Full-automatic brake disc cleaning equipment

A fully automatic cleaning and brake disc technology, applied in cleaning methods and utensils, cleaning methods using liquids, surface pretreatment, etc., can solve problems such as inability to fully automate cleaning, poor cleaning quality, and waste of cleaning fluid, etc. Achieve the effect of saving water and chemicals, ensuring cleaning quality, and reducing waste water discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] A preferred embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

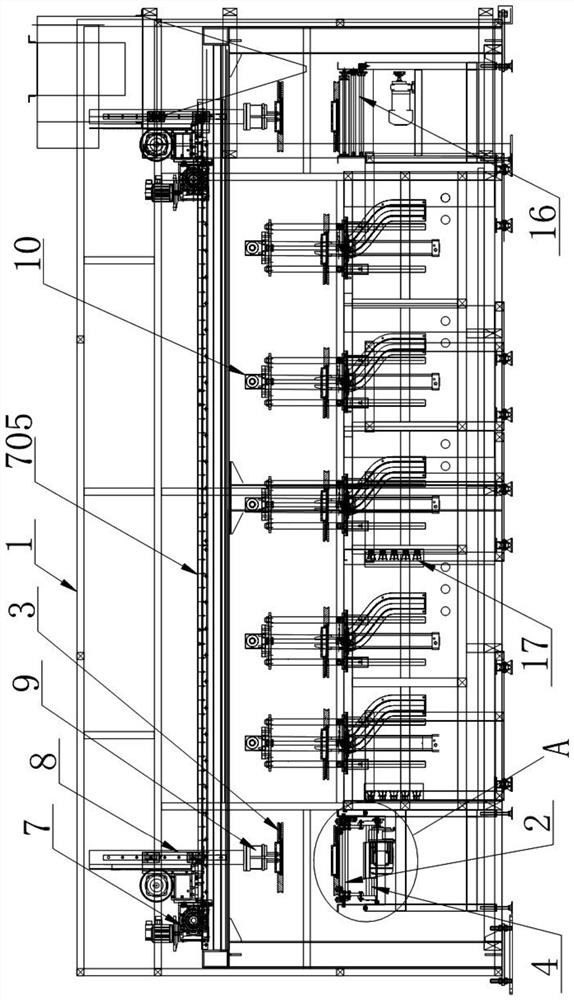

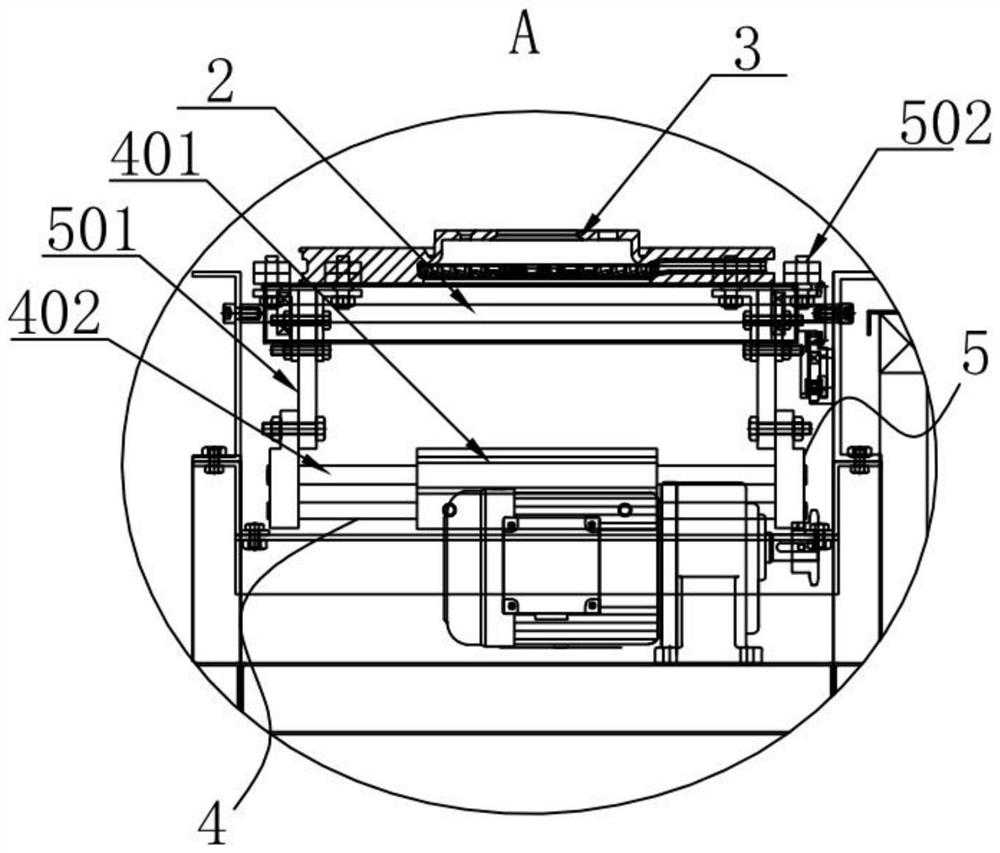

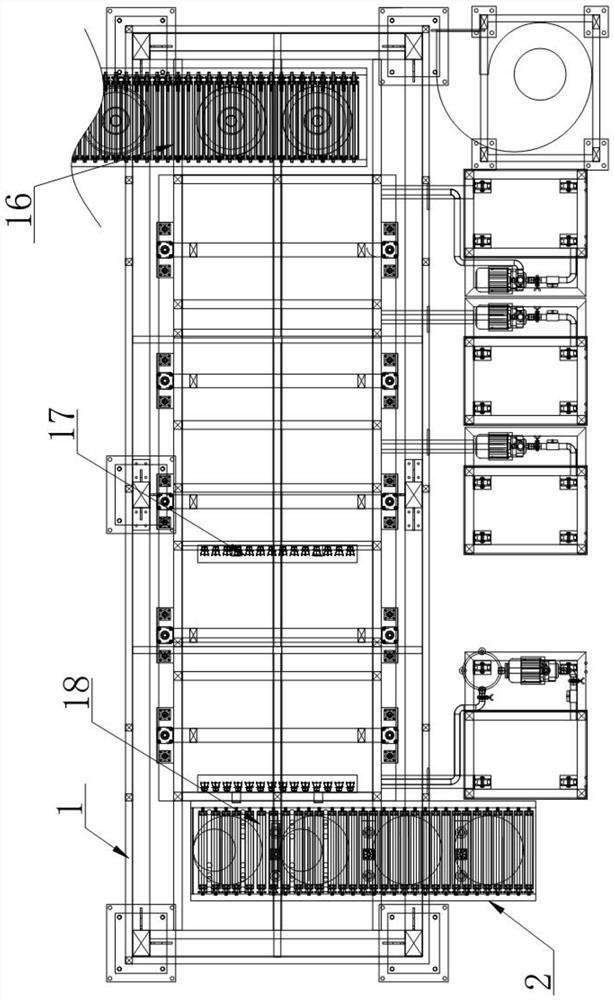

[0050] refer to Figure 1 to Figure 8 , The present invention provides a fully automatic cleaning equipment for brake discs, including: a frame 1, a feeding conveyor 2, a workpiece positioning device 4, a workpiece transfer module 6, a jig lifting module 10 and a feeding conveyor 16.

[0051] refer to figure 1 , the frame 1 is used to carry the cleaning equipment, and the frame 1 is provided with four cleaning tanks, which are the first cleaning tank, the second cleaning tank, the third cleaning tank, and the fourth cleaning tank in turn, and the one close to the feeding conveyor 2 It is the first cleaning tank, and an ultrasonic module 17 is installed in the first cleaning tank, which can perform ultrasonic cleaning. The second cleaning tank, the third cleaning tank and the fourth cleaning tank have different cleaning functions respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com