Patents

Literature

71results about How to "No fumes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

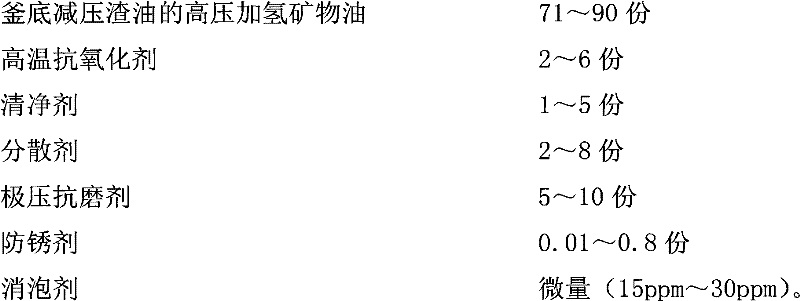

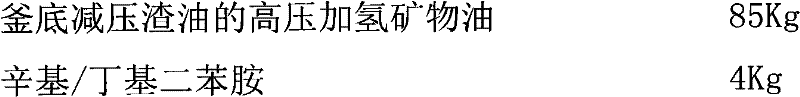

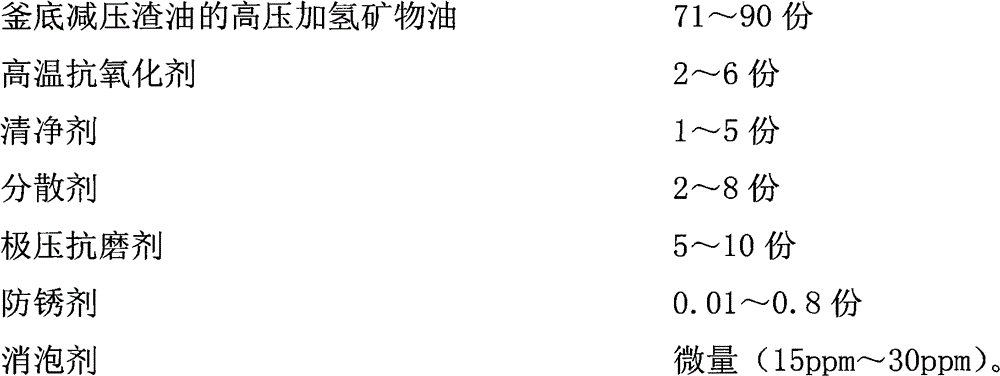

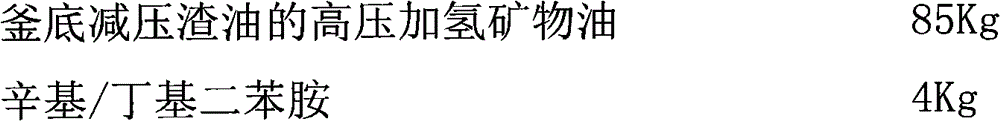

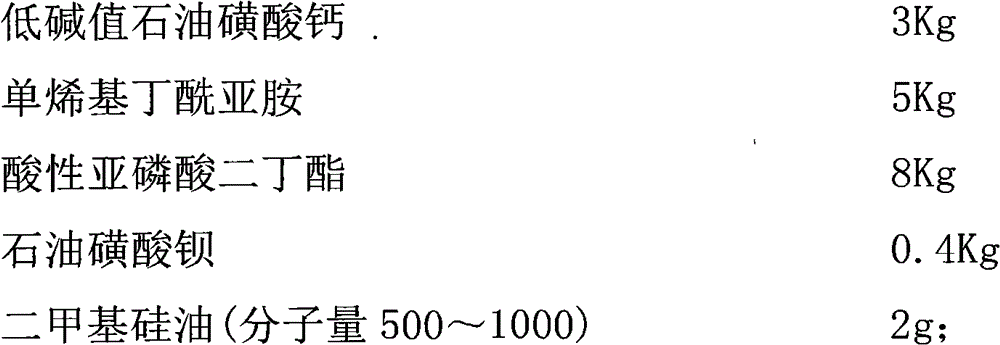

Mineral-oil-based high-temperature chain oil and preparation method thereof

The invention discloses mineral-oil-based high-temperature chain oil and a preparation method thereof, belonging to the field of chain oil production. The high-temperature chain oil is prepared from the following raw materials in proportions by weight: high-pressure hydrogenated mineral oil of kettle bottom vacuum residue, a high-temperature antioxidant, a detergent, a dispersant, an extreme-pressure anti-wear agent, a rust inhibitor and an antifoaming agent. Compared with the prior art, the mineral-oil-based high-temperature chain oil disclosed by the invention has the characteristics of lowevaporation loss, almost no smoke, no carbon deposition, excellent lubricating properties and wear resistance and the like, and can be widely applied to high-temperature chain lubrication occasions below 300 DEG C.

Owner:SHANDONG YUANGEN PETROLEUM CHEM

Heat treatment process of preparing bearing roller by using G20CrNi2MoA steel instead of G20Cr2Ni4A steel

InactiveCN101660165ACarburizing process is easy to controlShorten the high temperature tempering timeSolid state diffusion coatingFurnace typesQuenchingOperational performance

The invention relates to a heat treatment process of preparing bearing rollers by using G20CrNi2MoA steel instead of G20Cr2Ni4A steel, belonging to the technical field of bearing production. The method comprises the following steps: using 10-110mm of G20CrNi2MoA steel to prepare carburizing steel rollers, separately adopting quenching mediums--quenching oil, polyving alcohol water solution and alkaline solution to cool the steel rollers according to different diameter of steel rollers and performing high temperature tempering at 600 DEG C for 5h after carburization. The big size carburizing bearing rollers prepared by replacing G20Cr2Ni4A steel and G15CrNi4MoA steel with G20CrNi2MoA steel can not only meet the demands of the operational performance, but also increase the technological properties, shorten the processing cycle, lower the processing cost, save a large number of noble alloying elements--Cr and Ni, reduce the material cost and have higher economic benefit and popularizationand application value.

Owner:LUOYANG LYC BEARING

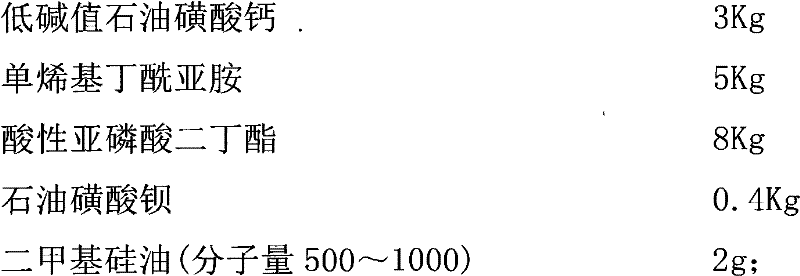

Smokeless cast iron wok and manufacturing method thereof

The invention discloses a smokeless cast iron wok and a manufacturing method thereof, and belongs to the field of kitchenware. The smokeless cast iron wok comprises a wok body, wherein the work body comprises an outer wok body, an inner wok body and a stainless steel coating; the outer wok body is cast from copper; the bottom of the outer surface of the outer wok body adopts a plane structure; the inner surface of the outer wok body and the outer surface of the inner wok body are combined in a fusion manner; the inner wok body is cast from cast iron; the bottoms of both the outer surface and the inner surface of the inner wok body adopt a circular-arc structure; the stainless steel coating is sprayed onto the inner surface of the inner wok body; and the stainless steel coating contains silicon, manganese, chromium, nickel, molybdenum, nitrogen, copper, cobalt, boron, carbon, niobium, calcium, phosphorus, sulfur and the balance of iron. The invention further provides the manufacturing method of the smokeless cast iron wok. The smokeless cast iron wok disclosed by the invention can be heated uniformly, can be prevented from generating smoke, is large in heated area and low in breakage possibility, and can be protected from rust erosion.

Owner:陆川县南发厨具有限公司

Aluminum alloy quenching medium and preparation method thereof

The invention discloses an aluminum alloy quenching medium. The invention is characterized in that the quenching medium is prepared from the following raw materials in parts by weight: 0.5-1 part of N-methylpyrrolidone, 3-5 parts of sodium chloride, 0.5-1 part of lauric acid, 0.5-1 part of lauroyl diethanolamine, 1-2 parts of mannitol, 2-4 parts of glycerol, 1-2 parts of urea, 0.5-1 part of sodium carboxymethyl cellulose, 0.5-1 part of sodium bicarbonate, 0.3-0.5 part of sodium lignosulfonate, 1-2 parts of water-soluble lanolin, 3-5 parts of assistant and 70-80 parts of water. The quenching medium satisfies the deep quenching requirements; the treated workpiece has the advantages of high hardness, favorable tensile property and long service life; and the quenching medium effectively prevents cracking and is suitable for aluminum alloy quenching.

Owner:安徽东星汽车部件有限公司

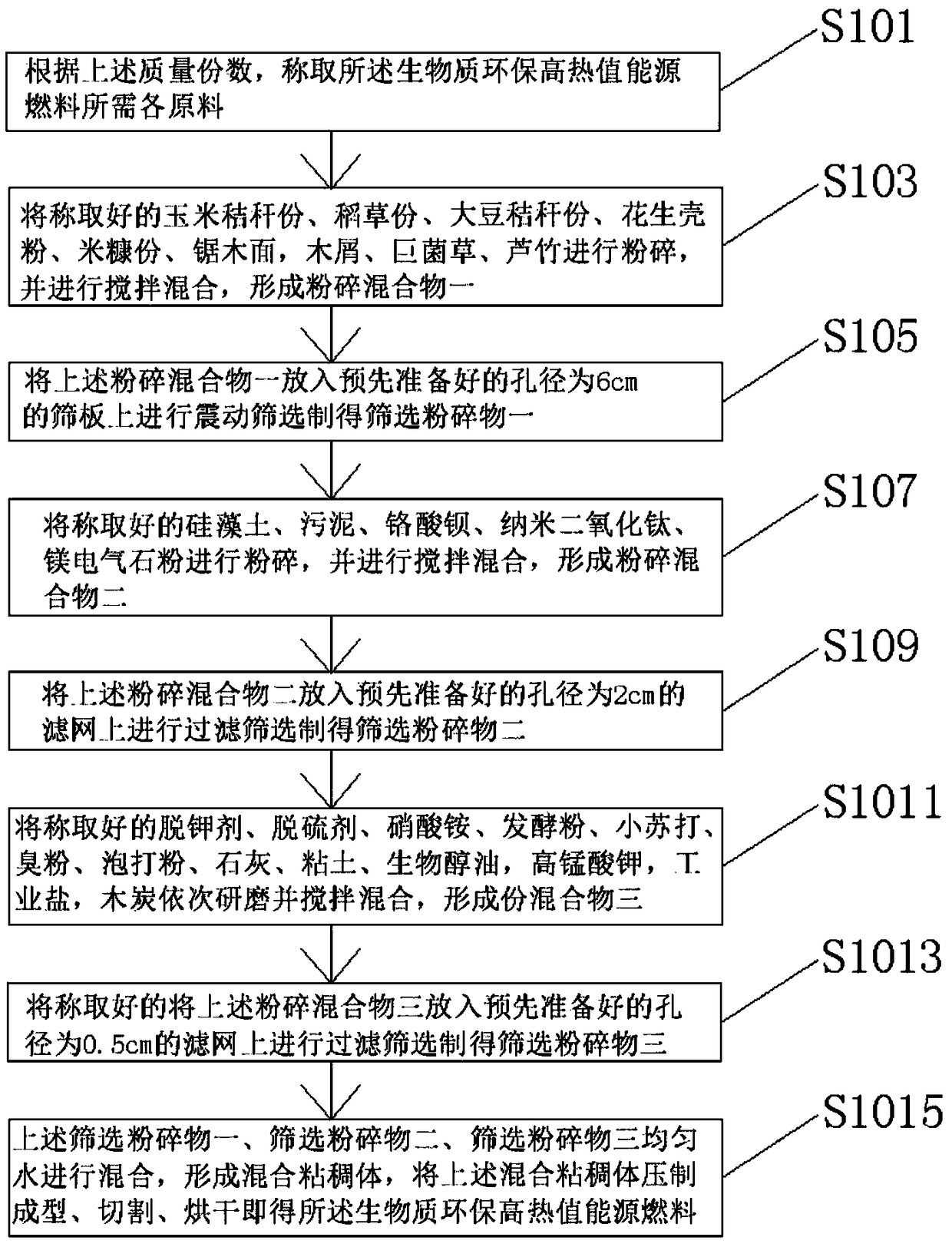

Biomass environment-friendly high-calorific-value energy fuel and preparation method thereof

The invention discloses biomass environment-friendly high-calorific-value energy fuel and a preparation method thereof. The biomass environment-friendly high-calorific-value energy fuel is prepared from the following raw materials in parts by weight: 50-70 parts of corn strawstalks, 35-40 parts of straw, 20-25 parts of soybean strawstalks, 30-70 parts of peanut husk powder, 20-25 parts of rice bran, 20-30 parts of sawdust, 35-55 parts of wood chippings, 25-45 parts of pennisetum sinese, 25-40 parts of arundo donax, 2-5 parts of diatomite, 8-20 parts of sludge, 2-5 parts of barium chromate, 1-4 parts of nano titanium dioxide, 2-6 parts of dravite powder, 10-30 parts of water, 5-10 parts of a potassium removal agent, 5-10 parts of a desulfurizing agent, 2-5 parts of a swelling agent, 20-30of a binding agent and 20-30 parts of a combustion improver. The biomass environment-friendly high-calorific-value energy fuel has the beneficial effects that the low-cost, environment-friendly and high-quality biomass-based fuel is high in combustion rate and convenient to produce in batches.

