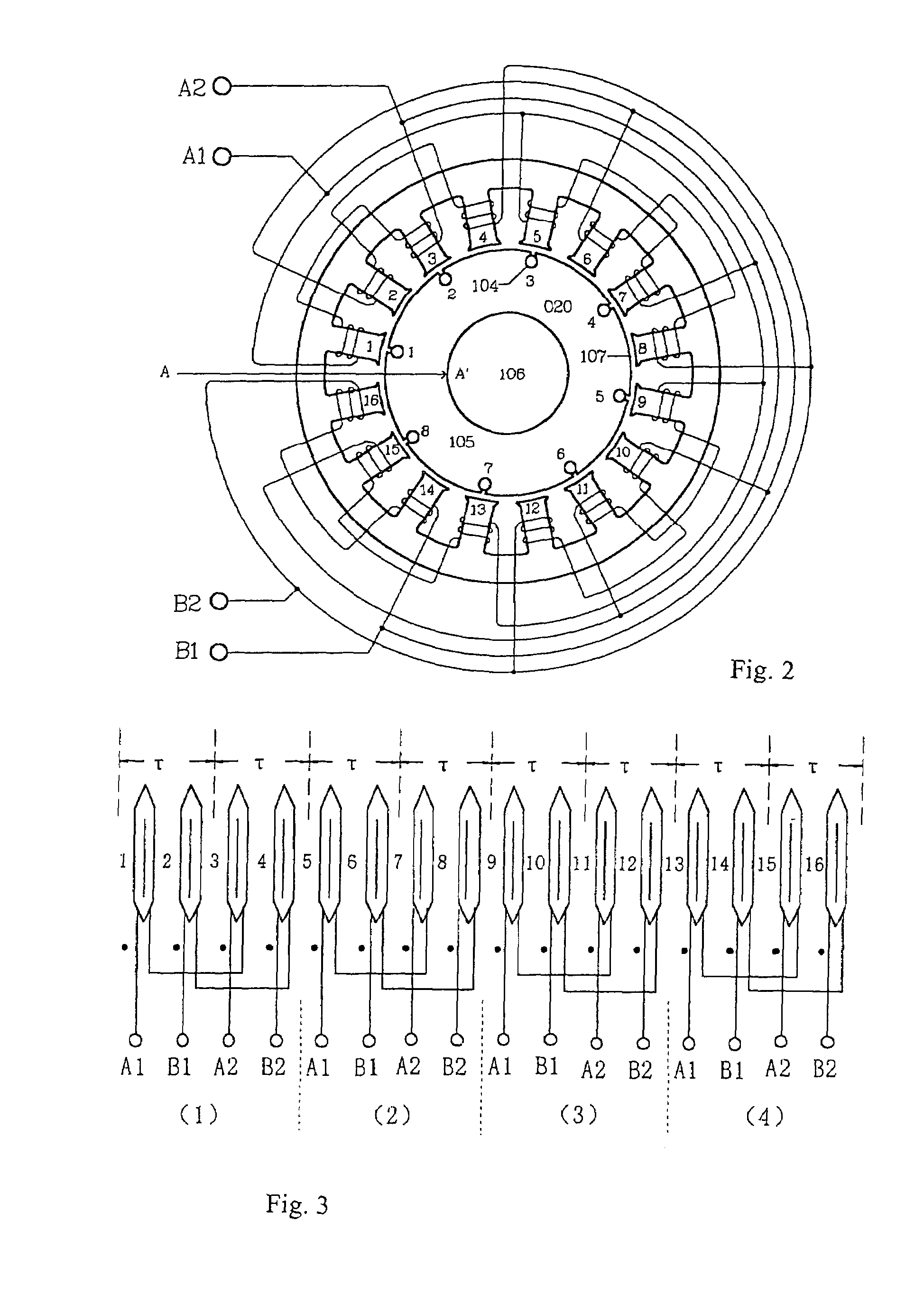

Switching pattern ac induction motor

ActiveUS20050151438A1Smooth output torqueOvercome expensiveSingle-phase induction motor startersSynchronous generatorsPhysicsSine wave

Both the stator core and the rotor core of a switching pattern AC induction motor are fabricated by soft magnetic material laminations or ferrite material, etc., both of which have corresponding frequency characteristic. The rotor is a squirrel cage rotor. Switching pattern excitation is adopted in the stator pole, of which the excitation voltage is sine wave pulse width modulated or sine wave pulse amplitude modulated within the frequency range of voice and ultrasonic. Under the condition of the same power output, the present motor reduces its size and mass to a fraction of or tenth of that of an ordinary one. Meanwhile, it reduces the cost of manufacture. It realizes stepless speed regulating from zero to several thousand rpm while keeping well mechanical characteristic performance.

