Patents

Literature

33results about How to "Fully tempered" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-performance hydrogen sulfide corrosion resistant oil drill rocker and its heat treatment process

InactiveCN101117683AGuaranteed hardenabilityGuaranteed sulfur resistanceDrilling rodsFurnace typesMechanical propertyPetroleum

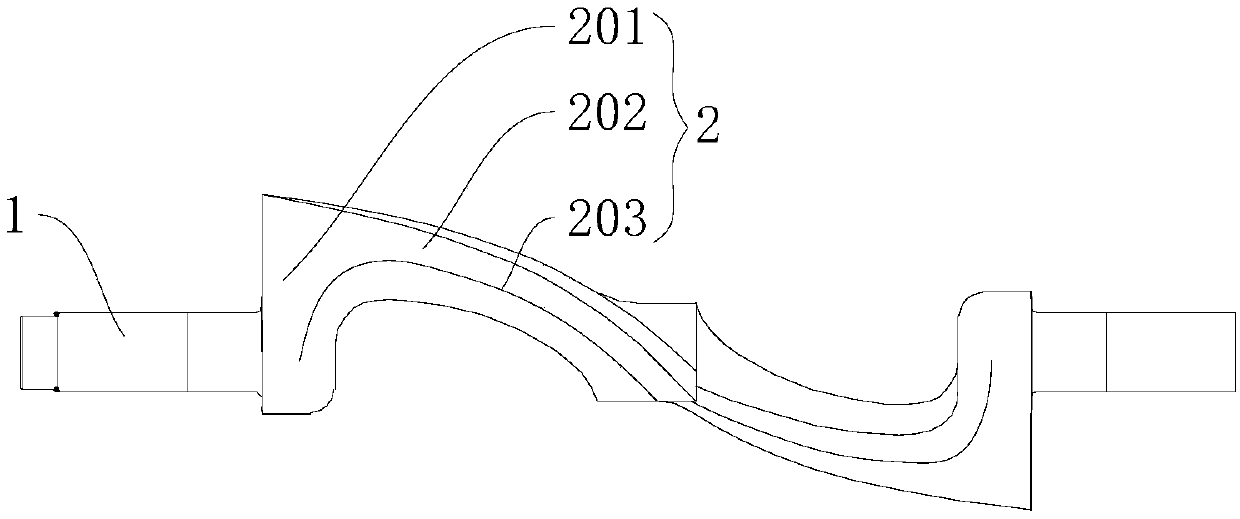

The present invention relates to a high-performance hydrogen sulfide corrosion resistant petroleum drill pipe with a weight percentage of components as follows: C 0.20-0.32 percent, Si 0.1-0.5 percent, Mn 1.0-1.5 percent, Cr 0.5-1.5 percent, Mo 0.8-1.2 percent, P less than or equal to 0.015 percent, S less than or equal to 0.01 percent and the remainders are Fe and unavoidable impurities. The drill pipe of the present invention has a higher content of Mn, which can guarantee an upset end with a thickness of over 30mms to be fully hardened, thereby guaranteeing the sulfur-resistant performance of the upset end. The drill pipe of the present invention has a higher content of Mo, which can improve the backfire-preventive stability of the material, thereby raising the backfire temperature, reducing the residual stress and guaranteeing the sulfur-resistant performance. Simultaneously, the invention can make the pipe body with a different wall thickness and the upset end have the same cooling speed by controlling the outer water injection of the upset end and pipe body of the steel pipe, reducing the water injection outside the pipe body or increasing the water injection outside the upset end of the drill pipe, to ensure that the pipe body and the upset end have the same quenching structure, and the same mechanical property can be achieved after the backfire.

Owner:BAOSHAN IRON & STEEL CO LTD

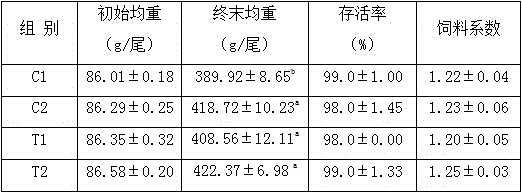

Slowly-sinking puffed compound feed for channel catfish and preparation method thereof

InactiveCN105815603AEasy feedingIncrease food intakeFood processingClimate change adaptationBiotechnologyVitamin C

The invention relates to a slowly-sinking puffed compound feed for channel catfish and a preparation method thereof and belongs to the technical field of production of puffed feeds for aquatic products. The feed contains fish meal, pork powder, rice protein powder, fermented soybean meal, rapeseed meal, soybean meal, rapeseed dregs, cottonseed meal, rice bran, flour, wheat, soybean oil, monocalcium phosphate, bentonite, 98.5% lysine hydrochloride, 99% DL-methionine, choline chloride, a compound vitamin premix, 35% vitamin C phosphate, vitamin A acetate, vitamin E, a composite mineral substance premix, a micro-ecological preparation, an antioxidant and a mildew preventive. The feed is conveniently eaten by the channel catfish, improves the feeding rate, has good water resistance and has not higher the technical requirement for feeding. In addition, intestinal health of the channel catfish can be improved, then the feed utilization efficiency of the channel catfish can be improved, eventually the growth speed and yield per unit volume of the channel catfish can be improved, and the breeding benefits of farmers can be improved.

Owner:TONGWEI

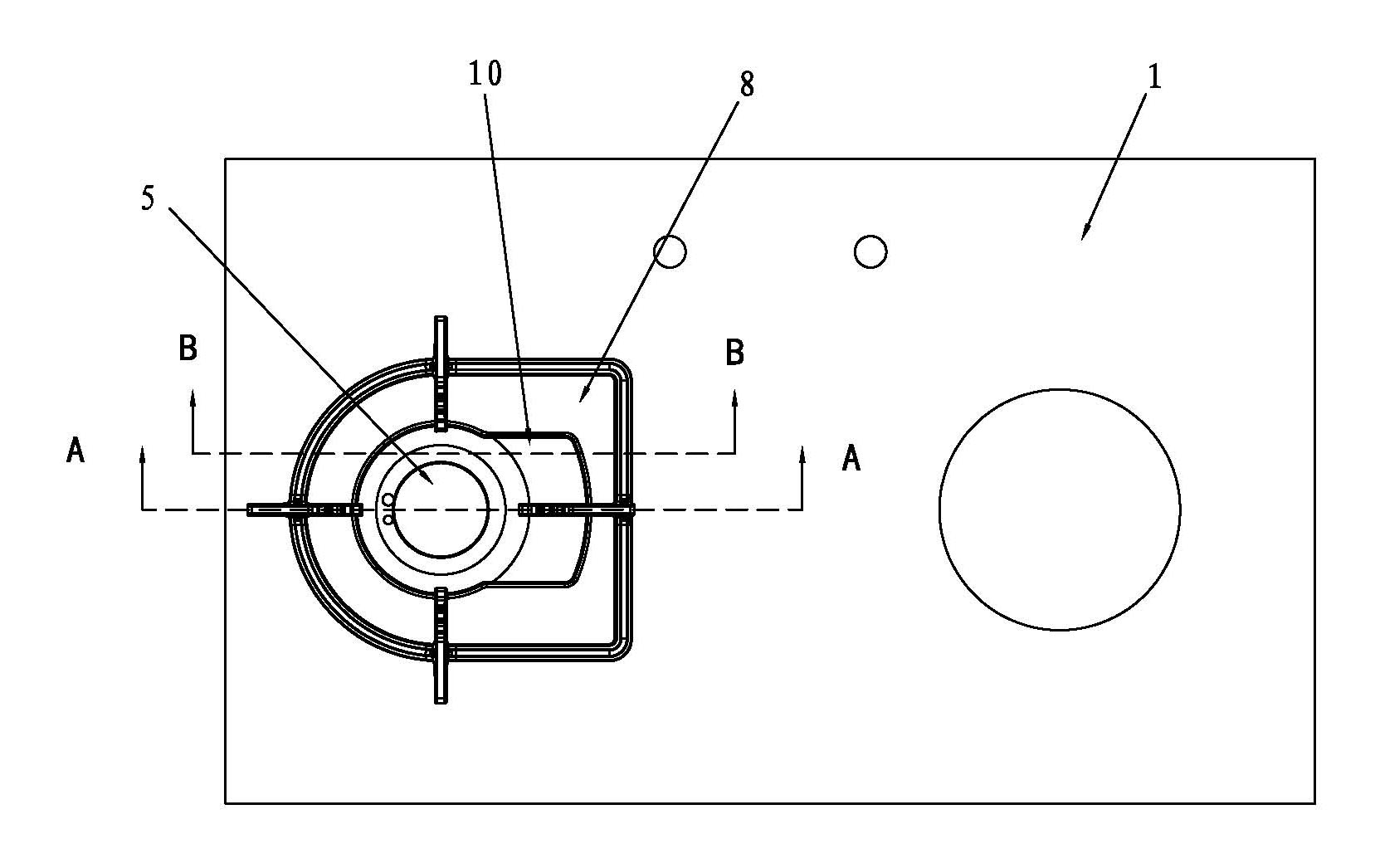

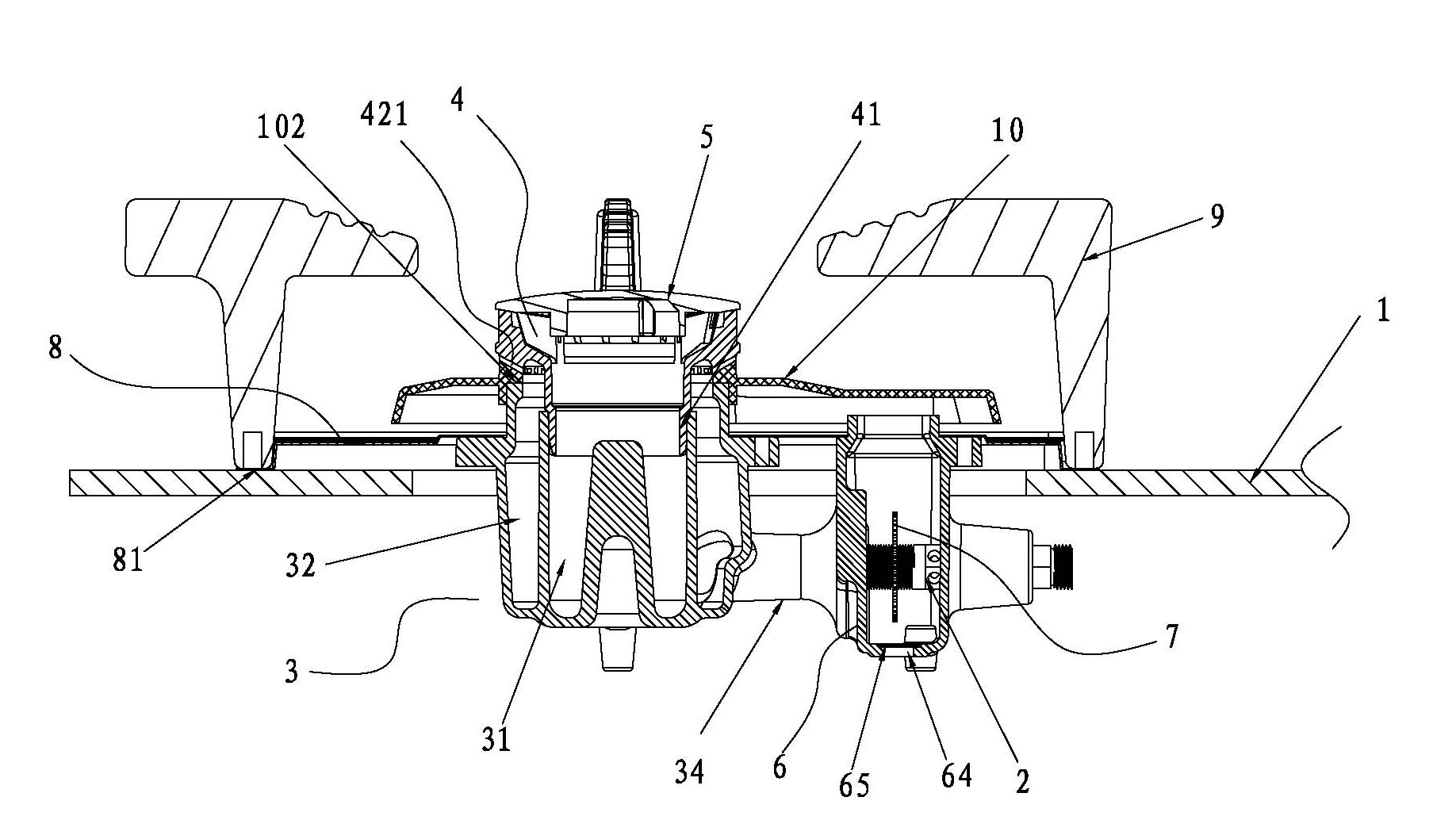

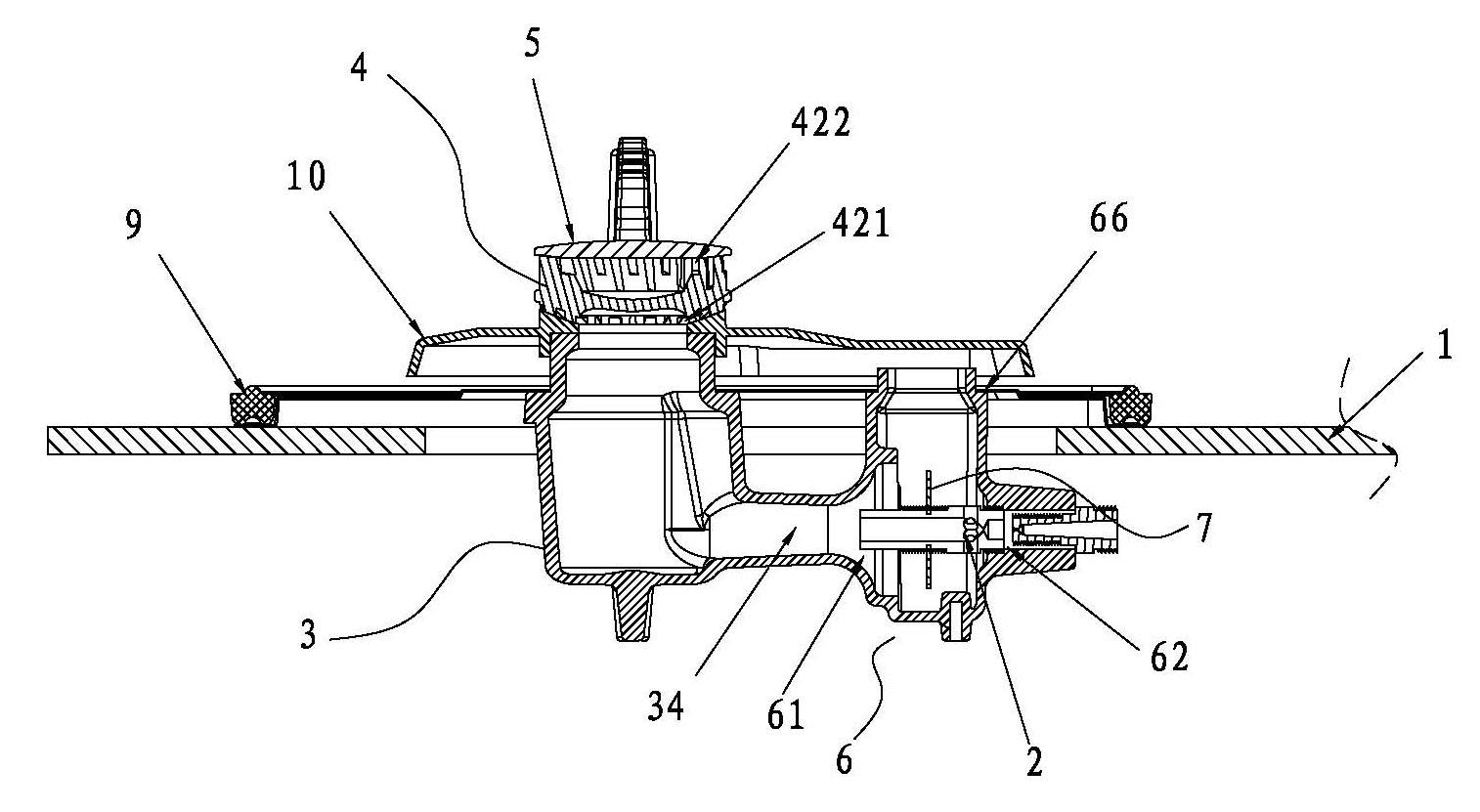

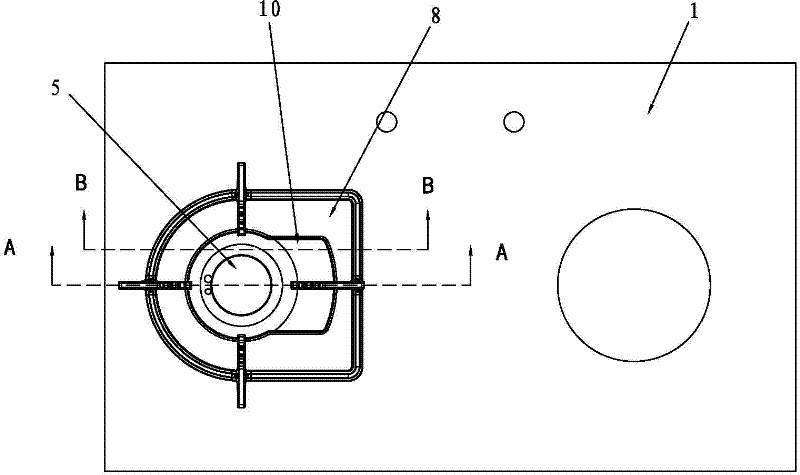

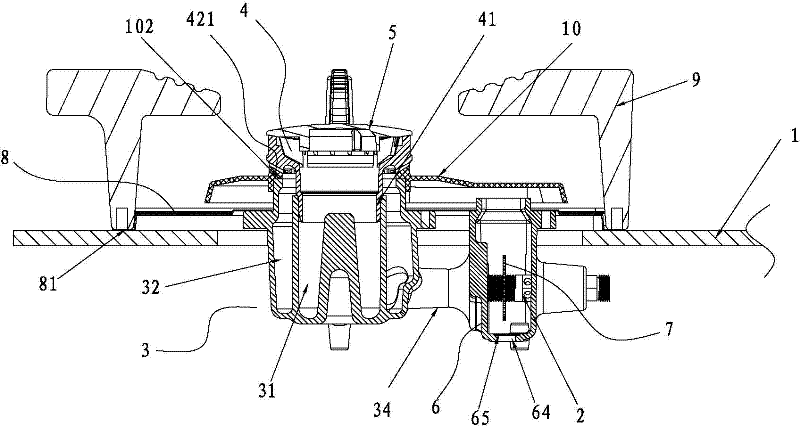

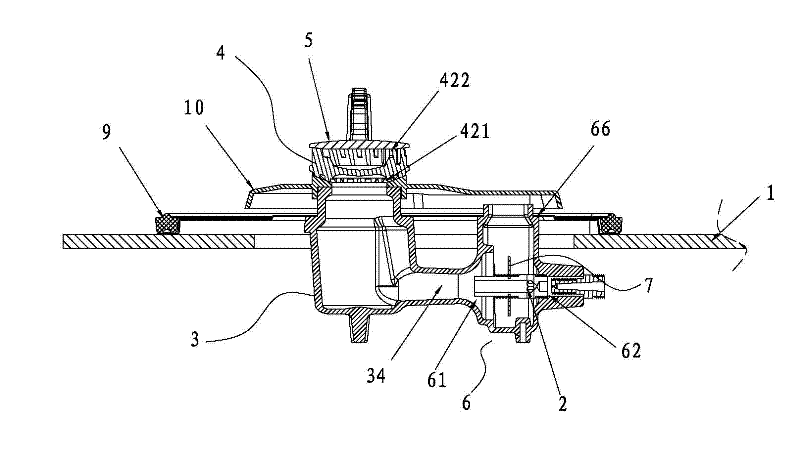

Tempering-resistant air adjusting type gas stove with upper air inlet

ActiveCN102147117AAdjust air intakeFully temperedDomestic stoves or rangesGaseous fuel burnerScrew threadAir cavity

The invention relates to a tempering-resistant air adjusting type gas stove with an upper air inlet, which comprises a panel, a combustor, a nozzle, an air cavity with an upper opening and a cover plate, wherein a burner comprises a premixing cavity and an ejector tube; the cover plate is positioned above the upper opening of the air cavity; a gap is formed between the cover plate and the upper opening; the upper opening of the air cavity is stretched out of the panel after passing through the panel; the front and rear side walls of the air cavity are respectively provided with an air outlet hole and an air inlet hole; the air inlet hole is communicated with the ejector tube; the nozzle is arranged on the air inlet hole; the air inlet end of the nozzle is in screw thread fit with the air outlet hole; the air outlet end of the nozzle is opposite to the air outlet hole; a door plate arranged on the air outlet end of the nozzle is matched with the air outlet hole; and the door plate is in screw thread fit with the nozzle. Because the structure is adopted, the nozzle can be exchanged; the door plate is rotated, so that the door plate is far away from or close to the air outlet of the air cavity to achieve the purpose of adjusting the air intake flow of the air once to supply sufficient air to gas, thereby achieving full combustion; and a temperature sensor is provided to prevent the explosion because the tempering occurs.