Owner:梁丰

Smokeless environment-friendly charbroiling stove

InactiveCN106724916AImprove baking efficiencyDeliciousClimate change adaptationRoasters/grillsEngineeringEnergy conservation

The invention relates to a charbroiling stove, in particular to a smokeless environment-friendly charbroiling stove. The smokeless environment-friendly charbroiling stove includes a stove body installed on a supporting frame body, the stove body is internally provided with an upper chain transmission mechanism and a lower chain transmission mechanism which rotate synchronously, the upper chain transmission mechanism and the lower chain transmission mechanism penetrate through the whole stove body in the length direction, a plurality of charcoal boxes of which the tops are opened and the side walls are provided with net-shaped heat dissipation holes are arranged between the upper chain transmission mechanism and the lower chain transmission mechanism, a plurality of barbecue sticks are arranged in the length directions of the outer sides of the charcoal boxes, the upper ends of the barbecue sticks are inserted in the upper chain transmission mechanism, the lower ends of the barbecue sticks are inserted in the lower chain transmission mechanism, and the stove body is further provided with a driving device used for driving the upper chain transmission mechanism and the lower chain transmission mechanism to move. By means of the smokeless environment-friendly charbroiling stove, smokeless food baking is achieved, environmental protection and energy conservation are achieved, the baking efficiency is high, and the roasted food is delicious and does not contain carcinogenic substances.

Owner:陈化会

Novel efficient working solution for cutting machine

The invention discloses a novel efficient working solution for a cutting machine. The efficient working solution comprises the following components in percentage by weight: 15%-30% of base oil, 25%-35% of deionized water, 8%-10% of higher aliphatic alcohol, 8%-12% of polyether, 3%-7% of a surfactant, 2%-6% of a blasting agent, 1%-3% of a preservative, 2%-5% of a rust inhibitor, 3%-5% of a solubilizer, 1.5-2% of an anti-mildew bactericide and 3%-5% of an extreme pressure additive. The novel efficient working solution has the advantages that 1) the processability is good, and a work-piece of which the maximal thickness is 1200nm can be processed; 2) the surface smoothness is good, and the efficiency is improved by 20% in comparison with a water-based working solution when hard metal materials such as chromium are processed; 3) the novel efficient working solution accords with the environmental protection requirements, does not contain toxic and harmful substances, and does not generate lampblack in the processing process; and 4) the evaporation speed is low; the phenomena of corrosion and rust deposition are not generated on a work bench after long-time use.

Owner:SUZHOU BAOMA NUMERICAL CONTROL EQUIP

Hot-rolling functional liquid containing aqueous molybdenum and preparation method of hot-rolling functional liquid

The invention provides a hot-rolling functional liquid containing aqueous molybdenum and a preparation method of the hot-rolling functional liquid, belongs to the technical field of lubricant, and is characterized in that glycerine, the aqueous molybdenum, triethanolamine and oleinic acid are added in sequence and placed into a reaction kettle with the rotational speed of 80 to120 circles per minute to be heated and stirred, and when the temperature reaches 80 DEG C, heat preservation and continuous stirring are carried out for 60 minutes; and then the temperature is reduced to 70 DEG C, polyethyleneglycol, benzotriazole and isothiazolinone are added in sequence, the temperature is maintained at 70 DEG C, and stirring is carried out for 90 minutes, after that, heating is stopped, stirringis carried out while water is added until the solution is diluted to be light tan, so that the aqueous hot-rolling functional liquid is prepared. The aqueous hot-rolling liquid provided by the invention is diluted by water to be a rolling functional liquid with the volume concentration of 2 to 6 percent. The rolling liquid is simple to use and convenient to operate, is nontoxic and free of pungent odor and oil smoke in a hot-rolling process, and further enhances the corrosion resistance of rolled pieces.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method for water-based steel strip-rolling solution containing nano ZnO

ActiveCN102417857AImprove the finishHigh surface finishLubricant compositionVulcanizationPolythylene glycol

The invention relates to a preparation method for a water-based steel strip-rolling solution containing nano ZnO, which belongs to the technical field of lubricant. The preparation method includes the following steps: glycerin, vulcanized castor oil, triethanolamine and oleic acid are sequentially added and heated and stirred in a reaction kettle at the rotation speed of 90 to 110 rotations per minute, and when the temperature reaches 80 DEG C, the temperature is kept and stirring is continuously carried out for 60 minutes; afterwards, the temperature is decreased to 70 DEG C, polyethylene glycol (PEG-4000), fatty acid imidazoline borate and fatty alcohol-polyoxyethylene (15) ether are sequentially added, and the temperature of 70 DEG C is kept and stirring is carried out for 30 minutes; and stirring is continued, the temperature is decreased to 60 DEG C, the nano ZnO is added, the temperature of 60 DEG C is kept constant and stirring is carried out for 60 minutes, heating is then stopped, water is added during stirring, and after being diluted to light milk white, the nano water-based steel strip cold rolling solution is prepared. The rolling solution is easy to use and convenient to operate, and is non-toxic and cannot produce pungent smell and oily fume in the process of rolling, the surface finish of a rolled steel strip is high, the annealing detergence is excellent, and the rolled steel strip does not have oily dirt.

Owner:UNIV OF SCI & TECH BEIJING

Process for preparing wild tea seed oil

InactiveCN102007973AProtect active substancesReduce the degree of oxidationEdible oils/fatsPlanting seedRaw material

The invention relates to a process for preparing wild tea seed oil. The process comprises the following steps of: (1) drying wild tea plant seeds serving as raw materials in a drying furnace at the temperature of between 85 and 95 DEG C; (2) pressing the dried wild tea plant seeds at the temperature of between 45 and 55 DEG C; (3) filtering the wild tea seed oil obtained by pressing at the temperature of between 2 and 5 DEG C; (4) dewaxing the filtered wild tea seed oil at the temperature of between 0 and 3 DEG C; and (5) finally dehydrating the dewaxed wild tea seed oil at the temperature of between 120 and 130 DEG C to obtain the finished wild tea seed oil. In the process, low-temperature pressing technology and low-temperature freezing and dewaxing technology are adopted, and the prepared finished wild tea seed oil contains rich monounsaturated fatty acid.

Owner:常州金海棠茶果专业合作社

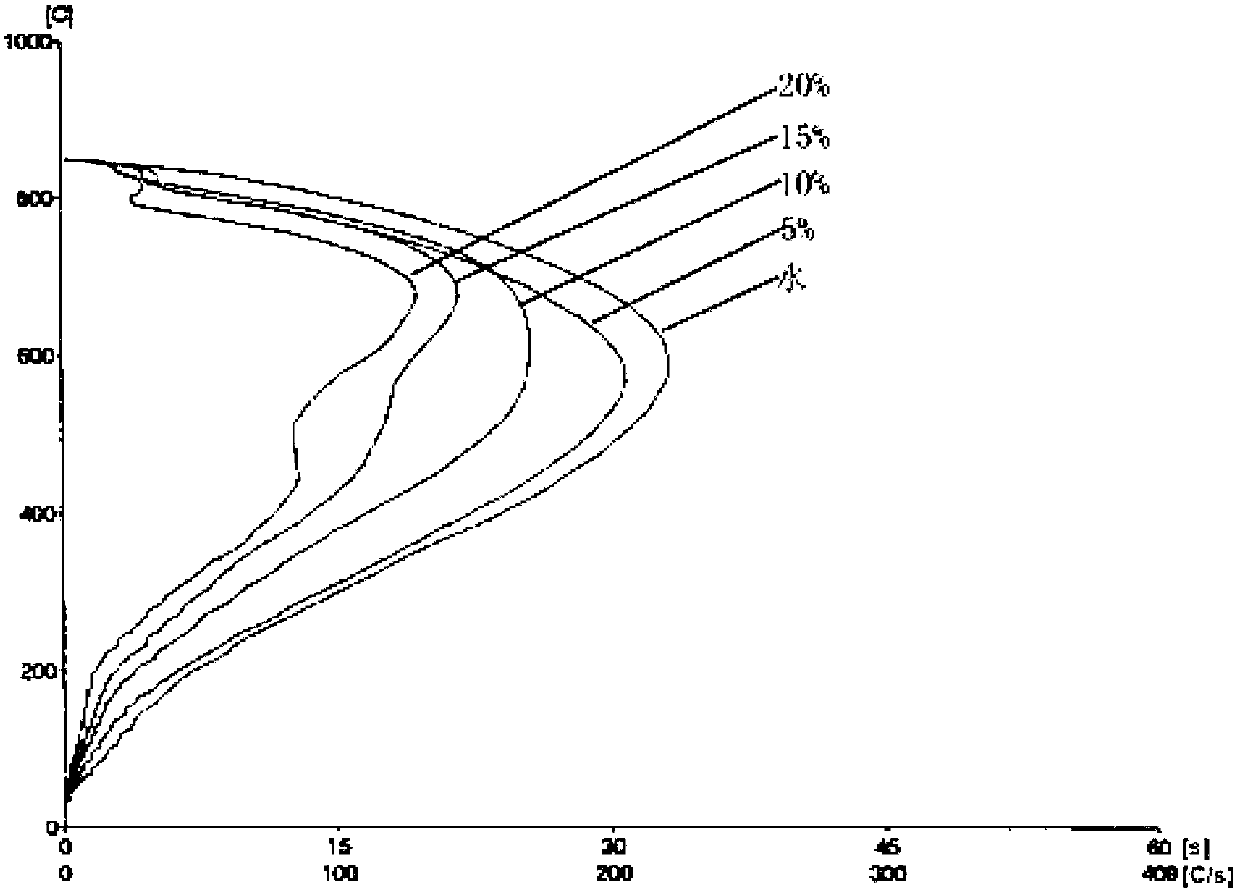

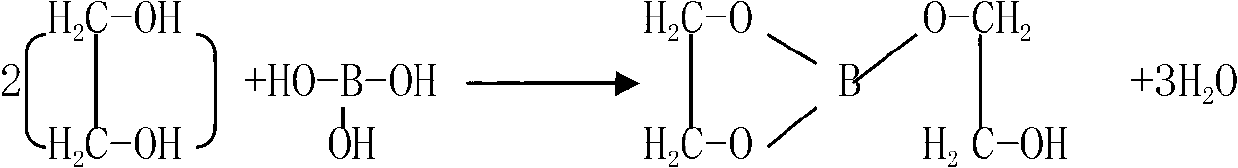

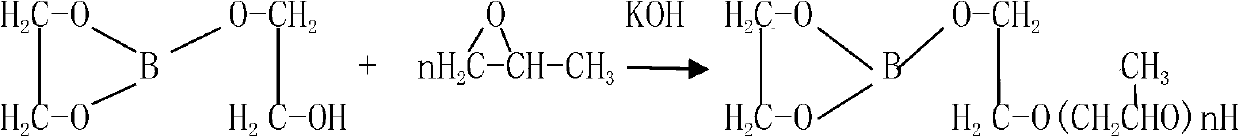

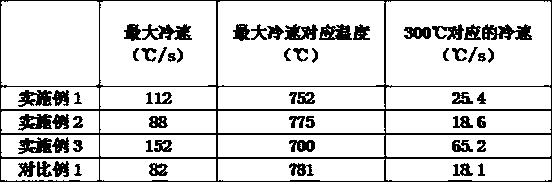

Polyoxy propane diethylene glycol borate polymer, preparation method thereof and environment-friendly water-soluble anti-rust quenching liquid prepared with the polymer

ActiveCN102942690ADifferent cooling ratesUniform quenching hardnessQuenching agentsEpoxyPotassium hydroxide

The invention provides a polyoxy propane diethylene glycol borate polymer, a preparation method thereof and an environment-friendly water-soluble anti-rust quenching liquid prepared with the polymer. The polymer has a chemical formula shown in the description, wherein n is an integer from 30 to 40. The preparation method of the polymer comprises the steps of: reacting ethylene glycol with boric acid in a molar ratio of 2:1 to obtain diethylene glycol borate; and reacting the diethylene glycol borate with epoxy propane in a molar ratio of 1:(30-40) to obtain the polymer. The environment-friendly water-soluble anti-rust quenching liquid comprises the following components, by weight: 40-80% of polyoxy propane diethylene glycol borate polymer (containing a small amount of potassium hydroxide, diethylene glycol poly propyl ether and boric acid potassium salt), 2-3% of potassium borate, 0.1-0.5% of potassium sorbate, and the balance of water. The environment-friendly water-soluble anti-rust quenching liquid provided by the invention has rapid cooling capacity similar to that of water at a low temperature zone, slow cooling performance similar to that of oil at a high temperature zone, and inverse solubility to water; and because of the special cooling performance of the quenching liquid, it can effectively substitute a traditional process of water quenching and oil cooling, and is convenient and reliable for operation, healthful and environment-friendly.

