Patents

Literature

86results about How to "Realize fully automatic cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

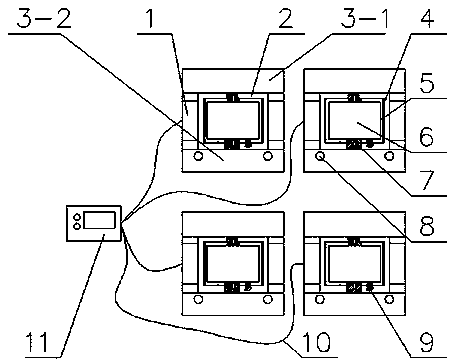

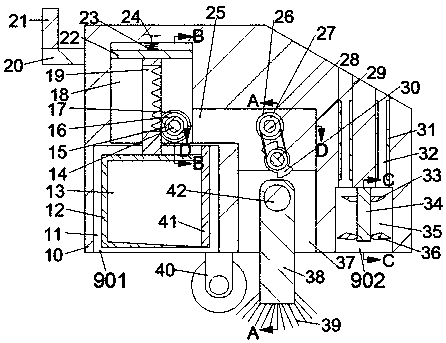

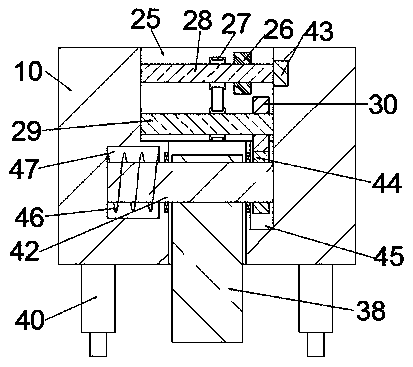

Tea table capable of automatically cleaning teacups

InactiveCN102772016ABlock water splashBlock sound insulationTableware washing/rinsing machine detailsServing tablesMechanical engineeringWater supply

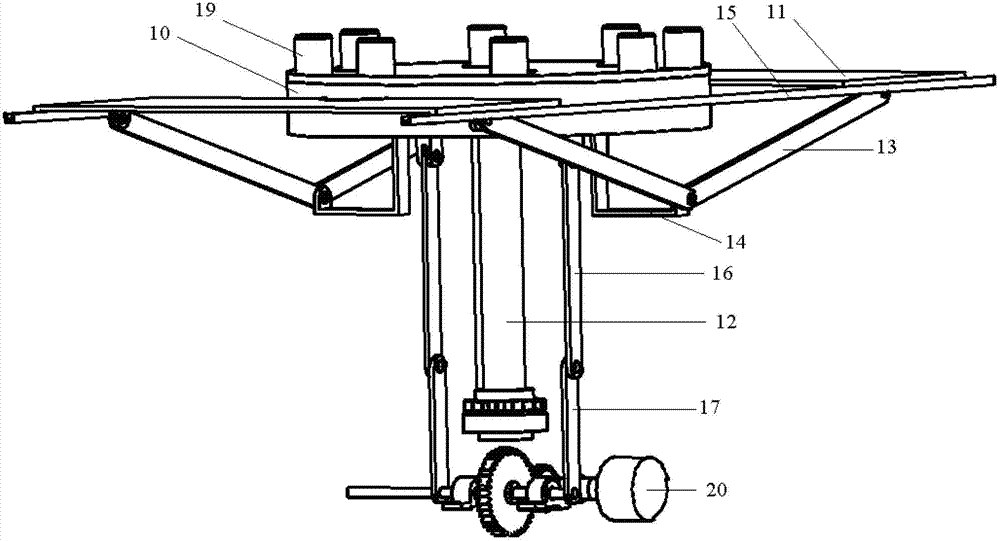

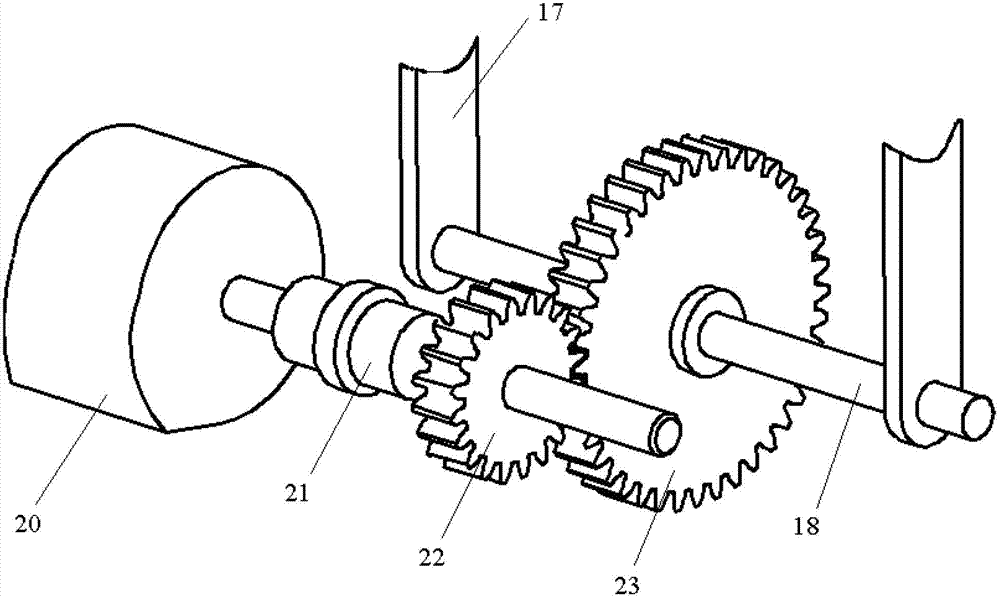

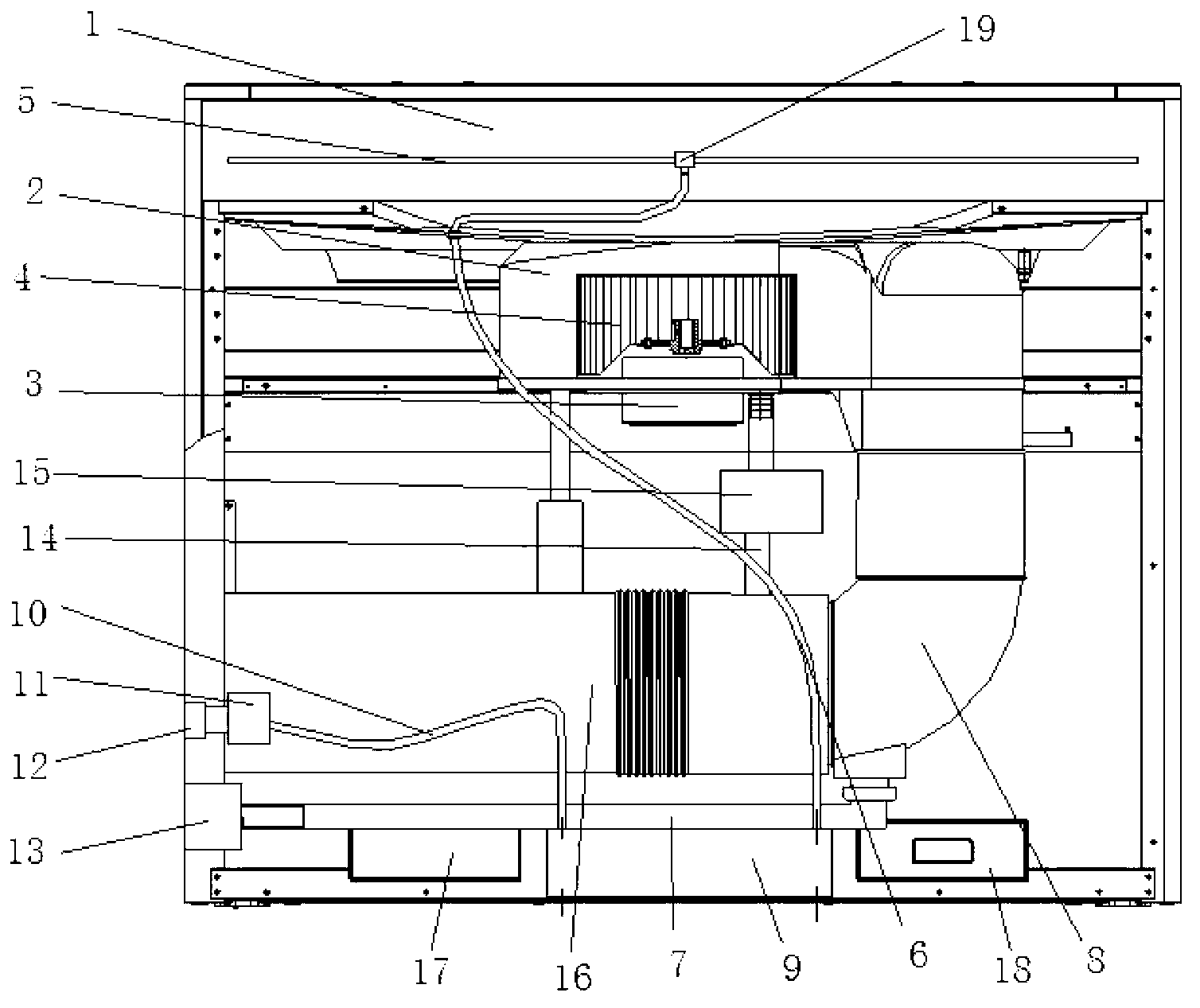

The invention relates to a tea table capable of automatically cleaning teacups and belongs to the technical field of leisure products. The existing frame-type cup washing machine actually is a semi-artificial teacup washing device and cannot implement the full-automatic cleaning of the teacups; and when the teacups are placed into cleaning stations and held by adopting a manual mode, the teacups are easy to damage due to collision and impact. The tea table is characterized by consisting of the following two parts: 1, a tea tray and tea table surface mechanism and 2, a cleaning mechanism, wherein the tea tray and tea table surface mechanism comprises a tea tray lifting and tea table surface translation mechanism and a tea tray rotating mechanism; and the cleaning mechanism comprises a clamping mechanism, a washing mechanism and a water supply and drainage system. According to the invention, the full-automatic cleaning of the teacups is implemented, so that people are released from the labor at the leisure; meanwhile, the teacups are avoided being damaged in the cleaning process; the teacups are washed more clean; and the integration of two purposes into the teacup cleaning device is implemented, i.e. the tea table has the following two working states: 1, a working state of cleaning the teacups; and 2, a working state as the tea table.

Owner:CHANGCHUN UNIV OF SCI & TECH

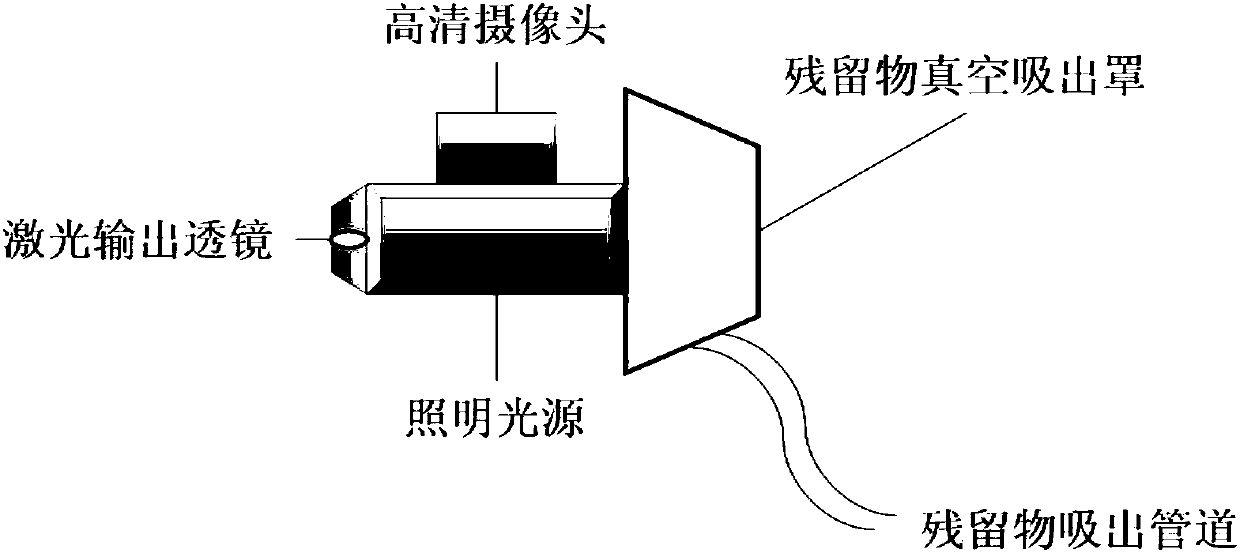

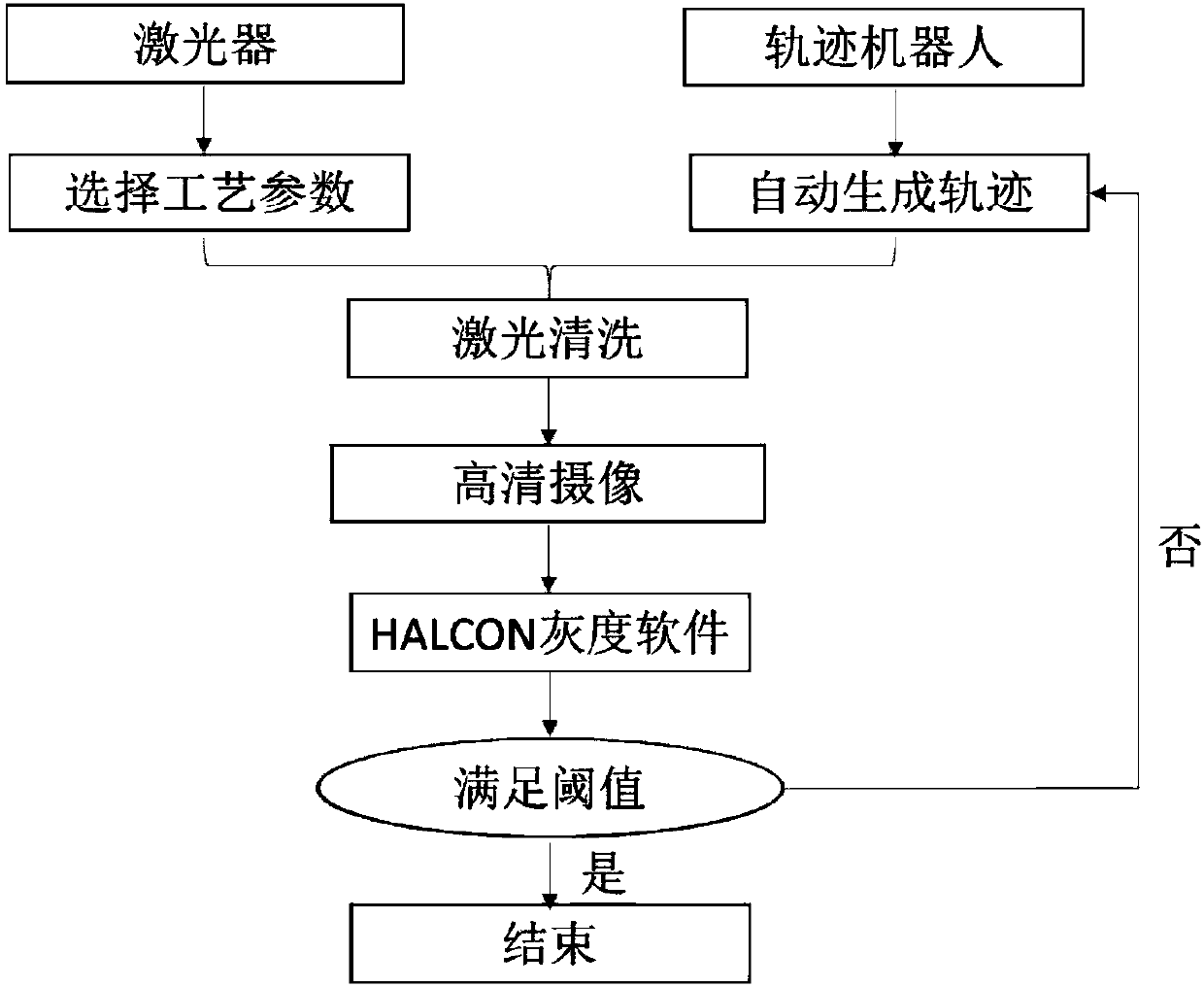

Automatic online laser cleaning device for large cavity inner wall dirt and method thereof

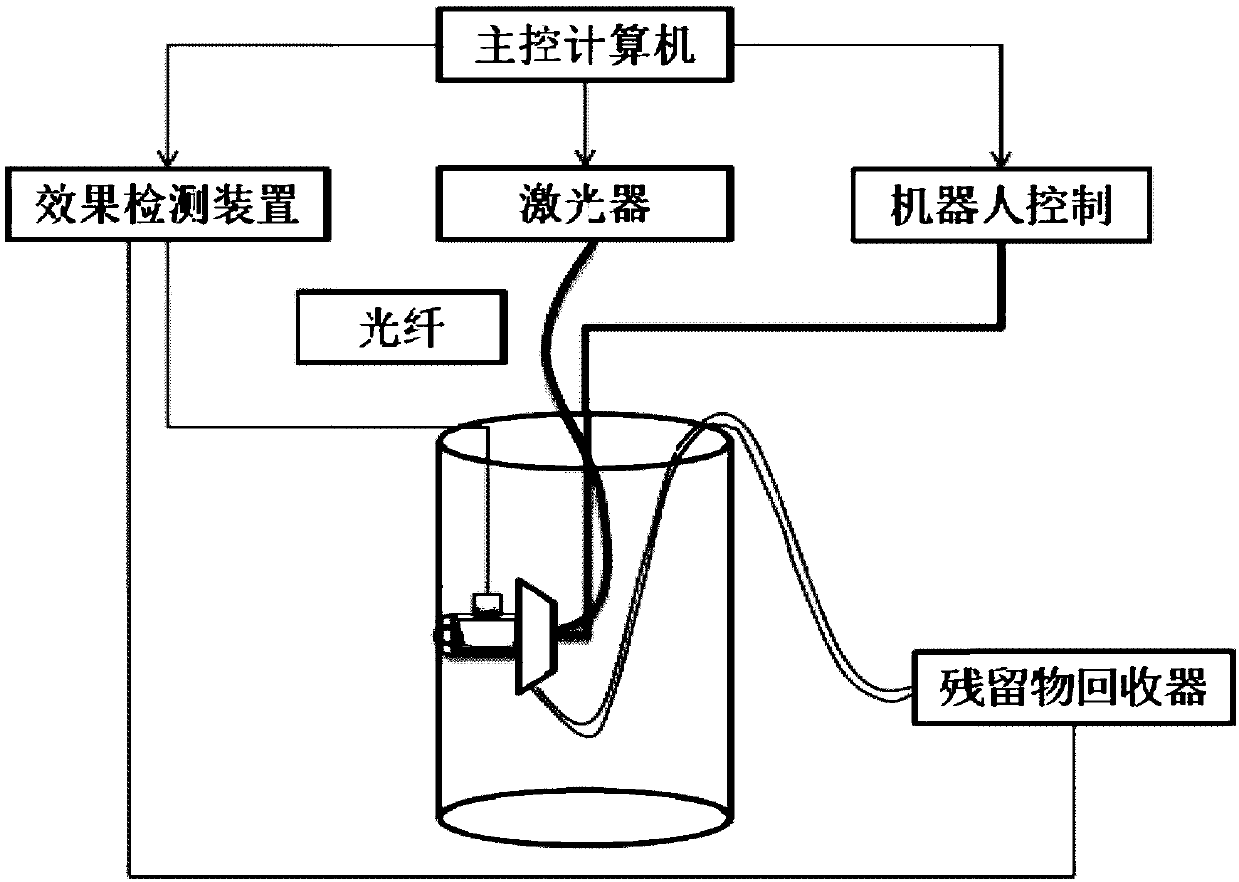

InactiveCN107931251AGood stabilityGood cleaning effectLaser beam welding apparatusCleaning processes and apparatusEngineeringLaser

The invention relates to an automatic online laser cleaning device for large cavity inner wall dirt. The device comprises a main control computer, and a laser, a robot and an effect monitoring deviceconnected with the main control computer; the tail end of the robot is fixedly connected with a laser head of the laser; the effect monitoring device is arranged on the laser head of the laser; the main control computer obtains a machining cleaning motion trajectory of the inner wall surface of a cavity according to a model of the cavity, then, controls the robot to enable the laser head to move in the cavity along the motion trajectory, and meanwhile, controls the laser head to emit laser to the inner wall of the cavity to realize laser cleaning; and images are sent to the main control computer. The device is excellent in stability and obvious in cleaning effect, improves the cleaning efficiency, and saves the time.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