Owner:中山市秋意厨卫电器有限公司

Tempering-resistant air adjusting type gas stove with upper air inlet

ActiveCN102147117BAdjust air intakeFully temperedDomestic stoves or rangesGaseous fuel burnerEngineeringScrew thread

The invention relates to a tempering-resistant air adjusting type gas stove with an upper air inlet, which comprises a panel, a combustor, a nozzle, an air cavity with an upper opening and a cover plate, wherein a burner comprises a premixing cavity and an ejector tube; the cover plate is positioned above the upper opening of the air cavity; a gap is formed between the cover plate and the upper opening; the upper opening of the air cavity is stretched out of the panel after passing through the panel; the front and rear side walls of the air cavity are respectively provided with an air outlet hole and an air inlet hole; the air inlet hole is communicated with the ejector tube; the nozzle is arranged on the air inlet hole; the air inlet end of the nozzle is in screw thread fit with the air outlet hole; the air outlet end of the nozzle is opposite to the air outlet hole; a door plate arranged on the air outlet end of the nozzle is matched with the air outlet hole; and the door plate is in screw thread fit with the nozzle. Because the structure is adopted, the nozzle can be exchanged; the door plate is rotated, so that the door plate is far away from or close to the air outlet of the air cavity to achieve the purpose of adjusting the air intake flow of the air once to supply sufficient air to gas, thereby achieving full combustion; and a temperature sensor is provided to prevent the explosion because the tempering occurs.