Owner:上海德润宝特种润滑剂有限公司

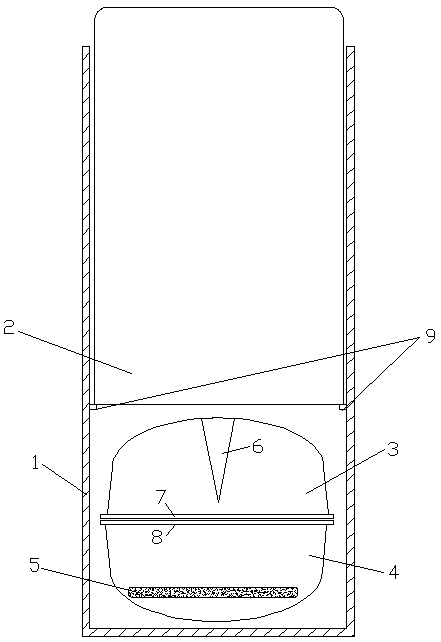

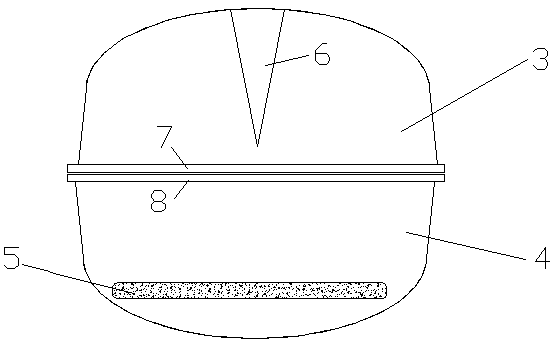

Pressing type self-heating food container

PendingCN110254963AImprove experienceEasy to operateContainers for heating foodPackaging foodstuffsFood contact materialsEngineering

The invention relates to a pressing type self-heating food container, and belongs to the technical field of food self-heating devices. The pressing type self-heating food container comprises a self-heating box body, wherein a self-heating bag and a liquid box are placed on the lower portion of the self-heating box body, a raised pressing part is arranged on the side face of the liquid box, a notch is formed in the outer edge of the pressing part, the pressing part is located in the middle of the notch, and a limiting part is arranged at the tail end of the liquid box or male and female grooves limiting parts are arranged on the outer side face of the liquid box or the inner side face of the self-heating box body. The pressing type self-heating food container is convenient to open, simple in manufacture process, and convenient to use.

Owner:NANCHANG STEAMING POT TECH DEV

Temperature display pot

The invention relates to the field of a stir-frying pot, in particular to a temperature display pot, which solves the problem that the temperature of the stir-frying pot is difficult to master in the prior art. A 150-DEG C color change temperature indicating sheet and an 180-DEG C color change temperature indicating sheet are arranged on a pot handle of the temperature display pot, and the 150-DEG C color change temperature indicating sheet is near the stir-frying pot. The stir-frying temperature can be controlled, and delicious dishes can be stir-fried according to requirements. In addition, oil smoke can be completely avoided during the cooking at the temperature, and the vitamin loss is also little.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

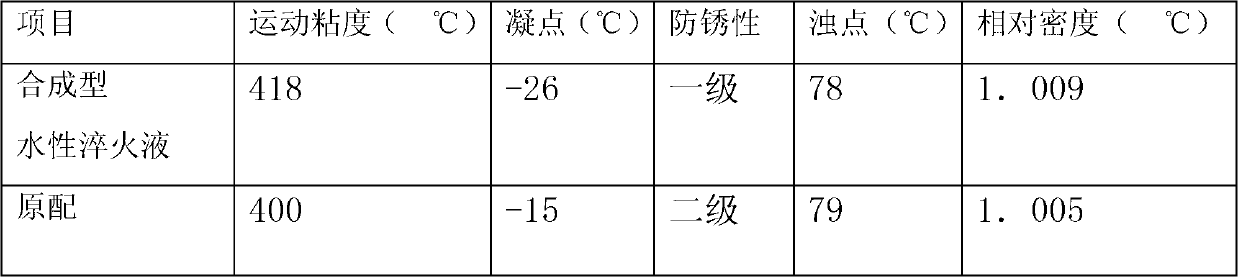

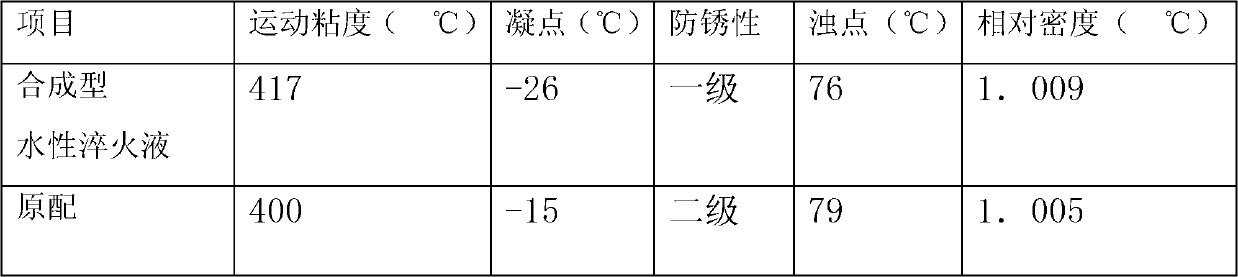

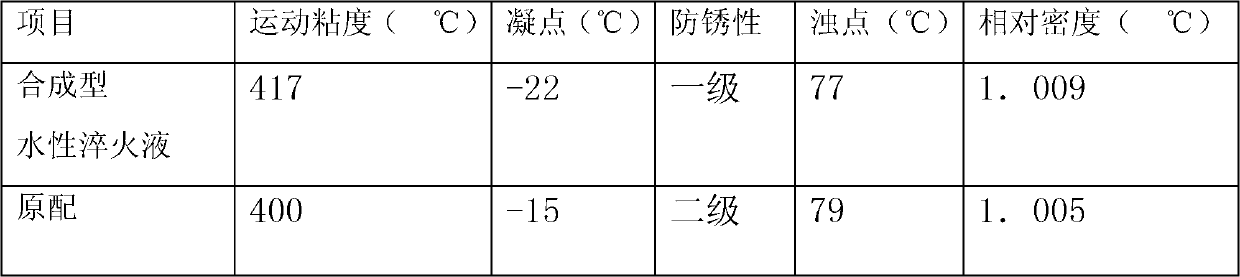

Synthetic aqueous quenching liquid and use method thereof

ActiveCN102816905AImprove quenching qualityMeet production needsQuenching agentsAntioxidantShort terms

The present invention discloses a synthetic aqueous quenching liquid and a use method thereof. Raw materials of the lubricating oil comprise, by weight, composite PAG, a cooling accelerant, and an antioxidant. The synthetic aqueous quenching liquid has the following advantages that: high difficulty heat treatment requirements of aqueous quenching are met; hardness HRC is in a range of 28-63, and can be randomly adjusted; metallography can be 3-5 grade; non-renewable energy source utilization is reduced; compared with the traditional quenching oil, the oil is saved by 80-90% with the synthetic aqueous quenching liquid of the present invention; magnetic inspection results show that no quenching crack is generated, hardness is moderate, and the metallography structure is qualified and meets enterprise production needs and harsh machining requirements; a quench-hardened layer of the quenching liquid is deep, quenching hardness is uniform, and no soft spot is generated, such that tendencies of quenching deformation and cracking are substantially reduced; no corrosion is generated to ferrous metals and nonferrous metals; the resulting quenched workpiece has characteristics of brightness, short-term antirust, aging resistance, deterioration resistance and long service life; and the synthetic aqueous quenching liquid further has characteristics of no toxicity, no oil fume, no burning, no fire disaster risk, safe use, improved working environment, and no environmental pollution.

Owner:AMER TECH CO LTD

Environment-friendly waterborne cutting fluid

InactiveCN110283651AHigh glossImprove cooling effectLubricant compositionPolyethylene glycolSelf emulsifying

The invention relates to the technical field of cutting fluid, in particular to environment-friendly waterborne cutting fluid. The environment-friendly waterborne cutting fluid is prepared from the following components: 50-68 parts of deionized water, 1-3 parts of a sulfur-containing agent, 5-10 parts of ethanol, 4-8 parts of polyethylene glycol, 8-12 parts of polyacrylamide, 10-15 parts of hnositol hexaphosphate, 12-15 parts of self-emulsifying ester, 8-15 parts of sulfurized fatty acid ester, 0.5-1 part of benzotriazole, 5-10 parts of a dispersing agent, 3-5 parts of a detergent and 1-3 parts of a corrosion inhibitor. Through scientific proportioning of polyethylene glycol with hnositol hexaphosphate, the detergent, a penetrant, the dispersing agent, the corrosion inhibitor and the like, high-lustre and non-forming waterborne cutting fluid is obtained. With adoption of cooperative synergy among the components, the cutting fluid can be suitable for grinding processing of magnesium and aluminum by 60000-turn high gloss machine. The cutting fluid has the advantages of no adhesion to knives, small odor, no lampblack, environmental friendliness, no corrosion and the like.