Owner:HUANG YOUGUO +1

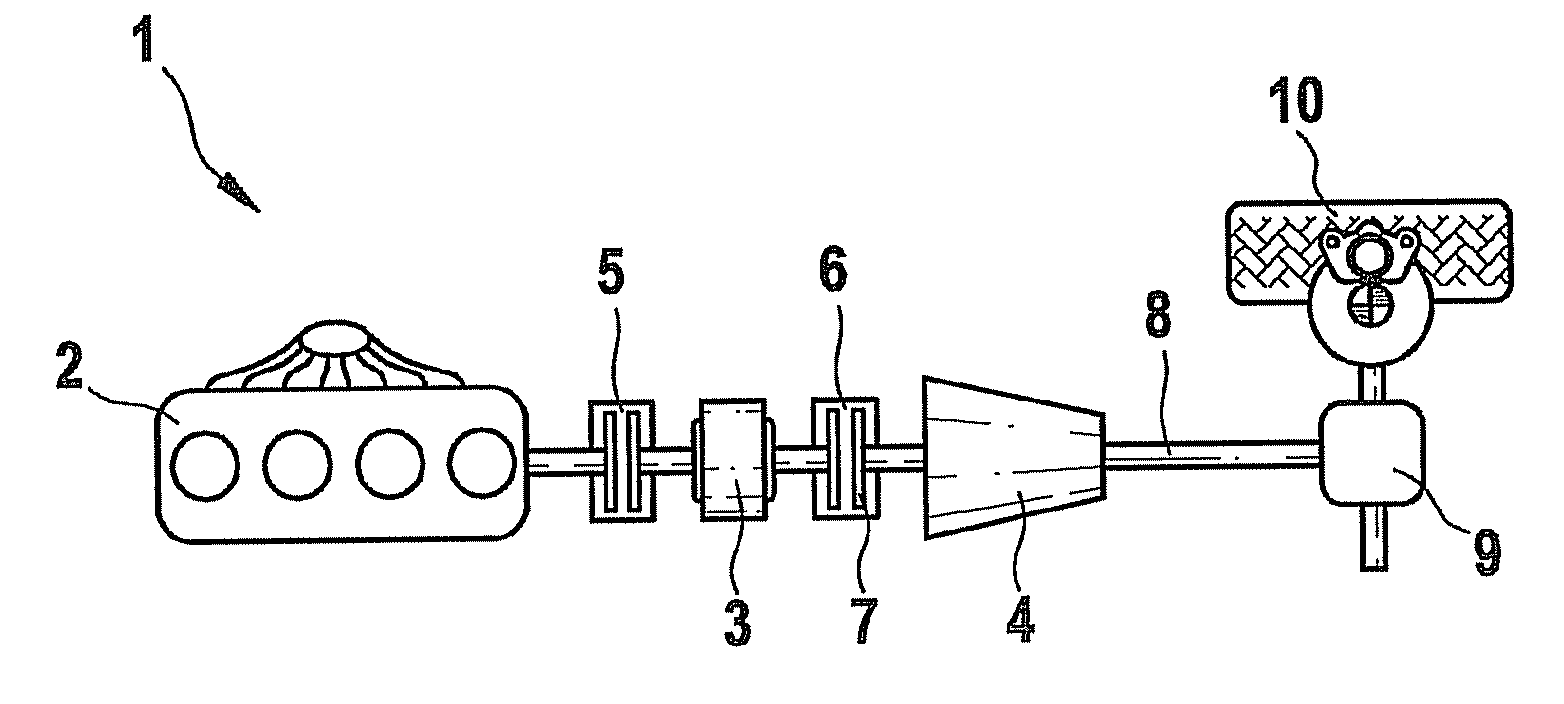

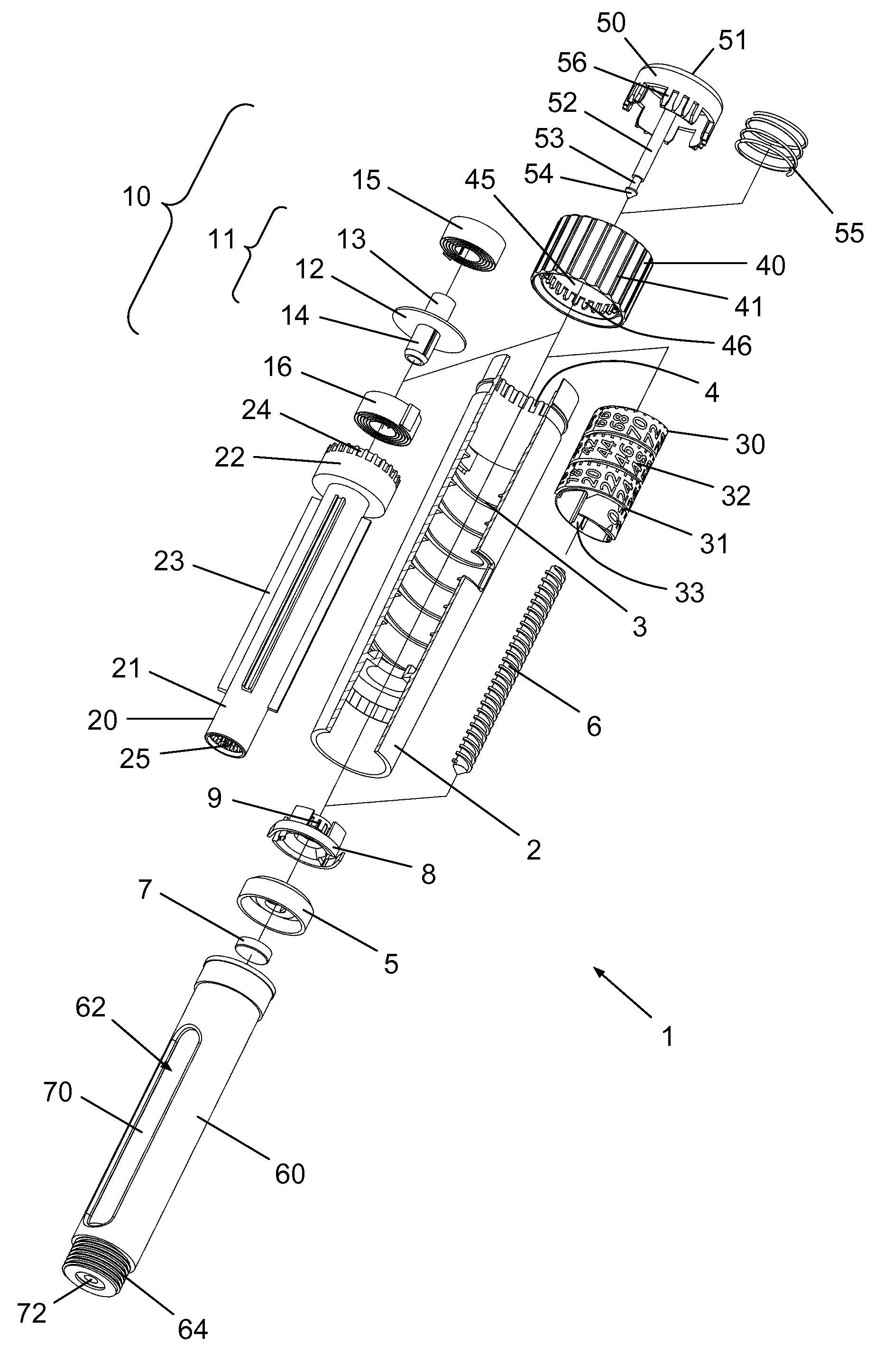

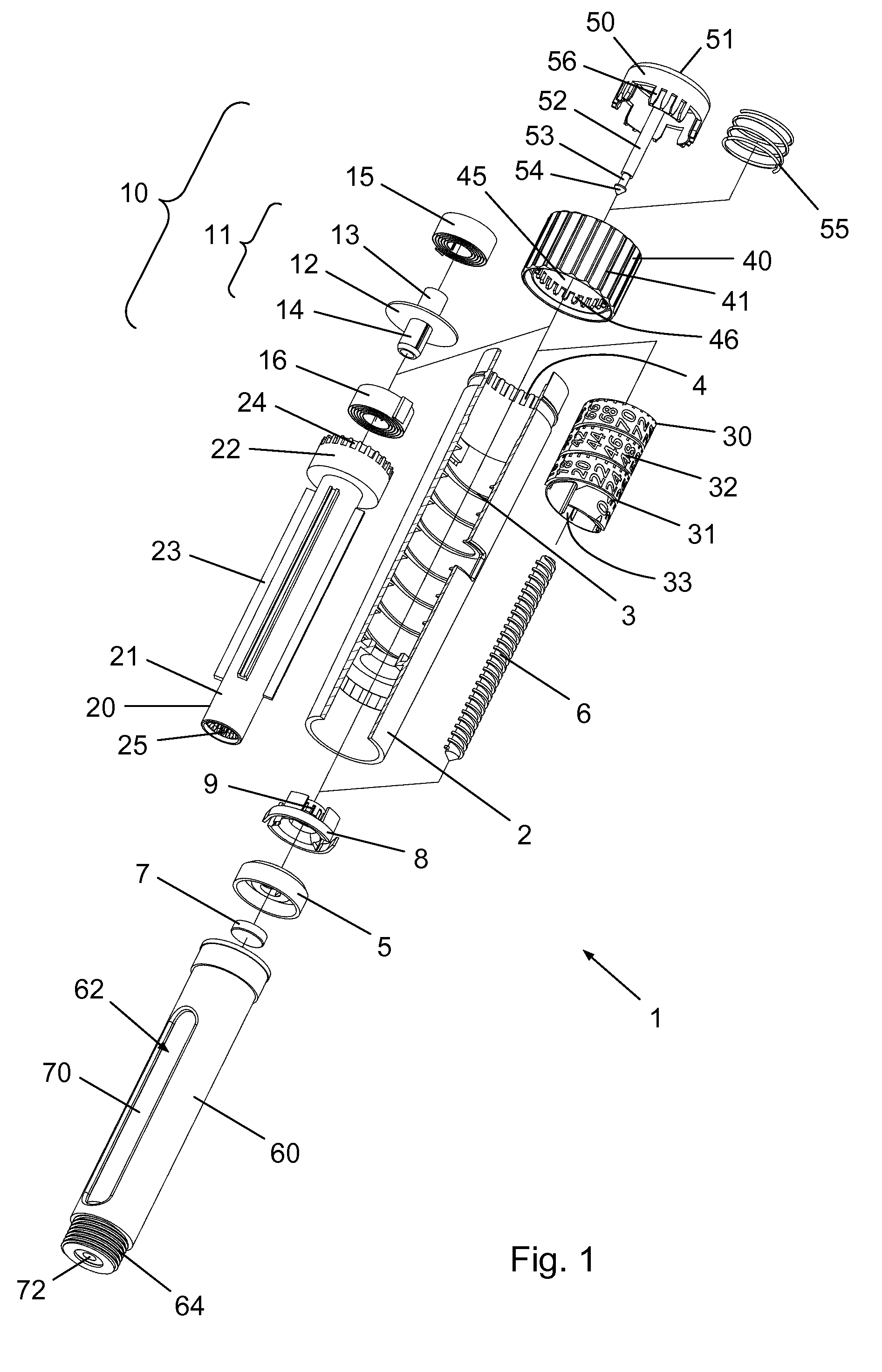

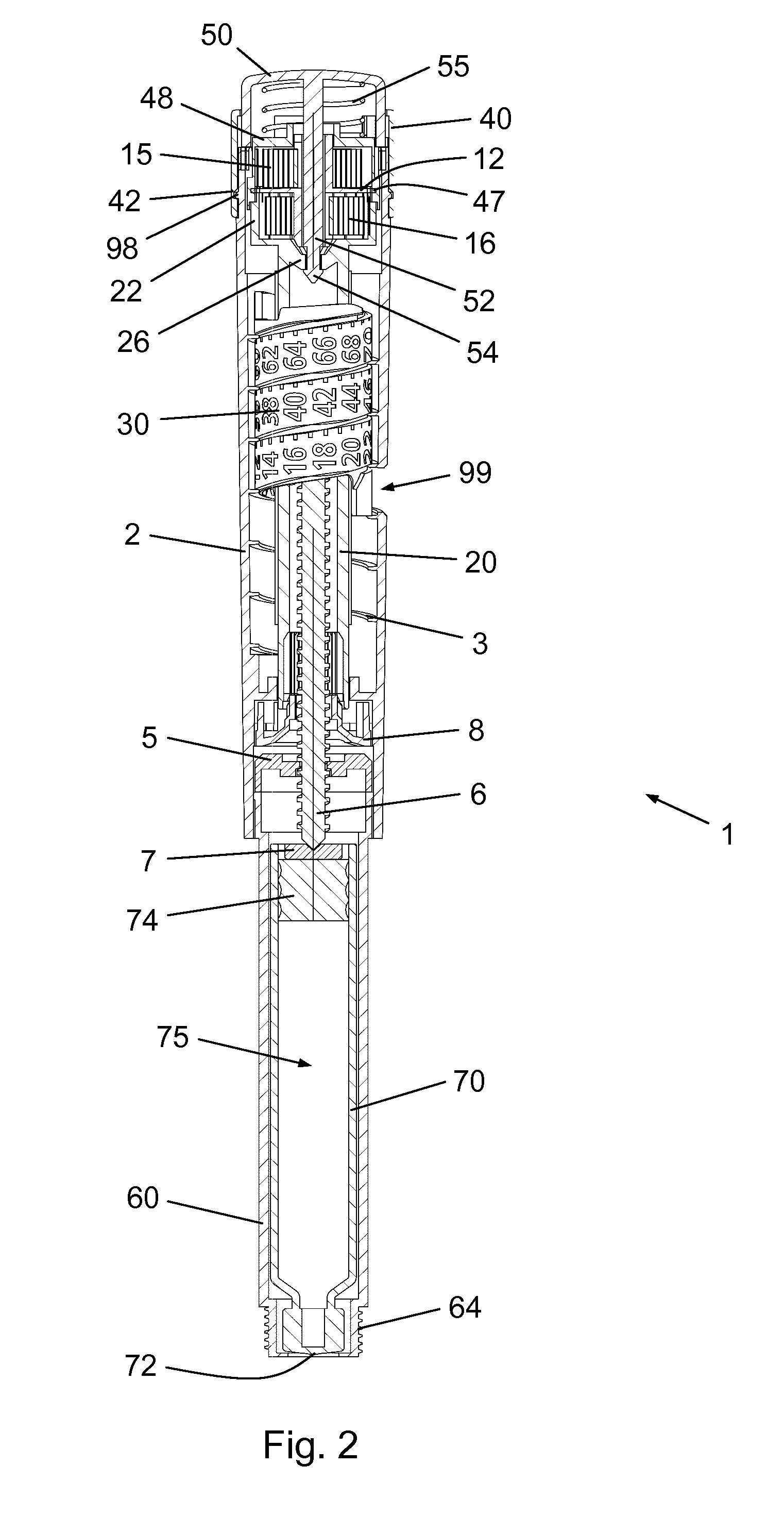

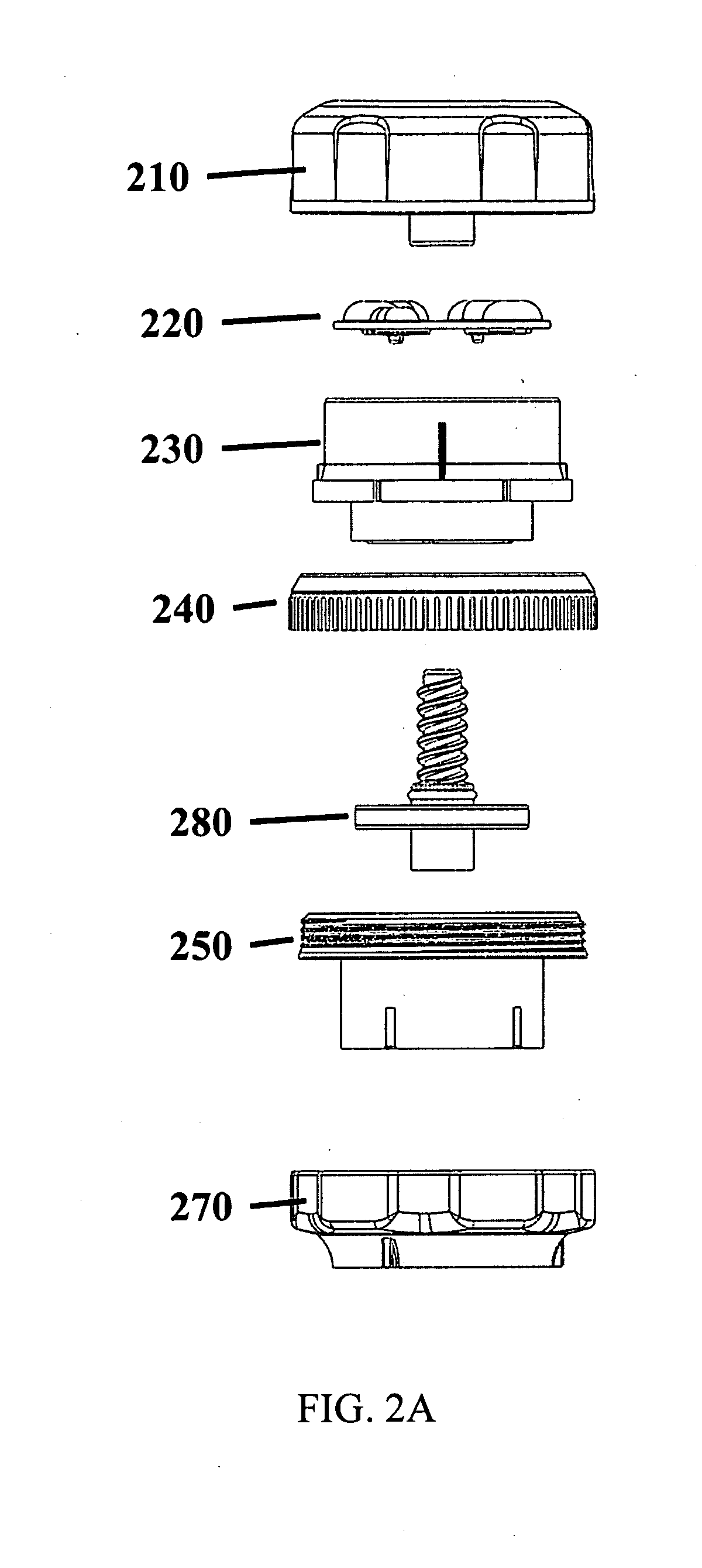