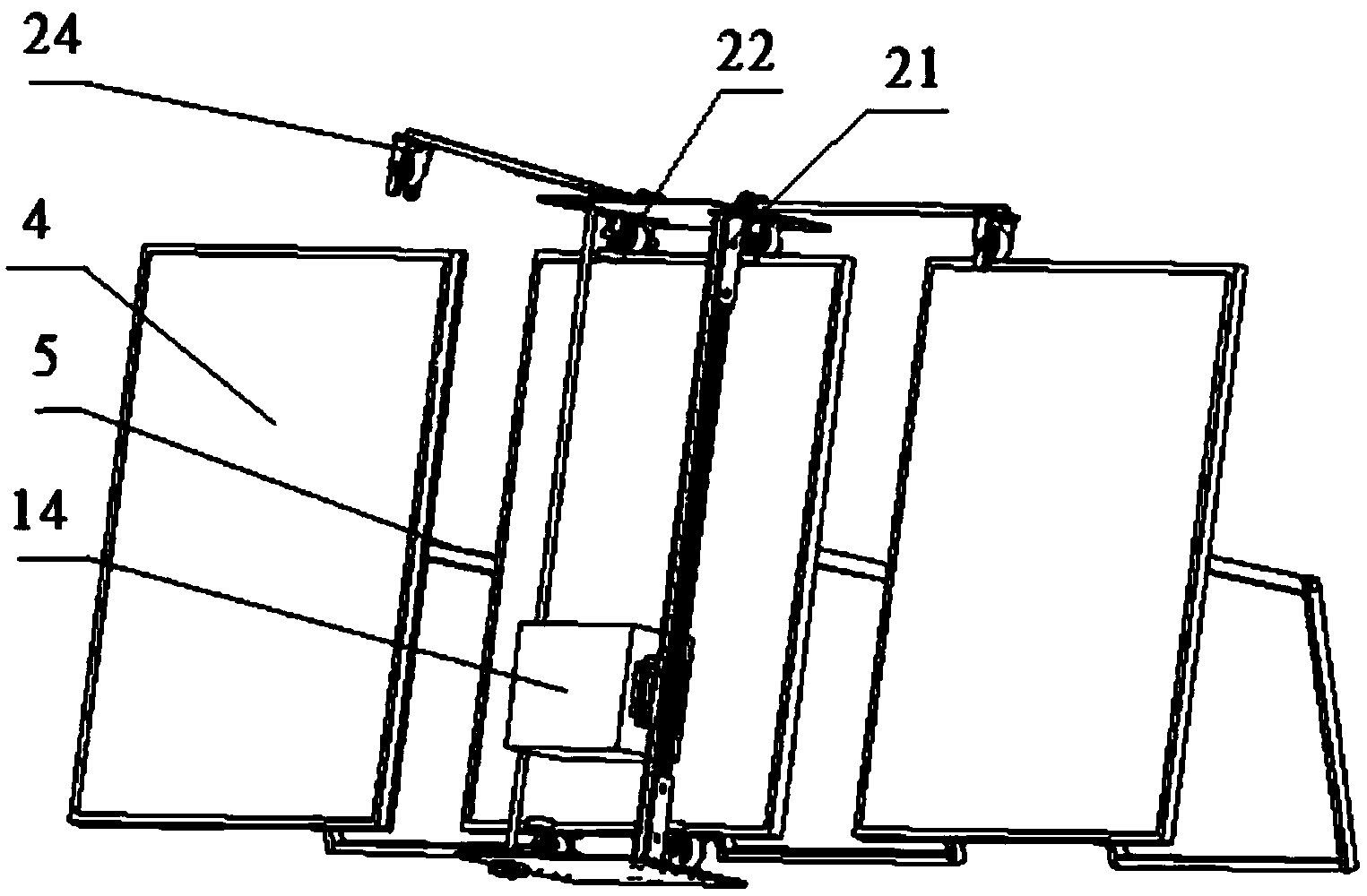

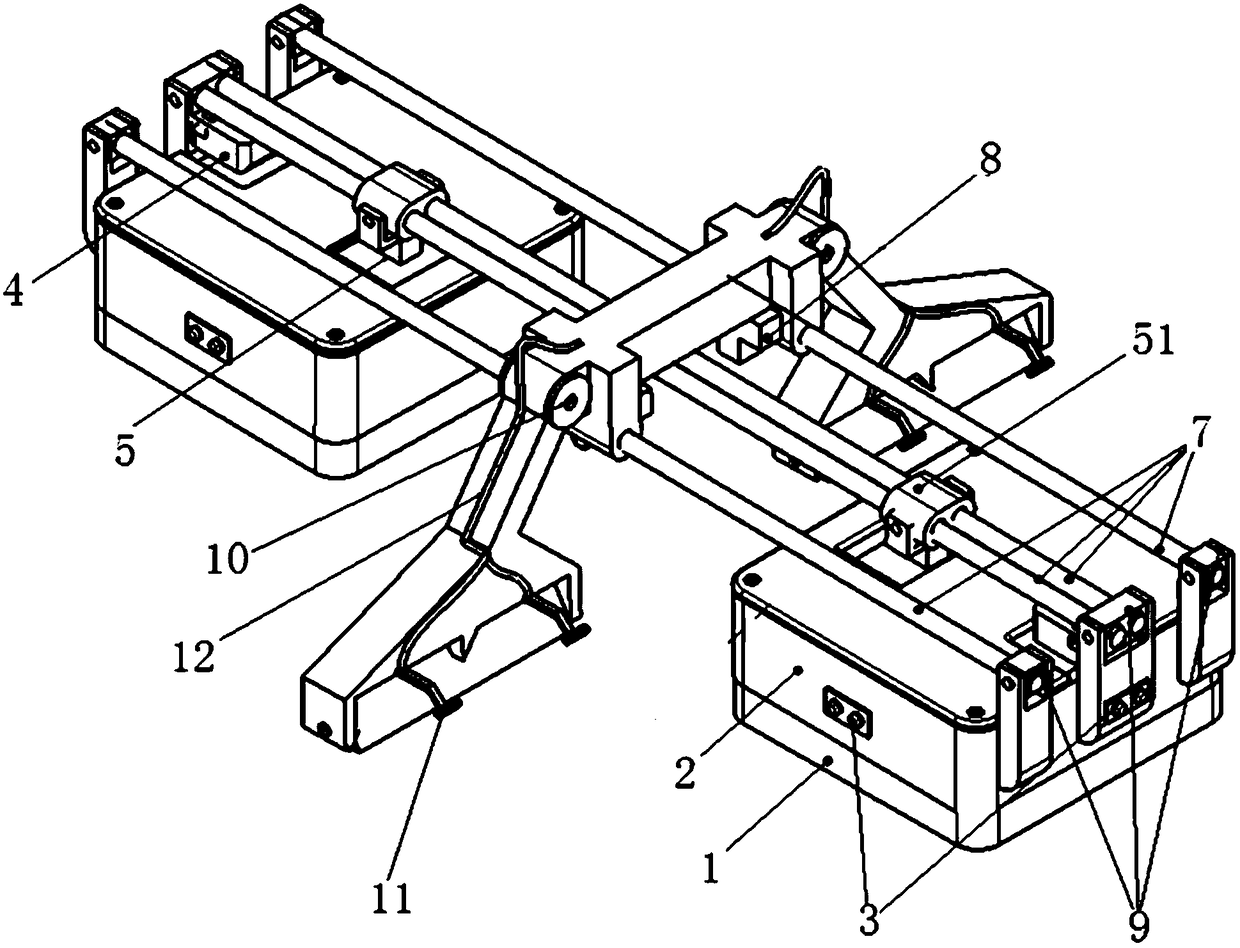

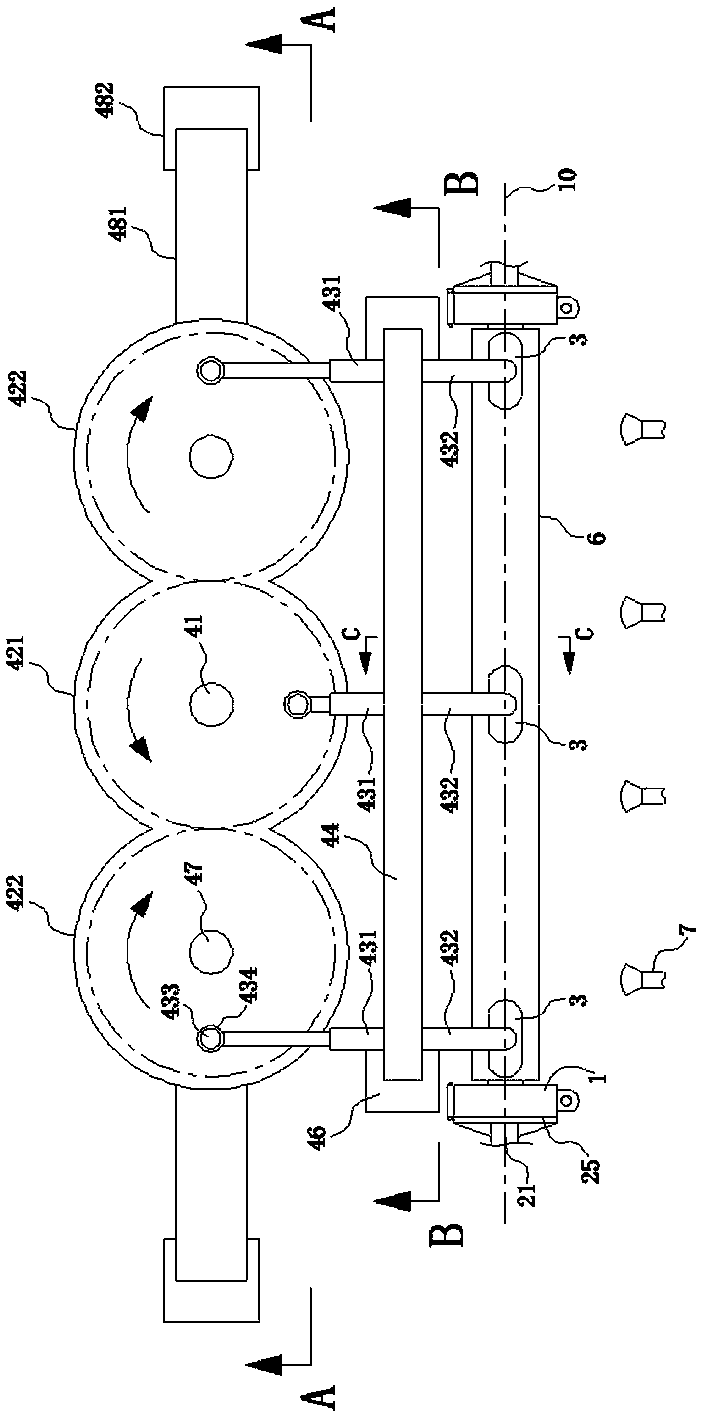

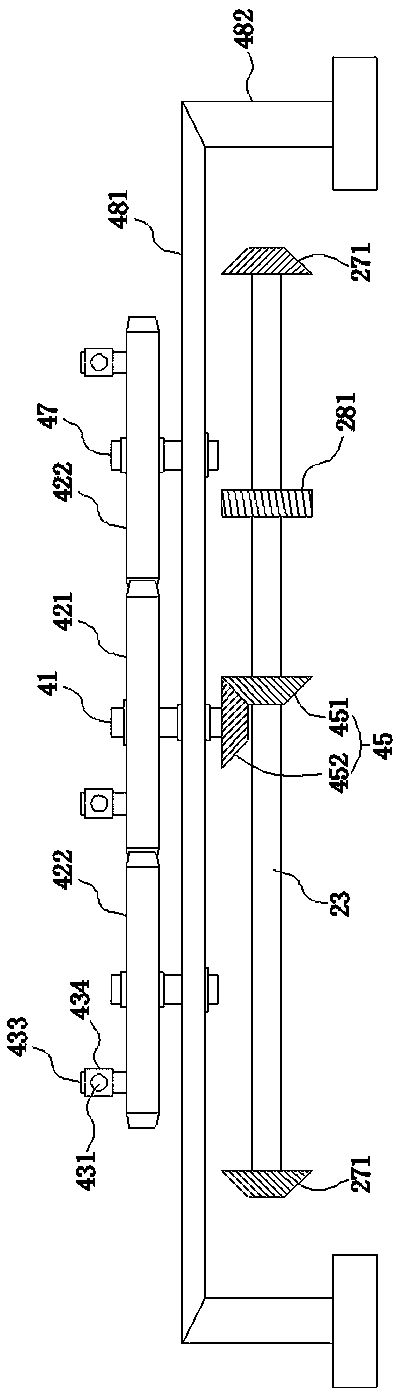

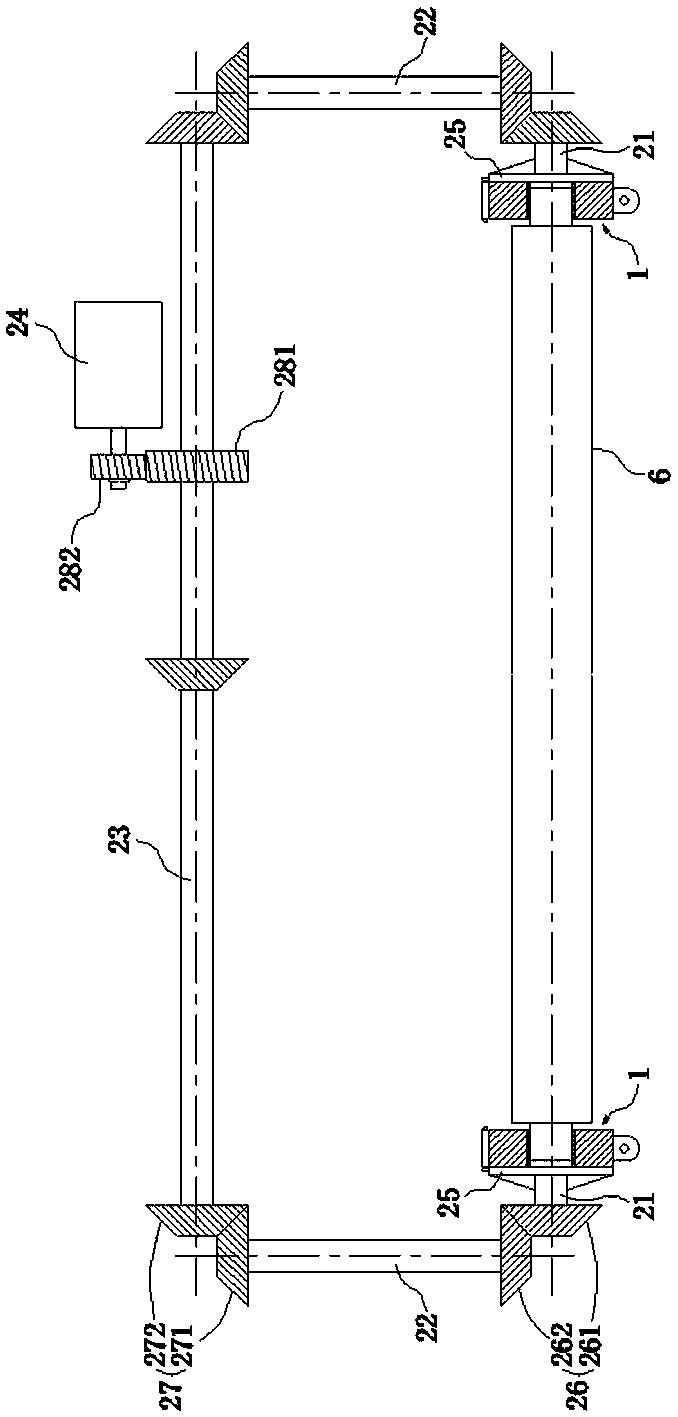

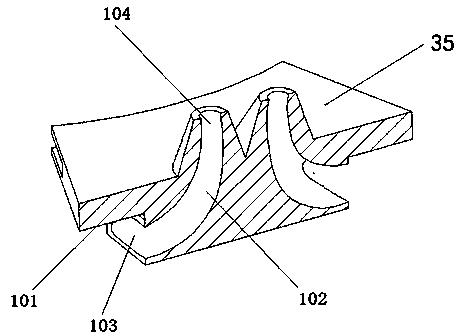

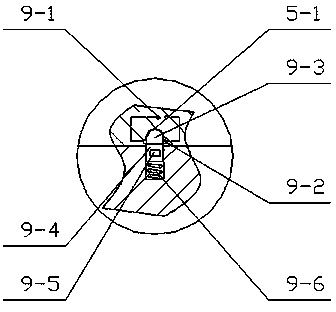

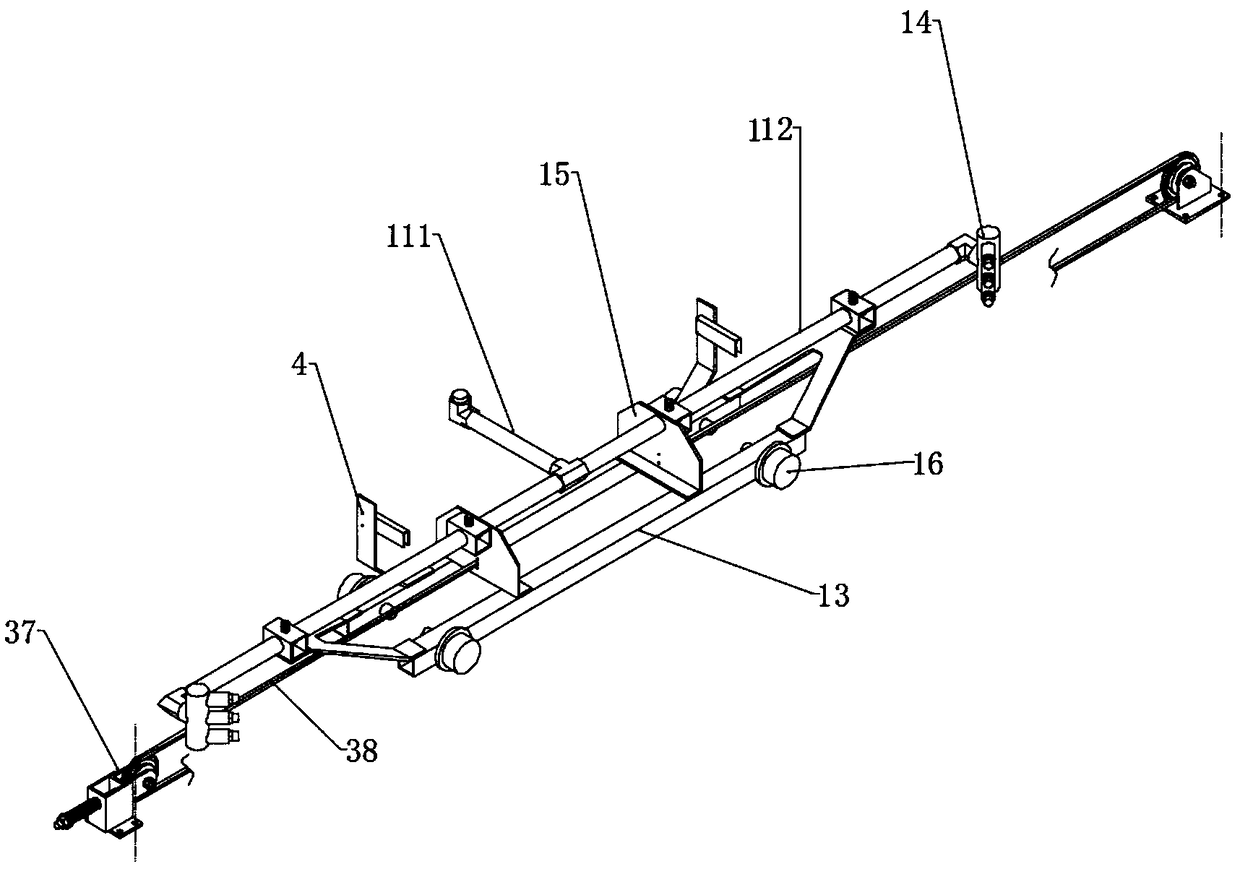

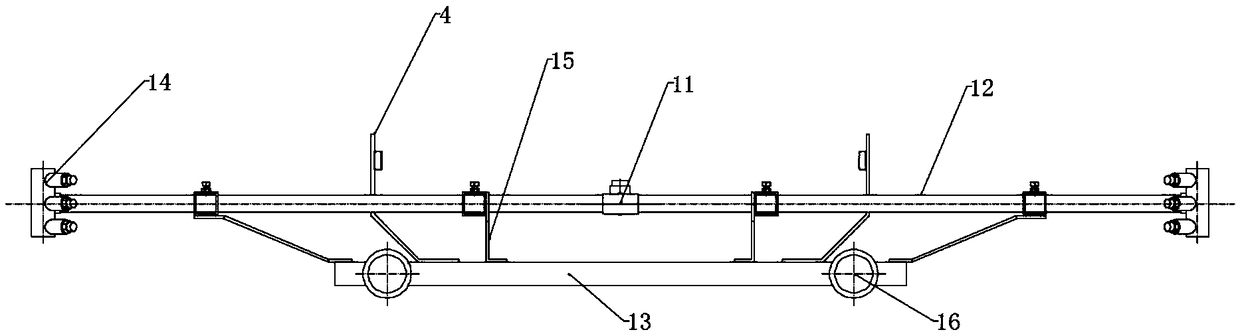

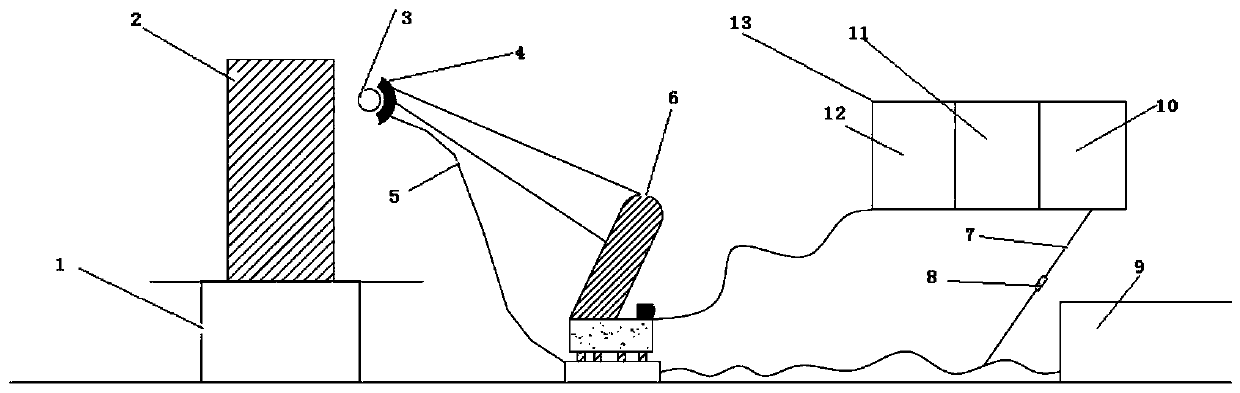

Device and method for cleaning multiple rows of photovoltaic cell panel groups

InactiveCN103878130ARealize fully automatic cleaningTo achieve the purpose of cross-row cleaningCleaning using toolsCells panelDrive wheel

The invention relates to a device and a method for cleaning multiple rows of photovoltaic cell panel groups, and belongs to the field of cleaning for photovoltaic cell panels. The device for cleaning the multiple rows of photovoltaic cell panel groups comprises a cell panel dust removing and cleaning mechanism, a water supplying mechanism and a traveling mechanism. The traveling mechanism comprises a top plate and traveling wheels, the top plate is elastically fixedly suspended on a main framework, the traveling wheels are arranged among the upper end surfaces of photovoltaic cell panels or a bottom plate and the lower end surfaces of the photovoltaic cell panels and comprise driving wheels, driven wheels and crossing wheels, and each two crossing wheels are respectively arranged on two sides of the corresponding traveling wheel and are used for forwards or rearwards crossing the corresponding rows of photovoltaic cell panel groups under the control of a controller. The method for cleaning the multiple rows of photovoltaic cell panel groups by the aid of the device includes connecting each two adjacent rows of photovoltaic cell panel groups with each other in an end-to-end manner; arranging three 'y'-shaped photovoltaic cell panels at a joint of each two adjacent rows of photovoltaic cell panel groups; changing rails twice to cross the front and rear rows of photovoltaic cell panel groups so as to clean the photovoltaic cell panel groups.

Owner:ZHENJIANG RUIDE ENERGY SAVING TECH +1

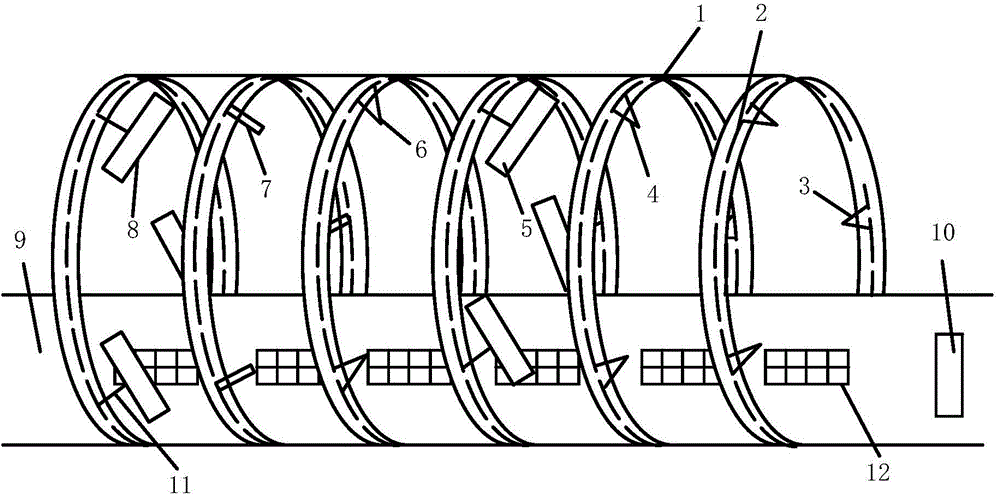

Fully automatic energy-saving car washer

InactiveCN104554186AHigh degree of standardizationRealize fully automatic cleaningVehicle drying apparatusCleaning apparatus for vehicle exteriorsEngineeringFully automatic

The invention discloses a fully automatic energy-saving car washer, comprising an arc-shaped tunnel frame structurally. Six guide rails are arranged on the inner side of the arc-shaped tunnel frame in parallel; three first high pressure nozzles, three cleaning fluid nozzles, three rotating brushes, three second high pressure nozzles, three hot air outlets and three water absorption sponge brush heads are movably arranged in the guide rails in sequence; a conveyor belt is arranged at the bottom of the arc-shaped tunnel frame; a pressure sensor is arranged below the conveyor belt at the inlet of the arc-shaped tunnel frame; and catch basins are arranged at the two sides of the bottom end of the arc-shaped tunnel frame. By adopting the fully automatic energy-saving car washer, the defects in the prior art can be overcome; fully automatic cleaning and drying of a vehicle can be realized by arranging six groups of the cleaning devices which can be regulated flexibly and the pressure sensor which can sense the position of the vehicle automatically; and the degree of standardization is high.

Owner:NINGXIA QIKAI ENERGY SAVING EQUIP

A fully automatic window cleaning robot capable of surmounting obstacles

PendingCN109199209ARealize fully automatic cleaningGet rid of the bondageWindow cleanersEngineeringDistance sensors

The invention belongs to the technical field of automatic window cleaning robot, in particular to a fully automatic window cleaning robot capable of surmounting obstacles, comprising a shell structureand a scrubbing structure. The lower layer is a steering chassis, the upper layer is a main body structure, the main body structure and the steering chassis are connected through a central shaft arranged in the main body structure, the bottom surface of the steering chassis is connected with a suction cup, and the interior of the main body structure is provided with a water supply device, a powersupply device and a steering gear; a distance sensor is arranged outside the main structure. The surface of the shell structure is provided with a motor reduction box, a lifter and a rack fixing device. The invention can automatically plan the cleaning route, automatically identify and surmount obstacles such as window frames, realize automatic cleaning, and feed back working information to usersat any time through an intelligent interactive system, which is more convenient and quick.