Owner:中山市秋意厨卫电器有限公司

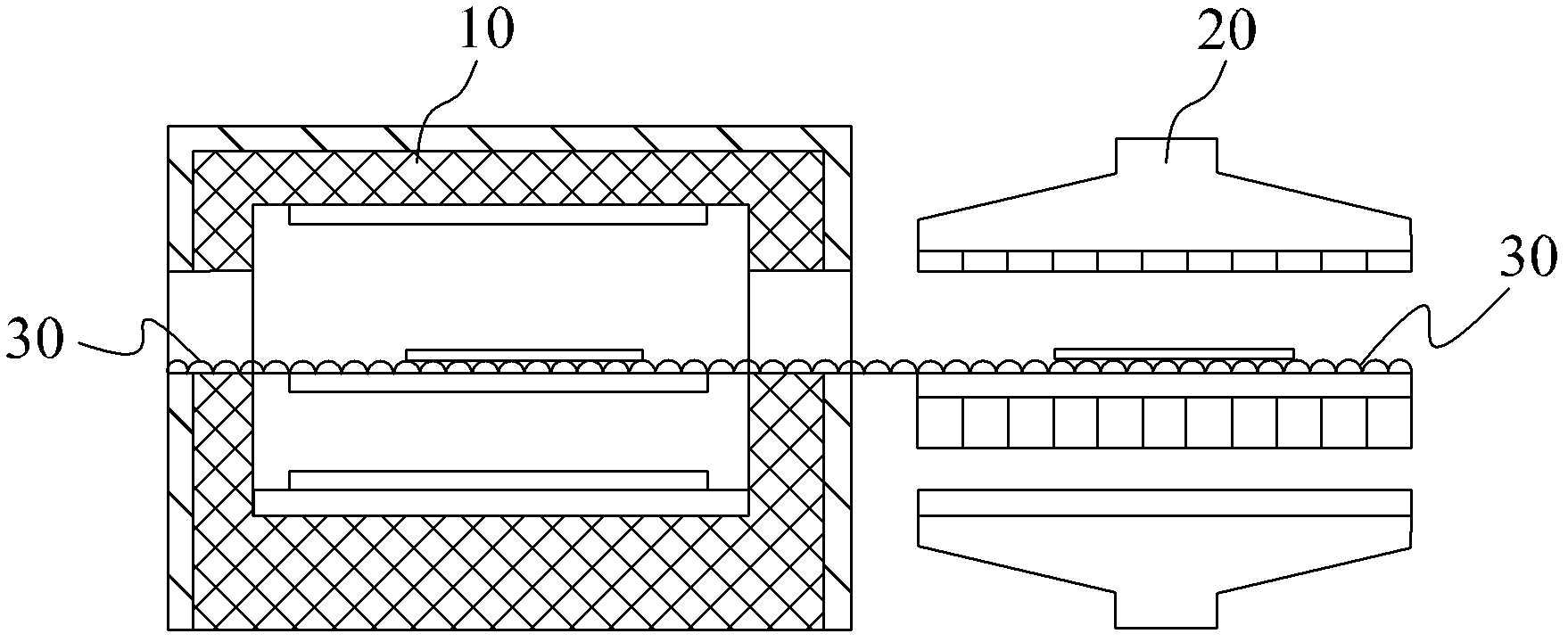

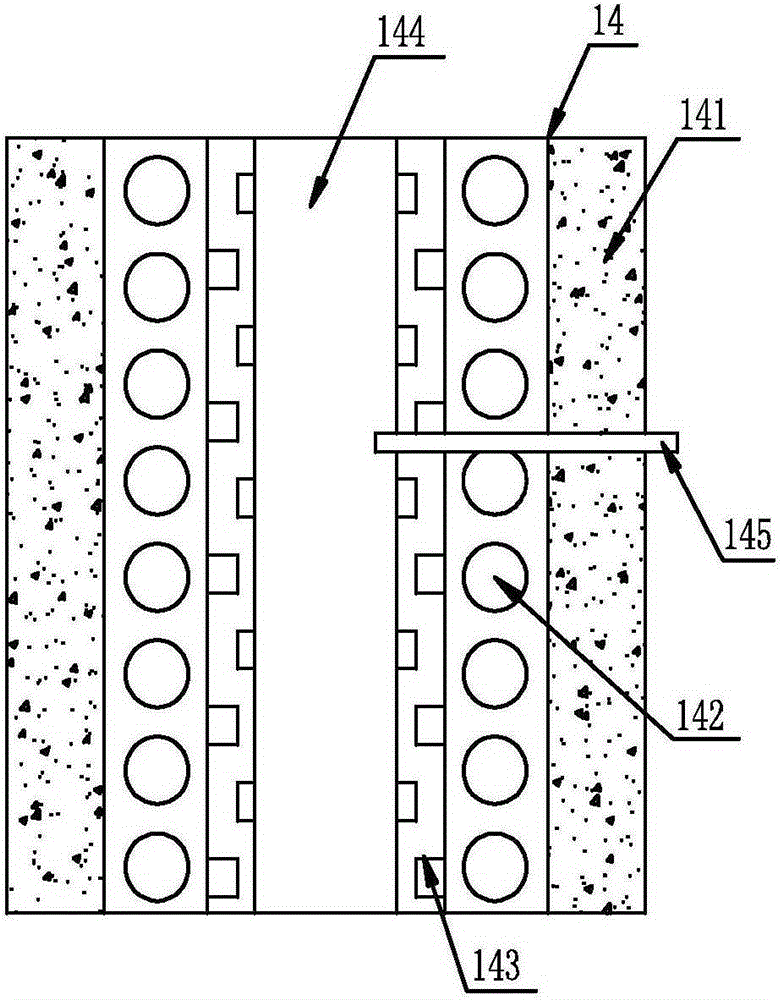

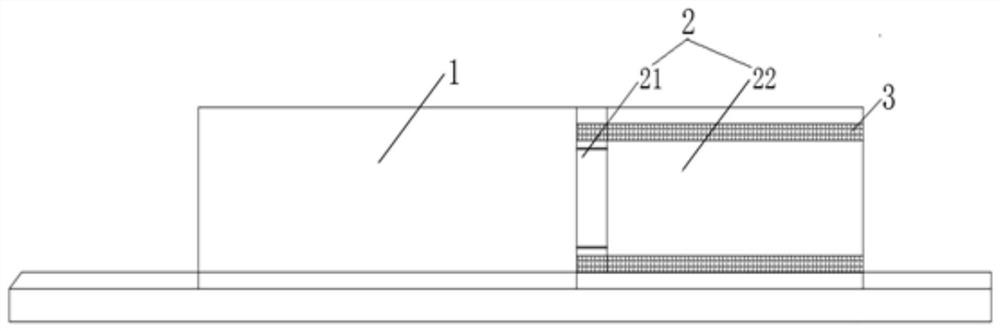

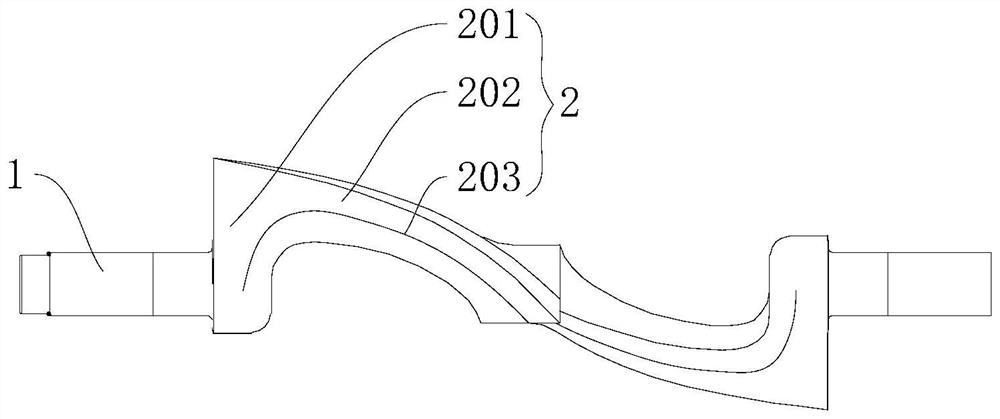

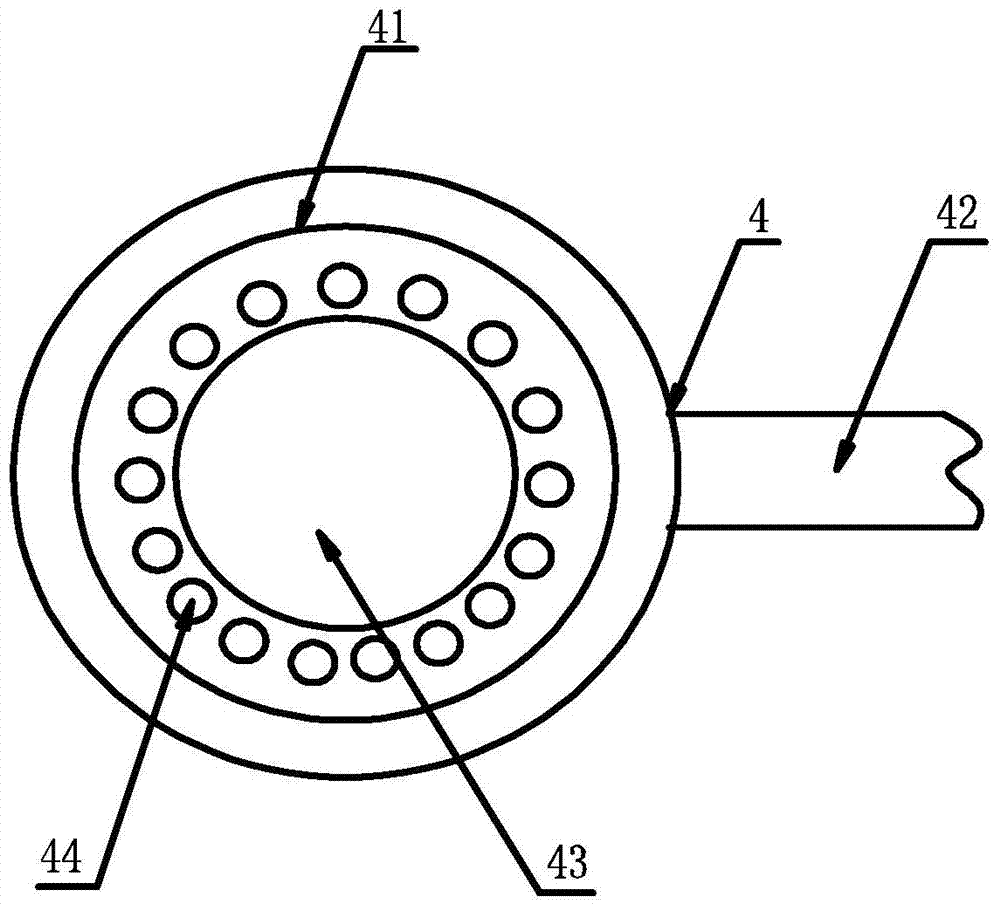

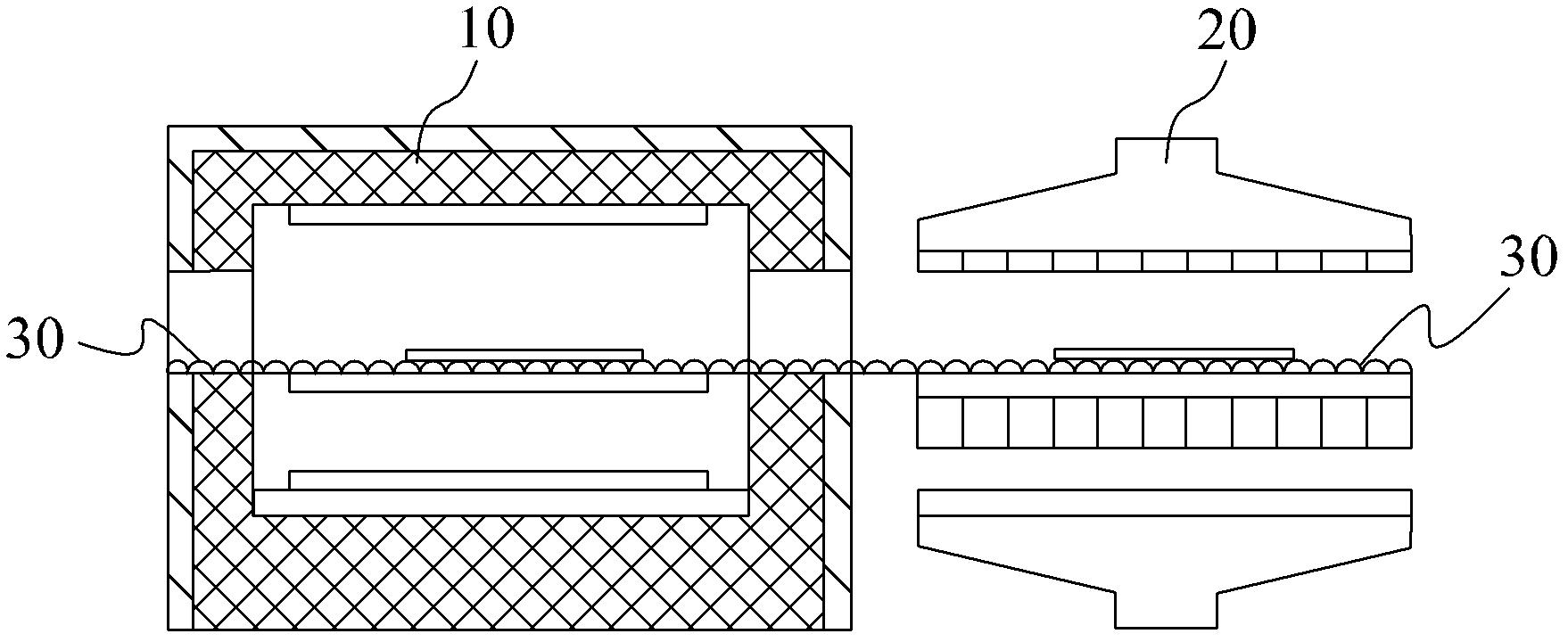

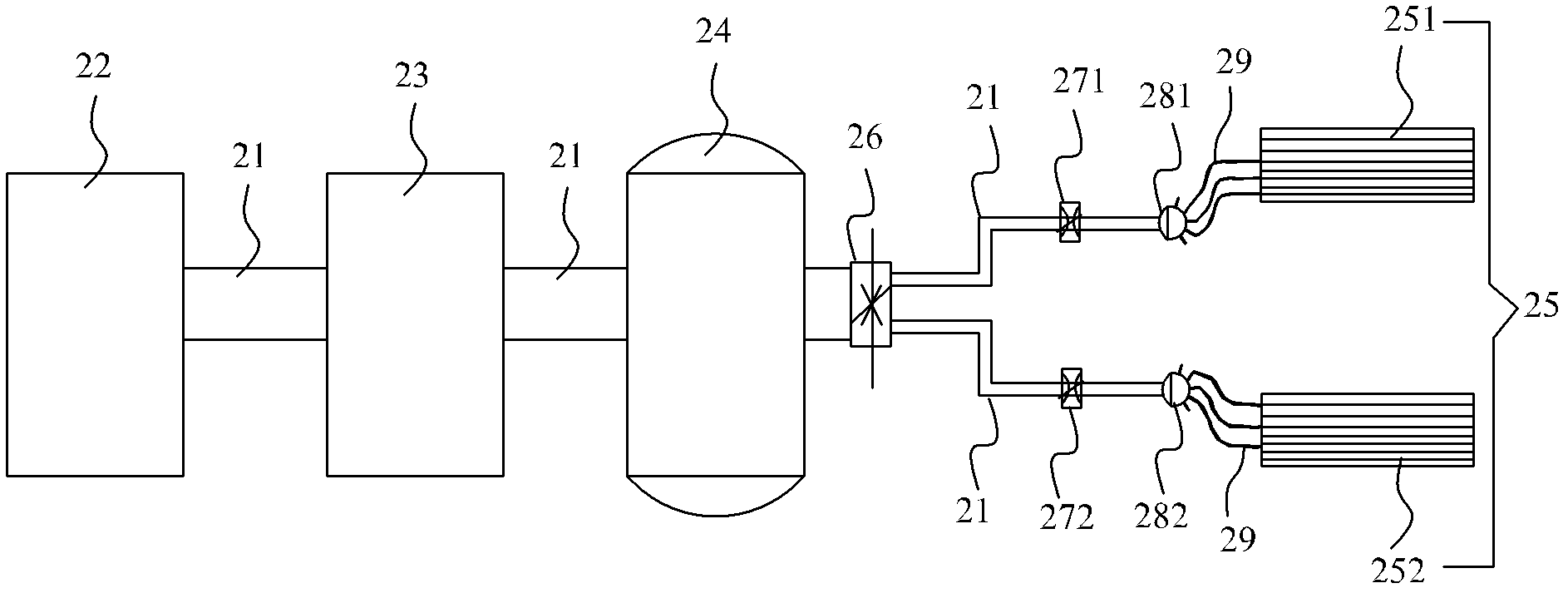

Device and method for producing toughened glass

ActiveCN102603175AImprove efficiencyReduce power consumptionGlass tempering apparatusCold airLow noise

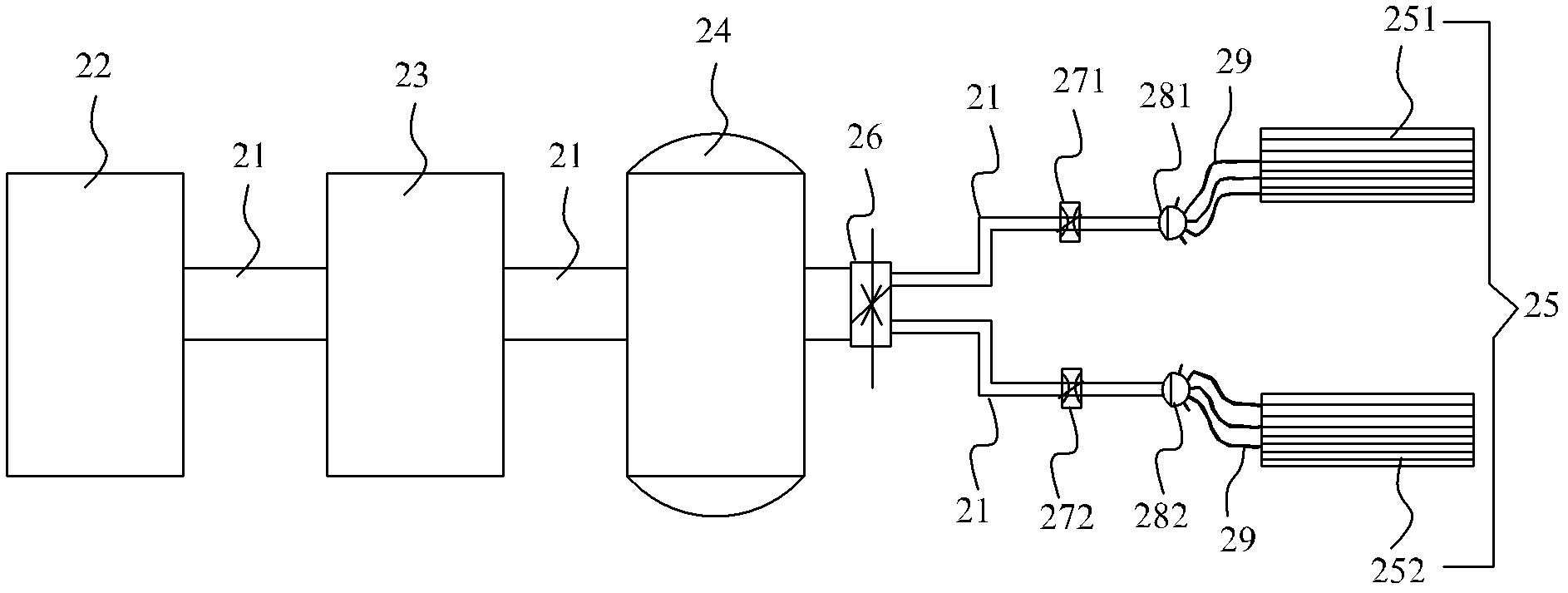

The invention discloses a device for producing toughened glass, comprising a heating device, a toughening device and a roller way device connected between the heating device and the toughening device. The toughening device comprises a screw air compressor, an air filter, an air tank and a quenching cold air grid sequentially connected by an air supply pipeline. The invention also discloses a method for producing toughened glass by utilizing the device above. the device and the method can be used for completely toughening ultra-thin glass with the thickness of 2mm and have the advantages of low energy consumption, low noise, and the like.