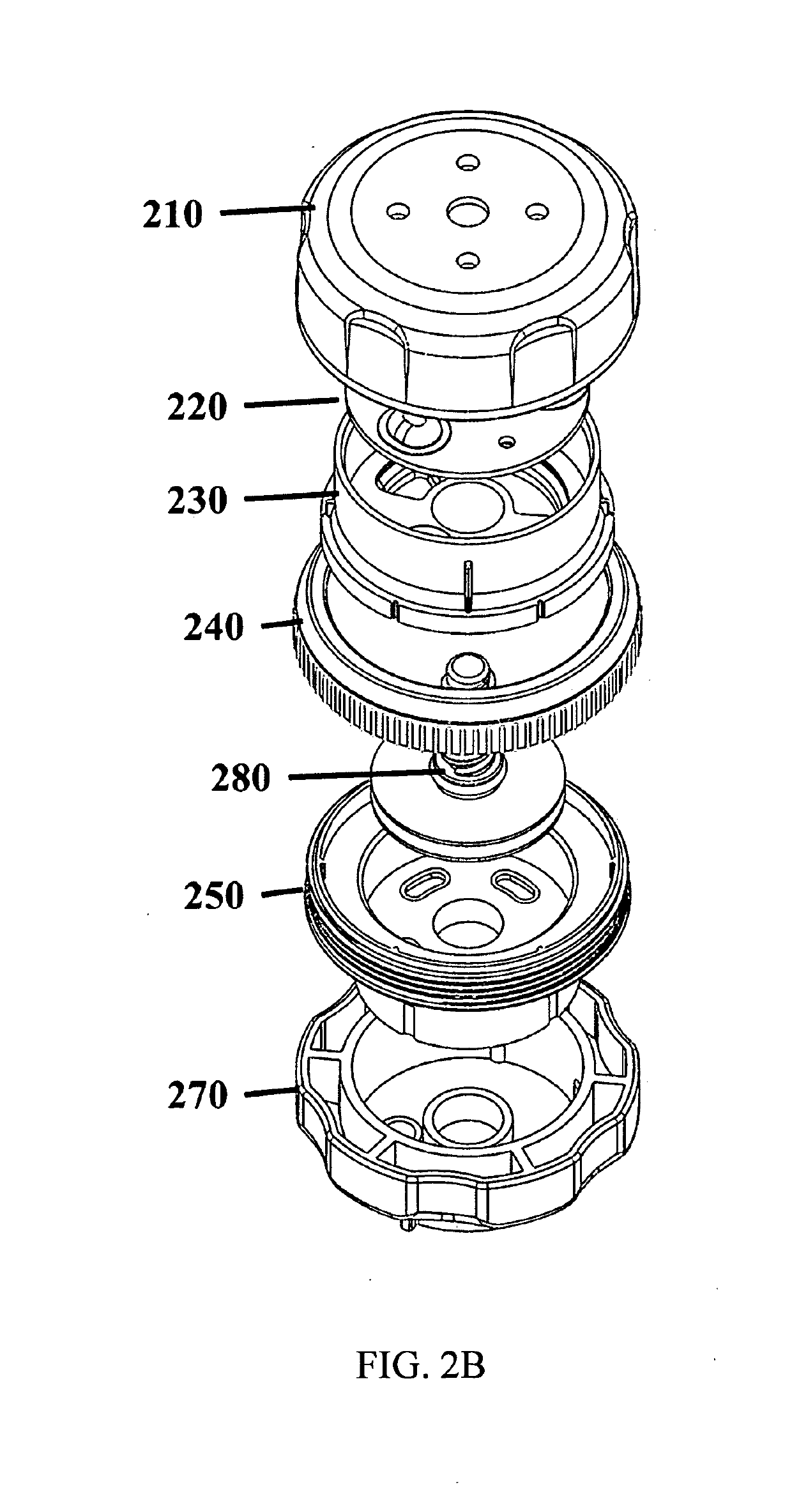

Drug Delivery Device with Compact Power Unit

InactiveUS20160038677A1Constant torqueCompact structureAmpoule syringesAutomatic syringesCoil springEngineering

