Patents

Literature

39results about How to "Adjust air intake" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

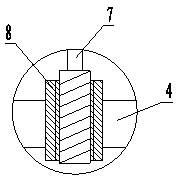

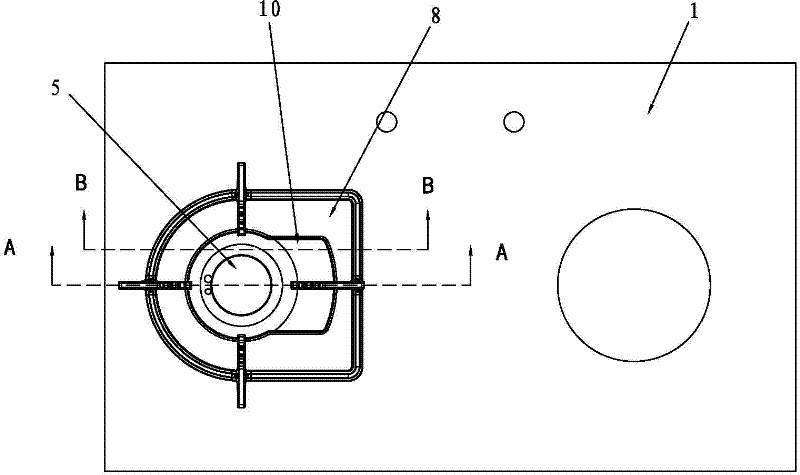

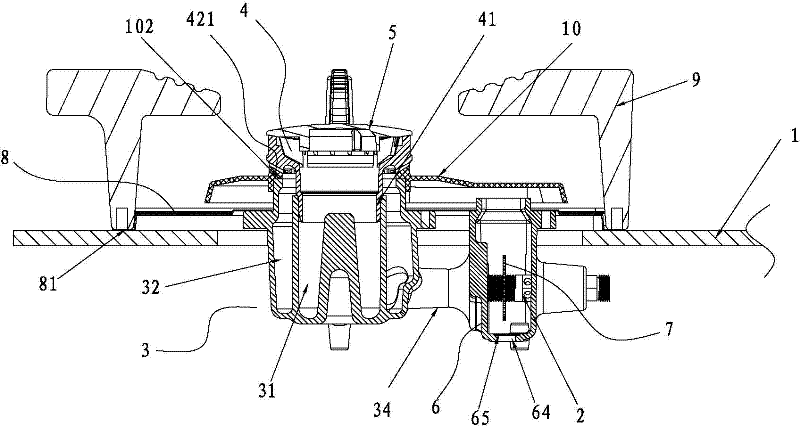

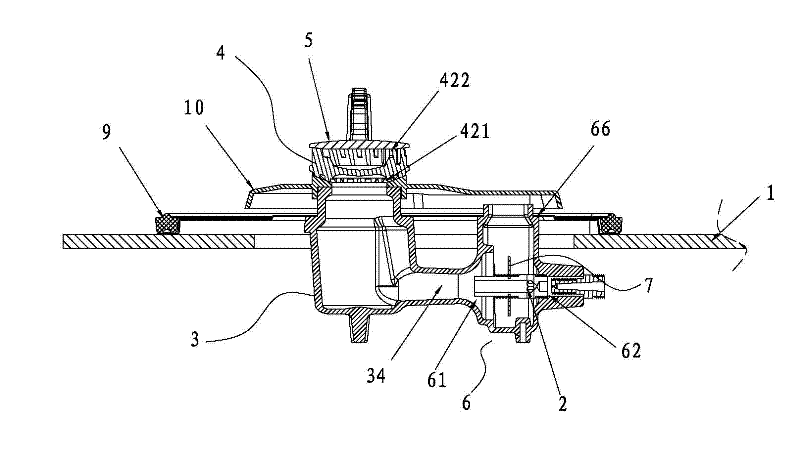

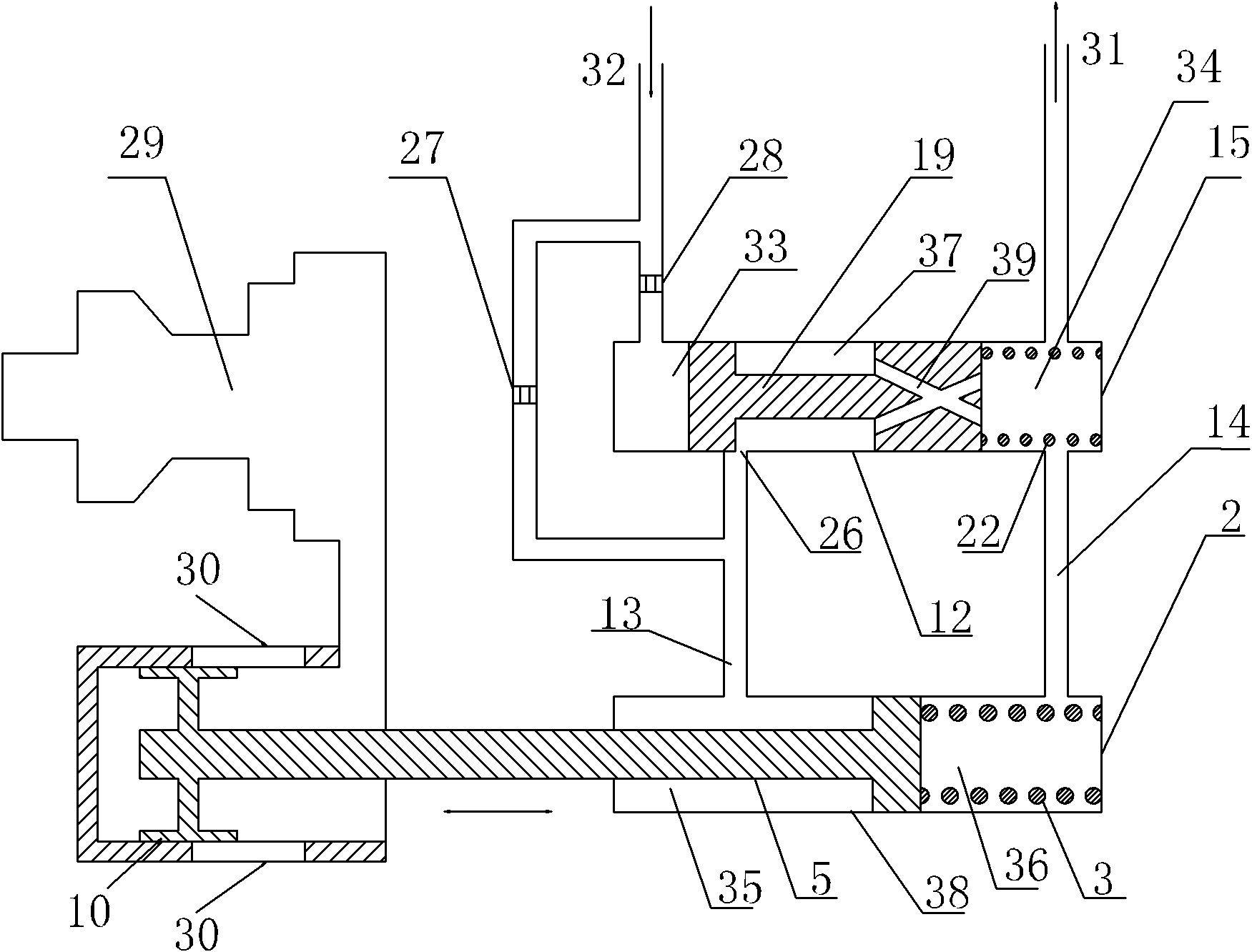

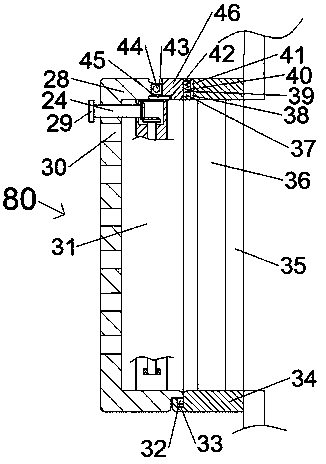

Tempering-resistant air adjusting type gas stove with upper air inlet

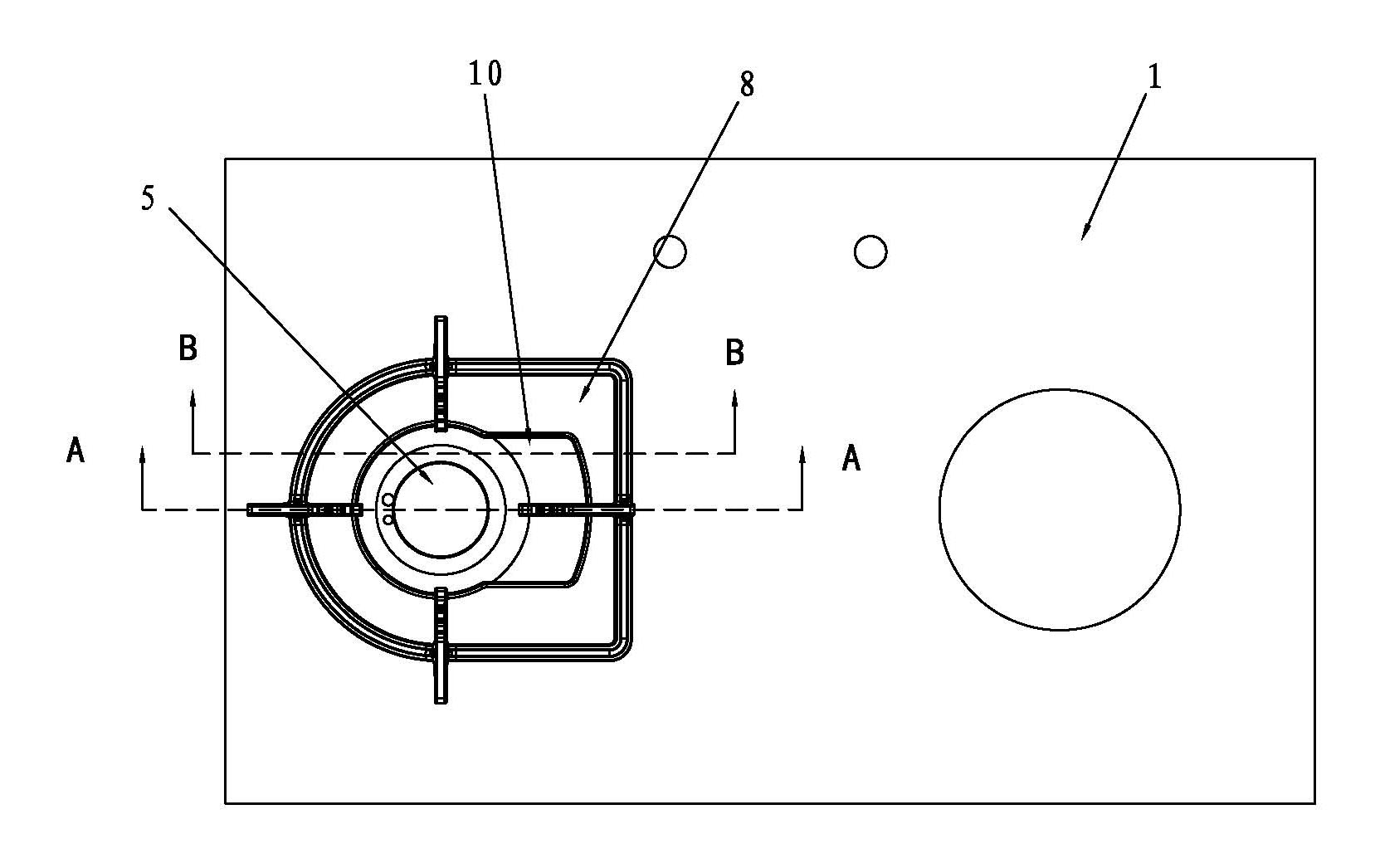

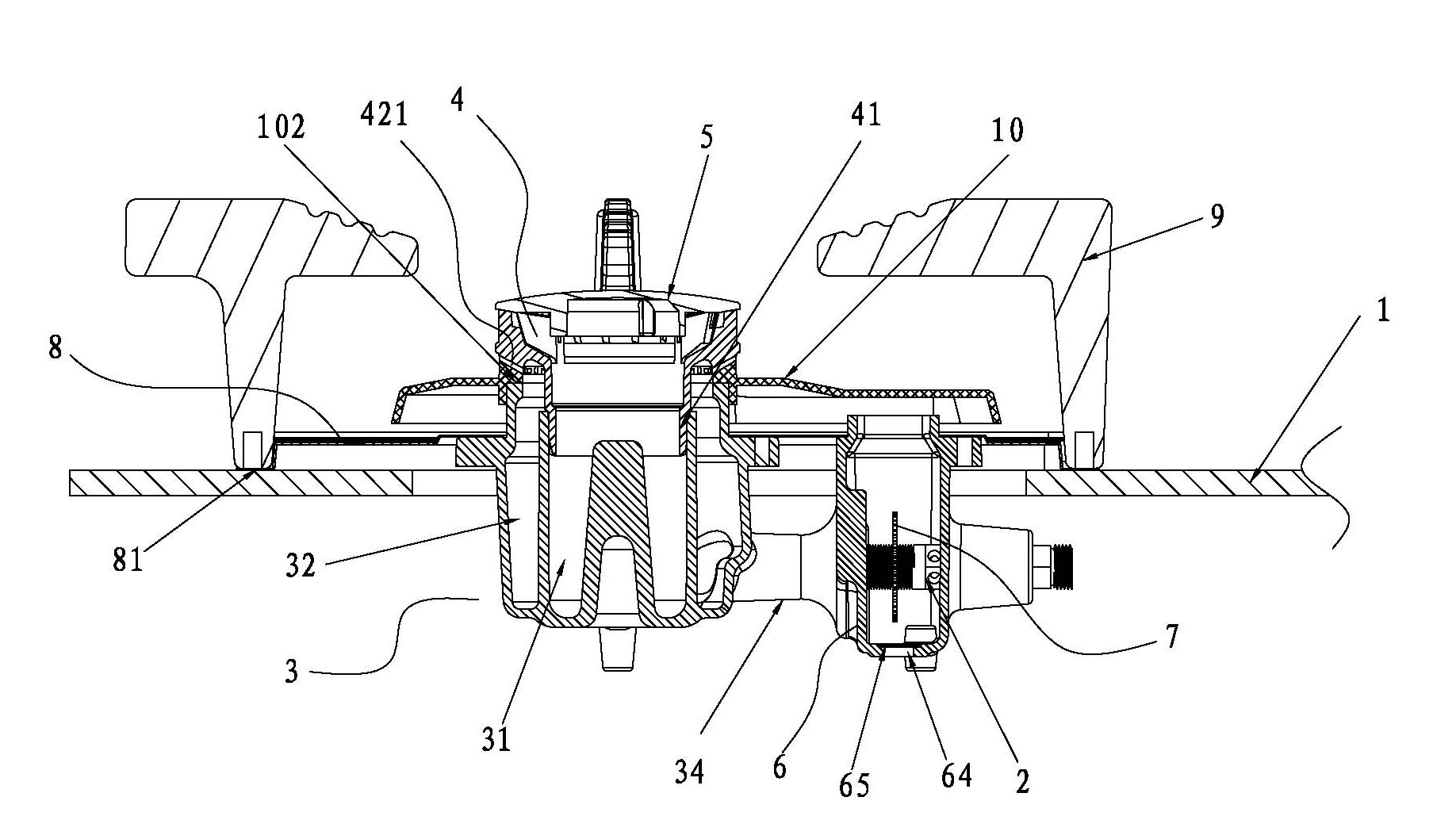

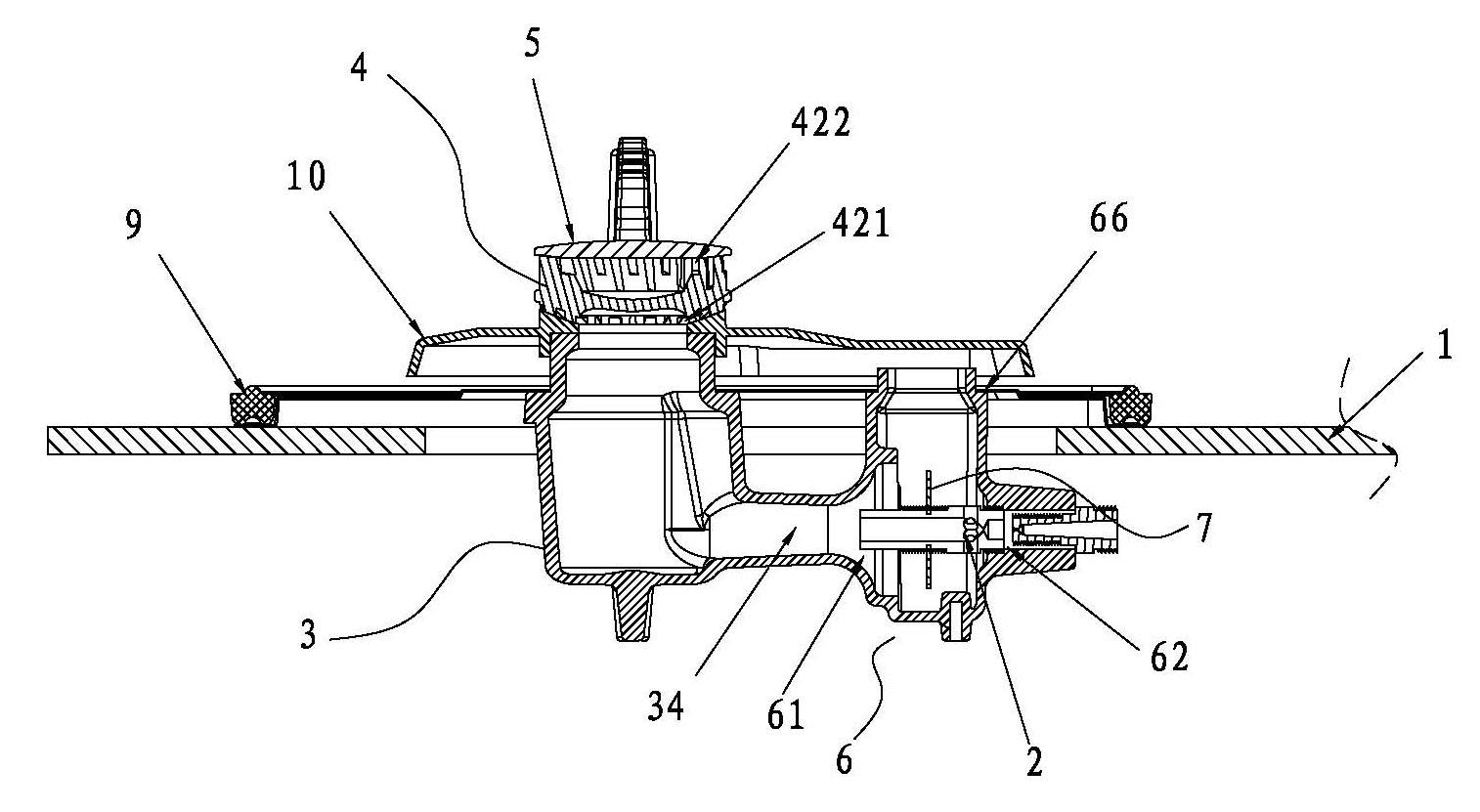

ActiveCN102147117AAdjust air intakeFully temperedDomestic stoves or rangesGaseous fuel burnerScrew threadAir cavity