Owner:江苏方成生物科技有限公司

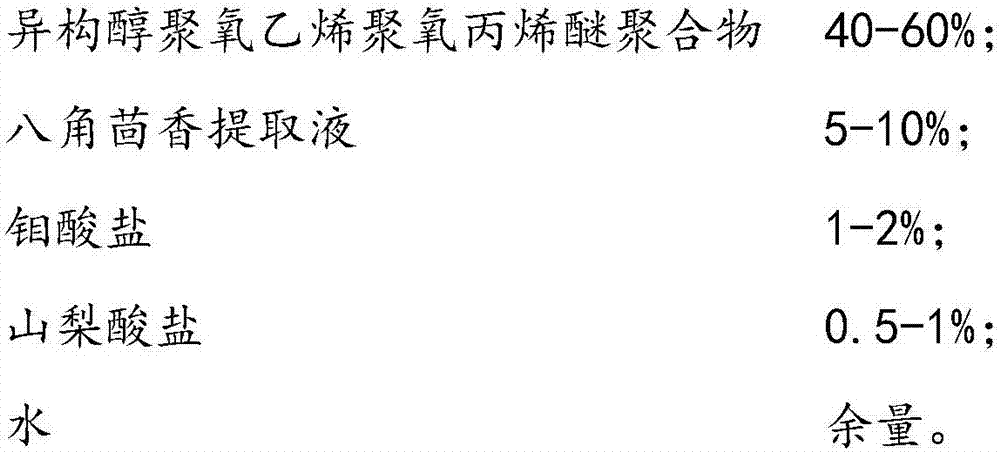

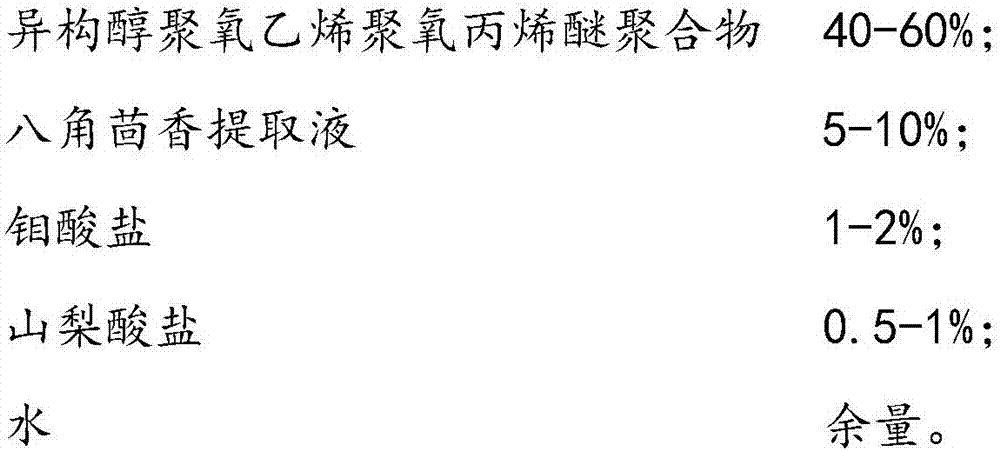

Environment-friendly quenching liquid and preparation method thereof

ActiveCN107190125AImprove rust resistanceReduce use costQuenching agentsInduction hardeningQuenching

The invention provides an environment-friendly quenching liquid combination. The quenching liquid combination is characterized by being composed of, by weight, 100 parts of isomer alcohol, 50-150 parts of ethylene oxide and 50-150 parts of epoxypropane. According to the environment-friendly quenching liquid combination prepared by the method, 5-20% of water solutions can be used for replacing oil for induction quenching of low-carbon and medium-carbon steel and integral quenching of large parts; different cooling speeds can be obtained by adjusting the concentration, and the application range is wide; the quenching hardness is uniform, the hardening layer is deep, no soft point exists, and the tendency of quenching deformation and cracking is effectively reduced; the workpiece is clean and bright after being quenched, has a certain rust-proof function, and can be free of cleaning and tempering; the rust-proof effect on ferrous metal and nonferrous metal is good; the carrying quantity is small, the use cost is low, and the comprehensive economical efficiency is good; and oil smoke and combustion are avoided, the fire hazard is avoided, and the labor environment is obviously improved.

Owner:山东思科工业介质有限公司

Oily water-soluble quenching liquid and preparation method thereof

InactiveCN111004898ADifferent cooling ratesReduce distortionQuenching agentsBoronic acidPyrrolidinones

The invention discloses an oily water-soluble quenching liquid and a preparation method thereof. The liquid comprises the following components of, in percentage by mass, 5%-15% of polyvinylpyrrolidone, 5%-10% of complex amine, 1%-5% of polycarboxylic acid, 1%-5% of boric acid, 0%-2% of defoamer, 0%-2% of corrosion inhibitor, and the balance deionized water. The method comprises the following stepsthat firstly, the complex amine is dissolved, the polycarboxylic acid is added, the mixture is uniformly mixed at the temperature of 40-70 DEG C, the corrosion inhibitor is continuously added, then the polyvinylpyrrolidone and the defoamer are sequentially added, and uniform stirring is conducted. According to the oily water-soluble quenching liquid, the application range is wider, different cooling speeds can be obtained by adjusting the concentration, the oily water-soluble quenching liquid has smaller deformation compared with other polymers, and can be used for quenching and cooling a high hardenability material or a small size alloy material, so that mineral oil for quenching is replaced, fire hazards are eliminated, and safety is higher.

Owner:沙索(广州)工业介质科技有限公司

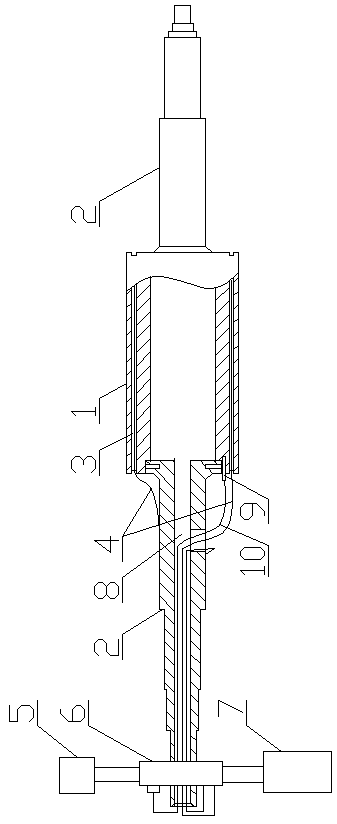

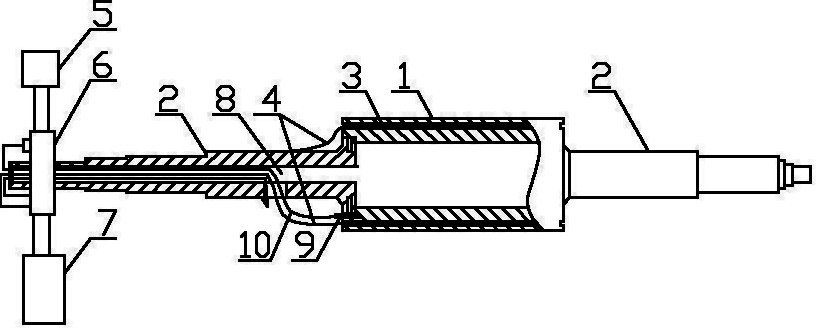

Bronzing roller electric heater for cork paper bobbin bronzing machine

InactiveCN102700242ASimple structureReduce volumeBronze printingRotary pressesTemperature controlBobbin

The invention discloses a bronzing roller electric heater for a cork paper bobbin bronzing machine. The electric heater comprises a bronzing roller and rotation shafts at two ends of the bronzing roller, wherein heating holes are axially arranged on the circumferential wall of the bronzing roller, heating wires are arranged in the heating holes, electric brushes are connected at the outer ends of the heating wires and connected with a power supply and a temperature control system. The heater has the advantages of simple structure, small size, temperature control range being 20-300 DEG C and temperature control precision of plus or minus 5 DEG C, accurate temperature control, short temperature rise time being not more than 15 minutes, fast temperature adjustment and high bronzing process quality, has no soot, no noise, low energy consumption, energy conservation and environment friendliness, and convenience and fastness in version change since the heating lines are used for direct heating, and can greatly improve the product quality and working efficiency, effectively enhance the operation environment and thoroughly eliminate the hidden safety hazard.

Owner:CHINA TOBACCO HENAN IND

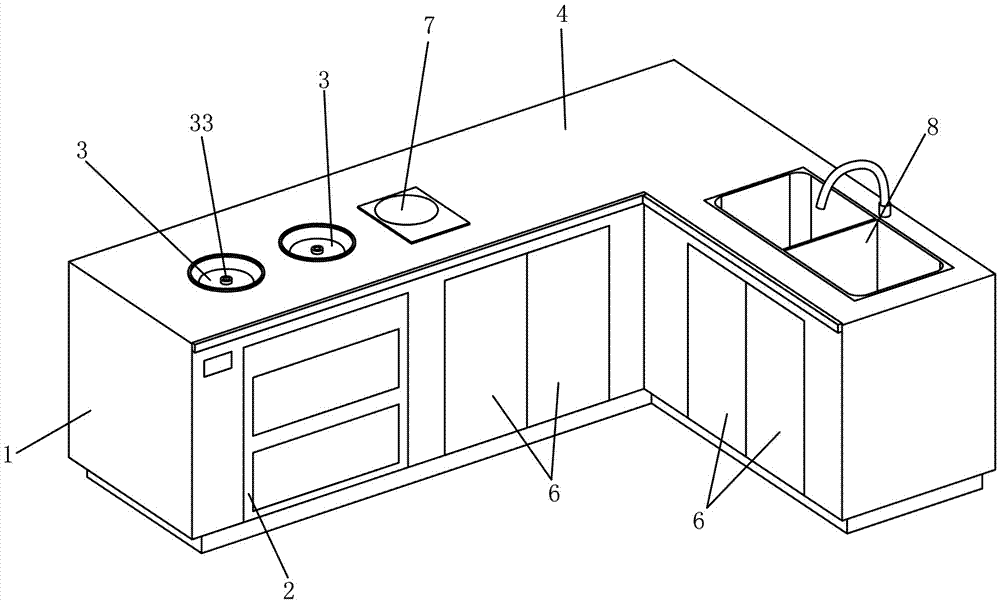

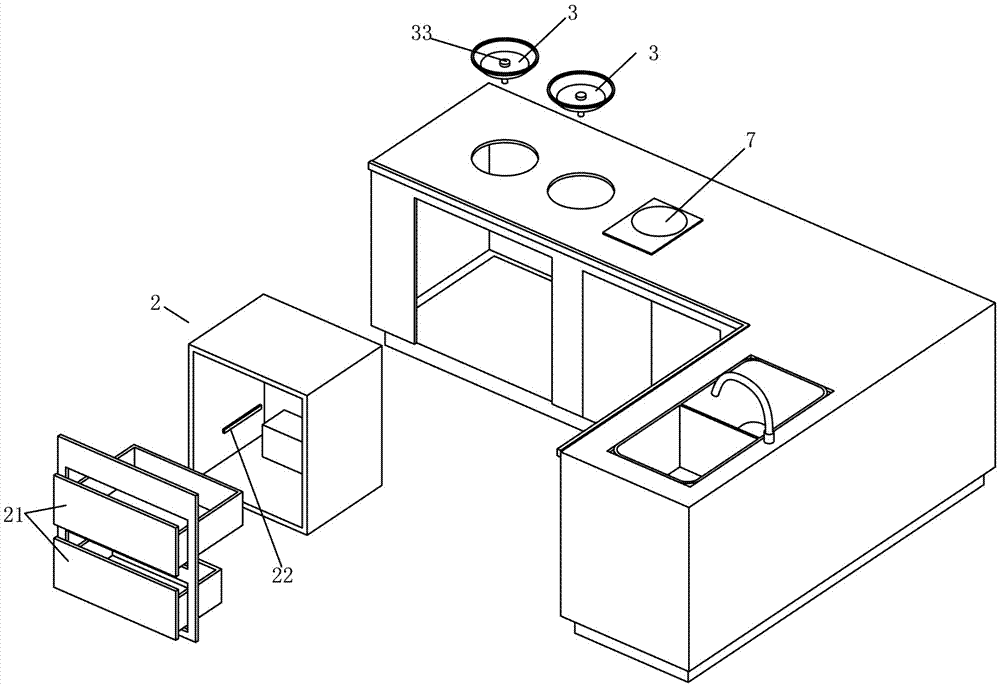

Intelligent kitchen system utilizing steam

ActiveCN106923527ASo as not to damageImprove energy efficiencyKitchen cabinetsWater vaporEngineering

Provided is an intelligent kitchen system utilizing steam, relating to the technical field of kitchen equipment. The invention particularly relates to equipment used for tableware disinfection and food heating in a kitchen. The intelligent kitchen system utilizing steam comprises a main cabinet body. The top of the main cabinet body is provided with a table surface and is embedded with a tableware disinfecting cabinet. The intelligent kitchen system utilizing steam is characterized in that a steam generator is arranged in the main cabinet body or the tableware disinfecting cabinet and connected with a disinfecting chamber of the tableware disinfecting cabinet through a steam pipeline; more than one steam kettle base is arranged on the table surface; and the center of the steam kettle base is provided with a steam joint connected with the steam generator. The intelligent kitchen system utilizing steam has the following beneficial effects: high-temperature water steam is utilized directly for tableware disinfection and food heating; food can be directly steamed by high-temperature water vapor of 100 DEG C produced by the steam generator, boiled and fried; utilization rate of energy is high; nutrition loss is few; oil smoke is avoided; food tastes good; and the system is convenient to use.