Owner:SHENYANG AEROSPACE UNIVERSITY

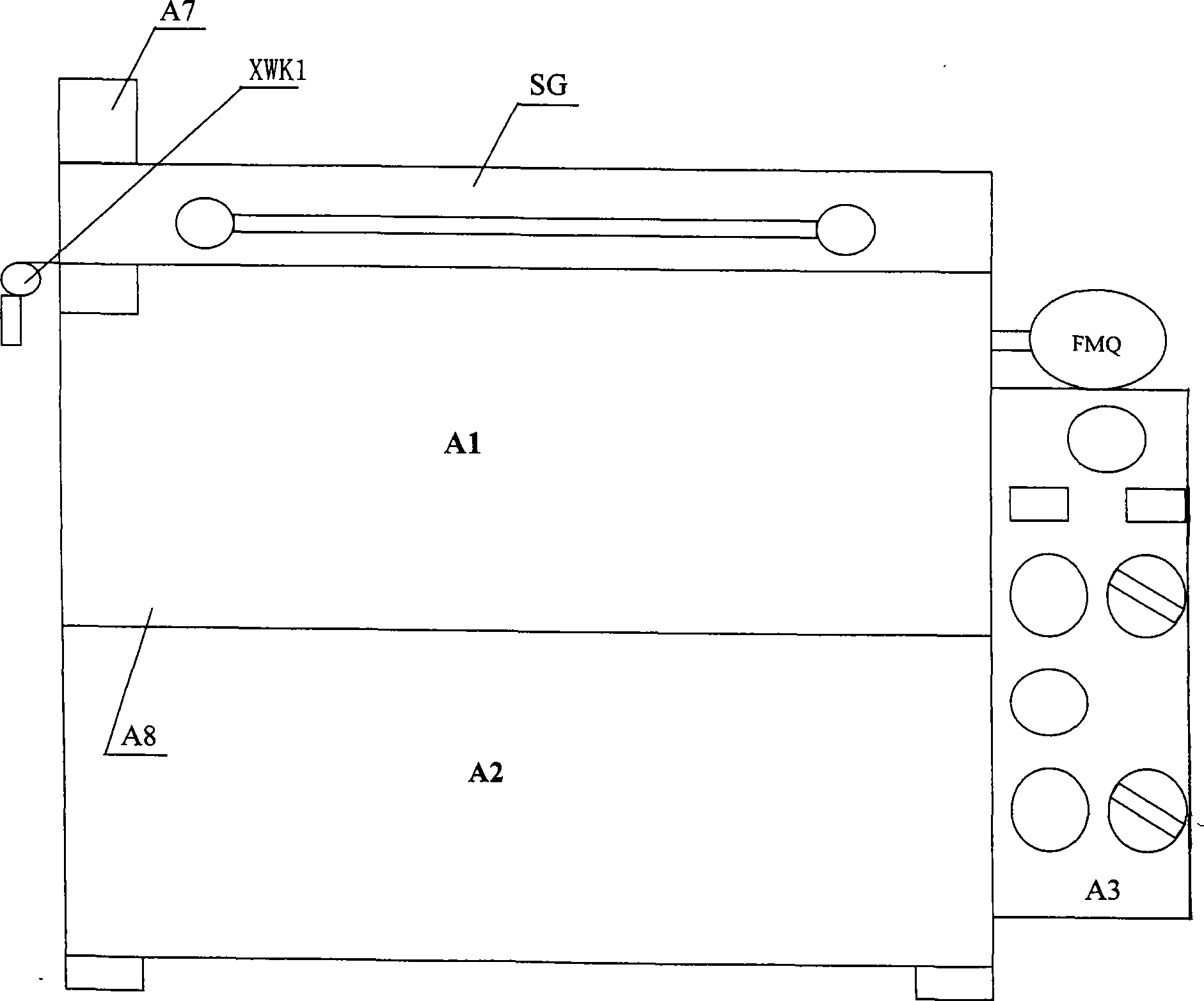

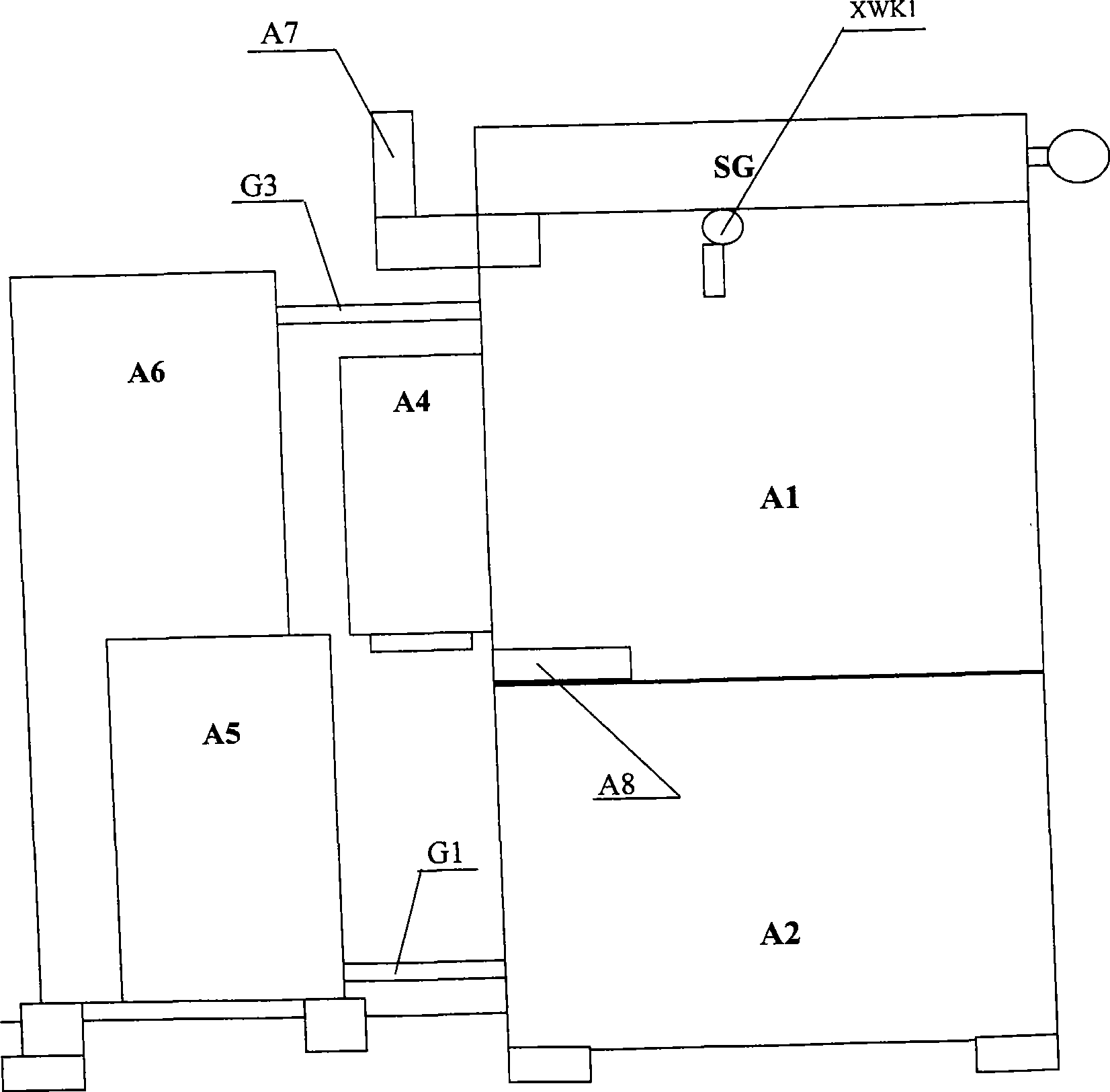

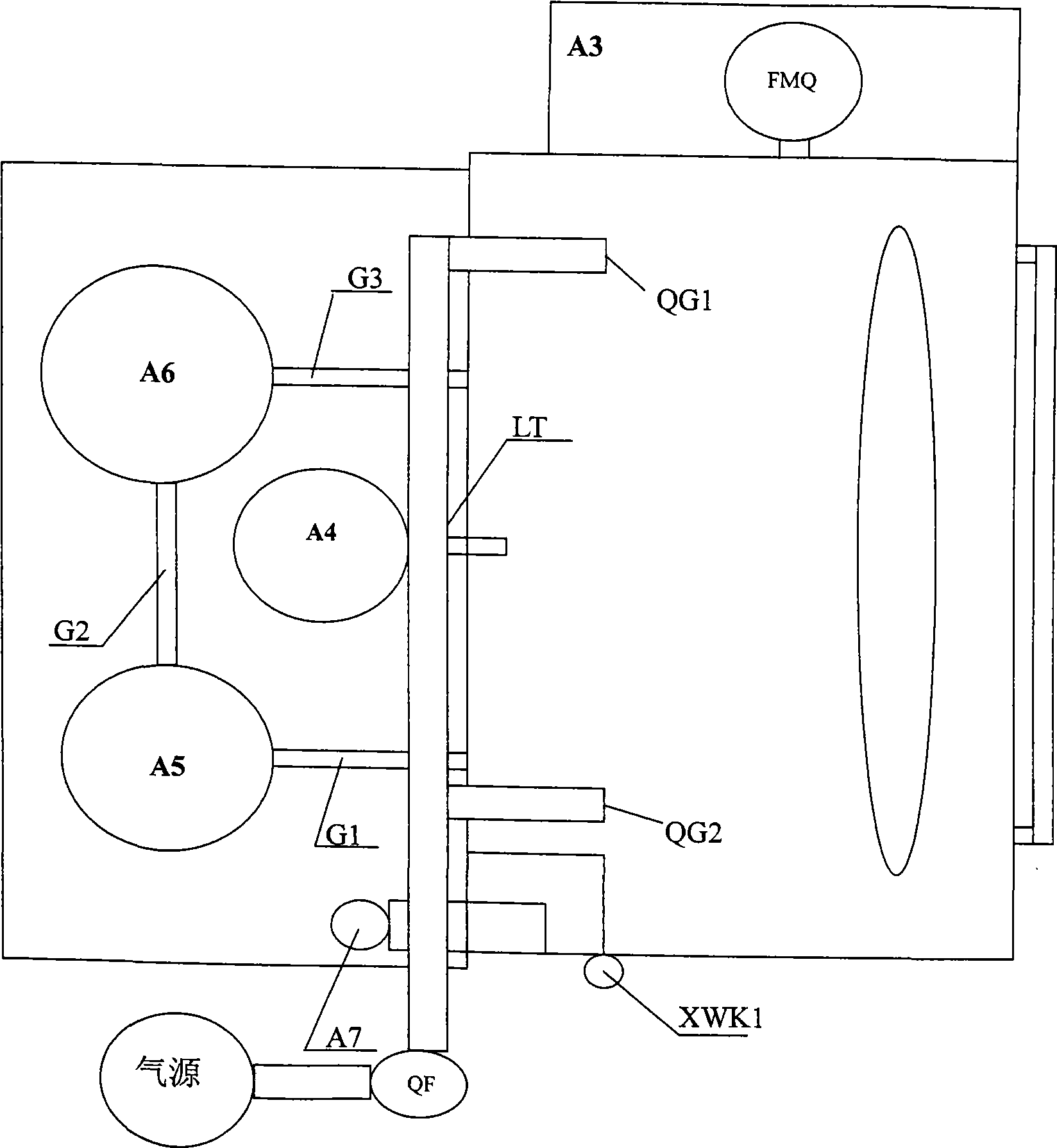

Device and method for cleaning middle shell cavity of automotive turbine supercharger

The invention provides a device and a method for cleaning a middle shell cavity of an automotive turbine supercharger. The invention adopts the technical proposal that the device comprises a cleaning room and is characterized in that a netlike turntable is arranged in the cleaning room, the periphery of the netlike turntable is provided with at least one seat, a first branch pipe on a first pipeline is extended into the cleaning room and connected with a high-pressure oil distributing valve, at least one second branch pipe on the first pipeline is extended into the cleaning room, an electric control air valve is connected with an air pipe, and the end parts of the air pipe are extended into the cleaning room and arranged on the upper part and the lower part of the netlike turntable respectively. The method comprises: putting a middle shell of the automotive turbine supercharger into the cleaning room, then cleaning a cavity of the middle shell by using the high-pressure oil distributing valve, and cleaning the outer surface of the middle shell by using the second branch pipe and the air pipe. The device and the method for cleaning the middle shell cavity of the automotive turbine supercharger have the advantage that the device and the method can achieve full-automatic cleaning.

Owner:SHANGHAI XIECHANG HUONING MACHINERY MFG

Rubber roller cleaning device for printing equipment

InactiveCN108859412ARealize automatic cleaningAvoid health hazardsPrinting press partsHealth hazardWater tanks

The invention discloses a rubber roller cleaning device for printing equipment. The rubber roller cleaning device comprises two clamping end heads, a rotating mechanism, three cleaning brushes, a cleaning brush driving mechanism, a water tank, a fan nozzle and a hot air nozzle; the clamping end heads are used for clamping rubber rollers to be cleaned, the clamping end heads correspondingly clamp the two ends of the rubber rollers; the rotating mechanism is used for driving the clamped rubber rollers to rotate around the shaft axes of the clamped rubber rollers; the cleaning brushes are correspondingly used for cleaning both sides and the middle portions of the rubber rollers; the cleaning brush driving mechanism is used for driving the three cleaning brushes to reciprocate along the axes of the rubber rollers; the fan nozzle is used for washing the rubber rollers to be cleaned; and the hot air nozzle is used for drying the cleaned rubber rollers. The rubber roller cleaning device realizes the automatic cleaning of the rubber rollers of the printing equipment, replaces the manual cleaning, improves the cleaning efficiency, reduces the cleaning cost, and further avoids the health hazard caused by ink attached to the rubber rollers to cleaning personnel.

Owner:李春雨

Automatic cleaning device for travel cups

Owner:ZHEJIANG HAODA TECH CO LTD

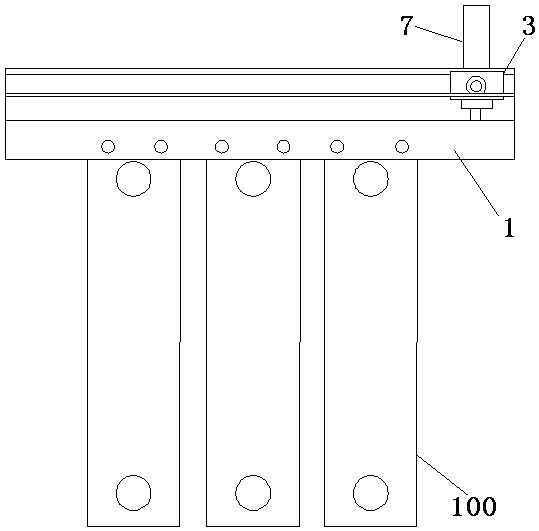

Automatic cleaning device of arc sieve

InactiveCN103691671ARealize fully automatic cleaningSimple structureSievingScreeningElectric machineryEngineering

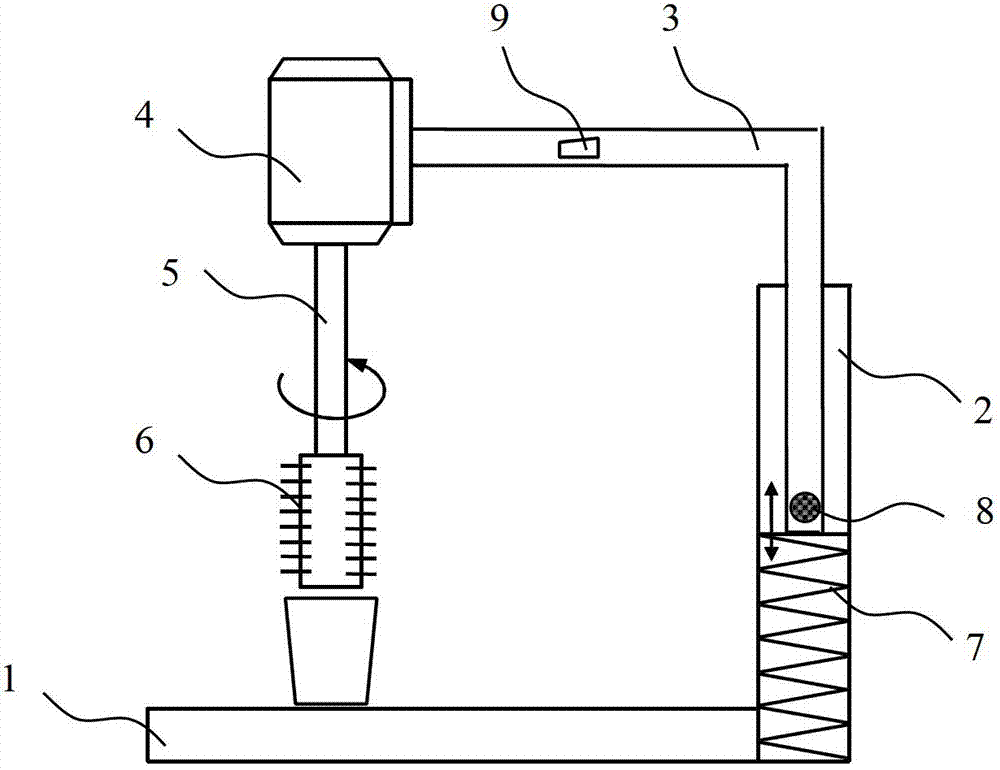

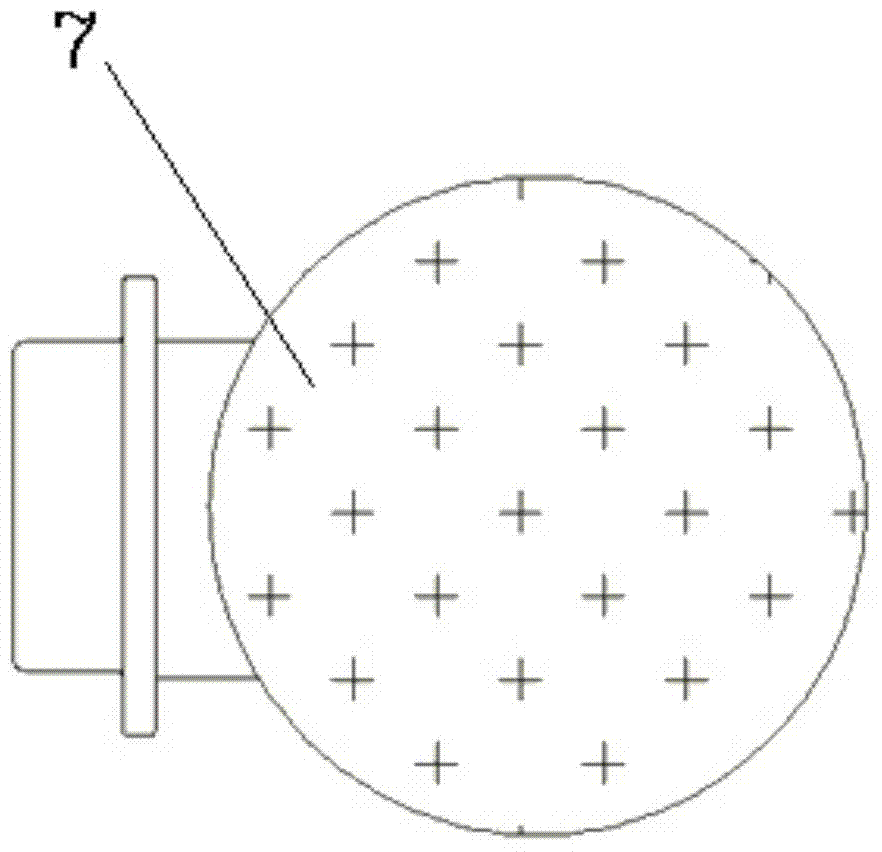

The invention discloses an automatic cleaning device of an arc sieve. The automatic cleaning device is characterized by comprising a bracket (2) fixedly arranged above the arc sieve (1) and following with the arc sieve (1), wherein a motor (3) is fixedly supported on the bracket (2); a soft hairbrush roller (4), an ordinary hairbrush roller (5) and a hard hairbrush roller (6) which are sequentially arranged from top to bottom are also rotationally supported on the bracket (2); the motor (3) drives the soft hairbrush roller (4), the ordinary hairbrush roller (5) and the hard hairbrush roller (6) through a belt driving pair; a water pump (8) is also arranged in a water-collecting groove (7) positioned below the arc sieve (1); an outlet end of a secondary flushing pipeline (9) connected with the water pump (8) is positioned above the arc sieve (1). The automatic cleaning device is the device which is simple in structure and ingenious in design and can automatically run and simply and quickly clean the arc sieve.