Owner:GUANGDONG SHUNDE TIMBERY TECH GLASS

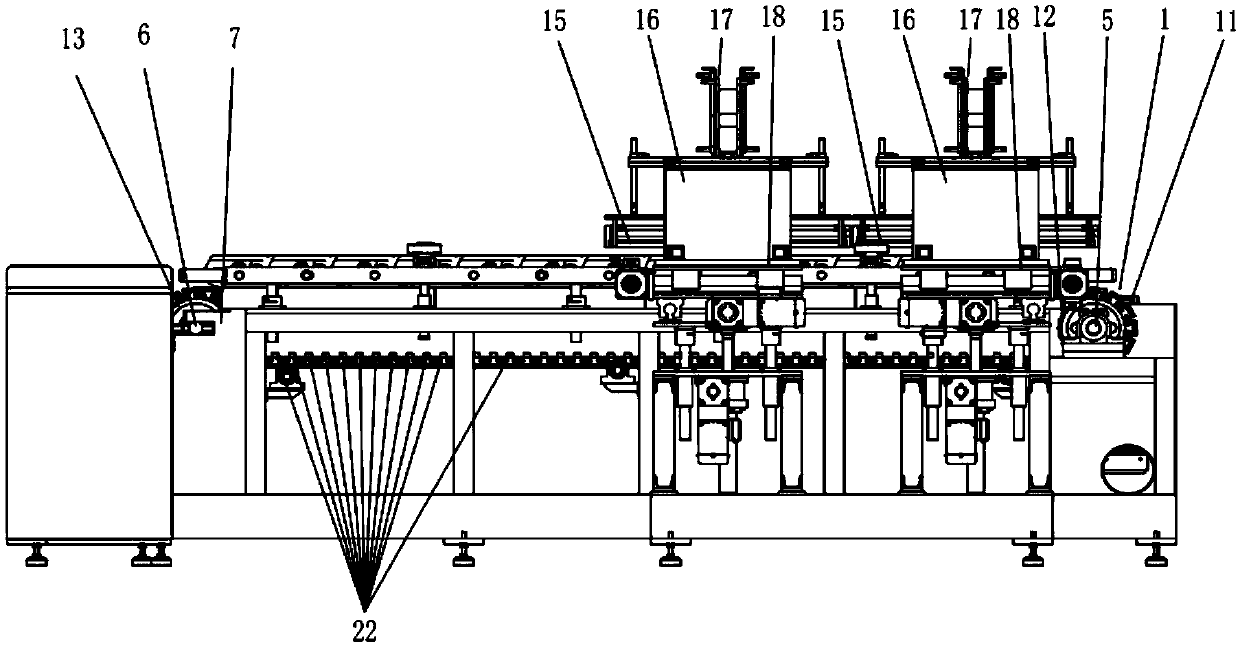

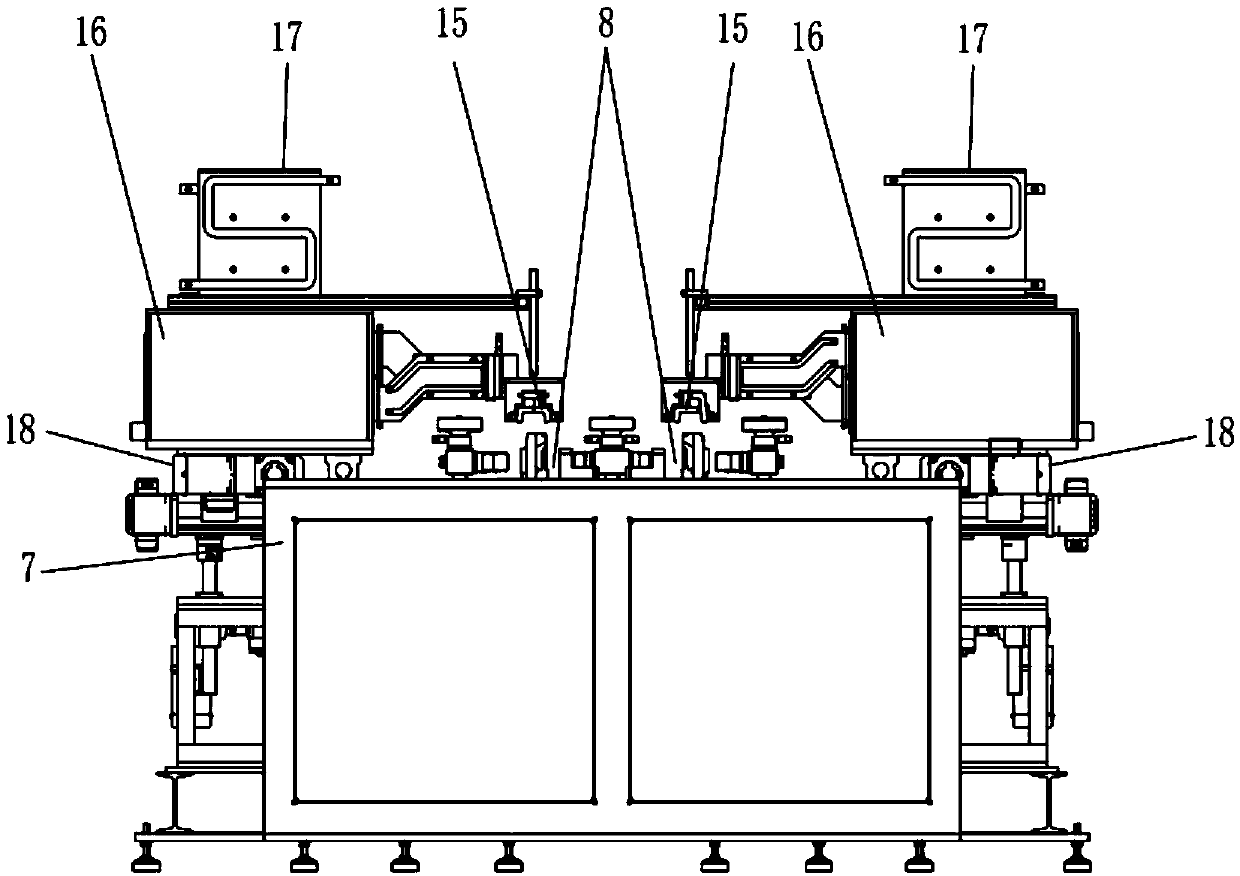

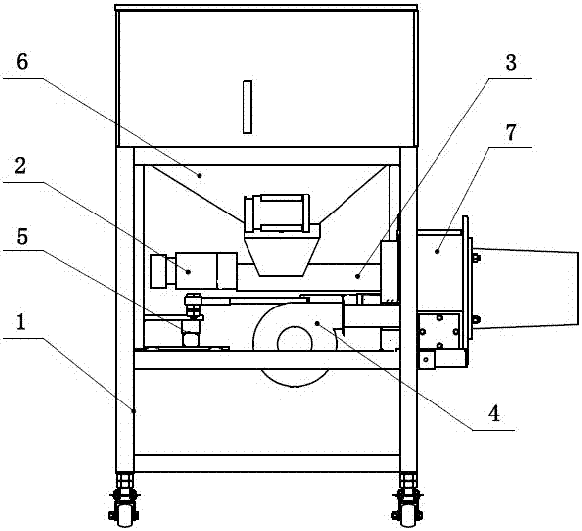

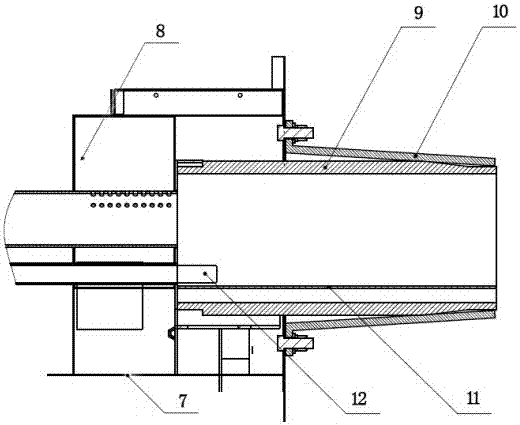

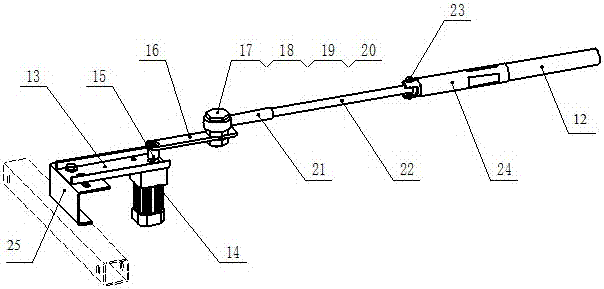

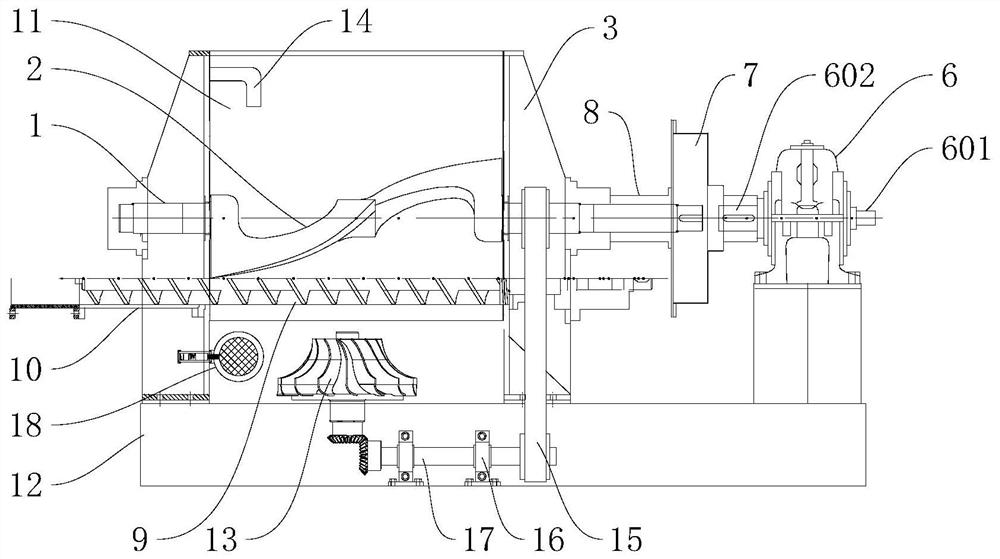

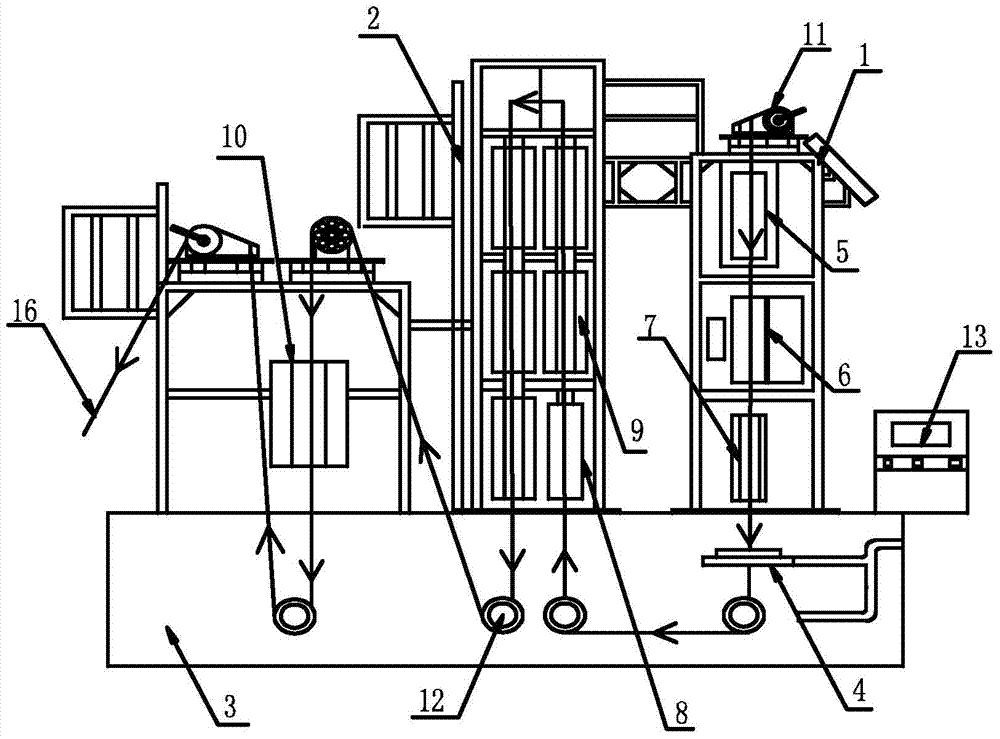

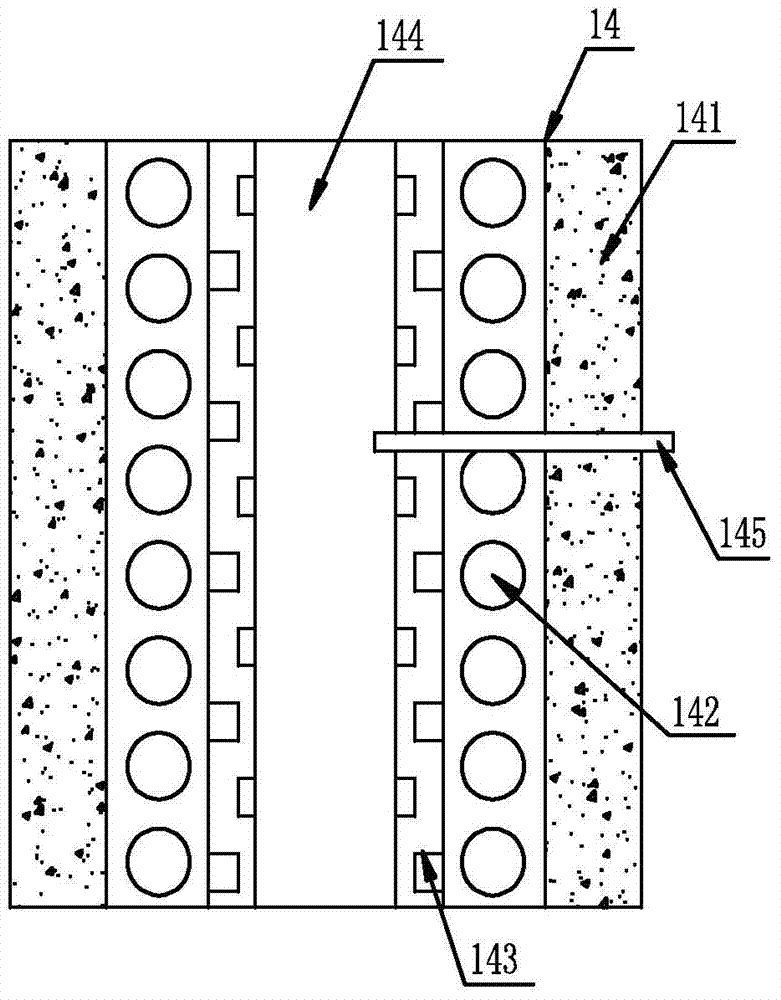

Heat treatment device for round-link chain and application method thereof

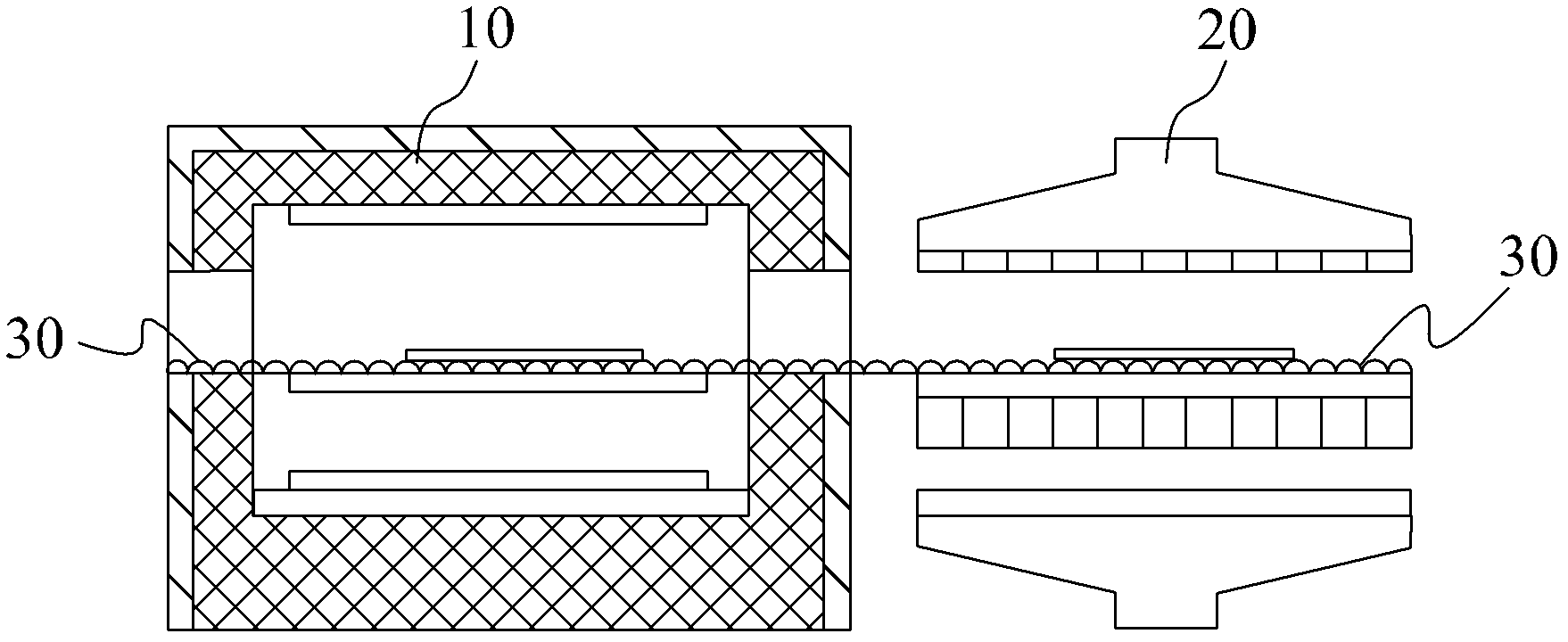

ActiveCN105349757AHigh degree of integrationImprove work efficiencyFurnace typesHeat treatment furnacesHardnessLath

The invention discloses a heat treatment device for a round-link chain and an application method thereof. The device comprises a quenching part and a tempering part which are sequentially arranged, wherein first cooling parts are arranged at the quenching part and the tempering part; the quenching part is provided with a quenching temperature regulating box; the tempering part is sequentially provided with an uniform-temperature tempering heating box, at least one tempering temperature regulating box and a differential-temperature tempering heating box; the quenching temperature regulating box is provided with a second cooling part. The device has the characteristics of being high in integration degree and high in working efficiency; after the round-link chain is quenched, an uniform and small low-carbon lath martensite structure can be obtained; the quenching quality is high; the second cooling part and the first cooling parts are correspondingly connected to a cooling source, so that the cooling quality can be improved, and the requirements of each part of the round-link chain on hardness and toughness can be met.

Owner:SHANDONG LUNAN GRP ENERGY EQUIP MFG

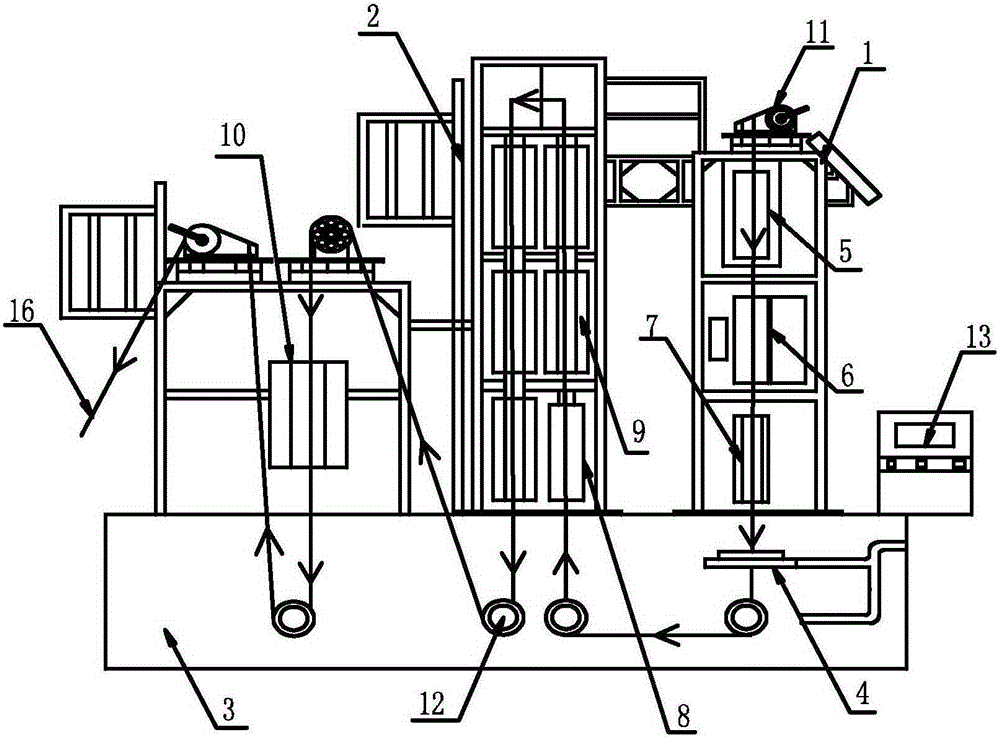

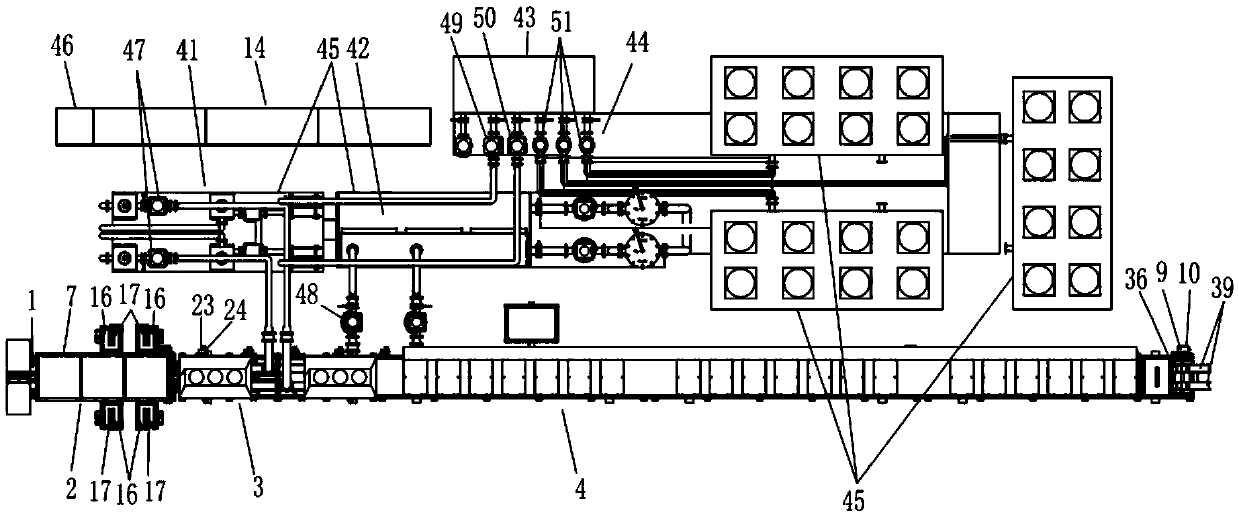

Caterpillar track section induction quenching and tempering machine tool and circuit protection method

PendingCN109609740AImprove adaptabilityReasonable functionFurnace typesIncreasing energy efficiencyElectricityTransformer

A caterpillar track section induction quenching and tempering machine tool comprises modular conveying devices in groups. Various functional components and sealing frames are arranged on the modular conveying devices to form an induction heating chamber, a liquid spray quenching chamber and a tempering induction chamber correspondingly, the modular conveying devices comprise the modular plate typechain wheel conveying devices and the modular roller wheel conveying devices, the induction heating chamber comprises inductors, quenching transformers and three-dimensional sliding tables, the two quenching transformers on the same side of two tracks are connected in parallel to a same IGBT power unit, the two sets of inductors in two columns are suspended over the front track and the rear track, the liquid spray quenching chamber comprises the multiple stages of modular roller wheel conveying devices which are each provided with a liquid spray pipeline and a liquid spray device right opposite to the top of two roll gangs, the bottoms of the two roll gangs are provided with quenching liquid collection grooves, a tempering induction station comprises three stages of tempering induction chambers, a tunnel tempering inductor is suspended above two caterpillar tracks in a right opposite mode and electrically connected with a tempering capacitor box, and the tempering capacitor box is electrically connected with an IGBT tempering power source.

Owner:十堰高周波科工贸有限公司

Method for machining male mould of flywheel extrusion mould

InactiveCN101745562AImproved segregation distributionAvoid failureExtrusion profiling toolsCutting toolsCarbideHeating temperature

The invention discloses a method for machining a male mould of a flywheel extrusion mould, aiming at providing the machining method capable of improving the segregation distribution of the carbide in the mould, preventing the mould from being invalid, and improving the service life of the mould. The method comprises the steps of: forging, wherein the heating temperature is 1100-1150 DEG C, the heat preservation time is 0.8-1.2 min / mm, the initial forging temperature is 1040-1080 DEG C and the finish forging temperature is 850-900 DEG C, and embedding in a cooling way with sand ash; annealing forged mould material; slowly heating the mould material at 840-860 DEG C; preserving temperature for 4 h; opening a furnace door and reducing the temperature at 740-760 DEG C; preserving temperature for 6 h; cooling the furnace at 550 DEG C; putting the material out of the furnace and cooling in air; mechanically machining the processed mould material to obtain the male mould of the flywheel extrusion mould; and quenching the male mould of the flywheel extrusion mould and tempering at three times to obtain a final product. The method crushes the carbide in a forging way, promotes the carbide to be evenly distributed, improves the segregation distribution of the carbide in the mould, and prolongs the service life of the mould.

Owner:TIANJIN FLYWHEEL CO LTD

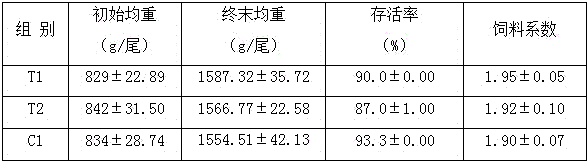

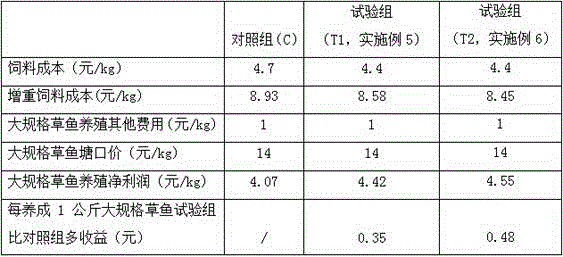

Specific large-scale grass carp puffed compound feed and preparation method thereof

InactiveCN105795160ADoes not affect productivityImprove farming efficiencyFood processingClimate change adaptationAnimal scienceAntioxidant

The present invention relates to a specific large-scale grass carp puffed compound feed and a preparation method thereof, and belongs to the technical field of aquatic product puffed feed production. The feed comprises 10-35 parts of soybean meal, 10-35 parts of rapeseed meal, 5-15 parts of cottonseed meal, 8-15 parts of DDGS, 5-15 parts of rice bran, 8-20 parts of flour, 3-8 parts of cassavas, 3-8 parts of sorghum, 2-4 parts of soybean oil, 1-3 parts of calcium dihydrogen phosphate, 1-2.5 parts of bentonite, 0.05-0.2 part of 98.5% lysine hydrochloride, 0.01-0.05 part of Kelikang (a feed additive), 0.05-0.1 part of choline chloride, 0.3-0.5 part of multivitamin premix, 1.0-3.0 parts of compound mineral premix, 0.01-0.05 part of antioxidant and 0.1-0.15 part of mildew preventive. The provided large-scale grass carp specific floated and puffed compound feed aims at the situation that no specific feed is provided in the breeding process of the large-scale grass carps currently. By combining the nutrient demand and digestive physiology demand characteristics, the puffed compound feed can greatly improve the breeding efficiency under the premise of not affecting the production performances.