Owner:王佰忠

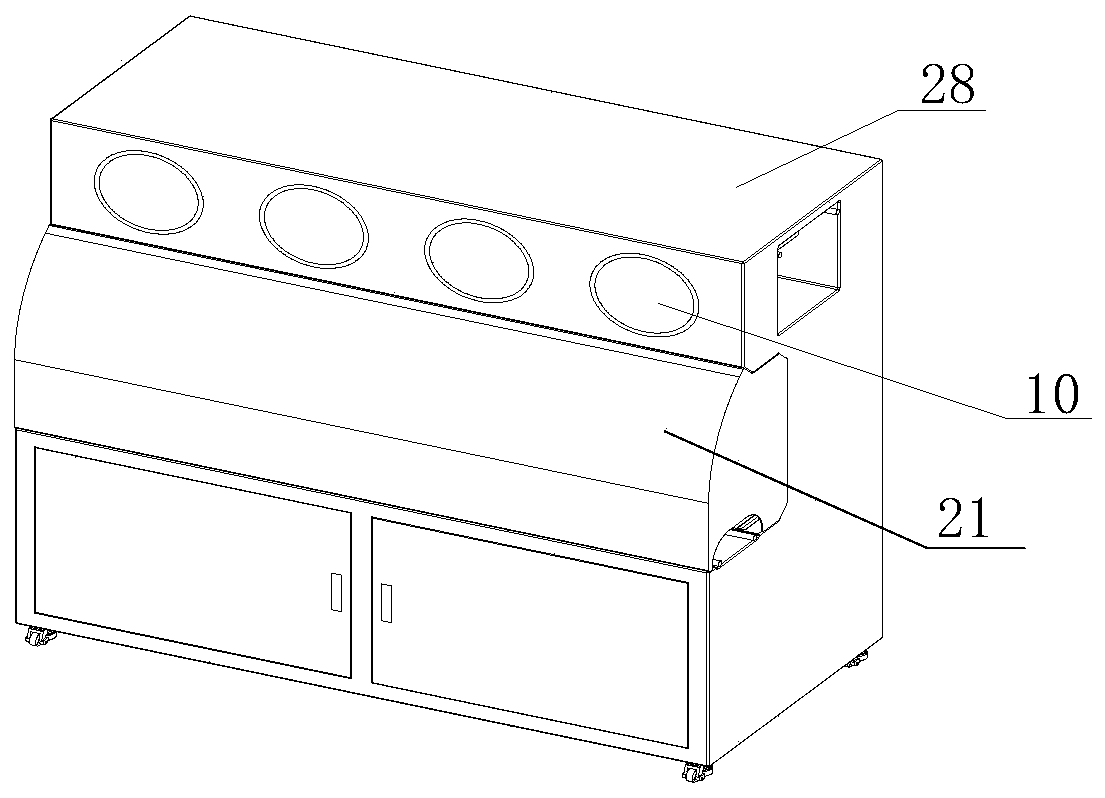

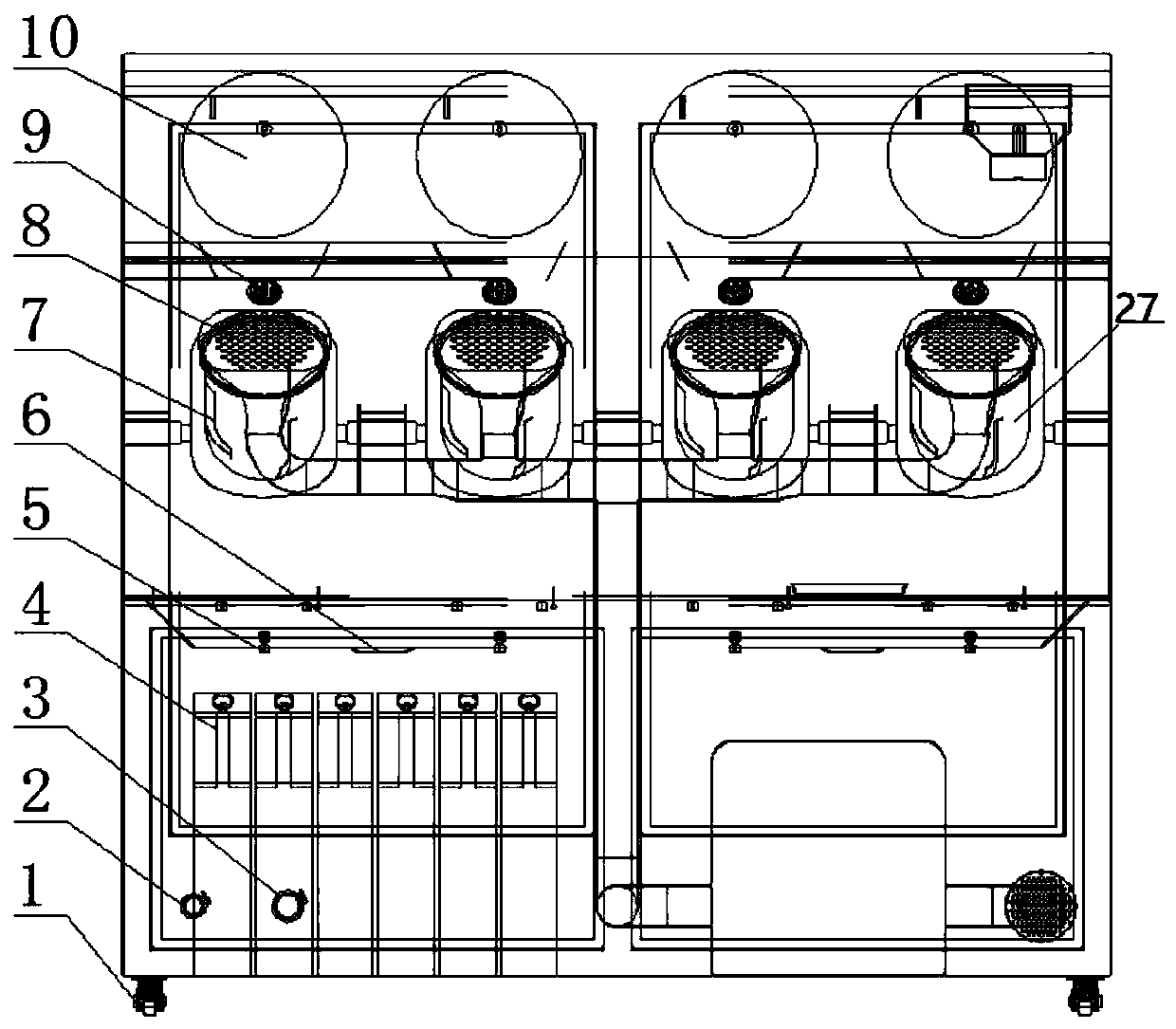

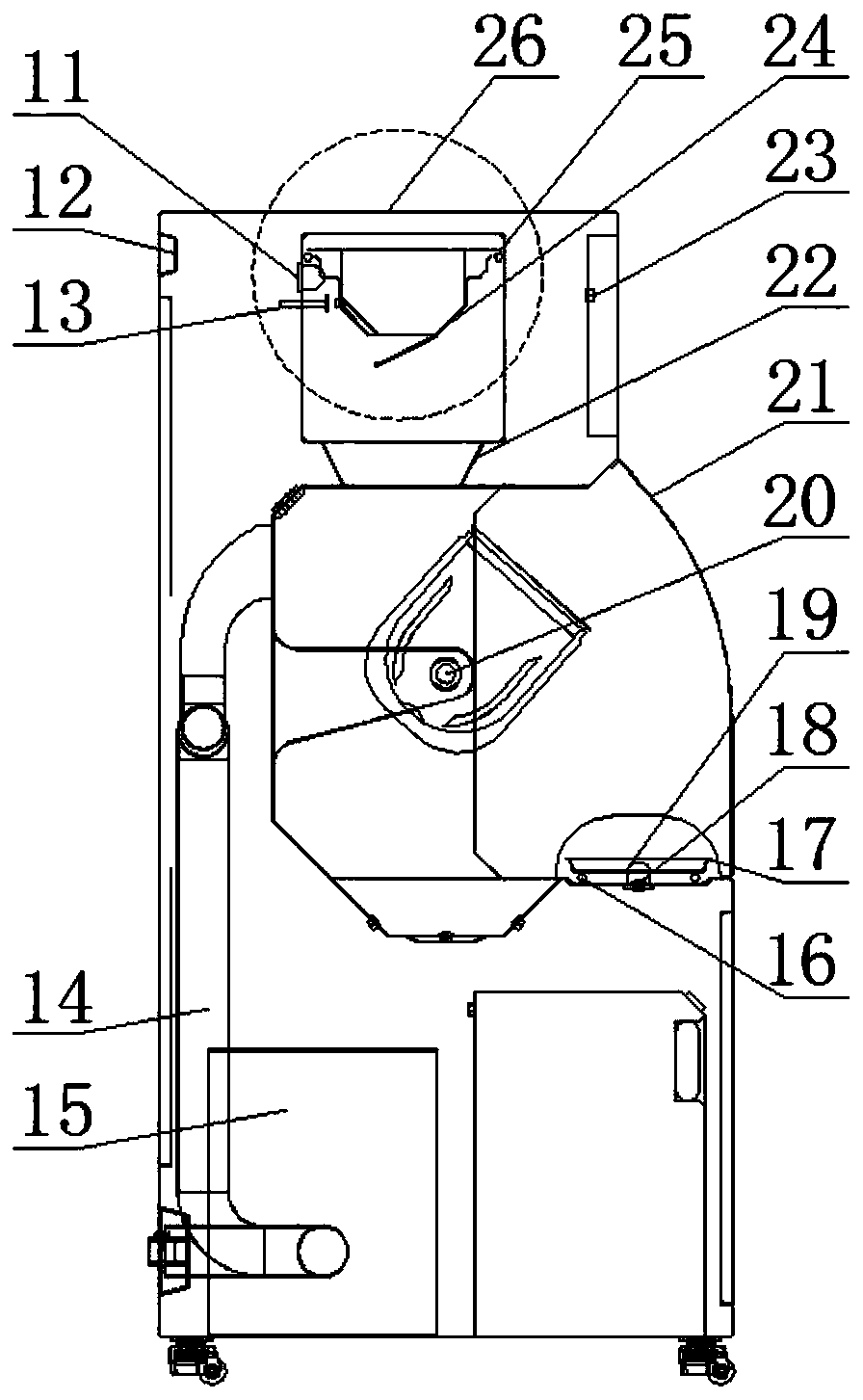

Full-automatic multi-bin commercial cooking machine

InactiveCN111110028ARealize one-key operationRealize fully automatic cleaningCooking-vessel materialsDomestic stoves or rangesSide dishIndustrial engineering

The invention discloses a full-automatic multi-bin commercial cooking machine. The cooking machine comprises a shell, a plurality of electromagnetic stir-frying pans arranged side by side are arrangedin the shell, a conveying belt is arranged above the electromagnetic stir-frying pans, a side dish color box can be erected on the conveying belt, the conveying belt is driven by a motor to convey the side dish box to the position over the electromagnetic stir-frying pans, and a bin door at the bottom of the side dish box can be controlled to be opened. A bin opening guide rod, a dish box baffle,a bin opening button, a bin opening hook, an infrared sensor and a bin door capable of being used for opening the bottom of the dish distribution box are arranged below the conveying belt. The invention provides a full-automatic multi-bin commercial cooking machine, wherein a plurality of frying pans are arranged in the shell. One-key operation of cooking can be achieved, no cooking fume, no famous fire and no kitchen waste exist, and full-automatic cleaning is achieved.

Owner:京山京慧智能科技有限公司

Double-seal cup body press type beverage or liquid food self-heating container

PendingCN110254965AImprove experienceEasy to operateContainers for heating foodPackaging foodstuffsEngineeringMechanical engineering

The invention relates to a double-seal cup body press type beverage or liquid food self-heating container and belongs to the technical field of self-heating containers. The bottom of a main tank body of the self-heating container is provided with a cup body and a self-heating packet cup body. The self-heating packet cup body is placed at the very bottom, and an opening of the self-heating packet cup body faces upwards. The cup body is placed on the self-heating packet cup body, and an opening of the cup body faces downwards. A first sealing film and a second sealing film are arranged at the openings of the cup body and the self-heating packet cup body in a sealing mode correspondingly. A poke is arranged in the cup body. The front end of the poke faces the first sealing film at the opening. The double-seal cup body press type beverage or liquid food self-heating container is convenient to open, simple in manufacturing process and convenient to use.