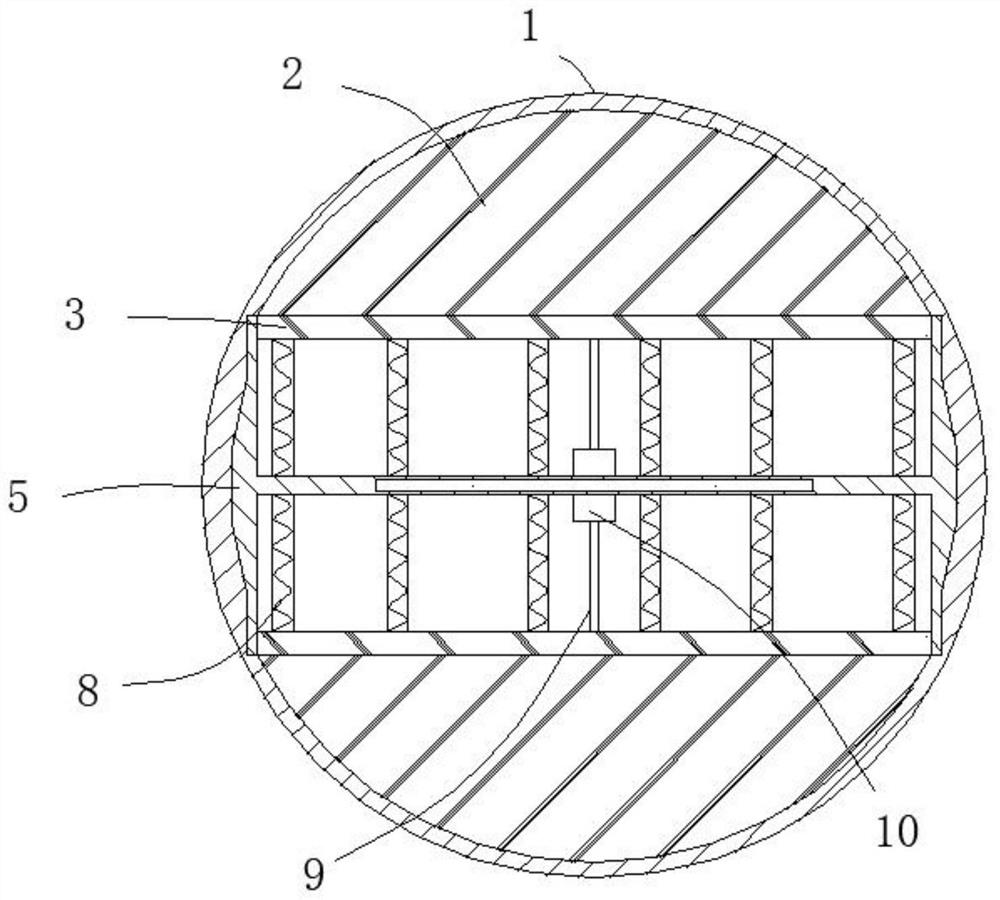

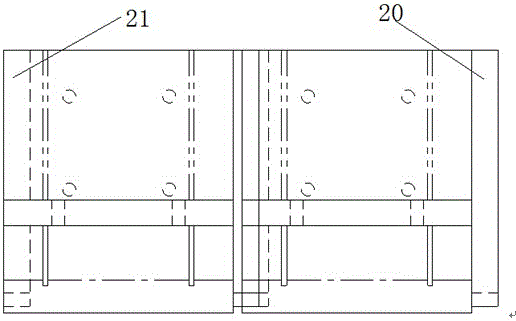

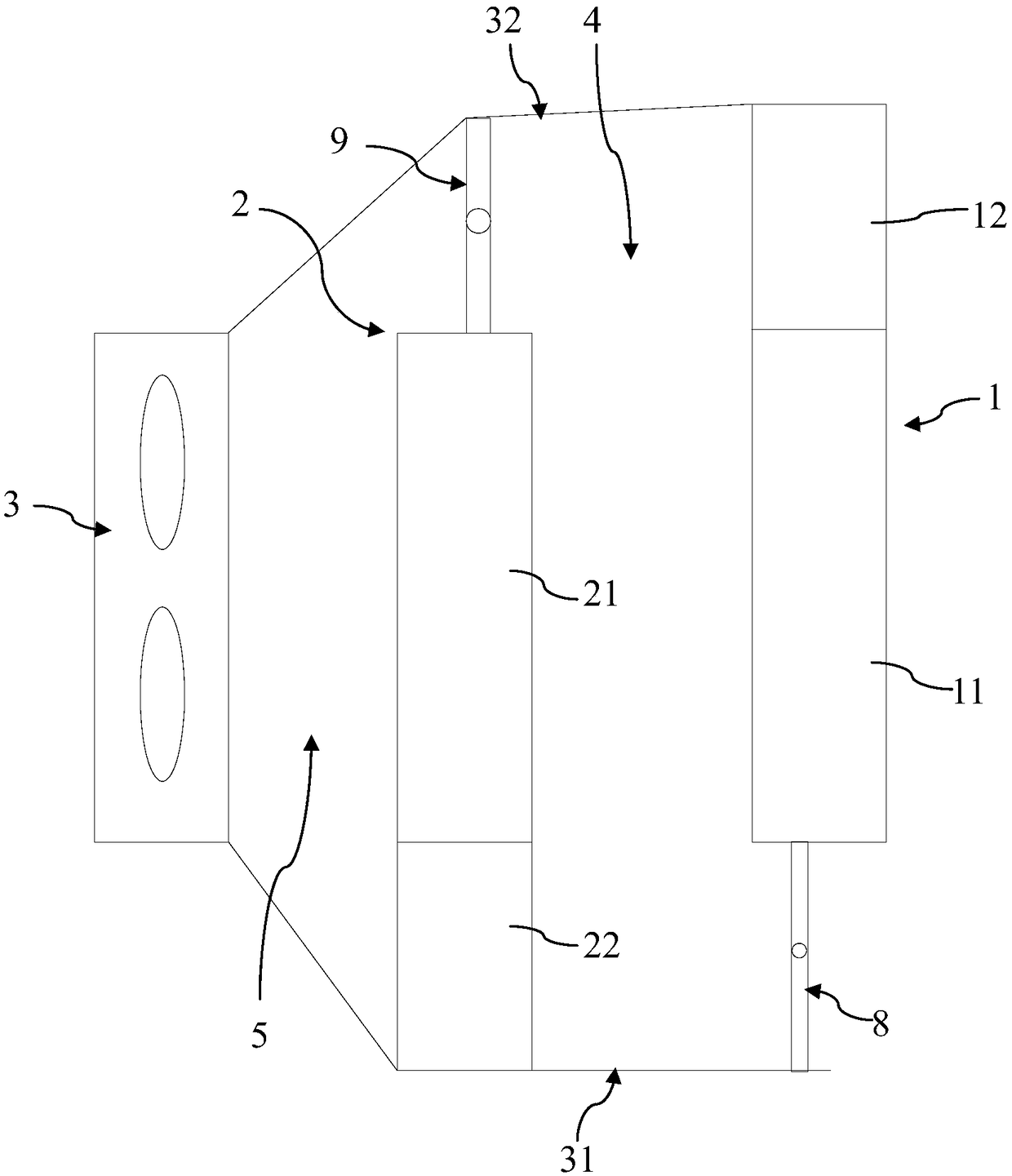

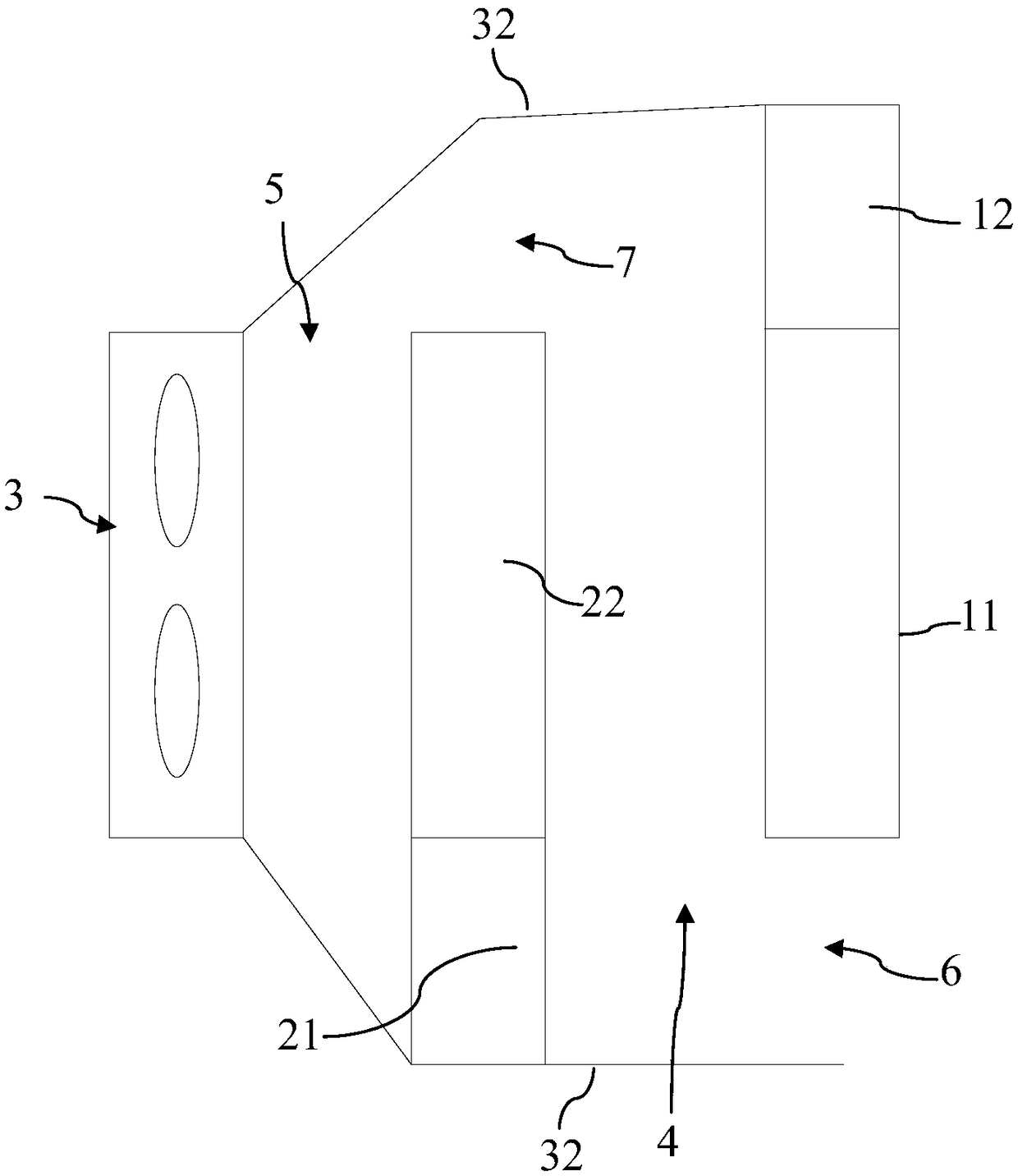

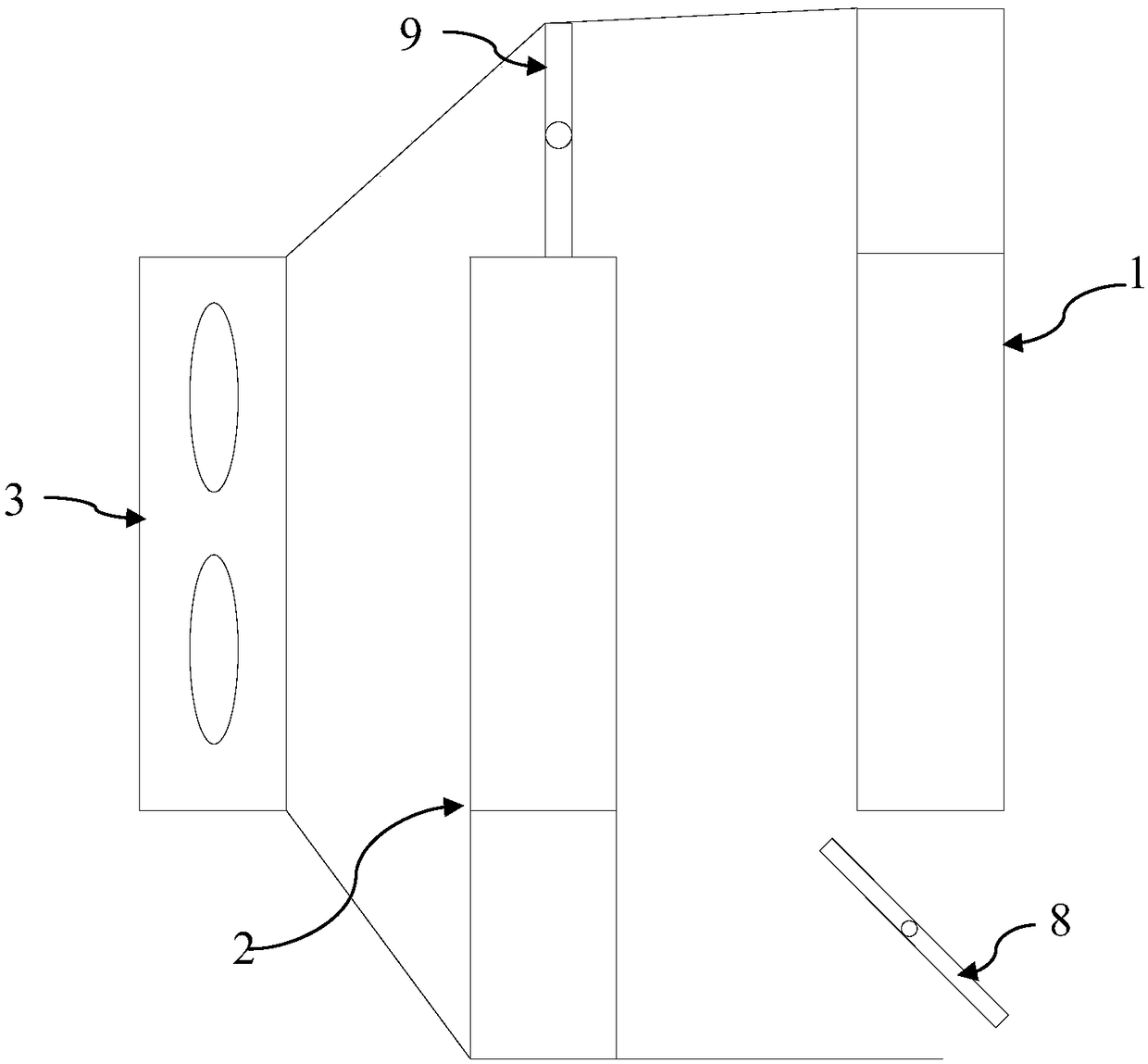

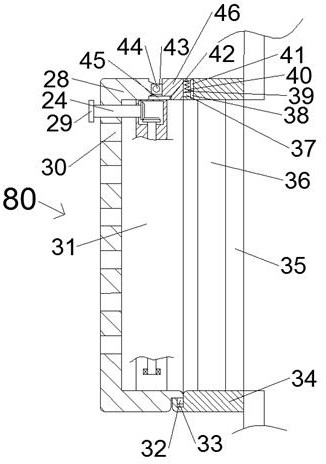

The invention relates to a tempering-resistant air adjusting type gas stove with an upper air inlet, which comprises a panel, a combustor, a nozzle, an air cavity with an upper opening and a cover plate, wherein a burner comprises a premixing cavity and an ejector tube; the cover plate is positioned above the upper opening of the air cavity; a gap is formed between the cover plate and the upper opening; the upper opening of the air cavity is stretched out of the panel after passing through the panel; the front and rear side walls of the air cavity are respectively provided with an air outlet hole and an air inlet hole; the air inlet hole is communicated with the ejector tube; the nozzle is arranged on the air inlet hole; the air inlet end of the nozzle is in screw thread fit with the air outlet hole; the air outlet end of the nozzle is opposite to the air outlet hole; a door plate arranged on the air outlet end of the nozzle is matched with the air outlet hole; and the door plate is in screw thread fit with the nozzle. Because the structure is adopted, the nozzle can be exchanged; the door plate is rotated, so that the door plate is far away from or close to the air outlet of the air cavity to achieve the purpose of adjusting the air intake flow of the air once to supply sufficient air to gas, thereby achieving full combustion; and a temperature sensor is provided to prevent the explosion because the tempering occurs.

Owner:中山市秋意厨卫电器有限公司

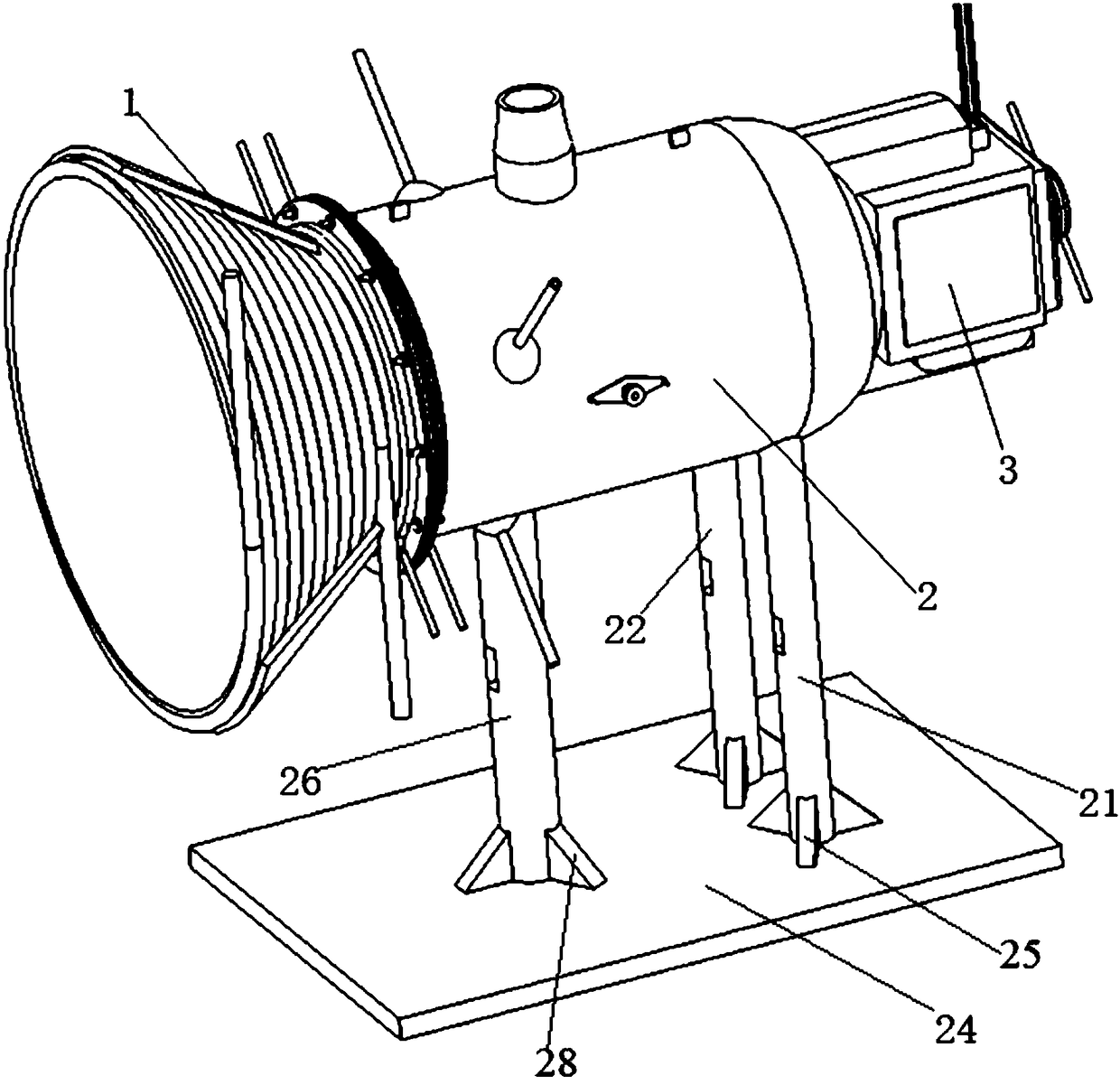

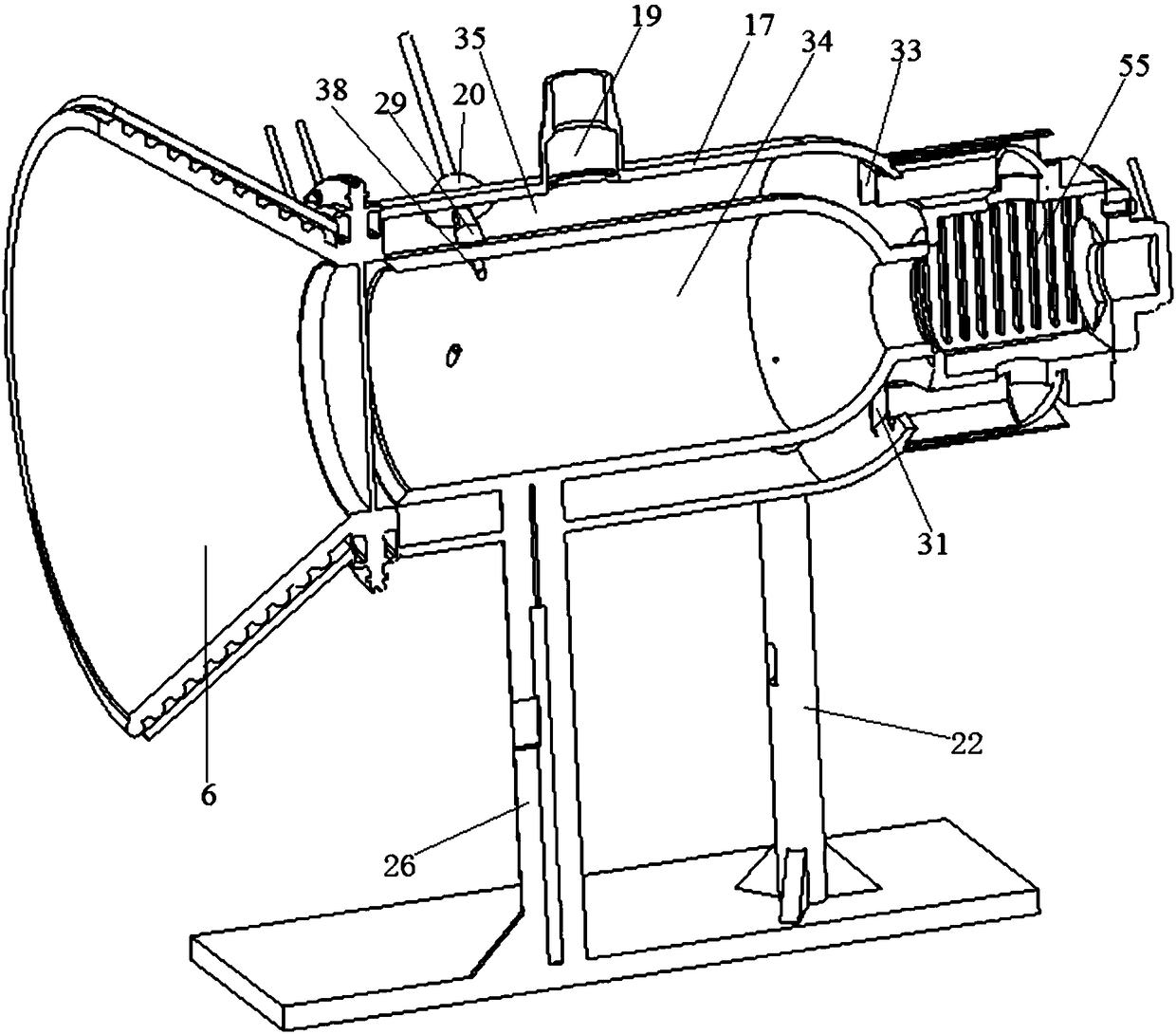

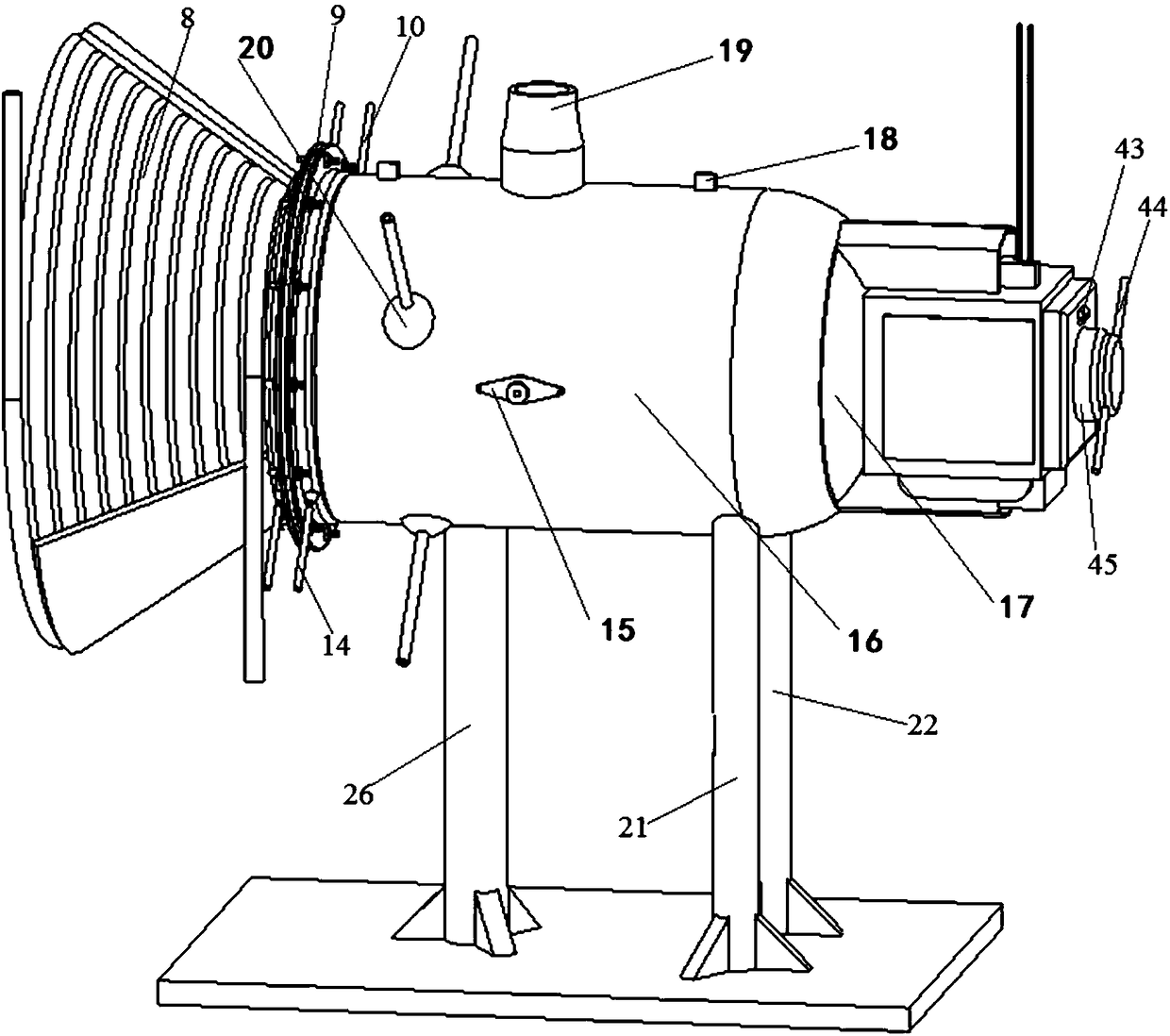

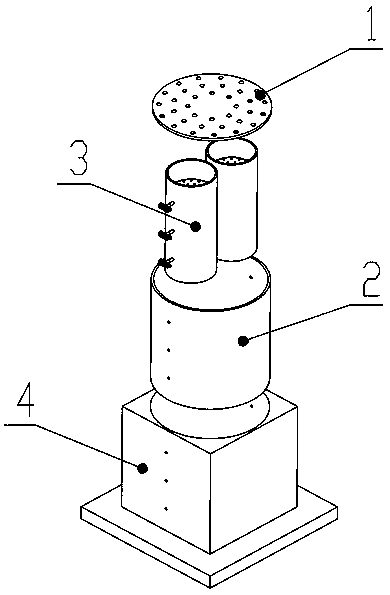

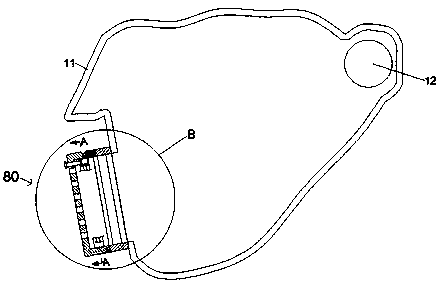

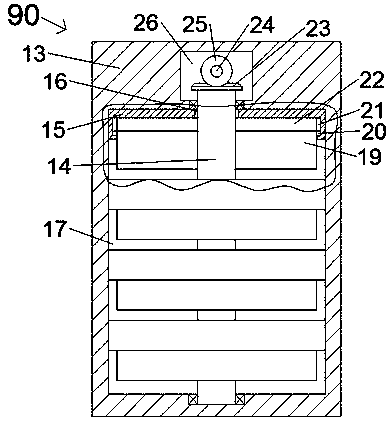

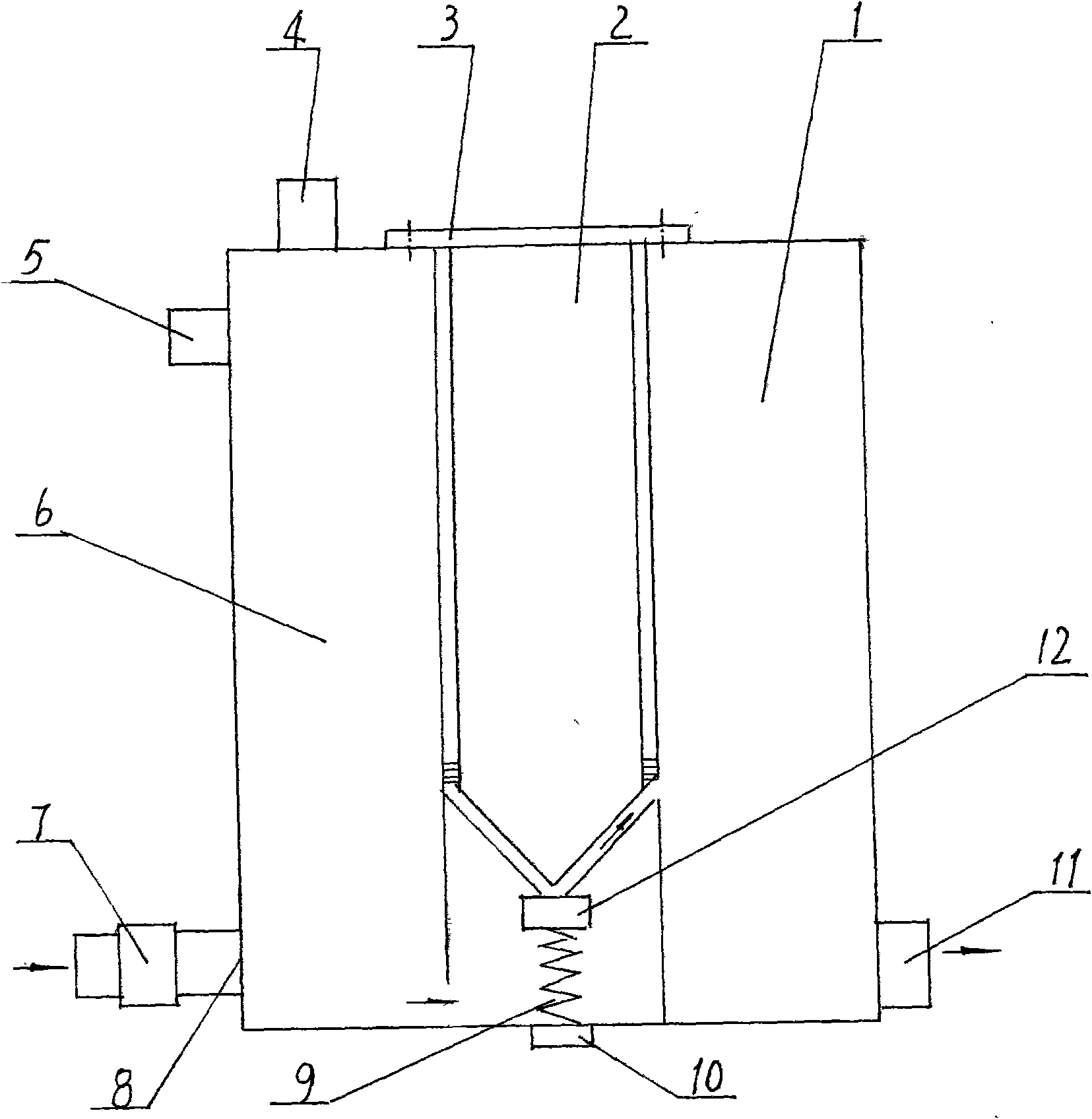

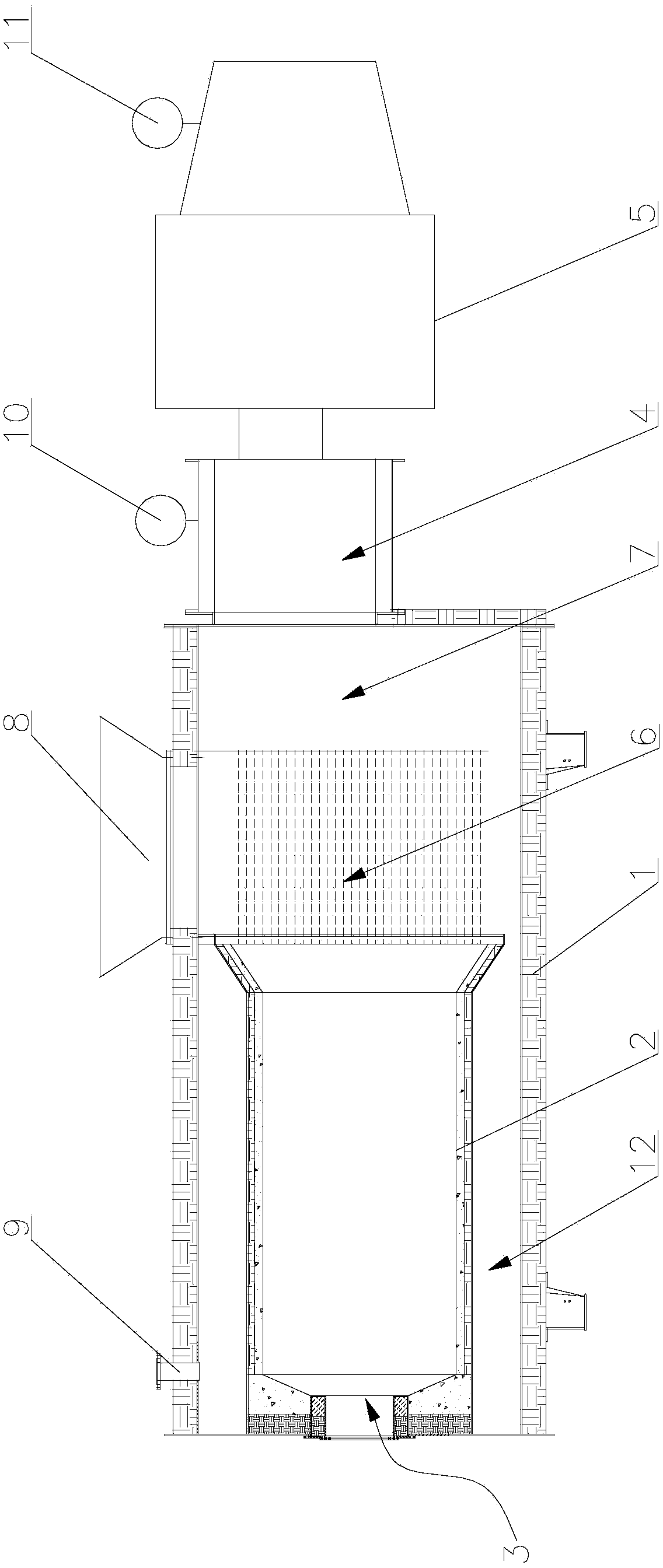

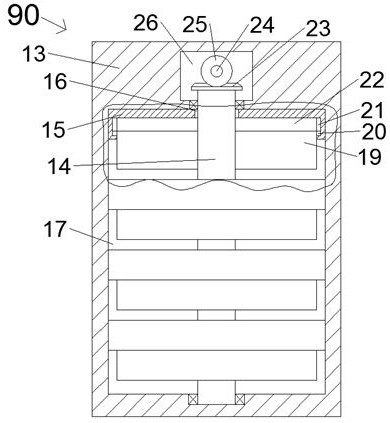

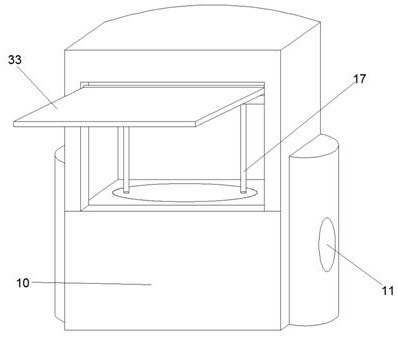

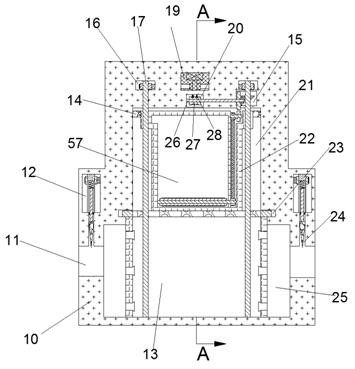

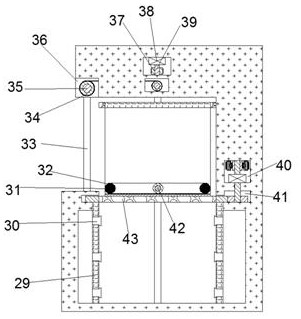

Energy-saving and environment-friendly solar reactor for hydrogen production by methanol reforming

