Automatic cleaning device

An automatic and fuel-injecting device technology, which is applied in the direction of cleaning methods, chemical instruments and methods, cleaning methods and utensils using gas flow, etc., can solve the problem that the cleanliness of products does not meet the qualified requirements, the labor intensity is high, and the products are easy to produce. rust and other problems, to reduce the labor intensity of employees, improve production efficiency, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

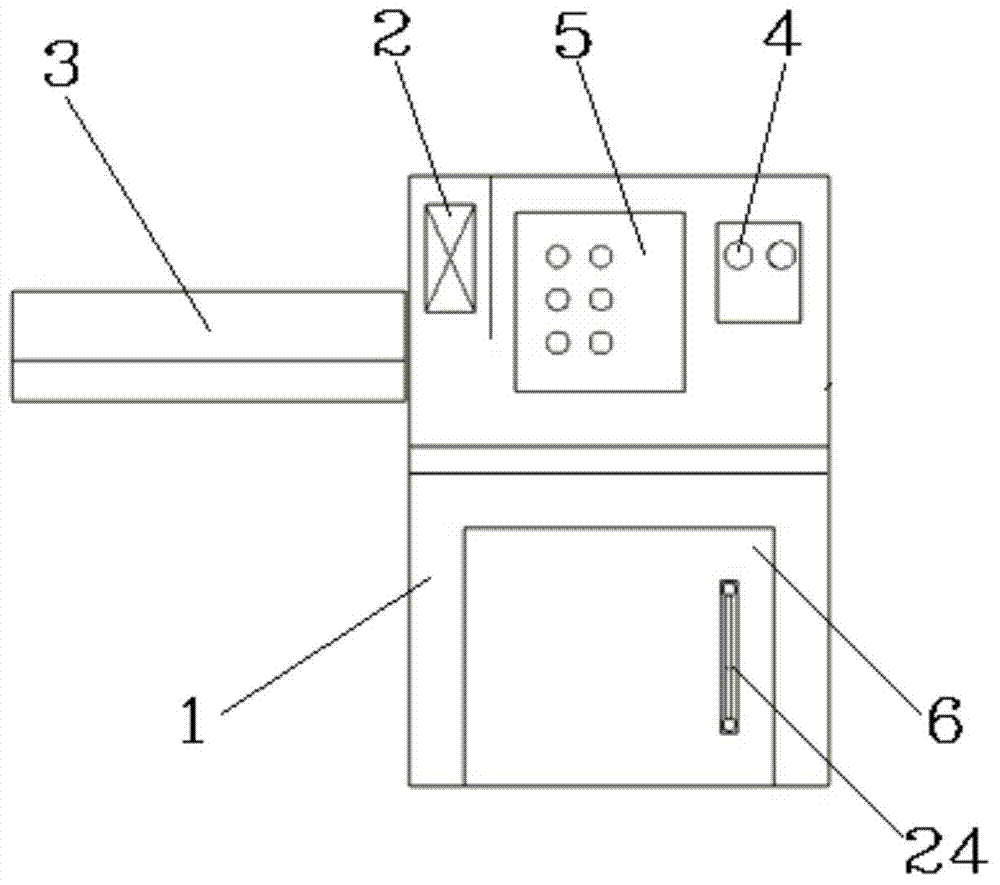

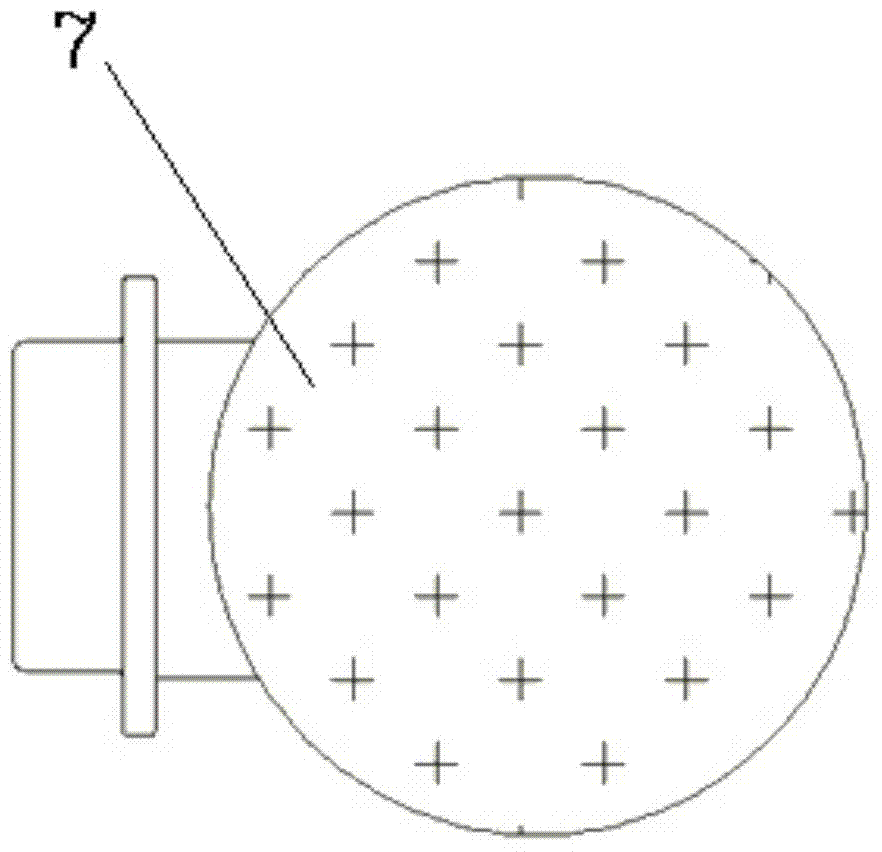

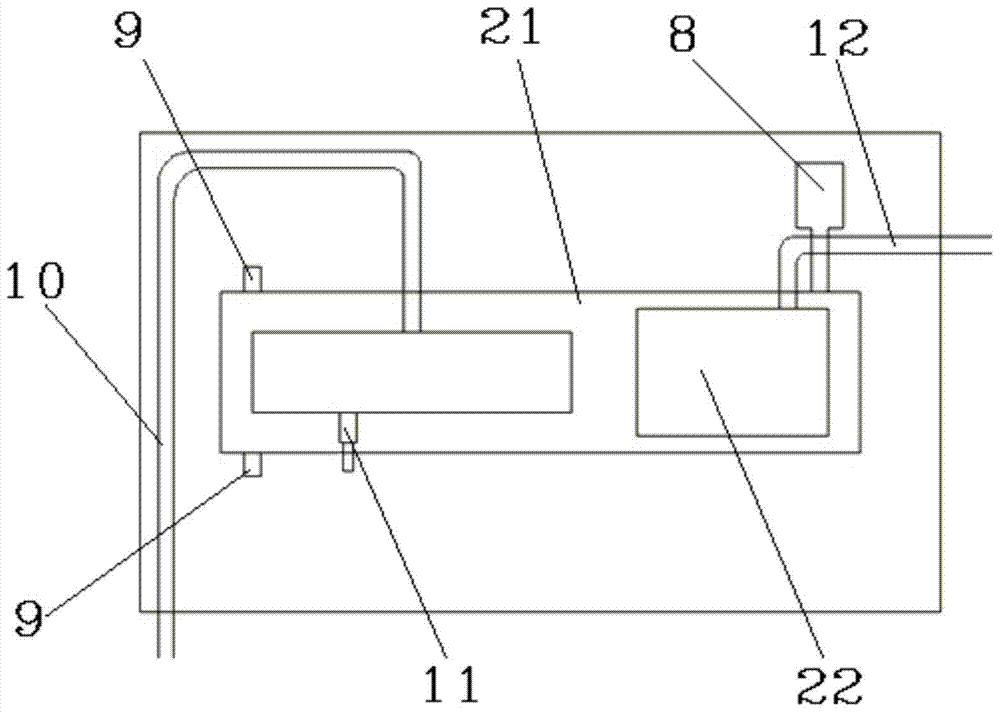

[0020] Such as Figure 1 to Figure 7 As shown, the embodiment of the present invention relates to an automatic cleaning device for nuts, including a machine base 1, a cleaning transmission control device 2, a product input device 3, an air pressure regulating device 4, an electrical control system 5, an oil tank 6, and an oil suction tank Machine 7, cleaning conveyor 8, product sensor 9, first oil delivery pipe 10, oil quantity regulating valve 11, first air delivery pipe 12, washing oil cleaner 13, oil pressure gauge 14, second oil delivery pipe 15, main pressure Regulating valve 16, air pressure regulating valve 17, air switch 18, second air pipe 19, PLC control system 20, cleaning device 21, air injection device 22, fuel injection nozzle 23, oil gauge 24, transmission belt 25. There is a product cleaning device 21 on the machine base 1. The product cleaning device 21 is connected to the product input device 3. The product input device 3 is connected to the product sensor 9....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com