Owner:NANCHANG STEAMING POT TECH DEV

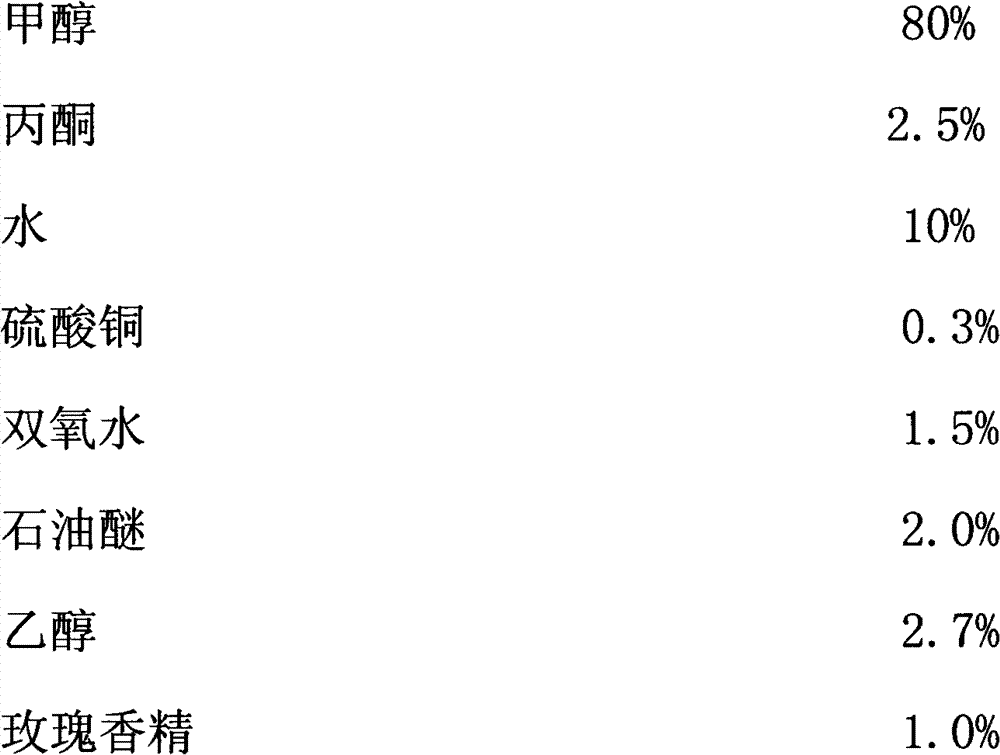

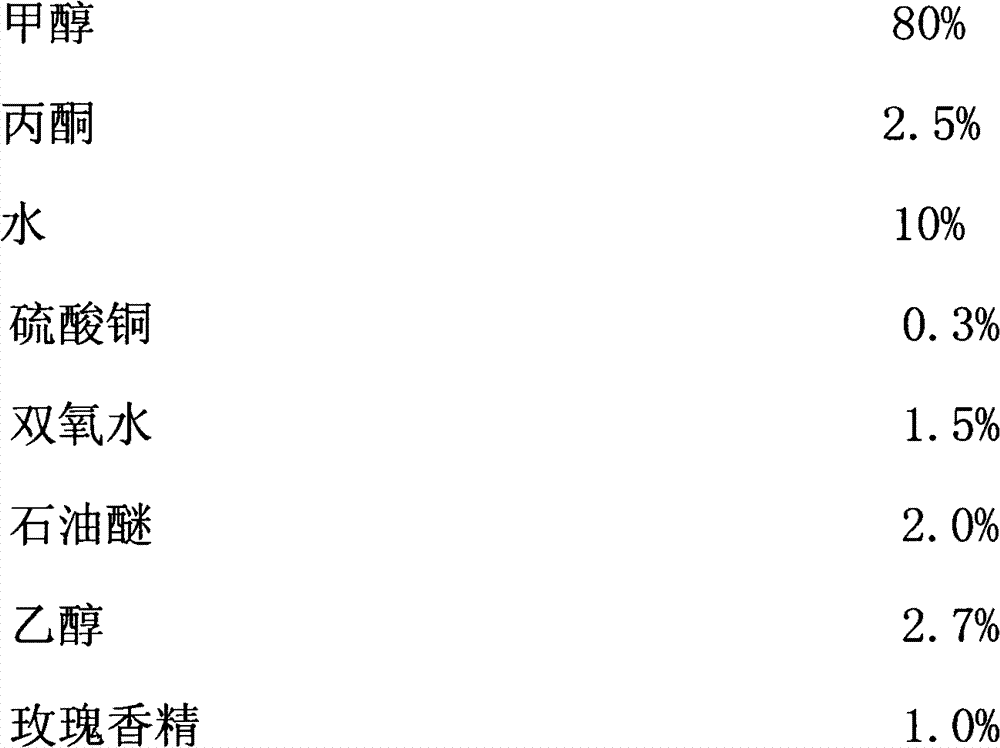

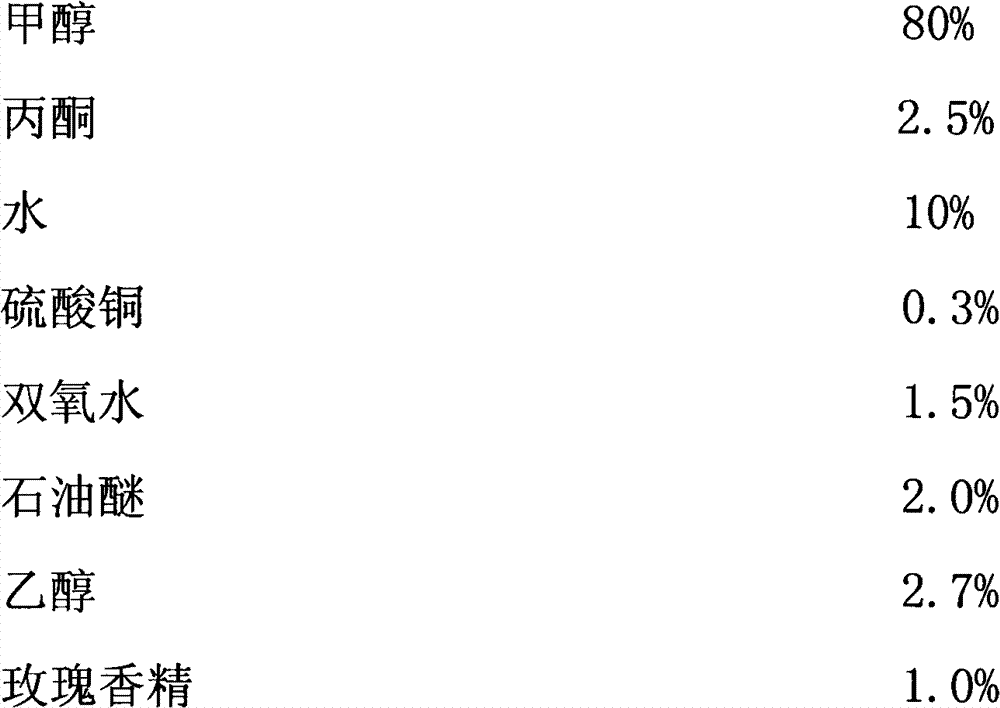

High-energy alcohol-based fuel oil

InactiveCN103710053AHigh flame temperatureReduce consumptionLiquid carbonaceous fuelsAlcoholCombustion

The invention discloses a high-energy alcohol-based fuel oil, which is formed by the following steps: adding a synthesizing fuel additive in methanol with purity of 90-95%, and then stirring and standing, wherein the main raw material methanol in the fuel oil is mixed with other ingredients at a time. The high-energy alcohol-based fuel oil has the beneficial effects of low cost, good combustion effect and wide application.

Owner:天津滨海新区金火焰科技有限公司

Water-air-water quenching heat treatment process for T10 steel screw taps for machines

InactiveCN104726650ANo harm to healthNo fumesFurnace typesHeat treatment furnacesPhysical healthEconomic benefits

The invention relates to a water-air-water quenching heat treatment process for T10 steel screw taps for machines. The water-air-water quenching heat treatment process includes steps of 1), heating the screw taps for the machines, preserving heat of the screw taps and austenitizing the screw taps for the machines; 2), quenching and cooling the screw taps in water media; 3), taking the screw taps out of water and cooling the screw taps in air; 4), cooling the screw taps in water media until the temperatures of the screw taps reach the room temperature; 5), shifting the screw taps for the machines into tempering furnaces and carrying out tempering heat treatment on the screw taps for the machines; 6), cooling the screw taps for the machines by air until the temperatures of the screw taps for the machines reach the room temperature. Compared with the traditional process, the water-air-water quenching heat treatment process has the advantages that the water-air-water quenching heat treatment process is free of lampblack or fire hazards or harm to the physical health of operators and is low in medium cost and high in economic benefit; international service standards can be completely met by the treated screw taps for the machines, the surface hardness of the screw taps for the machines can reach 61HRC at least, the hardness of cores of the screw taps for the machines can reach 50HRC at least, the toughness of the screw taps for the machines can be improved as compared with conventional heat treatment, the service lives of the screw taps for the machines can be prolonged as compared with the conventional heat treatment, and deformation and cracking of the screw taps for the machines can be greatly reduced.

Owner:WUHAN UNIV OF TECH

Production method of refined soybean oil

InactiveCN104830521AMeet the requirements of practical essential oilsNo fumesFatty-oils/fats refiningEssential-oils/perfumesSOYBEAN SEED OILEdible oil

The invention provides a production method of refined soybean oil, and belongs to the technical field of edible oil processing. The production method comprises the steps of coarse filtering, heating, acid refining to remove colloid, alkali refining to remove acid, primary centrifugal separating, secondary centrifugal separating, drying, discoloring, filtering, discolored oil refining, deodorizing, and deodorized oil refining. The erucic acid and phosphatide contents of the refined soybean oil prepared by the provided production method are both qualified, moreover, the refined soybean oil does not generate oil smoke at a high temperature, and thus the refined soybean oil can be used to high-temperature cooking modes such as frying, stir frying, and the like.

Owner:广西明华晟粮油科技有限公司

Flavor mountain delicacy meat rice and preparation method thereof

InactiveCN106333228AGood protectionPrevent high blood pressureFood ingredient functionsMushroomStar Anises

The invention discloses flavor mountain delicacy meat rice and a preparation method thereof; the flavor mountain delicacy meat rice is prepared from the following component raw materials in parts by weight: 500-1500 parts of rice, 20-30 parts of mushroom, 40-60 parts of meat, 1-3 parts of Chinese prickly ash, 2-4 parts of star anise, 1-3 parts of cassia bark, 0.5-1.5 parts of bay leaves, 4-6 parts of ginger, 40-60 parts of dried bean curd, 2-4 parts of salt, and 4-6 parts of soy sauce. The preparation method comprises the steps: cutting the meat into cubes, boiling for 3-5 minutes, and pouring the meat water away; adding boiling water, continuing to boil for 5-12 minutes, and adding the broth into the raw materials of rice, mushroom, Chinese prickly ash, star anise, cassia bark, bay leaves, ginger, dried bean curd, salt and soy sauce; continuing to boil for 5-12 minutes, boiling to be 60% cooked, mixing the rice material evenly, and adding boiling water to be 1-3 cm greater than the height of a rice layer; and cooking to boil with a pot, then stirring for one time and covering a pot or steaming, and carrying out sealed heating for 15-25 minutes. The food prepared by the preparation method has the advantages of rich nutrition and strong and unique flavor.