ActiveCN108190834AWide range of usesImprove securityHydrogenEnergy inputEnergy conservationHydrogen production

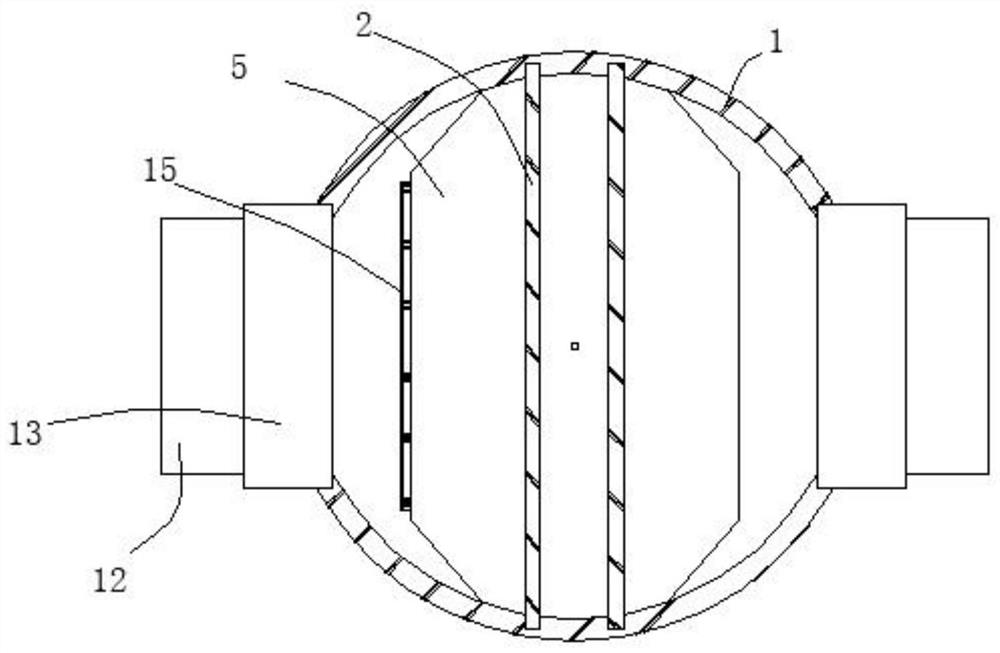

The invention relates to an energy-saving and environment-friendly solar reactor for hydrogen production by methanol reforming and belongs to the technical field of photovoltaic heating equipment. Thereactor comprises a solar reception system, a methanol reforming reaction system, a tail gas dedusting treatment system and a support base, wherein the solar reception system, the methanol reformingreaction system and the tail gas dedusting treatment system are fixedly arranged on the support base sequentially, located on the same horizontal plane and communicated mutually. The energy-saving andenvironment-friendly solar reactor has the advantages that energy use ratio can be increased greatly, and losses of optical energy and waste heat can be reduced; dust pollution caused by nanoparticles and thermal pollution caused by excessive released waste heat are reduced, environment is protected, and energy is saved; operating data is monitored in real time by the equipment, feedback controlis realized by a computer, and the reactor has the characteristics of being high in automation degree, efficient, clean, environmentally friendly and energy-saving.

Owner:KUNMING UNIV OF SCI & TECH

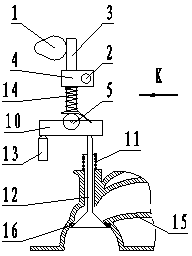

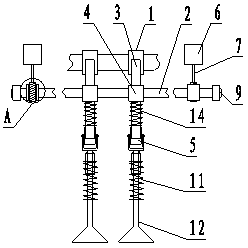

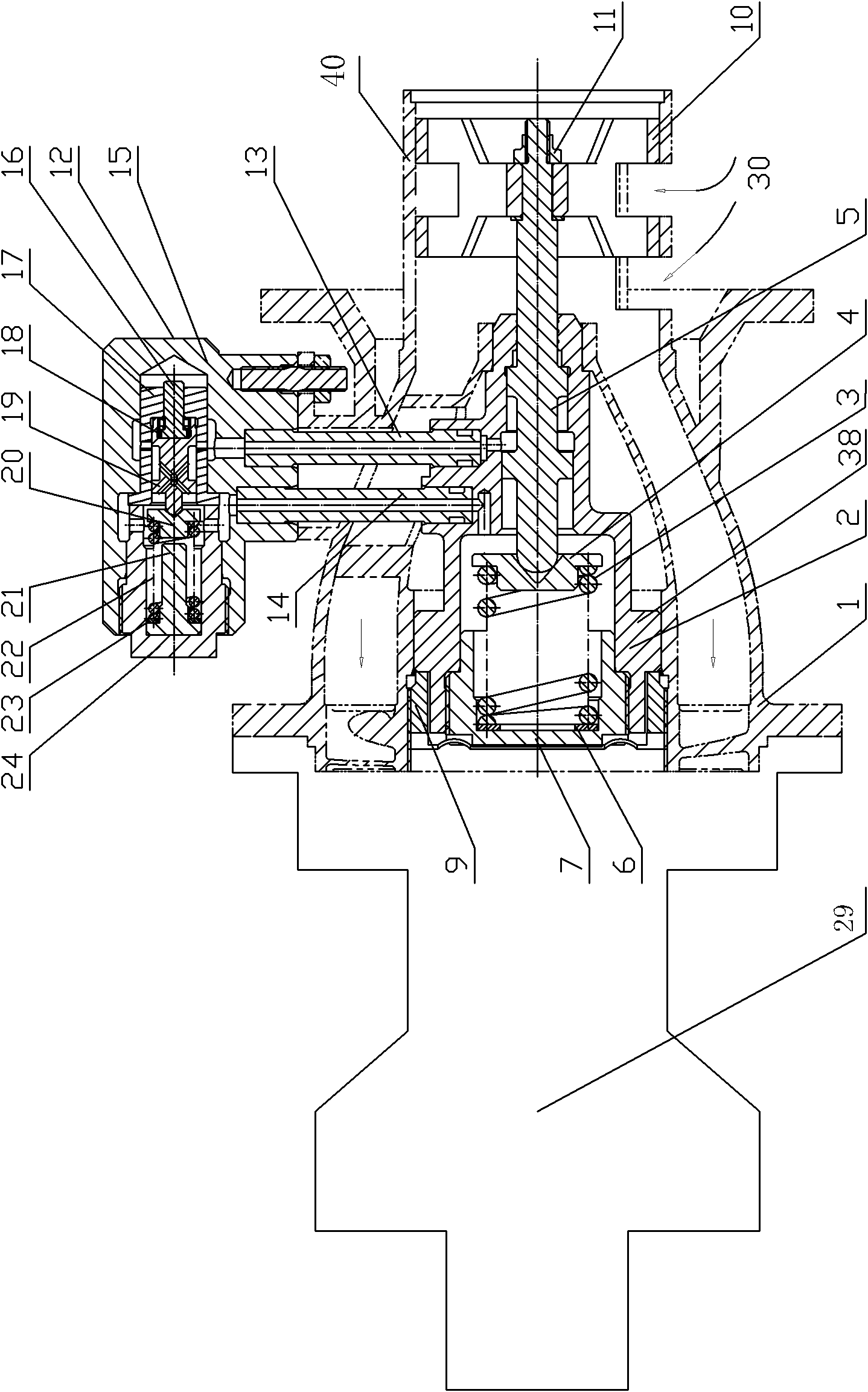

Continuous and changeable valve lift control mechanism

InactiveCN102852585AGood inflation efficiencyImprove powerValve arrangementsMachines/enginesVariable valve timingEngineering

Disclosed is a continuous and changeable valve lift control mechanism. The control mechanism is used for solving the control problem of valve lift matched with different working conditions of an engine. The control mechanism comprises a transmission component and a valve component. The transmission component comprises a cam, a rocker, a rocker supporting block, a rocker shaft, a rocker arm roller, a rocker arm and a hydraulic tappet. The control mechanism is characterized in that the rocker shaft can move up and down driven by a height adjusting motor which is fixedly mounted on an engine cylinder cover. The continuous and changeable valve lift control mechanism matched with a variable valve timing (VVT) system can be matched with the engine working conditions to adjust the valve opening lasting period and opening and closing moments, so that the gas feeding efficiency of the engine in all working conditions is the best, and the control mechanism is helpful for improving dynamic and economic properties and the discharge of the engine.

Owner:GREAT WALL MOTOR CO LTD

Tempering-resistant air adjusting type gas stove with upper air inlet

ActiveCN102147117BAdjust air intakeFully temperedDomestic stoves or rangesGaseous fuel burnerEngineeringScrew thread

The invention relates to a tempering-resistant air adjusting type gas stove with an upper air inlet, which comprises a panel, a combustor, a nozzle, an air cavity with an upper opening and a cover plate, wherein a burner comprises a premixing cavity and an ejector tube; the cover plate is positioned above the upper opening of the air cavity; a gap is formed between the cover plate and the upper opening; the upper opening of the air cavity is stretched out of the panel after passing through the panel; the front and rear side walls of the air cavity are respectively provided with an air outlet hole and an air inlet hole; the air inlet hole is communicated with the ejector tube; the nozzle is arranged on the air inlet hole; the air inlet end of the nozzle is in screw thread fit with the air outlet hole; the air outlet end of the nozzle is opposite to the air outlet hole; a door plate arranged on the air outlet end of the nozzle is matched with the air outlet hole; and the door plate is in screw thread fit with the nozzle. Because the structure is adopted, the nozzle can be exchanged; the door plate is rotated, so that the door plate is far away from or close to the air outlet of the air cavity to achieve the purpose of adjusting the air intake flow of the air once to supply sufficient air to gas, thereby achieving full combustion; and a temperature sensor is provided to prevent the explosion because the tempering occurs.

Owner:中山市秋意厨卫电器有限公司

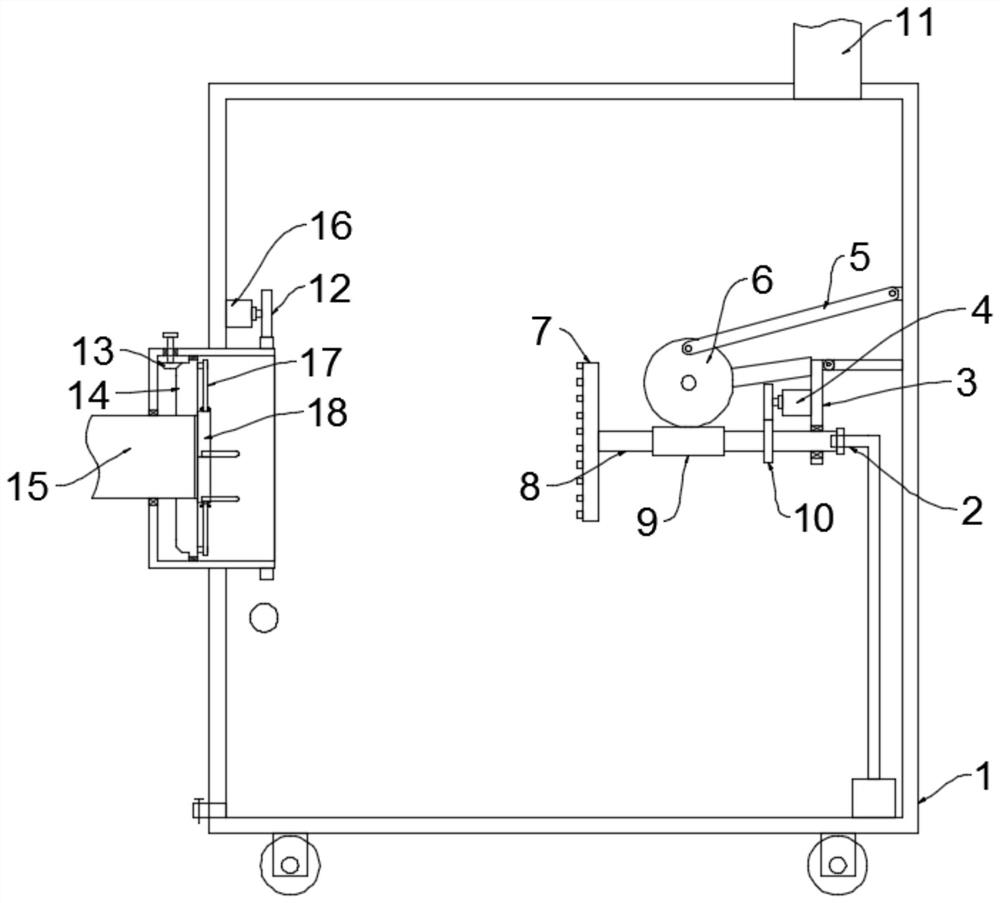

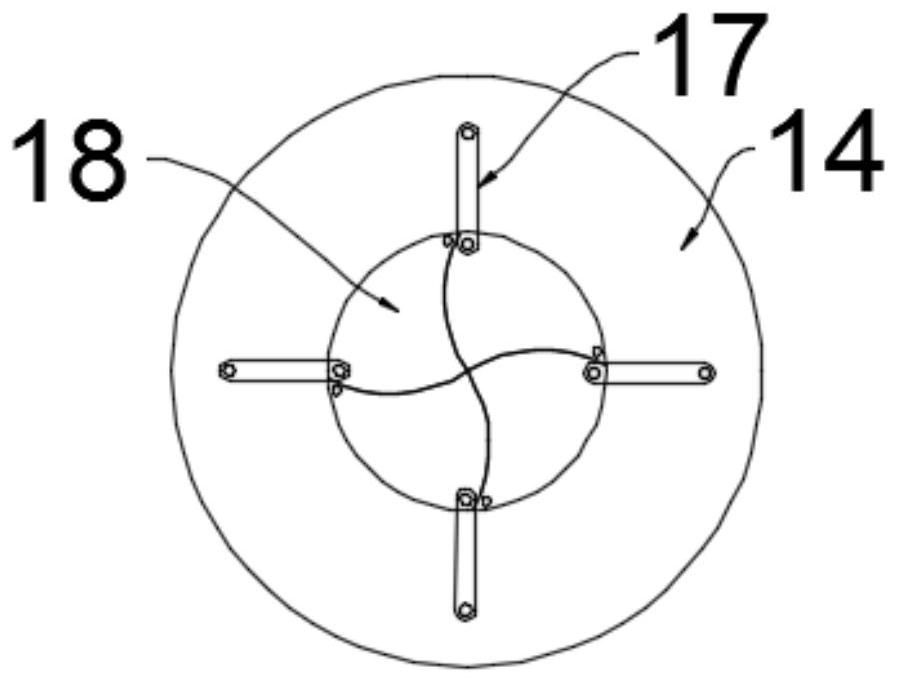

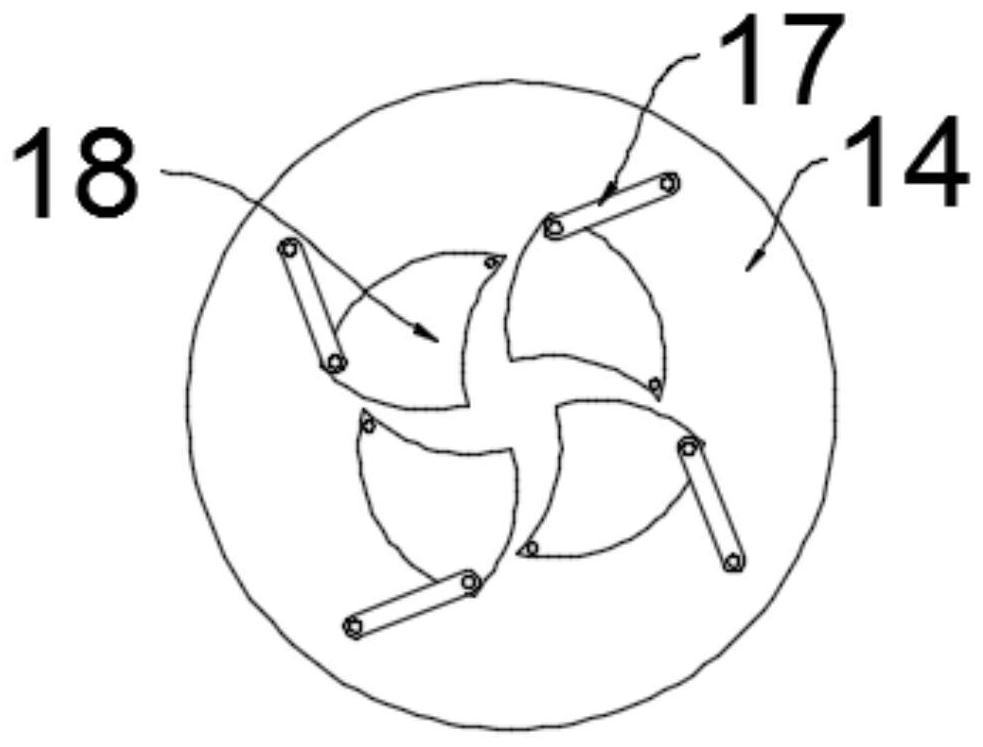

Full spraying device for environmental-friendly machine

InactiveCN111744689AFull sprayExpand the spraying rangeUsing liquid separation agentMovable spraying apparatusEnvironmental engineeringWaste gas

The invention discloses a full spraying device for an environmental-friendly machine, and relates to the technical field of environmental-friendly machines. The full spraying device is mainly used forsolving the problem of insufficient spraying of existing environmental-friendly mechanical waste gas. The full spraying device comprises a box body and a spraying unit arranged in the box body. The spraying unit is arranged in the position, opposite to a pipe opening of a gas inlet pipe, in the box body. The spraying unit comprises a spraying disc, a hollow rotating shaft, a first driving mechanism for driving the hollow rotating shaft to rotate, a worm, a worm wheel and a first connecting rod. An adjusting unit is arranged at the gas inlet pipe. The adjusting unit comprises a cylinder body,a second driving mechanism for driving the cylinder body to rotate and a valve assembly. The spraying unit is arranged for rotating type spraying, the spraying is sufficient and comprehensive, the spraying disc swings up and down, and the spraying range is enlarged; and the adjusting unit is arranged and used for adjusting the gas inlet amount, the phenomenon that spraying is insufficient due to too fast gas inlet is avoided, the cylinder body rotates, the cylinder body drives the valve assembly to rotate, the waste gas forms spiral cyclone, the spraying distance is longer, the waste gas is more fully contacted with spraying liquid, and the spraying efficiency is further improved.

Owner:李秀英

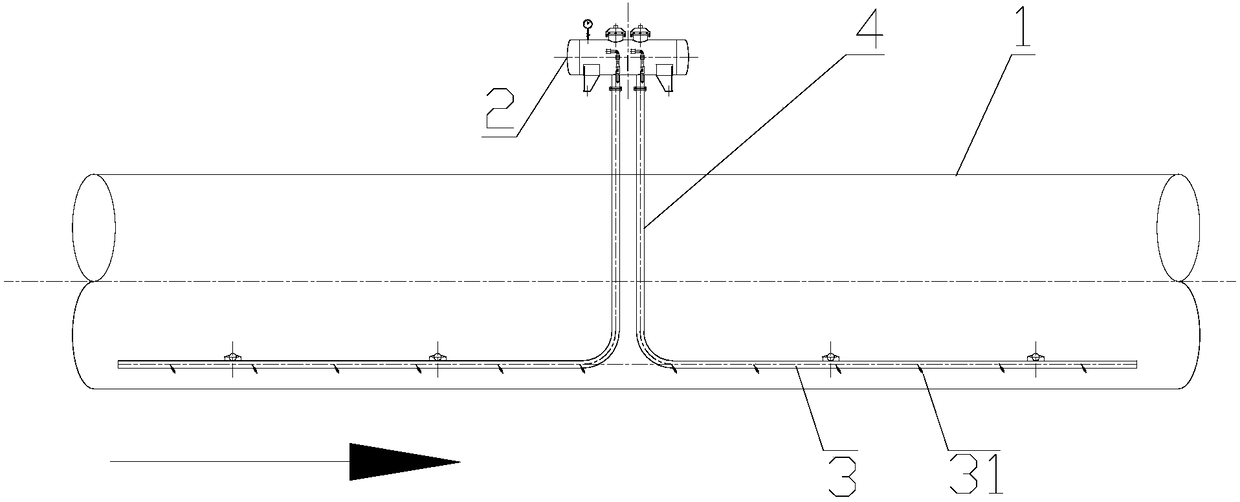

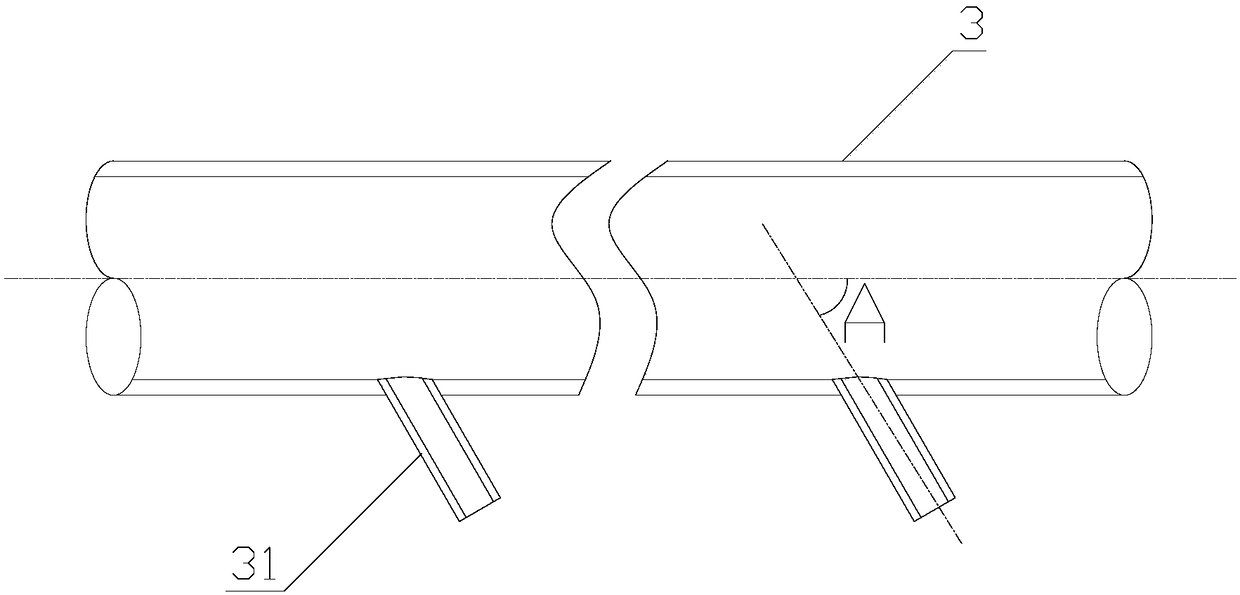

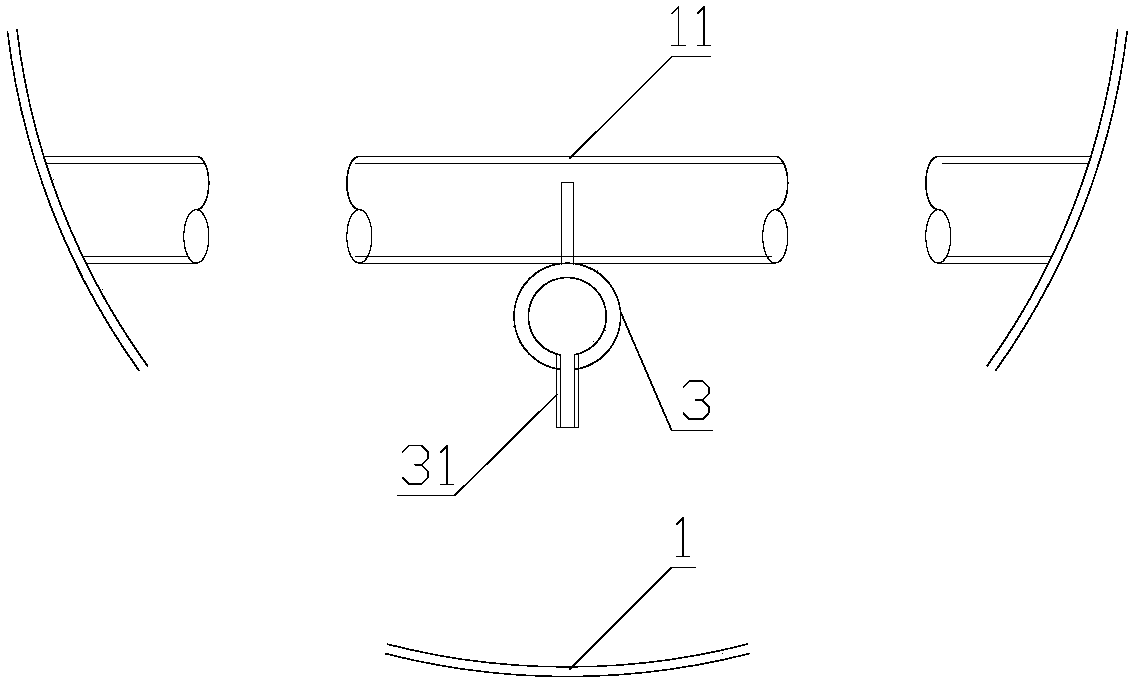

Online accumulated dust removal device for dust-gas pipeline

PendingCN108380603AFully automatedNo need for manual cleaningHollow article cleaningEngineeringGas pipeline

The invention relates to an online accumulated dust removal device for a dust-gas pipeline. The device is characterized in that the dust-gas pipeline is horizontally arranged, and the device comprisesa blowing valve group and a blowing pipe, wherein the blowing valve group is positioned above the dust-gas pipeline, an air inlet of the blowing valve group communicates with compressed air through an air supply pipe, and an air outlet is connected with an air guide pip; the blowing pipe is arranged in the dust-gas pipeline, one end of the blowing pipe is connected with the air guide pipe, and the blowing pipe communicates with a plurality of nozzles, and preset angles are correspondingly formed between the plurality of nozzles and the flowing direction of the air in the dust-gas pipeline. According to the online accumulated dust removal device for the dust-gas pipeline, the blowing valve group and the blowing pipe are arranged, the compressed air enters the blowing pipe through pulse airflow, and the compressed air is blown out by the plurality of nozzles, so that dust is blown, the dust flows by means of the flow velocity of smoke in the dust-gas pipeline, and the dust is collectedafter entering a dust remover; and automatic dust removal is achieved, manual dust removal is not needed, online dust removal can be achieved, and the defect that the flow state of the dust-gas pipeline is periodically changed by treating a maintenance period as a period is overcome.