Owner:DALIAN OCEAN UNIV +1

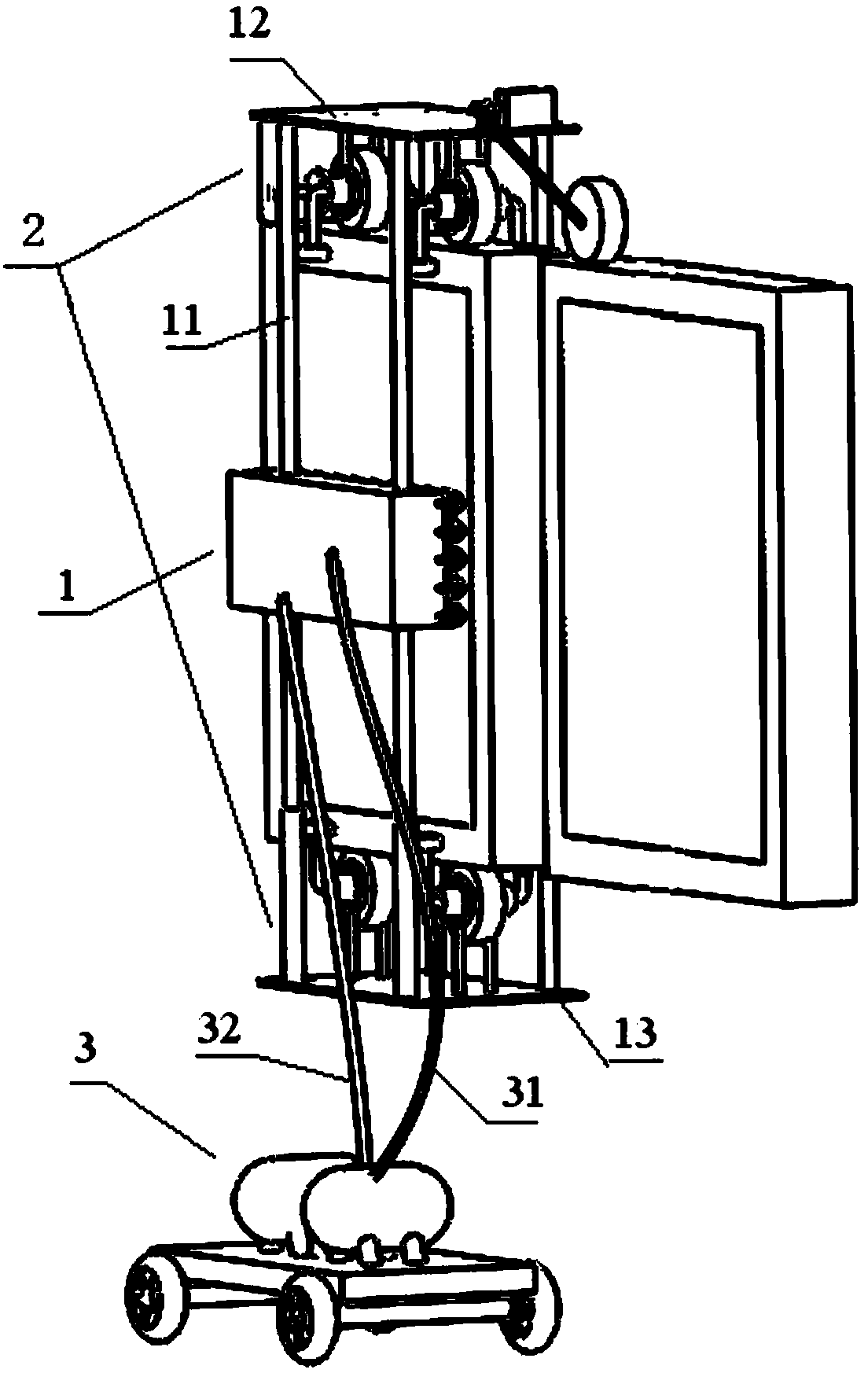

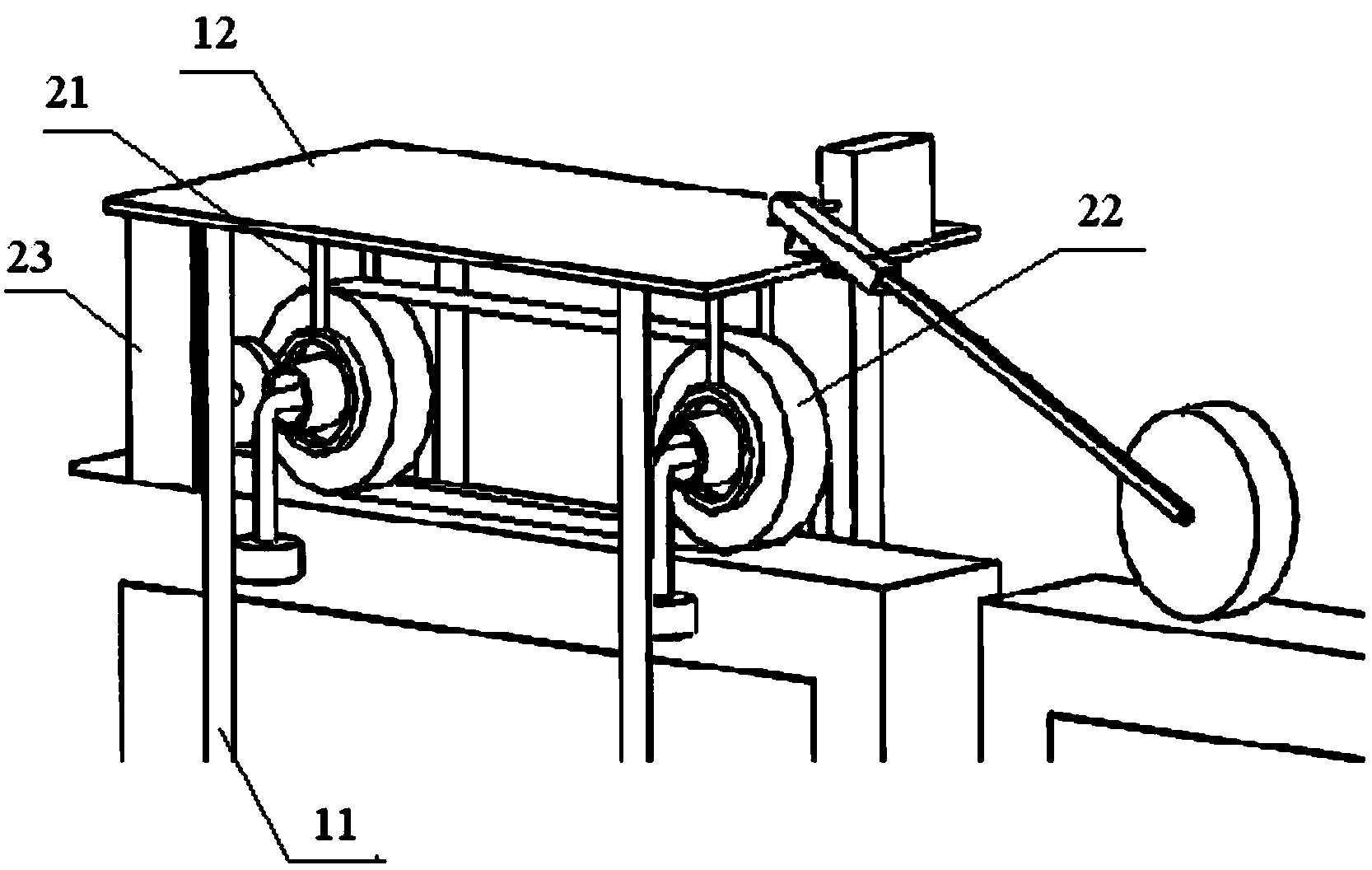

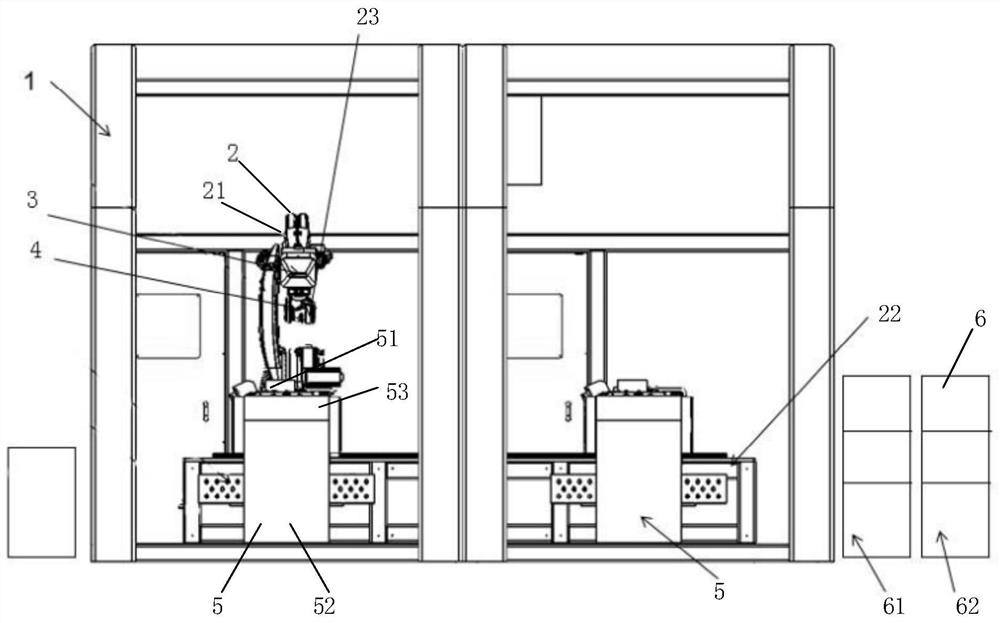

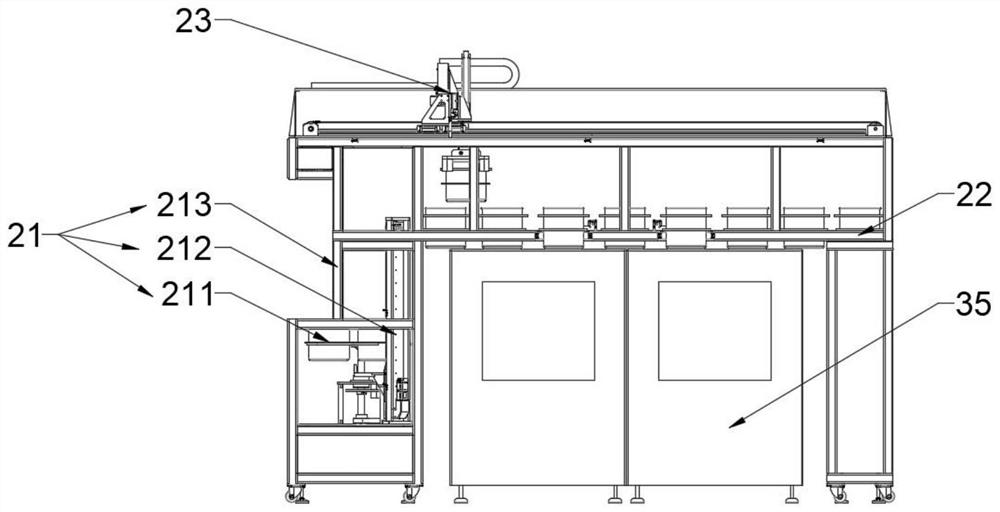

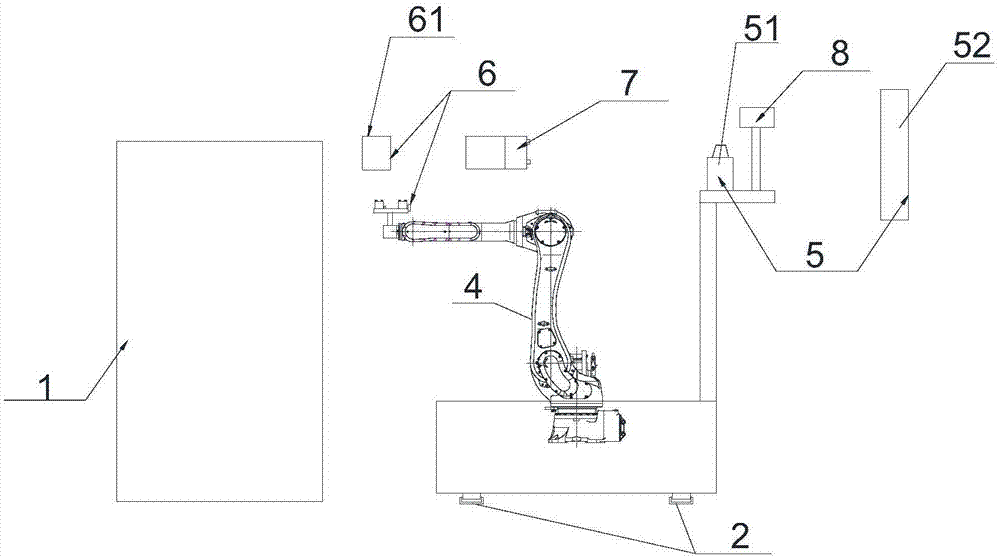

Automatic laser cleaning system and method for traction motor of rail transit vehicle

InactiveCN112934856ARealize fully automatic cleaningFacilitates fully automated cleaningCleaning processes and apparatusElectric machineryControl cell

The invention discloses an automatic laser cleaning system and method for a traction motor of a rail transit vehicle. The system comprises a robot unit, a workpiece moving unit and a control unit. The workpiece moving unit is used for fixing a to-be-cleaned workpiece and driving the to-be-cleaned workpiece to rotate and overturn; the robot unit comprises a manipulator, and a laser head and a three-dimensional scanning unit are mounted on the manipulator; the three-dimensional scanning unit is used for scanning the to-be-cleaned workpiece to obtain a three-dimensional shape and a to-be-cleaned area of the to-be-cleaned workpiece; the control unit is connected with the three-dimensional scanning unit and the laser head and used for determining a movement track, a scanning mode and a deflection angle in the cleaning process of the laser head according to the three-dimensional shape and the to-be-cleaned area of the to-be-cleaned workpiece; and the laser head is used for emitting laser beams and is matched with the operation of the manipulator and the overturning of the workpiece moving unit to realize automatic cleaning of the to-be-cleaned workpiece. The automatic laser cleaning system has the advantages of high automation degree, high cleaning efficiency, good cleaning effect and the like.

Owner:ZHUZHOU NAT INNOVATION RAILWAY TECH CO LTD

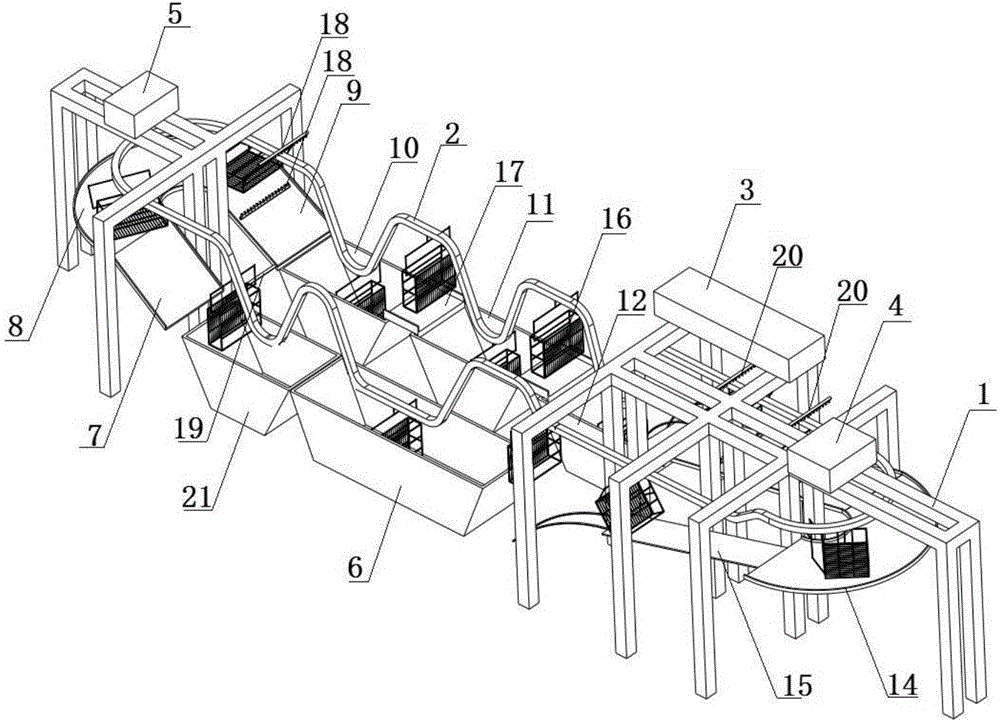

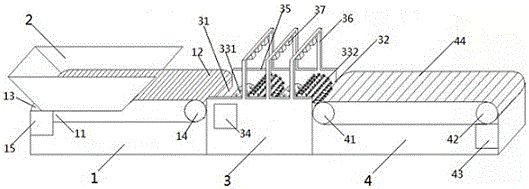

Summer orange cleaning and classifying device

InactiveCN106040571ARealize fully automatic cleaningNon-perishableSievingScreeningBristleBiochemical engineering

The invention discloses a summer orange cleaning and classifying device and relates to the field of vegetable and fruit processing mechanical equipment. Full-automatic cleaning of summer oranges is achieved, and workloads are greatly relived; cleaning roller brushes are arranged in a staggered manner, the cleaning path is lengthened, the coarse-bristle cleaning roller bushes and the fine-bristle cleaning roller brushes are arranged at intervals, cleaning is complete, and the cleaning effect is good; and showering type cleaning is adopted, fruit bodies make contact with a small amount of cleaning water while the cleaning effect is guaranteed, decaying is not likely to be caused, and a powerful guarantee is provided for long-time storage. According to the scheme, a fruit entering table is arranged at the inlet end of a first conveying roller belt; the outlet end of the first conveying roller belt is connected with the inlet end of a cleaning tank, the multiple cleaning roller brushes are distributed in the cleaning tank, the vertical heights of the adjacent cleaning roller brushes are different, and preset horizontal intervals exist; the cleaning roller brushes are driven by a cleaning motor; a showering washing pipe is fixed to the tank wall of the cleaning tank and provided with a showering washing sprayer; and the outlet end of the cleaning tank is connected with a classifying roller belt. The summer orange cleaning and classifying device is mainly used for vegetable and fruit cleaning.

Owner:荔浦宏发包装厂

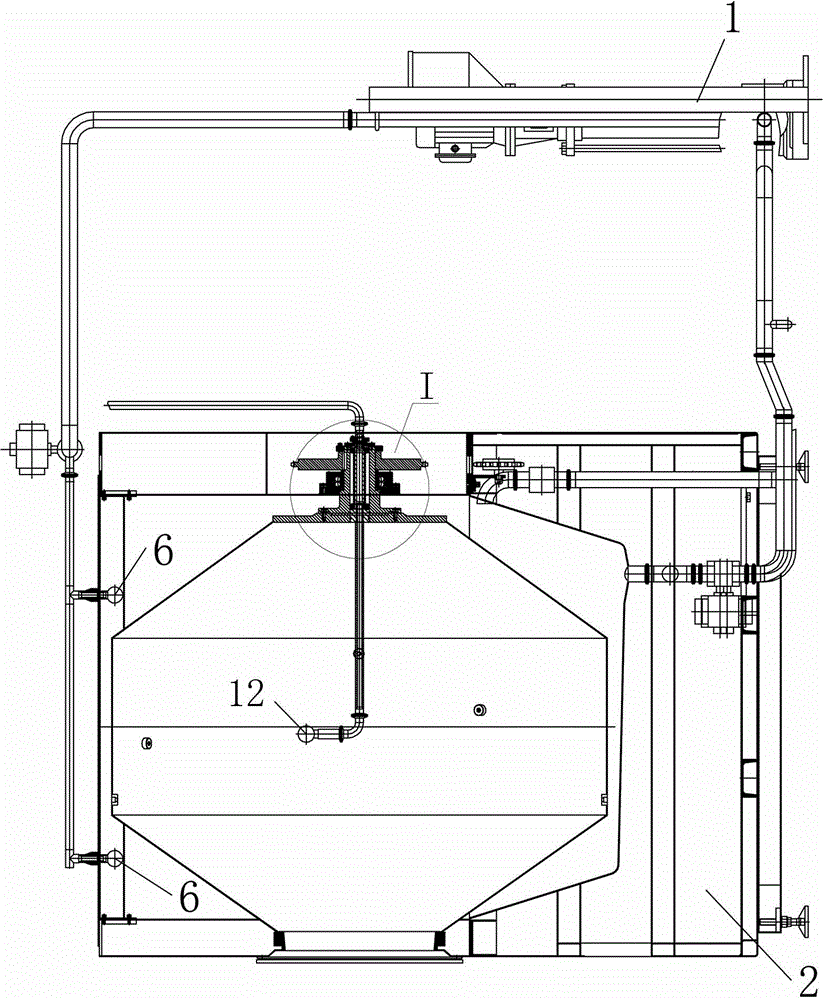

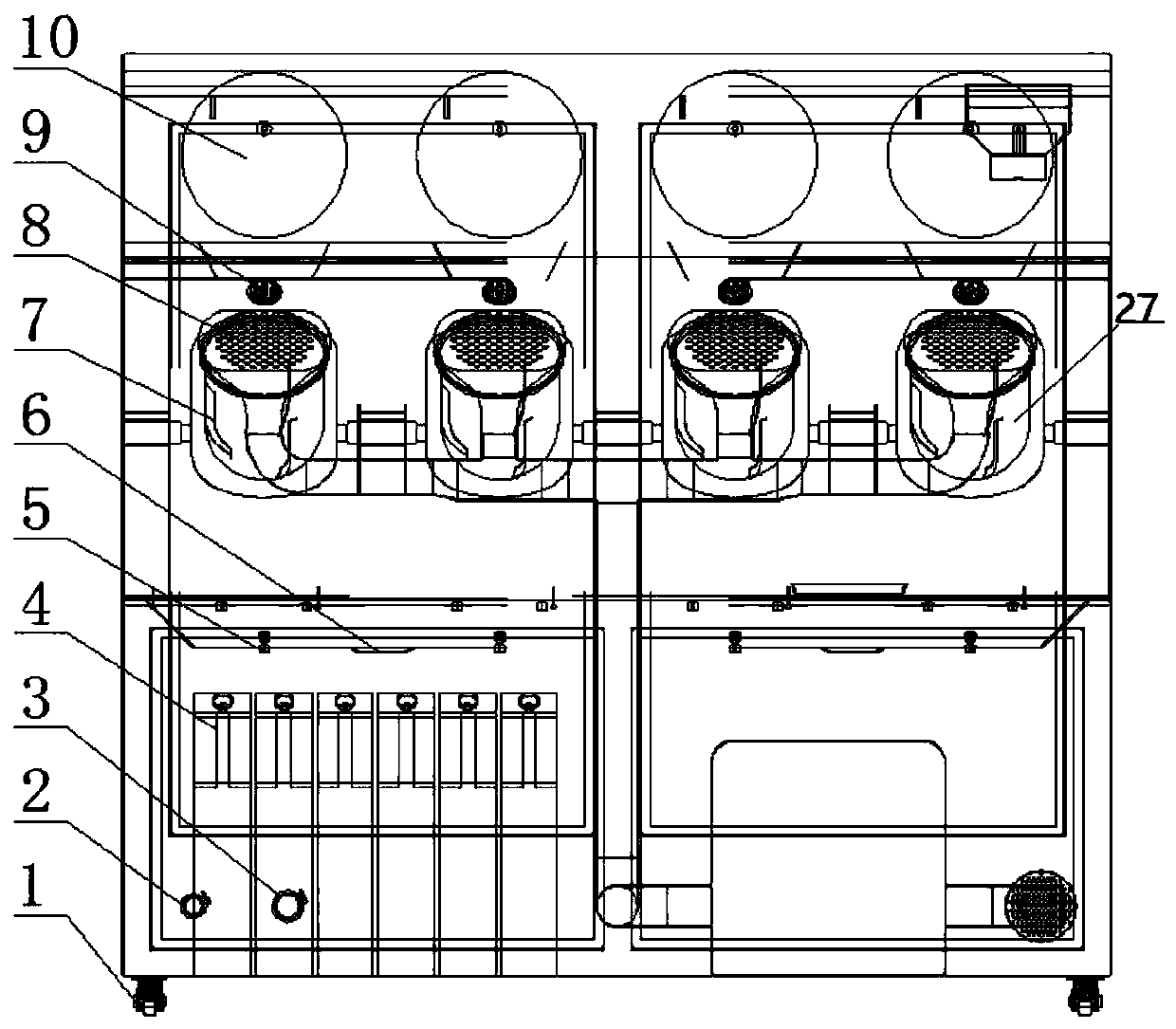

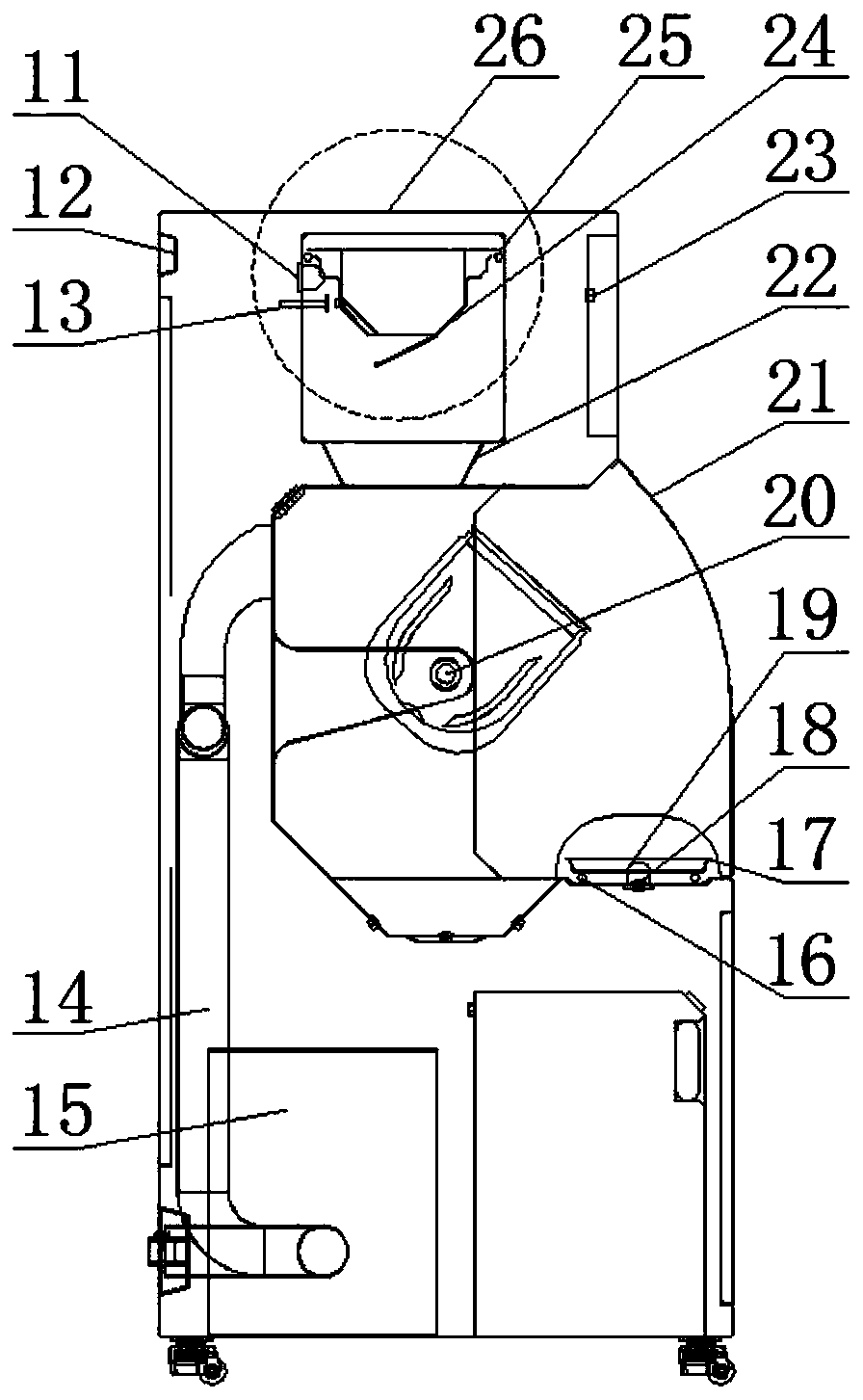

Automatic medicine decocting and subpackaging system

PendingCN111658528ADissolve fastAchieve cleaningPharmaceutical product form changeMedicinal herbsBiomedical engineering

The invention discloses an automatic medicine decocting and subpackaging system. The automatic medicine decocting and subpackaging system comprises a wall body, a medicine soaking unit, a medicine decocting unit and a subpackaging unit, wherein the medicine soaking unit, the medicine decocting unit and the subpackaging unit are arranged on the inner side of the wall body; the wall body is providedwith a medicine adding window and a medicine taking window; the medicine soaking unit comprises a multi-station medicine receiving mechanism, a standing frame body and a three-axis transplanting clamping jaw; the standing frame body is provided with a plurality of placing holes and a pushing-out station; the medicine decocting unit comprises a medicine decocting pot, a medicine adding robot and aliquid medicine filtering mechanism; the subpackaging unit comprises a conveying mechanism and a sterilization packaging machine; prepared medicinal materials are soaked in the medicine soaking unitand then are conveyed to the medicine decocting pot for two-time decocting, and decocted liquid medicine flows into the sterilization packaging machine for packaging and is finally conveyed to the medicine taking window through the conveying mechanism; the decocting unit is further provided with a medicine soaking barrel cleaning mechanism, a filter screen cleaning machine, an automatic residue discharging mechanism and the like, so that automatic cleaning of a medicine soaking barrel, the medicine decocting pot and a filter screen and automatic collection of medicine residues can be realized;and the structure is ingenious, full-automatic decocting and full-automatic cleaning are realized, and manual interference is not needed.

