Automatic cleaning method for liquefied gas steel cylinder

An automatic cleaning and liquefied gas technology, applied in cleaning methods and utensils, chemical instruments and methods, cleaning hollow objects, etc., can solve the problems of time-consuming, labor-intensive, low efficiency, and inability to judge the liquefied gas cylinder logo from the appearance, etc. Cleaning efficiency, the effect of fully automated cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

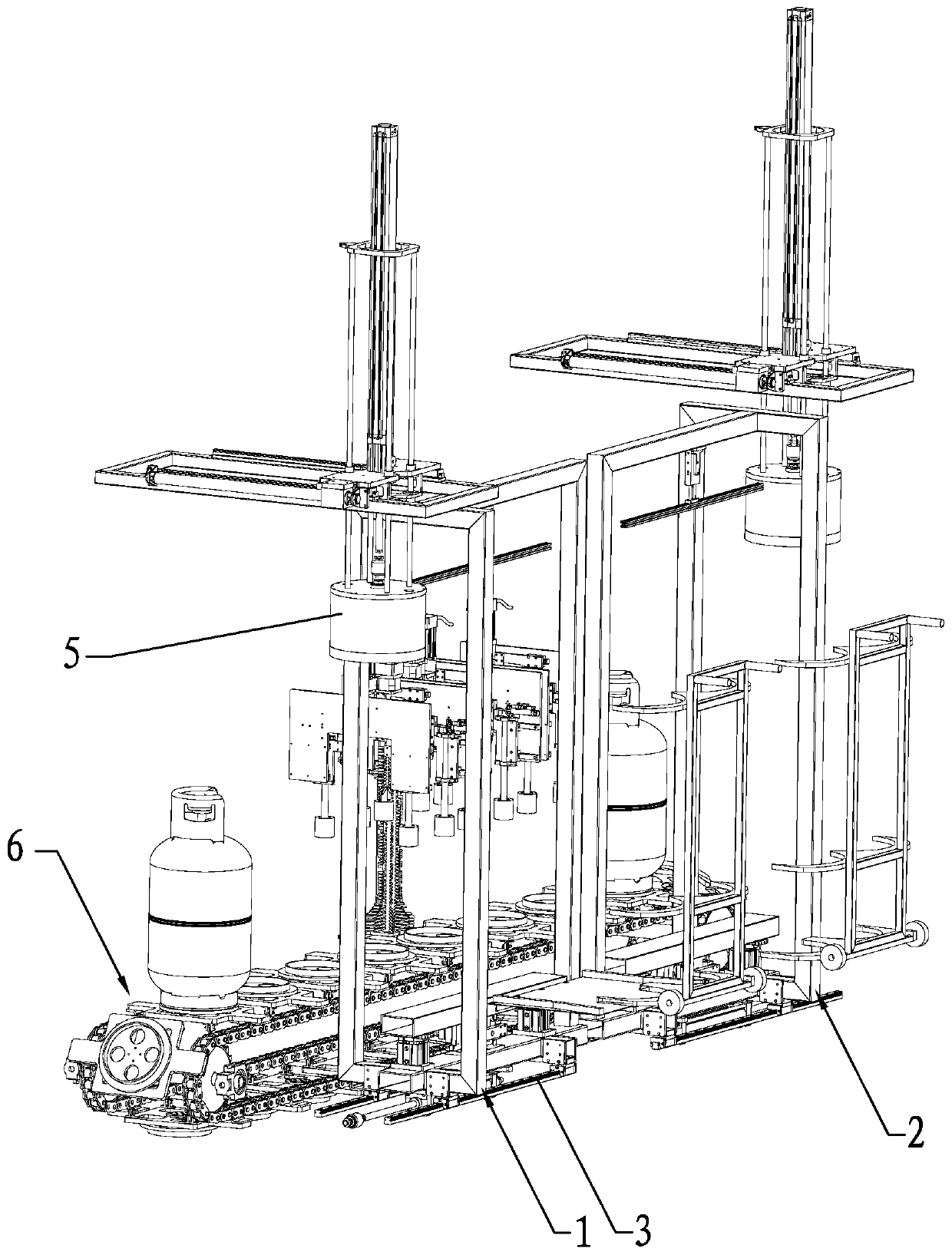