Owner:矫健

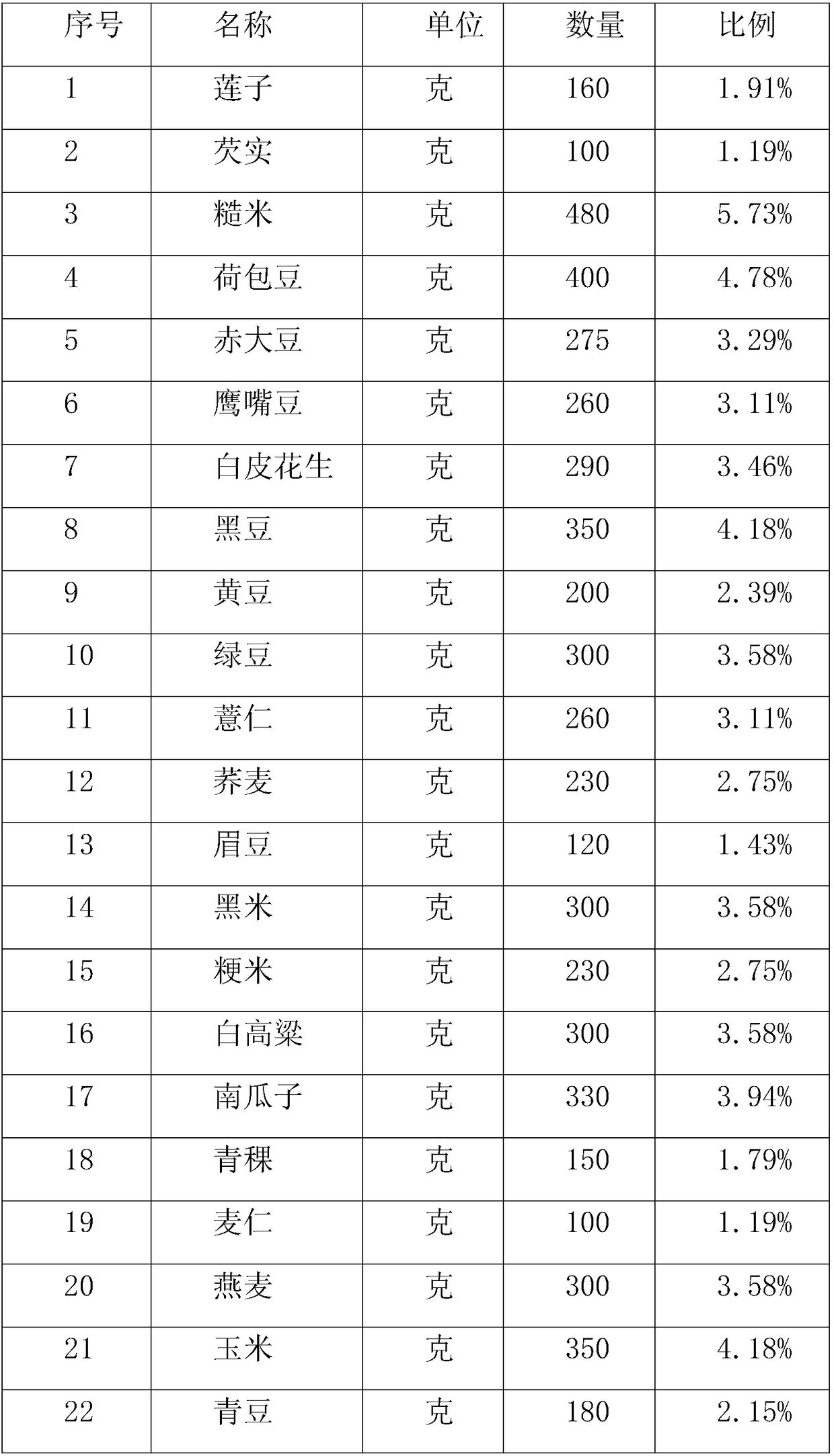

Making method of holographic nutritious food

InactiveCN108783198AProportional balanceImprove absorption and utilizationLipidic food ingredientsFood ingredient functionsWarm waterFood material

The invention discloses a making method of holographic nutritious food. The method includes a phase of food material preparation and a phase of nutritious food making. The phase of food material preparation includes soaking, cooking and packaging of food materials in sequence, wherein the soaking is to repeatedly wash coarse grains with clear water, soak the coarse grains with warm water after thewashing, wash the coarse grains again when the clear water is turbid and soak the coarse grains with warm water until mung beans sprout, the cooking is to put the soaked coarse grains into an electric rice cooker, add water according to a ratio of 1:1 by volume and cook until the water is dried, and the packaging is to cool the cooked food materials, equally divide the food materials according toneeds, package by using fresh-keeping bags and put the food materials into a freezing chamber of a refrigerator for storage for later use. The phase of nutritious food making includes the following steps: taking a proper amount of the frozen food materials, adding the food materials into a stirring cup of a food machine after the food materials are thawed, adding hot water, a proper amount of teaseed oil, banana pieces and apple pieces, and then stirring into paste. The beneficial effects of the making method are that the material taking is convenient, the nutrition is comprehensive and balanced, the making is convenient and fast and the making cost is low.

Owner:三早(上海)健康管理咨询有限公司

Method for processing Polyodonspathala

The invention discloses a method for processing Polyodonspathala and belongs to the technical field of food processing. The Polyodonspathala food is prepared from Polyodonspathala, pleurotus eryngii, fresh mushrooms, red pimento, yellow pimento, green pimento, black fungus, ginger bud, garlic, chilli sauce, oyster sauce, table salt, sugar, taurine, fish soup powder, chicken extract, soup-stock, water starch, Guilin Sanhua liquor, EM original dew and tinfoil. The microbial EM original dew can remove a fishlike smell and odor of Polyodonspathala, eliminate harmful micro-organisms, resists decay and retains freshness. The use of acupuncture, salting and mechanical dehydration, excess water of the Polyodonspathala can be removed at the highest degree. The method does not damage skin, makes fish firm and delicious and improves quality. Compared with the traditional high oil consumption processing methods such as frying and baking, the method using tinfoil and an oven does not produce oil fume, reduces pollution, utilizes less oil, is free of carbon fire so that carcinogenic substances are avoided, does not damage Polyodonspathala nutrients, improves food quality, is good for health and realizes a unique and vivid food shape.

Owner:FOSHAN SHUNDE BAOTONG METAL TECH

Water molecule cooking cabinet

PendingCN111671296AWon't happenWill not polluteSteam cooking vesselsChemical/physical/physico-chemical processesEnvironmental engineeringElectromagnetic heating

The invention discloses a water molecule cooking cabinet, which comprises a supporting frame, wherein a distribution box is mounted on the left side in the supporting frame; an electromagnetic heatingpower supply is arranged in the distribution box; a balance water tank and a boiler are arranged at the bottom part in the supporting frame; the balance water tank is communicated with the boiler through a first communicating pipe; a water molecule generator is arranged above the boiler in the supporting frame; an air inlet end of the water molecule generator is fixedly communicated with the boiler through a second communicating pipe; a cooking cabin assembly is fixed to the top part of the supporting frame; an air outlet end of the water molecule generator is communicated with the cooking cabin through a third communicating pipe; and the water molecule generator is electrically connected with the electromagnetic heating power supply. The water molecule cooking cabinet has the advantagesof labor saving, no oil smoke, no environmental pollution, high cooking speed, high efficiency and the like.