Owner:苏州迅益科系统科技有限公司

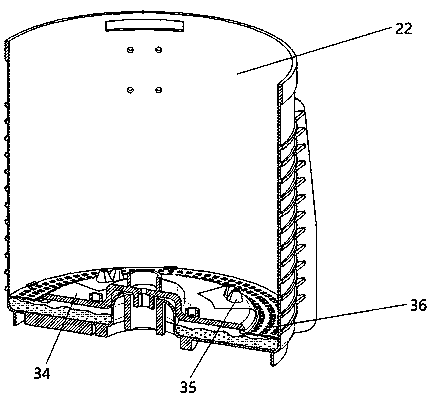

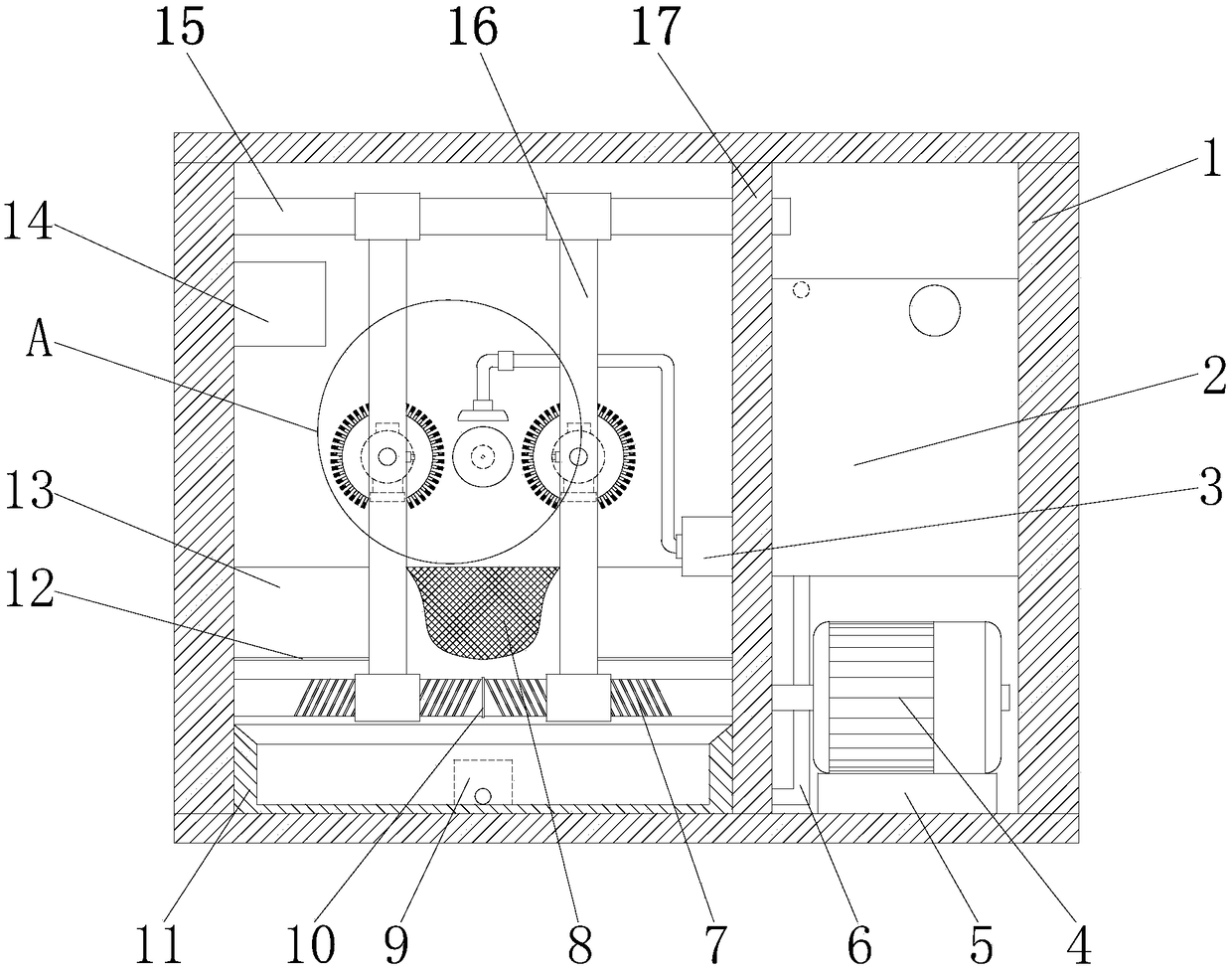

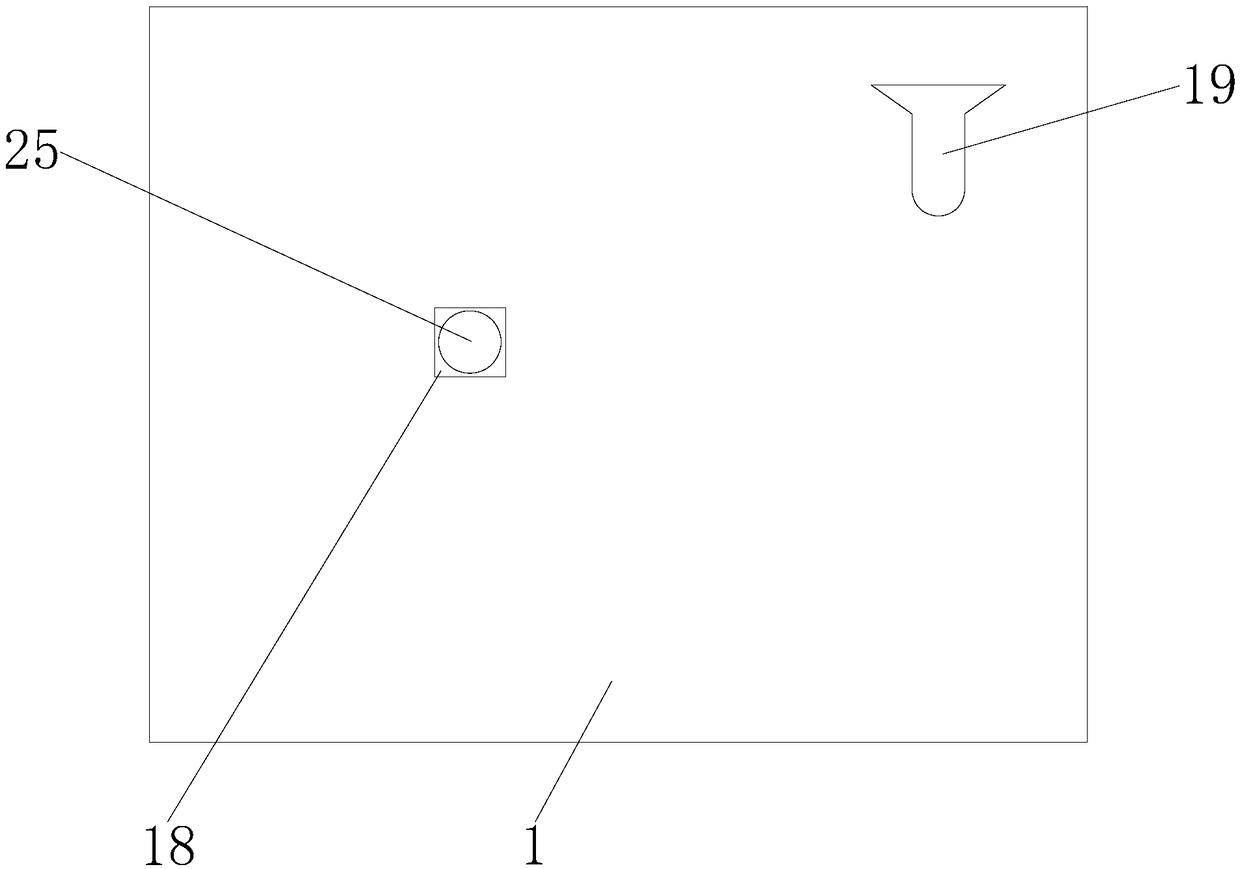

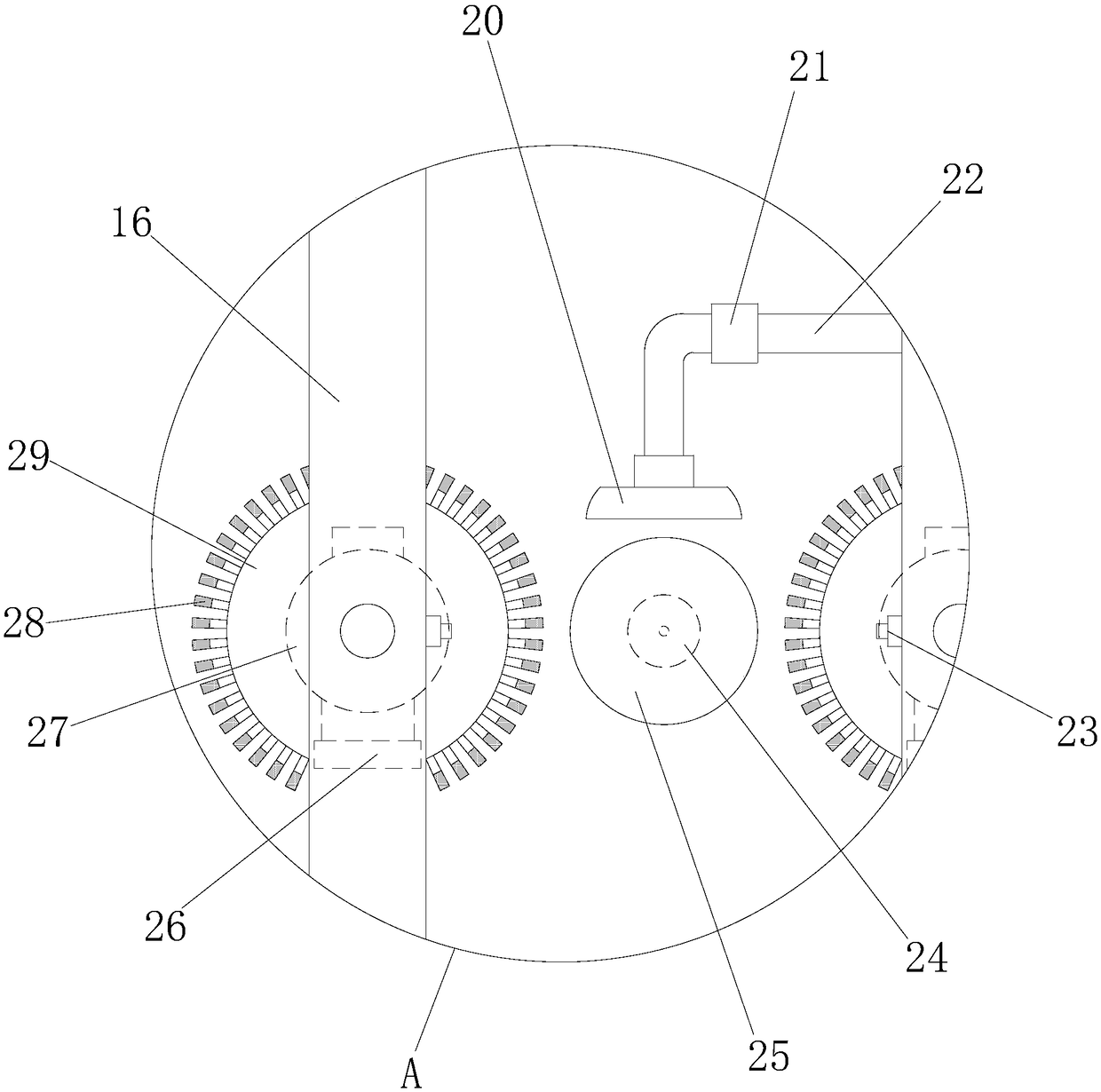

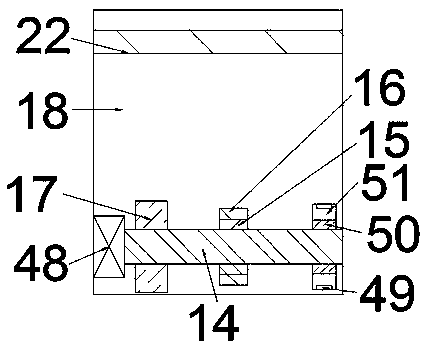

Cleaning device for shoe washing machine

The invention discloses a cleaning device for a shoe washing machine. The cleaning device comprises an outer drum, the outer drum is internally provided with a hidden hairbrush drum mechanism, the bottom of the outer drum is provided with a motor transmission mechanism, the motor transmission mechanism is connected with a turntable mechanism, the turntable mechanism is provided with a shoe rack hairbrush device, and the shoe rack hairbrush device is internally provided with a spraying pipe hairbrush device. The cleaning device can comprehensively clean fixed shoes, has a good cleaning effect and can also ensure the service life of the shoes.

Owner:WENZHOU UNIVERSITY

Integrated kitchen range with automatic cleaning device

InactiveCN102798163AAchieve cleaning effectRealize fully automatic cleaningDomestic stoves or rangesLighting and heating apparatusImpellerInternal cavity

The invention discloses an integrated kitchen range with an automatic cleaning device. The integrated kitchen range with an automatic cleaning device comprises a spiral case, a motor, an impeller, an electrical circuit board, a condensate oil collecting mechanism, an oil receiving box, and a gas collecting bin arranged around a suction opening of range holes, wherein the gas collecting bin is connected with the air inlet end of the spiral case, the motor is fixed on the spiral case, the impeller is arranged in the internal cavity of the spiral case and fixed on the rotary shaft of the motor. The automatic cleaning device comprises a heater arranged at the bottom of the integrated kitchen range and is characterized in that: the water inlet of the heater is provided with a first solenoid valve; the hot water outlet pipe of the heater is connectedly arranged on a spray pipe in the gas collecting bin, the spray pipe is provided with a second solenoid valve; and the control port of a power switch of the heater, a temperature sensor, the first solenoid valve and the second solenoid valve are all connected with the central processor of the electrical circuit board. The invention has the advantages of simple structure, convenient usage, reduced cleaning cost, and significant cleaning effect.

Owner:JIANGSU MEIDA ELECTRICAL APPLIANCE CO LTD

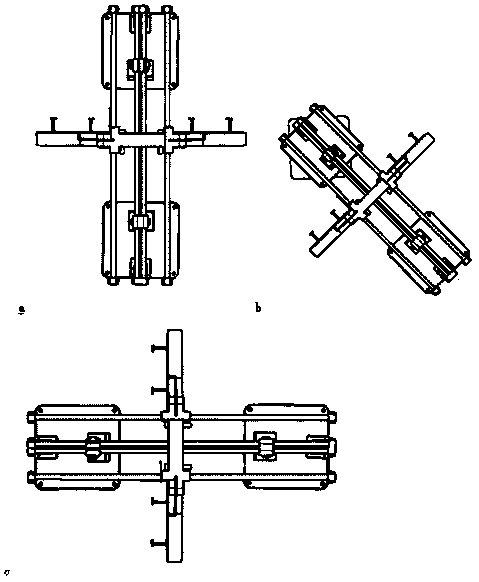

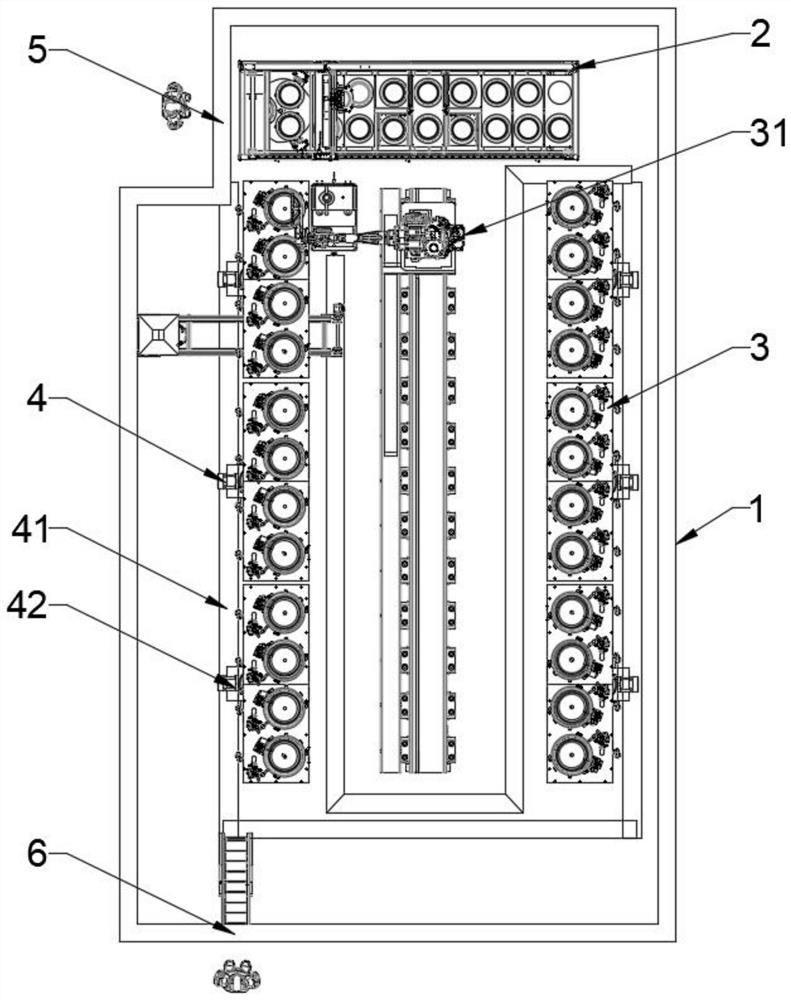

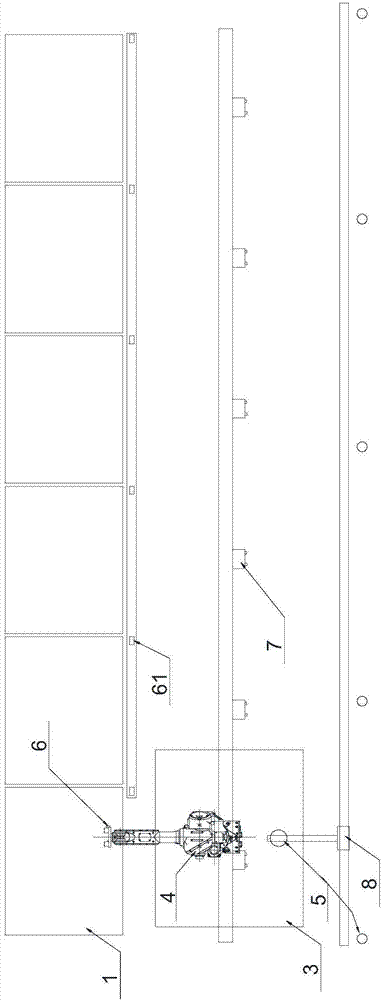

Automatic plate clearing system and automatic plate clearing process thereof

The invention discloses an automatic plate clearing system, which is used for clearing spinning nozzles on chemical fiber equipment and preventing a spinning hole from being blocked. The spinning nozzles are arranged in lines and rows on the chemical fiber equipment, and multiple pieces of chemical fiber equipment are distributed in lines and columns. The automatic plate clearing system comprises a plate clearing robot, a traveling system, a traveling track, a navigation system, a positioning system, a calling control system, a power collection system, a background control system and the like. The invention also discloses an automatic plate clearing process. By adopting the automatic plate clearing system and the automatic plate clearing process, the manual intervention can be maximally reduced, and the clearing of the chemical fiber equipment can be automatically completed; and in the operation process, the automatic navigation and autonomous power supply as well as precise positioning of the spinning nozzles can be realized, a scraper head is accurately sent to the position of each spinning nozzle, and the collision or friction between each scraper head and the chemical fiber equipment is prevented. The process is simple, the precision is high, the positioning speed is high, and the production efficiency is high.

Owner:HANGZHOU RUIGUAN TECH

Magnet automatic cleaning device

ActiveCN108687004AImprove cleanlinessImprove qualityCleaning using toolsCleaning using liquidsWater pipeDistance sensors

The invention discloses a magnet automatic cleaning device comprising a housing, a rotating disk which is magnetically attractive to the magnet, a cleaning mechanism and a washing structure. The cleaning mechanism comprises a guide rod, two slide rods, two mounting plates which are symmetrical about the center of the rotating disk, two range sensors which are mounted on side surfaces of the two slide rods, multiple hairbrushes, two threaded rods which are paralleled to the guide rod and the thread spiral directions are opposite; the washing structure comprises a nozzle, a water pipe I, a waterpump I and a water storage tank. According to the invention, by installing the rotating disk, the cleaning mechanism and the washing structure, the magnet is adsorbed on the rotating disk and rotatesalong with the magnet; a mounting plate is rotated so as to clean the rotating magnet by the hairbrush, thereby improving the cleanliness of the magnets and the quality of the magnets. The cleaning mechanism can spray water or spray cleaning agent to thoroughly clean the rotating magnet, thereby further improving the purity of the magnet and improving the cleaning efficiency.

Owner:安徽万磁电子有限公司

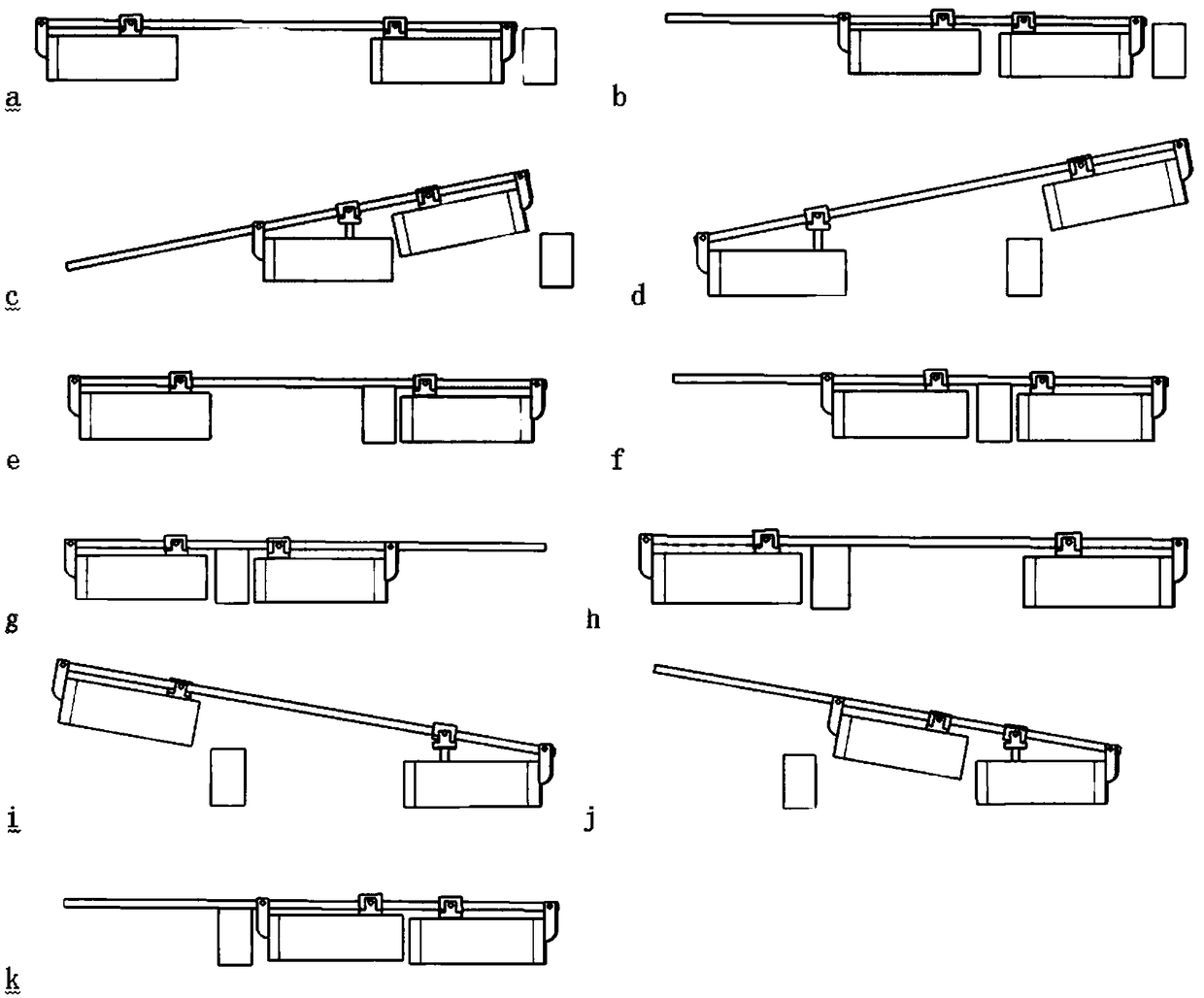

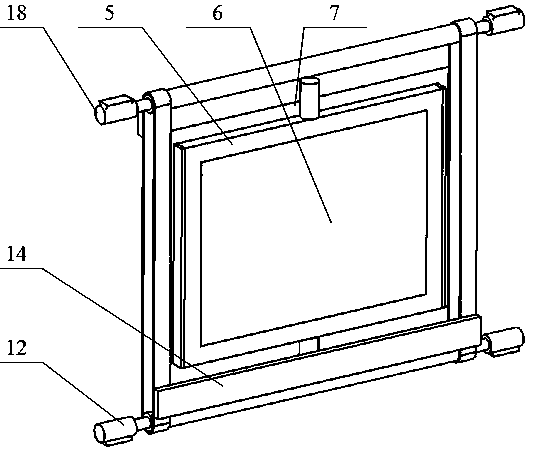

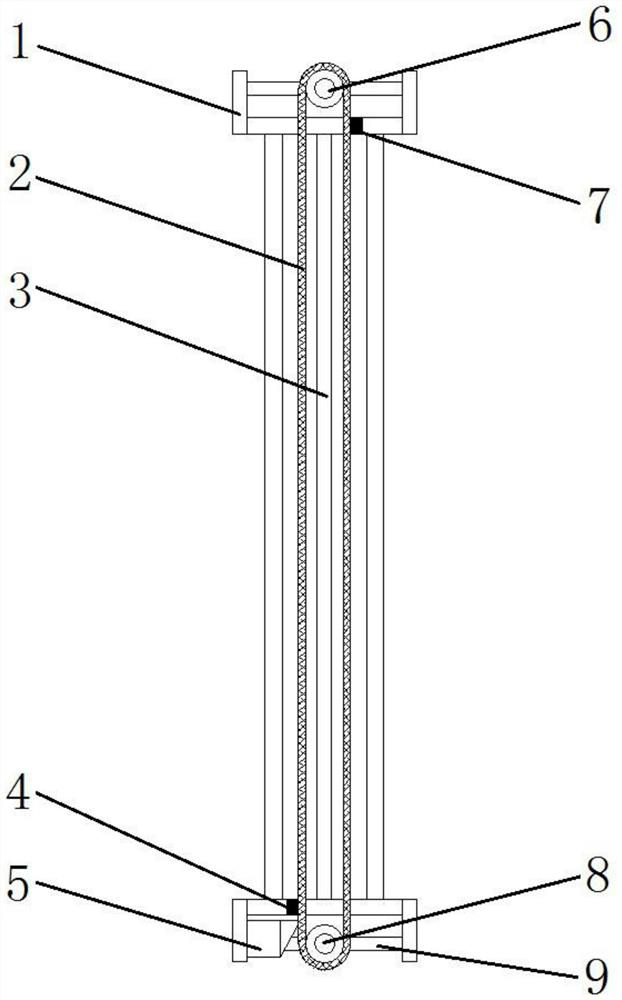

Full-automatic cleaning window and control circuit and working mode thereof

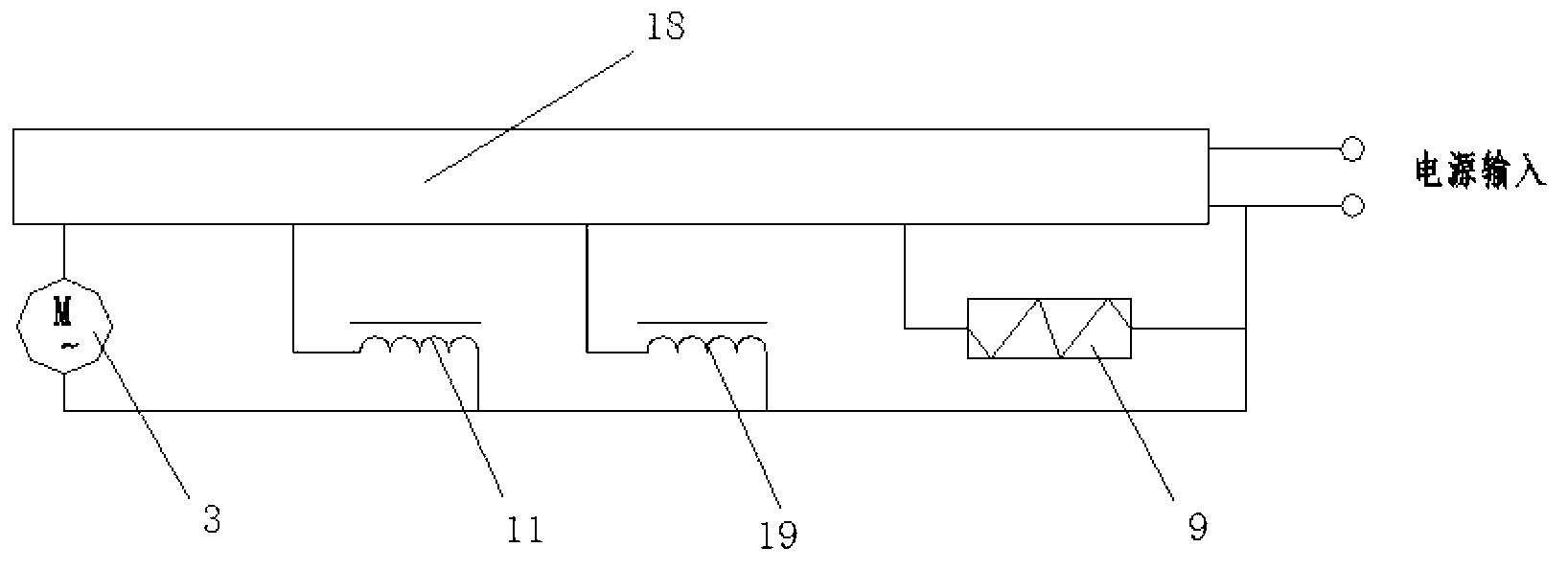

ActiveCN103527059ADoes not affect aestheticsSimple structureConstruction fastening devicesWindow cleanersRotational axisTransmission belt

A full-automatic cleaning window comprises a window support, an installing support, a U-shaped cover plate, a movable window frame, glass, rotating shafts, a transmission belt, brushes, a motor and a movable door, the installing support is arranged inside the window support, the glass is arranged inside the movable window frame, the movable window frame is installed inside an installing support groove through revolving shafts, the two rotating shafts are arranged on the upper portion and the lower portion of the installing support respectively, the end portions of the rotating shafts are connected with a motor output shaft, the two outer sides of the transmission belt are respectively provided with one brush, a motor amphenol connector is connected with a controller through a connecting wire, an upper U-shaped cover plate body is arranged at the upper end of the window support, a lower U-shaped cover plate body is arranged at the lower end of the window support, a hole is formed in one side of the lower U-shaped cover plate body, an end cover is arranged on the hole of the lower U-shaped cover plate body, two installing grooves are formed inside the lower U-shaped cover plate body, and the movable door is installed inside the installing grooves of the lower U-shaped cover plate body through a supporting spring. The purposes that a window can be regularly and automatically cleaned and the window can be cleaned at any time when a user presses a button can be achieved according to needs, and therefore work difficulty of cleaning staff can be greatly reduced.