Owner:中钢集团工程设计研究院有限公司

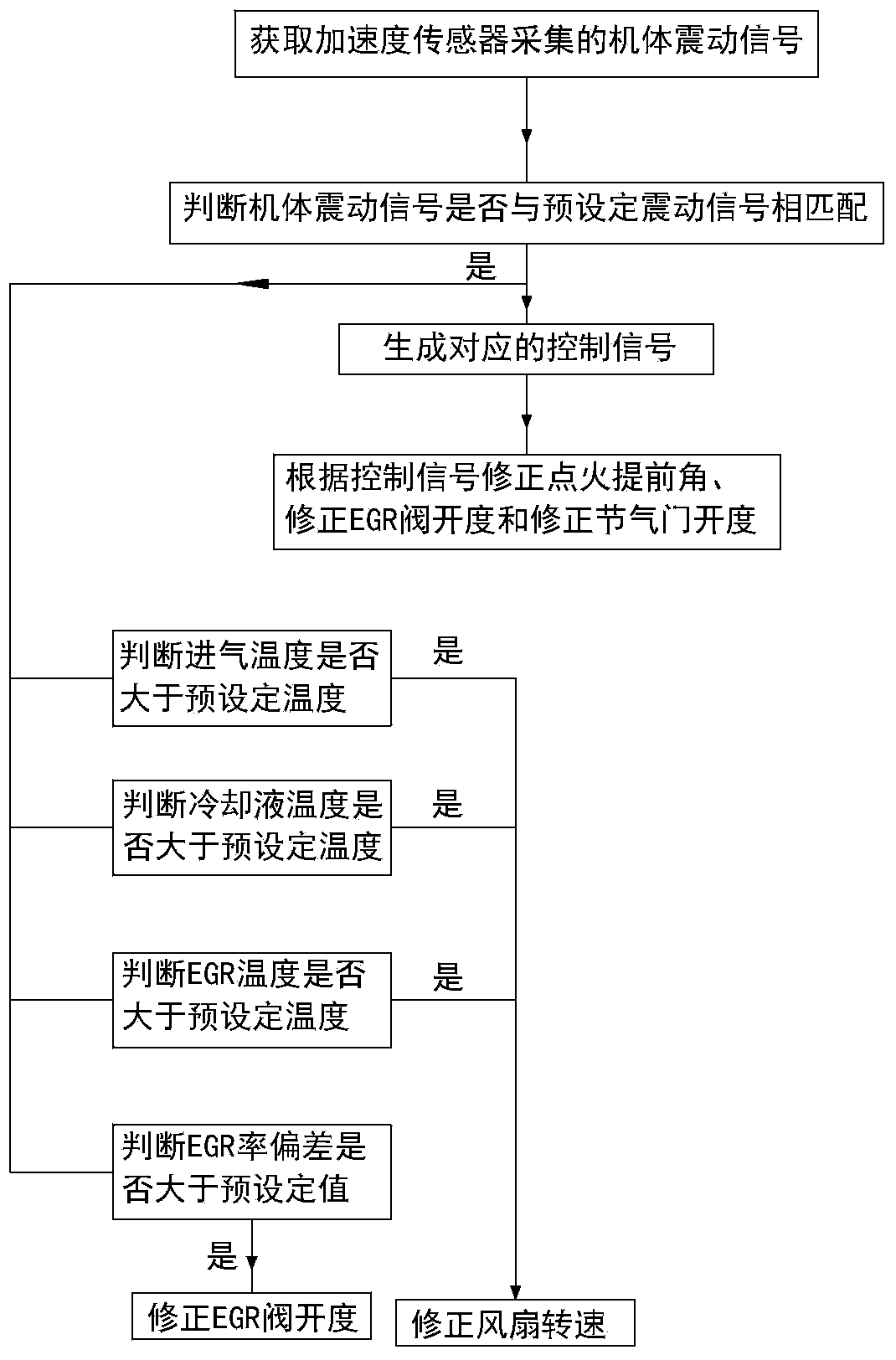

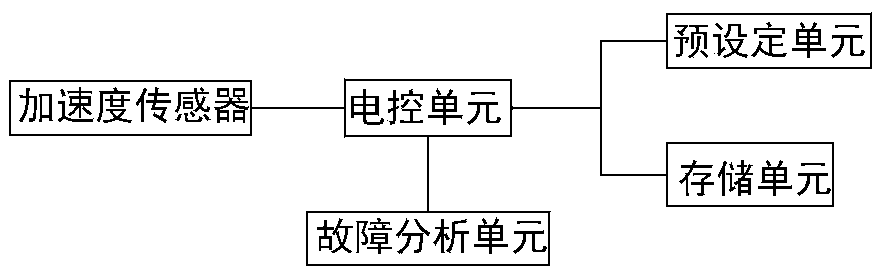

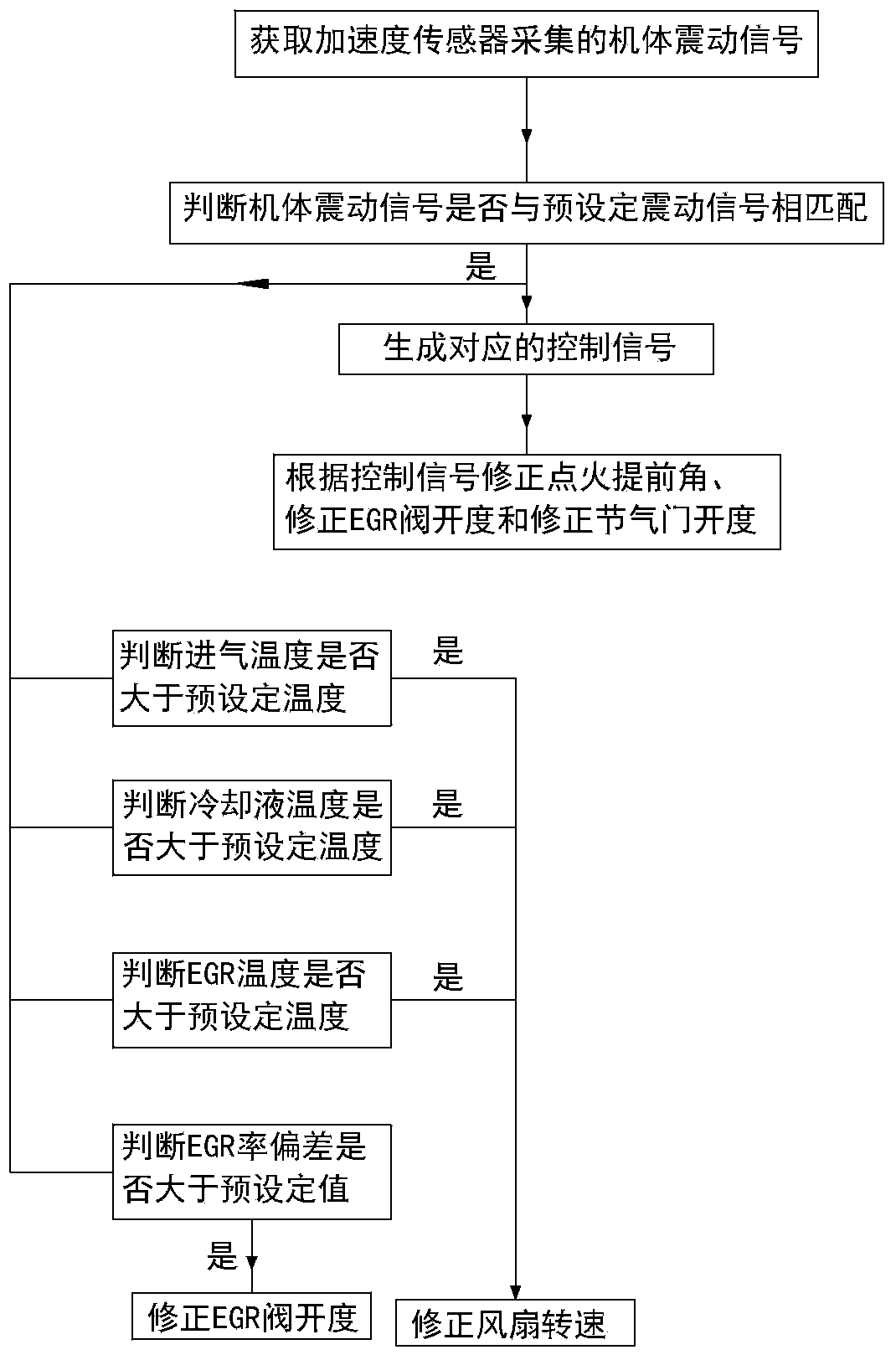

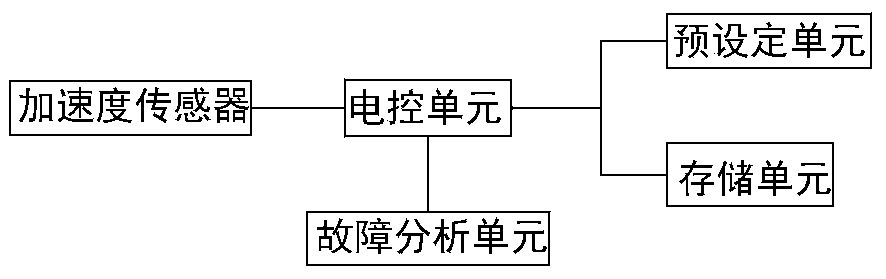

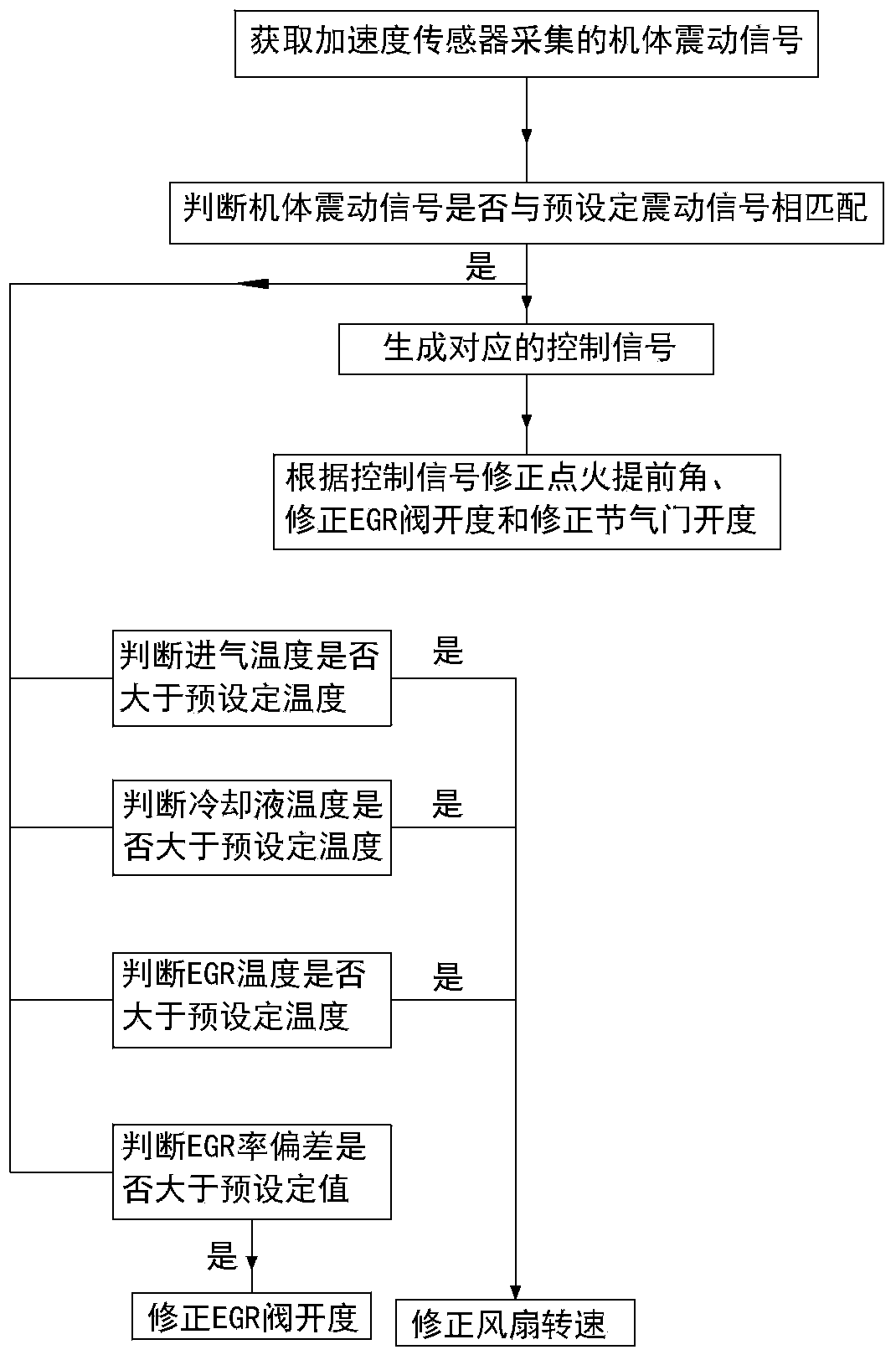

Control method and system for natural gas engine EGR knocking correction

ActiveCN110748430AAdjust air intakeEnsure safetyElectrical controlCoolant flow controlElectric controlControl theory

The invention discloses a control method and system for natural gas engine EGR knocking correction. The system comprises an acceleration sensor arranged on a engine body, wherein the acceleration sensor collects the vibration of the engine body, converts the vibration of the engine body into a corresponding electric signal and transmits the corresponding electric signal to an electric control unit, the electric control unit compares the electric signal corresponding to the vibration of the engine body with a preset vibration signal, and judges whether knocking occurs or not according to the comparison result; and if knocking occurs, the spark advance angle is corrected, and the EGR valve opening degree and / or the throttle valve opening degree are / is corrected so that knocking is quickly controlled. When knocking occurs, the output power of an engine is calculated, whether the output power exceeds the required power or not is judged, and if yes, the throttle valve opening degree is corrected, so that the intake gas amount is adjusted and driving safety is ensured. Therefore, the control method and system for natural gas engine EGR knocking correction can quickly control knocking, prevent re-occurrence of knocking and ensure driving safety.

Owner:WEICHAI XIGANG NEW ENERGY POWER

Device for automatically adjusting power of turbine pump

ActiveCN101865143AAdjust air intakeGuaranteed output powerPump controlNon-positive displacement fluid enginesInlet valveTurbopump

The invention relates to a device for automatically adjusting the power of a turbine pump. The device comprises a lift valve arranged outside a turbine air inlet casing, an air inlet valve arranged in the turbine air inlet casing, and an inlet chamber control channel and an outlet chamber control channel which are used for connecting an air inlet valve oil circuit and a lift valve oil circuit. The device solves the technical problem that the jet pipe and air inlet passage of an aspirated engine, which works under large airspace, high Mach number and large-scale variable working conditions, are difficult to adjust, ensures that the output power of the turbine pump is within a rated value range and improves the processing and assembly manufacturability of the turbine pump.

Owner:NO 11 INST OF NO 6 ACADEMY OF CHINA AEROSPACE SCI & TECH

Efficient air filtration and dehumidification apparatus

InactiveCN110538523AImprove air qualityImprove convenienceMechanical apparatusGas treatmentActivated carbonUser needs

The invention discloses an efficient air filtration and dehumidification apparatus. The apparatus comprises a protective shell for support and connection, a support shell movably connected with an inner end surface of the protective shell, and a capping shell for capping the protective shell. The apparatus is provided with a filtering mechanism, when a dehumidifier works, if a user needs to adjustan air intake amount, the user can turn connecting handles, the connecting handles can drive activated carbon adsorption plates inside connecting cylinders to rotate through connecting shafts, when the three connecting handles are vertical, the three activated carbon adsorption plates are perpendicular to the connecting cylinders, at this time, no particulate matter filtering operation is performed, and at the same time an air intake amount of the dehumidifier is maximized, when the three connecting handles are at the horizontal level, the activated carbon adsorption plates can carry out adsorption of particulate matters in air in all directions, and the air quality after subsequent moisture removal is improved. At the same time, the user can adjust an air intake amount of the dehumidifier by adjusting any angle of the connecting handles.

Owner:SUZHOU DEJIA PURIFICATION STEEL STRUCTURE CO LTD

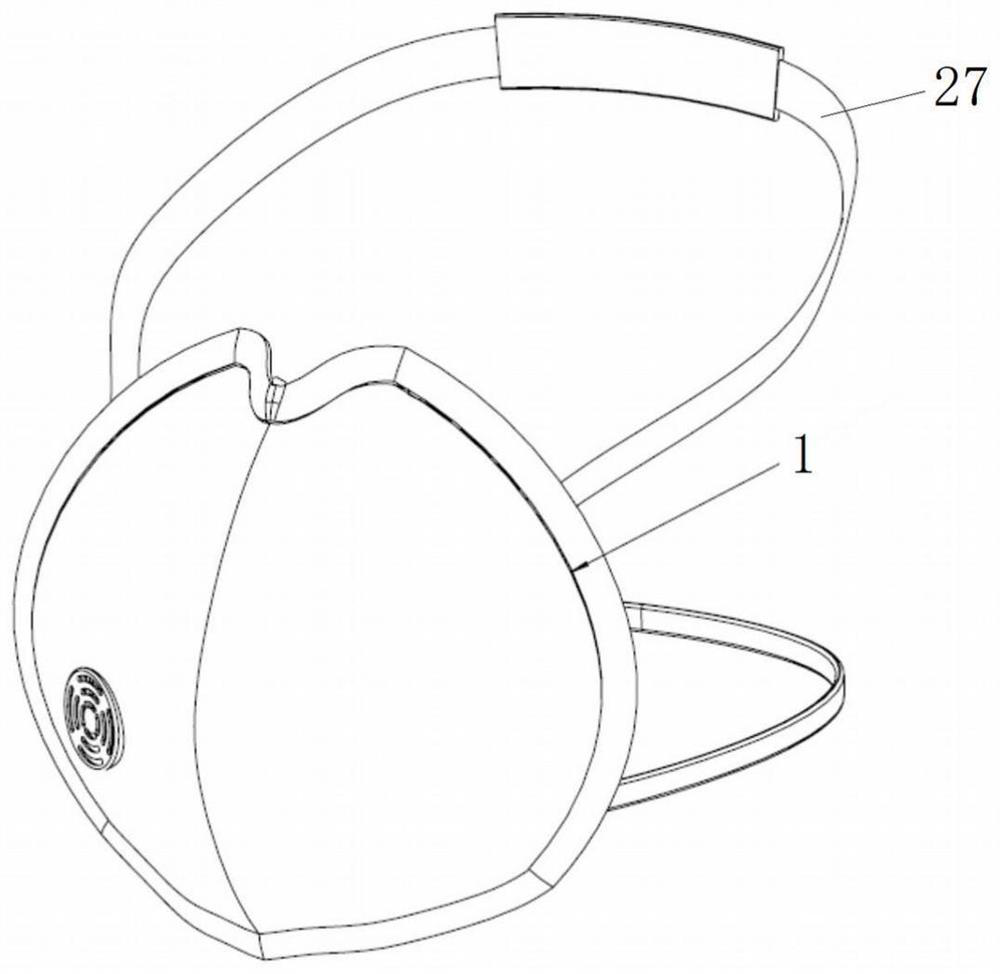

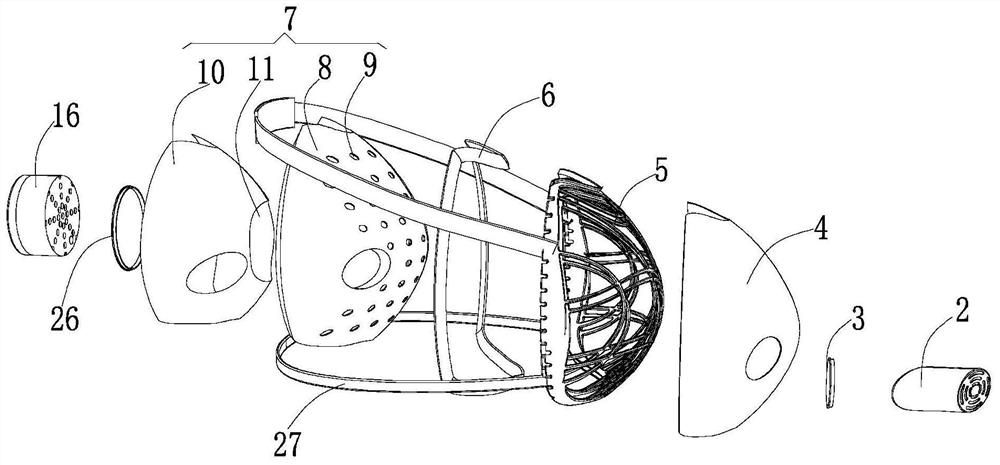

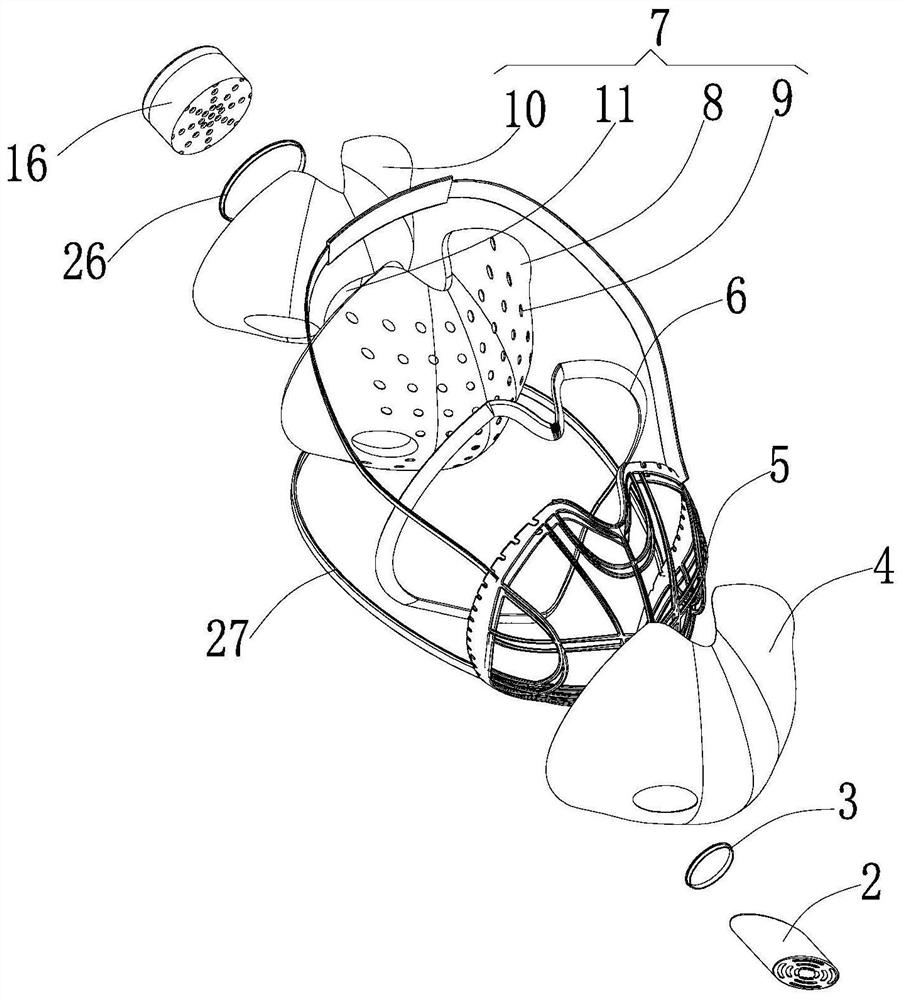

Haze-preventing riding mask

ActiveCN110250613AKeep healthyAdjustable sizeFire rescueRespiratory apparatusEngineeringMechanical engineering

The invention discloses a haze-preventing riding mask, which comprises a mask body. Wearing holes are formed in the mask body in a front-back symmetrical mode; a cover plate is moved upwards, a clamping block slides out from a clamping groove, and a sliding block and a moving block slide in a sliding cavity and a moving cavity correspondingly; and the cover plate is rotated and then can be opened, and a filter element is replaced. A filtering mechanism has a haze-preventing function, the filter element filters haze, and thus body health of pedestrians is ensured; and the cover plate can be opened, the filter element is replaced, the resource is saved, a rotary knob in an air inlet mechanism is rotated, and the size of an air inlet opening can be adjusted to adjust the air inflow.

