Pulverized coal feeder frequency converter control system with low voltage ride-through power supply device

A technology of low-voltage ride-through and frequency converter control, which is applied in the direction of reducing/preventing power oscillation, etc. It can solve problems such as powder feeding machine outage, speed, torque, and power changes, and achieve the effect of fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

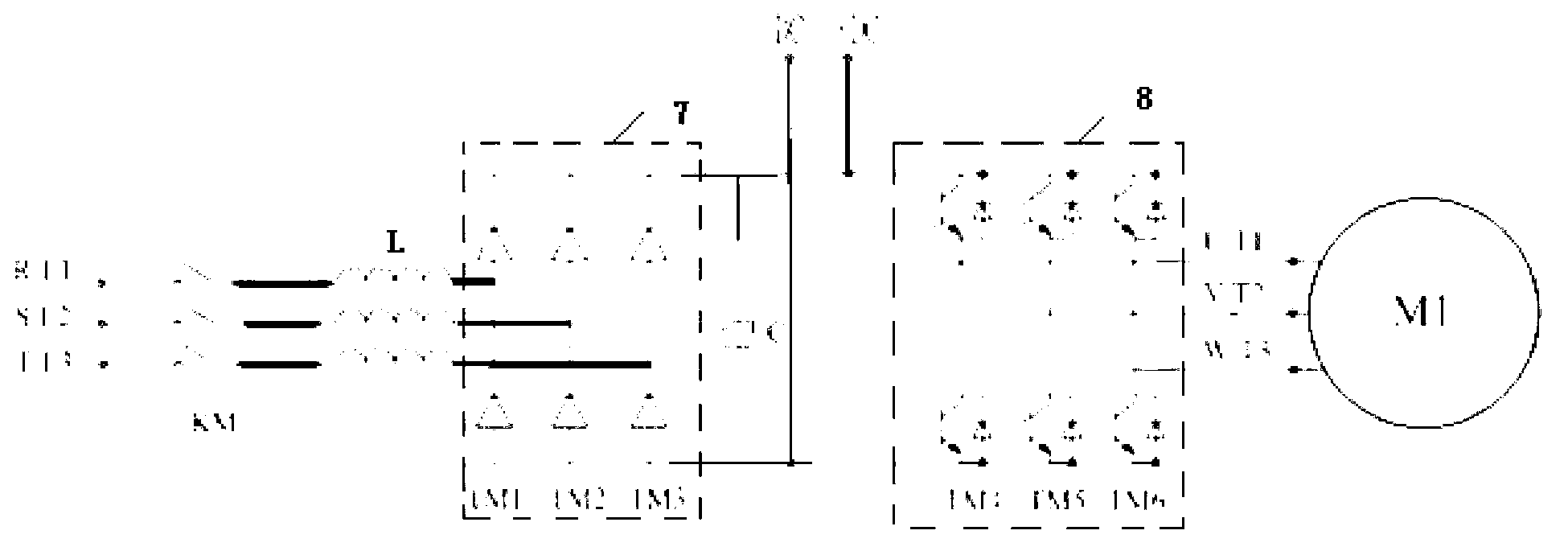

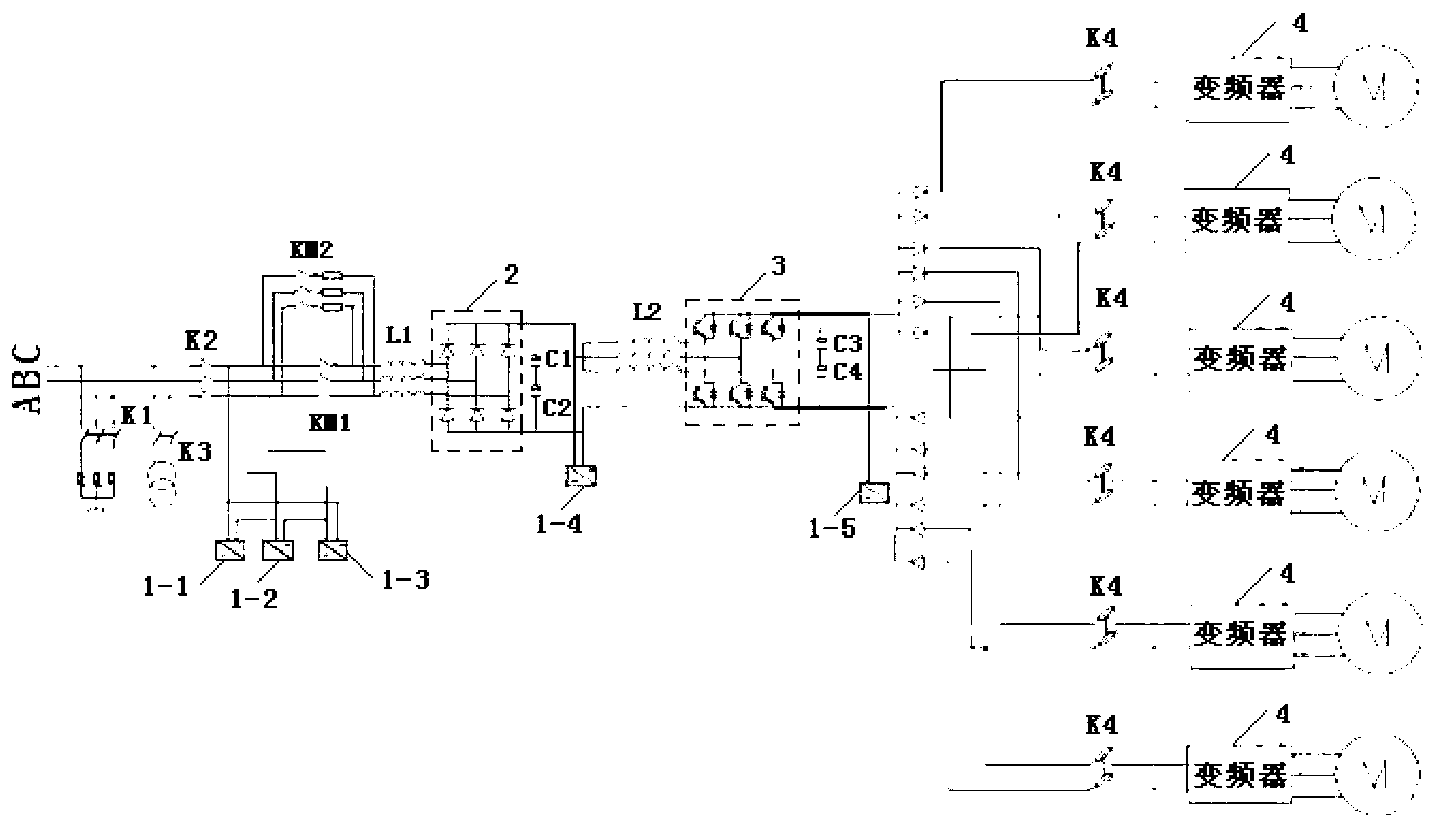

[0023] Specific implementation mode one: see figure 2 Describe this embodiment, the powder feeder inverter control system with low voltage ride-through power supply device described in this embodiment, it includes the first two-phase switch K3, the first three-phase switch K1, the second three-phase switch K2, the second A three-phase inductance L1, a second three-phase inductance L2, a first contactor KM1, a second contactor KM2, a transformer, a diode rectifier bridge 2, a three-phase inverter circuit 3, a first voltage detection module 1-1, a second Voltage detection module 1-2, third voltage detection module 1-3, fourth voltage detection module 1-4, fifth voltage detection module 1-5, first capacitor C1, second capacitor C2, third capacitor C3, Four capacitors C4, multiple cells and 6 resistors,

[0024] The 6 resistors are divided into two groups, each group has 3 resistors,

[0025] Multiple units have the same structure, and each unit includes a first diode, a second...

specific Embodiment approach 2

[0031] Specific implementation mode two: see figure 2 Describe this embodiment. The difference between this embodiment and the powder feeder inverter control system with a low-voltage ride-through power supply device described in the first embodiment is that the number of the multiple units described is greater than or equal to 2 and less than or equal to 12 .

specific Embodiment approach 3

[0032] Specific implementation mode three: see figure 2 Describe this embodiment. The difference between this embodiment and the powder feeder inverter control system with a low voltage ride-through power supply device described in the first embodiment is that the first voltage detection module 1-1 and the second voltage detection module 1-1 The structures of the module 1-2, the third voltage detection module 1-3, the fourth voltage detection module 1-4 and the fifth voltage detection module 1-5 are exactly the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com