Owner:JINLING INST OF TECH

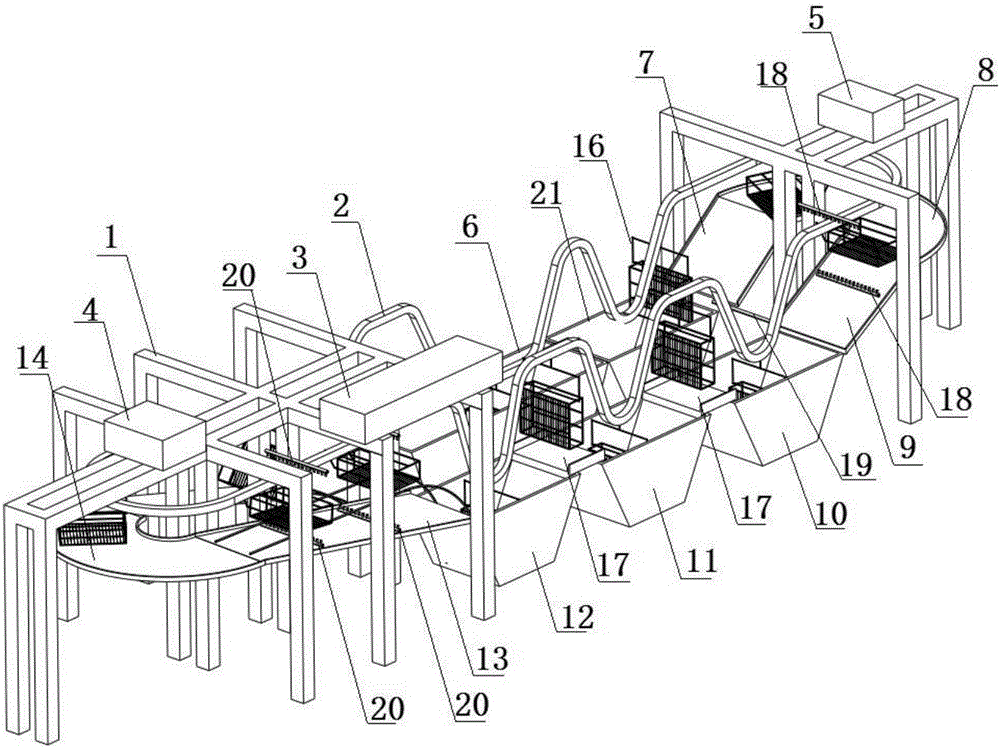

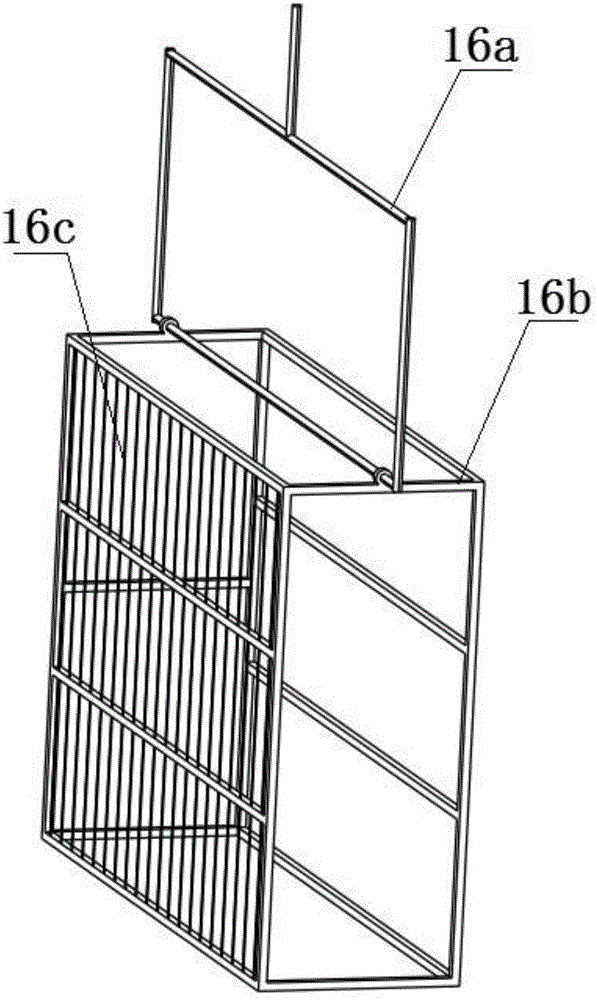

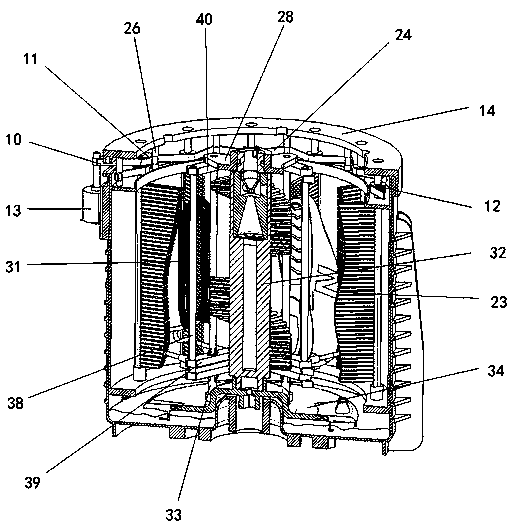

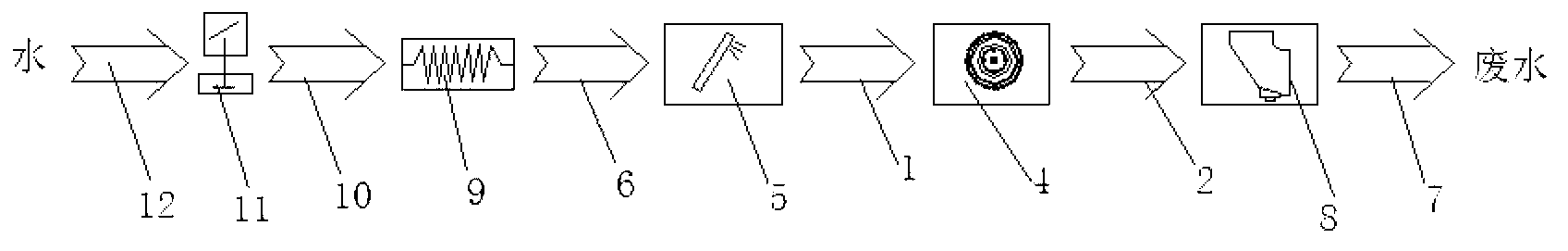

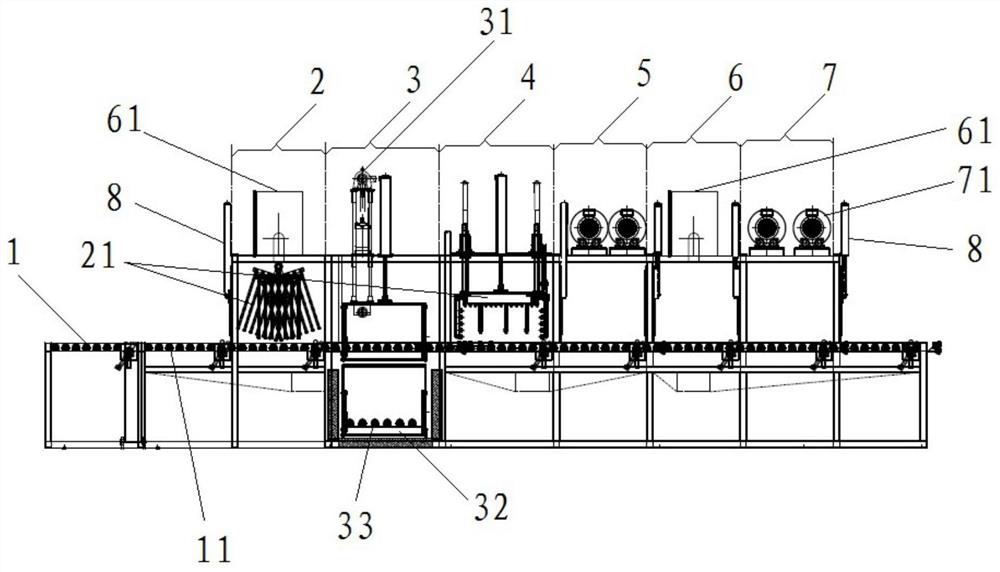

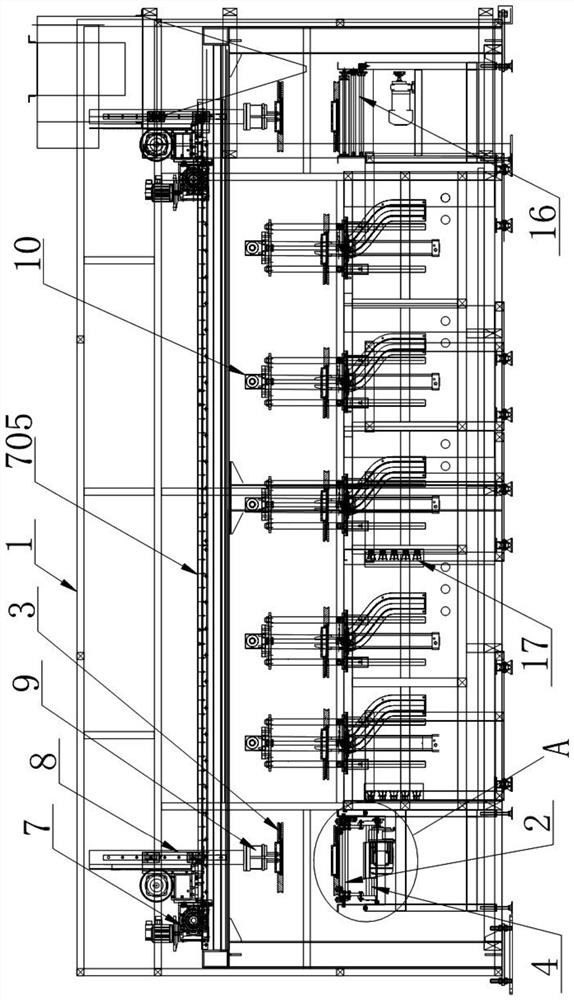

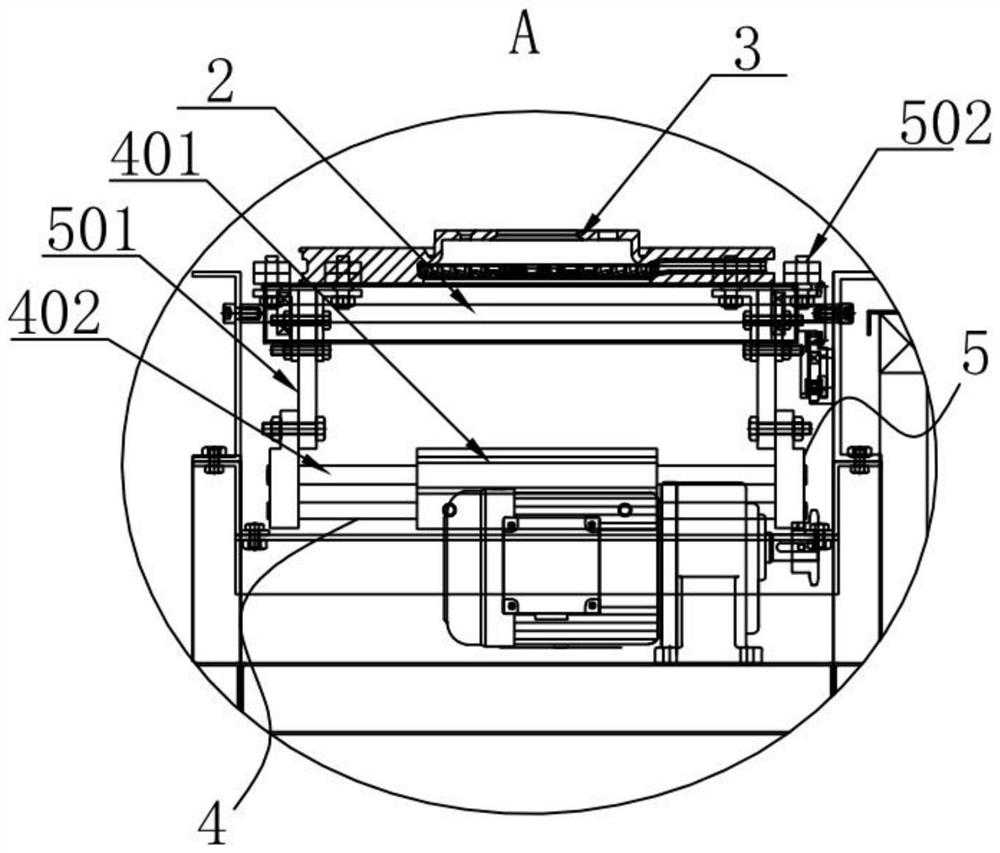

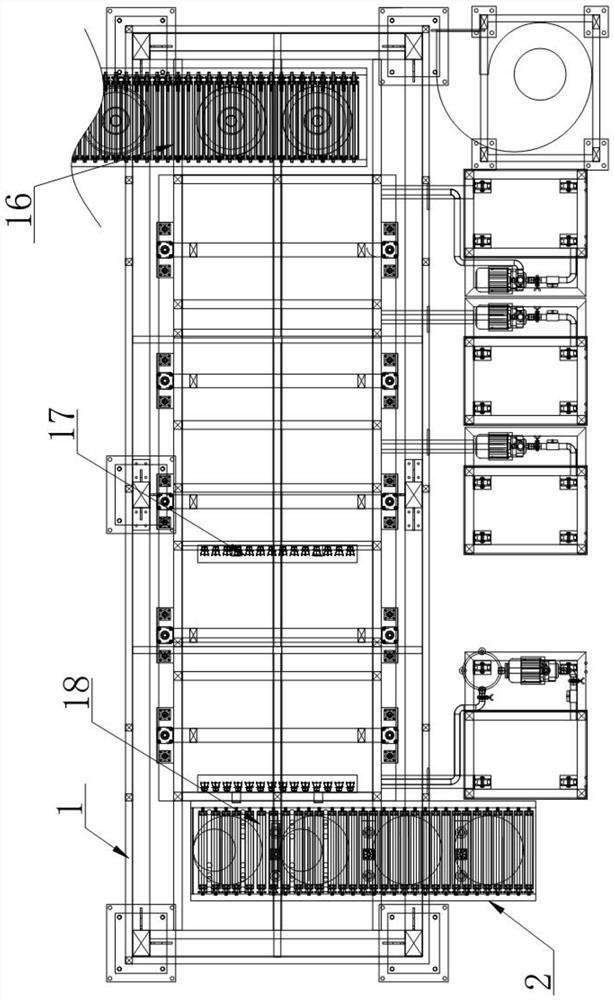

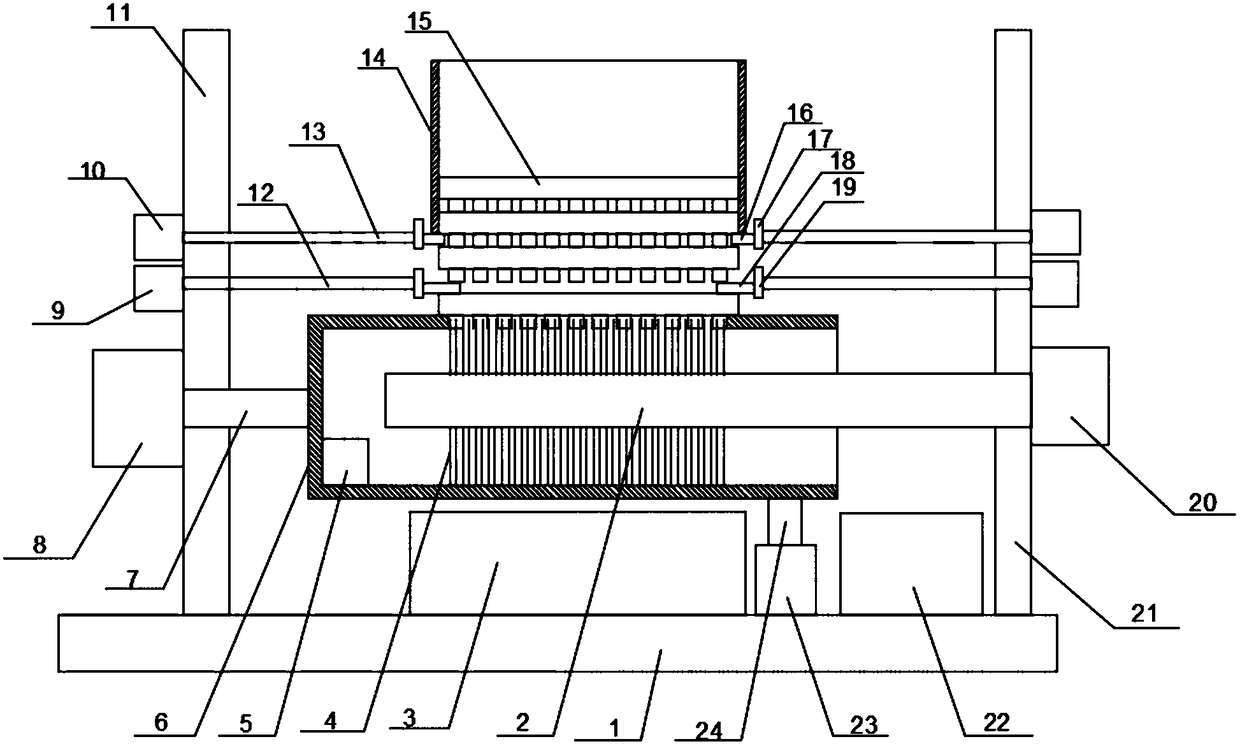

Centralized cleaning machine

PendingCN113798281AAvoid inefficiencyImprove cleaning efficiency and qualityHollow article cleaningDrying gas arrangementsProcess engineeringEnvironmental geology

The invention discloses a centralized cleaning machine. The centralized cleaning machine comprises a machine body, a control device, a conveying device, a rough cleaning device, an ultrasonic cleaning device, a fine cleaning device, a cleaning fluid wind shear device, an atomization oil coating device and an anti-rust oil wind shear device, wherein the conveying device, the rough cleaning device, the ultrasonic cleaning device, the fine cleaning device, the cleaning fluid wind shear device, the atomization oil coating device and the anti-rust oil wind shear device are sequentially arranged in the machine body. The conveying device is controlled by a control system to be matched with the rough cleaning device, the ultrasonic cleaning device, the fine cleaning device, the cleaning fluid wind shear device, the atomization oil coating device and the anti-rust oil wind shear device to perform full-automatic cleaning on a circular pipe cylinder sleeve; the full-automatic cleaning functions of cleaning, blow-drying, oil coating, wind shear and the like of the circular pipe cylinder sleeve can be achieved; manual intervention is not needed; the problems of low efficiency, large occupied space and the like caused by manual operation are effectively avoided; the cleaning efficiency and quality are greatly improved; and meanwhile, the labor cost is reduced.