Owner:江西欧丽达实业有限公司

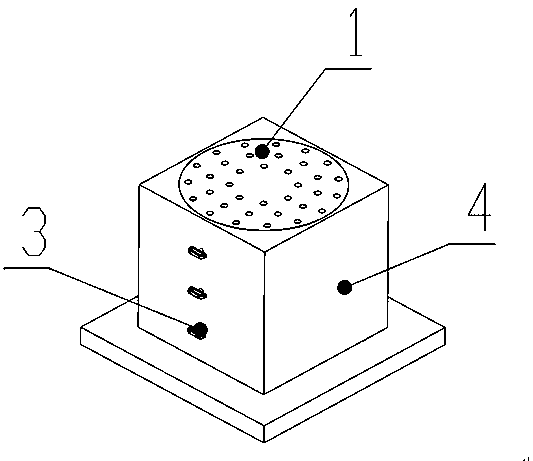

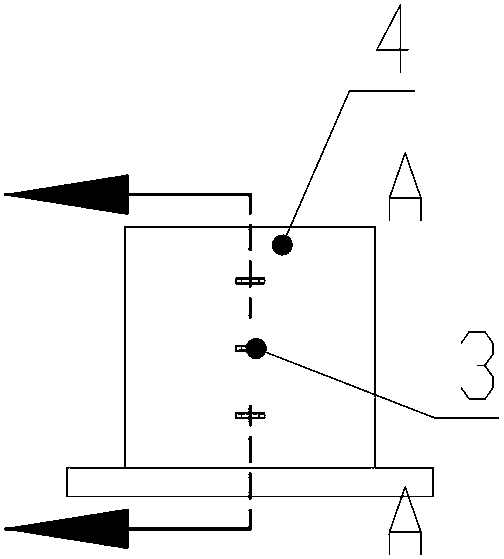

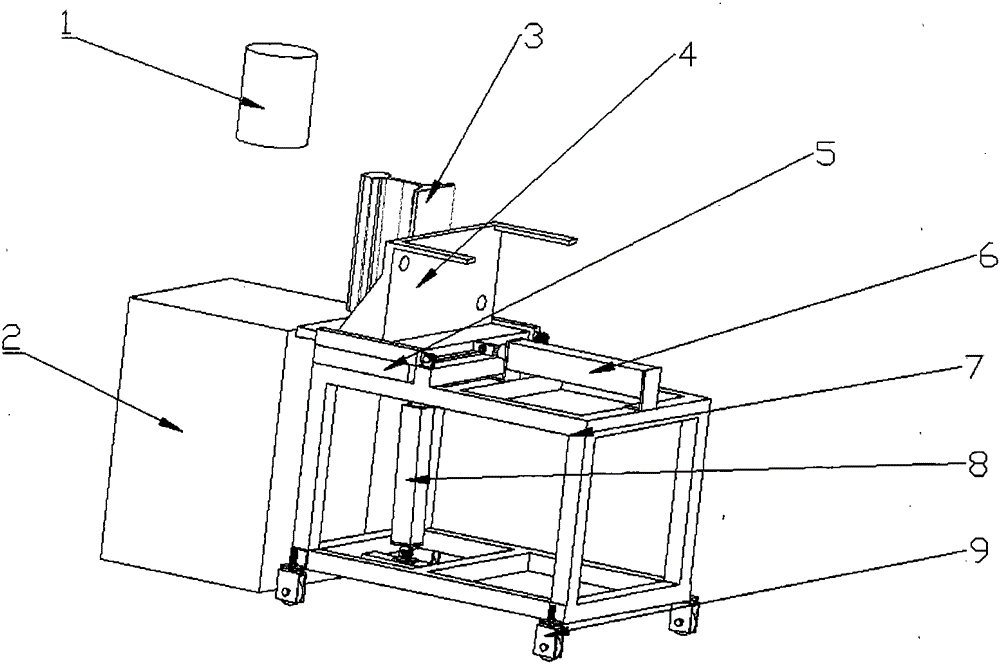

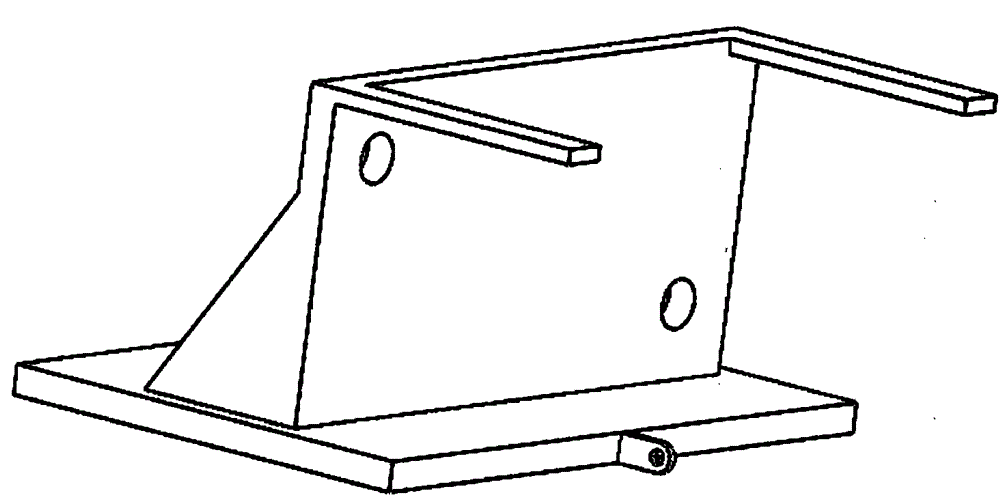

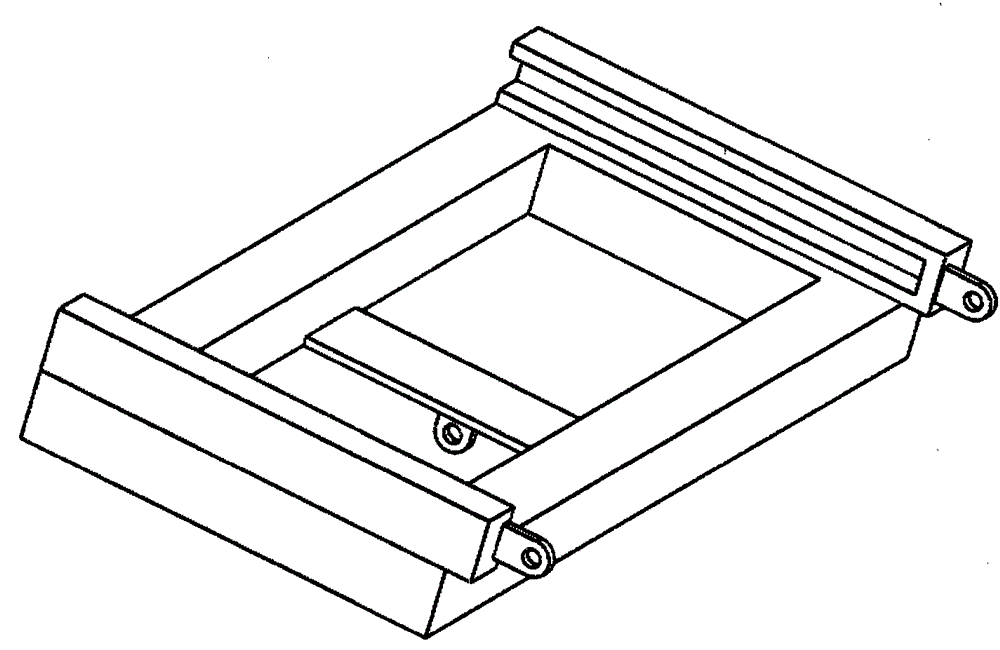

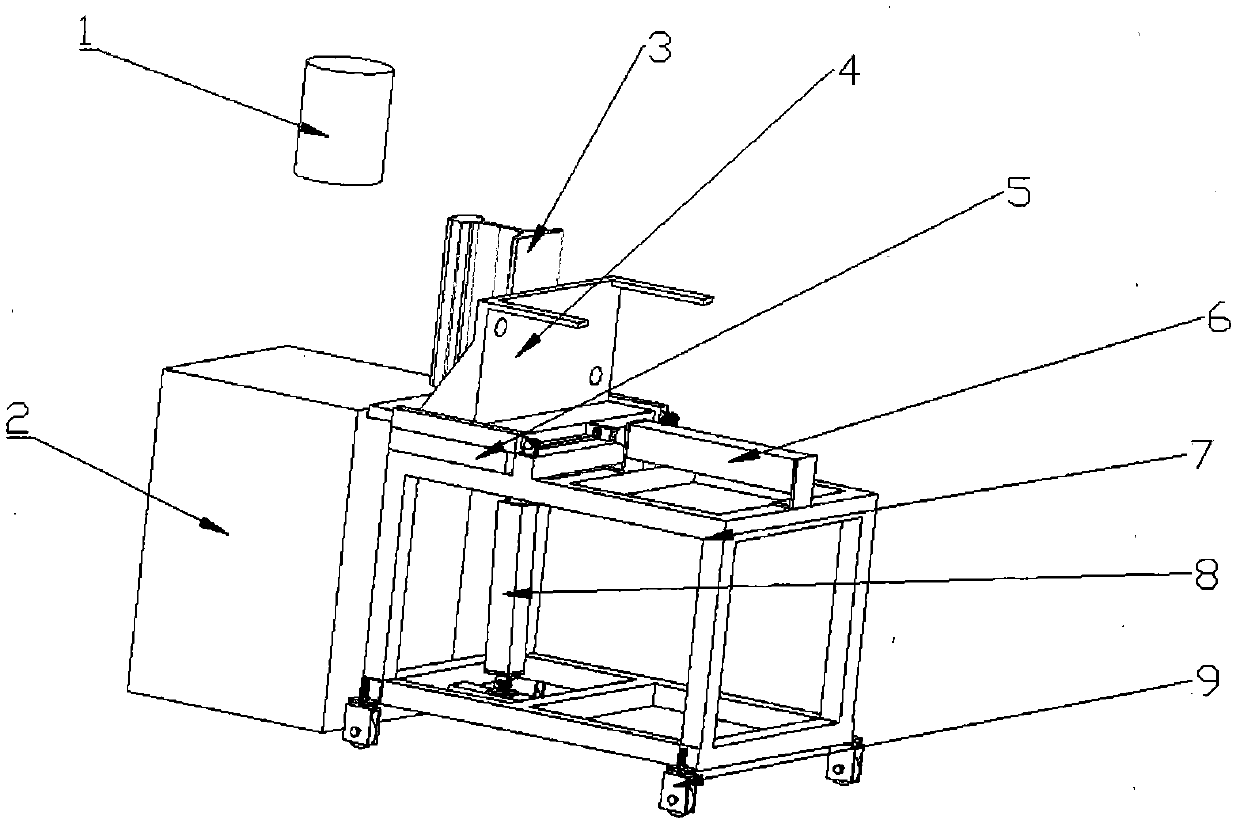

Fastener longitudinal resistance measuring device

ActiveCN106289606AGood versatilityReduce procurement costsApparatus for force/torque/work measurementFastenerPurchase cost

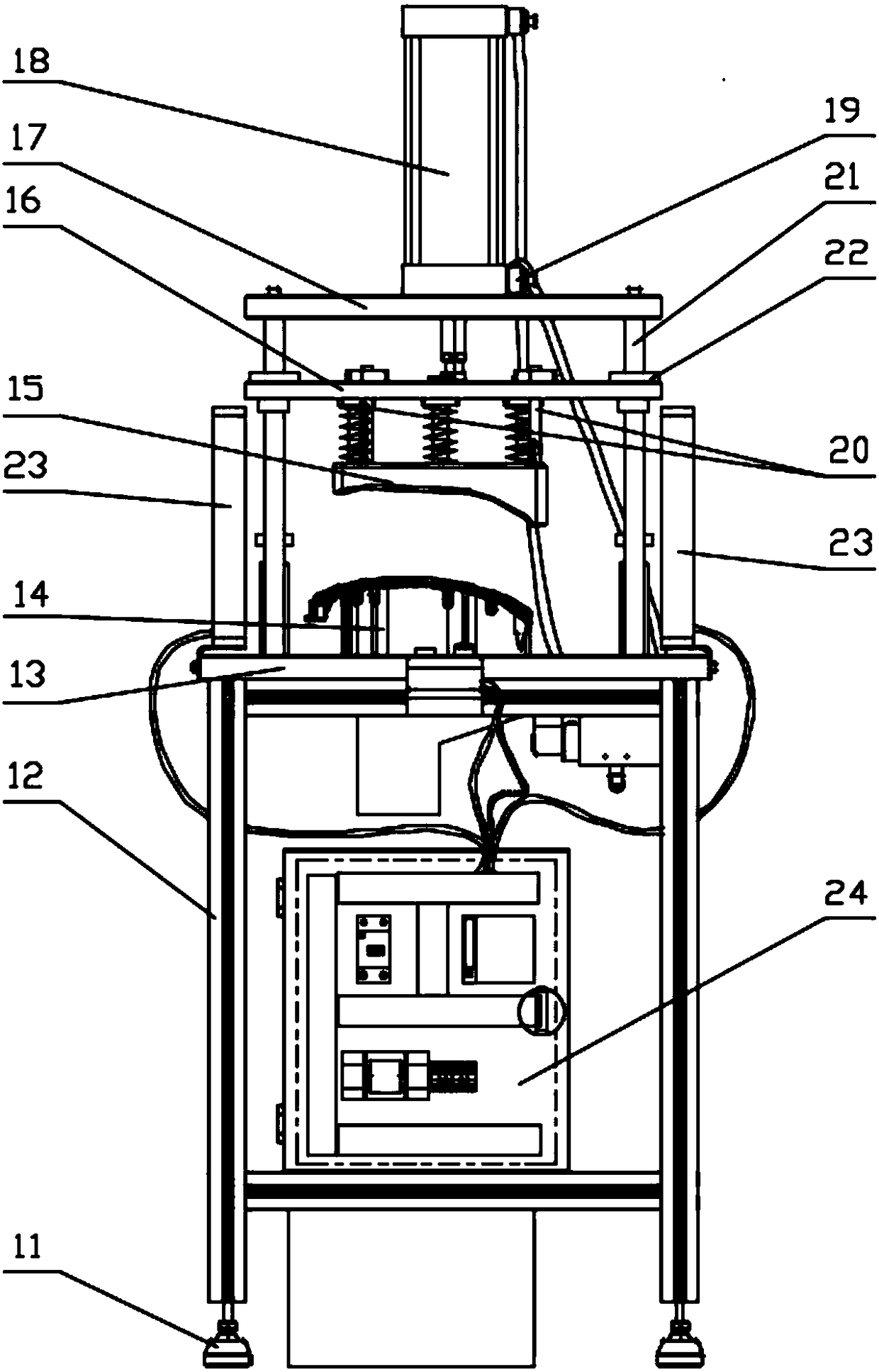

The invention discloses a fastener longitudinal resistance measuring device. The fastener longitudinal resistance measuring device includes a fastener seat 4, a turning table 5, a rack 7, a first air cylinder 6, a second air cylinder 8 and wheels 9; the second air cylinder 8 makes the turning table 5 stand upright, and a steel rail 3 and a fastener are mounted on the fastener seat 4; the first air cylinder 6 pushes the fastener seat 4 out to a test platform 2; a pressing head 1 provided with a displacement and force sensor applies a force onto the steel rail 3; and the longitudinal resistance of the fastener is tested according to procedures. The fastener longitudinal resistance measuring device of the invention is applicable to a plurality of kinds of fasteners and has high universality; a universal electronic testing machine in a laboratory can be adopted as the pressing head 1 provided with the displacement and force sensor, and therefore, part purchase cost can be reduced, and the multi-purpose performance of the fastener longitudinal resistance measuring device can be achieved; pneumatic control is adopted, so that labor force consumption can be decreased; the extending and stretching speed of the air cylinders can be controlled through adjusting air inflow, and therefore, injuries to operators can be avoided; and the fastener longitudinal resistance measuring device is convenient to move, and the fastener longitudinal resistance measuring device can be moved away with easiness when the fastener longitudinal resistance measuring device is not used. The fastener longitudinal resistance measuring device has the advantages of compactness, lightweight, structural simplicity and easiness in maintenance.

Owner:BEIJING ZKYT TECH CO LTD

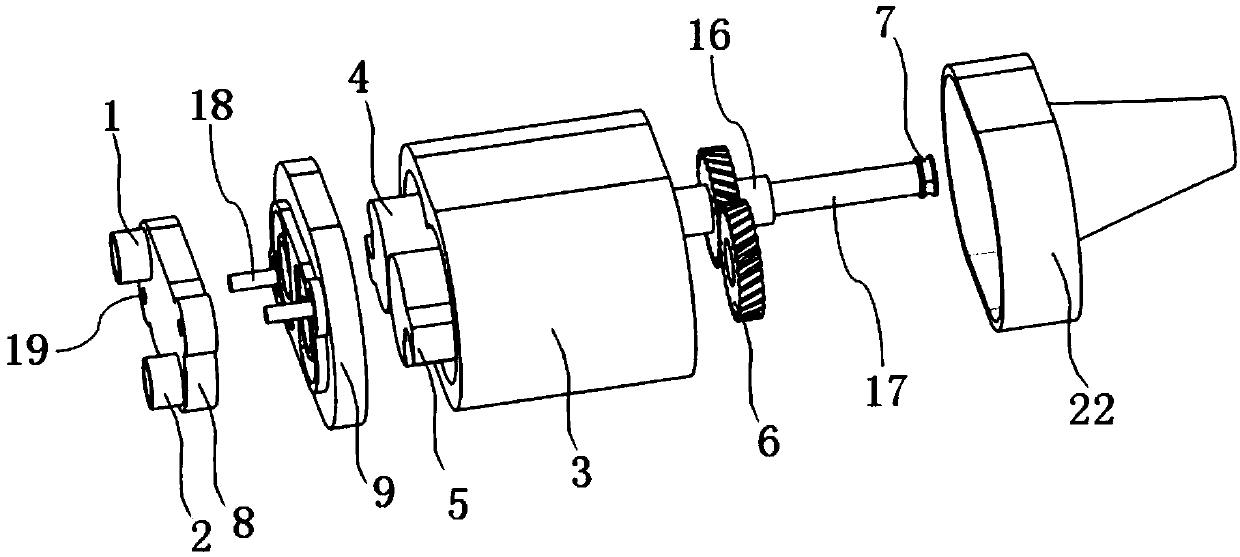

Sterilizing mask capable of adjusting air flow

The invention relates to the technical field of emergency protection, and discloses a sterilization mask capable of adjusting air flow. The mask comprises a mask body, wherein the mask body comprisesa composite filter membrane on the outermost layer; a polymer framework is arranged on the inner side of the composite filter membrane; headbands are arranged on the edges of the upper side edge and the lower side edge of the polymer framework; a silica gel mask is arranged on the edge of the inner side of the polymer framework; a sterilization mechanism is arranged on the inner side of the silicagel mask; a fan assembly is arranged on the inner side of the sterilization mechanism; and a one-way air outlet valve penetrates through one side of the middle part of the mask body. According to theinvention, the sterilization mechanism is matched with the fan assembly, an ultrasonic atomization module can atomize a disinfectant in a liquid containing bottle, the fan assembly can increase the outside air suction force of the mask, a micro motor drives turbofan blades to rotate to achieve air suction, the micro motor achieves rotation speed adjustment through a switch on the circuit board, and therefore, the air inflow is adjusted, and human respiration is facilitated.

Owner:合肥为开科技有限公司

Supercharger capable of changing compression ratio, application of supercharger and engine regulation technology

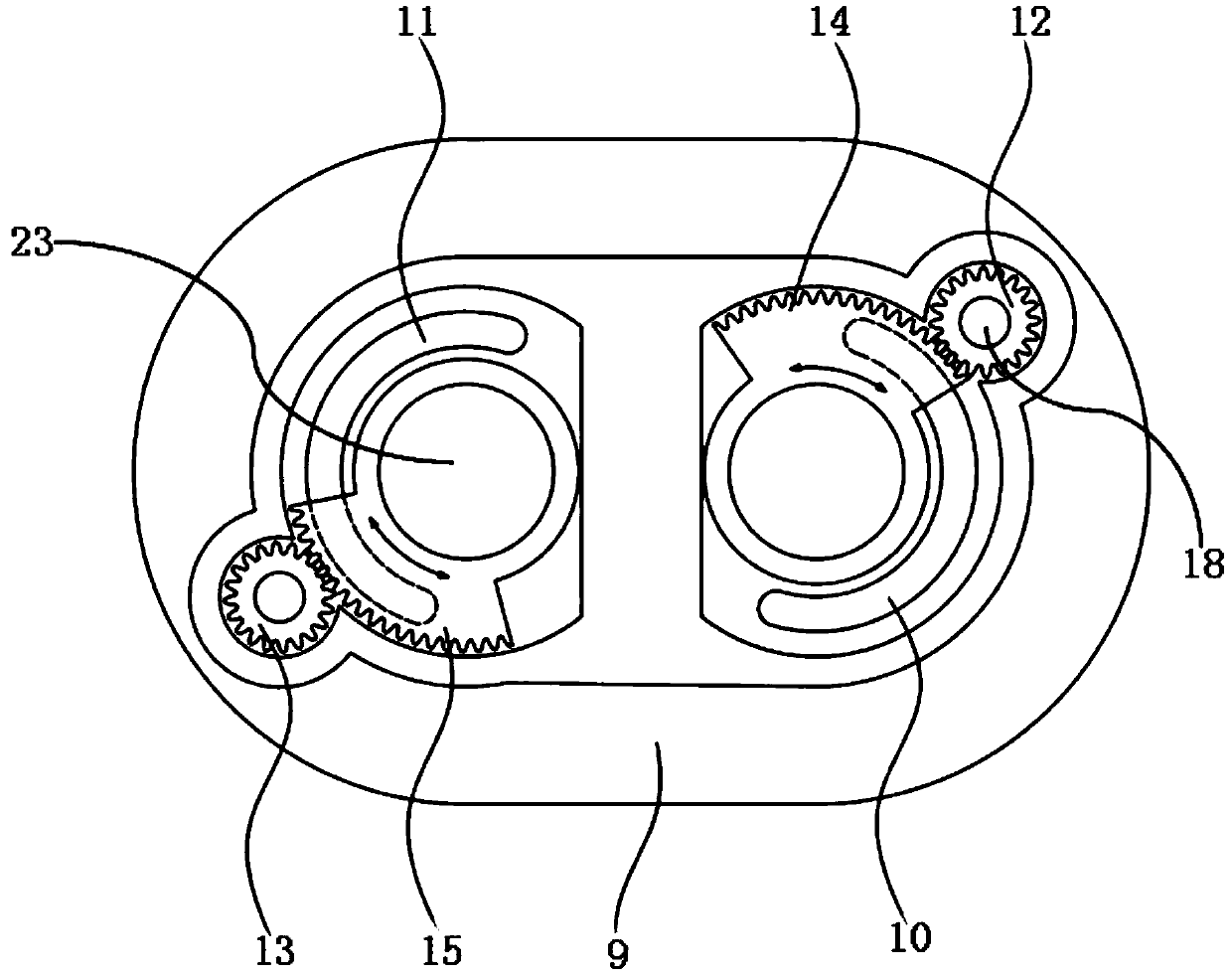

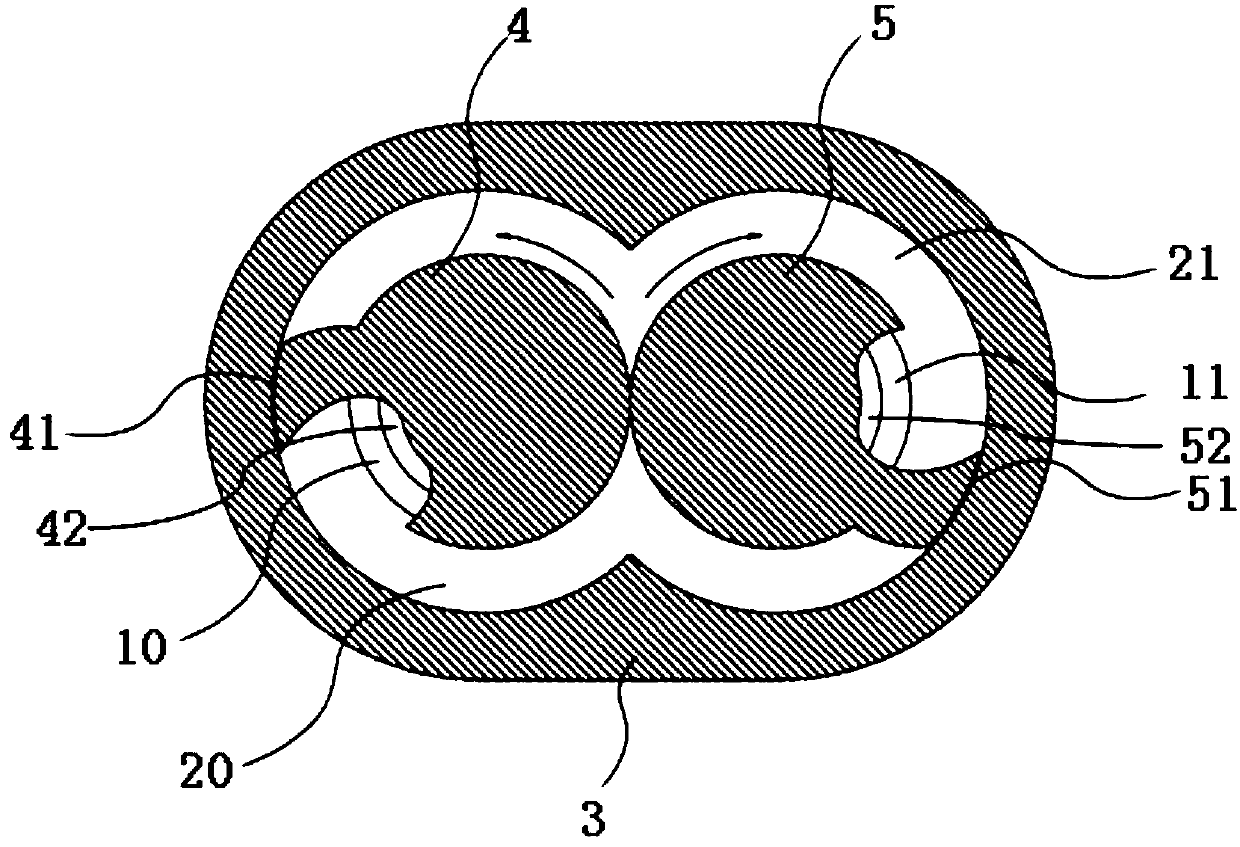

ActiveCN109630411AImprove efficiencySolve the problem of serious backflow leakageInternal combustion piston enginesRotary piston pumpsPre compressionEngineering

The invention discloses a supercharger capable of changing the compression ratio. The supercharger comprises a gas inlet pipe, an exhaust pipe, a shell, a first rotor, a second rotor, a gear set and abelt pulley; and meanwhile, the invention discloses an engine compression ratio regulation technology, and the engine compression ratio regulation technology comprises the following specific regulation steps that S1, an exhaust port of the exhaust pipe is connected to an engine gas inlet in series; S2, a gas inlet baffle or / and a gas outlet baffle is / are adjusted to pre-compress gas entering an engine air cylinder; and S3, the gas inlet baffle or / and the gas outlet baffle is / are readjusted, and thus the pressure of the gas entering the engine air cylinder is different from the pressure of thegas entering the engine air cylinder in the step S2 so as to regulate the engine compression ratio. According to the supercharger capable of changing the compression ratio, application of the supercharger to an engine and a regulation method, the engine compression ratio is changed by adjusting the gas inlet pre-compression ratio under the situation of not changing the engine structure, and engine performance is improved in a low-cost mode.

Owner:莱州市增峰石业有限公司

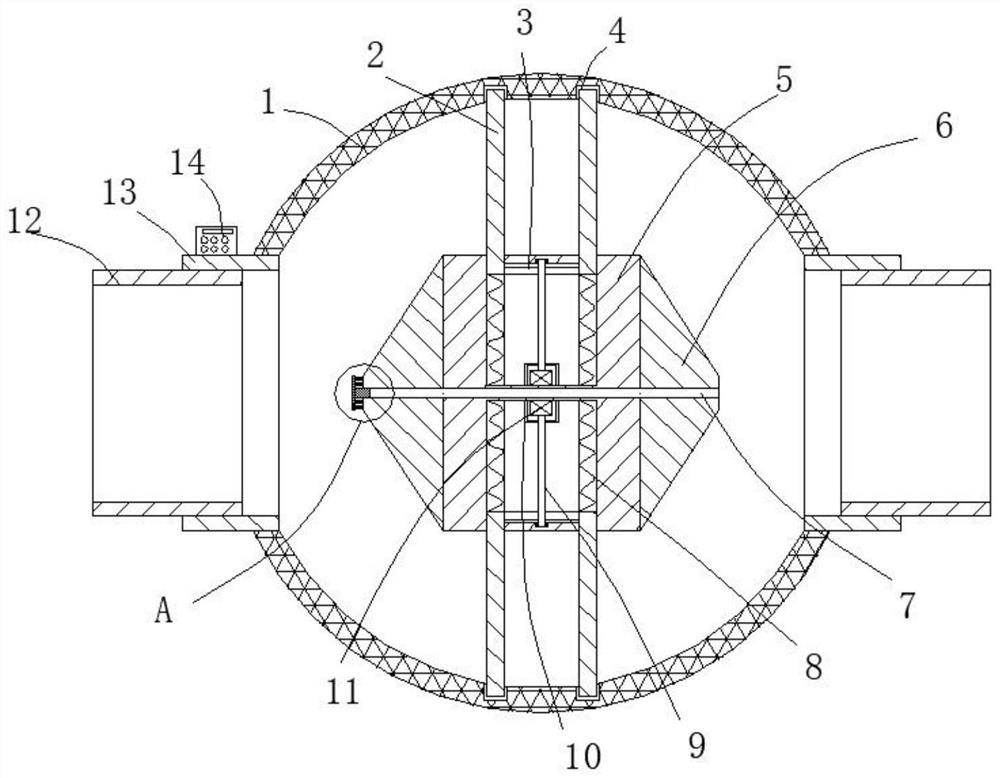

Rubber valve capable of randomly adjusting air inflow

InactiveCN110578813ASimple structureSmall sizeDiaphragm valvesEngine diaphragmsAutomatic controlDifferential pressure

The invention relates to a rubber valve capable of randomly adjusting air inflow. The rubber valve capable of randomly adjusting the air inflow is arranged in the circumferential direction of a main pipeline and comprises a valve body section and positioning sections, wherein the valve body section and the positioning sections are mutually and vertically connected; the positioning sections are arranged at the upper end part and the lower end part of the valve body section; a positioning device is arranged on the main pipeline to position the rubber valve; the positioning device is tightly matched with the valve positioning sections and is in clearance fit with the valve body section, and an air inlet pipeline is arranged and connected to an annular clearance between the positioning deviceand the valve body section. The rubber valve capable of randomly adjusting the air inflow realizes the deformation of the middle part in different degrees by utilizing the pressure difference of air so as to achieve the effect of adjusting the cross section area of a channel and realize the random adjustment of air flow. The valve is simple in structure, small in size and convenient to automatically control. In addition, the sealing of the contact interfaces of the upper end part and the lower end part is realized by the elasticity of the rubber, so that sealing measures are saved.