Owner:TONGWEI

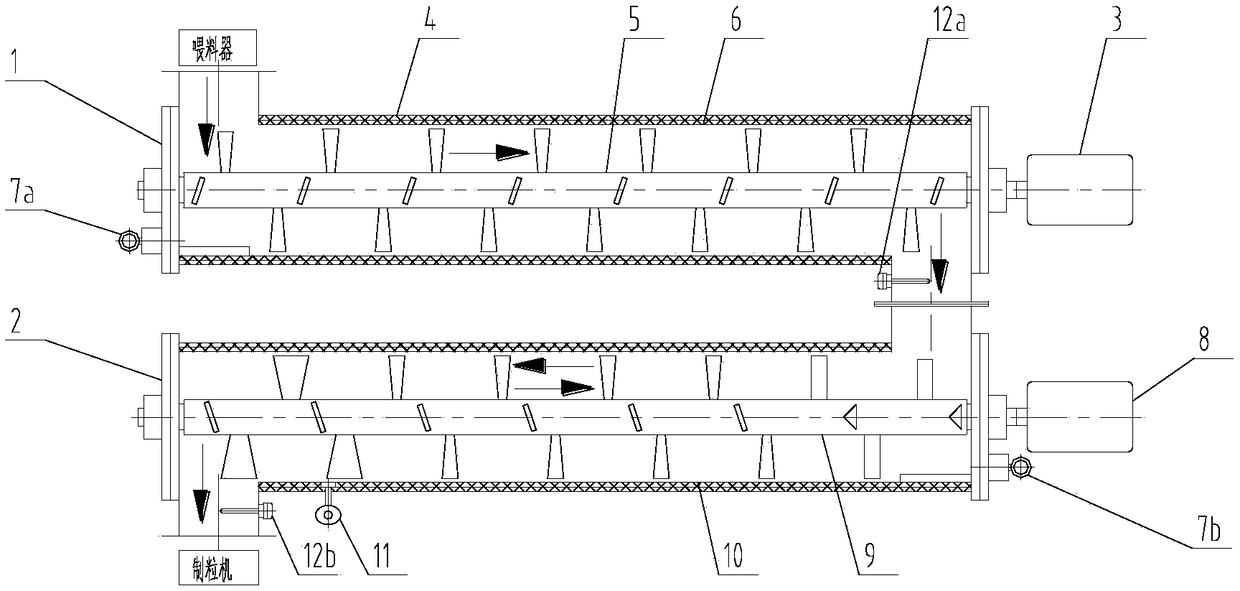

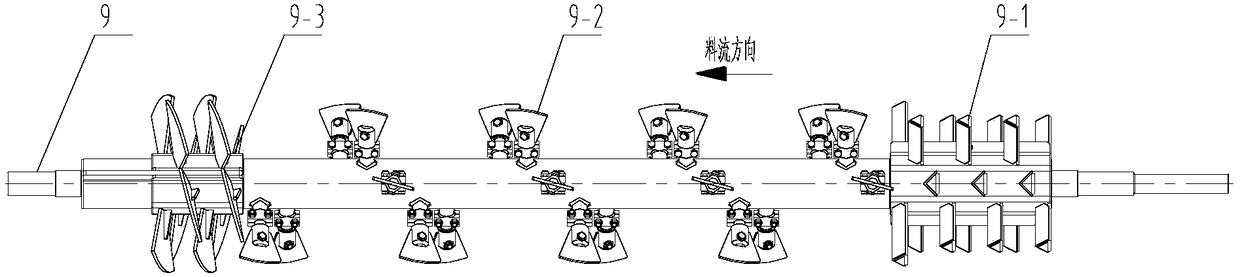

Quality adjusting method and device

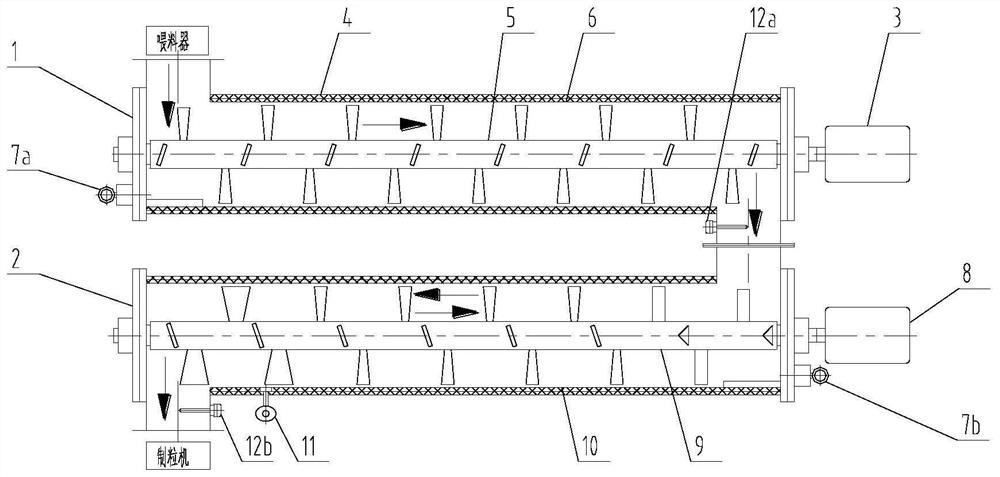

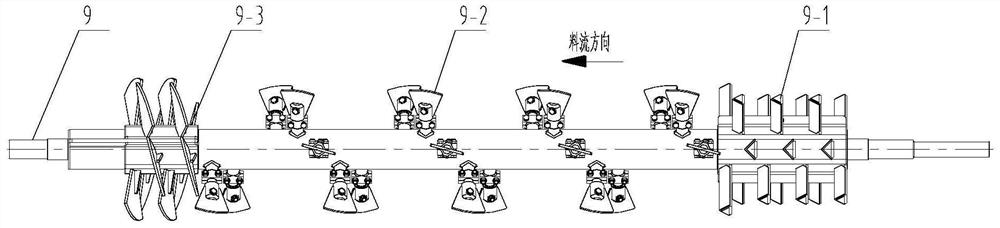

ActiveCN109315813AEmission reductionReduce labor intensityFeeding-stuffEngineeringUltimate tensile strength

The invention discloses a quality adjusting method and device and is characterized in that a material after quality adjusting layer treatment enters a quality keeping layer, the material is further mixed with steam for quality adjusting and quality keeping in the quality keeping layer, a quality keeping layer rotor operates forward and backward, the material flows back and forth in a quality keeping machine body, enough temperature rising quality adjusting time is obtained, the temperature rises rapidly under the joint action of the heating and temperature keeping system and the steam, after the temperature rises to the preset value, and the material is discharged to the downstream for granulation. The device comprises a pre-quality-adjusting layer, the quality keeping layer, a pre-quality-adjusting driving system, the heating and temperature keeping system, a pre-quality-adjusting rotor, a pre-quality-adjusting machine body, a steam adding system, a quality keeping driving system, a quality keeping rotor, the quality keeping machine body, a material temperature sensor and a temperature sensor. According to the quality adjusting method and device, the discharge of machine end materials can be reduced in the starting-up process, the production process layout is simplified, the raw material utilization rate and the feed safety and sanitation are improved, the granulator energy consumption is reduced, and the labor intensity of the workers is reduced.

Owner:JIANGSU MUYANG HLDG

Method for reducing fracture zones of high-hardenability cold-rolled high-strength steel cold-rolled edges

ActiveCN110449465AEasy to changeAvoid generatingTemperature control deviceWork cooling devicesLaminar coolingFracture zone

The invention relates to a method for reducing fracture zones of high-hardenability cold-rolled high-strength steel cold-rolled edges. The method comprises the steps of high-strength steel smelting, heating by heating furnace, rough rolling, descaling, 2250 mm hot continuous rolling, laminar cooling and reeling, wherein the laminar cooling adopts a rear section 1 / 2, and meanwhile, the water spraying on the fine adjusting area side is closed. According to the method, the defect of fracture zones of the high-hardenability high-strength steel cold-rolled edges can be effectively solved under thecondition that normal production and product performance are not influenced, and the yield and the instant production of strip steel are improved.

Owner:HANDAN IRON & STEEL GROUP +1

Heat treatment technology for high-carbon chromium bearing ring with extremely low retained austenite

InactiveCN108504825AEasy to changeFully transformedFurnace typesProcess efficiency improvementTemperature controlHigh carbon

The invention relates to a heat treatment technology for a high-carbon chromium bearing ring with extremely low retained austenite, and relates to the technical field of heat treatment technologies. The heat treatment technology specifically comprises the following steps of holding the high-carbon chromium bearing ring heat-treated for 60+ / -5 min at 835+ / -5 DEG in a quenching heat preservation area; cooling the high-carbon chromium bearing ring held in the first step, the temperature of cooling medium which is salt is 190+ / -5 DEG C; air-cooling the high-carbon chromium bearing ring cooled in the second step, the level of the air cooling is 4, and the time for a single station is 6 min; going on the last step, performing secondary cleaning, the cleaning temperature is controlled within 50+ / -5 DEG C, then performing cleaning at room temperature, the time for the single station is 6 min; and performing secondary cooling and tempering. According to the heat treatment technology, through multi-stage air cooling, cleaning, selection of a proper cooling amount and cleaning temperature, adding of secondary cooling and the tempering process, the retained austenite is changed thoroughly, andfinally the retained austenite of the high-carbon chromium bearing ring is no more than 3%.

Owner:LUOYANG LUOLING BEARING SCI & TECH

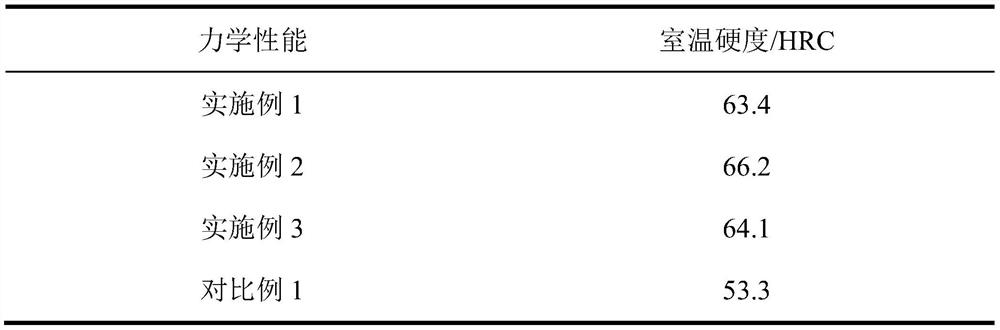

Heat treatment process for powder metallurgical high-speed steel

InactiveCN103849738AImprove impact toughnessGuaranteed quenching process requirementsQuenchingHeat treated

The invention discloses a heat treatment process for powder metallurgical high-speed steel. The heat treatment process comprises the following steps: A, carrying out annealing treatment, heating the powder metallurgical high-speed steel to 850 DEG C, then carrying out heat preservation, cooling to 750 DEG C along with a furnace, carrying out heat preservation again for 3 h, then cooling to 500 DEG C along with the furnace, and discharging out of the furnace; B, carrying out quenching treatment with the quenching temperature of 1230-1260 DEG C and the austenitizing heat preservation time of 12-15 s / mm; and C, carrying out tempering treatment, tempering for 3-4 times with the tempering temperature of 540 DEG C. The invention discloses the heat treatment process for the powder metallurgical high-speed steel; in the quenching process, the quenching process requirements are ensured, and the impact toughness of the material is enhanced; and three times of tempering treatment are carried out, so that tempering is allowed to be more full.

Owner:DALIAN QIANBAO CAST IRON FOUNDRY

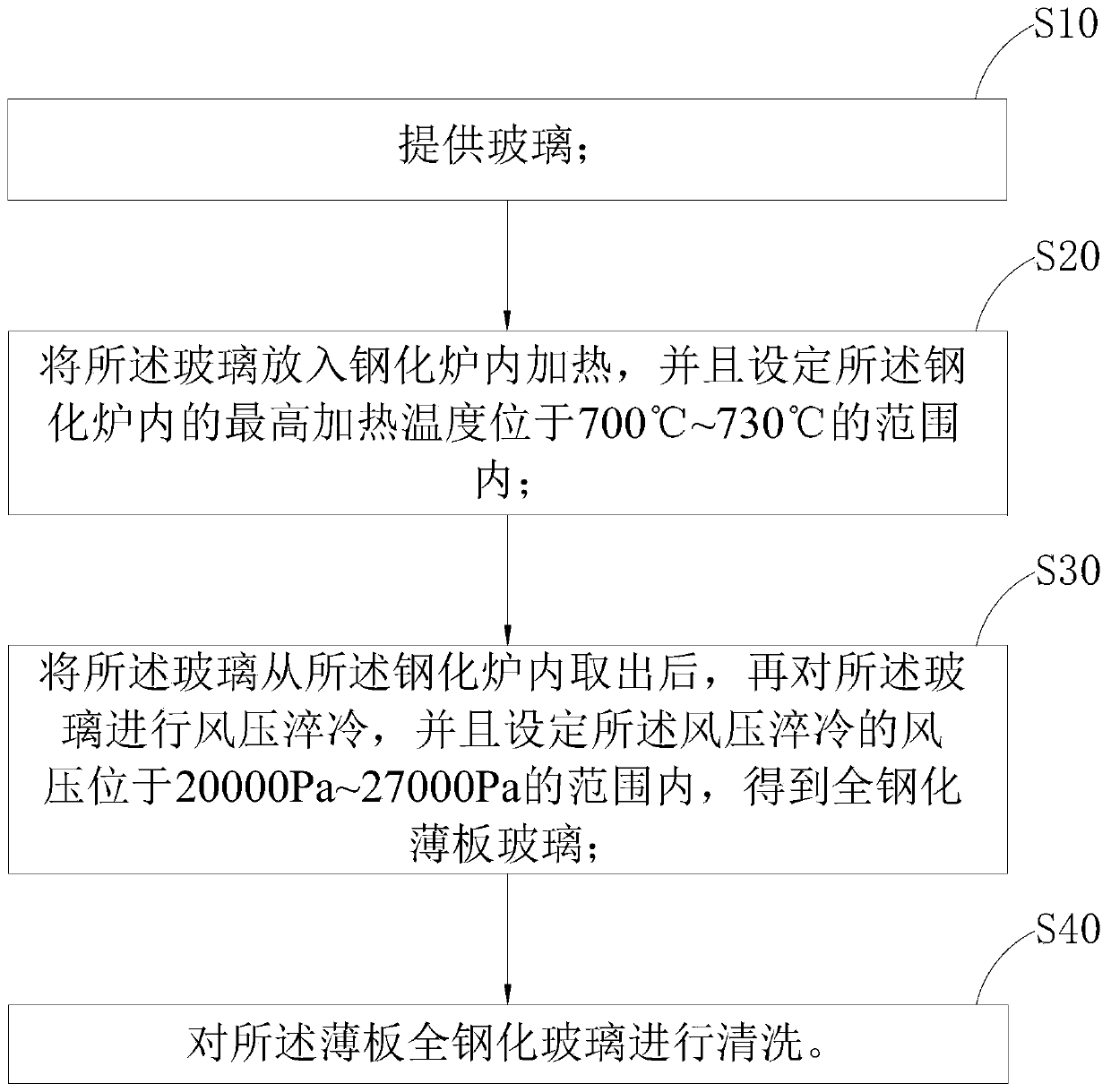

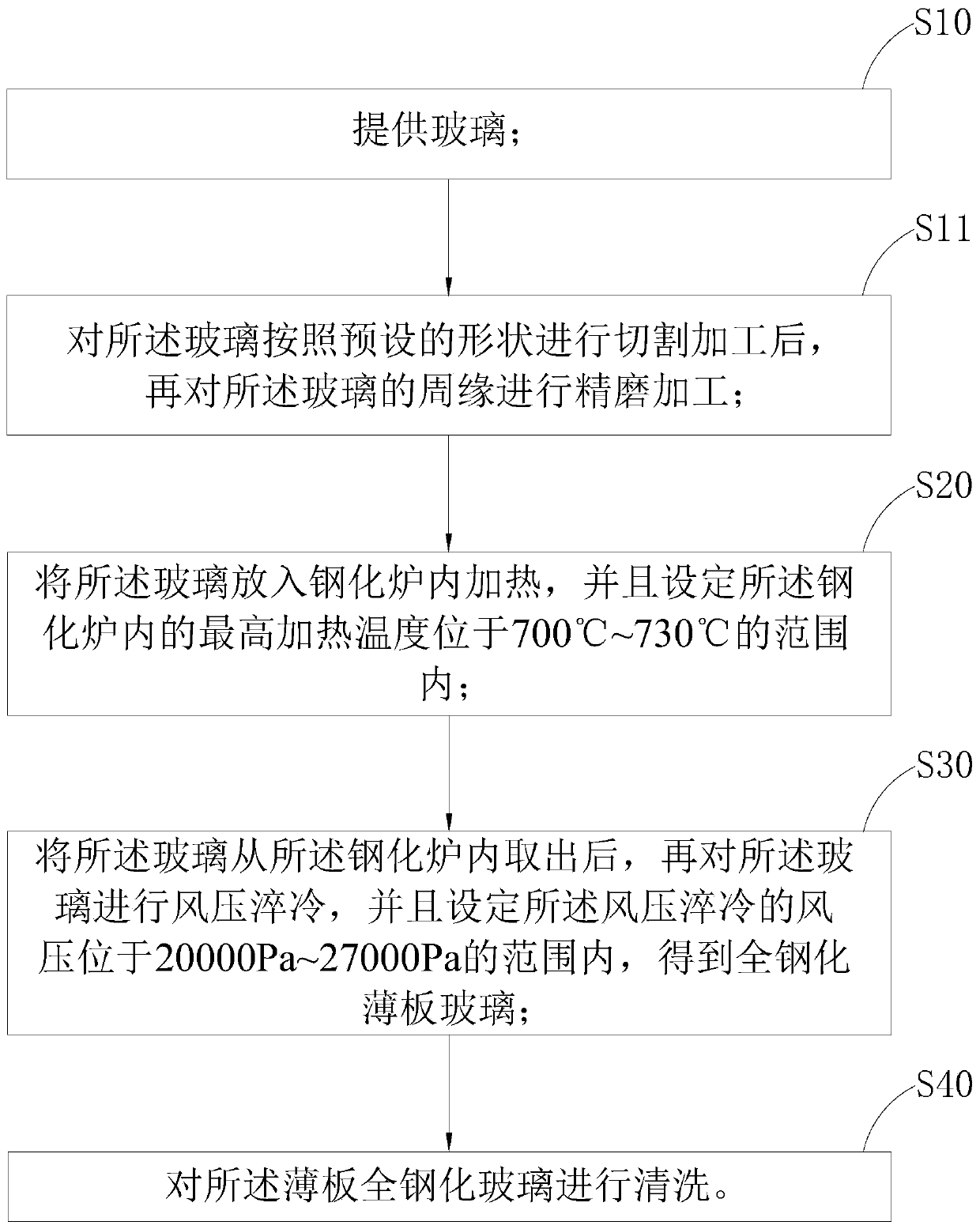

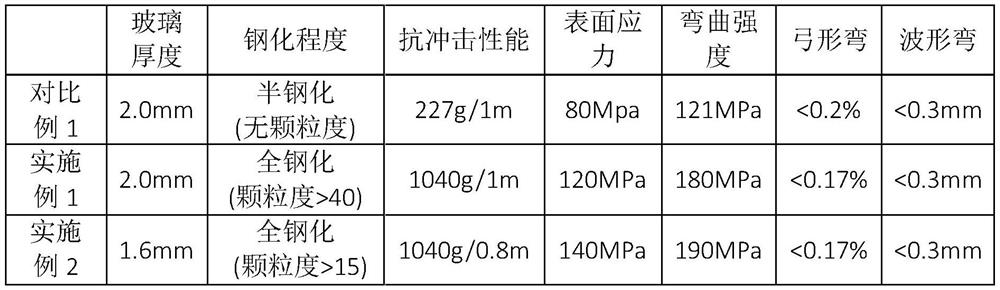

Sheet glass full-toughening method and fully toughened sheet glass

InactiveCN110526562AFully temperedEasy to shapeGlass tempering apparatusGlass manufacturingMetallurgy

The invention belongs to the technical field of glass manufacturing methods, and particularly relates to a sheet glass full-toughening method and fully toughened sheet glass. The sheet glass full-toughening method is suitable for manufacturing glass with the thickness of 2 mm-3 mm, and comprises the following steps: S10) providing glass; S20) placing the glass into a toughening furnace for heating, and setting the maximum heating temperature in the toughening furnace to be in the range of 700 DEG C-730 DEG C; S30) taking out the glass from the toughening furnace, then carrying out wind pressure quenching on the glass, and setting the wind pressure of the wind pressure quenching to be in the range of 20000 Pa-27000 Pa to obtain the fully toughened sheet glass. According to the sheet glass full-toughening method, on the basis of ensuring that the glass has a good appearance, the problem of half-toughening of the glass can be avoided, so that full-toughening of the glass with the thickness of 2 mm-3 mm is realized, after the glass with the thickness of 2 mm-3 mm is fully toughened, the stresses are respectively uniform, the strength is high, the performance of the glass with the thickness of 2 mm-3 mm is effectively improved, and the use demands of customers can be met.