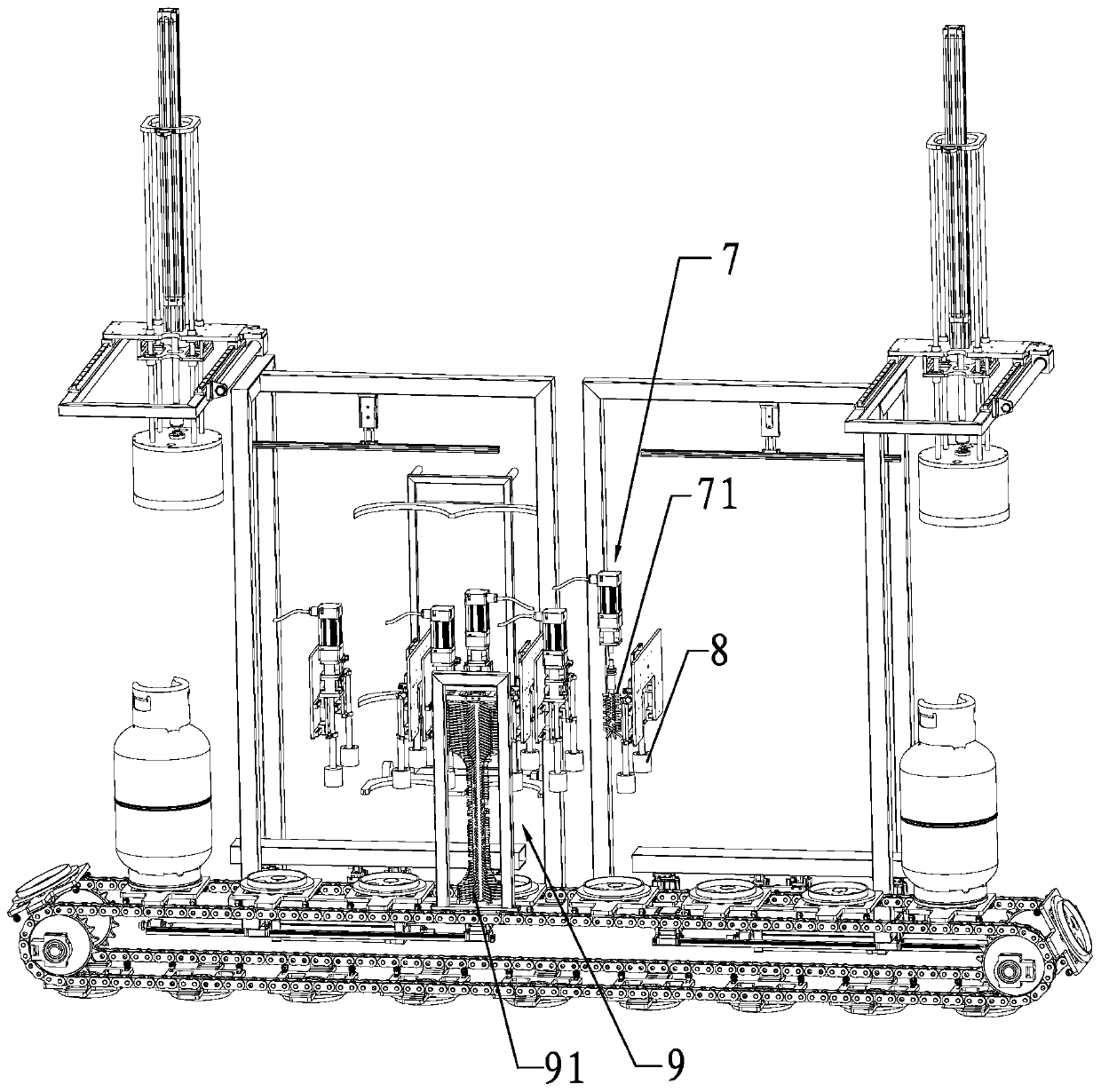

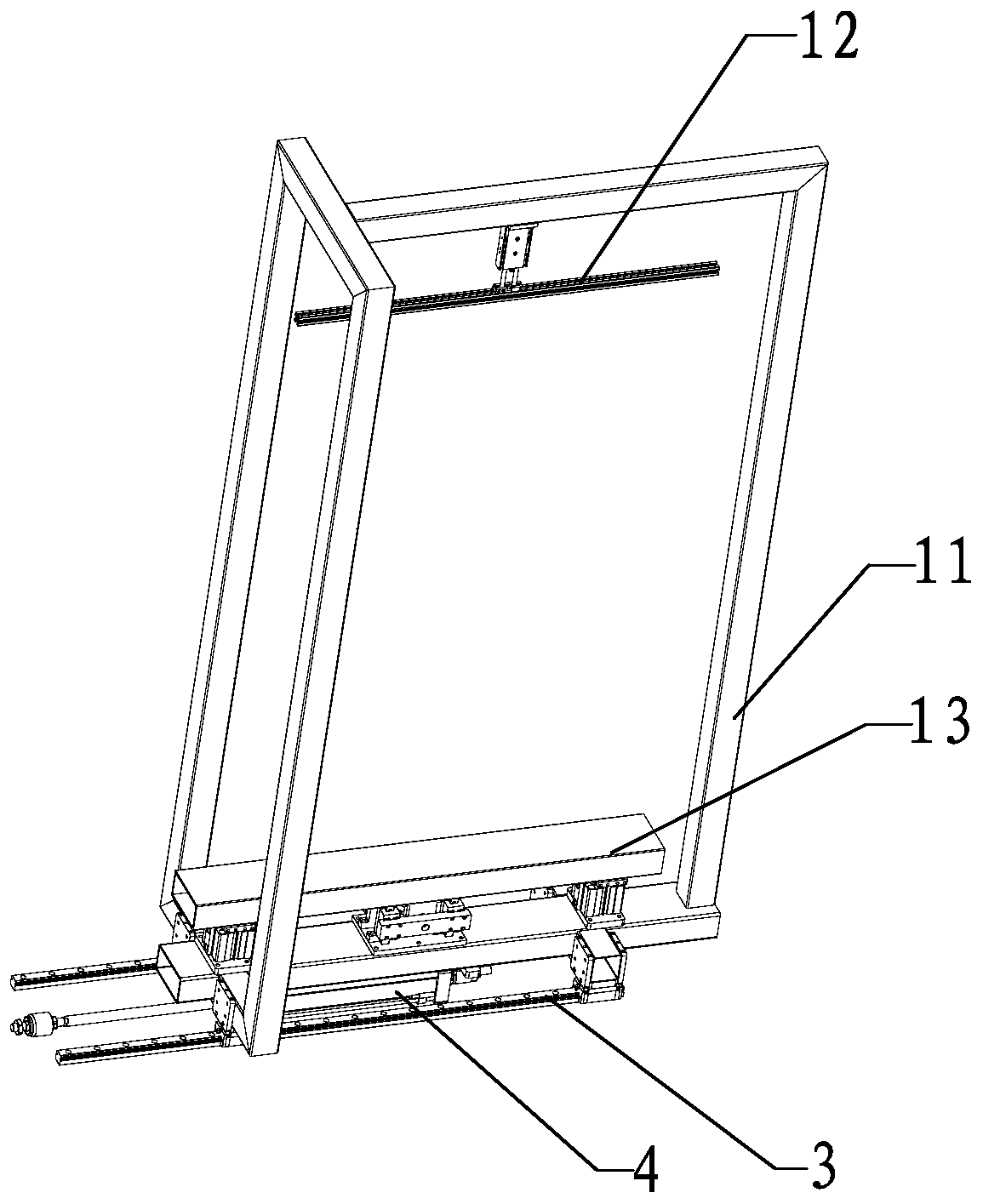

[0036] Existing cylinder carts such as Figure 4 As shown, by setting the matching semi-circular support at the bottom of the steel cylinder, the steel cylinder can be transported after the trolley is slightly tilted, and the trolley can be pushed onto the frame 100 at the first clamping mechanism 1, After the trolley is laid flat and withdrawn, the steel cylinder remains on the frame 100 , and the steel cylinder on the frame 100 can be clamped and moved by the first clamping mechanism 1 .

[0037] The first clamping mechanism 1 comprises an external support 11, and the upper and lower sides of the external support 11 are respectively provided with an upper clamping rod 12 and a lower clamping rod 13 driven by a cylinder, and the upper clamping rod 12 and the lower clamping rod 13 are arranged on the cylinder. Clamp the single-layer or double-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com