Heat treatment technology of bar shearing die blade

A die cutter and bar technology, applied in the field of heat treatment, can solve the problems of low tempering temperature of bar cutting die blades, prone to stress concentration, short tempering and holding time, etc., to meet the needs of production development, eliminate residual stress, The effect of strength and toughness improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] This embodiment includes the following steps:

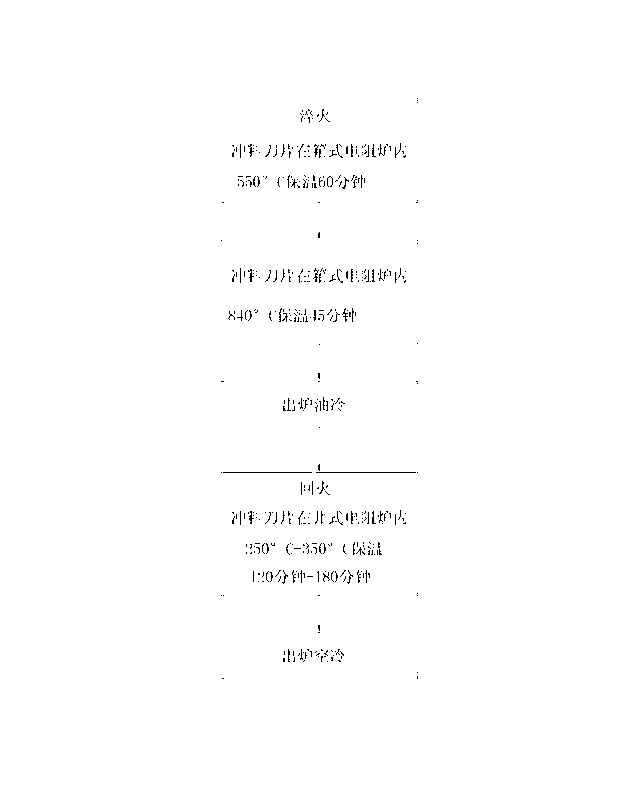

[0019] 1) Quenching: After raising the temperature of the box-type resistance furnace to 550°C, install the bar cutting die blade into the furnace, and keep it in the furnace at 550°C for 60 minutes;

[0020] 2) Continue to raise the temperature of the box-type resistance furnace to 840°C and keep it warm for 45 minutes;

[0021] 3) The blades of the bar cutting die are cooled by oil;

[0022] 4) Tempering: first raise the temperature of the well-type resistance furnace to 250°C, then put the quenched bar cutting die blade into the well-type resistance furnace, and keep it at 250°C for 120 minutes;

[0023] 5) Take it out of the oven and air cool.

[0024] In this embodiment, the surface hardness value of the bar shearing die blades is HRC59, and a pair of bar shearing die blades can produce about 4,000 bar shearing dies.

Embodiment 2

[0026] This example is basically the same as Example 1, except that the tempering temperature in this example is 300°C, the tempering holding time is 150 minutes, and the surface hardness value of the bar cutting die blade after heat treatment is HRC56. A pair of bars The cutting die blade can cut about 10,000 pieces of bar material.

Embodiment 3

[0028] This example is basically the same as Example 1, except that the tempering temperature in this example is 350°C, the tempering holding time is 180 minutes, the surface hardness value of the bar cutting die blade after heat treatment is HRC54, and a pair of bars The cutting die blade can cut about 20,000 to 30,000 bars.

[0029] After the heat treatment of the above process, the basic structure of the bar shearing die blade is fine tempered troostite plus evenly distributed fine-grained carbides. The tempered troostite structure has good elasticity and high hardness, which greatly improves the quality of the bar. Comprehensive mechanical properties of material shearing die blades.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com