Owner:信义光伏产业(安徽)控股有限公司

Environment-friendly degradable cushion packaging material and preparation method thereof

The invention relates to the technical field of environment-friendly packaging materials, and in particular, relates to an environment-friendly degradable cushion packaging material and a preparationmethod thereof. The environment-friendly degradable cushion packaging material is prepared from the following raw materials in parts by weight: 1 to 6 parts of a composite foaming agent, 40 to 70 parts of plant fiber powder, 50 to 80 parts of edible starch, 30 to 50 parts of wheat flour, 40 to 70 parts of vegetable oil, 0.5 to 5 parts of an emulsifying agent and 150 to 250 parts of deionized waterA. The degradable cushion packaging material disclosed by the invention is pollution-free in production and use processes, is extremely easy to degrade, is green and environment-friendly, also has controllable elasticity and good buffering performance, and can effectively protect products inside the package; in addition, the preparation method is simple and efficient, convenient to operate and control, high in product quality, beneficial to industrial production, free of generation of three wastes in the production process, and green and environment-friendly.

Owner:张绍为

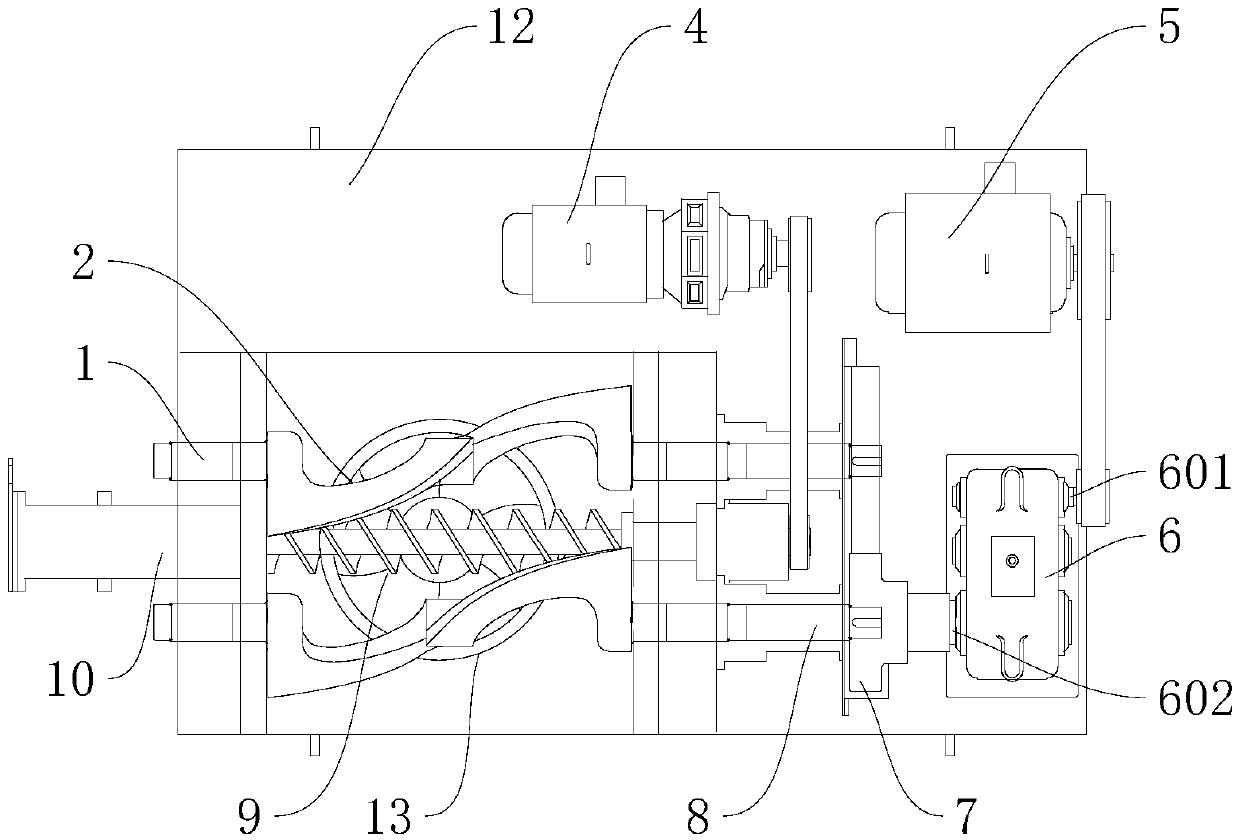

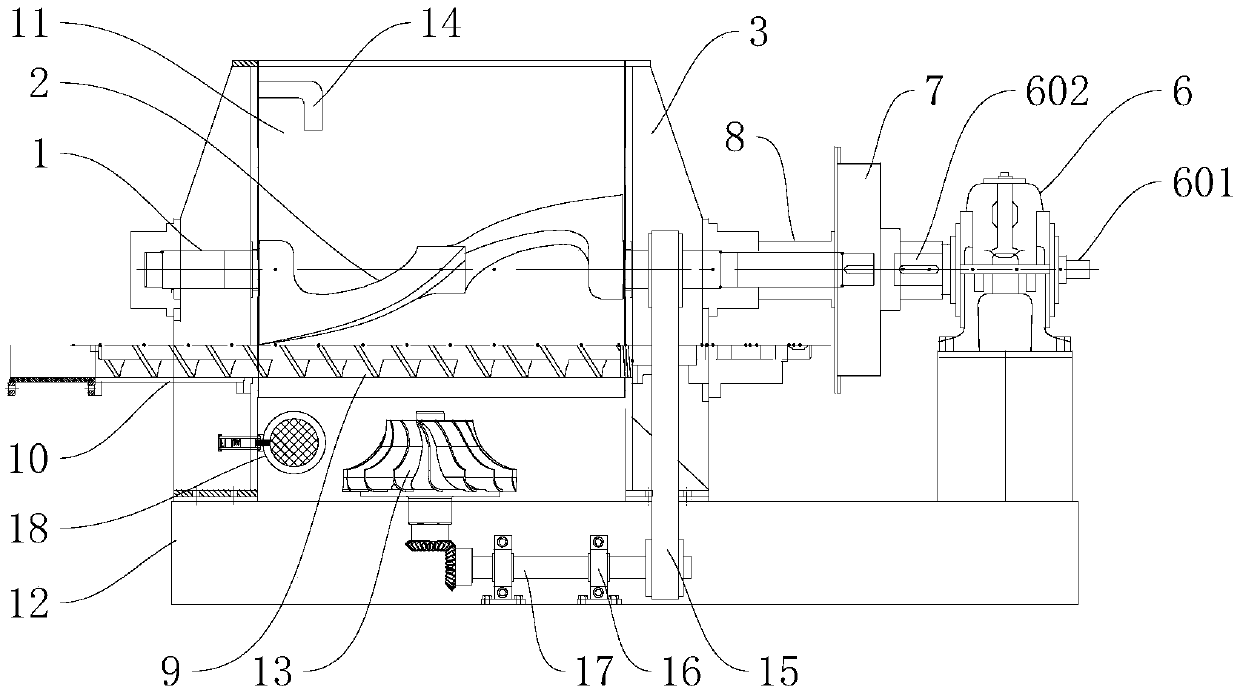

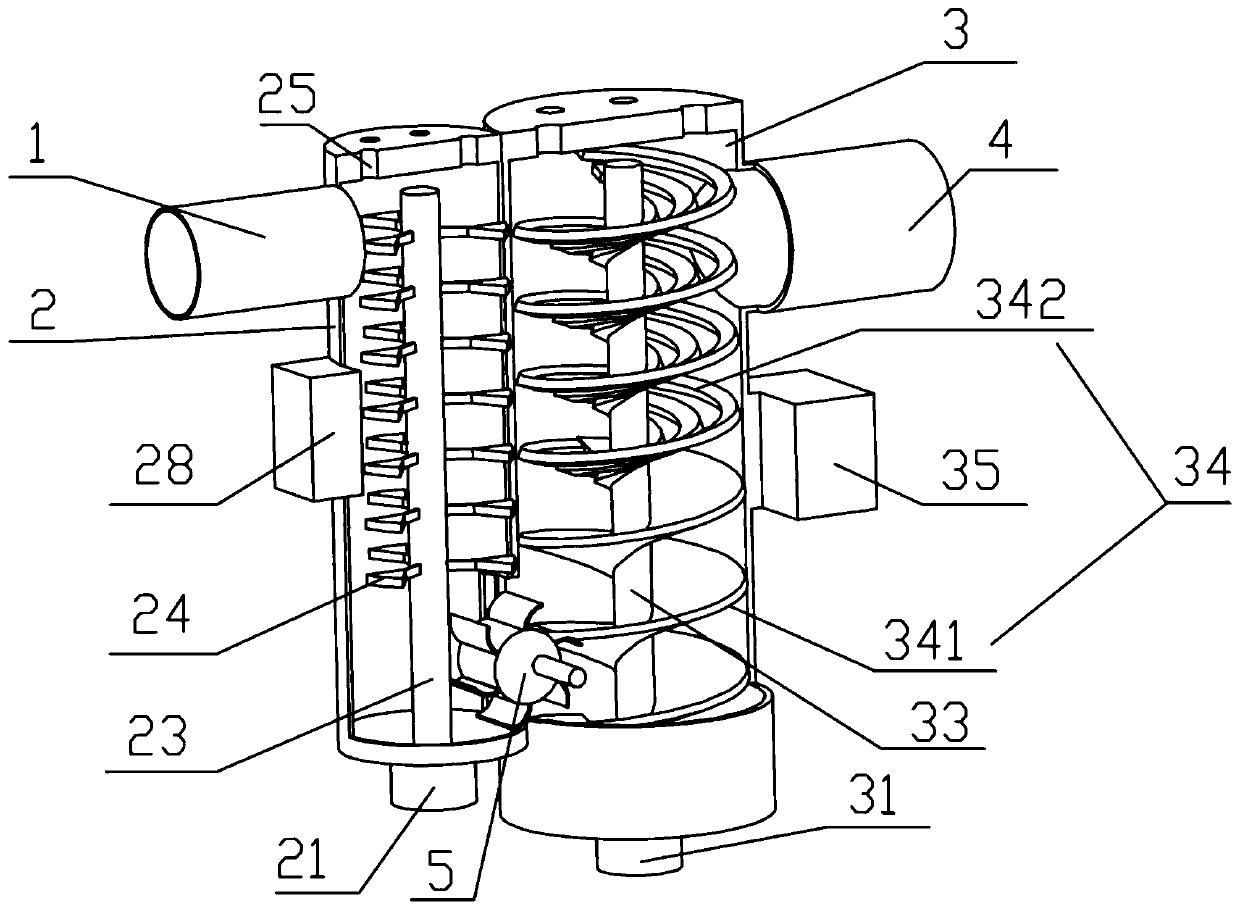

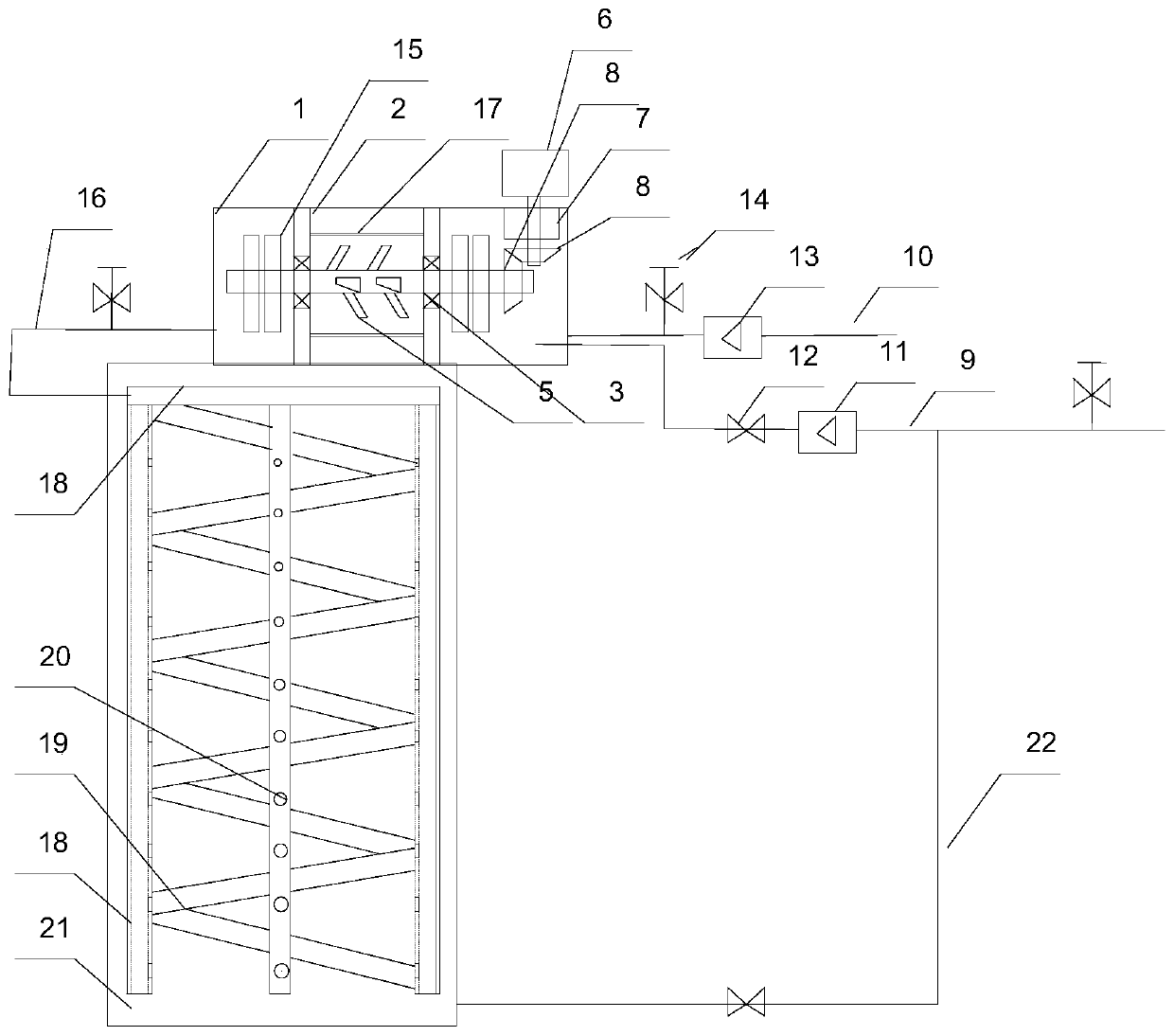

Quenching and tempering system for oil-containing sludge

ActiveCN109650687AAchieving deep reductionFully temperedSludge treatmentRotary stirring mixersOil sludgeQuenching

The invention relates to the technical field of oil-containing sludge treatment, in particular to a quenching and tempering system for oil-containing sludge. The system comprises a body, the body is provided with a quenching and tempering chamber and a quenching and tempering device. The quenching and tempering device comprises two quenching and tempering blades which are located in the quenchingand tempering chamber of the body with opposite rotation directions, the quenching and tempering blades comprise two quenching and tempering parts which are symmetrically arranged, the quenching and tempering parts comprise rotary members and stirring members which are mutually connected, and the stirring parts of the two quenching and tempering parts are mutually connected and coaxial with the rotary members; the quenching and tempering chamber is internally provided with a viscosity level detecting device, the body is provided with a water inlet device, and the starting and stopping of the water inlet device are controlled by the viscosity level detecting device. According to the quenching and tempering system, a quenching and tempering agent is added to the quenching and tempering chamber when quenching and tempering are conducted, oil-containing sludge is fully quenched and tempered by the rotation of the two quenching and tempering blades; by arranging multiple quenching and tempering blades which achieve quenching and tempering by rotating in different directions, the quenching and tempering is thorougher, the quenching and tempering effect is better, deep reduction of oil-containing sludge quenching and tempering is achieved; the refining and using of resources can be achieved by quenched and tempered oil-containing sludge more easily.

Owner:北京净界新宇环保科技有限公司

Biomass particle tobacco dryer capable of achieving automatic slag removing

PendingCN107420882AFully temperedIdeal for unobstructed combustionTobacco preparationFuel feeding arrangementsSlagFuel oil

The invention discloses a biomass particle tobacco dryer capable of achieving automatic slag removing. The biomass particle tobacco dryer comprises a support frame and a burning device installed on the support frame; the burning device comprises a feeding pipe and a burning pool, a discharging outlet of the feeding pipe communicates with the burning pool, a reciprocating propulsion slag removing device is installed under the feeding pipe, and the slag removing device comprises a rocking rod, a connecting rod, a slag removing rod and a fixed sliding way, wherein one end of the rocking rod is movably connected with one end of the connecting rod, the other end of the connecting rod is movably connected with the slag removing rod, the slag removing rod does reciprocating slag removing motion in the fixed sliding way, and the fixed sliding way is fixed behind the burning pool; the burning pool is provided with a through hole used for allowing the slag removing rod to pass, and the slag removing rod slides along the fixed sliding way, stretches into the burning pool from the through hole and pushes away ash slag in the burning pool. According to the biomass particle tobacco dryer capable of achieving automatic slag removing, the problems that when an existing traditional coal burning burner or firewood burner or fuel oil burner provides heat for a tobacco drying room, biomass fuel can not be fully burnt, ash deposition and slag bonding are generated, and generated heat is low are solved.