The present invention relates to a drug delivery device (1) with a power unit (10, 110, 210, 310) adapted to release energy for inducing relative rotation between a first interface portion (45) of the drug delivery device (1) and a second interface portion (22) of the drug delivery device (1). The power unit (10, 110, 210, 310) comprises a first spiral spring member (15, 15, 215, 315) and a second spiral spring member (16, 116, 216, 316) arranged in series along an axially extending structure (11; 111; 211, 285, 281; 311, 385, 1381, 386, 381).

Owner:NOVO NORDISK AS

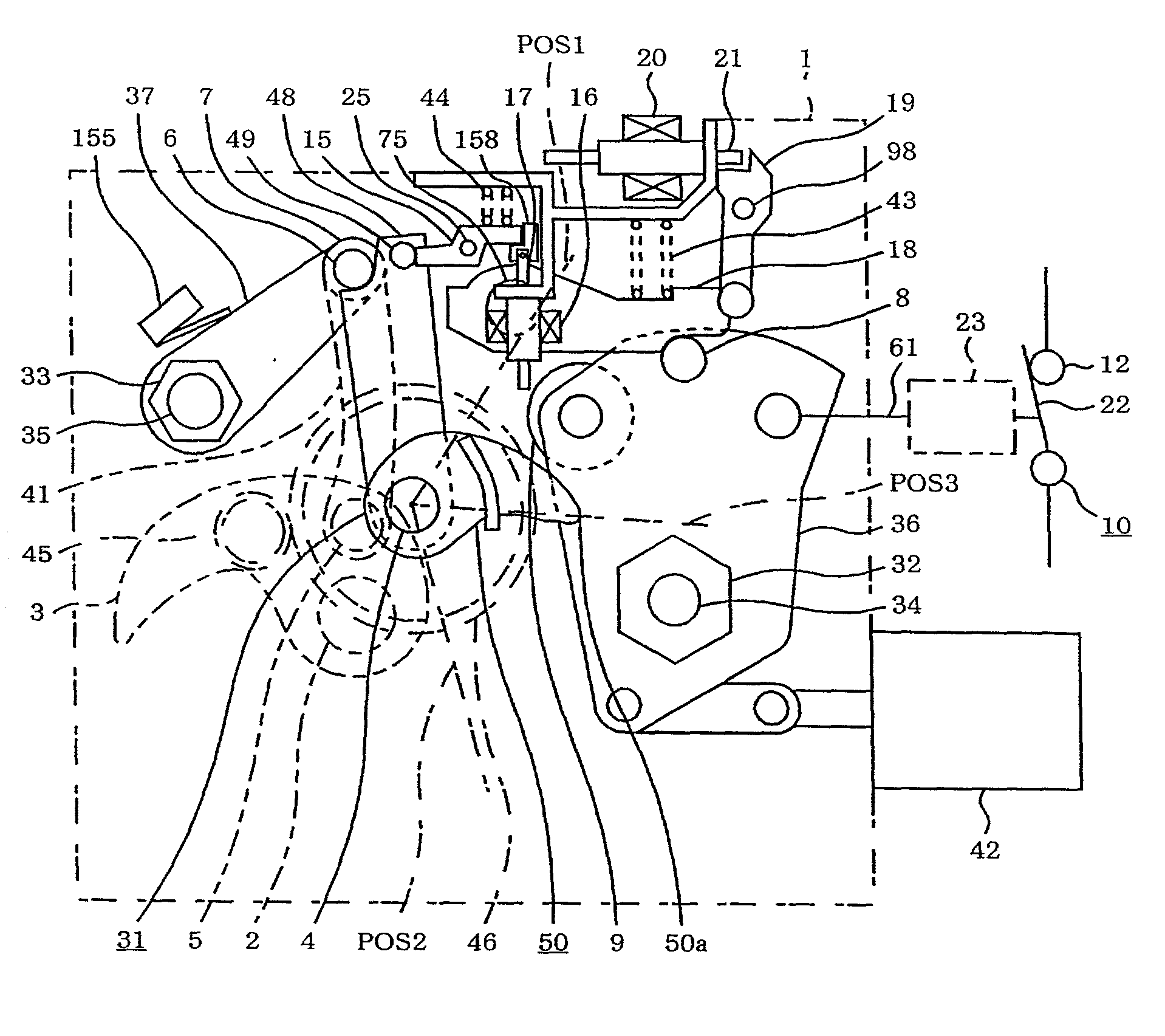

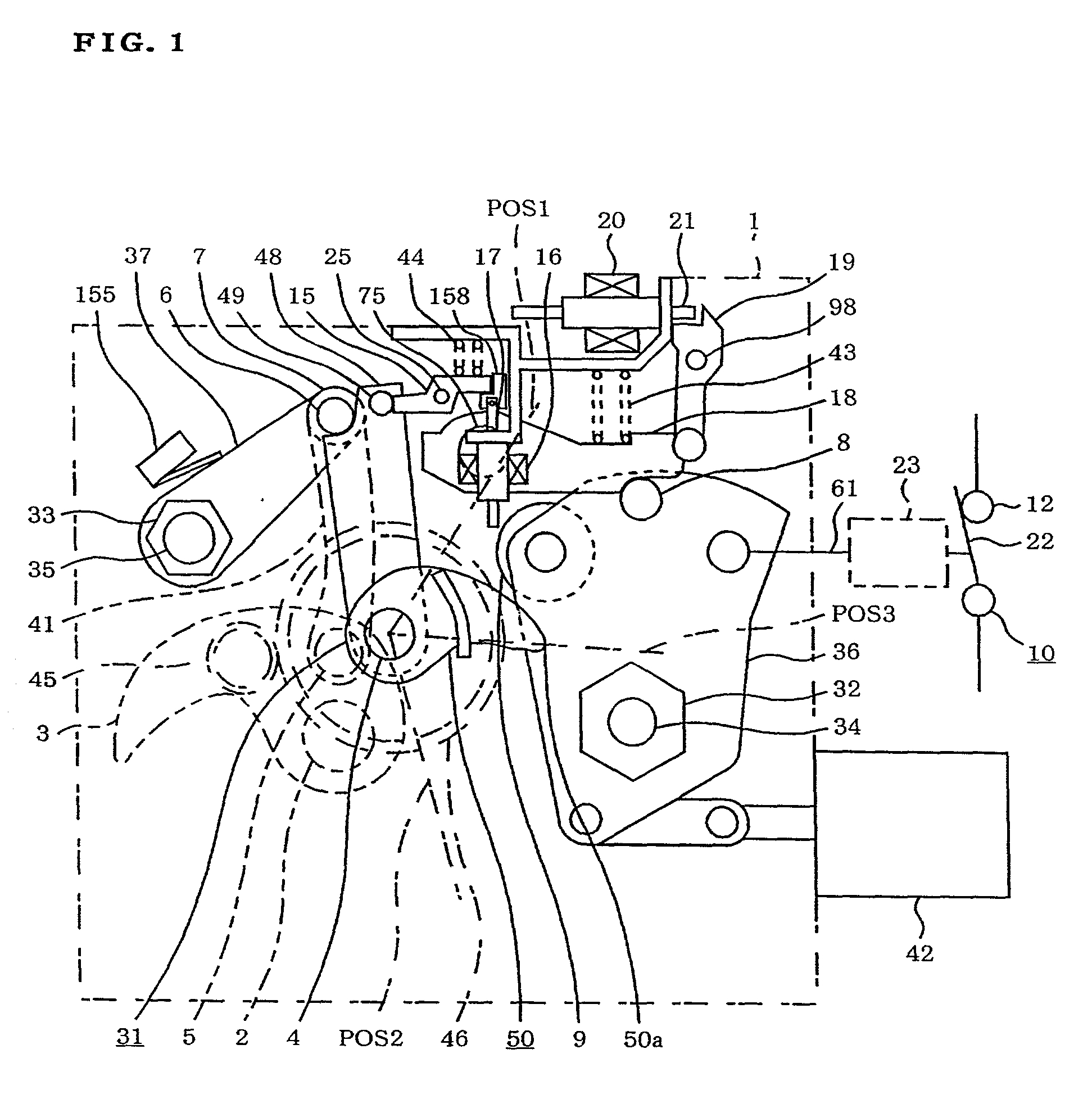

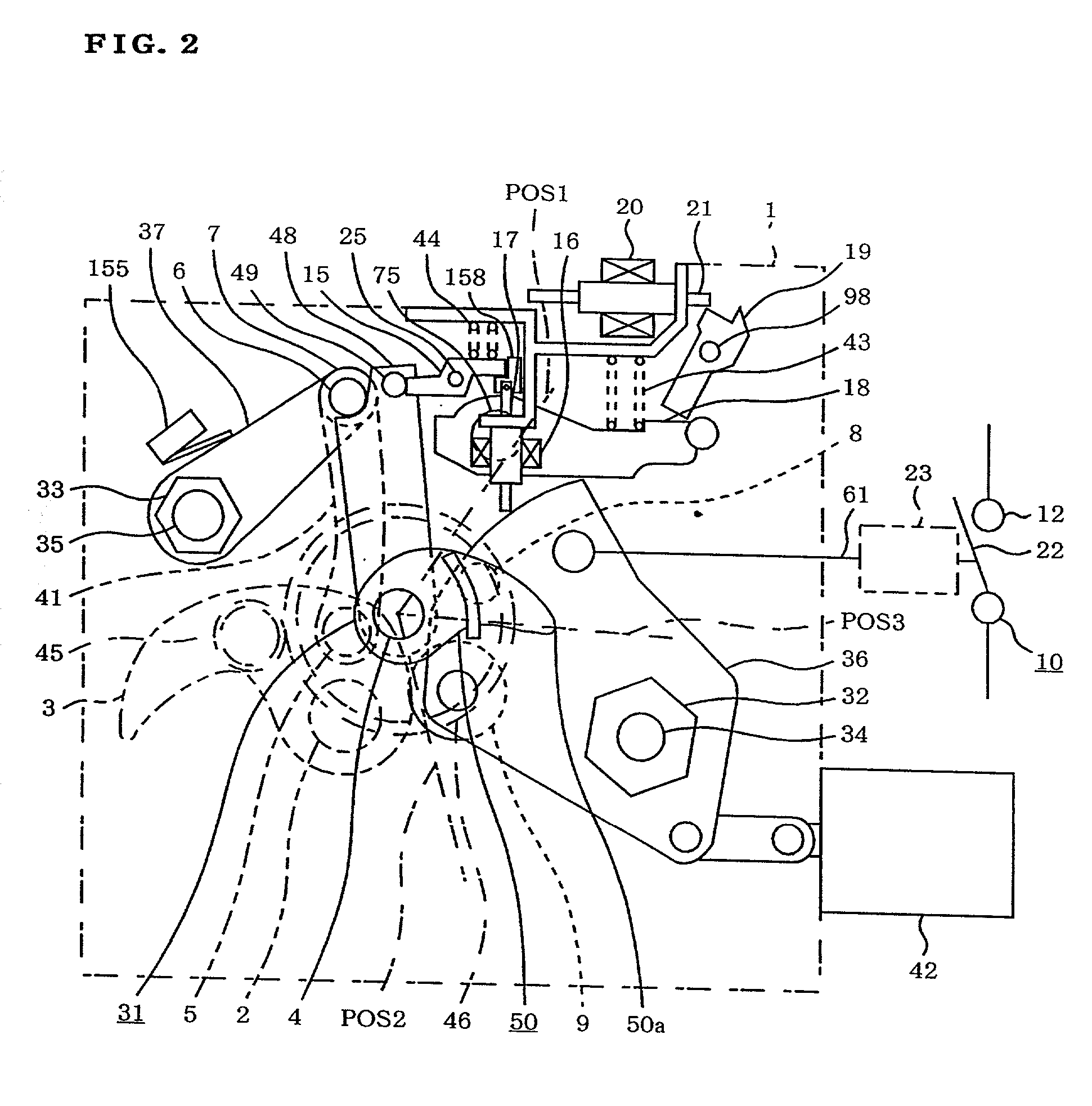

Switchgear operating apparatuses

InactiveUS20030034242A1Avoid turningAvoid strong impactSwitch lubricationSwitch power arrangementsCoil springEngineering

The invention provides a compact, lightweight and low-cost operating apparatus for a switchgear. A second cam (50) turned counterclockwise by an electric motor begins to maintain contact with a closing lever (37) at a first angular position (POS1), turns the closing lever (37) counterclockwise to energize a circuit-making coil spring (77), and causes a closing latch (48) to lock the closing lever (37). The second cam (50) further turning counterclockwise becomes separated from the closing lever (37) and actuates a cam switch (156) at a second angular position (POS2) to interrupt an electric current supplied to the electric motor. The second cam (50) further turns due to inertial turning of the electric motor and is braked by a elastic brake member (159) at a third angular position (POS3), whereby the second cam (50) stops within a specific angular range DELTAtheta of rotation. Despite its simple structure, the elastic brake member (159) can halt the second cam (50) in a reliable fashion.