Owner:深圳市日亿升实业有限公司

Mineral-oil-based high-temperature chain oil and preparation method thereof

Owner:SHANDONG YUANGEN PETROLEUM CHEM

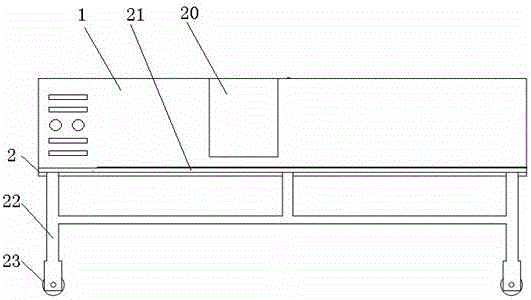

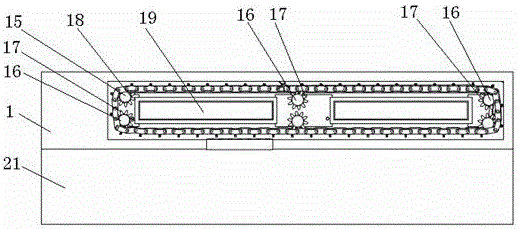

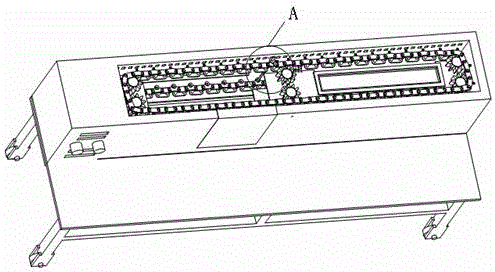

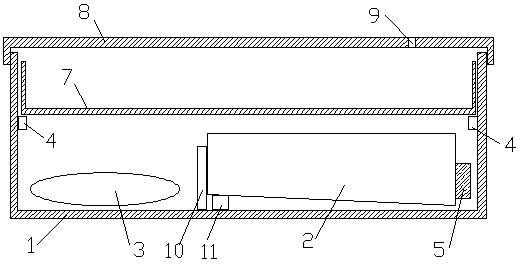

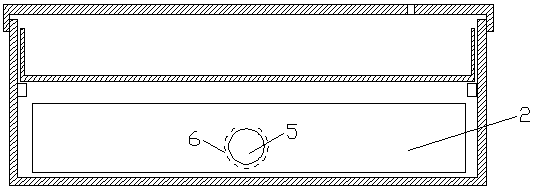

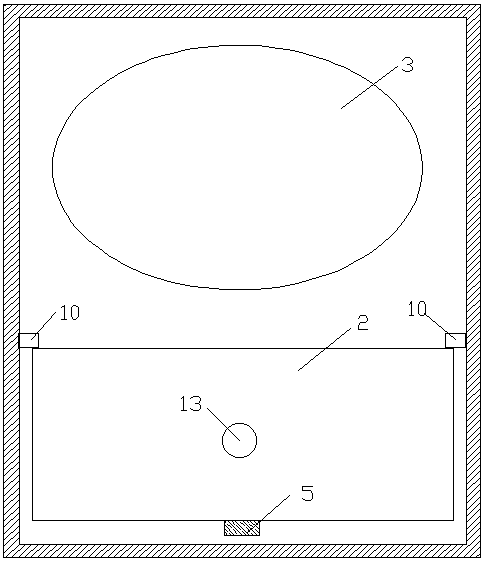

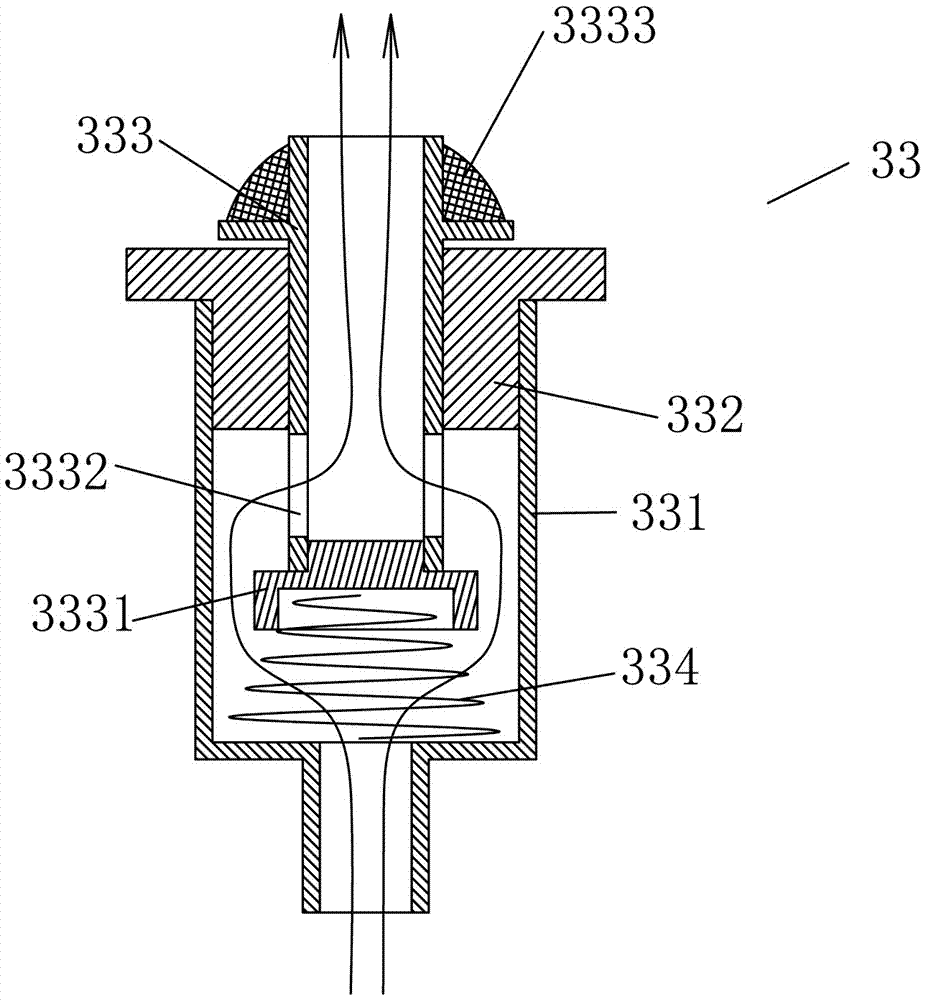

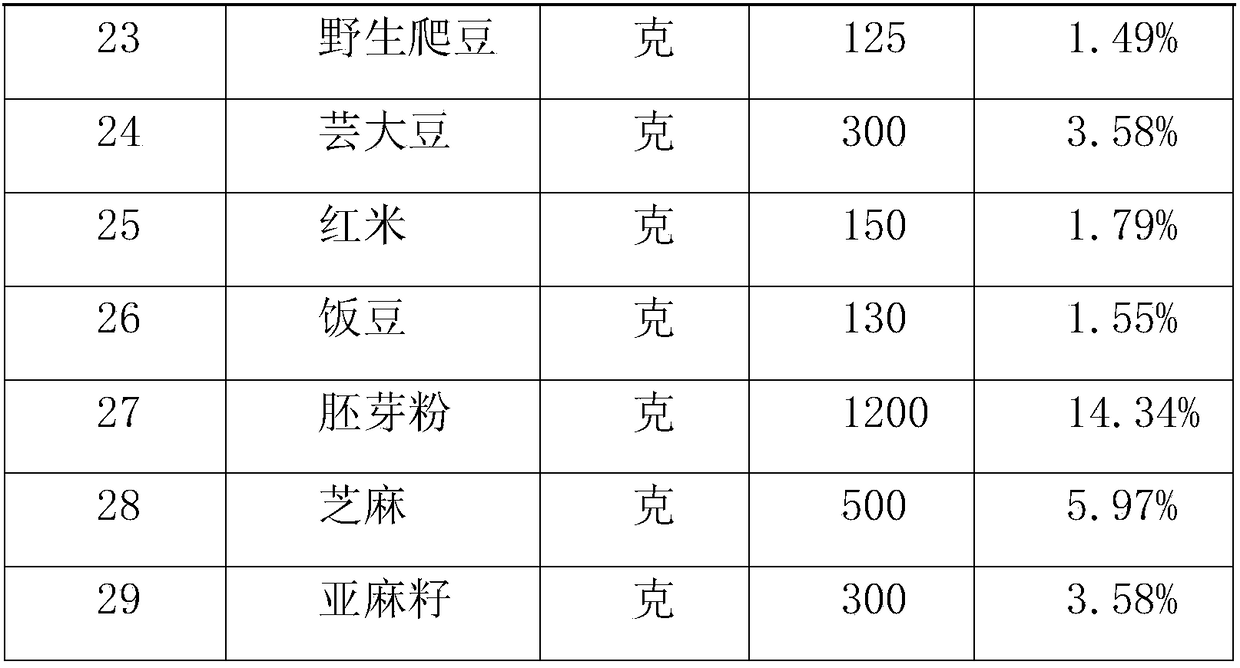

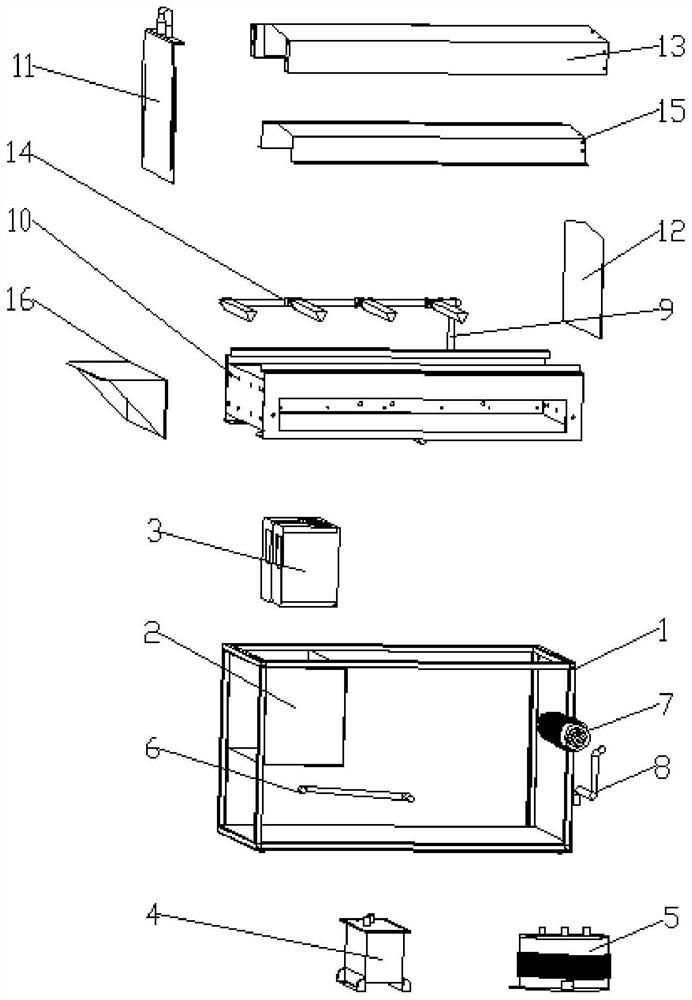

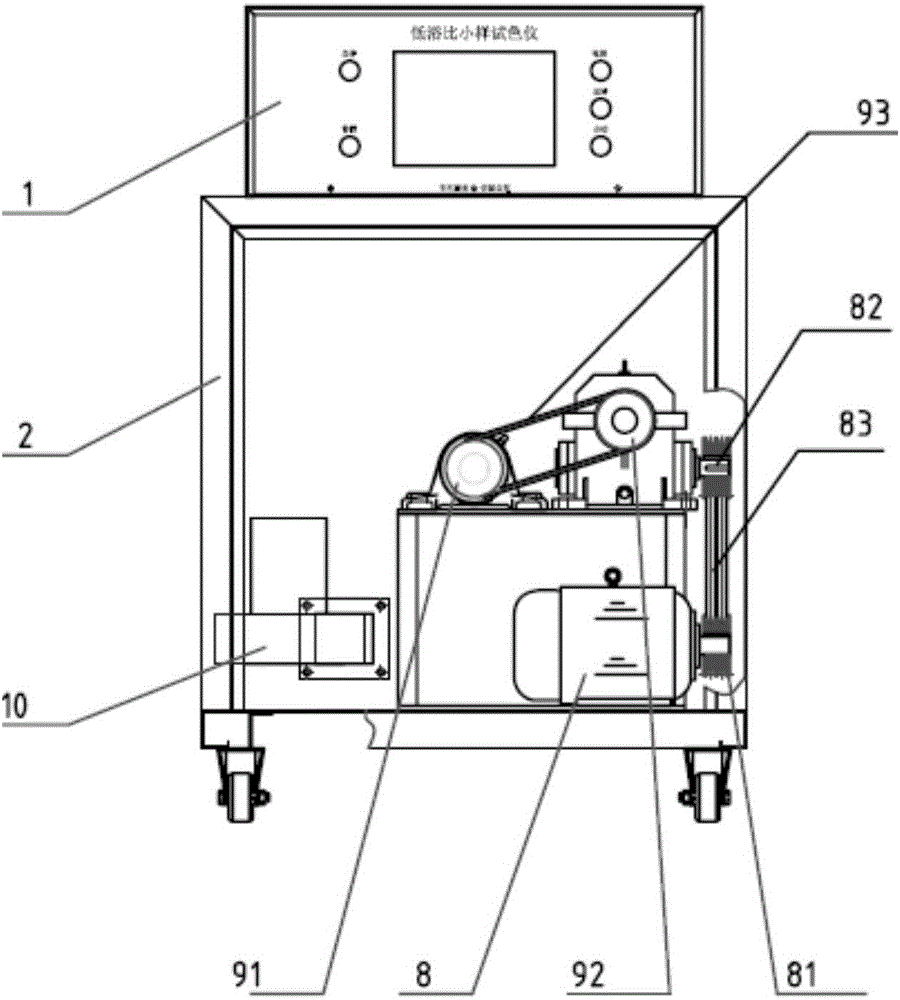

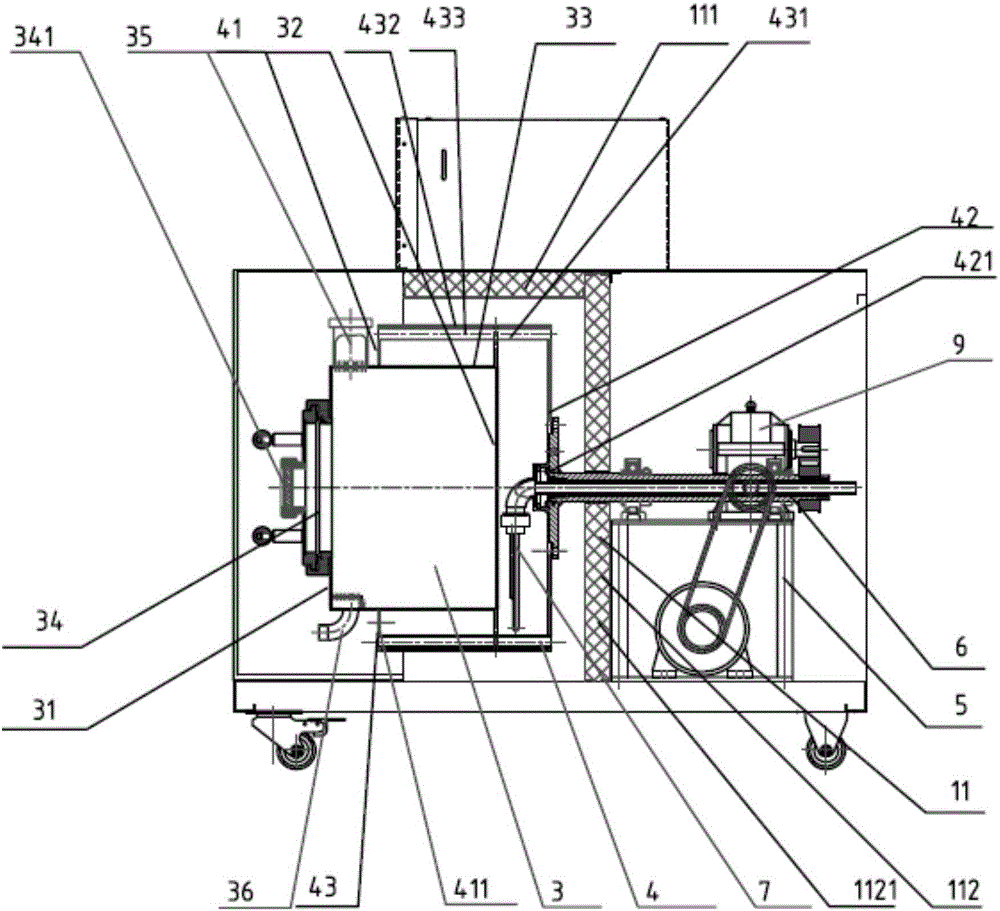

Low-bath ratio sample color test instrument

PendingCN106835571AReduce the amount of dye solutionSmall footprintTextile treatment dyeing devicesTextile treatment machine arrangementsEngineeringColor test

The invention relates to a low-bath ratio sample color test instrument, which comprises a control device and a machine body, wherein the control device is arranged on the machine body and fixedly connected with the machine body; a dye vat, a dye vat outer cage, a fixed mechanism, a transmission mechanism and a heating mechanism are arranged in the machine body; the dye vat is laterally inserted into the groove of the dye vat outer cage and fixedly connected with the dye vat outer cage; the fixed mechanism comprises a fixed frame; the transmission mechanism is fixedly connected with the machine body through the fixed frame; one end of the rotating shaft is fixedly connected with the dye vat outer cage and the other end is connected with the transmission mechanism; when the transmission mechanism drives the rotating shaft to rotate, the rotating shaft drives the dye vat to rotate; the heating mechanism comprises a heater and heat-conducting oil; the heater is electrically connected with the control device; and the heater and the heat-conducting oil are arranged in the dye vat outer cage. The low-bath ratio sample color test instrument is compact in structure and good in heating effect; the quality of a product is ensured; the cost is reduced; and the production efficiency is improved.

Owner:JINGJIANG HUAXIA TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com