Owner:QINGDAO UNIV OF SCI & TECH

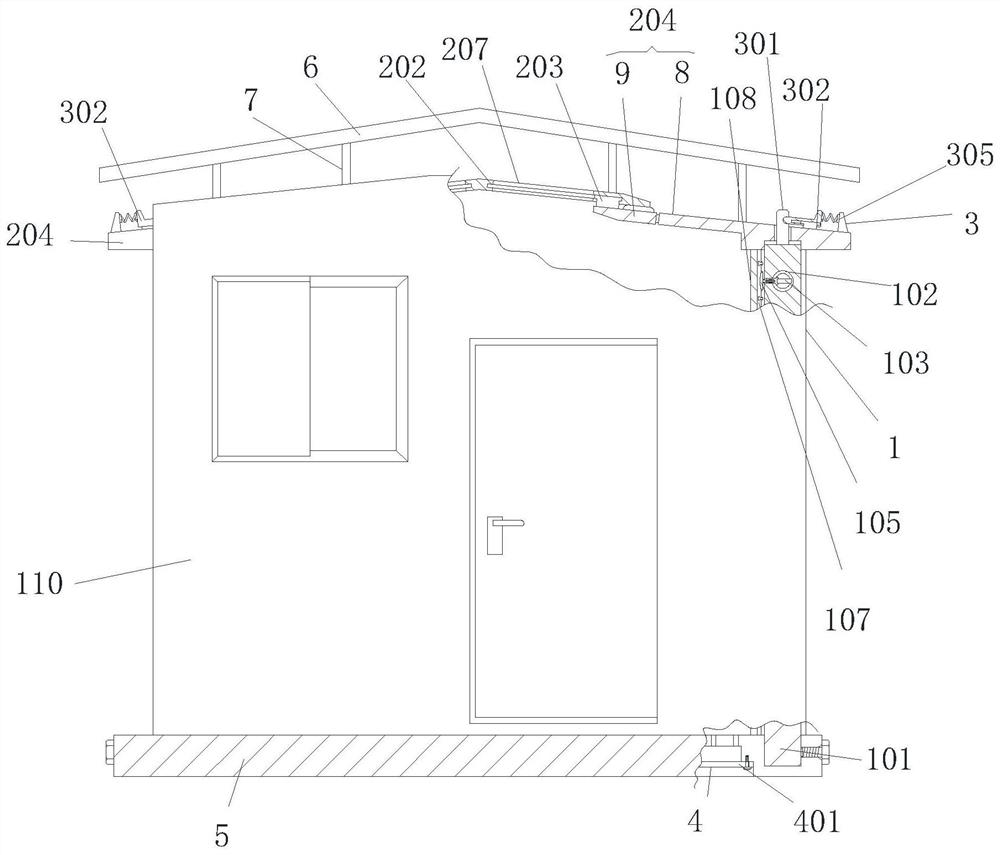

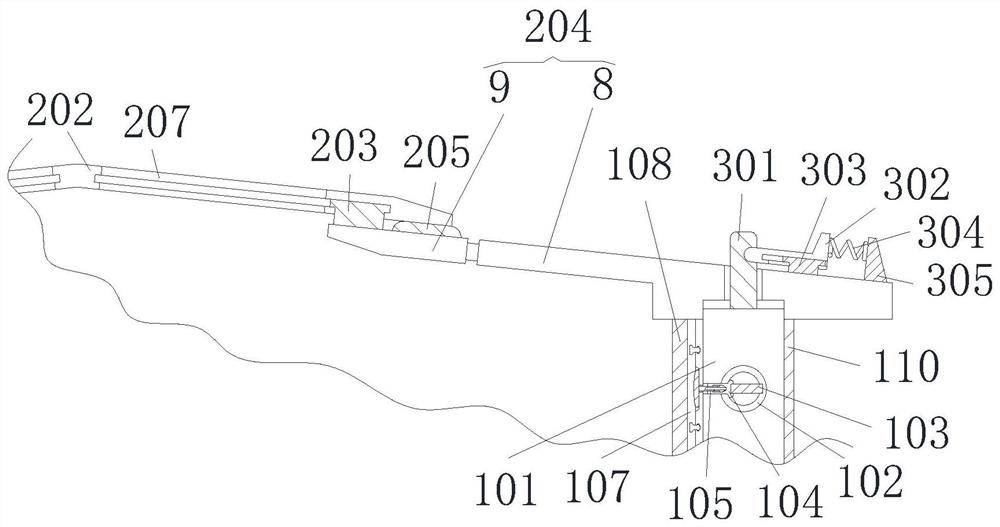

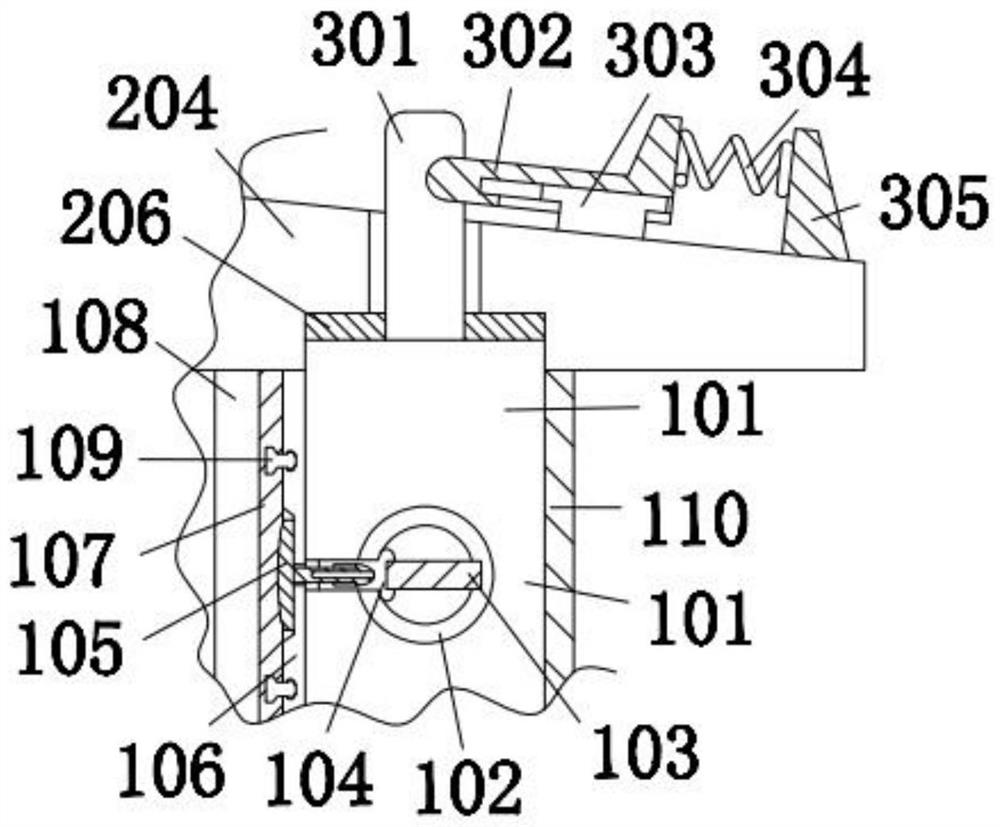

Adjustable breathable roof and wall assembling system

ActiveCN111980161AReduce the difficulty of homeworkThe job takes less timeBuilding roofsRoof coveringClassical mechanicsStructural engineering

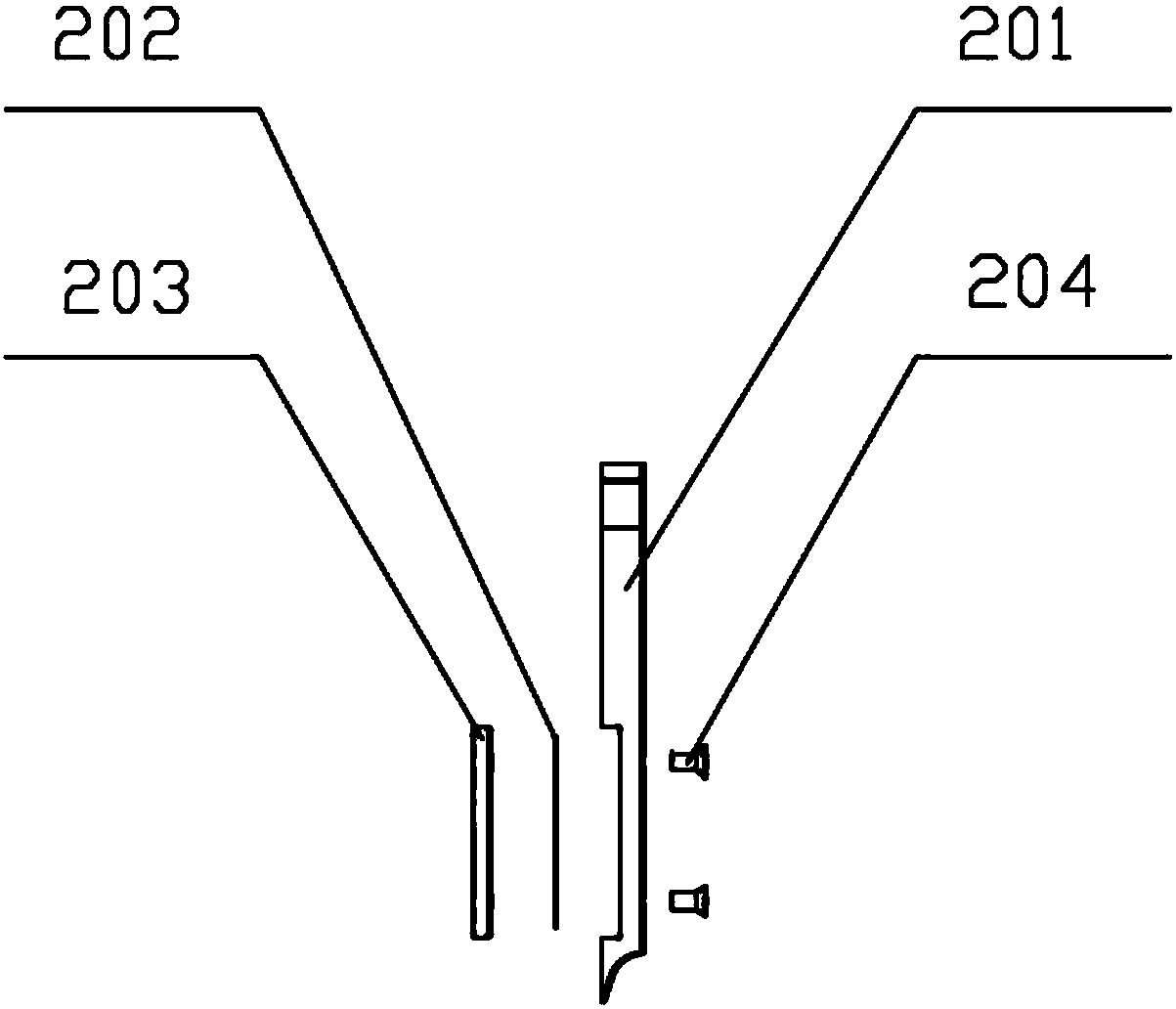

The invention discloses an adjustable breathable roof and wall assembling system. The adjustable breathable roof and wall assembling system comprises a bottom plate, a wall is arranged above the bottom plate, a cover is arranged above the wall, and the cover comprises a first inclined plate (202), a first sliding block, a second inclined plate, a rubber plate and a rubber pad; and a roof with a fixed angle is arranged above the cover body, and connecting rods are arranged below the roof and connected to fixing plates of the first inclined plate and the second inclined plate correspondingly. The assembly type building is low in operation difficulty and short in overall operation time, and therefore the use requirements of people can be better met. Through cooperation of the first inclined plate, the second inclined plate, the sliding block, the rubber plate, a short rod, a supporting rod, a spring and a second sliding block, the ceiling installation process is simple, and meanwhile through stretching and retracting of the second inclined plate, the opening size of a window in the first inclined plate is influenced, and the air inflow is adjusted.

Owner:蚌埠知聪信息技术有限公司

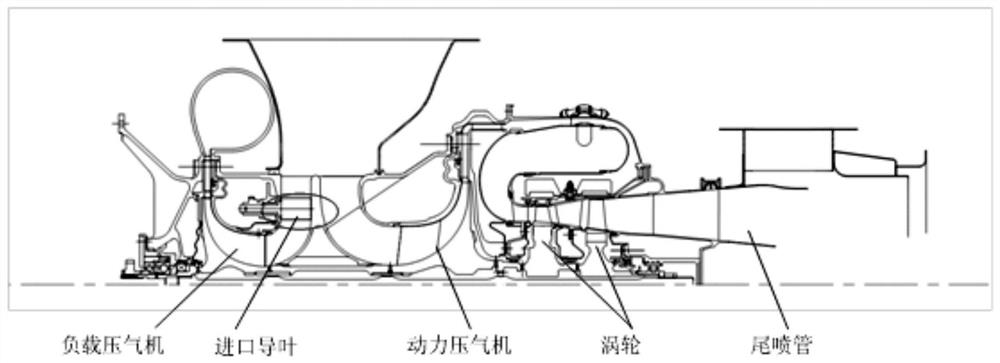

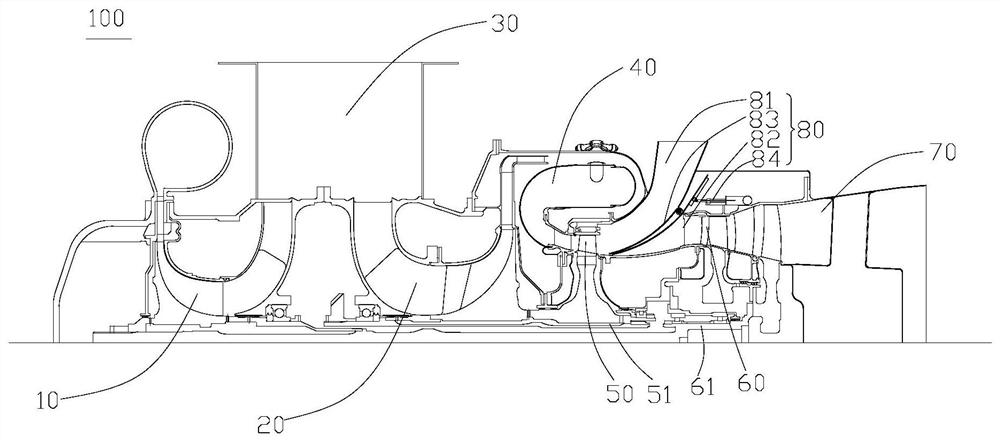

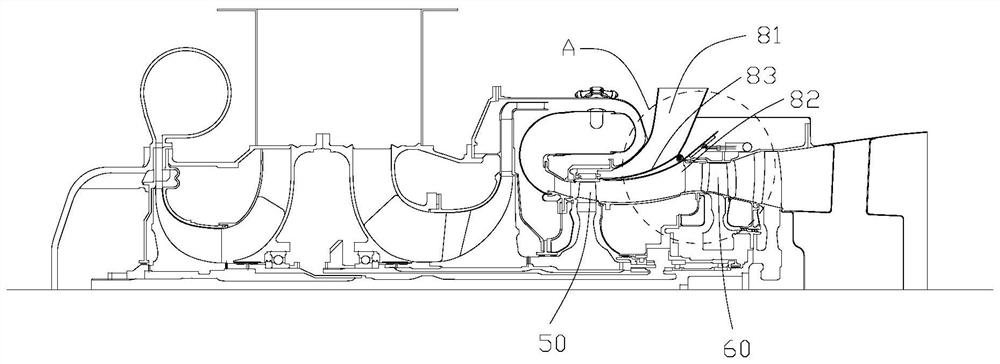

Auxiliary power device and exhaust control method of auxiliary power device

ActiveCN113022863AAdjust air intakeReduce power consumptionPower plant exhaust arrangementsPower installationsCombustion chamberGas compressor

The invention discloses an auxiliary power device and an exhaust control method of the auxiliary power device. The device comprises a load gas compressor, a power gas compressor, a combustion chamber located at an airflow outlet of the power gas compressor, a gas turbine located at the downstream of the combustion chamber, a free turbine located at the downstream of the gas turbine and an exhaust nozzle located at the downstream of the free turbine and used for discharging high-temperature gas output by the free turbine. An exhaust adjusting mechanism is arranged between the free turbine and the gas turbine and used for guiding high-temperature gas output by the gas turbine into the free turbine so as to drive the free turbine to rotate or used for guiding the high-temperature gas output by the gas turbine out of the free turbine from the gas inlet side of the free turbine. According to the auxiliary power device, normal functions of air entraining, power generation and the like of a load air compressor of an existing auxiliary power device can be achieved, the load air compressor does not work in the non-air-entraining state of the load air compressor, then power consumption of the load air compressor is reduced, and economic benefits are good.