Owner:MITSUBISHI ELECTRIC CORP

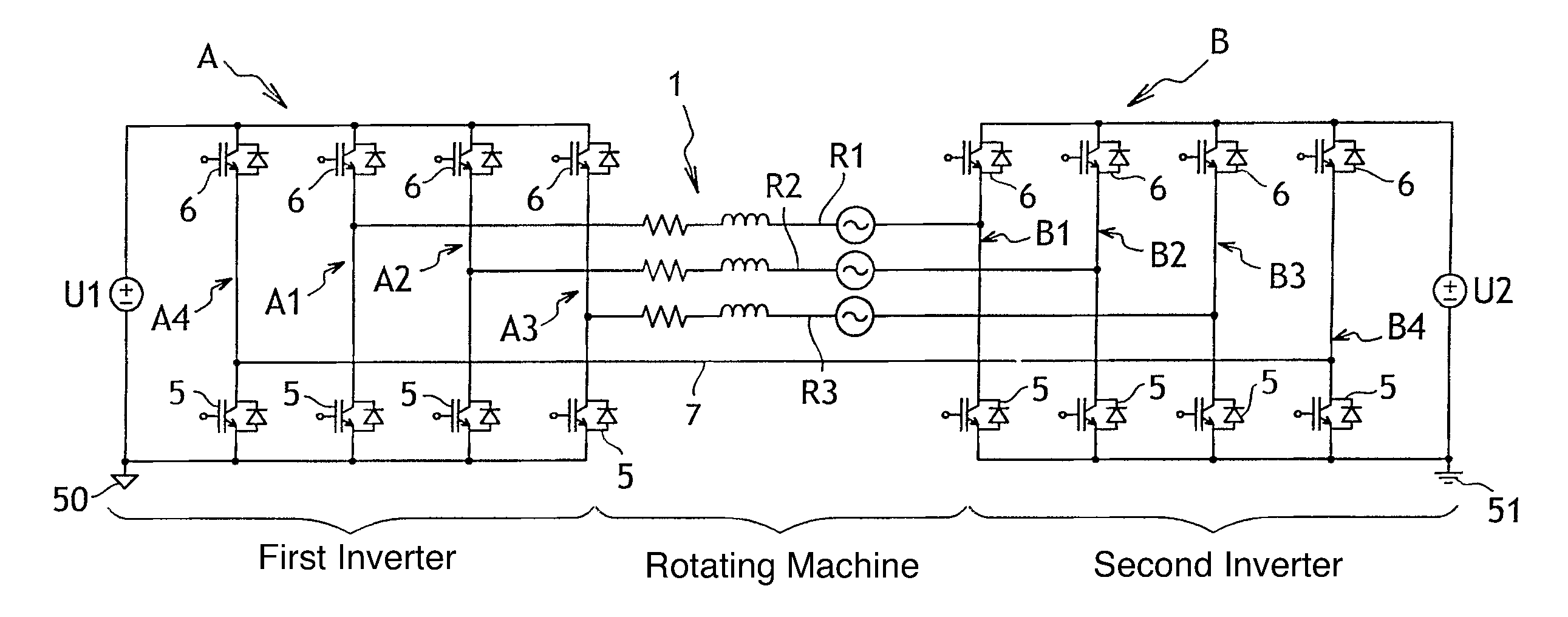

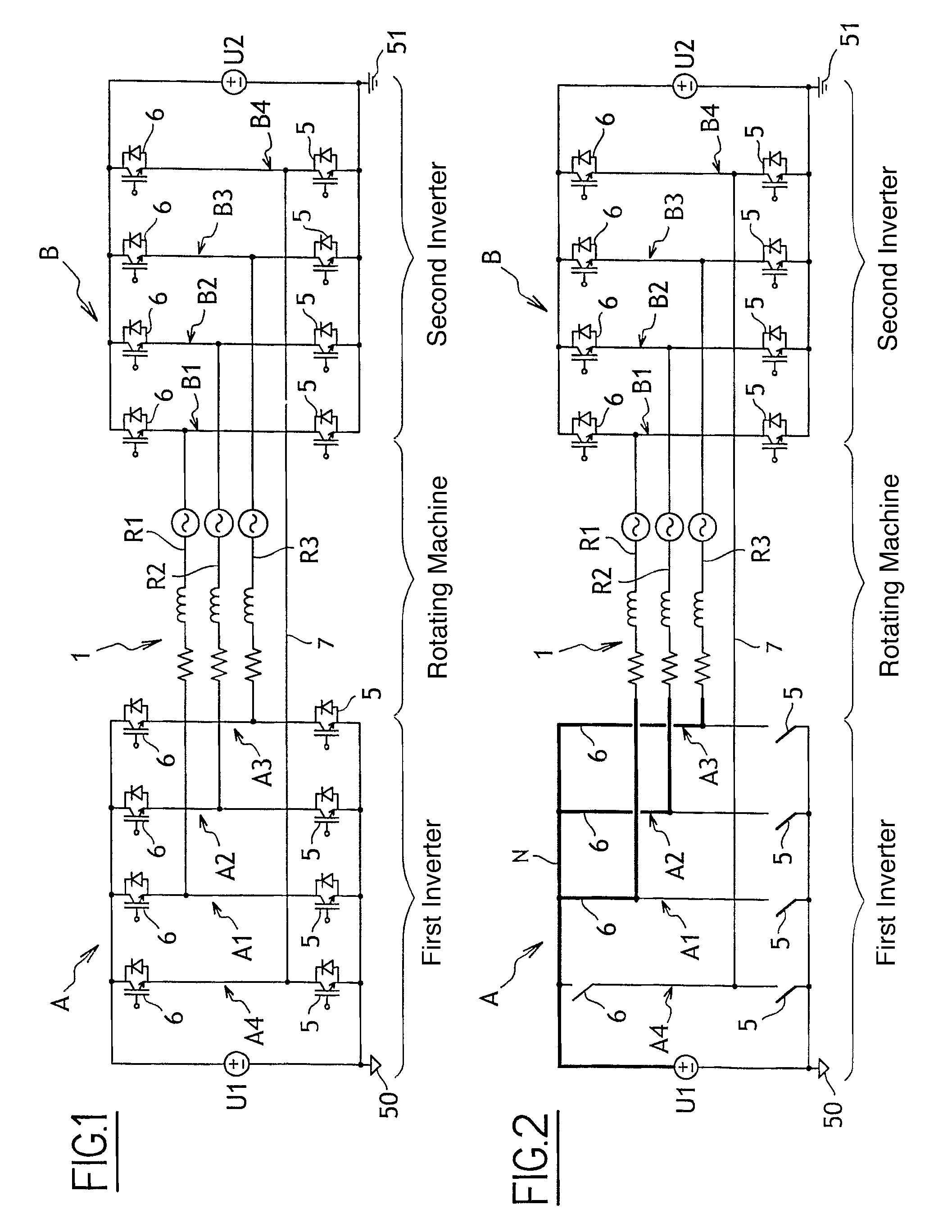

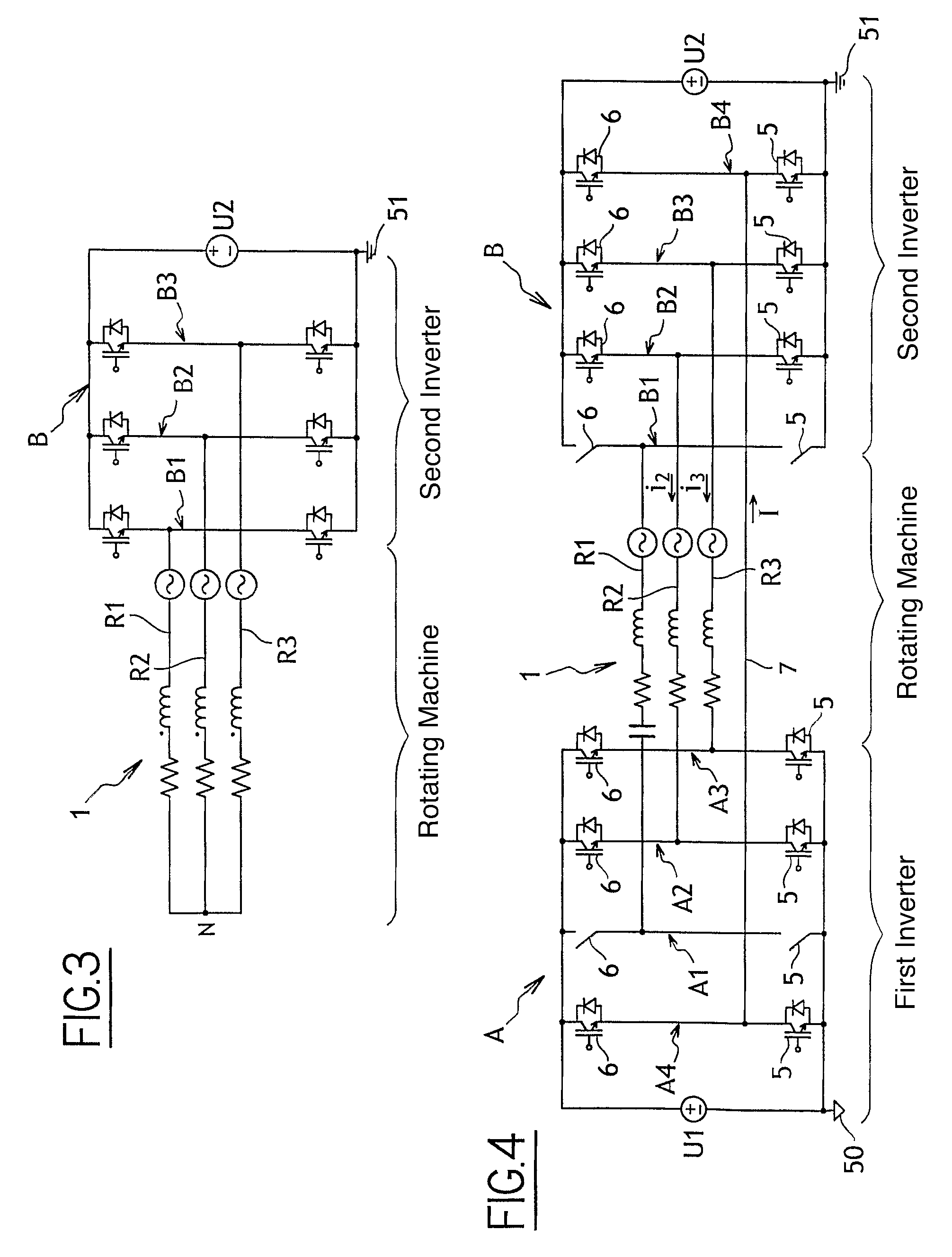

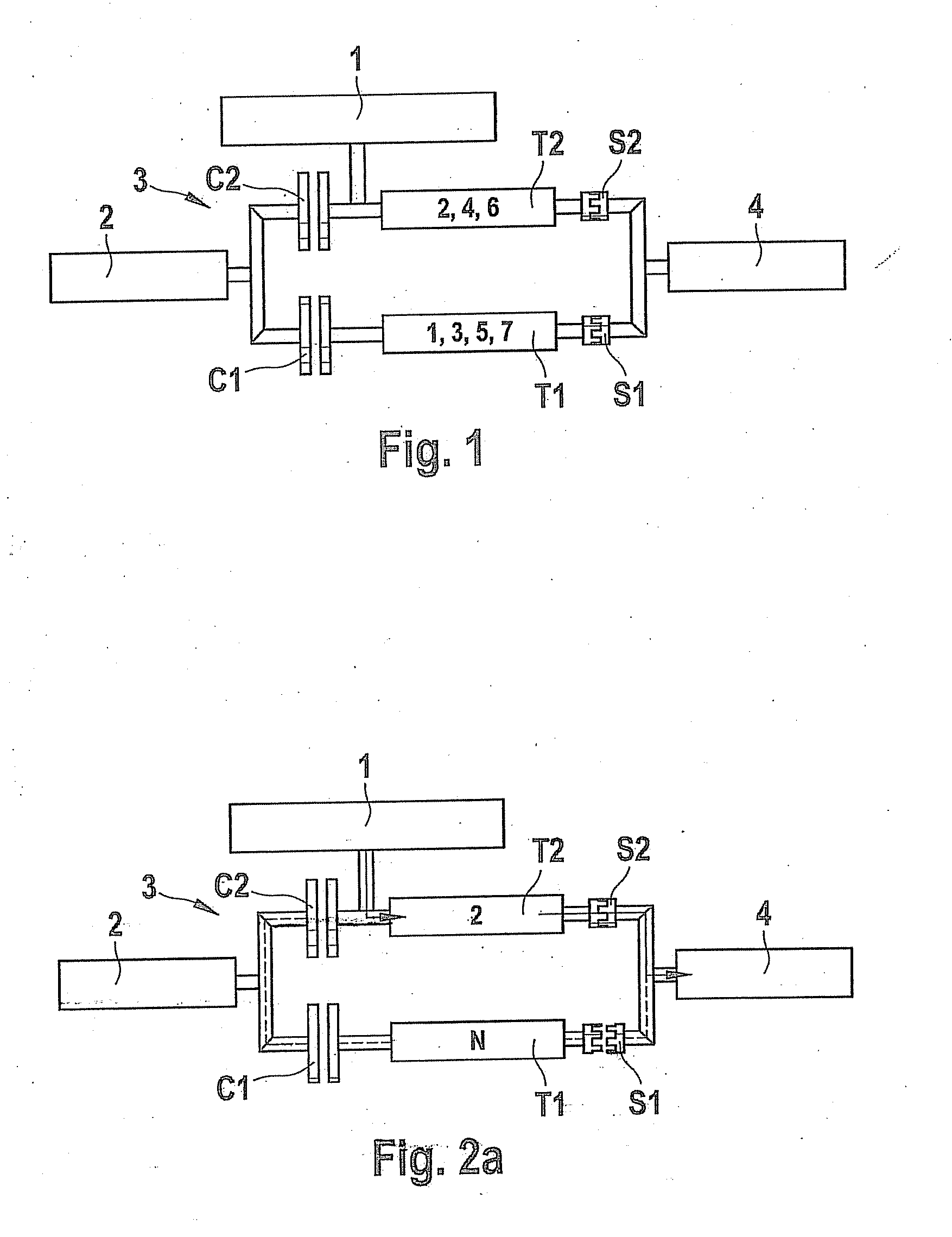

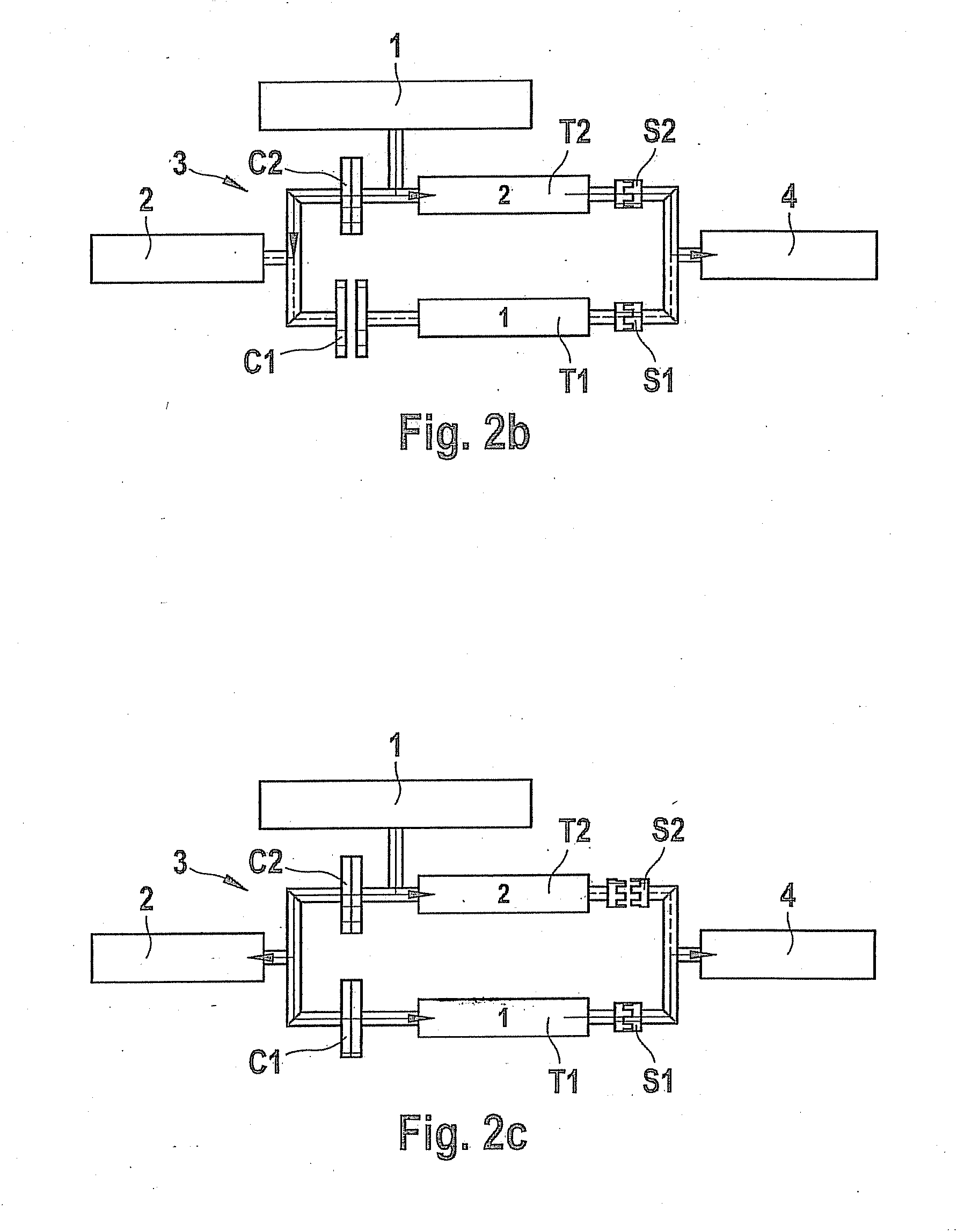

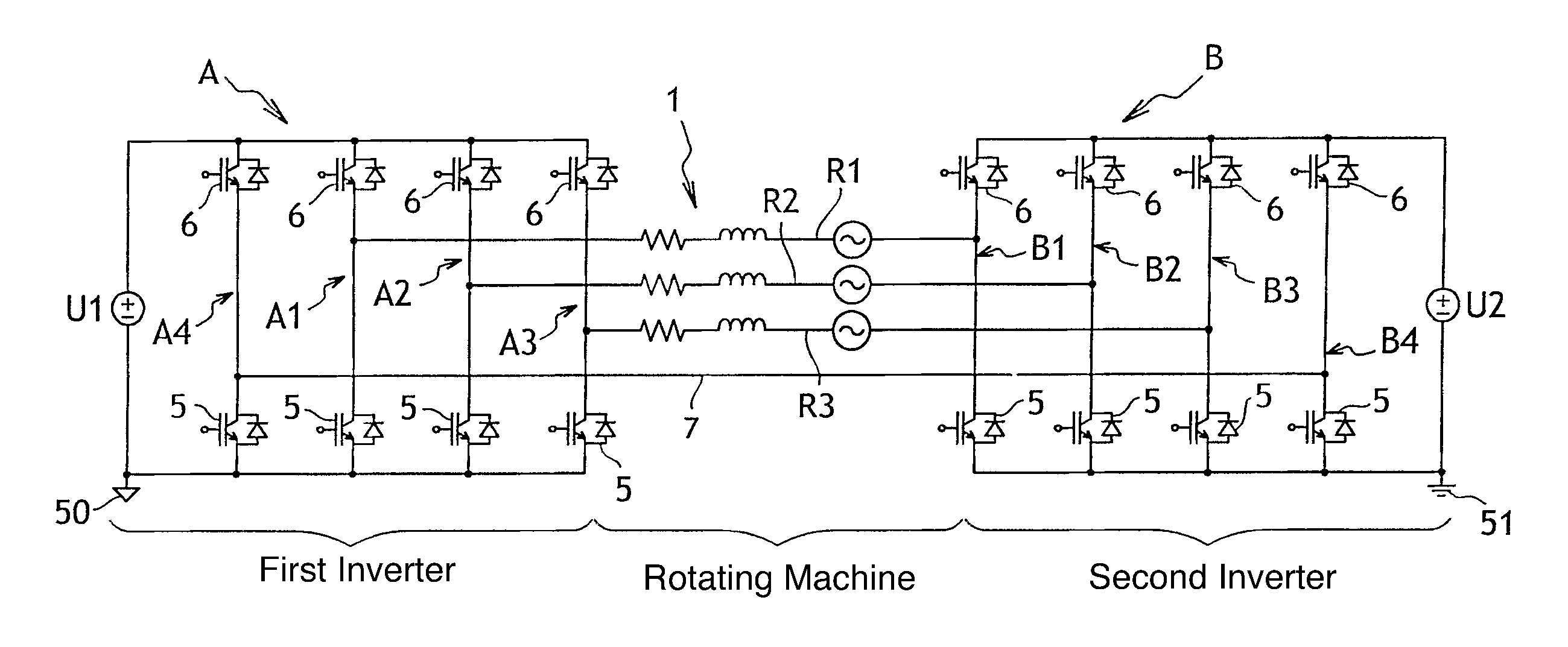

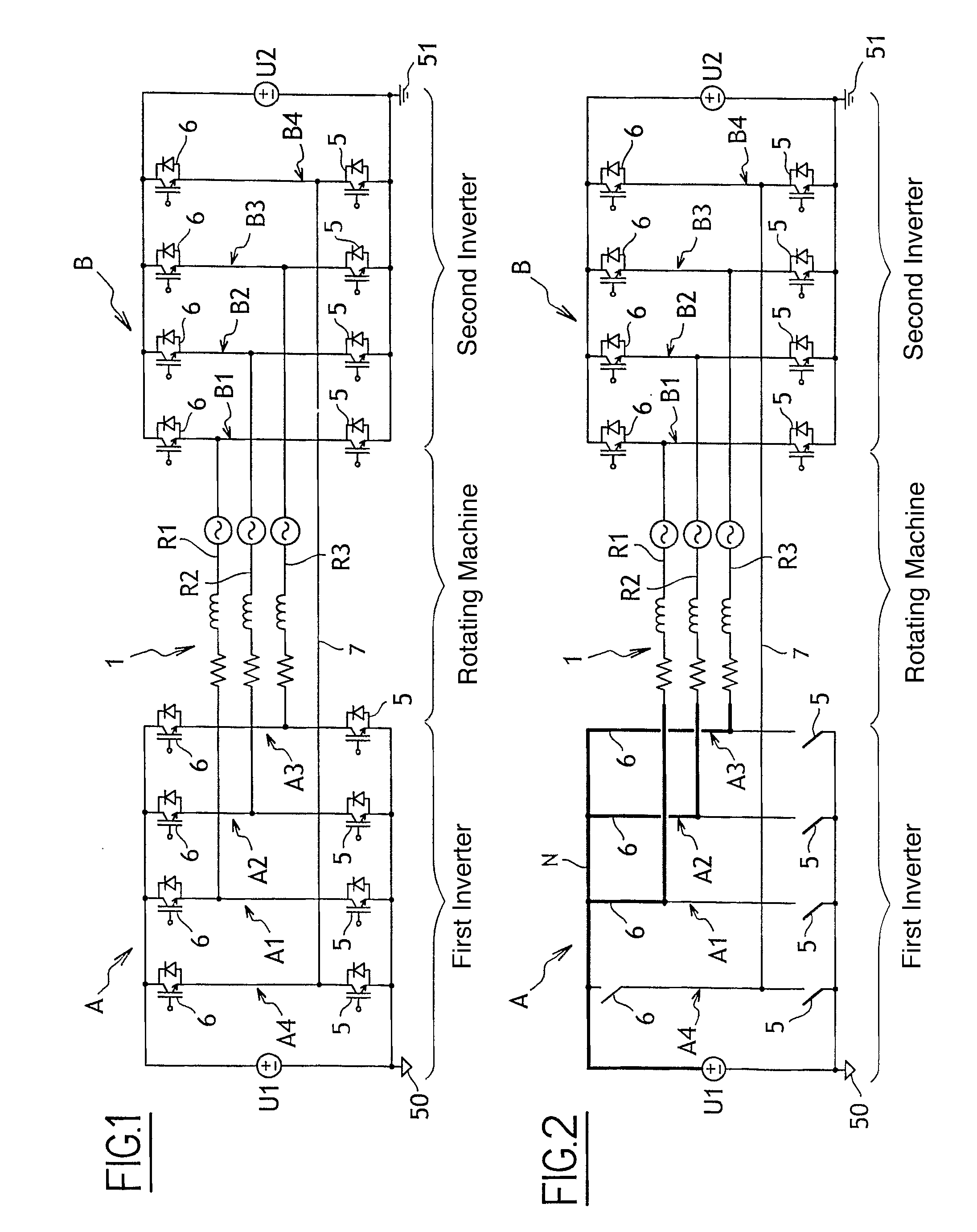

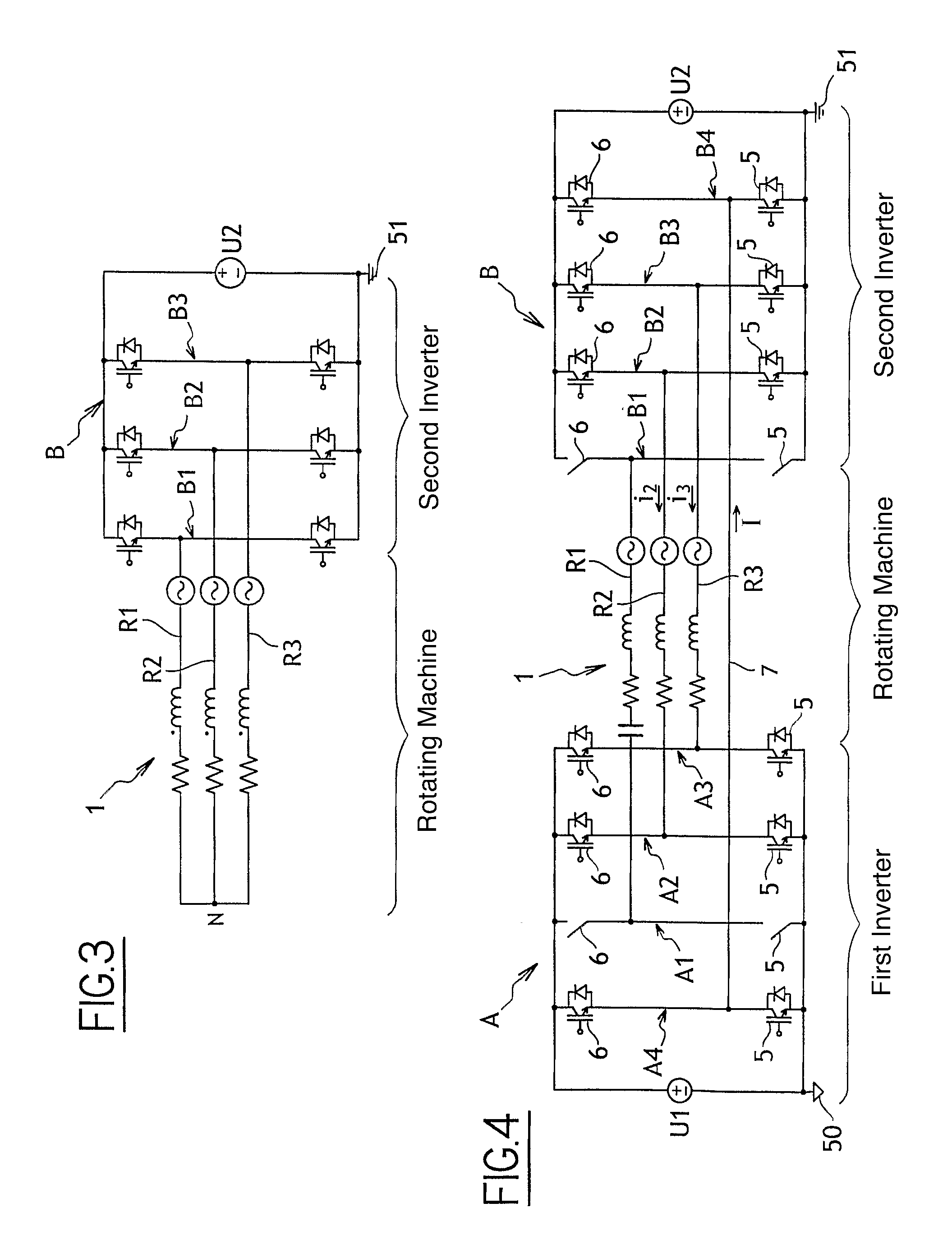

Power supply with two series inverters for a polyphase electromechanical actuator

ActiveUS8294408B2Constant torqueSingle-phase induction motor startersMotor/generator/converter stoppersVoltage sourceControl switch

The invention relates to a power supply having two inverters (A, B) in series for powering an electromechanical actuator having an electric motor including a plurality of windings (R1, R2, R3) forming phases, each inverter being connected to its own ground (50; 51) and having a voltage source (U1; U2) having as many arms (A1, A2, A3; B1, B2, B3) as there are windings to be powered, each arm including two controlled switches (5, 6) connected in series, with a point therebetween being provided for connection to one end of one of the windings. According to the invention, each inverter includes an additional arm (A4; B4) having two controlled switches, the two additional arms being interconnected by a bridge (7) that is connected to each of the additional arms at a point that is situated between the switches.

