Tire follow-up washing vehicle washing device for engineering vehicles

A technology for engineering vehicles and cleaning devices is applied in the field of vehicle tire washing systems, which can solve the problems of inability to wash the tires of dump trucks, difficult to adjust vehicles, and easy damage to cleaning brushes, so as to save labor costs, improve passing speed, and prolong cleaning. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

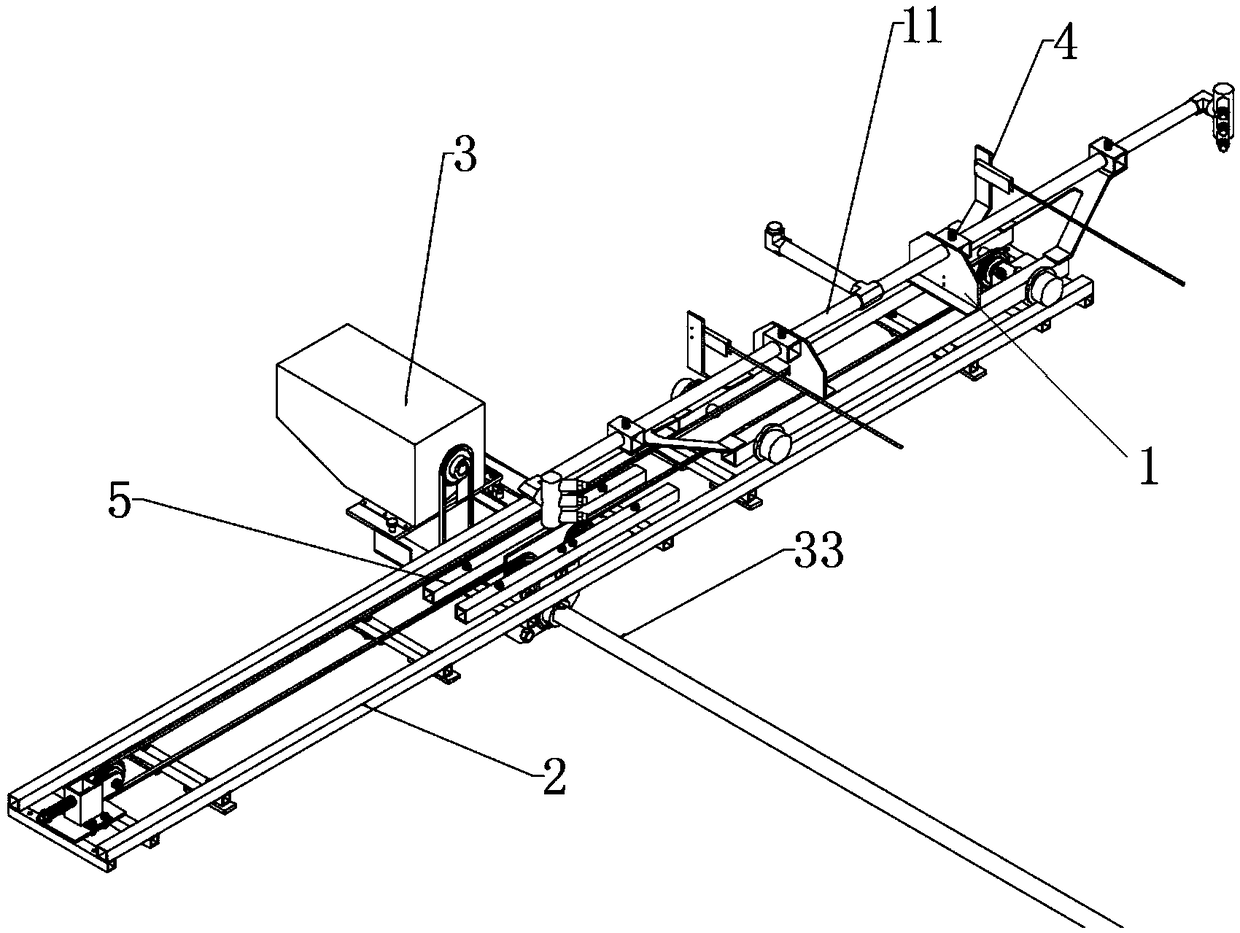

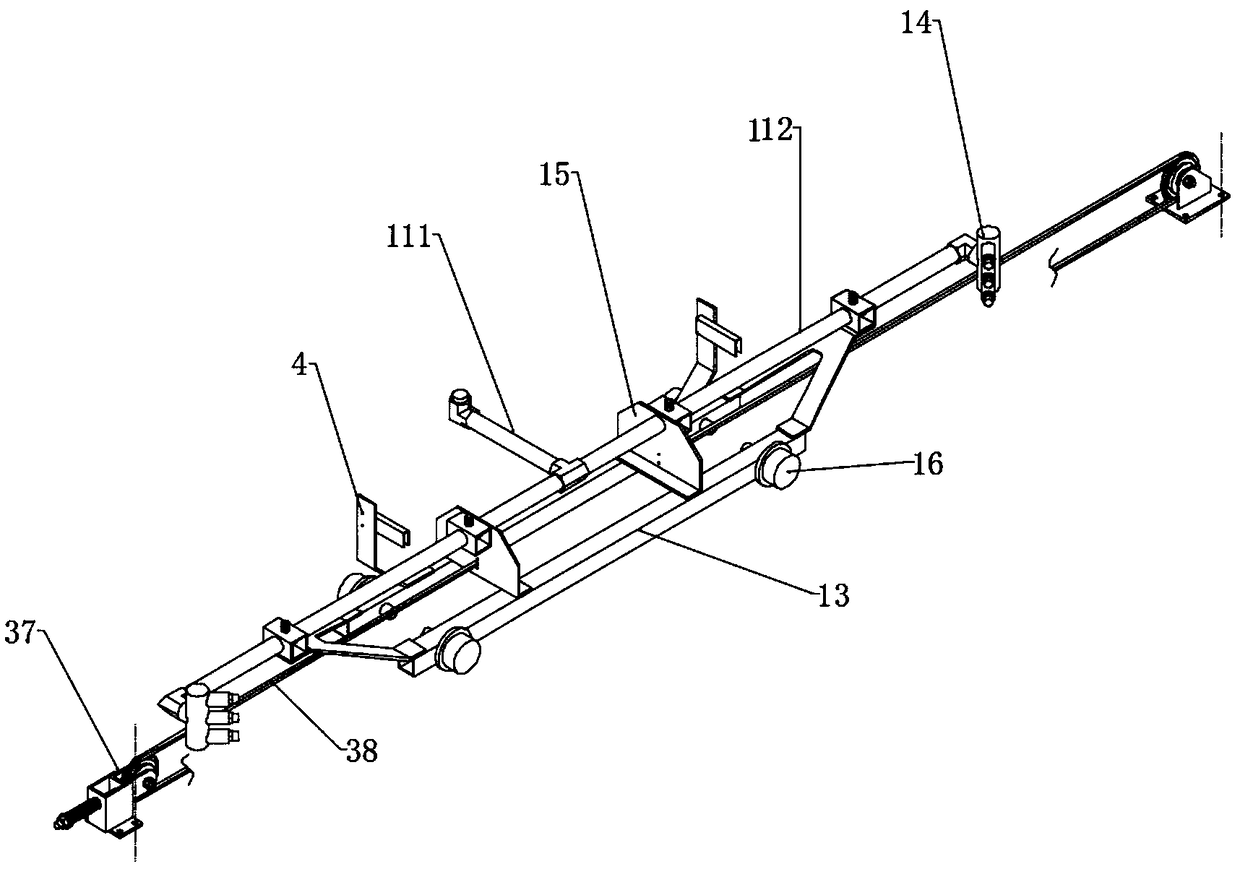

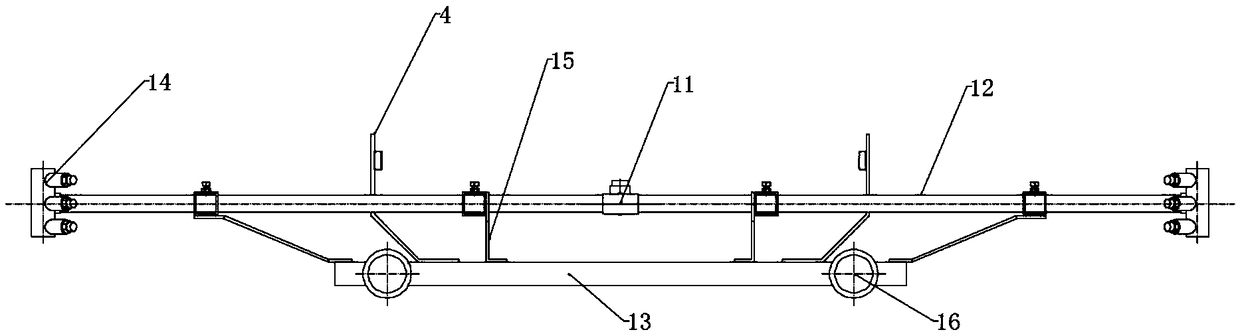

[0052] A tire follow-up cleaning device for engineering vehicles, comprising an automatic cleaning trolley 1, a slide rail 2, a power system 3, and a sensor 4; the automatic cleaning trolley 1 is arranged on the slide rail 2; the power system 3 is arranged on the slide rail 2, and is connected with the The automatic cleaning trolley 1 is connected; the sensor 4 is arranged on the automatic cleaning trolley 1; the automatic cleaning trolley 1 includes a water supply pipe 11, a trolley chassis 13; the water supply pipe 11 is fixed on the trolley chassis 13, and the water supply pipe 11 is provided with a high-pressure nozzle 