Owner:AECC HUNAN AVIATION POWERPLANT RES INST

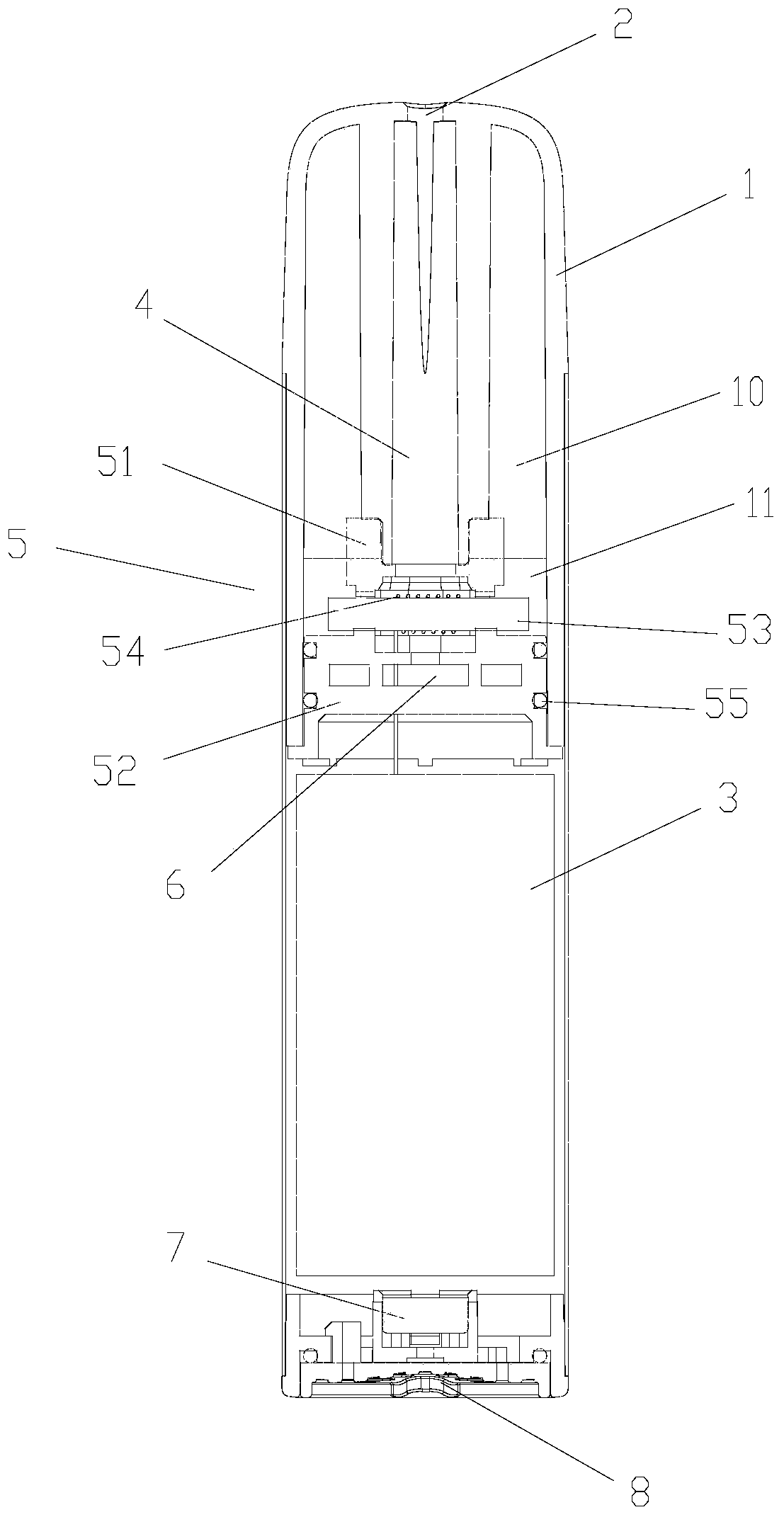

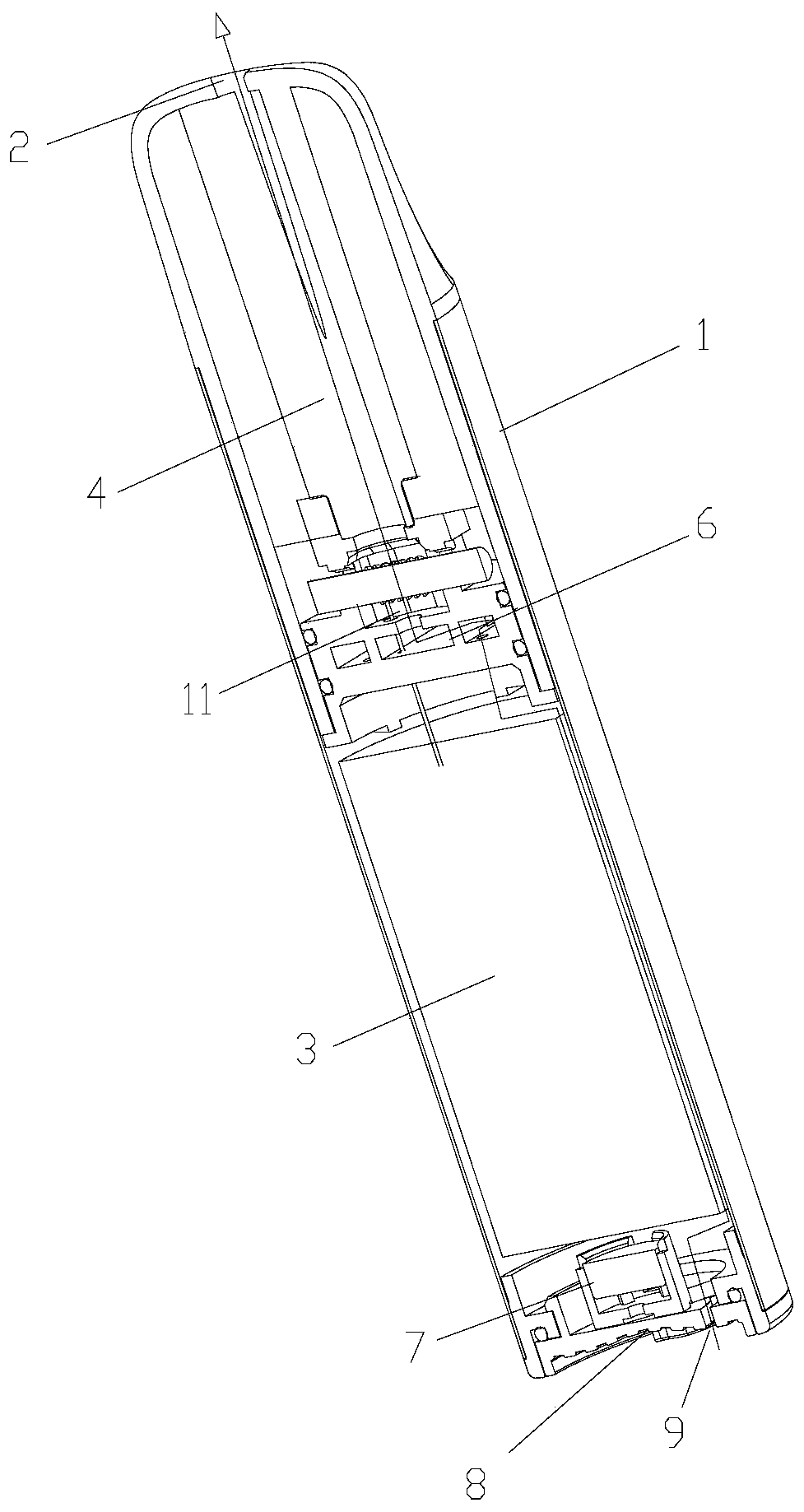

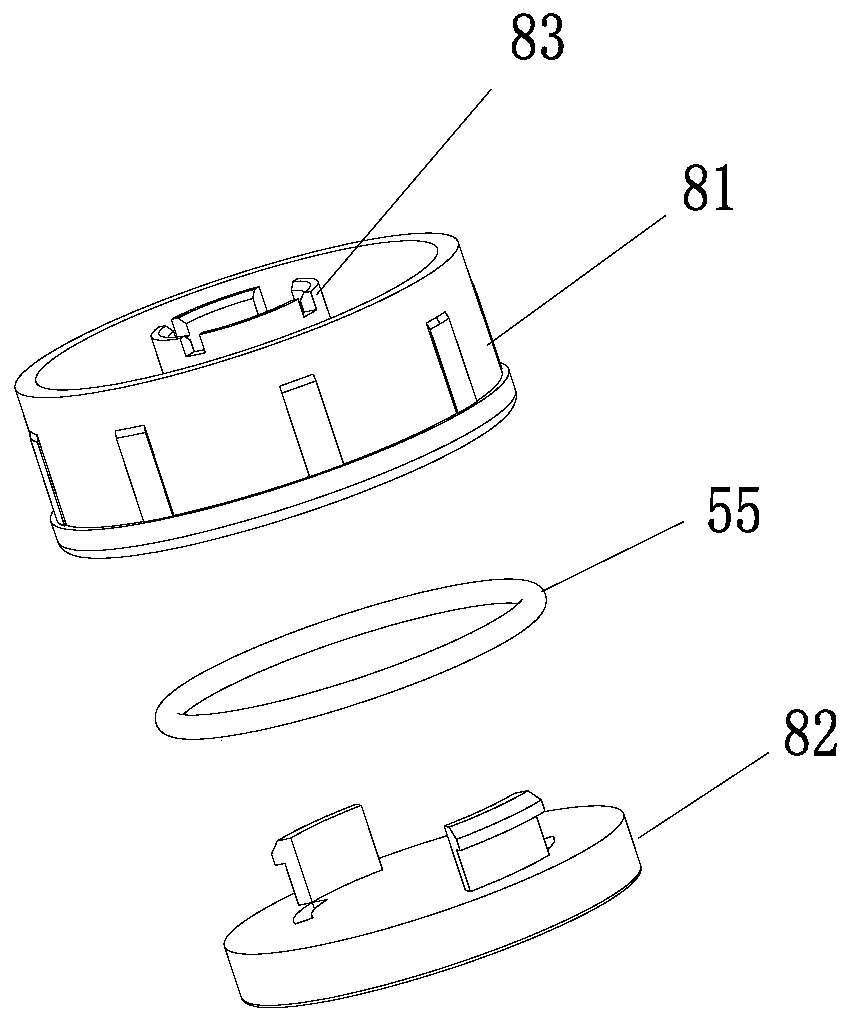

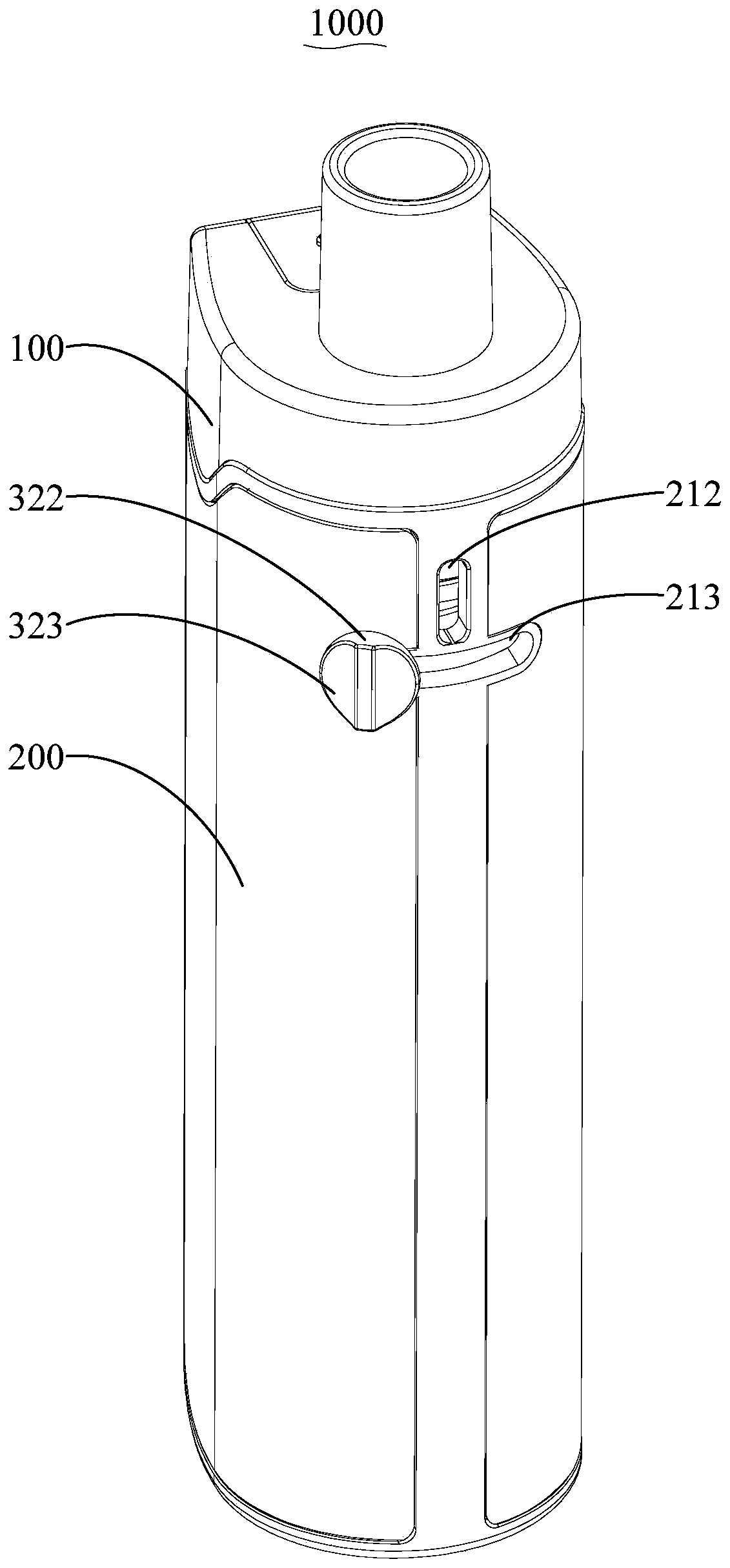

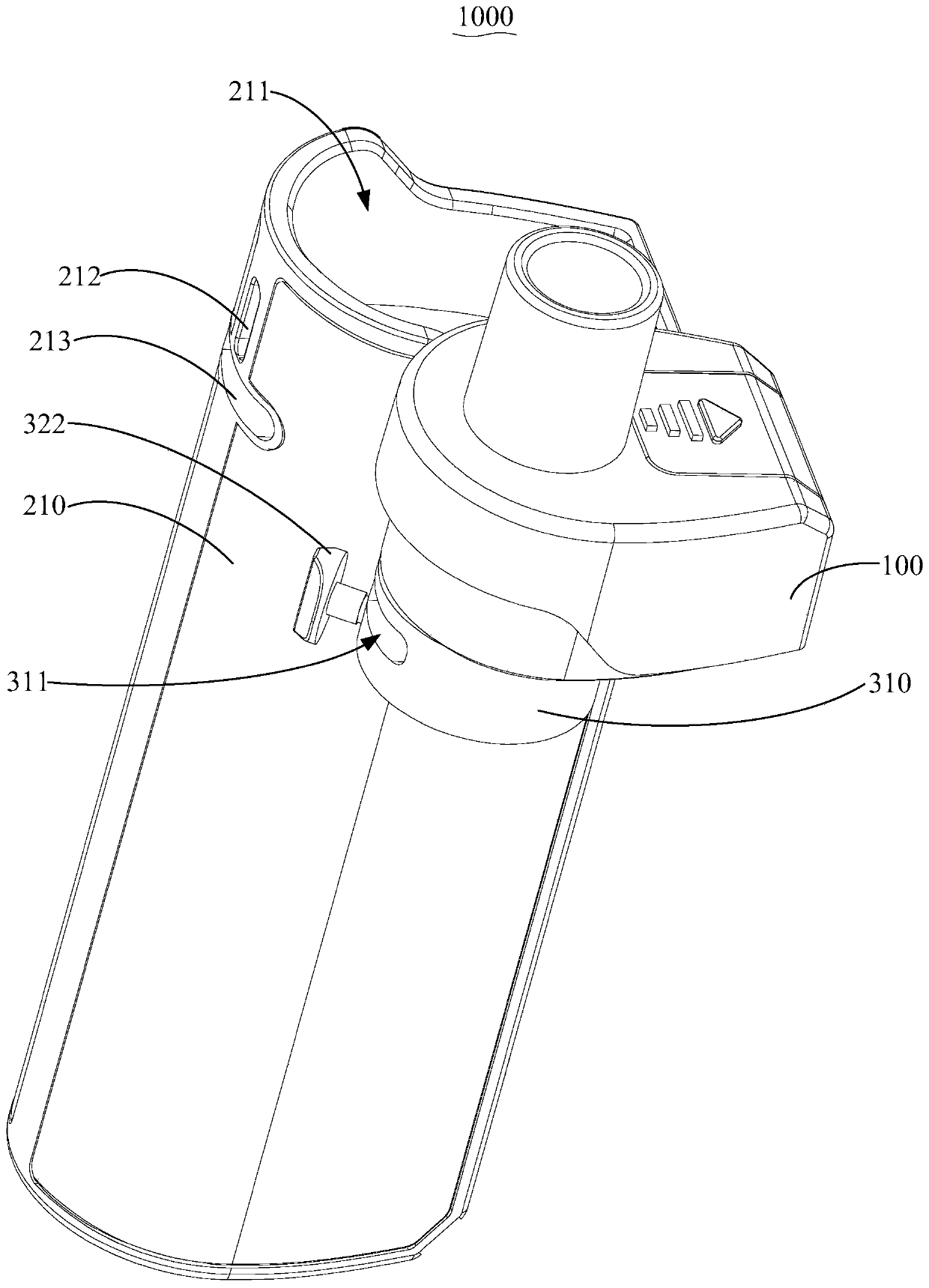

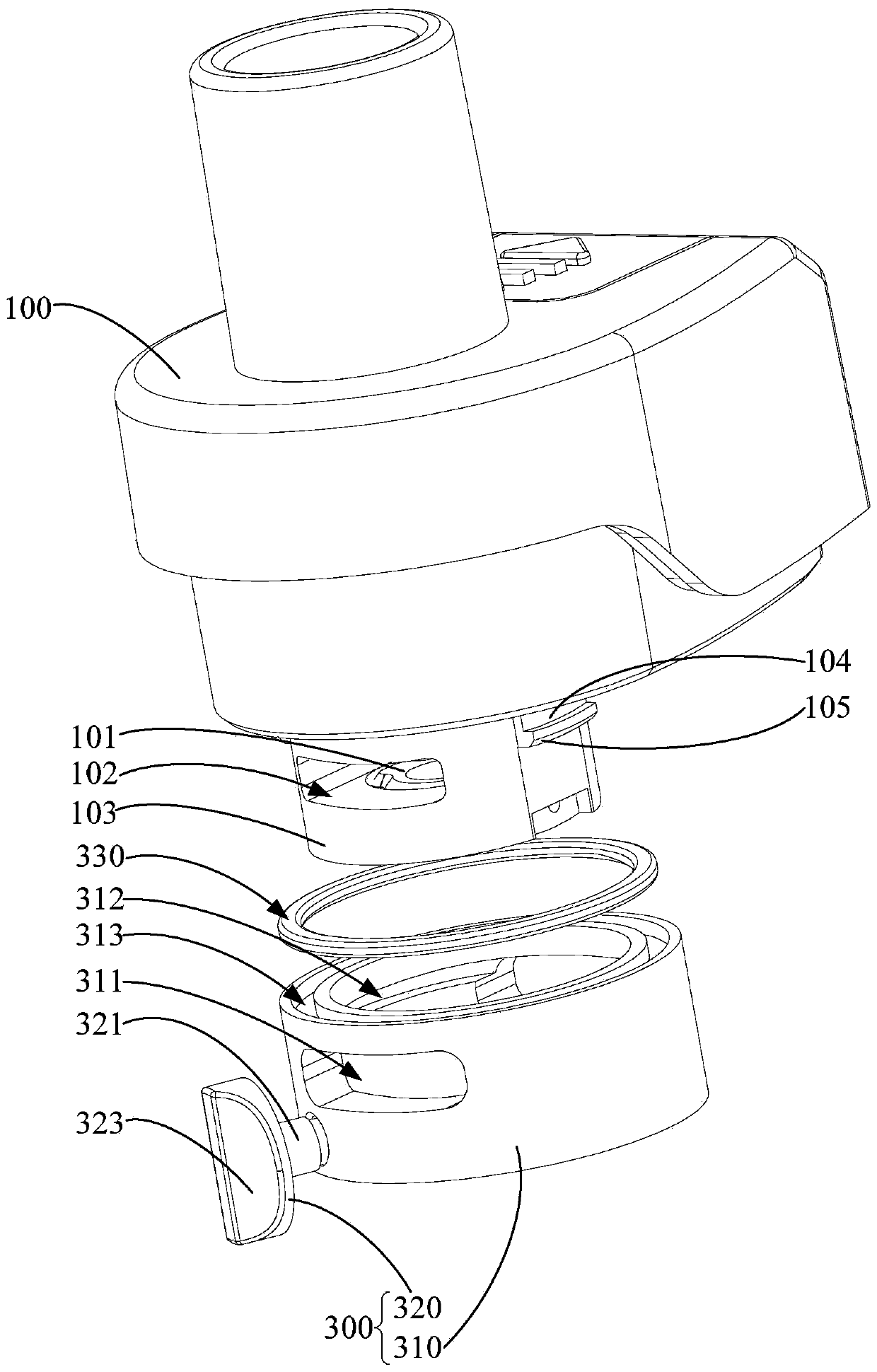

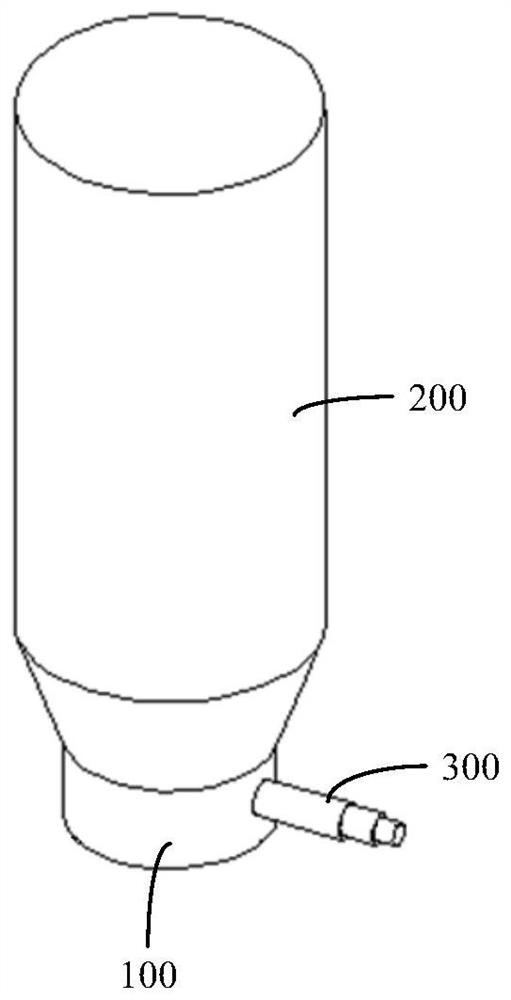

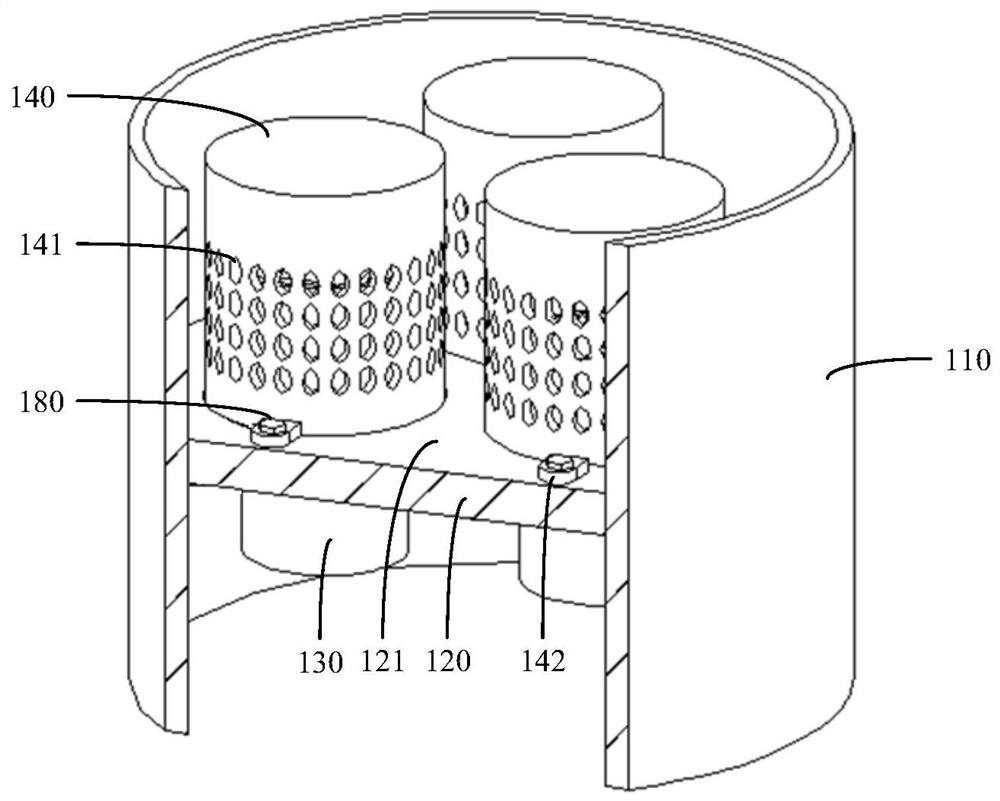

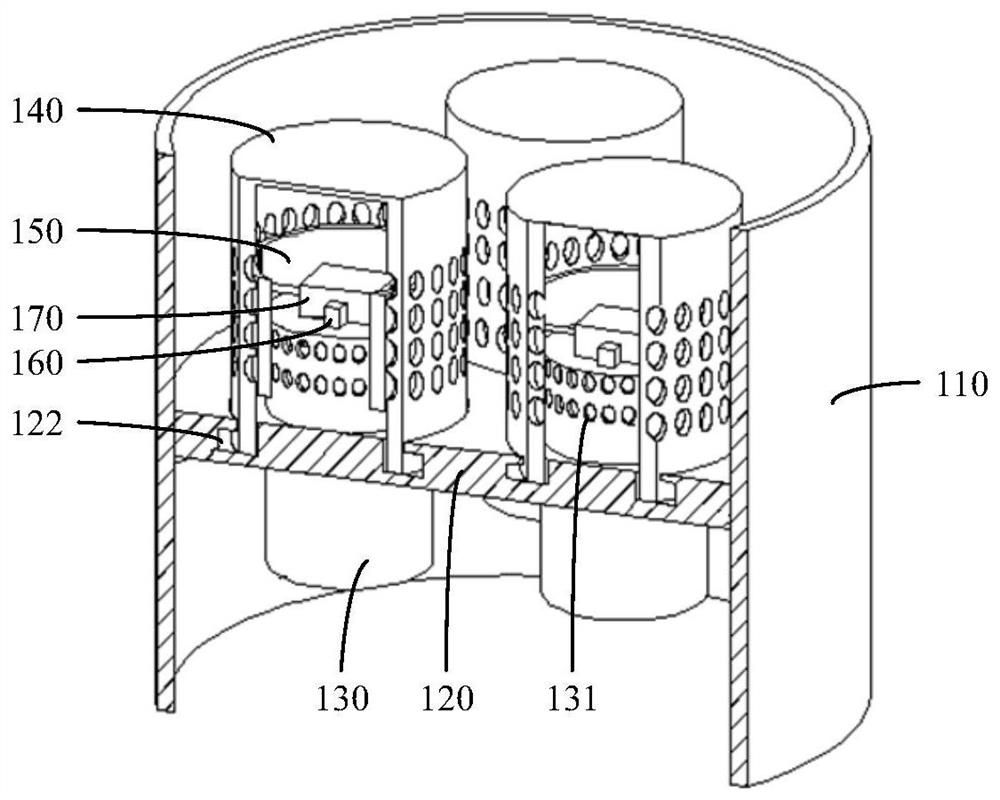

Disposable aerosol generating device with air adjusting structure

The invention relates to the technical field of electronic products and relates to a disposable aerosol generating device with an air adjusting structure. The device comprises a main housing, a suction nozzle is arranged at the top of the main housing, an oil storage bin used for storing oil and a battery bin used for containing a battery are arranged in the main housing, a battery assembly is arranged in the battery bin, an air guide pipe communicated with the suction nozzle is arranged in the oil storage bin, an atomization core assembly is arranged at the lower end of the air guide pipe, anair inlet hole is formed in the bottom of the main housing, and an air adjusting structure is arranged on the air inlet hole. The device can prevent a user from accidentally touching the air inlet hole, is convenient for the user to operate, can change the size of the air inlet hole and adjust the air inflow, meets the personalized requirements of the user, and can prevent the situation that theaerosol generating device cannot work due to the fact that the air inflow of the aerosol generating device is zero.

Owner:SHENZEN ZUN YI PIN TECH CO LTD

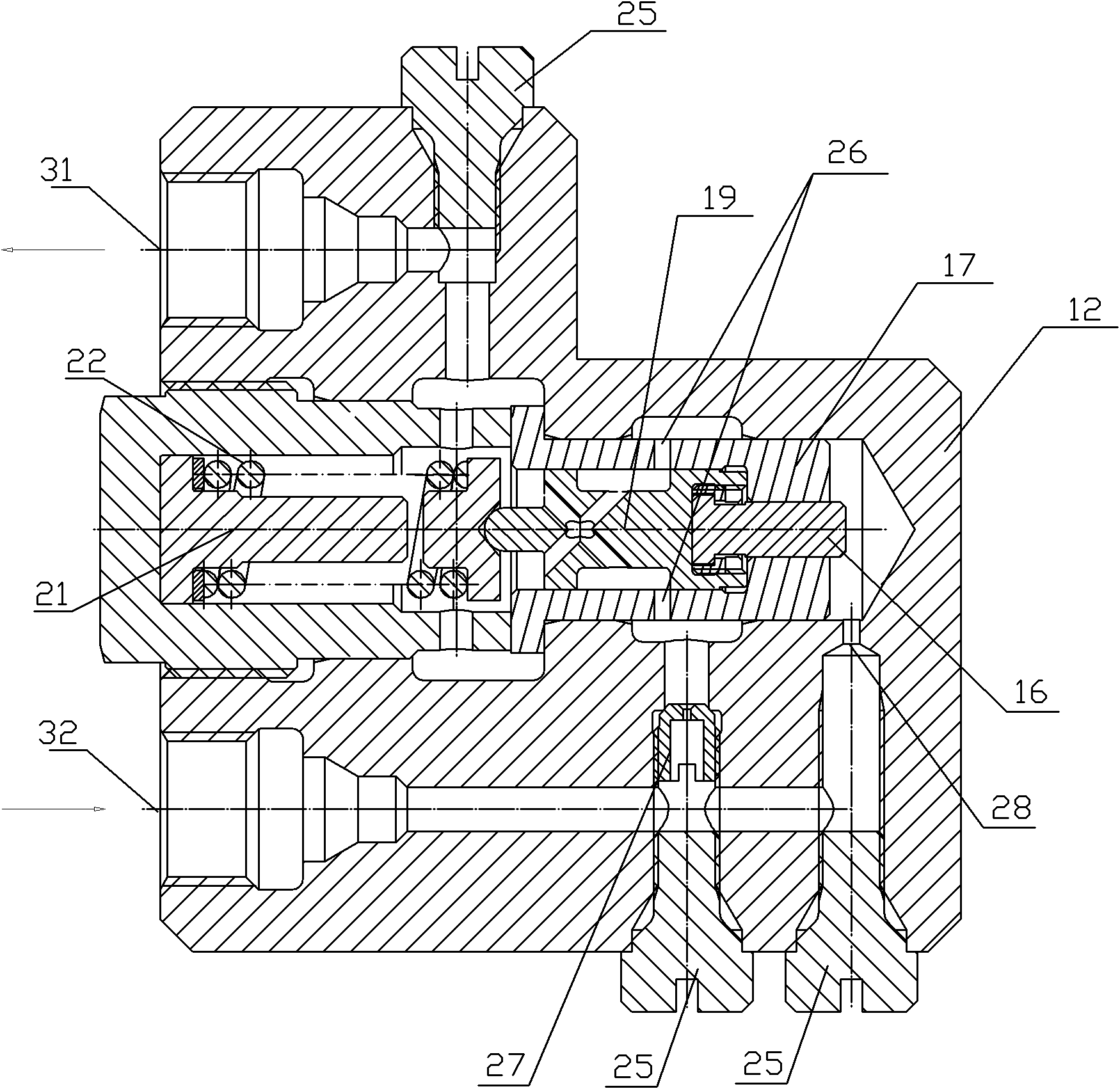

Decompressor of coke-oven gas fuel gas vehicle

InactiveCN101608583AAdjust air intakeAchieve normal workInternal combustion piston enginesFuel supply apparatusCoke ovenHigh pressure chamber

The invention relates to a decompressor of a coke-oven gas fuel gas vehicle, belonging to a fuel gas decompressor. An adjusting bolt (2) is arranged at the upper side between a low-pressure chamber (1) and a high-pressure chamber (6) and is fixed at the upper end by a lock sheet (3), and the lower side is provided with an air outlet valve (12) and a limit bolt (10) corresponding to the adjusting bolt (2), wherein, the air outlet valve is supported by a spring (9); a high-pressure digital sensor (4) and a safety valve (5) are arranged on the high-pressure chamber (6); a high-pressure electromagnetic valve (7) is arranged on a high-pressure gas inlet (8), and a low-pressure gas inlet (11) is arranged on the low-pressure chamber (1). The invention can use coke-oven gas fuel gas as a novel fuel on a vehicle. By experiments, the invention can effectively regulate input of the coke-oven gas fuel gas when the vehicle runs, thus the vehicle can normally work under various states. The decompressor of the invention is suitable for decompression of the coke-oven gas fuel gas vehicle.

Owner:王旭光

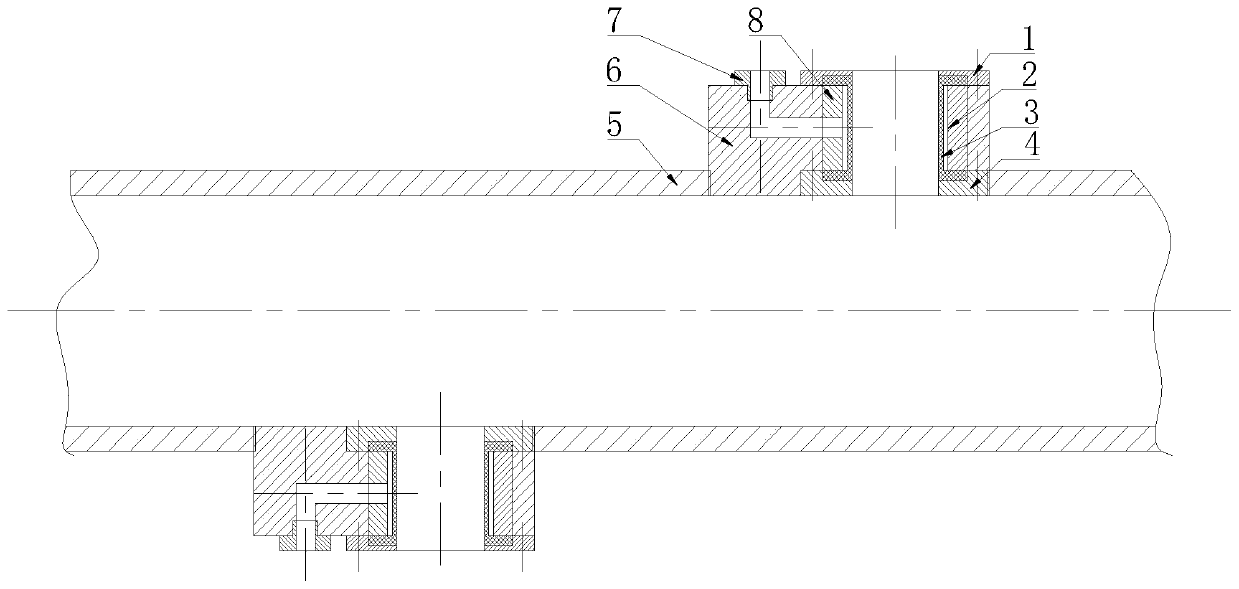

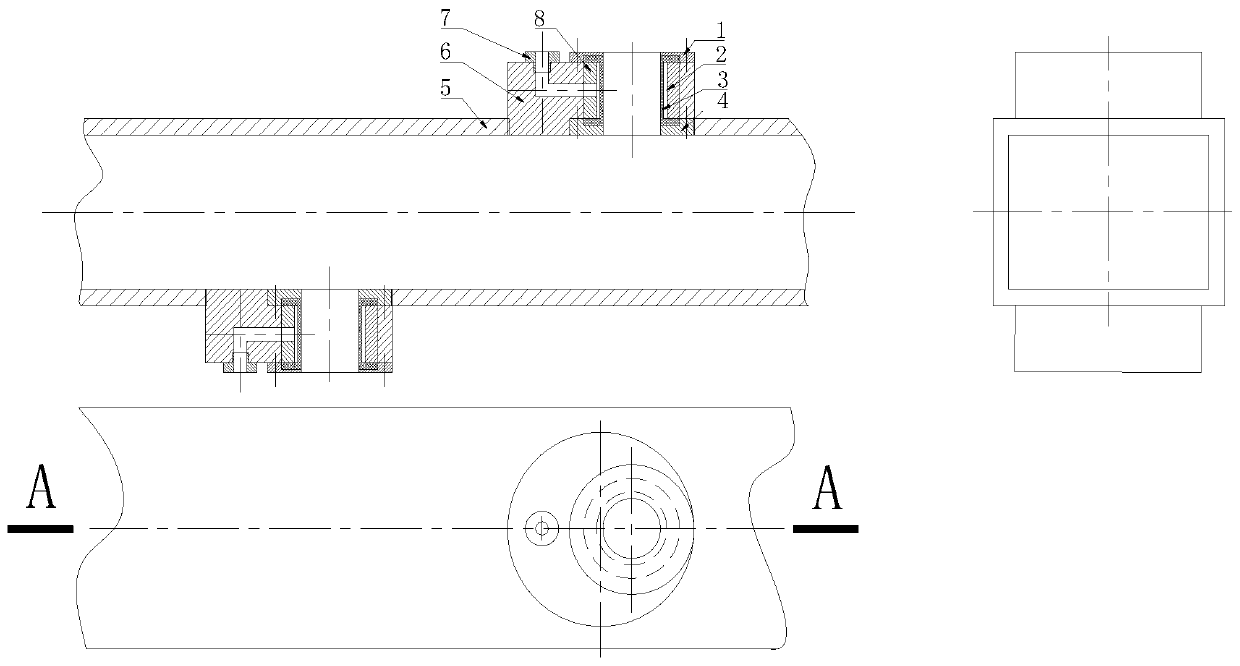

An energy-saving intake valve of frequency conversion compressor for mine

ActiveCN109681647BAdjust air intakeEasy to implementOperating means/releasing devices for valvesValve members for absorbing fluid energyFrequency conversionInlet valve

The invention discloses an air intake valve of an energy-saving mine variable frequency compressor, which relates to the technical field of valves. Aiming at the problem that the existing air intake valve cannot well cooperate with the operation of the compressor, the following scheme is proposed, which includes a valve The two sides of the valve body are fixedly welded with symmetrically arranged connecting pipes, the connecting pipe flanges are connected with communicating pipes, the valve body is fixedly welded with a fixed seat, and both sides of the fixed seat are fixedly welded with A guide plate, a ventilation groove is arranged in the middle of the fixed seat and the guide plate, a first spring is fixedly connected to one side of the guide plate, and a moving plate is fixedly connected to the end of the first spring away from the guide plate, and the moving plate One end away from the first spring is slidably connected with the groove wall of the ventilation groove. The invention is simple in structure and convenient in use, and can meet the needs of production. The mechanical connection of threads makes the device more stable, easy to realize, and can be well adapted to the frequency conversion compressor.