Owner:SAFRAN LANDING SYSTEMS

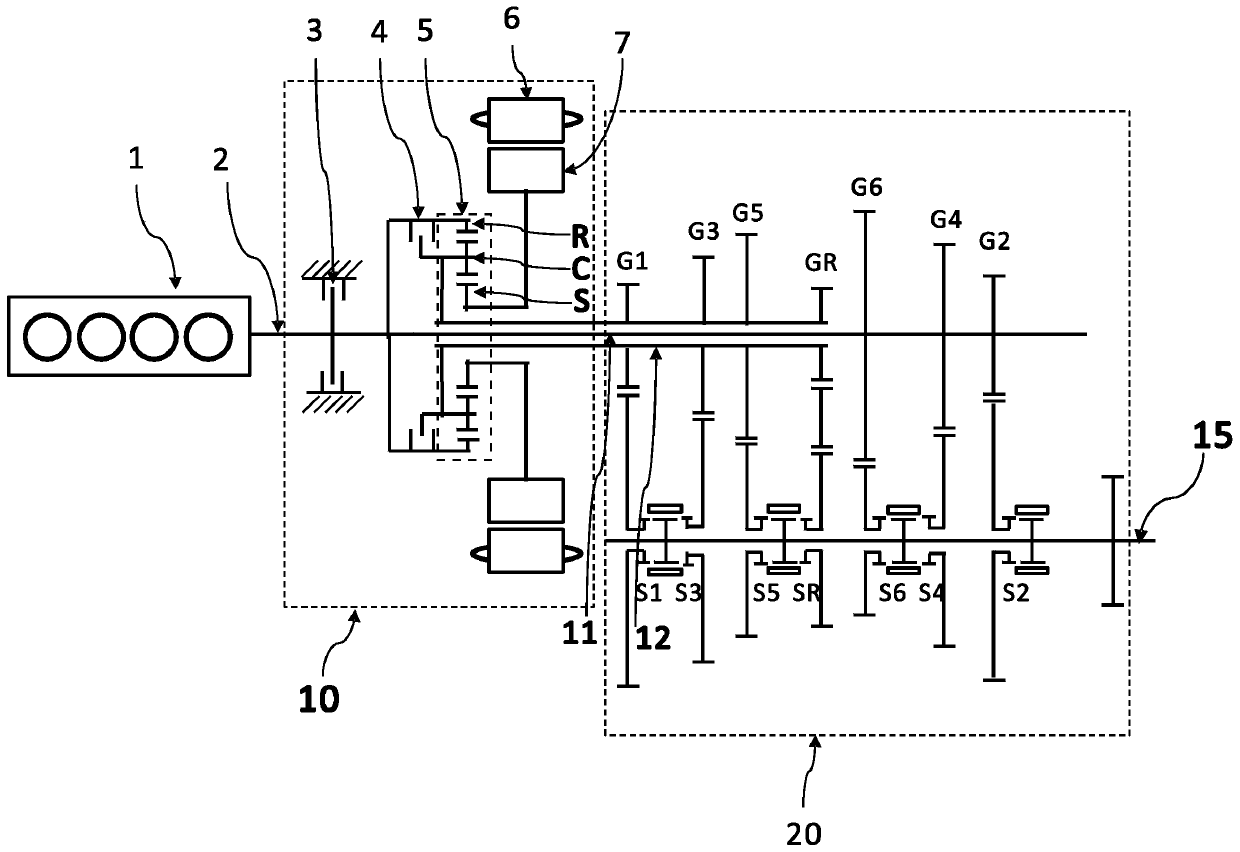

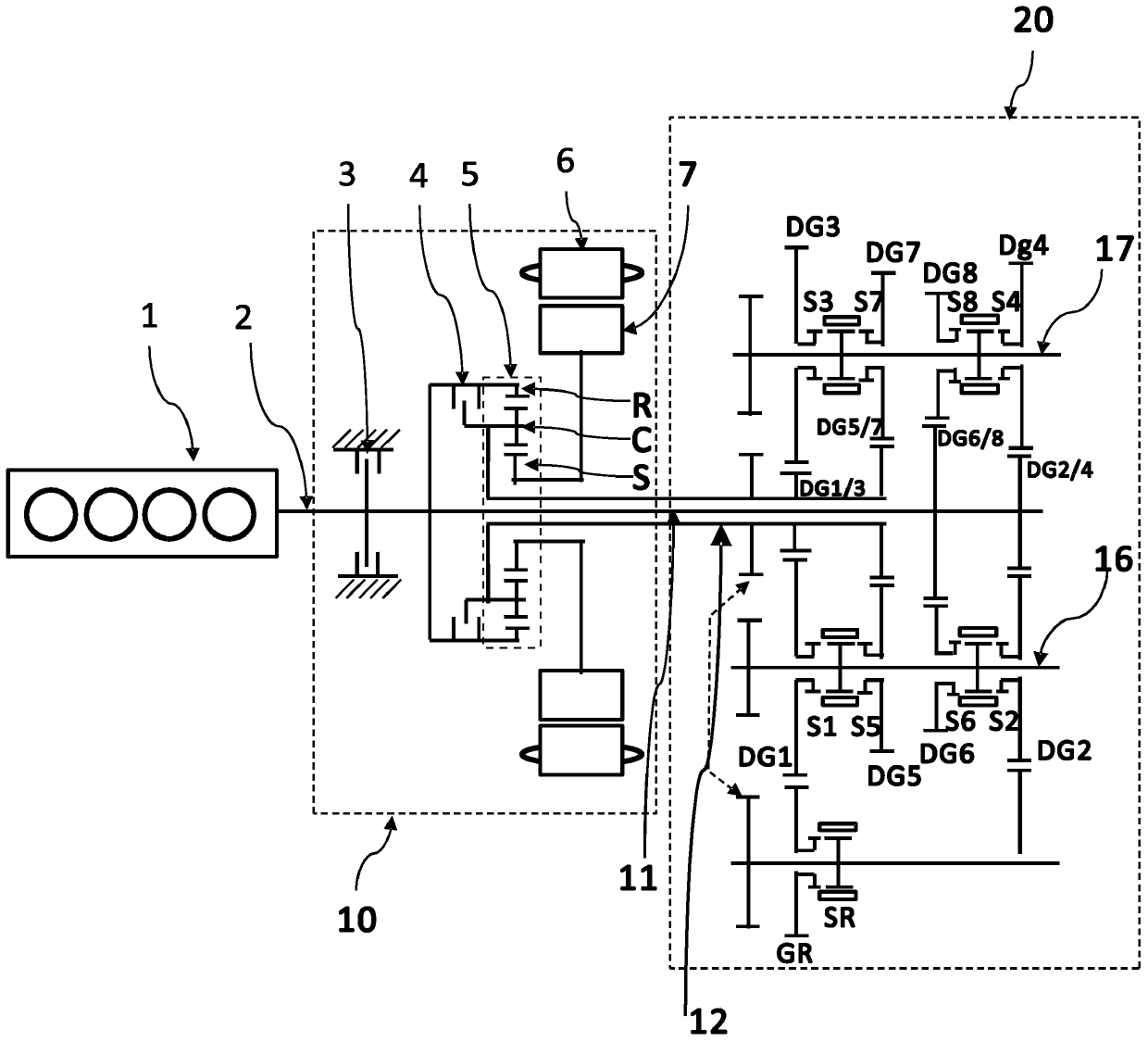

Vehicle hybrid power system and control method thereof

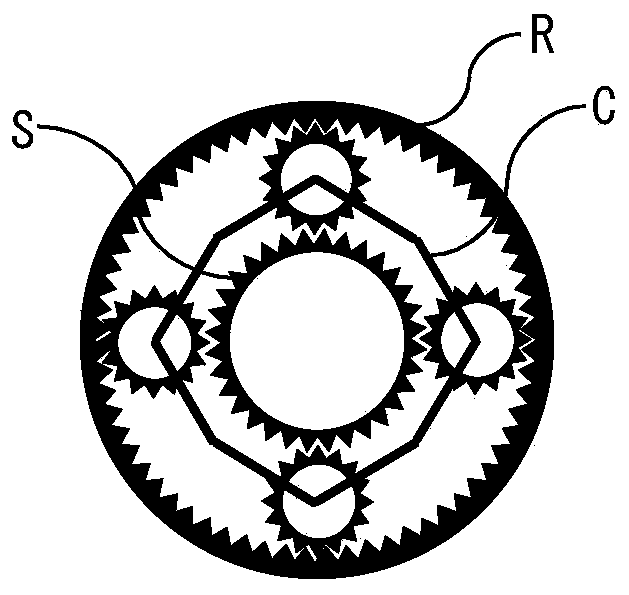

ActiveCN110525191AAdjust torqueTorque balanceHybrid vehiclesGas pressure propulsion mountingElectric machineGear wheel

The invention discloses a vehicle hybrid power system and a control method thereof. The system involves an engine, a hybrid power module and a double-input-shaft speed change mechanism, wherein the hybrid power module is composed of a motor, a planetary gear train and a first clutch, the planetary gear train is provided with at least three rotating shafts, the three rotating shafts comprise a rotating shaft X1, a rotating shaft X2 and a rotating shaft X3, axes of the three rotating shafts are on one straight line, the rotating speed of the rotating shaft X2 is between the rotating speed of therotating shaft X1 and the rotating speed of the rotating shaft X3, a first clutch is arranged between any two of the three rotating shafts, a power output shaft of the engine is connected with the rotating shaft X3 or the rotating shaft X1 of the planetary gear train and a second input shaft of the double-input-shaft speed change mechanism, a rotor of the motor is connected with the rotating shaft X1 or the rotating shaft X3, and the rotating shaft X2 is connected with a first input shaft of a double-input-shaft gearbox. According to the system and the method, the transmission efficiency is high, multiple gears are provided, the three-axis double-freedom-degree planetary gear train is introduced, a vehicle is driven to start by the differential between the engine and the motor, starting of the vehicle is stable, the smoothness of gear shifting is good, and the impact of gear shifting is small.

Owner:段志辉

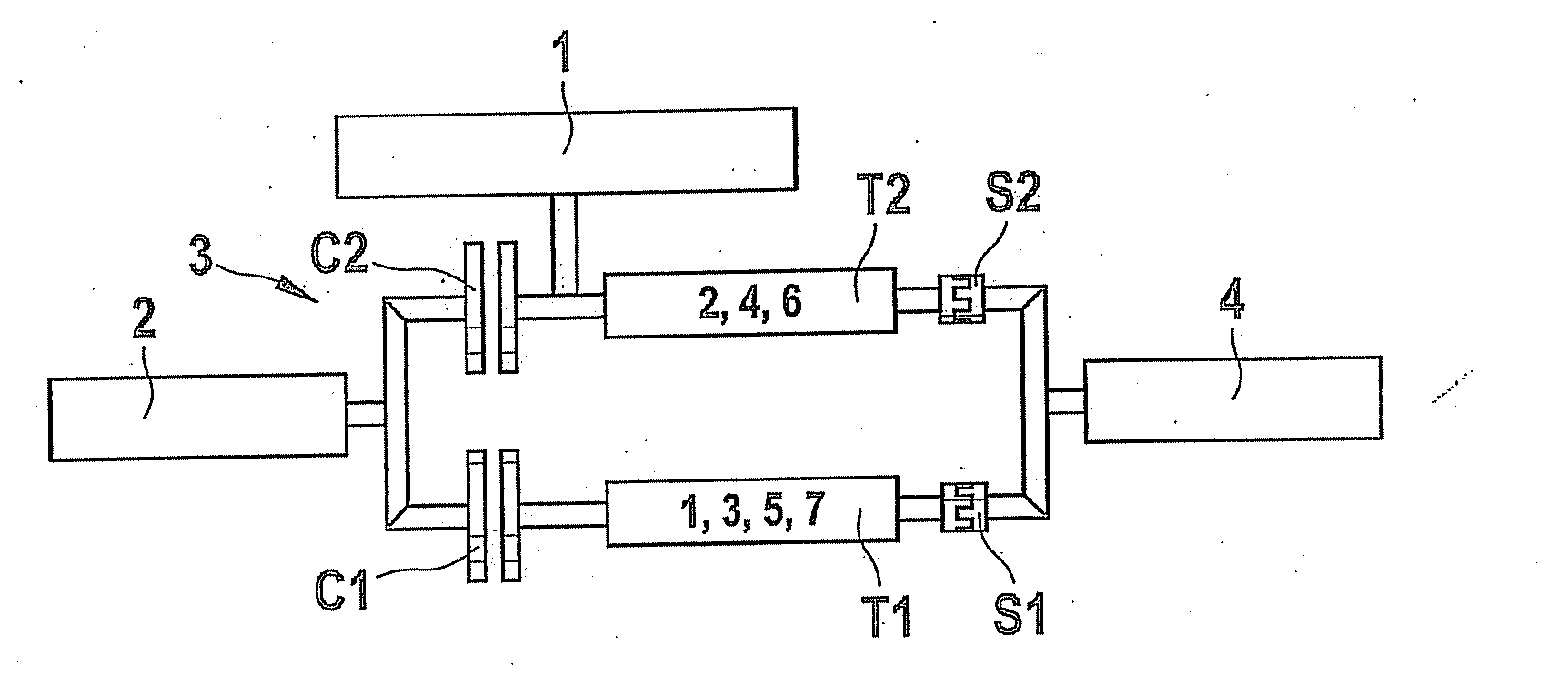

Method and device for starting the movement of a hybrid vehicle

InactiveUS20110186369A1Great driving forceMaintaining their functionalityClutchesVehicle sub-unit featuresHybrid vehicleClutch

A method for starting the movement of a hybrid vehicle, which has a first and a second drive unit, the first drive unit being disposed on a first sub-transmission of a twin-clutch transmission having two sub-transmissions. In order to avoid rolling backwards when starting to move the hybrid vehicle in an attempt to start the movement using the first drive unit, the second drive unit is started when starting the movement of the hybrid vehicle using the first drive unit, without interrupting the stress applied on the drive train comprising the twin-clutch transmission.

Owner:ROBERT BOSCH GMBH

Power supply with two series inverters for a polyphase electromechanical actuator

ActiveUS20100141189A1Constant torqueSingle-phase induction motor startersMotor/generator/converter stoppersEngineeringVoltage source

The invention relates to a power supply having two inverters (A, B) in series for powering an electromechanical actuator having an electric motor including a plurality of windings (R1, R2, R3) forming phases, each inverter being connected to its own ground (50; 51) and having a voltage source (U1; U2) having as many arms (A1, A2, A3; B1, B2, B3) as there are windings to be powered, each arm including two controlled switches (5, 6) connected in series, with a point therebetween being provided for connection to one end of one of the windings. According to the invention, each inverter includes an additional arm (A4; B4) having two controlled switches, the two additional arms being interconnected by a bridge (7) that is connected to each of the additional arms at a point that is situated between the switches.