Owner:ZYNP GRP

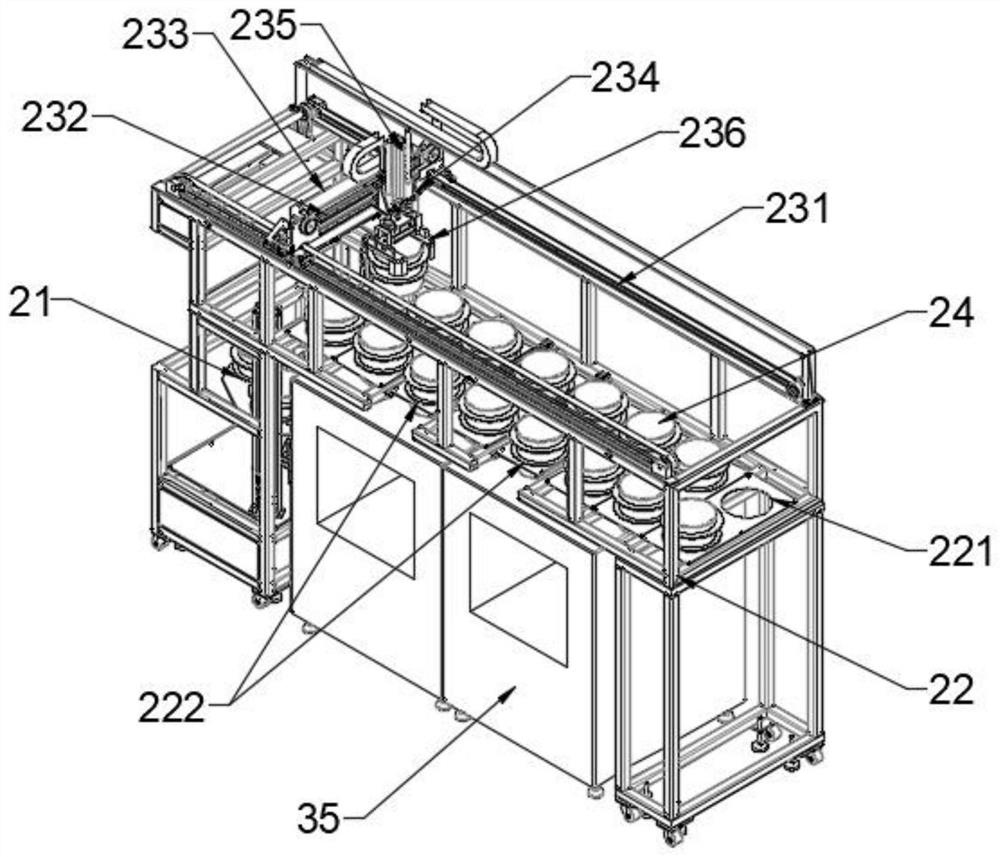

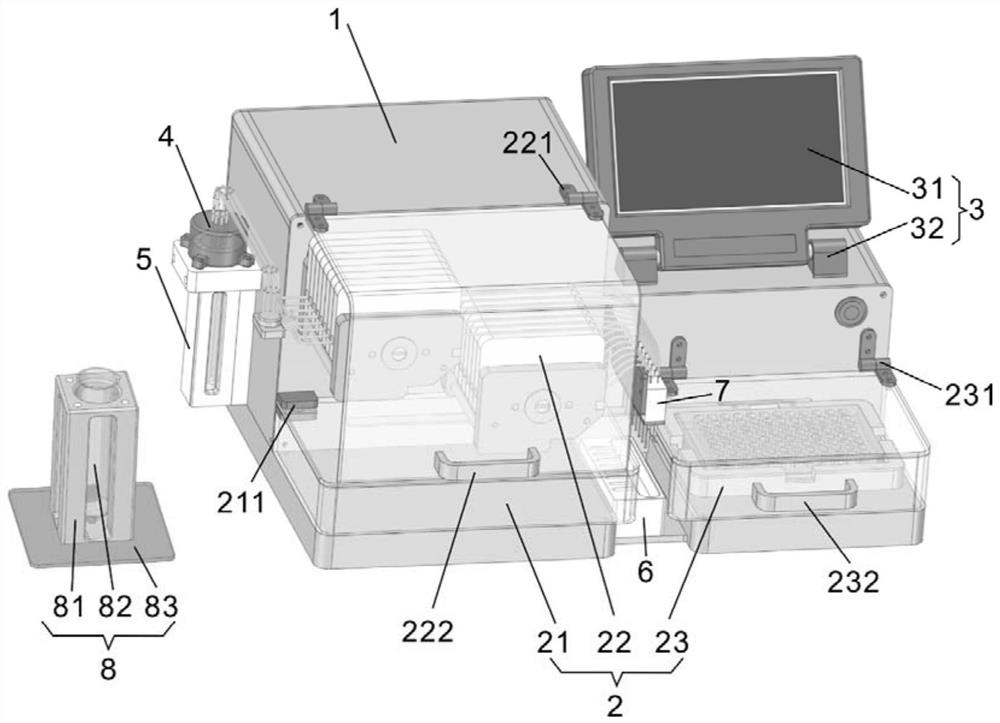

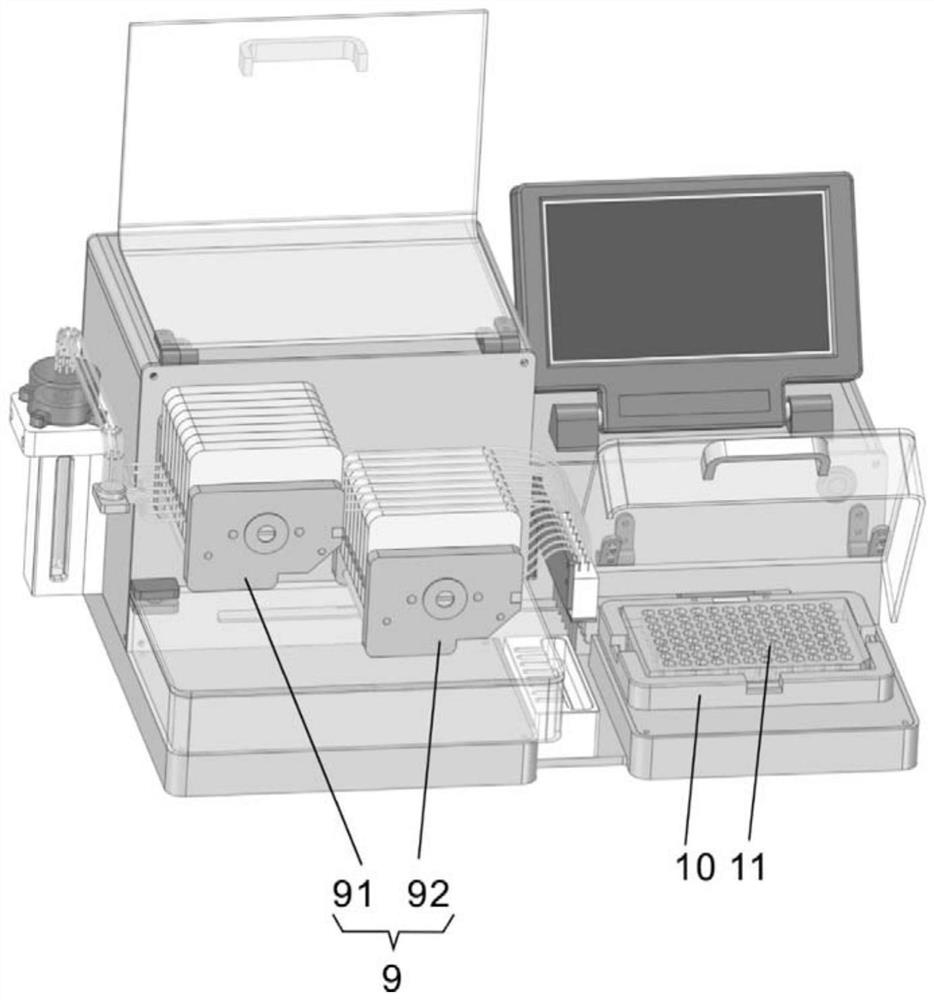

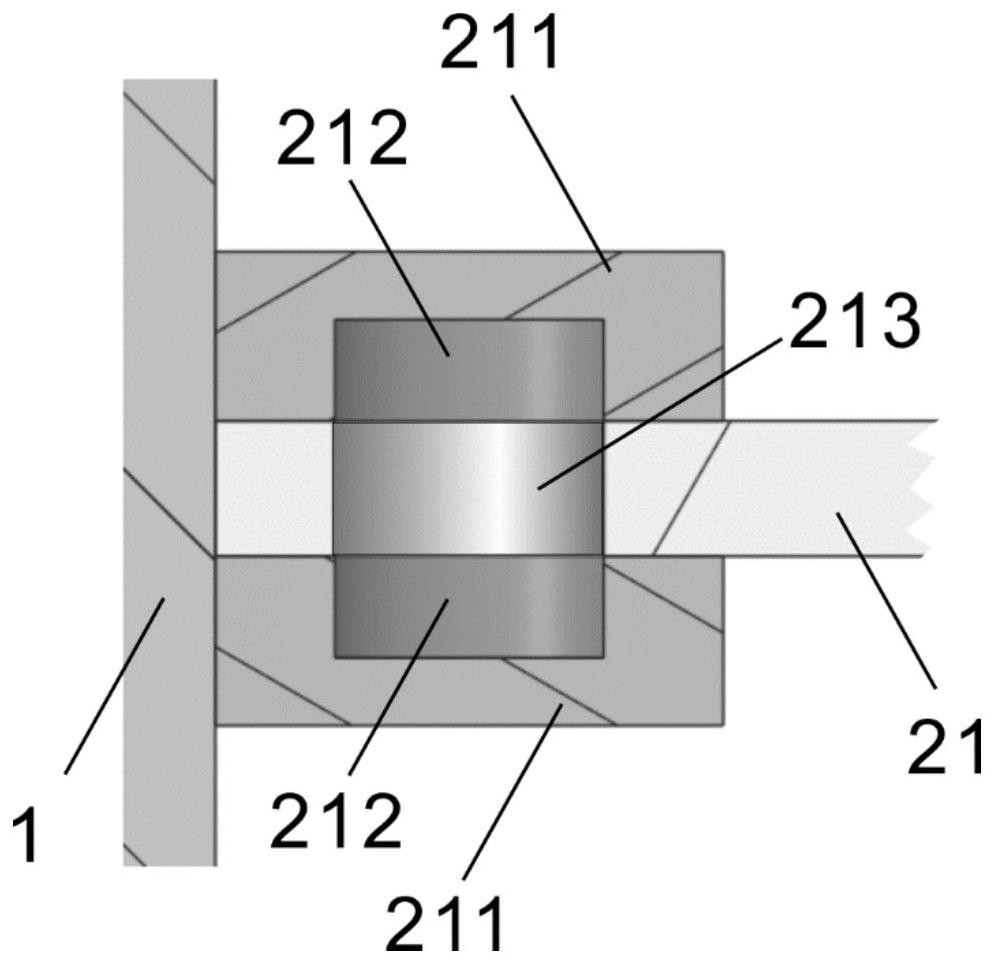

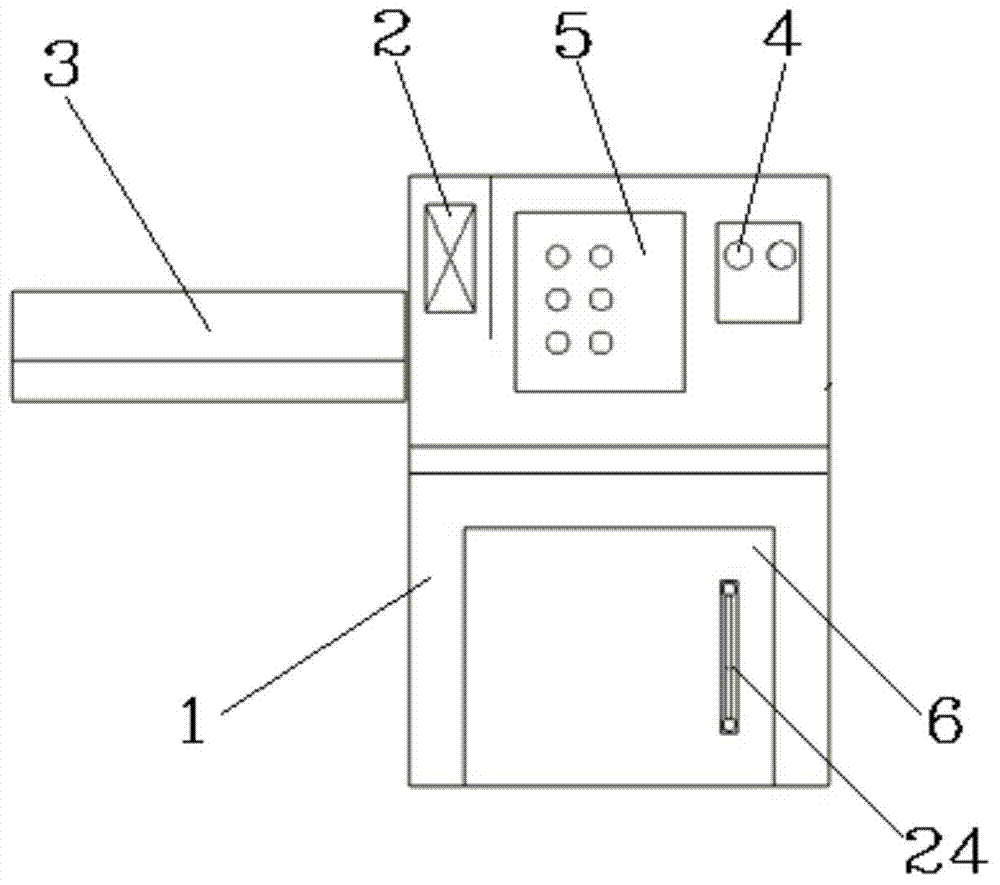

Automatic solution replacing device for culture of three-dimensional organoid spheres

PendingCN111961589AAvoid damageControl fluid flowBioreactor/fermenter combinationsBiological substance pretreatmentsPeristaltic pumpEngineering

The invention discloses an automatic solution replacing device for culture of three-dimensional organoid spheres. The automatic solution replacing device comprises a sample introduction container assembly and / or a sample introduction needle cleaning assembly, a sample introduction needle assembly, a sample application needle assembly and a spent solution collecting bottle, wherein one end of the sample introduction needle assembly is in pipeline connection with a sample application needle assembly, and the other end of the sample introduction needle assembly can selectively extend into the sample introduction container assembly or sample introduction needle cleaning assembly; and the sample application needle assembly comprises an aspirating needle and a sample application needle, the aspirating needle is connected with the spent solution collecting bottle through an aspirating peristaltic pump pipe, and the sample application needle is connected with the sample introduction needle assembly through a sample introduction peristaltic pump pipe. Through driving the aspirating needle and the sample application needle to perform solution replacing operation on organoid cell spheres separately by employing two sets of high-precision self-adapting peristaltic pumps, the flow rate of solution replacing can be accurately controlled, and injury to the cell spheres caused by uncontrollable fluid shearing stress is avoided as much as possible.

Owner:江苏信安佳医疗科技有限公司

Automatic cleaning device

ActiveCN104259125AReduce labor intensitySimple structureCleaning using gasesCleaning using liquidsControl systemFuel tank

The invention relates to an automatic cleaning device which comprises a machine base, an electric apparatus control system, a product input device, a cleaning and conveying control device, an oil tank and a pneumatic pressure regulation device. A product cleaning device is arranged on the machine base and is connected with the product input device. The product input device is connected with a product sensor. The product sensor is connected with a cleaning and conveying device. The cleaning and conveying device is connected with the cleaning and conveying control device. The cleaning and conveying device is connected with an oil tank oil suction machine. The automatic cleaning device is simple in structure, an automatic feeding structure, an automatic cleaning structure and an automatic discharging structure are adopted, fully-automatic cleaning is achieved, production effectiveness is improved, the labor intensity of staff is lowered, and the stability of the products is guaranteed.

Owner:宁波长华布施螺子有限公司

Three-way cleaning device of sugar coating machine

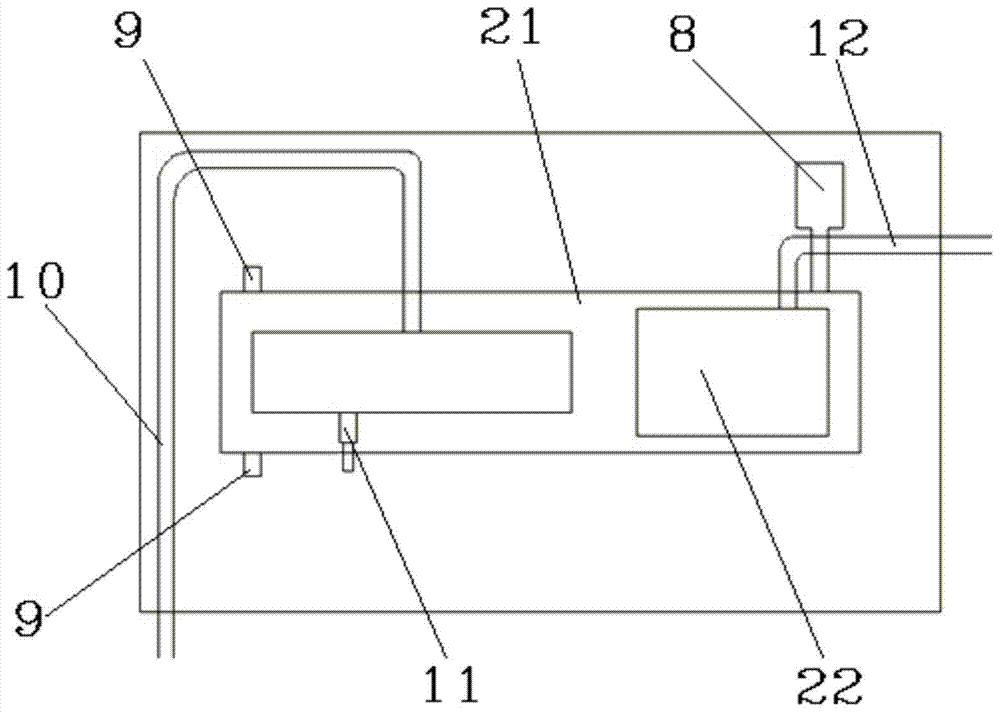

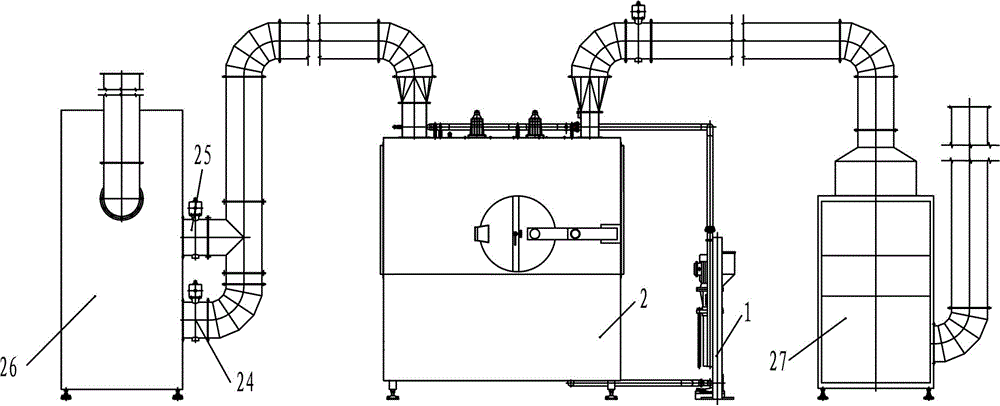

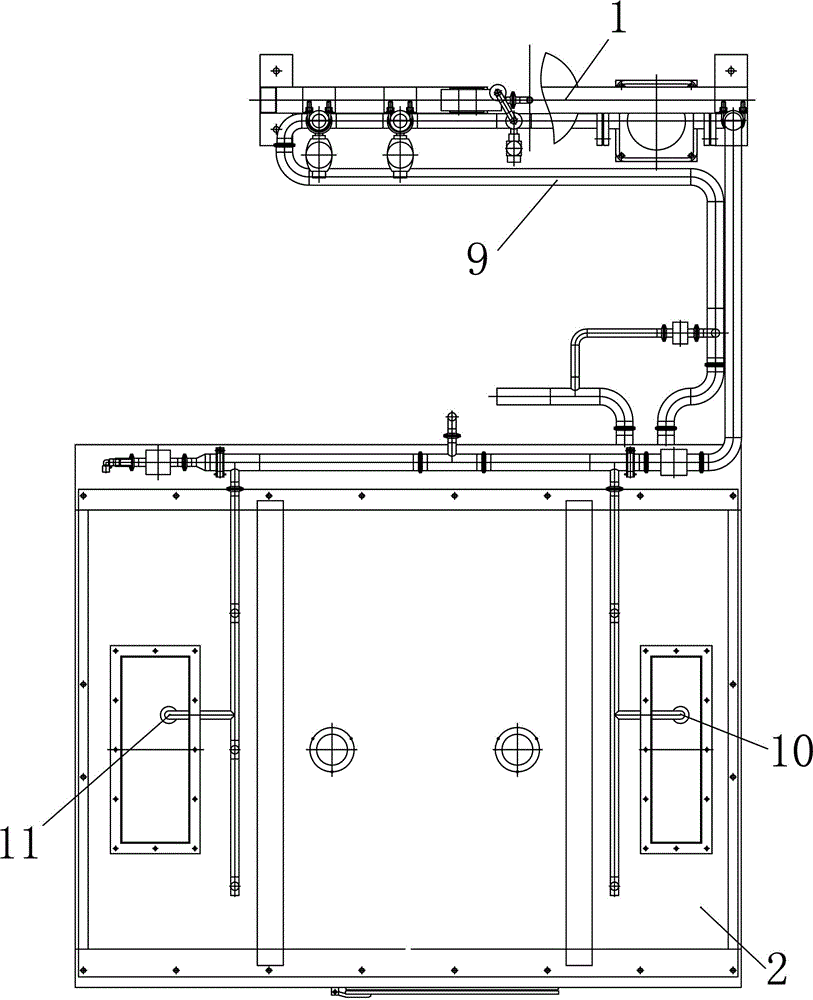

ActiveCN103817115APrevent backflowRealize fully automatic cleaningDrying solid materials with heatHearth type furnacesControl systemTap water

The invention relates to cleaning equipment of sugar coating machines for medicine tablet processing, in particular to a three-way cleaning device of a sugar coating machine. The three-way cleaning device comprises a cleaning station (1) which adopts a plurality of cleaning pipes. The cleaning pipes are externally connected with a tap water connector (3), a pure water connector (4) and a circular cleaning pipeline (9) and clean a main unit (2), a hot blast cabinet (27) and an exhaust cabinet (26) in place, and the cleaning state is controlled by a microcomputer control system. The cleaning device performs fully automatic online cleaning, is controlled through a touch screen and is simple to operate. Besides, cleaning time and schemes can be planned according to needs.

Owner:ZHEJIANG JIANGNAN PHARMA MACHINERY

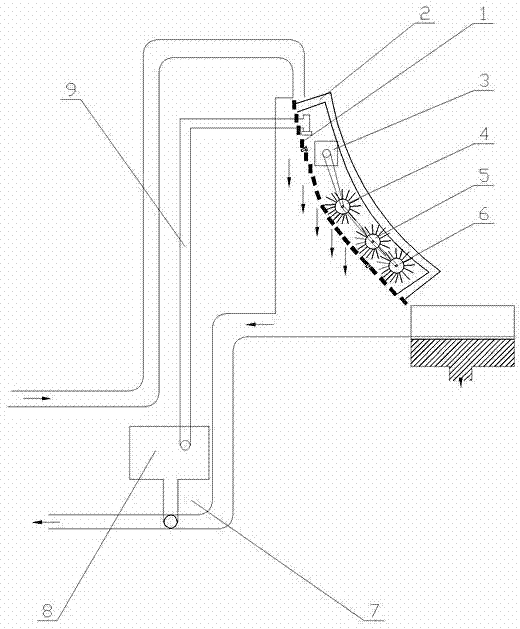

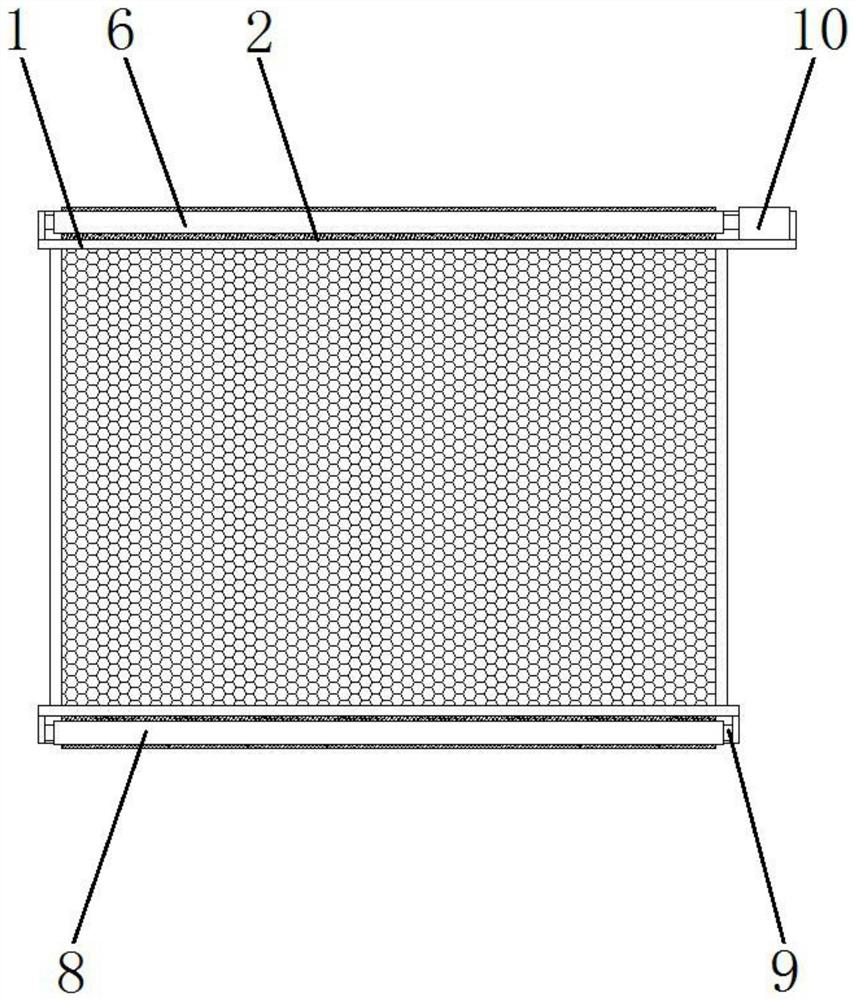

Self-cleaning fan coil filter screen

InactiveCN111744278ARealize fully automatic cleaningWill not affect the useDispersed particle filtrationLighting and heating apparatusDrive shaftElectric machinery

Owner:苏州百佳信能源科技有限公司

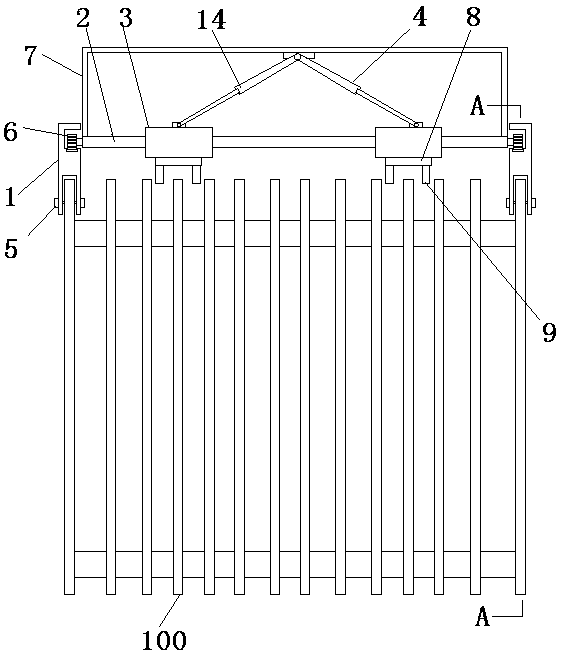

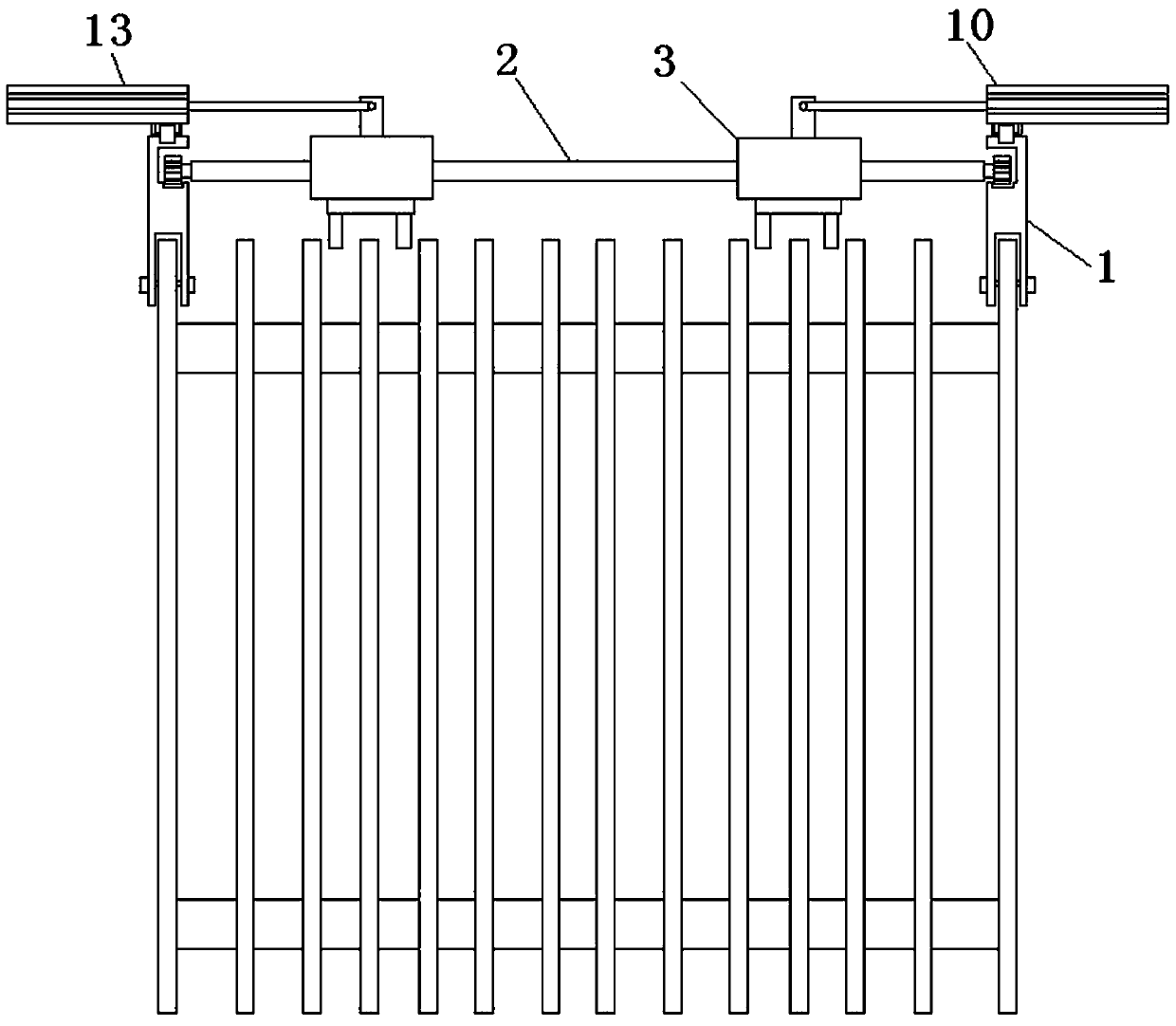

High-efficiency blowing type transformer radiator cleaning device and cleaning method

InactiveCN111112231AAchieve cleaningImprove work efficiencyTransformers/inductances coolingCleaning using gasesEngineeringHigh voltage transformer

The invention discloses a high-efficiency blowing type transformer radiator cleaning device. The cleaning device is installed on a transformer radiator, and the cleaning device comprises a longitudinal walking mechanism, a transverse walking mechanism and high-pressure air blowing devices. The longitudinal walking mechanism comprises two symmetrical fixed guide rails and a moving guide rail, wherein one fixed guide rail is mounted on the top of each of two heat dissipation sheets at the outermost side of a high-voltage transformer; the moving guide rail spans between the two fixed guide rails,and the operation of the moving guide rail is realized through a longitudinal walking component. The transverse walking mechanism comprises two box bodies, wherein the two box bodies are slidably connected to the moving guide rail; the left side box body runs in the left half part of the moving guide rail through a left side transverse walking component, and the right side box body runs in the right half part of the moving guide rail through a right side transverse walking component. The high-pressure air blowing devices are installed on the box bodies and used for blowing air between the twoadjacent dissipation sheets. According to the invention, full-automatic cleaning is achieved, manual adjustment is not needed, and the working efficiency is improved.