Owner:广西中立源能源技术有限公司

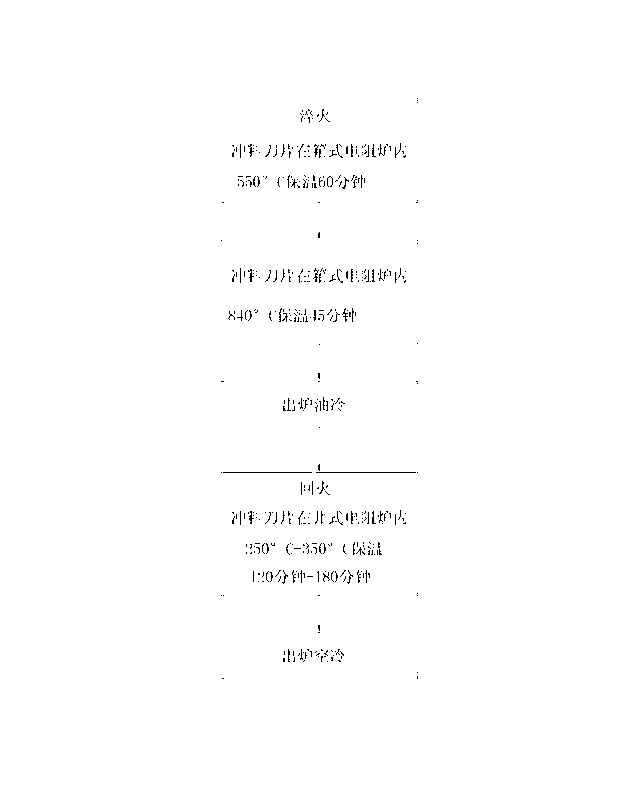

Heat treatment technology of bar shearing die blade

InactiveCN103014294ARaise tempering temperatureImprove mechanical propertiesFurnace typesHeat treatment furnacesFurnace temperatureBrittle fracture

The invention discloses a heat treatment technology of a bar shearing die blade, which comprises the following steps of: 1) quenching: heating a box-type resistance furnace to 550 DEG C, putting the bar shearing die blade into the furnace, and preserving heat at 550 DEG C for 60 minutes; and further increasing the furnace temperature to 840 DEG C, preserving heat for 45 minutes, and discharging the bar shearing die blade from the furnace and performing oil cooling; and 2) annealing: heating a pit-type resistance furnace to 250-350 DEG C, putting the quenched bar shearing die blade into the pit-type resistance furnace, preserving heat at 250-350 DEG C for 120-180 minutes, discharging and performing air cooling. The bar shearing die blade disclosed by the invention does not experience brittle fracture easily, and the cutting edge is not easily disintegrated; one bar shearing die blade can cut 20-30 thousand bars; after long-term use, the shearing die blade is still useful after coping, and the service life is prolonged by over 30 times; and moreover, the utilization rate is high, the needs for production and development are met, and the production cost is greatly saved.

Owner:亚星(镇江)系泊链有限公司

Physical full tempering method for ultrathin glass

The invention discloses a physical full-tempering method for ultra-thin glass. The physical full-tempering method comprises the following steps: S1, heating the ultra-thin glass in tempering equipment; and S2, firstly subjecting the heated ultra-thin glass to shock cooling, and then performing conventional cooling to complete tempering of the ultra-thin glass. The shock cooling adopts a tandem type fan and an air grid for combined cooling, the air grid is internally provided with a heat exchange pipeline, and the heat exchange pipeline is filled with dry ice. The tandem type fan is used for pressurizing air, and the pressurized air impacts the surface of the ultra-thin glass through the air grid. The physical full-tempering method for the ultrathin glass, provided by the invention, is simple and low in process cost. According to the method disclosed by the invention, the ultra-thin glass can be tempered, the tempering strength is high, the glass is not easy to break, and the flatness and the mechanical strength of the tempered glass are excellent. The physical full-tempering method for the ultra-thin glass, provided by the invention, is good in tempering effect and has a very good development prospect in the field of manufacturing of the ultra-thin tempered glass.

Owner:CHANGZHOU ALMADEN

A conditioning system for oily sludge

ActiveCN109650687BAchieving deep reductionFully temperedSludge treatmentRotary stirring mixersProcess engineeringOil sludge

Owner:北京净界新宇环保科技有限公司

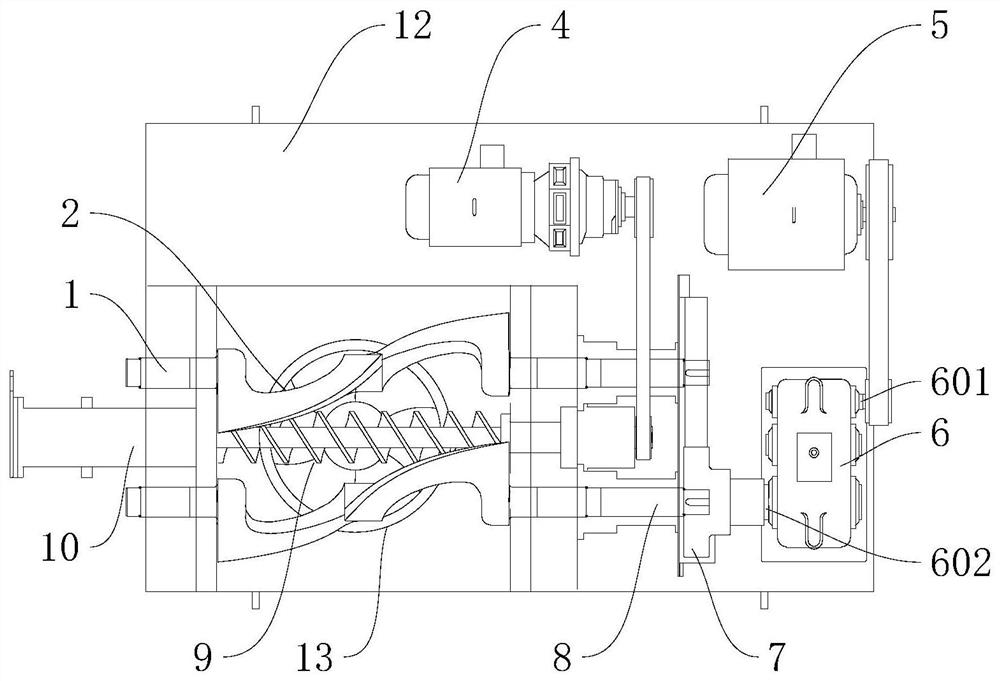

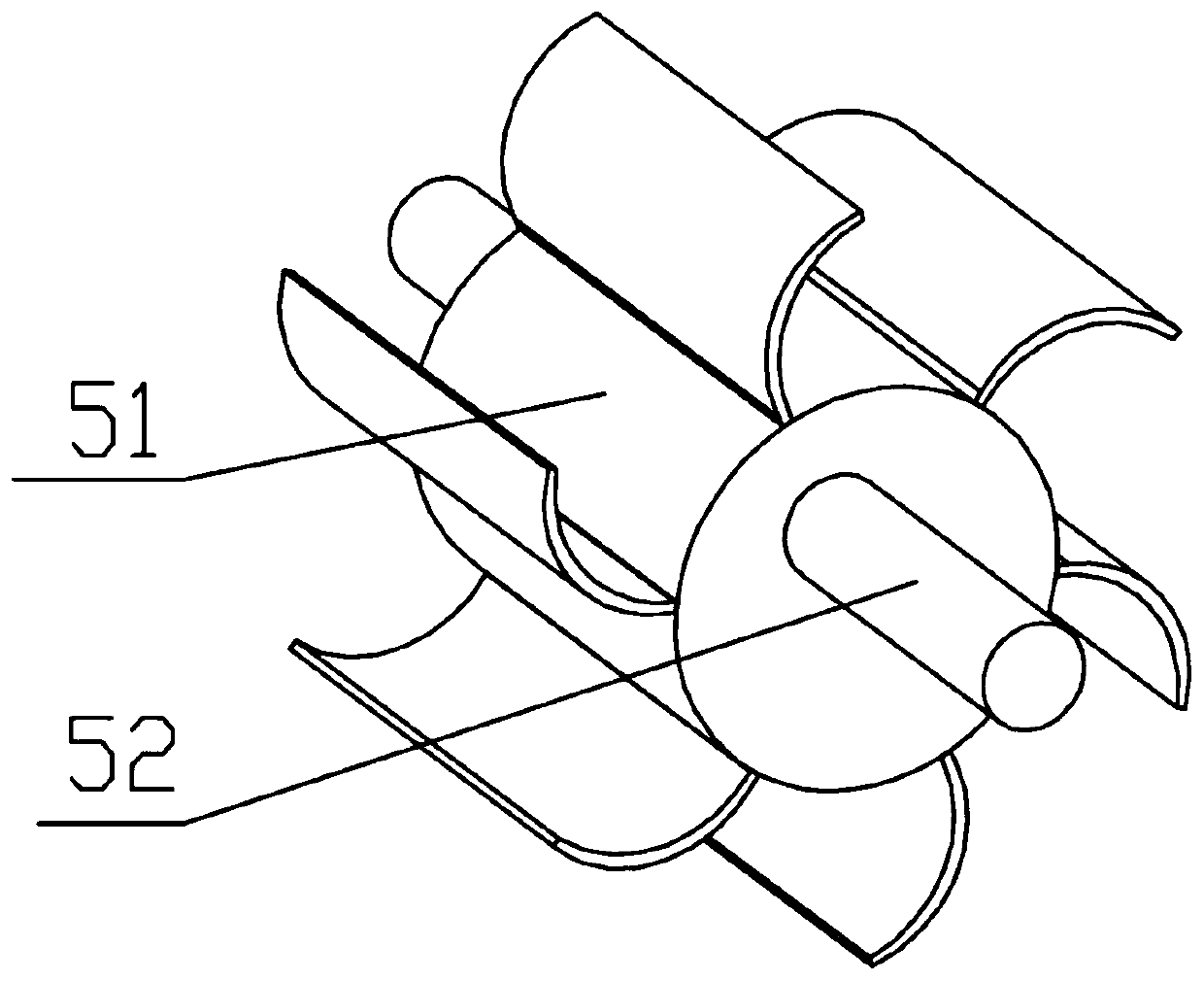

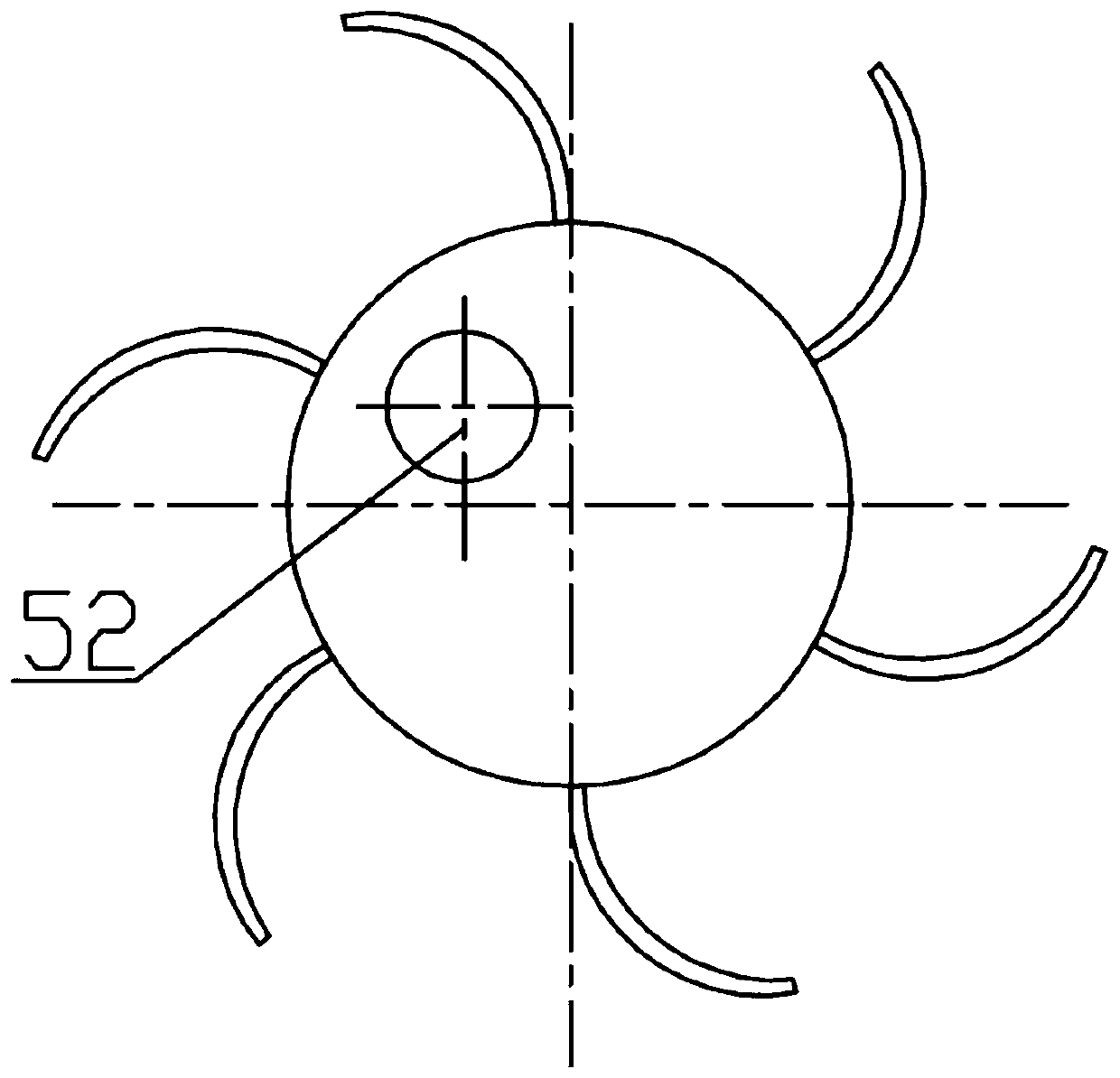

Suckling pig feed tempering equipment and working method thereof

PendingCN111150083AFully temperedImprove ripenessFeeding-stuffFood preservationElectric machineryEngineering

The invention discloses suckling pig feed tempering equipment and a working method thereof. The equipment comprises a feeding hole, a first cavity, a second cavity and a discharge hole, wherein the feeding hole is positioned in the upper part of the first cavity; the feeding hole communicates with the first cavity; a first motor is fixedly mounted at the bottom of the first cavity; a first rotating shaft is fixedly mounted on the output shaft of the first motor; first blades are connected with the first rotating shaft; a steam inlet is formed in the top of the first cavity; a microwave deviceis mounted at a side part of the first cavity; a second motor is fixedly mounted at the bottom of the second cavity; second blades are mounted on the second rotating shaft; the bottom of the first cavity is positioned at the bottom of the first cavity; an ultrasonic generation device is fixedly mounted at a side part of the second cavity; the second blades consist of lower blades and upper blades;and the discharge hole is positioned in the upper part of the second cavity. Compared with the prior art, the equipment has the beneficial effects that a suckling pig feed is high in aging degree, high in nutrition value, good in molding quality and sanitary and safe.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

High-speed steel heat treatment technology

InactiveCN106755767AImprove impact toughnessGuaranteed quenching process requirementsQuenchingHot Temperature

The invention discloses a high-speed steel heat treatment technology. The heat treatment technology includes the following steps that A, annealing treatment is performed, and annealing holding time should be 3-4h or above; B, quenching treatment is conducted, and preheating is performed for 1-3 times in the quenching process; and C, high-temperature tempering treatment is carried out. According to the high-speed steel heat treatment technology, preheating is performed for three times in the quenching process, the quenching technological requirements are guaranteed, impact toughness of a material is enhanced, and tempering is made more sufficient by means of tempering treatment for three times.

Owner:格润德(青岛)新型环保建材有限公司

A conditioning method and device

ActiveCN109315813BEmission reductionReduce labor intensityFeeding-stuffThermodynamicsProcess engineering