Owner:SAFRAN LANDING SYSTEMS

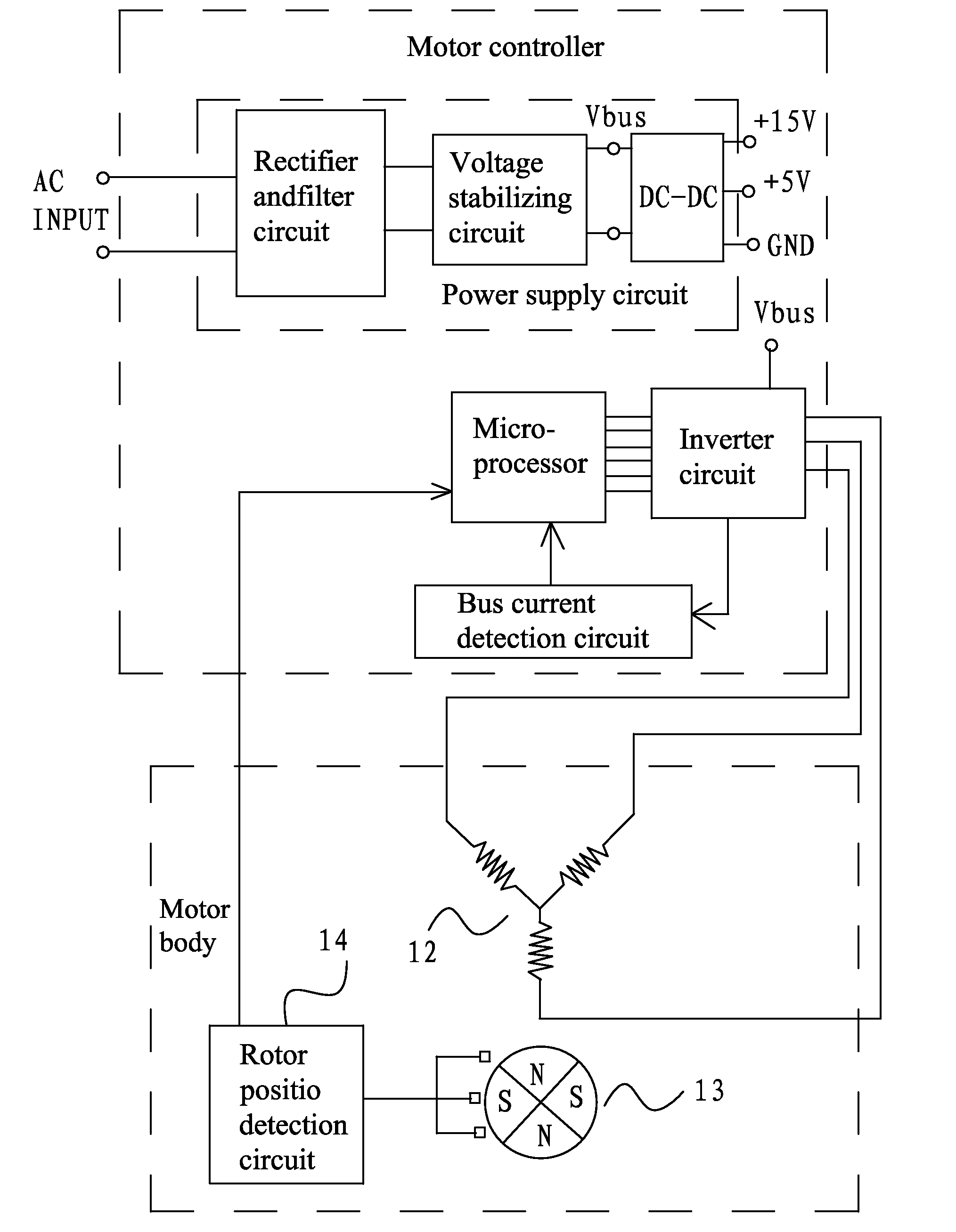

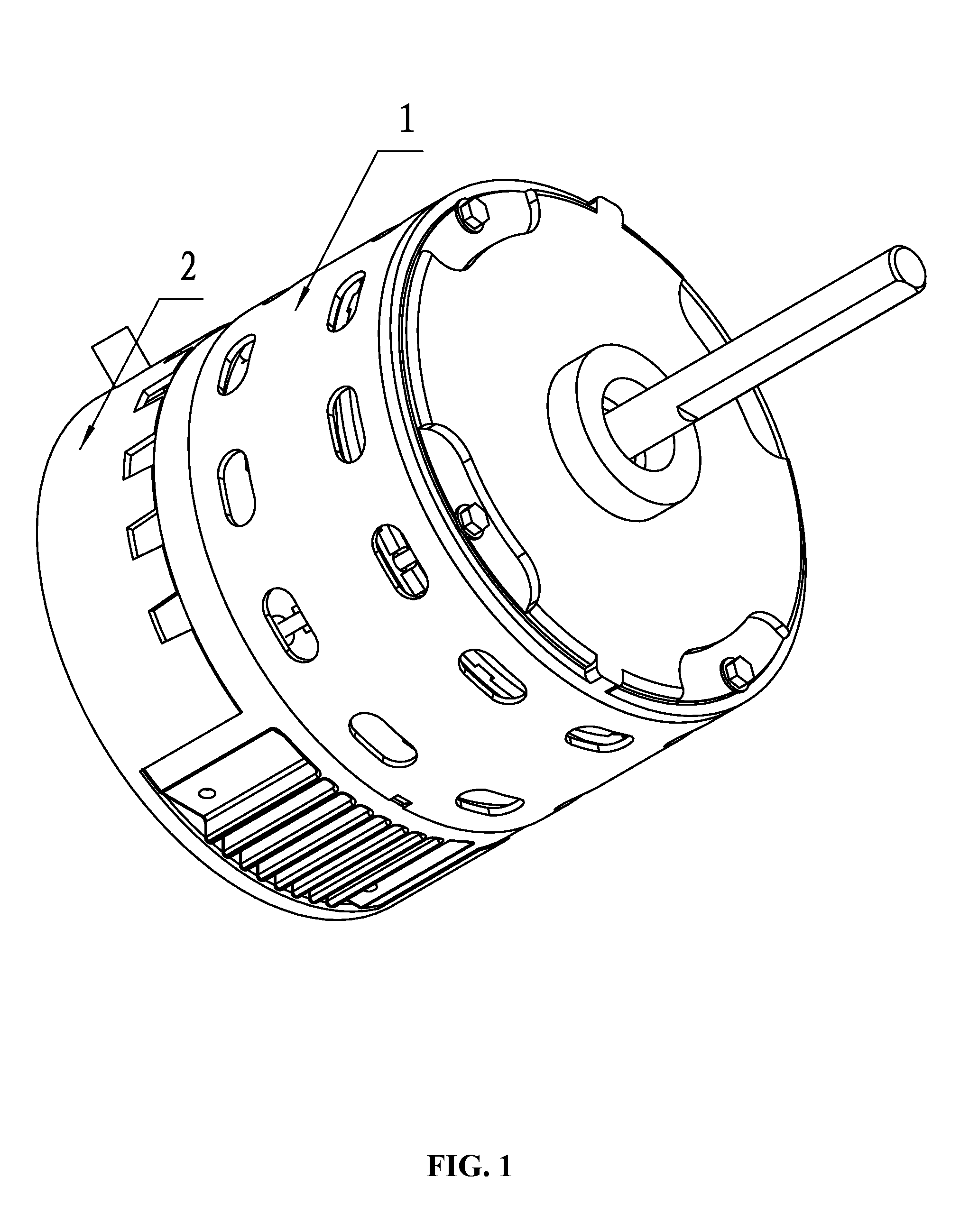

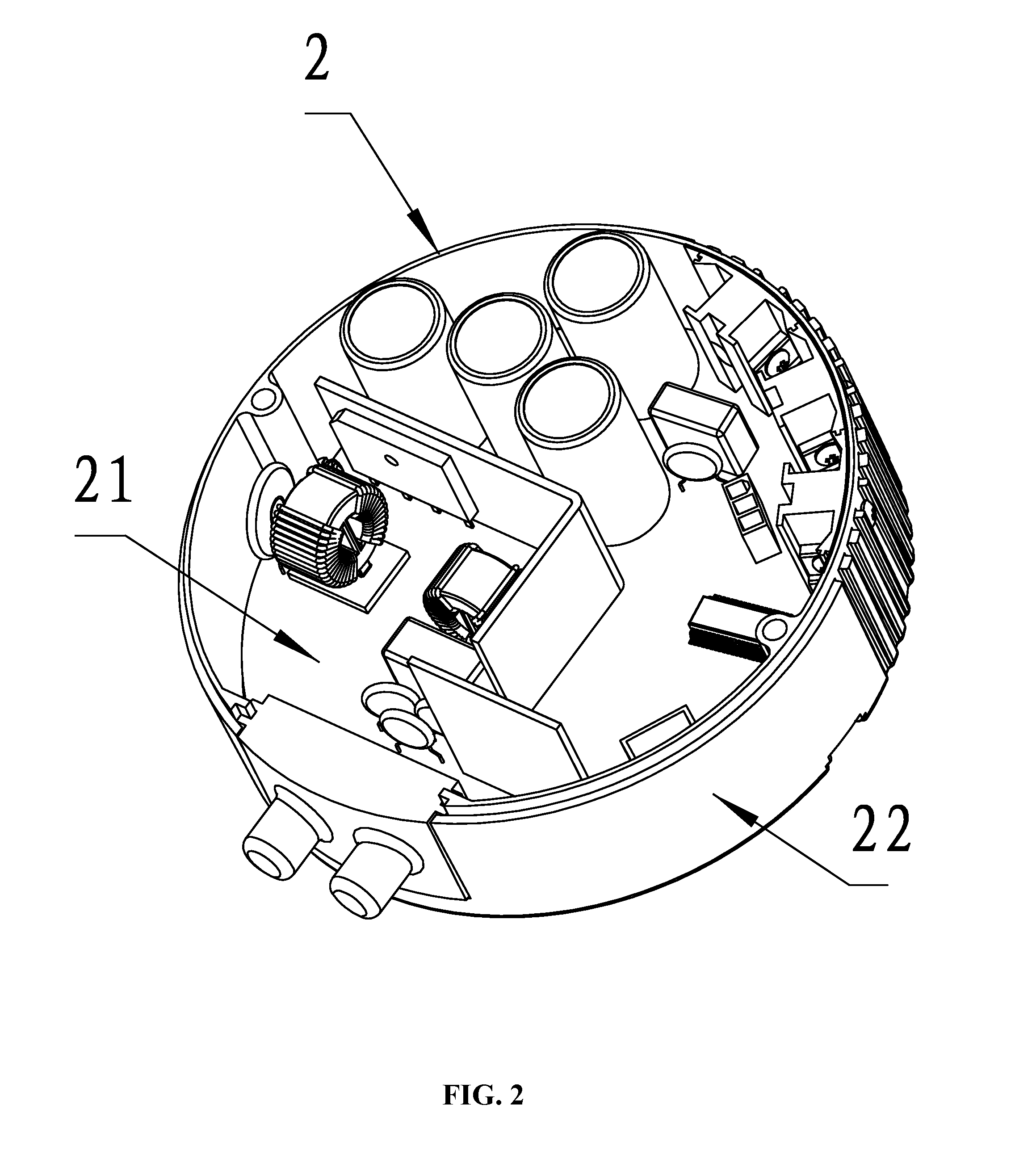

Method for controlling ecm motor to output constant torque

ActiveUS20150115851A1Low arithmetic capabilityLow production costMotor/generator/converter stoppersAC motor controlClosed loopEngineering

A method for controlling an ECM motor to output a constant torque. The method includes: 1) entering a target torque value T0 from an external device; when the motor is in a non-use state, starting the motor, and allowing the microprocessor to acquire an original output voltage value P chopped by a PWM signal; when the motor is in a running state, allowing the microprocessor to acquire a current output voltage value P chopped by the PWM signal; 2) enabling the microprocessor to calculate a target bus current value Itad using the function Itad=F(T,P) according to the target torque value T0 and the output voltage value P chopped by the PWM signal; and detecting a real-time bus current Ibus; and 3) allowing the microprocessor to compare the target bus current value Itad with the real-time bus current Ibus for conducting a closed-loop control.

Owner:ZHONGSHAN BROAD OCEAN

Switching pattern AC induction motor

InactiveUS7239061B2Wide speed rangeReduce manufacturing costSingle-phase induction motor startersAC motor controlFrequency characteristicPulse width modulated

Both the stator core and the rotor core of a switching pattern AC induction motor are fabricated by soft magnetic material laminations or ferrite material, etc., both of which have corresponding frequency characteristic. The rotor is a squirrel cage rotor. Switching pattern excitation is adopted in the stator pole, of which the excitation voltage is sine wave pulse width modulated or sine wave pulse amplitude modulated within the frequency range of voice and ultrasonic. Under the condition of the same power output, the present motor reduces its size and mass to a fraction of or tenth of that of an ordinary one. Meanwhile, it reduces the cost of manufacture. It realizes stepless speed regulating from zero to several thousand rpm while keeping well mechanical characteristic performance.

Owner:HUANG YOUGUO +1

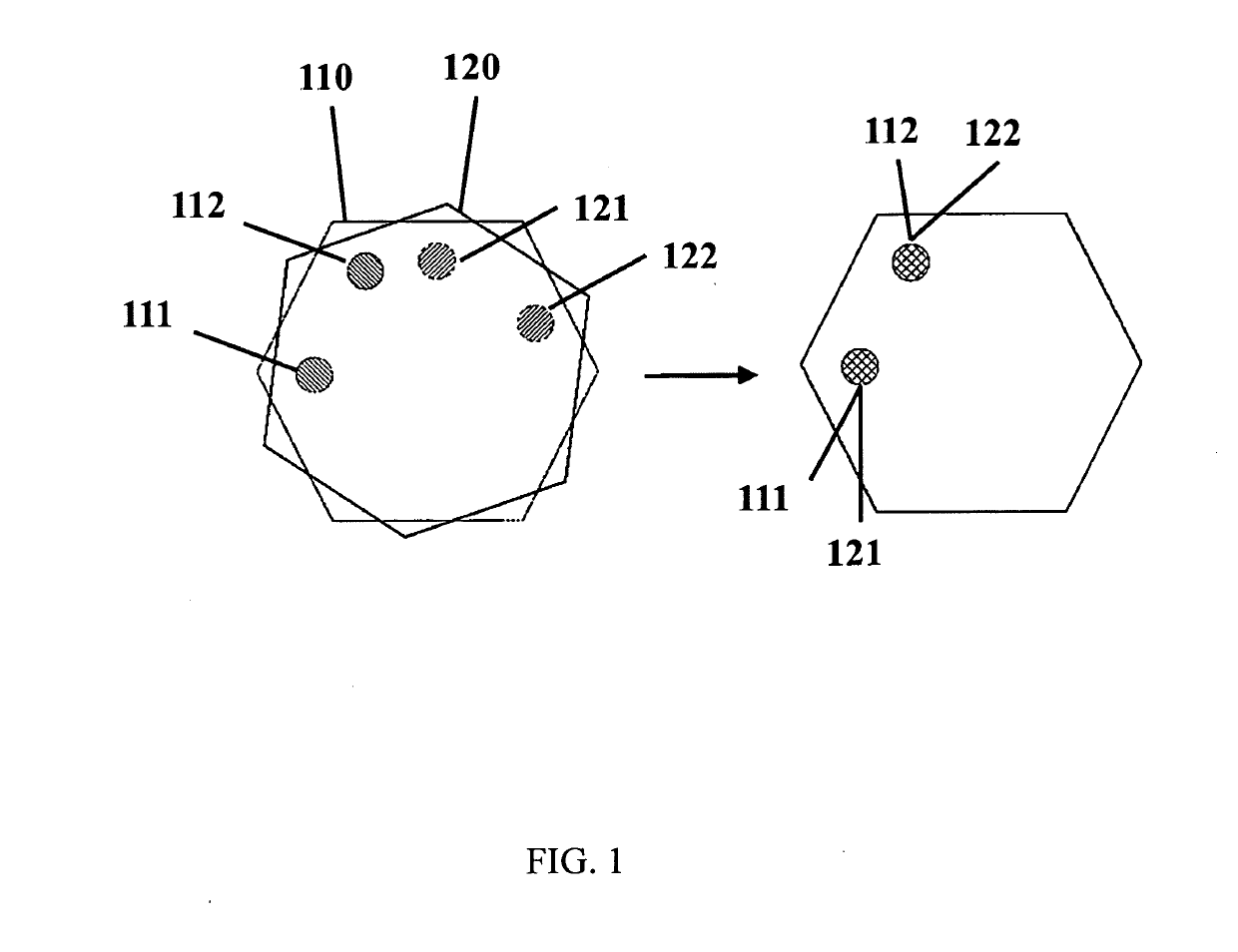

Devices and methods for autonomous measurements

InactiveUS20190111423A1Angular velocity stabilityReduce pressureHeating or cooling apparatusMicrobiological testing/measurementComputer scienceMultiple device

Disclosed herein are devices and methods for storing, processing, preparing and / or analyzing samples. The inventions herein also relate to strategies and methods for automating device operations and for combining multiple devices in an integrated platform.

Owner:CALIFORNIA INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com