14; Both sides of the trolley chassis 13 are provided with wheels 16, and the wheels 16 are respectively in contact with the slide rail 2; the power system 3 includes a motor 31, a fixed platform 32, and a drive wheel C37; 2-phase connection, the motor 31 is set on the fixed platform 32; two transmission wheels C37 are respectively provided at both ends of th...

Embodiment 2

[0058] A tire follow-up cleaning device for engineering vehicles, comprising an automatic cleaning trolley 1, a slide rail 2, a power system 3, and a sensor 4; the automatic cleaning trolley 1 is arranged on the slide rail 2; the power system 3 is arranged on the slide rail 2, and is connected with the The automatic cleaning trolley 1 is connected; the sensor 4 is arranged on the automatic cleaning trolley 1; the automatic cleaning trolley 1 includes a water supply pipe 11, a trolley chassis 13; the water supply pipe 11 is fixed on the trolley chassis 13, and the water supply pipe 11 is provided with a high-pressure nozzle 14; Both sides of the trolley chassis 13 are provided with wheels 16, and the wheels 16 are respectively in contact with the slide rail 2; the power system 3 includes a motor 31, a fixed platform 32, and a drive wheel C37; 2-phase connection, the motor 31 is set on the fixed platform 32; two transmission wheels C37 are respectively provided at both ends of th...

Embodiment 3

[0064] A tire follow-up cleaning device for engineering vehicles, comprising an automatic cleaning trolley 1, a slide rail 2, a power system 3, and a sensor 4; the automatic cleaning trolley 1 is arranged on the slide rail 2; the power system 3 is arranged on the slide rail 2, and is connected with the The automatic cleaning trolley 1 is connected; the sensor 4 is arranged on the automatic cleaning trolley 1; the automatic cleaning trolley 1 includes a water supply pipe 11, a trolley chassis 13; the water supply pipe 11 is fixed on the trolley chassis 13, and the water supply pipe 11 is provided with a high-pressure nozzle 14; Both sides of the trolley chassis 13 are provided with wheels 16, and the wheels 16 are respectively in contact with the slide rail 2; the power system 3 includes a motor 31, a fixed platform 32, and a drive wheel C37; 2-phase connection, the motor 31 is set on the fixed platform 32; two transmission wheels C37 are respectively provided at both ends of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com