Automatic plate clearing system and automatic plate clearing process thereof

An automatic cleaning and plate cleaning technology, which is applied in the direction of spinneret assemblies, textiles and papermaking, etc., can solve the problems of easy to cause industrial accidents, difficult manual cleaning, time-consuming and labor-intensive, etc., to prevent collision or friction, and reduce labor costs. The effect of fast intervention and positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

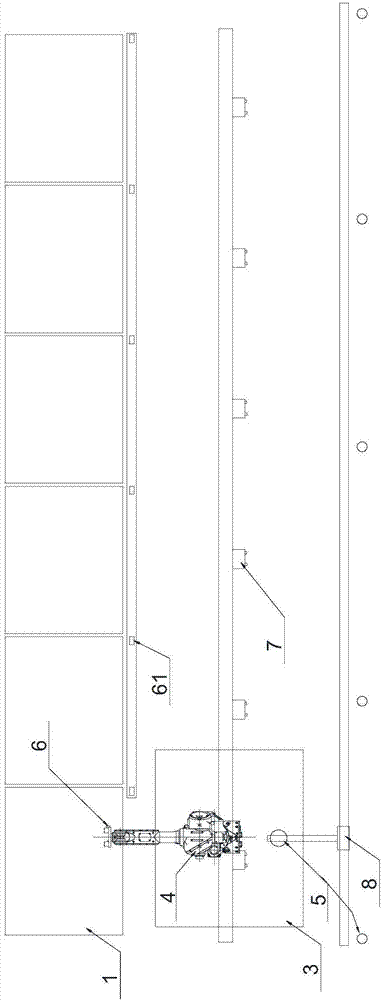

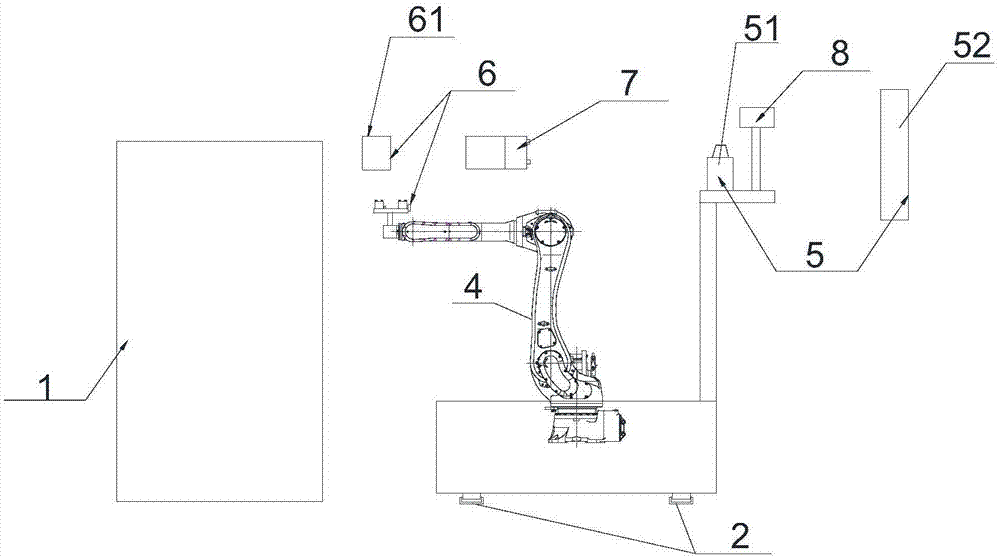

[0032] Such as figure 1 , figure 2 As shown, the automatic plate cleaning system of the present invention is used to clean the spinnerets on the chemical fiber equipment 1 to prevent the clogging of the spinning holes. The spinnerets are arranged in rows on the chemical fiber equipment. The devices 1 are arranged in rows and columns, figure 1 , taking six chemical fiber equipment as an example, the six chemical fiber equipment are arranged in a straight line.

[0033] On the ground in front of the chemical fiber equipment, a walking track 2 parallel to the arrangement direction of the chemical fiber equipment is provided, and the walking track public walking system 3 walks, and the walking system can be various types of carrying cars. In this embodiment, the walking system is an AGV car; The walking system 3 is used to carry the plate cleaning robot 4. The plate cleaning robot 4 has a bendable multi-joint arm and a plate cleaning scraper arranged at the end of the arm, and ...

Embodiment 2

[0041] Another aspect of the present invention provides an automatic plate cleaning process, comprising the following steps:

[0042]S1: Set the cleaning conditions for chemical fiber equipment. When the cleaning conditions are met, the cleaning will be automatically started; or, when the operator thinks that cleaning is necessary, the cleaning will be started manually; measure the distance between the positioning block on each chemical fiber equipment and the first spinneret at the starting end Information on the three-dimensional positional relationship; information on measuring the three-dimensional positional relationship between the cleaning scraper and the positioning probe; storing the above-mentioned setting and measurement information into the background control system; the set cleaning conditions can be based on time as a cycle, with a certain interval Time starts cleaning, or it can start cleaning when the detection equipment detects that the spinneret is blocked;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com