Owner:河南省森电智能装备有限公司

Road fallen leaf cleaning device

InactiveCN111395237AEfficient cleaningRealize fully automatic cleaningRoad cleaningAgricultural scienceAgricultural engineering

The invention discloses a road fallen leaf cleaning device. The device comprises a cleaning vehicle and a connecting rod fixedly connected to the left end face of the cleaning vehicle; a grip is fixedly arranged on the upper end surface of the connecting rod; and moving wheels capable of enabling the cleaning vehicle to move are fixedly arranged in the lower end face of the cleaning vehicle, and are symmetrically arranged front and back. An air-drying device of the invention can be used for effectively air-drying accumulated water on the fallen leaf edge; a heating resistance wire is used forheating air entering the device; therefore, the air drying efficiency of the device is improved; after water on the ground is air-dried, fallen leaves on the ground are swept into a collecting box tobe collected through a sweeping device, full-automatic sweeping of the fallen leaves can be achieved, the working burden of sanitation workers for sweeping the fallen leaves in autumn and rainy days is relieved, the working efficiency is high, and the sweeping effect is good.

Owner:JINHUA NAER ENVIRONMENTAL TECH CO LTD

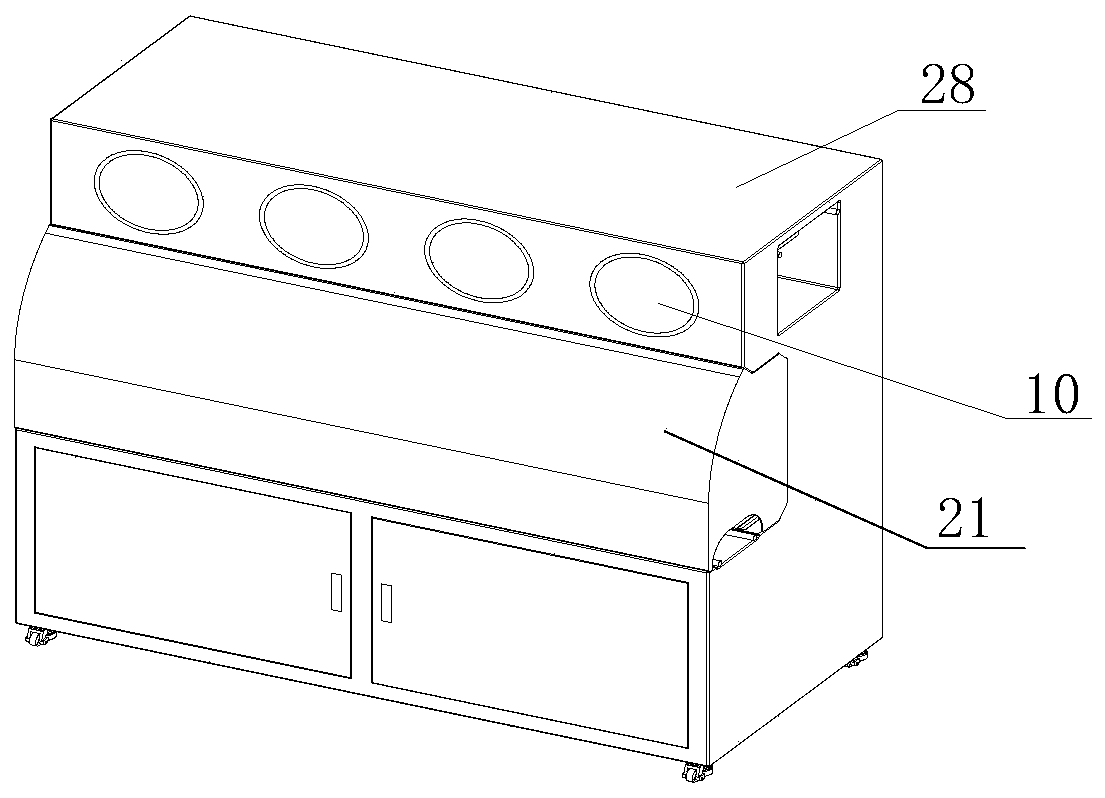

Full-automatic multi-bin commercial cooking machine

InactiveCN111110028ARealize one-key operationRealize fully automatic cleaningCooking-vessel materialsDomestic stoves or rangesSide dishIndustrial engineering

The invention discloses a full-automatic multi-bin commercial cooking machine. The cooking machine comprises a shell, a plurality of electromagnetic stir-frying pans arranged side by side are arrangedin the shell, a conveying belt is arranged above the electromagnetic stir-frying pans, a side dish color box can be erected on the conveying belt, the conveying belt is driven by a motor to convey the side dish box to the position over the electromagnetic stir-frying pans, and a bin door at the bottom of the side dish box can be controlled to be opened. A bin opening guide rod, a dish box baffle,a bin opening button, a bin opening hook, an infrared sensor and a bin door capable of being used for opening the bottom of the dish distribution box are arranged below the conveying belt. The invention provides a full-automatic multi-bin commercial cooking machine, wherein a plurality of frying pans are arranged in the shell. One-key operation of cooking can be achieved, no cooking fume, no famous fire and no kitchen waste exist, and full-automatic cleaning is achieved.

Owner:京山京慧智能科技有限公司

Full-automatic brake disc cleaning equipment

PendingCN112024523AEmission reductionGuaranteed cleaning qualityPretreated surfacesCoatingsBrakeEngineering

The invention discloses full-automatic brake disc cleaning equipment. The equipment comprises a rack, a feeding conveyor, a workpiece positioning device, a workpiece transferring module, a jig liftingmodule and a discharging conveyor, wherein the workpiece positioning device is installed on the feeding conveyor; the workpiece transferring module is installed on the top of the rack in a sliding mode and comprises a transverse moving module, a workpiece lifting module and a workpiece grabbing pneumatic claw, wherein the workpiece lifting module is installed on the transverse moving module, andthe workpiece grabbing pneumatic claw is installed at the bottom of the workpiece lifting module; and the jig lifting module is installed in a cleaning tank and comprises a jig frame, a linear liftingguide rail, a jig frame lifting guide rail and a lifting driving device, wherein a jig frame swing mechanism is installed at the top of the linear lifting guide rail, and the two ends of the jig frame are connected to the jig frame swing mechanism and the interior of the jig frame lifting guide rail separately. The full-automatic brake disc cleaning equipment is wide in application range, compactin structure, and capable of improving the working efficiency.

Owner:苏州市全昱自动化机械设备有限公司

Device for cleaning away sundries in keyboard

InactiveCN109261567AReduce labor intensityImprove work efficiencyCleaning using toolsCleaning using gasesBristleMechanical engineering

Owner:成都捷科菲友信息技术有限公司

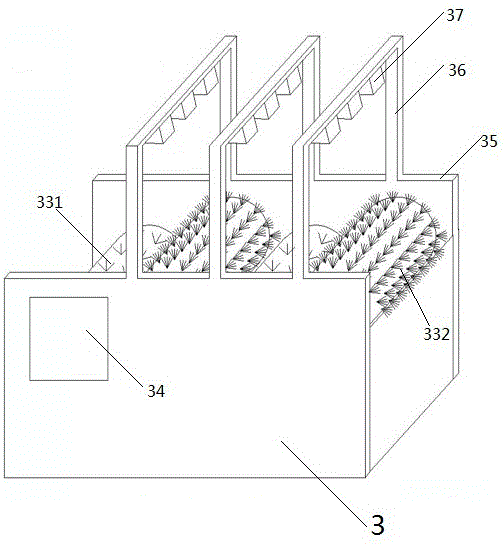

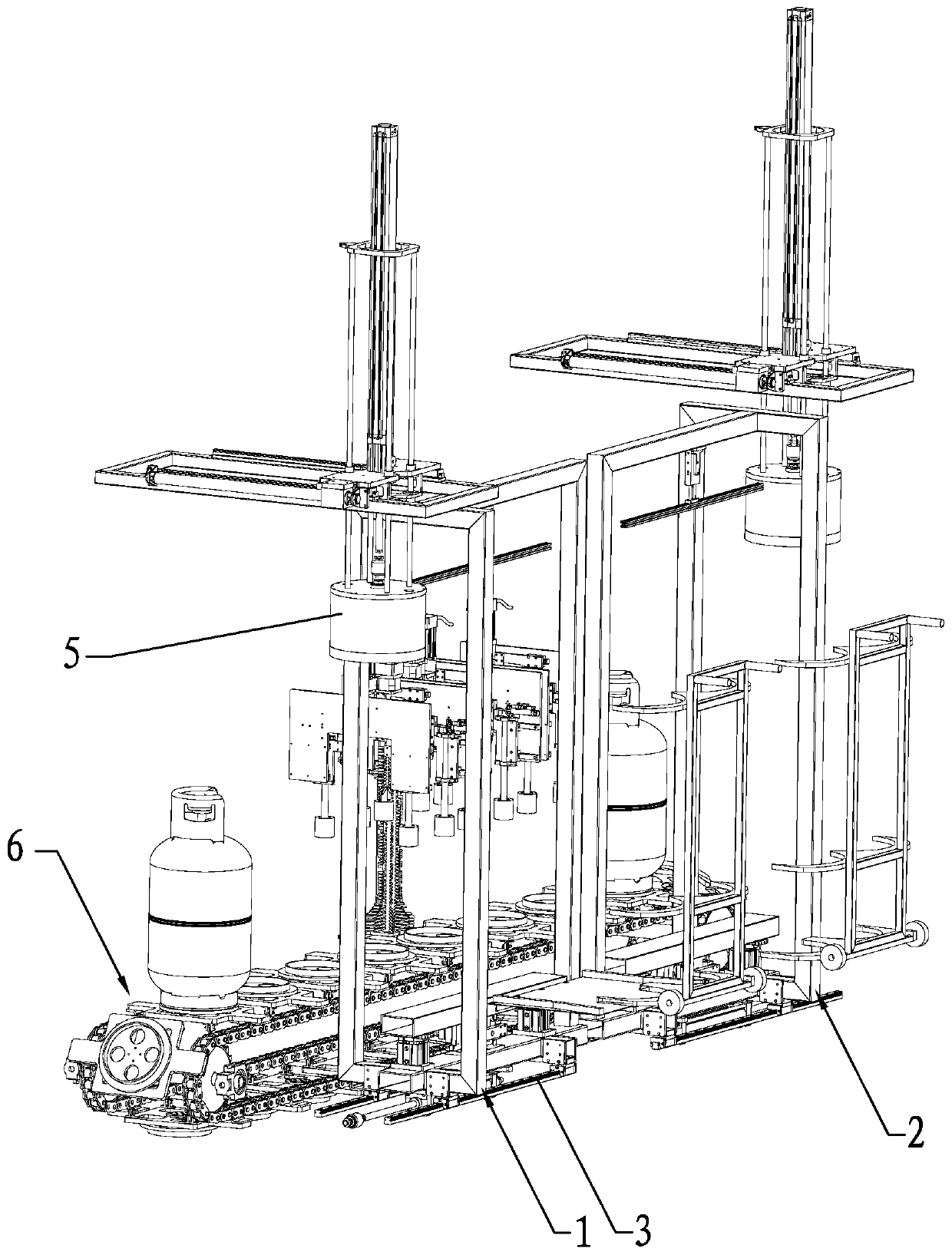

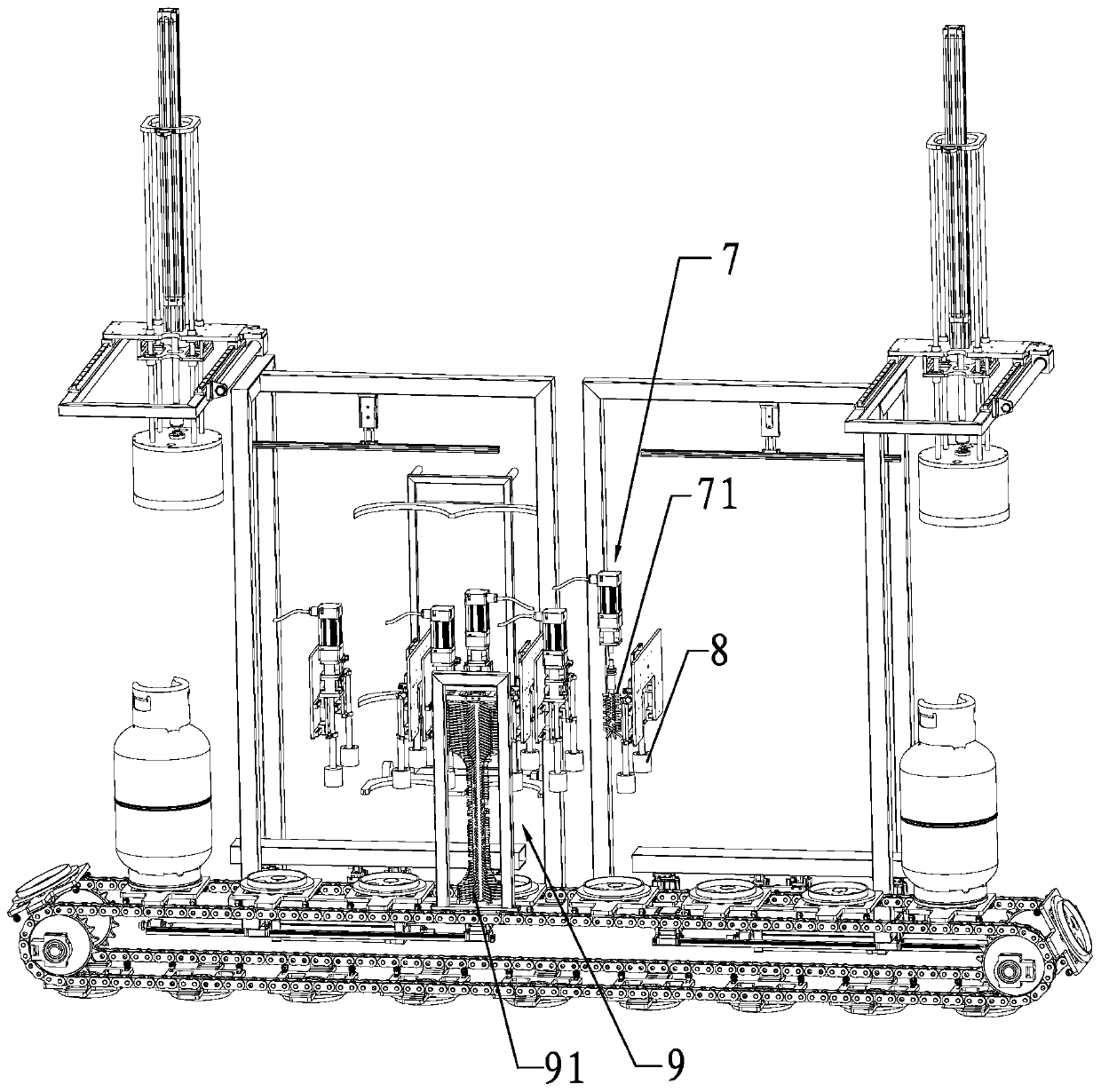

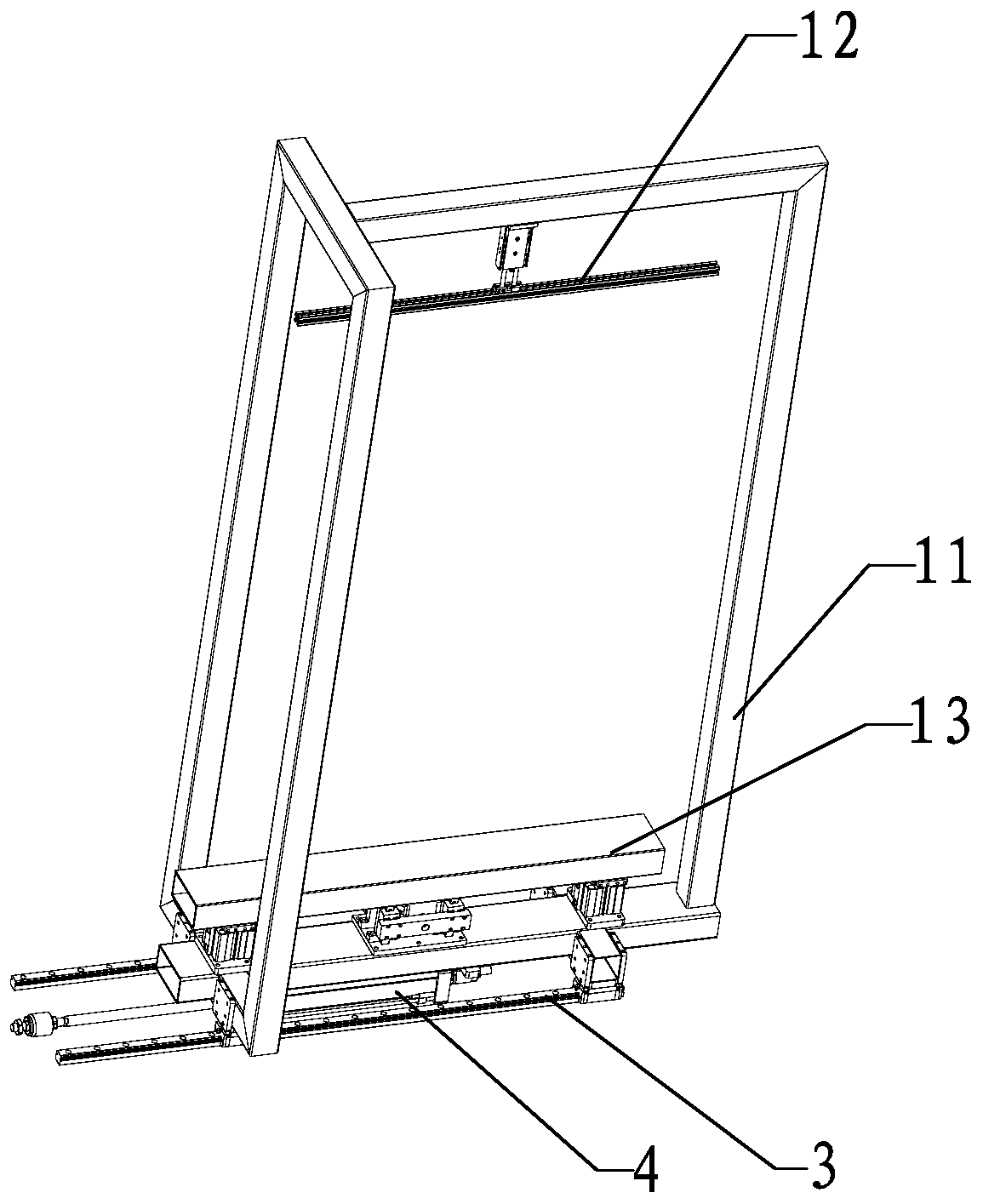

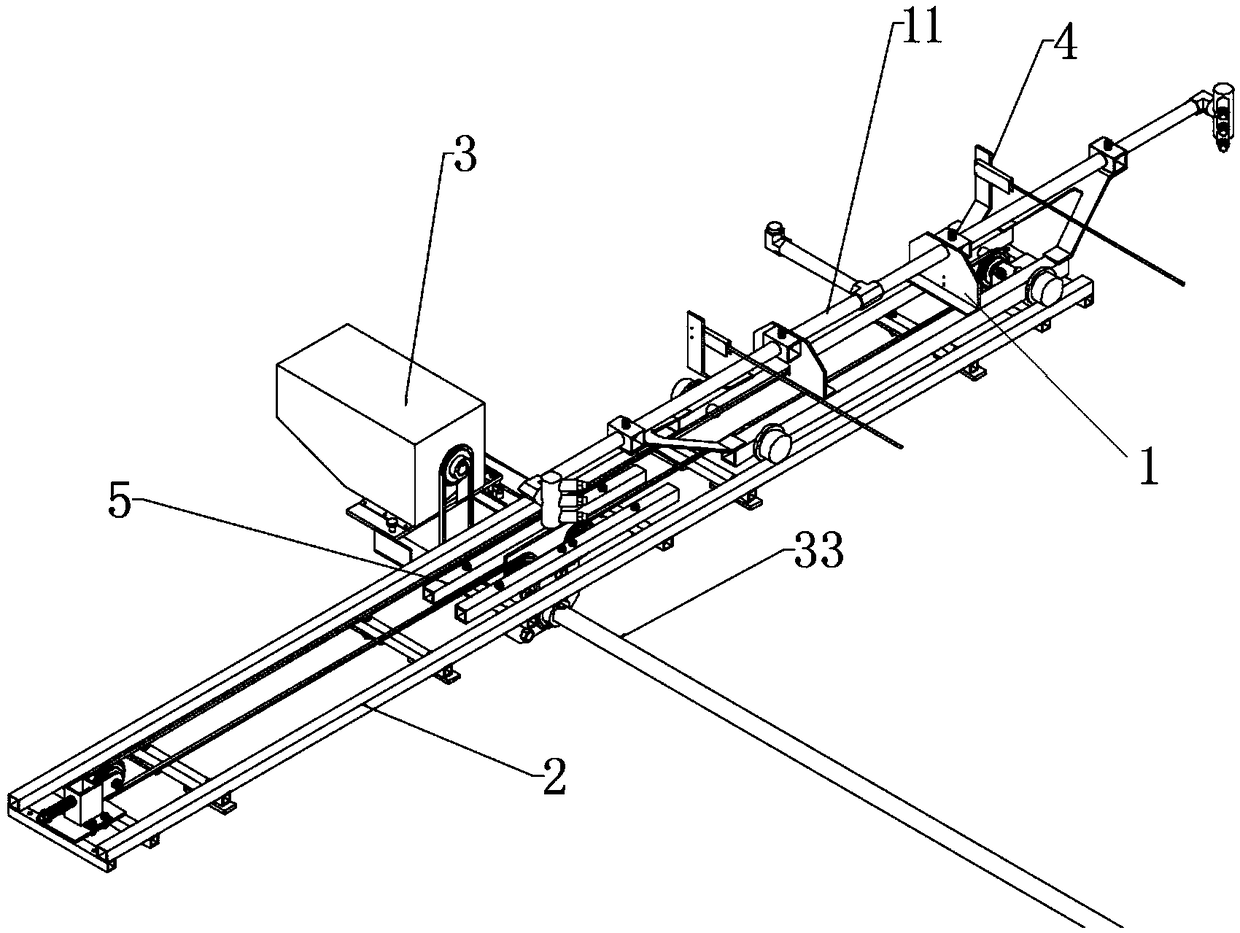

Automatic cleaning method for liquefied gas steel cylinder

InactiveCN109807146AFully automatic cleaningImprove cleaning efficiencyHollow article cleaningManipulatorEngineering

The invention relates to the field of cleaning liquefied gas steel cylinders, specifically an automatic cleaning method for a liquefied gas steel cylinder. The automatic cleaning method for the liquefied gas steel cylinder comprises the following steps of: pushing the steel cylinder to a first clamping mechanism by a cart, withdrawing the cart, transferring the steel cylinder by the first clampingmechanism, then transferring the steel cylinder to a conveyor belt from the end of the first clamping mechanism by a manipulator, spraying cleaning liquid on the steel cylinder, brushing the steel cylinder by a cleaning mechanism, and finally moving the steel cylinder out of the conveyor belt. After adopting the above scheme, the automatic cleaning of liquefied gas cylinder is realized, and the automatic cleaning method provided by the invention has practical commercial application prospect.

Owner:绍兴恒研机电科技有限公司

Tire follow-up washing vehicle washing device for engineering vehicles

PendingCN109131253ARealize fully automatic cleaningReasonable structural designCleaning apparatus with conveyorsCleaning apparatus for vehicle exteriorsCost savingsAutomotive engineering

The invention discloses a tire follow-up washing vehicle washing device for engineering vehicles, which comprises an automatic washing trolley, a slide rail, a power system and a sensor. The automaticcleaning trolley is arranged on the slide rail; the power system is arranged on the slide rail and is connected with the automatic cleaning trolley. The sensor is arranged on the automatic washing trolley. The invention has the advantages of reasonable structure design, high working efficiency, cost saving, simple operation, stable structure, and long service life, realizes the full automatic cleaning of the vehicle tire, can automatically identify and track the vehicle tires, and automatically washes the tire of the vehicle entering the washing area.

Owner:广西腾子熙科技有限公司

Automatic laser cleaning device and method of OLED organic evaporation device

InactiveCN111069187AReal-time assessmentRapid assessmentMaterial analysis by optical meansDirt cleaningLaser scanningEngineering

The invention discloses an automatic laser cleaning method of an OLED organic evaporation device. The automatic laser cleaning method of the OLED organic evaporation device comprises a master controldevice, a robot transmission device, a laser generation device, a combustion product processing device, a residual component analyzing device and a workbench and clamp device. The robot device conducts laser scanning and radiation on the organic contaminants on the surface of an attachment preventing plate, so that the contaminants are heated and expanded or ablated, then thermal stress or thermalvibration is generated to enable the contaminants to be stripped or disengaged from the surface of an object to be cleaned, and full-automatic cleaning is achieved; and meanwhile, the residual component analyzing device conducts real-time and rapid evaluation on the cleaning effect.

Owner:安徽富乐德科技发展股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com