Owner:浙江意格特机械制造有限公司

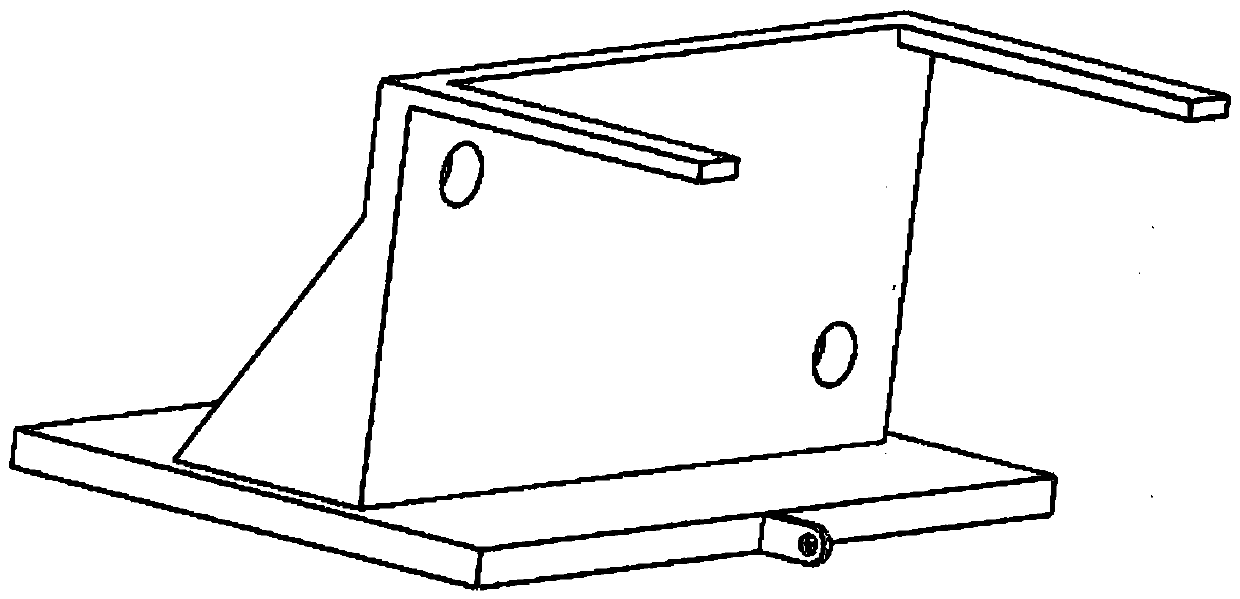

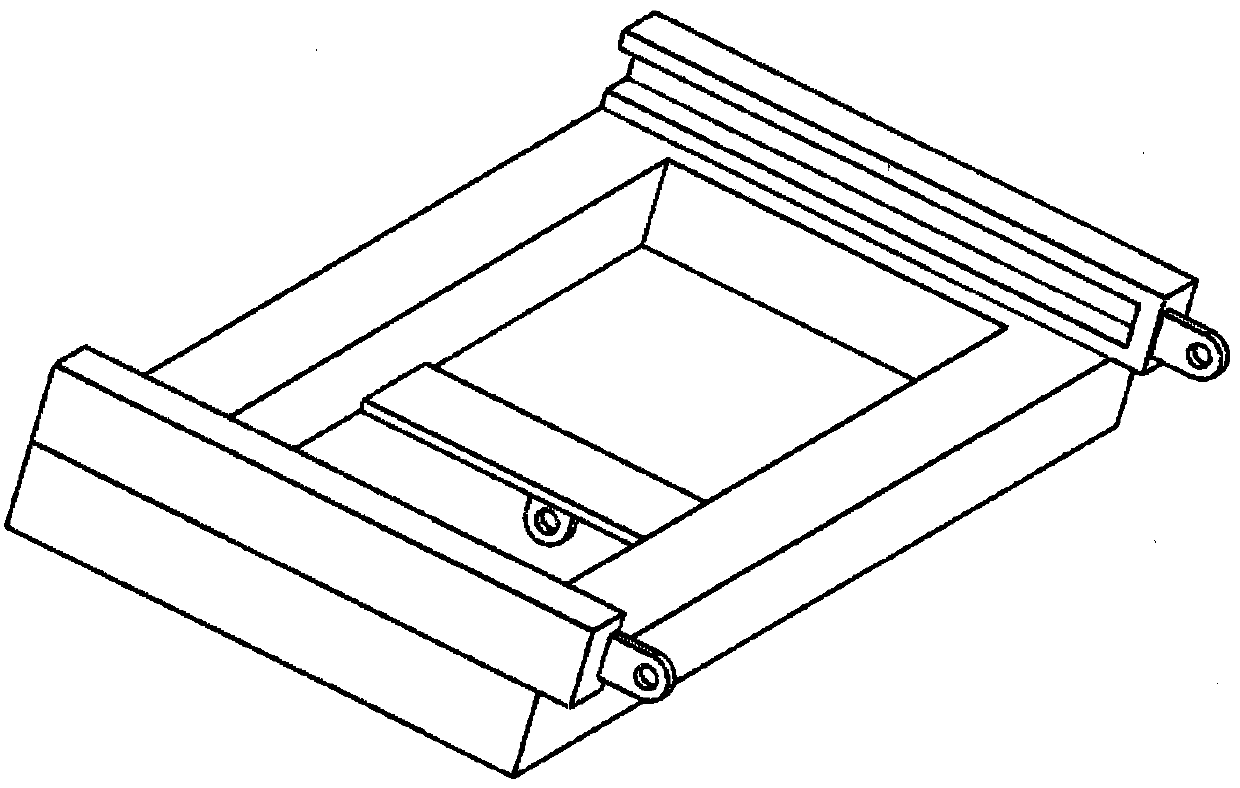

A device for deburring

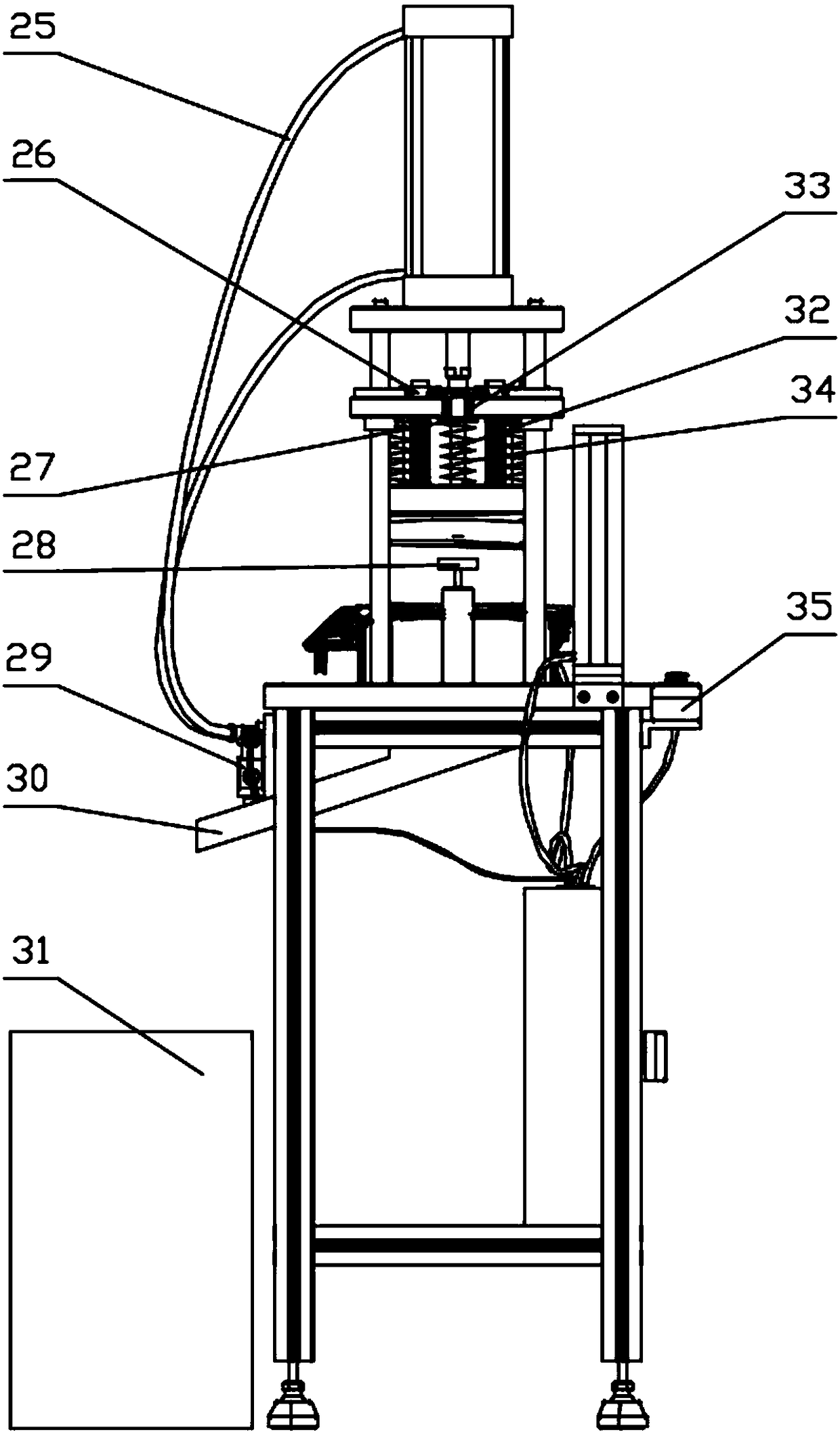

ActiveCN106584731BImprove stabilitySimple structural designEdge grinding machinesGrinding/polishing safety devicesEngineeringProduct processing

The invention relates to the field of plastic product processing and particularly relates to deburring equipment. The deburring equipment comprises a lower mold plate, an upper mold plate, a supporting plate, a fixed plate, an air cylinder mounted on the fixed plate, a knife rest mounted on the supporting plate and a combined knife mounted on the knife rest; a switch is pressed down, so that the air cylinder moves downward to drive the supporting plate, the upper mold plate, the combined knife and the like to move downward, the lower mold plate is in contact with a product to stop moving to play a compressing role under the action of a spring, the supporting plate and the combined knife continuously move downward, the combined knife removes flash, burrs and the like, after removal, the switch is pressed down, and the air cylinder returns under the action of an electromagnetic reversing valve to drive the supporting plate, the upper model plate, the combined knife and the like to move upward to accomplish a work process. The deburring equipment provided by the invention is simple in structural design and high in processing efficiency, improves the stability of the deburring quality, ensures the quality which is hard to control, and further improves the stability of the equipment.

Owner:江苏蔚金汽车零部件有限公司

Fastener longitudinal resistance test device

ActiveCN106289606BReduce procurement costsRealize one machine with multiple functionsApparatus for force/torque/work measurementProgram testingEngineering

The invention discloses a fastener longitudinal resistance measuring device. The fastener longitudinal resistance measuring device includes a fastener seat 4, a turning table 5, a rack 7, a first air cylinder 6, a second air cylinder 8 and wheels 9; the second air cylinder 8 makes the turning table 5 stand upright, and a steel rail 3 and a fastener are mounted on the fastener seat 4; the first air cylinder 6 pushes the fastener seat 4 out to a test platform 2; a pressing head 1 provided with a displacement and force sensor applies a force onto the steel rail 3; and the longitudinal resistance of the fastener is tested according to procedures. The fastener longitudinal resistance measuring device of the invention is applicable to a plurality of kinds of fasteners and has high universality; a universal electronic testing machine in a laboratory can be adopted as the pressing head 1 provided with the displacement and force sensor, and therefore, part purchase cost can be reduced, and the multi-purpose performance of the fastener longitudinal resistance measuring device can be achieved; pneumatic control is adopted, so that labor force consumption can be decreased; the extending and stretching speed of the air cylinders can be controlled through adjusting air inflow, and therefore, injuries to operators can be avoided; and the fastener longitudinal resistance measuring device is convenient to move, and the fastener longitudinal resistance measuring device can be moved away with easiness when the fastener longitudinal resistance measuring device is not used. The fastener longitudinal resistance measuring device has the advantages of compactness, lightweight, structural simplicity and easiness in maintenance.

Owner:BEIJING ZKYT TECH CO LTD

Hot-blast stove with automatic heat supply temperature adjustment function

InactiveCN103743097AIncrease temperature and radiation intensityAdjust air intakeAir heatersHot blastCombustion chamber

The invention provides a hot-blast stove with an automatic heat supply temperature adjustment function. The hot-blast stove comprises a stove body and a combustion chamber installed in the stove body. A mixing chamber is further arranged inside the stove body. The mixing chamber is communicated with the combustion chamber. The mixing chamber is divided into a first mixing chamber body and a second mixing chamber body, wherein the first mixing chamber body and the second mixing chamber body are mutually communicated. The stove body is provided with a first opening and a second opening. Normal-temperature air is blown into the first mixing chamber body through the first opening. Cold air is blown into the second mixing chamber body through the second opening. The second mixing chamber body is communicated with an air outlet. According to the hot-blast stove with the automatic heat supply temperature adjustment function, the size of the combustion chamber is set more reasonably, so that the temperature of combustion is increased, and radiation intensity of combustion is enhanced; combustion is kept in the most reasonable working condition by adjusting the fuel quantity and air quantity inside the combustion chamber; the first mixing chamber body and the second mixing chamber body are arranged, the air inflow of the normal-temperature air of the first mixing chamber body is adjusted, and therefore process requirements of a heat-consuming device are better met.

Owner:CHANGZHOU OLYMSPAN THERMAL ENERGY EQUIP

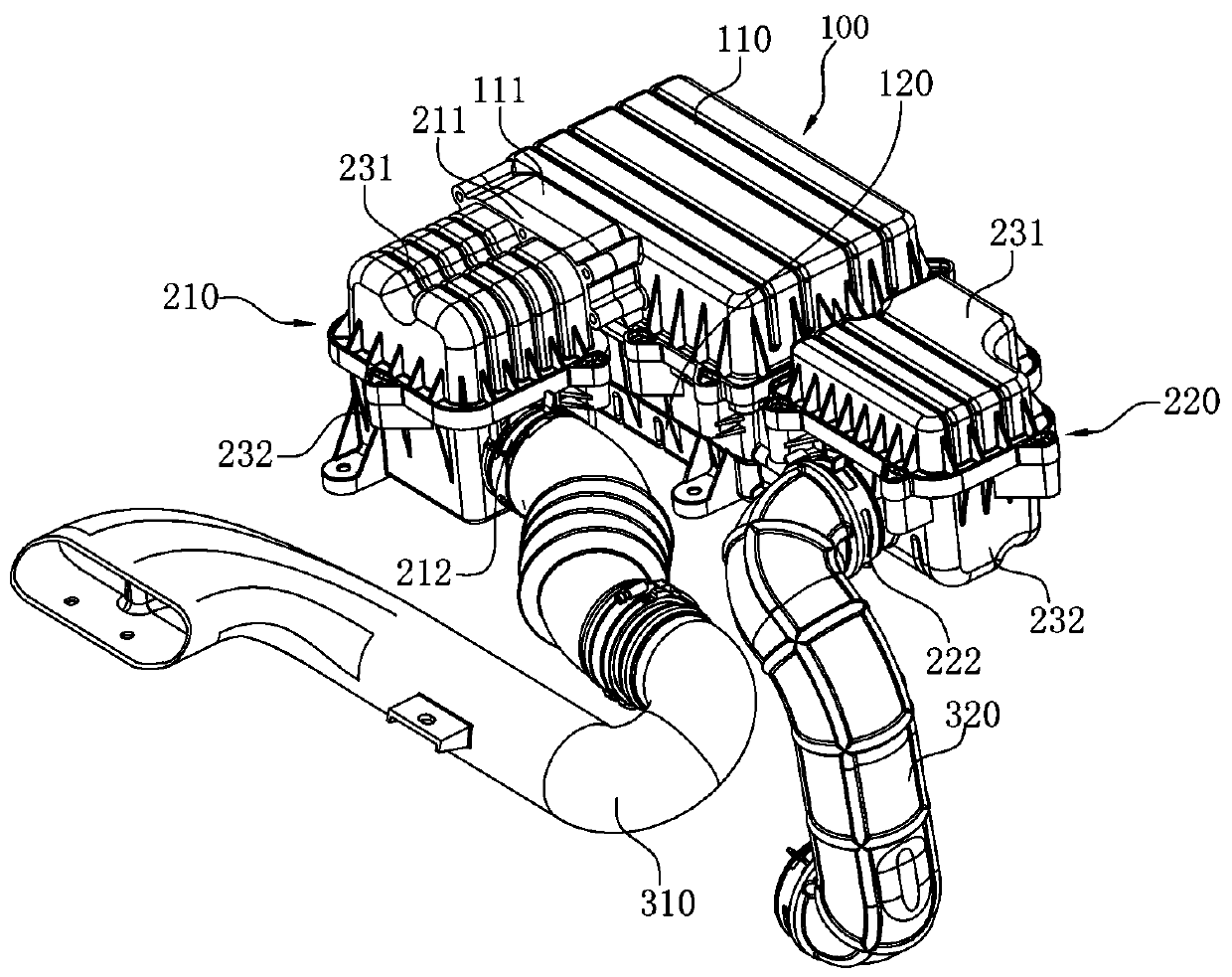

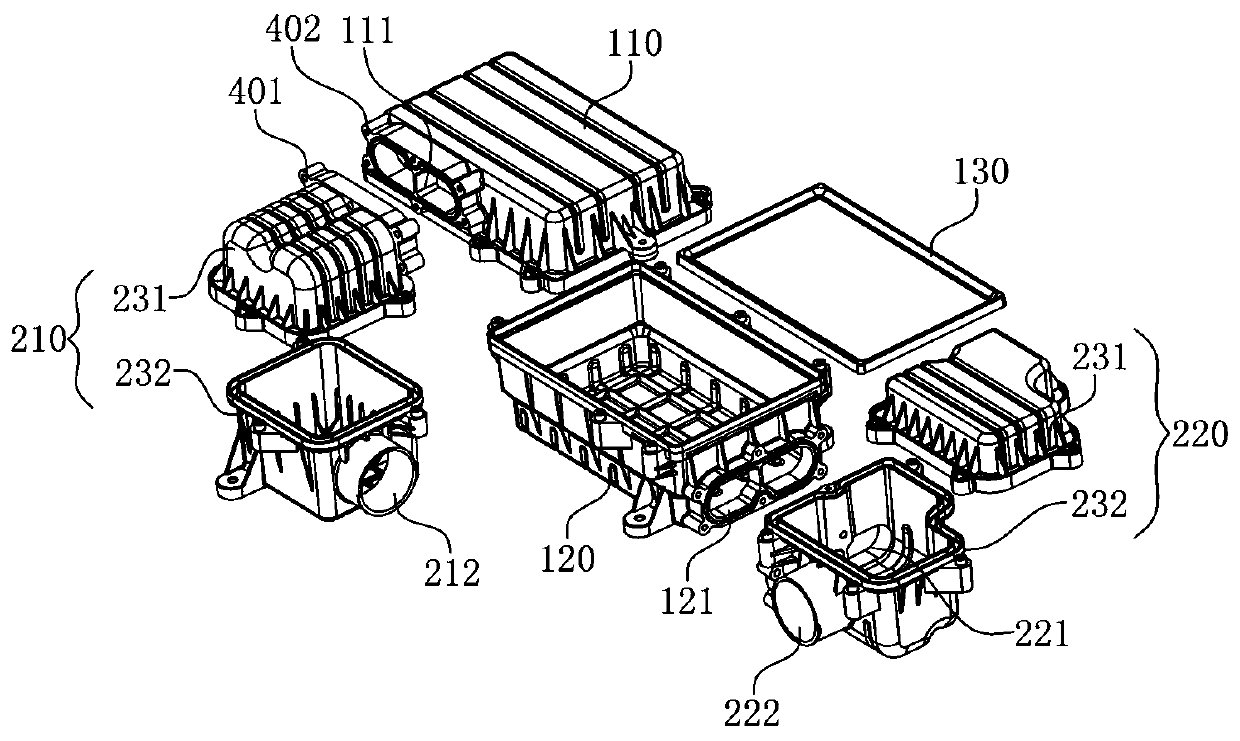

Integrated type car air filter system

PendingCN111022225AReasonable structural designSmall footprintMachines/enginesAir cleaners for fuelAir filtrationAir filter

The invention belongs to the technical field of air filters, and provides an integrated type car air filter system. The system comprises an air filter chamber, an air inlet buffer chamber, an air suction buffer chamber, a filter element, an air inlet pipe and an air suction pipe. The air filter chamber comprises a filter chamber upper shell and a filter chamber lower shell, a first flange type communication opening is formed in the filter chamber upper shell, a second flange type communication opening is formed in the filter chamber lower shell, the air inlet buffer chamber is fixedly connected with the filter chamber upper shell, the air inlet buffer chamber communicates with the first flange opening communication opening, the air suction buffer chamber is fixedly connected with the filter chamber lower shell, the air suction buffer chamber communicates with the second flange communication opening, the filter element is arranged between the filter chamber upper shell and the filter chamber lower shell, and the air inlet pipe and the air suction pipe communicate with the air inlet buffer chamber and the air suction buffer chamber correspondingly. The system is reasonable in whole structure design, small in occupied space, high in integration, capable of greatly saving the space of a forward engine room, and more suitable for forward engine room layout of an extended-range electric car.

Owner:韩群山

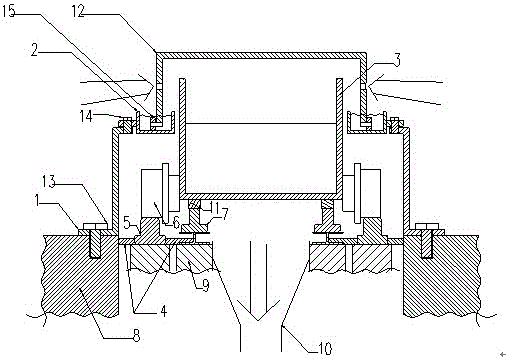

The first-level water-sealed anti-heat transpiration shield device of the sintering machine trolley

The invention discloses a sintering machine trolley first-grade water sealing heat transpiration protection shield device which comprises supports, U-shaped water sealing grooves and a shield. The supports are installed on trolley foundations on the two sides of a trolley. The U-shaped water sealing grooves are connected with the upper ends of the supports through bolts. The lower ends of the shield walk into the U-shaped water sealing grooves through walking wheels. The whole shield covers the space of the upper end of a sintering trolley, and the top of the shield is higher than side baffles of the trolley. The two side walls of the shield are provided with adjusting windows adjusting the air flow, and the adjusting windows are used as cold air suction inlets. The sintering machine trolley first-grade water sealing heat transpiration protection shield device further comprises sealing steel plates. The sealing steel plates are sealed between trolley guide rails and the trolley foundations and sealed between the trolley guide rails and trolley bottom sealing strip guide rails. The sintering machine trolley first-grade water sealing heat transpiration protection shield device can improve the sintered ore combustion rate, and meanwhile lower energy consumption, sintered material heat losses are avoided, and it is ensured that cold air exchanges from top to bottom.

Owner:马春强

Automobile air conditioning cooling module

PendingCN109263435AAdjust air intakeImprove cooling effectAir-treating devicesVehicle heating/cooling devicesAutomobile air conditioningEngineering

The invention discloses an automobile air conditioning cooling module, which comprises a condenser unit, a fan unit and a radiator unit. The condenser unit and the radiator unit are staggered; a firstsidewall and a second sidewall extending toward the condenser unit are provided on both sides of the fan unit, respectively. One end of the radiator unit is connected with the first side wall, and apassage connecting port communicating the first ventilation passage and the second ventilation passage is formed between the other end of the radiator unit and the second side wall; an air inlet communicating with the first ventilation passage is formed between one end of the condenser unit and the first side wall, and the other end of the condenser unit is connected with the second side wall. Anair inlet damper for controlling the air inlet switch is arranged in the air inlet, and a connecting port damper for controlling the channel connecting port switch is arranged in the channel connecting port. The automobile air conditioning cooling module disclosed by the invention can adjust the intake air quantity, thereby improving the cooling effect and reducing the energy consumption.

Owner:WM SMART MOBILITY (SHANGHAI) CO LTD

Electronic cigarette

PendingCN111387554AAdjust air intakeAvoid removing the atomizing componentsTobaccoAerosolizeElectronic cigarette

The invention discloses an electronic cigarette. The electronic cigarette comprises an atomization assembly, a power supply assembly and an adjusting assembly. The atomization assembly comprises an atomization core, wherein the atomization core is provided with an air inlet; the power supply assembly comprises a base body; the atomization assembly is arranged in a storage cavity of the base body;an air inlet hole communicated with the air inlet is formed in the side wall of the storage cavity; the adjusting assembly comprises an air flow adjusting ring and an adjusting piece, wherein the airflow adjusting ring is stored at the bottom of the storage cavity, a part of the adjusting piece is exposed out of the base body, an air passing hole is formed in the air flow adjusting ring, and theadjusting piece drives the air flow adjusting ring to move so as to adjust the air inflow of the air inlet or the air inlet hole. According to the technical scheme, by arranging the adjusting piece, the airflow adjusting ring is driven by the adjusting piece to rotate or slide, so that the air flow adjusting ring adjusts the opening size of the air inlet or the air inlet hole, the air inflow of the atomization assembly is adjusted, the adjusting piece is partially exposed out of the base body, and a user can directly adjust the air inflow of the atomization assembly conveniently.

Owner:SHENZHEN IVPS TECH

A control method and system for egr corrected knocking of a natural gas engine

ActiveCN110748430BAdjust air intakeEnsure safetyElectrical controlCoolant flow controlElectric controlControl theory

Owner:WEICHAI XIGANG NEW ENERGY POWER

Anti-smog riding mask

ActiveCN110250613BKeep healthyAdjustable sizeFire rescueRespiratory apparatusClassical mechanicsEngineering

The invention discloses a haze-preventing riding mask, which comprises a mask body. Wearing holes are formed in the mask body in a front-back symmetrical mode; a cover plate is moved upwards, a clamping block slides out from a clamping groove, and a sliding block and a moving block slide in a sliding cavity and a moving cavity correspondingly; and the cover plate is rotated and then can be opened, and a filter element is replaced. A filtering mechanism has a haze-preventing function, the filter element filters haze, and thus body health of pedestrians is ensured; and the cover plate can be opened, the filter element is replaced, the resource is saved, a rotary knob in an air inlet mechanism is rotated, and the size of an air inlet opening can be adjusted to adjust the air inflow.

Owner:江西欧丽达实业有限公司

Tempering furnace for heat treatment system

InactiveCN114196816AHeating evenlyAdjust air intakeFurnace typesHeat treatment furnacesTemperingEngineering

The tempering furnace for the heat treatment system comprises a machine shell, a power cavity is formed in the machine shell, two belt wheel cavities are symmetrically formed in the left end wall and the right end wall of the power cavity, a conical wheel cavity is formed in the lower end wall of the belt wheel cavity on the right side, and a heating mechanism, a lifting mechanism and a transmission mechanism are arranged in the machine shell. The lifting mechanism can transport workpieces, the transmission mechanism can provide power for the heating mechanism and the lifting mechanism, uniform heating of the workpieces is achieved through a rotatable heating ring arranged in the heating mechanism and a heating opening formed in the heating ring, and therefore conveying of the workpieces is achieved through a liftable placing block arranged in the lifting mechanism; the discharging cavity and the hot air cavity are separated through the lifting heat insulation ring and the heat insulation plate, so that heat loss is reduced, the rotating door is automatically opened in the discharging process through the arranged winding wheel capable of rotating, and workers are prevented from being scalded.

Owner:朱清林

Air chamber of circulating fluidized bed boiler and circulating fluidized bed boiler

PendingCN113237055AAdjust air intakeGuaranteed uptimeFluidized bed combustionApparatus for fluidised bed combustionFluidized bedMechanics

The invention discloses an air chamber of a circulating fluidized bed boiler and the circulating fluidized bed boiler. The air chamber comprises a shell which is provided with an air inlet side and an air outlet side, an air distribution plate, an air guide pipe, an air cap, a movable baffle and a driving mechanism; the air distribution plate is arranged in the shell, the air distribution plate is provided with a first surface and a second surface which are opposite to each other, the first surface faces the air inlet side, and the second surface faces the air outlet side; the air guide pipe is arranged on the air distribution plate, the first end of the air guide pipe is located on the air inlet side, the second end of the air guide pipe is located on the air outlet side, and a first air outlet is formed in the second end; the air cap is arranged on the air distribution plate, the air cap is located on the air outlet side, the air cap is arranged outside the second end of the air guide pipe in a sleeving mode, and the air cap is provided with a second air outlet; the movable baffle is arranged between the second end of the air guide pipe and the air cap; and the driving mechanism is arranged in the shell, the driving mechanism is connected with the movable baffle, and the driving mechanism drives the movable baffle to move so as to adjust the air inlet amount of the air chamber. According to the scheme, the problem that the air inflow cannot be controlled can be solved.

Owner:国能神福(龙岩)发电有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com