Owner:JIANGSU MUYANG HLDG

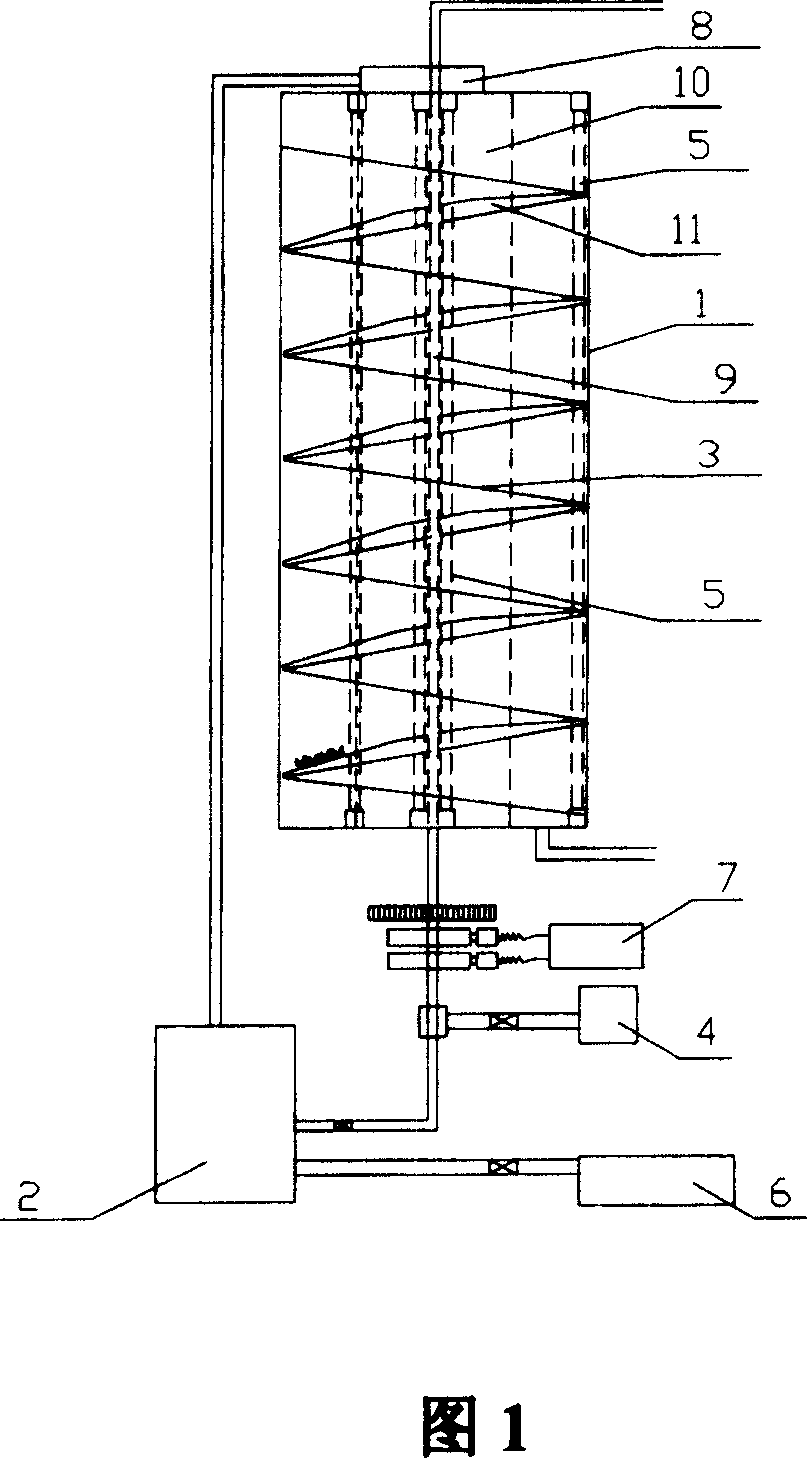

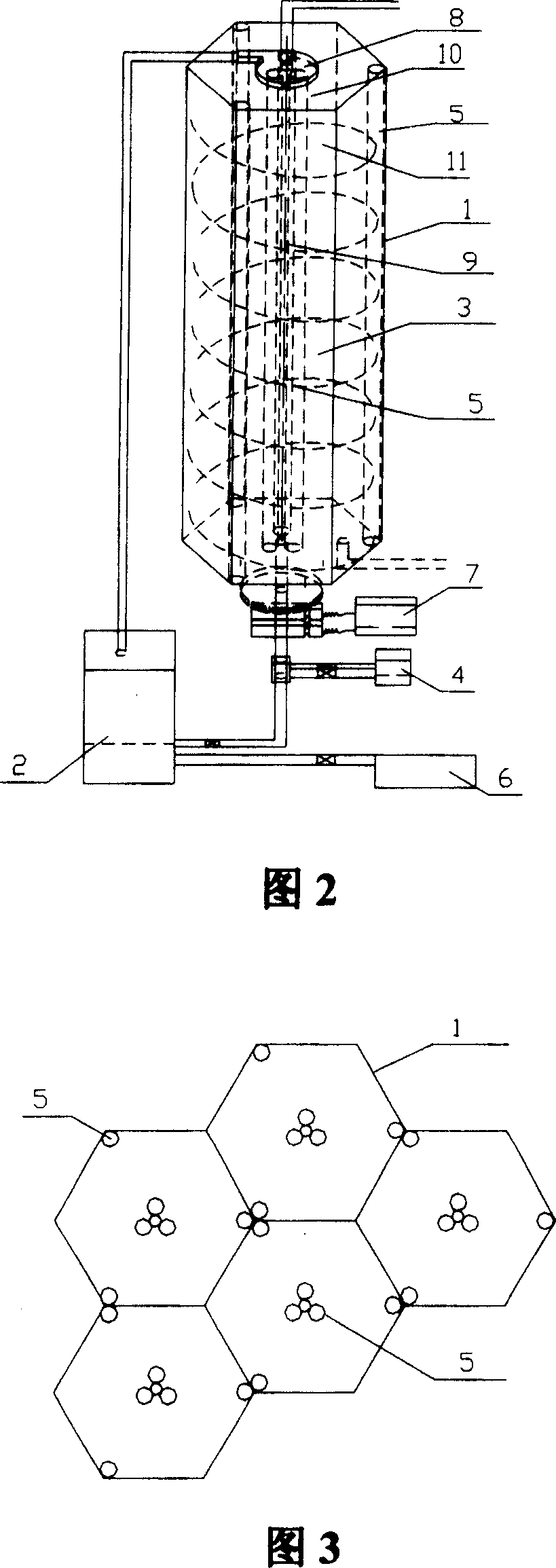

Assembled plant culturing apparatus

InactiveCN1311729CPromote accumulationImprove photosynthesis efficiencyClimate change adaptationGreenhouse cultivationGrowth plantTemperature control

A combined equipment for artificially culturing plants is composed of a number of hexagonal transparent culture containers which are combined in cellular mode, the overflow unit of nutritive liquid, nano lamp, humidity controller, CO2 source, speed-adjustable motor, blower and pipelines. Its advantages are low pollution, high quality of seedlings and short culture period.

Owner:章永泰

Gas mixing and supplying device in saw blade tempering furnace

PendingCN110079657AHave the effect of oxidationReduce generationFurnace typesHeat treatment furnacesProcess engineering

The invention discloses a gas mixing and supplying device in a tempering furnace. By means of the gas mixing and supplying device in the tempering furnace, gas in the tempering furnace can be evenly distributed, and convex points capable of easily adhering to a paint surface are easily generated on the surface of a tempered saw blade. The device comprises a spiral gas supply pipe arranged on the inner wall of a furnace body, and at least three gas distribution pipes which penetrate through the gas supply pipe and are arranged on the inner wall of the furnace body in the axial direction of thefurnace body. The device further comprises a closed cylinder arranged outside the furnace body. Two annular supports are oppositely arranged in the cylinder, bearing blocks are arranged on the annularsupports, a mixing shaft penetrates between the two bearing blocks, and a power device for driving the mixing shaft to rotate is arranged on the cylinder. A plurality of circulating holes allowing gas to pass are formed in the supports, and an oxygen inlet pipe and a nitrogen inlet pipe are arranged on one side of the cylinder. Two to four turbine blades are arranged at the two ends, outside thebearing blocks, on the mixing shaft respectively, a gas outlet pipe is arranged on the other side of the cylinder, the gas outlet pipe is connected with the gas supply pipe in the tempering furnace, and an air guide cylinder sleeves the mixing shaft and is arranged between the two supports.

Owner:东台艺新金属材料有限公司

A circular chain heat treatment device and its application method

ActiveCN105349757BHigh degree of integrationImprove work efficiencyFurnace typesHeat treatment furnacesHardnessLath

The invention discloses a heat treatment device for a round-link chain and an application method thereof. The device comprises a quenching part and a tempering part which are sequentially arranged, wherein first cooling parts are arranged at the quenching part and the tempering part; the quenching part is provided with a quenching temperature regulating box; the tempering part is sequentially provided with an uniform-temperature tempering heating box, at least one tempering temperature regulating box and a differential-temperature tempering heating box; the quenching temperature regulating box is provided with a second cooling part. The device has the characteristics of being high in integration degree and high in working efficiency; after the round-link chain is quenched, an uniform and small low-carbon lath martensite structure can be obtained; the quenching quality is high; the second cooling part and the first cooling parts are correspondingly connected to a cooling source, so that the cooling quality can be improved, and the requirements of each part of the round-link chain on hardness and toughness can be met.

Owner:SHANDONG LUNAN GRP ENERGY EQUIP MFG

Device and method for producing toughened glass

ActiveCN102603175BImprove efficiencyReduce power consumptionGlass tempering apparatusCold airLow noise

The invention discloses a device for producing toughened glass, comprising a heating device, a toughening device and a roller way device connected between the heating device and the toughening device. The toughening device comprises a screw air compressor, an air filter, an air tank and a quenching cold air grid sequentially connected by an air supply pipeline. The invention also discloses a method for producing toughened glass by utilizing the device above. the device and the method can be used for completely toughening ultra-thin glass with the thickness of 2mm and have the advantages of low energy consumption, low noise, and the like.

Owner:GUANGDONG SHUNDE TIMBERY TECH GLASS

Heat treatment process of high-speed steel

InactiveCN108148967AImprove impact toughnessGuaranteed quenching process requirementsQuenchingHeat treated

The invention discloses a heat treatment process of high-speed steel. The heat treatment process comprises the following steps that A, annealing treatment is carried out, the annealing heat preservation time is over 3-4h; B, quenching treatment is carried out, and preheating for 1-3 times is carried out during quenching; and C, high-temperature tempering treatment is carried out. According to theheat treatment process of the high-speed steel, the preheating for 3 times is carried out in the quenching process, so that the process requirement for quenching is guaranteed, the impact toughness ofthe materials is enhanced, the tempering treatment for 3 times is carried out, and the tempering is more sufficient.

Owner:QINGDAO XIAOMIXING ELECTRONICS TECH CO LTD

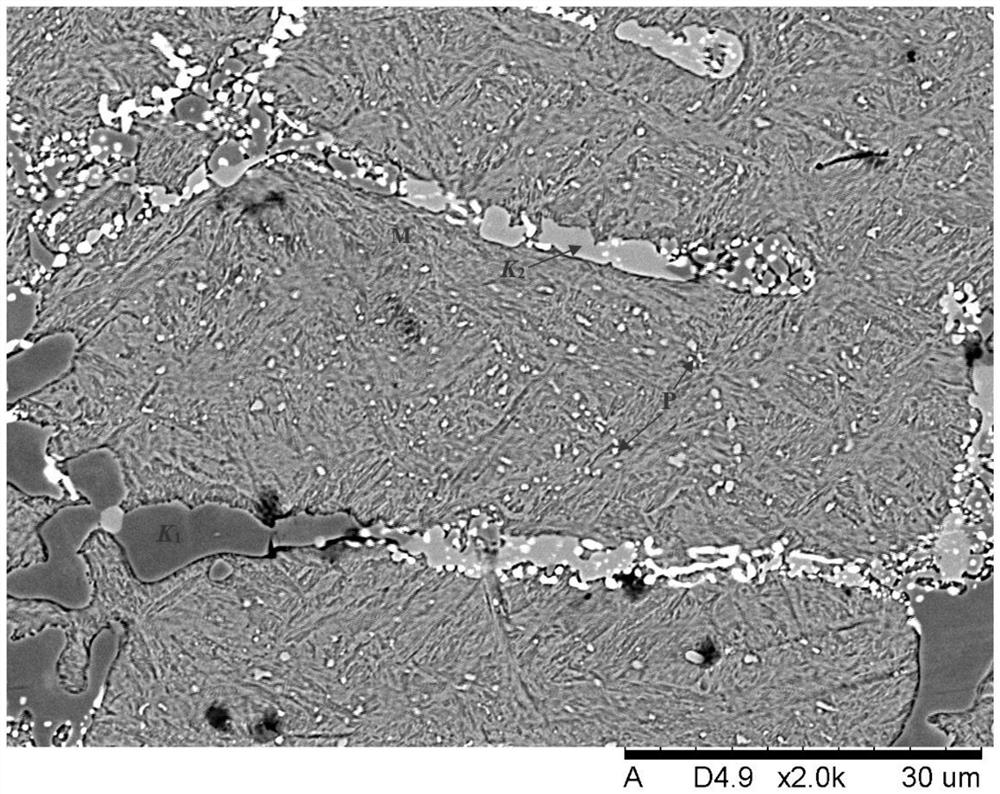

Heat-treated vanadium-containing high-boron high-speed steel and heat treatment method thereof

The invention discloses a heat-treated vanadium-containing high-boron high-speed steel and a heat treatment method thereof. According to the heat treatment method, quenching treatment is conducted on the vanadium-containing high-boron high-speed steel at the temperature of 1010-1060 DEG C to obtain a quenched part; and the quenched part is subjected to tempering treatment twice, and after the part is subjected to air cooling to the room temperature, the heat-treated vanadium-containing high-boron high-speed steel is obtained. According to the vanadium-containing high-boron high-speed steel and the preparation method thereof, the form of boron carbide is improved through vanadium addition and a heat treatment process, matrix strengthening is promoted, the vanadium-containing high-boron high-speed steel with excellent strength and toughness is obtained, and the vanadium-containing high-boron high-speed steel subjected to heat treatment can be better adapted to severe working conditions when being applied to actual production.

Owner:XI AN JIAOTONG UNIV

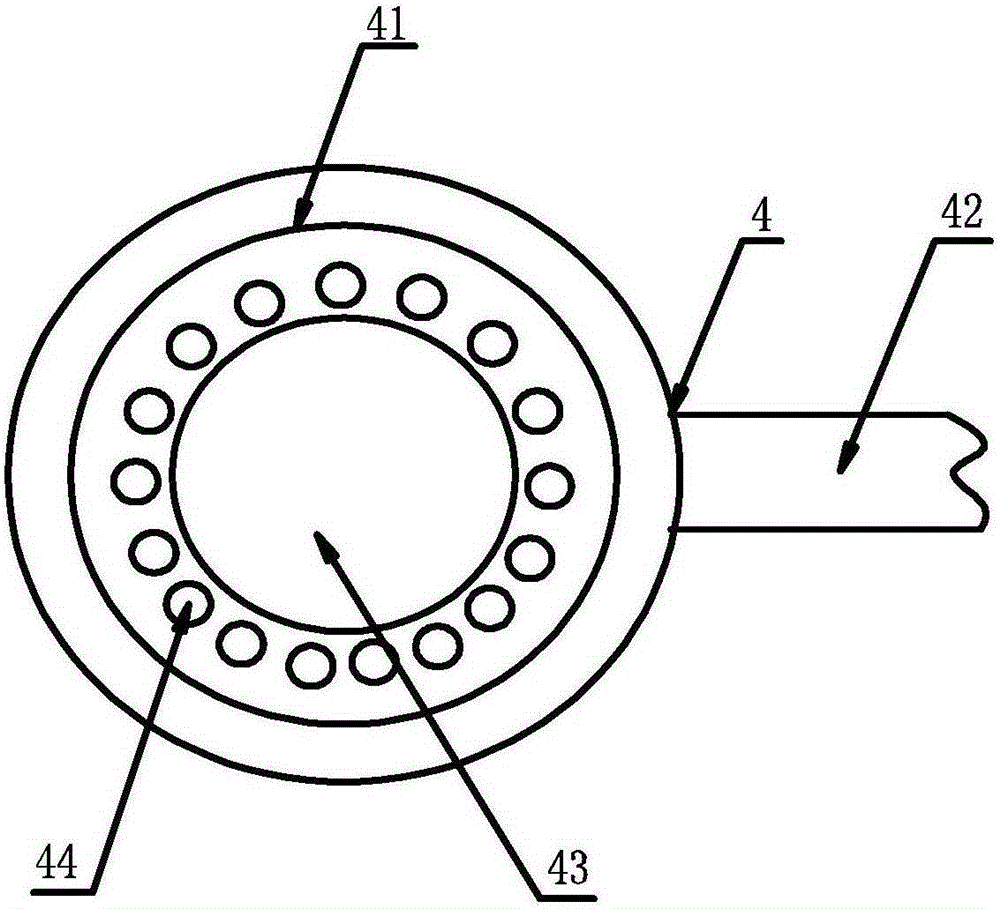

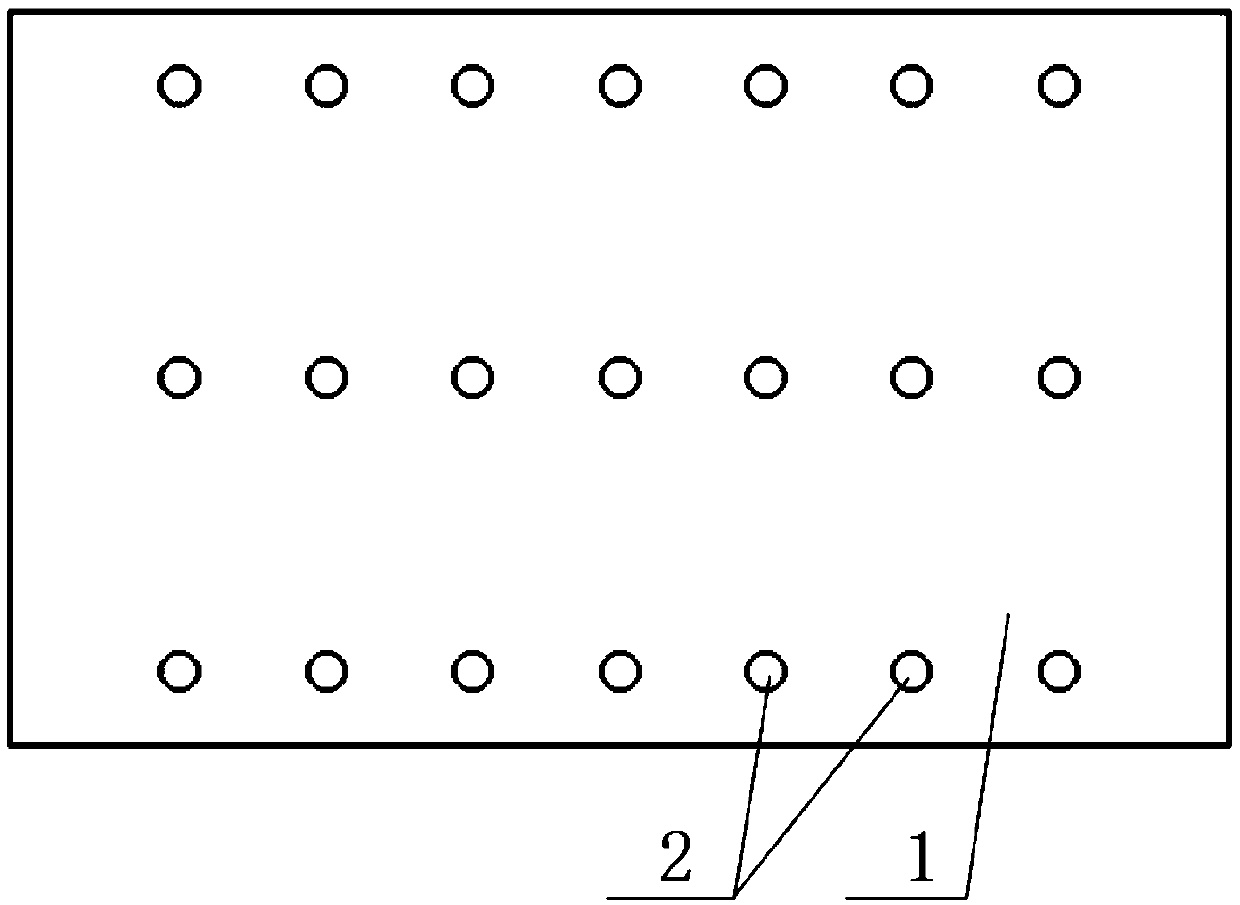

Tempering air ventilating cylinder

PendingCN107805687AFully temperedQuality improvementFurnace typesHeat treatment furnacesTemperingMechanical engineering

The invention discloses a tempering air ventilating cylinder. The tempering air ventilating cylinder comprises a cylinder body, wherein the cylinder body is used for containing a plurality of to-be-treated parts; a plurality of through holes are uniformly formed in the surface of the cylinder body in the circumferential direction. The tempering air ventilating cylinder has the advantage that whenthe multiple parts from the same batch are tempered, the parts can be paved on the surface of the cylinder body; because the through holes are uniformly formed in the surface of the cylinder body in the circumferential direction, when the tempering heat treatment is performed, the hot air flow can simultaneously flow into the cylinder body via the through holes in the surface of the cylinder body,and then can heat the parts in the cylinder body, so that the temperature uniformity of each position in the cylinder body is guaranteed, thereby improving the tempering uniformity of each part in the cylinder body, ensuring the sufficient tempering of each part, and improving the quality and qualified rate of each part.

Owner:四川银钢一通凸轮轴有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com